Page 1

9782 Series Two Cell

Conductivity/Resistivity

Analyzer/Controller

Operator’s Manual

70-82-25-74

Rev 3

6/99

Page 2

Copyright, Notices, and Trademarks

Printed in U.S.A. – © Copyright 1999 by Honeywell Inc.

Revision 3 – 6/99

While this information is presented in good faith and believed to be accurate, Honeywell

disclaims the implied warranties of merchantability and fitness for a particular purpose and

makes no express warranties except as may be stated in its written agreement with and for its

customer.

In no event is Honeywell liable to anyone for any indirect, special or consequential damages.

The information and specifications in this document are subject to change without notice.

CE CONFORMITY

This product is in conformance with the protection requirements of the following European Council

Directives: 89/336/EEC, the Electromagnetic Compatibility Directive and 73/23/EEC, the Low Voltage

Directive. Conformance of this product with any other “CE Mark” Directive(s) shall not be assumed.

ATTENTION

The emission limits of EN 50081-2 are designed to provide reasonable protection against harmful

interference when this equipment is operated in an industrial environment. Operation of this equipment in a

residential area may cause harmful interference. This equipment generates, uses and can radiate radio

frequency energy and may cause interference to radio and television reception when the equipment is used

closer than 30 m to the antenna(e). In special cases, when highly susceptible apparatus is used in close

proximity, the user may have to employ additional mitigating measures to further reduce the

electromagnetic emissions of this equipment.

SYMBOL DEFINITIONS

This CAUTION symbol on the equipment refers the user to the Product Manual for additional

!

information. This symbol appears next to required information in the manual.

WARNING, risk of electric shock. This symbol on the equipment warns the user of potential

shock hazard where voltages greater than 30 Vrms, 42.4 Vpeak, or 60 Vdc may be accessible.

Earth Connnection.

Honeywell

Industrial Automation and Control

Automation College

2820 West Kelton Lane

Phoenix, AZ 85023

(602) 313-5669

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99ii

Page 3

About This Document

Abstract

This manual contains instructions for installation and operation of the 9782 Series

Conductivity/Resistivity Analyzer/Controller.

Revision Notes

The following list provides notes concerning all revisions of this document.

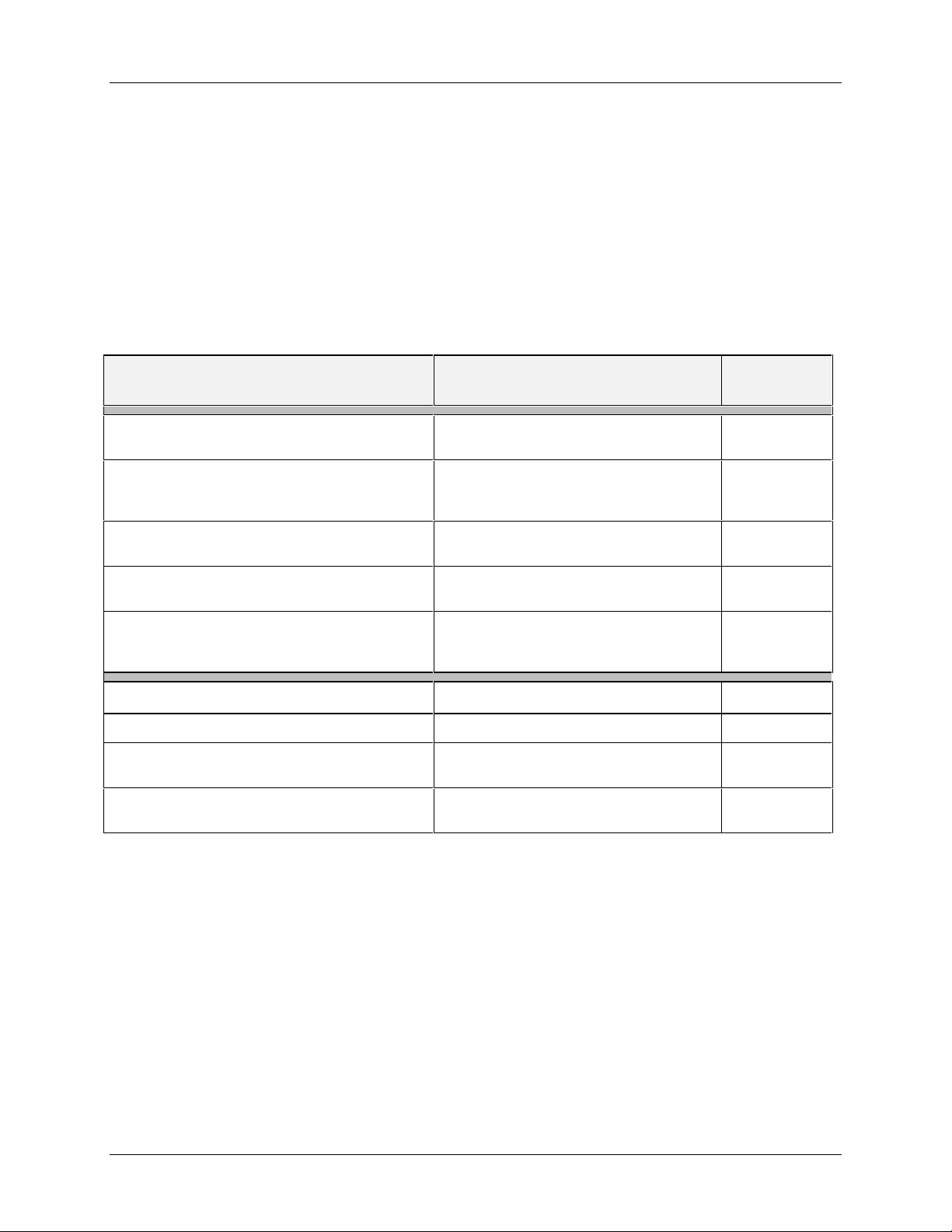

Rev. ID Date Notes

0 6/98 This manual accompanies the initial release of the 9782 Series

Conductivity/Resistivity Analyzer/Controller.

1 7/98 Changes were made to Section 9 to reflect changes in the software.

2 12/98 Included dimension drawings for backlit and non-backlit option (Sec. 3)

3 6/99 Edits were made to standardize terminology and to add the latest MSG.

References

Honeywell Documents

The following list identifies all Honeywell documents that may be sources of reference for the material

discussed in this publication.

Document Title ID # Binder Title Binder ID #

Trademarks

AutoClean is a trademark of Honeywell Inc.

Noryl is a trademark of GE Company.

Contacts

The following list identifies important contacts within Honeywell.

Organization Telephone Address

Honeywell Technical Assist ance Center 1-800-423-9883

(USA and Canada)

1100 Virginia Avenue

Fort Washington, PA 19038

6/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual iii

Page 4

Contents

1. INTRODUCTION ..................................................................................................... 1-1

1.1 Description ..................................................................................................................................... 1-1

Multi-function instrument...............................................................................................................................1-1

User interface..................................................................................................................................................1-1

Easy to configure............................................................................................................................................1-1

Input................................................................................................................................................................1-2

Outputs............................................................................................................................................................1-2

DE (Digital integration)..................................................................................................................................1-2

Relays.............................................................................................................................................................1-2

1.2 Features .......................................................................................................................................... 1-3

Automatic cell washing...................................................................................................................................1-3

Computed values.............................................................................................................................................1-3

Automatic range scaling..................................................................................................................................1-3

Password protection........................................................................................................................................1-3

Extensive diagnostics......................................................................................................................................1-3

Watertight corrosion-resistant case.................................................................................................................1-4

Solution Temperature Compensation..............................................................................................................1-4

1.3 Operating the Analyzer/Controller................................................................................................. 1-6

1.3.1 Keypad Use ........................................................................................................................... 1-6

Front panel keys used for all operator tasks....................................................................................................1-6

Selecting a parameter for edit.........................................................................................................................1-7

Editing a parameter assignment from a list of available choices.....................................................................1-7

Editing a parameter numeric value .................................................................................................................1-7

Controlling an AutoClean operation manually................................................................................................1-7

1.3.2 Online Displays.....................................................................................................................1-8

Introduction ....................................................................................................................................................1-8

Individual cell display.....................................................................................................................................1-8

Combined display...........................................................................................................................................1-9

Computed value..............................................................................................................................................1-9

Clock and AutoClean....................................................................................................................................1-10

1.4 Menu Hierarchy............................................................................................................................ 1-11

Menus for every task.....................................................................................................................................1-11

1.5 Planning........................................................................................................................................ 1-13

1.5.1 Overview............................................................................................................................. 1-13

Configuration system minimizes decisions...................................................................................................1-13

1.5.2 Using Relays........................................................................................................................ 1-13

Relays assigned during I/O setup..................................................................................................................1-13

Interactions affecting permitted relay assignments.......................................................................................1-14

1.5.3 Deciding on a Control Strategy........................................................................................... 1-16

All 9782 models can use relays for control...................................................................................................1-16

Optional analog outputs for control ..............................................................................................................1-16

Selecting a strategy.......................................................................................................................................1-16

1.6 Overview of Installation and Setup Tasks....................................................................................1-17

Setup tasks described in this manual.............................................................................................................1-17

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99iv

Page 5

2. SPECIFICATIONS AND MODEL NUMBER............................................................ 2-1

2.1 Specifications ................................................................................................................................. 2-1

2.1.1 User Interface........................................................................................................................ 2-1

Display............................................................................................................................................................2-1

Keypad............................................................................................................................................................2-1

2.1.2 Physical ................................................................................................................................. 2-1

Case ................................................................................................................................................................2-1

Case Dimensions.............................................................................................................................................2-1

Weight ............................................................................................................................................................2-1

Mounting ........................................................................................................................................................2-1

2.1.3 Compliance............................................................................................................................ 2-2

CE conformity.................................................................................................................................................2-2

Year 2000 .......................................................................................................................................................2-2

2.1.4 Electrical................................................................................................................................ 2-2

Power Requirements....................................................................................................................................... 2-2

Fuse Rating.....................................................................................................................................................2-2

2.1.5 Model Ranges........................................................................................................................ 2-2

Standard range models....................................................................................................................................2-2

Wide range models.........................................................................................................................................2-3

2.1.6 Operating Conditions ............................................................................................................ 2-3

Operating Conditions......................................................................................................................................2-3

Performance under reference operating conditions.........................................................................................2-4

Operating Influences under normal operating conditions...............................................................................2-4

2.1.7 Outputs .................................................................................................................................. 2-4

Standard alarm/control relays .........................................................................................................................2-4

Optional alarm/control relays .........................................................................................................................2-4

Optional analog outputs.................................................................................................................................. 2-4

Optional Digital Communication Link............................................................................................................2-5

2.1.8 Temperature Compensation ..................................................................................................2-5

Availability.....................................................................................................................................................2-5

2.1.9 AutoClean.............................................................................................................................. 2-5

Cell rinse schedule settings.............................................................................................................................2-5

2.1.10 Control................................................................................................................................. 2-5

Settings...........................................................................................................................................................2-5

2.1.11 Computed Values................................................................................................................ 2-6

Available selections........................................................................................................................................2-6

2.2 Model Number Breakdown............................................................................................................ 2-7

Introduction ....................................................................................................................................................2-7

3. UNPACKING, PREPARATION, AND MOUNTING ................................................. 3-1

3.1 Overview ........................................................................................................................................ 3-1

Introduction ....................................................................................................................................................3-1

What’s in this section?....................................................................................................................................3-1

3.2 Unpacking and Preparing............................................................................................................... 3-2

Procedure........................................................................................................................................................3-2

3.3 Mounting........................................................................................................................................ 3-3

Introduction ....................................................................................................................................................3-3

Panel-mounting...............................................................................................................................................3-3

Wall- and pipe-mounting................................................................................................................................3-3

6/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual v

Page 6

4. POWER WIRING..................................................................................................... 4-1

4.1 Overview ........................................................................................................................................ 4-1

Introduction ....................................................................................................................................................4-1

What’s in this section?....................................................................................................................................4-1

4.2 General Wiring Practices for Power Wiring..................................................................................4-2

Safety precautions...........................................................................................................................................4-2

Avoid damage to components.........................................................................................................................4-2

Wiring for immunity compliance ....................................................................................................................4-2

Conform to code.............................................................................................................................................4-3

4.3 Power Wiring Considerations ........................................................................................................ 4-3

Recommended wire size .................................................................................................................................4-3

Power supply voltage and frequency within specs..........................................................................................4-3

4.4 Installing Power Wiring................................................................................................................. 4-4

Procedure........................................................................................................................................................4-4

5. I/O SETUP AND SYSTEM CONFIGURATION........................................................ 5-1

5.1 Overview ........................................................................................................................................ 5-1

Introduction ....................................................................................................................................................5-1

What’s in this section?....................................................................................................................................5-1

Powering up the Analyzer/Controller .............................................................................................................5-1

5.2 I/O Setup and Configuration Tasks................................................................................................ 5-2

Ease of configuration......................................................................................................................................5-2

Accessing the I/O setup and configuration menus..........................................................................................5-2

Purpose of I/O setup.......................................................................................................................................5-2

Purpose of configuration menu items..............................................................................................................5-2

Illustrations.....................................................................................................................................................5-3

System defaults...............................................................................................................................................5-3

5.3 Performing I/O Setup ..................................................................................................................... 5-4

Purpose...........................................................................................................................................................5-4

Display resolution and unit of measure...........................................................................................................5-4

5.4 Configuring Current Adjusting Type (CAT) Control and/or Retransmission of Process Variables5-10

Purpose.........................................................................................................................................................5-10

Procedure......................................................................................................................................................5-10

5.5 Configuring On/Off, Duration Adjusting Type (DAT), or Pulse Frequency Type (PFT) Control5-12

Purpose.........................................................................................................................................................5-12

Procedure......................................................................................................................................................5-12

5.6 Configuring Alarms...................................................................................................................... 5-16

Purpose.........................................................................................................................................................5-16

Procedure......................................................................................................................................................5-16

5.7 Setting the Clock.......................................................................................................................... 5-17

Purpose.........................................................................................................................................................5-17

Procedure......................................................................................................................................................5-17

5.8 Configuring AutoClean................................................................................................................ 5-18

Purpose.........................................................................................................................................................5-18

Timer-initiated operation..............................................................................................................................5-18

Operator-initiated operation..........................................................................................................................5-18

Hold mode....................................................................................................................................................5-19

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99vi

Page 7

5.9 Selecting a Computed Value to Be Displayed............................................................................. 5-21

Purpose.........................................................................................................................................................5-21

Procedure......................................................................................................................................................5-21

5.10 Summary of Menu Choices and System Defaults......................................................................5-23

Introduction ..................................................................................................................................................5-23

6. INPUT AND OUTPUT WIRING ............................................................................... 6-1

6.1 Overview ........................................................................................................................................ 6-1

Introduction ....................................................................................................................................................6-1

What’s in this section?....................................................................................................................................6-1

6.2 General Wiring Practices for I/O Wiring....................................................................................... 6-2

Safety precaution............................................................................................................................................6-2

Avoid damage to components.........................................................................................................................6-2

Immunity Compliance.....................................................................................................................................6-2

Conform to code.............................................................................................................................................6-2

Recommended maximum wire size.................................................................................................................6-3

Cables for locations without interference........................................................................................................6-3

Shielded wiring for locations with interference..............................................................................................6-3

Avoiding interference .....................................................................................................................................6-3

References ......................................................................................................................................................6-3

6.3 Wiring Analog Inputs and Outputs................................................................................................. 6-4

Introduction ....................................................................................................................................................6-4

Cell identification significant to computed value............................................................................................6-4

Procedure........................................................................................................................................................6-4

6.4 Wiring Relays................................................................................................................................. 6-7

6.4.1 Installation............................................................................................................................. 6-7

Introduction ....................................................................................................................................................6-7

Procedure........................................................................................................................................................6-7

6.4.2 Disconnecting RC Arc Suppression Circuits........................................................................ 6-9

Introduction ....................................................................................................................................................6-9

Procedure........................................................................................................................................................6-9

6.4.3 Wiring a Device to the Relay Indicating Output Range Status........................................... 6-10

Introduction ..................................................................................................................................................6-10

Interconnections............................................................................................................................................6-10

7. AUTOCLEAN THEORY AND PIPING..................................................................... 7-1

7.1 Overview ........................................................................................................................................ 7-1

Introduction ....................................................................................................................................................7-1

What’s in this section?....................................................................................................................................7-1

7.2 AutoClean Sequence and Piping.................................................................................................... 7-2

Rinse sequence................................................................................................................................................7-2

Select valves and fittings with appropriate pressure ratings............................................................................7-3

Minimize liquid volume in system..................................................................................................................7-3

6/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual vii

Page 8

8. CALIBRATION ........................................................................................................ 8-1

8.1 Overview ........................................................................................................................................ 8-1

Introduction ....................................................................................................................................................8-1

What’s in this section?....................................................................................................................................8-1

Calibration menu customized for different configurations..............................................................................8-1

8.2 Recommendations for Successful Measurement and Calibration.................................................. 8-3

Selection and care of cell essential.................................................................................................................8-3

Recommendations...........................................................................................................................................8-3

8.3 Entering the Cal Factor for Each Cell............................................................................................ 8-4

Introduction ....................................................................................................................................................8-4

Procedure........................................................................................................................................................8-4

8.4 Performing Calibration Trim.......................................................................................................... 8-5

Introduction ....................................................................................................................................................8-5

8.5 Removing Calibration Trim Values............................................................................................... 8-7

Introduction ....................................................................................................................................................8-7

Procedure........................................................................................................................................................8-7

8.6 Determining and Entering the TDS Conversion Factor................................................................. 8-8

Introduction ....................................................................................................................................................8-8

Determining TDS conversion factor...............................................................................................................8-8

Out-of range-values forced to closest limit.....................................................................................................8-8

Calibrate the Analyzer/Controller before entering TDS conversion factor.....................................................8-8

Procedure........................................................................................................................................................8-9

9. DIAGNOSTICS AND MESSAGES .......................................................................... 9-1

9.1 Overview ........................................................................................................................................ 9-1

Introduction ....................................................................................................................................................9-1

What’s in this section?....................................................................................................................................9-1

9.2 System Status Messages................................................................................................................. 9-2

Related to operation of Analyzer/Controller...................................................................................................9-2

9.3 Process Alarm Messages................................................................................................................ 9-3

Alarms dependent on configuration................................................................................................................9-3

9.4 On-Line Diagnostics and System Error Messages......................................................................... 9-4

Self-tests at 0.5 second intervals.....................................................................................................................9-4

Output affected by error..................................................................................................................................9-4

9.5 Off-Line Diagnostics...................................................................................................................... 9-5

Introduction ....................................................................................................................................................9-5

9.5.1 Display and Keyboard Test................................................................................................... 9-5

Procedure........................................................................................................................................................9-5

9.5.2 Output Tests .......................................................................................................................... 9-7

Procedure........................................................................................................................................................9-7

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99viii

Page 9

10. MAINTENANCE................................................................................................... 10-1

10.1 Overview .................................................................................................................................... 10-1

Introduction ..................................................................................................................................................10-1

What’s in this section?..................................................................................................................................10-1

10.2 Output Calibration...................................................................................................................... 10-3

Introduction ..................................................................................................................................................10-3

Required equipment......................................................................................................................................10-3

Procedure......................................................................................................................................................10-3

10.3 Specifying a Tagname or Other Display String......................................................................... 10-6

Introduction ..................................................................................................................................................10-6

Procedure......................................................................................................................................................10-6

10.4 Viewing Product Information and Changing Model Number Stored in Memory...................... 10-7

Introduction ..................................................................................................................................................10-7

Procedure......................................................................................................................................................10-7

10.5 Adjusting the Screen Contrast.................................................................................................... 10-9

Introduction ..................................................................................................................................................10-9

Procedure......................................................................................................................................................10-9

10.6 Entering a Password for Security............................................................................................. 10-10

Introduction ................................................................................................................................................10-10

Procedure....................................................................................................................................................10-10

10.7 Resetting All Configuration and Calibration Values to Factory Settings................................10-11

Introduction ................................................................................................................................................10-11

Procedure....................................................................................................................................................10-11

10.8 Entering Values for Lead Resistance Compensation (Wide Range Only)............................... 10-12

Introduction ................................................................................................................................................10-12

Procedure....................................................................................................................................................10-14

10.9 Replacing the Fuse ................................................................................................................... 10-15

Introduction ................................................................................................................................................10-15

Procedure....................................................................................................................................................10-15

11. ACCESSORIES AND REPLACEMENT PARTS LIST ........................................ 11-1

11.1 Overview .................................................................................................................................... 11-1

Introduction ..................................................................................................................................................11-1

What’s in this section?..................................................................................................................................11-1

11.2 Part Numbers.............................................................................................................................. 11-2

Introduction ..................................................................................................................................................11-2

APPENDIX A PROPORTIONAL CONTROL TUNING................................................A-1

Adjust effective proportional band width ......................................................................................................A-1

Treatment takes too long, but no unacceptable overshoot .............................................................................A-1

Unacceptable overshoot.................................................................................................................................A-1

6/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual ix

Page 10

APPENDIX B TWO-CELL APPLICATIONS................................................................B-1

Ion Exchange.................................................................................................................................................B-1

Reverse Osmosis............................................................................................................................................B-1

Conductivity/Resistivity/TDS Difference......................................................................................................B-2

Parts Rinsing..................................................................................................................................................B-2

Softener Monitoring.......................................................................................................................................B-3

Steam Power Measurements..........................................................................................................................B-3

Sodium Hydroxide & Hydrochloric Acid Concentration Measurements.......................................................B-4

APPENDIX C MICROPROCESSOR BOARD SWITCH SETTINGS ...........................C-1

Introduction ...................................................................................................................................................C-1

Location of switches ......................................................................................................................................C-1

SW1 - all positions set to off .........................................................................................................................C-1

SW2 - settings are dependent on options.......................................................................................................C-1

APPENDIX D USING A PRECISION CHECK RESISTOR..........................................D-1

Introduction ...................................................................................................................................................D-1

Set cal factor and calibration trim for ideal conditions..................................................................................D-1

Calculations for conductivity, resistivity, and TDS.......................................................................................D-1

Concentration values......................................................................................................................................D-2

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99x

Page 11

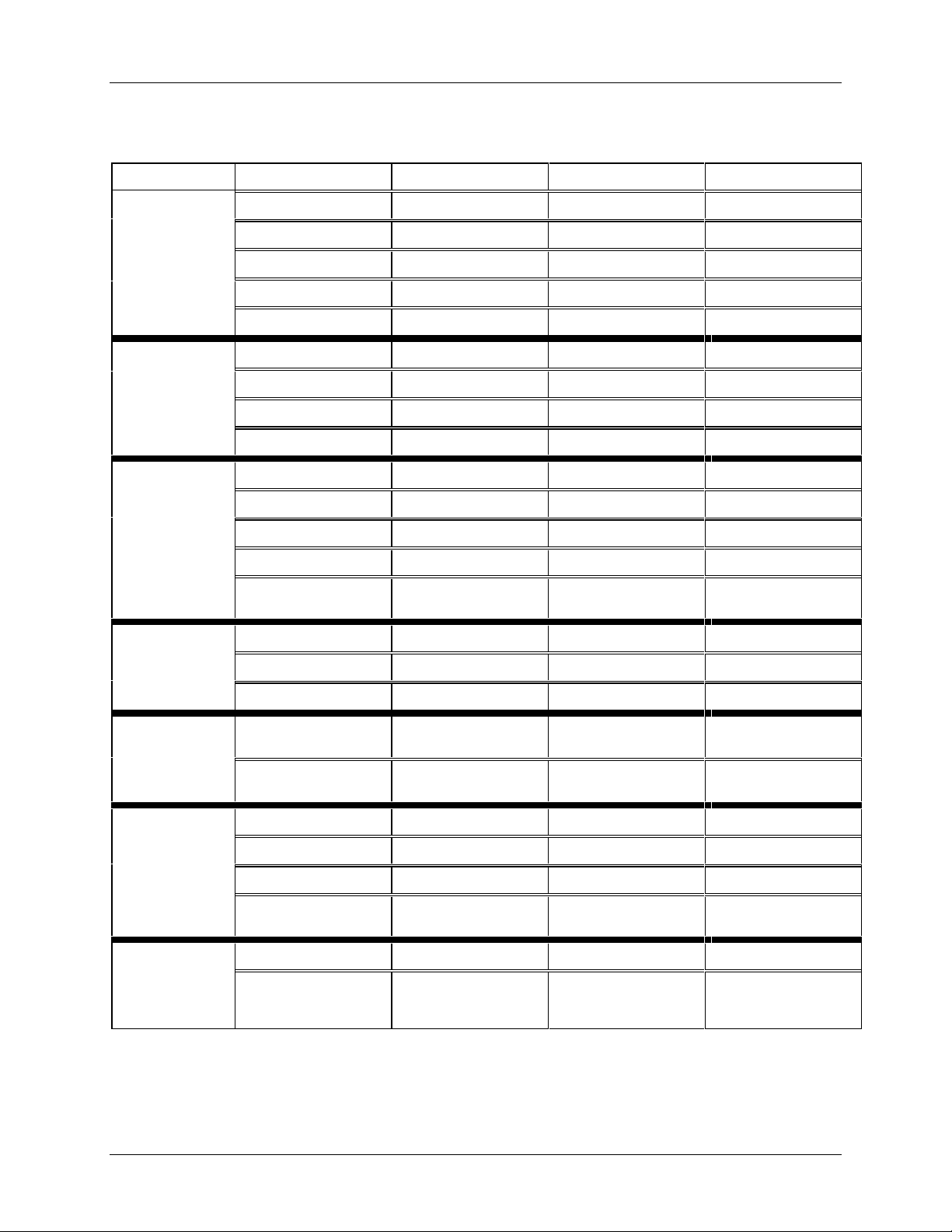

Tables

Table 1-1 Key Functions.......................................................................................................................... 1-6

Table 1-2 9782 Conductivity/Resistivity Analyzer/Controller Menu Hierarchy................................... 1-11

Table 1-3 Available Combinations of Relay Assigments ...................................................................... 1-15

Table 1-4 Overview of Analyzer/Controller Installation Tasks............................................................. 1-17

Table 3-1 Procedure for Unpacking and Preparing the 9782................................................................... 3-2

Table 4-1 Procedure for Installing AC Power Wiring.............................................................................4-4

Table 5-1 Procedure for Performing I/O Setup........................................................................................ 5-6

Table 5-2 Procedure for Configuring CAT Control and/or Retransmission of Process Variables........ 5-10

Table 5-3 Procedure for Configuring On/Off Control...........................................................................5-13

Table 5-4 Procedure for Configuring PFT Control................................................................................5-14

Table 5-5 Procedure for Configuring DAT Control............................................................................... 5-15

Table 5-6 Procedure for Configuring Alarms........................................................................................ 5-16

Table 5-7 Procedure for Setting the Clock.............................................................................................5-17

Table 5-8 Procedure for Configuring AutoClean................................................................................... 5-19

Table 5-9 Procedure for Specifying a Computed Value........................................................................5-21

Table 5-10 Menu Choices and System Defaults....................................................................................5-23

Table 6-1 Recommended Maximum Wire Size ....................................................................................... 6-3

Table 6-2 Procedure for Installing Analog I/O Wiring............................................................................ 6-5

Table 6-3 Relay Contact Maximum Ratings............................................................................................ 6-7

Table 6-4 Procedure for Wiring Relays................................................................................................... 6-8

Table 6-5 Procedure for Disconnecting RC Arc Suppression Circuits.................................................... 6-9

Table 8-1 Procedure for Entering Cal Factor...........................................................................................8-4

Table 8-2 Conductivity of Potassium Chloride Solutions at 25 °C ......................................................... 8-5

Table 8-3 Procedure for Performing Calibration Trim Using a Reference Solution............................... 8-6

Table 8-4 Procedure for Removing Calibration Trim Values.................................................................. 8-7

Table 8-5 Procedure for Entering TDS Conversion Factor...................................................................... 8-9

Table 9-1 System Status Message............................................................................................................ 9-2

Table 9-2 Process Alarm Messages.......................................................................................................... 9-3

Table 9-3 On-Line Diagnostics and System Error Messages................................................................... 9-4

Table 9-4 Procedure For Initiating Display and Keyboard Tests............................................................. 9-5

Table 9-5 Procedure for Testing Relays and Analog Outputs ................................................................. 9-7

Table 10-1 Procedure for Calibrating Outputs....................................................................................... 10-4

Table 10-2 Procedure for Specifying a Tagname or Other Display String............................................ 10-6

Table 10-3 Procedure for Viewing Product Information and Changing the Stored Model Number....10-7

Table 10-4 Procedure for Adjusting the Screen Contrast ...................................................................... 10-9

Table 10-5 Procedure for Entering a Password.................................................................................... 10-10

Table 10-6 Procedure for Resetting All Configuration to Factory Settings......................................... 10-11

Table 10-7 Procedure for Entering Values for Lead Resistance Compensation.................................. 10-14

6/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual xi

Page 12

Table 10-8 Procedure for Replacing the Fuse...................................................................................... 10-16

Table 11-1 Part Numbers ....................................................................................................................... 11-2

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99xii

Page 13

Figures

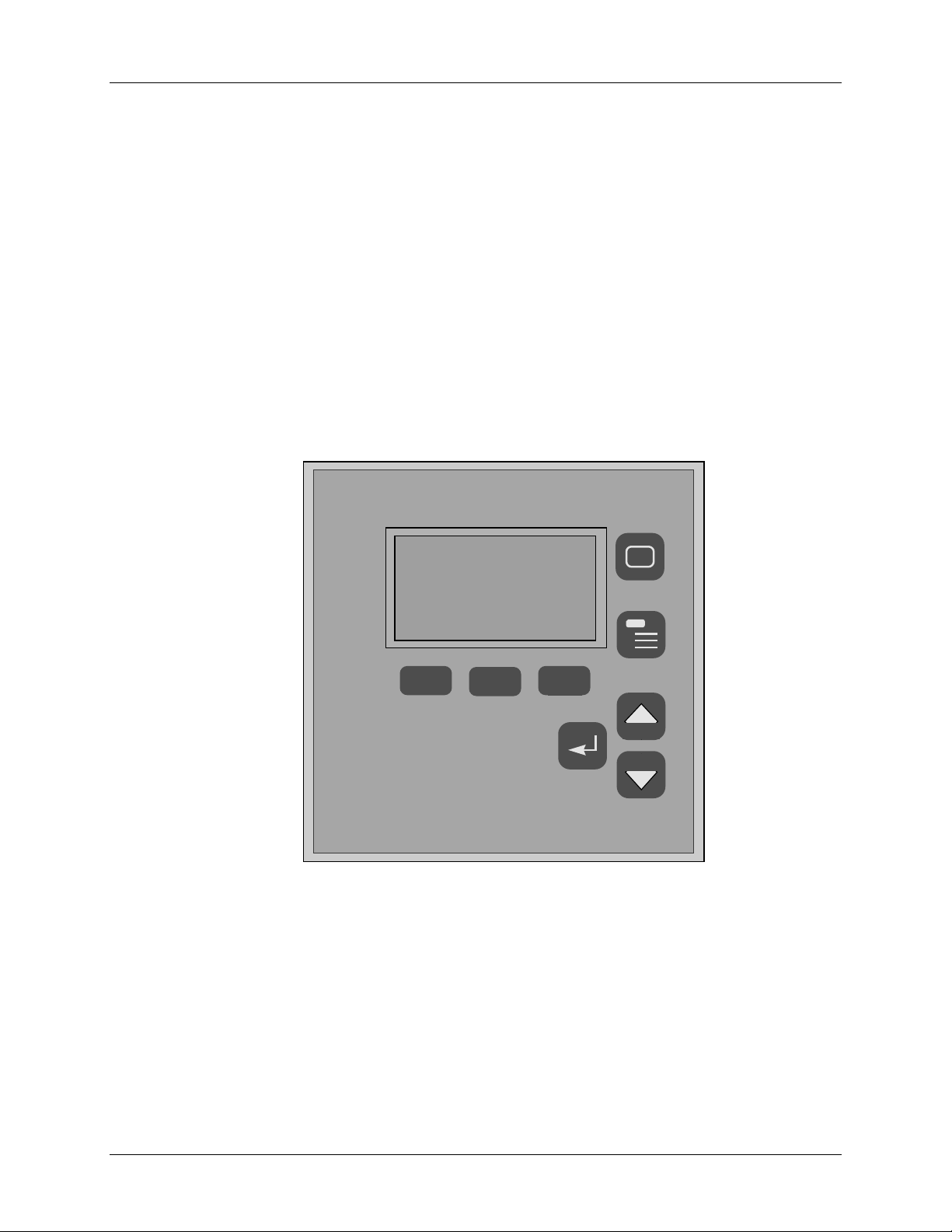

Figure 1-1 9782 Front Panel..................................................................................................................... 1-5

Figure 1-2 Representative Process Value Display for a Cell in Standard Range Analyzer..................... 1-8

Figure 1-3 Representative Combined Display ......................................................................................... 1-9

Figure 1-4 Representative Computed Value Display...............................................................................1-9

Figure 1-5 AutoClean Display ............................................................................................................... 1-10

Figure 3-1 Sample Nameplate.................................................................................................................. 3-3

Figure 3-2-1 Mounting and Dimensions - Non-Backlit Display Option.................................................. 3-4

Figure 3-2-2 Mounting and Dimensions - Non-Backlit Display Option.................................................. 3-4

Figure 3-3-1 Mounting and Dimensions - Backlit Display Option.......................................................... 3-4

Figure 3-3-2 Mounting and Dimensions - Backlit Display Option.......................................................... 3-4

Figure 4-1 AC Power Terminals.............................................................................................................. 4-5

Figure 6-1 Terminal Connections............................................................................................................. 6-6

Figure 6-2 Sample Multipoint Recorder Chart Illustrating Auto Output Range Change for Steam

Condensate Monitoring.................................................................................................................... 6-10

Figure 6-3 Interconnections between 9782 and Recorder with Range Identification by Point Change 6-11

Figure 7-1 Automatic Cell Wash Setup................................................................................................... 7-3

Figure 10-1 Example of a Conductivity Loop...................................................................................... 10-14

Figure 10-2 Location of Power Fuse.................................................................................................... 10-18

6/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual xiii

Page 14

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 6/99xiv

Page 15

1.1 Description

Multi-function instrument

The Honeywell 9782 Conductivity/Resistivity Analyzer/Controller (Figure 1-1) is a

microprocessor-based instrument for analysis of conductivity, resistivity, total dissolved solids,

or concentration in industrial processes. The resolution for all measurements is +/- 0.5% of

reading (except for temperature; see below). The units of measure are:

• conductivity: microSiemens per centimeter, microSiemens per meter, or milliSiemens per

centimeter

• resistivity: megohms or kilohms

• TDS: PPT, PPM or PPB

• concentration: percent by weight

Introduction

1. Introduction

• temperature: resolution 0.1% for 0 to 99.9 °C, and 1 C° for 100 C° and higher

User interface

An easy-to-read display provides instant access to process values. The displays of process values

show the instrument’s tagname (or other configurable text) at the top of the screen.

Every display includes an “alarm stripe”, a line dedicated to displaying process alarm messages,

status messages, and system diagnostic messages, whenever any are active. (One or more relays

can also be used for alarm annunciation; see 1.5.2.)

Dedicated-function membrane keys to the right of the display on the front panel are used to:

• cycle through the displays of real-time values

• access configuration, calibration, and maintenance menus

• change and enter setpoints and other parameters

In addition, three variable function keys are below the display. The function of each of these

“soft keys” depends on the purpose of the screen currently on display. Soft key labels are always

displayed at the bottom of the screen, immediately above the relevant function key.

Easy to configure

Menu-driven configuration is fast and easy. Only configuration parameters related to features

supported by the hardware and relevant to the specific application are displayed.

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-1

Page 16

Conductivity/Resistivity Analyzer/Controller

Input

Input to the 9782 can be from any Honeywell conductivity cell at distances up to 1500 feet.

Outputs

Optional isolated 0 to 1 V, 0 to 10 V and 4 to 20 mA outputs are available. Use these analog

outputs for retransmission of process variables, or for Current Adjusting Type control using an

output signal that is directly proportional to the input (see 1.5.3).

Relays

Two 2A SPDT alarm/control relays are standard, with an additional two 3A relays (either general

purpose or hermetically sealed) available as an option (see Sub-Section 2.17). These relays can

be used to:

• take advantage of special features such as automatic cleaning of cells

• control process variables (see 1.5.3)

• annunciate alarms

More details about use of relays are provided in 1.5.2.

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 7/991-2

Page 17

1.2 Features

Automatic cell washing

The standard AutoClean feature can periodically rinse cells automatically. The schedule and

duration of the operation are configurable. An internal relay actuates external solenoid valves to

control the flow of rinse water to the cells.

Computed values

The Analyzer/Controller can calculate and display your choice of the following values:

• ratio of the two cell inputs

• difference between two cell inputs

• percent passage

• percent rejection

• parts per million carbon dioxide (9782C-S0 only)

The equations used are in the specifications in Section 2.

Introduction

Automatic range scaling

The Analyzer/Controller supports automatic range scaling of the output. If this feature is

enabled, then when the measured value falls below 10% of the output scaling limit, the output is

scaled by a factor of 10. An internal relay can be dedicated to this function. The relay closes

contacts

NC-COM when the output is scaled to the low range, and closes contacts NO-COM when the

range shift occurs. The relay can be used to control an indicator or to switch the output to a

second channel of a multipoint recorder when the range change occurs.

This output range scaling has no effect on the display. Display scaling is specified independent

of output scaling.

Password protection

A password (up to four digits) can be configured. If the security feature is enabled, the password

will be required to access configuration, calibration, and maintenance software functions.

Extensive diagnostics

The 9782 Analyzer/Controller performs extensive self-diagnostics as a background task during

normal operation. If a problem is detected, a message is displayed on the alarm stripe to alert the

operator. In addition, the operator can initiate keypad and display tests using Maintenance Menu

functions.

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-3

Page 18

Conductivity/Resistivity Analyzer/Controller

Watertight corrosion-resistant case

The 9782 is enclosed in a watertight and corrosion resistant industrial case, designed for panel,

pipe or wall mounting. It has an EMI/RFI shielded plastic case.

Solution Temperature Compensation

There are two types of 9782C Analyzer/Controller models: standard range and wide range. Both

types provide temperature compensation as described below. The standard range

Analyzer/Controller is ideal for high-purity water applications. The wide range

Analyzer/Controller is suitable for chemical solutions.

To take advantage of the temperature compensation capabilities, the appropriate solution

temperature compensation type must be entered for each cell as described in Section 5.

Standard Range - A standard range 9782 Analyzer/Controller provides true high purity

temperature compensation for deionized water as well as for routine applications. The

Analyzer/Controller also employs unique compensation algorithms for the highest accuracy in

power industry water treatment using ammonia or morpholine, as well as for cation conductivity

samples. Semiconductor resistivity measurements on acid etch rinse operations, especially with

hot deionized water, also achieve the highest available accuracy. For pharmaceutical

applications, raw conductivity data is available at the touch of a button.

For high-purity water special temperature compensation is required in the range of 0.055 to 5

microsiemens/cm per 0.2 to 18 Megohms-cm. Traditional compensation techniques used in most

analog instruments require temperature compensator selection for a reference conductivity

represented by a single curve. This method lacks the capability to accurately reflect the changing

temperature coefficient of water for variations in temperature and conductivity on either side of

that reference value. Advanced high-purity water temperature compensation determines the

conductivity of an impurity at any concentration of water at any temperature, and the interaction

between the two. It compensates these values to obtain the conductivity referenced to 25 °C.

Because the temperature coefficients involved are both high and variable, a precise temperature

measurement is required to achieve accurate compensation. To accomplish this the 9782

Analyzer/Controller first makes precise temperature measurements over a wide range, even with

long sensor leads. Second, an accurate conductivity measurement is assured by use of the cell

constant trim factor. Third, internal high resolution algorithms are used to make exact highpurity water calculations. This high level of performance in an inexpensive, yet highly reliable

instrument is the result of over seventy years of experience in making industrial conductivity

measurements.

For power plant cation/ammonia conductivity measurements temperature compensation provides

the highest accuracy for measurements of cation exchanger effluent and acidic cation

conductivity samples with Larson Lane-type analyzers.

This compensation matches both strong inorganic and weak organic acid temperature

characteristics. Measurements of steam and condensate samples containing ammonia are also

greatly improved using this algorithm.

For power plant morphonline conductivity measurements temperature compensation was

developed specifically for this market’s water chemistry. Morpholine has unique temperature

characteristics that are handled automatically by the 9782 Analyzer/Controller.

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 7/991-4

Page 19

Introduction

For semiconductor etch rinse resistivity measurements temperature compensation provides the

most accurate measurements of used rinsewater containing traces of acidic etchants. Rinse

quality control and water reclamation monitoring can be made with greater precision when this

compensation is used.

Wide Range - A wide range Analyzer/Controller uses precise algorithms to compute

temperature-compensated conductivity, total dissolved solids (TDS), or concentration for display

and output, based on conductivity and temperature inputs. The wide range instruments are ideal

for controlling deionizer and softener regenerant dilutions. Full spectrum temperature

compensation, specifically for sodium hydroxide, sulfuric acid, hydrochloric acid and sodium

chloride, automatically provides exact correction of temperature influences as they vary with

both concentration and temperature. Readout in conductivity or ppm TDS units may also be

selected.

+RQH\ZHOO

+RQH\ZHOO

Figure 1-1 9782 Front Panel

F1

F2

F2

F3

F3

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-5

Page 20

Conductivity/Resistivity Analyzer/Controller

1.3 Operating the Analyzer/Controller

1.3.1 Keypad Use

Front panel keys used for all operator tasks

As shown in Figure 1-1, five keys with dedicated functions are on the front panel. In addition,

three “soft keys” vary their function according to the needs of the screen on display. Use of the

keys is described in Table 1-1.

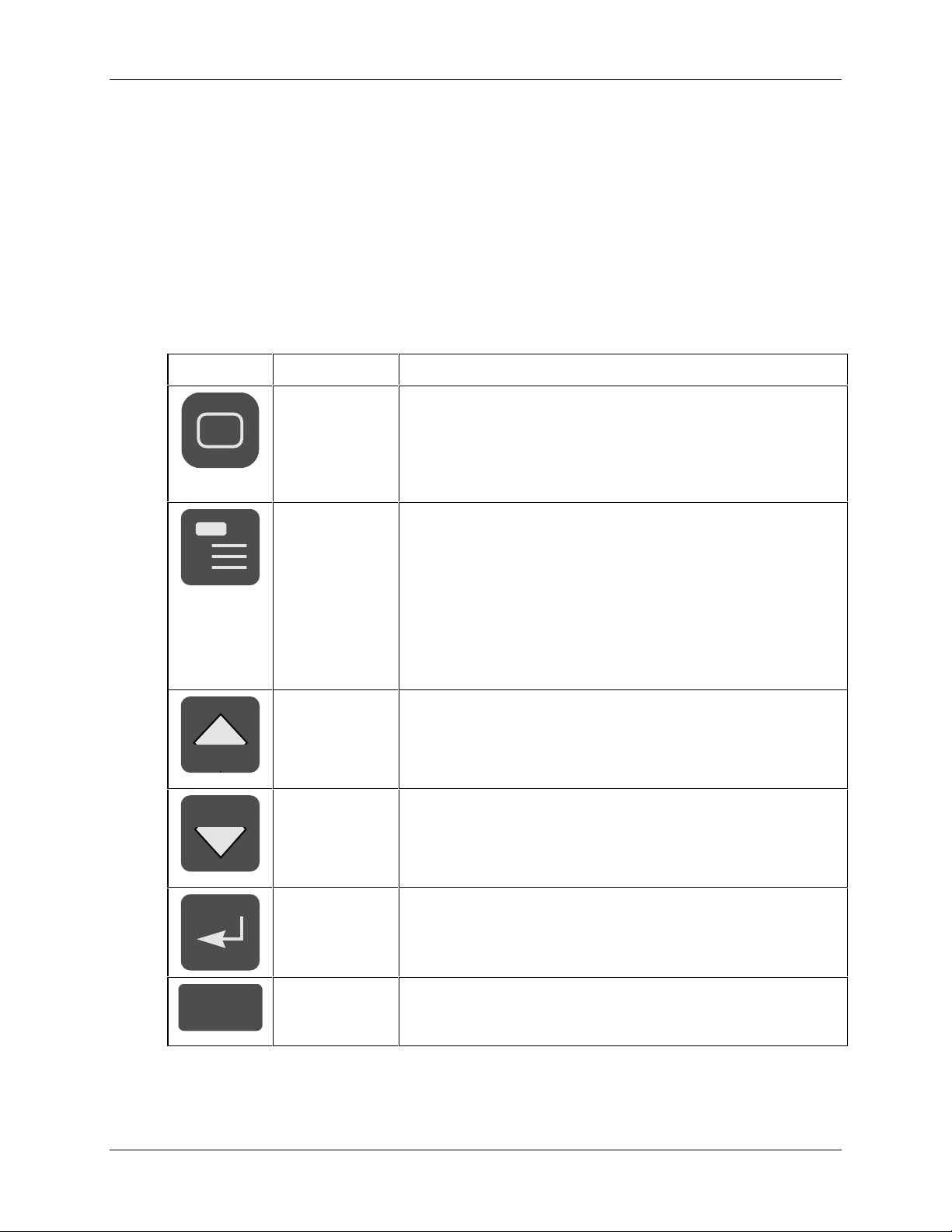

Table 1-1 Key Functions

Key Name Use

DISPLAY When process values are on display: Use DISPLAY to cycle

through available real-time displays.

When the main menu (Configuration, Calibration,

Maintenance, I/O Setup) is on display: Use DISPLAY to

return to displaying process values.

MENU When process values are on display: Use MENU to access

the menus. If the security feature is enabled, the display will

prompt for entry of the password before access to the menus

is permitted. (Enter the password using the procedure for

editing a parameter numeric value as described on the next

page.)

F1

When any menu or configuration screen is on display: Use

MENU to go up a level in the display hierarchy. Frequently this

means returning to the main menu.

UP When a menu or configuration screen is on display: Use

UP to highlight a different item.

When changing a numerical value: Use UP key to increment

the value of the digit at the cursor.

DOWN When a menu or configuration screen is on display: Use

DOWN to highlight a different item.

When changing a numerical value: Use DOWN to

decrement the value of the digit at the cursor.

ENTER When a menu item is highlighted: Use ENTER to select it.

When editing a parameter: Use ENTER to save the new

value.

F1, F2, F3

[function

keys]

When a “soft key” label is displayed below the alarm

stripe: Use the function key directly below the label to perform

the action.

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 7/991-6

Page 21

Selecting a parameter for edit

To select a parameter for edit:

• display the screen containing the parameter

• use the UP or DOWN keys to highlight the parameter name

• press the ENTER key to highlight the displayed current value

Editing a parameter assignment from a list of available choices

To edit a parameter having a text string as an assigned value:

• select the parameter and highlight its current value as described above

• use the UP or DOWN keys to display the other valid choices

• when your choice is displayed, press ENTER

Editing a parameter numeric value

To edit a parameter having a numeric value:

• select the parameter and highlight its current value as described above; the “DPP”, ←

and → soft keys will be displayed (During calibration the ← and → soft keys will be

displayed once the UP or DOWN key has been pressed.)

Introduction

• use the “DPP” soft key to position the decimal point

• use the ← or → soft keys to move the cursor to the digit to be changed

• use the UP and DOWN keys to increment or decrement the value

• when all digits necessary have been changed, press ENTER

Controlling an AutoClean operation manually

To initiate an AutoClean operation manually, press the DISPLAY key until the AutoClean

screen is displayed. Next press the “START” soft key.

This display can also be used to see how much time is remaining until the next scheduled

AutoClean operation. When AutoClean is active, the alarm stripe will display “AUTO CLEAN”,

and the AutoClean display will show 00:00:00.

If necessary, pause the operation using the “PAUSE” soft key. To resume the operation, press

“PAUSE” again. To cancel the operation, use the “STOP” soft key. If pause is left on, the

sequence will resume automatically after twenty minutes.

At the start of the AutoClean operation alarms and outputs will be held at current levels,

regardless of whether the AutoClean was scheduled or started manually. The alarms and outputs

will be held throughout the AutoClean operation.

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-7

Page 22

Conductivity/Resistivity Analyzer/Controller

1.3.2 Online Displays

Introduction

The online displays available when the operator presses the DISPLAY key depend on the

number of cells connected to the Analyzer/Controller, and on the special features used. The

instrument’s tagname (or other configurable text) is at the top of the screen for all displays

except the digital clock and the AutoClean Sequence display. Every display includes an “alarm

stripe”, a line dedicated to displaying process alarm messages, status messages, and system

diagnostic messages, whenever any are active.

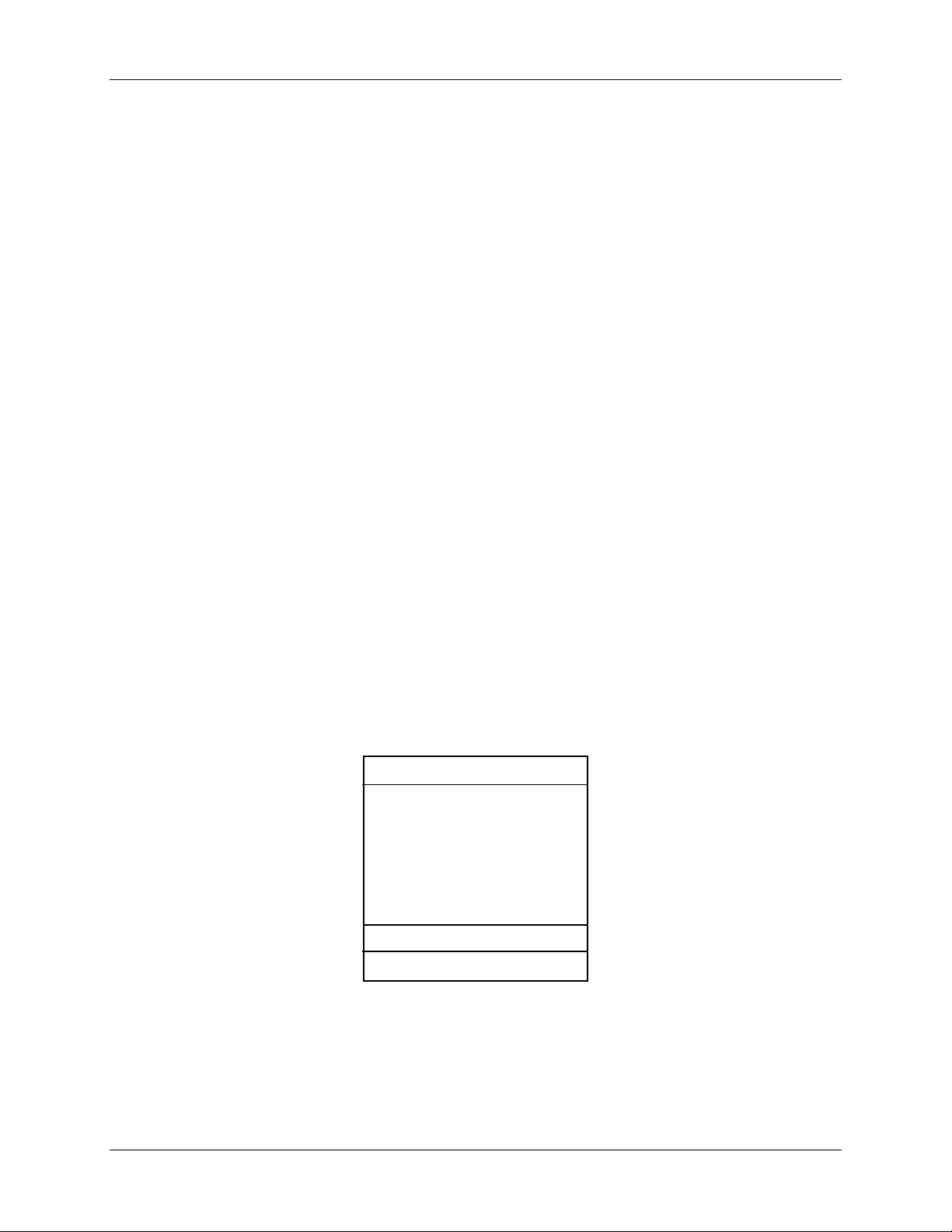

Individual cell display

For each cell connected to the Analyzer/Controller an online display similar to Figure 1-2 is

provided. The information on this display includes:

• the value measured by the cell, with the appropriate unit of measure filled in

• an indication of whether the value is temperature compensated (TC) or not

compensated (NC); the display can be toggled between displaying compensated and

raw data using the F1 function key

• the temperature in °C

• if the value displayed is a percent concentration (9782C-W0 only), the chemical will

be identified above the alarm stripe

In addition of the function key used to toggle the temperature compensation display, function

keys are available to access calibration displays (without going through the menus), and to

acknowledge alarm stripe messages.

CONDENSATE T105

TC

8.59

25. 2°C

ALARM STRIPE

NC CAL ACK

Figure 1-2 Representative Process Value Display for a Cell in Standard Range Analyzer

C1

µS

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 7/991-8

Page 23

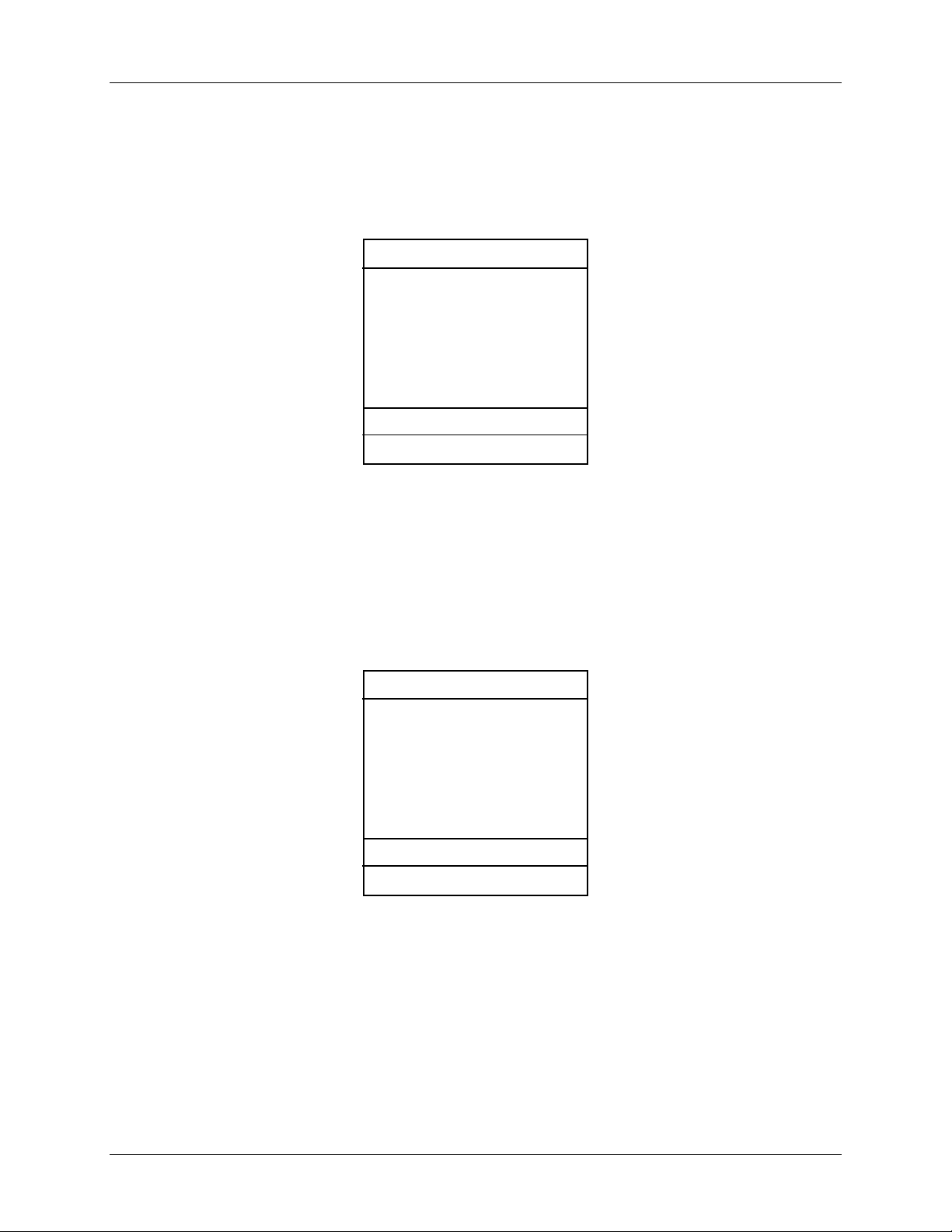

Combined display

If two cells are connected to the Analyzer/Controller, then a display is available that includes the

measured variable for both cells (see Figure 1-3). Another combined display also includes the

temperature measured by each cell.

Introduction

MIXED BEDS 1 AND 2

TC

C1 0.58 µS

C2 0.25 µS

ALARM STRIPE

NC CAL ACK

Figure 1-3 Representative Combined Display

Computed value

If the Analyzer/Controller is configured to calculate a computed value such as the ratio between

the cells’ readings, a screen will be available to display the value, along with a label (see Figure

1-4).

CATION TRAIN A

0.67

RATI O

ALARM STRIPE

NC CAL ACK

Figure 1-4 Representative Computed Value Display

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-9

Page 24

Conductivity/Resistivity Analyzer/Controller

Clock and AutoClean

If the 24-hour clock is turned on, a time display will be available. If AutoClean is configured,

then the AutoClean screen will be included in the display cycle (see Figure 1-5). When

AutoClean is active, the screen will display the time remaining. When this screen is on display,

the function keys can be used to control the AutoClean operation as described in 1.3.1.

START PAUSE STOP

AUTO CLEAN

TIME RE MAINING

01: 58:29

ALARM STRIPE

Figure 1-5 AutoClean Display

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 7/991-10

Page 25

1.4 Menu Hierarchy

Menus for every task

For your convenience, menus are provided for configuration, calibration, maintenance, and I/O

setup tasks. The menu hierarchy is shown in Table 1-2. Not every menu item applies to every

system.

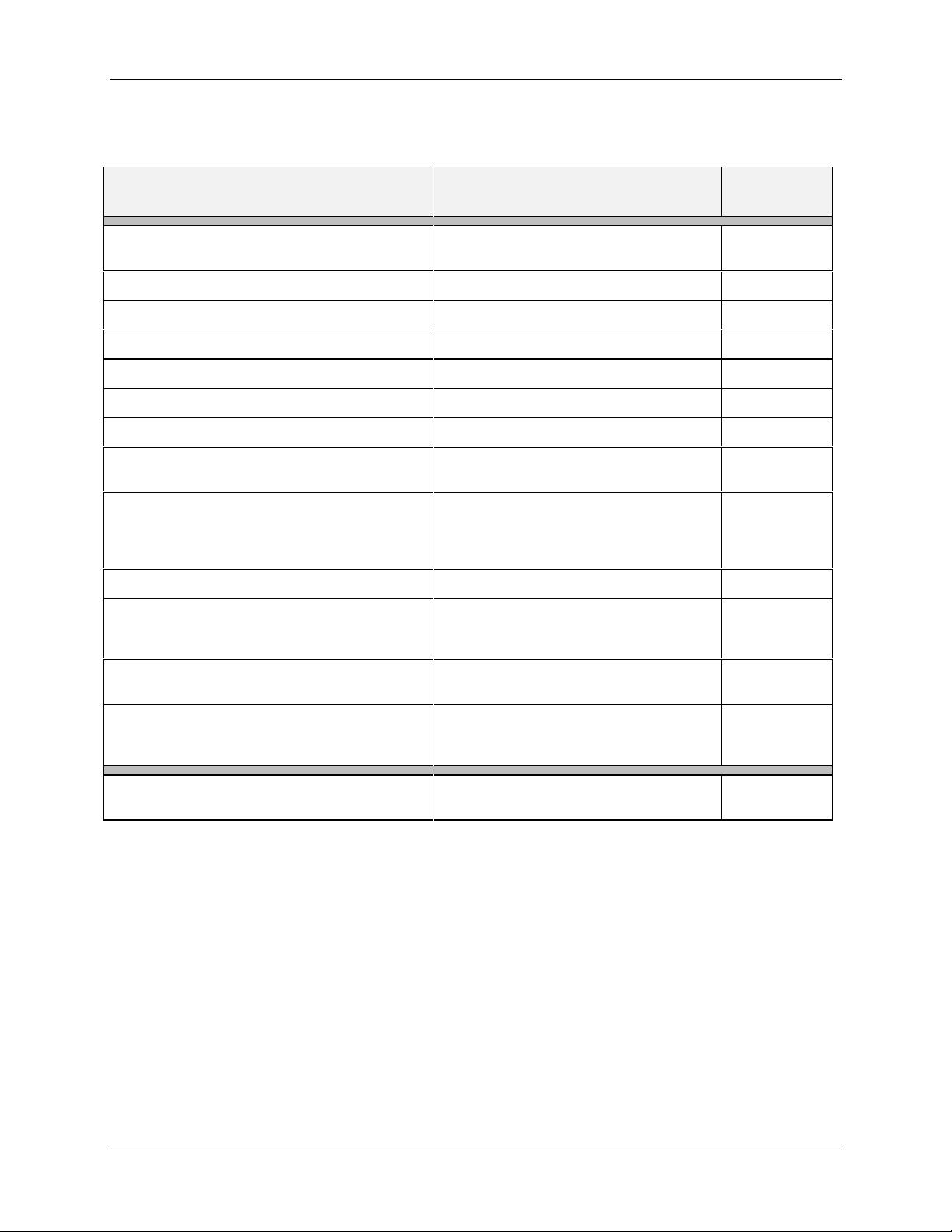

Table 1-2 9782 Conductivity/Resistivity Analyzer/Controller Menu Hierarchy

Menu Item Purpose Where

Introduction

Described

CONFIGURATION

CAT/RETRANSMISSION configure parameters for using analog

ALARMS specify value to be alarmed, alarm

DISCRETE CONTROL specify setpoints, range limits, etc. to use

ADVANCED FEATURES set the clock, set up automatic cell

CALIBRATION

CELL CAL FACTOR enter cell-specific cal factor 8.3

CALIBRATION TRIM calibrate system using a reference solution

TDS CONVERSION FACTOR C1

TDS CONVERSION FACTOR C2

set up Analyzer/Controller to implement

your alarm and control strategy

outputs for control and retransmission of

process values

setpoints, deadbands, and delay

relays for control

cleaning, and specify the computed value

to be displayed

calibration functions Section 8

with each cell; remove trim

enter a process-specific total dissolved

solids conversion factor for each cell

Section 5

5.4

5.6

5.5

5.7, 5.8, 5.9

8.4, 8.5

8.6

Table 1-2 continued on next page

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-11

Page 26

Conductivity/Resistivity Analyzer/Controller

Table 1-2 9782 Conductivity/Resistivity Analyzer/Controller Menu Hierarchy

Menu Item Purpose Where

Described

MAINTENANCE

OFF-LINE FUNCTIONS

INSTRUMENT SETUP

do occasional system tasks Sections 9 and

10

[see functions listed below] [see below]

DISPLAY TEST test display 9.5.1

KEYBOARD TEST test keyboard 9.5.1

OUTPUT TESTS test relays and analog outputs 9.5.2

OUTPUT CALIBRATION calibrate outputs electrically 10.2

[see functions listed below] [see below]

INSTRUMENT TAGGING configure tagname or other text to be

displayed at the top of the screen

PRODUCT INFORMATION view software version and stored model

number; if a special technical support

password is known, alter model number in

memory (in case of hardware upgrades)

SCREEN CONTRAST adjust display contrast 10.5

SECURITY assign password to limit access to

configuration, calibration, and maintenance

functions

RESET UNIT reset all configuration and calibration

values back to factory settings

10.3

10.4

10.6

10.7

I/O SETUP

LEAD RESISTANCE COMP

[wide range models only]

9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual 7/991-12

specify wire gauge and length when long

leads are used; instrument will compensate

for these long leads

choose features, make relay and analog

output assignments

10.8

5.3

Page 27

1.5 Planning

1.5.1 Overview

Configuration system minimizes decisions

The 9782C Analyzer/Controller was designed for easy configuration using menu displays and the

keys on the front panel. Numeric values such as setpoints and range limits are easy to enter using

the UP and DOWN keys and function keys (see 1.3). Other configuration parameter

assignments are selected by scrolling through a list of available choices using the UP and

DOWN keys.

During configuration only those parameters and choices relevant to features supported by your

Analyzer/Controller’s hardware will be available for configuration. For example, if the model

purchased does not contain hardware for the optional analog outputs, then none of the screens

relating to output configuration will be applicable.

Although configuration is a simple process, to make best use of the 9782C Analyzer/Controller

and its features, a little advance planning is recommended.

Introduction

1.5.2 Using Relays

Relays assigned during I/O setup

Every 9782 model includes two internal relays. Two more relays are available as an option.

During I/O setup (see 5.3) the 9782’s software will assign relays to the features you select. The

design of the Analyzer/Controller allows multiple alarms to be assigned to one relay, allowing

greater flexibility with fewer relays. All other 9782 features using relays (AutoClean, range

status indication, and discrete control) require one relay per instance of the feature. You will not

be permitted to select features requiring more that the available number of relays.

Once a relay has been dedicated to a function, the relay will not be available for assignment to

another function. In order to get the most functionality from the available relays, plan your

strategy before implementation. The order in which features are presented (during I/O setup) for

relay assignment is:

1. Cell 1 “Advanced Features” AutoClean and range status indication

2. discrete control (both cells)

3. alarm annunciation (both cells), and Cell 2 AutoClean and range status

7/99 9782 Series Conductivity/Resistivity Analyzer/Controller - Operator’s Manual

1-13

Page 28

Conductivity/Resistivity Analyzer/Controller

Interactions affecting permitted relay assignments

Table 1-3 is provided so that you can optimize your use of relays to implement your control

strategy. Each row in the table represents an available combination of relay assignments for a

single feature or multiple alarms.

ATTENTION