Honeywell 900R12R-0200, 900R04-0200, 900CP1-0200, 900R08R-0200, 900SP1-0200 Getting Started

...Page 1

ControlEdge PLC and ControlEdge RTU

Getting Started

RTDOC-X287-en-152A

April 2019

Release 152

ControlEdge PLC

ControlEdge RTU

Page 2

DISCLAIMER

This document contains Honeywell proprietary information.

Information contained herein is to be used solely for the purpose

submitted, and no part of this document or its contents shall be

reproduced, published, or disclosed to a third party without the

express permission of Honeywell International Sàrl.

While this information is presented in good faith and believed to be

accurate, Honeywell disclaims the implied warranties of

merchantability and fitness for a purpose and makes no express

warranties except as may be stated in its written agreement with and

for its customer.

In no event is Honeywell liable to anyone for any direct, special, or

consequential damages. The information and specifications in this

document are subject to change without notice.

Copyright 2019 - Honeywell International Sàrl

2

Page 3

CONTENTS

Contents 3

Chapter 1 - About this guide 7

Chapter 2 - Overview 11

Chapter 3 - Hardware 15

ControlEdge 900 platform 15

Hardware components 16

Installing the assembly 24

Wiring and cabling 25

I/O network Topology 27

Power on 31

Contents

ControlEdge 2020 platform 31

Hardware components 32

Installing the assembly 37

Wiring and cabling 37

I/O network topology 39

Power on 39

Chapter 4 - Software 41

Installing ControlEdge Builder 41

Launching ControlEdge Builder 41

Checking firmware versions 42

Creating a project 42

Configuring hardware 44

Setting controller name 44

Configuring the controller IP address 44

Configuring controller start up 45

3

Page 4

Contents

Configuring controller redundancy 46

Configuring an I/O module 47

Configuring serial modules 49

Configuring a controller simulator 52

Programming with IEC 61131-3 58

Adding a library 58

Creating a data type 58

Creating a variable 61

Creating a Programming Organization Unit 62

Associating a program to a task 64

Compiling a project 65

Chapter 5 - Operating 67

Connecting a controller 67

Downloading a project to the controller 68

Configuring date/time 69

Setting time source 69

Setting time zone 70

Upgrading firmware 70

Upgrading firmware for a non-redundant controller 71

Upgrading firmware for a redundant controller 72

Upgrading EPM firmware 75

Upgrading ControlEdge 900 I/O module firmware 76

Upgrading serial module firmware 77

Upgrading ControlEdge 2020 Expansion I/O firmware 78

Upgrading the FDAP and field device firmware via Wireless 79

Upgrading the field device firmware 79

Upgrading the FDAP firmware 81

Uploading a project 82

4

Page 5

Contents

Chapter 6 - Communication 83

Configuring Modbus 83

Configuring a Modbus Slave 83

Configuring a Modbus TCP Master 84

Configuring a Modbus Serial Master 86

Configuring EtherNet/IP devices 92

Configuring OPC UA 94

Configuring an OPC UA Server 94

Configuring an OPC UA Client 97

Communicating with Experion via OPC UA 99

Configuring an OPC UA server 99

Publishing to Experion 100

Configuring DNP3 Slave 100

Communicating with Experion via DNP3 102

Configuring a DNP3 slave 102

Publishing to Experion 102

Configuring HART 103

Configuring a HART-IP Server 103

Configuring a HART Function Block 104

Configuring CDA 106

Installing ControlEdge integration service 107

Configuring a CDA Responder 108

Publishing to Experion 110

Configuring Wireless I/O 111

Configuring User Defined protocol 113

Chapter 7 - Application 115

FDM integration 115

Getting started with FDM 115

5

Page 6

Contents

Updating the FDM license 115

Configuring FDM for ControlEdge PLC/RTU network 116

Building networks 118

Chapter 8 - Security 119

Logon feature 119

Setting operating modes 119

Built-in Firewall 122

Configuring IPsec 122

Notices 124

6

Page 7

CHAPTER

ABOUT THIS GUIDE

1

Revision history

Revision Date Description

A April 2019 Initial release of this document

Intended audience

This documentation allows the following audience to quickly startup

ControlEdge PLC and ControlEdge RTU system: Users who plan,

install, configure, or operate ControlEdge PLC and ControlEdge RTU

running the eCLR (IEC 61131-3) execution environment.

Prerequisite skills

Knowledge of SCADA systems and experience of working in a

Microsoft Windows environment are required.

Introduction to ControlEdge Technology

Item Description

ControlEdge

PLC

ControlEdge

RTU

ControlEdge

UOC

ControlEdge 900 controllers running the eCLR (IEC 61131-3) execution

environment with PLC software options configured with ControlEdge

Builder.

ControlEdge 2020 controllers running the eCLR (IEC 61131-3)

execution environment with RTU software options configured with

ControlEdge Builder.

ControlEdge 900 controllers running the Honeywell control execution

environment (CEE) configured with Experion Control Builder.

Special terms

The following table describes some commonly used industry-wide

and Honeywell-specific terminology:

7

Page 8

Chapter 1 - About this guide

Terminology Description

ACE Application Control Environment

Adapter A communication device which connects to the EtherNet/IP network to

serve data from a set of devices or modules underneath it. Adapter

typically supports I/O connectivity from Scanners via implicit

EtherNet/IP connections.

Assembly A set of data passed between a Originator and a Target after an implicit

I/O connection has been established on an EtherNet/IP network.

CDA Control Data Access

ControlEdge

Builder

A integrated configuration tool to design, configure, program and

maintain ControlEdge controllers.

CPM Control Processor Module

DTM Device Type Manager

EDS Electronic Data Sheet. A text file which specifies all the properties of an

EtherNet/IP device necessary for a Scanner module to communicate

with it. EDS files my be used in the first step of creating an I/O module

or device type for interfacing to an EtherNet/IP device.

EPM Expansion Processor Module

Expansion

I/O rack with EPM installed

I/O rack

Expansion

I/O Module (IOM) external to the CPM that expand the I/O capacity

IOM

FDAP Field Device Access Point

FDM Field Device Manager

FTE Fault Tolerant Ethernet

HMI Human Machine Interface

IOTA Input Output Termination Assembly

Left End

Plate

Left end plate is used only in multi-row 2020 I/O systems. It starts a new

row of IOMs and provides connections for 24Vdc supply to the row

along with I/O Network connections.

Local I/O

I/O rack with CPM installed (non-redundant)

rack

Mixed IOM Mixed input/output module, which supports DC current or voltage type

8

Page 9

Terminology Description

signals, such as analog input, analog output, digital input, digital output

and pulse input.

Chapter 1 - About this guide

Onboard

I/O Module (IOM) 'onboard' with the CPM

IOM

OPC UA An industrial machine-to-machine (M2M) communication protocol is

developed by the OPC Foundation, which provides a path forward from

the original OPC communications model (namely the Microsoft

Windows only process exchange COM/DCOM) to a cross-platform

service-oriented architecture (SOA) for process control, while enhancing

security and providing an information model.

Originator Originator is the controller that initiate any data exchange with

EtherNet/IP devices on the EtherNet/IP network.

PSM Power Status Module

PSU Power Supply Unit

Redundant

Rack installed redundant CPM

CPM Rack

Right End

Plate

A right end plate is required at the end of each row of expansion I/O

modules, including the row connected to a controller. It allows

additional rows to be added or terminates the I/O network.

RIUP Removal and Insertion Under Power

RPI Requested Packet Interval. The repetitive interval by which assemblies

are periodically transported over EtherNet/IP I/O connections between

Producer and Consumer.

RTU Remote Terminal Unit

SCADA Supervisory Control and Data Acquisition

Scanner A device which connects to the EtherNet/IP network to act as a client of

other EtherNet/IP connected devices. ControlEdge 900 Controller acts

as EtherNet/IP Scanner. It connects to and exchanges data with

Adapters of Modular IO stations, directly connected devices and

Rockwell AB ControLogix controllers.

SIM-300 Simulation for C300

SIM-ACE Simulation for ACE

Target Target is the EtherNet/IP device that address any data requests

9

Page 10

Chapter 1 - About this guide

Terminology Description

generated by the controller.

UIO Universal Input/Output Module

Related documents

The following list identifies publications that may contain information

relevant to the information in this document.

n ControlEdge Builder Software Installation User’s Guide

n ControlEdge Builder Software Change Notice

n ControlEdge Builder User’s Guide

n ControlEdge 900 Platform Hardware Planning and Installation

Guide

n ControlEdge Builder Function and Function Block Configuration

Reference

n ControlEdge Builder Protocol Configuration Reference Guide

n ControlEdge PLC and ControlEdge RTU Network and Security

Planning Guide

n ControlEdge EtherNet/IP User's Guide

n ControlEdge_PLC_Interface_Reference

n DNP3 Interface Reference

n FDM User's Guide

10

Page 11

CHAPTER

2

OVERVIEW

This document introduces an example for a redundant ControlEdge

900 controller connected with 4-slot, 8-slot and 12-slot expansion I/O

racks, and a redundant ControlEdge 2020 controller, to get you

quickly set up the hardware, connect and configure the controller

from ControlEdge Builder.

This document does not provide any detailed instructions. Please

refer to other related documents, and online helps embedded in

ControlEdge Builder for more information.

Make sure all the hardware modules used in the system are installed

with the right firmware version and the engineering station has the

latest ControlEdge Builder. You can find the firmware and software

updates on http://honeywellprocess.com with valid credentials.

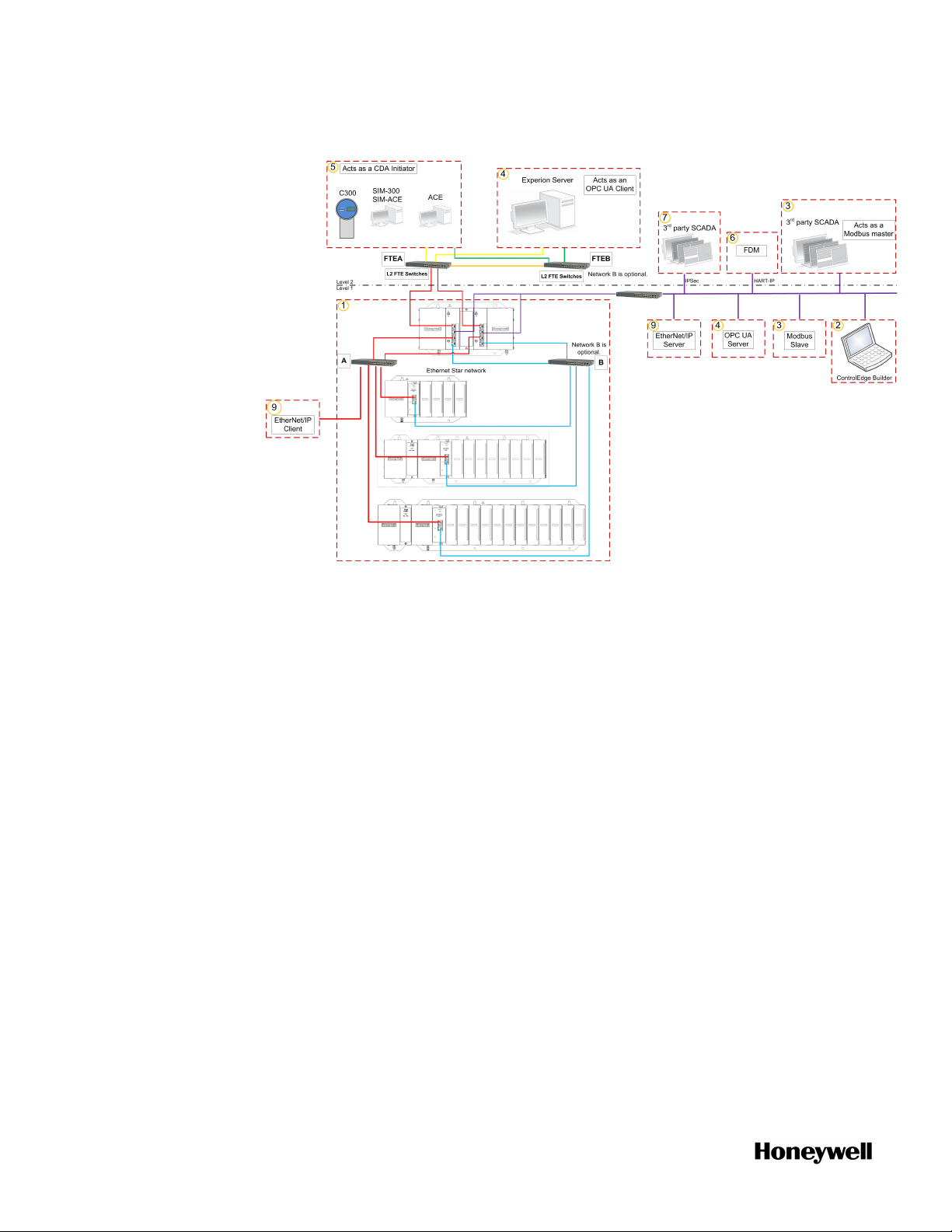

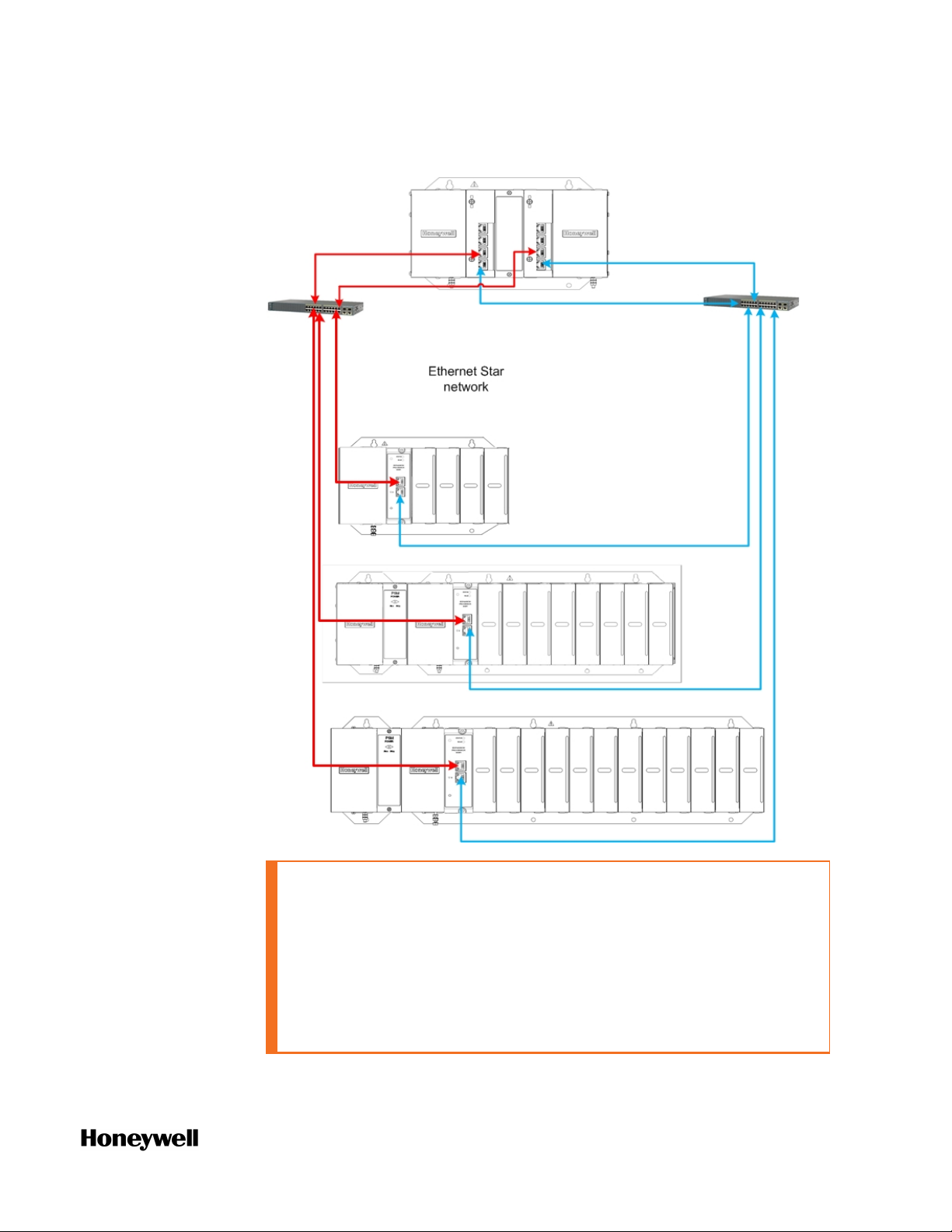

See the following example of system architectures for ControlEdge

PLC and ControlEdge RTU.

11

Page 12

Chapter 2 - Overview

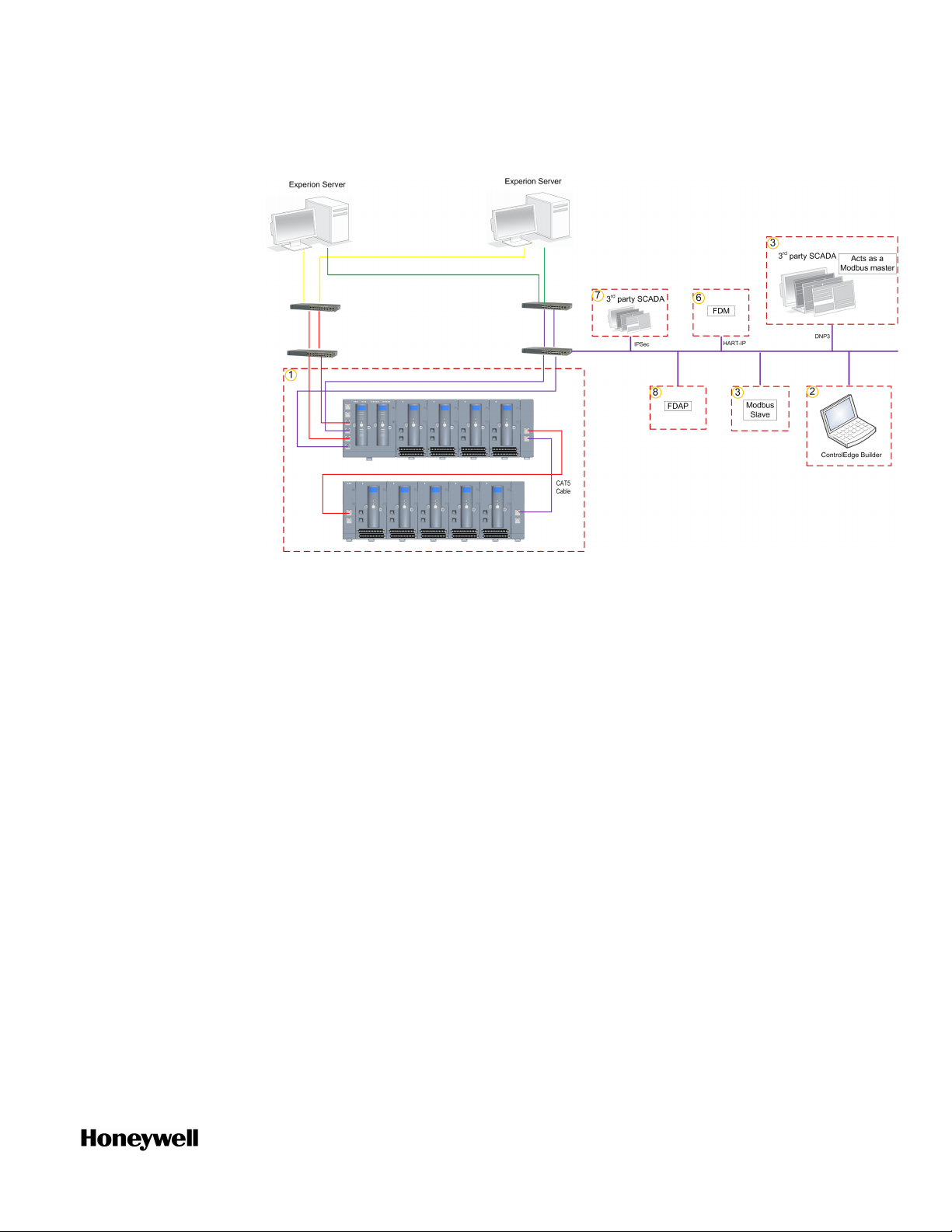

Figure 2-1: System architecture for ControlEdge PLC

ControlEdge PLC system has two network levels, while level 1 network

is used for internal I/O communication between CPM and related

IOMs, and level 2 is aimed for the communication with the third party

devices, HMI, SCADA or Engineering Workstation.

On the level 1 network, CPMs and EPMs connect to a switch, this

network is the most critical network in the system as a failure or loss

of service on this network can result in loss of control. On the level 2

network, the Engineering Workstation, third party devices, HMI, and

SCADA connect to the switch at this level. A failure of this level

network may result in a loss of view of the process if HMI or SCADA is

employed. The two network levels must be isolated with each other.

ETH1/ETH2 ports are required to be protected using a firewall device

configured to prevent uncontrolled messages into the controller.

Built-in firewall is supported on CPM of ControlEdge PLC.

12

Page 13

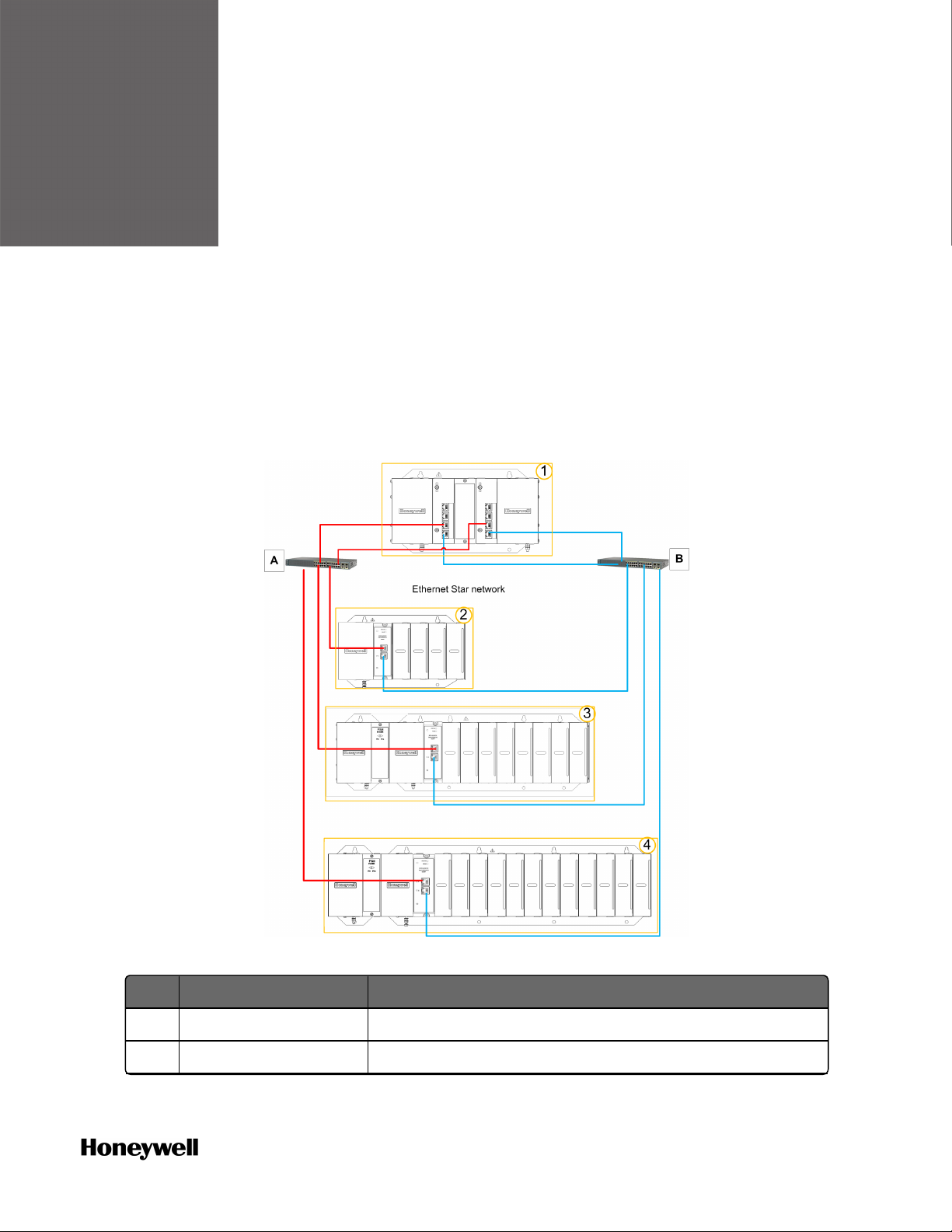

Figure 2-2: System architecture for ControlEdge RTU

Chapter 2 - Overview

ControlEdge 2020 system has two networks, I/O network is used for

internal I/O communication between CPM and Expansion IOMs,

control network is aimed for the communication with the third party

devices, HMI, SCADA or Engineering Workstation.

I/O network is the most critical network in the system as a failure or

loss of service on this network can result in loss of control.

At control network, Engineering Workstation, third party devices, HMI,

and SCADA connect to the switches. A failure of this level network may

result in a loss of view for operator of the process if HMI or SCADA is

employed.

The two networks must be isolated from each other.

13

Page 14

Chapter 2 - Overview

Item Go to...

1 See "Hardware" on page15 for more information.

2 See "Software" on page41 for more information.

3 See "Configuring Modbus " on page83 for more information.

4 See "Configuring OPC UA " on page94 for more information.

5 See "CDA Configuration" on page1 for more information.

6 See "FDM integration" on page115 for more information.

7 See "Security" on page119 for more information.

See the following table for the relevant configuration.

See "I/O network topologies" on page1 for more information.

See "Operating" on page67 for more information.

See "Modbus Slave Configuration" on page1 for more information.

8 See "Configuring Wireless I/O" on page111 for more information.

9 See "Configuring EtherNet/IP devices" on page92 for more

information.

14

Page 15

CHAPTER

HARDWARE

3

ControlEdge 900 platform

The Honeywell ControlEdge 900 family comprises a set of hardware

and software enabling users and OEMs to assemble a system that fits

a broad range of requirements. Any configuration can be readily

modified or expanded as requirements dictate.

ControlEdge PLC can be deployed standalone or with a SCADA

system such as Experion.

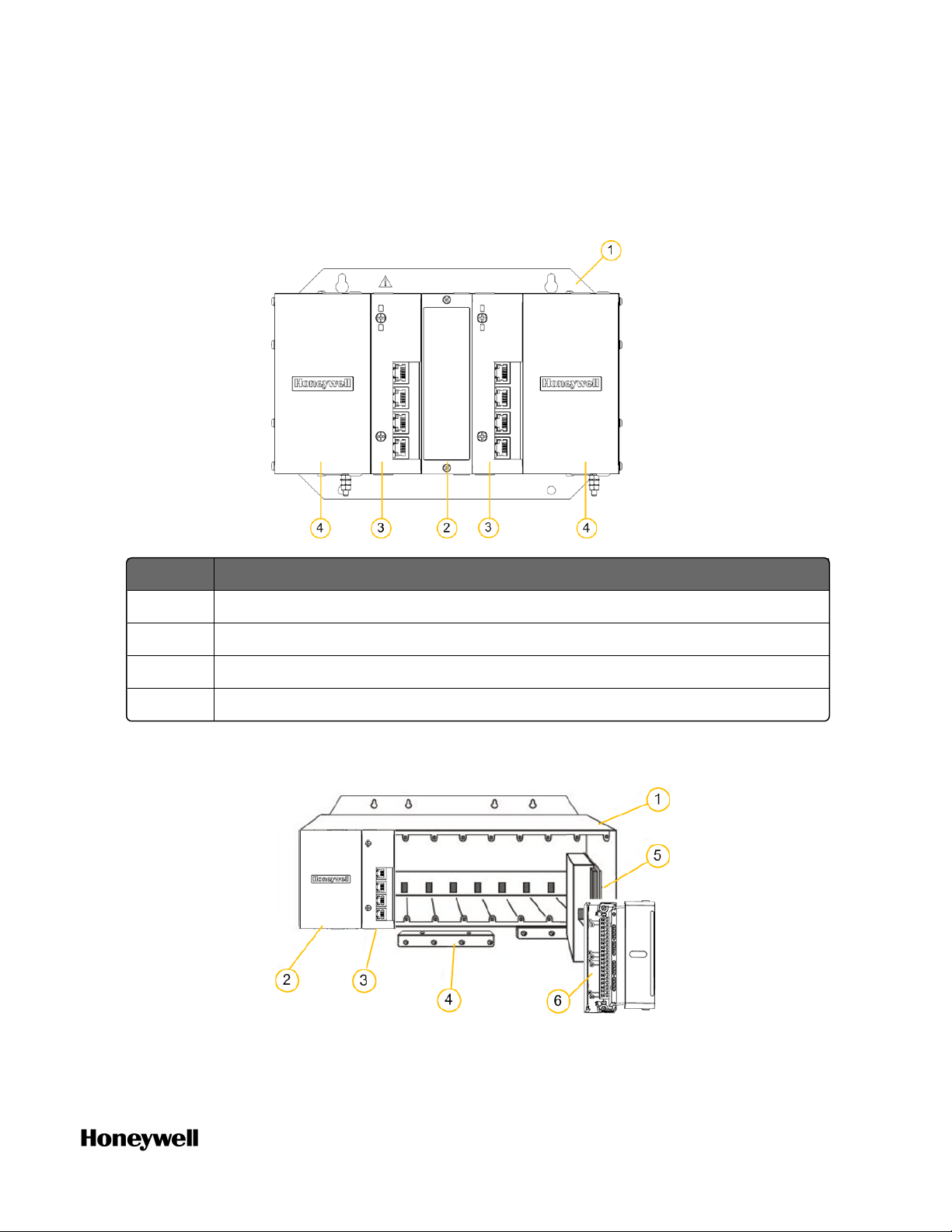

Item Model number Description

1 900RR0-0200 Redundant CPM Rack

2 900R04-0200 I/O Rack (4-slot)

15

Page 16

Chapter 3 - Hardware

Item Model number Description

3 900R08R-0200 I/O Rack (8-slot) can include either a redundant power

4 900R12R-0200 I/O Rack (12-slot) can include either a redundant power

supply or non-redundant power supply. A Power Status

Module (PSM) is required with redundant power

supplies.

The diagram shows the rack with a redundant power

supply.

The model number of the rack with a non-redundant

power supply is 900R08-0200.

supply or non-redundant power supply. A Power Status

Module (PSM) is required with redundant power

supplies.

The diagram shows the rack with a redundant power

supply.

The model number of the rack with a non-redundant

power supply is 900R12-0200.

Hardware components

This section provides a description of the major components that can

be included in a ControlEdge 900 Controller physical configuration

and indicates how the components can be combined. Some of the

components are required in all configuration. Others are optional and

can be used to provide additional functions, or to "size" the system, or

to modify or expand the system to meet changing requirements.

Rack

There are two types of racks:

n Redundant CPM Rack

Rack installed redundant CPMs

n I/O Rack, containing 4, 8 or 12 slots

I/O racks can include a topology with; either a non-redundant

power supply or with redundant power supplies, accommodate a

CPM or an EPM, and additional input/output modules. The I/O

rack inserted with an EPM enables I/O modules to be located

close to the field devices and remote from the CPM.

16

Page 17

Chapter 3 - Hardware

Slot number from left to right is 1~n, and n stands for the quantity of

the slots.

Figure 3-1: Redundant CPM Rack Components

Item Description

1 Redundant CPM rack

2 Redundant Switchover Module Slot Filler

3 Primary/Secondary CPMs

4 Two Power Supplies

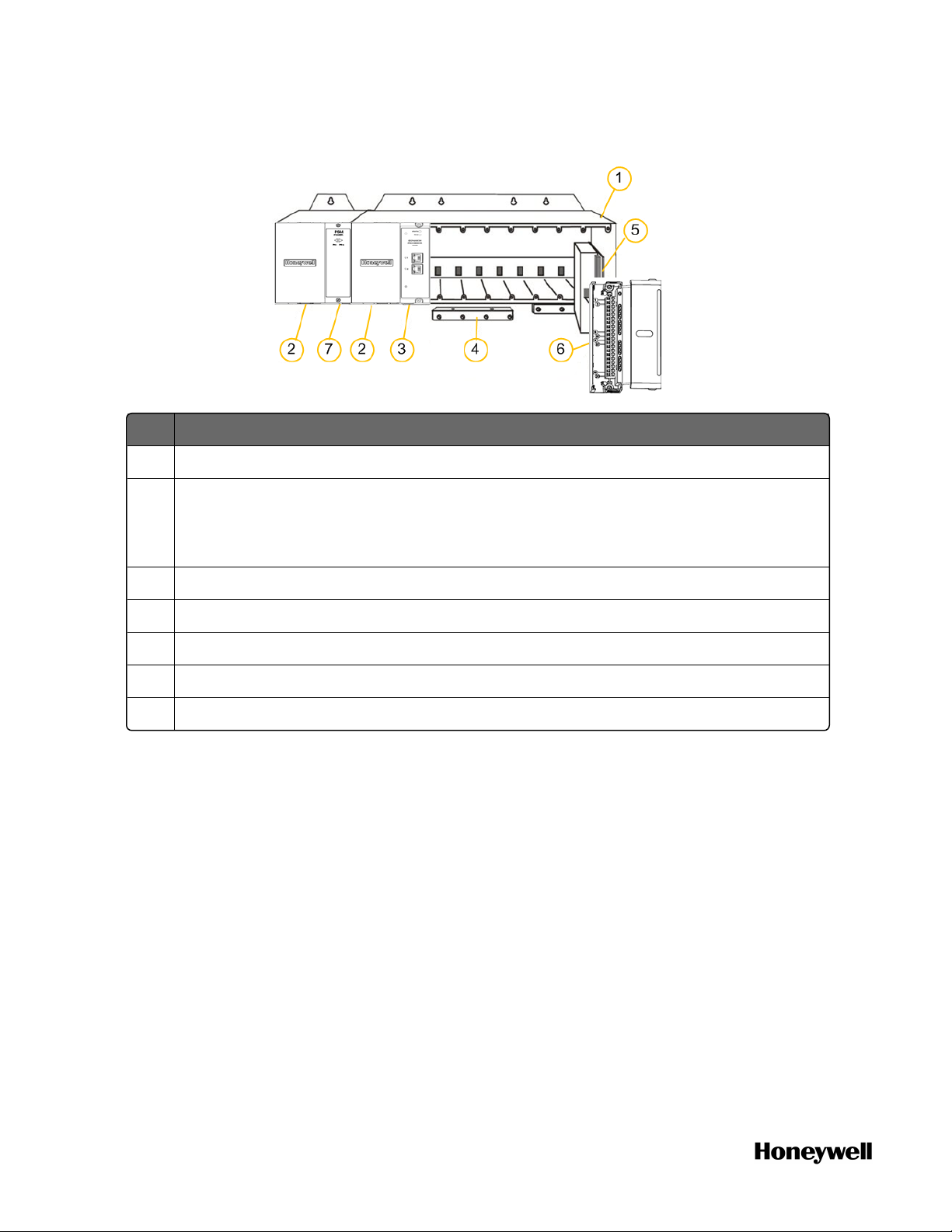

Figure 3-2: I/O rack with non-redundant power supply

17

Page 18

Chapter 3 - Hardware

Item Description

1 Rack, available in 4-, 8- or 12-slot versions

2 Power Supply

Figure 3-3: I/O rack with redundant power supplies

Redundant power supply is optional and only available in 8- or 12-slot racks.

You can only install one power supply in either of the two slots.

3 CPM or EPM with Security Cover

4 Grounding bars (for I/O wiring; optional; required for safety applications)

5 Input/Output modules

6 I/O Terminal Blocks

7 Power Status Module (PSM) (required if using redundant power supply)

Control Processor Module (CPM)

CPM (900CP1-0200) contains most of the electronics required to

perform the function of a process controller. A redundant CPM rack

contains two CPMs. Either CPM can be primary.

The CPM is shown in the following figure.

18

Page 19

Chapter 3 - Hardware

Item Description

1 Status LED indicator for the CPM.

2 Role LED indicator for the CPM.

3 SD card slot: supports 32GB Class 6 / Class 10 industry standard, not hot-

swappable, maximum weight 3g (0.0066 lb, 0.1058 oz)

An SD card can be inserted and used to reset the controller to factory settings, or

save datalog or DNP3 event.

CAUTION: Do not insert or remove the SD card when the CPM is powered

unless the area is known to be non-hazardous.

4 Mode switch.

There are four mode switch positions on CPM: STOP, RUN, and two REMOTE

positions. Two REMOTE positions are identical.

Rotate the four positions in clockwise or counter-clockwise. When the mode

switch is in REMOTE position, the operating modes can be configured in the

Configuration tool. For more information for the operating modes, see “Selecting

operating modes” in ControlEdge Builder User’s Guide.

ATTENTION: For redundant controller system, the position of mode

switch in primary CPM determines the system operating mode. If the

19

Page 20

Chapter 3 - Hardware

Item Description

mode switches on the primary and secondary CPMs are in different

positions, the system will drop sync.

5 First (ETH1) and second Ethernet (ETH2) Host ports to PC applications and/or

other CPMs, or other devices.

6 Third (ETH3) and fourth (ETH4) ports connect to the Ethernet ports of EPM,

switch (for star topology), or CPM (for the interconnection between redundant

CPM in Ring topology).

7 Ethernet LED status indicators for communications functions.

Expansion Processor Module (EPM)

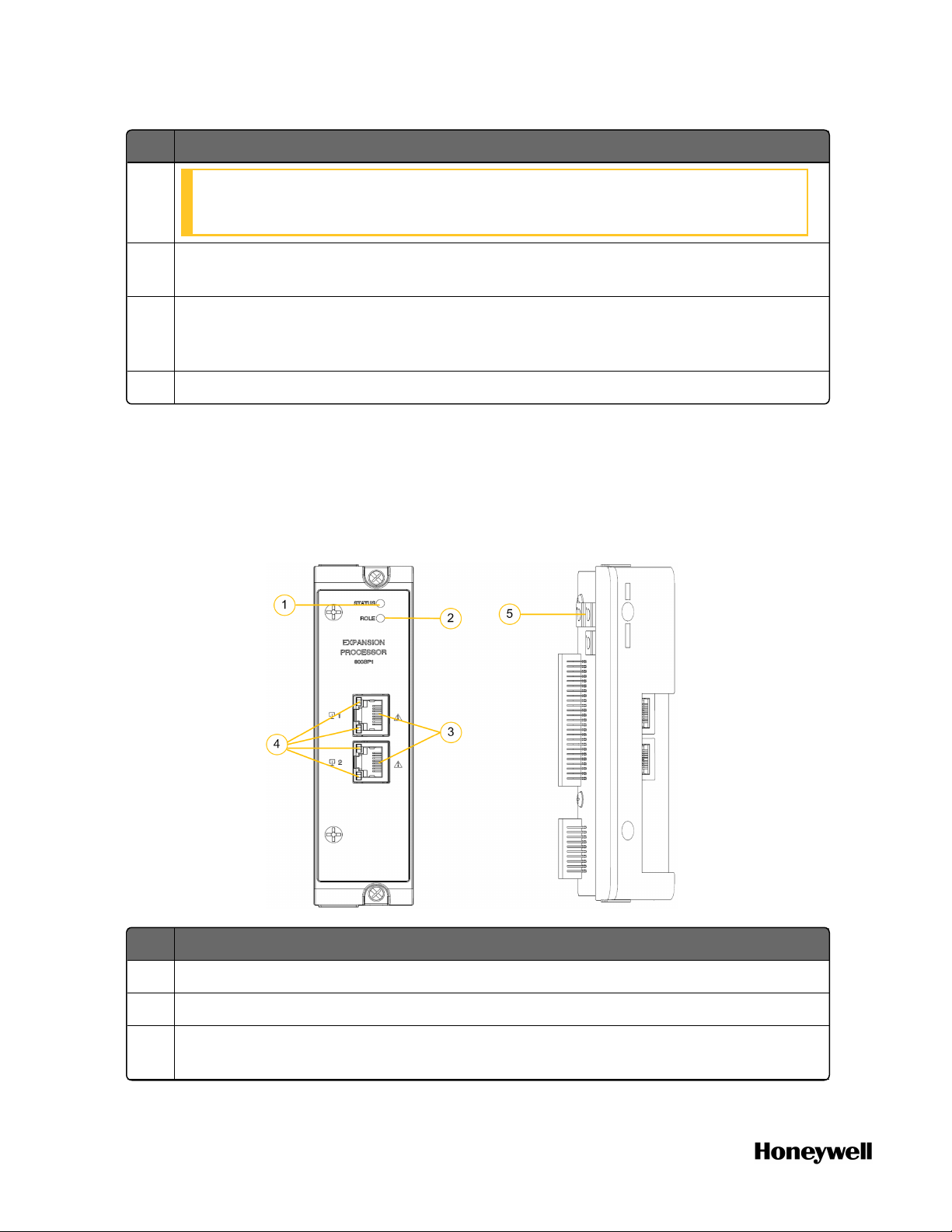

EPM (900SP1-0200) is installed in the expansion I/O rack and

provides the link between the CPM and remote I/O modules.

The EPM is shown in the following figure.

Item Description

1 Status LED indicator for EPM functions.

20

2 Role LED indicator for EPM functions.

3 Ethernet 10/100 Base-T Ports; connect to the ports on other EPMs, CPM, or a

switch that connects to the CPM (for star topology).

Page 21

Item Description

4 Ethernet LED status indicators for communications functions.

Chapter 3 - Hardware

5

Rotary switch: used to set the EPM address and network topology for the I/O

rack.

Set the 10x and 1x switches to the two digit address ranging from 01 to 99. The

lower switch (10x) is used to set the tens digit and the upper switch (1x) sets the

ones digit. A small slotted screwdriver works well; avoid pencils.

Set the network topology using the 100x switch. 3 is for Ring network topology

and 4 is for Star network topology.

Input/Output module

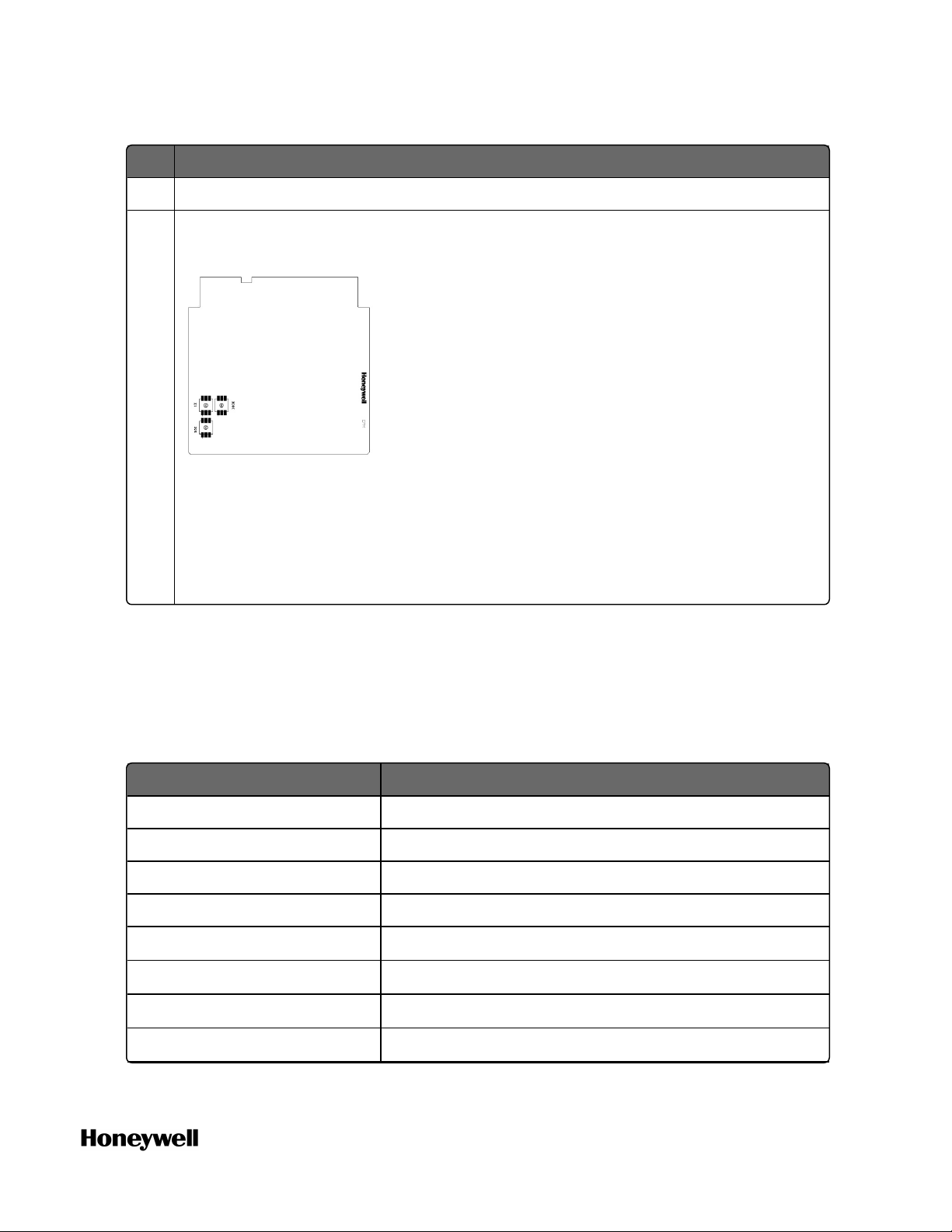

ControlEdge PLC supports the following I/O modules.

For more information, see "I/O module specification" in the

ControlEdge 900 Platform Hardware Planning and Installation Guide.

Model number I/O module

900U01-0100 Universal Input/Output Module (UIO)

900A01-0202 Universal Analog Input Module (UAI)

900A16-0103 High Level Analog Input Module (16 channels)

900B01-0301 Analog Output Module (4 channels)

900G03-0202 Digital Input Module (16 channels) - AC Voltage Type

900G32-0101 Digital Input Module (32 channels) - DC Voltage Type

900G01-0202 Digital Input Module - Contact Type (16 channels)

900H03-0202 Digital Output Module (8 channels) - AC Voltage Type

21

Page 22

Chapter 3 - Hardware

Model number I/O module

900H32-0102 Digital Output Module (32 channels) - DC Voltage

900H01-0202 Relay Output Module (8 channels)

900K01-0201 Pulse Input/Frequency Input Module (4 channels)

Type

Power supply

Both AC power supply (900P01-0301) and DC power supply (900P24-

0301) can be used in Redundant CPM rack, Local I/O rack and

Expansion I/O rack.

For more information, see "Power supply" in the ControlEdge 900

Platform Hardware Planning and Installation Guide.

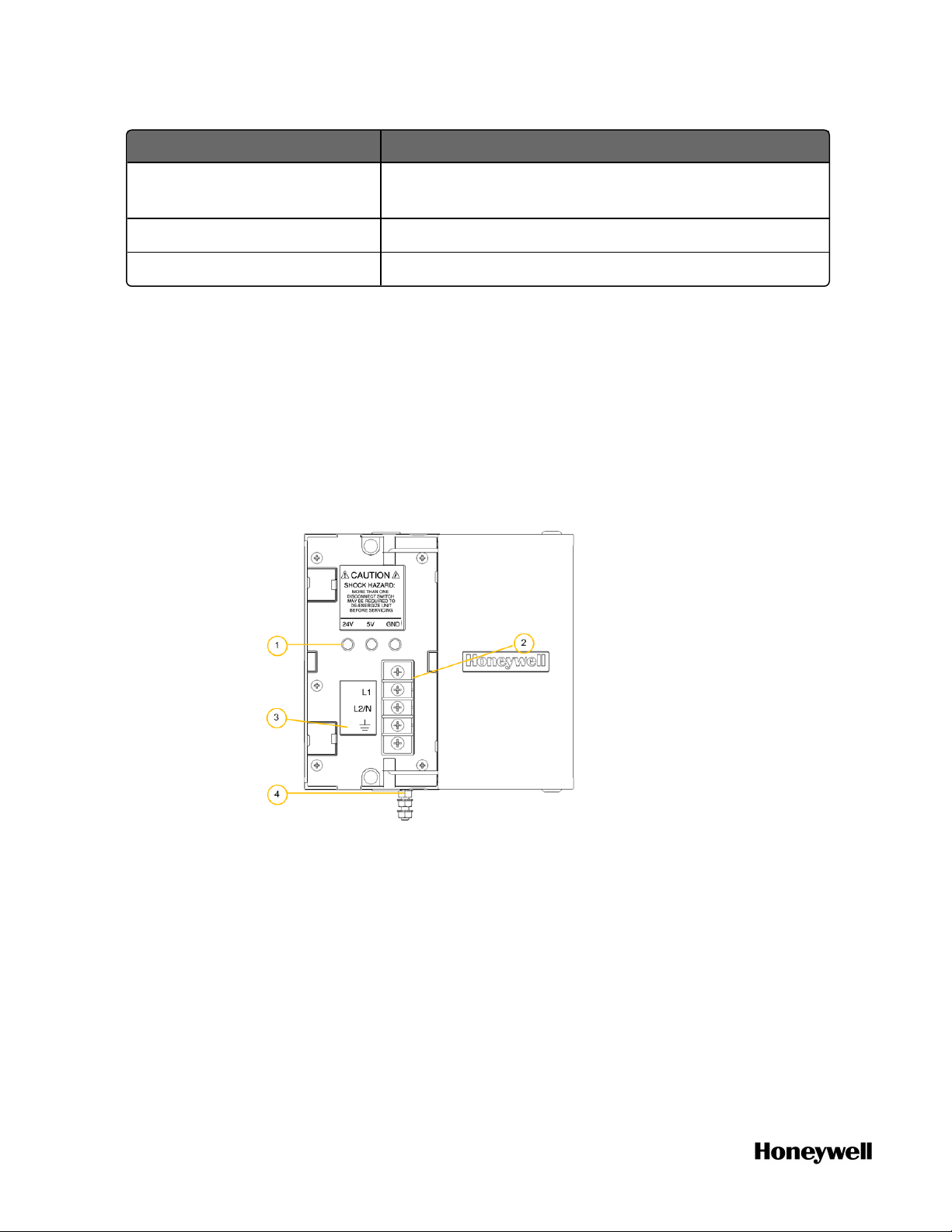

Figure 3-4: AC Power Supply

22

Page 23

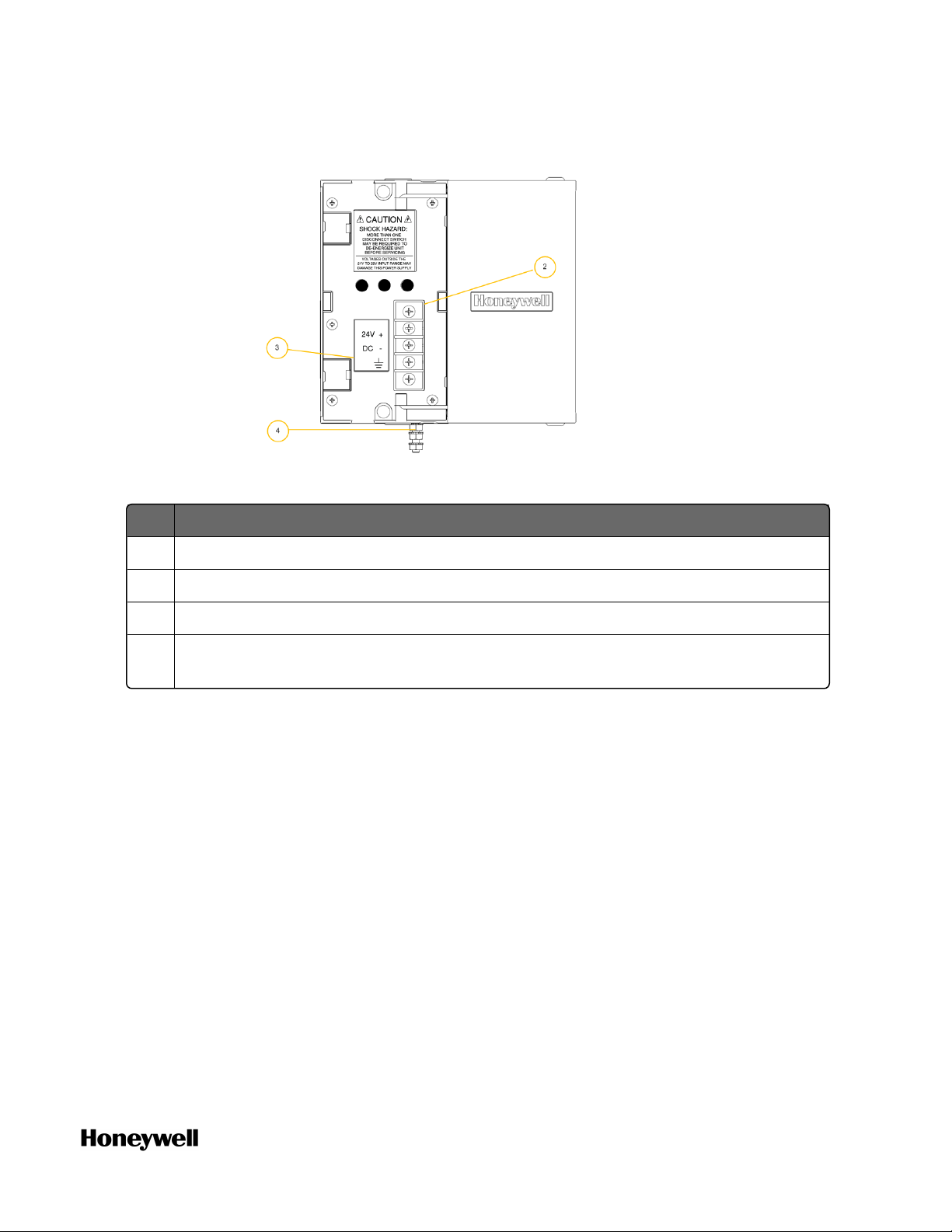

Figure 3-5: DC Power Supply

As indicated in the figures, the power supplies include:

Chapter 3 - Hardware

Item Description

1 Voltage test points

2 AC/DC Input terminal block

3 Wiring label

4 Grounding lug (Reference; lug is not part of power supply; it is mounted to

bottom of rack.)

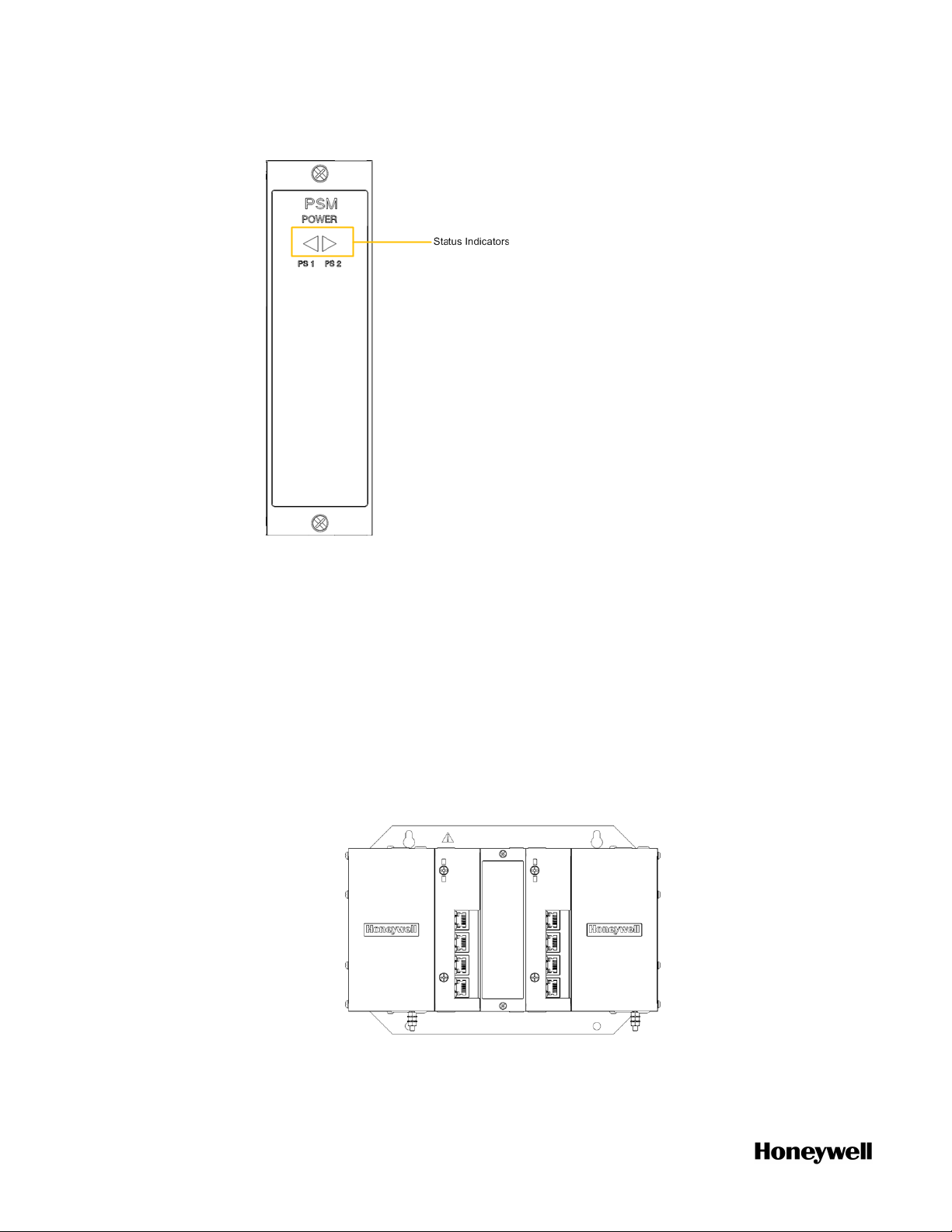

Power Status Module (PSM)

The PSM (900PSM-0200), shown in the following figure, sits between

redundant power supplies on the I/O rack. It is a status module for

both power supplies and indicates which are powered, PS-1 (left) or

PS-2 (right) or both (typical).

When the status indicator for either or both of the power supplies is

lit, it is reporting that the status of the associated power supply is

good and that the outputs are within specified limits. When the status

is off, either the power supply is off or the voltages are out of

tolerance.

23

Page 24

Chapter 3 - Hardware

Figure 3-6: Power Status Module

Installing the assembly

This section introduces you to mount the assembly.

1. Mount the rack in the enclosure.

2. Check if your configuration needs a redundant controller.

l If yes, assemble the redundant CPM rack.

a. Insert the power supplies in the slots in the rack.

b. Insert the CPMs in the rack, adjacent to the power supplies.

c. Insert the filler block cover in the middle slot.

24

l If no, assemble I/O racks, take the 8-slot I/O rack as an

Page 25

Chapter 3 - Hardware

example.

a. Insert the power supply.

b. Insert the PSM between the two power supplies.

c. If a CPM will be inserted, set the mode switch for CPM

optionally.

d. If a EPM will be inserted, set the EPM address and network

topology for the I/O rack using the rotary switch.

e. Insert CPM or EPM as required.

3. Install I/O modules.

ATTENTION: For each configured and labeled I/O module,

ONLY break off the "key-tabs" in the pattern that matches

that module type. For more information, see "Installing I/O

modules" in the ControlEdge 900 Platform Hardware

Planning and Installation Guide.

Wiring and cabling

Terminal Block Wiring can be routed through the terminal block at

the top, at the bottom, or both. Wiring should be fixed in place using

wire ties at the slotted tabs that are molded in at top and bottom of

each terminal block. The terminal block is removable.

The optional Remote Termination Panel (RTP) provides an easy way to

connect the ControlEdge 900 Controller to the field wiring. The RTP

integrates some of the typical externally connected components,

reducing wiring and setup time. It also minimizes the need for

multiple wires under a single screw connection by expanding the

connectivity of the shared terminals of the I/O modules.

25

Page 26

Chapter 3 - Hardware

Routing and securing wires

Typically, field wiring is routed to connections at a terminal panel near

the racks, and then from the terminal panel to the terminal blocks on

the I/O modules.

Whatever method of routing is used, wiring must be mechanically

supported along its length, and must be protected from physical

damage and electromagnetic (noise) interference.

ATTENTION: All wires must be securely terminated, using

appropriate wiring practices.

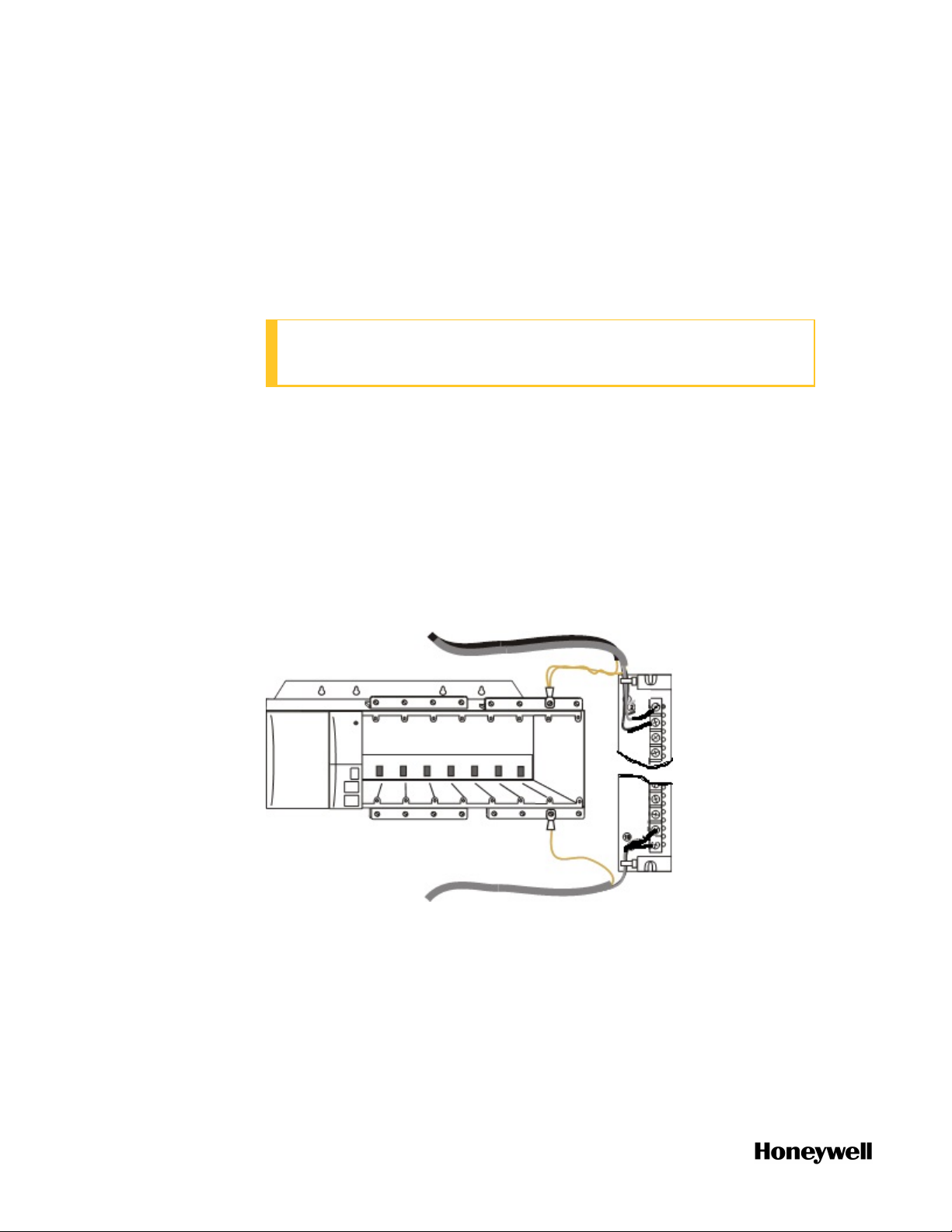

Wire shield grounding

Aluminum grounding bars for I/O wiring are available as options.

When selected for use, they are fastened to the top and/or bottom of

each rack, as indicated in the following figure. To enable connection

of multiple ground wires with a single screw, the wires can be twisted

together and secured with a wire lug.

Figure 3-7: Wire-Shield Grounding

To facilitate module replacement, it is advisable in most cases to route

all wiring through either the top or the bottom of the terminal block.

This allows the terminal block to pivot up or down, allowing ready

access to the module, and is the preferred method for a limited

number of wires.

26

Page 27

Chapter 3 - Hardware

For more information about each I/O module wiring, see "Terminal

Block-to-Field (Signal) Wiring" in the ControlEdge 900 Platform

Hardware Planning and Installation Guide.

I/O network Topology

ControlEdge PLC can be configured as a redundant controller system

or non-redundant controller system. It includes provisions for

communication via Ethernet with host systems and the Ethernet ports

provide a layer of protection against cyberattacks. Honeywell

recommends use of Solarwinds and/or Honeywell Risk Manager to

detect unintended and excess network traffic.

ControlEdge PLC supports star and ring I/O topologies for I/O

communication.

Star Topology

The following diagram shows an example of the star topology. A

switch is required for this topology.

27

Page 28

Chapter 3 - Hardware

Figure 3-8: Single star topology

28

Page 29

Figure 3-9: Redundant Star topology

Chapter 3 - Hardware

CAUTION: ControlEdge PLC-I/O network is a private network, and

the switch used for the interconnection of CPM and EPM must

not be connected to any other LAN or WAN. Likewise, no devices

or communication traffic other than the ControlEdge PLC

components should be connected to the I/O network switch.

Failure to comply will cause communication failures on the I/O

network causing I/O modules to go in and out of their failsafe

settings.

29

Page 30

Chapter 3 - Hardware

Ring Topology

The following diagram shows an example of the ring topology.

30

n CPM port 3 (ETH3) must be connected to CPM port 4 (ETH4) or

EPM port 2 (ETH2).

n CPM port 4 (ETH4) must be connected to CPM port 3 (ETH3) or

EPM port 1 (ETH1).

n EPM port 1 (ETH1) must be connected to EPM port 2 (ETH2) or

CPM port 4 (EHT4).

n EPM port 2 (ETH2) must be connected to EPM port 1 (ETH1) or

CPM port 3 (EHT3).

For more information, see “Planning for network topology” in the

ControlEdge 900 Controller Hardware Planning and Installation Guide.

Page 31

Chapter 3 - Hardware

Power on

Both AC power supply and DC power supply can be used in

ControlEdge PLC.

1. Connect 24 VDC supply or 120/240 VAC power supply to the

controller.

2. Connect an Ethernet cable to the CPM port most appropriate for

your situation.

3. Connect the other end of the Ethernet cable to the PC installed

ControlEdge Builder directly or through a switch.

ControlEdge 2020 platform

The Honeywell ControlEdge 2020 process controller is a modular,

powerful, and scalable system capable of all remote automation and

control applications. When combined with Experion® PKS and its

simplified SCADA configuration, it solves the remote automation

requirements.

ControlEdge RTU supports controller redundancy, Honeywell wired

and wireless I/O and enhanced Experion SCADA integration.

See the following figure for reference as a redundant controller

system.

31

Page 32

Chapter 3 - Hardware

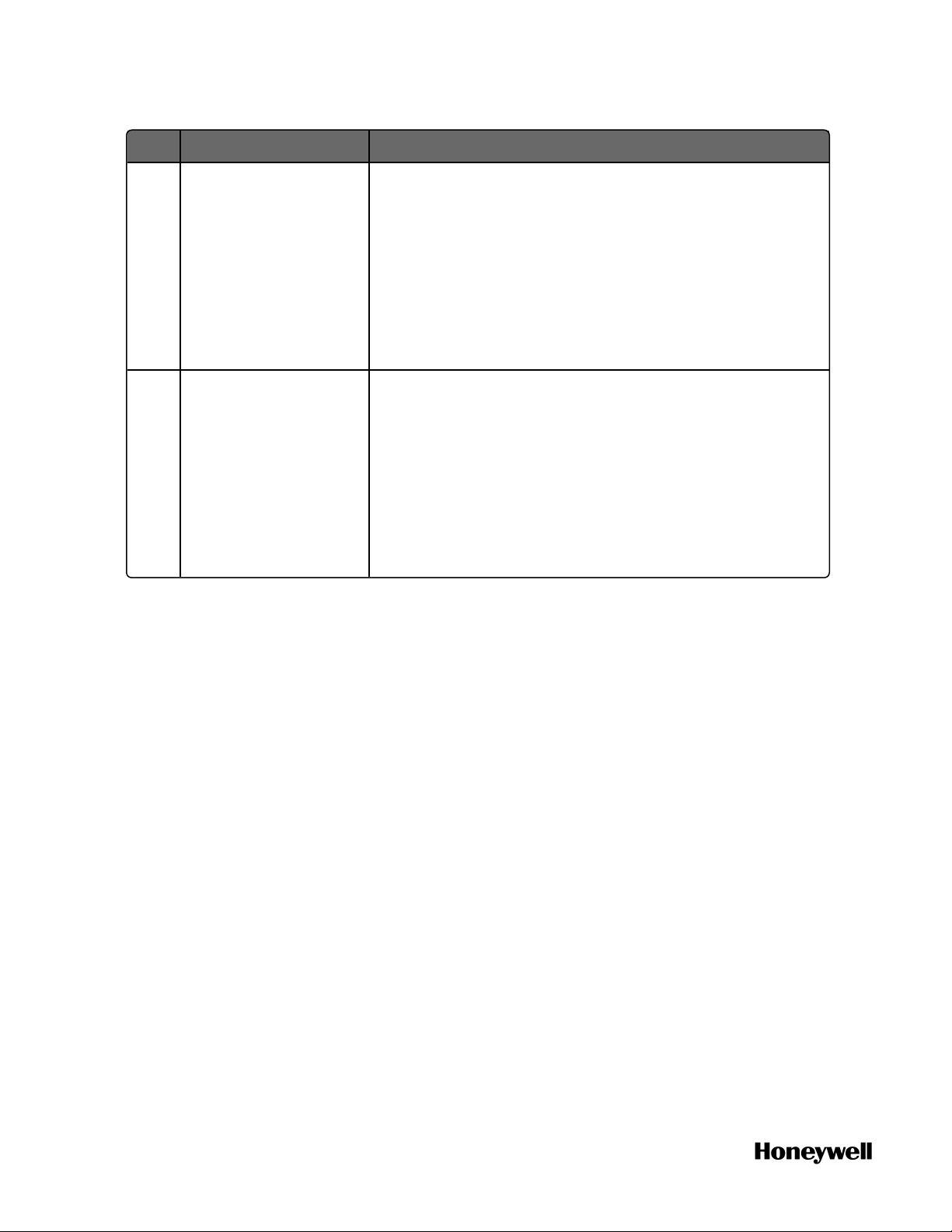

Figure 3-10: Redundant ControlEdge 2020 Controller System Diagram

Item Model Number Description

1 SC-UCNN11 ControlEdge 2020 Redundant Controller

2 SC-UMIX01 ControlEdge 2020 Mixed I/O Module with 28 I/O

3 SC-TEPR01 ControlEdge 2020 expansion I/O right end plate, includes

a CAT-5 termination cable

4 SC-TEPL01 ControlEdge 2020 expansion I/O left end plate

Hardware components

ControlEdge RTU system consists of a controller, expansion I/O

modules, right end plate, and left end plate. These components are

combined with field devices to make a complete system.

Redundant Controller

The redundant controller consists of two CPMs and an IOTA.

32

Page 33

Figure 3-11: Redundant Controller

Item Description

1 18-30 VDC power supply (two)

Chapter 3 - Hardware

2 RS485 Ports (two)

3 RS232 Ports (two)

4 Ethernet Ports (four) Ethernet port1 and port2 for the left CPM (SLOT1).

Ethernet port3 and port4 for the right CPM (SLOT2).

5 Screw hole: used for locking controller IOTA and expansion I/O IOTA.

6 Expansion Connector: used for connecting with expansion I/O module.

Expansion I/O

An Expansion I/O consists of an IOM and an IOTA.

An I/O Module (IOM) contains most of the electronics required to

perform a specific I/O function. The IOM plugs onto the IOTA.

ATTENTION: Up to 30 expansion IOMs of Revision B can be

connected with the controller.

33

Page 34

Chapter 3 - Hardware

Item Description

1 Chassis ground

Figure 3-12: Expansion I/O

2 Left expansion connector: used for connecting with controller, expansion I/O

module or left end plate.

3 Rotary switch (two): used for setting the address of IOM. The controller can

configure and communicate with IOM according to this address. Set the

switches to the two digit address ranging from 01 to 98. The upper switch (10) is

used to set the tens digit and the lower switch (1) sets the ones digit. See

"Mounting the Controller with Expansion IOM" on page1 for more information.

ATTENTION:

l The address must be unique across all I/O modules connected to

the same ControlEdge 2020 controller.

l Unless the location is known to be non-hazardous, do not adjust the

switches while the equipment is powered.

l Do not set the switch index bigger than 98, or else the system LED

of IOM status indicator would blink with yellow, reflecting that IOM is

unable to establish the communication with the Controller.

4 Terminal strips: used for connecting I/O cable from the field.

5 Screw holes: used for locking IOTAs between two expansion I/O Modules.

34

6 Right expansion connector: used for connecting with expansion I/O module or

right end plate.

Page 35

Chapter 3 - Hardware

ATTENTION: The non-redundant controller IOTA (51307198-

175) must be at hardware version ‘B’ or later to work with

expansion I/O modules. The hardware version is detailed on the

controller IOTA label.

Expansion IOMs and CPMs communicate via a ring topology

providing two link paths. If the running link path breaks, the other link

path re-establishes communication within in 250ms.

Right End Plate

A right end plate is required at the end of each row of expansion I/O

modules including the row connected to a controller. It allows

additional rows to be added or terminates the I/O link. The right end

plate has two Ethernet ports and a left expansion connector, as

numbered in the following picture.

Figure 3-13: Right End Plate

Item Description

1 Left expansion connector: connects to a controller or an expansion I/O module.

2 Ethernet port 1: allows additional rows to be added or terminates the I/O link.

3 Ethernet port 2: allows additional rows to be added or terminates the I/O link.

35

Page 36

Chapter 3 - Hardware

ATTENTION: Two ports of the last right end plate should be

connected with a termination cable to complete ring formation.

Left End Plate

Left end plate is used only in multi-row ControlEdge 2020 systems for

the IOM power supply and Ethernet connection. Left end plate has an

18-30 VDC Power Input, two Ethernet ports and a right expansion

connector, as numbered in the following picture.

Figure 3-14: Left End Plate

36

Item Description

1 18-30 VDC power supply

2 Right expansion connector: connects to an expansion I/O module.

3 Screw holes: used for locking left end plate and expansion I/O IOTA.

4, 5 Ethernet port 1 and Ethernet port 2: extends the I/O link to another row.

Page 37

Chapter 3 - Hardware

Installing the assembly

This section introduces you to mount the assembly.

To install the controller with expansion I/O modules

1. Remove the connector cover on the right side of controller IOTA.

2. Mount the controller IOTA onto the DIN rail.

3. Mount the expansion I/O IOTAs onto the DIN rail and insert the

IOTA into the controller IOTA.

4. Set the rotary switch to the address of the IOM, ranging from 1 to

99.

5. Insert the CPM onto the IOTA and secure it.

6. Insert IOM onto the expansion I/O IOTA and sure it.

Wiring and cabling

All I/O channels share the power source with the system components

while the two analog output devices are powered internally. In most

cases, the other 26 channels require external cabling to introduce the

voltage to field loops from the system power source.

Grounding and Shielding

CAUTION: ControlEdge 2020 controller must be connected to

earth ground.

Connect ControlEdge 2020 Controller to earth ground through power

input terminal chassis ground pin (pin 33) as illustrated in the

following figure.

Figure 3-15: Redundant Controller Grounding

Connect Expansion I/O to earth ground through pin 31 as illustrated

in the following figure.

37

Page 38

Chapter 3 - Hardware

Figure 3-16: Non-redundant Controller Grounding

Figure 3-17: Expansion I/O Grounding

For more information about each I/O module wiring, see "I/O Wiring"

in the ControlEdge 2020 Platform Hardware Planning and Installation

Guide.

38

Page 39

Chapter 3 - Hardware

I/O network topology

ControlEdge RTU can be configured as a redundant controller system

or non-redundant controller system.

ControlEdge RTU supports ring I/O topology for I/O communication.

The following diagram shows an example of the topology.

For more information, see “Planning for network topology” in the

ControlEdge 2020 Controller Hardware Planning and Installation

Guide.

Power on

1. Connect 24 VDC supply to the controller.

2. Connect an Ethernet cable to the port most appropriate for your

situation.

3. Connect the other end of the Ethernet cable to the PC installed

ControlEdge Builder directly or through a switch.

39

Page 40

Chapter 3 - Hardware

40

Page 41

CHAPTER

SOFTWARE

4

Installing ControlEdge Builder

The following table lists the operation system and resolution

requirements for the PC installed ControlEdge Builder.

Item Specification

Operation system

Resolution Recommended: 1280x800 or above

Windows 7 32-bit or 64-bit with SP1

Windows 2008 32-bit or 64-bit with SP1

Windows 10 32-bit or 64-bit (Support secure communication)

Windows Server 2016 Standard Edition 64-bit

Optimal: 1920x1080, 1366x768, 1280x1024 and 1280x800

To install ControlEdge Builder

1. Insert the ControlEdge Builder Media Kit into the DVD-ROM drive.

2. Browse to the folder containing ControlEdge_builder_setup.exe.

Double-click this file.

3. Follow the screen prompts to install ControlEdge Builder.

For full instructions on how to install ControlEdge Builder, see the

ControlEdge Builder Software Installation User’s Guide.

Launching ControlEdge Builder

Click Start > All Programs > Honeywell > ControlEdge Builder > ControlEdge

Builder to launch ControlEdge Builder and the Start Page appears.

Start Page is outside any project context, and enables the user to

select an action to start. It provides several actions:

n Create Project: click the icon to create a new project with the

default controller configuration.

n Open Project: click the icon to open an existing project.

n Connect: click the icon to connect to a controller.

41

Page 42

Chapter 4 - Software

Checking firmware versions

Figure 4-1: Start Page

Before configure the controller, make sure all the hardware modules

used in the system are installed with the right firmware version.

Otherwise, you should upgrade the firmware first. See "Upgrading

firmware" on page70 for more information.

Creating a project

This section introduces how to create a new project. The

configuration and programming details are stored in the project.

To create a new project

1. From the Start Page, click Create Project.

2. In the Create New Project from Template window, click General and

select the target template from the Available Templates list.

l Select 900cp1 to create a project for a ControlEdge 900

controller.

l Select SC-UCMX01 or SC-UCNN11 to create a project for a

ControlEdge 2020 controller.

l SC-UCMX01 is for a non-redundant controller.

l SC-UCNN11 is for a redundant controller.

3. Click Next. The Save As window appears.

4. Select an appropriate directory to save the project and enter a

name for the project in the File name field.

42

Page 43

Chapter 4 - Software

l The project name must not contain any of the following

characters: '.\/:*?"<>|'.

l The project name must not exceed 24 characters.

l The directory path length must not exceed 171 characters.

5. Click Save. A project is created and the Home Page appears. Take

the home page of ControlEdge 900 controller as an example here.

Item Description

1 This area contains toolbar and menu bar. You can

navigate to IEC Programming Workspace, compile a

project, build a project, debug on/off, etc.

2 This area contains the following options: open an

existing project, connect a controller, upgrade a

project and download a project.

3 This area contains configuration options for the

controller and project. You can configure the IP

address, configure I/O, upgrade firmwares and

program the project, etc.

For more information, see "Creating a project" in the ControlEdge

Builder User's Guide.

43

Page 44

Chapter 4 - Software

Configuring hardware

Setting controller name

You can set a new name for a controller.

1. From the Home Page, under Controller and Programming, click Set

Controller Name.

2. Enter the desired name for the controller, and click Save.

If using Experion integration with ControlEdge 900 or 2020

controller, this name is used to identify the controller during Experion

configuration.

Configuring the controller IP address

The first thing you will normally want to do is set the IP address for

the controller. The following steps describe how to configure a fixed

IP address starting with creating a new project.

The following table lists the factory default network settings. If your

controller has been previously configured, these settings may have

been changed.

Table 4-1: Factory default network settings of the non-redundant controller

Port Default setting

ETH1 IP address is dynamically assigned from a DHCP server.

If no DHCP server is found by the controller, an IPv4 link-local address will be

assigned (169.254.x.x).

ETH2 Static IP address: 192.168.1.50

Table 4-2: Factory default network settings of the redundant controller

Port Default setting

ETH1 IP address is dynamically assigned from a DHCP server.

If no DHCP server is found by the controller, an IPv4 link-local address will be

assigned (169.254.x.x).

44

The secondary controller IP address is incremented by 1 from the primary

controller IP address.

ETH2 The primary controller static IP address: 192.168.1.50

Page 45

Port Default setting

The secondary controller static IP address: 192.168.1.51

To configure IP address

1. From the Home Page, click the arrow beside Configure Ethernet

Ports, and select ETH1 or ETH2.

2. Under Network Setting, configure the IP address of the Ethernet

port for the controller.

3. Under the Protocol Binding, select the protocol which you want to

bind to the port.

4. Click Save to complete the Ethernet port configuration.

5. Click Back to return to the Home Page.

TIP: If new IP settings are compiled and downloaded, the

controller will be disconnected from the configuring device.

Chapter 4 - Software

Configuring controller start up

This function enables you to configure the controller status after the

power cycle.

For ControlEdge 900 controller, this feature is only applicable when

the mode switch is in REMOTE position.

Under Controller and Programming, select Configure Controller Start Up,

the Configure Controller Start Up page appears. There are four options

for controller start up:

n

Last operating mode, or Running after an abnormal stop

This option is the default setting for ControlEdge 2020 controller.

The controller will start in the operating mode that it was last in

prior to a power off, unless there was an abnormal stop caused by

a system error such as a watchdog timeout issue. It will then start

in Running mode.

l If the controller was in Running mode before power off, the

controller will warm start in Running. If the warm start fails, the

controller will go to Stopped mode.

l If the controller was stopped manually before power off, the

controller will start in Stopped mode.

l If the controller was stopped abnormally before power off, the

45

Page 46

Chapter 4 - Software

controller will warm start in Running mode. If the warm start

fails, the controller will go to Stopped mode.

n

Last operating mode, or Stopped after an abnormal stop

This option is the default setting for ControlEdge 900 controller.

The controller will start in the operating mode that it was last in

prior to a power off, unless there was an abnormal stop caused by

a system error such as a watchdog timeout issue. It will then start

in Stopped mode.

l If the controller was in Running mode before power off, the

controller will warm start in Running. If the warm start fails, the

controller will go to Stopped mode.

l If the controller was stopped manually before power off, the

controller will start in Stopped mode.

l If the controller was stopped abnormally before power off, the

controller will start in Stopped mode.

n

Running

The controller will warm start in Running mode. If the warm start

fails, the controller will go to Stopped mode.

n

Stopped

The controller will start in Stopped mode.

ATTENTION: If you reboot the controller manually, the

configuration in this section will not take effect. For example: If

you select Running here, and you select Reboot Controller under

Maintenance, and click Cold Reboot. The controller will perform

cold start, but not warm start after it reboots.

Configuring controller redundancy

To disable redundancy

1. Under Controller and Programming, select Configure Controller

Redundancy.

2. Select Disable Controller Redundancy to disable the redundancy

function.

46

3. Click OK. Redundancy has been disabled. The IP address

configured for the secondary controller will be disabled.

To enable redundancy

Page 47

Chapter 4 - Software

1. Under Controller and Programming, select Configure Controller

Redundancy.

2. Select Enable Controller Redundancy, and then click OK.

The configuration of I/O modules in the rack local to the

controller will be removed and a static IP address must be

configured for the secondary controller.

3. Configure the IP address of the controllers.

l If the Obtain an IP Address Automatically options of ETH1 and

ETH2 were enabled, this option will be disabled automatically.

Configure Primary Controller IP Address and Secondary Controller

IP Address manually.

l If the Obtain an IP Address Automatically options of ETH1 and

ETH2 were disabled, configure the Secondary Controller IP

Address manually.

Configuring an I/O module

Configure an I/O module for ControlEdge 900

controller

1. From the Home Page, under I/O and Communications and click

Configure Modules > Configure I/O Modules.

2. Click Add I/O Module, the Add I/O Module dialog appears.

3. Select the Type, assign the Rack and Slot, and set the IOM Scan Time

for the Module.

4. Click OK to add the I/O module.

5. Select the corresponding I/O module, configure I/O channels.

Configure an I/O module for ControlEdge 2020

controller

You can configure onboard I/O modules, expansion I/O modules and

a third party I/O ST103A for ControlEdge 2020 controller.

To configure an onboard I/O

1. From the Home Page, under I/O and Communications and click

Configure I/O.

47

Page 48

Chapter 4 - Software

2. Click Onboard I/O and you can view the five channels AI, AO, DI, DO

and PI.

3. Select the corresponding channel, and configure parameters.

To add and configure an expansion I/O module

1. From the Home Page, under I/O and Communications and click

Configure I/O.

2. Click Add I/O Module > SC-UMIX01 Mixed I/O Module, 28, the Add I/O

Module dialog appears.

3. Enter the Description and select the Address for the I/O module

which must be same as the rotary switch setting of the physical

device. The range of the address is from one to nine.

4. Click OK to add the I/O module.

5. Click the corresponding expansion I/O module to view channels.

6. Select the corresponding channel, and configure parameters.

To add and configure an third-party I/O, ST103A

1. From the Home Page, under I/O and Communications, click

Configure Third-Party I/O > ST103A.

2. Click Add ST103A Module. The Add I/O Module dialog appears.

3. Enter Description for ST103A module which will be a unique

identifier for binding with specific meter runs.

4. Select Slave ID for the drop-down list. The valid value is from 1 to

15.

The ST103A should be opened to set Slave ID and row 4 bit

switches will be available to configure the value from 1 to 15. See

"Configuring ST103A" in the ControlEdge 2020 Platform Hardware

Planning and Installation Guide for how to set Slave ID.

ATTENTION: If there are other Modbus devices connected to

the same RS485 port along with ST103A, ensure that they

do not conflict with each other.

5. Select the port number, and provide values for Retries and Timeout.

6. Click OK to add ST103A module.

48

7. Click the corresponding module to view channels.

Only ST103A's analog input, pulse input, frequency and raw pulse

Page 49

Chapter 4 - Software

output can be configured via ControlEdge Builder.

8. Select the corresponding channel, and configure parameters.

Configuring serial modules

The section introduces how to add and configure a serial

communication module. Up to six serial modules can be added.

1. From the Home Page, under I/O and Communications, click

Configure Modules > Configure Serial Modules.

2. Click Add Serial Module, the Add Serial Module dialog appears.

3. Select the Type, assign the Rack and Slot for the module.

See the following table for the parameter descriptions:

Parameter Description

Type Serial module type: 900ES1: Serial Comm

Rack Rack address:

l If controller redundancy is enabled, the rack

address range is from 1 to 99.

l If controller redundancy is disabled, the rack

address range is from 0 to 99. 0 is only for the

local I/O rack.

l For an expansion I/O rack, the address must be

the same with the EPM address configured on

1x and 10x rotary switches.

For details about the rotary switches, see

“Assembling I/O racks” in the ControlEdge 900

Controller Hardware Planning and Installation

Guide.

Slot Slot number: the location of the I/O module mounted

in the rack

l If the I/O module is installed in a 4-slot rack, the

slot number is ranging from 1 to 4.

l If the I/O module is installed in an 8-slot rack,

the slot number is ranging from 1 to 8.

l If the I/O module is installed in a 12-slot rack,

the slot number is ranging from 1 to 12.

49

Page 50

Chapter 4 - Software

4. Click OK to add the serial module.

5. Select a serial module. There are four serial ports to be configured,

RS232-1, RS232-2, RS485-1 and RS485-2. Select the target port

and configure appropriate values for the following parameters.

Parameter Description

Baud

Rate

300, 600, 1200, 2400, 4800, 9600, 19200, 38400,

57600, 115200

Parity None, ODD, EVEN

Data Bits 7, 8

If you select Modbus RTU Slave or Modbus RTU

Master for the Protocol Binding, the Data Bits is set

as 8 by default.

Stop Bits 1, 2

For RS232-1 and RS232-2, you should configure one more

option: Flow Control. See the following table for the parameter

descriptions.

Parameter Description

Flow Control Only for RS232-1 and RS232-2

l None

l RTS-CTS

50

l RTS

6. Under Protocol Binding, select a protocol from the Port Protocol

drop-down list.

The following table provides information about various protocols

supported by serial ports.

Protocol Description

Modbus

RTU

The controller acts as the Modbus Slave and used for

communication between:

Slave

l Controller and SCADA

l Controller and third-party Modbus Master

devices

Page 51

Protocol Description

If you select Modbus RTU Slave:

l Data Bits is set as 8 by default.

l There are two more options to configure: Slave ID

and Mapping.

If the Mapping is empty, you must add a mapping

table first. See "Adding a Modbus Slave mapping

table" on page1 for more information.

Chapter 4 - Software

Modbus

RTU

Master

Modbus

ASCII

Slave

Modbus

ASCII

Master

User

Defined

The controller acts as the Modbus Master and used for

communication between The controller and third-party

Modbus Slave devices, for example I/O modules.

If you select Modbus RTU Master, Data Bits is set as 8

by default.

The controller acts as the Modbus Slave and used for

communication between:

l Controller and SCADA

l Controller and third-party Modbus Master

If you select Modbus ASCII Slave, you must configure

two more options: Slave ID and Mapping. If the Mapping

is empty, you must add a mapping table first. See

"Adding a Modbus Slave mapping table" on page1 for

more information.

The controller acts as the Modbus Master and used for

communication between The controller and third-party

Modbus Slave devices, for example: I/O modules.

User Defined protocol.

When you select this option, the Delimiter Mode

(Optional) panel appears including three settings: Readinterval Timeout (ms), Max Length (Bytes) and End

Delimiter (Hex). You can configure them optionally to

validate if a data frame is sent completely.

l Read-interval Timeout (ms): The interval between the

last data packet sent and the first keepalive probe,

ranging from 0 to 10000 (ms). If the interval

between the arrivals of any two bytes exceeds this

51

Page 52

Chapter 4 - Software

Protocol Description

Timeout, system regards it has already received a

complete data frame.

The default value is 0 which means this option is

disabled.

l Max Length (Bytes): The maximum number of bytes

for a data frame, ranging from 0 to 532. If the length

of a received data frame exceeds the Max Length,

system regards it has already received a complete

data frame.

The default value is 0 which means this option is

disabled.

l End Delimiter (Hex): Configured special characters in

hexadecimal and based on bytes validates if a data

frame is sent completely. If the received data frame

has same characters with the End Delimiter, system

regards it has already received a complete data

frame.

The default setting is blank which means this option

is disabled.

For how to configure User Defined protocol, see

"User Defined Protocol" in the ControlEdge Builder

Function and Function Block Configuration

Reference.

7. Click Save to complete the configuration.

Configuring a controller simulator

Controller simulator can be deployed on a Virtual Machine, and

enables the user to configure a controller without connecting a

physical controller.

For this release, the controller simulator does not support I/O

communication.

52

Page 53

Chapter 4 - Software

ATTENTION: It is not recommended to use the simulator in a

production environment, because simulator does not support

secured communication.

The following table lists the supported and non-supported features of

the controller simulator.

Features Support

Connect a controller simulator Yes

Download a project to a controller simulator Yes

Download a redundant project to a controller simulator Yes

Debug a program Yes

Force I/O value through I/O variables Yes

Force I/O value through I/O channels No

Upload system event log Yes

Monitor link status Yes

System diagnostics Yes

Secure communication No

Communication between SCADA and controller simulator Yes

Communication between controller simulators Yes

Communication between virtual and physical controllers Yes

Modbus TCP master/slave Yes

Modbus UDP slave No

Enron Modbus slave No

DNP3 slave No

OPC UA Server Yes

OPC UA Client No

CDA responder No

EtherNet/IP No

HART/HART-IP No

53

Page 54

Chapter 4 - Software

Features Support

Wireless I/O No

Data logging No

EFM No

Secured communication No

Prerequisite

Make sure the IP addresses for the PCs installed simulator and

ControlEdge Builder are on the same subnet.

One virtual machine only supports one controller simulator.

Procedures

1. Install a virtual machine. Two virtual machines are verified:

l VMware Workstation Player 12.5.8 or higher hypervisor

l VMware vCenter Server 6.0.0 or higher hypervisor

For more information, see the vendor's documents.

2. Import or open an OVA file in the virtual machine, and play the

virtual machine. Honeywell provides three OVA files stored in

Simulator folder in the Media.

RXXX indicates the release number.

l ControlEdge 900 controller: ControlEdge_PLC_900CP1_

RXXX.ova

l ControlEdge 2020 controller:

l Non-redundant controller: ControlEdge_RTU_SCUCMX01_

RXXX.ova

l Redundant controller: ControlEdge_RTU_SCUCNN11_

RXXX.ova

Take VMware Workstation Player 12.5.8 as an example here:

a. Click Player > File > Open, the Open Virtual Machine dialog

appears.

54

Page 55

Chapter 4 - Software

b. Browse to the location stored the target OVA file, select the OVA

file and click Open.

c. From the Import Virtual Machine dialog, name the virtual

machine, and select a storage location for the virtual machine.

Click Import.

55

Page 56

Chapter 4 - Software

d. Click Play virtual machine.

56

e. For ControlEdge 900 controller, you should configure the

controller type.

l Enter 0 to configure the controller type as non-redundant.

l Enter 1 to configure the controller type as redundant.

Page 57

Chapter 4 - Software

NOTE: The controller type cannot be changed once you

configure it, and you should re-import the OVA file and

configure it again.

An OVA file defines a controller simulator. To change the

controller simulator version, import the corresponding OVA file.

For more information, see the vendor's documents.

3. Connect to a controller simulator. See "Connecting a controller"

on page1 for more information.

After you connect to a controller simulator, make sure the build

settings is I486_LE_GCC3. Click IEC Programming Workspace and

check the following parameter:

4. Configure a controller simulator. See the table above for the

supported configuration. Project version must match with the

controller simulator version.

5. Compile the project. See "Compiling a project" on page1 for more

information.

6. Download the project to the controller simulator. See

"Downloading a project to the controller" on page1 for more

information.

57

Page 58

Chapter 4 - Software

Programming with IEC 61131-3

This chapter introduces general information about programming with

IEC 61131-3.

See the embedded help for details about programming. Select Help >

Contents from the toolbar. In the pop-up help, expand Programming

System Help and click Programming a project.

Adding a library

The Libraries that are included in your project are either user-defined

libraries or firmware libraries.

n User Library: contains programs, function blocks, functions and

user-defined data types, and can be reused across projects.

Honeywell provides user libraries and user can create their own.

The file extensions for user library are *.mwt and *.mwe.

n Firmware Library: contains function blocks and functions

prepared by Honeywell for specific hardware. The file extension for

firmware library is *.fwl.

For more information about the function and function block, see the

ControlEdge Builder Function and Function Block Configuration

Reference Guide.

To add a library

1. Click IEC Programming Workspace from the toolbar, or from Home

Page, click Program with IEC61131-3.

2. Right-click Libraries and click Insert. Select User Library or Firmware

Library.

l For User Library, select .mwt file and click Include.

l For Firmware Library, click the corresponding folder and select

the target .fwl file, and then click Include.

Creating a data type

Honeywell provides some read-only user-defined data types, and user

can also create and define data types. The maximum number of user

defined data types is 1024. User-defined data types can be used

within user function blocks and programs. They cannot be used in

user functions.

58

To create a data type

Page 59

Chapter 4 - Software

1. Click IEC Programming Workspace from the toolbar, or from Home

Page, click Program with IEC61131-3.

2. From the Project Tree Window, right-click Data Type and select Insert

> Datatypes and name the target data type.

3. Double-click the newly added data type, you can edit it in the text

editor.

For I/O_DataTypes, each I/O Channel has one or two structures. All of

the related information for this channel is grouped together in the

structures as shown below. You can use this information as reference

for I/O channel configuration and programming.

Table 4-3: I/O channel structures of the I/O_DataTypes

Structure type Parameter Parameter type

ANALOG_INPUT_TYPE STS USINT

PV REAL

EUHI REAL

EULO REAL

EUHIEX REAL

EULOEX REAL

ANALOG_OUTPUT_TYPE OP REAL

ANALOG_OUTPUT_READBACK_

TYPE

STS USINT

OP_READBACK REAL

EUHI REAL

EULO REAL

EUHIEX REAL

EULOEX REAL

DIGITAL_INPUT_TYPE STS USINT

PV BOOL

DIGITAL_OUTPUT_TYPE OP BOOL

59

Page 60

Chapter 4 - Software

Structure type Parameter Parameter type

DIGITAL_OUTPUT_READBACK_TYPE STS USINT

PULSE_INPUT_TYPE STS USINT

OP_READBACK BOOL

COUNTER

RATE

PREI

PULSE_INPUT_CONTROL_TYPE RST

HOLD

4

1

2

3

UDINT

REAL

BOOL

BOOL

5

BOOL

FREQUENCY_INPUT_TYPE STS USINT

FREQUENCY REAL

PULSE_OUTPUT_TYPE PULSES UDINT

ENABLE BOOL

START BOOL

CONTINUE BOOL

PULSE_OUTPUT_READBACK_TYPE STS USINT

REMAIN UDINT

1. COUNTER: The accumulated Engineering Unit (EU) count.

60

2. RATE: Rate in EU/Time Period. Input pulses are counted over a specified Sample

Time and scaled to EU/Second, EU/Minute or EU/Hour.

3. PREI: Preset indicator. OFF [0] when COUNTER = less than the local or remote

preset value, ON when the count reaches the local or remote preset value. The

hardware module determines the state of the PREI output. PREI is cleared by the

RST input. A preset value of 0 effectively turns off the Preset allowing the counter to

count continuously until held or reset.

4. RST: An OFF to ON transition resets the module's pulse counter and the OUT to

zero. It also clears the FAIL, Overflow in STS and PREI.

5. HOLD: A Boolean value when set to 1 holds the EU count at its current value.

Page 61

Chapter 4 - Software

Creating a variable

This section introduces how to create and declare variables to

diagnose and monitor the system.

To create a variable

1. Click IEC Programming Workspace from the toolbar, or from Home

Page, click Program with IEC61131-3.

2. You can create local variables or global variables from the

corresponding grid worksheet. is the grid worksheet for local

variables, and is the grid worksheet for global variables.

For the following steps, let us take the global variable as an

example.

3. Double-click Global_Variables under Physical Hardware, the global

variable sheet appears.

4. Right-click under the corresponding group, and select Insert

variable to add a new I/O variable.

For output channel variables, you must add corresponding read

back variables with suffix “_READBACK” in the Input I/O Variables

group.

5. Double-click the Name and Description fields to modify, and select

Type and Usage from the drop-down lists.

The maximum quantity of characters for a variable name is 30.

IEC address of the I/O variable is generated automatically after

you bind it with an I/O channel and click Make. If you add a new

I/O variable by copying an existing bound one in a compiled

project, you should delete the IEC address of the new variable

manually and click Make to generate it automatically.

6. If a variable will be used for Modbus, EFM or PID, you should

select Retain for it. Perform either of the following methods:

l From the variable sheets, select Retain.

61

Page 62

Chapter 4 - Software

l From the variable properties dialog, select Retain, and click OK.

Creating a Programming Organization Unit

Logical Program Organization Units (POUs) are the language

elements of a program. They are small, independent software units

containing the program code. The name of a POU must be unique

within the project.

There are three different POU types:

n Program: contains a logical combination of function or function

block calls. Programs have input and output parameters and they

can have an internal memory.

n Function Block: POUs with multiple input/output parameters and

internal memory.

n Function: POUs with multiple input parameters and exactly one

output parameter.

To create a POU

1. Click IEC Programming Workspace from the toolbar, or from Home

Page, click Program with IEC61131-3.

2. From the Project Tree Window, right-click Logical POUs and select

Insert > Program/Function Block/Function, the Insert dialog appears.

62

3. Enter the Name for the new POU.

Page 63

Chapter 4 - Software

4. Select the desired programming Language. Depending on your

system configuration, some programming language are possibly

not available.

5. Enter a PLC type and/or a Process type if required.

6. Click OK, the new POU is inserted in the project tree. It contains

one code worksheet in the chosen language, a variable worksheet

and a description worksheet.

7. Expand the POU, and double-click the code worksheet, the

workplace appears.

8. Drag the target function or function block from the Edit Wizard

pane, and the function or function block is displayed.

9. Double-click the pin-outs of the function or function block, the

Variable Properties dialog appears.

10. Accept the proposed name, or enter a new name or select an

already existing name from the Name combo box.

11. Select the Data Type and Usage from the drop-down lists.

l If you are creating a Program, there are two options for Usage:

VAR and VAR_GLOBAL.

l If you are creating a Function Block, there are five options for

Usage: VAR, VAR_INPUT, VAR_OUTPUT, VAR_IN_OUT and VAR_

GLOBAL.

l If you are creating a Function, there are two options for Usage:

VAR and VAR_INPUT.

See the following table for the description of variables.

Variable Description

VAR Local variable

VAR_GLOBAL Global variable

VAR_INPUT Local FB input variable

VAR_OUTPUT Local FB output variable

VAR_IN_OUT Local input/output variable

12. Assign the initial value and I/O address.

13. It is optional to select the target group from Global Variable Groups.

Click OK and the new variables are added to the selected groups.

63

Page 64

Chapter 4 - Software

If you do not select a Global Variable Group, the variables are added

to the Common Variables group by default.

Associating a program to a task

Tasks determine the time scheduling of the programs associated with

them. This means that programs have to be associated to tasks in

order to be executed. The settings of the task determine the time

scheduling.

To create a task and associate a program

1. Click IEC Programming Workspace from the toolbar.

2. From the Project Tree Window, under Physical Hardware, right-click

Task and select Insert > Task.

3. Enter the Name.

Task name and Instance name must start with a letter or an

underscore. The rest of the characters can be letters, numbers or

underscores. The maximum quantity of characters which a task

name can have is 7 and that of a program instance is 24.

4. Select the Task type. See the following table for the descriptions of

task types.

Task type Description

DEFAULT Each resource can contain one default task. It is the

task with the lowest priority (lower than cyclic tasks)

and is not time scheduled.

CYCLIC Cyclic task executes their associated programs in

fixed time intervals.

EVENT Event task executes their associated programs each

time a particular event occurs.

SYSTEM System task executes its associated programs each

time a particular system event occurs.

5. Click OK.

6. Configure the parameters as required in the Task settings dialog.

Depending on the associated task type, only some of the

parameters are available.

64

7. Click OK. The new task is inserted.

8. Right-click the task you have inserted, and select Insert > Program

Page 65

instance.

9. Enter a name in the Program instance field.

The program instance must not be named “RTU” or

“GlobalVariable”.

10. Select the program you want to associate in the Program type

drop-down list.

11. Click OK.

Compiling a project

After configuring the project, you have to compile it.

To compile a project

Click Make or Rebuild Project as required to compile the project.

n Make: It is used to compile the changed worksheets.

Chapter 4 - Software

n Rebuild Project: It is used to compile the whole project for the first

time or if an announced user library has been changed. The

command Rebuild Project should only be used if 'Make' generates

compiling errors or you have unzipped your project without the

frontend code.

While compiling, the message window displays the compilation

process. Any detected errors and warnings (e.g. syntax errors, memory

or file problems) and additional information are also displayed in the

appropriate message window sheet. You can use the message window

to access the suspected code body worksheet by double clicking on

the error message.

After compiling without any error, you have to download the project

to the controller. See "Downloading a project to the controller" on

page1 for more information.

65

Page 66

Chapter 4 - Software

66

Page 67

CHAPTER

OPERATING

5

Connecting a controller

Click Connect from the Home Page, and the Connect controller page

appears.

1. From the Home Page, click Connect, the Connect controller page

appears.

2. Click Scan and Select tab and select the target controller.

Or click IP Address tab and enter the IP address of the target

controller.

You can connect to a physical controller or a controller

simulator. Select the controller type:

l

: ControlEdge 2020 controller

l

: ControlEdge 2020 controller simulator

l : ControlEdge 900 controller

l

3. Select the user name and enter the password.

4. Click Connect.

If the current and previously connected controller types are

different, the following dialog appears. Click OK to automatically

configure the settings.

TIP: Due to the cyber security, ControlEdge Builder will

disconnect with the controller automatically if there is no

communication between them including displaying the

diagnostic view, uploading the datalog, downloading the

: ControlEdge 900 controller simulator

67

Page 68

Chapter 5 - Operating

Downloading a project to the controller

configuration, and upgrading the firmware for over ten

minutes.

After compiling a project without any error, you have to download the

project to the controller.

Before downloading the project to the controller, you have to ensure:

n The project is opened in ControlEdge Builder.

n The project is compiled without any error. See "Compiling a

project" on page65 for more information.

n Log in as the Administrator or Engineer to connect the target

controller. See "Connecting a controller" on the previous page for

more information.

n The primary CPM is connected if the controller is redundant.

n See "Connecting a controller" on the previous page for more

information.

To download a project

1. From the Home Page, click Download. A eclrRes window appears:

For more information about the items in the eclrRes window, see

the embedded online help. Select Help > Contents, and search for

PLC state machine to display the corresponding content.

2. A Download confirmation dialog appears to make sure you want

to download. Click Yes.

ATTENTION: If you want to upload this project in the future,

you should select Download the project archive, and a zip file

of the archived project will be stored in the controller.

3. There are two scenarios:

l If the controller does not contain any project or the project you

are going to download has a different name with the project is

already stored in the controller, you should click Stop in the

eclrRes window to stop the program execution. Then click

Download in the eclrRes window to continue the download.

68

l If the project with the same name is already stored in the

Page 69

controller, the system recognizes the differences between the

"old" and the modified project version.

l If there is a lot of differences, a warning message appears

indicating that the program execution will be stopped if you

continue the download. Click Yes to continue the download.

Click No to cancel the download.

l If there is a few of differences, the modified project is

downloading without stopping program execution.

4. Click OK after the project is downloaded to the controller

successfully.

Configuring date/time

Setting time source

Chapter 5 - Operating

The section introduces how to synchronize the controller time to the

SNTP server.

For ControlEdge 900 controller, the synchronization is required in

order to ensure robust operation of the embedded OPC UA server.

1. From the Home Page, under Miscellaneous, click Configure

Date/Time Options.

2. Select Enable and enter the IP addresses of SNTP servers in the

Primary Server and Secondary Server fields.

If you select Enable here, under Configure ProtocolsDNP3 Slave, you

should not select Enable DNP3 Time Synchronization in Application

Layer tab at the same time.

3. Adjust the Poll Interval to synchronize current controller time to

the SNTP server.

The SNTP message poll interval is Poll Interval power of 2 (2

Interval)

) in unit of second.

(Poll

The maximum poll interval is 17 (approx. 36 hours) and the

minimum is 6 (64 seconds).

It is recommended to set Poll Interval as 16 (approx. 18 hours). To

avoid the communication storm, the controller will pick a random

poll interval time in the range [2(Poll Interval), 2(Poll Interval+1)],

not exactly what is configured.

If the NTP server is not available, you can use the function block

(Set_RTC) to configure the controller time. For more information,

69

Page 70

Chapter 5 - Operating

Upgrading firmware

see “Set_RTC” in the ControlEdge Builder Function and Function

Block Configuration Reference Guide.

TIP: The recommended poll interval for EFM application is

14.

Setting time zone

1. Click Configure Date/Time Options under Miscellaneous.

2. Select Set Time Zone tab, and select the target time zone from the

Time Zone drop-down list.

3. Select Automatically Switch to Daylight Saving Time if it is applicable.

ATTENTION: Do not power off when upgrading firmware.

n If a connected field device or FDAP is OWR300 firmware, the

controller must be upgraded to R140 or later releases.

n If a connected field device is Honeywell OW R300 or Third party

ISA100 2011 device, the controller must be upgraded to R140 or

later releases, and FDAP must be upgraded to OW R300.

n For ControlEdge 2020 controller:

l You can upgrade firmware from R110 to R151, R140 to R151,