Honeywell APT2000, APT2000TC-0-00, APT2000TC-0-IS, APT2000TC-H-00, APT2000TC-H-IS User Manual

Page 1

APT2000 Series

70-82-25-96

MU1I-6251

Revision 1 – 03/00

2-Wire Toroidal

Conductivity Transmitters

User Manual

Page 2

Software release: 1.x

TA-194.350-HWE01 210700

Copyright, Notices, and Trademarks

E Copyright 1999 by Honeywell Inc.

Revision 1 – 03/00

While this information is presented in good faith and believed to be accurate,

Honeywell disclaims the implied warranties of merchantability and fitness for a

particular purpose and makes no express warranties except as may be stated in

its written agreement with and for its customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages. The information and specifications in this document are subject to

change without notice.

Honeywell

Industrial Automation and Control

Automation College

1100 Virginia Drive

Ft. Washington, PA. 19034

Honeywell S. A.

Espace Industriel Nord

rue André Durouchez

80084 Amiens Cedex 2

France

Contacts

The following list identifies important contacts within Honeywell.

Organization Telephone Address

Honeywell Technical

Assistance Center

1-800-423-9883

(USA and Canada)

1100 Virginia Avenue

Fort Washington, PA 19034

Honeywell S.A. 33-3-22-54-56-56

(Europe)

80084 Amiens Cedex 2

France

Page 3

Warning

Warning

Warning

Information

3

Safety Precautions

Be sure to read and observe the following requirements!

The APT2000TC-0(H)-00 Transmitter is approved for operation in safe areas and hazardous

locations DIV 2 (USA/Canada only).

Before connecting the Transmitter to a power supply unit, make sure that this is not capable

of outputting more than 40 Vdc (safe areas) / 30 Vdc (DIV 2).

The APT 2000PH-0(H)-IS Transmitter is approved for operation in hazardous locations

DIV 1 (USA/Canada) / Zone 1 (Europe).

Before connecting the Transmitter to a power supply unit, make sure that this is an associated apparatus.

The measuring inputs of the APT 2000PH-0(H)-IS Transmitter may be led into Zone 0

(Europe).

However, be sure to observe the national regulations concerning Zone 0 applications.

The Transmitter itself is not approved for operation in Zone 0!

Whenever it is likely that the protection has been impaired, the Transmitter shall be made inoperative and

secured against unintended operation.

The protection is likely to be impaired if, for example:

❏ the Transmitter shows visible damage

❏ the Transmitter fails to perform the intended measurements

❏ after prolonged storage at temperatures above 70 °C

❏ after severe transport stresses

Before recommissioning the T ransmitter, a professional routine test must be performed. This test should be

carried out at our factory.

The Transmitter shall not be used in a manner not specified by this manual.

Page 4

CAL

Note

Warning

CONF

CAL

Information

4

Information on this Instruction Manual

ITALICS are used for texts which appear in the APT2000TC Transmitter display.

Bold print is used to represent keys, e.g. CAL.

Keys for which the functions are explained are frequently shown in the

left-hand column.

Notes provide important information that should be strictly followed when using the Transmitter.

Warning means that the instructions given must always be followed for your own safety.

Failure to follow these instructions may result in injuries.

Mode Codes

After pressing CONF or CAL you can enter one of the following codes to access the desig-

nated mode:

CONF, 0000: Error info

CONF, 1200: Configuration

CONF, 5555: Current source

CAL, 0000: Cal info

CAL, 1001: Zero point calibration

CAL, 1015: Temp probe adjustment

CAL, 1 100: Cell factor calibration

CAL, 1 125: Input/adjustment of sensor factor

CAL, 2222: Test mode

Page 5

Contents

5

Contents

Safety Precautions 3. . . . . . . . . . . . . . . . . . . . . .

Information on this Instruction Manual 4. . .

Mode Codes 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 Assembly 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Package Contents and Unpacking 6. . . .

Assembly 6. . . . . . . . . . . . . . . . . . . . . . . . . .

2 Installation, Connection

and Commissioning 10. . . . . . . . . . . . . . . . .

Proper Use 10. . . . . . . . . . . . . . . . . . . . . . . .

Overview of the

Conductivity Transmitter 1 1. . . . . . . . . . . . .

Terminal Assignment 12. . . . . . . . . . . . . . . .

Installation and Commissioning 13. . . . . . .

Typical Wiring 14. . . . . . . . . . . . . . . . . . . . . .

3 Operation 15. . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface 15. . . . . . . . . . . . . . . . . . . . . .

Display 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Functions 17. . . . . . . . . . . . . . . . . . . .

Outputs 18. . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 19. . . . . . . . . . . . . . . . . . . . . . .

Calibration 21. . . . . . . . . . . . . . . . . . . . . . . . .

Measurement 25. . . . . . . . . . . . . . . . . . . . . .

4 Diagnostics, Maintenance and Cleaning 26

Sensoface

, Sensocheck

26. . . . . . . . . .

Error Messages 26. . . . . . . . . . . . . . . . . . . .

Diagnostics Functions 28. . . . . . . . . . . . . . .

Maintenance and Cleaning 29. . . . . . . . . . .

5 Appendix 30. . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Line 30. . . . . . . . . . . . . . . . . . . . . . .

Specifications 31. . . . . . . . . . . . . . . . . . . . . .

Type Examination Certificate 35. . . . . . . . .

Calibration Solutions 38. . . . . . . . . . . . . . . .

Concentration Curves 39. . . . . . . . . . . . . . .

Index 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Assembly

6

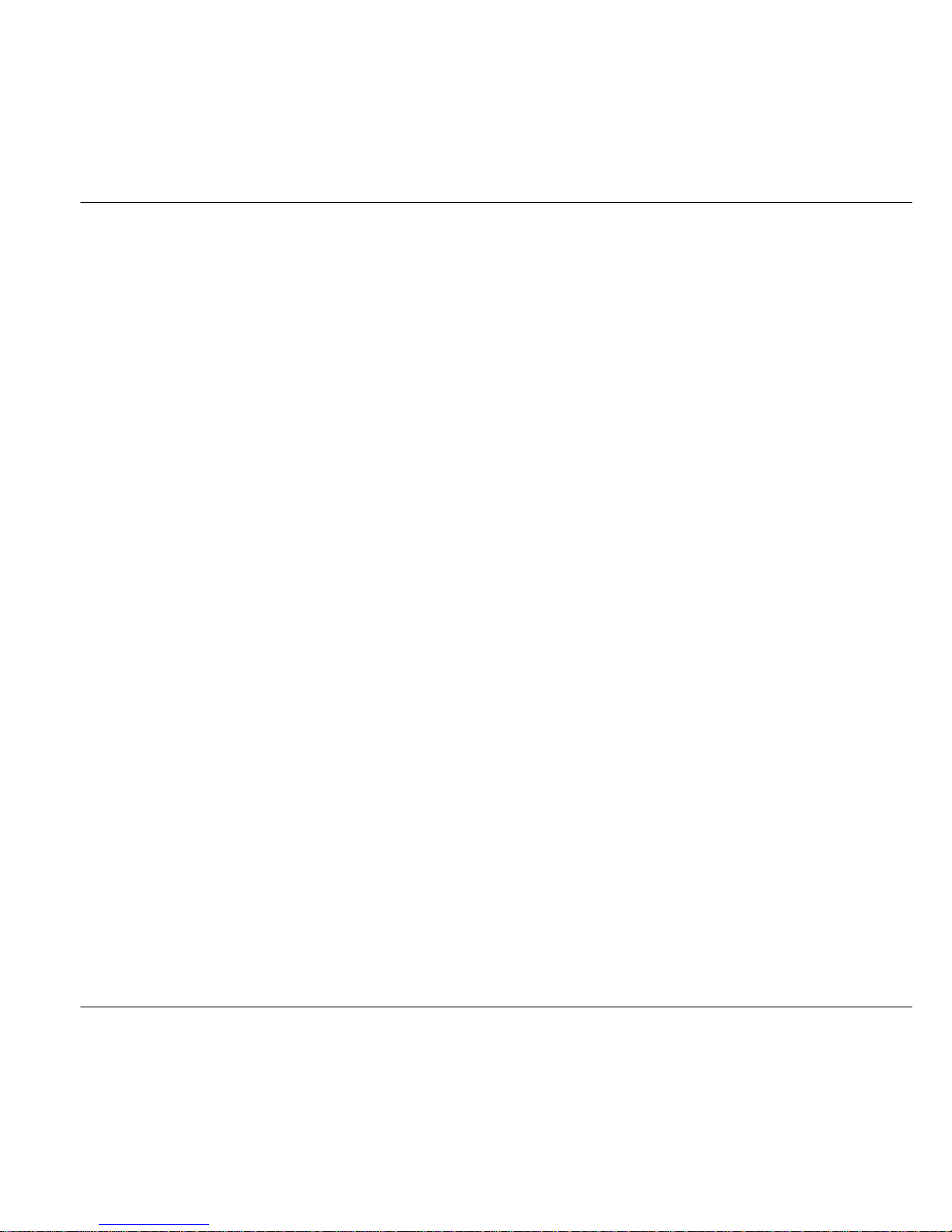

1 Assembly

Package Contents and Unpacking

Unpack the unit carefully and check the shipment for

transport damage and completeness.

The package contains:

–Front unit of Transmitter

–Lower case

–Short instruction sheet

–This instruction manual

–HART description

(only for Model APT2000TC-H-..)

–Bag containing:

➀ 2 plastic plugs ➆ 1 hinge pin

➁ 5 hexagon nuts ➇ 3 cable ties

➂ 3 Pg cable glands ➈ 3 filler plugs

➃ 1 rubber reducer ➉ 3 sealing rings

➄ 1 Pg plug

11 1 metal plate

➅ 4 set screws for conduit

12

1 jumper

Assembly

Fig. 1 Assembling the case

➀

(For sealing in case

of wall mounting)

➁

➂

➃

➄

➅

➆

(Can be inserted

from either side)

➇

➈

➉

11

For conduit mounting:

Place washer

between enclosure

and nut.

11

12

Page 7

Assembly

7

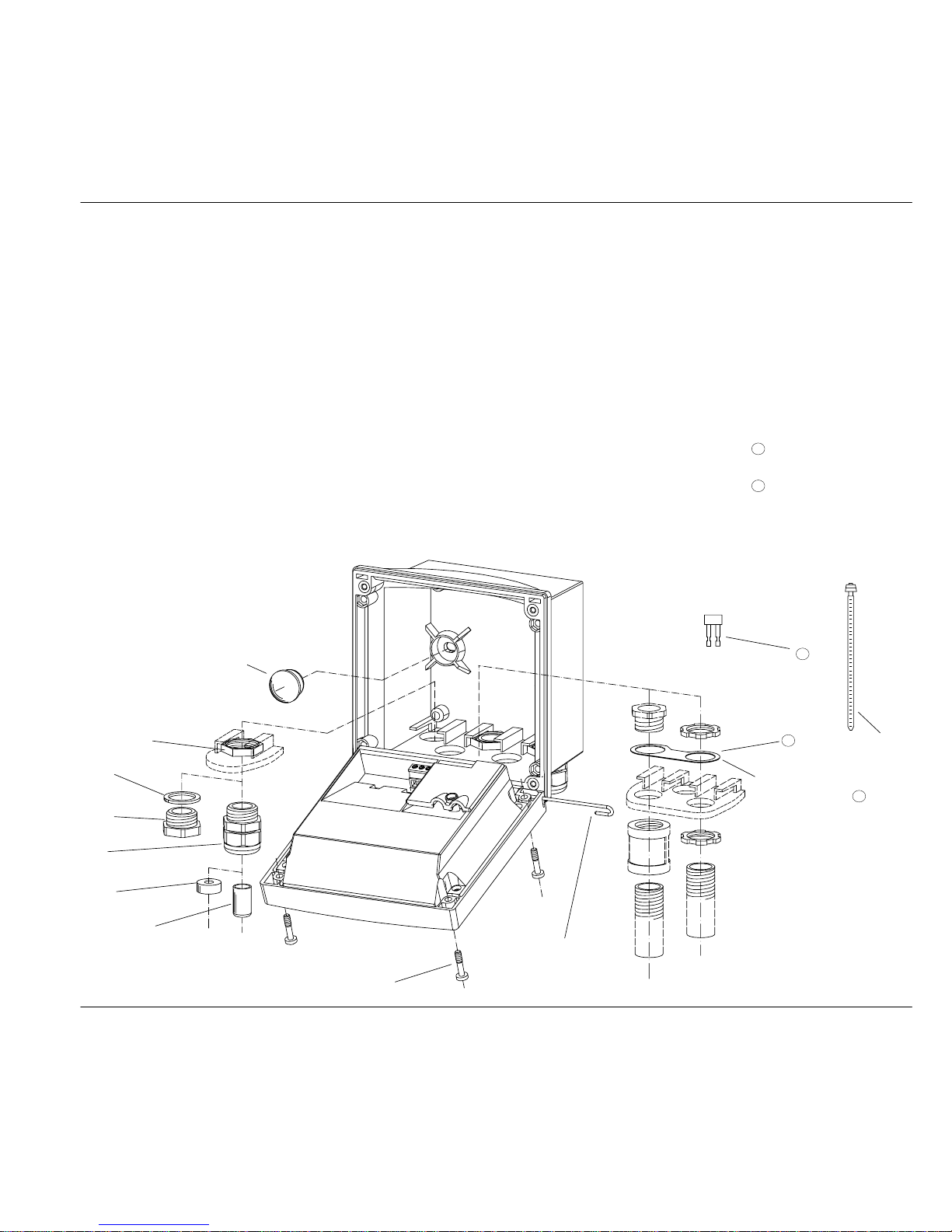

80 [3.15]

32 [1.26]

72 [2.83]

6.2 [0.24]

approx. 14

84 [3.31]

42 [1.65]

Pg 13.5 (3 pcs.)

144 [5.67]

144 [5.67]

21

43 [1.69]

105 [4.13]

27

Control panel 1 – 22 mm

max. 25

78 [3.07]

27

Control panel cutout

138 x 138 mm (DIN 43700)

Panel-mount kit

consisting of:

4 screws

4 span pieces

4 threaded sleeves

1 seal

➀

➁

➂

➃

➃

➀

➁

➂

Holes for

post mounting

Holes for

wall mounting

(4 x)

(2 x)

[0.55]

[1.06]

[0.83]

[0.98]

[1.06]

[5.43 x 5.43]

[0.04 – 0.87]

Note: All dimensions

in mm [inches]

(not included in supply)

2 holes 21.5 mm dia. [8.47] for Pg 13.5

I

or 1/2 conduit

Fig. 2 Dimension drawing for Transmitter, mounting diagram and P/N 51205990-001 panel-mount kit

Page 8

Assembly

8

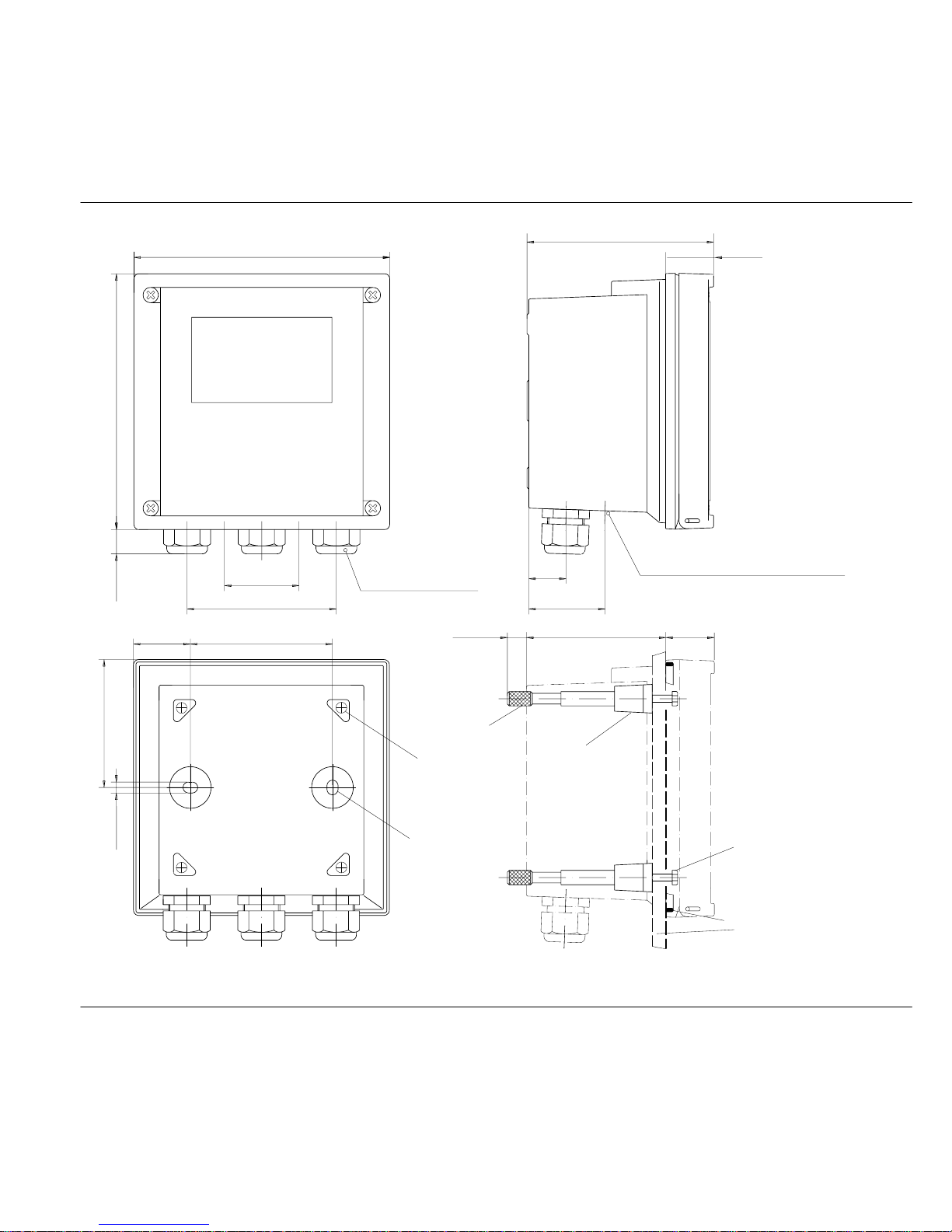

horizontal post/

40–60 mm dia.

➀

➁

➂

51205989-001

(if required)

For vertical or

pipe mounting

Pipe-mount kit

consisting of:

4 self-tapping screws

1 pipe mounting plate

2 hose clamps with

➀

➁

➂

worm gear drive

to DIN 3017

[1.57–2.36]

protective hood

Fig. 3 P/N 51205988-001 pipe-mount kit

165 [6.5]

173 [6.81]

132 [5.2]

Fig. 4 P/N 51205989-001 protective hood for wall and pipe mounting

Page 9

Assembly

9

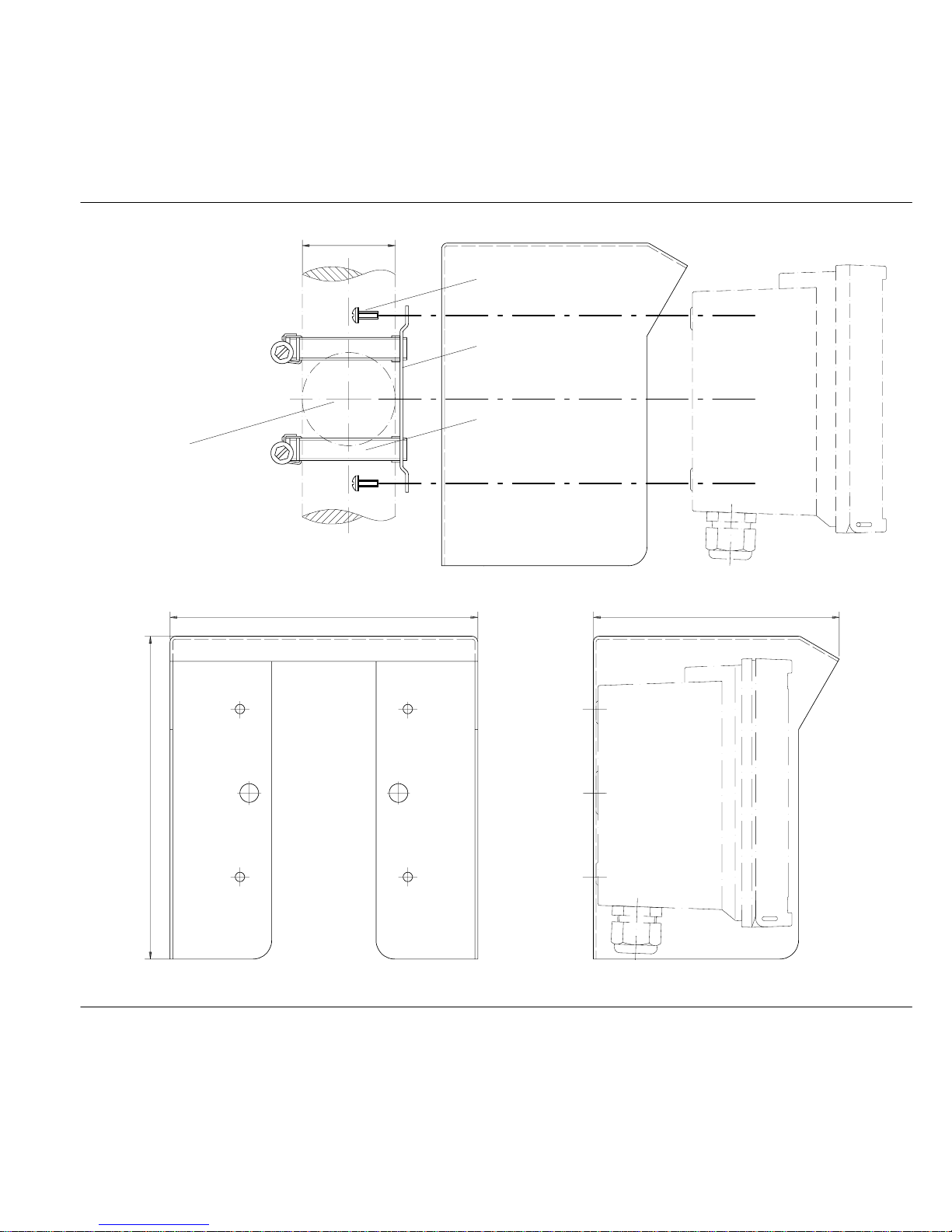

280 [11.03]

7 [0.28]

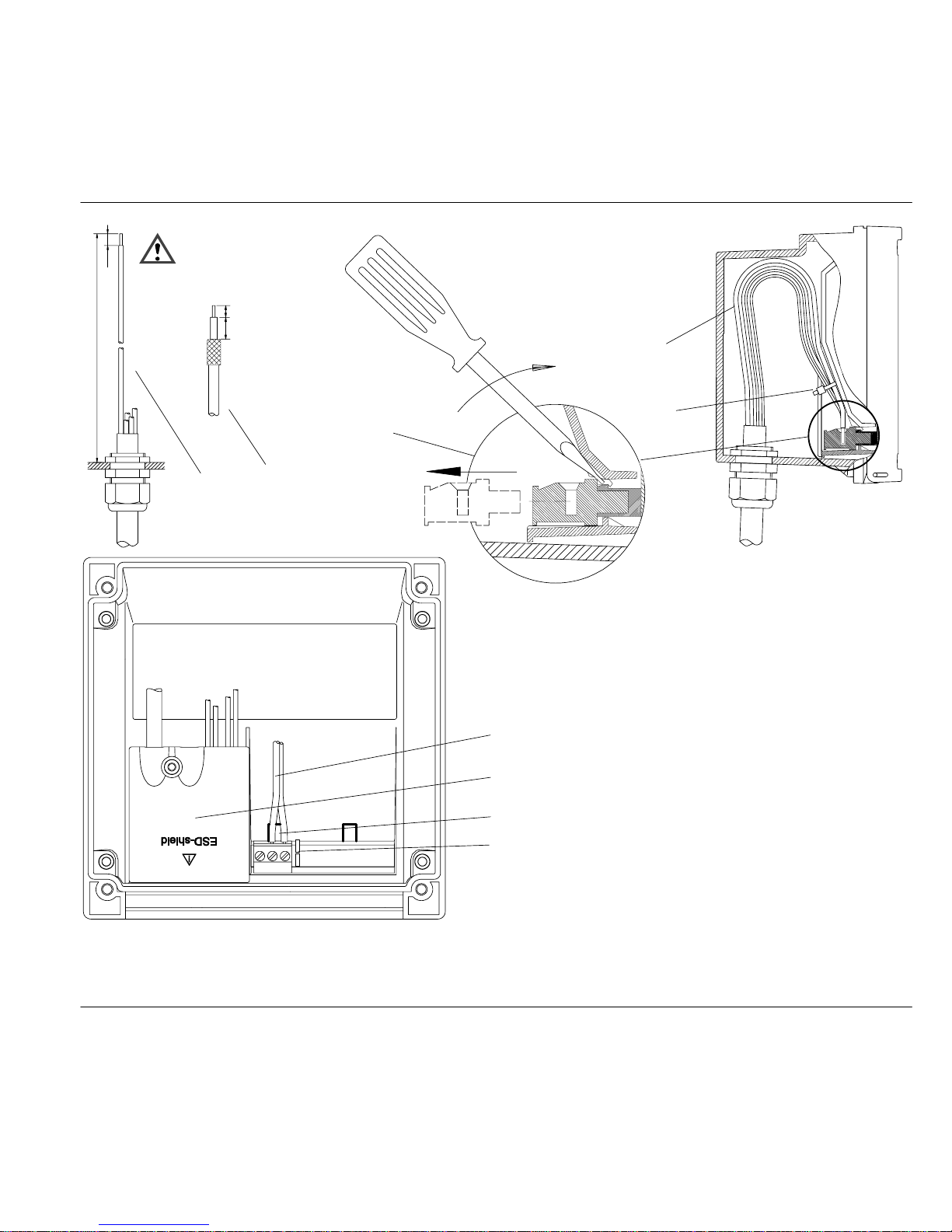

➀ Recommended stripping lengths for

multi-core cables

➁ Recommended stripping length for

coaxial cable

➂ Pulling out the terminals using a

screwdriver (also see

➆)

➃

Cable laying in the Transmitter

➄ Connecting lines for loop current

➅ Cover for sensor and temperature

probe terminals

➆ Areas for placing the screwdriver to

pull out the terminals

➇ Connection of handheld terminal

➀

➁

➃

➄

Be sure not to

notch the cable

cores when stripping

the insulation!

Dimensions in mm [inches].

➄

➅

➆

➇

Coaxial cable

13 mm [0.5]

7 mm [0.28]

➂

Fig. 5 Installation information

Page 10

Warning

Warning

Warning

Capabilities, Connection

10

2 Installation, Connection and Commissioning

Proper Use

The APT2000TC Transmitter is used for conductivity

and temperature measurement in chemical, pulp and

paper , biotechnology, food processing, pharmaceutical, electroplating, and water/wastewater industries.

It can either be mounted on site or in a control panel.

The APT2000TC-0(H)-00

Transmitter is approved for operation in safe areas and hazardous

locations DIV 2 (USA/Canada only).

Before connecting the Transmitter

to a power supply unit, make sure

that this is not capable of outputting

more than 40 Vdc (safe areas) /

30 Vdc (DIV 2).

The APT2000TC-0(H)-IS Transmitter is approved for operation in hazardous locations DIV 1 (USA/Canada) / Zone 1 (Europe).

Before connecting the Transmitter

to a power supply unit, make sure

that this is an associated apparatus.

The measuring inputs of the APT

2000PH-0(H)-IS Transmitter may

be led into Zone 0 (Europe).

However, be sure to observe the

national regulations concerning

Zone 0 applications.

The Transmitter itself is not approved for operation in Zone 0!

Page 11

Capabilities, Connection

11

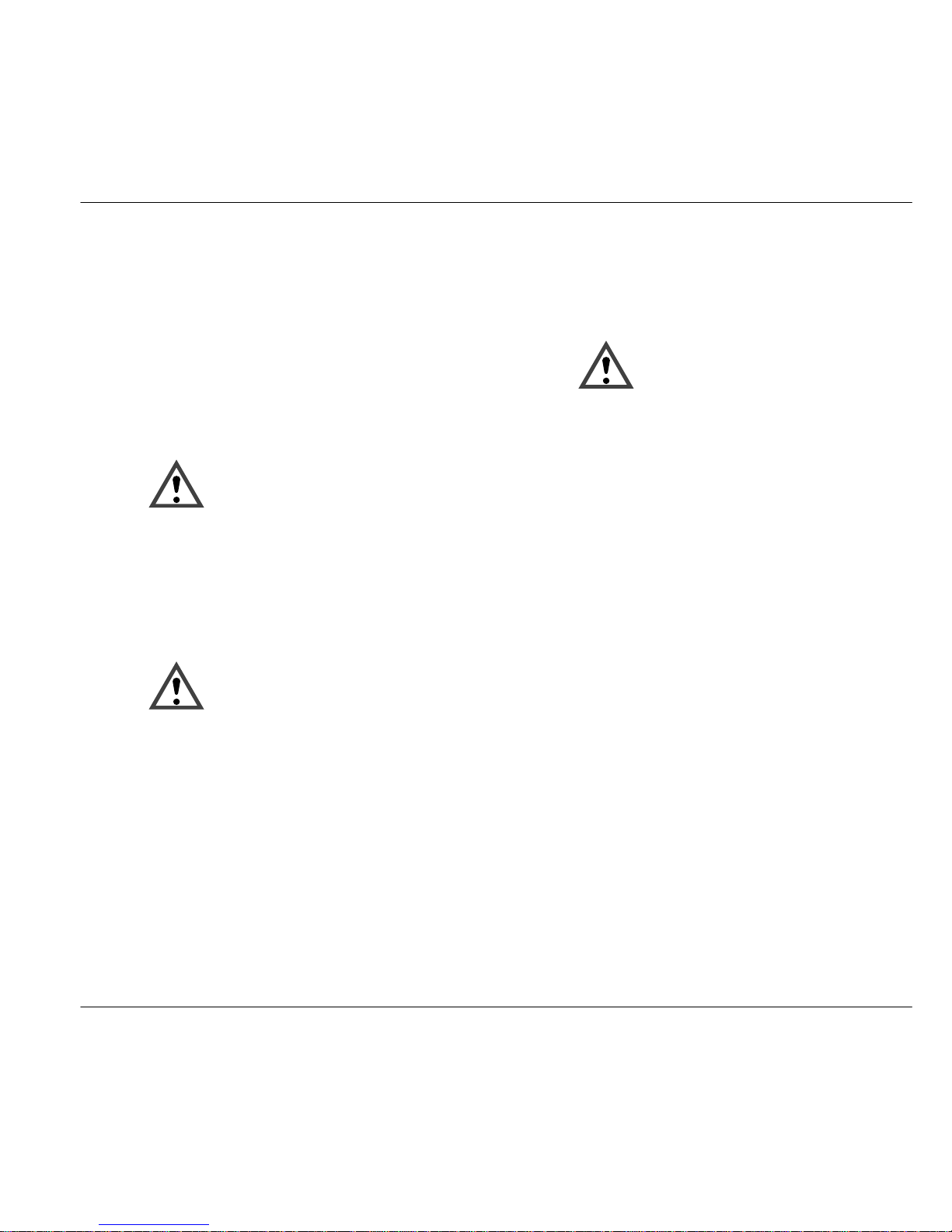

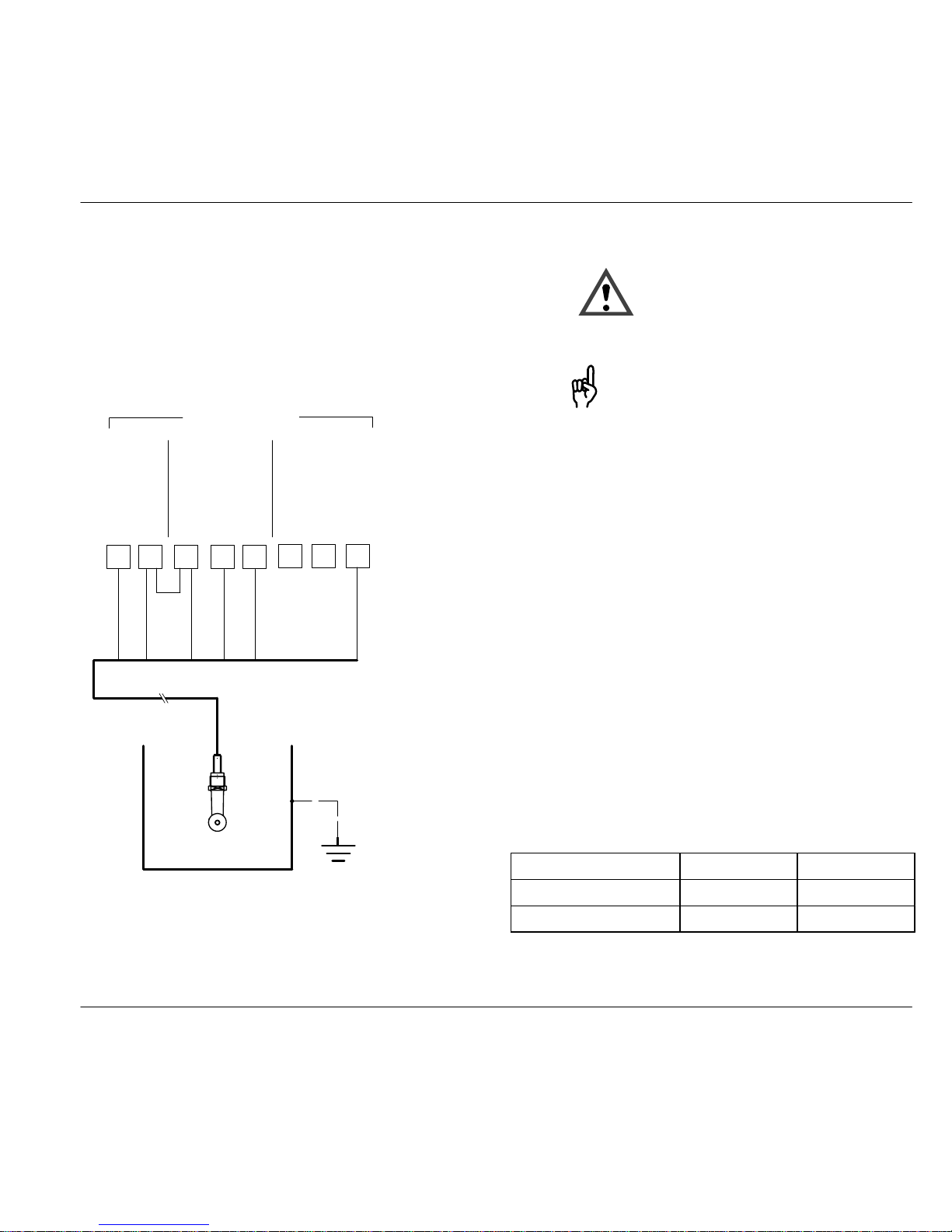

Overview of the Conductivity Transmitter

mS/cm,

% by wt, SAL

Temperature

Pt 100/1000/

NTC 100 kW

mA

APT2000TC Transmitter

➀

➁

➃

➂

Fig. 6 System functions of APT2000TC Transmitter

➀ Inputs for toroidal conductivity sensors

➁ Input for temperature probe

➂ Current loop 4 – 20 mA,

transports power to and output signal from the

transmitter,

with APT2000TC-H-.. Transmitter also for HARTr

communication

➃ Equipotential bonding (only with

APT2000TC-0(H)-IS Transmitter)

Page 12

Capabilities, Connection

12

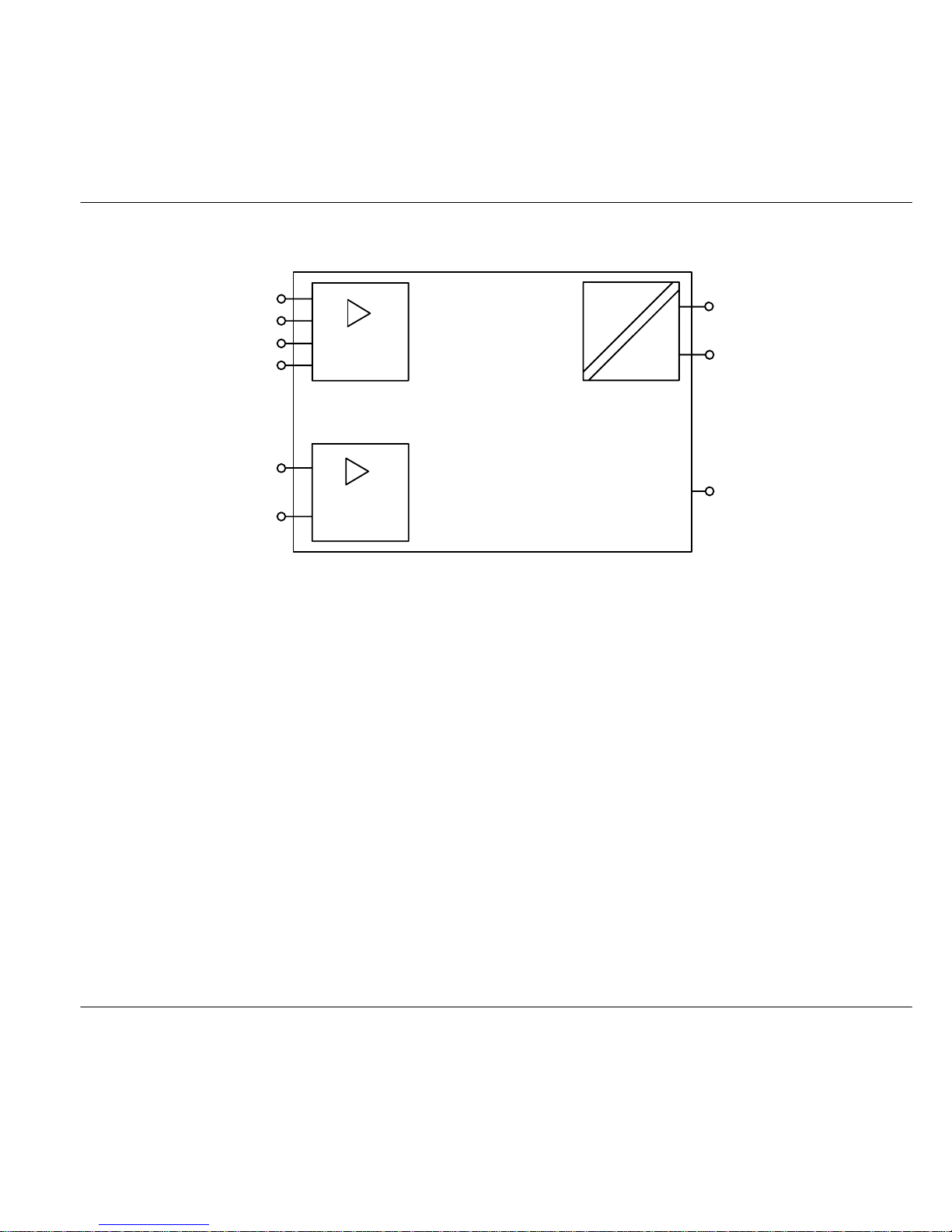

Terminal Assignment

8 7 6 5 4 2 1

3

T1

temp

n.c.

+ 11 10

4 to

+

9

output

–

HART

20 mA

supply/

do not

connect

toroidal

conductivity sensor

lo hilohi

send receive

WT

BL

YW

GN

shield

RD

–

Fig. 7 Terminal assignment of APT2000TC-0(H)-00 Transmitter

NI, Class 1, Div 2, Group A – D, T4

8 7 6 5 4 2 1

3

T1

temp

n.c.

+ 11 10

4 to

+

9

output

–

HART

20 mA

supply/ toroidal

conductivity sensor

lo hilohi

send receive

WT

BL

YW

GN

shield

RD

–

Fig. 8 Terminal assignment of APT2000TC-0(H)-IS T ransmitter

IS, Class I, Div 1, Group A – D, T4

II 2(1) G EEx ib [ia] IIC T6

Page 13

Warning

Warning

Warning

Warning

Warning

Capabilities, Connection

13

Installation and Commissioning

Installation and commissioning of

the Transmitter may only be carried

out in accordance with this instruction manual and per applicable local

and national codes. Be sure to observe the technical specifications

and input ratings.

Before connecting the

APT2000TC-0(H)-00 Transmitter to

a power supply unit, make sure that

this is not capable of outputting

more than 40 Vdc (safe areas) /

30 Vdc (DIV 2).

Before connecting the

APT2000TC-0(H)-IS Transmitter

to a power supply unit, make sure

that this is an associated apparatus

(for input ratings refer to the Control

Drawing or the annex of the EC

Type Examination Certificate).

Do not use alternating current or

mains power supply!

When commissioning, a complete

configuration must be carried out.

For easier installation, the terminal strips are of a

plug-in design. The terminals are suitable for single

wires and flexible leads up to 2.5 mm

2

(AWG 14)

(see Pg. 9).

A connection example is shown on Pg. 14.

Page 14

Warning

Note

Capabilities, Connection

14

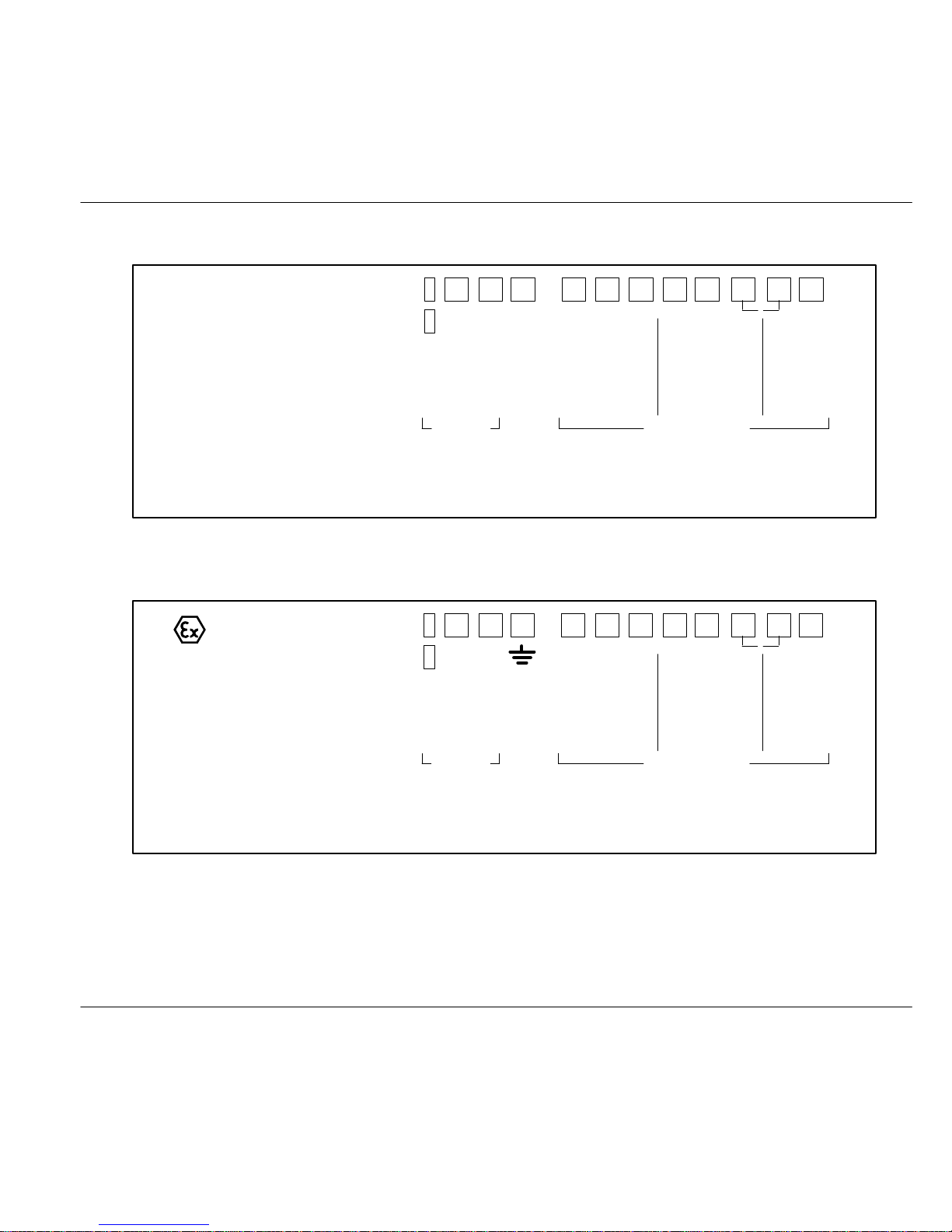

Typical Wiring

Conductivity measurement with Honeywell

5000TC toroidal conductivity sensor

The Honeywell 5000TC toroidal conductivity sensor

is used to measure low to highest conductivity values. It can be used for measurements in safe areas.

WHITE

BLUE

YELLOW

GREEN

RED

SHIELD

toroidal

cond. sensor

5421

3

temp

lohi lo hi

sendreceive

WT

BL

YW

GN

shield

RD

87

6

T1

T2

n.c.

Fig. 9 Conductivity measurement with Honeywell

5000TC toroidal conductivity sensor

The Honeywell 5000TC toroidal

conductivity sensor may only be

used in combination with the

APT2000TC-0(H)-00 Transmitter.

For special mounting conditions of

the sensor, the cell factor can vary

between 4.0 and 4.5. Therefore the

user should perform a wet calibration of each new sensor to determine the exact cell factor.

Settings for Honeywell 5000TC toroidal conductivity

sensor

Menu Setting

Temp probe conf 1200 Pt 1000

Cell factor cal 1100 4.44

Page 15

Operation

15

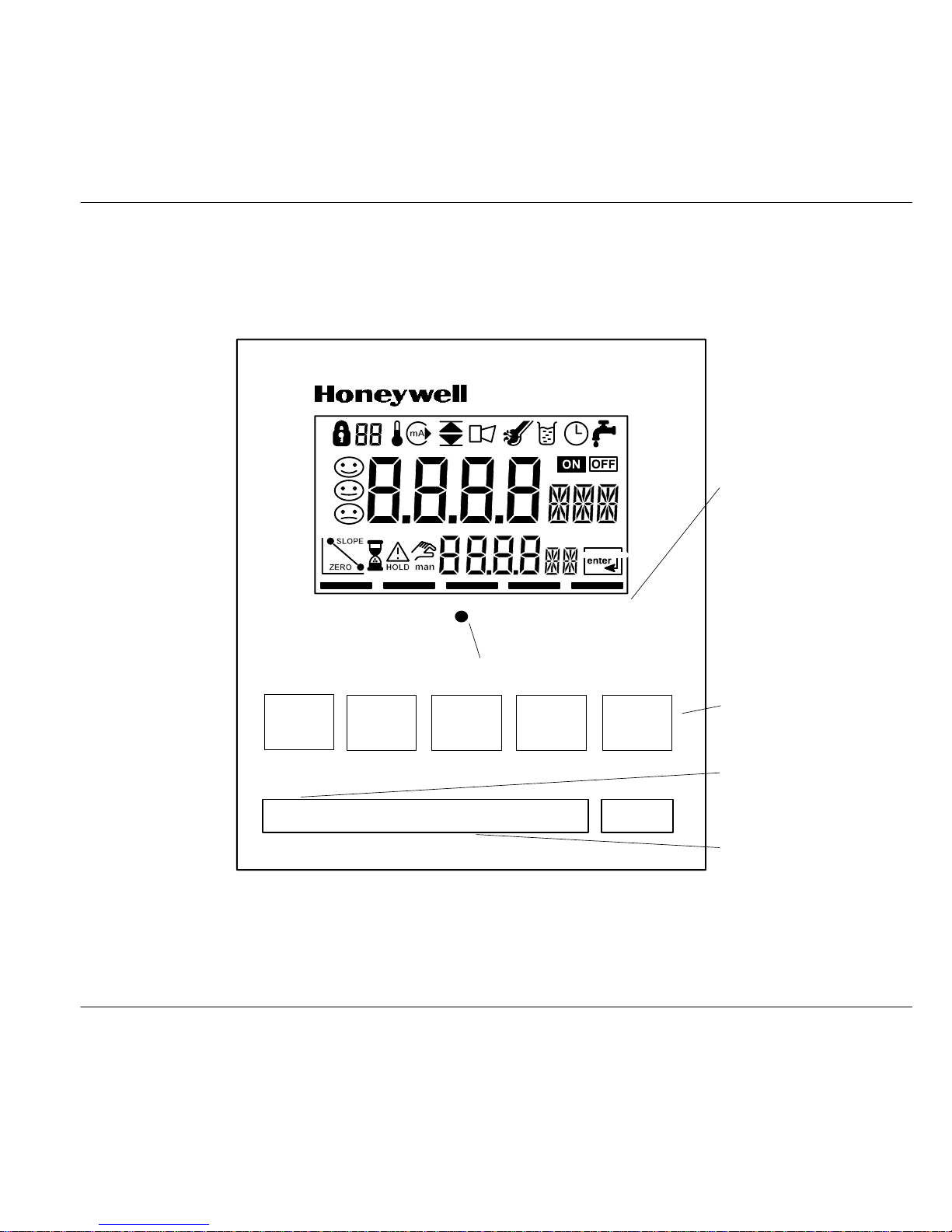

3 Operation

User Interface

MEAS

Alarm LED

Keypad

Model designation

Rating plate

Status fields:

- Measuring mode

- Calibration mode

- Alarm

- Configuration mode

CAL ALARM CONF

CONF ENTER

CAL

"

"

Fig. 10 Front view of Transmitter

Page 16

CAL

CONF

"

Y

ENTER

➔

CAL

ENTER

➔

CONF

ENTER

+

Y

"

Operation

16

Display

Mode code entry

Interval/

Response time

Hold state

active

Continue with

ENTER

Measurement symbols

Tempera-

ture

Loop

current

Alarm

setting

Sensocheck

Calibration

Sensor

data

Sensoface

Wait

Display/

Process variable

Bar for

instrument status

Fig. 11 Display of Transmitter

Keypad

Start, end calibration

Start, end configuration

Select digit position

(selected position flashes)

Change digit

Prompt in display:

continue in program sequence,

Configuration:

Confirm entries, next

configuration step,

Measuring mode:

Display loop cur-

rent

Cal info, display cell factor and zero

point (see Pg. 25)

Error info, display last output error

message (see Pg. 25)

Start GainCheck

manual instru-

ment self-test (see Pg. 17)

Page 17

+

Y

"

Operation

17

Safety Functions

Sensoface sensor monitoring

Sensoface

provides information

on the sensor condition. A sad

“Smiley” indicates that there is a

Sensocheck

message.

Sensocheck

signals a short circuit of the primary coil and its lines

as well as an interruption at the

secondary coil and its lines. Sensocheck

can be switched off. With

Sensocheck

switched off, no

friendly Smiley appears.

For more detailed information, see chapter “Diagnostic, Maintenance and Cleaning” (Pg. 26).

GainCheck

manual instrument self-test

Simultaneously pressing Y and "

starts the manual instrument selftest.

A display test is carried out, the software version is

displayed and the memory and measured value

transmission are checked.

Automatic instrument self-test

The automatic unit self-test checks the memory and

the measured-value transmission. It runs automatically in the background at fixed intervals.

Page 18

Operation

18

Outputs

Current loop (4 to 20 mA)

The current loop transports power to and output signals from the Transmitter. The current is controlled

by the process variable selected in the configuration.

The current characteristic can be configured as linear or logarithmic curve for conductivity and resistivity.

The current beginning and end can be set to represent any desired value.

If LIN (linear characteristic) is chosen, the minimum

span is 5% of the selected process variable / measurement range. If LOG (logarithmic characteristic) is

chosen, the minimum span is one decade within the

chosen range.

To check connected peripherals (e.g. limit switches,

controllers), the loop current can be manually specified (see Pg. 28).

HART

communication

The APT2000TC-H-.. Transmitter can be remote

controlled via HART

communication. It can be configured using a handheld terminal or from the control

room. Measured values, messages and instrument

identification can be downloaded at any time. This

allows easy integration also in fully automatic process sequences.

For more detailed information, refer to the HART

Command Specification.

Alarm

During an error message the alarm LED flashes.

Alarm response time is permanently set to 10 sec.

Error messages can also be signaled with a 22 mA

signal via the loop current (see Configuration,

Pg. 20).

Page 19

CONF

Note

Operation

19

Configuration

The instrument arrives from the factory configured

and ready to operate as a conductivity transmitter.

This section provides detailed procedures for changing operation values for specific applications.

Activate with CONF

change parameter with Y and ",

confirm/continue with ENTER,

end with CONF.

Mode code “1200”

During configuration the Transmitter

is in the Hold state, the loop current

is frozen.

When the configuration mode is exited, the Transmitter remains in the Hold state for safety reasons. This

prevents undesirable reactions of the connected peripherals (e.g. limit switches, controllers) due to incorrect settings. The measured value and Hold are

displayed alternately. Now you can check whether

the measured value is plausible and specifically end

the Hold state with ENTER. After a relax time of

20 sec (for measured value stabilization) the Transmitter returns to measuring mode.

The configuration parameters are

checked during the input. In the

case of an incorrect input “ERR” is

displayed for 3 sec. The parameters cannot be stored with ENTER

until the input has been repeated.

Configuration parameters

Before attempting any changes refer to the parameter setup list shown below. This table presents the possible options and the factory settings.

Pictograph

Parameter Choices Factory

setting

Process variable / meas. range

Selected process variable and

measuring range control loop cur-

rent, limit values and display.

Complete configuration required

after change.

oo.oo mS / ooo.o mS / oooo mS

ooo.o %

ooo.o SAL

ooo.o mS

Concentration

(only with %)

-01- NaCl (0 – 28 % by wt)

-02- HCl (0 – 17 % by wt)

-03- NaOH (0 – 22 % by wt)

-04- H2SO4(0 – 35 % by wt)

-05- HNO

3

(0 – 28 % by wt)

-06- H

2SO4

(95 – 99 % by wt)

-01-

Temperature display °C

°F

°C

Page 20

Operation

20

Temperature probe Pt 100 / Pt 1000 /

NTC 100 kW

Pt 1000

T emperature compensation

(not with % and SAL)

OFF

LIN

NLF (natural waters)

OFF

Temperature coefficient

(only with tc LIN)

xx.xx %/K 02.00 %/K

Current characteristic

(not with % and SAL)

LIN

LOG

LIN

Current beginning (4 mA)

(only with LIN)

mS / % / SAL 000.0 mS

Current end (20 mA)

(only with LIN)

mS / % / SAL

100.0 mS

Current beginning (4 mA)

(only with LOG)

mS *

0.1 mS

Current end (20 mA)

(only with LOG)

mS *

100 mS

Hold state Last:Last current value

Fix: Current specified

Last

Hold value

(only with Fix)

xx.xx mA 21.00 mA

22 mA signal for error message ON / OFF OFF

Sensocheck

ON / OFF OFF

* 0.1 / 1 / 10 / 100 / 1000 mS

Configuration is cyclical. To stop, press CONF.

Page 21

CAL

CAL

ENTER

Operation

21

Calibration

In the calibration mode the cell factor can be modified in two ways. If the cell factor of the sensor in use

is known under consideration of the installation conditions, it can be entered directly. Furthermore, the

cell factor can be determined with a known calibration solution under consideration of the temperature.

Activate with CAL,

confirm/continue with ENTER,

abort with CAL ➜ ENTER

During calibration the Transmitter is

in the Hold state. The loop current

is frozen.

When the calibration mode is exited, the Transmitter

remains in the Hold state for safety reasons. This

prevents undesirable reactions of the connected peripherals (e.g. limit switches, controllers) due to incorrect settings. The measured value and Hold are

displayed alternately. Now you can check whether

the measured value is plausible and specifically end

the Hold state with ENTER or repeat calibration with

CAL. When you end the Hold state, the Transmitter

will return to measuring mode after 20 sec (measured value stabilization).

Calibration by input of cell factor

Activate calibration by pressing the

CAL key.

Using the Y , " keys enter

mode code “1100” and then press

ENTER.

Using the Y , " keys enter the cell

factor. The lower display shows the

conductivity value.

A change in the cell factor also

changes the conductivity value.

When there has not been an entry

for approx. 6 sec, conductivity and

temperature are displayed alternately.

Press ENTER to confirm the cell

factor.

The Transmitter remains in the Hold

state. You can end the Hold state

with ENTER. After 20 sec (measured value stabilization) the Transmitter returns to measuring mode.

Page 22

Note

CAL

ENTER

Operation

22

Calibration with calibration solution

Be sure to use known calibration

solutions and the respective temperature-corrected table values (see

Calibration Solutions, Pg. 38).

Activate calibration by pressing the

CAL key.

Using the Y , " keys enter

mode code “1100” and then press

ENTER.

Immerse the sensor in the calibration solution.

After approx. 6 sec the lower display alternately shows the conductivity and temperature values. Read

the conductivity value corresponding to the displayed temperature

from the table of the used calibration solution (for tables see Pg. 38).

Using the Y , " keys change the

cell factor until the display shows

the conductivity value from the

table.

Make sure that the temperature is

stable during the calibration procedure.

Press ENTER to confirm the cell

factor.

The Transmitter remains in the Hold

state. You can end the Hold state

with ENTER. After 20 sec (measured value stabilization) the Transmitter returns to measuring mode.

Page 23

Note

Note

CAL

ENTER

Note

Note

CAL

Operation

23

Zero point calibration in air

Zero point calibration is only required when very low conductivity

values are to be measured.

Before you start calibration, remove

the sensor from the process, clean

it and dry it up.

Activate calibration by pressing the

CAL key.

Using the Y , " keys enter

mode code “1001” and then press

ENTER.

Using the Y , " keys modify the

zero point until the lower display

reads 0 mS. If required, change the

sign of the zero point!

When there has not been an entry

for approx. 6 sec, the lower display

alternately shows the zero-corrected conductivity value and the

temperature value.

Press ENTER to confirm the zero

point.

The Transmitter remains in the Hold

state. You can end the Hold state

with ENTER. After 20 sec (measured value stabilization) the Transmitter returns to measuring mode.

Input and adjustment of sensor factor

This function should only be used

by experts. Incorrectly set parameters may go unnoticed, but change

the measuring properties.

The Transmitter comes with a preset sensor factor of

24.6 for the 5000TC sensor. Should you use another

sensor , you must enter another sensor factor or determine it using a comparison resistor. After that, you

can calibrate the sensor (see Pg. 21).

Resistance measurement in test

mode can only show the correct

value of the test resistor when the

sensor factor has been correctly

determined.

Activate calibration by pressing the

CAL key.

Using the Y , " keys enter

mode code “1125” and then press

ENTER.

Using the Y , " keys enter the

sensor factor of the sensor in the

main display .

If you do not know the sensor factor, it can be determined using a

comparison resistor (recommended

resistance value: 100 W). The sensor factor must be adjusted until the

corresponding resistance value is

shown in the lower display.

Page 24

ENTER

Note

CAL

ENTER

Operation

24

Press ENTER to confirm the sensor factor.

The Transmitter remains in the Hold

state. You can end the Hold state

with ENTER. After 20 sec (measured value stabilization) the Transmitter returns to measuring mode.

Adjustment of temperature probe

This function should only be used

by experts. Incorrectly set parameters may go unnoticed, but change

the measuring properties.

Especially for Pt 100 temperature

probe, it is advisable to perform an

adjustment.

Activate calibration by pressing the

CAL key.

Using the Y , " keys enter

mode code “1015” and then press

ENTER.

Measure the temperature of the

process medium using an external

thermometer.

Using the Y , " keys enter the determined temperature value in the

main display. If you take over the

temperature value shown in the

lower display, the correction is without effect.

Press ENTER to confirm the temperature value.

The Transmitter remains in the Hold

state. You can end the Hold state

with ENTER. After a relax time of

20 sec (for measured value stabilization) the Transmitter returns to

measuring mode.

Page 25

Note

Operation

25

Measurement

Measuring mode

In the measuring mode the main display shows the

configured process variable and the lower display

the temperature.

Cal info

With CAL and mode code “0000” you can activate

the cal info. Cal info shows the current calibration

data for approx. 20 sec. The 20 sec can be reduced

by pressing ENTER. During cal info the Transmitter

is not

in Hold state.

Error info

With CONF and mode code “0000” you can activate

the error info. Error info shows the most recent error

message for approx. 20 sec. After that the message

will be deleted. The 20 sec can be reduced by pressing ENTER. During error info the Transmitter is not

in Hold state.

Hold state

The Transmitter will enter the Hold state under the

following conditions:

For calibration: Mode code 1001

Mode code 1015

Mode code 1100

Mode code 1125

Mode code 2222

configuration: Mode code 1200

Mode code 5555

The loop current is frozen at Last or Fix (configuration Pg. 20).

If the calibration or configuration mode is exited, the

Transmitter remains in the Hold state for safety reasons. This prevents undesirable reactions of the connected peripherals (e.g. limit switches, controllers)

due to incorrect settings. The measured value and

Hold are displayed alternately. Now you can check

whether the measured value is plausible and specifically end the Hold state with ENTER. After a relax

time of 20 sec (for measured value stabilization) the

Transmitter returns to measuring mode.

During error conditions the Hold

state will not be active.

Page 26

CONF

ENTER

Troubleshooting, Cleaning

26

4 Diagnostics, Maintenance and Cleaning

Sensoface, Sensocheck

Sensoface provides information

on the sensor condition. A sad

“Smiley” indicates that there is a

Sensocheck

message.

Sensocheck

signals a short circuit of the primary

coil and its lines as well as an interruption at the secondary coil and its lines. Sensocheck

can be

switched off. With Sensocheck

switched off, no

friendly Smiley appears.

Error Messages

When one of the following error messages is output,

the Transmitter can no longer correctly determine the

process variable or output it via the loop current.

During an error message the alarm LED flashes. The

alarm response time is permanently set to 10 sec.

Error messages can also be signaled with a 22 mA

signal via the loop current (see Configuration,

Pg. 20).

Error info

With CONF and mode code “0000”

you can activate the error info.

Error info shows the most recent

error message for approx. 20 sec.

After that the message will be deleted. The 20 sec can be reduced by

pressing ENTER. During error info

the Transmitter is not

in Hold state.

Error

number

Display

(flashing)

Problem Possible causes

Err 01 Sensor - Wrong cell factor

- Outside measurement range

- SAL > 45 ‰

- Sensor connection or cable defective

Err 02 Sensor - Unsuitable sensor

Err 03 Temperature probe - Outside temp range

- Outside temp range for TC

- Outside temp range for SAL

- Outside temp range for concentration

Err 21 Loop current - Meas. value below configured current beginning

- Wrong configuration for current beginning (see Pg. 20)

Page 27

Troubleshooting, Cleaning

27

Error

number

Possible causesProblemDisplay

(flashing)

Err 22 Loop current - Meas. value above configured current end

- Wrong configuration for current end (see Pg. 20)

Err 23 Loop current - Configured current span too small

(Difference between current beginning and end)

Err 33 Sensocheck

- Short circuit in primary coil

- Short circuit of cable

Err 34 Sensocheck

- Open circuit in secondary coil

- Cable interrupted

Err 98 System error - Configuration or calibration data defective; completely

reconfigure and recalibrate the Transmitter

- Measured value transmission defective

- Memory error in Transmitter program (PROM defective)

Err 99 Factory settings - EEPROM or RAM defective

- Error in factory settings

This error message normally should not occur, as the

data are protected from loss by multiple safety functions.

Should this error message nevertheless occur, there is

no remedy. The Transmitter must be repaired and recalibrated at the factory.

Page 28

Warning

Troubleshooting, Cleaning

28

Diagnostics Functions

Cal info

Pressing CAL and entering mode code “0000” is

going to activate the cal info. Cal info shows the current calibration data for approx. 20 sec. During cal

info the Transmitter is not

in Hold state.

Test mode

Pressing CAL and entering mode code “2222” is

going to activate the test mode. In the test mode you

can check the measuring equipment with a resistor.

Sensoface

is disabled.

To do so, a comparison resistor is

looped through the sensor. The

comparison resistance value is indicated in the main display in kW.

When the resistance value exceeds

2 kW, the display shows “– – – –”.

R: e.g. 100 W

Pressing ENTER ends the test mode. The T ransmitter goes to Hold state.

Error info

Pressing CONF and entering mode code “0000” is

going to activate the error info. Error info shows the

most recent error message for approx. 20 sec. After

that the message will be deleted. During error info

the Transmitter is not

in Hold state.

Display loop current

Pressing ENTER in measuring mode displays the

loop current for a few seconds.

Current source

To check the connected peripherals (e.g. limit

switches, controllers), the loop current can be manually specified.

In the current source mode the loop

current no longer follows the measured value! It is manually specified.

Therefore, it must be ensured that

the connected devices (control

room, controllers, indicators) do not

interpret the current value as a

measured value!

Pressing CONF and entering mode code “5555” is

going to activate the current source mode. Specify

the loop current using ", Y and ENTER. The actually flowing loop current is shown in the lower display.

Pressing CONF exits the current source mode

again.

GainCheck

manual instrument self-test

The manual instrument self-test is started by simultaneously pressing Y and ".

A display test is carried out, the software version is

displayed and the memory and measured-value

transmission are checked.

Page 29

Troubleshooting, Cleaning

29

Automatic self-test

The automatic self-test checks the memory and the

measured-value transmission. It runs automatically

in the background at fixed intervals.

Maintenance and Cleaning

Maintenance

The Transmitter contains no user repairable components. If problems persist even after reviewing section 4, please contact the factory.

Cleaning

To remove dust, dirt and spots, the external surfaces

of the Transmitter may be wiped with a damp, lintfree cloth. A mild household cleaner may also be

used if necessary .

Page 30

Specifications

30

5 Appendix

Product Line

Units

Ref. No.

Toroidal Conductivity Transmitter for application in safe

areas or hazardous locations

DIV 2 (USA/Canada only)

APT2000TC-0-00

Toroidal Conductivity IS

Transmitter for application in

hazardous locations

DIV 1 (USA/Canada) / Zone 1

(Europe)

APT2000TC-0-IS

Toroidal Conductivity Transmitter with HART

communication for application in safe

areas or hazardous locations

DIV 2 (USA/Canada only)

APT2000TC-H-00

Toroidal Conductivity IS

Transmitter with HART

communication, for application in

hazardous locations

DIV 1 (USA/Canada) / Zone 1

(Europe)

APT2000TC-H-IS

Mounting Accessories

Ref. No.

Pipe-mount kit 51205988-001

Panel-mount kit 51205990-001

Protective hood 51205989-001

Further Accessories

Ref. No.

HART

test socket, integrated in

Pg cable gland

(for APT2000TC-H-.. Transmitter

only)

51205991-001

Page 31

Specifications

31

Specifications

APT2000TC-0(H)-00 Transmitter

Cond input

Input for Series 5000 toroidal conductivity sensor

Process variable/ranges**

00.00 to 99.99 mS/cm

000.0 to 999.9 mS/cm

0000 to 9999 mS/cm

Concentration0.0 to 100.0 % by wt.

Salinity

0.0 to 45.0 ‰ (0 to 35 °C)

Accuracy***

< 1 % of meas. value ± 0.02 mS/cm

Sensor

monitoring

Sensocheck: monitoring of primary

and lines for short circuit and monitor-

ing of secondary for open circuit

(can be switched off)

Sensor standardization

*

– Entry of cell factor with display

of conductivity and temperature

– Zero point adjustment

– Temperature probe adjustment

– Input of sensor factor

Permissible

cell factor

0.100 to 19.999

Permissible

sensor factor

1.00 to 99.99

Permissible

offset

± 0.5 mS/cm

APT2000TC-0(H)-IS Transmitter

Cond input

Input for Series 5000 toroidal conductivity sensor

Process variable/ranges**

00.00 to 99.99 mS/cm

000.0 to 999.9 mS/cm

0000 to 9999 mS/cm

Concentration0.0 to 100.0 % by wt.

Salinity

0.0 to 45.0 ‰ (0 to 35 °C)

Accuracy***

< 1 % of meas. value ± 0.02 mS/cm

Sensor

monitoring

Sensocheck: monitoring of primary

and lines for short circuit and monitor-

ing of secondary for open circuit

(can be switched off)

Sensor standardization

*

– Entry of cell factor with display

of conductivity and temperature

– Zero point adjustment

– Temperature probe adjustment

– Input of sensor factor

Permissible

cell factor

0.100 to 19.999

Permissible

sensor factor

1.00 to 99.99

Permissible

offset

± 0.5 mS/cm

Page 32

Specifications

32

APT2000TC-0(H)-00 Transmitter

Temp input

Pt 100 / Pt 1000 / NTC 100 kW

Ranges

– NTC –10.0 to +130.0 °C

+14 to +266 °F

– Pt –20.0 to +150.0 °C

–4 to +302 °F

Resolution 0.1 °C / 1 °F

Accuracy < 0.5 K****

Temp com-

pensation

*

(Ref. temp

25 °C)

LIN 00.00 to 19.99 %/K

NLF Natural waters to

EN 27888 (0 to 36 °C)

Concentration determination

-01- NaCl 0-26.3 % by wt (0 °C) ...

0-28.1 % by wt (100 °C)

-02- HCl 0-17 % by wt (-20 °C) ...

0-17 % by wt (50 °C)

-03- NaOH 0-12 % by wt (0 °C) ...

0-22 % by wt (100 °C)

-04- H

2SO4

0-25 % by wt (-17 °C) ...

0-35 % by wt (110 °C)

-05- HNO

3

0-28 % by wt (-20 °C) ...

0-28 % by wt (50 °C)

-06- H

2SO4

95-99 % by wt (-10 °C) ...

95-99 % by wt (110 °C)

Display LC display, alarm LED

Loop current 4 to 20 mA, floating

22 mA for error message

*

supply voltage 14 to 40 V

Characteristic

*

Linear or logarithmic

Current error

< 0.3 % of current value ± 0.05 mA

APT2000TC-0(H)-IS Transmitter

Temp input

Pt 100 / Pt 1000 / NTC 100 kW

Ranges

– NTC –10.0 to +130.0 °C

+14 to +266 °F

– Pt –20.0 to +150.0 °C

–4 to +302 °F

Resolution 0.1 °C / 1 °F

Accuracy < 0.5 K****

Temp com-

pensation

*

(Ref. temp

25 °C)

LIN 00.00 to 19.99 %/K

NLF Natural waters to

EN 27888 (0 to 36 °C)

Concentration determination

-01- NaCl 0-26.3 % by wt (0 °C) ...

0-28.1 % by wt (100 °C)

-02- HCl 0-17 % by wt (-20 °C) ...

0-17 % by wt (50 °C)

-03- NaOH 0-12 % by wt (0 °C) ...

0-22 % by wt (100 °C)

-04- H

2SO4

0-25 % by wt (-17 °C) ...

0-35 % by wt (110 °C)

-05- HNO

3

0-28 % by wt (-20 °C) ...

0-28 % by wt (50 °C)

-06- H

2SO4

95-99 % by wt (-10 °C) ...

95-99 % by wt (110 °C)

Display LC display , alarm LED

Loop current

EEx ib IIC

4 to 20 mA, floating

22 mA for error message

*

supply voltage 14 to 30 V,

I

max

= 100 mA, P

max

= 0.8 W

Characteristic

*

Linear or logarithmic

Current error

< 0.3 % of current value ± 0.05 mA

Page 33

Specifications

33

APT2000TC-0(H)-00 Transmitter

Start/End of

scale

*

As desired within ranges for

mS, %, SAL

Min. span LIN 5 % of selected range

LOG 1 decade

Current

source

3.8 mA to 22.00 mA

HART

com-

munication

(HART transmitter only)

Digital communication via FSK modulation of loop current, reading of device identification, measured values,

status and messages

reading and writing of parameters

Explosion

protection

USA/Canada:

NI, Class I, Div 2, Group A – D, T4

Data

retention

> 10 years (EEPROM)

RFI suppression

To EN 50081-1 and EN 50081-2

Immunity to

interference

To EN 50082-1 and EN 50082-2

Temperature Operating/ambient temp

–20 to +55 °C

Transport and storage temp

–20 to +70 °C

Enclosure Material: thermoplastic polyester, re-

inforced (polybutylene terephthalate)

Protection: IP 65

Color: bluish gray RAL 7031

Cable glands 3 breakthroughs for Pg 13.5

2 breakthroughs for NPT 1/2 “ or

Rigid Metallic Conduit

APT2000TC-0(H)-IS Transmitter

Start/End of

scale

*

As desired within ranges for

mS, %, SAL

Min. span LIN 5 % of selected range

LOG 1 decade

Current

source

3.8 mA to 22.00 mA

HART

com-

munication

(HART transmitter only)

Digital communication via FSK modulation of loop current, reading of device identification, measured values,

status and messages

reading and writing of parameters

Explosion

protection

USA/Canada:

IS, Class I, Div 1, Group A – D, T4

Europe:

II 2G EEx ib [ia] IIC T6

CE 0032 TÜV 99 ATEX 1430

Data

retention

> 10 years (EEPROM)

RFI suppression

To EN 50081-1 and EN 50081-2

Immunity to

interference

To EN 50082-1 and EN 50082-2

Temperature Operating/ambient temp

–20 to +55 °C

Transport and storage temp

–20 to +70 °C

Enclosure Material: thermoplastic polyester, re-

inforced (polybutylene terephthalate)

Protection: IP 65

Color: bluish gray RAL 7031

Cable glands 3 breakthroughs for Pg 13.5

2 breakthroughs for NPT 1/2 “ or

Rigid Metallic Conduit

Page 34

Specifications

34

APT2000TC-0(H)-00 Transmitter

Dimensions

See Dimension drawings, Pg. 7 ff

Weight approx. 1 kg

* user defined

** displayed with 3 1/2 digits

*** ± 1 count

**** with Pt 100 < 1K, with NTC > 100 °C < 1 K

APT2000TC-0(H)-IS Transmitter

Dimensions

See Dimension drawings, Pg. 7 ff

Weight approx. 1 kg

* user defined

** displayed with 3 1/2 digits

*** ± 1 count

**** with Pt 100 < 1K, with NTC > 100 °C < 1 K

Page 35

Certificate of Conformity

35

Type Examination Certificate

Page 36

Certificate of Conformity

36

Page 37

Certificate of Conformity

37

Page 38

Calibration Solutions

38

Calibration Solutions

Potassium Chloride Solutions

Electrical Conductivity in mS/cm

Temperature

[°C]

Concentration

0.01 mol/l 0.1 mol/l 1 mol/l

0

0.776 7.15 65.41

5 0.896 8.22 74.14

10 1.020 9.33 83.19

15 1.147 10.48 92.52

16 1.173 10.72 94.41

17 1.199 10.95 96.31

18 1.225 11.19 98.22

19 1.251 11.43 100.14

20 1.278 11.67 102.07

21 1.305 11.91 104.00

22 1.332 12.15 105.94

23 1.359 12.39 107.89

24 1.386 12.64 109.84

25 1.413 12.88 111.80

26 1.441 13.13 113.77

27 1.468 13.37 115.74

28 1.496 13.62

29 1.524 13.87

30 1.552 14.12

31 1.581 14.37

32 1.609 14.62

33 1.638 14.88

34 1.667 15.13

35 1.696 15.39

36

15.64

Data source: K. H. Hellwege (Editor), H. Landolt, R. Börnstein: Zahlen-

werte und Funktionen .... Volume 2, Part. Volume 6

Data source: * K. H. Hellwege (Editor), H. Landolt, R. Börnstein: Zahlen-

werte und Funktionen .... Volume 2, Part. Volume 6

** Test solutions calculated according to IEC 746-3

Sodium Chloride Solutions

Electrical Conductivity in mS/cm

Temperature

[°C]

Concentration

saturated* 0.1 mol/l** 0.01 mol/l**

0

134.5 5.786 0.631

1 138.6 5.965 0.651

2 142.7 6.145 0.671

3 146.9 6.327 0.692

4 151.2 6.510 0.712

5 155.5 6.695 0.733

6 159.9 6.881 0.754

7 164.3 7.068 0.775

8 168.8 7.257 0.796

9 173.4 7.447 0.818

10 177.9 7.638 0.839

11 182.6 7.831 0.861

12 187.2 8.025 0.883

13 191.9 8.221 0.905

14 196.7 8.418 0.927

15 201.5 8.617 0.950

16 206.3 8.816 0.972

17 211.2 9.018 0.995

18 216.1 9.221 1.018

19 221.0 9.425 1.041

20 226.0 9.631 1.064

21 231.0 9.838 1.087

22 236.1 10.047 1.111

23 241.1 10.258 1.135

24 246.2 10.469 1.159

25 251.3 10.683 1.183

26 256.5 10.898 1.207

27 261.6 11.114 1.232

28 266.9 11.332 1.256

29 272.1 11.552 1.281

30 277.4 11.773 1.306

31 282.7 11.995 1.331

32 288.0 12.220 1.357

33 293.3 12.445 1.382

34 298.7 12.673 1.408

35 304.1 12.902 1.434

36

309.5 13.132 1.460

Page 39

Concentration Curves

39

Concentration Curves

Conductivity [mS/cm]

700

600

500

400

300

200

100

0

0 5 10 15 20 25 30

Concentration [% by wt]

Concentration calculation error [% by wt]

< 0.5 < 2

100 C

°

91 C°

82 C

°

73 C°

63 C°

53 C°

46 C°

34 C°

25 C°

15 C°

10 C°

0 C°

Fig. 12 Concentration curves NaCl (configuration: concentration -01-)

Page 40

Concentration Curves

40

Conductivity [mS/cm]

1200

1000

800

600

400

200

0

024681012

Concentration [% by wt.]

Concentration calculation error [% by wt]

< 0.2 < 1 < 2

14 16 18 20

–20 C°

–10 C°

50 C°

40 C°

30 C°

25 C°

20 C°

10 C°

0 C°

Fig. 13 Concentration curves HCl (configuration: concentration -02-)

Page 41

Concentration Curves

41

Conductivity [mS/cm]

1600

1400

1200

1000

800

600

400

200

0

0

5101520

25

Concentration [% by wt]

Concentration calculation error [% by wt]

< 0.2

100 C°

90 C°

80 C°

70 C°

60 C°

50 C°

40 C°

30 C°

20 C°

10 C°

0 C°

Fig. 14 Concentration curves NaOH (configuration: concentration -03-)

Page 42

Concentration Curves

42

Conductivity [mS/cm]

1600

1400

1200

1000

800

600

400

200

0

0

5101520

25 30

Concentration [% by wt]

< 0.5

100 C°

90 C°

80 C

°

70 C

°

60 C°

50 C°

40 C°

30 C°

20 C

°

–10 C°

10 C°

0 C°

35

1800

< 1

110 C°

Concentration calculation error [% by wt]

Fig. 15 Concentration curves H2SO4 (configuration: concentration -04-)

Page 43

Concentration Curves

43

Conductivity [mS/cm]

1200

1000

800

600

400

200

0

0 5 10 15 20 25

30

Concentration [% by wt.]

< 0.2 < 1 < 2

50 C°

40 C°

30 C°

–20 C

°

–10 C

°

25 C°

20 C

°

10 C°

0 C°

Concentration calculation error [% by wt]

Fig. 16 Concentration curves HNO3 (configuration: concentration -05-)

Page 44

Concentration Curves

44

Conductivity [mS/cm]

600

400

200

0

95.0 95.5 96.0 96.5

97.5

Concentration [% by wt]

Concentration calculation error [% by wt]

< 0.2

100 C°

90 C°

80 C°

70 C°

60 C

°

50 C°

40 C°

30 C°

20 C°

–10 C

°

10 C°

0 C

°

98.0

110 C°

300

500

98.5 99.0

100

97.0

Fig. 17 Concentration curves H2SO4 (range 95 to 99 % by wt), (configuration: concentration -06-)

Page 45

Index

45

Index

, 26

22 mA signal for alarm, 18, 26

configuring, 20

A

Alarm, 18

response time, 26

Alarm LED, 26

Alarm via loop current, 18, 26

configuring, 20

Assembly, 6

C

Cal info, 25, 28

Calibration, 21

input of cell factor, 21

sensor factor adjustment, 23

temp probe adjustment, 24

with calibration solution, 22

zero point, in air, 23

Calibration data, display , 28

Calibration solutions, 38

Cell factor, calibration, 22

Cleaning, 29

Concentration curves, 39

Conductivity measurement, 25

Configuration, 19

Connecting

handheld terminal, 9

lines, 9

Connecting cable, fixing, 9

Current characteristic, configur-

ing, 20

Current loop

Hold state, 20

Hold value, 20

Current source, 28

D

Diagnostics functions, 28

Dimension drawings, 7

Display, 16

E

Error info, 25, 26, 28

Error message, last, 25, 26, 28

Error message via loop current,

18, 26

configuring, 20

Error messages, 26–29

Explosion protection, APT2000,

33

G

GainCheck, 17, 28

H

HART communication, 18

Hold state, 25

I

Installation, 13

Instrument self–test

automatic, 17

manual, 17

K

Keypad, 16

L

Loop current, 18

display, instantaneous, 28

frozen, 25

M

Maintenance, 29

Measuring mode, 25

Messages, Sensoface, 26

Mode code, 4

Mounting diagram, 7

O

Outputs, 18

P

Packing list, 6

Page 46

Index

46

Pipe–mount kit, 8

Process variable, configuring, 19

Product line, 30

Protective hood, 8

S

Safety precautions, 3

Self–test

automatic, 29

manual, 28

Sensocheck, on or off, 20

Sensoface, 17, 26

diagnostics, 26

messages, 26

Sensor factor , adjustment, 23

Sensor monitoring, Sensoface, 26

Sensors, monitoring, 17

Smiley, 26

Software version, display , 17, 28

Specifications, 31

Stripping lengths, 9

T

Terminals, pulling out, 9

Test mode, 28

Type Examination Certificate, 35

U

User Interface, 15

W

Wiring example, 14

Page 47

Page 48

Sensing and Control

Honeywell Inc.

11 West Spring Street

Freeport, IL 61032

USA

Honeywell S. A.

Espace Industriel Nord

Rue André Durouchez

80084 Amiens Cedex 2

France

Loading...

Loading...