Page 1

Airport Systems

Installation and Operation Guide

Programmable Logic Controller

Manual Number EPM40002083-001

for

Health Monitoring System

Model 40002083

Honeywell Airport Systems

550 State Route

Urbana, OH 43078

Phone (937) 484-2000

Fax (937) 484-2101

www.oblighting.com

Copyright 2007 Honeywell International

All Rights Reserved

Page 2

Airport Systems

HISTORY OF REVISIONS

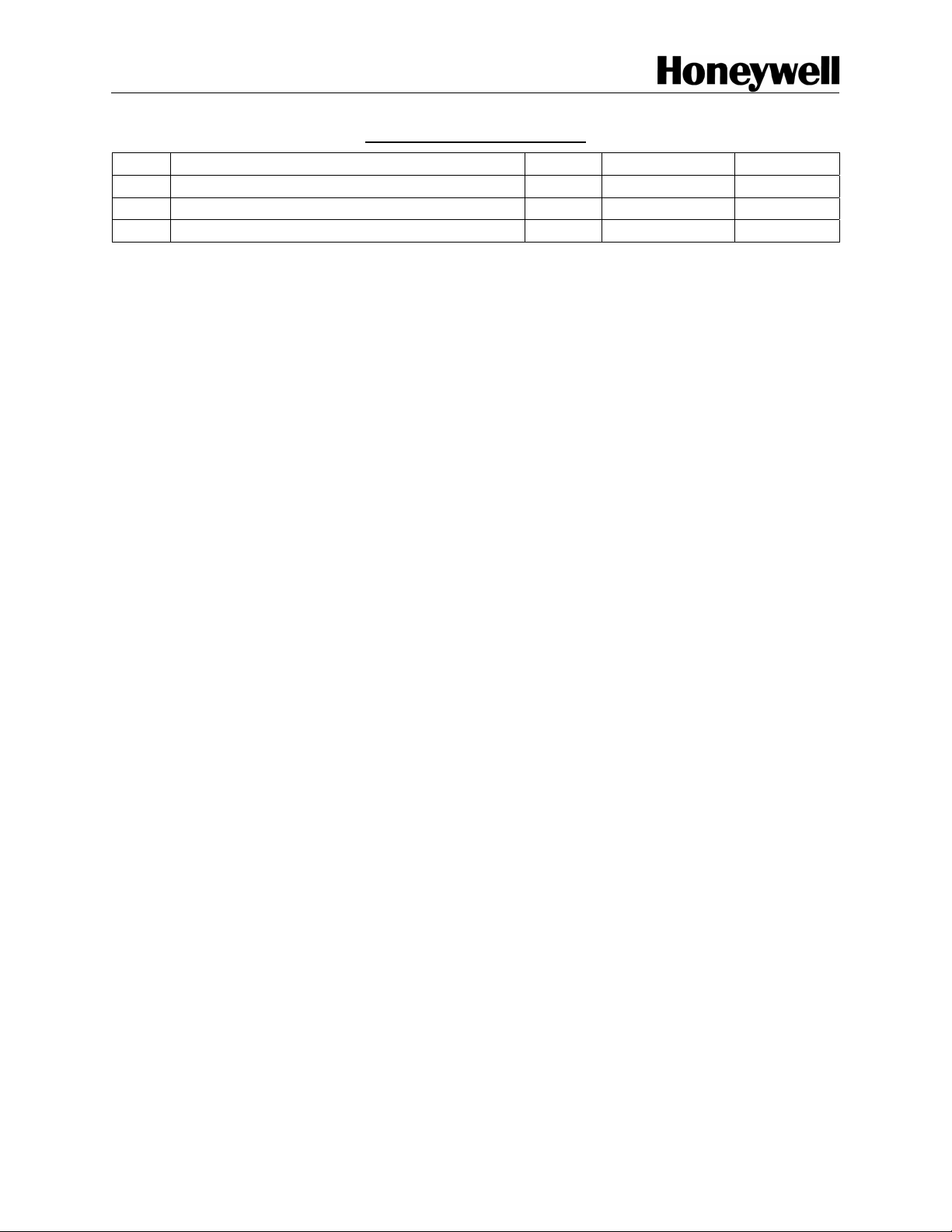

Rev. Comment ECO# Approved Date

1 Preliminary

The integrity and reliability of Honeywell airport lighting systems are dependent on the use of Honeywell parts and components. To ensure

the optimum performance and reliability of your Honeywell system, it is strongly advised that only components and modules provided by

Honeywell be used.

The following is Honeywell’s standard Limited Warranty for Airport Systems Products (“Products”). This warranty applies unless a

different warranty has been specifically agreed to and signed by Honeywell’s authorized representative.

1.1 LIMITED WARRANTY

(a) “Nonconformance” means a defect in workmanship or material; a failure to comply with applicable Honeywell drawings; or a

failure to comply with applicable FAA specifications. Normal wear and tear (including but not limited to incandescent lamp failure) or

the need for periodic maintenance shall not constitute a Nonconformance.

(b) Honeywell warrants that at time of delivery to Buyer, its Products will comply with applicable Honeywell drawings and FAA

specifications and will be free from defects in workmanship and material. These warranties shall run to Buyer, its successors and

NOTICE

assigns. The duration of these warranties shall be as follows:

(c) Buyer must notify Honeywell in writing of a Nonconformance within the warranty period and return the Product to Honeywell

within thirty (30) calendar days after such notice, in accordance with instructions which shall be issued by Honeywell. Honeywell's

obligation and Buyer's remedy under this warranty is limited to either repair or replacement, at Honeywell’s option, of the

nonconforming Product. All Products repaired or replaced hereunder shall be warranted only for the unexpired portion of the original

warranty period. Honeywell agrees to assume round trip transportation costs for a nonconforming Product in an amount not to

exceed normal ground shipping charges to the warranty service facility designated by Honeywell. The risk of loss or damage to all

Products in transit shall be borne by the Party initiating the transportation of such Products.

(d) Honeywell shall not be liable under this warranty if the Product has been exposed or subjected to (1) any maintenance, repair,

installation, handling, transportation, storage, operation or use which is improper or otherwise is not in compliance with Honeywell's

instructions; or (2) any alteration, modification or repair by anyone other than Honeywell or those specifically authorized in writing by

Honeywell; or (3) any accident, contamination, foreign object damage, abuse, neglect or negligence after delivery to Buyer; or (4)

any damage precipitated by failure of a Honeywell supplied Product not under warranty or by any product not supplied by Honeywell.

(e) THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES, WHETHER WRITTEN OR ORAL, EXPRESS,

IMPLIED OR STATUTORY, INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY,

FITNESS FOR PARTICULAR PURPOSE, OR NON-INFRINGEMENT, ALL OF WHICH ARE HEREBY EXPRESSLY DISCLAIMED.

NO EXTENSION OR EXPANSION OF THIS WARRANTY SHALL BE BINDING UPON HONEYWELL UNLESS SET FORTH IN

WRITING AND SIGNED BY HONEYWELL’S AUTHORIZED REPRESENTATIVE.

(f) IN NO EVENT SHALL HONEYWELL BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

UNDER THIS WARRANTY EVEN IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGES INCLUDING, WITHOUT LIMITATION,

INTERRUPTION OF BUSINESS, LOSS OF PROFITS, OR LOSS OF USE. THE EXCLUSION OF INCIDENTAL AND

CONSEQUENTIAL DAMAGES AS SET FORTH IN THIS WARRANTY SHALL BE DEEMED INDEPENDENT OF, AND SHALL

SURVIVE, ANY FAILURE OF THE ESSENTIAL PURPOSE OF ANY LIMITED REMEDY UNDER THE TERMS OF THIS

WARRANTY

(1) for non-LED-based obstruction lights, twenty-four (24) months after shipment of the Product;

(2) for non-LED-based airfield lights and for Control and Monitoring Systems (excluding software and third-party

components), twenty-four (24) months after shipment of the Product or twelve (12) months after date of first use,

whichever occurs first;

(3) for LED-based airfield and obstruction lights, five (5) years after shipment of the Product;

(4) for Control and Monitoring System software developed by Honeywell, ninety (90) days from date of first use; and

(5) for third party hardware and software components of Control and Monitoring Systems, in accordance with the warranty

from the third party.

PLC Health Monitoring & Reporting Sys i Manual EPM40002083-001 Rev -

Page 3

Airport Systems

DISCLAIMERS

This manual could contain technical inaccuracies or typographical errors. Honeywell

reserves the right to revise this manual from time to time of the contents thereof without

obligation of Honeywell to notify any person of such revision or change. Details and

values given in this manual are average values and have been compiled with care. They

are not binding, however, and Honeywell disclaims any liability for damages or

detriments suffered as a result of reliance on the information given herein or the use of

product, processes or equipment to which this manual refers. No warranty is made that

the use of the information or of the products processes or equipment to which this

manual refers will not infringe any third party’s patents or rights. The information given

does not release the buyers from making their own experiments and tests.

PLC Health Monitoring & Reporting Sys ii Manual EPM40002083-001 Rev -

Page 4

Airport Systems

TABLE OF CONTENTS

1.1 LIMITED WARRANTY ..................................................................................................................I

SAFETY INFORMATION................................................................................................V

SECTION 2. GENERAL INFORMATION..................................................................... 2-1

2.1 SCOPE .......................................................................................................................................2-1

2.2 GENERAL DESCRIPTION...............................................................................................................2-1

2.2.1 PLCHMR System Module......................................................................................................2-1

2.2.2 Model SGC-60 Master Controller replacement Micro-Controller Unit....................................2-1

2.2.3 Model SGF-60-E Flash-head replacement Micro-Controller Unit ..........................................2-2

SAFETY PRECAUTIONS .............................................................................................................................2-6

2.3 SPECIFICATIONS .........................................................................................................................2-9

SECTION 3. INSTALLATION & POWER UP .............................................................. 3-1

3.1 UNPACKING ................................................................................................................................3-1

3.2 USER SUPPLIED TOOLS ...............................................................................................................3-1

3.2.1 Master Controls Switch Setting For Installation ...................................................................3-1

3.2.2 Power Configuration.............................................................................................................3-2

3.3 INSTALLATION .............................................................................................................................3-2

3.3.1 Installation Overview ............................................................................................................3-2

3.3.2 SGC-60 Master Controller MCU Upgrade ...........................................................................3-2

3.3.3 PLCHMR Module Installation ...............................................................................................3-5

3.3.4 SGF-60-E Flash-head Digital Controller MCU Upgrade ......................................................3-8

3.4 FLASH HEAD STATUS REPORTING RELAY INSTALLATION WIRING .................................................3-11

3.5 FINAL INSTALLATION CHECK ......................................................................................................3-13

3.5.1 Preliminary..........................................................................................................................3-13

3.5.2 Verify Correct Wiring from the PLCHMR Module to Master Controller..............................3-13

3.6 POWER UP AND SYSTEM TESTS.................................................................................................3-13

3.6.1 PLCHMR Status Indicators ................................................................................................3-13

3.6.2 System Power Up...............................................................................................................3-13

3.7 PLCHMR SYSTEM MAINTENANCE AND CONFIGURATION MENUS ...................................................3-16

3.7.1 PLCHMR System Maintenance & Configuration Menus Overview ...................................3-16

3.7.2 HMS Maintenance Menu Login..........................................................................................3-18

3.7.3 HMS Light Configuration Menu ..........................................................................................3-19

3.7.4 PLCHMR Report Configuration Menu................................................................................3-21

3.7.5 PLCHMR Facility Configuration Menu ...............................................................................3-22

3.7.6 Verify Local Mode Operation..............................................................................................3-23

SECTION 4. PRINCIPLES OF OPERATION............................................................... 4-1

4.1 OVERALL DESCRIPTION ...............................................................................................................4-1

SECTION 5. MAINTENANCE...................................................................................... 5-1

5.1 PLCHMR MODULE .....................................................................................................................5-1

SECTION 6. REPLACEMENT PARTS ........................................................................ 6-1

SECTION 7. APPENDIX A – EXAMPLES...................................................................7-1

7.1 LIGHT CONFIGURATION EXAMPLES...............................................................................................7-1

PLC Health Monitoring & Reporting Sys iii Manual EPM40002083-001 Rev -

Page 5

Airport Systems

TABLE OF FIGURES

Figure 2.2-1 PLCHMR Module .....................................................................................2-3

Figure 2.2-2 Master Controller with PLCHMR Module Installed ...................................2-4

Figure 2.2-3: Model SGF-60E Flash Head ................................................................... 2-5

Figure 3.3-1 Model SGC-60 Master Controller with MCU High-lighted .......................3-4

Figure 3.3-2 PLCHMR Module Mounted on and Wired to Master Controller................ 3-6

Figure 3.3-3 Terminal Block- 8 +16V - Red and GND –Black Wire Connections ......... 3-7

Figure 3.3-4 StrobeGuard Control & Status Network Wiring Connections ...................3-8

Figure 3.3-5 MCU Location on Flash Head Digital Logic Controler ............................ 3-10

Figure 3.4-1 PLCHMR's Output Relay connection Diagram.......................................3-12

Figure 3.6-1 Master Controller Circuit Board..............................................................3-15

Figure 3.7-1 PC to PLCHMR RS-232 Serial Port Interface Cable Connections .........3-17

Figure 3.7-2 HMS Maintenance Menu Hierarchy ....................................................... 3-18

Figure 3.7-3 HMS Maintenance Menu........................................................................3-19

Figure 3.7-4 HMS Light Configuration Menu .............................................................. 3-20

Figure 3.7-5 HMS Modify Light Menu.........................................................................3-21

Figure 3.7-6 HMS Report Confguration Menu............................................................ 3-22

Figure 3.7-7 HMS Facility Conguration Menu ............................................................3-22

Figure 7.1-1 Tower Example with 9 Flash Heads on Three Physical Tiers .................. 7-2

Figure 7.1-2 Light Configuration Menus Settings for 9 Lights and 7 Relay Outputs ..... 7-3

Figure 7.1-3 System Configuration with 9 Flash Heads using 7 relays ........................7-4

Figure 7.1-4 Light Configuration Menus Settings for 24 Light and 8 Relay Outputs.....7-5

Figure 7.1-5 System Configuration with 24 Flash Heads using 8 relays ......................7-6

PLC Health Monitoring & Reporting Sys iv Manual EPM40002083-001 Rev -

Page 6

Airport Systems

SAFETY INFORMATION

This section contains general safety instructions for using your Honeywell equipment. Task

and equipment-specific Warnings are included in other sections of this manual where

appropriate. Read all Warnings and follow all instructions carefully. Failure to do so may

result in personal injury, death, or property damage. To use this equipment safely, refer to

the following:

1. Refer to the FAA Advisory Circular AC 150/5340-26, Maintenance of Airport Visual

Aids Facilities, for instructions on safety precautions.

2. Observe all safety regulations. To avoid injuries, always remove power prior to

making any wire connections and/or touching any parts. Refer to FAA Advisory

Circular AC 150/5340-26.

3. Read and become familiar with the general safety instructions provided in this section

of the manual before installing, operating, maintaining, or repairing this equipment.

4. Read and carefully follow the instructions given throughout this manual before

performing specific tasks and working with specific equipment.

5. Store this manual within easy reach of personnel installing, operating, maintaining, or

repairing this equipment.

6. Follow all applicable safety procedures required by your company, industry standards,

and government or other regulatory agencies.

7. Obtain and read Material Safety Data Sheets (MSDS) for all materials used.

SAFETY AND WORKMANSHIP ALERTS

This manual uses two types of markings when giving instructions requiring special

attention. The markings will be followed by indented text:

WARNING!

The WARNING sign in this manual denotes a hazard. The WARNING

calls attention to a procedure or practice which, if not correctly

performed or adhered to, could result in property damage, injury or

death. Do not proceed beyond a WARNING sign until the indicated

conditions are fully understood and met.

.

CAUTION

Failure to obey the instructions following a CAUTION marking may

result in equipment damage.

PLC Health Monitoring & Reporting Sys v Manual EPM40002083-001 Rev -

Page 7

Airport Systems

QUALIFIED PERSONNEL

The term “qualified personnel” is defined here as individuals who thoroughly understand

the equipment and its safe operation, maintenance, and repair. Qualified personnel are

physically capable of performing the required tasks, familiar with all relevant safety rules

and regulations and have been trained to safely install, operate, maintain, and repair the

equipment. It is the responsibility of the company operating this equipment to see that

its personnel meet these requirements.

INTERLOCKS

This equipment contains interlocks for your protection. To ensure safety, always

remove power from the equipment prior to opening access panels or doors if possible.

Do not depend on the interlocks or door switches when working with the equipment. Do

not short-circuit or tamper with any access gate, door or other safety interlock switch.

Discharge capacitors with an approved insulated grounding rod prior to touching any

part. When it is absolutely mandatory that an interlock be bypassed for the purpose of

tracing or correcting a malfunction, authorized maintenance personnel may perform the

bypass for the specific test to be made. Immediately after completing the test, restore

the interlock to working condition.

WARNING!

INTENDED USE

HONEYWELL IS NOT RESPONSIBLE FOR INJURIES OR DAMAGES

RESULTING FROM NONSTANDARD, UNINTENDED APPLICATIONS OF

ITS EQUIPMENT. THIS EQUIPMENT IS DESIGNED AND INTENDED

ONLY FOR THE PURPOSE DESCRIBED IN THIS MANUAL. USES NOT

DESCRIBED IN THIS MANUAL ARE CONSIDERED UNINTENDED USES

AND MAY RESULT IN SERIOUS PERSONAL INJURY, DEATH OR

PROPERTY DAMAGE. UNINTENDED USES MAY RESULT FROM

TAKING ANY OF THE ACTIONS LISTED BELOW.

1. Making changes to the equipment that have not been recommended

or described in this manual, or using parts that are not genuine

Honeywell replacement parts.

2. Failing to make sure that auxiliary equipment complies with

approval agency requirements, local codes, and all applicable

safety standards.

3. Using materials or auxiliary equipment that are inappropriate or

incompatible with your Honeywell equipment.

4. Allowing unqualified personnel to perform any task.

PLC Health Monitoring & Reporting Sys vi Manual EPM40002083-001 Rev -

Page 8

Airport Systems

KEEP AWAY FROM LIVE CIRCUITS. OPERATION AND MAINTENANCE

PERSONNEL MUST OBSERVE ALL SAFETY REGULATIONS AT ALL

TIMES. DO NOT CHANGE PLUG-IN COMPONENTS OR MAKE

ADJUSTMENTS INSIDE EQUIPMENT WITH THE HIGH VOLTAGE

SUPPLY ON. UNDER CERTAIN CONDITIONS, THERE IS A POTENTIAL

FOR SERIOUS INJURY FROM CIRCUITS WITH POWER CONTROLS IN

THE OFF POSITION. THIS IS DUE TO CHARGES RETAINED BY THE

CAPACITORS. TO AVOID SERIOUS INJURY, ALWAYS DISCONNECT

POWER, THEN DISCHARGE CAPACITORS BY USING AN APPROVED

GROUNDING ROD PRIOR TO TOUCHING ANY PART.

RESUSCITATION. MAINTENANCE PERSONNEL SHOULD BE TRAINED

IN CARDIOPULMONARY RESUSCITATION (CPR).

WARNING!

CAUTION

This equipment contains static sensitive semiconductor devices and

integrated circuits that may be damaged by Electro-Static Discharge

(ESD). Take the necessary precautions before attempting service.

Any replacement circuit boards should be kept in metallized anti-static

bags until immediately before installation. Ground yourself (touch the

outside of a grounded metal enclosure) before removing circuit boards

from their protective bags. Avoid touching components when handling

the boards.

PLC Health Monitoring & Reporting Sys vii Manual EPM40002083-001 Rev -

Page 9

Airport Systems

SECTION 2. GENERAL INFORMATION

2.1 Scope

This manual provides information about the installation, operation, and maintenance of

the Programmable Logic Controller Health Monitoring and Reporting (PLCHMR) System

manufactured by Honeywell.

2.2 General Description

The PLCHMR system is a retrofitable health monitoring and reporting system for

Honeywell’s high intensity flashing white obstruction lighting system. A majority of the

system’s functionality is contributed by the PLCHMR module. It is designed for use with

the StrobeGuard, Model SG-60E High Intensity Obstruction Lighting System. The

system is designed and manufactured in compliance with Federal Aviation

Administration Advisory Circular 150/5345-43E. The PLCHMR system will monitor and

report on up to 24 flash-heads controlled by a single controller at distances up to 2500

feet.

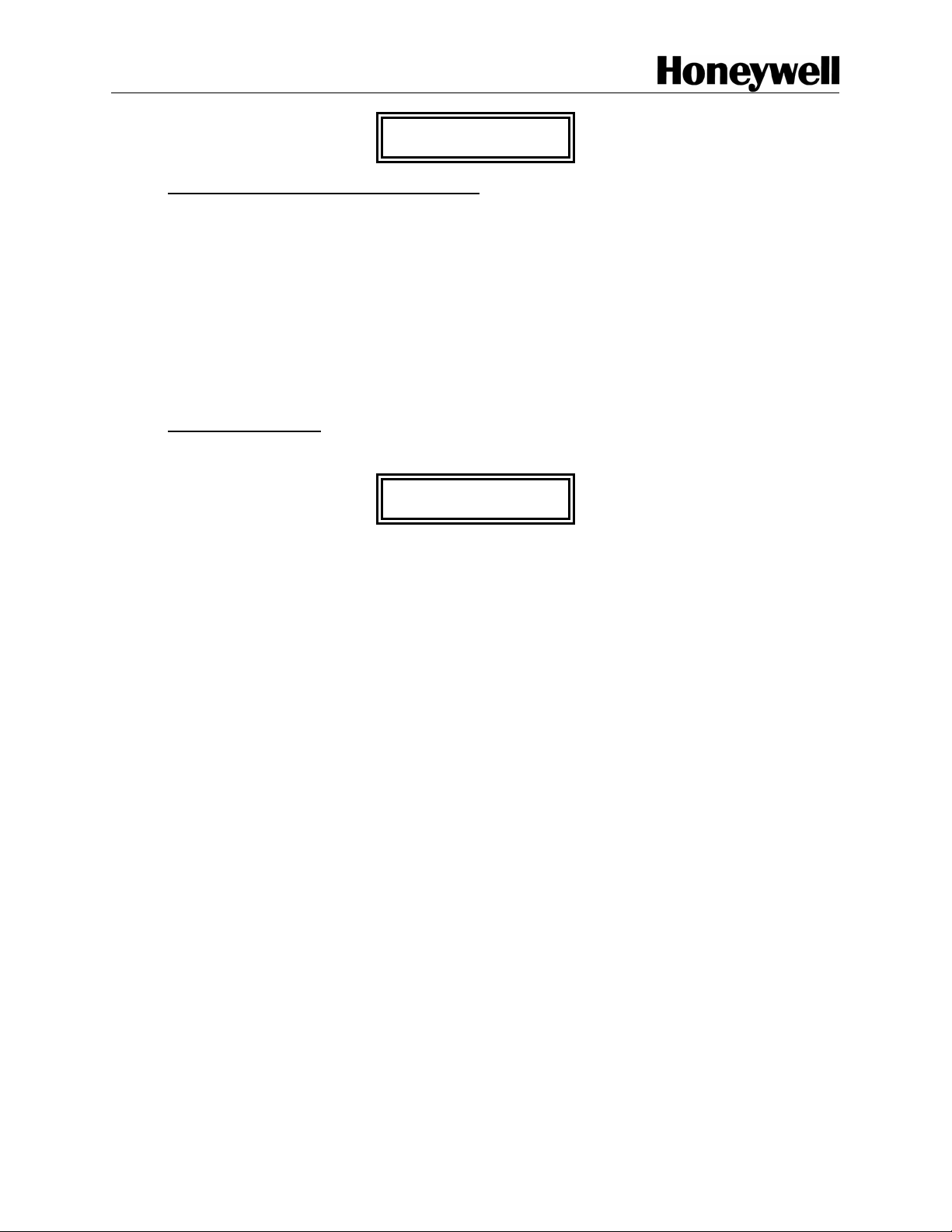

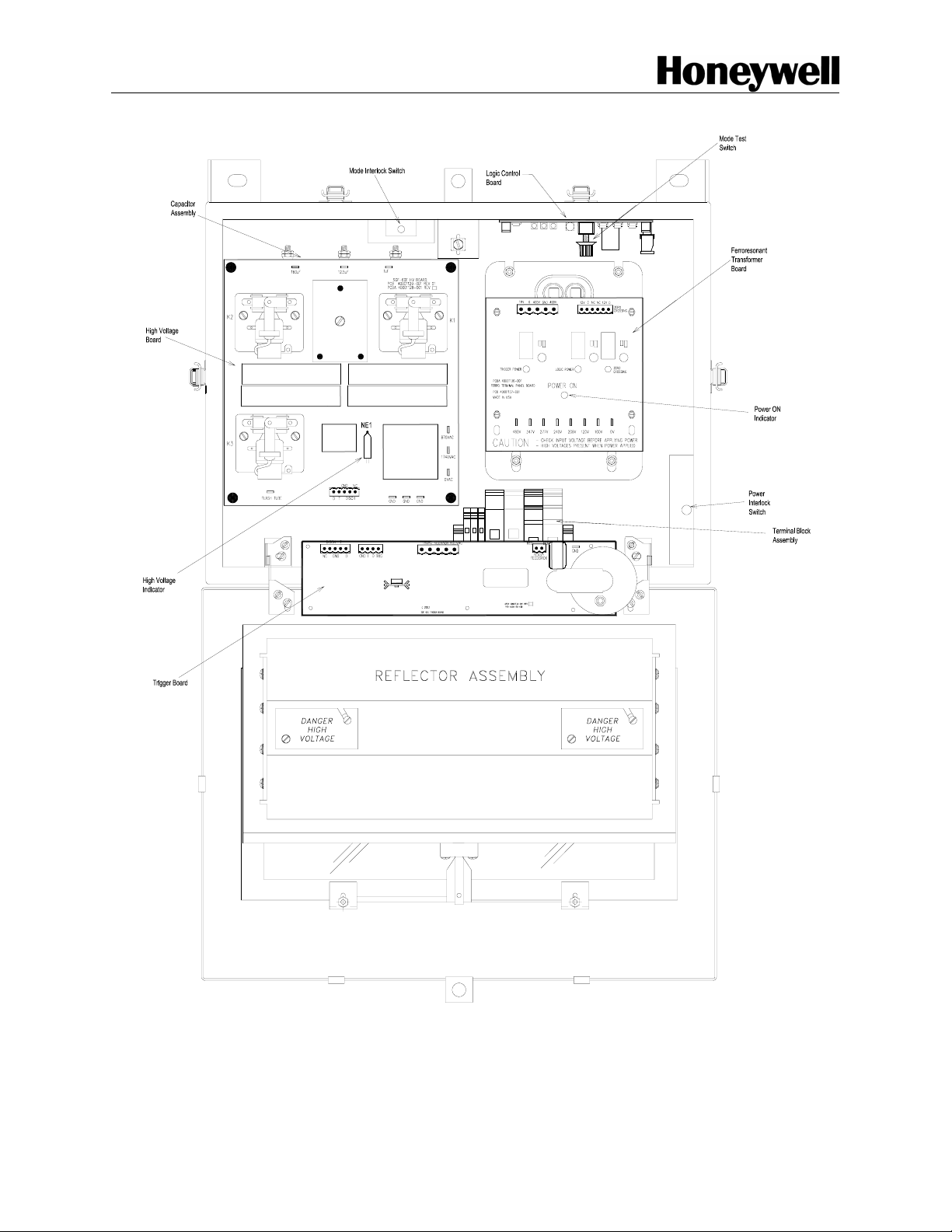

The PLCHMR System module is shown in Figure 2.2-1. The major components of the

retrofit kit consist of the following:

• PLCHMR System Module P/N 40002083-001

• Model SGC-60 Master Controller replacement Micro-Controller Unit (MCU P/N

40002085-001)

• Model SGF-60 Flash-head replacement micro-controller units (one for every flash

head P/N 40002084-001)

2.2.1 PLCHMR System Module

The PLCHMR module (see Figure 2.2-1) is a configurable microprocessor-based

system that monitors a StrobeGuard, Model SG-60E High Intensity Obstruction

Lighting system via the RS485 control and status network. The PLCHMR outputs alarm

status via dry contact relays to a remote alarm monitoring system. The PLCHMR

module is preassembled and consists of three circuit card assemblies affixed to

mounting plate. The module provides 2 wiring harnesses that must be attached to two

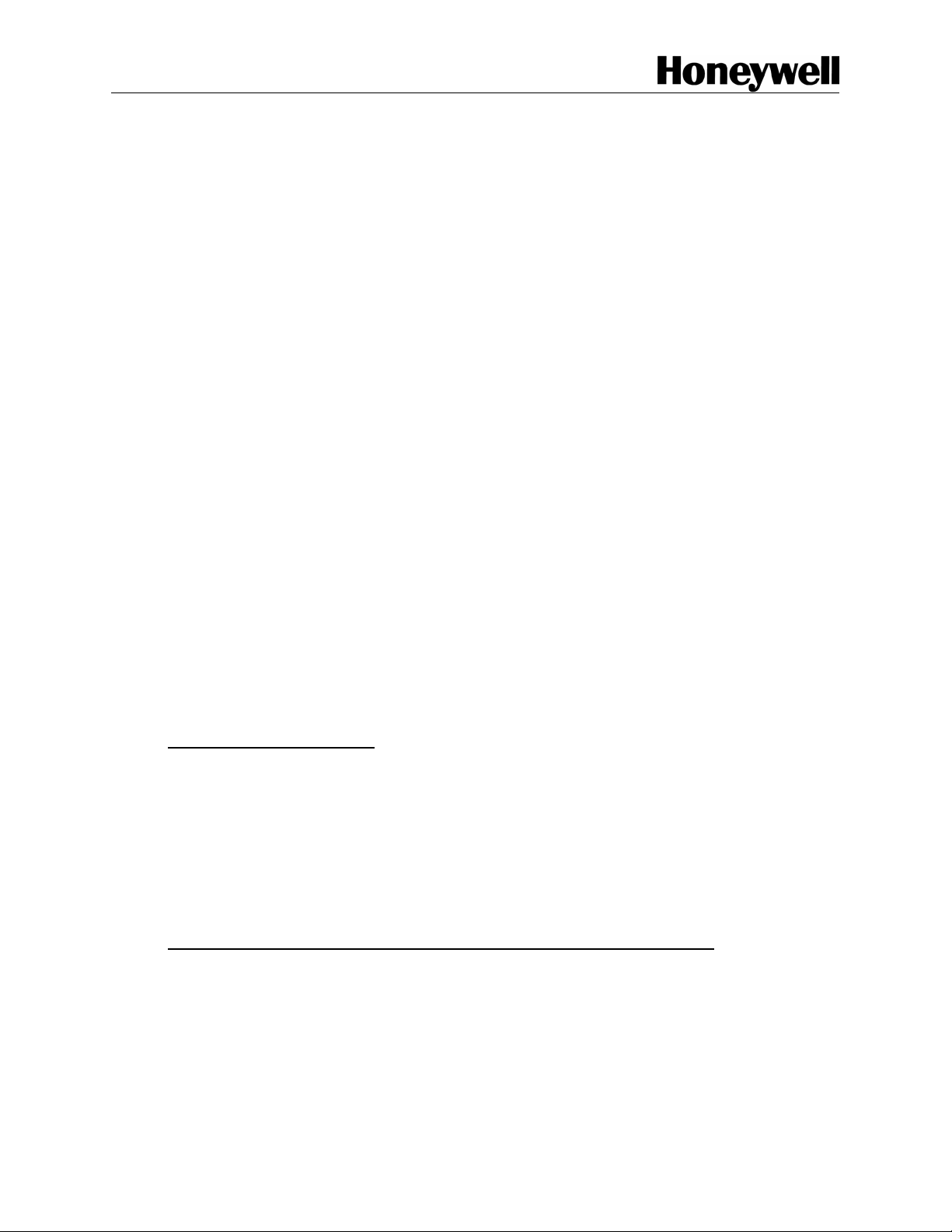

terminal connectors located on the Model SGC-60 Master Controller (See Figure 2.2-2).

2.2.2 Model SGC-60 Master Controller replacement Micro-Controller Unit

The Master Controller (see Figure 3.3-1) is a micro-controller based system that

controls the flash interval and timing, flash intensity, and monitors the complete

StrobeGuard system via the StrobeGuard RS485 control and status network

(SCSN). The MCU must be replaced during the installation process in order for the

PLCHMR to monitor the SCSN. Software in the new micro controller changes the baud

rate of the SCSN from 300 to 9600 baud. A replacement MCU is provided as part of the

upgrade kit (P/N 40002085-001 and replaces P/N40000328-001).

PLC Health Monitoring & Reporting Sys 2-1 Manual EPM40002083-001 Rev -

Page 10

Airport Systems

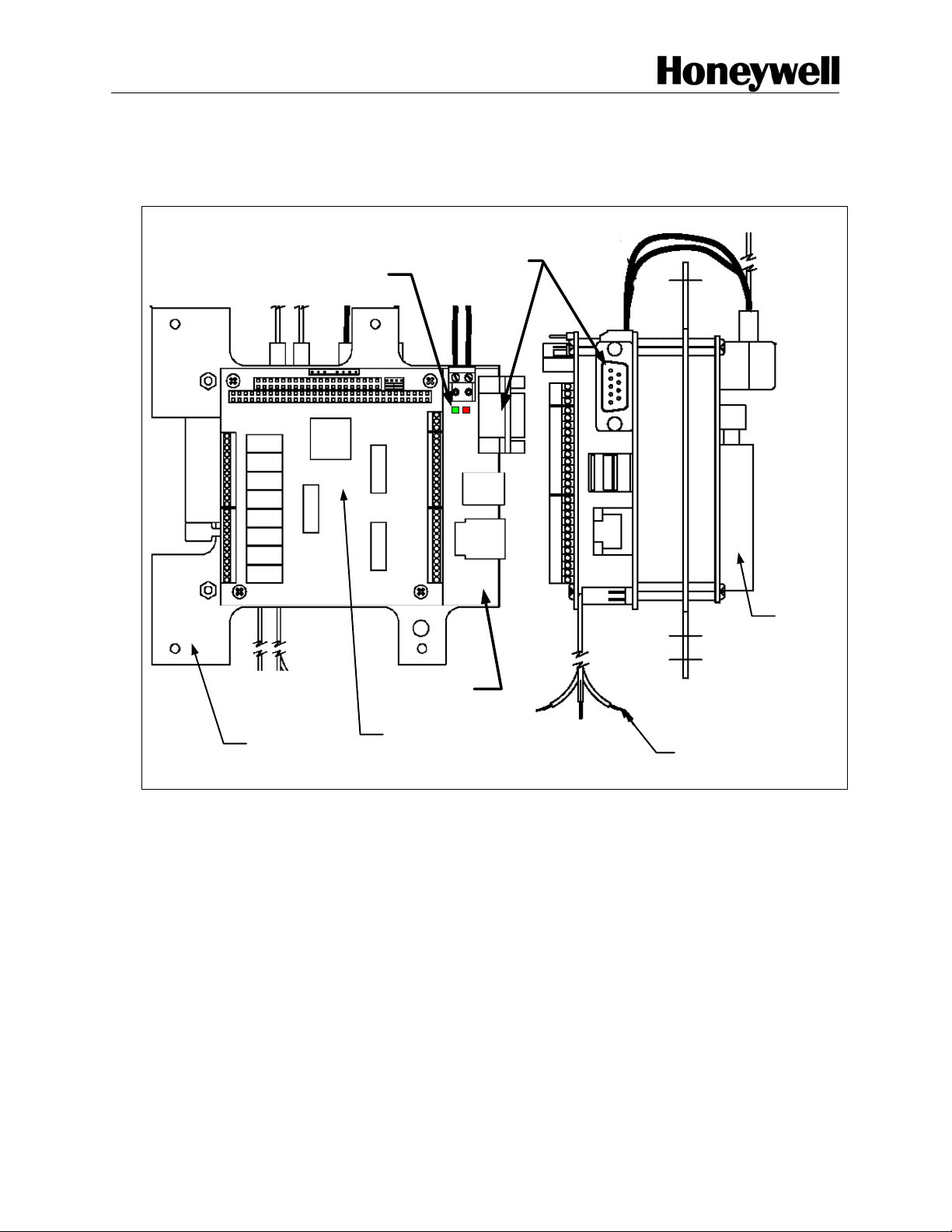

2.2.3 Model SGF-60-E Flash-head replacement Micro-Controller Unit

The SGF-60E Flash-head (see Figure 2.2-3) is a micro-controller based system that is

designed to control a capacitor discharge xenon flash tube unit. The Flash-head

receives its flash interval, timing, flash intensity commands from, and returns status to

the Master Controller via the SCSM. Replacement MCUs are provided as part of the

upgrade kit (P/N 40002084-001 and replaces old MCU P/N40000324-001).

PLC Health Monitoring & Reporting Sys 2-2 Manual EPM40002083-001 Rev -

Page 11

Airport Systems

Power On LED

PLCHMR

Configuration

Serial Port

Power Supply

Single Board

Top view Side view

Mounting Plate

Computer

Relay Interface

Card

StrobeGuard

Control and

Status Network

wiring.

Figure 2.2-1 PLCHMR Module

PLC Health Monitoring & Reporting Sys 2-3 Manual EPM40002083-001 Rev -

Page 12

Airport Systems

Figure 2.2-2 Master Controller with PLCHMR Module Installed

PLC Health Monitoring & Reporting Sys 2-4 Manual EPM40002083-001 Rev -

Page 13

Airport Systems

NO

NO

NC

C

NC

C

NO

+

AC

NC

C

AC

-

Figure 2.2-3: Model SGF-60E Flash Head

PLC Health Monitoring & Reporting Sys 2-5 Manual EPM40002083-001 Rev -

Page 14

Airport Systems

Safety Precautions

The following general safety precautions must be observed during all phases of operation,

service, and repair of this equipment. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of this equipment. Honeywell assumes no liability for the

customer’s failure to comply with these requirements, as listed below.

1. Any interruption of the protective grounding conductor (inside or

outside the instrument) or disconnecting the protective earth ground

terminal is likely to make this equipment dangerous. Intentional

interruption is prohibited.

2. Whenever it is likely that the ground protection has been impaired, the

equipment must be made inoperative by removing AC line power, and

then shall be secured against any unintended operation.

3. Ensure that only fuse / Breakers with the required rated current and of

the specified type (normal blow, time delay, etc.) are used for

replacement. The use of repaired fuses and the short-circuiting of fuse

holders must be avoided.

4. Electrical energy available at many points may result in personal injury

or death if touched. Any adjustment, maintenance, and repair of the

opened equipment while power is applied shall be avoided as much as

possible, however some maintenance described in this manual is

performed with power supplied to the equipment while protective

covers are removed. When repair with power applied is unavoidable,

only a skilled person who is aware of the hazard involved shall carry

out maintenance. Do not attempt internal service or adjustment unless

another person, capable of rendering first aid and resuscitation, is

present.

5. Do not install, substitute parts or perform any unauthorized

modification to the equipment.

6. Make sure the input voltage selection on the Ferroresonant

transformer assembly matches the line voltage before applying power

to the unit.

Capacitors inside the equipment may still be charged after the equipment has

been disconnected from its power source, even though the equipment was

designed to drain charge from the capacitors when power is removed. Do not put

hands or tools in the Flash-head if the High Voltage Indicator neon lamp NE1 is

ON, which is located on the High Voltage Circuit Board. (Refer to Figure 2.2-3)

7. Do not confuse the High Voltage Indicator NE1, with the POWER ON

Indicator located on the Ferro resonant Transformer Assembly. It is

possible for the High Voltage Indicator NE1 to be ON After the main

AC power to the unit is turned OFF (POWER ON Indicator is OFF). If

this happens, the energy stored in the capacitor Assembly must be

discharged before performing maintenance.

PLC Health Monitoring & Reporting Sys 2-6 Manual EPM40002083-001 Rev -

Page 15

Airport Systems

8. Capacitor Discharge Procedure. Attach one end of the capacitor

discharge tool to chassis ground first, then the other end to any of the

relay terminals. Hold for 3 seconds, or until the indicator turns off.

PLC Health Monitoring & Reporting Sys 2-7 Manual EPM40002083-001 Rev -

Page 16

Airport Systems

This system uses lethal voltages in the Flash-head. Unless absolutely

necessary, do not attempt to service or adjust the equipment with AC

line power applied.

Safety interlock switches are provided in the Flash-head enclosure to

interrupt main AC power to the power supply. These interlock switches

are activated when the Flash-head door is opened in a conventional

manner. No interlock is provided when other means of access are

used. Do not tamper with the interlocks by opening or shorting the

terminals.

The POWER ON Indicator is ON when the Ferroresonant Transformer is

powered. If the POWER ON Indicator is OFF, Line input AC power may

still be present in the system.

WARNING!

AC LINE VOLTAGE IS STILL PRESENT WHEN INTERLOCKS ARE

ACTIVATED. DISCONNECT POWER AT THE MAIN AC CIRCUIT

BREAKERS BEFORE INSPECTING OR SERVICING, UNLESS

ABSOLUTELY NECESSARY TO PERFORM MAINTENANCE WITH

POWER ON.

WARNING!

Flash tubes in this lighting system produce brilliant flashes of light

containing some ultraviolet radiation that can cause temporary or

permanent eye damage.

DO NOT LOOK DIRECTLY AT THE FLASH-HEAD WHILE IT IS IN

OPERATION.

PLC Health Monitoring & Reporting Sys 2-8 Manual EPM40002083-001 Rev -

Page 17

Airport Systems

2.3 Specifications

Electrical Input:

PLCHMR Module .................................................................................... 3 Watts. 5 VDC.

Mechanical Properties:

PLCHMR Module

Weight.............................................................................................2 pounds (4.4 kg)

Dimensions ......................................5.6"w (142mm) x 5.7"h (145mm) x 2"d (51mm)

Operating Environment:

Operating Temperature ............................................................................. -55ºC to +55ºC

Humidity...........................................................................................95% relative humidity

System Operating Status Indicators:

PLCHMR, DC line power present .............................. Green LED POWER ON Indicator

PLC Health Monitoring & Reporting Sys 2-9 Manual EPM40002083-001 Rev -

Page 18

Airport Systems

SECTION 3. INSTALLATION & POWER UP

WARNING!

Modifications to the Power Supply are required for certain applications.

Remove input power at circuit breakers and discharge capacitors with

an approved grounding rod before attempting any necessary

modifications.

3.1 Unpacking

Carefully unpack each item and remove any internal packing material from the

PLCHMR. Carefully check the supplied materials with the PLCHMR bill of materials.

There are many small items that should be supplied inside clear plastic bags, verify

each of these bags contain the proper amount of parts per the bill of materials. Report

any shortages of materials immediately to the Honeywell Technical Support.

Examine each item for obvious physical damage. Report any claims to the carrier

immediately. Pertinent information such as installation drawings, schematics,

interconnection drawings, and operation manuals are included in the carton. The

upgraded 8051 micro-controllers (MCU) replacements for the master control and each

flash head are in a separate package(s) inside the carton. Do not remove 8051 MCUs

from their respective packaging until you are ready to install them.

3.2 User Supplied Tools

PC computer with RS232 serial port,

Serial port parameters: 115200 baud, 8 data bits, no parity, 1 stop bit.

Terminal Emulator – MS Windows Hyper Terminal, Tera Term

Screwdriver ¼:” slot-type

Screwdriver 1/16” slot-type

Small Phillips screwdriver

DB9 to DB9 Female/Female RS2232 Null Modem Serial Interface Cable (Radio

Shack Model 03044 Catalog # 55010600 or equivalent)

3.2.1 Master Controls Switch Setting For Installation

Set Master Controller switches (Shown in Figure 2.2-2) as follows:

POWER SWITCH --------------------------------------------------------------------------- OFF

LOCAL / REMOTE Switch ------------------------------------------------------------ LOCAL

MODE Switch -------------------------------------------------------------------------------- DAY

The Master Controller has the following control switches (Figure 2.2-2):

PLC Health Monitoring & Reporting Sys 3-1 Manual EPM40002083-001 Rev -

Page 19

Airport Systems

• POWER SWITCH: Toggle switch that turns input AC line power on/off in the Master

Controller. Does not affect AC power to the Flash-heads. Input voltage is present

at terminal block PB1, even with the power switch turned off.

• RESET Switch: Momentary pushbutton that resets the Master Controller. Switch

must be held for about one second to activate.

• REMOTE / LOCAL Mode Switch: Two-position toggle switch that permits manual

(local) selection of the flash intensity level using the DAY / TWILIGHT / NIGHT

rotary switch. In normal (remote) operation, permits automatic operation controlled

by the Ambient Light Sensor photocell.

• DAY / TWILIGHT / NIGHT Switch: Three-position rotary switch that allows manual

selection of three light intensities of the system (DAY = high, TWILIGHT =

intermediate, and NIGHT = low). The REMOTE / LOCAL Mode Switch must be in

the LOCAL position to use this switch.

3.2.2 Power Configuration

The PLCHMR input voltage selection is set at the factory prior to shipping.

3.3 Installation

3.3.1 Installation Overview

The installation has four major activities:

First, replace the Master controller’s MCU with the one MCU provided by the kit

Second, mount and wire the PLCHMR module.

Third, replace the MCU in each Flash-head’s digital control board with the MCU

provided by the kit.

Fourth, the PLCHMR’s site specific configuration table must be edited to match

the configuration of the high intensity strobe system; this activity is described in

Section 3.7.

The following sub-sections feature detailed instructions for completing the installation

outlined above.

3.3.2 SGC-60 Master Controller MCU Upgrade

The installation kit provides one new MCU P/N 40002085-001 to replace the old MCU

P/N 40000328-001. It is important to install the MCU with the proper orientation since,

more often than not installing a MCU backwards will result in damage to the chip and/or

surrounding circuitry. First note the location of pin 1. To find pin 1 look for a small

rectangular notch on one of its short ends this denotes the top side of MCU; the first pin

counter-clockwise from this notch is pin 1

. The MCU is pressed into a socket. The

PLC Health Monitoring & Reporting Sys 3-2 Manual EPM40002083-001 Rev -

Page 20

Airport Systems

MCU’s socket has a notch along the outside edge on one of the short sides this is the

top side of the socket.

CAUTION!

Do not use excessive force when you remove or install the chip

from/into its socket. Excessive force can bend or damage the MCU

Pins or the socket.

Step 1

Gently remove the old MCU using a small flat head screwdriver to pry it free of its

socket. Set aside the old MCU.

Step 2

Carefully place the new MCU in the empty socket with top of the MCU and pin 1

in the same locations as noted earlier. Inspect all of MCU’s pins checking that

each pin is inserted into its respective contact and that none of the pins of have

"roll under" or "bend out" of the socket.

Step 3

Carefully press the new MCU into the empty socket until it is firmly seated on the

socket.

Step 4

Place the old MCU into the new MCUs empty shipping container.

A detailed drawing showing the location of the MCU in the Master Controller is shown in

Figure 3.3-1.

PLC Health Monitoring & Reporting Sys 3-3 Manual EPM40002083-001 Rev -

Page 21

Airport Systems

Replace existing

MCU PN40000328 with

new MCU PN40002085

40000328-001

Location of 4

Screws to be

removed for the

PLCHMR Module

Standoffs

Figure 3.3-1 Model SGC-60 Master Controller with MCU High-lighted

PLC Health Monitoring & Reporting Sys 3-4 Manual EPM40002083-001 Rev -

Page 22

Airport Systems

3.3.3 PLCHMR Module Installation

The installation kit provides a PLCHMR module P/N 40002083 that is mounted inside

the Master Controller Enclosure. This module is mounted to four 2.5” high standoffs

and has five (5) wires to connect to the Master Controller board.

3.3.3.1 PLCHMR Module 2.5” Standoff Installation

Remove and save the four (4) 6-32 screws that secure the Master Controller to the enclosure’s

bottom panel (Refer to

used in a later step to secure the PLCHMR module mounting plate to the standoffs.

Figure 3.3-1 for exact screw locations). The four saved screws will be

3.3.3.2 PLCHMR Module Power Supply Connections

The PLCHMR module receives 16VDC power from Terminal Block-8 located on the top left

hand corner of the Master Controller PCB as shown in

locations of the two positions on the plug-in terminal with respect to the +16 and GND Labels

shown on the Master Controller PCB. Remove the two position plug-in terminal and loosen both

of the plug-in terminal’s screw sufficiently to install the PLCHMR module’s red and black wires.

The red wire should be inserted into the screw terminal position labeled #2 as shown

Figure 3.3-2. Note the orientation and

Figure

3.3-3 which connects to the +16 contact on the Master Controller PCB. The black wire should

be inserted into the screw terminal position labeled #1 as shown

to the GND contact on the Master Controller PCB.

Figure 3.3-3 which connects

PLC Health Monitoring & Reporting Sys 3-5 Manual EPM40002083-001 Rev -

Page 23

Airport Systems

Output Relay

Terminal Blocks

TB8

Red

Black

PLCHMR

Module

TB-5

Figure 3.3-2 PLCHMR Module Mounted on and Wired to Master Controller

PLC Health Monitoring & Reporting Sys 3-6 Manual EPM40002083-001 Rev -

Page 24

Airport Systems

Black Wire

Red Wire

Figure 3.3-3 Terminal Block- 8 +16V - Red and GND –Black Wire Connections

3.3.3.3 PLCHMR Module Mount

The PLCHMR module mounts to the four 2.5” high standoffs that were installed per directions in

Section 3.3.3.1. Note the location and orientation of the PLCHMR module as shown in

Figure

3.3-2 relative to the Master Controller. Oriented the PLCHMR module and place it

approximately as shown per

position PLCHMR power supply plug-in with its mating header block on the Master Controller.

Carefully position the PLCHMR module so that the four (4) mounting plate holes line-up with

four tapped bores in the 2.5” standoff. Secure the mounting plate to the standoff by installing

the four (4) 6-32 screws removed during the Section 3.3.3.1 activities.

Figure 3.3-2 on the 2.5” high standoffs. Then re-connect the two

3.3.3.4 PLCHMR Module StrobeGuard Control and Status Network Connections

The PLCHMR module connects to the StrobeGuard Control and Status Network via

Terminal Block-5 which is located near the bottom center of the Master Controller PCB as

shown in

with their orientation and locations relative to the four position plug-in terminal connected to the

Master Controller. Remove the four position plug-in terminal. Install the White, Blue, and Black

PLCHMR’s network wires as directed:

Figure 3.3-2. Before starting this task, note any existing wiring connections along

a) Loosen the plug-in terminal’s screw labeled #1 as shown in

insert the PLCHMR module’s White wire into terminal position along with maintaining

any existing wiring connections.

PLC Health Monitoring & Reporting Sys 3-7 Manual EPM40002083-001 Rev -

Figure 3.3-4 sufficiently to

Page 25

Airport Systems

b) Next, loosen the plug-in terminal’s screw labeled #2 as shown in Figure 3.3-4

sufficiently to insert the PLCHMR module’s Blue wire into this terminal position along

with maintaining any existing wiring connections.

c) Finally, sufficiently loosen the plug-in terminal’s screw labeled #4 as shown in

and insert the PLCHMR module’s Black wire into the terminal position while

3.3-4

maintaining any existing wiring connections.

Reinstall the plug-in terminal onto its corresponding fixed mating header located on the Master

Controller.

Figure

1 2 3 4

Black WireWhite Wire

Blue Wire

Figure 3.3-4 StrobeGuard Control & Status Network Wiring Connections

3.3.4 SGF-60-E Flash-head Digital Controller MCU Upgrade

The installation kit provides new MCUs P/N 40002084-001 to replace all existing old

MCUs P/N 40000324-001 in Flash Head Logic Control Board. See Figure 2.2-3 for the

location of Logic Control Board in the Flash Head Enclosure. It is important to install the

MCU with the proper orientation since more often than not installing a MCU backwards

will result in damage to the chip and/or surrounding circuitry. First note the location of

pin 1. To find pin 1 look for a small rectangular notch on one of its short ends this

denotes the top side of MCU; the first pin counter-clockwise from this notch is pin 1

.

PLC Health Monitoring & Reporting Sys 3-8 Manual EPM40002083-001 Rev -

Page 26

Airport Systems

The MCU is pressed into a rectangular socket. This socket has a notch along the

outside edge on one of the short sides this is the top side of the socket.

CAUTION!

Do not use excessive force when you remove or install the chip

from/into its socket. Excessive force can bend or damage the MCU

Pins or the socket.

Step 1

Gently remove the old MCU using a small flat head screwdriver to pry it free of its

socket. Set aside the old MCU.

Step 2

Carefully place the new MCU in the empty socket with top of the MCU and pin 1

in the same locations as noted earlier. Inspect all of MCU’s pins checking that

each pin is inserted into its respective contact and that none of the pins of have

been "rolled under" or "bent out" of the socket.

Step 3

Carefully press the new MCU into the empty socket until it is firmly seated on the

socket.

Step 4

Place the old MCU into its replacement’s empty shipping container.

A detailed drawing showing the location of the MCU in the Flash-Head’s Digital Master

Controller is shown in Figure 3.3-5.

PLC Health Monitoring & Reporting Sys 3-9 Manual EPM40002083-001 Rev -

Page 27

Airport Systems

40000324-001

Figure 3.3-5 MCU Location on Flash Head Digital Logic Controler

PLC Health Monitoring & Reporting Sys 3-10 Manual EPM40002083-001 Rev -

Page 28

Airport Systems

3.4 Flash Head Status Reporting Relay Installation Wiring

The PLCHMR features eight (8) configurable status reporting outputs. Each output

connects to a form-c relay via three screw terminal connections. Each screw terminal

connection is uniquely tied to one of the relay’s contacts. In accordance with Figure

3.4-1:

1) Terminal labeled #1 connects to the normally-open contact

2) Terminal labeled #2 connects to the common contact

3) Terminal labeled #3 connects to the normally-closed contact,

Typically each discrete alarm reporting connections is made to the site’s alarm

monitoring system uses terminals 1 & 2. Using the typical connection ensures that a

fail/fault indication is reported in the event that power is interrupted to the SG-60 High

Intensity Strobe Light System.

Each relay’s state is controlled uniquely by its software Tier Reporting Mechanism

(TRM). The TRM is software configurable and enables the operator via a menu to

combine tier related flash-heads into a group that can be associated with a TRM. (See

Section 3.7.3 for additional details on software configuration)

The two operating states (activated/deactivated) of each relay represent the state of its

corresponding TRM. The TRM’s two states are Flash/OK and Fail/Fault. The TRM

state FLASH/OK represents a normal operation alarm level and is indicated by an

activated relay. The TRM state Fail/Fault represents an abnormal operation alarm level

and is indicated by a deactivated relay.

For example:

Assume that all the flash-heads on tier #1 are operating normally when some event

causes a tier’s flash-head to malfunction. While all of the flash-heads on tier 1 are ok,

TRM #1 is set to FLASH/OK and relay #1 is activated. After the fault event occurs

causing a flash-head on the tier to malfunction, then TRM #1 would automatically

change to the Fail/Fault state which would de-activate relay #1.

An activated relay cause the normally-open contact to be closed allowing any signal

applied to the common contact(#2) to appear on the normally-open contact (#1). For a

deactivated relay the normally-close contact is closed allowing any signal applied to the

common contact (#2) to appear normally-closed contact (#3).

PLC Health Monitoring & Reporting Sys 3-11 Manual EPM40002083-001 Rev -

Page 29

Airport Systems

Relay 1

Relay 2

Relay 3

Relay 4

Relay 5

Relay 6

Relay 7

Relay 8

-

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

R104-V2 0896

http://www.Tri-M.com

Tri-M Engineering

Figure 3.4-1 PLCHMR's Output Relay connection Diagram

Digital Inputs

Do Not Use

PLC Health Monitoring & Reporting Sys 3-12 Manual EPM40002083-001 Rev -

Page 30

Airport Systems

3.5 Final Installation Check

Before applying power to the equipment, perform the procedures in the following

sections. If any test does not pass, please consult Sections 3.3.3.2 and 3.3.3.4 in this

manual or call Honeywell Technical Support at (805) 581-5591.

3.5.1 Preliminary

1. Verify that all AC input power circuit breakers are turned off.

2. Check that the MCU on the Master Controller’s printed circuit boards is

properly seated in its socket.

3. Check that any user-installed wiring does not interfere with relay operation

when covers are closed.

4. Check that replacement MCUs have been installed in all Flash-heads.

Check that all Flash-head covers are shut properly for a weather-tight seal

with all latches closed.

5. Set Master Controller switches as follows:

POWER SWITCH ------------------------------------------------------------------ OFF

LOCAL / REMOTE Switch --------------------------------------------------- LOCAL

MODE Switch ----------------------------------------------------------------------- DAY

3.5.2 Verify Correct Wiring from the PLCHMR Module to Master Controller

Check that power supply and StrobeGuard Network connectors on the printed circuit

boards are properly seated in their sockets (Re-Verify that Sections 3.3.3.2 and 3.3.3.4

were performed correctly).

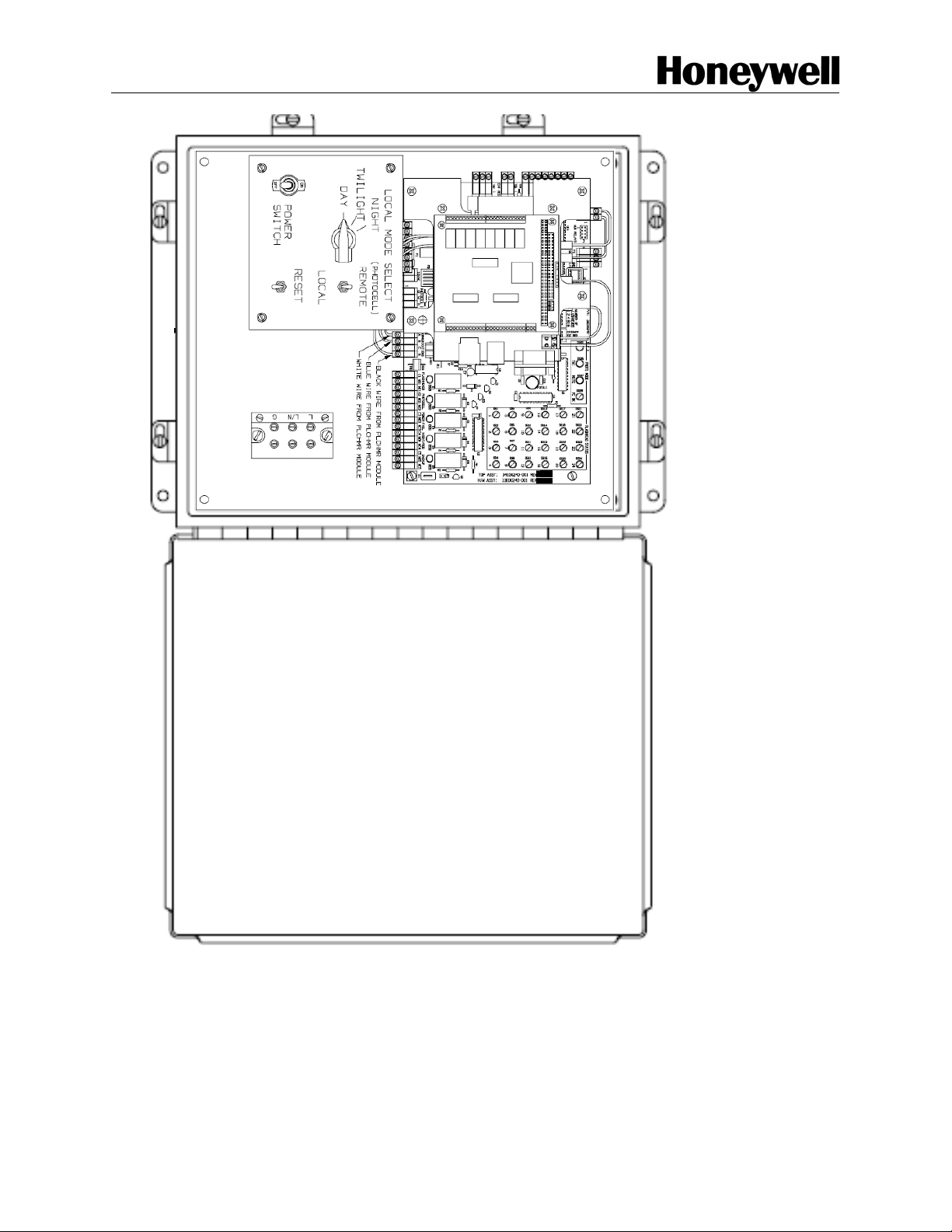

3.6 Power Up and System Tests

During the power up of the system, there are two LED lights, which will be checked to

verify correct operation and installation. The following is a description of all the

indicators on PLCHMR.

3.6.1 PLCHMR Status Indicators

• Power Status Indicators (Figure 2.2-1)

Red LED after power-up indicates Single Board Computer Fault

Green LED indicates Power is OK

3.6.2 System Power Up

All switches and indicators listed in this section are in the Master Controller, except for

the external system circuit breakers.

PLC Health Monitoring & Reporting Sys 3-13 Manual EPM40002083-001 Rev -

Page 31

Airport Systems

1. Verify POWER SWITCH is turned OFF.

2. Verify LOCAL / REMOTE switch is set to LOCAL.

3. Verify MODE switch is set to DAY.

4. Turn on circuit breaker to apply power to Master Controller.

5. Turn on circuit breaker to apply power to Flash-heads.

6. Turn POWER SWITCH to ON.

7. Verify that the Master Controller LED test sequence has started (See

EPM-00001152 - Installation and Operating Guide for High Intensity

Obstruction lighting). The test sequence will exercise every LED and relay

(e.g. it will quickly sweep through the Flash-head Status LEDs in red and

green mode).

After the test sequence completes, the Flash-head status LEDs for the

selected number of Flash-heads shall be lit red then change to green as

the Flash-heads report (DS1 - DS24, Figure 3.6-1 Item 4).

8. After 1 minute, verify the number of Flash-head status LEDs (DS1 - DS24,

Figure 3.6-1 Item 4) that are lit green matches the total number of white

Flash-head lights (including AOL) on the tower (if there are n Flash-heads

on the tower, Flash-head status LEDs DS1 - DSn shall be lit green). Verify

that the remaining unused Flash-head status LEDs (DSn+1 - DS24) are

turned off.

9. After all the flash-heads report good (green), check the Master Control

board’s relay monitoring LEDs which should display following:

i. DS29-DS32 GREEN,

ii. DS33 OFF (DS29 - DS33, Figure 3.6-1 Item 5.) Verify Photocell

status LED DS28 (Figure 3.6-1, Item 3) is lit green.

iii. Verify Day Mode LED DS25 (Figure 3.6-1, Item 3) is lit red, and

the Twilight and Night LEDs (DS26 and DS27 respectively Figure

3.6-1, Item 3) are not lit.

iv. Hold down the RESET switch for approximately 1 second and

verify the LED test sequence has restarted.

PLC Health Monitoring & Reporting Sys 3-14 Manual EPM40002083-001 Rev -

Page 32

Airport Systems

Wait 1 minute and measure the voltage between TB1-1 and TB1-2 to verify the voltage

is 12-18 VAC. Repeat steps 7 - 10 to assure proper recovery after reset.

Figure 3.6-1 Master Controller Circuit Board

PLC Health Monitoring & Reporting Sys 3-15 Manual EPM40002083-001 Rev -

Page 33

Airport Systems

Note: Before performing any tests of the Flash Head

Reporting Relay wiring the system must be configured

using the PLCHMR System Maintenance and

Configuration Menus.

3.7 PLCHMR System Maintenance and Configuration Menus

3.7.1 PLCHMR System Maintenance & Configuration Menus Overview

The PLCHMR system must be configured as part of the on-site installation. The

PLCHMR’s maintenance menus are used to view and modify the site specific

configuration data. The maintenance menus use a text window interface along with a

command entry prompt. The command entry prompt is posted at the bottom of terminal

window and is marked with “maint>”. Configuration data in the maintenance menus

contains information about the site’s lights, its reporting mechanism, and the facility

information. The site’s light configuration data contains information on how many lights,

which tiers the lights are located, and height above ground level. The reporting

configuration will specify if the reports are to be made via Ethernet or relays. The facility

information will include: the owner, contact number, address, FCC number, Altitude,

Longitude, and Latitude.

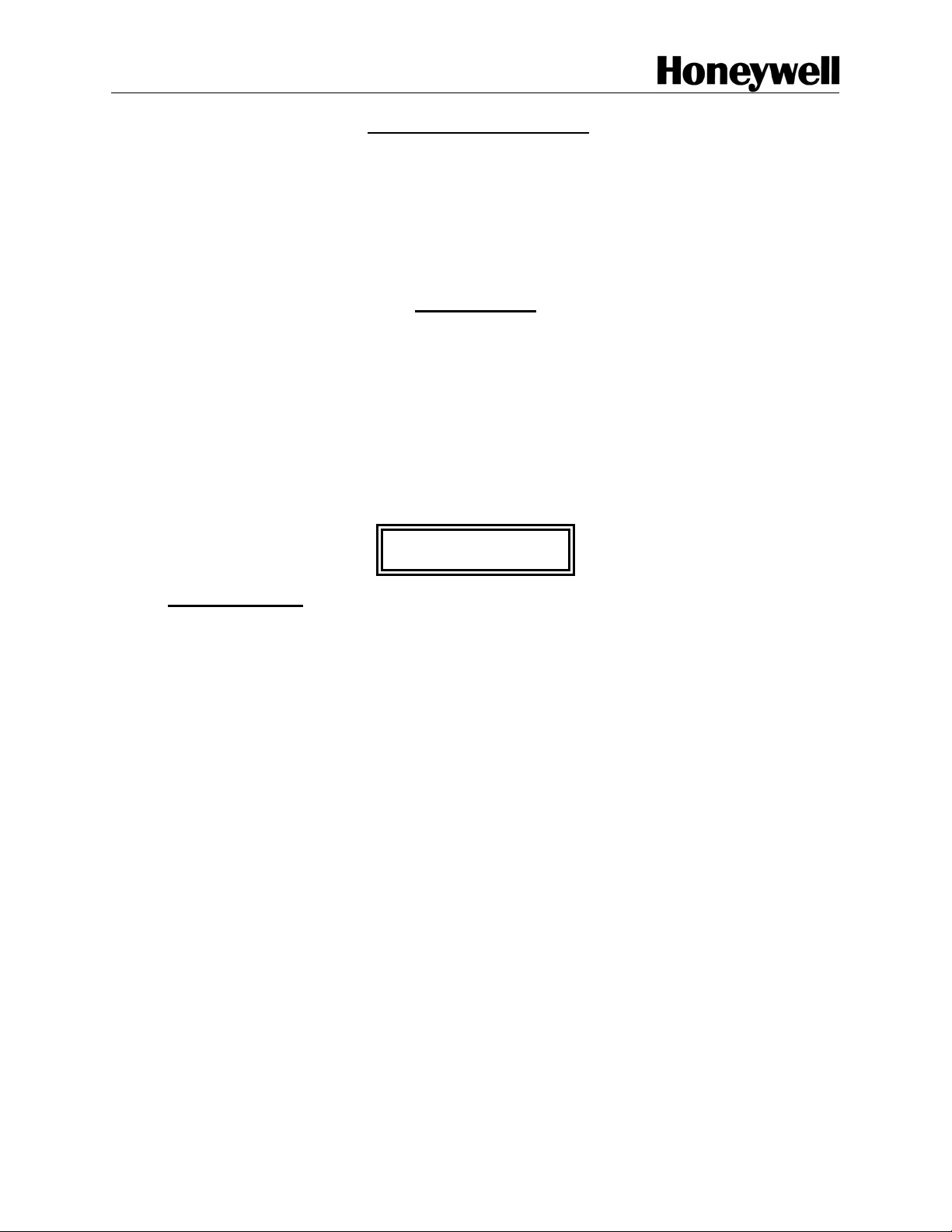

The maintenance menu system has a hierarchical structure which begins with the

Health Monitoring System (HMS) home maintenance menu (see Figure 3.7-2). The

home maintenance menu is the initial menu presented after the maintenance login is

completed. The home maintenance menu can be recognized by the “HMS

Maintenance Menu” title along with its four numbered menu items (See Figure 3.7-3).

PLC Health Monitoring & Reporting Sys 3-16 Manual EPM40002083-001 Rev -

Page 34

Airport Systems

Figure 3.7-1 PC to PLCHMR RS-232 Serial Port Interface Cable Connections

PLC Health Monitoring & Reporting Sys 3-17 Manual EPM40002083-001 Rev -

Page 35

Airport Systems

Press 1

Press 25

HMS Light Configuration Menu

Lamp_ID Tier_Lvl Height Facing_Dir Priority

1) 1 1 151 NW 1

2) 1 1 152 SE 2

3) 1 1 151 SW 1

25) Exit

HMS Maintenance Menu

1) Light Configuration

2) Report Configuration

3) Facility Information

4) Exit

Press 2

HMS Report Configuration Menu

Current Report Method: Relays + ETHERNET

1) NONE – Change report method to none

2) Relays – Change report method to relays

3) ETHERNET – Change report to ethernet

4) Relays & ETHERNET – Change report method to include both

5) Exit

Press 1

Press 5

Press 3

Press 9

HMS Facility Configuration Menu

1) OWNER

2) CONTACT NUMBER

3) ADDRESS LINE 1

4) FCC NUMBER

5) Altitude

7) Longitude

8) Latitude

9) Exit

HMS Modify Light Menu

1) Lamp ID: 1

2) Tier Level: 1

3) Height : 151 Feet AGL

4) Direction: NW

6 Clear All fields

Press 7

7)Exit

maint>1

Figure 3.7-2 HMS Maintenance Menu Hierarchy

The following is a detailed set of instructions for navigating and utilizing PLCHMR’s

maintenance menu system.

3.7.2 HMS Maintenance Menu Login

Access to the Maintenance Mode menus is restricted. A login id and password are

used to control access to the Maintenance Mode Menus. To gain access to the

maintenance mode menu use the following steps:

a) Connect one of the PC/Laptop’s serial ports to the PLCHMR’s serial port using a

female/female null modem serial interface cable as shown in Figure 3.7-1 (Radio

Shack Model 03044 Catalog # 55010600 or equivalent). The PLCHMR’s serial

port connection requires a DB-9 female connector.

b) On the PC/Laptop start a terminal emulator. Either HyperTerminal or Tera Term

is a suitable terminal emulator.

c) Configure the PC/Laptop’s terminal emulator’s serial port parameters to:

i) 115200 baud,

ii) 8 data bits,

PLC Health Monitoring & Reporting Sys 3-18 Manual EPM40002083-001 Rev -

Page 36

Airport Systems

iii) no parity,

iv) 1 stop bit.

d) Apply power and wait for login prompt. If power is already applied and a login

prompt is not shown press the enter key.

e) After the login prompt “login >” is displayed then type “maint” and wait for the

password prompt.

f) At the password prompt “password>” type “grimes” and wait for Home

Maintenance Window to be displayed (See Figure 3.7-3 ).

HMS Maintenance Menu

1) Light Configuration

2) Report Configuration

3) Facility Information

4) Exit Maintenance Mode

maint>

Command

Prompt

Menu Title

Menu Item

Figure 3.7-3 HMS Maintenance Menu

3.7.3 HMS Light Configuration Menu

The Light Configuration menu displays the current light configuration and allows the

user to modify the configuration lines by selecting a line number at the User Prompt

(See Figure 3.7-4). The Light Configuration menu can be recognized by the “HMS Light

Configuration Menu” title along with its 24 numbered rows of light data. The light

configuration menu is a table with six columns and 25 rows. The first column contains

the row number the remaining five columns have a unique heading. Each row

represents the location, orientation and priority data for a particular Flash head as

identified by the number in the Lamp Id column its row.

The column heading definitions are:

i. Lamp_ID – The unique address or ID# as set on Flash Head’s digital logic

board SW3. The maximum value for this entry is 24.

ii. Tier_Lvl – The tier or level number for the Flash Head defined s. Typically the

top tier of flash heads is numbered 1. The maximum value for this entry is 8.

Each Tier_Lvl is associated with a Tier Report Mechanism (TRM) which

controls the state of its reporting relay. The status of Tier_Lvl #1 is reported

via relay #1. Up to 24 flash heads could be assigned to one tier. Typically 3-

PLC Health Monitoring & Reporting Sys 3-19 Manual EPM40002083-001 Rev -

Page 37

Airport Systems

4 flash heads are assigned to a tier as this would represent the physical

installation of the flash heads on one tier of a tower.

iii. Height – The height as measured from ground level of the obstruction/tower.

iv. Facing_Dir – Nearest facing cardinal compass direction of the Flash Head.

System defines eight (8) valid cardinal directions and they are:

i. N

ii. NW

iii. E

iv. SE

v. S

vi. S

vii. SW

viii. W

ix. NW

v. Priority – Maintenance Priority associated with Flash Head. The range of

valid values is 0-25. Typically a value of 1 is used to represent the highest

priority maintenance issue.

HMS Light Configuration Menu

Lamp_ID Tier_Lvl Height Facing_Dir Priority

1) 1 1 151 NW 1

2) 2 2 152 SE 2

3) 3 2 153 SW 1

4) 4 3 164 N 1

5) 0 0 0 0

6) 0 0 0 0

7) 0 0 0 0

8) 0 0 0 0

9) 0 0 0 0

10) 0 0 0 0

11) 0 0 0 0

12) 0 0 0 0

13) 0 0 0 0

14) 0 0 0 0

15) 0 0 0 0

16) 0 0 0 0

17) 0 0 0 0

18) 0 0 0 0

19) 0 0 0 0

20) 0 0 0 0

21) 0 0 0 0

22) 0 0 0 0

23) 0 0 0 0

24) 0 0 0 0

25) Exit

maint>

Figure 3.7-4 HMS Light Configuration Menu

To edit the contents of a specific row in the HMS Light Configuration Menu, enter the

row number and press the enter key. This action will bring up the HMS Modify Light

PLC Health Monitoring & Reporting Sys 3-20 Manual EPM40002083-001 Rev -

Page 38

Airport Systems

Menu (see Figure 3.7-5. Once in the Modify Light Menus select the menu item to edit

by entering the row number of the menu item and pressing enter.

To erase all configuration data for a specific light listed in the HMS Light Configuration

Menu enter the row number of the light. This action brings up the HMS Modify Light

Menu. Next input the number 6 followed by the “Enter” key. After clearing all data

values input the number 7 along with an “Enter” key to exit to the HMS Light

Configuration Menu. Selecting the “Exit” menu option commits any changes made in

that menu to memory.

HMS Modify Light Menu

1) Lamp ID: 1

2) Tier Level: 1

3) Height: 151 Feet AGL

4) Direction: NW

5) Priority: 1

6) Clear all fields

7) Exit

maint>l

Figure 3.7-5 HMS Modify Light Menu

3.7.4 PLCHMR Report Configuration Menu

The Report Configuration Menu displays the current reporting configuration and allows

the user to select one of four reporting methods (See Figure 3.7-6). Do not change this

setting.

PLC Health Monitoring & Reporting Sys 3-21 Manual EPM40002083-001 Rev -

Page 39

Airport Systems

HMS Report Configuration Menu

Current Report Method: RELAYS + ETHERNET

1) NONE - Change Report method to none.

2) RELAYS - Change Report method to relays.

3) ETHERNET - Change Report method to ethernet.

4) RELAYS+ETHERNET - Change Report method to include both.

5) Exit

maint>

Figure 3.7-6 HMS Report Confguration Menu

3.7.5 PLCHMR Facility Configuration Menu

The Facility Configuration menu displays data about the facility’s operator and its

location. With this menu the user may edit any data line by selecting its line number at

the User Prompt and pressing the enter key (See Figure 3.7-7). The Facility

Configuration menu can be recognized by the “HMS Facility Configuration Menu” title

along with its 9 numbered rows of facility data.

HMS Facility Configuration Menu

1) OWNER: Obstruction Lighting

2) CONTACT NUMBER: 937-484-2000

3) ADDRESS LINE 1: 550 State Route 55

4) ADDRESS LINE 2: Urbana Oh 43078

5) FCC NUMBER: 10108227

6) Altitude: 1500.00

7) Longitude: 40.16

8) Latitude: -83.8

9) Exit

maint>

Figure 3.7-7 HMS Facility Conguration Menu

PLC Health Monitoring & Reporting Sys 3-22 Manual EPM40002083-001 Rev -

Page 40

Airport Systems

3.7.6 Verify Local Mode Operation

All switches and indicators listed in this section are in the Master Controller.

3.7.6.1 Day Mode:

1. Verify MODE Switch is set to DAY.

2. Verify Day mode LED DS25 (Figure 3.6-1, Item 3) is lit red.

3. After about 6 seconds, verify all Flash-heads are flashing in sync and in

Day mode (maximum brightness).

4. Verify that the Flash-head Status LED for each Flash-head on the tower is

lit green (including any AOL). Unused Flash-head status LEDs shall be

off. (DS1 - DS24: Figure 3.6-1, Item 4)

5. Verify relay status LEDs DS29-DS32 are lit green, and DS33 is OFF.

(Figure 3.6-1, Item 5)

6. If you have a Dual (Red/White) System

, the Red Lights should be OFF.

3.7.6.2 Twilight Mode:

1. Set MODE Switch to TWILIGHT.

2. Verify Day and Night mode LEDs (DS25 and DS27 respectively Figure

3.6-1, Item 3) are unlit and the Twilight mode LED DS26 is lit red.

3. After 6 seconds, Verify all Flash-heads are flashing in sync and in Twilight

mode (medium brightness).

4. Verify that the Flash-head Status LED for each Flash-head on the tower is

lit green (including any AOL). Unused Flash-head status LEDs shall be

off. (DS1 - DS24: Figure 3.6-1, Item 4)

5. Verify relay status LEDs DS29 - DS32 are lit green, and DS33 is off.

(Figure 3.6-1, Item 5)

6. If you have a Dual (Red/White) System, the Red Lights should be OFF.

3.7.6.3 Night Mode

1. Set MODE Switch to NIGHT.

2.

3. Verify Day and Twilight mode LEDs (DS25 and DS26 respectively (Figure

3.6-1, Item 3) are unlit and Night mode LED DS27 is lit red.

4. Verify that the Flash-head Status LED for each Flash-head on the tower is

lit green (including any AOL). Unused Flash-head status LEDs shall be

off. (DS1 - DS24: Figure 3.6-1, Item 4)

PLC Health Monitoring & Reporting Sys 3-23 Manual EPM40002083-001 Rev -

Page 41

Airport Systems

5. Verify relay status LEDs DS29-DS31 are lit green, and DS32 and DS33

are off. (DS29 - DS33: Figure 3.6-1, Item, 5,)

6. If you have a White-Only System: After 6 seconds, Verify all Flash-heads

are flashing in sync and in Night mode (lowest brightness, ~1/8 second

duration bursts at 40 bursts per minute).

7. If you have a Dual (Red/White) System: Verify normal red night mode

operation.

(a) Verify that all Flash-heads are OFF

(b) Verify that all Red Lights are ON and flashing properly, and the Red

(c) Verify that LED DS36 (EXT RED READY) is lit green (See Item 10,

8. If you have a Dual (Red/White) System: Perform the following steps to

check white night backup operation.

Light Controller does not indicate any alarms in the top-most Red

Beacons.

Figure 3.6-1).

(a) Simulate a Top Red Beacon failure.

On a Honeywell 9LCA Series Control, this may be done with the B1

circuit breaker in the Control. Turn the B1 breaker off to activate

the 9LCA Beacon Failure Alarm, or toggle the breaker momentarily

to activate the 9LCA Flasher Bypass Alarm.

Other Redlight systems have different controls, and may require

removing Red Beacon power at the input power circuit breakers.

(b) Verify that the DS36 (External Red Ready) LED is OFF.

(c) Verify that the DS32 (Night/Red) LED is ON

(d) Verify that the DS33 (Backup) LED is ON

(e) Verify that all the Red Lights are OFF

(f) Verify that all Flash-heads are flashing in sync and in Night mode

(lowest brightness, ~1/8 second duration bursts at 40 bursts per

minute).

(g) Repair the simulated Red Beacon failure.

(h) Verify that DS36 (External Red Ready) LED is ON.

(i) Verify that the lighting system is still operating white strobes, and

not red-lights.

(j) Set the MODE switch to DAY. Wait for the Flash-heads to switch to

DAY mode (about 6 seconds). Set the MODE switch back to

NIGHT. Wait for the Flash-heads to switch to OFF mode (about 6

seconds).

(k) Verify normal red night mode operation per Step 6 above.

PLC Health Monitoring & Reporting Sys 3-24 Manual EPM40002083-001 Rev -

Page 42

Airport Systems

(l) If you have more than one Red Beacon at the top level, repeat the

simulated failure test for each Red Beacon.

PLC Health Monitoring & Reporting Sys 3-25 Manual EPM40002083-001 Rev -

Page 43

Airport Systems

SECTION 4. PRINCIPLES OF OPERATION

4.1 Overall Description

The PLCHMR is a product that consists of hardware and software to provide health

monitoring and remote reporting services. PLCHMR is integrated into the

StrobeGuard® System. The PLCHMR uses a single board computer; manufactured by

a respected industrial supplier of single board computers (SBC). The SBC provides

sufficient processor bandwidth and memory support the intended health monitoring and

reporting tasks. The SBC has an industry standard PC/104 bus to provide a common

interface bus for a variety of off-the-shelf daughter boards. Industry standard daughter

boards have been selected to provide the required input/output interfaces consistent

with the demand of customer provided monitoring systems. In addition the SBC

provides a 10/100 Ethernet interface and an RS-485 serial port interface. The PLCHMR

will use its RS-485 serial network connection to receive and process health status data

from the SGC-60. The RS-485 serial network bus will be referred to as the

StrobeGuard Control and Status Network (SCSN). SCSN will be used to send

commands and collect status data from each SGF-60 Flash Head connected to the RS485 network. The PLCHMR is collocated within the SGC-60 Master Controller

enclosure.

The PLCHMR reports each flash heads’ health status via discrete outputs. Each flash

heads’ discretely reported status data will be a Flash/Fail report. PLCHMR System

uses a uniquely configured relay output daughter board. This daughter board drives

logic inputs provide by the customer at the remote facility. The relay output daughter

board will provides 8 Form C relays to report the system’s status. Screw terminals on

the relay output board will enable setting the relay’s output voltage. The normally

closed relay contact will be used to report the fail condition.

The PLCHMR provides an interactive character based menu -oriented Maintenance

Mode Service (MMS). The MMS is accessed via the SBC’s Serial RS232 interface.

The MMS is an interactive character-oriented communications session. A PC based

client terminal service initiates a MMS session by logging onto the system as the “maint”

user. The MMS validates the “maint” user via a password; it proceeds to establish a

session with the client terminal service by initially presenting the Maintenance Mode

menu.

4.1.1.1 Power Supply

The PLCHMR receive 16VDC power from the Master Controllers TB8 terminal

connector. The 16VDC power is fed to a single output DC/DC Converter which

produces 5VDC for the SBC.

4.1.1.2 Communications

The PLCHMR monitors commands from the Master Controller and Flash Head status

reports via the RS485 serial link.

PLC Health Monitoring & Reporting Sys 4-1 Manual EPM40002083-001 Rev -

Page 44

Airport Systems

SECTION 5. MAINTENANCE

5.1 PLCHMR Module

The PLCHMR module requires no periodic maintenance.

PLC Health Monitoring & Reporting Sys 5-1 Manual EPM40002083-001 Rev -

Page 45

Airport Systems

SECTION 6. REPLACEMENT PARTS

Description Part Number

SGC-60 Master Controller

Master Controller Replacement MCU-------------------- 40002085-001

SGF-60-E Flash-head

Digital Controller, Replacement MCU-------------------- 40002084-001

PLCHMR Module

Module, Assembly -------------------------------------------- 40002083-001

PLC Health Monitoring & Reporting Sys 6-1 Manual EPM40002083-001 Rev -

Page 46

Airport Systems

SECTION 7. APPENDIX A – EXAMPLES

7.1 Light Configuration Examples

The HMS Light Configuration Menu provides the flexibility and configurability to address

most field installations. This section provides specific examples that demonstrate some

possible configuration values that are the results of choices made in the Light

Configuration Menu. The PLCHMR system has eight (8) relays that can report the

status of up to 24 Flash Heads. The Light Configuration menu enables the user to map

the status reporting from any combination of Flash Heads to any one or all 8 of the

relays. In section 3.4 it was declared that the relay’s state is controlled by the software

configured Tier Reporting Mechanism (TRM). Section 3.4 also indicated the TRM has

two states FLASH/OK and FAIL/FAULT. Software configuration of the TRM is

performed through the HMS Light Configuration Menu. Each TRM can be assigned

from zero to 24 Flash Heads. A Flash Head is assigned to a specific TRM via a

numeric entry in its corresponding Tier_Lvl column in the Light Configuration Menu. For

a TRM to activate its relay the status reported of all Flash Heads assigned to that tier

must be FLASH/OK. The TRM will deactivate its relay if any Flash Head assigned to it

reports a FAIL/FAULT status.

For instance consider the following example on how a system with 24 Flash Heads

could be configured:

In the following example consider a system with nine Flash Heads arrange on 3 physical

tiers as shown in Figure 7.1-1.

A typical configuration could use seven Tier Reporting Mechanisms TRMs. Each of the

top six Flash Heads could be assigned to its own individual TRM. The three lowest

Flash Heads would be assigned to one of the remaining TRMs. The Flash/Fail status

for the top six Flash Head would be collected by their assigned TRM and then reported

by a relay whose number identifies the tier or (TRM) number. This would result in the

top six Flash Heads having individualized status reports and the bottom three flash

Heads having a collective status report. The Light Configuration Menu setting would

appear as shown in Figure 7.1-2. An alternative view is presented in Figure 7.1-3 which

shows the individual groups Flash Head groups reporting status to their assigned TRM

which is connected to the reporting relay.

PLC Health Monitoring & Reporting Sys 7-1 Manual EPM40002083-001 Rev -

Page 47

Airport Systems

Tier 3

Tier 2

23Tier 1

56

9

8

1

Flash Head Installation

with 9 Flash Heads, installed on

three tiers (levels). Each tier has

three Flash Heads. Flash Heads

4

7

numbers correspond to the unique

ID or address set on the Flash

Head’s digital logic board switch

#3.

Flash

Head #

Figure 7.1-1 Tower Example with 9 Flash Heads on Three Physical Tiers

PLC Health Monitoring & Reporting Sys 7-2 Manual EPM40002083-001 Rev -

Page 48

Airport Systems

HMS Light Configuration Menu

Lamp_ID Tier_Lvl Height Facing_Dir Priority

1) 1 1 151 NW 1

2) 2 2 152 SE 1

3) 3 3 153 SW 1

4) 4 4 133 NW 2

5) 5 5 133 SE 2

6) 6 6 133 SW 2

7) 7 7 113 NW 5

8) 8 7 113 SE 5

9) 9 7 113 SW 5

10)

11)

12)

13)

14)

15)

16)

17)

18)

19)

20)

21)

22)

23)

24)

25) Exit

maint>

Figure 7.1-2 Light Configuration Menus Settings for 9 Lights and 7 Relay Outputs

PLC Health Monitoring & Reporting Sys 7-3 Manual EPM40002083-001 Rev -

Page 49

Airport Systems

FLASH

HEAD 1

FLASH

HEAD 2

FLASH

HEAD 3

FLASH

HEAD 4

FLASH

HEAD 5

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

TRM

#1

TRM

#2

TRM

#3

TRM

#4

TRM

#5

Relay

State

Relay

State

Relay

State

Relay

State

Relay

State

Relay #1

Relay #2

Relay #3

Relay #4

Relay #5

132

132

132

132

132

FLASH

HEAD 6

FLASH

HEAD 7

FLASH

HEAD 8

FLASH

HEAD 9

Flash/Fail Status

Flash/Fail Status

TRM

#6

&

7

8

9

TRM #7

Relay #6

Relay

State

Relay #7

Relay

State

132

132

Figure 7.1-3 System Configuration with 9 Flash Heads using 7 relays

PLC Health Monitoring & Reporting Sys 7-4 Manual EPM40002083-001 Rev -

Page 50

Airport Systems

A typical configuration would be to create eight tiers (or groups). Each tier would be a

collection of three Flash Heads. Each tier’s status would be collect by its assigned TRM

and then reported by the relay whose number identifies the tier or (TRM) number. The

Light Configuration Menu setting would appear as shown in Figure 7.1-4. An alternative

view is presented in Figure 7.1-5 which shows the individual groups Flash Head groups

reporting status to their assigned TRM which is connected to the reporting relay.

HMS Light Configuration Menu

Lamp_ID Tier_Lvl Height Facing_Dir Priority

1) 1 1 1510 NW 1

2) 2 1 1520 SE 1

3) 3 1 1530 SW 1

4) 4 2 1330 Nw 2

5) 5 2 1330 SE 2

6) 6 2 1330 SW 2

7) 7 3 1130 NW 2

8) 8 3 1130 SE 2

9) 9 3 1130 SW 2

10) 10 4 1030 NW 3

11) 11 4 1030 SE 3

12) 12 4 1030 SW 3

13) 13 5 930 NW 3

14) 14 5 930 SE 3

15) 15 5 930 SW 3

16) 16 6 830 NW 4

17) 17 6 830 SE 4

18) 18 6 830 SW 4

19) 19 7 530 NW 5

20) 20 7 530 SE 5

21) 21 7 530 SW 5

22) 22 8 230 NW 5

23) 23 8 230 SE 5

24) 24 8 230 SW 5

25) Exit

maint>

Figure 7.1-4 Light Configuration Menus Settings for 24 Light and 8 Relay Outputs

PLC Health Monitoring & Reporting Sys 7-5 Manual EPM40002083-001 Rev -

Page 51

Airport Systems

FLASH

HEAD 1

FLASH

HEAD 2

FLASH

HEAD 3

FLASH

HEAD 4

FLASH

HEAD 5

FLASH

HEAD 6

FLASH

HEAD7

FLASH

HEAD 8

FLASH

HEAD 9

FLASH

HEAD

10

FLASH

HEAD

11

FLASH

HEAD

12

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

&

1

20

3

TRM #1

&

4

5

6

Relay

State

TRM #2

&

7

80

9

Relay

State

TRM #3

&

10

11 0

12

Relay

State

TRM #4

Relay

State

Relay #1

Relay #2

Relay #3

Relay #4

FLASH

HEAD

13

FLASH

132

HEAD

14

FLASH

HEAD

15

FLASH

HEAD

16

FLASH

132

132

132

HEAD

17

FLASH

HEAD

18

FLASH

HEAD

19

FLASH

HEAD

20

FLASH

HEAD

21

FLASH

HEAD

22

FLASH

HEAD

23

FLASH

HEAD

24

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

Flash/Fail Status

&

13

14

15

TRM #5

&

16

17

18

TRM #6

&

19

20

21

TRM #7

&

22

23 0

24

TRM #8

Relay

State

Relay

State

Relay

State

Relay

State

Relay #5

Relay #6

Relay #7

Relay #8

132

132

132

132

Figure 7.1-5 System Configuration with 24 Flash Heads using 8 relays

PLC Health Monitoring & Reporting Sys 7-6 Manual EPM40002083-001 Rev -

Loading...

Loading...