Page 1

8600 Ring Scanner

User’s Guide

Page 2

Disclaimer

Honeywell International Inc. (“HII”) reserves the right to make changes in specifications and other information contained in this

document without prior notice, and the reader should in all cases consult HII to determine whether any such changes have been

made. The information in this publication does not represent a commitment on the part of HII.

HII shall not be liable for technical or editorial errors or omissions contained herein; nor for incidental or consequential damages

resulting from the furnishing, performance, or use of this material.

This document contains proprietary information that is protected by copyright. All rights are reserved. No part of this document

may be photocopied, reproduced, or translated into another language without the prior written consent of HII.

© 2008-2015 Honeywell International Inc. All rights reserved.

Web Address: www.honeywellaidc.com

Trademarks

RFTerm is a trademark or registered trademark of EMS Technologies, Inc. in the United States and/or other countries.

The Bluetooth

Symbol® is a registered trademark of Symbol Technologies. MOTOROLA, MOTO, MOTOROLA SOLUTIONS and the Stylized M

Logo are trademarks or registered trademarks of Motorola Trademark Holdings, LLC and are used under license.

Other product names or marks mentioned in this document may be trademarks or registered trademarks of other companies

and are the property of their respective owners.

®

word mark and logos are owned by the Bluetooth SIG, Inc.

Patents

For patent information, please refer to www.hsmpats.com.

Page 3

Table of Contents

Chapter 1 - Ring Scanner Agency Compliance

Label Locations....................................................................................................................1-1

Laser Label ..........................................................................................................................1-1

Laser Safety Statement .......................................................................................................1-1

Beam Divergence ................................................................................................................1-2

FCC Part 15 Statement........................................................................................................1-2

Canadian Compliance..........................................................................................................1-3

CE Mark ...............................................................................................................................1-3

Honeywell Scanning & Mobility Product Environmental Information....................................1-3

Dealer License - Republic of Singapore ..............................................................................1-3

Chapter 2 - Getting Started

Overview ..............................................................................................................................2-1

About this Guide ..................................................................................................................2-1

Out of the Box ......................................................................................................................2-1

Initial Setup ..........................................................................................................................2-2

Hardware Setup .............................................................................................................2-2

Components.........................................................................................................................2-2

Ring Imager / Ring Scanner...........................................................................................2-2

Ring Imager / Ring Scanner for Dolphin 70e Black in Wearable Sled. ....................2-2

Ring Imager / Ring Scanner for HX2 and HX3.........................................................2-2

Assembly .............................................................................................................................2-3

Determine Left or Right Orientation ...............................................................................2-3

Adjusting the Ring Device Strap ..........................................................................................2-3

Connect to Terminal.............................................................................................................2-4

Dolphin 70e in Wearable Sled........................................................................................2-4

Connect....................................................................................................................2-4

Disconnect ...............................................................................................................2-4

HX2 / HX3 ......................................................................................................................2-4

Removing / Replacing the Trigger Module...........................................................................2-5

Remove Finger Strap Assembly ....................................................................................2-5

Replace Trigger Module.................................................................................................2-5

How To Scan a Bar Code ....................................................................................................2-6

Scan a Linear Bar Code.................................................................................................2-6

Good Read / Bad Read Indicators .................................................................................2-6

Factors That May Impact Scanner Performance .................................................................2-7

Bar Code Scanning Help .....................................................................................................2-7

Miscellaneous Programmable Bar Codes............................................................................2-8

Beep After Good Decode...............................................................................................2-8

Beeper Frequency Adjustment.......................................................................................2-8

Event Reporting .............................................................................................................2-8

LED Mode ......................................................................................................................2-8

Return to Factory Default Settings.................................................................................2-9

Chapter 3 - 1D Laser Scanner Programming Bar Codes

i

Page 4

Introduction..........................................................................................................................3-1

Aiming Modes......................................................................................................................3-2

SE955 Ring Scanner .....................................................................................................3-2

Prefix / Suffix .......................................................................................................................3-2

Set Default Parameter ...................................................................................................3-6

Scanner Parameters – General...........................................................................................3-7

Aim Duration.................................................................................................................. 3-7

Bi-Directional Redundancy ............................................................................................3-7

Disable All Symbologies ................................................................................................ 3-8

Data Options........................................................................................................................3-8

Prefix and Suffix.............................................................................................................3-8

Prefix........................................................................................................................3-8

Suffix 1.....................................................................................................................3-8

Suffix 2.....................................................................................................................3-9

Scan Data Transmission Format ................................................................................... 3-9

Transmit Code ID Character........................................................................................ 3-11

Transmit No Code ID Character ............................................................................ 3-11

Transmit Symbol Code ID Character..................................................................... 3-11

Transmit AIM Code ID Character .......................................................................... 3-12

Laser On Time............................................................................................................. 3-14

Linear Code Type Security Level (Redundancy Level) ............................................... 3-15

Parameter Pass Through.............................................................................................3-16

Parameter Scanning.................................................................................................... 3-16

Power Mode.................................................................................................................3-17

Scan Angle (SE955 only).............................................................................................3-17

Simple Serial Interface (SSI) Options.......................................................................... 3-18

SSI Defaults...........................................................................................................3-18

Beep on BEL.......................................................................................................... 3-18

Baud Rate..............................................................................................................3-18

Decode Data Packet Format ................................................................................. 3-19

Host Character Time-out .......................................................................................3-19

Intercharacter Delay .............................................................................................. 3-20

Software Handshaking........................................................................................... 3-22

Stop Bit Select ....................................................................................................... 3-23

Time-out Between Decodes, Same Symbol................................................................ 3-23

Transmit “No Read / Decode” Message ...................................................................... 3-24

Trigger Mode ...............................................................................................................3-25

Scanner Parameters – Bar Code Type Specific................................................................3-26

Chinese 2 of 5..............................................................................................................3-26

Codabar....................................................................................................................... 3-27

CLSI Editing...........................................................................................................3-27

NOTIS Editing........................................................................................................3-28

Set Lengths for Codabar........................................................................................3-28

One Discrete Length (Parameter L1) .............................................................. 3-28

Two Discrete Lengths (Parameter L2) ............................................................ 3-29

Length Within Range ...................................................................................... 3-29

Any Length ...................................................................................................... 3-29

Code 11 .......................................................................................................................3-30

ii

Page 5

Set Lengths for Code 11........................................................................................3-30

One Discrete Length (Parameter L1) .............................................................. 3-30

Two Discrete Lengths (Parameter L2) ............................................................ 3-30

Length Within Range ...................................................................................... 3-31

Any Length ...................................................................................................... 3-31

Code 11 Check Digit Verification ...........................................................................3-32

Transmit Code 11 Check Digits .............................................................................3-32

Code 128 .....................................................................................................................3-33

GS1-128 (formerly UCC/EAN-128)........................................................................ 3-33

ISBT-128................................................................................................................ 3-34

Lengths for Code 128 ............................................................................................ 3-34

Code 39 .......................................................................................................................3-35

Code 39 Check Digit Verification ...........................................................................3-35

Code 32 Prefix .......................................................................................................3-36

Convert Code 39 to Code 32 .................................................................................3-36

Code 39 Full ASCII Conversion............................................................................. 3-37

Set Lengths for Code 39........................................................................................3-37

Code 39 One Discrete Length (Parameter L1) ............................................... 3-37

Code 39 Two Discrete Lengths (Parameter L2) ............................................. 3-38

Code 39 Length Within Range ........................................................................ 3-38

Code 39 Any Length ....................................................................................... 3-38

Transmit Code 39 Check Digit............................................................................... 3-39

Trioptic Code 39 .................................................................................................... 3-39

Code 93 .......................................................................................................................3-40

Set Lengths for Code 93........................................................................................3-40

One Discrete Length (Parameter L1) .............................................................. 3-40

Two Discrete Lengths (Parameter L2) ............................................................ 3-41

Length Within Range ...................................................................................... 3-41

Any Length ...................................................................................................... 3-41

Discrete 2 of 5..............................................................................................................3-42

Set Lengths for Discrete 2 of 5 .............................................................................. 3-42

One Discrete Length (Parameter L1) .............................................................. 3-42

Two Discrete Lengths (Parameter L2) ............................................................ 3-43

Length Within Range ...................................................................................... 3-43

Any Length ...................................................................................................... 3-43

Interleaved 2 of 5......................................................................................................... 3-44

I 2 of 5 Check Digit Verification.............................................................................. 3-44

Convert I 2 of 5 to EAN-13..................................................................................... 3-45

Set Lengths for I 2 of 5 .......................................................................................... 3-45

One Discrete Length (Parameter L1) .............................................................. 3-45

Two Discrete Lengths (Parameter L2) ............................................................ 3-46

Length Within Range ...................................................................................... 3-46

Any Length ...................................................................................................... 3-46

Transmit I 2 of 5 Check Digit ................................................................................. 3-47

MSI Plessey................................................................................................................. 3-48

MSI Plessey Check Digit Algorithm .......................................................................3-48

MSI Plessey Check Digits...................................................................................... 3-49

Set Lengths for MSI Plessey ................................................................................. 3-49

iii

Page 6

One Discrete Length (Parameter L1) .............................................................. 3-49

Two Discrete Lengths (Parameter L2) ............................................................ 3-50

Length Within Range ...................................................................................... 3-50

Any Length ...................................................................................................... 3-50

Transmit MSI Plessey Check Digit ........................................................................3-51

UPC/EAN.....................................................................................................................3-52

UPC-A....................................................................................................................3-52

UPC-E....................................................................................................................3-52

UPC-E1.................................................................................................................. 3-53

EAN-8 .................................................................................................................... 3-53

EAN-13 .................................................................................................................. 3-54

Bookland EAN ....................................................................................................... 3-54

Bookland ISBN Format ..........................................................................................3-55

Check Digits........................................................................................................... 3-55

Transmit UPC-A Check Digit .......................................................................... 3-55

Transmit UPC-E Check Digit .......................................................................... 3-56

Transmit UPC-E1 Check Digit ........................................................................ 3-56

Conversions...........................................................................................................3-57

Convert UPC-E to UPC-A ............................................................................... 3-57

Convert UPC-E1 to UPC-A .............................................................................3-57

Convert EAN-8 to EAN-13 Type ..................................................................... 3-58

Preambles.............................................................................................................. 3-59

UPC-A Preamble ............................................................................................ 3-59

UPC-E Preamble ............................................................................................ 3-60

UPC-E1 Preamble .......................................................................................... 3-61

Supplementals .......................................................................................................3-62

Decode UPC/EAN Supplementals .................................................................. 3-62

User-Programmable Supplementals ............................................................... 3-64

Decode UPC/EAN Supplemental Redundancy .............................................. 3-64

EAN-8 Zero Extend................................................................................................ 3-65

UCC Coupon Extended Code................................................................................ 3-65

UPC/EAN Security Level .......................................................................................3-66

GS1 DataBar (RSS) Codes ......................................................................................... 3-67

GS1 DataBar Omnidirectional (RSS-14) ...............................................................3-67

GS1 DataBar Limited (RSS-Limited) .....................................................................3-67

GS1 DataBar Expanded (RSS-Expanded) ............................................................3-68

Convert GS1 DataBar (RSS) to UPC/EAN ............................................................3-68

Appendix............................................................................................................................ 3-69

Laser On Time (superseded).......................................................................................3-69

Scan Angle (SE955 only) superseded......................................................................... 3-69

Set Lengths for I 2 of 5 (superseded) ..........................................................................3-70

One Discrete Length (Parameter L1)..................................................................... 3-70

Two Discrete Lengths (Parameter L2)................................................................... 3-70

Length Within Range ............................................................................................. 3-71

Any Length............................................................................................................. 3-71

Keypad Number Symbols..................................................................................................3-72

Chapter 4 - 2D Laser Imager Programming Bar Codes

iv

Page 7

Introduction..........................................................................................................................4-1

Set All Defaults/Cancel Bar Codes...................................................................................... 4-5

Enable / Disable Parameter Scanning.................................................................................4-6

Imager Parameters – General .............................................................................................4-6

Decode Session Timeout...............................................................................................4-6

Decode Aiming Pattern.................................................................................................. 4-7

Decoding Autoexposure ................................................................................................4-7

Decoding Illumination ....................................................................................................4-8

Focus Mode................................................................................................................... 4-9

LED Illumination...........................................................................................................4-10

Operational Mode ........................................................................................................4-11

Power Mode.................................................................................................................4-12

Presentation Mode Session Timeout........................................................................... 4-12

Time Delay to Low Power Mode..................................................................................4-13

Time-out between Decodes, Same Symbol ................................................................4-14

Trigger Modes..............................................................................................................4-15

Report Version.............................................................................................................4-16

Transmit Code ID Character........................................................................................ 4-16

Transmit No Code ID Character ............................................................................ 4-16

Transmit Symbol Code ID Character..................................................................... 4-17

Transmit AIM Code ID Character .......................................................................... 4-18

Prefix / Suffix Values....................................................................................................4-22

Suffix 1...................................................................................................................4-22

Suffix 2...................................................................................................................4-22

Scan Data Transmission Format ................................................................................. 4-23

Transmit “No Read” Message......................................................................................4-25

UPC/EAN...........................................................................................................................4-26

UPC-A..........................................................................................................................4-26

UPC-E..........................................................................................................................4-26

UPC-E1........................................................................................................................4-27

EAN-8/JAN-8 ...............................................................................................................4-27

EAN-13/JAN-13 ...........................................................................................................4-28

Bookland EAN .............................................................................................................4-28

Bookland Format .........................................................................................................4-29

Decode UPC/EAN/JAN Supplementals (2 and 5 digits).............................................. 4-29

UPC/EAN/JAN Supplemental Redundancy................................................................. 4-31

Transmit UPC-A Check Digit ....................................................................................... 4-31

Transmit UPC-E Check Digit ....................................................................................... 4-32

Transmit UPC-E1 Check Digit ..................................................................................... 4-32

UPC-A Preamble .........................................................................................................4-33

UPC-E Preamble .........................................................................................................4-34

UPC-E1 Preamble .......................................................................................................4-35

Convert UPC-E to UPC-A............................................................................................4-36

Convert UPC-E1 to UPC-A..........................................................................................4-36

EAN-8/JAN-8 Extend................................................................................................... 4-37

UCC Coupon Extended Code......................................................................................4-37

Code 128 ........................................................................................................................... 4-38

UCC/EAN-128 ............................................................................................................. 4-38

v

Page 8

ISBT-128......................................................................................................................4-39

Code 39 .......................................................................................................................4-39

Trioptic Code 39 ..........................................................................................................4-40

Convert Code 39 to Code 32....................................................................................... 4-40

Code 32 Prefix............................................................................................................. 4-41

Set Length(s) for Code 39 ........................................................................................... 4-42

One Discrete Length (Parameter L1)..................................................................... 4-42

Two Discrete Lengths (Parameter L2)................................................................... 4-42

Length Within Range ............................................................................................. 4-42

Any Length............................................................................................................. 4-43

Code 39 Check Digit Verification................................................................................. 4-43

Transmit Code 39 Check Digit..................................................................................... 4-44

Code 39 Full ASCII Conversion...................................................................................4-44

Code 93 ............................................................................................................................. 4-45

Set Lengths for Code 93.............................................................................................. 4-45

One Discrete Length (Parameter L1)..................................................................... 4-45

Two Discrete Lengths (Parameter L2)................................................................... 4-46

Length Within Range ............................................................................................. 4-46

Any Length............................................................................................................. 4-46

Code 11 ............................................................................................................................. 4-47

Set Lengths for Code 11.............................................................................................. 4-47

One Discrete Length (Parameter L1)..................................................................... 4-47

Two Discrete Lengths (Parameter L2)................................................................... 4-48

Length Within Range ............................................................................................. 4-48

Any Length............................................................................................................. 4-48

Code 11 Check Digit Verification................................................................................. 4-49

Transmit Code 11 Check Digits................................................................................... 4-49

Interleaved 2 of 5 (ITF) ......................................................................................................4-50

Set Lengths for I 2 of 5 ................................................................................................4-50

One Discrete Length (Parameter L1)..................................................................... 4-50

Two Discrete Lengths (Parameter L2)................................................................... 4-51

Length Within Range ............................................................................................. 4-51

Any Length............................................................................................................. 4-51

I 2 of 5 Check Digit Verification....................................................................................4-52

Transmit I 2 of 5 Check Digit .......................................................................................4-52

Convert I 2 of 5 to EAN 13........................................................................................... 4-53

Discrete 2 of 5 (DTF) .........................................................................................................4-53

Set Lengths for Discrete 2 of 5 ....................................................................................4-54

Two Discrete Lengths (Parameter L2)................................................................... 4-54

Length Within Range ............................................................................................. 4-55

Any Length............................................................................................................. 4-55

Codabar.............................................................................................................................4-56

CLSI Editing................................................................................................................. 4-56

NOTIS Editing..............................................................................................................4-57

Set Lengths for Codabar.............................................................................................. 4-57

One Discrete Length (Parameter L1)..................................................................... 4-57

Two Discrete Lengths (Parameter L2)................................................................... 4-58

Length Within Range ............................................................................................. 4-58

vi

Page 9

Any Length............................................................................................................. 4-58

MSI .................................................................................................................................... 4-59

Set Length(s) for MSI................................................................................................... 4-59

Two Discrete Lengths (Parameter L2)................................................................... 4-60

Length Within Range ............................................................................................. 4-60

Any Length............................................................................................................. 4-60

MSI Check Digits ......................................................................................................... 4-61

Transmit MSI Check Digit............................................................................................ 4-61

MSI Check Digit Algorithm...........................................................................................4-62

Postal Codes ..................................................................................................................... 4-62

US Postnet...................................................................................................................4-62

US Planet.....................................................................................................................4-63

UK Postal..................................................................................................................... 4-63

Transmit UK Postal Check Digit ............................................................................4-64

Japan Postal................................................................................................................ 4-64

Australian Postal..........................................................................................................4-65

Dutch Postal ................................................................................................................4-65

Transmit US Postal Check Digit ..................................................................................4-66

4 State Postal ..............................................................................................................4-66

GS1 DataBar (RSS).....................................................................................................4-67

GS1 DataBar Omnidirectional (RSS-14) ..................................................................... 4-67

GS1 DataBar Limited (RSS Limited) ...........................................................................4-67

GS1 DataBar Expanded (RSS Expanded) .................................................................. 4-68

Convert GS1 DataBar (RSS) to UPC/EAN.................................................................. 4-68

Composite ......................................................................................................................... 4-69

Composite CC-C..........................................................................................................4-69

Composite CC-A/B ......................................................................................................4-69

Composite TLC-39.......................................................................................................4-70

UPC Composite Mode................................................................................................. 4-70

2D Symbologies ................................................................................................................ 4-71

Aztec............................................................................................................................ 4-71

Aztec Inverse............................................................................................................... 4-72

PDF417........................................................................................................................4-72

MicroPDF417...............................................................................................................4-73

Code 128 Emulation ....................................................................................................4-73

Data Matrix ..................................................................................................................4-74

Data Matrix Inverse......................................................................................................4-74

Maxicode .....................................................................................................................4-75

MicroQR.......................................................................................................................4-75

QR Code...................................................................................................................... 4-76

QR Inverse...................................................................................................................4-76

Redundancy Level.............................................................................................................4-77

Security Level .................................................................................................................... 4-79

Intercharacter Gap Size..................................................................................................... 4-80

Imager Keypad Number Symbols...................................................................................... 4-81

Chapter 5 - Decode Zones

Introduction..........................................................................................................................5-1

vii

Page 10

Ring Laser ........................................................................................................................... 5-1

Ring Imager ......................................................................................................................... 5-2

PL4407 Near Focus Decode Distances.........................................................................5-2

PL4407 Far Focus Decode Distances........................................................................... 5-2

PL4407 Toggled Focus Decode Distances ...................................................................5-3

PL4407 Decode Distances in Darkness ........................................................................ 5-3

Chapter 6 - Technical Specifications

Ring Scanner / Imager.........................................................................................................6-1

Technical Specifications ................................................................................................ 6-1

Environmental Specifications.........................................................................................6-1

ASCII Character Equivalents...............................................................................................6-1

Chapter 7 - Customer Support

Technical Assistance...........................................................................................................7-1

Product Service and Repair.................................................................................................7-1

Limited Warranty .................................................................................................................7-1

viii

Page 11

1

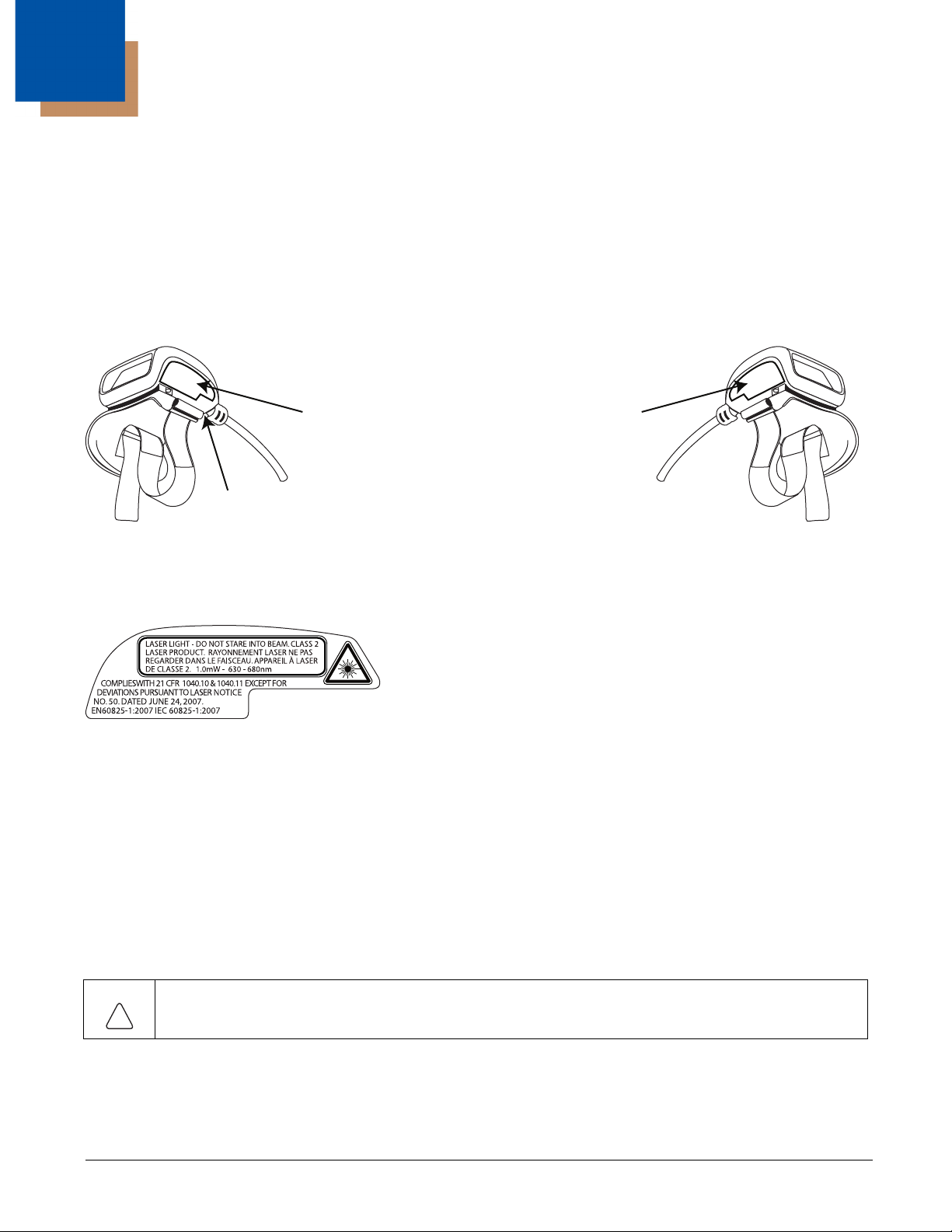

Laser Safety Label

Part Number and Serial Number Label

Compliance Label

!

Ring Scanner Agency Compliance

Ring bar code decoders meet or exceed the requirements of all applicable standards organizations for safe operation. However,

as with any electrical equipment, the best way to ensure safe operation is to operate them according to the agency guidelines

that follow. Read these guidelines carefully before using your Ring Scanner.

This documentation is relevant for the following models: 8600 series (861x, 862x) Ring Scanners.

Label Locations

Left Side of Scanner head Right Side of Scanner Head

Laser Label

If the following label is attached to your ring bar code decoder, it indicates the ring bar code decoder contains an engine with a

laser aimer:

Laser Safety Statement

This device has been tested in accordance with and complies with IEC60825-1:2007 and EN60825-1:2007). Complies with 21

CFR 1040.10 and 1040.11, except for deviations pursuant to Laser Notice No. 50, dated June 24, 2007.

LASER LIGHT, DO NOT STARE INTO BEAM, CLASS 2 LASER PRODUCT, 1.0 mW MAX OUTPUT: 630-680nM.

Laser Warnings

• Do not look into the laser’s lens.

• Do not stare directly into the laser beam.

• Do not remove the laser caution labels from the Ring Scanner ring bar code decoders.

• Do not connect the laser bar code aperture to any other device. The laser bar code aperture is certified for use with either the

HX2/HX3 or the Dolphin 70e Black in the Honeywell Wearable Solution only.

Caution:

Laser radiation when open. Read the caution labels. Use of controls, adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

1 - 1

Page 12

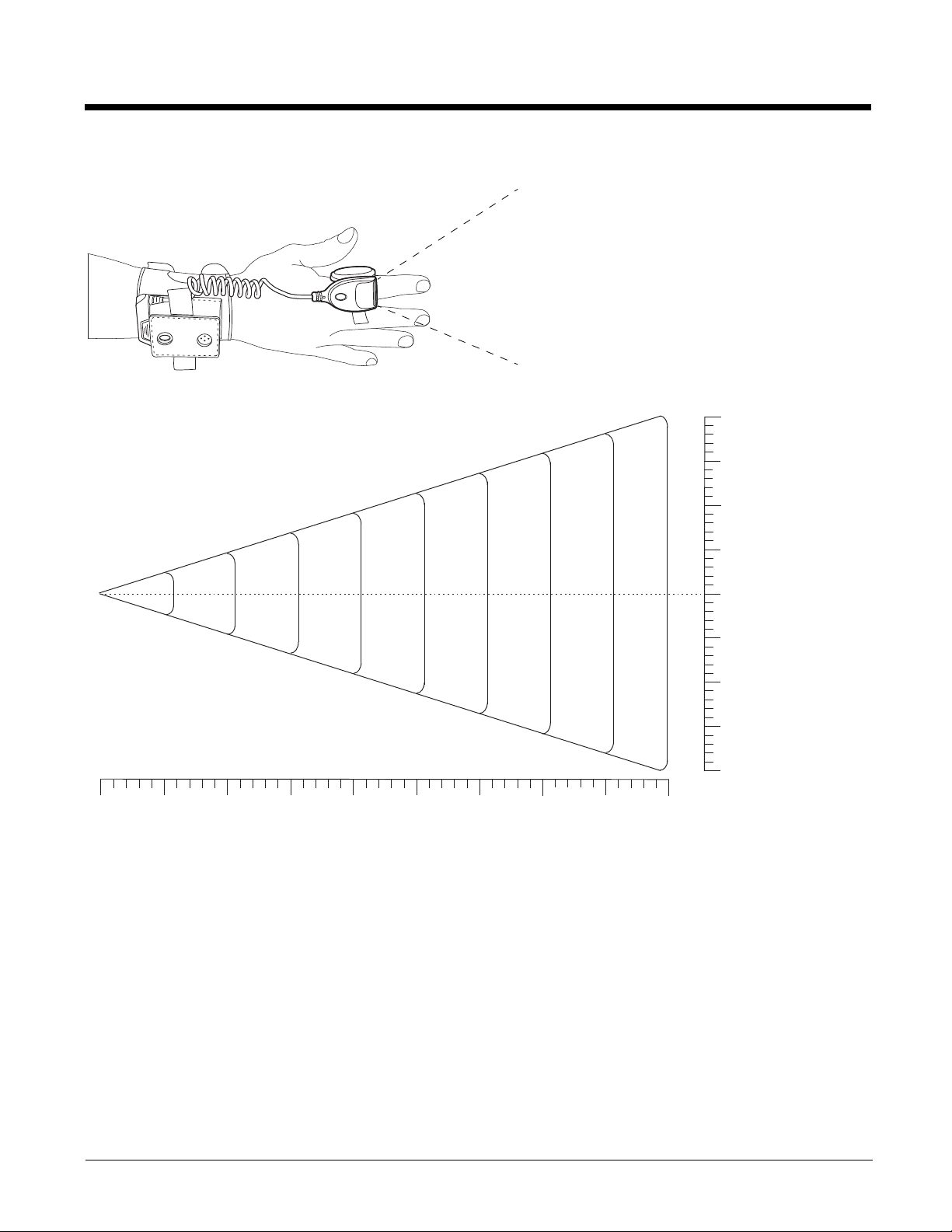

Beam Divergence

See dimension

of eld below

20” 50.8 cm

15” 38.1 cm

10” 31.6 cm

5” 12.7 cm

0” 0 cm

20” 50.8 cm

15” 38.1 cm

10” 31.6 cm

5” 12.7 cm

0”

5”

12.7 cm

10”

25.4 cm

15”

38.1 cm

20”

50.8 cm

25”

63.5 cm

30”

76.2 cm

35”

88.9 cm

40”

101.6 cm

45”

114.3 cm

Width of Field

0 cm

Depth of Field

FCC Part 15 Statement

This device has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

1 - 2

Page 13

Canadian Compliance

10

This ISM device complies with Canadian RSS-210.

Operation is subject to the following conditions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired operation.

This Class B digital apparatus complies with Canadian ICES-003.

IMPORTANT NOTE:

Radiation Exposure Statement:

This equipment complies with IC radiation exposure limits set forth for an uncontrolled environment. End users must follow the

specific operating instructions for satisfying RF exposure compliance. To maintain compliance with IC RF exposure compliance

requirements, please follow operation instruction as documented in this manual.

CE Mark

The CE marking indicates compliance with the following directives:

• 1995/5/EC R&TTE

• 2011/65/EU RoHS (Recast)

In addition, complies to 2006/95/EC Low Voltage Directive, when shipped with recommended power supply. European contact::

Hand Held Products Europe BV

Nijverheidsweg 9-13

5627 BT Eindhoven

The Netherlands

Honeywell shall not be liable for use of our product with equipment (i.e., power supplies, personal computers, etc.) that is not CE

marked and does not comply with the Low Voltage Directive.

Honeywell Scanning & Mobility Product Environmental Information

Refer to www.honeywellaidc.com/environmental for the RoHS / REACH / WEEE information.

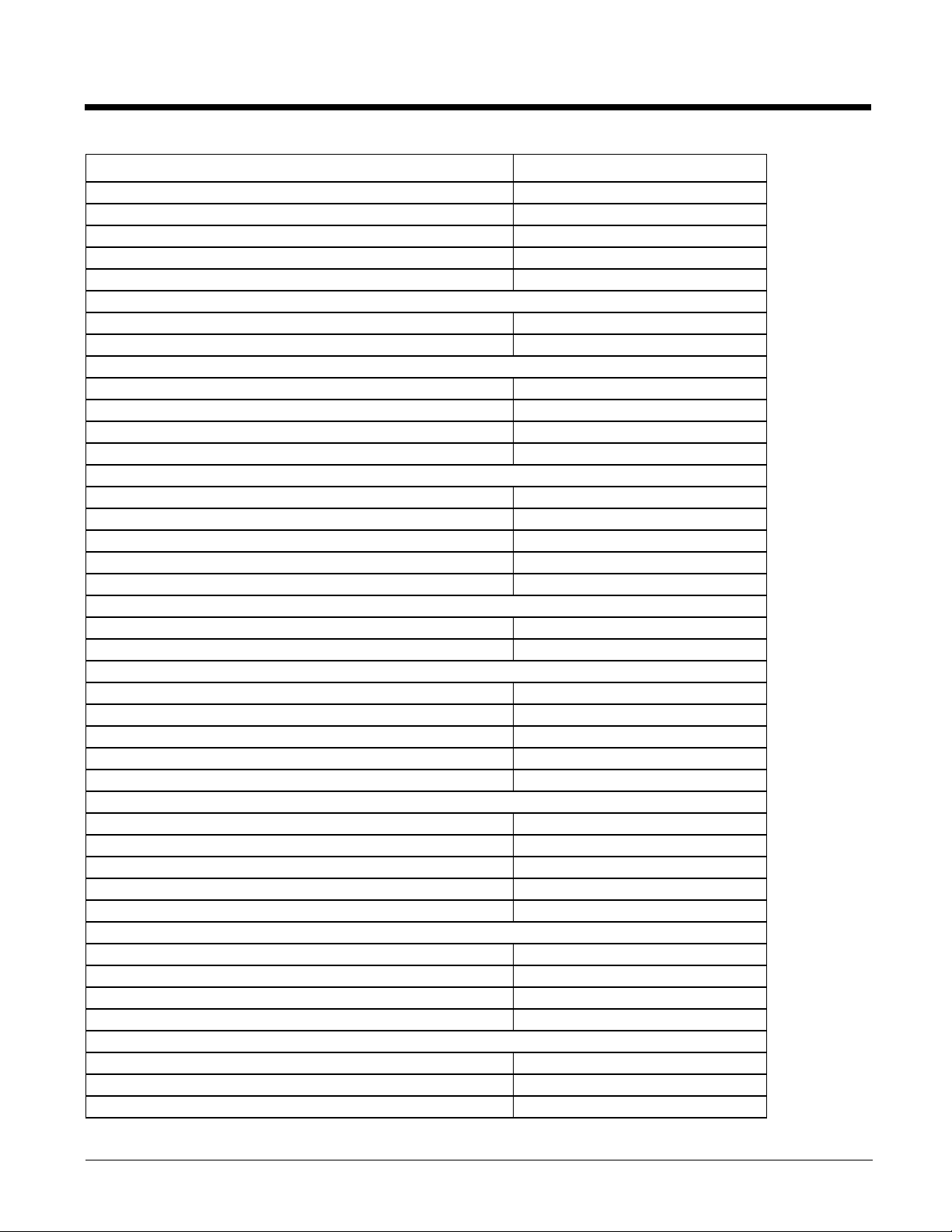

China RoHS

有毒有害物质名称及含量的标识 (Names and Content of Hazardous Substances or Elements)

部件名称 (Parts Name) 有毒有害物质或元素 (Toxic and Hazardous Substances or Elements)

铅 (Pb) 汞 (Hg) 镉 (Cd) 六价铬 (Cr6+) 多溴联苯 (PBB) 多溴二苯醚 (PBDE)

扫描模块 (Scanner Module)

印刷电路部件 (PCA)

外壳 (Housing)

连接线 (Cable)

o: 表示该有毒有害物质在该部件所有均质材料中的含量均在 SJ/T11363-2006 标准规定的限量要求以下 (Indicates that this toxic or hazardous substance contained in all of the

homogeneous materials for this part is below the limit requirement in China’s SJ/T11363-2006)

x: 表示该有毒有害物质至少在该部件的某一均质材料中的含量超出 SJ/T11363-2006 标准规定的限量要求 (Indicates that this toxic or hazardous substance contained in at least one of

the homogeneous materials for this part is above the limit requirement in China’s SJ/T11363-2006)

xooooo

xooooo

xooooo

xooooo

Dealer License - Republic of Singapore

1 - 3

Page 14

1 - 4

Page 15

2

Getting Started

Overview

This guide contains installation and configuration instructions for the Honeywell 8650 Ring Scanner. The Ring Scanner is

available with either a 1D laser scanner or 2D laser imager.

Bar code decoding laser engines and imager engines are designed to read, decode and collect bar coded data from any nearby

compatible bar code label that is visible and on printed media.

The ring scanner consists of a ring decoder with a cable to tether to a Honeywell HX2 or HX3. The HX2 or HX3 provides power

to the ring decoder. The hand strap assembly is designed to be worn on the back of either hand..

The Ring Scanner is compatible with the Honeywell HX2 and HX3. The ring scanner communicates to the serial port on the

HX2 or HX3 via the cable connection.

For information about other scanners, such as internal scanners, scanners connected to a COM port or Bluetooth scanners,

refer to www.honeywellaidc.com or the scanner manufacturer’s website.

About this Guide

This guide provides instruction for the end-user or system administrator to follow when setting up a new Ring Scanner bar code

decoder. This guide includes all programming bar codes and decode zones.

Out of the Box

After you open the shipping carton verify it contains the following items:

• Ring bar code decoder

• Hand strap

• Quick Start Guide

If you ordered accessories for the 8600-series Ring Scanner, verify they are also included with the order. Keep the original

packaging material in the event the Ring Scanner should need to be returned for service. For details, see Product Service and

Repair (page 7-1).

2 - 1

Page 16

Initial Setup

Following are the steps you might take when setting up a new Ring Scanner. More instruction for each step is listed later in this

guide. Contact Customer Support (page 7-1) if you need additional help.

Accessory installation or removal should be performed on a clean, well-lit surface. When necessary, protect the work surface,

the Ring Scanner, and components from electrostatic discharge.

Hardware Setup

1. Determine which hand will contain the assembly. See Determine Left or Right Orientation (page 2-3).

2. Connect the ring cable connector to the body worn computer. See Connect to Terminal (page 2-4).

Components

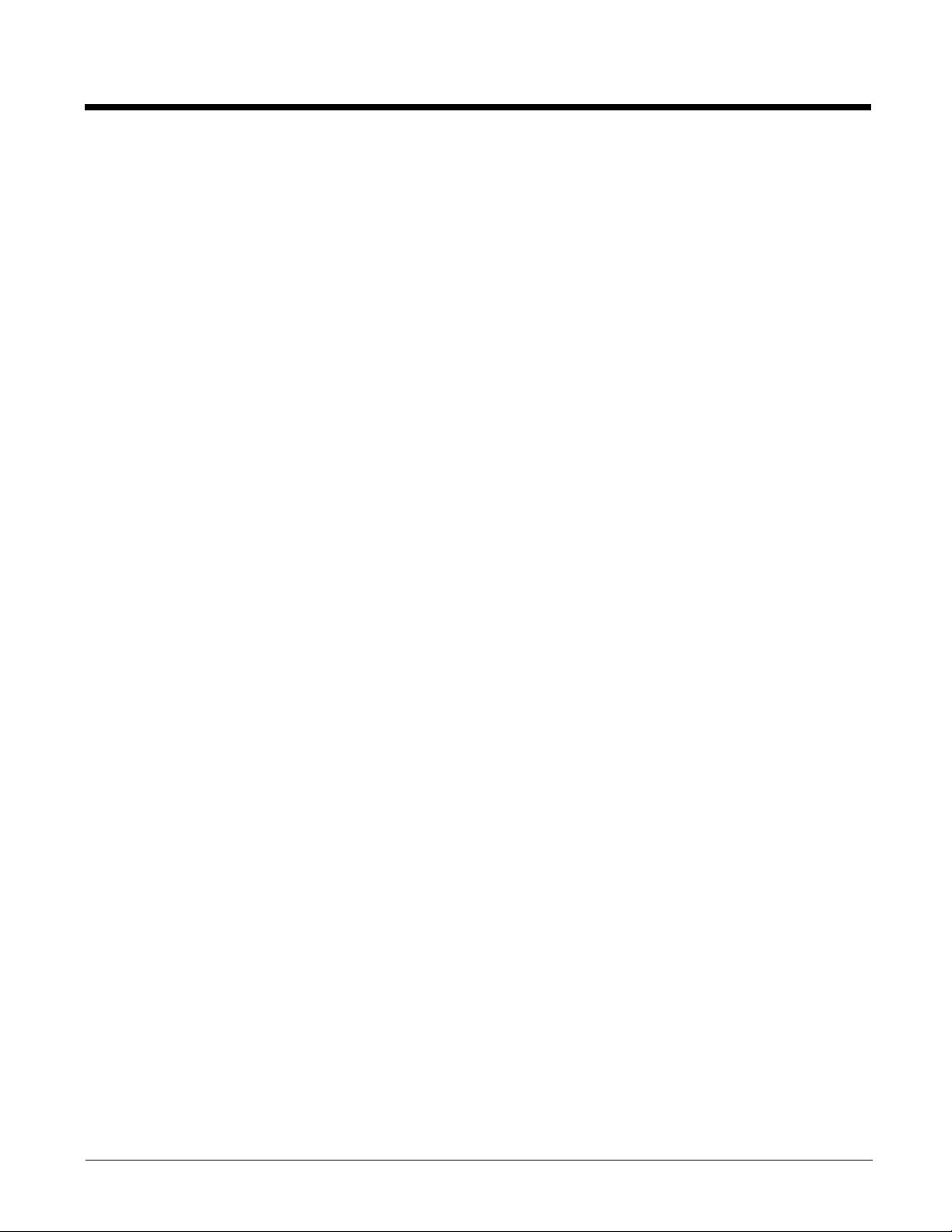

Ring Imager / Ring Scanner

The ring imager can scan and decode 1D and 2D bar codes. The imager has three small illumination LEDs at the top of the

scan window or aperture.

The ring scanner can scan and decode 1D bar codes. The scanner does not have illumination LEDs.

The ring sends the collected bar code data to the mobile computer for processing.

Do not touch, push against or brace your finger on the scan aperture at any time.

When new, there is a clear, tabbed protective film covering the ring decoder scan window. Remove and discard the clear,

tabbed protective film before scanning a bar code.

Ring Imager / Ring Scanner for Dolphin 70e Black in Wearable Sled.

2 - 2

Ring Imager Ring Scanner Cable Connector

Ring Imager / Ring Scanner for HX2 and HX3.

Ring Imager Ring Scanner Cable Connector

Page 17

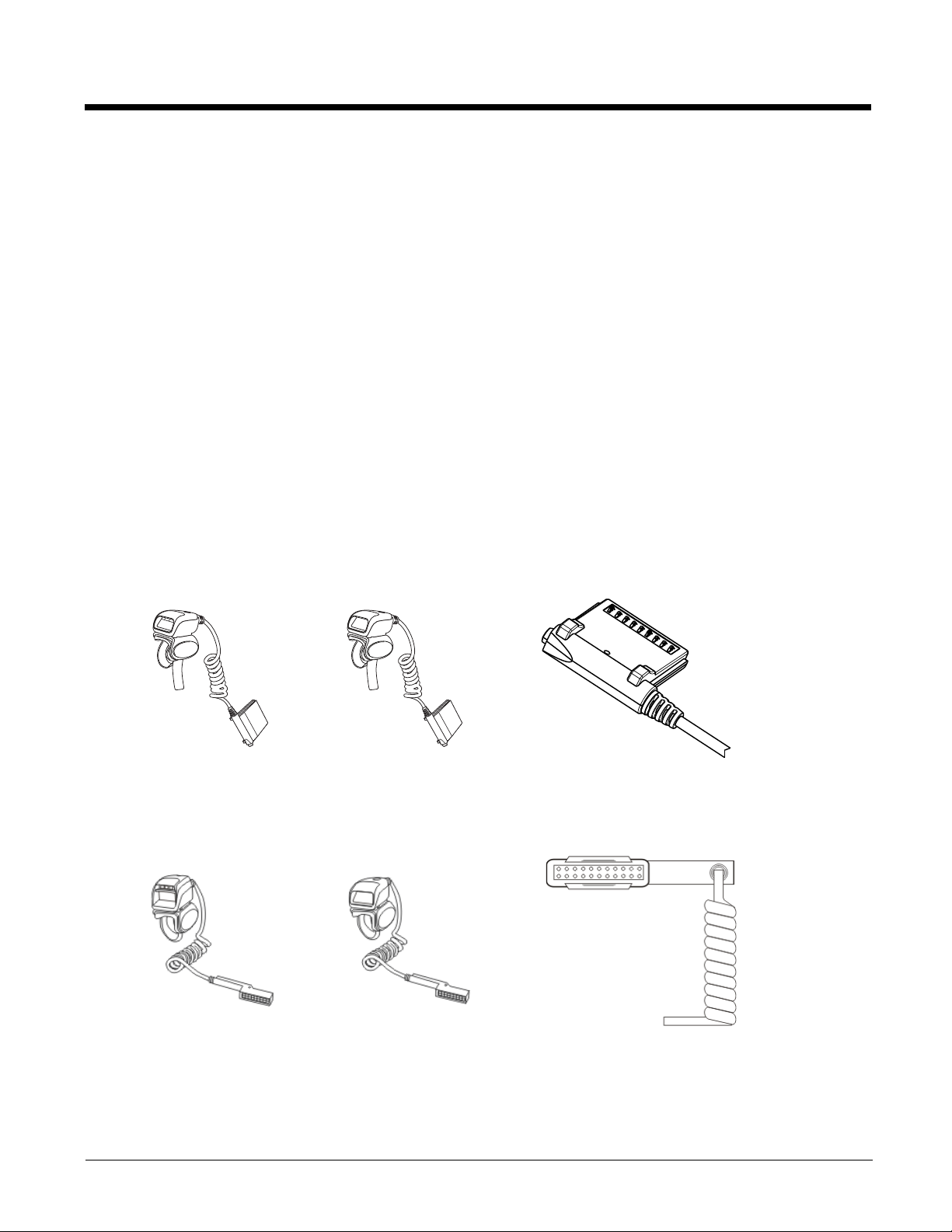

Assembly

Determine Left or Right Orientation

Determining whether to wear the module assembly on the left or right has a bearing on how the ring cable is attached to the

module and the ring to the finger. The ring cable should not cross over or under the hand.

Adjusting the Ring Device Strap

The ring device finger loop is located under the ring device. The ring device has a built-in quick disconnect designed for safety

hazards. The quick disconnect is not intended for daily removal of the ring device.

1. Pull gently on the end of the finger loop strap to separate the hook and loop fabric.

2. Slide your finger into the opened loop under the ring device.

3. Grasp the end of the finger loop strap and gently pull to loosen then tighten the finger strap until the ring device is

comfortably snug and the scan aperture is in the desired location.

4. Secure the ring strap at the desired location by pressing the hook fabric to the loop fabric on the strap surrounding the finger.

2 - 3

Page 18

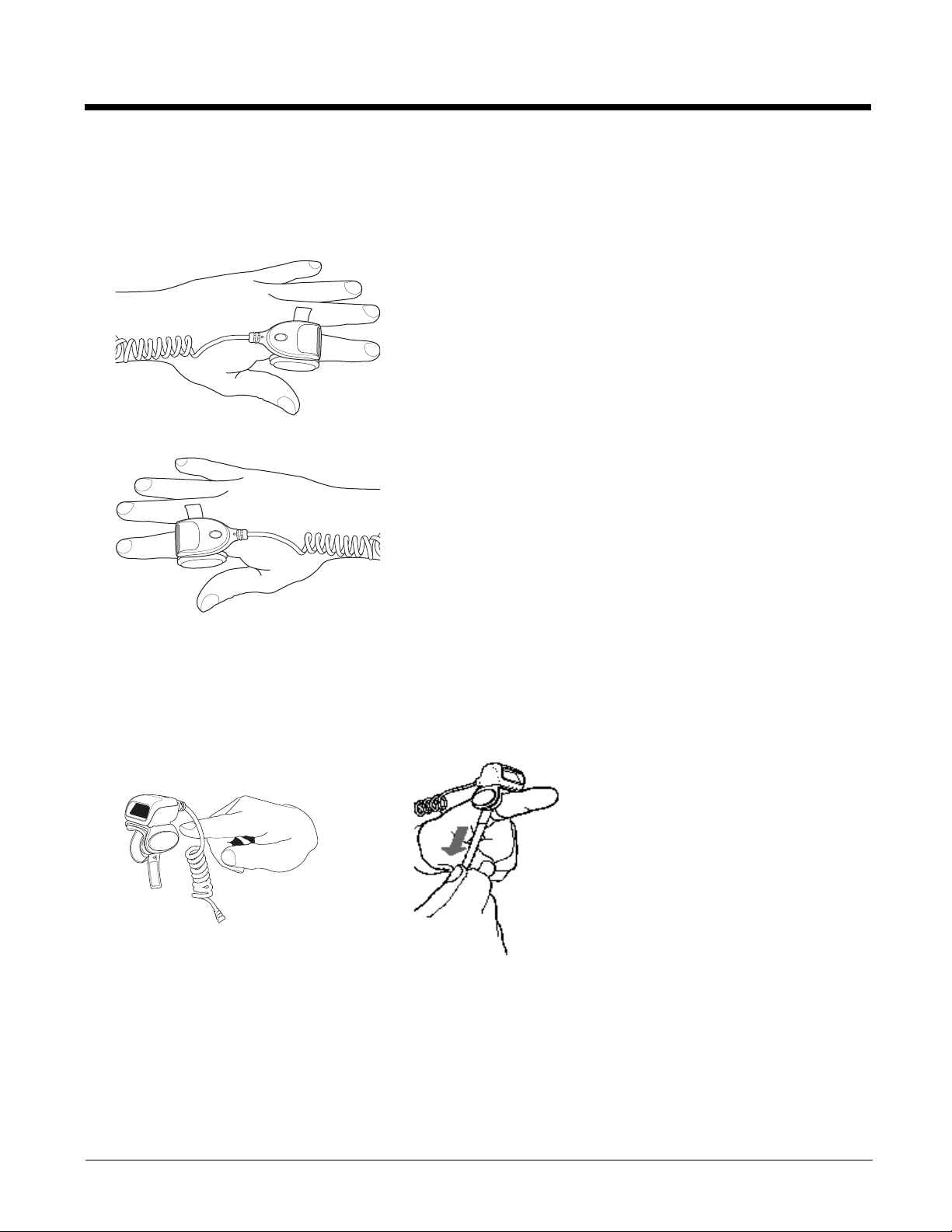

Connect to Terminal

1

2

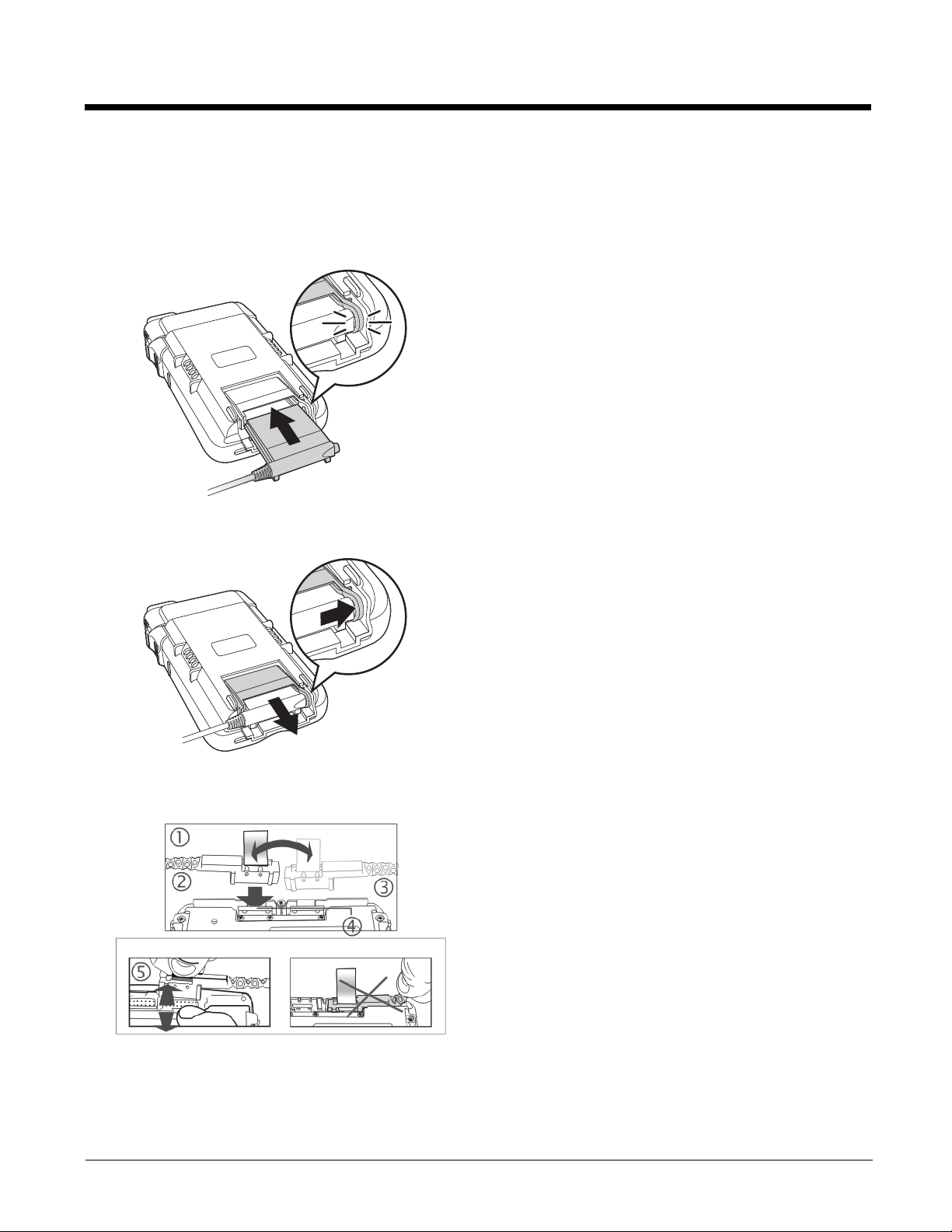

Dolphin 70e in Wearable Sled

Connect

Disconnect

1. Slide the ring scanner cable connector into the bottom

of the sled until the connector ring clicks shut.

1. To eject the ring scanner, open the connector ring with

one hand, pulling toward the outside of the sled.

2. Push the ring scanner connector out of the sled.

HX2 / HX3

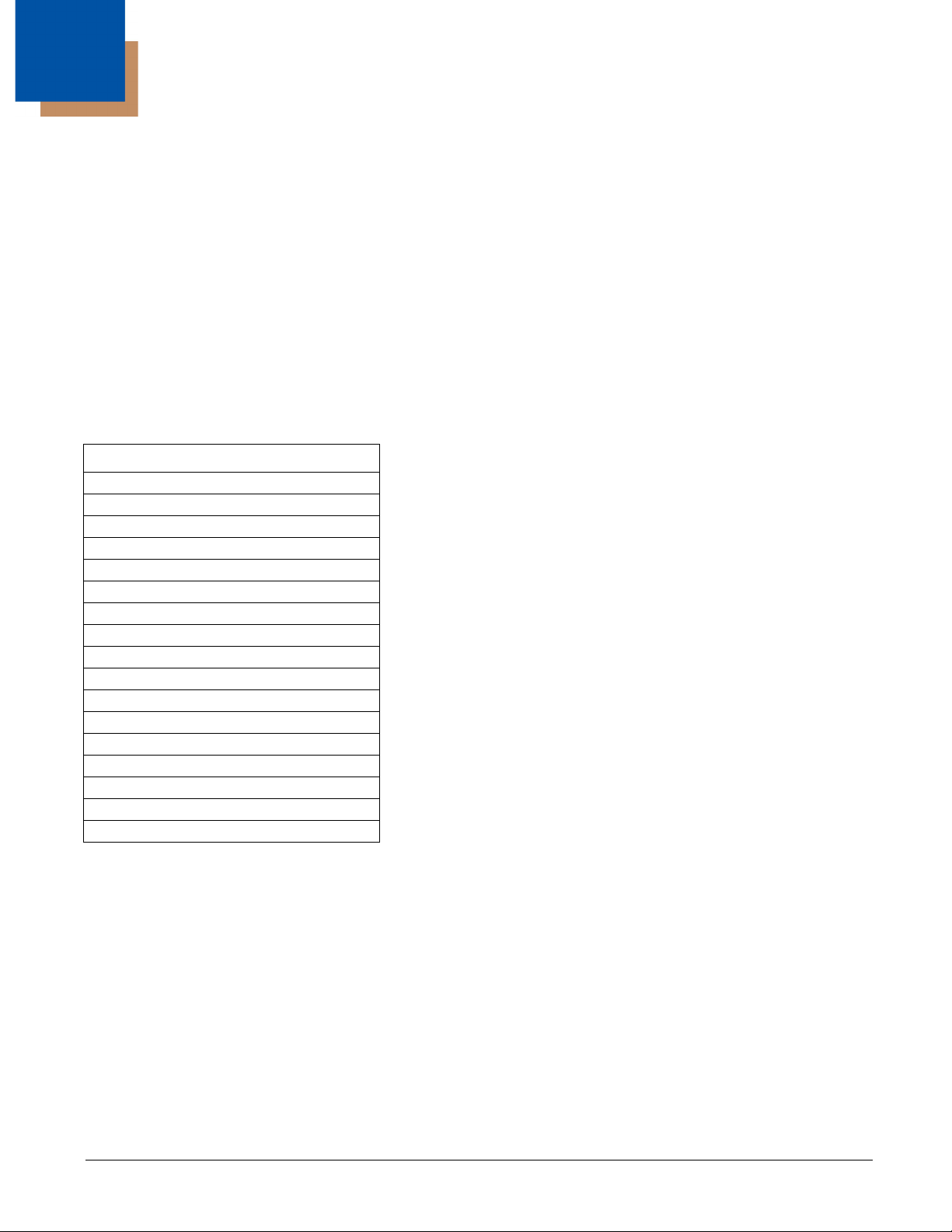

1. Connect

2. Ring on Left Hand

3. Ring on Right Hand

4. Press Down

5. Remove

When you want to switch connectors from left to right, or vice versa, first gently press downward on the Retaining Clip, then

pinch and pull the cable connector (not the cable!) straight up and away from the Ring Scanner. Do not use a metal object,

or extreme force, to remove the cable connector from the Ring Scanner.

Re-connect cables and reassemble the Ring Scanner body-worn components.

2 - 4

Page 19

Removing / Replacing the Trigger Module

Equipment Needed: Phillips screwdriver with a blade diameter of 1/8” (.4mm). Not supplied.

Caution: Do not perform the following procedures if the ring bar code reader is tethered to a mobile computer There is a

possibility the Scan button may be pressed inadvertently and the laser beam emitted. Disconnect the ring scanner before

attempting to remove or replace the trigger module.

Do not touch, push on or brace your finger against the scan aperture at any time.

Installing and removing accessories should be performed on a clean, well-lit surface. When necessary, protect the work

surface, the mobile device, and components from electrostatic discharge.

A 20-pak of full Trigger assemblies is available. Contact Customer Support (page 7-1) for the latest updates and accessories.

Remove Finger Strap Assembly

Fold the flexible liner back until the screw hole is visible.

Rotate the trigger module until the black screw is visible.

1. Using a Phillips screwdriver with a blade diameter of 1/8” (.4mm) loosen the black screw counter-clockwise and set the

screw aside in a safe place.

2. Remove the trigger module.

Replace Trigger Module

1. Position the trigger module on the base of the Ring Scanner, making sure the empty screw hole is visible.

2. Find the tiny black screw that you removed previously.

3. Using a Phillips screwdriver with a blade diameter of 1/8” (.4mm) rotate the black screw clockwise until the trigger

module is secured to the ring scanner.

4. Install the finger strap.

5. Removing / Replacing the Ring Finger Strap Assembly

Note: Do not pull on the finger strap or the flexible liner to remove the finger strap assembly. This quick disconnect function is

designed for occasional safety hazards and is not intended for daily removal.

Using the Quick Disconnect Function, grasp the finger strap and pull the finger strap out and away from the ring scanner.

Before attaching the finger strap to the trigger module, thread the finger strap first through the hinge, then under and over the pin

next to the scan button.

It should slide easily.

Cleaning the Beam Aperture

Note: These instructions are for components made of glass. If there is a removable protective film sheet on the beam aperture,

remove the film sheet before cleaning and before first use.

Keep fingers and rough, sharp or abrasive objects away from the beam aperture.

If the aperture becomes soiled or smudged, clean only with a standard household cleaner such as Windex® without vinegar or

use Isopropyl Alcohol.

Do not use paper towels or harsh-chemical-based cleaning fluids since they may result in damage to the aperture surface. Use

a clean, damp, lint-free cloth. Do not scrub optical surfaces.

If possible, clean only those areas which are soiled. Lint/particulates can be removed with clean, filtered canned air.

2 - 5

Page 20

How To Scan a Bar Code

The function to use an imager like a camera (or for OCR decoding) is not supported. Using a Continuous Scan option, if

available, to scan programming bar codes is not supported.

The linear bar codes in this guide were created using Code 128 symbology. Your Ring Scanner has been set up by Honeywell

to automatically read / decode Code 128 bar codes.

Using the bar codes contained in this guide, you can change bar code reader system parameters or reset all parameters to their

factory default values.

It is important to use the correct bar codes when programming the scanner/imager:

• 1D Laser Scanner Programming Bar Codes (page 3-1)

• 2D Laser Imager Programming Bar Codes (page 4-1)

All bar code reader parameters are programmed into and stored by the bar code reader engine.

If this guide is not in print form, locate the page in this electronic guide that contains the bar code you wish to use. Print the

page on white paper using a 600dpi laser printer (or equivalent).

Print the page containing the Reset and Cancel bar codes as well as the page containing the A – F and 0 – 9 number bar codes.

Select the parameter you want to scan. If this guide is in print form, lay it flat on a table or propped up at an angle.

Scan a Linear Bar Code

Holding the beam aperture approximately 3 – 12 inches away from the bar code, aim the scan aperture toward the selected

bar code. Refer to the bar code reader engine type in Decode Zones later in this guide for recommended decode ranges.

Press the Scan button. Align the scan beam so that the bar code is centered within the beam. The beam must cross the

entire bar code. Move the bar code reader towards or away from the bar code so that the bar code takes up approximately

two-thirds the width of the beam.

Refer to the recommended decode zones for the ring bar code reader engine if you are having difficulty with this process.

Do not position the scan aperture exactly perpendicular to the bar code being read. In this position, light can bounce back

into the scan aperture, and possibly prevent a successful decode.

Good Read / Bad Read Indicators

The scan On indicator illuminates (usually red) when the beam is on. Following a bar code scan and “good read” the indicator turns green indicating a successful scan. The connected mobile device may also beep or play a WAV file while

decoding the signal from the ring scanner.

The laser beam and scan On indicator automatically turn off after a successful or unsuccessful read and the bar code

reader is ready to scan again.

2 - 6

Page 21

Factors That May Impact Scanner Performance

Successful scanning range of a bar code decoder is dependent upon many outside influences including size of the bar code,

quality of the bar code printing, material the bar code is printed on, condition of the scan lens (scratches) and angle of the beam

aperture relative to the bar code label. Any of these factors may result in having to re-scan the label from a different distance or

angle.

Bar Code Quality

Check the bar code for marks or physical damage e.g., ripped label, missing section, correct size for the scanner being used,

etc.

In general, the bigger the bar code the further the distance from which it can be read. If the bar code is smaller than the

specified size for the scanner being used, the distance, in almost all cases, will shrink.

Large bar codes can be scanned at the maximum distance. Hold the scanner closer to small bar codes (or with bars that are

very close together).

Do not position the scanner exactly perpendicular to the bar code being scanned. In this position, light can bounce back into the

scan aperture, and possibly prevent a successful decode.

Bar Code Source

Using a graphics program to clip/copy a bar code from an online file (e.g., Adobe, Word) will copy the bar code at your monitor's

dot per inch setting, a level too low for successful bar code scanning.

Copy a Bar Code -- Use your browser's right-click menu to download an individual bar code using the Save Picture As option.

Save the picture to a location on your computer's hard drive. The individual bar code can be added, as a file, to any delivery

vehicle e.g., email, Word document.

Bar Code Symbology

Bar codes such as UPC codes and Code 128 are more complex than Code 39 and Interleaved 2 of 5. When attempting to get

the maximum read distance possible, particularly with reflective labels, use Code 39. The use of Code 128 or other more

complex symbologies will almost always result in a reduction in maximum read distance. Scanner maximum distances (from

Decode Zones) when symbologies other than Code 39 are used are not supported.

Lens Damage

A scratched scan beam aperture can impact read rates and distances. Beam apertures should be inspected frequently,

particularly if scanning quality or distances get worse over time.

Ambient Lighting

High ambient conditions, particularly outdoor environments, will produce enough light to somewhat “blind” the scanner. This will

result in shorter read distances.

Temperature

While small deviations from room temperature will have no impact on scanner performance, severe conditions like those found

in freezers will have a negative impact on both the distance scanners can read and the speed the read is acquired.

Some scanner engines contain protection circuitry that shuts the scanner down in temperatures that exceed the recommended

operating temperature.

Bar Code Scanning Help

Notes

• Decrease decode time by disabling unused bar code types. The scan engine can store several different bar code symbologies

at the same time. This means the Ring Scanner is able to scan a Code 39 bar code, then an Interleaved 2 of 5 bar code, then

a different bar code without requiring a parameter reset.

• The mobile device Scanner (or Data Collection Wedge) panel parameters are applied to the data resulting from successful

bar code scans sent to the host (e.g., Thor VM2) for processing. The wedge panel does not affect or change the programming

bar code parameter settings in this guide.

• After scanning the Reset All to default (or equivalent) bar code with the tethered ring scanner, the next step is to open the

Scanner (or Data Collection Wedge) panel on the host, click the OK button and then close the panel. This action will

synchronize all scanner formats.

2 - 7

Page 22

Issue:

Bar codes on the printed page are too compact to be scanned, especially with a long range scanner.

Solution 1 - Printing Adobe Acrobat PDF File Pages:

When printing pages from an Adobe Acrobat PDF file, there is a difference between laser printer types and how they handle

some Adobe Acrobat print functions – specifically, the “shrink to fit” option on the Print Options screen. Before clicking Print,

make sure the “Shrink oversized pages to paper size” checkbox is unchecked. If the bar code is still too small to be read by the

scanner engine, run the printed page through the laser printer again using the laser printer’s Zoom feature until the bar code is

large enough to scan satisfactorily.

When printing pages from an on-line Web page, run the printed page through a laser copier using the laser copier's Zoom

feature until the bar code is large enough to scan satisfactorily.

Solution 2 - Printing from a Browser Page:

Use the Print button on the browser menu. Bar codes must be printed at 600 dots per inch (dpi) before they can be successfully

scanned with a bar code reader.

Miscellaneous Programmable Bar Codes

Beep After Good Decode

Audible scan progress indicators are generated by the scanner driver on mobile devices, not the bar code decoder engine.

Use the Windows wedge panel options to set up the mobile device audible indicators.

Beeper Frequency Adjustment

Audible scan progress indicators are generated by the scanner driver on mobile devices, not the bar code decoder engine.

Use the Windows wedge panel options to set up the mobile device audible indicators.

Event Reporting

Mobile devices aren’t designed to process events triggered by a bar code decoder engine. Events are processed by the

operating system resident on the mobile device. Use Windows Control Panel options to set up the mobile device event

reporting parameters.

LED Mode

This parameter is disabled/inactive as the scan LEDs are controlled by the scanner driver, not the scanner engine.

2 - 8

Page 23

Return to Factory Default Settings

Choose one of the following methods to restore factory defaults in the module, scan the Set Default Parameter (page 3-6)

or Set All Defaults/Cancel Bar Codes (page 4-5)bar code.

Important: - HX2 and HX3 only:

After resetting the module to factory default settings, the next step is to open the bar code wedge panel on the host mobile

device collecting the scanned data. Click the OK button to close the panel. This action will synchronize all scanner formats.

2 - 9

Page 24

2 - 10

Page 25

3

1D Laser Scanner Programming Bar Codes

Introduction

These bar codes, explanations and instructions are for programming the SE955 laser scanner engine in your ring scanner. Do

not scan the bar codes in this section with any other imager or laser engine.

Note: A ring scanner does not have beep / audio capability.

Assumption: The user is familiar with Windows on-screen functions.

Scan engine manufacturers may offer more bar codes and options than are contained in this chapter. Note that the bar codes in

this chapter are only those supported by Honeywell and the mobile devices it manufactures or supports. Contact Customer

Support (page 7-1) if you need help using the bar codes in this guide.

To change a parameter value: Scan the appropriate bar code in this section. The new value replaces the standard default

value in memory.

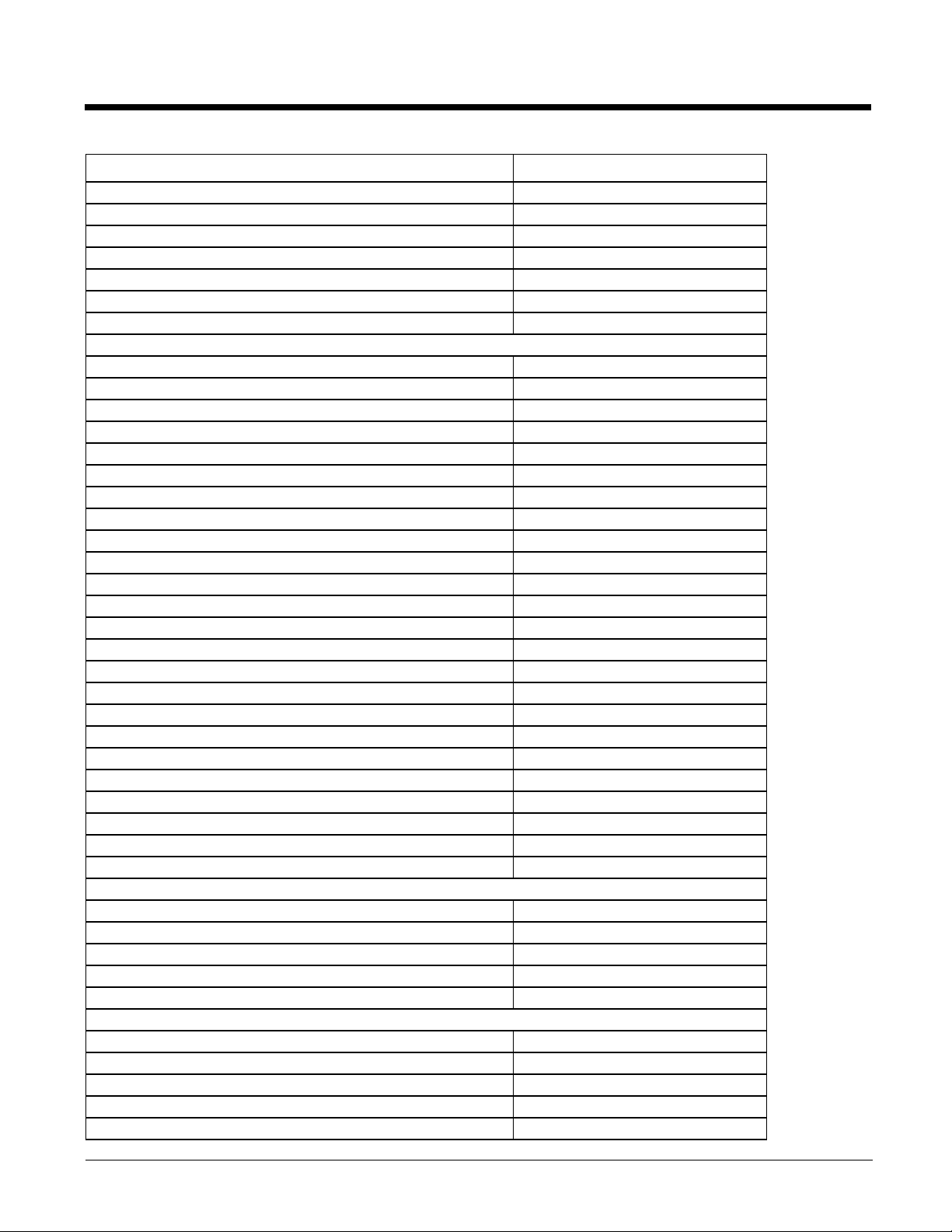

The following bar code symbologies are supported on the Ring Scanner:

Symbology

DataBar (RSS)

GS1Chinese 2 of 5

Codabar

Code 11

Code 128

Code 39

Code 93

Discrete 2 of 5

Interleaved 2 of 5

MSI Plessey

GS1 Databar (RSS) and Composite Codes

UPC/EAN

UPC-A

UPC-E

UPC-E1

EAN-8

EAN-13

3 - 1

Page 26

Aiming Modes

There are many aiming “modes” for laser bar code scanners – aiming dots, aiming patterns, aim duration, etc. All aiming

“modes” concern the length of time the beam is sent out, how wide the beam is and what happens when the timer expires. The

terms are used interchangeably and may be confusing for the novice bar code laser scanner user.

Note: Decoding algorithms released by the bar code engine manufacturer often change upon each new release. Programming

parameters that were available at one release may not be available upon a later software release. Honeywell supports

the programming bar codes for the specific engines in this guide only.

SE955 Ring Scanner

The scan engine can have it's aiming beam/aiming dot setup using these bar codes:

• Use Laser On Time (page 3-14)

• Aim Duration (page 3-7), and

• Scan Angle (SE955 only) (page 3-17)

Aiming Dot Help

How to get an aiming dot when there is no “Aiming Dot” parameter:

Set Aim Duration to .5 seconds and an aiming “dot” is sent while the scan trigger is held down. When the timer expires, the

aiming beam widens and the bar code is read.

Prefix / Suffix

Ring decoder engine prefix and suffix parameters should not be set, changed, or reset using the Prefix and Suffix bar codes

shown in this section. When the Ring Scanner module is reset to defaults, the prefix and suffix settings revert to their default

values and need to be scanned again. Use the ScanWedge NGW Power Tool (Dolphin 70e) or Scanner control panel (HX2 or

HX3) in the host computer to store prefix and suffix values.

Refer to the host computer’s user guide for information and instruction on setting up the following scanner parameters:

• Enable/Disable decoding sounds

• Imager LED Illumination

• COM1 Serial Parameters

• Code ID: AIM, Symbol, Custom

• Symbology Settings including Prefix/Suffix

• Control Character Mapping

• Custom Identifiers

• Pre-Configured Default Values

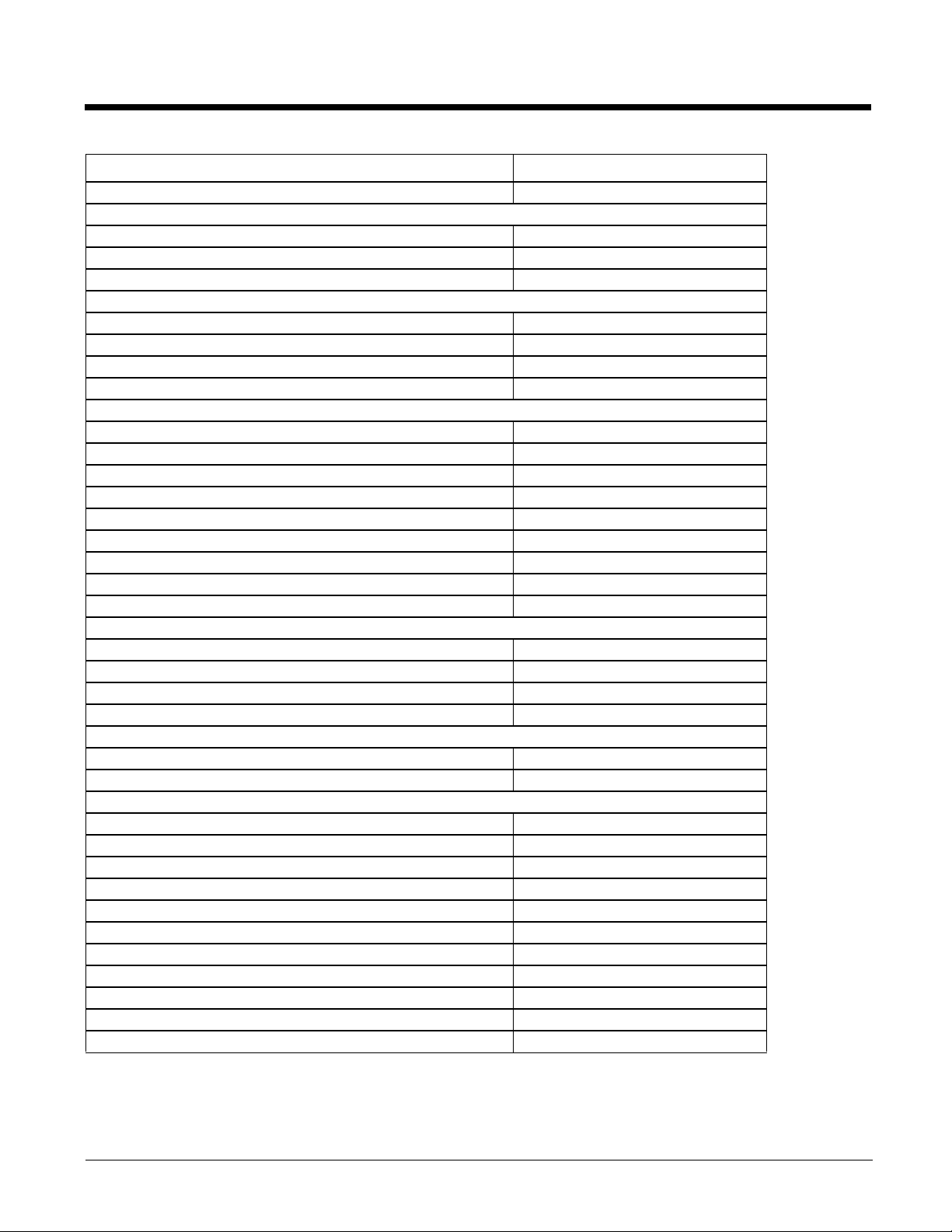

Ring Scanner Setting 955 Default

Set Default Parameter (page 3-6) All Defaults

Scanning Options

Aim Duration (page 3-7) 0.0 sec

Aiming Mode Not Supported

Beeper Volume Not Supported

Bi-Directional Redundancy (page 3-7) Disable

Laser On Time (page 3-14) 3.0 sec.

Linear Code Type Security Level (Redundancy Level) (page

3-15)

Parameter Pass Through (page 3-16) Disable

Parameter Scanning (page 3-16) Enable

Power Mode (page 3-17) Low Power

Raster Expansion Rate Not Supported

Raster Height Not Supported

1

3 - 2

Page 27

Ring Scanner Setting 955 Default

Scan Angle (SE955 only) (page 3-17) Wide

Scanning Mode Not Supported

Time Delay to Low Power Not Supported

Time-out Between Different Symbols Not Supported

Time-out Between Same Symbol Not Supported

Transmit “No Read / Decode” Message (page 3-24) Disable

Trigger Mode (page 3-25) Host

UPC/EAN

UPC-A (page 3-52) Enable

UPC-E (page 3-52) Enable

UPC-E1 (page 3-53) Disable

EAN-8 (page 3-53) Enable

EAN-13 (page 3-54) Enable

Bookland EAN (page 3-54) Disable

Bookland ISBN Format (page 3-55) Bookland ISBN-10

Decode UPC/EAN Supplementals (page 3-62) Ignore

Decode UPC/EAN Supplemental Redundancy (page 3-64) 7

Transmit UPC-A Check Digit (page 3-55) Enable

Transmit UPC-E Check Digit (page 3-56) Enable

Transmit UPC-E1 Check Digit (page 3-56) Enable

UPC-A Preamble (page 3-59) System Character

UPC-E Preamble (page 3-60) System Character

UPC-E1 Preamble (page 3-61) System Character

Convert UPC-E to UPC-A (page 3-57) Disable

Convert UPC-E1 to UPC-A (page 3-57) Disable

Convert EAN-8 to EAN-13 Type (page 3-58) Type is EAN-13

EAN-8 Zero Extend (page 3-65) Disable

UPC/EAN Security Level (page 3-66) 0

UCC Coupon Extended Code (page 3-65) Disable

Linear UPC/EAN Decode Not Supported

UPC Half Block Stitching Not Supported

UPC Composite Mode Not Supported

Code 128

Code 128 (page 3-33) Enable

GS1-128 (formerly UCC/EAN-128) (page 3-33) Enable

ISBT-128 (page 3-34) Enable

Code 128 Decode Performance Not Supported

Code 128 Decode Performance Level Not Supported

Code 39

Code 39 (page 3-35) Enable

Trioptic Code 39 (page 3-39) Disable

Convert Code 39 to Code 32 (page 3-36) Disable

Code 32 Prefix (page 3-36) Disable

Set Lengths for Code 39 (page 3-37) Length within Range: 02 – 55

3 - 3

Page 28

Ring Scanner Setting 955 Default

Code 39 Check Digit Verification (page 3-35) Disable

Transmit Code 39 Check Digit (page 3-39) Disable

Code 39 Full ASCII Conversion (page 3-37) Disable

Code 39 Decode Performance Not Supported

Code 39 Decode Performance Level Not Supported

Code 93

Code 93 (page 3-40) Disable

Set Lengths for Code 93 (page 3-40) Length within Range: 04 – 55

Code 11

Code 11 (page 3-30) Disable

Set Lengths for Code 11 (page 3-30) Length within Range: 04 – 55

Code 11 Check Digit Verification (page 3-32) Disable

Transmit Code 11 Check Digits (page 3-32) Disable

Interleaved 2 of 5

Interleaved 2 of 5 (page 3-44) Enable

Set Lengths for I 2 of 5 (page 3-45) 14

I 2 of 5 Check Digit Verification (page 3-44) Disable

Transmit I 2 of 5 Check Digit (page 3-47) Disable

Convert I 2 of 5 to EAN-13 (page 3-45) Disable

Discrete 2 of 5

Discrete 2 of 5 (page 3-42) Disable

Set Lengths for Discrete 2 of 5 (page 3-42) 12

Chinese 2 of 5

Chinese 2 of 5 (page 3-26) Disable

Codabar (page 3-27)

CLSI Editing (page 3-27) Disable

NOTIS Editing (page 3-28) Disable

Set Lengths for Codabar (page 3-28) Length within Range: 05-55

MSI Plessey

MSI Plessey (page 3-48) Disable

Set Lengths for MSI Plessey (page 3-49) Length within Range: 06-55

MSI Plessey Check Digits (page 3-49) One

Transmit MSI Plessey Check Digit (page 3-51) Disable

MSI Plessey Check Digit Algorithm (page 3-48) Mod 10/Mod 10

PDF417/MicroPDF417

PDF417 Not Supported

MicroPDF417 Not Supported

Decode Linked Symbol Not Supported

Code 128 Emulation Not Supported

GS1 DataBar (RSS) Codes

GS1 DataBar Omnidirectional (RSS-14) (page 3-67) Disable

GS1 DataBar Limited (RSS-Limited) (page 3-67) Disable

Convert GS1 DataBar (RSS) to UPC/EAN (page 3-68) Disable

3 - 4

Page 29

Ring Scanner Setting 955 Default

Convert GS1 DataBar (RSS) to UPC/EAN Disable

Composite

CC-C Not Supported

CC-AB Not Supported

TLC-39 Not Supported

Data Options

Prefix and Suffix (page 3-8) Prefix: NULL, Suffix 1: LF, Suffix 2:CR

Scan Data Transmission Format (page 3-9) Data as is

Transmit Code ID Character (page 3-11) None

Decode Buffering Not Supported

Simple Serial Interface (SSI) Options

Baud Rate (page 3-18) 9600

Parity (page 3-20) None

Check Parity Not Supported

Software Handshaking (page 3-22) Enable

Decode Data Packet Format (page 3-19) Unpacketed

Stop Bit Select (page 3-23) 1

Intercharacter Delay (page 3-20) 0

Host Serial Response Time-out (page 3-19) 2 sec

Host Character Time-out (page 3-19) 200 msec

Macro PDF

Macro PDF Transmit/Decode Mode Not Supported

Transmit Each Symbol in Codeword Format Not Supported

Transmit Unknown Codewords Not Supported

Escape Character Not Supported

ECI

Delete Character Set ECIs Not Supported

ECI Decoder Not Supported

Transmit Macro PDF User-Selected Field

Transmit File Name Not Supported

Transmit Block Count Not Supported

Transmit Time Stamp Not Supported

Transmit Sender Not Supported

Transmit Addressee Not Supported

Transmit Checksum Not Supported

Transmit File Size Not Supported

Transmit Macro PDF Control Header Not Supported

Last Block Marker Not Supported

Flush Macro Buffer Not Supported

Abort Macro PDF Entry Not Supported

3 - 5

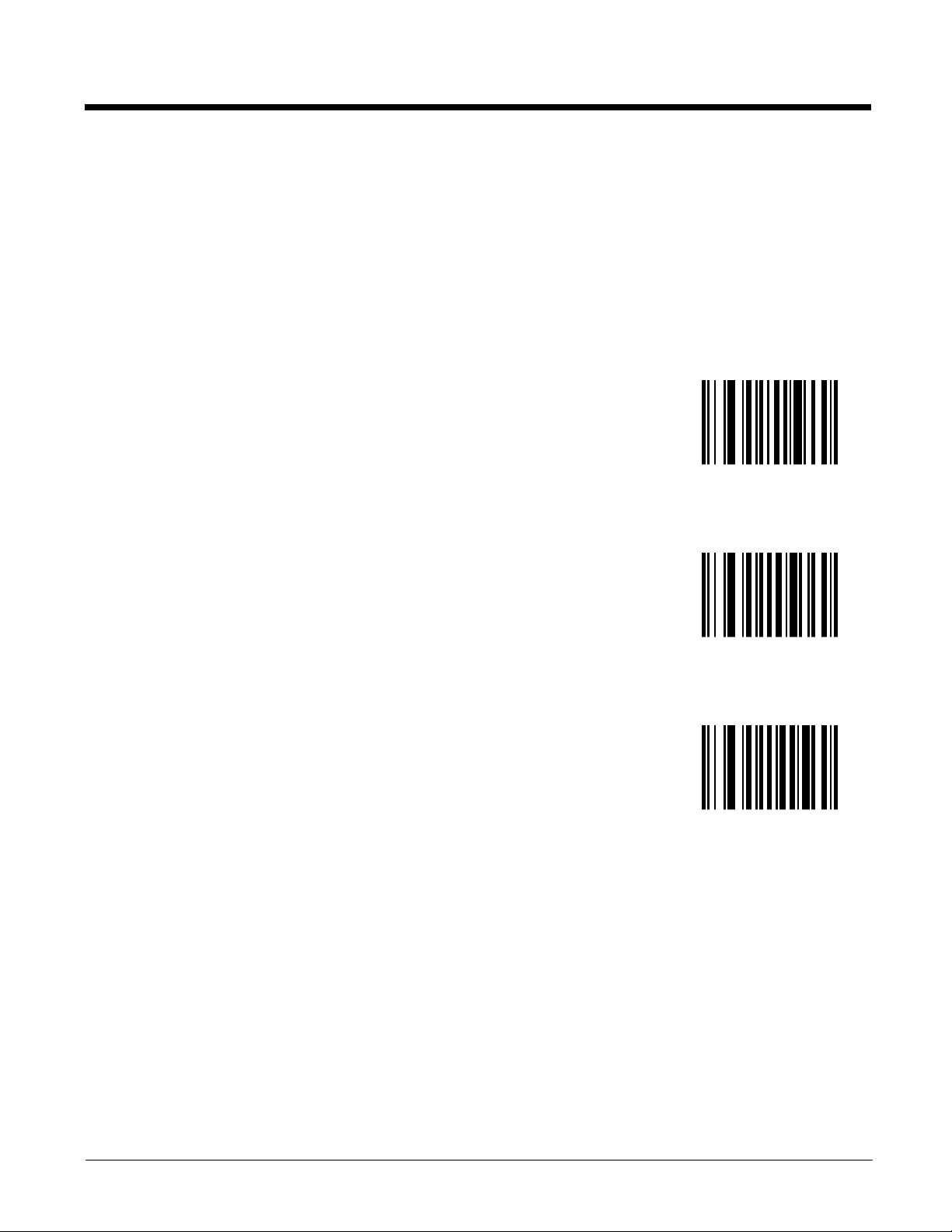

Page 30

Set Default Parameter

Restore Defaults

If custom defaults were set by scanning Write Custom Defaults, scan Restore Defaults to retrieve and restore the scanner’s

custom default settings. If no custom defaults were set, scan Restore Defaults to restore the factory default values.

Set Factory Defaults

Restore the factory default values. If custom defaults were set, they are eliminated.

Write Custom Defaults

Store the current scanner settings as custom defaults. Once custom default settings are stored, they can be recovered at

any time by scanning the Restore Defaults bar code.

Restore Defaults

Set Factory Defaults

Write Custom Defaults

See Also: Return to Factory Default Settings (page 2-9).

3 - 6

Page 31

Scanner Parameters – General

Aim Duration

Note: For correct operation, reboot the mobile device after changing this value.

When a scanner with an aim mode is triggered either by a Scan button press, or a Start_Decode command, this parameter

sets the duration the aiming pattern is seen before a scan attempt begins. It does not apply to the aim signal or the

Aim_On command. It is programmable in 0.1 second increments from 0.0 to 9.9 seconds. No aim pattern is visible when

the value is 0.0.

To set aim duration, scan the bar code below:

Next scan two numeric bar codes that correspond to the desired aim duration. Times less than 1.0 second must have a

leading zero. For example, to set an aim duration of 0.5 seconds, scan the bar code above, then scan the “0” and “5” bar

codes on Keypad Number Symbols (page 3-72). If you make an error, or wish to change your selection, scan the Cancel

bar code.

Bi-Directional Redundancy