Page 1

PRODUCT DESCRIPTION

A new generation of professional movement

Activ8

Activ8 BG

Activ8 Activ8

BG

BGBG

PROFESSIONAL

PASSIVE INFRARED

SHOCK & BREAKAGE

DETECTORS

With PET IMMUNITY

INSTALLATION INSTRUCTIONS

P/N 7101493 REV. A A.Y.

Activ8 BG FEATURES DETECTION PATTE R N

FEATURES

• Quad (Four element) pyrosensor.

• Two independent relay outputs for

GLASS/SHOCK and PIR alarm

signals.

• VLSI SMD technology.

• PIR sensitivity adjustment.

• GLASS sensitivity adjustment.

• SHOCK sensitivity adjustment.

• Volume protection.

• Automatic temperature

compensation.

• Height installation calibrations

free.

• Environmental immunity.

• The Activ8 BG provides pet immunity

up to 25Kg. Pet active bellow 1m.

REMOVAL OF FRONT COVER MOUNTING DETECTOR BASE

Unscrew the holding

screw and open base

spread spectrum analyzing PIR, Shock & Glass

Breakage detectors.

The detector provides an analysis of

environmental conditions through the entire

movement spread frequency spectrum.

It listens for sounds of breaking glass, which

produces two sequential signals of different

frequencies “SHOCK” and “GLASS”. The unique

phased frequency detection circuitry of this

detector allows detection of both shock signal and

the strong signal of glass breakage creating a

false alarm free detector.

The detector does not need to be attached to the

window, providing volume protection, and

allowing you to protect several windows with one

detector.

15m

1. To remove the front cover, unscrew the holding

screw and gently raise the front cover.

2. To remove the PC board, carefully unscrew the

holding screw located on the PC board.

3. Break out the desired holes for proper installing.

4. The circular and rectangular indentations at the

bottom base are the knockout holes for wire

entry. You may also use mounting holes that are

not in use for running the wiring into the

detector.(For option with bracket - lead wire

through the bracket)

5. Mount the detector base to the wall, corner or

ceiling. (For option with bracket install bracket).

6. Reinstall the PC board by fully tightening the

holding screw. Connect wire to terminal block.

7. Replace the cover by inserting it back in the

appropriate closing pins and screw in the holding

screw.

MOUNTING THE DETECTOR

SELECT MOUNTING LO CATION

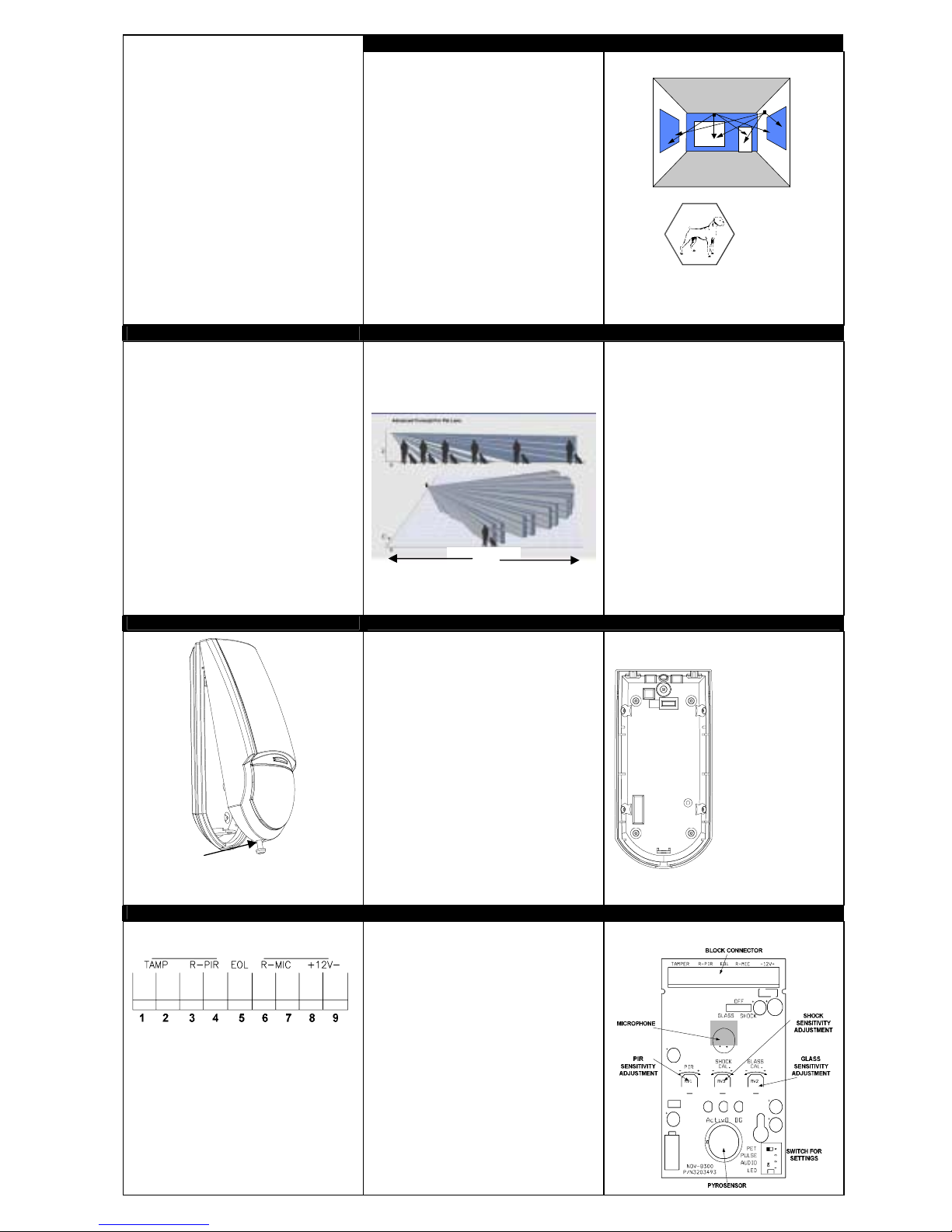

DETECTOR INSTALL ATIO N CIRCUIT LAYOUT

TERMINAL BLOCK CONNECTIONS

Terminals 1 & 2 - Marked “ TAMPER ”

If a Tamper function is required connect these

terminals to a 24-hour normally closed protective

zone in the control unit. If the front cover of the

detector is opened, an immediate alarm signal will

be sent to the control unit.

Terminals 3 & 4 - Marked “ R-PIR ”

These are the output PIR relay contacts of the

detector. Connect to a normally closed zone in the

control panel.

Terminal 5 - Marked “ EOL ” – End of line option.

Terminals 6 & 7 - Marked “ R-MIC ”

These are the output MICROPHONE relay

contacts of the detector. Connect to a normally

closed zone in the control panel.

Terminal 8 - Marked “ + ” (+12V)

Connect to a positive Voltage output of 8.2 -16Vdc

source (usually from the alar control unit)

Terminal 9 - Marked “ - ” (gnd)

Connect to the negative Voltage output or ground

of the control panel.

The Activ8 BG provides immunity up to 25Kg.

For better immunity avoid installation in areas

where pets can reach upwards.

TYPICAL INSTALLATIO N

Choose a location in front of the protected

windows, in direct line of sight within 4.5m. In

case of more then one window, place the detector

in the center area facing the windows, make sure

that this location will be most likely to intercept an

intruder, that may across the PIR beams.

See PIR detection beams.

See SHOCK and GLASS detection area.

If heavy blinds or curtains cover the glass, you

must locate the detector behind the blinds on

the window frame or above it, otherwise the

blinds might block the sound.

AVOID THE FOLLOWING LOCATIONS

∗ Facing direct sunlight.

∗ Facing areas subject with temperature

changes.

∗ Areas with air ducts or substantial air flows.

∗ Facing metal doors.

∗ Close to door entrance bells measuring 2” (or

larger) in diameter.

KNOCKOUT HOLES

CC

C

A

A

BBB

A

D

A. Wire access

holes

B. Use for flat wall

mounting

C. Corner mounting -

use all 4 holes.

Sharp left or right

angle mounting use 2 holes (top

C

B

and bottom)

D. For bracket

mounting

Page 2

SETTING UP THE DE TE CTOR

PIR SENSITIVITY ADJUSTMENT

SWITCH 3 OF DIP-4 SWITCH FOR SETTINGS

“PULSE” - provides sensitivity control of PIR

according to the environment.

Position Left – “On” – High sensitivity

For stable environments.

Position Right – “OFF” – Low sensitivity

For harsh environments.

POTENTIOMETER RV1 “PIR” –

adjustment according to protected area

range.

For high-risk locations, the sensitivity should be

adjusted close to MIN (9%). In low risk situations,

the sensitivity should be adjusted closer to MAX

(100%) factory set to 54%.

Always walk test and re-adjust if required.

ADJUSTMENT

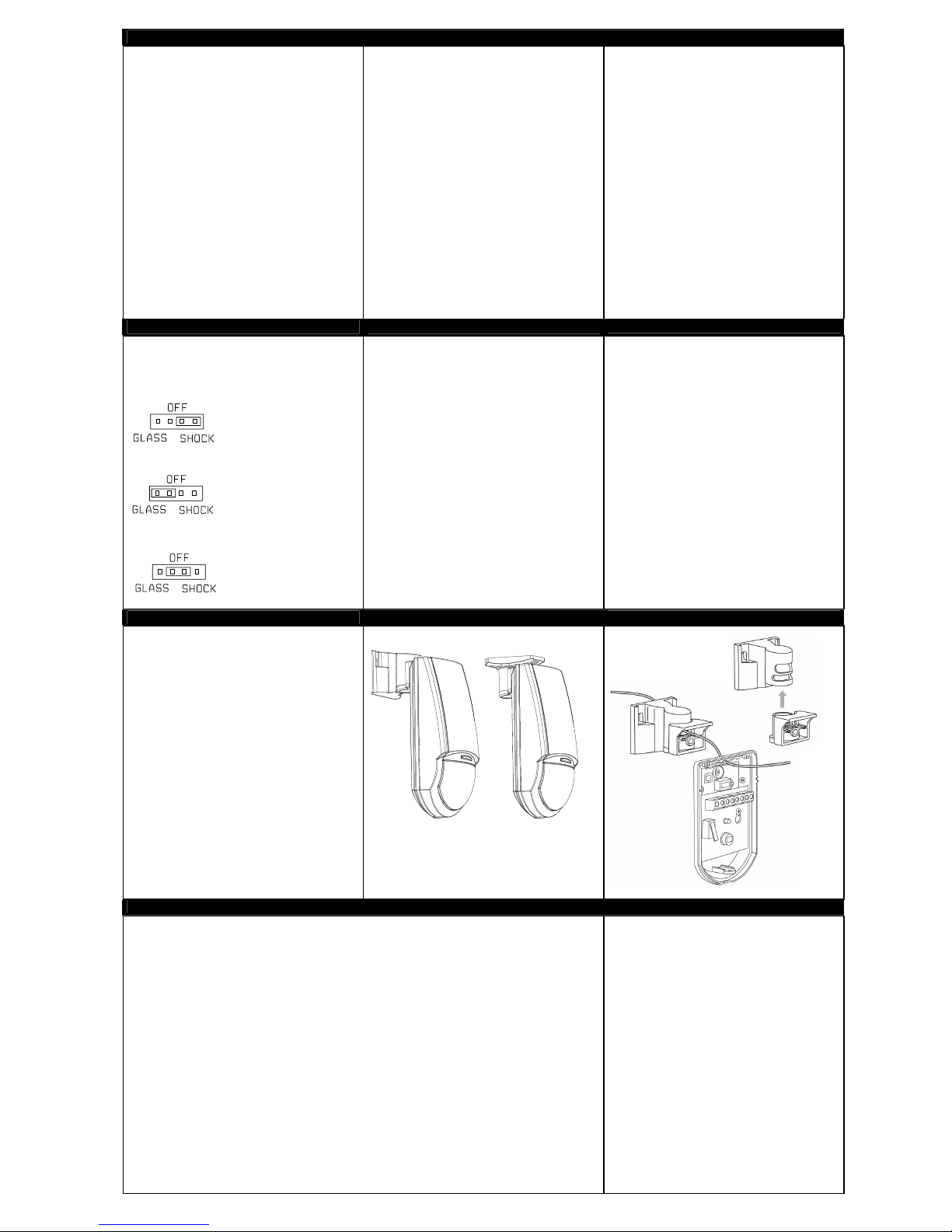

SHOCK / GLASS ADJUSTMENT

Use only during testing and setting

SHOCK - for adjustment

of the low frequency

sensitivity with

potentiometer “SHOCK”

GLASS - for

adjustment of the

high frequency

sensitivity with

potentiometer

GLASS

OFF - for regular

operation

SHOCK/GLASS TEST PROCEDURE WALL AND CEILING INSTALLATION OPTIONS

FINAL TESTING

• Make sure to set jumper “GLASS/SHOCK” in

position OFF. When the jumper is in this

position, the detector will detect both shock

and sound frequencies.

•••• To ensure maximum protection against false

alarms, activate any device in the area, which

might automatically cycle pumps, generators,

heating/air conditioning units, etc. If the

devices trigger an alarm, mount the

cycling

unit in a different location.

LED INDIC ATION OF ALARM SIGNAL

SWITCH 1 OF DIP-4 SWITCH FOR SETTINGS

“LED” – provide control of Alarm signal LED

indication.

Position Left – “On” – LED enable.

Position Right – “OFF” – LED disable.

SOUND SENSITIVITY ADJUSTMENT

SWITCH 2 OF DIP-4 SWITCH FOR SETTINGS

“AUDIO” – provide control of sound detection

sensitivity.

Position Left – “On” – reducing the sensitivity of

sound detection by 50%. (Use in small room)

Position Right – “OFF” – LED disable.

PET IMMUNI TY SETTING

SWITCH 4 OF DIP-4 SWITCH FOR SETTINGS

“PET” 15kg – 25kg

Position Left “ON” Immunity to PET up to 15 kg

Position Right “OFF” Immunity to PET up to 25 kg

GLASS BREAK ADJUSTMENT

To adjust the glass break sensitivity, place the

jumper below the GLASS marking. Green

(SHOCK) LED is constantly ON.

Now you can adjust the sensitivity by rotating the

GLASS potentiometer.

Operate the Sound Break Simulator* near the

protected window and rotate the potentiometer

GLASS clock-wise to increase sensitivity, and

counter-clock-wise to decrease sensitivity until

the Yellow and Red LEDs are illuminating for

each glass break sound.

Note:

When the jumper is set for GLASS adjustment,

only the high frequency sound of breaking glass is

detected.

*It is recommended to use GLASS-BREAK

Simulator FG-701 (CROW p/n 004001)

TEST PROCEDURES.

Wait for one minute warm up time after applying

12-Vdc power. Conduct testing with the protected

.

area cleared of all people

unit thoroughly for proper detection.

Walk test

1. Remove front cover.

Set “PULSE” to “ON” position, and set “LED” to

“ON” position.

2. Replace the front cover.

3. Start walking slowly across the detection area.

4. Observe that the red led lights whenever

motion is detected.

5. Allow 5 sec. between each test for the detector

to stabilize.

6. After the walk test is completed, you can set

the “LED” to “OFF” position.

NOTE:

Walk tests should be conducted, at least once a

year, to confirm proper operation and coverage of the

detector.

Make sure to test the

SHOCK ADJUSTMENT

To adjust the shock setting (increase/decrease

sensitivity) place the jumper below the SHOCK Yellow (GLASS) LED is constantly ON.

Now you can adjust the sensitivity by rotating the

potentiometer SHOCK.

Hit gently on the protected glass and rotate the

potentiometer clock-wise to increase sensitivity,

and counter-clock-wise to decrease sensitivity

until the Green and Red LEDs are illuminating for

each hit.

Note:

When the jumper is set for SHOCK adjustment,

only the low frequency of the shock signal prior to

glass breakage is detected.

BRACKET INSTALLATION

Detection Method Quad (Four element) PIR & electret microphone

Detection Speed 0.15 – 3.6 m/sec

Power Input 7.8 - 16 Vdc

Current Draw Alarm PIR :16.5mA; Alarm Shock & Glass 22mA; Alarm all: 18mA

Standby: 16.5 mA

BI Directional Temperature Comp. YES

Pulse Count 1, AUTO

Alarm Period 2 sec

Alarm Output N.C 28Vdc 0.1 A with 10 Ohm series protection resistors

Tamper Switch N.C 28Vdc 0.1A with 10 Ohm series protection resistor – open

when cover is removed

Warm Up Period 60 sec

Operating Temperature -20

RFI Protection 30V/m 10 - 1000MHz

EMI Protection 50,000V of electrical interference from lighting

Visible Light Protection stable against halogen light 2.4m (8ft )or reflected light

Detection range Glass up to 10m ( 90

LEDs indicator Yellow LED (GLASS) - glass break signal for testing & adjustment

Green LED (SHOCK) - shock signal for testing & adjustment

Red LED (ALARM) - alarm signal:

Fleshing light - glass & break detection or glass & shock & PIR

detection

Constant light - PIR detection

Dimensions 121mm x 60mm x 37mm

Weight (inc. battery) 110 gr.

35493AE50

TECHNICAL SPECIFICAT IO N

°

C to +50°C

°

); PIR up to 15m (WA lens)

For Technical Support, please

call 01268 563 247.

Loading...

Loading...