Page 1

FEATURES

AQ2002

Room unit (optional)

APPLICATION

Aquatrol 2002 is a straightforward, versatile controller which

forms the basis of an outside compensated control system

for single or dual zone low pressure hot water heating

systems. The controller offers build-in optimizer and many

other advanced featured whilst still retaining simple user

adjustments.

It provides self adaptive heating curve, optimum start/stop

operation, outside air compensated mixed water control

using a 3-port motorized valve and pump, boiler, and

domestic hot water control using a valve and/or pump.

A wide range of compatible sensors, a remote unit, valves

and actuators complement the control system.

AQ2002

OPTIMISER/COMPENSATOR

CONTROLLER

PRODUCT SPECIFICATION SHEET

• Digital control technology with easy to understand

analogue installation adjustments

• Outside compensated control of low pressure hot

water heating system

• Fixed or self-adaptive heating curve (with optional

remote unit)

• Two independent heating curves for 1st and 2nd

heating zone

• Heating time programme offering switching between

comfort and economy operation up to 6 times per

day, independently for each day of the week

(selectable night off period is also available)

• Optimum Start/Stop (with optional space sensor) or

Heating Boost on start-up (without space sensor)

• Domestic Hot Water (DHW) time programme offering

up to 6 switching points per day independently for

each day of the week

• DHW programme can alternatively be used as the

heating programme for second heating zone

• Holiday mode with programmable 1 to 99 day holiday

period and dynamic countdown display

• Automatic, DHW only, Holiday or Standby operation

• LED’s indicate control output status

• Pump and valve exercise which helps prevent

sticking during long periods of inactivity

• Frost protection of the pipework, hot water cylinder

and the building fabric (with optional space sensor)

• Automatic summer heating mode changeover (user

adjustable)

• Automatic heating shutdown under minimal load

conditions

• Softstart to help prevent pipe expansion noise

• Service switch to assist installer on start-up and

technician during service

• Intelligent pump control with energy efficient pump

overrun

• Built-in user programme

• Optional remote unit providing space temperature

sensing, space temperature adjustment,

comfort/economy override switch and 3 hour comfort

extension button with confirmation LED

1 EN0R8527R0

Page 2

AQ2002 Optimiser/Compensator Controller

: IP40 (with base fitted and when installed

: 144 x 96 x 107 mm (with standard base)

SPECIFICATIONS

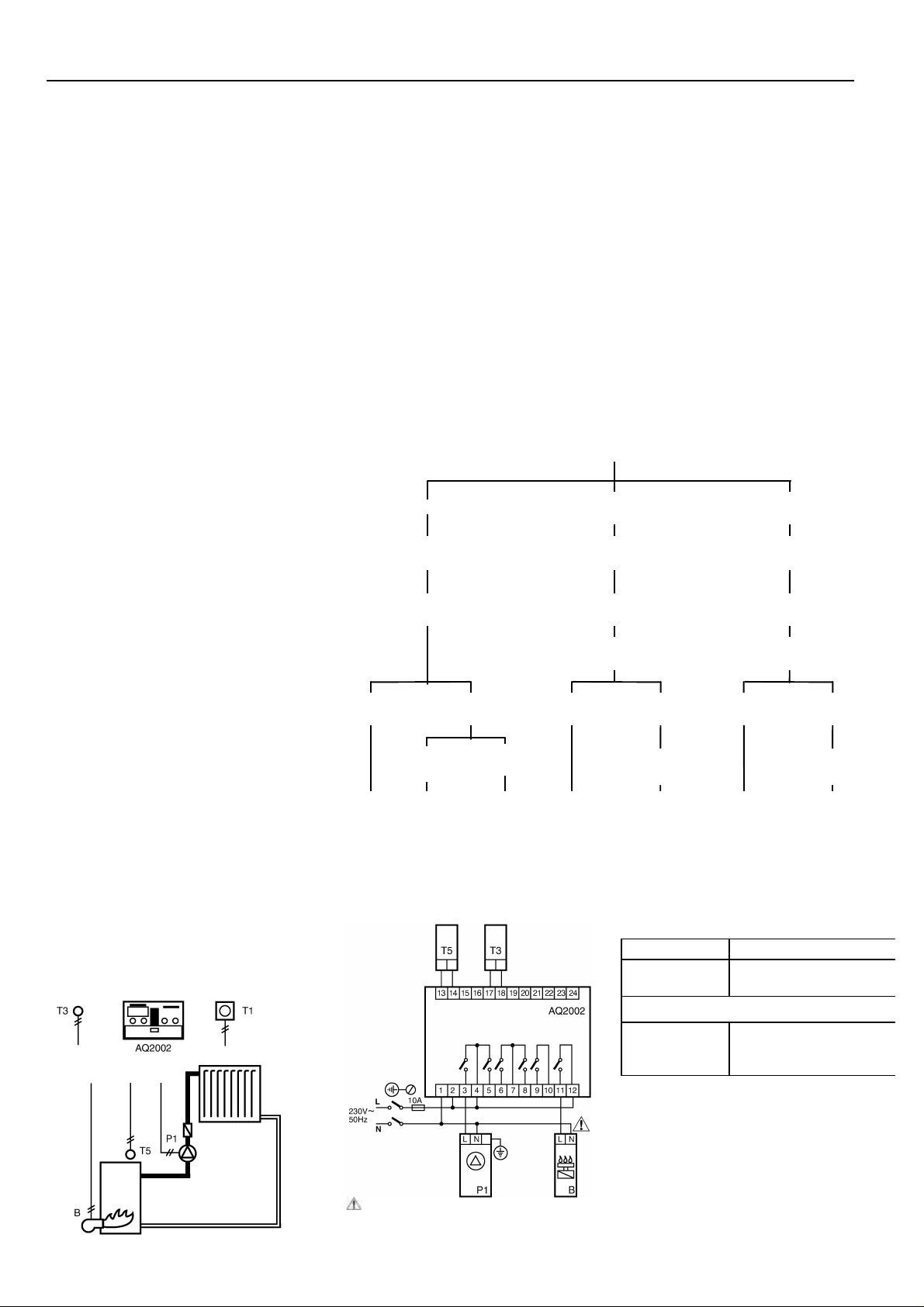

SYSTEM SELECTION CHART

Radiator or

With

On/Off Burner

Radiator

Single

Without

Pumped

Diverting

Radiator or

Radiator and

Single

Dual

On/Off Burner

On/Off Burner

With

With

Without

With

With

Pumped

Pumped

67134

5

2

Without

Without

APPLICATIONS

Supply voltage: 230 V~, +10% -15%, 50 Hz

Power

: 8 W

Consumption

Relay ratings : Pumps and boiler:

3 A, 230 V~ @ 0.6 pf - 400,000 oper.

Mixing valve:

0.25 A, 230 V~ @ 0.4 pf - 1,000,000

oper

Sensor accuracy : Water sensors: 20°C to 90°C ±2 K

Outside sensor: -20°C to +20°C ±2 K

Room sensor: 10°C to 25°C ±0.5 K

Ambient temp.

: 0 to 50°C

rating

The chart can be used to determine the

system number (1-7) corresponding to the

required application.

Systems 1, 2 and 3 are typical Radiator

applications without mixing valve.

Systems 4 and 5 are Radiator OR

Underfloor applications with mixing valve.

Systems 6 and 7 are Dual loop Radiator

AND Underfloor applications.

Loop Systems

Humidity rating: 0 to 90% rh (non-condensing)

Storage/shipping

: -30°C to +70°C

temperature

Electromagnetic

compatibility

: Emissions to EN55014-1

Immunity to EN55014-2

Protection class

to EN60529)

Dimensions

(w x h x d)

Panel cut-out

144 x 153 x 109 mm (with wiring centre)

: 138 x 92 mm

(w x h)

Weight : 600 g

AQ2002

Underfloor

Underfloor

Loop Systems

Loop Systems

Underfloor

SYSTEM 1

Application

This system offers intelligent ON/OFF

burner and pump control for radiator

heating.

Control

DHW

DHW

DHW

Valve

Electrical Connections

Mixing Valve

DHW

Control

DHW

DHW

DHW

DHW

Temperature sensors

T3 Outside air T7043E

T5 Boiler

supply

Optional

T1 Remote

unit

Control

Mixing Valve

DHW

DHW

T7076D insertion or

T7043F immersion

T8102B1001 Full

function remote unit

including wall plate.

EN0R 8527 R0 2

For potential free connection, please refer

to boiler connection section

Page 3

AQ2002 Optimiser/Compensator Controller

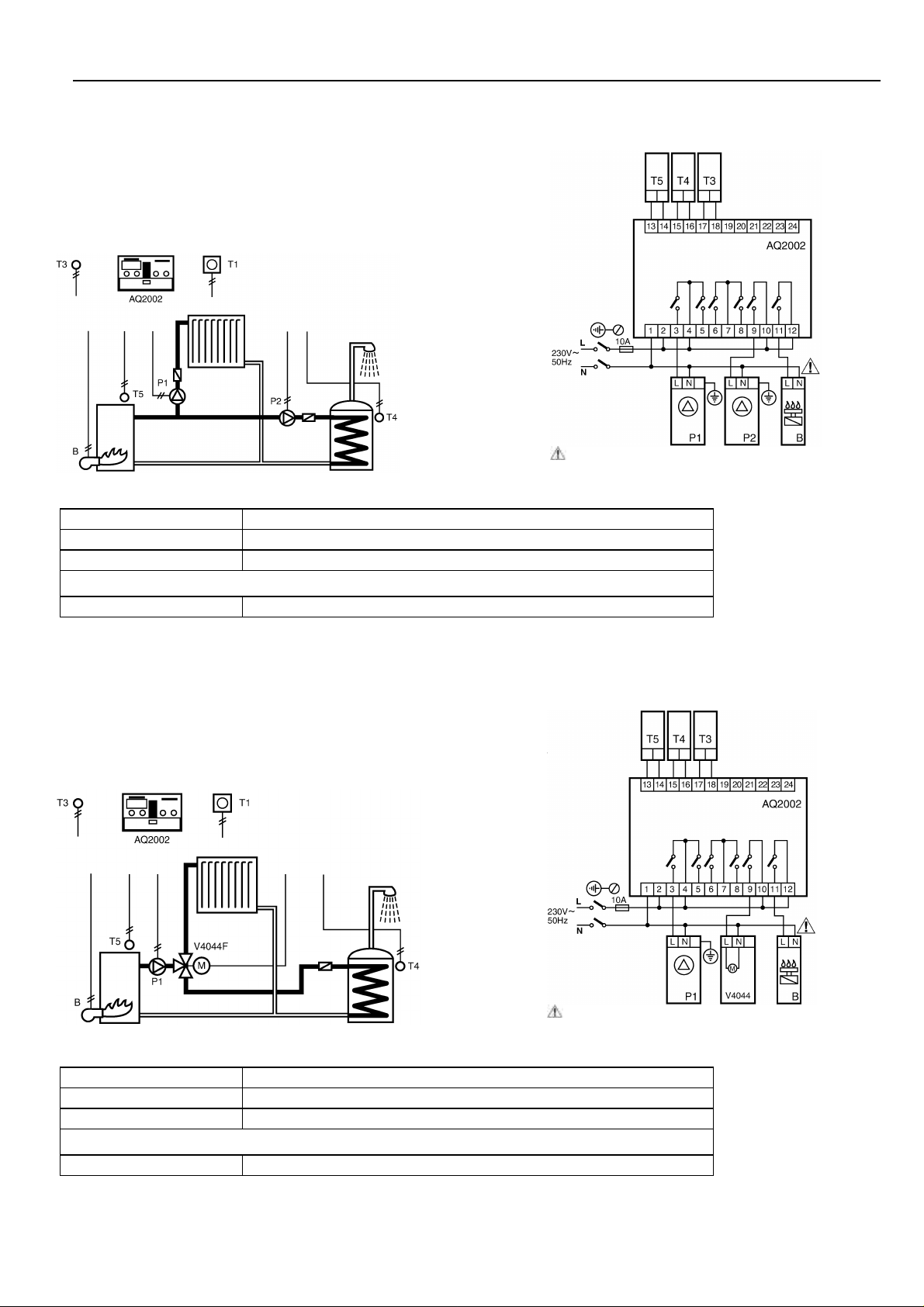

SYSTEM 2

SYSTEM 3

Application

This system offers intelligent ON/OFF burner and pump

control for radiator heating.

This system also provides a second pump to meet the

demands for domestic hot water.

Electrical Connections

For boiler potential free connection, please refer

to boiler connection section

Temperature sensors

T3 Outside air T7043E

T4 Domestic hot water T7076D insertion or T7043F immersion

T5 Boiler supply T7076D insertion or T7043F immersion

Optional

T1 Remote unit T8102B1001 Full function remote unit including wall plate.

Application

This system offers intelligent ON/OFF burner and pumps

control for radiator heating and uses a diverted valve to meet

the demands of domestic hot water

Electrical Connections

For boiler potential free connection, please refer

to boiler connection section

Temperature sensors

T3 Outside air T7043E

T4 Domestic hot water T7076D insertion or T7043F immersion

T5 Boiler supply T7076D insertion or T7043F immersion

Optional

T1 Remote unit T8102B1001 Full function remote unit including wall plate.

EN0R 8527 R03

Page 4

AQ2002 Optimiser/Compensator Controller

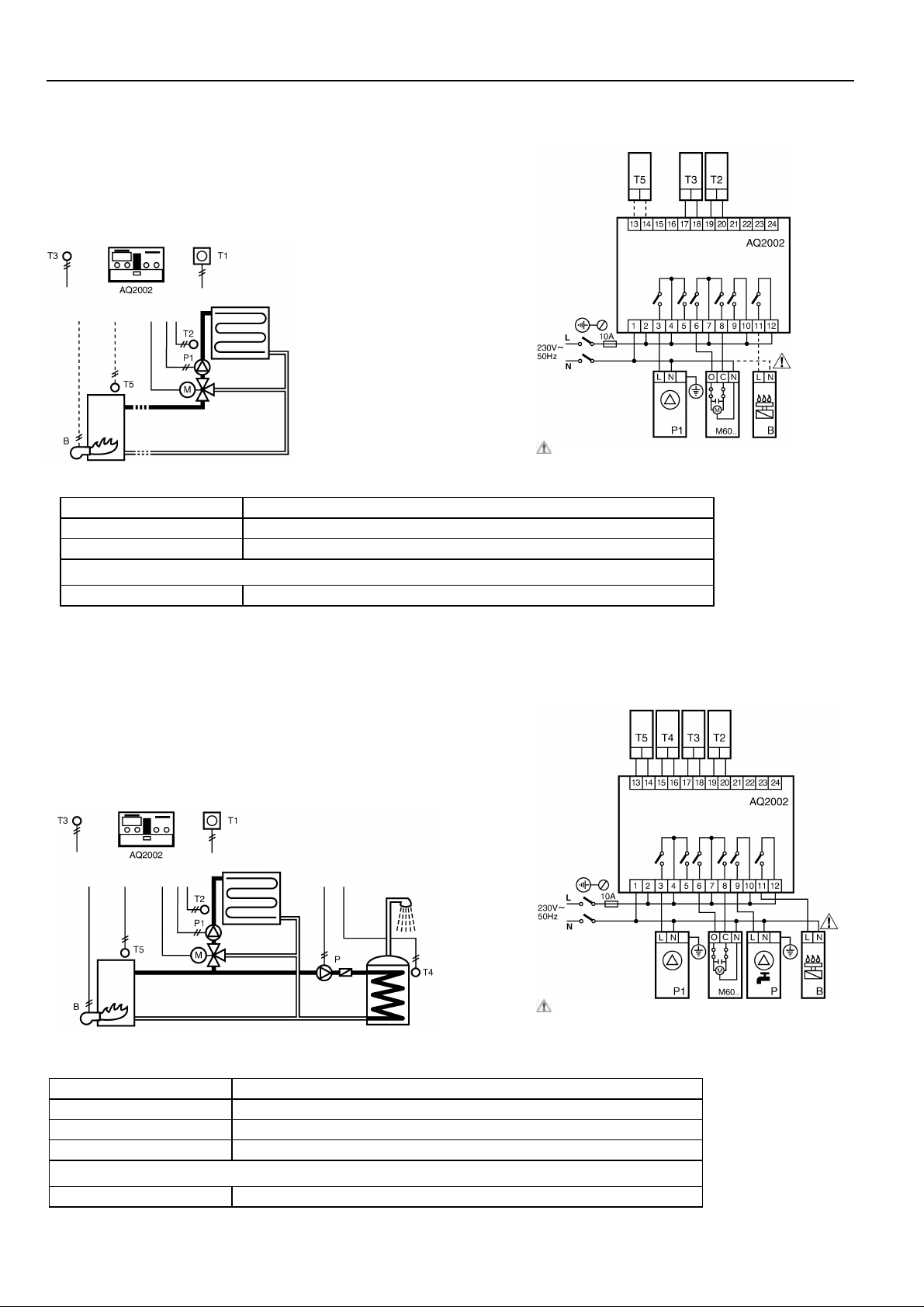

SYSTEM 4

with mixing valve control for radiator or underfloor heating.

with a mixing valve and a pump control without boiler control.

SYSTEM 5

with mixing valve control for radiator or underfloor heating.

Application

This system offers intelligent ON/OFF burner and pump control

This system can also be used for a single heating loop equipped

Electrical Connections

For boiler potential free connection, please refer

to boiler connection section

Temperature sensors

T2 Mixed water T7044C strap on or T7043F immersion

T3 Outside air T7043E

T5 Boiler supply T7076D insertion or T7043F immersion

Optional

T1 Remote unit T8102B1001 Full function remote unit including wall plate.

Application

This system offers intelligent ON/OFF burner and pump control

This system also provides a second pump to meet the demands

for domestic hot water.

Electrical Connections

For boiler potential free connection, please refer to

boiler connection section

Temperature sensors

T2 Mixed water T7044C strap on or T7043F immersion

T3 Outside air T7043E

T4 Domestic hot water T7076D insertion or T7043F immersion

T5 Boiler supply T7076D insertion or T7043F immersion

Optional

T1 Remote unit T8102B1001 Full function remote unit including wall plate.

EN0R 8527 R0 4

Page 5

AQ2002 Optimiser/Compensator Controller

SYSTEM 6

SYSTEM 7

Application

This dual loop system offers intelligent ON/OFF burner and

pump control for radiator loop and mixing valve control for

underfloor loop.

Electrical Connections

For boiler potential free connection, please refer to

boiler connection section

Temperature sensors

T2 Mixed water T7044C strap on or T7043F immersion

T3 Outside air T7043E

T5 Boiler supply T7076D insertion or T7043F immersion

Optional

T1 Remote unit T8102B1001 Full function remote unit including wall plate.

Application

This dual loop system offers intelligent ON/OFF burner and pump

control for radiator loop and mixing valve control for underfloor

loop.

This system also provides a third pump to meet the demands for

domestic hot water.

Electrical Connections

For boiler potential free connection, please refer to boiler

connection section

Temperature sensors

T2 Mixed water T7044C strap on or T7043F immersion

T3 Outside air T7043E

T4 Domestic hot water T7076D insertion or T7043F immersion

T5 Boiler supply T7076D insertion or T7043F immersion

Optional

T1 Remote unit T8102B1001 Full function remote unit including wall plate.

EN0R 8527 R05

Page 6

AQ2002 Optimiser/Compensator Controller

within the range 40 to 70°C.

within the range 10 to 30°C. When the

CONTROLLER FEATURES

within the range 4 to 40 using this

Comfort Setpoint

LCD Display

User

Adjustments

Installer

Adjustments

The desired space Comfort temperature

can be set within the range 12 to 28°C.

Override

Buttons

System Selector Switches

Programming/Operating

Buttons

Cycle Rate Adjustment

The cycle rate adjustment allows the cycle

rate as recommended by the boiler

manufacturer to be set directly on the

controller.

Output Status

Indicators

User

Adjustments

Installer

Adjustments

Economy Setpoint

The desired Economy temperature can

be set within the range 8 to 22°C.

Economy OFF can be selected by

turning the knob to the OFF position.

Domestic Hot Water Setpoint

The DHWS temperature can be set

Automatic Summer/Winter Changeover

Temperature Setpoint

Boiler/Mixed Flow Temperature High Limit

In systems with no mixing valve (no T2

sensor) the maximum value of the boiler

supply water temperature (T5) can be

adjusted by this setting.

In systems with T2 sensor and mixing valve

the maximum mixed water temperature will

be adjusted by this setting. In this case, the

maximum boiler supply temperature is fixed

at 90°C.

Heating Curve Ratio Adjustment

Two Heating Curve Ratio Adjustments

are proposed, one for each loop.

If a fixed value of the heating curve ratio

is required then this value can be set

potentiometer.

To determine the heating curve required

refer to the graph displayed below.

Ratio

The automatic Summer/Winter

changeover temperature can be set

average daily outdoor temperature is

above the automatic Summer/Winter

setpoint the heating will be turned off.

EN0R 8527 R0 6

Outside Air Temperature oC (T3)

Page 7

AQ2002 Optimiser/Compensator Controller

USER OPERATION

will operate at the economy space setpoint and the hot water

will be restarted in automatic mode and controlled according

Built-in Heating and DHW Program

Two different built programs are available, the first one is

designed for the first heating loop, and the second one can be

assigned either for second heating loop or DHW system

(depending of switch S2 position).

Heating program offer switching between comfort and

economy operation up to 6 times per day, independent for

each day of the week.

DHW program offer switching between ON and OFF operation

up to 6 times per day, independent for each day of the week.

Holiday Program

When the holiday mode of operation is selected, the heating

control will be inactive (except for frost protection) until the set

number of days has elapsed. When the heating and hot water

to the programmed data.

The return to automatic occurs at 0:00 the day the heating is

required.

System Temperature Enquiry

By switching to the enquiry mode all system temperature and

the adapted heating curve value (or the value of the heating

curve compensation slope knob if fixed compensation is

selected) can be displayed on the LCD.

Only the current temperature and parameter value will be

displayed.

This facility is not available during the initial start-up

procedure

REMOTE UNIT

Electrical connection

Room

Unit

CONTROLLER OPERATION

Outside temperature compensation

The Aquatrol 2002 is an outside temperature controller

compensated designed for most of heating systems

composed by boiler, circuit with or without mixing valve, and

domestic hot water.

Fixed or Self Adaptive Heating Curve

Room temperature compensation is available (in CH zone 1

only) when a remote room unit is connected. The fixed or

self adaptive heating curve function is selected by switch

S7.

Optimum Start/Stop

If a remote room unit is present, the controller automatically

calculates the ideal times for starting the setback and

heating-up phases defined by the heating program, in order

to save energy without sacrificing comfort. Without a room

sensor, optimum start/stop is not possible and a heating

boost is implemented in advance of an upward heating

setpoint change.

Note: optimum start and stop are applicable only to CH

zone 1 since only that zone can have a remote room

unit.

The AQ2002 controller can be completed by a remote unit

(optional) , its allow the user to adjust rapidly on controller

setpoints without going to the boiler room.

The remote unit incorporates a space temperature sensor, a

remote setpoint adjustment knob with adjustable range stops,

a 3 hour extension push button with LED indication, and a

manual switch to override the operating mode. The day or

night flag will flash on controller when the mode is overridden.

When used as a space temperature sensor, the same

mounting directions for the space sensor temperature applies.

The unit is a 2 wire connection polarized.

Comfort/Economy

Override Switch

Comfort

Extension

Button Remote Space

Temperature

Adjustment

Comfort Extension Indicator (LED)

Frost Protection of the Pipework

Frost protection of the heating system applies at all times

and in all operating modes of the controller.

Automatic Shutdown

During periods when there is no requirement for heat, the

controller will shut down the system including turning off the

heating pumps.

Automatic Summer/Winter Changeover

When the daily average outdoor temperature is high, then

the heating is turned off (pumps off, boiler off, valve closed).

The summer/winter changeover temperature is adjustable

via a potentiometer.

Pump and Valve Exercise

In order to prevent sticking or jamming of components

during long periods of inactivity, for example in the summer,

then a pump/valve exercise will take place once a week at

12:00 on Fridays.

DHWS Operation

When a DHW temperature (T4) sensor is connected, the

DHW temperature is controlled to a user-adjustable set

point.

There are two variants for combined DHWS; DHWS

Priority/Shifting or Parallel priority operation. In all two

EN0R 8527 R07

Page 8

AQ2002 Optimiser/Compensator Controller

DHWS Priority/Shifting Priority

In heating circuits with no mixing valve (and no mixed flow

temperature sensor), the DHWS has priority over the

heating.

In heating circuits with mixing valve, operation is as follows:

While the boiler temperature is less than a differential of

10K above the DHW setpoint, the mixing valve will be

closed giving DHW priority. However if there is surplus heat

available and the boiler temperature is more than 20K (the

differential plus a proportional-band of 10K) above the DHW

setpoint then the mixed heating loop will control at its

calculated setpoint, servicing the heating in parallel with the

DHW. If the boiler temperature is between these two values

then the mixed water setpoint is reduced.

Note: In dual loop systems, the CH zone 2 pump will be

switched off during a DHW service.

DHWS Parallel

In heating circuits with mixing valve when parallel operation

has been selected central heating will continue to operate

normally during a DHW service.

Note: In some systems selection of parallel operation may

result in extended DHW recovery times or in extreme

cases DHW never being satisfied

Note: Any heating loop supplied directly from the boiler will

be shut down during DHW demand period no matter

what is the position of S4 switch.

• If a DHWS sensor (T4) is present then combined or

separate temperature control of the DHWS will be

available. If no DHWS sensor (T4) is present only time

control is available on the DHWS output.

Automatic system detection takes place during the first minute

after powering the controller.

System Selection Switches

SwitchDescription Position A Position B

S1 Boiler low limit 20°C 45°C

S2 2nd time programme DHW CH zone 2

S3 DHWS program programmed continuous

S4 DHWS operation

S5 DHW actuator device pump valve

S6 Type of heating radiator underfloor

S7 Adaptive heat curve 1 yes no

Priority/ Shifting

operation

parallel

INSTALLER START UP SEQUENCE

To initiate the installer start up sequence the service switch

must be set to the "1" position with the power to the

controller switched OFF.

When power is now switched ON the above sequence will

start. The sequence can be stopped at any time by moving

the service switch to the "0" position.

SYSTEM SELECTION

System selection is achieved in two manners:

• Automatic System Selection

• System Selector Switches

Automatic System Selection

The AQ2002 is able to recognize which temperature sensor

is connected.

• If a mixed flow water sensor (T2) is connected, the

controller assumes that a mixing valve is present.

• If a Remote Unit (T1) is present the controller activates

the space temperature compensation, the optimum

Start/Stop and the self-adaptive heating curve (if switch

S7 on position A).

S8 Heating zones one/single loop two/dual loop

Shading indicates position as supplied from the factory

S1 Boiler Minimum Temperature

Allows to set the minimum boiler temperature:

- Position A: 20°C, no boiler temperature low limit

- Position B: 45°C

NOTE: Low limit will apply also to the 2nd CH heating zone flow

temperature

S2 Second time program

See table

S3 DHW Time Programme

Allows to select the timed or continuous operation of DHW.

If the S2 is in position B and S3 in position A, DHW will operate

according to both heating zone programmes.

S4 DHW Operation

DHW demand can be served in one of the following modes:

- Position A: Priority or Shifting Priority.

Please refer to “DHWS Operation” section

- Position B: parallel.

Please refer to “DHWS Operation” section

S5 DHW Actuator Device

S5 allows you to configure AQ2002 for systems where diverting

valve is used to switch the boiler output to CH or DHW

installation. Use of diverting valve is only allowed in systems

without mixing valve.

- Position A: on DHW demand the DHW pump will be switched

on.

- Position B: on DHW demand the diverting valve will be driven

to DHW position and CH pump will continue to run forcing the

flow through the hot water heat exchanger.

EN0R 8527 R0 8

S6 Type of heating

Page 9

AQ2002 Optimiser/Compensator Controller

S6 Type of heating

See table

S7 Adaptive Heating Curve 1

To benefit from this feature a remote unit must be installed.

During normal heating periods estimates are made for the

heating curve ratio 1. Each day controller compares its

performance to meet the criteria of achieving the day space

temperature.

A new value for the heating curve ratio 1 is stored daily in the

controller’s memory such that within 4 to 6 days, from the

initial start-up it will have changed the initial heating curve to

one that more closely matches the building’s thermal

characteristics.

During this learning phase the room compensation will assist

in providing comfortable space temperature conditions.

S8 Heating zones

See table

SYSTEM ON INDICATION

Each output is monitored by LED.

Fault

Description Controller Action

Code

F1 Dual loop ratio

setting fault

CH1 ratio has priority: set ratio 1 under

ratio 2 following installation requirements

F2 T2 sensor fault Acts as system without mixing valve.

F3 T3 sensor fault Heating on at or above frost protection

values.

F4 Not used

F5 T4 sensor fault DHW output held off.

F6 T5 sensor fault If frost protection active: Boiler cycles at

20%.

If no frost protection: Boiler off

F7 T1 remote unit.

Acts as system without remote unit.

fault

F8 Internal fault Boiler cycles at 20%, valve opens.

F9 Remote unit

Acts as system without remote unit.

fault

DIMENSIONS

Controller Dimension in mm

When the LED is illuminated it indicates that:

The mixing valve actuator is being driven closed,

reducing Heating.

The mixing valve actuator is being driven open,

increasing Heating.

Heating pump 2 is ON.

The DHW is ON.

Heating pump 1 is ON.

Boiler output is ON.

FAULT CODES

Should a fault occur in the system a fault code will be

displayed on the LCD. The table below gives details of the

codes and the action taken by the controller.

Information:

The above table also indicates the priority of the fault. The

lower the code the higher the priority.

An open circuit is used to automatically select the control

system configuration for DHW, mixing systems and for the

Remote Unit. A fault is not displayed if an open circuit is

detected on the T2, T4 & T5 sensors or the Remote Unit

terminals within the first minute after switching power on.

Surface Mounting

The Aquatrol 2000 controller can be surface mounted in either

a control panel or directly on the wall.

Panel Mounting

The controller can be panel mounted in a control panel door

and features integral panel mounting clips for ease of

installation.

Panel cut-out (w x h) : 138 x 92 mm

EN0R 8527 R09

Page 10

AQ2002 Optimiser/Compensator Controller

INSTALLATION

wiring.

Important

1. The installer must be a trained engineer

2. Disconnect the power supply before beginning

installation

The recommended wiring is as follow:

From Controller to … Maximum Length Type of wire

Temperature sensor 100m

Remote unit 50m

Boiler/Burner 100m

Motorized valve 100m

Pumps 100m

Other devices 100m

To meet the

requirements of

local standards

Boiler connection

ON/OFF boilers can be connected and controlled by two

different manners:

• ON/OFF boiler supplied and controlled by line voltage

Tamper-Proofing

The controller can be made tamperproof, if required, by

inserting a wire link through the hole in the front clear cover

and the front housing at the top center of the front panel

and twisting or crimping to fix the front panel permanently

shut, thus preventing unauthorized adjustment.

Wall Mounting using Wiring Centre (Optional)

For wall mounting the optional Wiring Center K42007745005 can be used for protection and termination of electrical

conduits, MICC cable or Pirelli FP200 cables with suitable

adapters.

CONNECTIONS

Controller Connection

The controller operates from a 230V 50Hz power supply.

Cables providing power to the controller should be sized to

match the individual installation requirements for distance

and power consumption. The AQ2002 controller requires an

effective earth directly from the building’s consumer unit in

order to meet the same earthing requirements for the

temperature sensors.

Each terminal within the controller is capable of accepting

either two cables with a maximum cross sectional area of

1.5mm2 or one cable with a maximum cross sectional area

of 2.5mm2.

Please refer to your system for the correct input/output

• ON/OFF boiler supplied by the line voltage and control

by a free voltage contact

Boiler relay ratings

Boiler: 3 A, 230 V~ @ 0.6 pf

EN0R 8527 R0 10

Page 11

CONTROLLER ORDERING SPECIFICATION

Ordering specification: W6060C1141 Belgium and French version

Specifications

water pipe providing a temperature input

water pipe, or inserted in a well, and

W6060C1158 English version

OTHER SYSTEM COMPONENTS (to be ordered separately)

Outside Temperature Sensor T7043E

Application

The Outside Temperature Sensor consists

of a thermistor element housed in a tough

plastic case. It is mounted outside the

building providing a temperature input

signal to the controller.

Ordering Specification: T7043E1008

Flow Temperature Sensor T7044C

Sensing range : -30 to +40°C

Sensor : NTS type 10 kΩ @ 25°C

Enclosure : Plastic with integral

Pg11 fitting

Dimensions : 66 ∅ x 35 mm

AQ2002 Optimiser/Compensator Controller

Application

The T7044C Strap-on Flow Water

Temperature Sensor consists of a

thermistor sensing element housed in a

tough plastic case. It is strapped to the flow

signal to the controller.

Ordering Specification: T7044C1002

Flow Temperature Sensor T7043F

Application

The T7043F Immersion Flow Water

Temperature Sensor consists of a

thermistor sensing element housed in an

immersion pocket. It should be mounted on

a bend on the flow water pipe providing a

temperature input signal to the controller

Ordering Specification: T7043F1006

Insertion Temperature Sensor T7076D

Application

The T7076D tape-on or insertion sensor

consists of a thermistor sensing element

encapsulated in plastic. It is designed for

use in outside temperature compensated

heating systems. It can be taped on to a hot

provides a temperature input signal to the

controller. For tape-on installation, a

polyester and an aluminium tape are

supplied.

Ordering Specification: T7076D1001

Specifications

Sensing range : 0 to 115°C

Sensor : NTS type 10 kΩ @ 25°C

Enclosure : Plastic with integral

Pg11 fitting

Dimensions : 72 ∅ x 48 mm

Specifications

Sensing range : 0 to 115°C

Sensor : NTS type 10 kΩ @ 25°C

Enclosure : Plastic with integral

Pg11 fitting

Dimensions : 72 ∅ x 45 mm

Well : ½" BSPT x 100 mm

Specifications

Sensing range : 0 to 110°C

Maximum

Ambient temp. : 115°C

Wire dimensions : 1.3mm ∅ x 1.5m long.

Sensor : NTS type 10 kΩ @ 25°C

Wire rating : -30 to +115°C

Dimensions : 7 Ø x 25 mm

Temperature Sensor Characteristics

EN0R 8527 R011

Page 12

AQ2000 OPTIMISER/COMPENSATOR CONTROLLER

Specifications

RELATED LITERATURE

Remote Unit T8102B

Application

The Remote Unit provides a space

temperature sensor input signal to the

AQ2000 for space temperature

compensation and to enable the

optimization and adaptive ratio to function.

Remote adjustment of the setpoint is also

possible and an override switch gives the

possibility of selecting permanent comfort

or economy settings. A "party" button

allows a three hour comfort extension to be

selected.

Ordering Specification:

T8102B1001 with English literature

T8102B1050 with French literature

T8102B1068 with Italian literature

Sensor : NTS type 10 kΩ @ 25°C

Housing : White plastic

Weight : 70 g

Dimensions : 70 x 75 x 31 mm (w x h x

d)

Setpoint : ± 3 K

adjustment

Wiring Centre K42007745-005

Application

The Wiring Centre is an essential

component when mounting the controller

on a wall. It provides a number of conduit

entries through the bottom, back and

sides. In addition, it provides extra

terminals to link multiple incoming cables

such as line, neutral and earth.

Ordering Specification:

K42007745-005

Specifications

Housing : White Plastic

Cable entries : 17 x 19 mm conduit entries

Dimensions : 70 x 75 x 31 mm (w x h x

d)

(9 bottom, 3 right side, 1 left

side, 4 back)

AQ2002 Installation Guide 42010344-001 in English

42010344-002 in French

AQ2002 User Guide 42010345-001 in English

42010345-002 in French

Honeywell Control Systems Limited http://europe.hbc.honeywell.com

Newhouse Industrial Estate

Motherwell ML1 5SB

United Kingdom

EN0R 8527 R0

Loading...

Loading...