Page 1

68-0306-05

AQ250 Series Hydronic Control Panels

Need new photo of AQ250

PRODUCT DATA

PRODUCT DESCRIPTION

The AQ250 easily converts a single-zone heating system into

a room-by-room comfort control system, or upgrades a basic,

relay-logic zoning system to intelligent Zone of Greatest

Demand control. The boiler control of the AQ250 can ensure

ample supply of hot water for both space heating and priority

generation of domestic hot water for bathing, dishes and

laundry.

FEATURES

The AQ250 Series Hydronic Control Panels have the following

features:

• Zoning Control for up to four, single-stage zones or

two, two-stage zones as shipped; can be expanded to

a total of 16 zones with AQ255 or AQ257 expansion

zoning panels, and up to 64 zones by us ing up to thre e

AQ254 Add-a-Temperature expansion panels and

additional expansion zoning modules.

• Controls one boiler loop.

• Zone synchronization through Zone of Greatest

Demand control.

• Domestic hot water (DHW) priority and priority

override protection.

• Use with digital non-communicating thermostats or

AQ1000 2-wire polarity insensitive communicating

thermostats.

• Automated test feature for quick start-up and

simplified troubleshooting.

• Boiler freeze protection (in the event of network

communication failure).

• Boiler short cycling protection, post purge, and shock

prevention from cold water returning to boiler.

• Line or low-voltage output for zoning equipment

(pumps or valves).

• Integral 38 VA transformer with self resetting

electronic fuse.

IMPORTANT

T o ensure correct installation and proper operation of

the control, perform the 7 installation steps in the

order numbered in the “Contents” below.

Contents

Specifications ................................................................... 2

1 Installation Preparation .................................................. 3

2 Mounting ........................................................................ 4

3 Wiring Procedure ........................................................... 5

4 Configure the Control Panel DIP Switches .................... 14

5 Test and Check Out the Installation ............................... 17

6 Purge Air from all System and Zone Piping .................. 19

7 Document and Keep a record of all System Settings .... 19

Troubleshooting ................................................................ 19

Page 2

AQ250 SERIES HYDRONIC CONTROL PANELS

• When using non-communicating thermos tats, the

following features are not available:

• Outdoor temperature is not displayed on the

thermostat.

• Individual zone freeze protection.

SPECIFICATIONS

The AQ250 Control Panels and corresponding attached

equipment are listed in Table 1.

Table 1. AQ250 Series Control Panel Models.

Control Panel

AQ25042B AQ15000B AQ15540B

AQ25044B AQ15000B AQ15740B

Application: Controls one boiler loop as well as domestic hot

water (DHW) management and zoning operation in a

hydronic zoning system.

Power and Electrical Ratings:

Power Supply: 120 Vac / 60Hz

Auxiliary Pump Contact Rating: 120/250 Vac, 5A,

1/3 HP

Boiler (T-T) Contact Rating: 24 Vac, 0.5A, 12 VA

Boiler Pump Output Rating: 120 Vac, 5A, 1/3 HP

DHW Pump/Valve Output Rating: 120 Vac, 5A, 1/3 HP

B–B Communication Bus Terminals: Low voltage,

Class II, 2-wire polarity-insensitive, digital

communicating link to other Control or Zoning modules.

Electrical Connections (Line Voltage): Wire-clamp

screw terminals; maximum 2 x 14 AWG each on line

voltage terminals

Environmental Ratings:

Control and Zoning Panel Temperature Rating: 32°F to

130°F (0°C to 55°C)

Corresponding

Control Module

Corresponding

Zoning Module

Operating Humidity Range (% RH): 5 to 90% RH, non-

condensing

Temperature Ratings:

Return Minimum Control Temperature: 140°F (60°C);

This is the temperature at which the bypass pump

(Aux. Pump contacts) is activated.

Sensor Temperature Rating: -58°F to 230°F (-50°C to

110°C)

Inputs/Outputs:

DHW Demand Input: External dry contacts connection

only

Heat Demand (Thermostat R-W) Input: External dry

contacts connection only

R–C Input (on Control and Zoning Modules): 24 Vac

Class II

R–C Output (on transformer): 38 VA, 24 Vac Class II

Interface and Timings:

User Interface: DIP Switch settings

Boiler Heat Post Purge: 30 seconds; not adjustable

Pump/Valve exercise: 30 seconds per 2 weeks of space

heating inactivity; not adjustable

Thermostat Compatibility: Digital thermostats and/or

AQ1000 Series 2-wire communicating thermostats

Supply/Return Loop Sensor: 10K ohm NTC thermistor at

77°F (25°C) ± 0.5°F (±0.3°C). Lead length: 10 ft. (3.0 m);

up to 500 ft. (150 m) using 18 AWG or larger wire,

beta=3892.

Dimensions (HxWxD): 8.0 x 13 x 3.3 in. (20.3 x 32.9 x

8.5 cm) approximate

Weight: 4.9 lb. (2.2 kg)

Approvals: Canadian Standards Association: Certified, File

No. LR76030

ORDERING INFORMATION

When purchasing replacement and modernization products from your TRADELINE® wholesaler or distributor, refer to the

TRADELINE® Catalog or price sheets for complete ordering number.

If you have additional questions, need further information, or would like to comment on our products or services, please write or

phone:

1. Your local Honeywell Automation and Control Products Sales Office (check white pages of your phone directory).

2. Honeywell Customer Care

1885 Douglas Drive North

Minneapolis, Minnesota 55422-4386

In Canada—Honeywell Limited/Honeywell Limitée, 35 Dynamic Drive, Toronto, Ontario M1V 4Z9.

International Sales and Service Offices in all principal cities of the world. Manufacturing in Australia, Canada, Finland, France,

Germany, Japan, Mexico, Netherlands, Spain, Taiwan, United Kingdom, U.S.A.

68-0306—05 2

Page 3

AQ250 SERIES HYDRONIC CONTROL PANELS

WARNING

1 INSTALLATION PREPARATION

NOTES: Through out these instructions, the following

terminology conventions are used:

— AQ150 refers to the AQ15000B Control Module;

— AQ155 refers to the AQ15540B Zoning Module.

— AQ157 refers to the AQ15740B Zoning Module.

— AQ250 is used when the information applies to both

the AQ25042B and AQ25044B Control Panels. Where

there are specific instructions or details relating to the “42B” or “-44B” Control Panels, the full model number

(i.e. AQ25044B) is used;

— AQ255 refers to all of the AQ25542B, AQ25582B and

AQ25742B Expansion Zoning Panels

— AQ257 refers to the AQ25744B Expansion Zoning

Panel. Where there are specific instructions or details

relating to the “-42B”, “-82B”, “-42B”, or “-44B”

Expansion Zoning Panels, the full model number (i.e.

AQ25744B) is used;

— Control Module refers to the component within an

AQ2000 Series Control Panel that performs the master

control operations. See Table 1 on page 2 for specific

models.

— Control Panel refers to an assembled product,

consisting of a transformer, Control Module and Zoning

Module, all contained within an AQ2000 panel

enclosure;

— Expansion Zoning Panel refers to an assembled

product, consisting of a Zoning Module and, if

applicable, a transformer, contained within an AQ2000

panel enclosure. Zoning Modules are available in either

4-zone or 8-zone configurations. Refer to Honeywell

literature Form No. 69-1981 for more information on

these products.

— Zoning Module refers to the component within an

AQ2000 Series Control Panel or Zoning Expansion

Panel.

When Installing this Product…

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a

hazardous condition.

2. Check the ratings given in the instructions and on

the product to make sure the product is suitable for

the application.

3. Installers must be trained, experienced, and licensed

service technicians.

4. Follow local codes for installation and application.

5. After installation is complete, check out the product

operation as printed in these instructions.

Risk of electrical shock.

Can cause severe injury, property damage or death.

Disconnect power supply before installation and before

servicing.

Check That You Have All the Necessary

Equipment For a Successful Installation

• AQ2000 Series components:

— AQ250 Control Panel

— AQ Expansion Zoning Panels (if more than four space

heating zones in the system)

— Digital thermostats (one for every space heating zone

being controlled)

• Boiler supply and return temperature sensors (included with

the AQ250 Control Panel)

• Low voltage thermostat wire

• Zoning equipment (zone valves or pumps)

Read All Instructions Carefully Before

Proceeding

The AQ250 Control Panels are a part of a totally new series of

hydronic controls. And although they - and other AQ2000

system components - are very easy to install and operate, they

are different than other hydronic controls that you have

previously installed. So take a moment to read through this

quick installation guide before

Failure to follow them could damage the product or cause a

hazardous condition.

beginning the installation.

Familiarize Yourself With the AQ250 Control

Panel Layout

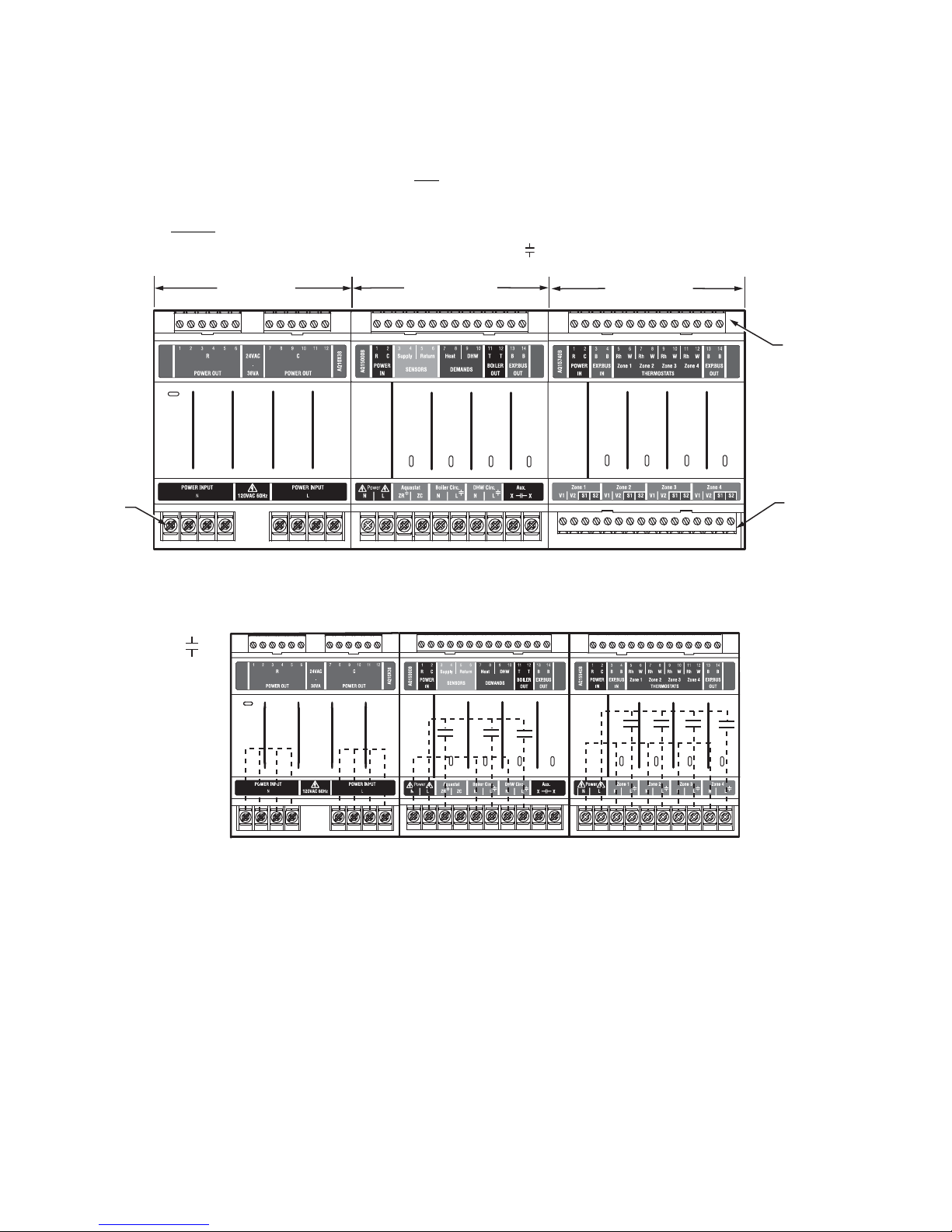

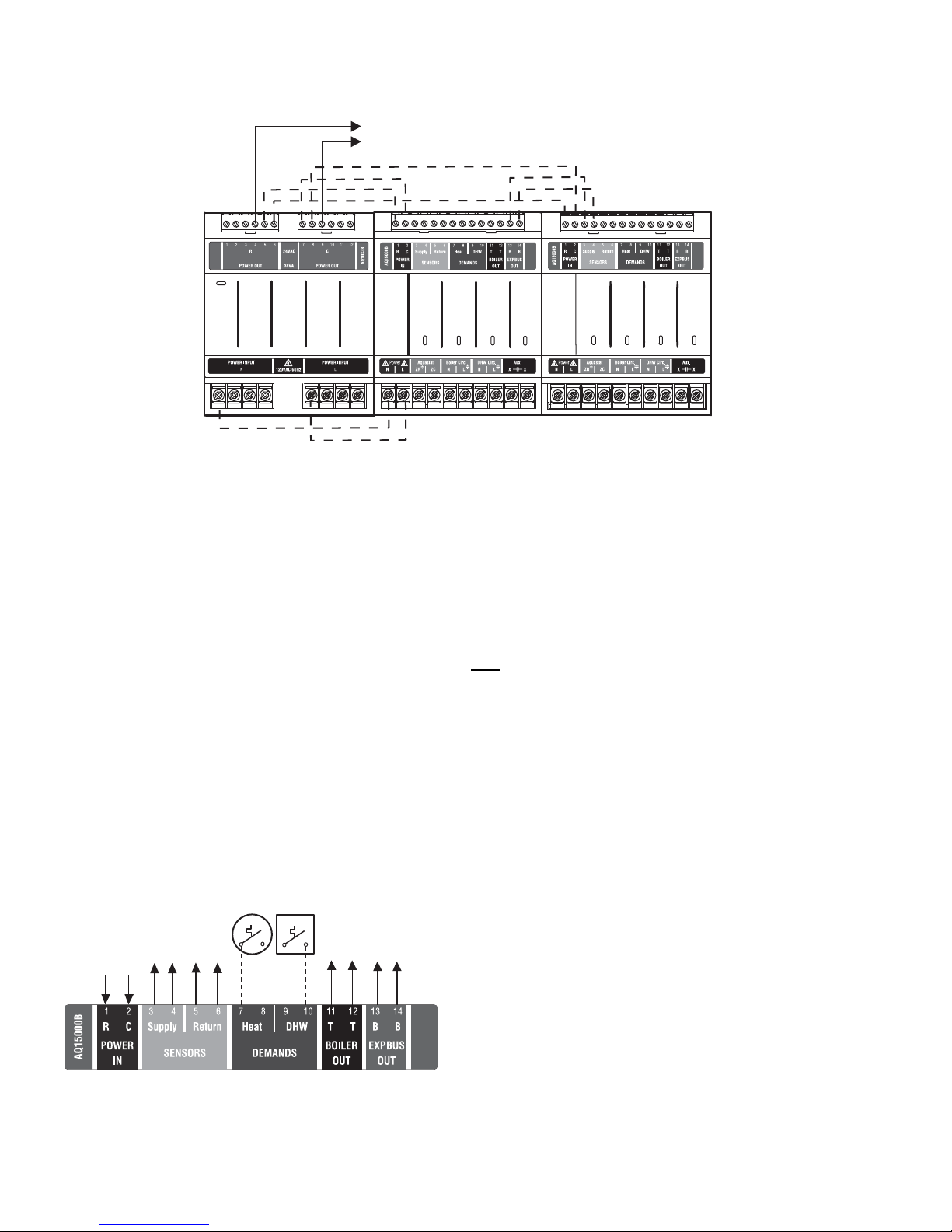

Refer to Fig. 1 on page 4. All AQ250 Control Panels consist of

three functional components:

1. AQ10X38 transformer (power supply module), which

connects to 120 V ac power and supplies 24 V ac power to

the Control Module and Zoning Modules

2. AQ15000B boiler / DHW Control Module, which controls

the boiler and domestic hot water (DHW) functions as

well as coordinating the overall operation of the hydronic

system.

3. One of two different 4-zone Zoning Modules:

• AQ15740B (part of the AQ25044B Control Panel)

for zoning with 24 Vac zone valves with

switches.

• AQ15540B (part of the AQ25042B Control Panel)

for zoning with either line voltage circulators or 24

Vac zone valves without

AQ250 Control Panels can control a maximum of 16 zones by

connecting additional Expansion Zoning Panels to the AQ250

Control Panel. Each Expansion Zoning Panel is configured

with its own bank of DIP switches, located in the left-most

section of each Zoning Module. To expand the capacity of an

AQ250 Control Panel beyond 16 zones, an AQ254 Add-ATemperature Expansion Control Panel is required. The

hydronic system can be expanded by 16 zones for each

AQ254 connected to the AQ2000 network. A maximum of

three (3) AQ254 Panels may be connected to an existing

AQ2000 Control Panel for a maximum of 64 zones connected

on the AQUATROL® network

NOTE: If an AQ254 Add-A-Temperature Expansion Control

Panel is used for controlling the temperature in a

mixed loop, it can reset the mixed loop temperature

using LOAD reset, but not OUTDOOR reset, as the

AQ250 panel does not have input terminals for an

outdoor sensor.

end switches.

end

3 68-0306—05

Page 4

AQ250 SERIES HYDRONIC CONTROL PANELS

A

In general, the top terminals of the AQ2000 Series components

carry low voltage (24 Vac) power and the bottom terminals

carry line voltage (120 Vac) power. This is illustrated in Fig. 1.

The two exceptions to this are:

1. AQ15740B Zoning Module for use with zone valves with

end switches.

2. AQ15540B Zoning Module when used with low voltage

zone valves without

LINE VOLTAGE

(120 V)

end switches.

TRANSFORMER

CONTROL MODULE

ZR

For these the two exceptions, the bottom terminals of the

Transformer and Control Module carry line voltage (120 Vac),

but the bottom terminals of the Zoning Module will carry low

voltage (24 Vac) power.

The powered terminals on the bottom of the AQ2000 Series

Control Modules and Zoning Modules are connected internally,

as shown in Fig. 2. The voltage supplied to the N and L

terminals is also available at the adjacent terminal pairs when

the hot ( ) relays are switched.

ZONING MODULE

Boiler

DHW

Aux

Zone 1

Zone 2

Zone 3

Zone 4

M29032A

LOW VOLTAGE

(24 V)

LOW VOLTAGE

(24 V)

Fig. 1. AQ250 Control Panel layout (AQ25044B shown).

CONTACTS

SYMBOL

Fig. 2. Internal wiring for AQ2000 Series components line voltage relays.

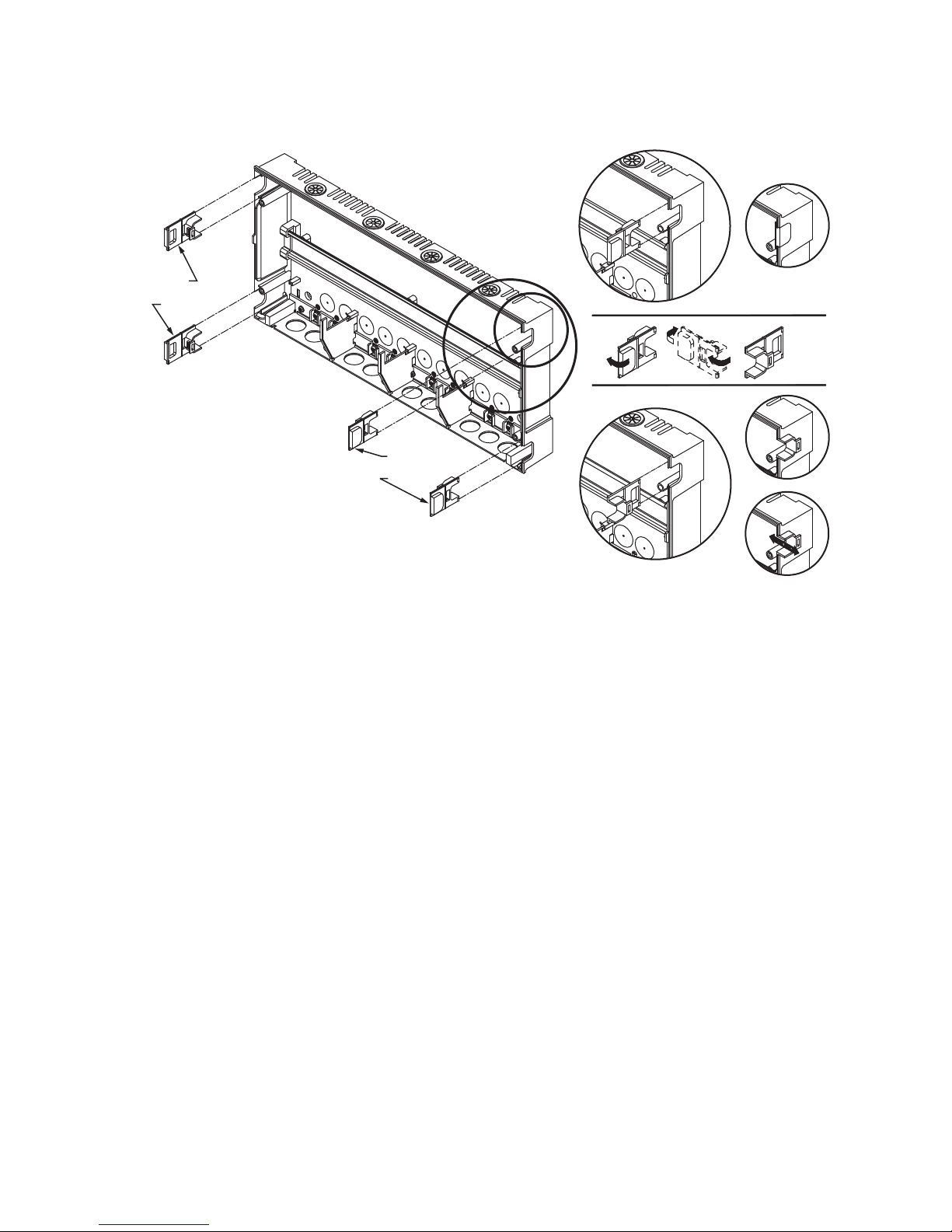

2MOUNTING

This section describes how to mount the Control Panel,

Expansion Zoning Panels, and the Thermostats.

Mount AQ250 Control Panel

Mount the control panel on the wall:

1. Use the template supplied with the AQ250 Series

Control Panel to mark the four mounting holes for the

panel.

2. Install two top screws, mount the panel, and install the

two lower screws.

ZR

Boiler

DHW

Aux

Zone 1

Zone 2

Zone 3

Zone 4

M29033

Mount Expansion Zoning Panels

If there are Expansion Zoning Panels to install, mount them to

the wall now:

1. Remove wire channel plugs from the AQ250 Control

Panel and any Expansion Zoning Panels (see Fig. 3 on

page 5).

2. Mount Expansion Zoning Panel on the right-hand end of

the AQ250 Control Panel. Install two top screws of the

Expansion Zoning Panel, ensuring it is level with the

adjoining Control Panel, and install two lower screws.

3. Reverse wire channel plugs and re-insert them into their

slot, to form a wiring channel between the Control Panel

and the Expansion Zoning Panel (see Fig. 3 on page 5)

and to connect the two panels together.

68-0306—05 4

Page 5

4. For any additional Expansion Zoning Panels, repeat

M23733A

WIRE

CHANNEL

PLUGS

WIRE

CHANNEL

PLUGS

steps 1–3.

AQ250 SERIES HYDRONIC CONTROL PANELS

Fig. 3. Orientation of wire channel plugs for creating pass-through wire channel and

for joining Control Panel to Expansion Zoning Panels.

Mount and Wire Thermostats in the Zones

Install the thermostats on the walls in the zones that are to be

controlled by the AQ250 Control Panel.

When using AQ1000 thermostats refer to the installation

instructions included with the AQ1000 thermostats.

If not done already, run low voltage thermostat wire (24 gauge

or heavier) from the thermostats back to the Zoning Modules

connected to the AQ250 Control Panel.

NOTES: If not otherwise specified, low voltage wiring should

be run with 18 gauge thermostat wire and line voltage

wiring should be run with 14 gauge wire. AQUATROL

line voltage screw terminals are only approved for use

with 22 to 12 gauge copper conductors.

Several wiring diagrams are included in this document. For additional information, refer to

http:// customer.honeywell.com or your local distributor.

3 WIRING PROCEDURE

The AQ250 Control Panel is pre-wired at the factory, making

for faster installation.

For all models, the low voltage output terminals located at the

top of the transformer secondary are wired to the R and C input

terminals of the Control Module, as well as the R and C inputs

of the Zoning Module. The B-B Exp. Bus terminals (13 and 14)

of the Control Module are wired to the B-B Exp. Bus IN

terminals of the Zoning Module.

Beginning with the top left of Fig. 4 on page 6 and moving

clockwise around the panel, wire components to the AQ250

Control Panel and Expansion Zoning Panels (if installed) in the

following six steps:

• “Step 1 – Transformer Wiring” on page 6

• “Step 2 – Control Panel Wiring” on page 6

• “Step 3 – Thermostats Wiring” on page 8

• “Step 4 – Zoning Equipment Wiring” on page 8

• “Step 5 – Line Volt age System Output s” on p age10

• “Step 6 – Connection To Line Voltage Power” on page 13

5 68-0306—05

Page 6

AQ250 SERIES HYDRONIC CONTROL PANELS

A

STEP 1 STEP 2 STEP 3

TO EXPANSION ZONING MODULES

(IF INSTALLED)

ZR

Fig. 4. Wiring sequence.

Step 1 – Transformer Wiring

Factory pre-wiring of the Control Panels is shown as dotted

lines in Fig. 4.

In addition to the pre-wiring, run low voltage jumper wires from

available R and C terminals on the secondary of the

transformer to the R and C terminals of any Expansion Zoning

Panel.

Step 2 – Control Panel Wiring

Wire the Temperature Sensors, System Demands, Low

Voltage Outputs, and Communication Bus (Refer to Fig. 5 for

wiring terminals on the top of the AQ250):

• “Temperature Sensor Wiring”

• “System Demands Wiring” on page 7

• “Low Voltage Outputs Wiring” on page 7

• “Communication Bus Wiring” on page 7

DHW

Boiler

Aux

STEP 5STEP 6

ZR Boi l er

STEP 4

Aux.

DHW

M29034

Temperature Sensor Wiring

Connect the lead wires of each sensor to the corresponding

terminals on top of the AQ15000B Control Module. See Fig. 5.

The Boiler Supply and Return sensors can be installed either

as strap-on sensors or inserted into an immersion well that is

packed with thermally-conductive paste.

BOILER SUPPLY AND RETURN SENSORS

the Supply and Return Sensors should be installed on the

Both

supply and return piping of the boiler for proper operation of

the AQ250 Control Panel. Even if the AQ250 is connected to a

modulating condensing boiler with its own supply and/or return

sensors, the AQ250’s sensors should still be installed for the

control to operate.

The Boiler Supply water sensor should be installed on the

supply piping close to the exit port of the boiler, using one of

the AQ12C11 strap-on sensors supplied with the AQ250. See

Fig. 6 on page 7.

TO DHW AQUASTAT

(OPTIONAL)

IN FROM “C” TERMINAL

ON TRANSFORMER MODULE

ON TRANSFORMER MODULE

(FACTORY-WIRED)

(FACTORY-WIRED)

IN FROM “R” TERMINAL

TO BOILER SUPPLY SENSOR

TO BOILER RETURN SENSOR

TO SETPOINT LOAD

Fig. 5. Low voltage wiring for the AQ1520M0 Control

Module.

68-0306—05 6

TO “T-T” TERMINALS ON

BOILER AQUASTAT

TO B-B “EXP.BUS IN”

TERMINALS ON CONNECTED

The Boiler Return sensor should be installed on the return

piping as close to the entrance port to the boiler as practical,

using the other AQ12C11 strap-on sensor supplied with the

AQ250. The correct location is one that will measure the

temperature of all combined sources of water returning back to

the boiler.

ZONING MODULE

Insulate strap-on sensors with pipe wrap to ensure accurate

boiler temperature sensing.

The Boiler Supply and Return water sensors come with 10 ft.

(3m) of wire to minimize the need for splicing.

M29035A

Page 7

Fig. 6. Strap-on temperature sensor installation.

M13763

Zone 1

Zone 2

Zone 3

Zone 4

ZR

Boiler

DHW

Aux

Zone 1

Zone 2

Zone 3

Zone 4

DATA BUS

COMMUNICATION

WIRING

M29036A

AQ25744B

AQ25042B

IMPORTANT

Do not run sensor wires parallel, or close, to

telephone, Ethernet, or power cables. Cross all

power, Ethernet, and telephone wiring at right angles.

If sensor wires are located in an area with strong

sources of electromagnetic interference, or EMI, (e.g.,

if sensor wires are run in the same electrical chase as

line voltage wiring) use twisted pair, shielded cable, or

run wires in a grounded metal conduit.

This is important because the calculated temperature

- based on the sensor's resistance reading - can be

distorted by high EMI, potentially causing the AQ250

to not operate properly.

If using shielded cable or conduit, connect the shield

wire to earth ground only

at the AQ250 panel. Do not

ground the shield or conduit at any other location or

electromagnetic shielding will be ineffective. If

shielded cable is used, Honeywell recommends the

use of shielded cable with a continuous ground plane,

such as foil, with an integral drain wire for bonding to

earth ground.

System Demands Wiring

HEAT DEMAND

Wire the Heat Demand (terminals 7 and 8) to a system setpoint

demand (dry contact closure), such as a pool or spa

Aquastat®.

DOMESTIC HOT WATER (OPTIONAL)

If used, wire the DHW (terminals 9 and 10) to the Aquastat or

thermostat on the domestic hot water tank.

AQ250 SERIES HYDRONIC CONTROL PANELS

DHW priority allows only DHW heat for the first 30 minutes of a

call for DHW and then allows the space heating needs to be

added in for the next 30 minutes. This cycle continues until the

call for DHW is satisfied.

NOTE: If the AQ panel is to be connected to a modulating

condensing boiler with built-in DHW management, it

is recommended to use an AQ25A or AQ251 control.

If using an AQ250 panel, it is necessary to install

DPST (Double pole, single throw) relay to clos e th e

DHW Demand on the boiler and the DHW Demand

on the AQ panel based on a call from the DHW

Aquastat.

Low Voltage Outputs Wiring

BOILER

Wire the Boiler dry contact output (terminals 11 and 12) to the

T-T terminals on the boiler Aquastat or the boiler's control

panel. See Fig. 14 on page 11 for wiring connections to a

typical boiler Aquastat.

It is not necessary to use the T-T terminals if connecting to a

Triple Aquastat, since the signal to the Aquastat is received

from the ZR/ZC terminals. See Fig. 14 and Fig. 15 beginning

on page 11 for line voltage connection to boiler Aquastats.

These contacts are made any time the system has a request

for boiler operation. When this occurs, the system’s primary

boiler pump comes on.

Communication Bus Wiring

All AQ2000 components communicate with each other on the

AQUATROL network using communication bus wiring. This

wiring must

features that depend on this networked communication (e.g.,

zone synchronization) will not function.

The communication bus wiring is polarity insensitive. The

installer does not need to worry about a +ve or –ve orientation

of the wires. If there are two wires connected between the B-B

Bus Exp. In on one module and B-B Bus Exp. Out on another

module, there will be communication. See example in Fig. 7 for

how this wiring is to be installed.

The communication bus connections for AQ250 Control

Panels are pre-wired at the factory.

connect all AQ2000 components. Otherwise,

Fig. 7. Wiring for communication bus.

7 68-0306—05

Page 8

AQ250 SERIES HYDRONIC CONTROL PANELS

FROM B-B “EXP. BUS”

TERMINALS ON

CONTROL MODULE

TO B-B “EXP. BUS IN” TERMINALS

ON CONNECTED ZONING MODULE

(IF AN EXPANSION ZONING PANEL

IS CONNECTED)

THERMOSTAT ON ZONE 1

THERMOSTAT ON ZONE 2

THERMOSTAT ON ZONE 3

THERMOSTAT ON ZONE 4

M13776C

FROM LINE VOLTAGE

120V TERMINALS

(N AND L) ON BOTTOM

OF TRANSFORMER

M29037A

M27688A

Step 3 – Thermostats Wiring

NOTE: The new AQ2000 panels will work with either digital

(electronic) non-communicating thermostats or

AQ1000 communicating thermostats.

1. Using low voltage thermostat wire, connect one

thermostat from each zone to the corresponding

THERMOSTATS Zone X inputs on top of the Zoning

Module (see Fig. 8).

2. If there are additional zones (on Expansion Zoning

Panels) connected to this Zoning Module, run low

voltage thermostat wiring from the B-B Exp. Bus Out

connection (terminals 13 and 14) of the Zoning Module

to the B-B Exp. Bus. In connection (terminals 3 and 4) on

the Expansion Zoning Panel.

IMPORTANT

Do not run thermostat wires parallel, or close, to

telephone, Ethernet, or power cables. Cross all

power, Ethernet, and telephone wiring at right angles.

If thermostat wires are located in an area with strong

sources of electromagnetic interference, or EMI, (e.g.,

if thermostat wires are run in the same electrical

chase as line voltage wiring) use twisted pair,

shielded cable, or run wires in a grounded metal

conduit.

Step 4 – Zoning Equipment Wiring

Because the Zoning Module of the AQ25042B Control Panel

can be used with either line voltage pumps or valves, or low

voltage zone valves (with or without end switches), field

installed wiring of the correct voltage needs to be connected to

the zoning equipment terminals on the bottom left portion of

the Zoning Module.

Line Voltage – Circulators or Zone Valves

Refer to Fig. 9. Remove the plastic wiring barrier that is located

in the bottom wiring channel between the AQ15000B Control

Module and the Zoning Module. Run jumper wires from the N

and L terminals on the bottom of the AQ250 Control Panel’s

transformer, through the wiring channel across the bottom of

the Control Panel, and to the corresponding N and L terminals

of the Zoning Module.

This is important, because the AQ1000 thermostats

are communicating thermostats which send and

received data via the two wires connecting them to

the Zoning Module. This data can be distorted by the

EMI, potentially causing the AQ250 to not operate

properly.

3. Run low voltage thermostat wiring from the R and C

output terminals on the secondary of the AQ250 Control

Panel’s transformer to the R and C input terminals on the

Expansion Zoning Panel. As an alternative, you can run

low voltage thermostat wiring from the R and C terminals

on the Zoning Module to the R and C terminals on the

Expansion Zoning Panel.

Fig. 9. Wiring an AQ15540B Zoning Module for use

with line voltage circulators.

Low Voltage – Zone Valves With or Without End

Switches

IMPORTANT

If low voltage zone valves are used with the

AQ25042B Control Panel, the supplied Low Voltage

Output sticker (shown in Fig. 10) must

over the line voltage output sticker (see Fig. 9) that is

already attached to the Zoning Module.

Fig. 10. Low voltage output sticker.

WIRING ZONE VALVES WITHOUT

END SWITCHES

— Using Fig. 11 on page 9 as a guide, run jumper wires

from the R and C terminals on the secondary of the

AQ250’s transformer, through the wiring channel

across the top of the Control Panel, and down through

the wiring channel on the right side of the panel and

over to the R and C terminals on the bottom of the

Zoning Module.

be applied

Fig. 8. Connecting thermostats.

68-0306—05 8

Page 9

AQ250 SERIES HYDRONIC CONTROL PANELS

CAUTION

FROM LOW VOLTAGE

24 VAC TERMINALS

(C AND R) ON TOP

OF TRANSFORMER

M M M M

M27689A

M

M27690A

M

M

M

Equipment Damage Hazard.

Can damage internal circuitry of Zoning Module.

The ES1 and ES2 terminals of the AQ15740B Zoning

Module are powered terminals and must only

be

connected to a set of dry contacts, such as a zone

valve motor's end switch. If power is applied to these

contacts (for example, by running line voltage through

the zone valves’ end switches to bring on a circulator

feeding those valves), the internal circuitry of the

Zoning Module will be damaged, in which case the

warranty for this product will be voided.

Fig. 11. W i ring an AQ15540B Zoning Module for use

with low voltage zone valves without

end switches.

WIRING ZONE VALVES WITH END SWITCHES:

— See Fig. 12. 24 Vac power is pre-wired between the

transformer secondary at the top left of the AQ250’s

transformer and the AQ15740B Zoning Module. No

field wiring is required.

Fig. 12. Wiring an AQ15740B Zoning Module for use

with low voltage zone valves with end switches.

NOTE: When wiring zone valves with end switches, note the

transformer's VA:

If low voltage zone valves with end switches are used

for zone control, make sure the selected zone valves

do not draw more power (VA) than the 38 VA capacity

of the AQ10X38 transformer supplied with the AQ250

Control Panel. This integral transformer has enough

power to operate 4 motorized zone valves (such as

Honeywell V8043E valves or 4 valves using lowamperage draw, heat motor actuators, such as

Honeywell MV100 actuators), plus power the

electronics of the AQ250's Control Module and up to

16 AQ1000 thermostats. If zone valves with highamperage draw, heat motor actuators are used (such

as Taco 500 series zone valves), additional 24 Vac

transformer capacity will need to be wired to the

Zoning Module to power the valves. See Fig. 13 on

page 10 for recommended wiring of add itional low

voltage VA capacity to AQ2000 Series Zoning

Modules.

9 68-0306—05

Page 10

AQ250 SERIES HYDRONIC CONTROL PANELS

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

M29038A

THERMOSTATS

ZONE 1 ZONE 2 ZONE 3

ZONE 4

Zone 1

Zone 2

Zone 3

Zone 4

USING AN AQ15740B

VALVE ZONING MODULE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

1

Zone 1

Zone 2

Zone 3

Zone 4

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

24 VAC

100 VA

TRANSFORMER

115 VAC

115 VAC

24 VAC

100 VA

TRANSFORMER

1

1

USING AN AQ15540B

PUMP ZONING MODULE

Fig. 13. Wiring of additional low voltage VA capacity.

Step 5 – Line Voltage System Outputs

See Fig. 14 and Fig. 1 5 on page 11 for wiring diagrams for the

line voltage outputs.

NOTE: It is not necessary to connect the boiler equipment’s

“T-T” terminals to the low voltage BOILER dry

contacts (Terminals 11-12) of the AQ250 when using

a Triple Aquastat on the boiler. See Fig. 15 on

page 11.

Follow these steps to wire the devices to the AQ250 Control

Module.

“1. Boiler Pump” on page 12

“2. DHW Aquastat Device” on page 12

“3. Line Voltage Rated Aux Output (optional)” on page 12

68-0306—05 10

Page 11

AQ250 SERIES HYDRONIC CONTROL PANELS

TO BOILER

TERMINALS 11-12

ON TOP OF AQ15200B

CONTROL MODULE

ZC

ZR

B1

B2

C1C2

L1

L2

TT

G

L8124, L7224

R8184

BURNER AND

IGNITION

C554

F

F

T

T

BLACK

WHITE

ORANGE

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

L1

(HOT)

L2

1

2

1

DO NOT WIRE THE BOILER LOOP CIRCULATOR TO THE AQUASTAT'S C1/C2 TERMINALS; IT MUST BE CONNECTED TO THE BOILER PUMP TERMINALS

ON THE BOTTOM OF THE AQ15000B CONTROL MODULE WHEN MAINTAINING A MINIMUM BOILER TEMPERATURE (WITH A TRIPLE FUNCTION AQUASTAT).

2

BOILER

PUMP

M29039B

FROM LINE

VOLTAGE 120V

TERMINALS

(N AND L) ON

BOTTOM OF

TRANSFORMER

TO AUXILIARY DEVICE

(INSTALLER-DEFINED)

JUMPERED

AT FACTORY

Fig. 14. Line Voltage Connections for AQ250.

TO BOILER TERMINALS

11 AND 12 ON TOP OF

AQ15000B CONTROL MODULE

T

T

L2

G

L2

1

L1

(HOT)

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD PROTECTION AS REQUIRED.

2

FOR INSTALLATIONS USING A TRIPLE FUNCTION AQUASTAT, NOTE THAT THE FACTORY-INSTALLED JUMPER BETWEEN THE ZR AND ZC TERMINALS

MUST BE REMOVED. THE ZR AND ZC TERMINALS ON THE AQ15000B CONTROL MODULE MUST BE WIRED TO THE ZR AND ZC TERMINALS,

RESPECTIVELY, OF THE TRIPLE AQUASTAT.

L1

C2

BOILER

PUMP

TO LINE VOLTAGE 120V

TERMINALS (N AND L) ON

BOTTOM OF TRANSFORMER

L8124, L7224

ZC

2

C1

ZR

B1

B2

N

L

TO AUXILIARY DEVICE

(INSTALLER-DEFINED)

R8184

T

T

BLACK

F

F

WHITE

ORANGE

C554

BURNER AND

IGNITION

M29040B

Fig. 15. Line Voltage Connections for AQ250 using triple function Aquastat.

11 68-0306—05

Page 12

AQ250 SERIES HYDRONIC CONTROL PANELS

M29044A

1

2

DO NOT WIRE THE BOILER LOOP CIRCULATOR TO THE BOILER’S AQUASTAT TERMINALS C1/C2; IT MUST BE CONNECTED TO THE BOILER PUMP

TERMINALS ON THE BOTTOM OF THE AQ15000B CONTROL MODULE WHEN MAINTAINING A MINIMUM BOILER TEMPERATURE (WITH A TRIPLE

FUNCTION AQUASTAT).

FOR INSTALLATIONS USING A TRIPLE FUNCTION AQUASTAT, NOTE THAT THE FACTORY-INSTALLED JUMPER BETWEEN THE ZR AND ZC TERMINALS

OF THE AQ15000B CONTROL MODULE MUST BE REMOVED. THE ZR AND ZC TERMINALS ON THE AQ15000B CONTROL MODULE MUST BE WIRED TO

THE ZR AND ZC TERMINALS, RESPECTIVELY, OF THE TRIPLE AQUASTAT.

1

2

FROM LINE VOLTAGE

120V TERMINALS

(N AND L) ON BOTTOM

OF TRANSFORMER

TO AUXILIARY DEVICE

(INSTALLER-DEFINED)

JUMPERED

AT FACTORY

1. Boiler Pump

Connect the N and L wires of the boiler loop pump to the N and

switched hot ( ) terminals of the line voltage Boiler output,

shown in Fig. 17. The ground wire of the pump can be

connected to any of the 6 ground screw terminals located on

the back surface of the Control Panel enclosure.

NOTE: If the AQ250 is connected to a modulating

condensing boiler, the boiler pump may need to be

connected to the boiler, not

the AQ250. Confirm this

with the boiler’s installation manual.

2. DHW Aquastat Device

Wire the DHW pump or line voltage zone valve to the N and

switched hot ( ) terminals of the DHW output, as shown in

Fig. 17.

If using a low voltage zone valve, wire the primary of a spudmounted transformer (115V to 24V) to the DHW line voltage

contacts and connect the low voltage zone valve to the

secondary terminals of this transformer. A spud-mounted

transformer may be located in one of the conduit knockouts on

the bottom of the AQ250 Control Panel.

The DHW contacts are made when the DHW inputs on

terminals 9 and 10 are shorted by the controlling Aquastat.

When DHW Priority is enabled, the system has a 30 minute

priority over all calls for heat. After 30 minutes, calls for heat

are added back in to the operation for 30 minutes and then

turned off again, if the DHW demand is still active in the

system. This repeats until the DHW is satisfied.

NOTE: If the AQ250 is conne cted to a modulating

condensing boiler, the DHW pump will probably need

to be connected to the boiler, not

the AQ250. Confirm

this with the boiler’s installation manual.

3. Line Voltage Rated Aux Output (optional)

To connect a line voltage auxiliary device to these contacts,

such as a boiler bypass pump, power the device from the N

and L terminals on the bottom of the Control Module, running

the hot (L) lead through the Aux. Pump contacts. See Fig. 16

for details. The exact wiring schematic will depend on what is

connected to these dry contacts.

NOTE: Use of this output is opti onal. The Aux. pump dry

contacts are line voltage-rated but unpowered. A low

voltage device can be connected to these contacts,

but the wire's insulation must meet applicable codes

for use in line voltage enclosures.

BY-PASS PUMP

Fig. 16. Wiring of the Aux. pump line voltage rated dry

contacts (example shown is a by-pass pump).

M29045A

Fig. 17. Wiring for Boiler Pump, and DHW Device.

68-0306—05 12

Page 13

Step 6 – Connection To Line Voltage Power

CAUTION

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

M29041A

Menu

Home

OK

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

Zone 1

Zone 2

Zone 3

Zone 4

M29042A

Menu

Home

OK

Connect the N and L line voltage inputs of the primary on the

AQ250 transformer to the electrical distribution panel and

power up the Control. A service switch should be installed on

the hot (L) lead to the distribution panel.

If multiple Zoning Modules are connected to the AQ250

Control Panel, the line voltage wiring can either be run directly

from the N and L terminals on the primary of the transformer to

each Zoning Module (Fig. 18 on page 13), or run in a daisy

chain from the N and L terminals of one AQ2000 module to the

N and L terminals of the next AQ2000 module (see Fig. 19 on

page 13).

AQ250 SERIES HYDRONIC CONTROL PANELS

Electrical Shock or Equipment Damage Hazard.

Can shock individuals or short equipment circuitry.

When line voltage is applied to the AQ250 Control

Panel and the front cover of the Panel is removed,

there is a risk of electrocution. Be careful to avoid

contact with the line voltage (N and L) terminals, either

with your fingers or with metal tools (such as a

screwdriver) when power is applied to the Control

Panel.

Fig. 18. Connections for multiple Zoning Panels - parallel wiring.

Fig. 19. Alternate Connections for multiple Zoning Panels - daisy chain wiring.

13 68-0306—05

Page 14

AQ250 SERIES HYDRONIC CONTROL PANELS

M23731A

AQ15540B

4 CONFIGURE THE CONTROL PANEL

DIP SWITCHES

Only two steps are required to set up the AQ250 Series Control

Panel:

1. Check the DIP switch settings for the Control Module.

(see “AQ250 Control Module DIP Switch Settings” on

page 14)

2. Check the DIP switch settings for each Zoning Module.

(see “Zoning Module DIP Switch Settings” on page 15)

AQ250 Control Module DIP Switch Location

Operation of the AQ250’s Control Module is set by the

positions of its DIP switches, which are located behind the

blank cover in the left most section of the Control Module

(beside the section labeled ZR). See Fig. 20 for location of

these DIP switches.

Zoning Module DIP Switch Location

The AQ15540B (pump Zoning Module) and AQ15740B (valves

with end switches Zoning Module) both have DIP switches in

8-switch banks and are concealed behind snap-on covers, as

shown in Fig. 20.

DIP Switch Configuration

AQ250 Control Module DIP Switch Settings

AQ250 Control Panels come from the factory with pre-defined

settings for all DIP switches. These factory default settings

were chosen because they are commonly-used by hydronics

contractors across North America. That means that most of the

settings only need to be checked by the installing contractor to

make sure they’re suitable for the installation.

Although for many installations, these factory default values for

the Control Module and the Zoning Module(s) are suitable,

Honeywell recommends that they be reviewed, and changed

as necessary, to get optimal performance of the hydronic

system controlled by the AQ2000 Series products.

A chart of the setting options for each DIP switch is attached to

the inside of the DIP switch cover. More detailed explanations

for these settings, including the pre-set factory defaults for

each DIP switch, is shown in Table 2.

When you finish setting the DIP switches for the Control Panel,

replace the front cover of the AQ250 Control Panel.

NOTE: The snap-on DIP switch cover is designed so it

cannot be removed (exposing the DIP switches)

when the front cover of the AQ250 Control Panel is in

place.

Fig. 20. Location of concealed DIP switches for AQ15000B

Control Module and the AQ155/AQ157 Zoni ng Modules.

68-0306—05 14

Page 15

AQ250 SERIES HYDRONIC CONTROL PANELS

M23719A

AQ15000B

Table 2. AQ15000B Control Module DIP switch arrangeme nt

DIP Switch Switch Description Label and Factory Settings

Diagnostic

Diagnostic

Test

Test

1234567 8

DHW

Aux.

Mass

DHW Device: Pump or Valve

1

DHW Priority: Off or Priority

2

DHW Priority Override: Off or O/Ride (override)

3

Boiler post purge location: Off = zones only; Purge = DHW tank first, then zones

4

5 Aux output: Main = default; Group = group pump

6 Aux output: Main = default; Bypass = boiler bypass pump

Load Mass: Lo = Low mass (baseboard); Hi = High mass (radiant slab)

7

Not used at this time

8

ON

M29043

Zoning Module DIP Switch Settings

A chart of the different settings for each DIP switch is attached

to the inside of each DIP switch cover.

Refer to Table 3 on page 16, and check all DIP switch settings.

If necessary, change the switch settings to suit the desired

operation of the hydronic installation.

NOTES:

1. To set DIP switches 1 through 4, which identify the

unique address of each zone on the AQUATROL

network):

Refer to the descriptions in Table 3 for the correct

DIP switch settings for the Pump or Valve Zoning

Module.

Unpredictable zone behavior may occur if more

than one Zoning Module has DIP switches (1-4)

set to the same address.

2. DIP Switch 5 enables or disables Zone

Synchronization:

• The factory setting disables Zone Synchronization,

which is an energy saving feature of the AQ2000

panels. Zone Synchronization coordinates zone

demands to start at the same time when the boiler

cycle begins. The AQ2000 functions as activating

valves. The valve logic induces a delay before

activating the boiler pump even when zone pumps

are used. When Zone Synchronization is not

selected, the zone demands are served whenever

they call for heat.

• The Zone Synchronization feature replaces the

pump/valve selection of previous AQ2000 versions.

3. 4. DIP Switch 8 functionality:

• The factory setting enables 1-stage per zone

thermostat. The zoning module operates as four 1stage zones.

• When using a 2-stage thermostat, set DIP switch 8

to 2-Stg. The 2-stage selection uses TH1 and TH2

inputs for 2-stage thermostat control. For the

selected zone, TH1 is the first stage input from the

thermostat and TH2 is the second stage input.

Inputs TH3 and TH4 operate in same manner. The

2-stage selection reduces the zoning module to a 2

zone module from a 4 zone module.

• When using digital 2-stage thermostats (non

AQ1000 thermostats), the system set-up process

changes slightly. During system set-up, create an

artificial demand on the zoning module by

increasing the set point on the thermostat. The

artificial demand is required during the PRI/SEC

setup menu to select the primary and secondary

loop for each zone and stage.

Review the settings of all DIP switches for each Zoning Module

connected to an AQ15000B, to ensure they are correct before

system start-up.

When you finish setting the DIP switches for all the Zoning

Modules, replace the cover of each Expansion Zoning Panel.

NOTE: The snap-on DIP switch covers are designed so they

cannot be removed (exposing the DIP switches)

when the front cover of the AQ250 Control Panel is in

place.

15 68-0306—05

Page 16

AQ250 SERIES HYDRONIC CONTROL PANELS

M23720A

AQ15540B

Test

Diagnostic

Test

M34972

ON

12345678

Table 3. AQ15540B Zoning Module (Pump Zoning Module) DIP Switch Arrangement.

DIP

Switch Switch Description Label and Factory Settings

Zone Address: The positions of these 4 DIP switches define the unique address for

1

each zone on the AQUATROL network. For each group of 4 zones, there can be only

2

one DIP switch in the right hand (On) position.

3

4

The correct DIP switch settings for each zone module are:

• First Zone (1-4) Module: 1 = ON position; 2, 3, and 4 = OFF position

• Second Zone (5-8) Module: 2 = ON position; 1, 3, and 4 = OFF position

• Third Zone (9-12) Module: 3 = ON position; 1, 2, and 4 = OFF position

• Fourth Zone (13-16) Module: 4 = ON position; 1, 2, and 3 = OFF position

5•If set to SYNC, zone synchronization is enabled.

• If set to NOT, zone synchronization is disabled.

6•If zone valves are normally closed (N.C.), set the NC/NO DIP switch to the Off

position.

• If zone valves are normally open (N.O.), set the NC/NO DIP switch to the On

position.

7•If set to Group (ON position), the AUX Pump contacts on the Control Module are

switched when any of the zones on this Zoning Module are active.

a

• If set to - (OFF position), the AUX Pump contacts are not affected by activity on

these zones.

8•If set to 2-Stg (ON position), then 2-stage operation is activated on thermostat

inputs. The zoning module operates as two 2-stage zones or 3 zones (one 2-stage

and two 1-stage).

• If set to 1-Stg (OFF position), then operates as four 1-stage zones.

a

The AQ15000B Boiler Control Module DIP switch #5 must be set to GROUP position and DIP switch #6 must be set to MAIN position.

68-0306—05 16

Page 17

AQ250 SERIES HYDRONIC CONTROL PANELS

5 TEST AND CHECK OUT THE

INSTALLATION

Startup

IMPORTANT

Apply power to the AQ250 Control Panel only after

of the AQ2000 SERIES components (Control Panel,

thermostats, sensors, Zoning Modules/Panels) have

been connected to the other equipment in the

hydronic heating system (boiler, zone valves or

pumps, DHW, Aquastat, etc.).

When powered, the AQ250 Control Panel begins its start-up

routine, establishing communication with all other AQ2000

Series components on the AQUATROL network.

Auto Test

This section describes the Auto Test functions of the Control

Module and the Zoning Panel(s).

A) Auto Test– AQ15000B Control Module

Auto Test operation enables the installer to test the system

installation by sequentially activating all of the Control Module's

outputs for 15 seconds each. Each step of the Auto Test

routine may be paused or skipped by pressing the Test button,

which is located above the DIP switches on the AQ15000B

Control Module.

STATUS LEDS

Every status light (ZR, BOILER pump, AUXiliary pump, DHW

pump) will be turned on for 15 seconds when its corresponding

output is energized during Auto Test.

all

5. Pressing the T est button at any time during the Auto Test

routine pauses the routine indefinitely. While paused, the

Diagnostic LED blinks slowly.

6. Pressing the T est button while the Auto Test routine is

paused advances the routine to the start of the next step

in the routine (testing the next output) and the Auto Test

routine resumes its test procedure.

7. When the Auto T est routine is completed, the Diagnostic

LED returns to a constant ON status (no blinking).

8. To test each of the zone outputs (pumps or valves)

individually, proceed to “B) Auto Test– AQ155/AQ157

Zoning Modules” to run the Auto Test feature for each

AQ155 / AQ157 Zoning Module attached to the

AQ15000B Control Module.

SEQUENCE OF OPERATION—AQ15000B CONTROL MODULE

1. When the Test button is pressed, ALL space heating

zones connected to the Control Module are energized

and remain energized for the duration of the Auto Test

routine

2. At the same time, the Diagnostic LED on the AQ15000B

Control Module begins to blink quickl y, the ZR relay is

energized for 15 seconds, then the relay shuts off.

3. Next, the BOILER relay is energized for 15 seconds,

then shuts off.

4. Next, the AUX relay is energized for 15 seconds, then

shuts off.

5. Next, the DHW relay is energized for 15 seconds, then

shuts off.

6. Next, the Boiler T-T dry contacts are energized for 15

seconds, then re-opened.

7. Then the AQ15000B exits the Auto Test routine and the

Diagnostic LED on the Module returns to steady

illumination (no blinking).

CONTROL MODULE DIAGNOSTIC LED

This LED, which is labeled Diagnostic and is located above the

DIP switches on the AQ15000B Control Module, is used by the

AQ250 to communicate diagnostic data to the user:

• Constantly ON indicates that the unit is working properly.

• Constant, fast blinking indicates that the unit is in the Auto

Test mode.

• Constant, slow blinking indicates that Auto Test mode has

been paused.

• Coded blinking is used to communicate an error code to the

user. Refer to the Troubleshooting section of these

instructions for an explanation of these codes.

NOTE: The Diagnostic LED is OFF when the AQ250 Control

Panel is not powered.

If this is the first time the AQ250 has been started:

1. Remove the front cover of the AQ250 by loosening the

4 captive slot-Phillips screws.

2. Remove the AQ15000B Control Module’s DIP switch

cover (refer to Figure Fig. 20 on page 14 for the DIP

switch cover location)

3. Check to make sure that the LED, labelled Diagnostic, is

steadily illuminated (no blinking).

4. To begin the Auto Test, press the Test button until you

feel a click. The AQ250 now begins the Auto T est routine

and the Diagnostic LED on the AQ15000B Control

Module blinks quickly.

B) Auto Test– AQ155/AQ157 Zoning Modules

Auto Test operation for Zoning Modules enables the installer to

test all zones wired to the Zoning Module by sequentially

activating the equipment connected to each zone output (pump

or valve) for 15 seconds. Each step of the Auto Test routine

may be paused or skipped by pressing the Test button.

ZONING MODULE DIAGNOSTIC LED

The LED, which is labeled Diagnostic and is located above the

DIP switches on the AQ155/AQ157 Zoning Modules, is used

for communicating diagnostic data to the Installer.

Refer to “Troubleshooting” on page 19 for a description of the

Diagnostic LED error codes (blinking rates).

NOTE: The Diagnostic LED is OFF when the AQ155/AQ157

Zoning Module is not powered.

If this is the first time the AQ250 Control Panel has been

started:

1. With the front cover of the AQ250 Control Panel

removed and set aside, remove the AQ Zoning Module

DIP switch cover (refer to Figure Fig. 20 on page 14 for

the DIP switch cover location).

2. Check to make sure that the LED, labelled Diagnostic, is

steadily illuminated (no blinking).

3. To begin the Auto Test, press the Test button until you

feel a click. The AQ155/AQ157 Zoning Module now

begins the Auto Test routine, and the Diagnostic LED on

the Zoning Module blinks quickly.

17 68-0306—05

Page 18

AQ250 SERIES HYDRONIC CONTROL PANELS

4. Pressing the T est button at any time during the Auto Test

routine pauses the routine indefinitely. While paused, the

Diagnostic LED blinks slowly.

5. Pressing the Te st button while the Auto Test routine is

paused advances the routine to the start of the next step

in the routine (testing the next zoning output) and the

Auto Test routine resumes its test procedure.

6. When the Auto Test routine is completed, the Diagnostic

LED returns to a constant ON status (no blinking).

7. Replace the DIP switch cover on the Zoning Module.

8. For each AQ155/AQ157 Zoning Module connected to

the AQ250, repeat steps 1-7.

SEQUENCE OF OPERATION—AQ155/AQ157 ZONING MODULES

1. When the Auto Test button is pressed, Zone 1 of the

Zoning Module is energized and the Diagnostic LED on

the AQ155/AQ157 begins to blink quickly.

2. Zone 1 remains energized for 15 seconds, then shuts off.

3. Next, each of the remaining zones is energized,

sequentially for 15 seconds, starting with Zone 2, and

then shuts off.

4. After Zone 4 has de-energizes, the AQ155/AQ157 exits

the Auto Test routine and the Diagnostic LED on the

Module returns to steady illumination (no blinking).

C) End Auto Test

If no errors are detected in the Control Module or Zoning

Module Auto Test routines, the AQ250 is now ready for

operation. If errors are detected, refer to “Troubleshooting” on

page 19.

Checkout

1. If present, turn down the DHW Aquastat to avoid interfering with space heating control operation.

2. Turn up the setpoint of one of the AQ1000 zone

thermostats.

2.1 The zone valve or pump associated with that zone

turns on.

2.2 The Boiler and T-T relay outputs energize.

NOTE: When a setpoint is changed on an AQ1000

thermostat, the AQ250’s boiler short cycle

protection is disabled in favor of a faster

reaction for the user.

3. Turn down the setpoint of one of the AQ1000 zone

thermostats.

3.1 The zone valve or pump associated with that zone

should turn off.

3.2 The Boiler, and T-T relay outputs should de-energize.

4. Repeat steps 2 and 3 for all zones to verify each zone is

operating correctly. Thermostats may be exercised

individually or all together to accelerate the check out

process.

5. Turn up the DHW Aquastat to simulate a call for hot

water.

5.1 If the DHW device is a pump, the DHW relay output

energizes immediately, and the Boiler pump relay

remains off.

5.2 If the DHW device is a valve, the Boiler pump relay

energizes after a 15 second delay to allow the zone

valve to fully open.

5.3 Turn up the set point of one of the AQ1000 zone

thermostats.

5.3.1 If the DHW relay is configured to control a

pump, and DHW Priority is selected, the

Boiler and associated zone pumps relays

remain off.

5.3.2 If the DHW relay is configured to control a

valve, and DHW Priority is selected, the

associated zone relays remain off.

5.3.3 If DHW Priority is disabled, space heating

(zone pumps and valves) operates normally

even during a call for DHW.

68-0306—05 18

6. Turn down the DHW Aquastat to end the call for hot

water. Space heating operation should continue (if DHW

priority is disabled) or resume (if DHW PRIOrity is

enabled).

Page 19

AQ250 SERIES HYDRONIC CONTROL PANELS

6 PURGE AIR FROM ALL SYSTEM

AND ZONE PIPING

Purging air from all zones in the hydronic system is easily

accomplished with the AQ250 by using a modification to the

Auto Test feature (described in “Auto Test” on page 17) as

follows:

• To purge all zones on the AQUATROL network press the

T est button on the AQ15000B Control Module once to begin

the Auto T est routine. Quickly press it again 3 times until the

Boiler relay LED illuminates and

AQ15000B blinks slowly (which indicates the Auto Test

routine has been paused). The boiler pump now remains

energized for the duration of the Purge routine (and

therefore can be purging all loops of air) until the Test button

is pressed again.

• The Diagnostic LED blinks slowly while in paused mode.

Continue to purge the boiler loop as long as is needed to

remove air from the system.

• Leaving the boiler pump operating, push the Test button on

the Zoning Module for any space heating zones you wish to

purge.

• With the first zone's output energized (the LED for

Zone 1 illuminates), press the Test button again to

pause the Auto Test routine.

• When Zone 1 has been sufficiently purged, press

the Test button again to begin purging Zone 2.

• Again, press the Test button to pause the Auto Test

routine while purging Zone 2.

• Continue to purge all other space heating zones in

the system.

If additional purging is required for any zone, the Auto Test

procedure can be activated for any individual Zoning Module

by pressing the Test button located above that Zoning

Module’s DIP switches. Refer to “B) Auto Test– AQ155/AQ157

Zoning Modules” on page 17.

the Diagnostic LED of the

7 DOCUMENT AND KEEP A RECORD

OF ALL SYSTEM SETTINGS

After the AQ250 Series Control Panel and any AQ255/AQ257

Expansion Zoning Panels have been set up and the entire

hydronic installation is operating properly, it is important to

document all the system settings for future reference.

Job Records

All AQ2000 Series Panels are shipped with Installation Job

Records

filled out completely and saved in the Installing Contractor’s

files.

a

for documenting these settings.These should be

TROUBLESHOOTING

The following information helps the installer correctly identify

system problems, making troubleshooting much faster . Table 4

and Table 5 on page 20 describe the possible error codes that

can be communicated on the diagnostic LEDs of the

AQ15000B Control Module and AQ155/AQ157 Zoning Module.

Communications Loss

Because all AQ2000 Series components communicate with

each other via the dedicated AQUATROL network when

controlling a hydronic system, one possible failure mode of the

AQ250 would be loss of communication between the

AQ15000B Control Module and any connected Zoning

Modules, or between a Zoning Module and any zone

thermostats connected to the AQUA TROL network. In general,

the Control Module:

• Periodically tries to re-establish communication with any

lost components on the network.

• Initializes any component that re-establishes its

communication.

CONTROL MODULE REACTION

When the AQ15000B Control Module loses communication

with any number of zones for more than one minute (as long as

there is still at least one zone communicating on the

AQUATROL network), the AQ250 continues to deliver heat to

the other non-communicating zones.

When communication is lost with all

Freeze Protection mode, in which it fires the boiler and then

activates the Boiler (supply) pump and zone equipment for a

period of 4 minutes every hour. This should provide sufficient

heat to the system to prevent a building from freezing up until

communication is re-established between the AQ2000 Series

components.

ZONING MODULE REACTION

When a Zoning Module loses communication with the Control

Module (as long as there is at least one other Zoning Module

communicating with the Control Module), the Zoning Module

operates its pumps or valves in a conventional, nonsynchronized zoning fashion. That is, it operates according to

the demands from the thermostats, without zone

synchronization or waiting for permission from the AQ15000B

Control Module to operate. This allows the zones to extract any

heat provided by the boiler.

When using AQ1000 thermostats and communication is lost

between a Zoning Module and one of its thermostats, that zone

is invisible to the Control Module, and the Zoning Module stops

serving that zone and the zone’s pump or valve is deenergized.

zones, the AQ250 enters

a

For the AQ250 Series, refer to AQ25042B RelayPLUS Zone

Synchronizing Boiler Control, (form 69-1972) and AQ25044B

RelayPLUS Zone Synchronizing Boiler Control (form 69-

2030)

The AQ250 provides Zoning Module diagnostic information via

the Diagnostic LED located above the DIP switches on each

Zoning Module.

19 68-0306—05

Page 20

AQ250 SERIES HYDRONIC CONTROL PANELS

Table 4. AQ15000B Control Module LED Display and Error Codes.

Diagnostic Led Status System Condition Action Required

Steady (no blinking) No system problem detected None.

Fast blinking (4 blinks per second) Auto Test is in operation None. Permit the control to finish Auto

Test routine.

Slow blinking (2 blinks every 3 seconds) Auto Test has been paused Press the Test button to resume Auto

Test routine.

Coded blinking = ERROR 2 blinks then pause Freeze protection activated across

AQUATROL network

All zones have lost communication with

controller.

• Check B-B wiring between Control

Module and Zoning Module.

4 blinks then pause Return sensor open / short Check the return sensor wiring.

5 blinks then pause Supply sensor open / short Check the supply sensor wiring.

Table 5. AQ155/AQ157 Zoning Module LED Display and Error Codes.

Diagnostic Led Status System Condition Action Required

Steady (no blinking) No system problem detected None.

Fast blinking (4 blinks per second) Auto Test is in operation None. Permit the control to finish Auto

Test routine.

Slow blinking (2 blinks every 3 seconds) Auto Test has been paused Press the Test button to resume Auto

Test routine.

Coded blinking = ERROR • 2 blinks then

pause

Freeze protection activated on the

Zoning Module

Zoning module has lost communication

with controller.

• Check B-B wiring between Control

Module and Zoning Module.

• 3 blinks then

pause

Communication lost with ALL

thermostats

Check thermostat wiring to Zoning

Modules.

AQUATROL® is a registered trademark of Honeywell International Inc.

Aquastat® is a registered trademark of Honeywell International Inc.

Automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

customer.honeywell.com

® U.S. Registered Trademark

© 2013 Honeywell International Inc.

68-0306—05 L.L. Rev. 10-13

Printed in United States

Loading...

Loading...