Honda Power Equipment H5013 User Manual

Thank you for purchasing a Honda tractor.

This manual describes operation and maintenance of the Honda H5013

tractor, type A2. (Two Wheel Drive Model) and A4 (Four Wheel Drive

Model).

Information in this manual is based on the H5013 A4 model equipped with

a rear hydraulic lift unit which is available as an optional part.

All information in this manual is based on the latest product information

available at the time of printing.

Honda Motor Co., Ltd. reserves the right to make changes at any time

without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

This manual is considered a permanent part of the utility tractor and it

must stay with the tractor if resold.

READ THIS OWNER’S MANUAL CAREFULLY. Pay special attention to

these symbols and any instructions that follow:

pq

-Indicates serious injury or death WILL result if

instructions are not followed.

‘Indicates a strong possibility that serious injury or

death could result if instructions are not followed.

m -

1 IMPORTANT NoT’CE 1 -Indicates that equipment or property damage can

NOTE: Gives helpful information.

Honda tractors are designed to give safe and dependable service if

operated according to instructions. Operating this tractor requires special

effort on your part to ensure your safety and the safety of others.

y m

or property damage. Read and understand this Owner’s Manual before

operating this tractor.

If a problem should arise, or if you have any questions about your tractor,

consult an authorized Honda tractor dealer.

HONDA MOTOR CO., LTD. 1990, ALL RIGHTS RESERVED

Using this product for a purpose not intended may cause injury

‘Indicates a possibility that minor injury can result if

instructions are not followed.

result if instructions are not followed.

1

CONTENTS

1. SAFETY INFORMATION

2. SERIAL NUMBERS

3. COMPONENT IDENTIFICATION

4. CONTROLS

INSTRUMENT PANEL

1. Engine switch

2. Headlight switch

3. Fuel gauge

4. Engine oil warning light

5. Parking brake warning buzzer

DRIVE COMPONENTS

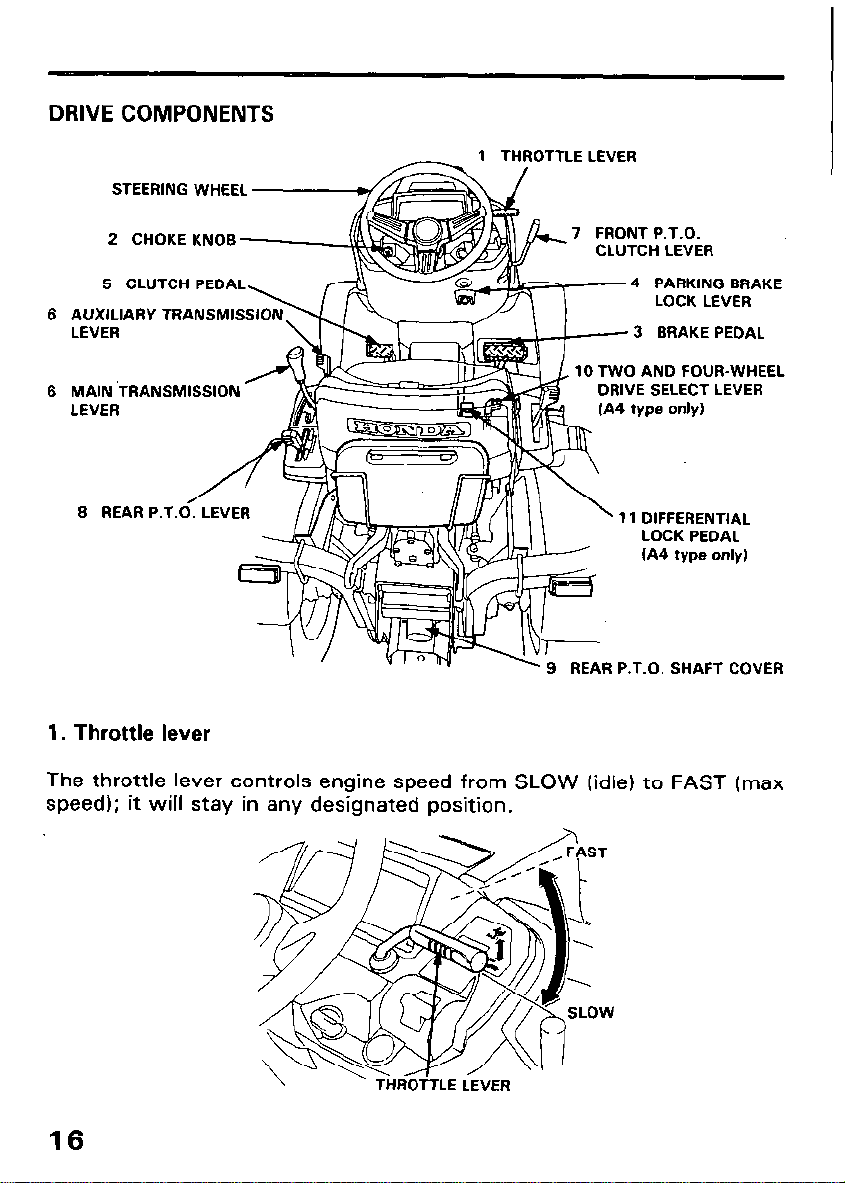

1 . Throttle lever

2. Choke knob

3. Brake pedal

4. Parking brake lock lever

5. Clutch pedal

6. Main transmission lever/Anxiliary transmission lever

7. Front P.T.O. clutch lever

8. Rear P.T.O. lever

9. Rear P.T.O. shaft/shaft cover

10. Two- and Four-Wheel Drive select lever (A4 Type only)

1 1. Differential lock pedal (A4 Type only)

HYDRAULIC LIFT SYSTEM

1. Hydraulic cylinder selector lever (Rear hydraulic lift type only,

option)

2. Hydraulic lift lever

3. Descent speed adjust knob

5. PRE-OPERATION CHECKS

Engine oil level

Air cleaner elements

.......................................................................

...............................................................

...................................................................

................................................................

..................................................................

..................................................................

.................................................................

........................................................................

...................................................... 5

..............................................................

............................................

..........................................................

...........................................................

...................................................

..........................................

.........................................................

..................................................

.................................................

...........................................................

..........................................

................................

...................................................

.........................................................

.............................................

...................................................

..............................................................

......................................................

...........

........ 21

10

12

13

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

22

23

24

25

26

27

28

2

Battery electrolyte level

Cooling shroud

Air intake screen

Fuel leakage

Hydraulic lift system oil leakage

Front P.T.O. belt

Brake pedal free play ......................................................

Brake wear indicator ......................................................

Clutch pedal free play

Tires/Wheels

Hydraulic lift system fluid

Seat adjustment

Steering

Fuel level .....................................................................

Gasoline Recommendation

GASOLINES CONTAINING ALCOHOL

Parking brake

Headlight

Safety interlock system

Hydraulic lift system

6. OPERATION

1. Starting the engine

2. Starting/driving .............................................................

3. How to use the differential lock (A4 Type only) ...................

4. Two and Four-Wheel Drive ..............................................

5. Turning

6. ATTACHMENT LIMITATIONS

7. Driving on a slope

8. Stopping the engine

9. Recommended working speed .........................................

10. High Altitude Operation

.......................................................................

.......................................................................

..............................................................

...........................................................

.................................................................

...........................................................

................................................................

............................................................

................................................................

.....................................................................

......................................................................

..................................................

.......................................

.....................................................

...............................................

..............................................

...............................

..................................................

.......................................................

........................................................

.........................................

..........................................................

.......................................................

..................................................

29

30

30

31

31

32

32

33

33

34

35

36

36

37

E

40

40

41

44

45

45

47

50

52

53

54

61

63

66

67

3

7. TRANSPORTING

8. INSTALLING AN ATTACHMENT

1. Rear 3-point hitch link installation (option)

2. Rear 3-point hitch attachment installation

9. MAINTENANCE

1. Tool kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

2. Maintenance Schedule

3. Engine oil change

4. Air cleaner service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Spark plug service

6. Battery service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Fuel sediment cup cleaning

8. Transmission oil inspection

9. All fastener tightness/Lubrication points

10. Spark arrester maintenance (optional part)

11. Wheel removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. Fuse replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

13. Headlight bulb replacement

10. LONG TERM STORAGE

Preparation for storage

Removal from storage

11. WIRING DIAGRAM

12. TROUBLESHOOTING

13. SPECIFICATIONS

14. WARRANTY SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . ..a.......

. . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . 68

70

70

72

74

. . . . . . . . . 76

77

78

79

81

84

. . . . . . . . . . 85

86

89

91

92

92

94

95

96

101

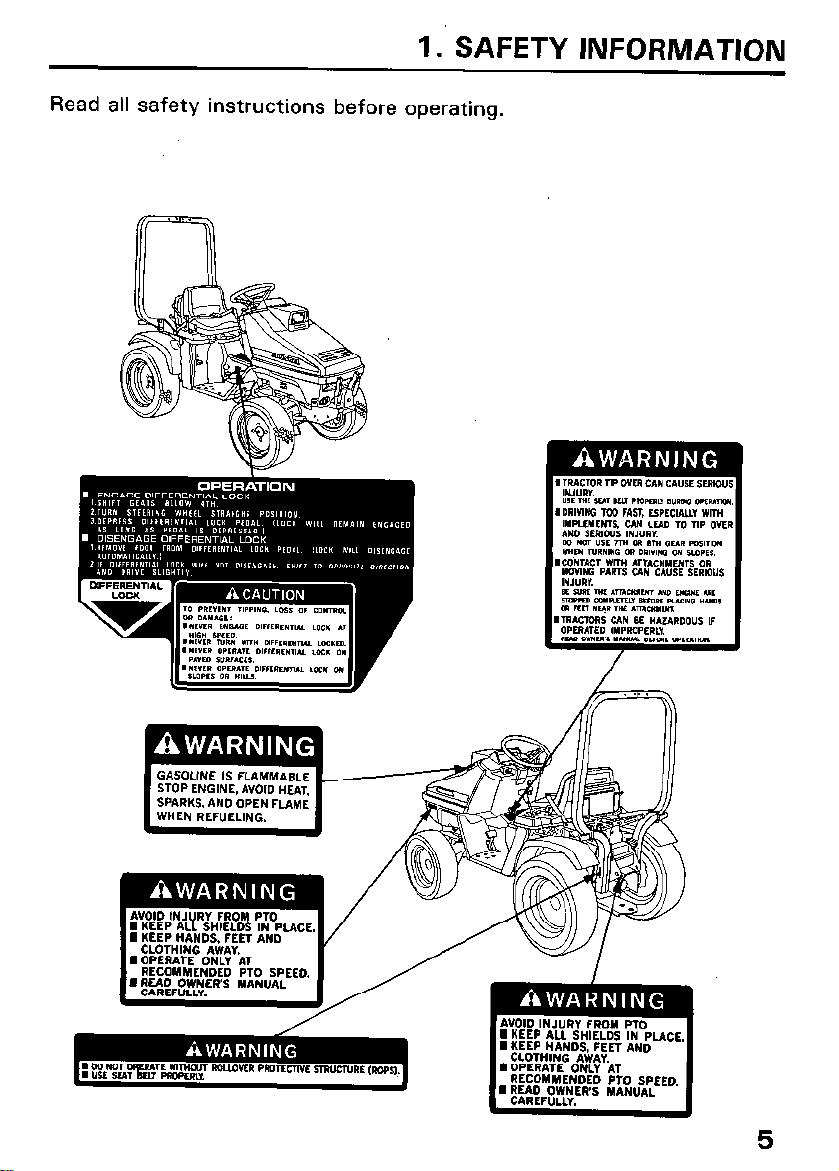

1. SAFETY INFORMATION

Read all safety instructions before operating.

.

/&==a

/

5

TRACTOR

SAFETY

m

Operation of the tractor and its attachments requires special

efforts on your part to ensure your safety and the safety of others. Know

these requirements before you operate the Tractor or its attachments:

SAFE OPERATING RULES

l Severe personal injury or equipment damage may result if the pre-

operation inspection (Page 26) is not performed before operating the

tractor or its attachments.

l To avoid severe personal injury or equipment damage, observe the

following precautions:

l All parts, epecially guards and shields, should be in good condition,

and securely fastened in place.

l Do not remove any guards, warning labels, shields or safety devices;

they are installed for your safety.

l The rollover protective structure (ROPS) will only help protect you

from injury, if:

-

you are also wearing the seat belt.

-

the ROPS is securely attached and has not been modified or struc-

turally damaged.

l Always wear sturdy shoes and avoid wearing bulky or loose clothing

while operating the tractor or its attachments.

l Never operate the tractor or its attachments when tired or while

under the influence of drugs or alcohol.

l In case of emergency, know how to stop the engine and thoroughly

understand the operation of ALL controls.

l Never permit anyone to operate the tractor or its attachments

without proper instructions.

l Children should not be permitted to operate the tractor or any of its

attachments.

. KEEP CHILDREN AND PETS AT A SAFE DISTANCE DURING OPE-

RATION

l This is an operator only vehicle, do not allow passengers to ride on

the tractor or on any of its attachments.

; The exhaust contains poisonous carbon monoxide gas that can

cause loss of consciousness and may lead to death, if the tractor is

operated in an enclosed space.

6

BEFORE STARTING

l The use of heavy equipment and/or pulling excessive loads may

adversely affect vehicle stability and control. To avoid loss of control

that can result in severe personal injury:

- Only use recommended hitch attachment points.

- Limit loads to as suggested on page 54.

- Be extra careful when turning or backing up.

- Use counterweight(s) as suggested on page 58.

l Before installing or using any attachment, carefully read all instructions

and precautions.

OPERATION

l

Be sure to fasten the seat belt whenever driving the tractor with the

Rollover Protective Structure (ROPS) attached. Use of either device

(seat belt or ROPS) without the other will increase the chance of injury

in a rollover.

l

Adjust the seat belt so that it is snug.

l

Be sure that the main Transmission lever is in “Neutral” and the front

and rear P.T.O. levers are in the “OFF” position before starting the

engine.

Operate the tractor at low speed until you become familiar with all of its

operating characteristics and controls.

Do not operate the tractor or its attachments without ensuring the area

in front and behind is clear of people and pets.

Sudden stops of the tractor while driving at high speed or sudden startup with the steering wheels turned fully in one direction, could cause

the tractor to overturn.

l

This tractor utilizes Four Wheel Steering (4WS) for a tighter turning circle and greater mobility than tractors with conventional steering.

However, the feel of 4WS is slightly different from other tractors. Prac-

tice driving in a wide, safe area.

l

Never operate the tractor or its attachments when visibility is diminished by darkness or bad weather; your ability to see obstacles will

become impaired.

Watch out for rocks, roots, holes and other obstacles that may cause

the Tractor to overturn.

This tractor and its attachments are intended for use on relatively flat

terrain.

It is illegal to operate this tractor on public streets, roads, or highways.

It is legal in some areas to operate a tractor without a U.S.D.A. qualified

spark arrester. Check local laws and regulations before operating. An

optional spark arrester for this product is available from your authorised

Honda tractor dealer.

7

l When operating the tractor on a slope, always drive up and down the

face of the grade. Turning or driving across the face of a slope may

cause the tractor to overturn.

l To avoid loss of control or overturning, always reduce speed and exer-

cise extreme caution when operating on sloping or uneven surfaces.

l Attempting to change gears while operating the tractor on a slope may

adversely affect vehicle stability and control and severe personal injury

could result.

l Do not back down, or rapidly accelerate up, a sloping surface.

l To avoid loss of control or overturning, do not turn or stop on sloping

surfaces.

l When descending a slope, disengaging the clutch or shifting to neutral

can cause a loss of control that may result in severe personal injury.

l Do not operate the tractor near the edge of a ditch or an embankment.

Slipping off the edge could lead to severe personal injury and equipment

damage.

To avoid injury to yourself and others, before leaving the Tractor unattended, ALWAYS.

- park on level ground.

- disengage the power take-off.

- lower the attachment(s).

- Lock the parking brake.

-

stop the engine.

-

and remove the key.

l If you find it necessary to park on a grade, be sure to lock the parking

brake and securely block the wheels.

l Be sure to follow the instructions below whenever applying the dif-

ferential lock.

-

Be sure that the main transmission lever is set in 4th gear or lower,

and reduce engine speed before applying the differential lock.

- Do not apply while turning the tractor.

Use the lock only when driving straight ahead.

-

Do not rest your foot on the lock pedal while the lock is not in use.

-

Never apply while driving on a paved surface.

MAINTENANCE SAFETY

Before performing maintenance/inspection, read the instructions

thoroughly.

Before cleaning, inspecting or servicing the tractor, be sure to

- Move the P.T.O. lever to the “OFF” position and lower any

attachments.

- Stop the engine and remove the key.

- Remove the spark plug cap.

If you hit an object, stop the engine and inspect the Tractor and its

attachments.

Fix any damage before you resume operation.

Operating the tractor with damaged, worn or broken parts may result in

severe personal injury.

Leaves, grass clippings,

oil and other combustible materials can

become a fire hazard. Be sure the body, engine and drive mechanism

areas are kept clean.

All nuts, bolts and fasteners must be tight.

Do not change the engine governor settings or the engine may be

damaged.

STORAGE SAFETY

l To avoid the possibility of fire, allow the engine and exhaust system to

cool before storing the tractor in an enclosed space or near combustible

materials.

l When storing the tractor, be sure to apply the parking brake and remove

the engine key.

l Drain all gasoline from the carburetor and fuel tank, and disconnect the

battery ground cable.

9

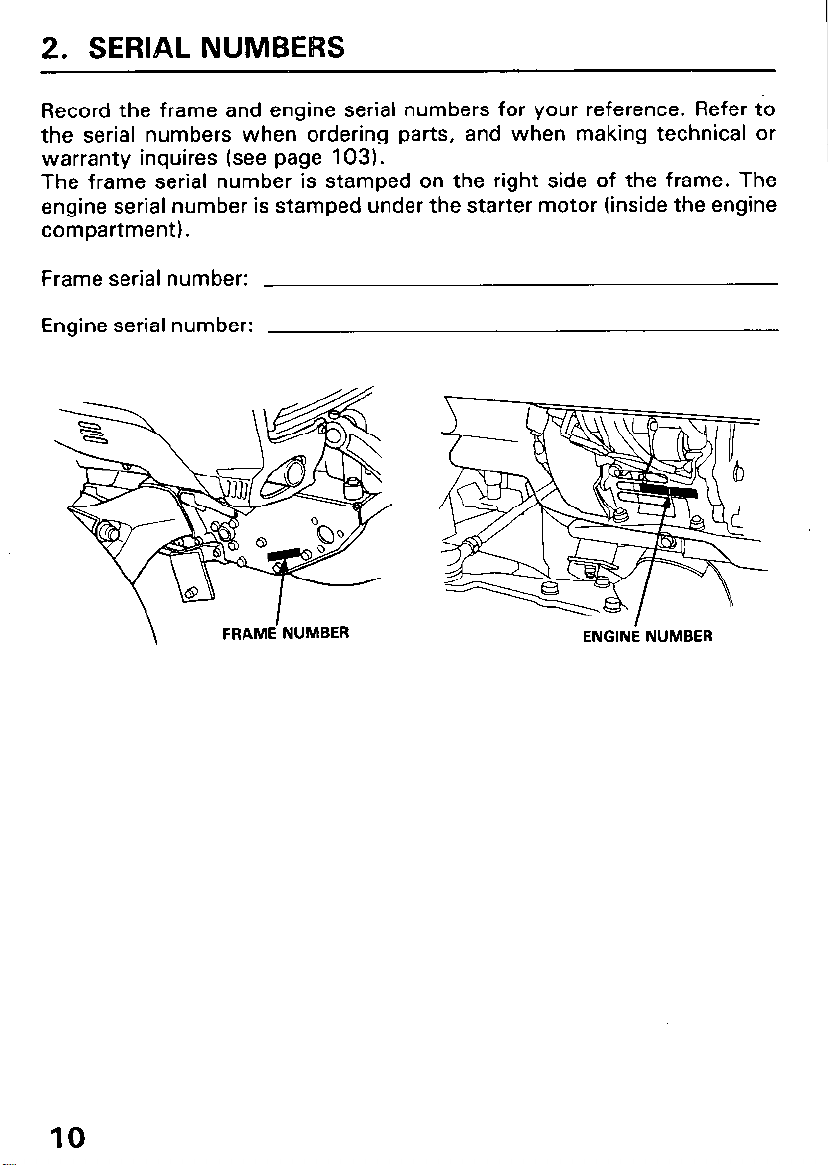

2. SERIAL NUMBERS

Record the frame and engine serial numbers for your reference. Refer to

the serial numbers when ordering parts, and when making technical or

warranty inquires (see page 103).

The frame serial number is stamped on the right side of the frame. The

engine serial number is stamped under the starter motor (inside the engine

compartment).

Frame serial number:

Engine serial number:

10

ENGINE NUMBER

SEAT BELT

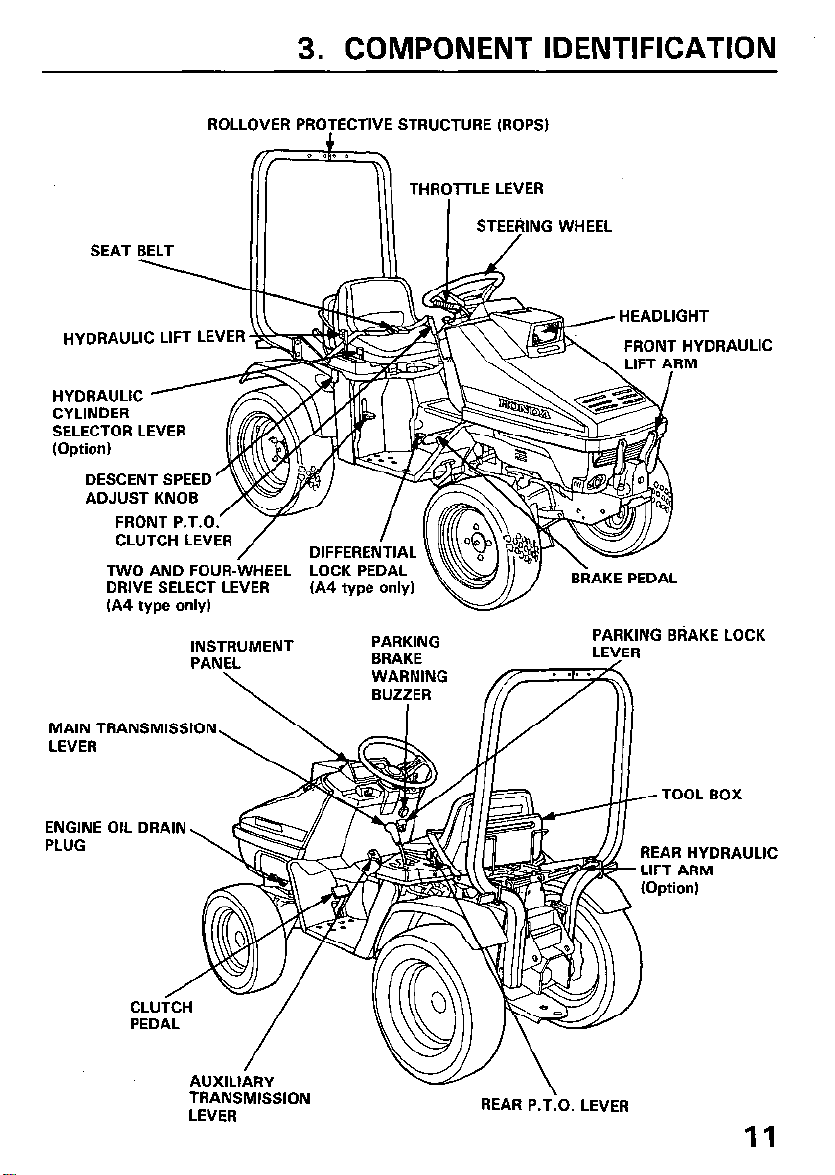

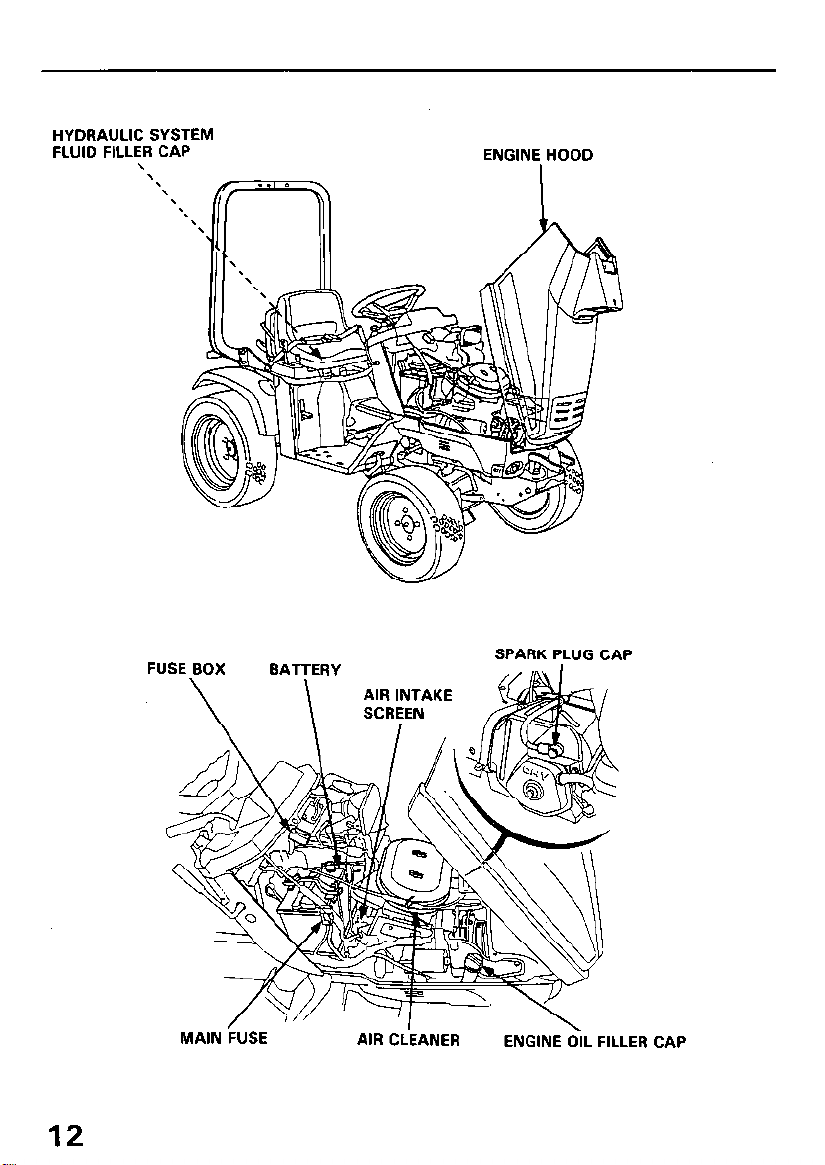

3. COMPONENT IDENTIFICATION

ROLLOVER PROTECTIVE STRUCTURE (ROPS)

THROTTLE LEVER

STEERING WHEEL

/

HYDRAULIC LIFT LEVER

HYDRAULIC

CYLINDER

SELECTOR LEVER

(Option)

DESCENT SPEED

ADJUST KNOB

FRONT P.T.O.

CLUTCH LEVER

TWO AND FOUR-WHEEL LOCK PEDAL

DRIVE SELECT LEVER

(A4 type only)

MAIN 1

‘RANSMISSION

LEVER

ENGINE

PLUG

/ DIFFEREN AL

INSTRUMENT

PANEL

\

(A4 type only)

PARKING

BRAKE

WARNING

JLIC

BRAKE PEDAL

PARKING BRAKE LOCK

LEVER

REAR HYDRAULIC

LEVER

11

HYDRAULIC SYSTEM

FLUID FILLER CAP

\

ENGINE HOOD

12

FUSE BOX

MAIN FUSE

AIR CLEANER

SPARK PLUG CAP

ENGINE OIL FILLER

CAP

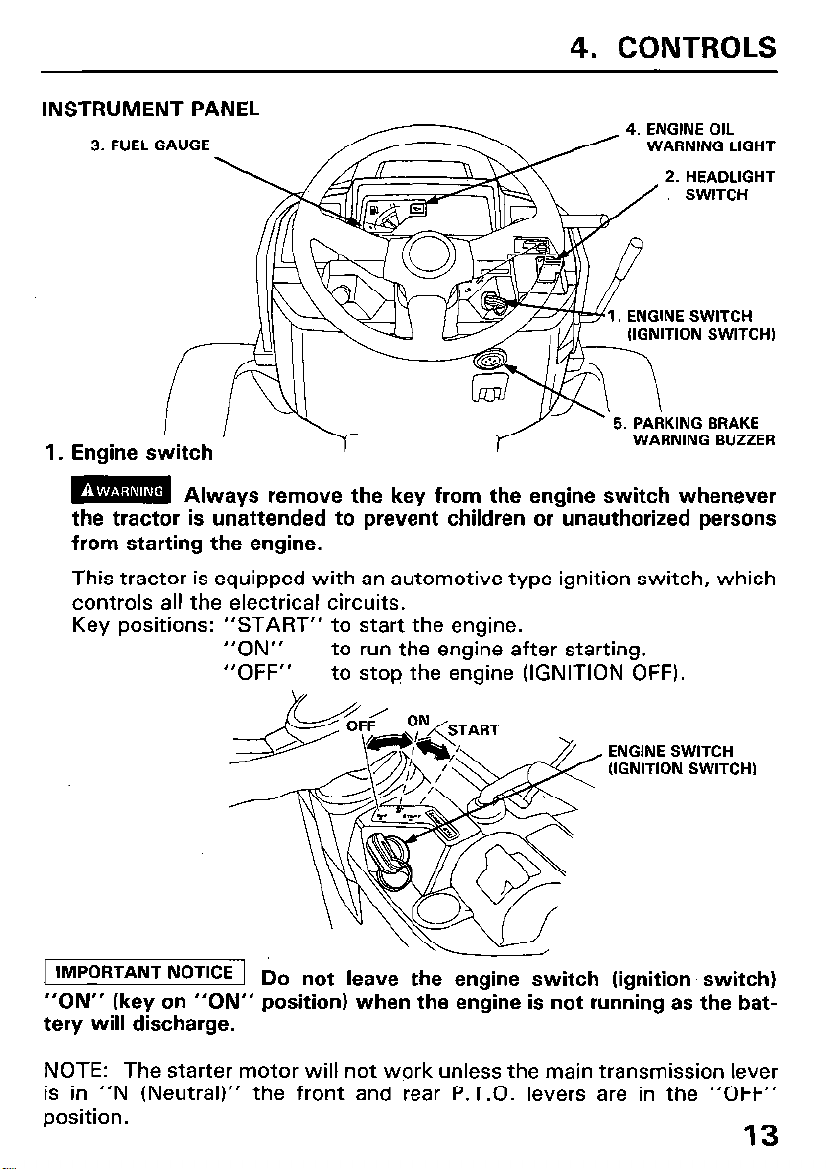

4. CONTROLS

INSTRUMENT PANEL

3. FUEL GAUGE

4. ENGINE OIL

WARNING LIGHT

2. HEADLIGHT

ITION SWITCH)

1. Engine switch

m

Always remove the key from the engine switch whenever

the tractor is unattended to prevent children or unauthorized persons

from starting the engine.

This tractor is equipped with an automotive type ignition switch, which

controls all the electrical circuits.

Key positions: “START” to start the engine.

“ON” to run the engine after starting.

“OFF”

to stop the engine (IGNITION OFF).

ENGINE SWITCH

(IGNITION SWITCHI

IMPORTANT NOTICE

1 Do not leave the engine switch (ignition’ switch)

“ON” (key on “ON” position) when the engine is not running as the battery will discharge.

NOTE: The starter motor will not work unless the main transmission lever

is in “N (Neutral)” the front and rear P.T.O. levers are in the “OFF”

position.

13

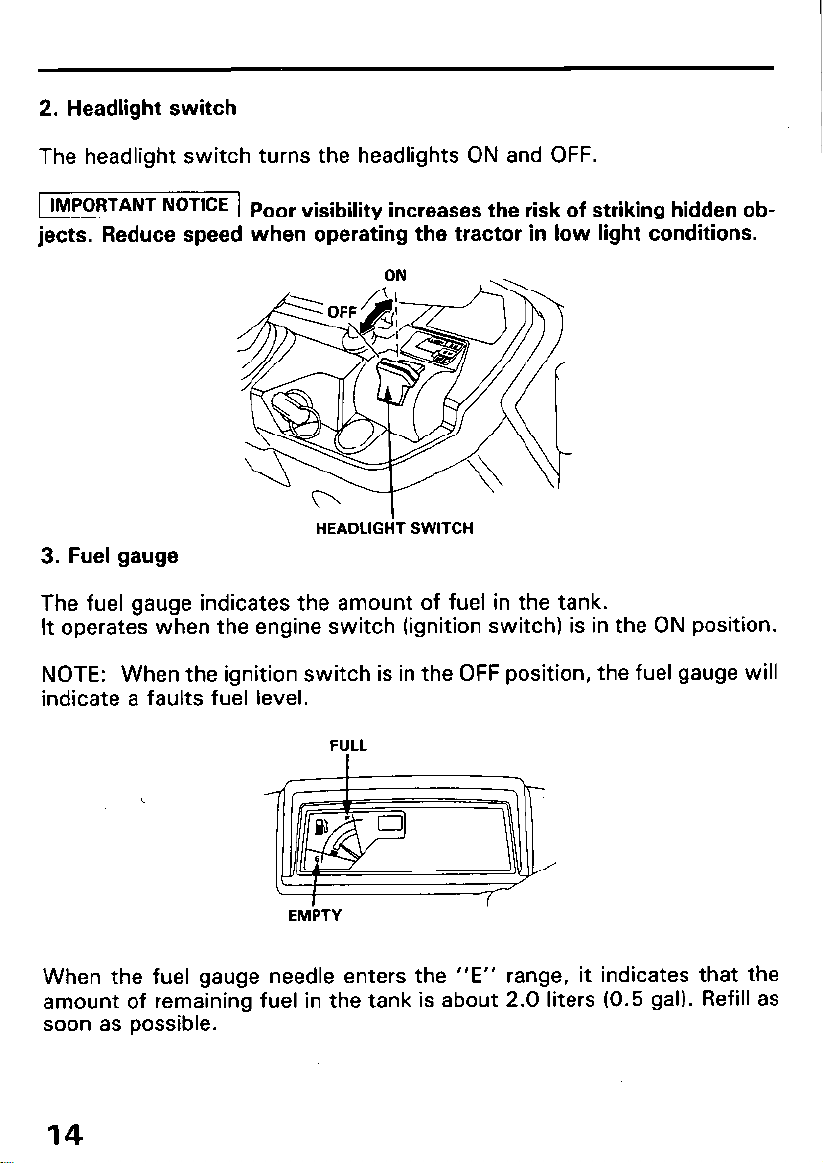

2. Headlight switch

The headlight switch turns the headlights ON and OFF.

[ IMPORTANT NOTICE 1

p

oor visibility increases the risk of striking hidden ob-

jects. Reduce speed when operating the tractor in low light conditions.

HEADLIGHT SWITCH

3. Fuel gauge

The fuel gauge indicates the amount of fuel in the tank.

It operates when the engine switch (ignition switch) is in the ON position.

NOTE: When the ignition switch is in the OFF position, the fuel gauge will

indicate a faults fuel level.

EMPTY EMPTY

When the fuel gauge needle enters the

“E” range, it indicates that the

amount of remaining fuel in the tank is about 2.0 liters (0.5 gal). Refill as

soon as possible.

14

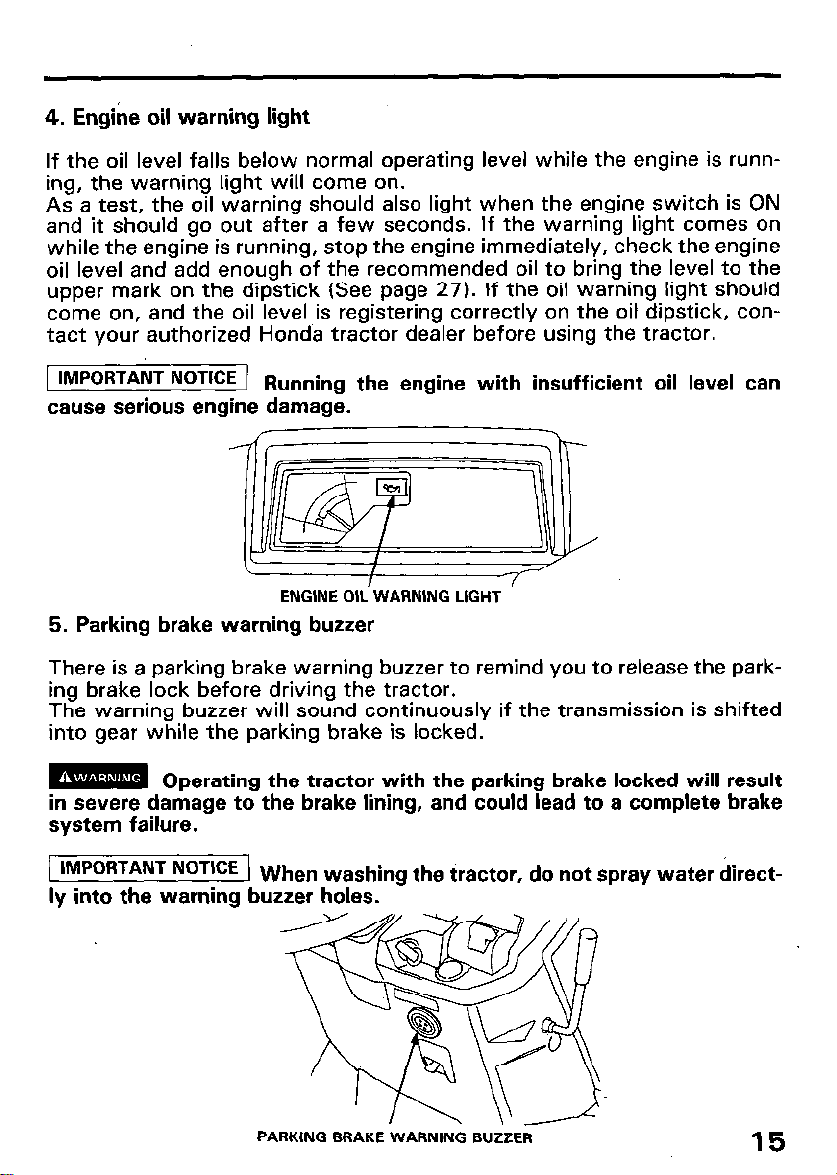

4. Engine oil warning light

If the oil level falls below normal operating level while the engine is running, the warning light will come on.

As a test, the oil warning should also light when the engine switch is ON

and it should go out after a few seconds. If the warning light comes on

while the engine is running, stop the engine immediately, check the engine

oil level and add enough of the recommended oil to bring the level to the

upper mark on the dipstick (See page 27). If the oil warning light should

come on, and the oil level is registering correctly on the oil dipstick, con-

tact your authorized Honda tractor dealer before using the tractor.

IMPORTANT NOTICE

1 Running the engine with insufficient oil level can

cause serious engine damage.

ENGINE OIL WARNING LIGHT

5. Parking brake warning buzzer

There is a parking brake warning buzzer to remind you to release the park-

ing brake lock before driving the tractor.

The warning buzzer will sound continuously if the transmission is shifted

into gear while the parking brake is locked.

m Operating the tractor with the parking brake locked will result

in severe damage to the brake lining, and could lead to a complete brake

system failure.

1 IMPORTANT NOTICE ) Wh

en washing the tractor, do not spray water direct-

ly into the warning buzzer holes.

PARKING BRAKE WARNING BUZZER

15

DRIVE COMPONENTS

STEERING WHEEL

ROTTLE LEVER

I

2 CHOKE KNOB

5 CLUTCH PEDAL

6 AUXILIARY TRANSMIS

LEVER

6 MAIN ‘TRANSMISSION

LEVER

8 REAR P.T.

7 FRONT P.T.O.

10 TWO AND FOUR-WHEEL

DRIVE SELECT LEVER

REAR P.T.O. SHAFT COVER

I I-\,#-”

4 PARKING BRAKE

LOCK LEVER

3 BRAKE PEDAL

11 DIFFERENTIAL

LOCK PEDAL

(A4 type only)

1. Throttle lever

The throttle lever controls engine speed from SLOW (idle) to FAST (max

speed); it will stay in any designated position.

16

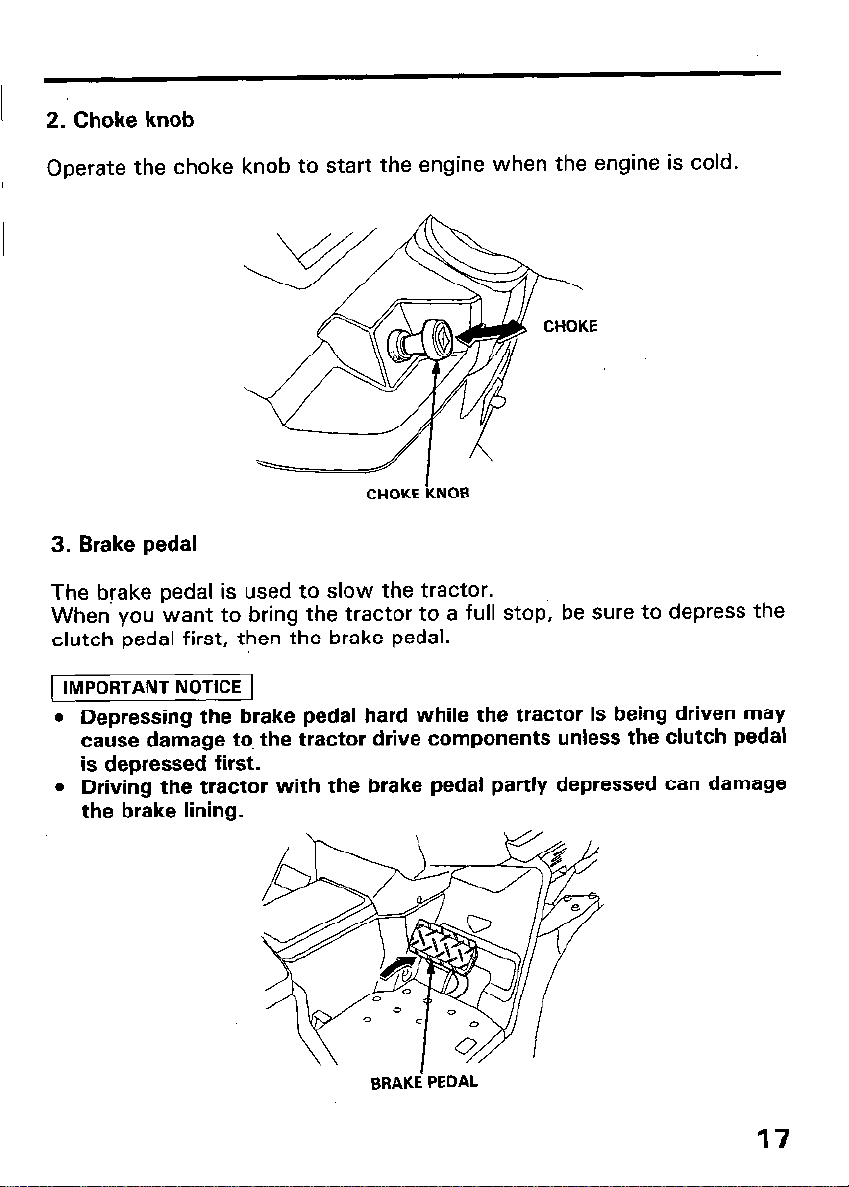

2. Choke knob

Operate the choke knob to start the engine when the engine is cold.

CHOKE KNOB

3. Brake pedal

The brake pedal is used to slow the tractor.

When you want to bring the tractor to a full stop, be sure to depress the

clutch pedal first, then the brake pedal.

[ IMPORTANT NOTICE 1

l Depressing the brake pedal hard while the tractor is being driven may

cause damage to the tractor drive components unless the clutch pedal

is depressed first.

l Driving the tractor with the brake pedal partly depressed can damage

the brake lining.

BRAKE’ PEDAL

17

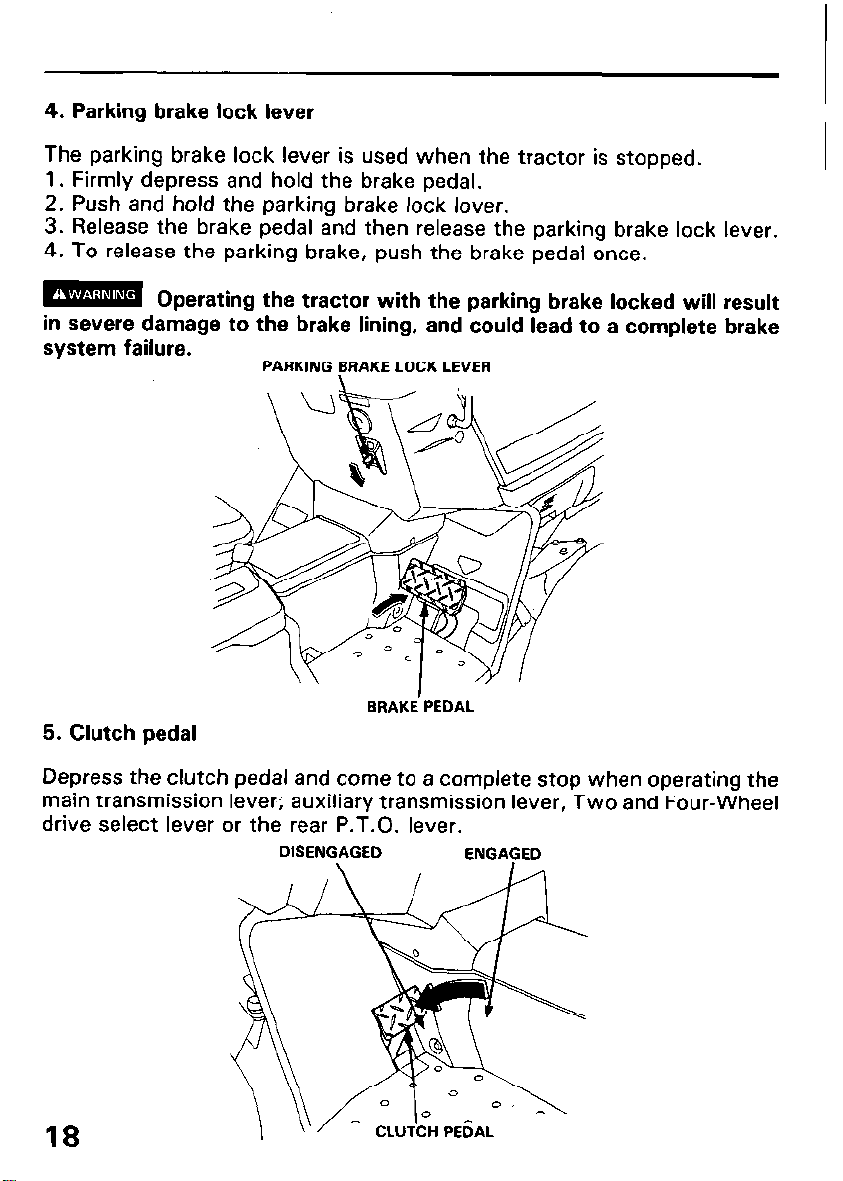

4. Parking brake lock lever

The parking brake lock lever is used when the tractor is stopped.

1. Firmly depress and hold the brake pedal.

2. Push and hold the parking brake lock lover.

3. Release the brake pedal and then release the parking brake lock lever.

4. To release the parking brake, push the brake pedal once.

m

Operating the tractor with the parking brake locked will result

in severe damage to the brake lining, and could lead to a complete brake

system failure.

PARKING BRAKE LOCK LEVER

BRAKE’PEDAL

5. Clutch pedal

Depress the clutch pedal and come to a complete stop when operating the

main transmission lever; auxiliary transmission lever, Two and Four-Wheel

drive select lever or the rear P.T.O. lever.

DISENGAGED ENGAGED

18

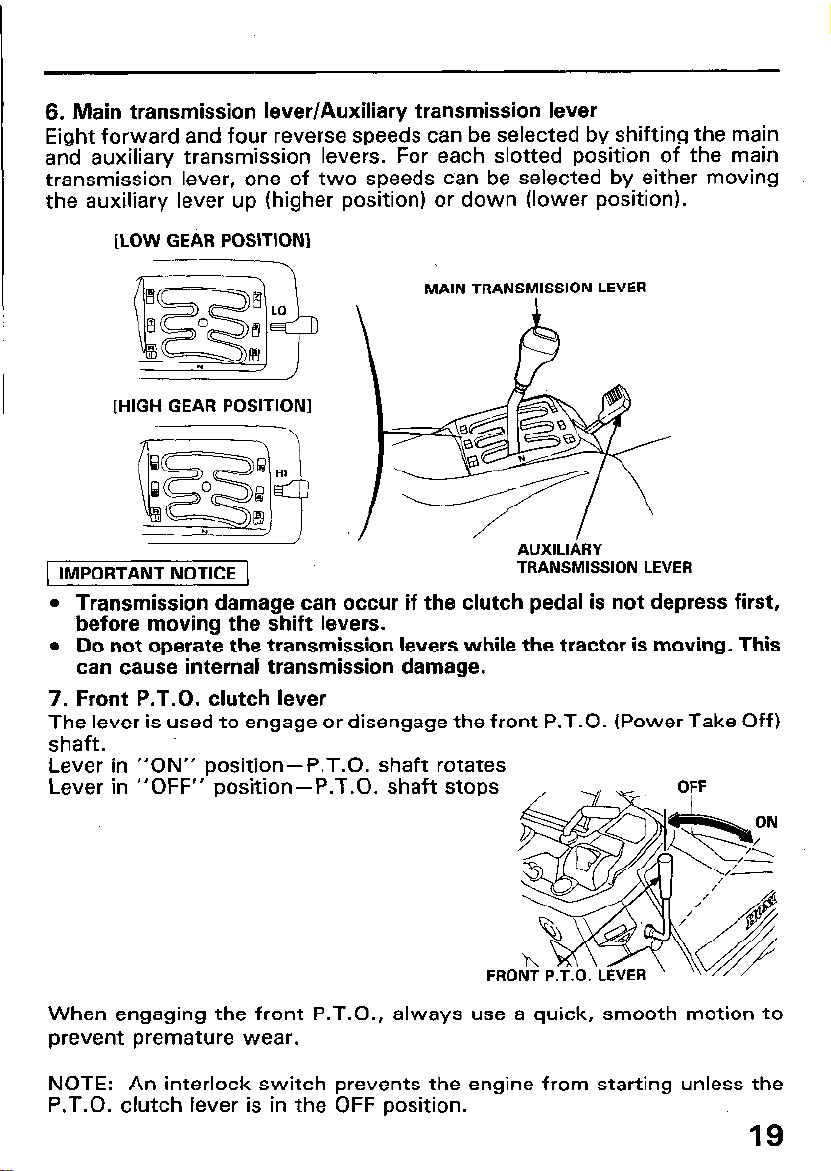

6. Main transmission lever/Auxiliary transmission lever

Eight forward and four reverse speeds can be selected by shifting the main

and auxiliary transmission levers. For each slotted position of the main

transmission lever, one of two speeds can be selected by either moving

the auxiliary lever up (higher position) or down (lower position).

[LOW GEAR POSITION1

c--,7

[HIGH GEAR POSITION]

r-----Y-\

( IMPORTANT NOTICE (

l Transmission damage can occur if the clutch pedal is not depress

MAIN TRANSMISSION LEVER

Al IXll IARY

. .-_..-._ . . . .

TRANSMISSION LEVER

first,

before moving the shift levers.

l Do not operate the transmission levers while the tractor is moving.

, This

can cause internal transmission damage.

7. Front P.T.O. clutch lever

The lever is used to engage or disengage the front P.T.O. (Power Take Off)

shaft.

Lever in “ON” position-P.T.O. shaft rotates

Lever in “OFF” position-P.T.O. shaft stops

When engaging the front P.T.O., always use a quick, smooth motion to

prevent premature wear.

NOTE: An interlock switch prevents the engine from starting unless the

P.T.O. clutch lever is in the OFF position.

19

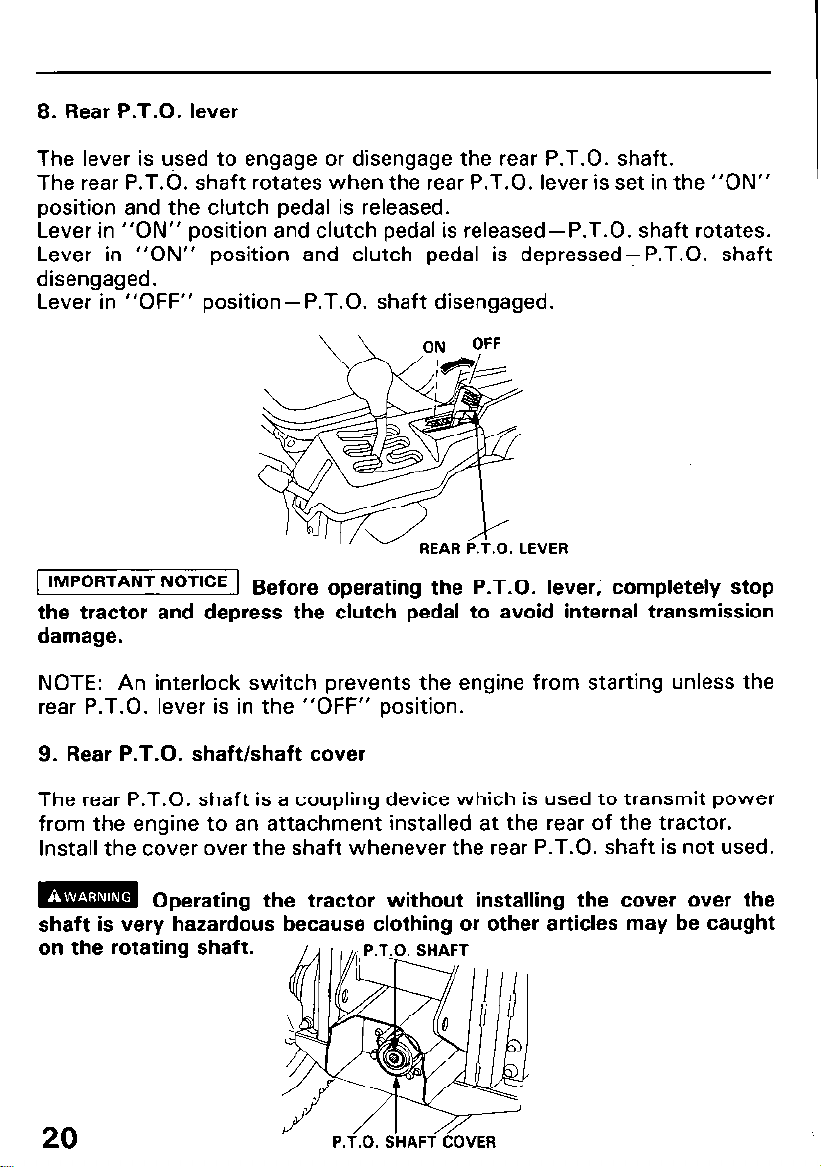

8. Rear P.T.O. lever

The lever is u,sed to engage or disengage the rear P.T.O. shaft.

The rear P.T.O. shaft rotates when the rear P.T.O. lever is set in the “ON”

position and the clutch pedal is released.

Lever in “ON” position and clutch pedal is released-P.T.O. shaft rotates.

Lever in “ON” position and clutch pedal is depressedTP.T.O. shaft

disengaged.

Lever in “OFF” position-P.T.O. shaft disengaged.

8

1 IMPORTANT NOTICE 1

the tractor and depress the clutch pedal to avoid internal transmission

damage.

NOTE: An interlock switch prevents the engine from starting unless the

rear P.T.O. lever is in the “OFF” position.

f

e ore operating the P.T.O. lever, completely stop

9. Rear P.T.O. shaft/shaft cover

The rear P.T.O. shaft is a coupling device which is used to transmit power

from the engine to an attachment installed at the rear of the tractor.

Install the cover over the shaft whenever the rear P.T.O. shaft is not used.

m

shaft is very hazardous because clothing or other articles may be caught

on the rotating shaft.

20

Operating the tractor without installing the cover over the

P.T.O. SHAFT COVER

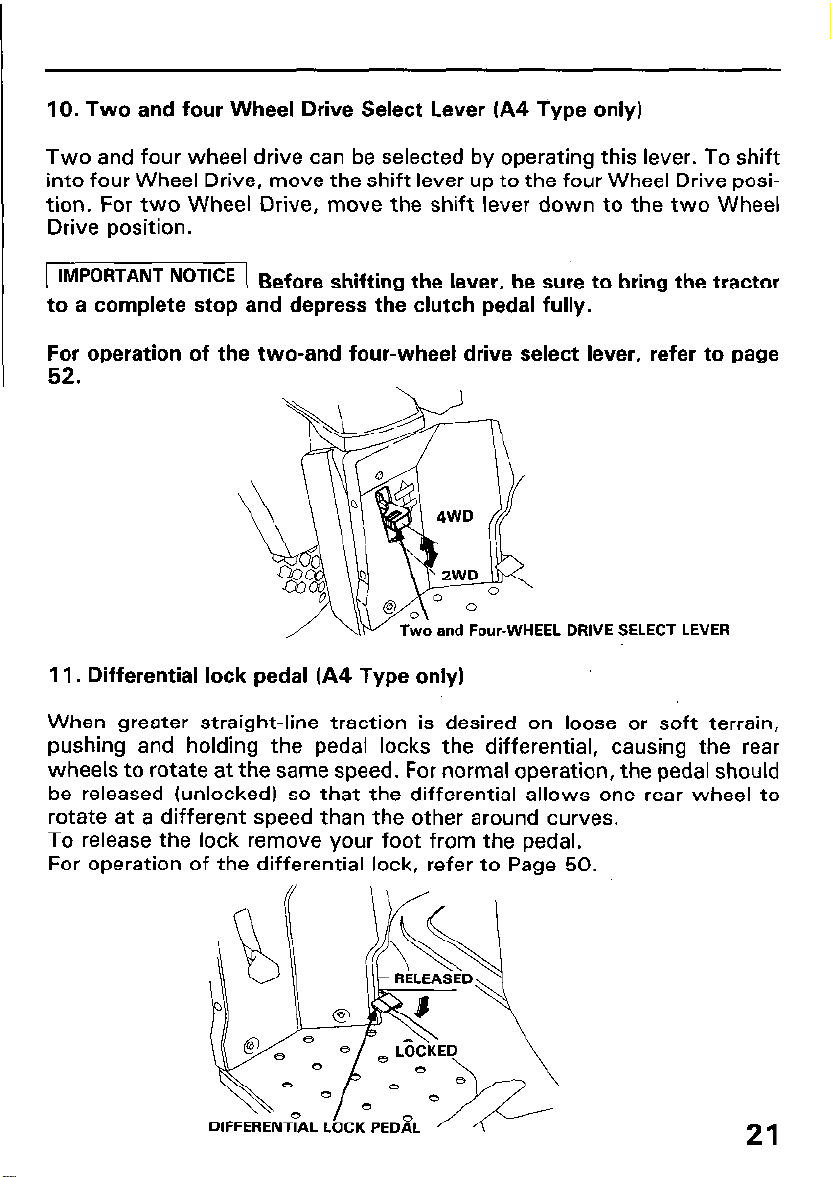

10. Two and four Wheel Drive Select Lever (A4 Type only)

Two and four wheel drive can be selected by operating this lever. To shift

into four Wheel Drive, move the shift lever up to the four Wheel Drive position. For two Wheel Drive, move the shift lever down to the two Wheel

Drive position.

f

( IMPORTANT NOTICE 1

B

ore shifting the lever, be sure to bring the tractor

e

to a complete stop and depress the clutch pedal fully.

the two-and four-wheel drive select lever, refer to page

For

operation

of

52.

DRIVE

SELECT

LEVER

11, Differential lock pedal (A4 Type only)

When greater straight-line traction is desired on loose or soft terrain,

pushing and holding the pedal locks the differential, causing the rear

wheels to rotate at the same speed. For normal operation, the pedal should

be released (unlocked) so that the differential allows one rear wheel to

rotate at a different speed than the other around curves.

To release the lock remove your foot from the pedal.

For operation of the differential lock, refer to Page 50.

21

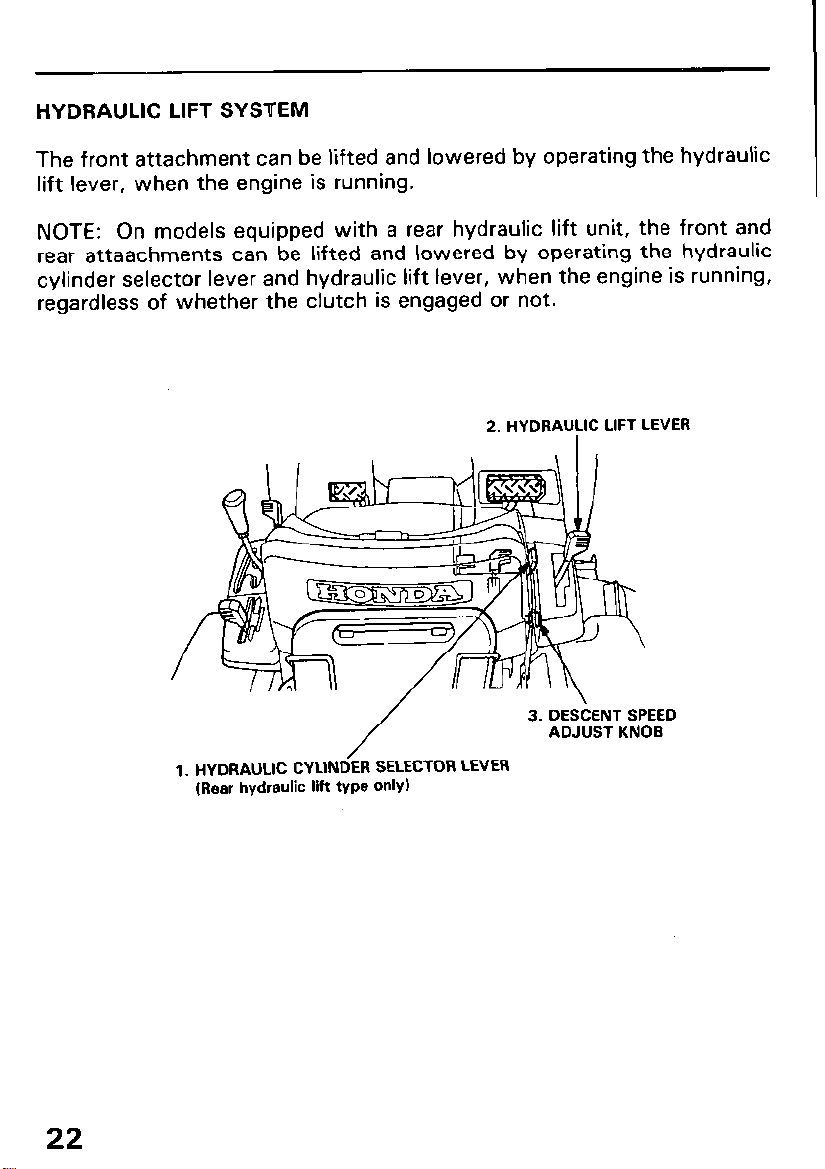

HYDRAULIC LIFT SYSTEM

The front attachment can be lifted and lowered by operating the hydraulic

lift lever, when the engine is running.

NOTE: On models equipped with a rear hydraulic lift unit, the front and

rear attaachments can be lifted and lowered by operating the hydraulic

cylinder selector lever and hydraulic lift lever, when the engine is running,

regardless of whether the clutch is engaged or not.

2. HYDRAULIC LIFT LEVER

22

/

1. HYDRAULIC CYLINDER SELECTOR LEVER

(Rear hydraulic lift type only)

ADJUST KNOB

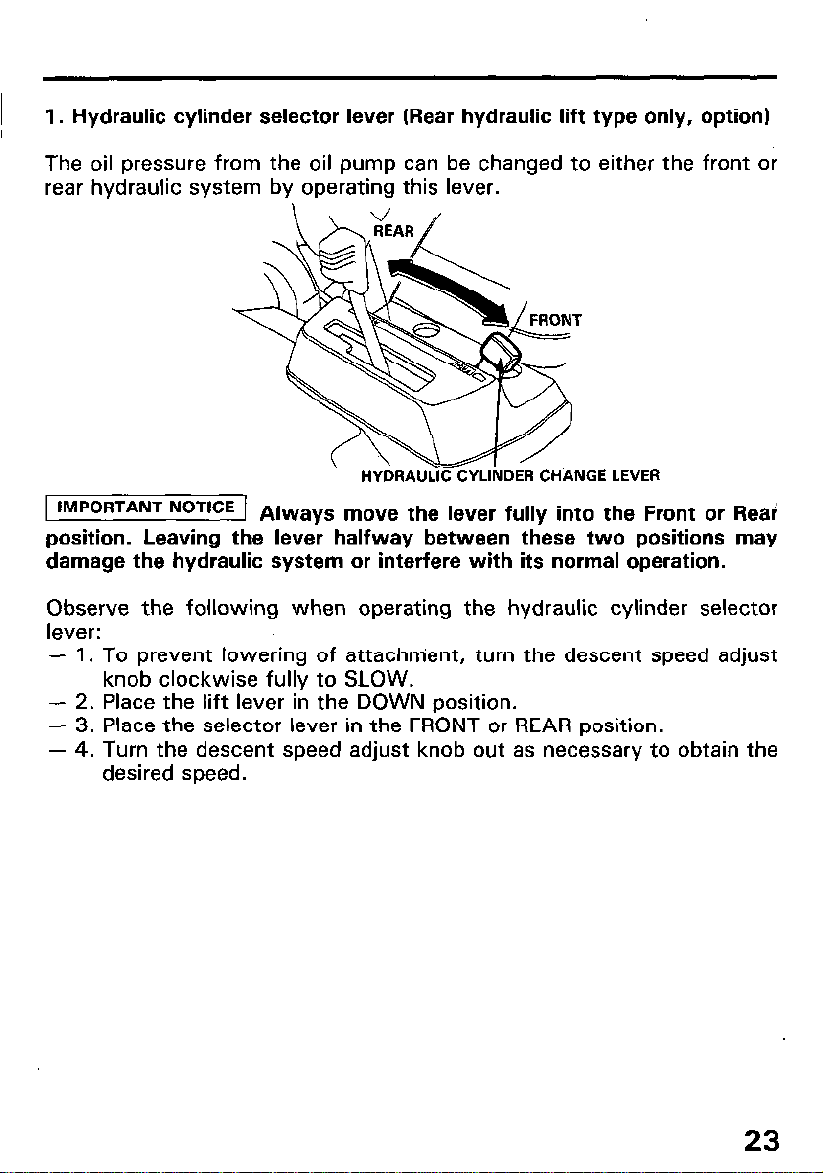

1. Hydraulic cylinder selector lever (Rear hydraulic lift type only, option)

oil pressure from the oil pump can be changed to either oil pressure from the oil pump can be changed to either the front or

The

rear

hydraulic system by operating this lever. hydraulic system by operating this lever.

T T

HYDRAULIC CYLINDER CHANGE LEVER HYDRAULIC CYLINDER CHANGE LEVER

the front or

I IMPORTANT NoTlCE 1 Always move the lever fully into the Front or Rear!

position. Leaving the lever halfway between these two positions may

damage the hydraulic system or interfere with its normal operation.

Observe the following when operating the hydraulic cylinder selector

lever:

- 1. To prevent lowering of attachn-ient, turn the descent speed adjust

knob clockwise fully to SLOW.

- 2. Place the lift lever in the DOWN position.

- 3. Place the selector lever in the FRONT or REAR position.

- 4. Turn the descent speed adjust knob out as necessary to obtain the

desired speed.

23

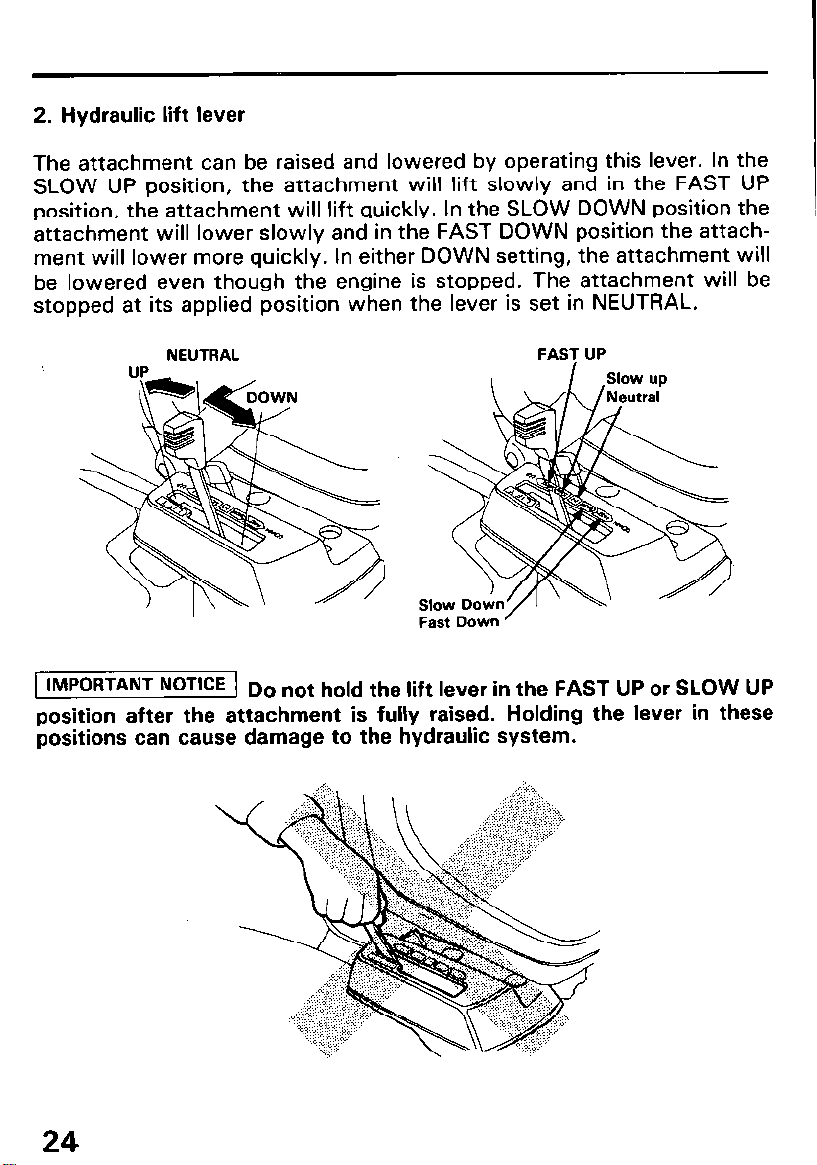

2. Hydraulic lift lever

The attachment can be raised and lowered by operating this lever. In the

SLOW UP position, the attachment will lift slowly and in the FAST UP

position, the attachment will lift quickly. In the SLOW DOWN position the

attachment will lower slowly and in the FAST DOWN position the attachment will lower more quickly. In either DOWN setting, the attachment will

be lowered even though the engine is stopped. The attachment will be

stopped at its applied position when the lever is set in NEUTRAL.

NEUTRAL

FAST UP

I IMPORTANT NoTlCE 1 Do not hold the lift lever in the FAST UP or SLOW UP

position after the attachment is fully raised. Holding the lever in these

positions can cause damage to the hydraulic system.

24

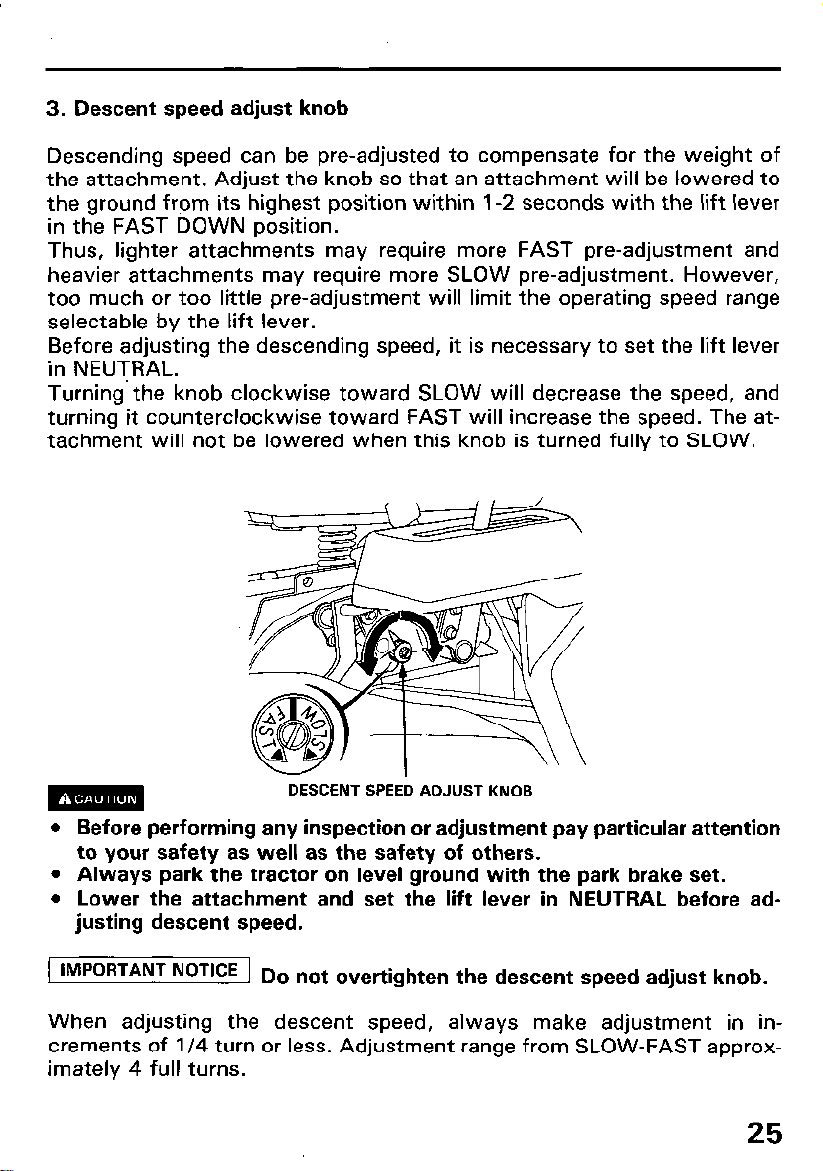

3. Descent speed adjust knob

Descending speed can be pre-adjusted to compensate for the weight of

the attachment. Adjust the knob so that an attachment will be lowered to

the ground from its highest position within l-2 seconds with the lift lever

in the FAST DOWN position.

Thus, lighter attachments may require more FAST pre-adjustment and

heavier attachments may require more SLOW pre-adjustment. However,

too much or too little pre-adjustment will limit the operating speed range

selectable by the lift lever.

Before adjusting the descending speed, it is necessary to set the lift lever

in NEUTRAL.

Turning the knob clockwise toward SLOW will decrease the speed, and

turning it counterclockwise toward FAST will increase the speed. The attachment will not be lowered when this knob is turned fully to SLOW.

w

l Before performing any inspection or adjustment pay particular attention

DESCENT SPEED ADJUST KNOB

to your safety as well as the safety of others.

l Always park the tractor on level ground with the park brake set.

l Lower the attachment and set the lift lever in NEUTRAL before ad-

justing descent speed.

1 IMPORTANT NoTKE 1 Do not overtighten the descent speed adjust knob.

When adjusting the descent speed, always make adjustment in in-

crements of l/4 turn or less. Adjustment range from SLOW-FAST approximately 4 full turns.

25

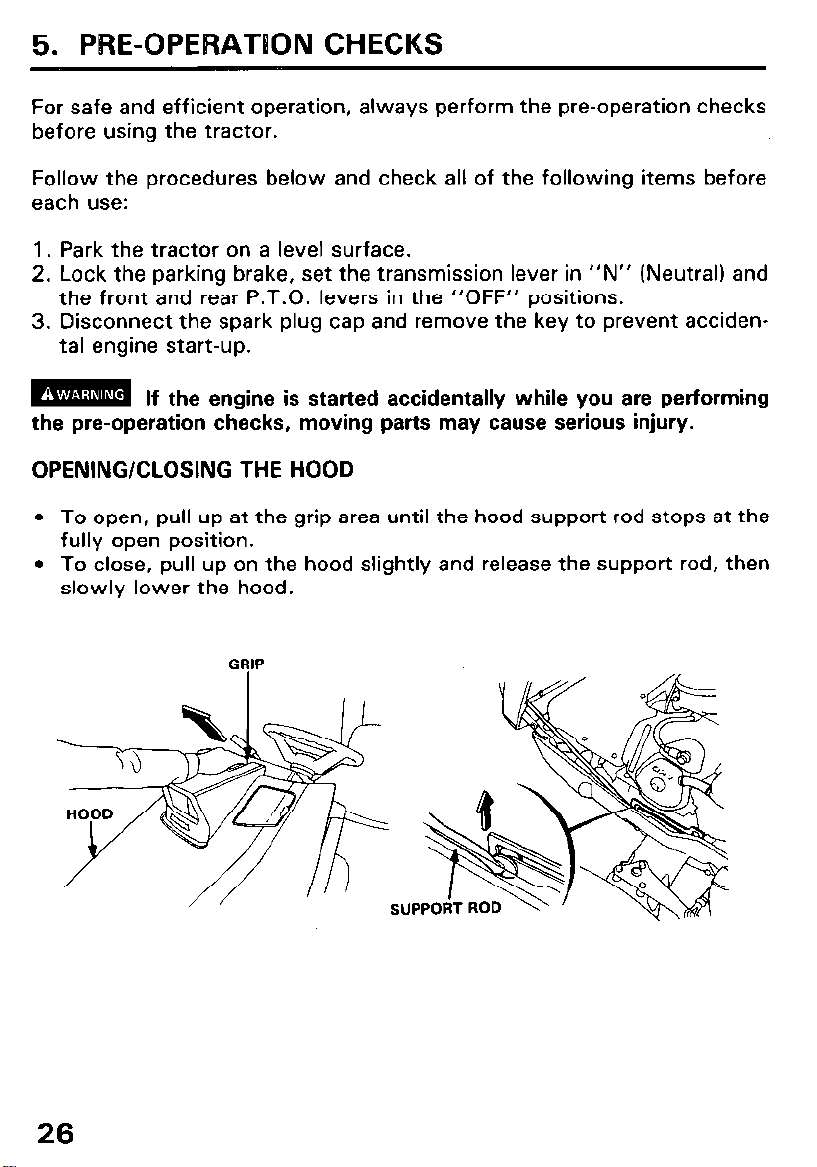

5. PRE-OPERATUON CHECKS

For safe and efficient operation, always perform the pre-operation checks

before using the tractor.

Follow the procedures below and check all of the following items before

each use:

1. Park the tractor on a level surface.

2. Lock the parking brake, set the transmission lever in “N” (Neutral) and

the front and rear P.T.O. levers in the “OFF” positions.

3. Disconnect the spark plug cap and remove the key to prevent accidental engine start-up.

m

If the engine is started accidentally while you are performing

the pre-operation checks, moving parts may cause serious injury.

OPENING/CLOSING THE HOOD

l To open, pull up at the grip area until the hood support rod stops at the

fully open position.

l To close, pull up on the hood slightly and release the support rod, then

slowly lower the hood.

GRIP

26

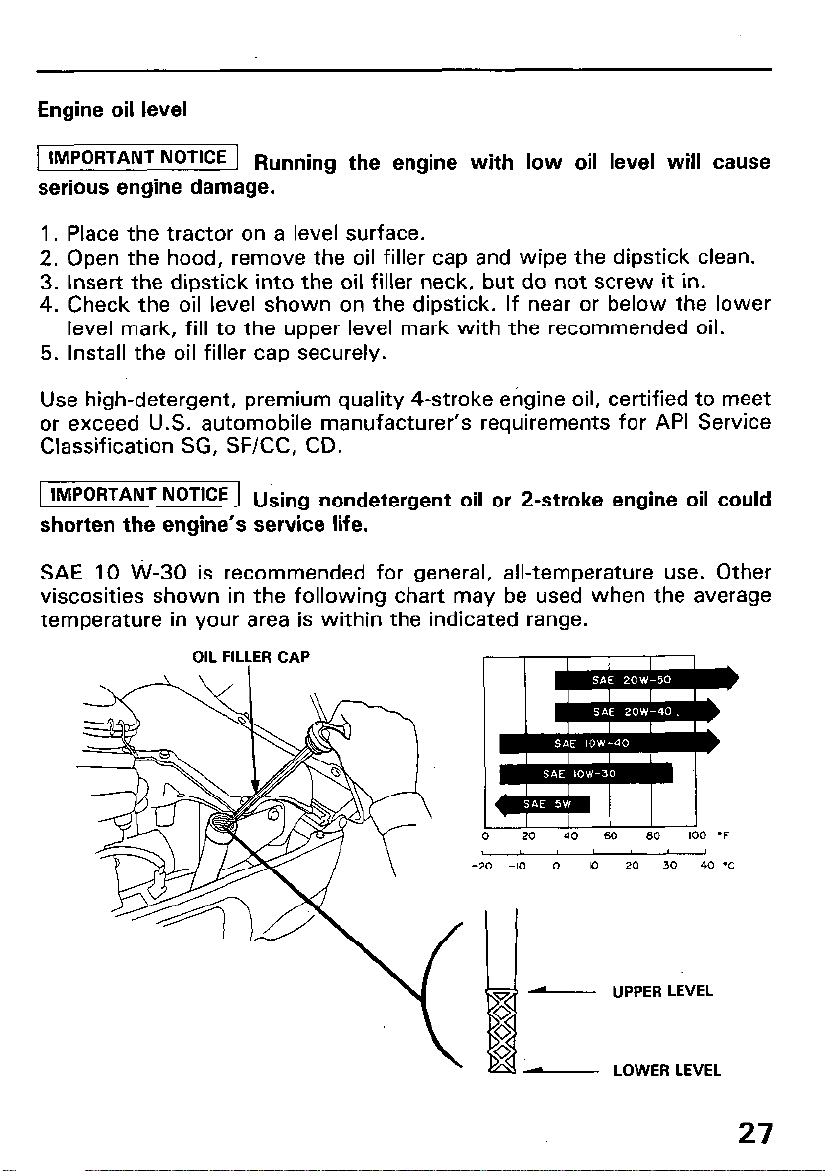

Engine oil level

1 ~~~~~~~~~ NoTlCE 1 Running the engine with low oil level will cause

serious engine damage.

1. Place the tractor on a level surface.

2. Open the hood, remove the oil filler cap and wipe the dipstick clean.

3. Insert the dipstick into the oil filler neck, but do not screw it in.

4. Check the oil level shown on the dipstick. If near or below the lower

level mark, fill to the upper level mark with the recommended oil.

5. Install the oil filler cap securely.

Use high-detergent, premium quality 4-stroke engine oil, certified to meet

or exceed U.S. automobile manufacturer’s requirements for API Service

Classification SG, SF/CC, CD.

1 IMPORTANT NoTKE 1 Using nondetergent oil or 2-stroke engine oil could

shorten the engine’s service life.

SAE 10 W-30 is recommended for general, all-temperature use. Other

viscosities shown in the following chart may be used when the average

temperature in your area is within the indicated range.

OIL FILLER CAP

0 20 40

-20

-10 0

- UPPER LEVEL

- LOWER LEVEL

60 SO

IO 20 30

100 *F

40 'C

27

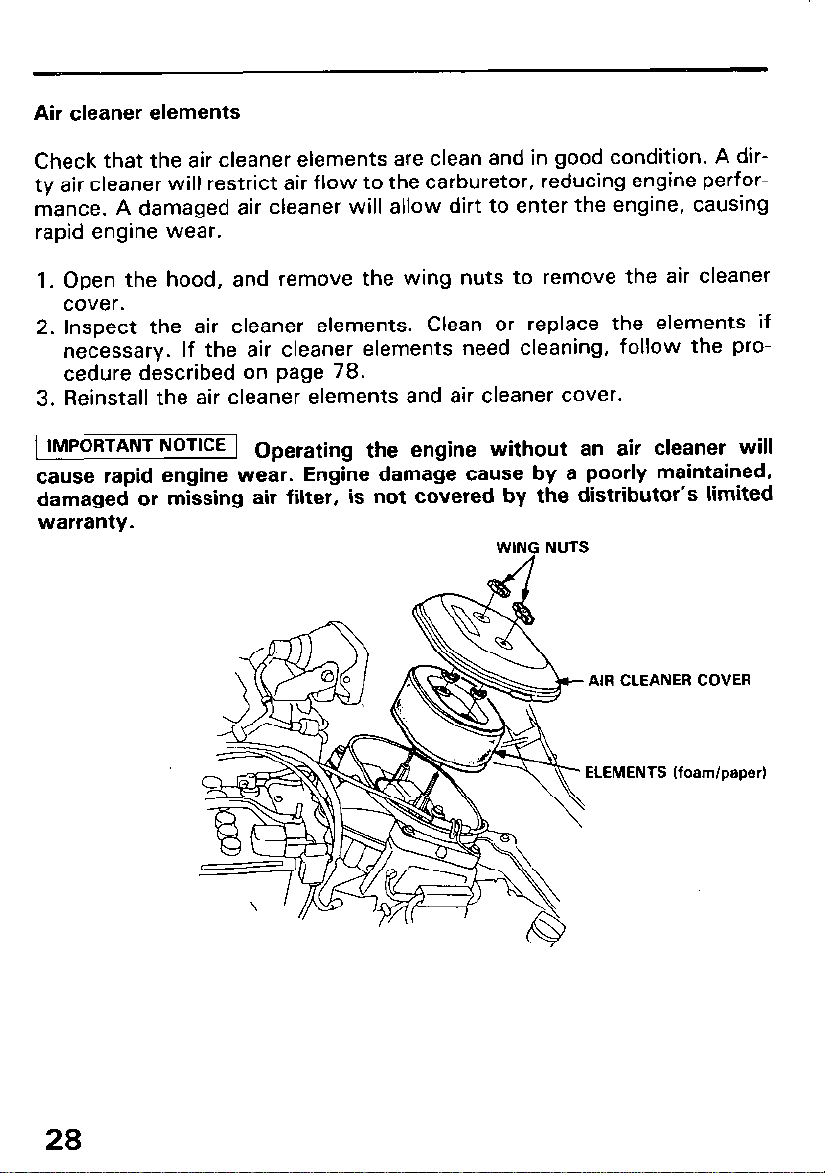

Air cleaner elements

Check that the air cleaner elements are clean and in good condition. A dirty air cleaner will restrict air flow to the carburetor, reducing engine perfor-

mance. A damaged air cleaner will allow dirt to enter the engine, causing

rapid engine wear.

1. Open the hood, and remove the wing nuts to remove the air cleaner

cover.

2. Inspect the air cleaner elements.

Clean or replace the elements if

necessary. If the air cleaner elements need cleaning, follow the procedure described on page 78.

3. Reinstall the air cleaner elements and air cleaner cover.

1 IMPORTANT NOTICE I Operating the engine without an air cleaner will

cause rapid engine wear. Engine damage cause by a poorly maintained,

damaged or missing air filter, is not covered by the distributor’s limited

warranty.

WING NUTS

AIR CLEANER COVER

28

ELEMENTS (foam/paper)

Loading...

Loading...