Page 1

AQUATROL Zone Synchronizing Universal

Injection/Mixing Boiler Reset Controls

AQ252

USER OPERATION AND MAINTENANCE

WARNING

Risk of electrical shock.

Can cause severe injury, property damage or

death.

Only trained, experienced, licensed service

technicians should service this Control Panel. The

front cover of the AQ251 Control Panel should not

be removed, as this will expose the user to

potentially dangerous line voltage (120V)

electricity.

Congratulations!

The AQUATROL AQ252 installed on your heating system is

the most powerful, yet user-friendly hydronic heating control

system available on the market for residential and light

commercial installations.

APPLICATION

The AQ252 series of AQUATROL® Universal Injection/Mixing

Boiler Reset Controls provides simplified, energy-efficient

outdoor temperature compensated control of a hightemperature boiler loop and a lower temperature mixed loop in

residential hydronic heating systems. The AQ252 easily

converts a single-zone heating system into a room-by-room

comfort control system, or upgrades a basic, relay-logic

zoning system to intelligent Zone of Greatest Demand control,

with outdoor reset for increased energy efficiency and with

reduced boiler cycling. The boiler controls of the AQ252 can

ensure ample supply of hot water for both space heating and

priority generation of domestic hot water for bathing, dishes

and laundry.

When AQ1000 communicating thermostats are used with the

AQ252 Zoning Modules, they can use the same wiring as

existing thermostats. Night setback operation can be

programmed from the AQ252 panel.

This AQUATROL AQ252 control panel was installed by a trained hydronic heating contractor.

To service this product, or for any questions relating to its installation, please contact:

Installing contractor: ___________________________________________________________________

Address: _____________________________________________________________________________

This document contains all the information you need to

program the comfort settings of the AQ252 and to customize

its operation for your home or business. For detailed

information on the operation of this control, please consult the

trained hydronic heating professional that installed the AQ252

control.

Application ........................................................................ 1

Familiarization with Control .............................................. 2

User Interface .................................................................. 2

LCD Display Panel Layout ................................................ 3

Programming Instructions ................................................. 4

Troubleshooting ................................................................ 6

System Status and Error Codes ....................................... 6

User Menu Structure ......................................................... 8

CONTENTS

Phone: (________) __________________________________________________________

69-1990-02

Page 2

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

A

A

Table 1. AQ252 Models

Model Function DHW Zones Zone Control

AQ25242B Universal Injection/Mixing

Boiler Reset Control Panel

Selectable DHW priority, with

optional priority override

2 – 16,

in sets of 4

Line voltage circulators or 2-wire zone

valves

with integrated zoning

AQ25244B Universal Injection/Mixing

Boiler Reset Control Panel

Selectable DHW priority, with

optional priority override

2 – 16,

in sets of 4

24 Vac zone valves with end switches

with integrated zoning

AQ252 Approvals and Standards:

Canadian Standards Association: Certified, File No. LR76030

Replacement Parts and Accessories:

AQ1000TN2: non-programmable zone thermostat

AQ15200B: Replacement universal injection/mixing reset

boiler control module

AQ15740B: 4-zone valve expansion module

AQ15540B: 4-zone pump expansion module

AQ10X38: 24 Vac 38 VA transformer

AQ12C10: Replacement sensor, outdoor

AQ12C11: Replacement sensor, supply and return on boiler

loop and supply sensor on secondary loop

AQ12C20: Floor / slab sensor

FAMILIARIZATION WITH CONTROL

User Interface

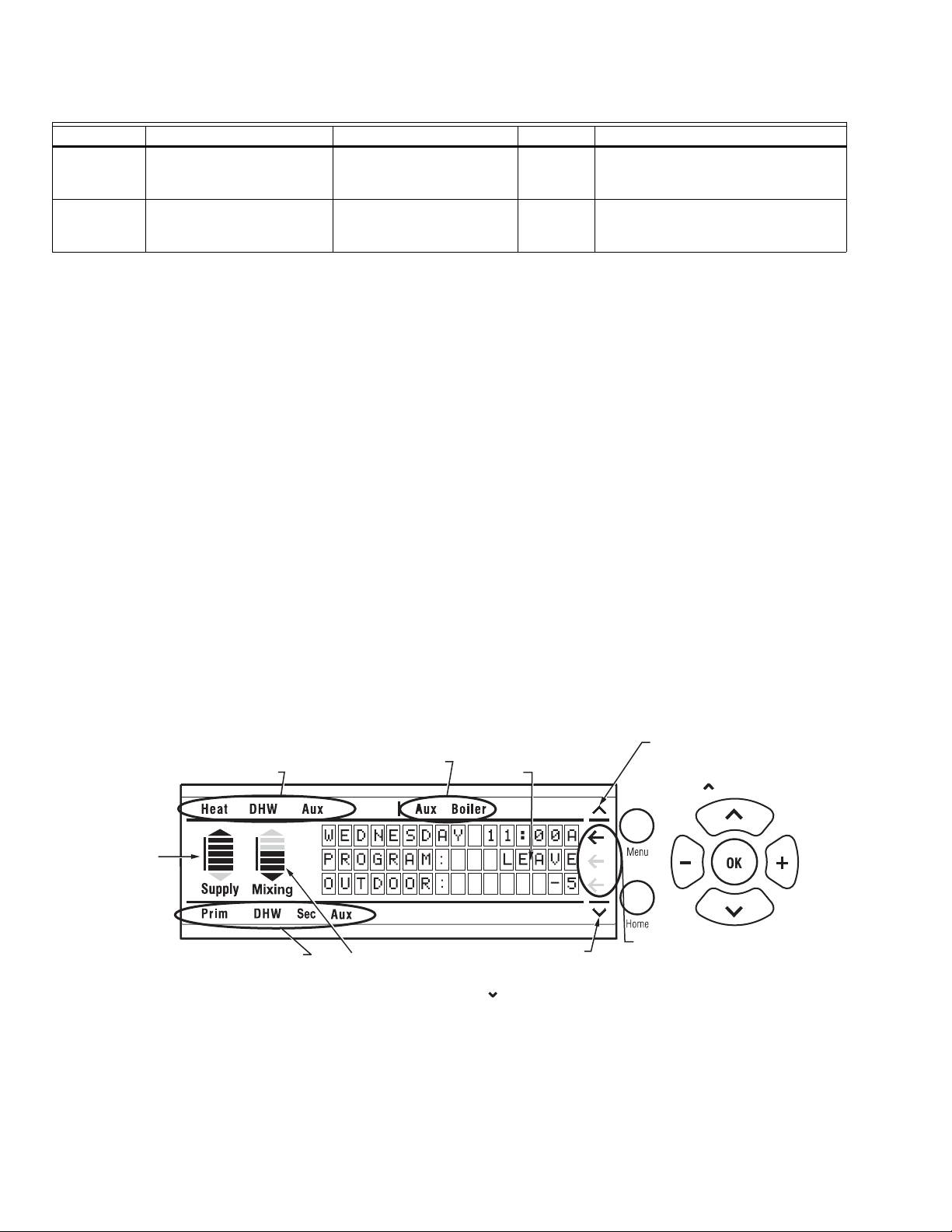

The AQ252 User Interface consists of an LCD screen (16

characters by 3 rows) and a 7-button keypad for navigating

the menus, as illustrated in Fig. 1.

Keypad

The 7- button keypad provides the following functions.

Menu Press this button to access the User Menu. When

pressed while in a sub-menu, the sub-menu’s

values are saved before going up one level in the

current menu.

Home Press this button to leave the User or Installer

Menu and return to the Home Page display screen.

OK Press this button to enter a sub-menu of the active

and v Press these buttons to scroll up/down in the menu

^

– and + Press these buttons to decrease/increase the value

menu item. A menu item is active when the

indicator arrow (←) is positioned beside the item.

items. Pressing one of these buttons automatically

exits the edit mode, and the selection moves to the

previous or next menu item.

of a selected menu item, or to scroll through a list of

pre-defined options.

- If the menu item being modified is a number, the

displayed value will decrease/increase by pressing

these buttons. When holding the – or + button for

more than a second, the values automatically

decrease/increase at a faster pace, similar to

setting the time on a digital clock radio

.

- If the menu item is an option, pressing these

buttons scrolls through the list of available options

one at a time.

STATUS OF SYSTEM DEMANDS

- CALL FOR HEAT

- CALL FOR DHW

- SIGNAL ON AUXILIARY INPUT

GRAPHIC SHOWING

THE PERCENTAGE

OF THE BOILER’S

HEATING CAPACITY

T WHICH IT’S

OPERATING; ARROWS

BOVE AND BELOW

THE BAR SHOW THE

TREND OF THE

BOILER’S

TEMPERATURE

(UP OR DOWN)

STATUS OF LINE VOLTAGE OUTPUTS

- PRIMARY (BOILER) HEAT

- DHW PUMP

- SECONDARY PUMP

- AUXILIARY “PUMP” OUTPUT

69-1990—02 2

STATUS OF SYSTEM OUTPUTS

- AUXILIARY OUTPUT ACTIVE

- BOILER T-T OUTPUT ACTIVE

GRAPHIC SHOWING THE DEGREE OF

MIXING IN THE SECONDARY LOOP:

# OF BARS INCREASES AS A) THE

INJECTION PUMP SPEED INCREASES,

B) THE VOLTAGE OF THE MODULATING

VALVE SIGNAL INCREASES OR C) THE

ACTUAL MIX TEMPERATURE APPROACHES

THE MAXIMUM MIX TEMPERATURE

Fig. 1. LCD display and keypad layout.

DISPLAY AREA SHOWING

SYSTEM STATUS AND MENU

OPTIONS AND SELECTIONS

MADE

DOWN ARROW, IF DISPLAYED,

INDICATES THAT OTHER MENU ITEMS

EXIST BELOW AND CAN BE VIEWED

BY SCROLLING DOWN WITH

THE BUTTON.

UP ARROW, IF DISPLAYED,

INDICATES THAT OTHER MENU

ITEMS EXIST ABOVE AND CAN

BE VIEWED BY SCROLLING

UP WITH THE BUTTON.

?? ARROW INDICATES

?

THE CURRENTLY SELECTED

“ACTIVE” MENU ITEM.

M27698

Page 3

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

LCD Display Panel Layout

The LCD on the AQ252 Control Panel is used to:

— Monitor system status and performance.

— Select and/or modify control settings for the hydronic

system.

— Diagnose and troubleshoot system problems.

The layout of the display is logical and simple to navigate. The

information displays so that you can see at a glance the

system’s operating temperatures, as well as the status of the

system equipment, such as a call for heat, DHW pump ON,

Boiler T-T terminals energized, etc. Fig. 1 on page 2 illustrates

the layout and features of the LCD display panel and keypad.

LCD Display Navigation

This section describes how the keypad is used to navigate the

LCD display and menus.

• The LCD displays up to three lines of text at a time. For

menus with more than three lines, use the up and down

buttons (

• As the menu is scrolled up or down, the indicator arrow (←)

shows which menu item is active.

• If the active menu item is part of a list of predefined options

(e.g., Day of the Week) press the – or + button to scroll

through the available options until the preferred option is

displayed. The option is automatically saved when the

indicator arrow is scrolled away from the value being

edited.

• If the active menu item requires you to define a value (e.g.,

a setpoint), use the – or + button to decrease or increase

the value until the desired value is displayed. The selection

will be saved when the indicator arrow is scrolled up or

down.

NOTES:

1. When setting times for the setback schedule, you

2. The OK button, when pressed, defaults the time

or v) to scroll through the menu options.

^

must

use the – or + button to change the time.

setting to “--:--” (midnight).

• If the active menu item leads to a further sub-menu,

pressing the OK button displays the sub-menu options on

the LCD. Scroll through this sub-menu to position the

indicator arrow (←) beside the desired menu item to input

or modify. Choose one of the options provided or input the

desired value for the menu item. When satisfied, scroll to

another item and your selection will be saved.

• To define or modify another item within the same menu,

scroll the up and down buttons (

arrow (←) is beside the desired option. Use the – or +

or v) until the indicator

^

buttons to set the value for that item.

• To move back (up) one level within a menu, press the

Menu button.

• To return to the Home Page display, press the Home

button.

NOTE: The AQ252 automatically returns to the Home Page

display after 60 minutes of inactivity on the keypad.

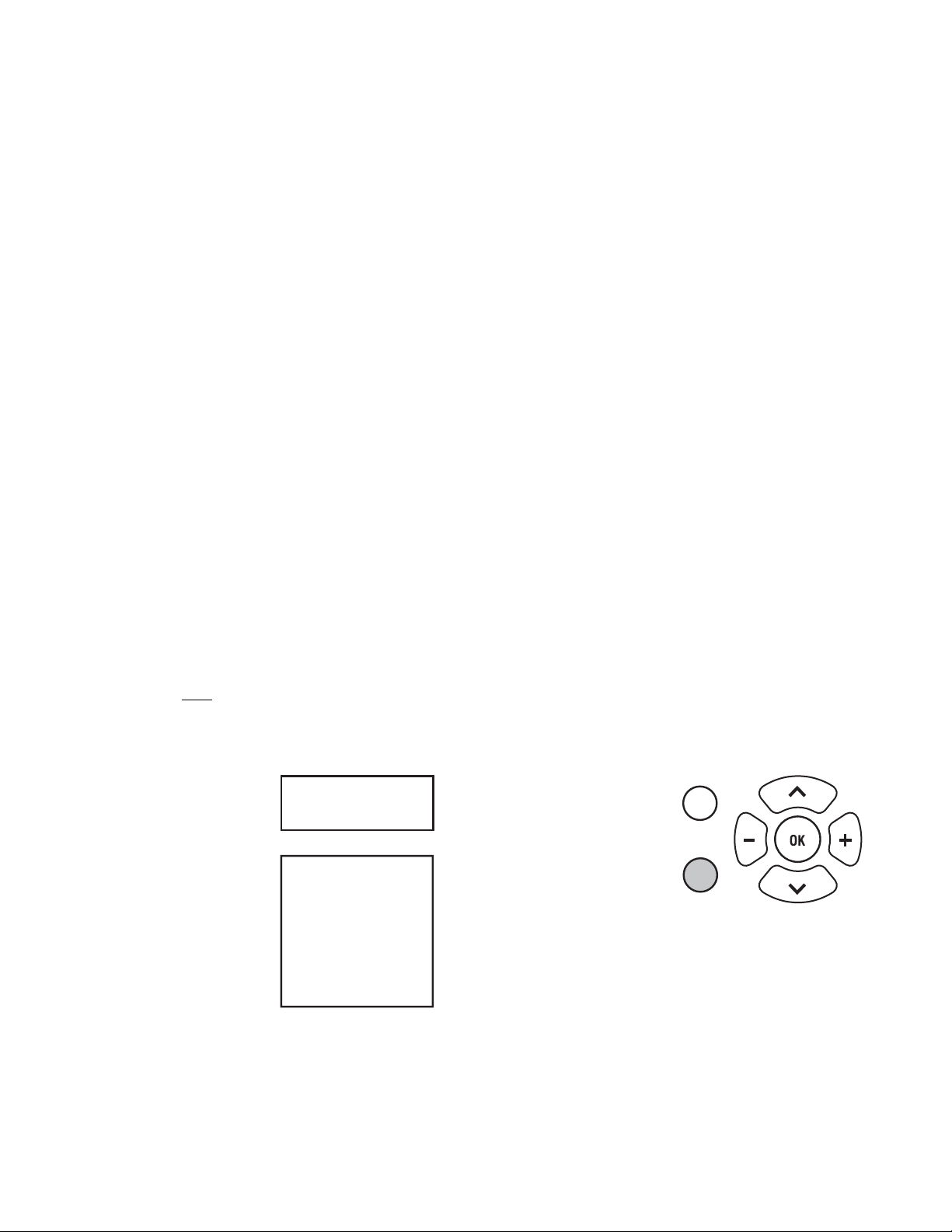

HOME PAGE DISPLAY

The Home Page is the default view displayed on the AQ252

Control Panel's LCD screen.

There are two Home Page views - Simple and Detail.

• Simple view shows 3 lines of text and is a brief description

of the system operation.

• Detail view includes the same 3 lines plus 10 lines of

additional information. Detail view is the factory default.

The choice of the Simple or Detail Home Page view is made

from the USER MENU > PREFERENCES/TIME menu option.

The Home Page display information for the Simple and Detail

views is illustrated in Fig. 2.

HOME PAGE (SIMPLE)

HOME PAGE (DETAIL)

LCD DISPLAY

WEDNESDAY 9:30A

PROGRAM: LEAVE

OUTDOOR: -5

WEDNESDAY 9:30A

PROGRAM: LEAVE RETRN SLEEP WAKE OCC UNOCC

OUTDOOR: -5

TARGET: 180 WWSD BOILER: 180

RETURN: 160

SECONDARY: 100

SEC TARGET: 100 WWSD DHW: 100

ZONE COUNT: 31

-

-

Fig. 2. Home Page displays (Simple and Detail).

3 69-1990—02

KEYPAD

Menu

Home

M27699

Page 4

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

Programming Instructions

Program the AQ252 by using the keypad and LCD display to

select parameters from the User Menu. Refer to Fig. 1 on

page 2 for an illustration of the LCD screen and keypad.

NOTE: The figures in “User Menu Structure” on page 8

provide a graphical layout of the AQ252’s User and

Installer menus.

When a new AQ2000 component is connected on the

AQUATROL network, it will be seamlessly integrated in the

system after a few seconds. If one or more components are

disconnected or stop providing data to the network, a

message will appear on the System Status display until the

fault is corrected.

User Menu Overview

The User Menu is intended for use by the building owner to

choose the LCD display preferences, Zone Settings (including

setpoint temperatures and setback times for each zone), and

temperatures for the WAKE, LEAVE, RETRN (return), and

SLEEP programs.

The Home Page and User Menu allow the building owner to:

• View the status of the system.

• Set up preferences for how the system information is

displayed.

• Set target temperatures for each zone (requires AQ1000

thermostats).

• Program times of the day when the system will set back the

temperatures for all zones (requires AQ1000 thermostats).

NOTE: If there are any problems with the system’s opera-

tion, the AQ252 displays error codes on the System

Status display of the LCD panel. For details on these,

refer to “Troubleshooting” on page 6.

— The time display in 12 hour (e.g., 7:00 PM) or 24 hour

format (e.g., 19:00).

— Date and time of day – allows building owner to reset

day and time of day in the event of a power outage of

more than 4 hours (refer to Troubleshooting section).

— The Home Page display view, Simple or Detail. The

factory default is Detail.

— The LCD Backlight – illuminated permanently (ON) or

set to automatically turn off backlight after 1 hour

(AUTO).

POWER FAILURE

If a power disruption lasts for more than 4 hours, the message

PLS SET DAY/TIME displays and optionally, the AQ252's

backlight flashes repeatedly. This displayed message

continues until the DATE and TIME OF DAY are updated. See

“Power Disruption Greater Than 4 Hours” on page 6.

ZONE SETTINGS (REQUIRES AQ1000 THERMOSTATS)

Settings in this sub-menu define:

— The temperature setpoints (target temperatures) for

each zone in the heating system.

— The temperature setback for each zone in the heating

system. This is the desired temperature drop when the

heating system enters the setback program SLEEP or

LEAVE.

— The maximum and minimum setpoints that can be

entered by a user at a thermostat screen for each

zone.

— Whether each zone can be set independently by the

AQ252 (i.e., some zones can be locked while others

are unlocked) depending on whether or not the keyboard on a thermostat is locked. When locked, no

changes can be made to a zone’s setpoint temperature through the thermostat. Changes can still be

made through the Zone Settings menu on the AQ252

control panel.

TO ACCESS THE USER MENU:

Press the Menu button on the keypad at any time to access

the User Menu.

User Menu Settings

The User menu has five sub-menus.

• “System Status”

• “Preferences/Time”

• “Zone Settings (requires AQ1000 thermostats)”

• “Program Settings”

• “Statistics” on page 5

To make changes to the parameter settings in the User Menu,

refer to “LCD Display Navigation” on page 3.

SYSTEM STATUS

This is a detailed list of activities going on in the heating

system (e.g., call for heat, DHW disabled), and provide the

building owner with a quick snapshot of the heating system’s

operation, primarily for purposes of troubleshooting and

system diagnostics.

PREFERENCES/TIME

The preferences that the building owner can change in this

sub-menu are:

— The temperature scale for the display (Fahrenheit or

Celsius) for both the AQ252 control’s LCD and the

zone thermostats.

PROGRAM SETTINGS

Using the Program Settings sub-menu, the building owner can

define the time of day when the entire heating system will

change programs (e.g., from SLEEP to WAKE).

The AQ252 has provision for four different schedule periods

per day. They are defined as WAKE, LEAVE, RETRN (return),

and SLEEP:

WAKE: Period when you awaken and want your

home at a comfortable temperature.

LEAVE: Period when you are away from home and

want an energy-saving temperature.

RETRN: Period when you return home and want

your home back to a comfortable

temperature.

SLEEP: Period when you are asleep and want an

energy-saving temperature.

There are three modes of operation – Automatic, Occupied

and Unoccupied:

AUTO: In AUTO mode, the AQ252 follows the

WAKE, LEAVE, RETRN, and SLEEP

programs.

OCC: In OCC mode, the AQ252 holds the

temperature of OCCUPIED programs

(WAKE and RETURN). This might be used

if the occupancy pattern of the building

69-1990—02 4

Page 5

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

changes temporarily, requiring the

temperature to be at a comfort level 24

hours/day.

UNOCC: In UNOCC mode, the AQ252 holds the

temperature of UNOCCUPIED programs

(LEAVE and SLEEP). This might be used if

the building will be unoccupied for an

extended period of time, such as a vacation

period.

There are two ways to set the schedule program times for

WAKE, LEAVE, RETRN, and SLEEP:

— One day at a time

— All days at the same time

1. One day at a time programming:

• Select EDIT DAILY from the Program Settings submenu.

• A list of four program times per day displays,

showing the factory pre-set times for all programs:

MON WAKE 6:00A

MON LEAVE 8:00A

MON RETRN 4:30P

MON SLEEP 10:00P

TUE WAKE 6:00A

TUE LEAVE 8:00A

TUE RETRN 4:30P

TUE SLEEP 10:00P

…

SAT WAKE 6:00A

SAT LEAVE --:-SAT RETRN --:-SAT SLEEP 10:00P

SUN WAKE 6:00A

SUN LEAVE --:-SUN RETRN --:-SUN SLEEP 10:00P

• Any of the times can be changed by scrolling to that

line and pressing the + or – button until the desired

program time is displayed.

2. Programming all days at the same time:

• Select EDIT ALL DAYS from the Program Settings

sub-menu.

• A sub-menu displays where you can change the

WAKE program time for all days, the LEAVE

program time for all days, etc.

• When all four programs have been set, select the

COPY TO ALL DAYS option. This displays the

prompt: COPY TO ALL DAYS - ARE YOU SURE?.

Select Yes by positioning the indicator arrow at YES

and press the OK button.

• Next, the same list of days as EDIT DAILY

(described in step 1) displays, except that all days

now show the times for the WAKE, LEAVE, RETRN,

and SLEEP programs that you set in the EDIT ALL

DAYS menu.

• If you do not want all days of the week to have the

same program schedule (e.g., weekdays different

than weekends), you can now scroll down and

change the program times for certain days by

positioning the indicator arrow beside the program

time to change and using the + or – button to

increase or decrease the scheduled program time.

When the program times have been set for all days, press the

Home button to leave the programming menus and return to

the Home Page display. All settings take effect immediately.

NOTES:

1. Schedule times are in 15-minute intervals.

2. To have the AQ252 ignore a program change

(and therefore keep the previous program's setpoint temperature), position the cursor beside the

period to be ignored and press the OK button.

The AQ252 will display “--:--” beside that program

and, when operating, will continue with the previous program's setpoint until the next program

change.

STATISTICS

This sub-menu provides information about system activity and

mix valve cycle counts. See Fig. 3 on page 8 for an illustration

of the statistical data that can be displayed.

5 69-1990—02

Page 6

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

TROUBLESHOOTING

Power Disruption

The AQ252’s system and thermostat (zone settings)

parameters are stored in non-volatile memory and are

updated as they change.

When a power disruption or loss of power occurs, the system

configuration is retained in memory.

When power is restored, the AQ252 Control Panel enters

auto-detection mode, reads its previously-stored settings, and

initializes all AQUATROL network components according to

their saved parameters.

POWER DISRUPTION GREATER THAN 4 HOURS

If a power disruption lasts for more than 4 hours, the AQ252

will have discharged its internal super capacitor, and the

DATE and TIME OF DAY settings will need to be reset.

Table 2. LCD Status Notices and Error Messages.

LCD Display Parameter Meaning

A/C MIN. OFF TIME n/a The A/C compressor is disabled, because the minimum OFF time has not yet elapsed.

A/C MIN. ON TIME n/a The A/C compressor is active and the minimum ON time has not yet elapsed.

AUX IN EM. SHUT n/a Auxiliary Input's Emergency Shut Down is active.

BOILER: EM SHUT Boiler is disabled, because the AQ252 is in Emergency Shut Down mode.

FRZ PROT Boiler freeze protection activated:

• Communication between Control Module and Zoning Module has been lost for more

than 1 minute

or

• Boiler supply temperature is less than 50°F (10°C)

HEAT DHW Boiler is active to serve DHW.

HEATING Boiler is active to serve zones.

IDLE Boiler is not active.

INIT Boiler contacts (terminals 22 and 23) on the AQ1520, which are connected to the boiler's

T-T terminals, have been shorted and the boiler is beginning its firing sequence.

INST PURG Boiler is active while the AQ252 is conducting the PURGE operation in the Installer

Setup.

INSTALL Boiler is in ready mode during Installer Setup.

PMP EXER Boiler is disabled while the AQ252 is exercising all pumps and valves connected to the

POST PURG Boiler is active with Post Purge operation and is sending the purged water to the Boiler

PURGE DHW Boiler is active with Post Purge operation and is sending the purged water to the DHW

CALL FOR COOL n/a At least one zone with a programmable thermostat requires cooling.

CALL FOR DHW n/a The DHW requires heat.

CALL FOR HEAT n/a At least one zone requires heat.

CWSD ACTIVE n/a Zone calls for cooling are not served because CWSD (Cold Weather Shutdown) is in

DHW DISABLE n/a DHW call is not served because it is disabled.

INJECTION%: xx% n/a The variable speed injection pump terminals are active and operating at xx% of full

LOST ZONE A-1

…

LOST ZONE D-16

n/a Lost communication with a zone (A-1 to A-16, B-1 to B-16, C-1 to C-16, or D-1 to D-16).

AQUATROL network.

(Primary) loop.

tank.

progress.

speed.

Upon restart, the AQ252 displays its clock settings as: YEAR

= 2008, MONTH = JAN, DATE = 1. The message PLS SET

DAY/TIME displays. This displayed message continues until

the DATE and TIME OF DAY are updated.

NOTE: If the power failure parameter is set to Backlight

(USER MENU > PREFERENCES/TIME), the LCD

backlight flashes repeatedly, along with the message.

The AQ252 remains permanently in OCCUPIED (or Comfort)

mode until the DAY and TIME OF DAY are updated.

System Status and Error Codes

System status alerts and error messages display on the

System Status Page. These messages are shown in Table 2.

69-1990—02 6

Page 7

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

Table 2. LCD Status Notices and Error Messages. (Continued)

LCD Display Parameter Meaning

MIN. RETURN PROT n/a The temperature measured by the return sensor is at or below the minimum return water

temperature.

NO DHW PROBE n/a No DHW sensor connected or it is defective.

NO LINE VOLTAGE n/a No line voltage has been detected on the N and L terminals on the line voltage input to

the control module.

NO OUTDOOR PROBE n/a No outdoor sensor connected or it is defective.

NO RETURN PROBE n/a No return sensor connected or it is defective.

NO SECOND. PROBE n/a No secondary (mixed) loop sensor connected or it is defective.

NO SUPPLY PROBE n/a No supply sensor connected or it is defective.

SHORT CYCLE PROT n/a There is a call for heat, but less than two minutes have elapsed since the last firing of the

boiler (prevents short cycling).

VALVE INIT n/a Motorized mixing valve controlling the secondary loop is being initialized and

repositioned (opening or closing) to meet the secondary loop target temperature.

WATER READY n/a Boiler Supply Water temperature is at or above the target temperature calculated by the

AQ252.

WWSD ACTIVE n/a Zone calls for heat is not served because WWSD (Warm Weather Shutdown) is in

progress.

When a new AQ2000 component is connected on the

AQUATROL network, its settings are communicated to the

AQ252's Boiler Control Module (AQ15200B) within 10

seconds of being connected. If the component is an AQ1000

thermostat, the setpoints for that zone thermostat can be

modified from the Boiler Control Module as soon as it is

recognized by the Control Module.

When an AQ thermostat is disconnected from the AQUATROL

network, a message displays on the System Status page of

the AQ252 indicating “Lost Zone A-xx”, where “xx” is the

specific identity, or address, of the lost zone. This helps the

servicing contractor quickly identify the lost zone and fix its

wiring, to re-establish communication with the Control Module.

7 69-1990—02

Page 8

AQUATROL ZONE SYNCHRONIZING UNIVERSAL INJECTION/MIXING BOILER RESET CONTROLS

USER MENU STRUCTURE

Press the Menu button on the keypad to display the User Menu. Fig. 3 illustrates all possible User Menu selections.

USER MENU

SYSTEM STATUS

PREFERENCES/TIME

ZONE SETTINGS

PROGRAM SETTINGS

STATISTICS

SYSTEM STATUS

A/C MIN OFF TIME

A/C MIN ON TIME

AUX IN EM.SHUT

BOILER: IDLE

CALL FOR COOL

CALL FOR DHW

CALL FOR HEAT

CWSD ACTIVE

DHW DISABLE

INJECTION%: 0%

LOST ZONE A-1

...

LOST ZONE D-16

MIN RETURN PROT

NO DHW PROBE

NO LINE VOLTAGE

NO OUTDOOR PROBE

NO RETURN PROBE

NO SECOND. PROBE

NO SUPPLY PROBE

SHORT CYCLE PROT

VALVE INIT

WATER READY

WWSD ACTIVE

1

THE SYMBOLS INDICATE ADDITIONAL SELECTIONS ARE POSSIBLE.

THE FACTORY DEFAULT VALUES ARE SHOWN.

TEMPERATURE VALUES ARE SHOWN IN DEGREES FAHRENHEIT,

2

WHICH IS THE FACTORY DEFAULT TEMPERATURE UNIT.

3

EITHER HEAT OR COOL DISPLAYS DEPENDING ON THE SYSTEM’S STATUS.

4

FACTORY DEFAULT TIMES FOR MON THROUGH FRI.

FACTORY DEFAULT TIMES FOR SAT AND SUN.

5

PREFERENCES / TIME

BOILER UNITS: °F

ZONE UNITS: °F

TIME DISP: 12H

D.S.T.: ENABLE

YEAR: 2008

MONTH: JAN

DATE: 1

DAY: MONDAY

TIME: 12:00A

HOMEPAGE: DETAIL

BACKLIGHT: AUTO

POWER FAILURE

NOTICE: BACKLIGHT

1

ZONE SETTINGS (All or Single)

EDIT ALL ZONES

EDIT SINGLE ZONE

ARE YOU SURE?

NO YES

ZONE A-1

ROOM TEMP

FLOOR TEMP

SETPOINT: 70

FLOOR SETPT: 70

HEAT/COOL STATUS

SETBACK: 7

SETPOINT MAX: 100

SETPOINT MIN: 41

FLOOR LIM HI: 100

FLOOR LIM LO: 41

SETPOINT VACANCY

HEAT: 41

SETPOINT VACANCY

COOL: 100

CHANGEOVER: 2

KEYBOARD: UNLOCK

PROGRAM SETTINGS

MODE: AUTO

EDIT ALL DAYS

EDIT DAILY

2

EDIT ALL DAYS

3

ALL WAKE 6:00A

ALL LEAVE 8:00A

ALL RETRN 4:30P

ALL SLEEP 10:00P

COPY TO ALL DAYS

COPY WAKE

COPY LEAVE

COPY RETRN

COPY SLEEP

EDIT DAILY

MON WAKE 6:00A

MON LEAVE 8:00A

MON RETRN 4:30P

MON SLEEP 10:00P

...

SUN WAKE 6:00A

SUN LEAVE --:--

SUN RETRN --:--

SUN SLEEP 10:00P

STATISTICS

LAST DATA RESET: 2000 JAN 01

BOILER FIRE ACTIV: 0H

BOILER PUMP ACTIV: 0H

DHW PUMP ACTIV: 0H

AUX PUMP ACTIV: 0H

SEC PUMP ACTIV: 0H

INJ PUMP ACTIV: 0H

AUX OUT ACTIV: 0H

MIX VLV. OPEN CYCLE: 0

MIX VLV. CLOSE CYCLE: 0

ZONE A-1

ACTIV: 0H

ARE YOU SURE?

NO YES

4

5

M27700

Fig. 3. User Menu Structure.

AQUATROL® is a registered trademark of Honeywell International Inc.

Automation and Control Solutions

Honeywell International Inc. Honeywell Limited-Honeywell Limitée

1985 Douglas Drive North 35 Dynamic Drive

Golden Valley, MN 55422 Toronto, Ontario M1V 4Z9

customer.honeywell.com

® U.S. Registered Trademark

© 2009 Honeywell International Inc.

69-1990—02 M.S. Rev. 09-09

Loading...

Loading...