Honda Power Equipment H6522 User Manual

Thank you for purchasing a Honda tractor.

This manual describes operation and maintenance of the Honda H6522

compact tractor, type A2. (Two Wheel Drive Model) and type A4 (Four

Wheel Drive Model).

Information in this manual is based on the H6522 A4 model.

All information in this manual is based on the latest product information

available at the time of printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual is considered a permanent part of the tractor and it must stay

with the tractor if resold.

READ THIS OWNER’S MANUAL CAREFULLY. Pay special attention to

these symbols and any instructions that follow:

m

M

m

riiGiq

NOTE: Gives helpful information.

Honda tractors are designed to give safe and dependable service if

operated according to instructions. Operating this tractor requires special

effort on your part to ensure your safety and the safety of others.

m

or property damage. Read and understand this Owner’s Manual before

operating this tractor.

If a problem should arise, or if you have any questions about your tractor,

consult an authorized Honda compact tractor dealer.

HONDA MOTOR CO., LTD. 1991, ALL RIGHTS RESERVED

-Indicates serious injuty or death WILL result if instructions

are not followed.

-Indicates a strong possibility that serious injury or death

could result if instructions are not followed.

-Indicates a possibility that minor injury can result if instructions are not followed.

-Indicates that equipment or property damage can result if

instructions are not followed.

Using this product for a purpose not intended may cause injury

1

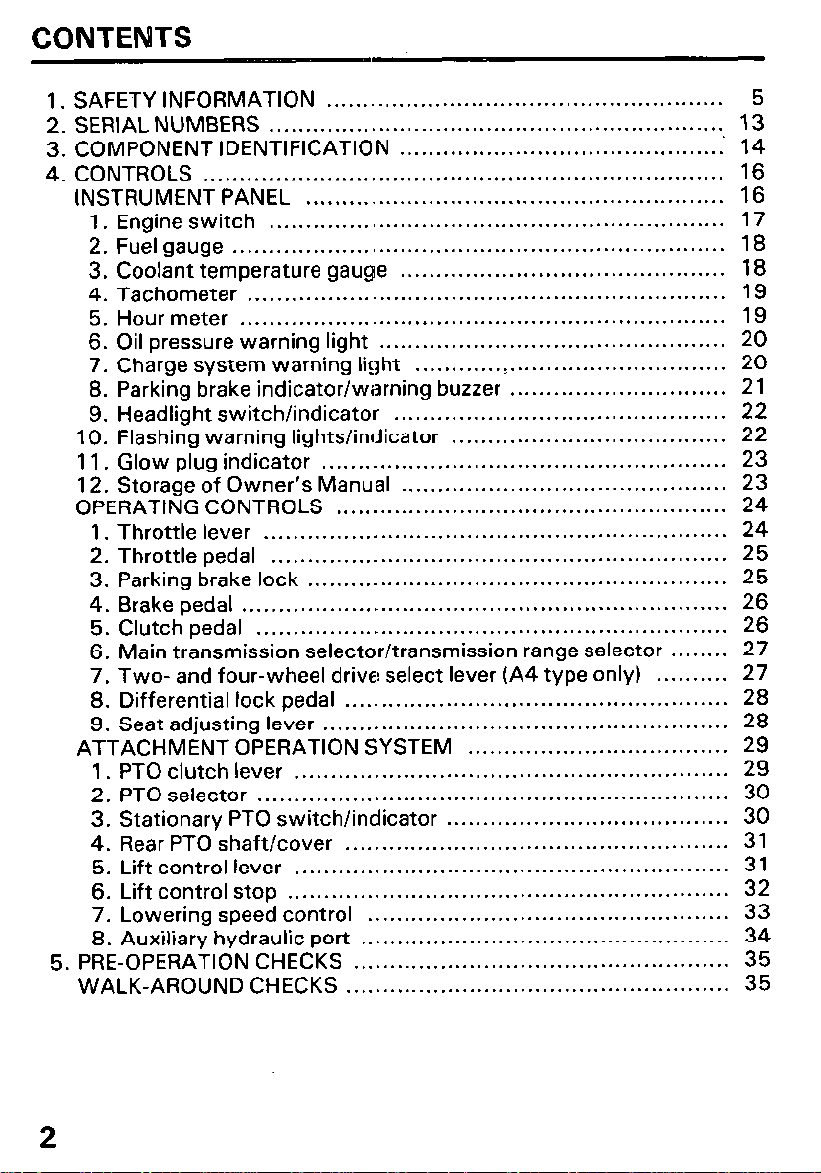

CONTENTS

1. SAFETY INFORMATION

2. SERIAL NUMBERS

3. COMPONENT IDENTIFICATION

4. CONTROLS

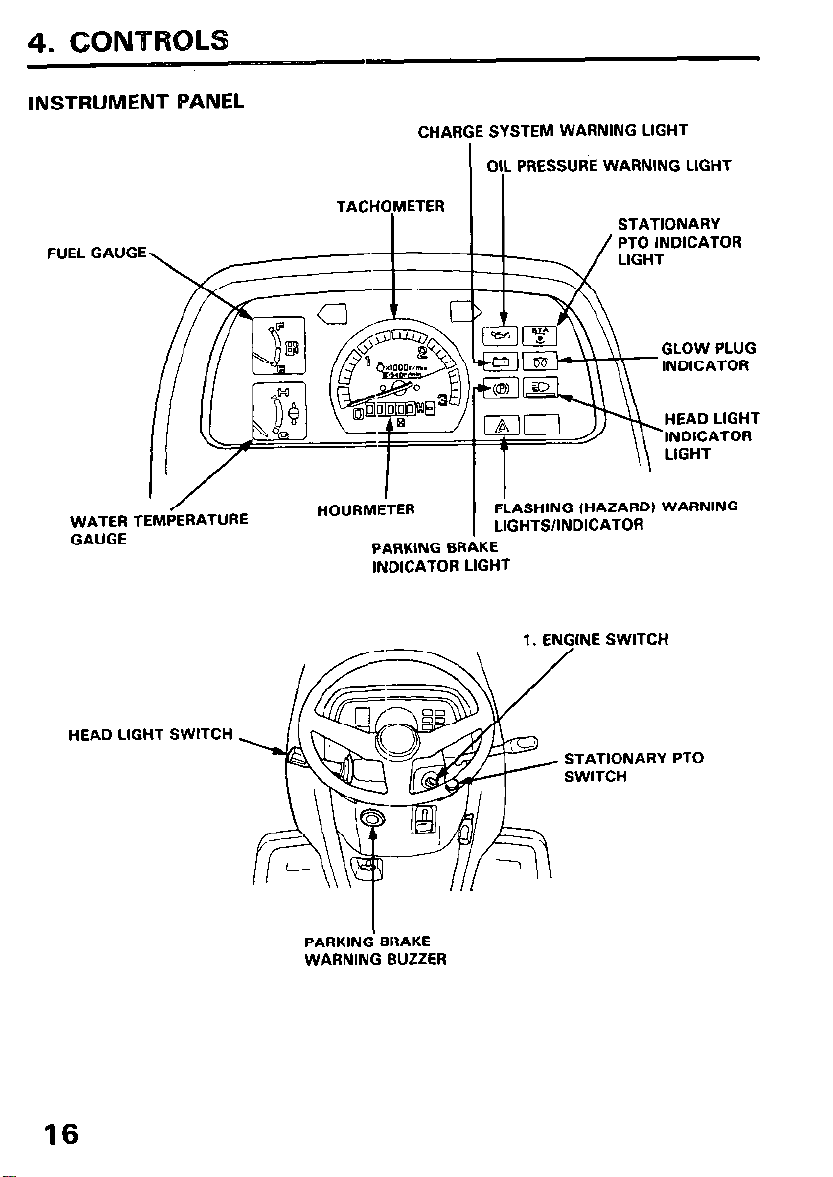

INSTRUMENT PANEL

1. Engine switch

2. Fuel gauge

........................................................................

....................................................................

3. Coolant temperature gauge

4. Tachometer

5. Hour meter

6. Oil pressure warning light

7. Charge system warning light

8. Parking brake indicator/warning buzzer

9. Headlight switch/indicator

Flashing warning lights/indicator

10.

1 1. Glow plug indicator

Storage of Owner’s Manual

12.

OPERATING CONTROLS

1. Throttle lever

2. Throttle pedal

3. Parking brake lock

4. Brake pedal

5. Clutch pedal

6. Main transmission selector/transmission range selector

7. Two- and four-wheel drive select lever (A4 type only)

8. Differential lock pedal

9. Seat adjusting lever

ATTACHMENT OPERATION SYSTEM

.

PTO clutch lever

1

PTO selector

2.

3. Stationary PTO switch/indicator

4. Rear PTO shaft/cover

Lift control lever

5.

6. Lift control stop

7. Lowering speed control

Auxiliary hydraulic port

8.

5. PRE-OPERATION CHECKS

WALK-AROUND CHECKS

..................................................................

...................................................................

................................................................

...................................................................

.................................................................

.................................................................

.......................................................

...............................................................

..............................................

..........................................................

...............................................................

.............................................

................................................

............

..............................................

........................................................

.............................................

......................................................

...............................................................

..........................................................

.....................................................

........................................................

............................................................ 29

.....................................................

............................................................

.............................................................

..................................................

...................................................

....................................................

.....................................................

. ..............................

..............................

...................................... 22

.................................... 29

.......................................

........

..........

5

13

14

16

16

17

18

18

19

19

20

20

21

22

23

23

24

24

I:

26

26

27

27

28

28

30

30

31

31

32

33

34

35

35

2

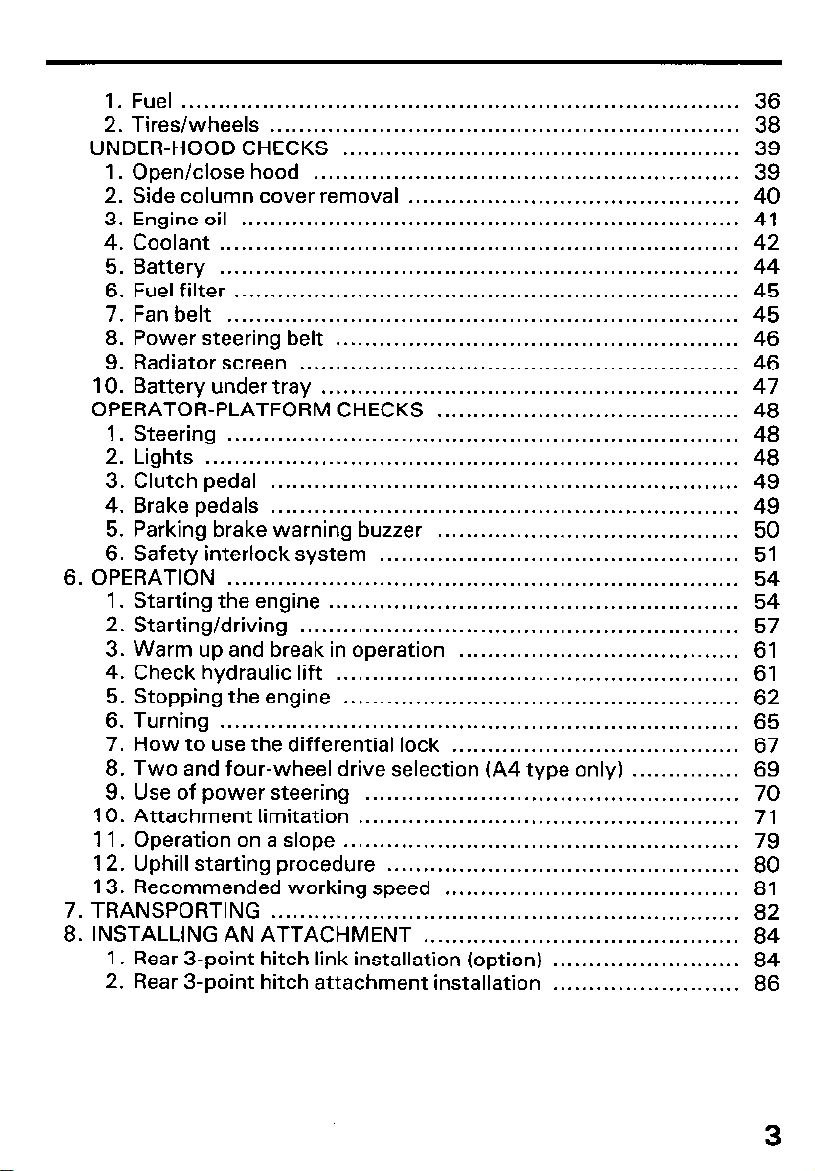

1. Fuel

2. Tires/wheels

UNDER-HOOD CHECKS

1. Open/close hood

2. Side column cover removal

3. Engine oil

4. Coolant

5. Battery

6. Fuel filter

7. Fan belt

8. Power steering belt

9. Radiator screen

10. Battery under tray ..........................................................

OPERATOR-PLATFORM CHECKS

1. Steering

2. Lights ..........................................................................

3. Clutch pedal

4. Brake pedals

5. Parking brake warning buzzer ..........................................

6. Safety interlock system

6. OPERATION

1. Starting the engine

2. Starting/driving

3. Warm up and break in operation

4. Check hydraulic lift

5. Stopping the engine .......................................................

6. Turning

7. How to use the differential lock

8. Two and four-wheel drive selection (A4 type only

9. Use of power steering

10. Attachment limitation

1 1 . Operation on a slope

12. Uphill starting procedure

13. Recommended working speed .........................................

7. TRANSPORTING

8. INSTALLING AN ATTACHMENT ............................................

1 . Rear 3-point hitch link installation (option)

2. Rear 3-point hitch attachment installation

.............................................................................

.................................................................

.......................................................

...........................................................

..............................................

.....................................................................

........................................................................

........................................................................

......................................................................

.......................................................................

........................................................

.............................................................

..........................................

.......................................................................

.................................................................

.................................................................

..................................................

.......................................................................

.........................................................

.............................................................

.......................................

........................................................ 61

. . . . . . . . . . y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

,i

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.................................................

.................................................................

..........................

..........................

36

38

39

39

40

41

42

44

45

45

46

46

47

48

48

48

49

49

50

51

54

54

57

61

62

................

................ 67

............... 69

................ 70

................

................ 79

65

71

80

81

82

84

84

86

3

9. MAINTENANCE

Tool kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 .

Maintenance schedule

2.

Engine oil change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

Air cleaner service

4.

Transmission fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

6. Power steering fluid

7. Front axle case oil change (A4 type only)

8. All fasteners tightness/lubrication points

9. Fuel filter

10. Radiator core cleaning

11. Battery service

12. Wheel removal

13. Fuse replacement

Bulb replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

14.

10. LONG TERM STORAGE

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 : y

Removal storage

11. TROUBLESHOOTING

12. SPECIFICATIONS

13. WARRANTY SERVICE

14. WIRING DIAGRAM

,...,.............................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..,.................................................

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .._................................................ 106

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . 1 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . 112

. . . . . . . . 115

. . . . . . . . 121

88

89

90

92

94

96

98

99

100

102

103

104

117

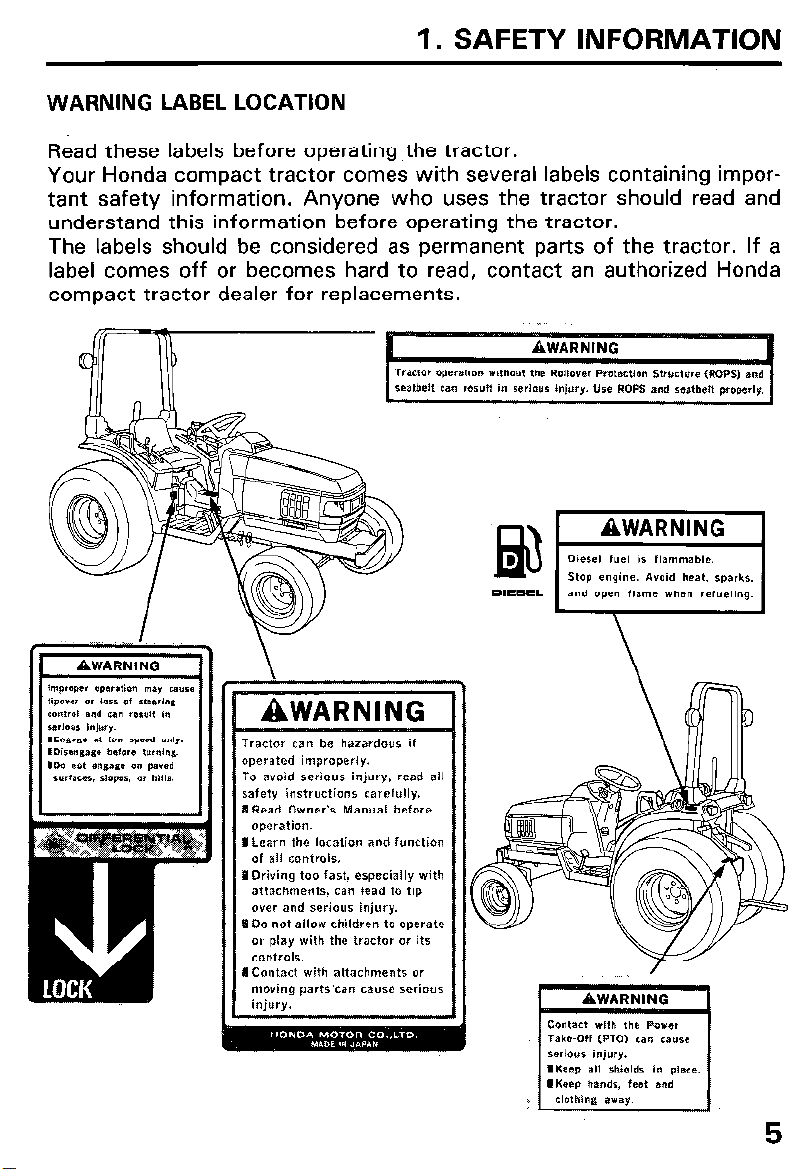

1. SAFETY INFORMATION

D’EeEL

WARNING LABEL LOCATION

Read these labels before operating,the tractor.

Your Honda compact tractor comes with several labels containing important safety information. Anyone who uses the tractor should read and

understand this information before operating the tractor.

The labels should be considered as permanent parts of the tractor. If a

label comes off or becomes hard to read, contact an authorized Honda

compact tractor dealer for replacements.

-_

AWARNING

Tractor can be hazardous if

operated improperly.

To avoid serious injury, read all

safety instructions carefully.

llRead Owner’s Manual before

operation.

I Learn the location and function

of all controls.

I Driving too fast. especially with

attachments. can lead to tip

over and serious injury.

I Do not allow children to operate

or play with the tractor or its

controls.

I Contact with attachments or

moving parts‘can cause serious

injury.

.ji$ I-~

Stop engine. &void heat. sparks,

and open flame when refueling.

\

Contact with the Pow,

Take-Off (PTO) can CaUSe

serious injury.

IKeep all shields in place.

IKeep hands, feet and

clothing away.

TRACTOR SAFETY INFORMATION

Your Honda Compact Tractor has the power to do an extraordinary

amount of work. In the hands of an operator without sufficient skill or

knowledge, it has the power to damage property and injure people. It is

your responsibility to ensure that any person operating your equipment is

aware of safe operating practices and knowledgeable with the contents of

this and other related manuals. Regardless of past experience, every

operator of your H6522 should read this section carefully before operating

the tractor or any equipment attached to it.

1. Before operating the tractor

Know your equipment and its limitations. Read this entire manual

(1)

before attempting to start and operate the tractor.

Pay special attention to the warning and caution labels on the tractor

(2)

itself.

We recommend the use of a Roll Over Protective Structures (ROPS)

(3)

and seat belt in almost all applications. This combination will reduce

the risk of serious injury or death should the tractor turn over.

If the ROPS is loosened or removed for any reason, make sure that all

parts are reinstalled correctly before operating the tractor. Never

modify or repair a ROPS because welding, bending, drilling, grinding,

or cutting any portion may weaken the structure.

A damaged ROPS structure must be replaced, not repaired or revised.

If any structural member of the ROPS is damaged, replace the entire

structure at your local Honda compact tractor dealer.

Install the HIGH-ROPS when the back hoe is used with the tractor as

it meets the safety standards established for the back hoe.

Always use the seat belt if the tractor has a ROPS. Do not use it if

(4)

there is no ROPS. Check the seat belt daily and replace if frayed or

damaged.

Do not operate tractor or any implement attached to it while fatigued

(5)

or under the influence of alcohol, medication, or other substances.

Carefully check the area before operating tractor or any implement at-

(6)

tached to it. Check for clearance to all sides and overhead. Do not

allow bystanders around or near tractor during operation.

6

(7) Before allowing other people to use your tractor, explain proper

operation to them and have them read this manual. It is your legal

obligation to instruct all operators in safe operation.

(8) Never wear loose, torn, or bulky clothing around the tractor. They

may be caught on moving parts or controls, increasing the risk of an

accident. Use additional safety items (hard hat, safety boots or

shoes, eye and hearing protection, gloves, etc.) as appropriate or

required.

(g) Do not allow passengers or non-,qualified operators on the tractor at

any time. The tractor is designed for only one occupant.

(IO) Check brakes, clutch, and other mechanical parts for adjustment and

wear. Replace worn or damaged parts promptly. Check the tightness

of all nuts and bolts regularly. (For further details, see

MAINTENANCE AND ADJUSTMENTS.)

(11) Keep your tractor clean. Dirt, grease, and trash accumulations con-

tribute to fires and may lead to personal injury.

(12) Use only implements meeting the specifications listed under IMPLE-

MENT LIMITATIONS in this manual. Use the recommended counter

weights to maintain the balance of the tractor and reduce the risk of

upsets. Follow the safe operating procedures specified in the

manuals included with the equipment.

(13) The Honda H6522 tractor is not factory equipped with a spark ar-

rester. In some areas, it is illegal to operate an engine without a

USDA-qualified spark arrester.

before operating. An optional spark arrester is available from an

authorized Honda tractor dealer.

Check local laws and regulations

2. Operating the tractor

(1) Never start engine or operate levers from anywhere other than the

seat.

(2) Before, starting the engine, make sure that all levers (including aux-

iliary control levers) are in their neutral positions, that the parking

brake is engaged, and that both the clutch and the Power Take Off

(PTO) are disengaged. Fasten the seat belt if the tractor has a ROPS.

(3) Do not start engine by shorting across starter terminals or bypassing

the safety start switch. The machine may start in gear and move if

normal starting circuitry is bypassed.

7

(4) Pull only from the drawbar. Never hitch to axle housing or any other

point except drawbar; such arrangements only increase the risk of

serious personal injury or death due to a tractor upset.

(5) Do not operate or idle engine in a non-ventilated area. Carbon monox-

ide gas is colorless, odorless, and deadly.

(6) Keep all shields and guards in place. Replace any that are missing or

damaged.

(7) Avoid sudden starts. To avoid upsets, slow down when turning, on

uneven terrain, and before stopping.

(8) The tractor cannot turn with the differential locked. Attempting to do

so could be dangerous.

(9) Do not operate near ditches, holes, embankments, or other terrain

which may collapse under the tractor’s weight. The risk of tractor

upset is even higher when the ground is loose or wet.

(I 0) Driving forward out of a ditch or up a steep slope may cause a tractor

to tip over backward. Always back out of these situations. Extra caution is required with fourwheel drive models because their higher

traction can give you the false confidence in the tractor’s ability to

climb slopes.

(I I) To avoid tipping the tractor over, always back up steep slopes. Stay

off hills and slopes too steep for safe operation.

(I 2) Watch where you are going at all times. Watch for and avoid

obstacles. Be alert at row ends, near trees, and other obstructions.

(13) When working in groups, always let the others know what you are

going to do before you do it.

(I 4) Never “coast.” Disengaging the clutch or shifting into neutral while

descending a slope could lead to loss of control.

(I 5) Never try to get on or off a moving tractor.

3. Driving the tractor on the road

(I 1 Lock the two brake pedals together to help assure straight-line stops.

Uneven braking at road speeds could cause the tractor to roll over.

8

(2) Always slow the tractor down before turning. Turning at high speed

may tip the tractor over.

(3) Make sure that the Slow-Moving Vehicle (SMV) emblem is clean and

visible. Use slow-moving vehicle warning lights as required.

(4) Observe all local traffic and safety regulations.

(5) Turn the headlights on. Dim them when meeting another vehicle.

(6) Drive at speeds that allow you to maintain control at all times.

(7) Do not apply the differential lock while traveling at road speeds. The

tractor will not turn correctly and may cause you to lose control.

(8) Avoid sudden movement of the steering wheel to avoid a dangerous

loss of stability. the risk is especially great when the tractor is traveling at road speeds.

(9) Do not operate an implement while the tractor is on the road. Lock it

in the raised position.

(I 0) When towing other equipment, use a safety chain in addition to the

drawbar hitch and place an SMV emblem on the towed equipment.

4. Stopping the tractor

(1) Disengage the PTO, lower all implements, place all control levers in

their neutral positions, apply parking brake, turn off the engine, and

remove the key.

(2) Make sure that the tractor has come to a complete stop before

dismounting.

5. Operating the PTO

(I) Wait until all moving components have completely stopped before

getting off the tractor, connecting, disconnecting, adjusting, clean-

ing, or servicing any PTO driven equipment.

9

(2) Keep the PTO shaft cover in place at all times. Replace the PTO shaft

cap when the shaft is not in use.

(3) Before installing or using PTO driven equipment, read the manufac-

turer’s manual and review the safety labels attached to the

equiprnent.

(4) Operate PTO-driven equipment at or below the rated RPM marked on

the tachometer.

(5) When operating stationary PTO-driven equipment, always apply the

tractor parking brake and place chocks behind and in front of the rear

wheels. Stay clear of all rotating parts.

6. Using 3-point hitch

(I I Use the 3-point hitch only with equipment designed for 3-point hitch

usage.

(2) When using a 3-point hitch mounted implement, be sure to install any

recommended counter-weight on the front of the tractor.

(3) When transporting on the road, set the implement lowering control in

the “lock” positon to hold the implement in the raised position.

7. Servicing the tractor

Before servicing the tractor, park it on a firm level surface, set the parking

brake, place the gear shift lever in neutral and stop the engine.

(1) Allow the tractor time to cool off before working on or near the

engine, muffler, radiator, etc.

(2) Always stop the engine before refueling. Avoid spills and overfilling.

(3) Do not smoke when working around battery or when refueling. Keep

all sparks and flames away from battery and fuel tank. The battery

presents an explosion hazard because it gives off hydrogen and

oxygen; especially when recharging.

(4) Before “jumping” a dead battery,

instructions.

(5) Keep first aid kit and fire extinguisher handy at all times.

read and follow all of the

10

(6) Do not remove radiator cap while coolant is hot. Add coolant to the

11

coolant recovery tank, not to the radiator.

(7) Disconnect the battery’s ground cable before working on or near

electric components.

(8) To avoid sparks from an accidental short circuit, always disconnect

the battery’s ground cable first and connect it last.

(9) Do not attempt to mount a tire on a rim unless qualified to do so and

all proper safety precautions are followed.

(IO) Provide adequate support when changing wheels.

(11) Make sure that wheel bolts have been tightened to the specified

torque.

(12) Escaping hydraulic fluid under pressure has sufficient force to

penetrate skin, causing serious personal injury. Before disconnecting

hydraulic lines, be sure to release all residual pressure. Before applying pressure to the hydraulic system, make sure that all connections

are tight and that all lines, pipes, and hoses are free of damage.

Fluid escaping from pinholes may not be visible. Do not use your bare

hands to search for suspected leaks. Use a piece of cardboard or

wood, instead. The use of safety goggles or other eye protection is

also highly recommended.

If injured by escaping fluid, see a medical doctor at once. Fluid can

produce severe reactions.

8. Jump starting instructions and precautions

If ice is present or the battery is cracked, do not attempt to “jump start”

the vehicle.

(I) Bring a helper vehicle with a battery of the same voltage as disabled

tractor within easy cable reach. THE VEHICLES MUST NOT TOUCH.

(2) Engage the parking brakes of both vehicles and put the shift levers in

neutral. Turn off both key switches.

(3) Put on safety goggles and rubber gloves.

(4) Remove the vent caps from both batteries.

(5) Cover vent holes with damp rags, Do not allow the rag to touch the

battery terminals.

(6) Attach the red clamp to the positive (red, (+) or pos.) terminal of the

dead battery and clamp the other end of the same cable to the

positive (red, (+) or pos.) termianl of the helper bettery.

(7) Clamp the other cable to the negative (black, (-) or neg.) terminal of

the helper battery.

(8) Clamp the other end to the engine block or frame of the disabled trac-

tor as far from the dead battery as possible.

(9) Start the helper vehicle and let its engine run for a few moments.

Start the disabled tractor.

(I 0) Disconnect the jumper cables in the exact reverse order of attach-

ment. (Steps 8, 7 and 6).

(I 1) Remove and discard the damp rags since they may contain sulfuric

acid. Reinstall the vent caps.

12

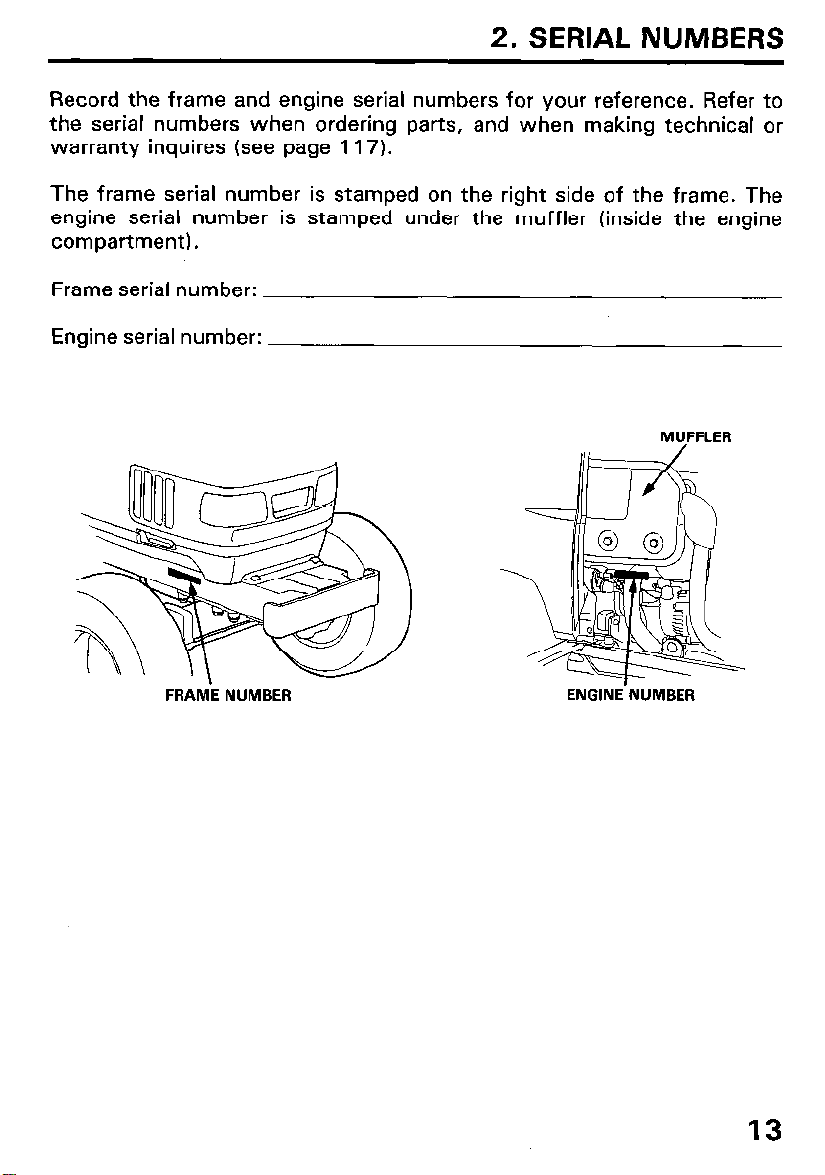

2. SERIAL NUMBERS

Record the frame and engine serial numbers for your reference. Refer to

the serial numbers when ordering parts, and when making technical or

warranty inquires (see page 117).

The frame serial number is stamped on the right side of the frame. The

engine serial number is stamped under the muffler (inside the engine

compartment).

Frame serial number:

Engine serial number:

MUFFLER

FRAME NUMBER

ENGINE’NUMBER

13

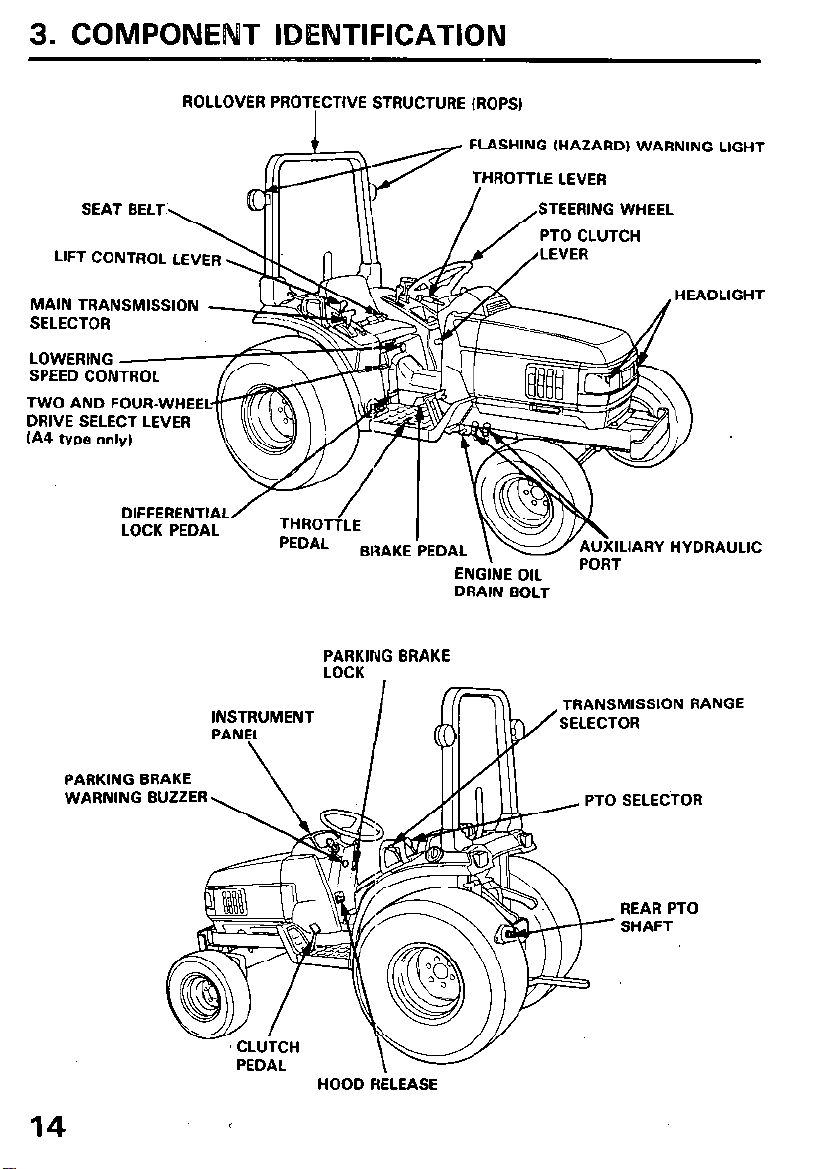

3. COMPONENT IDENTIFICATION

ROLLOVER PROTECTIVE STRUCTURE (ROPSJ

I

LlFT CONTROL LEVER

MAIN TRANSMISSION

SELECTOR

SPEED CONTROL

TWO AND FOUR-WHEE

DRIVE SELECT LEVER

IA4 type only)

DIFFERENTIAL

LOCK PEDAL

ENGINE OIL

DRAIN BOLT

FLASHING (HAZARD) WARNING LIGHT

THROTTLE LEVER

STEERING WHEEL

PTO CLUTCH

IARY HYDRAULIC

PARKING BRAKE

WARNING BUZZER

14

INSTRUMENT

-__.-.

CLUTCH

PARKING BRAKE

LOCK

TRANSMISSION RANGE

SELECTOR

_ PTO SELECTOR

REAR PTO

SHAFT

HOOD HELEASE

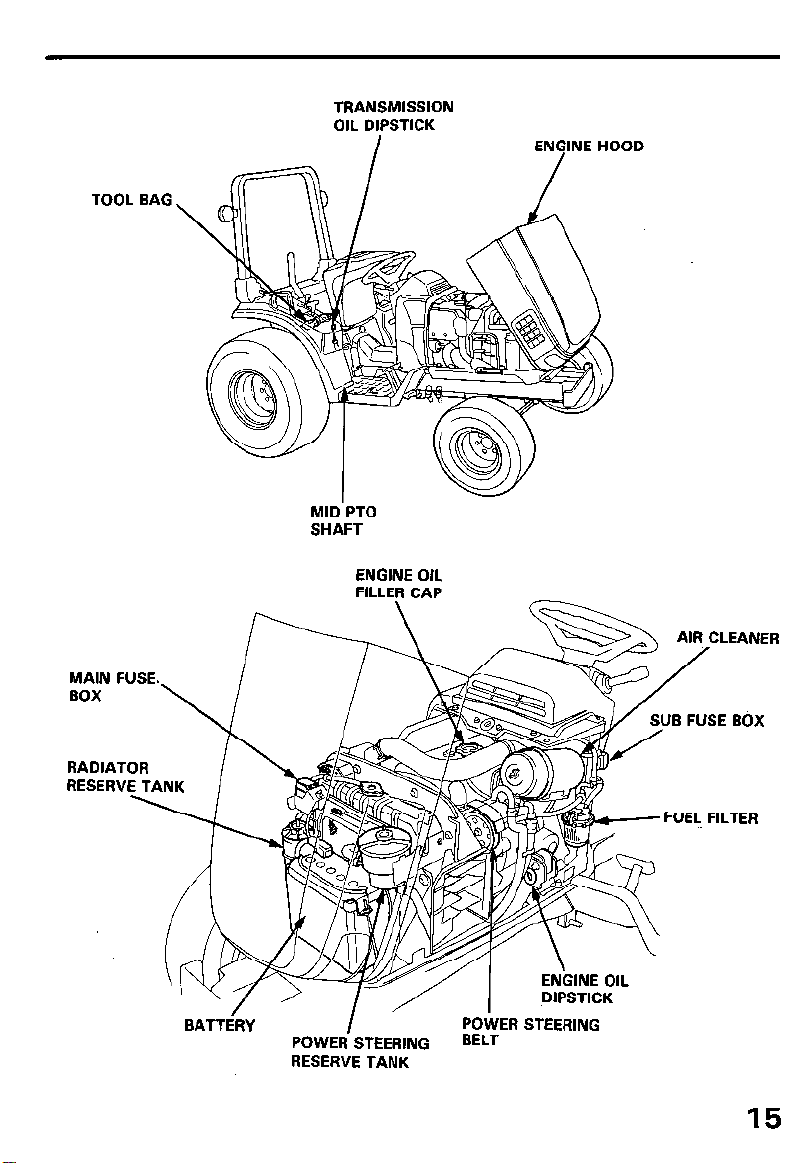

TOOL BAG

TRANSMISSION

OIL DIPSTICK

I

MID’PTO

SHAFT

ENGINE OIL

FILLER CAP

ENGINE HOOD

-7-A /---

MAIN FUSE. /

BOX

RADIATOR

RESERVE TANK

BATTERY

I

POWER STEERING

RESERVE TANK

POWER STEERING

BELT

YT-/

AIR CLEANER

15

4. CONTROLS

INSTRUMENT PANEL

CHARGE SYSTEM WARNING LIGHT

OIL PRESSURE WARNING LIGHT

I

I

LIGHT

GLOW PLUG

INDICATOR

HEAD LIGHT

INDICATOR

WATER TEMPERATURE

GAUGE

HEAD LIGHT SWITCH

/

HOURMETER

PARKING BRAKE

INDICATOR LIGHT

PARKINd BRAKE

WARNING BUZZER

FLASHING (HAZARD) WARNING

LIGHTS/INDICATOR

I

1. ENGINE SWITCH

STATIONARY PTO

16

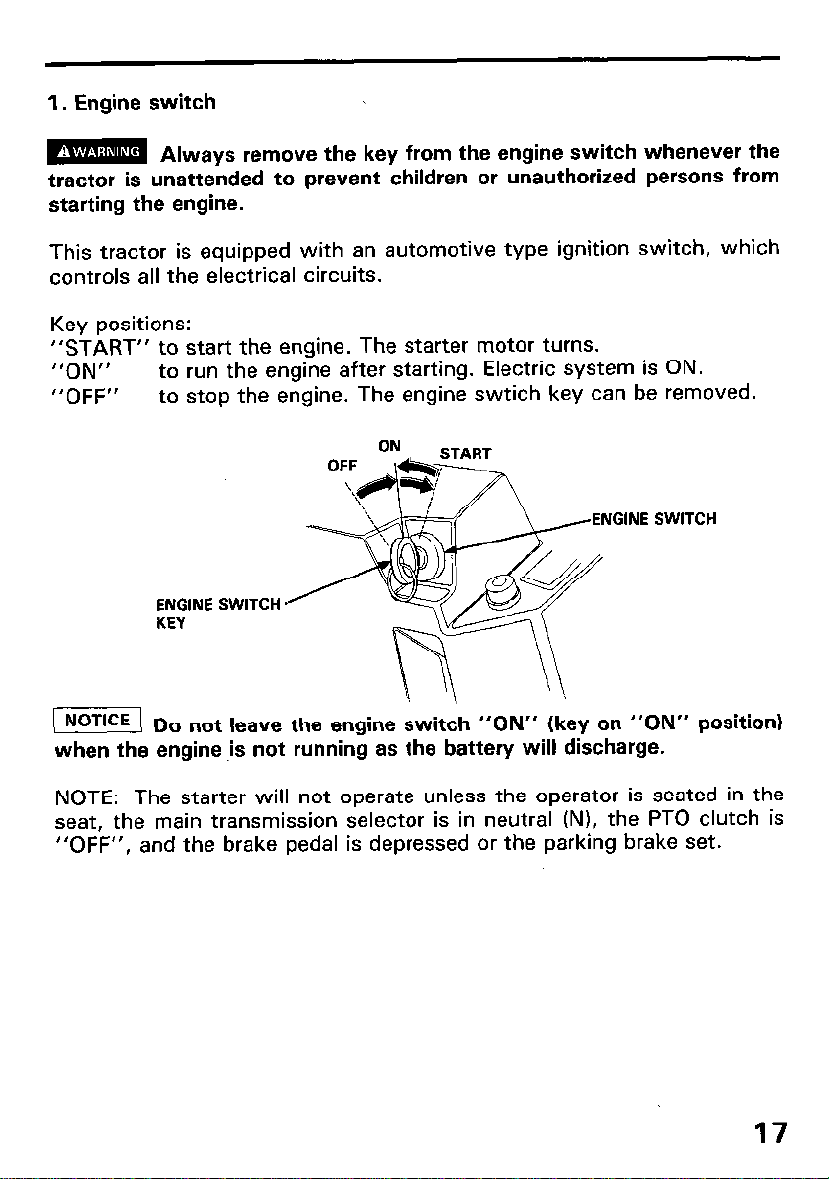

1. Engine switch

m

Always remove the key from the engine switch whenever the

tractor is unattended to prevent children or unauthorized persons from

starting the engine.

This tractor is equipped with an automotive type ignition switch, which

controls all the electrical circuits.

Key positions:

“START” to start the engine. The starter motor turns.

“ON”

to run the engine after starting. Electric system is ON.

“OFF” to stop the engine. The engine swtich key can be removed.

SWITCH

ENGINE SWITCH

KEY

1 NOTICE ( 0

o not leave the engine switch “ON” (key on “ON” position)

when the engine ,is not running as the battery will discharge.

NOTE: The starter will not operate unless the operator is seated in the

seat, the main transmission selector is in neutral (N), the PTO clutch is

“OFF”, and the brake pedal is depressed or the parking brake set.

17

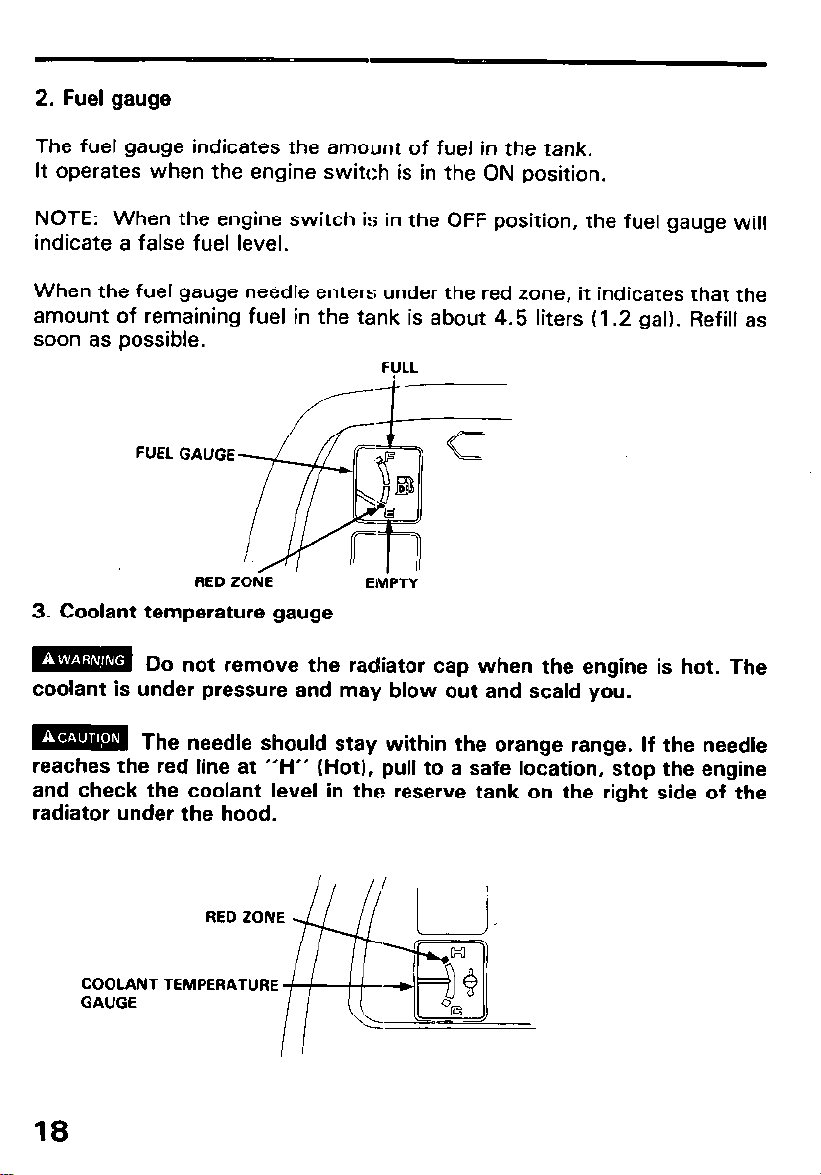

2. Fuel gauge

The fuel gauge indicates the amount of fuel in the tank.

It operates when the engine switch is in the ON position.

NOTE: When the engine switch is in the OFF position, the fuel gauge will

indicate a false fuel level.

When the fuel gauge needle enters under the red zone, it indicates that the

amount of remaining fuel in the tank is about 4.5 liters (1.2 gal). Refill as

soon as possible.

FUEL GAUGE

RED ZONE

EMPTY

3. Coolant temperature gauge

m Do not remove the radiator cap when the engine is hot. The

coolant is under pressure and may blow out and scald you.

m The needle should stay within the orange range. If the needle

reaches the red line at “H” (Hot), pull to a safe location, stop the engine

and check the coolant level in the reserve tank on the right side of the

radiator under the hood.

COOLANT

GAUGE

18

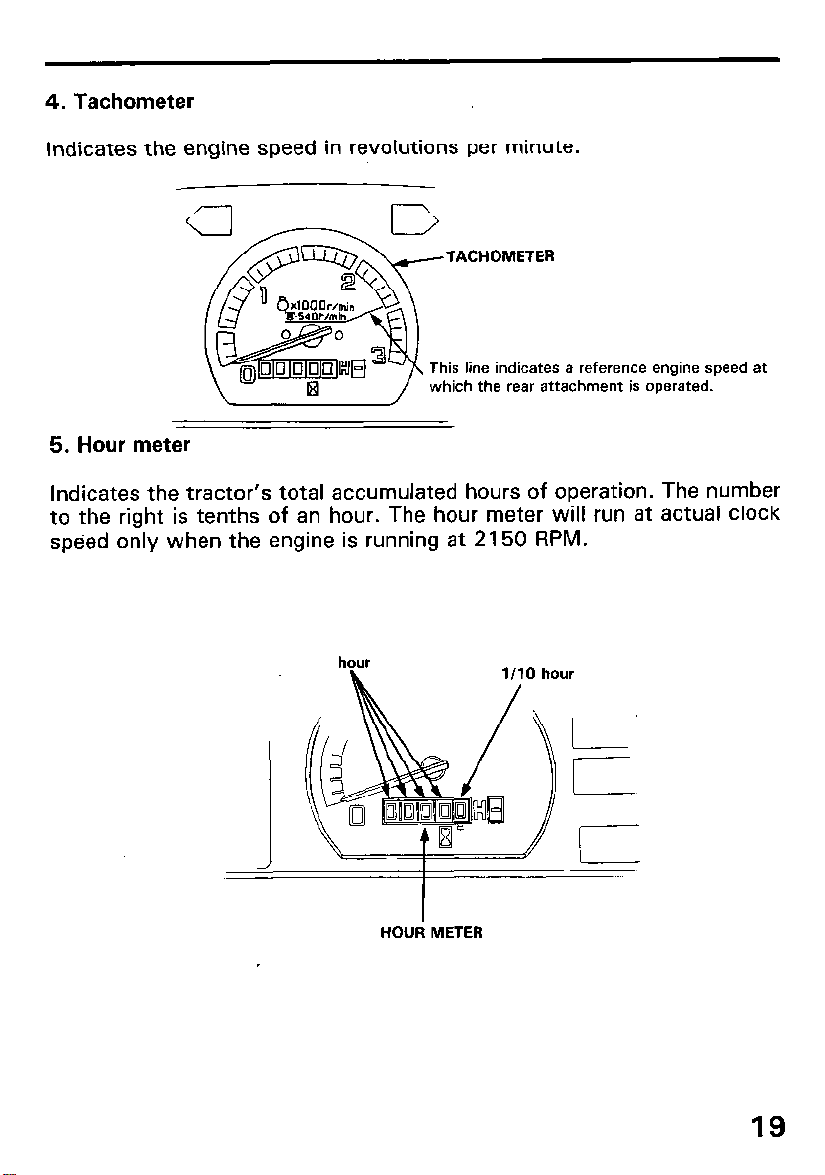

4. Tachometer

Indicates the engine speed in revolutions per minute.

TACHOMETER

This line indicates a reference engine speed at

which the rear attachment is operated.

5. Hour meter

Indicates the tractor’s total accumulated hours of operation. The number

to the right is tenths of an hour. The hour meter will run at actual clock

speed only when the engine is running at 2150 RPM.

HOUR METER

19

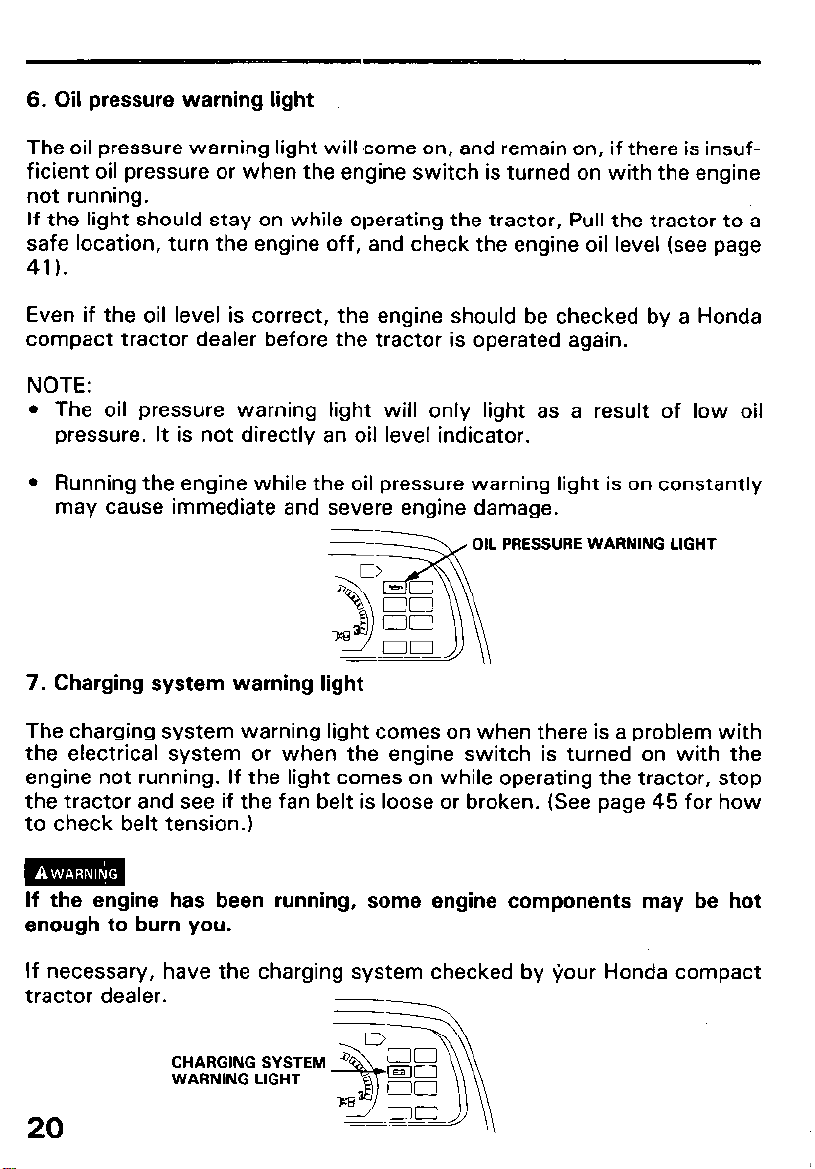

6. Oil pressure warning light

The oil pressure warning light will come on, and remain on, if there is insufficient oil pressure or when the engine switch is turned on with the engine

not running.

If the light should stay on while operating the tractor, Pull the tractor to a

safe location, turn the engine off, and check the engine oil level (see page

41).

Even if the oil level is correct, the engine should be checked by a Honda

compact tractor dealer before the tractor is operated again.

NOTE:

l The oil pressure warning light will only light as a result of low oil

pressure. It is not directly an oil level indicator.

l Running the engine while the oil pressure warning light is on constantly

may cause immediate and severe engine damage.

WARNING LIGHT

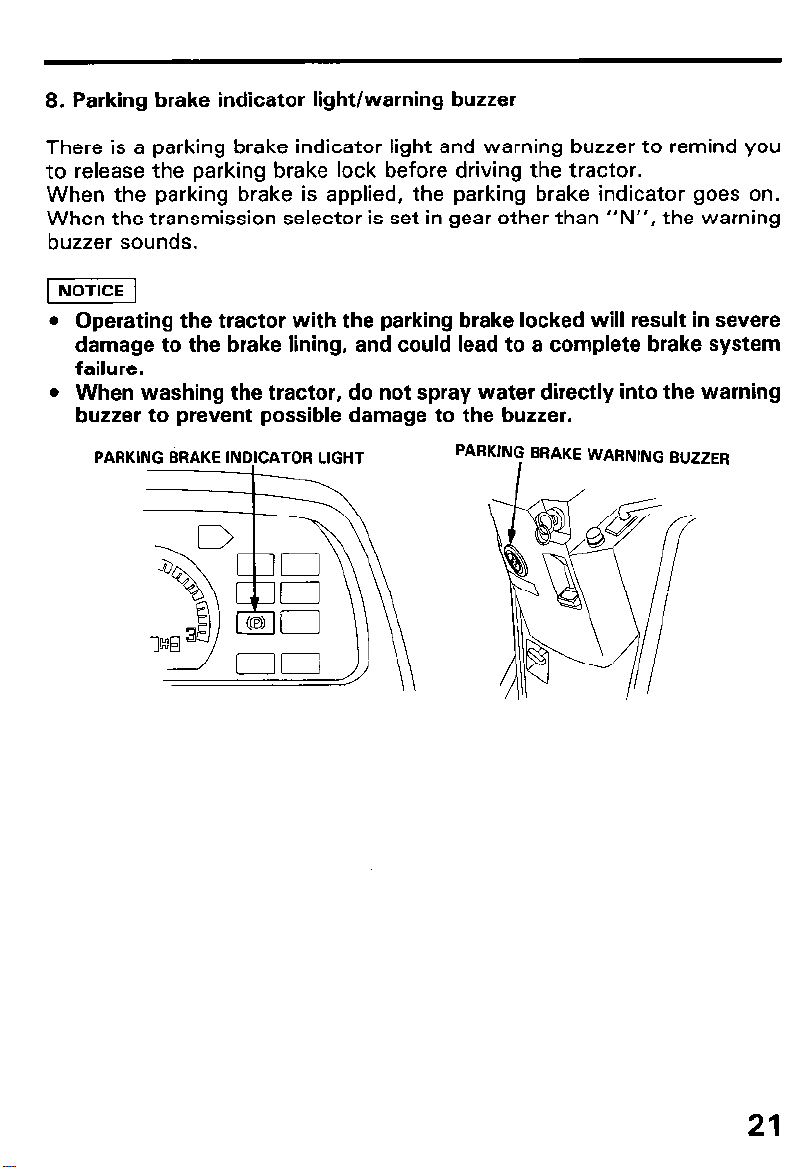

7. Charging system warning light

The charging system warning light comes on when there is a problem with

the electrical system or when the engine switch is turned on with the

engine not running. If the light comes on while operating the tractor, stop

the tractor and see if the fan belt is loose or broken. (See page 45 for how

to check belt tension.)

If the engine has been running, some engine components may be hot

enough to burn you.

If necessary, have the charging system checked by your Honda compact

tractor dealer.

CHARGING SYSTEM

WARNING LIGHT

20

8. Parking brake indicator light/warning buzzer

There is a parking brake indicator light and warning buzzer to remind you

to release the parking brake lock before driving the tractor.

When the parking brake is applied, the parking brake indicator goes on.

When the transmission selector is set in gear other than “N”, the warning

buzzer sounds.

1 NOTICE 1

l Operating the tractor with the parking brake locked will result in severe

damage to the brake lining, and could lead to a complete brake system

failure.

l When washing the tractor, do not spray water directly into the warning

buzzer to prevent possible damage to the buzzer.

PARKiNG BRAKE ~NO~CATOR LIGHT

21

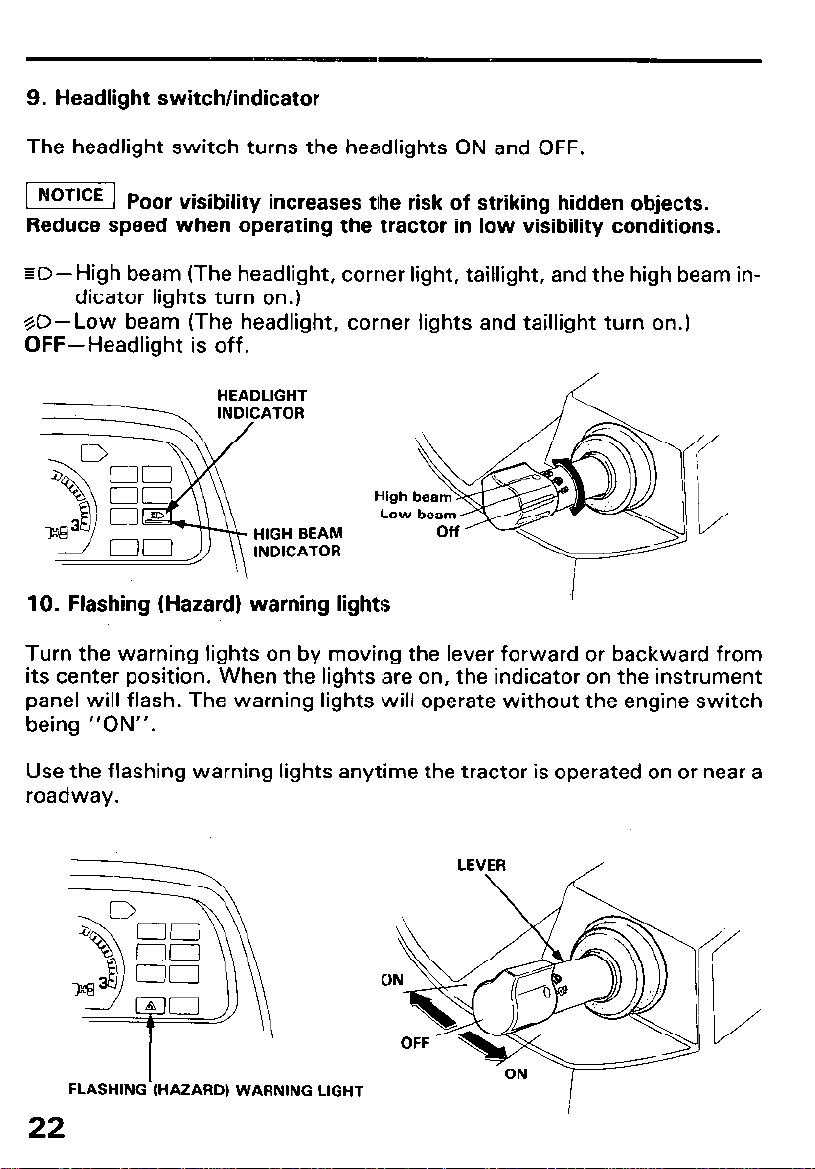

9. Headlight switch/indicator

The headlight switch turns the headlights ON and OFF.

1 NOTICE 1 p.

or visibility increases tlhe risk of striking hidden objects.

Reduce speed when operating the tractor in low visibility conditions.

ED-High beam (The headlight, corner light, taillight, and the high beam in-

dicator lights turn on.)

%O-Low beam (The headlight, corner lights and taillight turn on.)

OFF- Headlight is off.

HEADLIGHT

INDICATOR

HIGH SEAM

INDICATOR

10. Flashing (Hazard) warning lights

Turn the warning lights on by moving the lever forward or backward from

its center position. When the lights are on, the indicator on the instrument

panel will flash. The warning lights will operate without the engine switch

being “ON”.

Use the flashing warning lights anytime the tractor is operated on or near a

roadway.

FLASHING (HAZARD) WARNING LIGHT

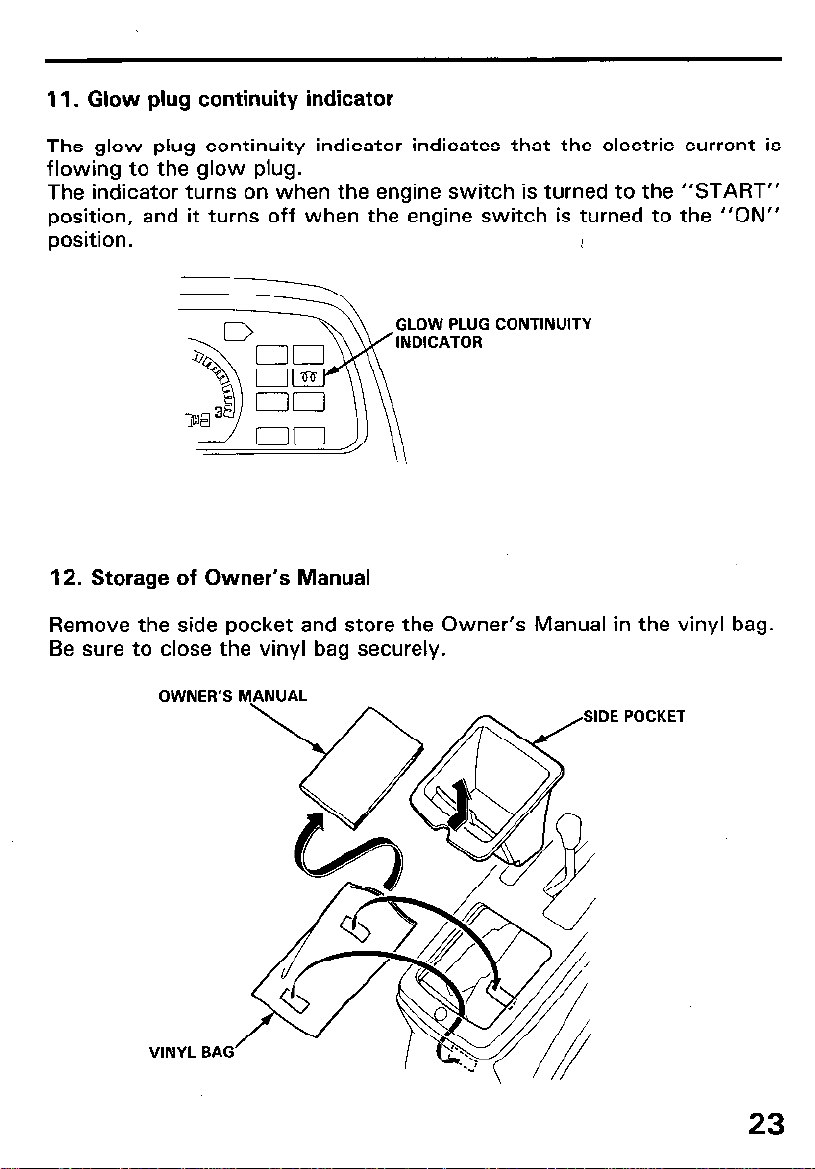

11. Glow plug continuity indicator

The glow plug continuity indicator indicates that the electric current is

flowing to the glow plug.

The indicator turns on when the engine switch is turned to the “START”

position, and it turns off when the engine switch is turned to the “ON”

position.

CONTINUITY

1

12. Storage of Owner’s Manual

Remove the side pocket and store the Owner’s Manual in the vinyl bag.

Be sure to close the vinyl bag securely.

OWNER’S MANUAL

VINYL BAG

POCKET

23

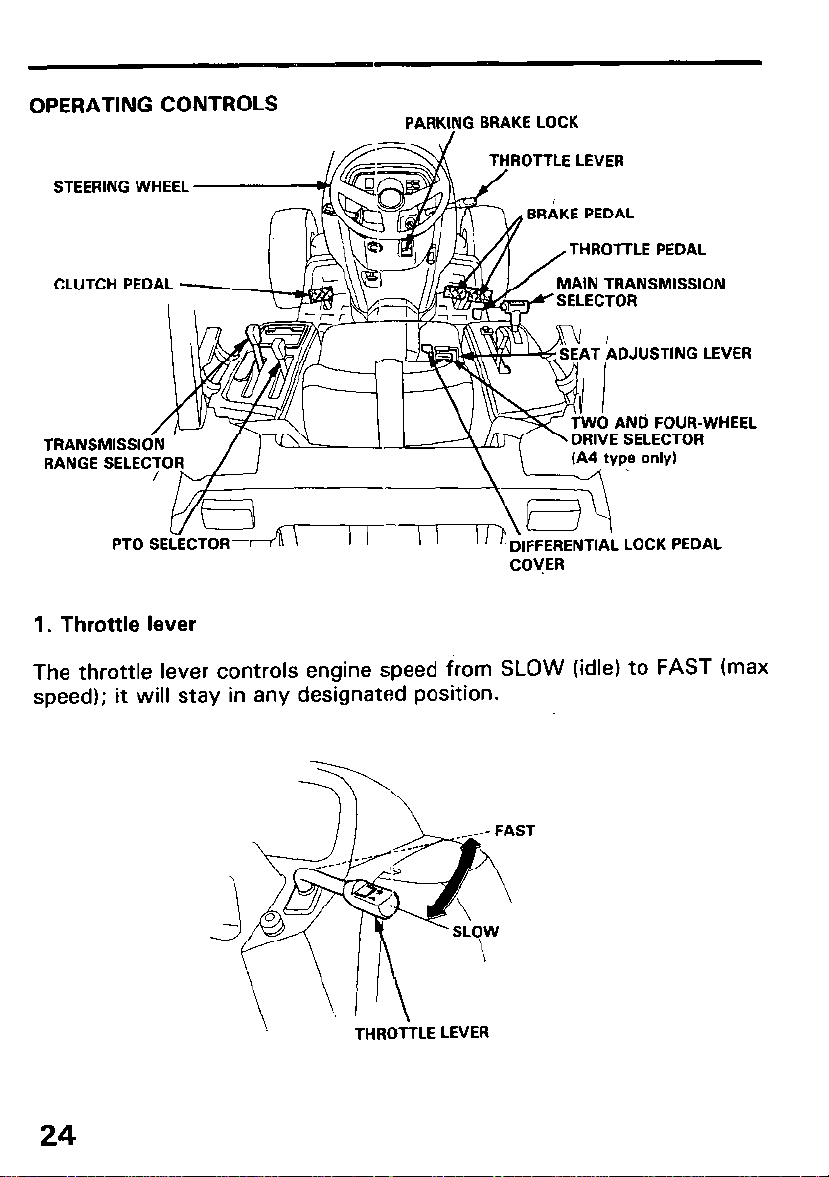

OPERATING CONTROLS

STEERING WHEEL -‘/)$$G

CLUTCH PEDAL

’ /

.ECTOR RANGE SEI

PARKIYG BRAKE LOCK

ROTTLE LEVER

THROTTLE PEDAL

MAIN TRANSMISSION

0 ANd FOUR-WHEEL

VE SELECTOR

PTO SELECTOR-‘+n \

I I

I I

I ’ ‘: DIFFERENTIAL LOCK PEDAL

COVER

1. Throttle lever

The throttle lever controls engine speed from SLOW (idle) to FAST (max

speed); it will stay in any designated position.

\.

THROtiLE LEVER

24

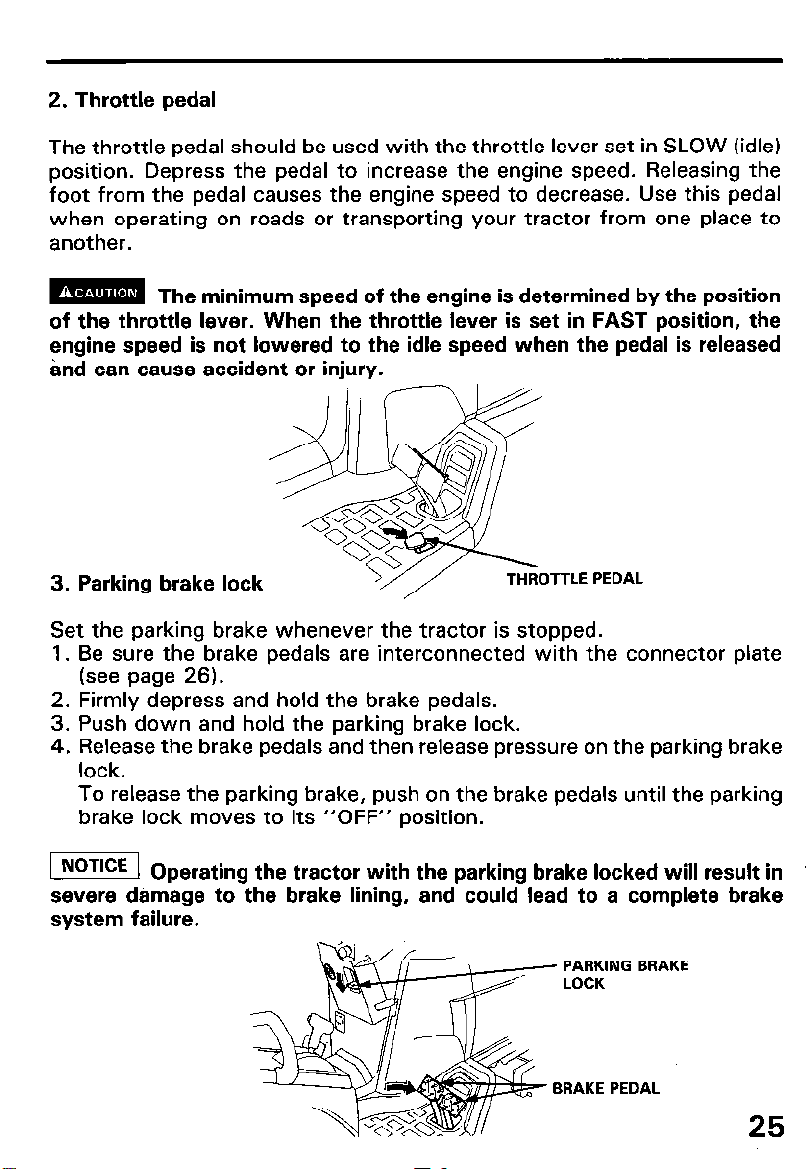

2. Throttle pedal

The throttle pedal should be used with the throttle lever set in SLOW (idle)

position. Depress the pedal to increase the engine speed. Releasing the

foot from the pedal causes the engine speed to decrease. Use this pedal

when operating on roads or transporting your tractor from one place to

another.

m

of the throttle lever. When the throttle lever is set in FAST position, the

engine speed is not lowered to the idle speed when the pedal is released

and can cause accident or injury.

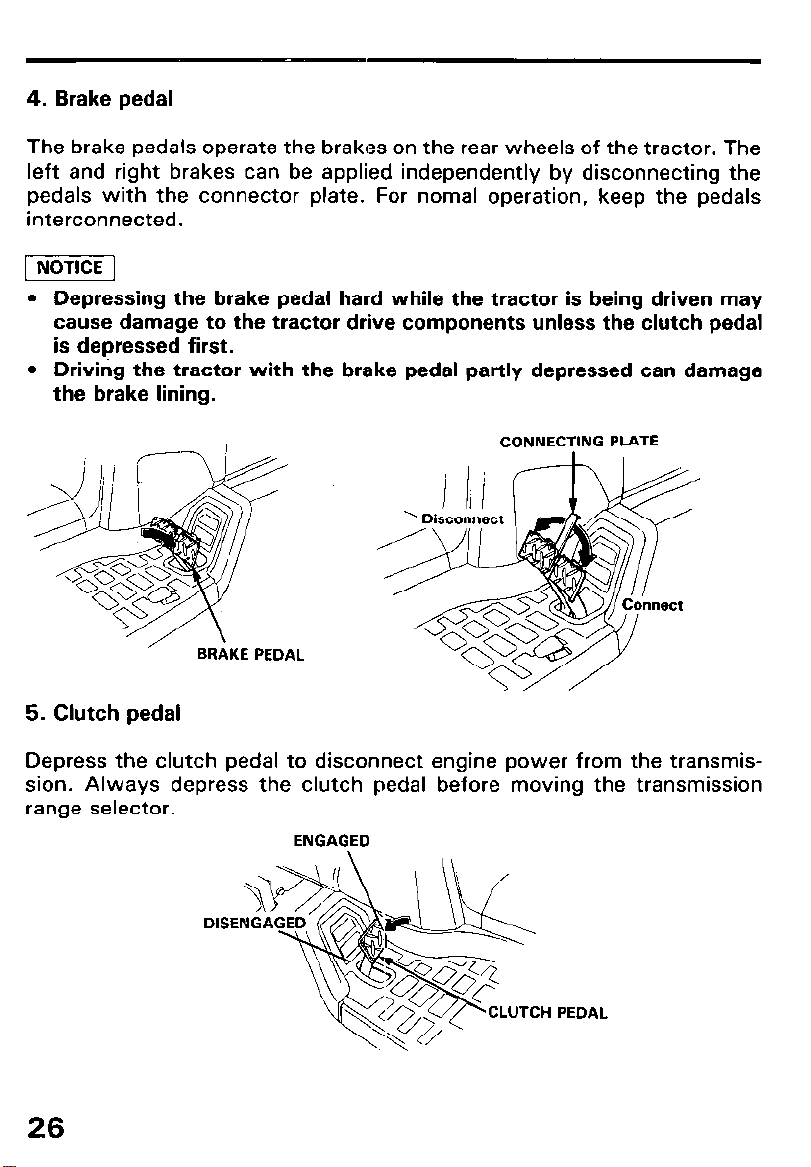

3. Parking brake lock

Set the parking brake whenever the tractor is stopped.

1. Be sure the brake pedals are interconnected with the connector plate

(see page 26).

2. Firmly depress and hold the brake pedals.

3. Push down and hold the parking brake lock.

4. Release the brake pedals and then release pressure on the parking brake

lock.

To release the parking brake, push on the brake pedals until the parking

brake lock moves to its “OFF” position.

[I op

severe damage to the brake lining, and could lead to a complete brake

system failure.

The minimum speed of the engine is determined by the position

OTTLE PEDAL

erating the tractor with the parking brake locked will result in

PARKING BRAKE LOCK

BRAKE PEDAL

25

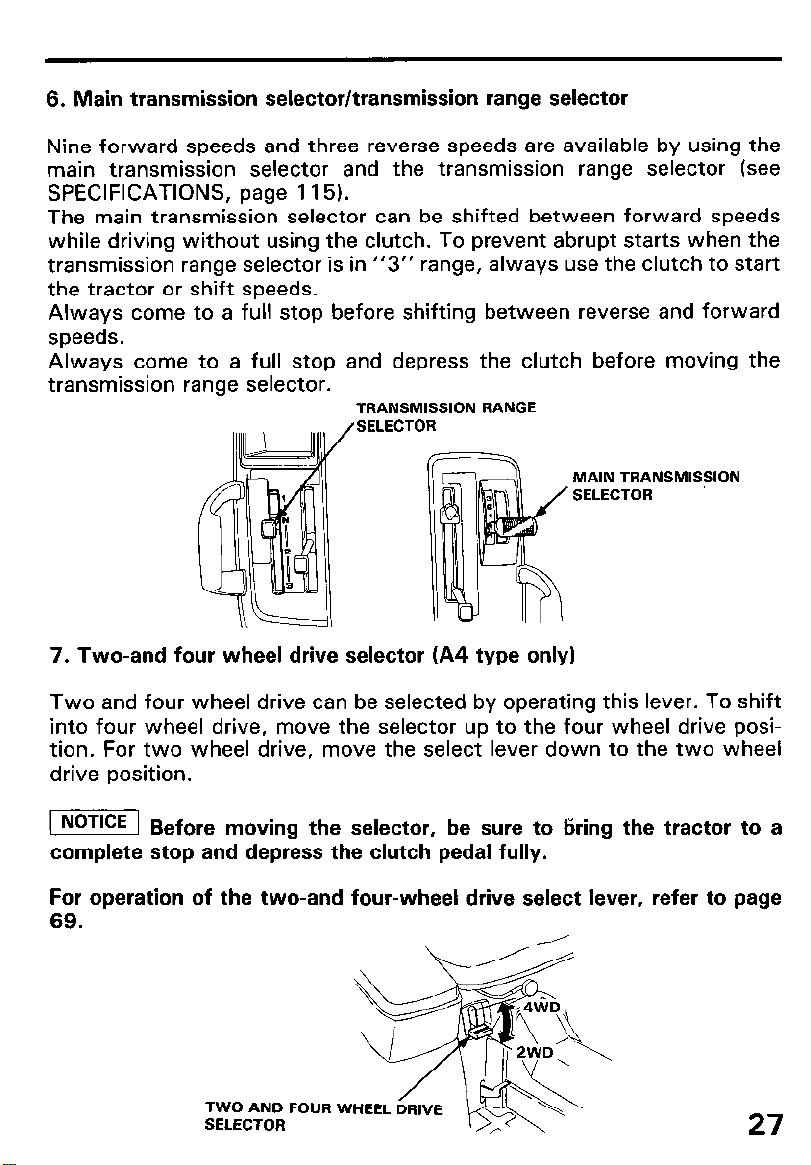

4. Brake pedal

The brake pedals operate the brakes on the rear wheels of the tractor. The

left and right brakes can be applied independently by disconnecting the

pedals with the connector plate. For nomal operation, keep the pedals

interconnected.

l Depressing the brake pedal hard while the tractor is being driven may

cause damage to the tractor drive components unless the clutch pedal

is depressed first.

l Driving the tractor with the brake pedal partly depressed can damage

the brake lining.

CONNECTING PLATE

BRAKE PEDAL

5. Clutch pedal

Depress the clutch pedal to disconnect engine power from the transmission. Always depress the clutch pedal before moving the transmission

range selector.

ENGAGED

CLUTCH PEDAL

26

6. Main transmission selector/transmission range selector

Nine forward speeds and three reverse speeds are available by using the

main transmission selector and the transmission range selector (see

SPECIFICATIONS, page 115).

The main transmission selector can be shifted between forward speeds

while driving without using the clutch. To prevent abrupt starts when the

transmission range selector is in

“3” range, always use the clutch to start

the tractor or shift speeds.

Always come to a full stop before shifting between reverse and forward

speeds.

Always come to a full stop and depress the clutch before moving the

transmission range selector.

TRANSMISSION RANGE

SELECTOR

MAIN TRANSMISSION

SELECTOR

7. Two-and four wheel drive selector (A4 type only)

Two and four wheel drive can be selected by operating this lever. To shift

into four wheel drive, move the selector up to the four wheel drive position. For two wheel drive, move the select lever down to the two wheel

drive position.

( Before moving the selector, be sure to tiring the tractor to a

complete stop and depress the clutch pedal fully.

For

operation of the two-and four-wheel drive select lever,

refer to

69.

TWO AND

SELECTOR

FOUR

27

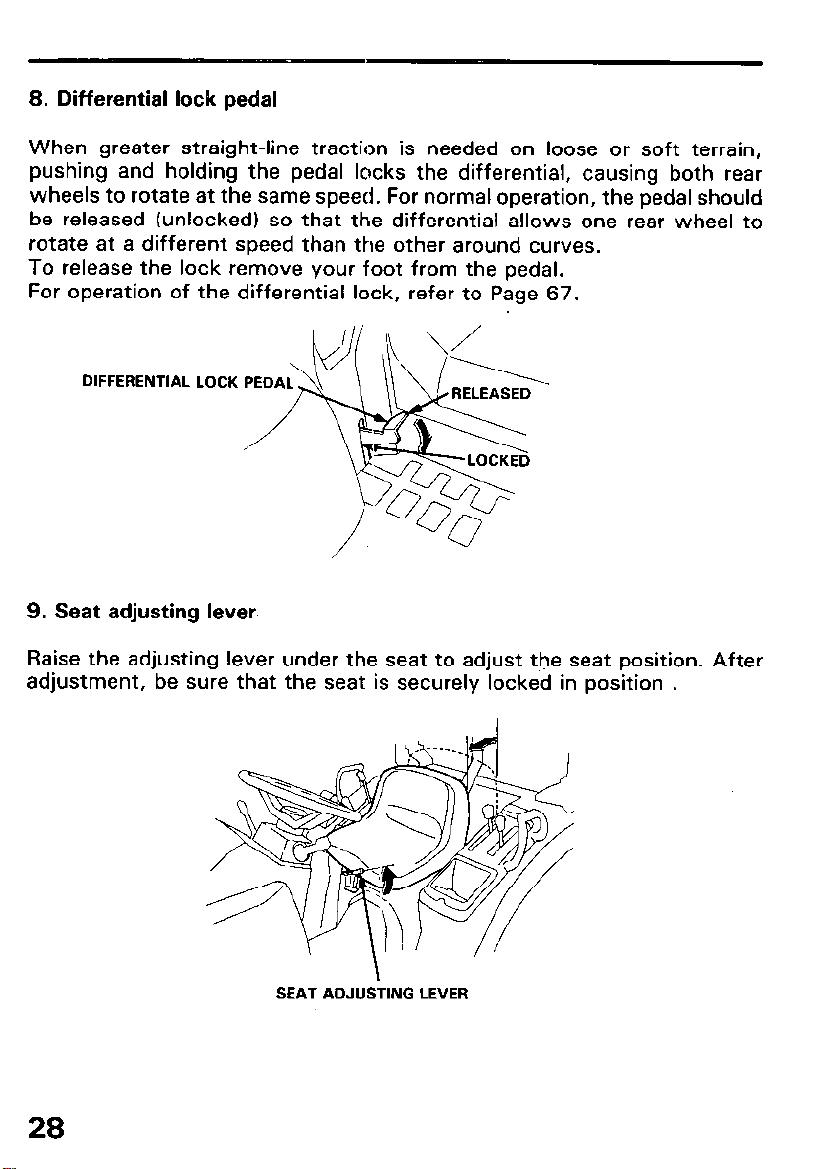

8. Differential lock pedal

When greater straight-line traction is needed on loose or soft terrain,

pushing and holding the pedal locks the differential, causing both rear

wheels to rotate at the same speed. For normal operation, the pedal should

be released (unlocked) so that the differential allows one rear wheel to

rotate at a different speed than the other around curves.

To release the lock remove your foot from the pedal.

For operation of the differential lock, refer to Page 67.

DIFFERENTIAL LOCK

9. Seat adjusting lever

Raise the adjusting lever under the seat to adjust the seat position. After

adjustment, be sure that the seat is securely locked in position .

28

SEAT ADJUSi-ING

LEVER

Loading...

Loading...