Page 1

WebVision™

CAUTION

USER GUIDE

PRODUCT DESCRIPTION

WebVision™ is a web-based building manager that allows

contractors and facility managers to view and command

HVAC controllers installed at their sites. It communicates over

the LonWorks

control of various devices and controllers through a web

browser. The WebVision Bundle (WWS-VL1A1000) includes

the WebVision controller pre-installed with a LON

communications card, and power supply.

WebVision is capable of:

• Discovering unitary controllers connected to WebVision

• Configuring controllers using configuration wizards

• Monitoring, raising, and e-mailing alarms on controller

points and system events

• Configuring and collecting trends on points

• Driving scheduled occupancy states

• Managing energy through Demand Limit Control (DLC)

• Providing single point of entry into the system to perform all

the above mentioned tasks.

• Managing access to information through user privileges

• Providing IT-friendly network interface for easy access and

management

WebVision acts as an offline configuration tool that helps the

contractor to configure site project that consists of multiple

unitary controllers. The contractor can commission all the

controllers by connecting through a LAN, WAN, or Dial-up.

WebVision also acts like a network time master to synchronize

time and date in devices connected to it with its own time and

date or with the Internet time servers. Its Device Discovery

feature enables you to discover online devices. You can

manage users and control their access to different resources

in the system. The System Administrator can configure

network settings, site information settings, system and control,

network data and time settings, and new module installation.

®

network to perform building management

Approvals

UL 916, C-UL listed to Canadian Standards Association (CSA)

C22.2 No. 205-M1983 “Signal Equipment”, CE, FCC part 15

Class A, C-tick (Australia)

Make sure that there is not more than one

WebVision accessing the same Lon

simultaneously. If more than one WebVision

accesses the same Lon network simultaneously,

there may be problems in downloading and

uploading parameters.

NOTE: WebVision is compatible with Microsoft

Explorer

resolution is 1280x1024 pixels.

IMPORTANT

Make sure that there is only one WebVision

accessing the L

time. If more than one WebVision accesses the

same LONWORKS network simultaneously, ensure

that its logical address is unique in the network to

avoid address conflicts. For a L

logical address refers to Subnet/NodeID.

®

(IE) 6.0 SP2 or higher. Suggested screen

ONWORKS network at a given point in

®

network

®

Internet

ONWORKS network,

Contents

Product Description ....................................................... 1

Features .......................................................................... 2

Operation and Use ......................................................... 2

Warranty and Returns .................................................... 33

Appendix A – Supported Devices ................................. 34

Appendix B – Device Point Tables ............................... 106

Topic Index ..................................................................... 175

95-7769-01

Page 2

WEBVISION™

FEATURES

• Support up to 120 XL10s, XL15Cs, VFDs, and 3rd Party

LON devices

• Perform Auto Discovery and Wizard based

configuration of controllers

• Support Default Alarms on each device

• Support Default Trends on each device

• Support default device graphic for each device

• Configure a maximum of 30 users and define their

roles in accessing and configuring devices and

WebVision

• Configure a maximum of 50 schedules

• Configure and schedule device occupancy

states

• Assign up to 120 devices per schedule

• Configure a maximum of 100 trends

• Store up to 1,000 samples per trend

• Configure up to 100 user defined alarms

• Store and view up to 5,000 alarm records

• E-mail alarm messages can be sent to a

maximum of 50 e-mail addresses

• Configure up to 50 loads for Demand Limit Control

• Configure default and up to 50 user-defined graphics

with support to command-able points

WebVision is built on Niagara-AX™ technology and extends

the capabilities of WebStat™.

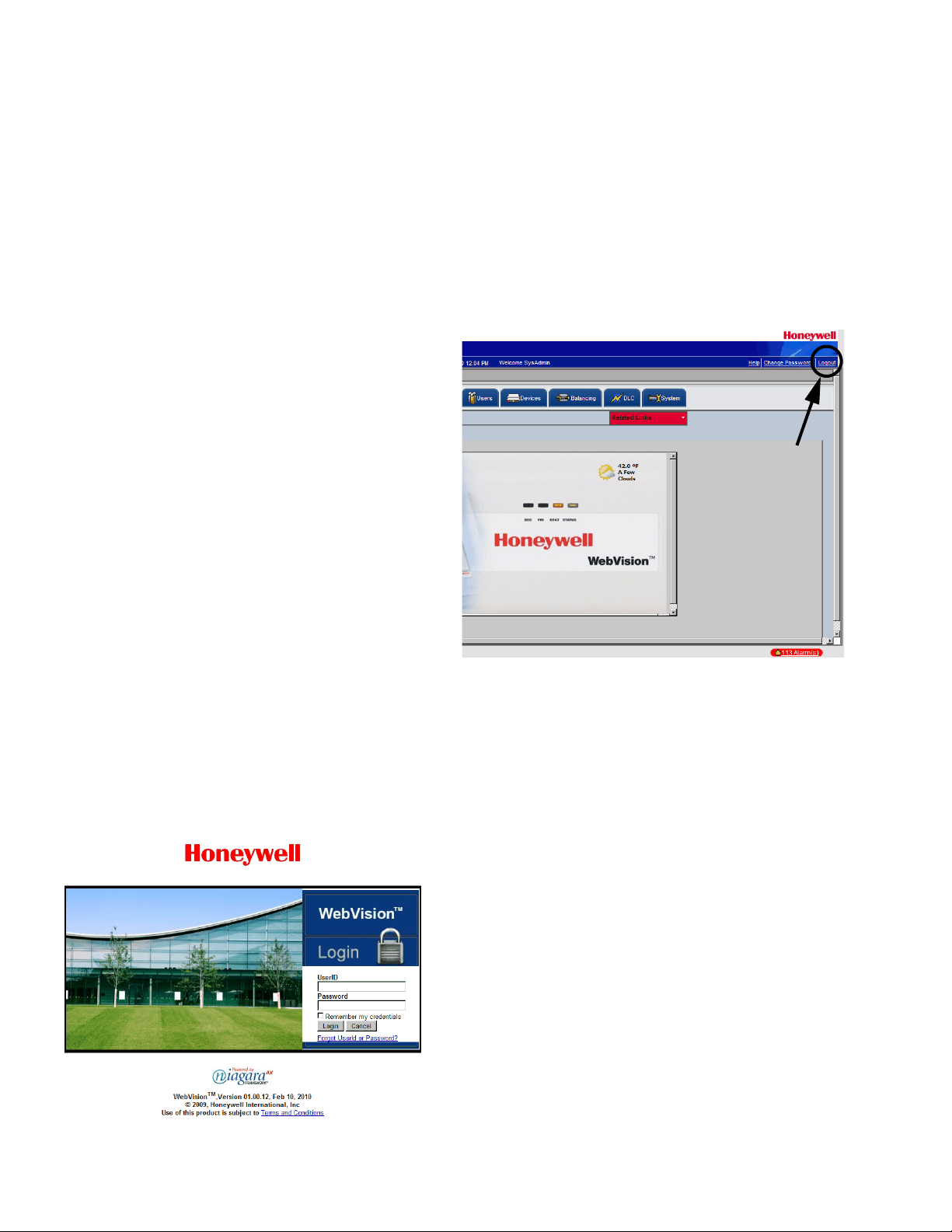

2. Type your WebVision login name in the User Name

field.

3. Type your Password.

4. Click Login or press Enter. The Properties page

appears.

To log off from WebVision:

— Click the Logout link located on the right top of your

screen to log off from WebVision. You are redirected to

the WebVision Login page.

OPERATION AND USE

This section describes how to use the WebVision controller.

Sign-in

To log on to WebVision:

1. Type the WebVision web address (URL) in the Address

field of Internet Explorer

appears.

®

. The WebVision Login page

Fig. 2. Logout Link.

Password Reminder

To be reminded of your UserID or Password, if you have

forgotten either of them, perform the following:

1. Type the WebVision web address (URL) in the Address

field of Internet Explorer. The WebVision Login page

appears.

2. Click Forgot UserID or Password? link on the Login

page.

You are directed to the Password Reminder screen.

3. Select your secret question (the one you selected while

creating your user account).

4. Enter the answer to the Password Reminder Question

(you are expected to enter the same answer that you

gave while creating your user account).

5. Enter your E-Mail ID (same as in your user account).

WebVision looks for account that matches the secret

question, the answer to the question, and the e-mail Id.

After validating, it sends the user Id/password to that

e-mail Id.

6. Click Submit.

Fig. 1. Login page.

95-7769—01 2

Page 3

Fig. 3. Password Reminder screen.

TIP: The information you provide is validated against the

information present in the WebVision database. If the

information is correct, WebVision will send the user ID

and password to your E-Mail account.

TIP: If you do not remember the password recovery

information and the answer provided by you is incorrect,

you can request the WebVision Administrator to reset

your password. In any other case, please contact the

Honeywell Support for assistance.

Working with Tables

Click the column header of a column that you want to sort in

ascending/descending order. Columns that you can sort are

distinguished by an underlined column header. Tables are, by

default, displayed in ascending order. However, for alarms,

default display is in the reverse chronological order (the most

current alarm is displayed on top).

• Click to move to the next page.

• Click to move to the previous page.

• Click to move to the last page.

• Click to move to the first page.

• Type the number of rows you want to view on each page in

the text box next to .

• Type the page number that you want to navigate to in the

Page field. This enables you to quickly move to the page of

your interest without having to wade through all intervening

pages.

Graphics

A graphic is a pictorial illustration of a building's layout

coupled with the placement of various devices within a

building. With the help of a graphic you can view the various

devices installed in your building.

WEBVISION™

Fig. 4. Graphics Tab.

There are 3 locations in the WebVision where you can view

and setup graphics. These are:

• Network Tree > WebVision Node (Max 1 Graphic)

• Network Tree > Device Node. One graphic for each device.

This is the default device graphic. You can add a maximum

of three links on the graphic pointing to an external URL or

to another graphic.

• Location Tree. You can create user defined location

hierarchy (as tree). For each location (tree node), there can

be one user defined graphic. You can customize the

graphic and set a background image, monitor and

command points, add links to external web sites, and add

links to a different graphic.

You can insert the following in a graphic:

• Background images

•Points

•Devices

•Text

• External Links

• Links to other graphics

NOTE: Apart from the Contractor (who has all the privileges

in WebVision) all the users who add/replicate new

graphics have access to all the graphics created by

them.

To view a graphic:

1. Click the Graphics tab. The View Graphics page

appears.

2. Select the graphic you want to view from the list. The

selected graphic appears.

To setup a graphic:

1. Click the Graphics tab. The View Graphic page

appears.

2. Click Setup Graphics. The Setup Graphics page

appears.

Use the following options to configure graphics:

TIP: Move the pointer over any button. A tool tip appears

describing the action performed by the button.

3 95-7769—01

Page 4

WEBVISION™

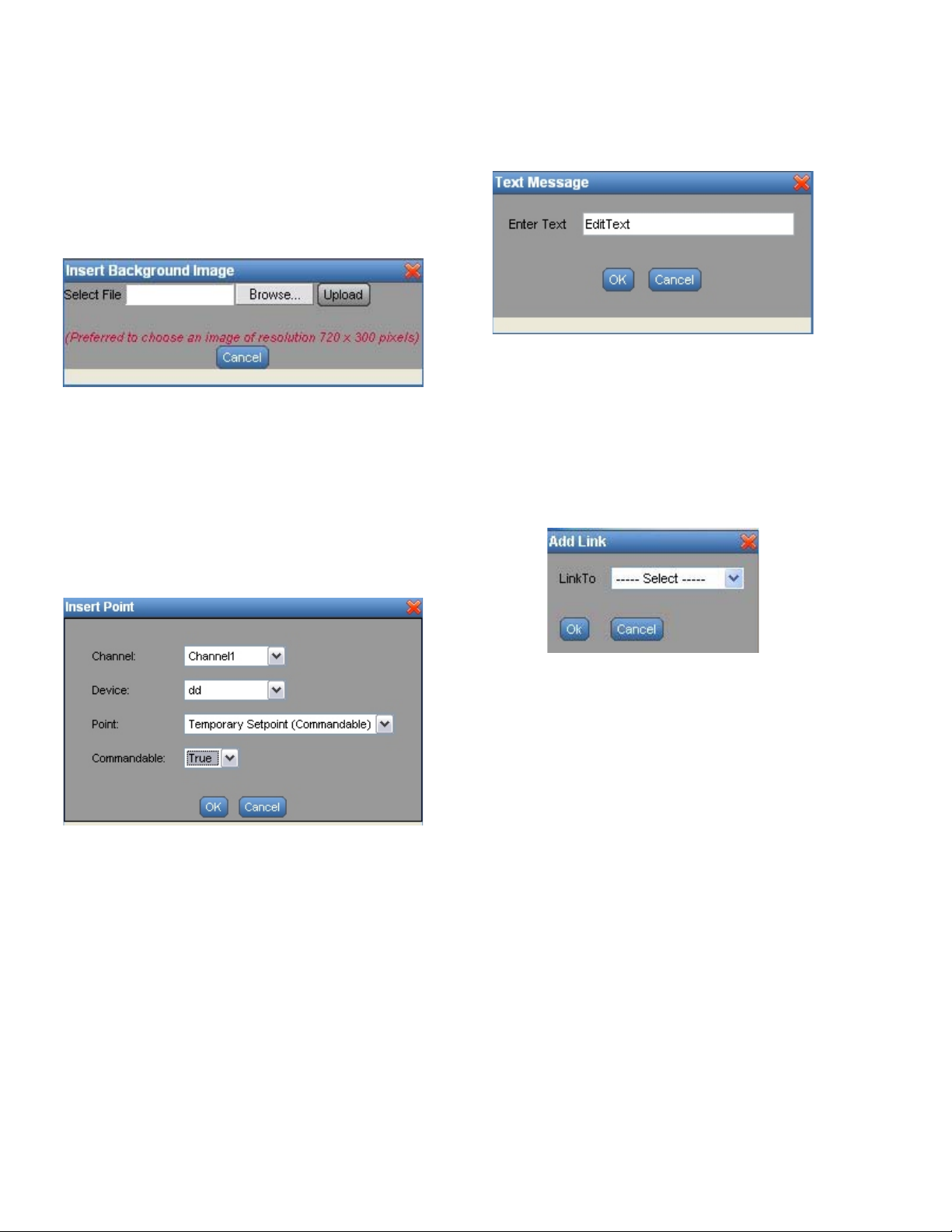

To insert a background image:

NOTE: The supported background image formats include:

jpg, jpeg, and gif.

The size of the image file must not exceed 1MB.

1. Click the Insert Background Image button. The Insert

Background Image dialog box appears.

Fig. 5. Insert Background Image dialog box.

2. Browse and select an image that you want to use as

background image.

3. Click Upload to insert the image.

NOTE: To abort the action, click Cancel.

To insert a point:

1. Click the Insert Point button. The Insert Point dialog

box appears.

To insert text:

1. Click the Insert Text button. A Text Message box

appears.

Fig. 7. Text Message Box.

2. Type the required text in the Edit Text field.

3. Click Save to reflect the changes in the image.

NOTE: To abort the action, click Cancel.

To insert an external link:

1. Click the Insert External Link button. The Add Link

dialog box appears.

Fig. 6. Insert Point dialog box.

2. Select the Channel, Device, and Point that you want to

add to the graphic from the corresponding drop-down

lists.

3. Click OK. The Point properties are displayed in the

background image.

NOTE: To abort the action, click Cancel.

Fig. 8. Add Link dialog box.

2. Select a link from the Link To drop-down list. You can

select from Device Graphics, Locations Graphics, or an

External URL.

3. If you select the Device Graphics option, the Insert

Device dialog box appears. Select a Channel and

Device and click OK.

4. If you select the Locations Graphics option, the Add

Link dialog box appears. Check the locations that you

want to add as link and click OK.

5. If you select the External URL option, the Insert

External Link dialog box appears. Type the Display

name for the url and type the url in the URL field.

6. Click OK to view the URL in the image.

NOTE: To abort the action, click Cancel.

NOTE: A maximum of fifty links can be inserted in a graphic

in WebVision.

95-7769—01 4

Page 5

WEBVISION™

To delete selected objects:

1. Select the object that you want to delete from the

graphic.

2. Click Delete Selected objects. The selected object is

deleted.

To copy graphics:

1. Click the button. The Copy Graphics From dialog

box appears.

2. Click Delete Selected objects. The selected object is

deleted.

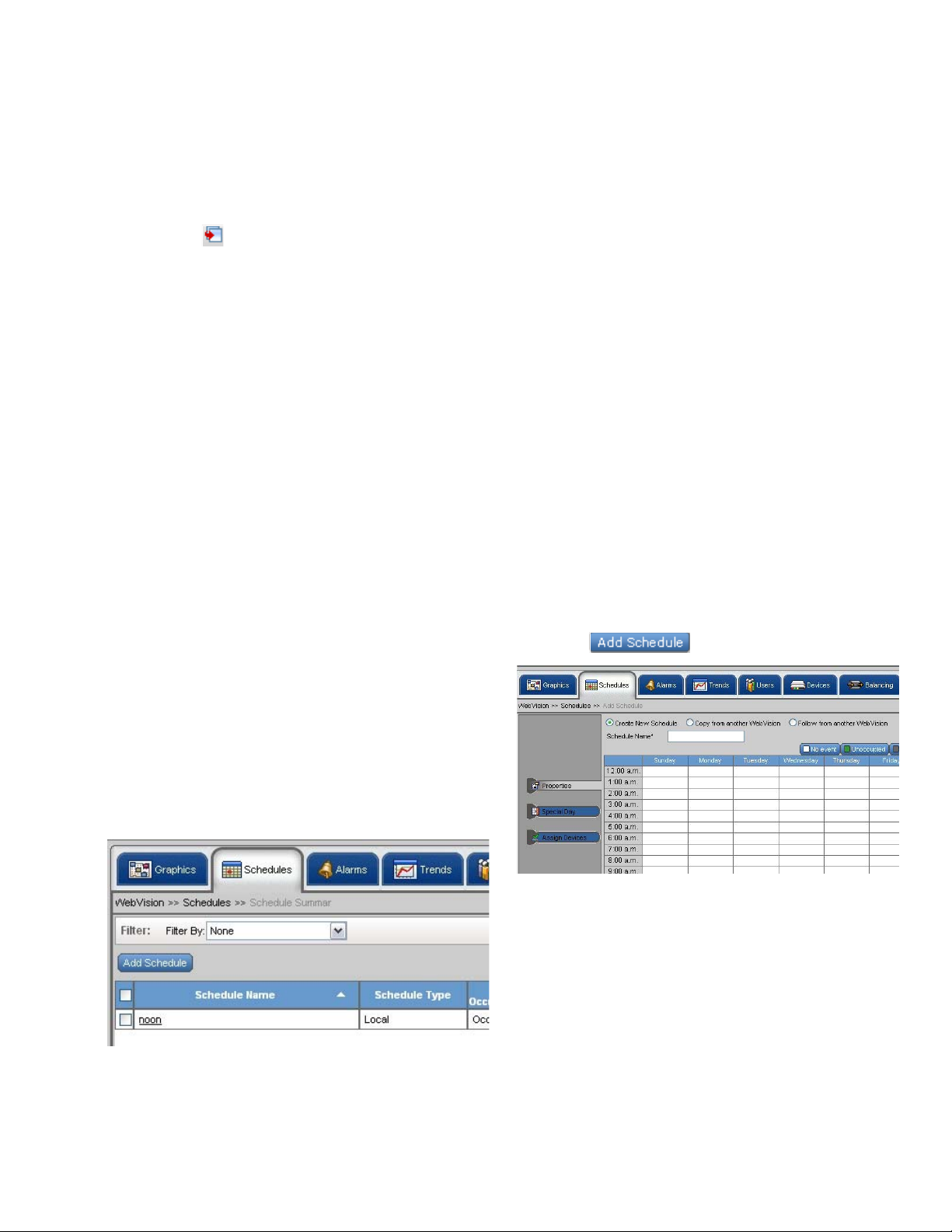

Schedules

Schedules define the days and times when an occupancy

event must occur. Schedules are weekly calendars for

occupancy mode changes. Schedules also contain special

event information such as holidays or unplanned events.

NOTE: You can have a maximum of 50 schedules in

WebVision.

You can create, modify or delete a schedule only if you have

these privileges assigned to you.

There are three occupancy modes:

• Occupied – A period of time when the controlled

environment is considered to be occupied. It requires a

closer control for comfort, health, and safety.

• Unoccupied – A period of time when the controlled

environment is considered to be unoccupied. It is used to

reduce energy consumption.

• Standby – A period during the normal occupied period

when the space may not be occupied. It is used for energy

saving programs.

• No Event – WebVision displays the default state as

Occupied when no event is configured.

Use one of the following filter options to search for the

required schedule:

• Schedule Name

• Current Occupancy State

TIP: To quickly search the schedules, type the first letter of

schedule name or occupancy state, (as the case may

be) in the Keyword text box and type *. This lists all the

names starting with the first letter that you have written

in the Keyword text box.

• Schedule Name – Indicates the name of the schedule.

• Schedule Type – Indicates if the schedule is configured in

the local system or followed from a remote system.

• Current Occupancy State – Indicates the occupancy state

as defined by the schedule at the moment.

NOTE: A maximum of 100 devices can be assigned to a

schedule.

• Next Occupancy State – Indicates the occupancy state for

the next defined schedule.

• Time Remaining (minutes) – Indicates the time remaining

in switching to next occupancy state.

• Replicate – Click Replicate to replicate the settings.

Add/Edit Schedules

You can add a maximum of 50 schedules.

NOTE: All fields marked with an asterisk (*) are mandatory.

To create a new schedule:

1. Click the Schedule tab. A list of schedules appears.

2. Click . The Properties page appears.

NOTE: Apart from the Contractor (who has all the privileges

in WebVision) all the users who add new schedules

have access to all the schedules created by them.

To view schedules:

1. Click the Schedule tab. A list of schedules appear with

the following details in a tabular format:

Fig. 9. Schedule Tab.

TIP: Use Filters to quickly search the required Schedules.

Fig. 10. Schedule Properties page.

3. Select the Create New Schedule option.

4. Type a schedule name in the Schedule Name field and

provide a description in the Description field.

5. Select the cells by dragging over the cells. Cells can be

selected horizontally and vertically. After selecting the

cells, click on the schedule occupancy state button to

indicate the state on the selected cell.

6. Click Apply to apply the schedule.

7. Click Finish to save the settings.

NOTE: Click Edit Time and type the Start Time and End

Time. You can change the start and end time of the

selected area.

5 95-7769—01

Page 6

WEBVISION™

To edit a schedule:

1. Click the Schedule tab. A list of schedules appears.

2. Click the schedule that you want to edit by clicking the

corresponding link in the Schedule Name column.

3. Follow the steps described in the above sections and

make the required changes.

Assign Devices

You can select a number of devices and assign them to a

current configuring schedule. You can change the settings as

and when required.

To assign devices:

1. Click the Schedule tab. The Schedule page appears.

2. Go to Add Schedule. The Add Schedule page

appears.

3. Type a unique name for the schedule.

4. Click Assign Devices. The Assign Devices page

appears.

5. Check the devices from the Device Name list that you

want to assign to the current schedule.

All the devices that are already assigned to schedules

are listed in the Currently Assigned Schedule column.

If a device is already assigned to a schedule,

WebVision un-assigns the device from the earlier

schedule and assigns it to the current schedule.

6. Click Finish to save the settings.

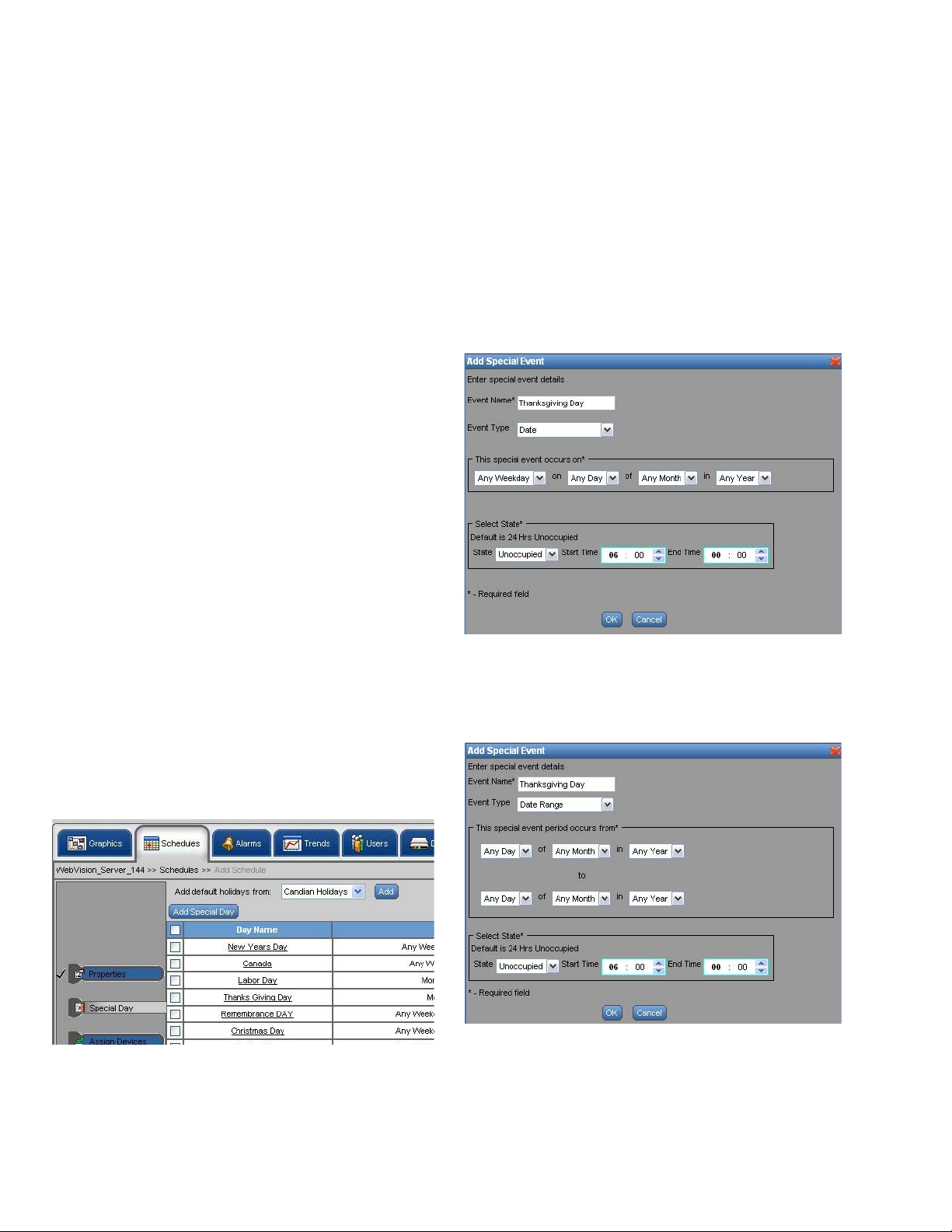

All the special events along with a summary appear in a

tabular format.

2. Click Add Special Event, to add new special events to

the list. The Add Special Event dialog box appears.

3. Enter/select the following information:

• Event Name – Name of the special event.

Example: Thanksgiving Day.

• Event Type – You can define the type of day using

the three options given: Date, Date Range, and

Week and Day. Depending on the selected criteria,

you get the following output:

Date – If you select Date, specify the day, date,

month, and year.

NOTE: To abort the action, click Cancel.

Define Special Event

Holiday schedules and schedules for special events differ

from the normal days. You can define schedules for special

events using WebVision.

NOTE: You can define any number of special events in a

schedule.

To define a schedule for special events:

1. Click Special Event on the Properties page. The

Special Event page appears.

Fig. 12. Add Special Event dialog box.

Date Range – If you select Date Range, specify the date

range, month, and year (Fig. 13).

Fig. 11. Schedule Properties page - Special Event.

95-7769—01 6

Fig. 13. Add Special Event dialog box - Date Range.

Page 7

WEBVISION™

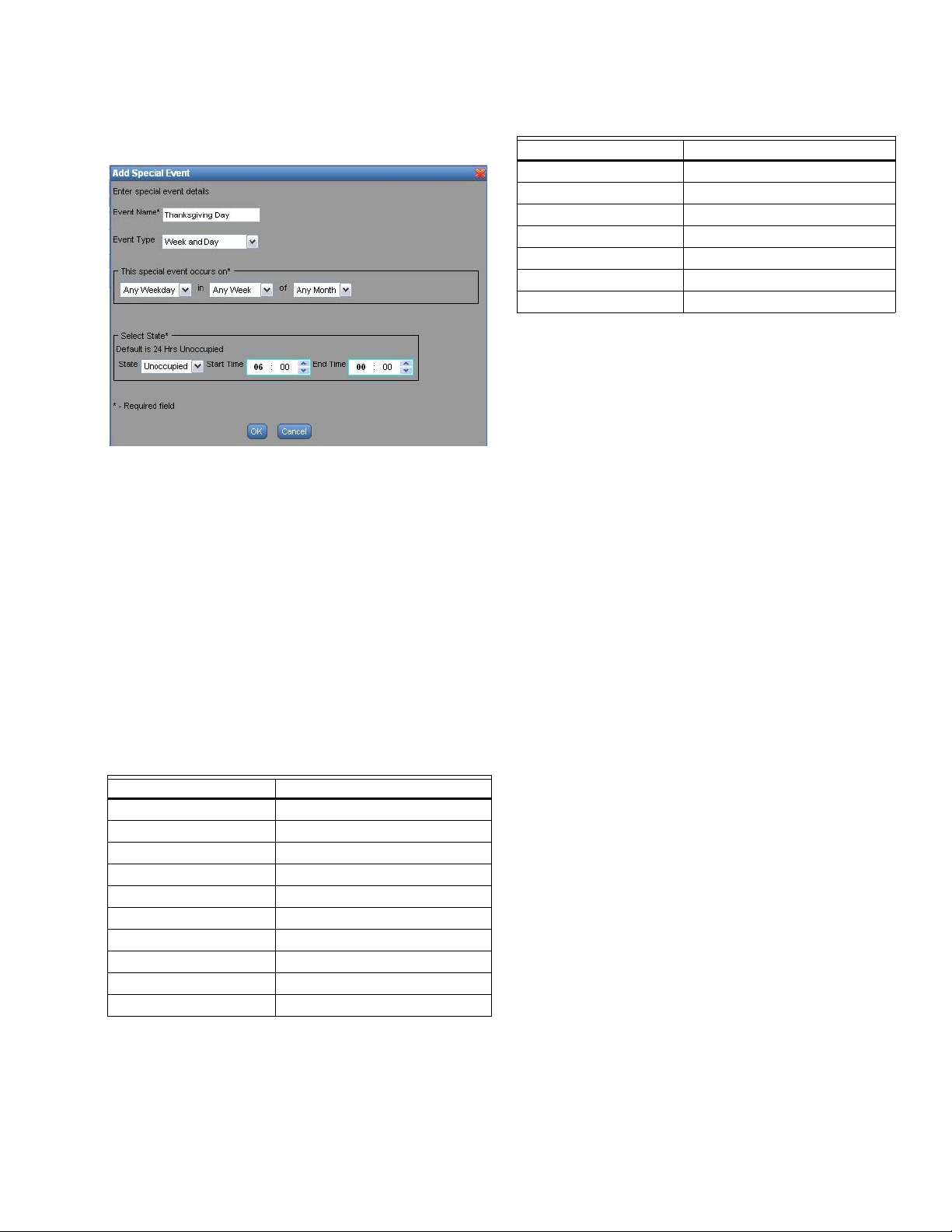

Week and Day – If you select Week and Day, specify the

month, week, and year (Fig. 14).

Fig. 14. Add Special Event dialog box - Week and Day.

4. Enter/select the following information under Select State

• State – Occupied, Unoccupied, and Standby.

• Start Time – The time to start the special event.

• End Time – The time to end the special event.

Table 2. Default Canadian Holidays.

Name Day

New Year’s Days January 1st

Canada Day July 1st

Labour Day The first Monday in September

Thanksgiving Day The second Monday in October

Remembrance Day November 11th

Christmas Day December 25th

Boxing Day December 26th

To add the pre-configured holidays:

1. Select the US Calendar or Canadian Holidays using the

drop-down list on the Special Event page.

2. Click Add. The selected (US or Canadian) preconfigured list of holidays is added and is displayed in

tabular format.

IMPORTANT

Special events are not executed if you commit an

error in specifying them. WebVision cannot validate

the dates you enter for a special event. No error is

shown if you configure wrong dates for special event,

provided the dates are in the specified format.

NOTE: By default the occupancy state is 24 hours

Unoccupied.

5. Click OK to save the settings.

NOTE: Click Cancel to close the window without saving the

changes.

Default holiday list

Table 1 and Table 2 list the default holidays for the US and

Canada.

Table 1. Default US Holidays.

Name Day

New Year’s Days January 1st

Martin Luther King Jr. Day The third Monday in January

Presidents Day The third Monday in February

Memorial Day The last Monday in May

Independence Day July 4th

Labor Day The first Monday in September

Columbus day The second Monday in October

Veterans Day November 11th

Thanksgiving Day The fourth Thursday in November

Christmas Day December 25th

Delete Schedules

To delete a schedule:

1. Click the Schedule tab.

2. Select the check box corresponding to the schedule you

want to delete from the Schedules Name list.

3. Click Delete. A confirmation message appears.

4. Click OK to confirm the deletion.

NOTE: Click Cancel to cancel deletion.

TIP: To delete all schedules at once, check the All check box

in the header and click Delete.

Replicate Schedule

You can replicate one schedule at a time. A maximum of 10

copies of the selected schedule can be replicated. Click

Replicate to replicate that schedule.

To replicate a schedule:

1. Click the Schedule tab.

2. Click Replicate. The Replicate Schedule box is

displayed.

3. Enter the number of copies that you want to create.

4. Add a prefix or suffix to the new replicated schedule's

name in the Label text box.

5. Click OK to confirm the replication.

NOTE: Click Cancel to cancel replication.

7 95-7769—01

Page 8

WEBVISION™

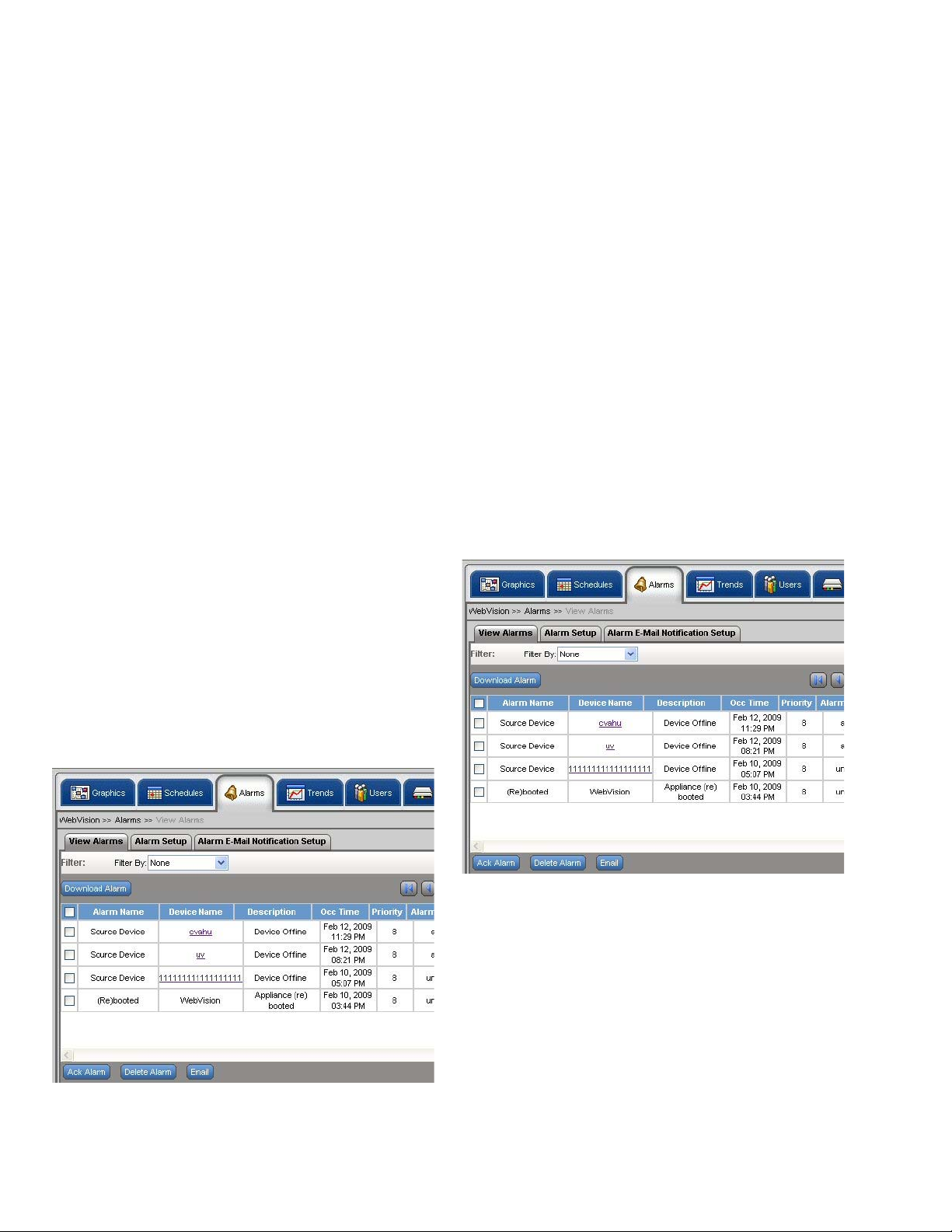

Alarms

Viewing alarms

A device configured with alarm settings is set when the value

of a point satisfies the alarm condition of that device.

Use the Alarms tab to view and acknowledge alarms that are

raised on various devices. You can filter alarms based on

occurrence, acknowledgment status, ack time, RTN time,

priority, and so on. You can setup alarms, define their limits,

and prioritize them. You can also acknowledge alarms and

delete acknowledged alarms.

Alarm priorities can be set for each type of alarm condition.

The alarm priority can range from 1 to 10 and is used to

determine E-Mail alarm message recipients. High priority

alarms have a higher reporting priority. For example, system

alarms (for example, low battery) are always high priority.

E-Mail alarm messages can be sent to a maximum of 50 EMail addresses. Any E-Mail alarm message can be sent to

any combination of 50 E-Mail addresses based on the priority

assigned.

When you add a device, all the default alarms present in that

device are added to WebVision. All the default alarms are

enabled.

NOTE: Select the check box in the header row to select all

the listed alarms.

• Alarm Name – List of all alarm names.

• Device Name – Lists all devices on which alarms are set.

To view the details of any device, click the respective

device.

• Description – Indicates the condition that raised the

alarm.

• Occurrence Time – Indicates the date and time when the

alarm was raised.

• Priority – Indicates the priority level of an alarm. There are

ten priority levels defined in WebVision - 1 through 10. 1 is

low and 10 is the highest priority level.

• Alarm State – Indicates alarm acknowledgement status.

• Acknowledged by – Indicates the user who acknowledged

the alarm.

• Acknowledge Time – Indicates the date and time when

the alarm was acknowledged.

• Return to Normal Time – Indicates the date and time

when the alarm returned to the normal condition.

TIP: Check the Enable Auto Refresh check box to enable

the auto refresh feature. The page is refreshed every 30

seconds.

To acknowledge an alarm:

1. Click the Alarms tab. The View Alarms page appears.

An alarm is raised when the value of a point on a device on

which an alarm condition is configured satisfies the alarm

condition. The View Alarms page displays a list of alarms

raised on devices along with information such as description

of the alarm, occurrence time of the alarm, the time when the

alarm was acknowledged, return to normal time, the priority of

the alarm, and so on.

To filter and view alarms:

1. Click the Alarms tab. The View Alarms page appears.

The following information appears in a tabular format:

Fig. 16. View Alarms page.

2. Select the check box corresponding to the alarm you

want to acknowledge.

3. Click Ack Alarm.

4. The alarm is acknowledged. The time and date when

the alarm is acknowledged appears in the Ack Time

column. The user name is displayed in the Ack By

column.

Fig. 15. Alarms Tab.

95-7769—01 8

TIP: Select the check box in the header row to select all the

alarms for acknowledgment simultaneously.

Page 9

WEBVISION™

Exporting Alarms

You can export alarms on WebVision.

To export alarms:

1. Click the Alarms tab. The View Alarms page appears.

2. Click Export All Alarms to download all the alarms at

once.

3. A .csv file is displayed.

4. Click Open to open the file and click Save to save the

file on your computer.

To E-Mail alarms:

1. Select the alarms you would want to e-mail by clicking

the corresponding check boxes.

2. Click E-Mail. An Enter Email Addresses box is

displayed. Enter a list of e-mail addresses to which the

selected alarms must be E-Mailed. The list must be

separated by a semicolon (;).

3. Click Ok. The selected alarms are E-Mailed to those

recipients.

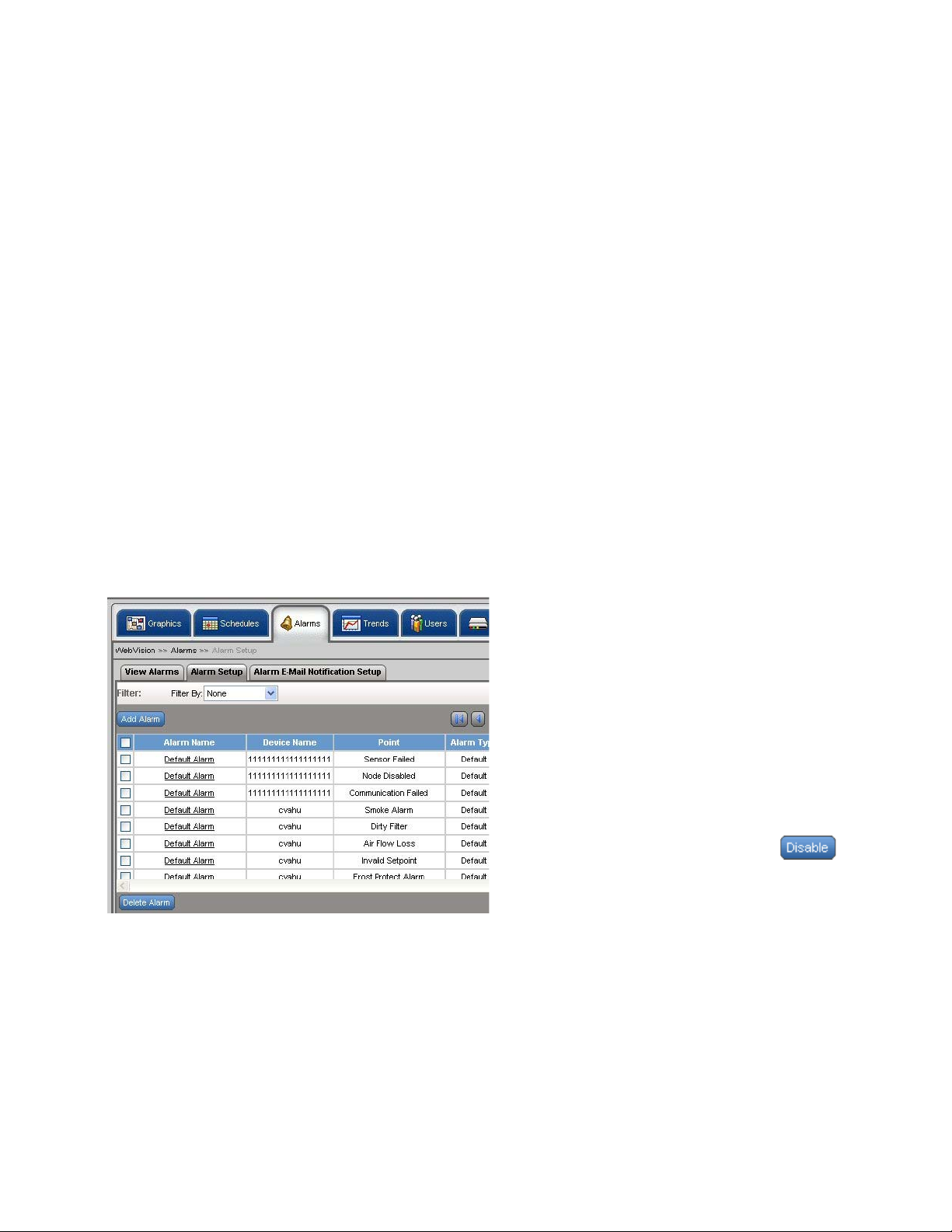

Alarm Configuration and Use

To add new alarms:

1. Click the Alarms tab. The View Alarms page appears.

2. Click the Alarm Setup tab on View Alarms page. The

Alarm Setup page appears.

down list. The selected values are reflected in

the Alarm Setup screen. Type a Display Name

for the point.

NOTE: The alarm condition depends on the type of selected

point. If it is a numeric point, you must provide Alarm

High Limit and Alarm Low Limit. If it is a discrete

value (Enumerated or Boolean) point, then select an

alarm value in the possible point value list in the

combo box.

Example: For Occupancy State, you can select alarm value as

Unoccupied in which case WebVision raises an alarm

whenever the point has Unoccupied as its value.

• Select Alarm value – This option is available for

enum and boolean values. Select the required

alarm value from the drop down list.

• Limits:

• High Limit – Select or type the higher limit of a

device beyond which an alarm is raised.

• Low Limit – Select or type the lower limit of the

device below which an alarm is raised.

NOTE: For numeric values, Limits are listed and for enum

and boolean values the Select Alarm Value is listed.

• Description – Description of the alarm.

• Set Priority As – Indicates the priority of the

alarm. Set 1 for low priority and 10 for High

priority. It can be Low, Medium, or High. Priority

is configured depending on the device's

configurations and settings

• Enable – Click Yes to enable the alarm along

with its configuration. Checking this option,

displays the alarm in the View Alarms page.

Click No to disable the alarm.

5. Click Save to save the settings.

Fig. 17. Alarm Setup page.

3. Click Add Alarm. The Add Alarm page appears.

4. Enter the Alarm Name and select the desired Points:

• Alarm Name – The name of the alarm.

•Select Points:

• Channel – The selected channel.

• Device – The selected device.

• Point – The selected point.

• Select Point – Click Select Point. The Select

Point dialog box is displayed. Select a Channel,

Device, and Point from the corresponding drop

To edit an alarm configuration:

1. Select an alarm from the alarm's list to edit it. The

selected alarm's details appear.

2. Modify the required fields as described in step 4 of “To

add new alarms:”.

3. Click Save to save the settings.

NOTE: You can enable or disable an alarm from the Alarm

Setup screen. For example, click from the

table on the Alarm Setup page to disable an alarm.

To delete an alarm:

1. Click the Alarms tab. The View Alarms page appears.

2. Select the check box corresponding to the alarm you

want to delete.

3. Click Delete Alarm. A confirmation message appears.

4. Click OK to confirm the deletion.

NOTES:

1. Click Cancel to cancel the deletion.

2. Only Acknowledged Alarms can be deleted.

TIP: To delete all alarms at once, select the Alarm Name

check box and click Delete Alarm.

9 95-7769—01

Page 10

WEBVISION™

To replicate an alarm:

1. Click the Alarms tab. The View Alarms page appears.

2. Click the Alarm Setup tab on the View Alarms page.

The Alarm Setup page appears.

3. Click corresponding to the alarm that you want to

replicate. The Replicate Alarm dialog box appears.

4. Type the alarm name in the Alarm Name text box.

5. Select an alarm and device that you want to replicate

from the Replicate Alarm and Device drop-down list.

6. Choose a prefix or suffix to name the replicated copy of

the alarm. Select the Prefix with or Suffix with option as

required.

7. Type a label name for the alarm in the Label text box.

8. Click Replicate to confirm the replication.

NOTE: Click Cancel to cancel the replication.

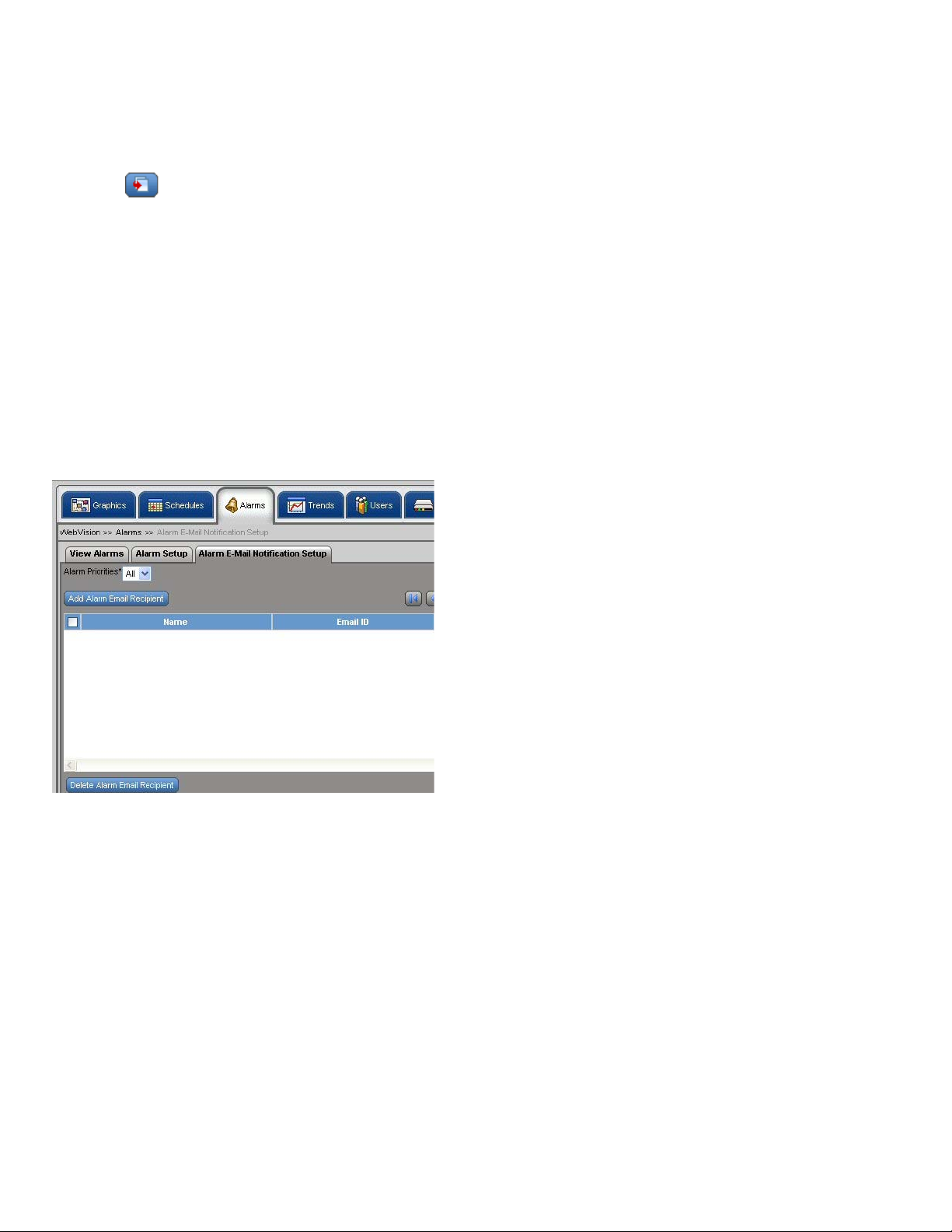

To setup alarm E-Mail notification:

1. Click the Alarms tab. The View Alarms page appears.

2. Click the Alarm E-Mail Notification Setup tab on the

View Alarms page.

Add, Edit, or Delete Alarm E-Mail Recipient

To add an alarm E-Mail recipient's details:

1. Click the Alarms tab. The View Alarms page appears.

2. Click the Alarm E-Mail Notification Setup tab on the

View Alarms page. The Alarm E-Mail Notification

Setup page appears.

3. Click Add Alarm E-Mail Recipient. The Add Alarm

E-Mail Recipient page appears.

4. Select the recipient type using the Select Recipient

Type drop-down list.

• For an External recipient, enter:

• Recipient Name – Name of the recipient.

• Recipient E-Mail ID – E-Mail ID of the recipient.

• For an Internal recipient, enter:

• Select User – Select the type of the user using

the drop-down list.

5. Select the alarm priorities that must be informed to the

recipient. Check the Select All check box to select all

the alarm priorities.

6. Click Save to add a new recipient.

NOTE: Click Cancel to abort the action.

To edit an alarm E-Mail recipient's details:

1. Click the Alarms tab. The View Alarms page appears.

2. Click the alarm name that you want to edit. The Alarm

Setup page of the selected alarm appears.

3. Edit the fields as explained in step 3 of “To add an alarm

E-Mail recipient's details:”.

4. Click Save to save the changes.

Fig. 18. Alarm E-Mail Notification Setup Tab.

3. The Alarm E-Mail Notification Setup page appears

with the following information in the tabular format:

TIP: Select the check box in the header row to select all the

listed alarms e-mail recipients.

• Name – Lists names of the users who will receive

the alarm E-Mail notification.

• E-Mail ID – Lists the E-Mail IDs of the

corresponding users.

• Recipient Type – Lists the type of user.

• Associated Alarm Priorities – Lists the alarm

priorities associated to the corresponding user if the

user is external. Alarm priorities range from 1 to 10.

1 being the lowest priority level and 10 being the

highest priority level. Check Select All to select all

the alarm priorities.

NOTE: Click Cancel to abort the action.

NOTE: The alarm priority information for internal user is

available in the user account configuration page.

To delete an alarm E-Mail notification recipient:

1. Click the Alarms tab. The View Alarms page appears.

2. Click Alarm E-Mail Notification Setup. The Alarm EMail Notification Setup page appears.

3. Select a user from the Name list that you want to delete.

4. Click Delete to delete the selected recipient.

TIP: To delete all recipients at once, check the All check box

in the header and click Delete.

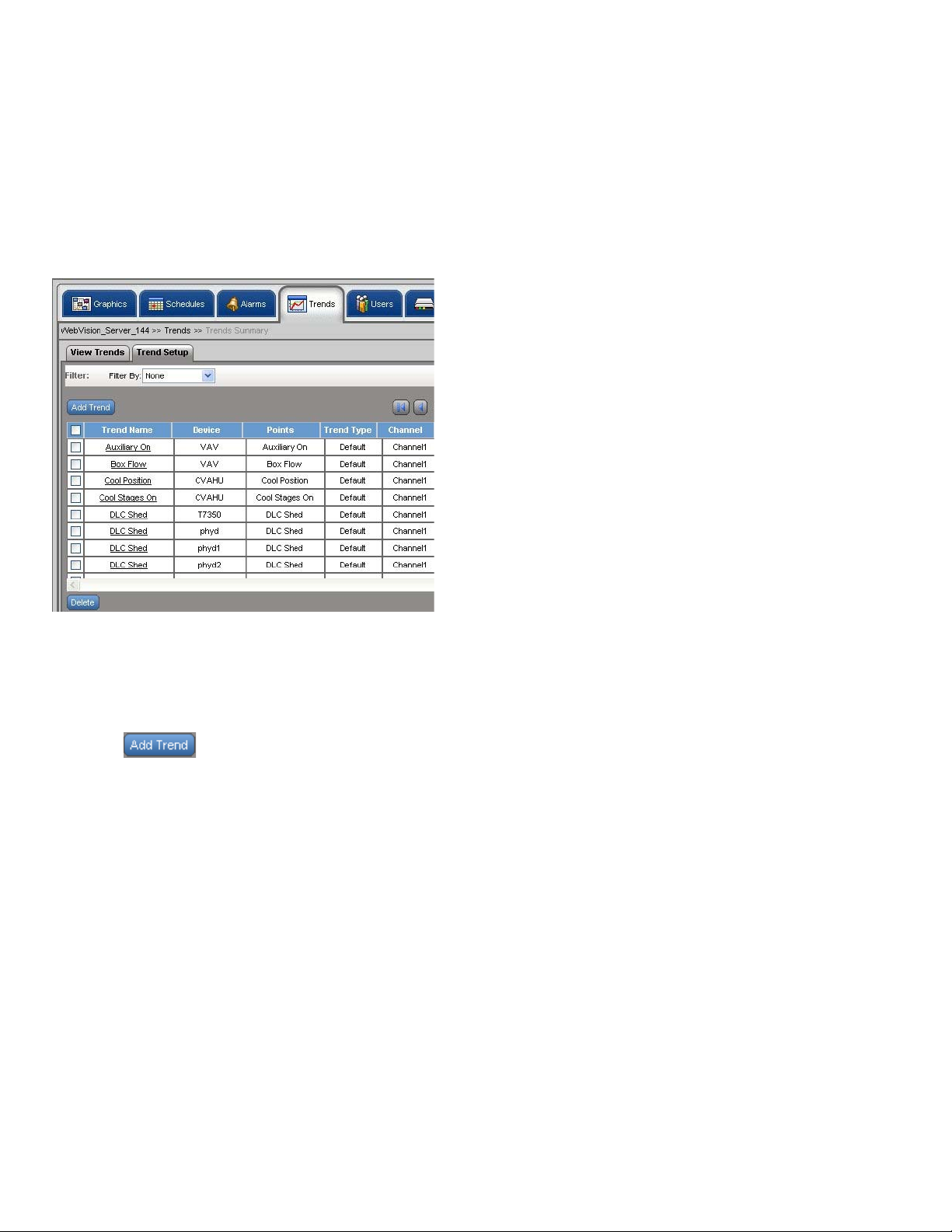

Trends

Trends depict the values of points over time in a graphical

format. Use the Trends tab to view trends for the selected

points over a period ranging from a day to a year.

You can store a maximum of 1000 samples per trend. By

default you can store 500 samples per trend. Once you cross

the limit, the oldest sample is overwritten and rolled over

based on trend configuration. Five trends can be plotted

simultaneously. For example, outside air temperature and

space temperature plotted for a period of one month.

A trend point can be a data point from any supported

L

ONWORKS network device. A data point can be used in

multiple trend configuration. There are few default sample

95-7769—01 10

Page 11

WEBVISION™

trends stored in WebVision. You cannot delete these sample

trends. However, you can create new trends. The trends

created by you are called User Defined trends.

When you add a device, all the default trends present in that

device are added to WebVision. All the default trends are

disabled.

You can create and view a maximum of 100 trends.

To view trends:

Click the Trends tab. The View Trends page appears with the

following information:

— Enable/Disable – Indicates if a trend is enabled or

disabled. Click the Enable or Disable buttons to

enable/disable the trend.

TIP: Use Filters to quickly search the required trend.

Use one of the following filter options to search for the

required trend:

• Channel Name

• Trend Type

• Trend Name

• Device Name

•Point Name

• Point Group

TIP: To quickly search the trends, type the first letter of the

required filter criteria in the Keyword text box and type

an asterisk (*). This lists all the names starting with the

first letter that you have written in the Keyword text box.

Plotting trends

NOTES:

1. A security warning message appears when you

access the Trends page and prompts you to

download the applet. Click Yes to continue.

2. A Java plug-in version 1.6 and above must be

installed to view the trend chart.

Fig. 19. Trends page.

— Tre nd Nam e – The unique name for the Trend.

— Device – Indicates the location on the device.

— Points – Indicates the points whose readings are

required to generate a trend.

— Trend Type – Indicates type of trend. For instance it

can be a user defined trend.

— Channel – Indicates the channel on which the devices

are present.

— Sampling Interval – Indicates the time interval

between two successive read operations on the point.

One hour is the default setting.

The sampling interval time can range from a few

minutes to a day. The range covered is:

• 15 seconds

• 30 seconds

• 60 seconds (1 minute)

• 900 seconds (15 minutes)

• 1800 seconds (30 minutes)

• 2700 seconds (45 minutes)

• 3600 seconds (60 minutes)

To plot a trend:

1. Click the Tren ds tab. The View Trends page appears.

2. Select a trend from the Configured Trends list to plot.

3. Click Plot Trend. The Plot Trend dialog box appears.

4. Enter the following parameters:

•Select Start Time – Click to select the start

date and enter the start time in hours and minutes.

•Select End Time – Click to select the end date

and enter the end time in hours and minutes.

NOTE: Start time must be less than the end time.

5. Click OK to view the graphical representation of the

trend or click Cancel to cancel the trend.

Viewing plotted trends

The view of the trends plotted have the following information:

• Plotted Trends – Lists the name of the trends that are

plotted.

• Start Time – Select the start time, if required.

• End Time – Select the end time, if required.

• Re-Plot Trends – After selecting the Start and End time

select this option to re-plot the trend with the new time

range.

• Download Trendlog – Click this button to download trend

log in .csv format for the plotted trends.

• Ok – Click Ok to go back to the View Trends screen.

11 95-7769—01

Page 12

WEBVISION™

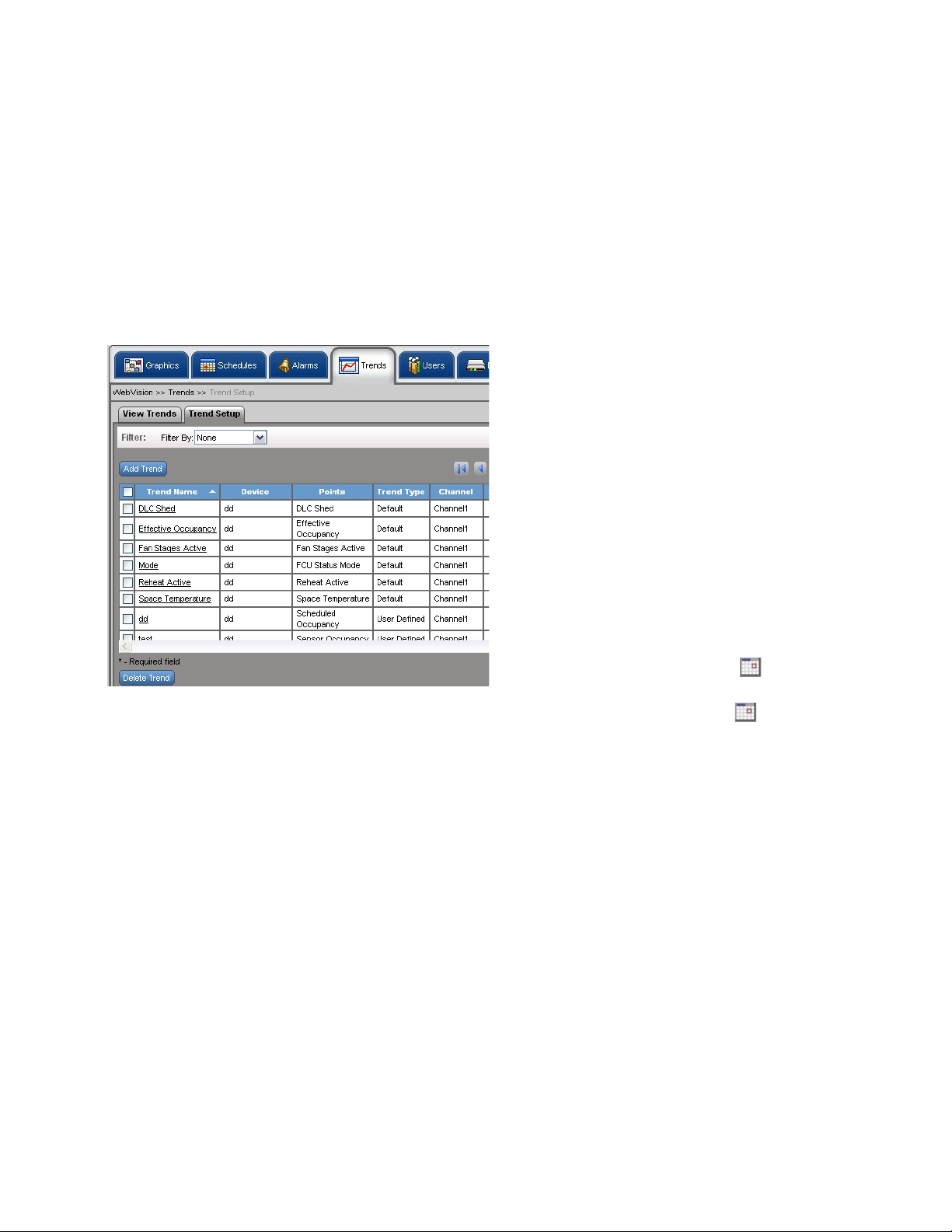

Trend Setup and Use

TIP: You can enable or disable trends from the Trends Setup

screen.

To setup a trend:

1. Click the Trends tab. The View Trends page appears.

2. Click the Trend Set up tab. The Trend Set up page

appears.

The sampling interval time can range from a few

seconds to a few minutes. The range covered is:

• 15 seconds

• 30 seconds

• 60 seconds (1 minute)

• 900 seconds (15 minutes)

• 1800 seconds (30 minutes)

• 2700 seconds (45 minutes)

• 3600 seconds (60 minutes)

• Change of Value – Indicates that the next sample

is collected when the point value changes. This

results in less number of samples getting collected

for plotting the same trend as compared to Periodic

Sampling. Change Tolerance is required only for

numeric points. Select a numeric point from the

Select Point option and type a tolerance value after

which the data logging begins.

• Trend L imit – Roll Over is the default selection.

This option trends the point forever.

• Roll Over – Indicates that the readings of

sampling are generated continuously. When the

sample limit is reached, the oldest sample is

replaced with the next sample and trending

continues in that fashion.

• Stop when full – Indicates that the trend

sampling is stopped after it reaches the set limit.

• Max number of Samples – The maximum

number of samples. Select the number of

samples to be generated from the list.

Fig. 20. Trend Setup tab.

To add a new trend:

1. Click the Trends tab. The View Trends page appears.

2. Click the Trend Set up tab. The Trend Set up page

appears.

3. Click . The Add New Trend page appears.

4. Enter/select the following details:

NOTE: All the fields in this section are mandatory.

NOTE: Start time must be less than the end time.

• Trend Nam e – The unique name for the trend.

• Select Point – Click Select Point. Select a Channel,

Device, and Point. Click OK. The selected values

appear in the respective fields.

• Start Time – The start time of the sampling period.

Click to select the date, month, and year

• End Time – Check Enable End Time to enable the

end time field. The end time of the sampling period.

Click to select the date, month, and year.

• Trend Type – Indicates the type of trend.

• Periodic Sampling – Indicates the time interval

between two successive read operations on the

point. Select Periodic Sampling option and in the

Sampling Interval list, select the desired time

interval.

NOTE: WebVision uses the polling mechanism to read point

values at regular interval. It may take up to 30

seconds to detect a point value. If the point value

changes at a higher frequency than 30 seconds,

WebVision may not be able to detect the changes.

5. Click Save to save the settings.

NOTE: Click Cancel to clear the fields.

To edit trends:

1. Click the Tren ds Se tup tab. The View Trends page

appears.

2. Select a Trend from the Trends list. The details of the

selected Trend appear.

3. Modify the required fields as described in step 4 of “To

add a new trend:”.

4. Click Save to save the settings.

NOTE: Click Cancel to cancel the settings.

To delete a trend:

1. Click the Tren ds tab. The View Trends page appears.

2. Go to Trends Setup. Select the trend that you want to

delete from the Trends listed on the left corner of the

screen.

3. Click Delete. A confirmation message appears.

4. Click OK to confirm the deletion.

NOTE: Click Cancel to cancel the deletion.

TIP: To delete all the trends simultaneously, select the check

box in the column header and click Delete Trend.

95-7769—01 12

Page 13

WEBVISION™

Users

You can create a maximum of 30 user profiles. You must be

familiar with User ID and Password security standards to

enforce user compliance when creating a user profile. As

WebVision is a secure server, you need to log in with a preassigned user ID and password. The user ID and password

combination determine your access level, which in turn

determine the kind of operator and configuration functions

performed.

The Network Administrator must be familiar with user ID and

password security standards and enforce user compliance.

The WebVision System Administrator can be accessed using

these initial default user ID and password: User ID SysAdmin and Password - !Sys!Admin.

It is a good practice to add one or more additional users with

Administrator access level to ensure top level access to

WebVision. Those with higher access levels have the

privileges of all the lower levels in addition to the privileges

unique to that level. These access levels are managed by the

System Administrator. There can be an individual or many

System Administrators who are assigned the task of

managing individuals at different access levels.

NOTE: For security compliance, it is mandatory to change

Use the Users tab to add users, assign devices to them and

define their privileges based on their roles. There are four

types of user roles (see Table 3):

• Contractor - Contractor is a user with all the privileges

• Facility Manager - This role represents a Building

• Tenant - The user assigned to this role has limited access

• Balancer - Balancer is a user who performs VAV Balancing

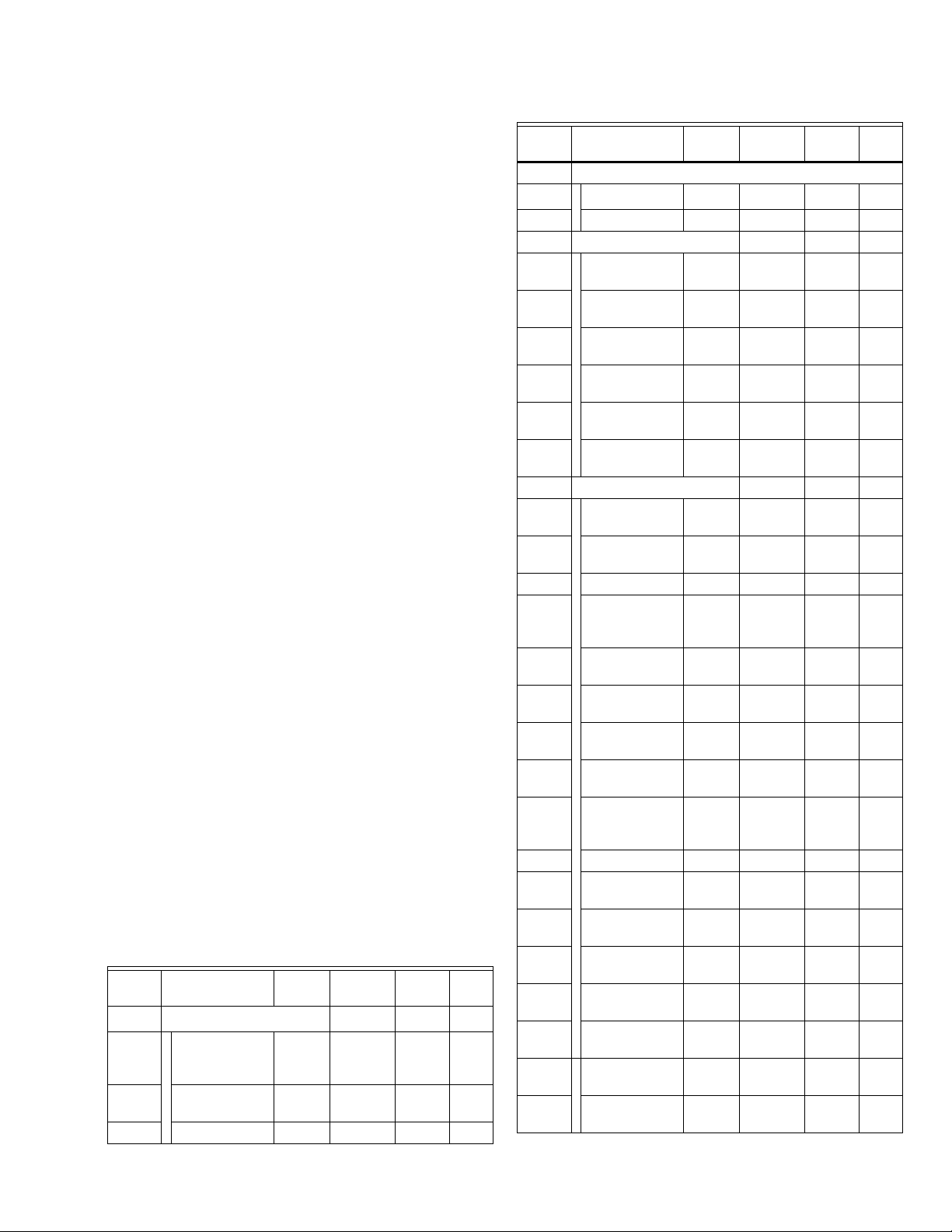

Role Matrix

See Table 3.

Privilege

your password after the initial login process. Once

changed, the default password will no longer work.

Exercise care to create a new password that meets

the security standards and can be easily

remembered by the System Administrator.

assigned and can perform all tasks. SysAdmin is a user

account with contractor privileges that cannot be deleted.

The privileges cannot be altered. This is to ensure that

there is at least one contractor available in the system.

Engineer who maintains HVAC equipment and monitors

the system with the help of WebVision.

to WebVision. The user with the Tenant role has access to

only those devices which are assigned to the user.

Job. The user assigned to this role has access to VAV

devices for WebVision.

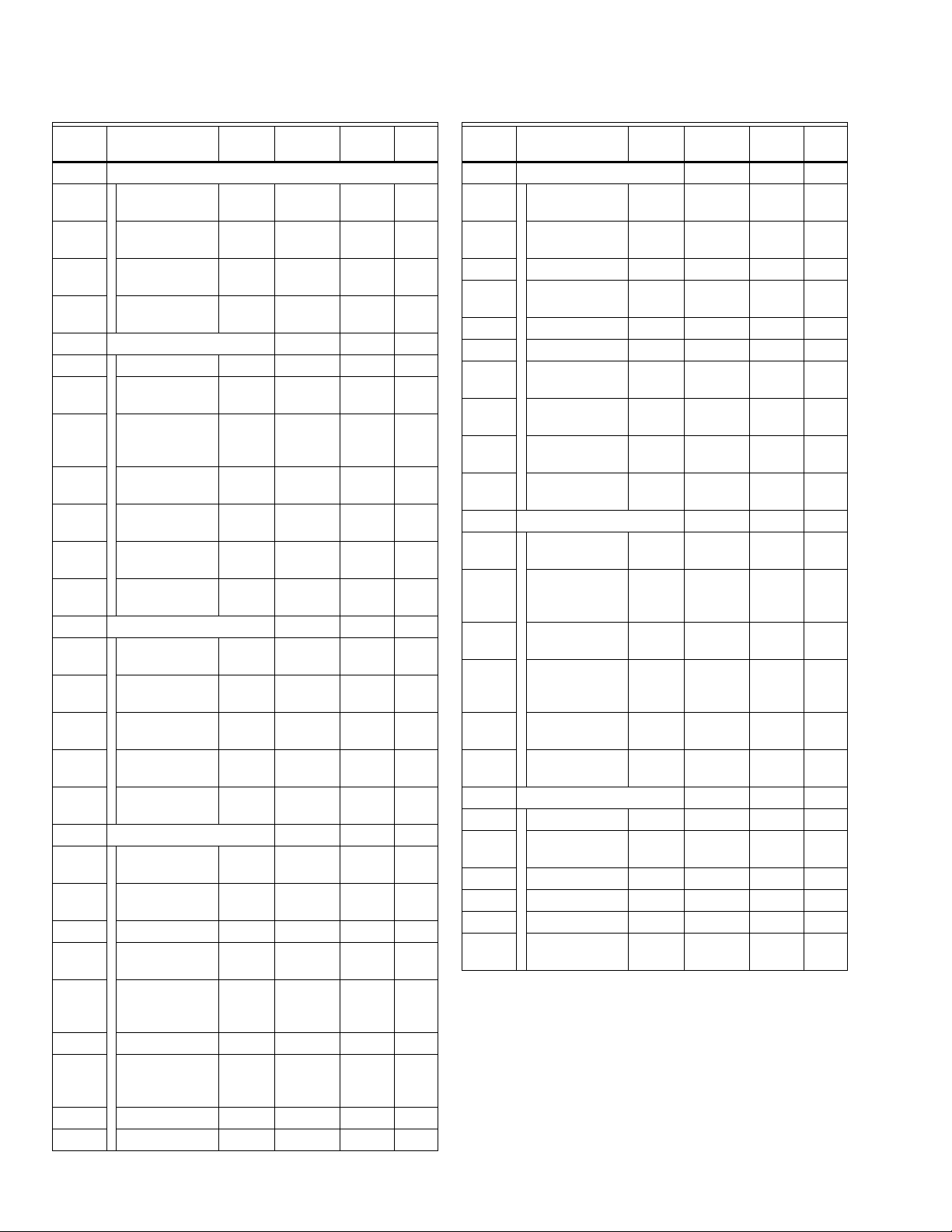

Table 3. Role Matrix.

ID Privileges

Depends

1

Graphics P

2 Change Controller

On Contractor

4PPP

Facility

Manager Tenant

a

PP

Setpoints

(temporary)

3 Override Schedule

4PPP

Occupancy

4 View Graphics P P P

Table 3. Role Matrix. (Continued)

Privilege

ID Privileges

Depends

On Contractor

Facility

Manager Tenant

Graphics (continued)

5 Edit Graphics 4 P

b

X

X

6 Add Graphics 4 P X X

7 Schedules PPP

8View Summary

PPP

Screen

9 View Schedule

9PPP

Configuration

10 Add Schedule

9PXX

Configuration

11 Edit Schedule

10 P P P

Configuration

12 Delete Schedule

9PXX

Configuration

13 Assign Devices to

9,11/12 P X X

Schedule

14 Alarms PPP

15 View Alarms

PPP

Summary

16 Acknowledge

16 P P X

Alarms

17 Delete Alarms 16 P X X

18 View Alarms

PPX

Configurations

Summary

19 View Alarm

19 P P X

Configurations

20 Add Alarm

19 P X X

Configurations

21 Edit Alarm

20 P P X

Configurations

22 Delete Alarm

19 P X X

Configurations

23 Download Alarm

16 P P X

Records as CSV

Files

24 Suppress Alarms 19 P P X

25 Setup Alarm E-

PPX

mail Notifications

26 View Priority 1

Alarms

27 View Priority 2

16

c

C

16 C C C

CC

Alarms

28 View Priority 3

16 C C C

Alarms

29 View Priority 4

16 C C C

Alarms

30 View Priority 5

16 C C C

Alarms

31 View Priority 6

16 C C C

Alarms

13 95-7769—01

Page 14

WEBVISION™

Table 3. Role Matrix. (Continued)

Privilege

ID Privileges

Depends

On Contractor

Facility

Manager Tenant

Alarms (continued)

32 View Priority 7

16 C C C

Alarms

33 View Priority 8

16 C C C

Alarms

34 View Priority 9

16 C C C

Alarms

35 View Priority 10

16 C C C

Alarms

36 Trends PPP

37 View Trend Graph P P P

38 Download Trend

38 P P X

Data CSV Files

39 View Trend

PPX

Configurations

Summary

40 View Trend

40 P P X

Configurations

41 Add Trend

40 P X X

Configurations

42 Edit Trend

41 P P X

Configuration

43 Delete Trend

40 P X X

Configuration

44 Users PP

45 View User

PPX

Summary

46 View User Account

46 P P X

Information

47 Add New User

46 P P X

Accounts

48 Edit User

47 P P X

Accounts

49 Delete User

46 P P X

Accounts

50 Devices PP

51 View Device

52 P P X

Summary

52 Discover Devices

52 P X X

on the Network

53 Add New Device 52 P X X

54 Copy an Existing

52 P X X

Device

55 Download/Upload

52 P P X

Device

Configuration

56 Delete Device 52 P X X

57 Invoke Device

52 P P X

Configuration

Wizard

58 Match Device 52 P X X

59 Change Setpoints 52 P P X

Table 3. Role Matrix. (Continued)

Privilege

ID Privileges

Depends

On Contractor

Facility

Manager Tenant

60 System PP

61 General

PPX

Configuration

62 IP Network

PXX

Configuration

63 Mail Configuration P P X

64 Change System

PPX

Date and Time

65 Upgrade Firmware P X X

66 Reboot System P P X

67 Download System

PPX

Load

68 Download Audit

PPX

Log

69 Network

PCC

Navigation

70 Physical

PCC

Navigation

71 WebSuite Network PP

72 View Appliance

PPX

Summary

73 Discover

73 P X X

Appliances on

Network

74 Add New

73 P X X

Appliance

75 Enable Network

73 P X X

Firmware at

Network Level

76 Change Master

73 P X X

Ownership

77 Change Network

73 P X X

User Password

78 DLC PP

79 Configure DLC P X X

80 View Load

PXX

Summary

81 Add Load 81 P X X

82 Delete Load 81 P X X

83 Edit Load 81 P X X

84 Monitor DLC

PPX

Status

a

The letter P means the role has that privilege.

b

The letter X means the role does not have that privilege.

c

The letter C means that the user can be given that privilege

when configuring his/her account.

95-7769—01 14

Page 15

WEBVISION™

View list of Users

The list of users provides information on WebVision users

such as their names, roles, and e-mail IDs.

To view the list of users:

1. Click the Users tab. The Users page appears.

Fig. 21. Users page.

TIP: Use Filters to quickly search the required user.

Use one of the following filter options to search for the

required user:

•User ID

•Role

•Email ID

To add a user:

1. On the Users page, click the Add User button. The

Properties page appears.

Fig. 22. Add User - Properties page.

2. Enter the account information of the user:

• User ID – The unique user ID. It must have a

minimum of 6 characters.

TIP: You can use a maximum of 30 characters and a

minimum of 6 characters to set your user ID. The

permitted characters include a-z, A-Z, _, 0-9. The

following characters are not allowed: !, @, #, $, %, ^, *, , and |.

TIP: To quickly search the users, type the first letter of the

required filter criteria in the Keyword text box and type

an asterisk (*). This lists all the names starting with the

first letter that you have written in the Keyword text box.

2. The following information appears in a tabular format:

• User Name – Displays the name of the user name.

• Role – Displays the role assigned to the user.

• Email ID – Displays the user's e-mail ID for

communication.

• Phone Number – Displays the user's phone

number.

• Enable/Disable – Displays the user's status. Click

Enable to enable the user or Disable to disable the

user.

NOTE: Select the check box in the header row to select all

the users listed.

Add/Edit Users

While adding a user:

• Configure information related to User Name, Password,

Contact Information, and User Role Information through

the Properties tab.

• Assign Devices to the user being created using the Access

on this WebVision tab.

• Add new User only in the WebVision that is configured as

Network Server in networked WebVision.

• User Name – The user name.

• Password – Type your password.

TIP: You can use a maximum of 30 characters and a

minimum of 6 characters to set your password. The

permitted characters include a-z, A-Z, _, 0-9. The

following characters are not allowed: !, @, #, $, %, ^, *, , and |.

• Confirm Password – Retype your password.

• Password Recovery Question – Select the

Password Reminder Question.

• Password Recovery Answer – Type an answer for

the above question.

• Role – The role or designation of the user. Select

the role from the list.

• Show this user – The view authorized to the user.

• Network Sidebar – The user is authorized to view

only the network side bar view.

• Locations Sidebar – The user is authorized to view

only the locations view.

• Preferred Language – The user defined language.

Select the language from the list.

3. Enter the Personal Information of the user:

• Email ID – Type the user's e-mail ID.

• Office Phone – The user's office contact number.

• Residence Phone – The user's residence contact

number.

• Mobile Phone – The user's mobile contact number.

4. Set the Show Alarm Status. Select the alarm priorities

for which you want status update. The numbers are

listed from 1 through 10. The user can see only those

alarms whose corresponding priority is checked in this

step. Check Select All to view all the alarms

simultaneously.

15 95-7769—01

Page 16

WEBVISION™

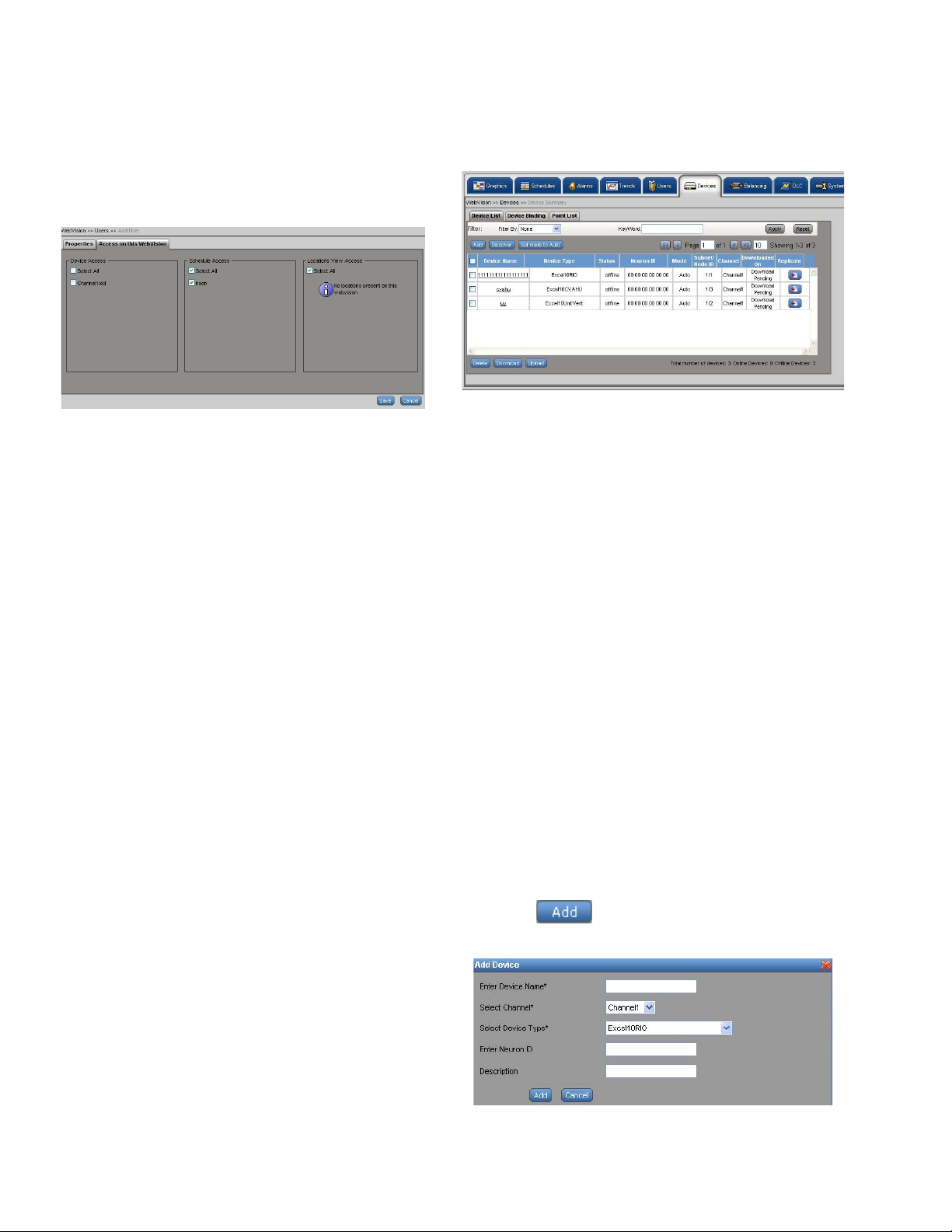

5. Click the Access on this WebVision tab. The Access

on this WebVision page appears. You can select

various options from Device Access, Schedule Access,

and Locations View Access. Check Select All to select

all the options simultaneously.

Use this option to assign customized access to users.

Fig. 23. Access on this WebVision page.

6. Click Save to save the user properties.

To edit a user:

Select a user from the User list, and make the required

changes as explained in the above section.

To delete users:

NOTE: Any user who has user management privileges can

add or remove a user.

1. On the Users page, click the name of the user you want

to delete from Users Name column.

2. Click Delete. A confirmation message appears.

3. Click OK to confirm the deletion.

IMPORTANT

SysAdmin is a user account with contractor

privileges that cannot be deleted. A SysAdmin's

privileges cannot be altered. This is to ensure that

there is at least one contractor available in the

system.

To enable/disable a user:

• Click Enable to enable a user.

• Click Disable to disable a user.

Devices

To view the list of devices:

1. Click the Devices tab. The Device List page appears.

The following information appears in a tabular format:

Fig. 24. Devices Tab - Device List page.

TIP: Use Filters to view the required list.

Use one of the following filter options to search for the

required device: Channel, Device Name, Device Type,

Status, Mode.

• Device Name – Name of the device.

• Device Type – Type of the device.

• Status – Status of the device, it can be online or

offline.

• Neuron ID – Each L

a 48 bit unique identifier, called the Neuron ID. This

is used to address the nodes on the LONWORKS

network.

• Mode – Mode of the device, it can be auto or

manual.

• Subnet/Node ID – A mask that is used to determine

the subnet of a network. Subnetting enables the

network administrator to further divide the host part

of the address into two or more subnets.

• Channel – The channel on which the device is

present.

• Synced On – Date and time on which the device is

last downloaded or uploaded.

• Replicate – Click Replicate to replicate the device

settings.

ONWORKS Controller node has

To add a device:

1. Click the Devices tab. The Device List page appears.

2. Click . The Add Device dialog box appears.

Enter the following details:

Device List

You can view all the devices present in WebVision. All the

information related to name, type, status, and so on is

available.

95-7769—01 16

Fig. 25. Add Device dialog box.

Page 17

• Device Name – Name of the device.

• Channel – The channel on which the device is

present.

• Device Type – Type of the device.

• Model – Type the model number of the device.

• Application Type – Type of application that is

required for the selected device.

• Application Version – Type the version of

application used.

• Application File – Application that must run on the

device. Click Browse to upload an application file.

• Neuron ID – The 48 bit unique identifier each

L

ONWORKS Controller node has. This is used to

address the nodes on a L

• Description – Description of the device.

NOTES:

1. All the fields marked with an asterisk (*) are

mandatory. However, it is advised to provide all

the information in the fields, so that WebVision

can provide more manageable features.

2. The above listed parameters form a

comprehensive list. The appearance of these

parameters vary depending upon the selected

device.

3. Click Add to add the device.

NOTE: Click Cancel to abort the action.

NOTE: To support 3rd party devices other than the

controllers listed in the dialog box, you must have a

corresponding Niagara LNML file that contains

information about the device and its points. This file

has to be uploaded while adding a device to

WebVision. WebVision allows you to create alarms

and trends on the 3rd party devices. WebVision

cannot drive the device's scheduled occupancy

state, do energy management using DLC, or do VAV

balancing for 3rd party devices.

ONWORKS network.

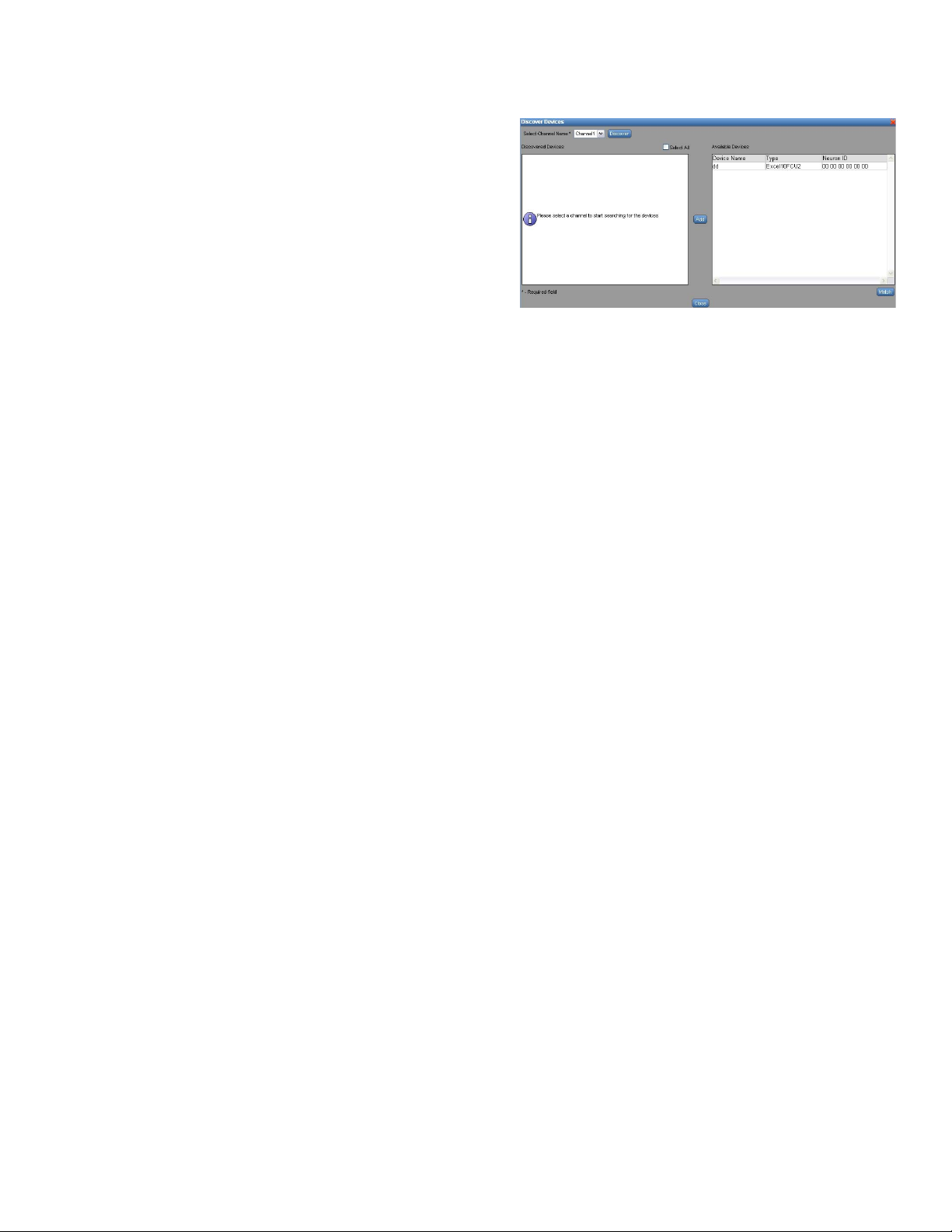

To discover devices:

You can discover the devices available on the network and

then add them to WebVision.

WEBVISION™

Fig. 26. Devices Tab - Device List - Discover button.

3. Select a channel on which you want to discover

devices.

4. Click Discover to start discovery. Once the discovery is

completed, WebVision lists the discovered new devices

on the left side list.

5. If you want to match a discovered device against an

existing device in WebVision, select the discovered

device on the left side list and select the existing device

on the right side list and click Match.

NOTE: Check the Select All check box to select all the

devices simultaneously.

6. Click Add to add discovered devices as new devices to

WebVision. The selected device gets added to the

Available Devices list.

7. Click OK to save the settings.

8. Click Log to view the discovery status.

NOTE: Click Cancel to abort the action.

NOTE: After discovering the devices you must upload the

device bindings to save the existing bindings onto

WebVision. This prevents you from losing the

existing binding, while downloading the new binding.

To upload, see “To upload device bindings:” on

page 19.

NOTE: Once a device is selected in the Discovered Device

table, only the matching device type in the Available

devices table is enabled for selection.

1. Click the Devices tab. The Device List page appears.

2. Click Discover. The Discover Device in the network

dialog box appears. The discovered devices are

displayed.

Deleting Devices

Deleting a device removes it from the device list as well as

from all other configurations such as trends, alarms, special

displays, DLC and schedules. Any alarms generated before

the device was deleted is still displayed on the Alarms page.

NOTE: You will not be able to see the deleted device in any

of the pages until it is discovered and added using

device add or discovery operation.

When you delete a device (that provides current power input),

the DLC service is disabled. All the alarms generated by a

device are available on the Alarms Summary screen.

However, the link present on the device fails, when the device

is deleted. Both trend configuration and trend data gets

deleted from the database.

To delete a device:

1. Click the Devices tab. The Device List page appears.

2. Select the devices that you want to delete by checking

the corresponding check box.

3. Click Delete to delete the devices.

17 95-7769—01

Page 18

WEBVISION™

4. Click OK to confirm the deletion.

TIP: To delete all devices at once, check the All check box in

the header and click Delete.

Set Mode to Auto

Sometimes when debugging a device, you set the mode to

manual. The Set Mode to Auto feature is a simple option to

set the devices back to auto mode.

To set the devices to auto mode:

1. Click the Devices tab. The Device List page appears.

2. Select the devices that you want to set to auto mode.

3. Click Set Mode to Auto to set the devices to auto

mode. A success message appears indicating that the

devices have been set to auto mode.

NOTE: Check the Select All check box to select all the

devices simultaneously.

Download Device Configuration

Once you have made all of the necessary configuration

settings to a device in WebVision, you will need to download

the configuration to the device.

To download a device:

1. Click the Devices tab. The Device List page appears.

2. Select the devices that you want to download by

checking the corresponding check boxes.

3. Click Download to download the selected devices. The

Downloading Device Information bar indicates the

progress of download.

4. Click Log to view the download status.

NOTE: Click Cancel to abort the action.

Upload Device Configuration

You can upload device configuration from a device on to

WebVision.

To upload configurations from a device:

1. Click the Devices tab. The Device List page appears.

2. Select the devices whose configurations you want to

upload.

3. Click Upload to upload the settings.

4. Click Log to view the upload status.

4. Choose a prefix or suffix to name the replicated copy of

the device. Select the Prefix with or Suffix with option as

required.

5. Type a label name for the device in the Label text box.

6. Click OK to save the settings.

NOTE: Click Cancel to abort the action.

Device Binding

Binding refers to a configured association either within a

device, or between separate devices on a L

network.

ONWORKS

To view a list of bound devices:

1. Click Devices on the WebVision page. The Device

List page is displayed.

2. Click Device Binding. The Device Binding page is

displayed.

NOTE: Select the required channel from the Select Channel

drop-down list.

3. The following information displays in tabular format:

• Source Device – Lists the source device involved in

the binding.

• Source Point – Lists the network object/point of the

source device that is involved in the binding.

• Target Device – Lists the target device involved in

the binding.

• Target Point – Lists the network object/point of the

target device that is involved in the binding.

• Link Status – Shows the binding status. The status

can be bound or unbound.

To add devices for binding:

1. Click Devices on the WebVision page. The Device

List page is displayed.

2. Click Device Binding. The Device Binding page is

displayed.

3. Click Add. The Add Device Binding box is displayed.

4. Select the following:

• Channel

• Source Device

•Source Point

• Target Device

• Target Point

5. Click OK. The binding is created in WebVision and has

to be downloaded to the controllers.

NOTE: Click Cancel to abort the action.

Replicate Devices

You can replicate existing devices in WebVision.

To replicate a device:

1. Click the Devices tab. The Device List page appears.

2. Click corresponding to the device that you want

to replicate. The Replicate Device dialog box displays

and the selected device displays in the Replicate

Device list.

3. Select the number of copies that you want to create

using the Number of copies to be created selection field.

95-7769—01 18

To delete bindings:

1. Click Devices on the WebVision page. The Device

List page is displayed.

2. Click Device Binding. The Device Binding page is

displayed.

3. Select a pair of bounded devices that you want to delete

and click Delete. The bindings in WebVision are

deleted. You have to invoke download to delete the

bindings in the devices.

To download device bindings:

1. Click Devices on the WebVision page. The Device

List page is displayed.

2. Click Device Binding. The Device Binding page is

displayed.

Page 19

WEBVISION™

3. Click Download. The binding settings are downloaded

on the selected channel.

To upload device bindings:

1. Click Devices on the WebVision page. The Device

List page is displayed.

2. Click Device Binding. The Device Binding page is

displayed.

3. Click Upload. The binding settings are uploaded on the

selected channel.

Point List

Point Group

Point groups are used for monitoring and diagnostics of

controllers. You can create a maximum of fifty point groups in

WebVision and add a maximum of fifty points to each point

group.

To view point groups:

1. Click the Devices tab. The Device List page appears.

2. Click the Point List tab. The Point List page appears

with points present in the first point group.

3. The list of points is displayed with the following

information in tabular format:

• Point Name – Indicates the name of the point.

• Device Name – Indicates the name of the device.

• Channel – Indicates the channel being used.

• Value – Indicates the value of the point. If the point

is read only point, it appears as a label. If the point is

writable point, it appears in a text box/select box

with a Write button against it.

• Write – Click Write to write a point value on a

controller.

To add a point group:

1. Click the Devices tab. The Device List page appears.

2. Click the Points tab. The Point List page appears.

3. Click Add Point Group. The Add Point page is

displayed.

4. Type the name of the point group in the Point Group

Name field.

5. All the points in that group are listed in a tabular format.

Click Add Point to add a point. A point selection dialog

comes up. Select a point and click OK to add the point

to the group.

6. Repeat step 5 to add all the required points to the

group.

7. Select the required points that you want to delete from

the Point List page.

8. Click Delete Point. A confirmation message appears.

9. Click Save to save settings.

NOTE: Click Cancel to abort the action.

TIP: You can create a maximum of fifty point groups in

WebVision and add a maximum of fifty points to each

point group.

To edit a point group:

1. Select a name of the point group that you want to edit in

the Point Groups drop-down list.

2. Click Edit Point Group. The selected details of the

Point Group are displayed. Follow the procedure as

explained in step 4 of “To add a point group:” and make

the required changes.

To delete a point group:

1. Click the Devices tab. The Device List page appears.

2. Click the Points tab. The Point List page appears.

3. Click Add Point Group. The Add Point page is

displayed.

4. Select a name of the point group that you want to delete

in the Point Groups drop-down list.

5. Click Delete Point Group. A confirmation message

appears.

6. Click Yes to delete the selected points.

NOTE: Click No to abort the action.

Device Configuration

This section describes how to view and setup a device

graphic and describes the configuration options.

To view device graphic:

1. On the left corner of the screen, WebVision is listed.

Expand WebVision to view all the devices associated

with it.

2. Select a device from the list of devices in WebVision.

Click the corresponding link to view the properties of

that device.

3. Click the Graphics tab. The View Graphics page

appears.

4. You can view the graphic linked to that device. All other

parameters, for example, Air Flow, Setpoint, Space (as

configured for the device) also appear on the screen.

To setup a graphic:

1. Select a device from the list of devices in WebVision.

Click the corresponding link to view the properties of

that device.

2. Click the Graphics tab. The View Graphics page

appears. Click Setup Graphic. The Setup Graphics

page appears.

3. You can add up to 3 links to the default graphic. The

links can point to another graphic or to an external Web

Site.

Configuration

The following options can be used for all the above mentioned

devices:

• Import Application – Use this option to restore the backed

up configuration.

• Export Application – Use this option to download

configuration settings.

• Reset – Use this option to reset the configuration settings

to the last saved configuration settings.

• Back – Use this option for navigation.

• Next – Use this option for navigation.

19 95-7769—01

Page 20

WEBVISION™

• Save – Any change done in the UI is automatically saved

locally in the Web UI. To save the modified configuration in

the WebVision click Save. To write the saved data onto

device, use the Device Download option.

Set Points

NOTE: The Setpoints tab appears only for the supported

devices.

To set the setpoint for a device:

On the left corner of the screen, WebVision is listed. Expand

WebVision to view all the devices associated with it.

1. Select a device from the list of devices in WebVision.

Click the corresponding link to view the properties of

that device.

2. Click the SetPoints tab. The SetPoints page appears.

3. Select the following parameters:

• Permanent Set points:

• Occupied: Specify the Cooling SetPoints and

the Heating SetPoints.

• Standby: Specify the Cooling SetPoints and the

Heating SetPoints.

• Unoccupied: Specify the Cooling SetPoints and

the Heating SetPoints.

• Select the override duration, if any, using the

Override Duration for Setpoint and

Occupancy State drop-down list.

• Fan and System Switch:

• System Switch: Specify the system switch

mode: Heat, Auto, Cool, or Off.

• Fan Switch: Specify the fan switch mode: On or

Auto.

4. Click Save to save the settings.

Sensor Calibration

NOTE: The Sensor Calibration tab appears only for the

supported devices that have analog inputs.

This is a process of configuring the controller to correct error

in the value provided by the sensor.

To calibrate a sensor:

On the left corner of the screen, WebVision is listed. Expand

WebVision to view all the devices associated with it.

1. Select a device from the list of devices in WebVision.

Click the corresponding link to view the properties of

that device.

2. Click the Sensor Calibration tab. The Sensor

Calibration page appears. All the sensors associated

with the selected device are listed in the Sensor Name

list. The Actual Reading column lists the actual value

measured by the sensor.

3. Specify the correct value that the controller is supposed

to measure in Calibrated Value column. The difference

between the two values is displayed in Calibrated

offset column. The controller adds the calibrated offset

value to the measured value to correct the error.

4. Click Save to save the settings.

Balancing

This process helps the VAV devices to calibrate their flow

sensors for better air flow control.

NOTE: To perform balancing ensure that the VAV device is

online.

To view the Balancing page:

1. Click the Balancing tab. The Balancing page appears.

2. The following information is displayed in tabular format:

• Device Name: Name of the device

• Channel Name: Name of the channel on which the

device exists.

• Balanced On: Balancing status. It can be Balanced

or Not Balanced.

NOTE: Use Filters to quickly search the required device.

Use one of the following filter options to search for the

required device:

• Device Name

• Device Type

• Is Balanced

NOTE: To quickly search the devices, type the first letter of

the required filter criteria in the Keyword text box

and type an asterisk (*). This lists all the names

starting with the first letter that you have written in the

Keyword text box.

To view Balancing details:

1. Click the Balancing tab to display the Balancing page.

2. Select a device from the list and click Balance to

display the balancing details of the selected device.

3. View/Edit the following details:

• Device Name: Name of the VAV device which is

selected for balancing.

• Damper Position: Displays the position of the

damper. This field is non-editable. The damper

position varies to attain stable air flow.

• Sensed Airflow: Displays the actual air flow that is

measured by a pressure sensor connected to the

VAV device. This field is non-editable.

• Max Airflow Setpoint: This allows you to set the

maximum airflow setpoint. The field is enabled by

default. Enter the maximum airflow setpoint value,

use Change max setpoint to write the maximum

airflow setpoint to the device.

• Start Max Balance: Click on this button to balance

the device for the maximum air flow setpoint.

• Min Airflow Setpoint: This allows you to set the

minimum air flow setpoint value which must be less

than the maximum value. The field is enabled by

default. It allows you to set the minimum airflow

setpoint value, use Change min setpoint to write

the minimum airflow setpoint to the device.

• Start Min Balance: Click on this button to balance

the device for the minimum air flow setpoint.

• Zero Airflow Setpoint: By default 0 is the setpoint

value and you cannot edit this field.

• Start Zero Balance: Click on this button to balance

the device for the zero air flow setpoint.

4. Click Save to save the settings.

95-7769—01 20

Page 21

WEBVISION™

To perform Min/Max Balancing:

Complete the following procedure to do min/max balancing.

NOTE: To do min/max balancing ensure that the VAV device

is online.

1. Damper position and Sensed airflow displays the

current damper position and flow sensed by the device.

2. Click the Start Zero Balance to attain the zero flow

setpoint. Job progress status is shown at the bottom of

the page, once the setpoint is attained, confirmation

message is displayed.

3. Once the Zero airflow setpoints is attained, flow sensed

by the device is displayed. Update the actual flow

sensed in the Measured Airflow field and click Apply

Measured Flow.

4. Enter Max Airflow Setpoint value and click Change

Max Setpoint to write the value to the device.

5. Click Start Max Balance to attain the maximum airflow

setpoint. Job progress status of maximum balancing is

shown at the bottom of the page, once the setpoint is

attained, confirmation message is displayed.

6. Update the actual flow sensed in the Measured Airflow

field and click Apply Measured Flow.

7. Enter Min Airflow Setpoint value and click Change

Min Setpoint to write the value to the device.

8. Click Start Min Balance to attain the minimum airflow

setpoint. Job progress status of minimum balancing is

shown at the bottom of the page, once the setpoint is

attained, confirmation message is displayed.

9. Once the balancing is completed, Click Done to set the

device back to Auto mode and go to the balancing

summary screen.

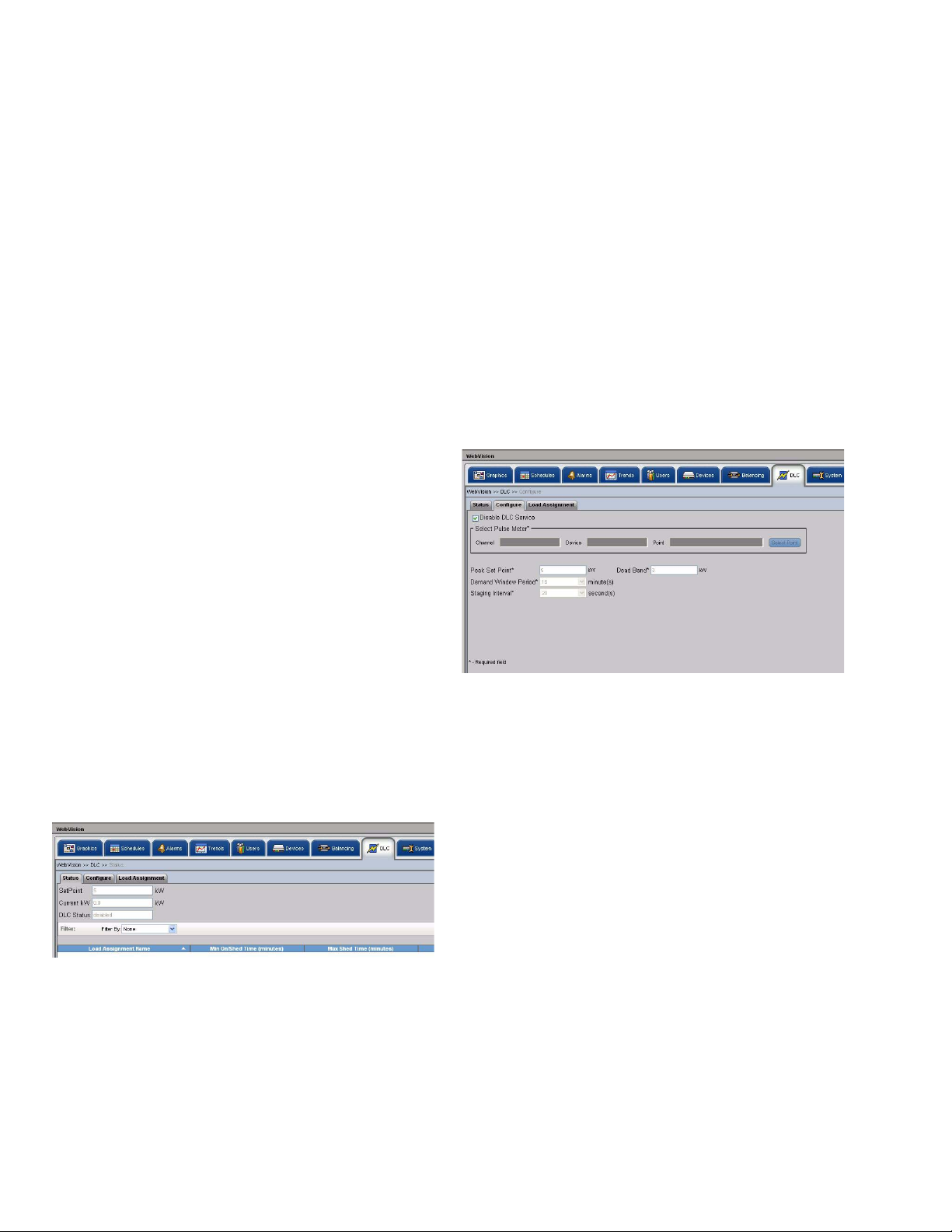

Demand Limit Control (DLC)

Demand Limit Control (DLC) continuously monitors the

building's rate of energy consumption. It automatically sheds

or restores loads to prevent the demand (load) from

exceeding the maximum allowable level or configured

setpoint. It is based on the building's power requirements and

operating characteristics. For DLC to have control over

energy savings, the configured setpoint must be less than the

actual demand allocated by the power generating plant. DLC

sheds or adjusts the loads during peak usages only. DLC is

driven from the current KW demand, which is an

instantaneous value averaged over a period of time (demand

averaging window period). It is a good practice to adjust the

DLC window close to the utility company's demand window

period. This in turn will help WebVision to follow the same

criteria as that of the utility company when taking KW demand

shed decisions. The energy history log must also match the

peak demand recorded by the utility company.

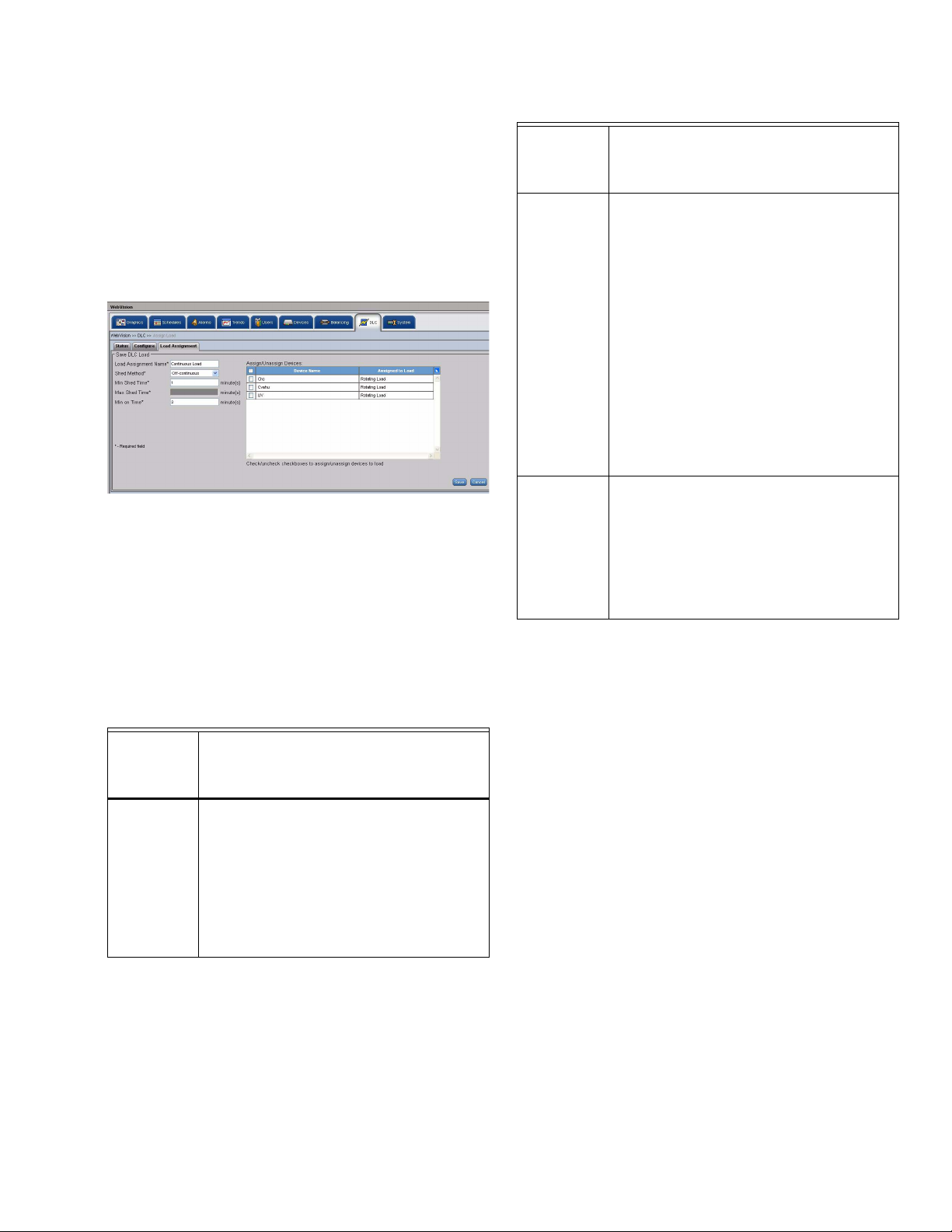

Load Assignments

Each device is considered to be an external object when

assigning it to a load. A load consists of a local configuration

that defines the behavior of the load and its association with

an object or a set of objects. These objects are discovered

Excel 10 or Excel 15C devices, which in turn control the

external electrical loads. All the objects associated under one

load assignment are shed at once, restored at once and

overwritten at once depending on the configuration of the load

assignment. Each load assignment is identified by a load

assignment number ranging from 1 to 50.

The following are the two types of loads that DLC sheds to

maintain demand below the peak setpoint:

Off Continuous Loads

Off Continuous loads are the first loads that are shed by DLC.

Once shed, they are not restored immediately. Loads marked

as Off Continuous generally control the loads that are least

important to overall operation of the facility. When KW

demand exceeds the peak setpoint, Off Continuous loads are

shed first starting from the lowest numbered load (1) to the