Honda Power Equipment GXV390 User Manual

05/04/12 20:08:50 32Z5N600_001

INTRODUCTION

Thank you for purchasing a Honda engine. We want to help you to

get the best results from your new engine and to operate it safely.

This manual contains information on how todo that; please read it

carefully before operating the engine. If a problem should arise, or

if you have any questions about your engine, consult an

authorized Honda servicing dealer.

All information in this publication is based on the latest product

information available at the time of printing. Honda Motor Co., Ltd.

reserves the right to make changes at any time without notice and

without incurring any obligation. No part of this publication may

be reproduced without written permission.

This manual should be considered a permanent part of the engine

and should remain with the engine if resold.

Review the instructions provided with the equipment powered by

this engine for any additional information regarding engine

startup, shutdown, operation, adjustments or any special

maintenance instructions.

United States, Puerto Rico, and U.S. Virgin Islands:

We suggest you read the warranty policy to fully understand its

coverage and your responsibilities of ownership.The warranty

policy is a separate document that should have been given to you

by your dealer.

SAFETY MESSAGES

OWNER’S MANUAL

MANUEL DE L’UTILISATEUR

MANUAL DEL PROPIETARIO

GXV340 · GXV390

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

ENGLISHFRANÇAISESPAÑOL

Your safety and the safety of others is very important. We have

provided important safety messages in this manual and on the

engine.Please read these messages carefully.

A safety message alerts you to potentialhazards that could hurt

you or others.Each safety message is preceded by a safety alert

symbol and one of three words, DANGER, WARNING, or

CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow

instructions.

Each message tells you what the hazard is, what can happen, and

what you can do to avoid or reduce injury.

DAMAGE PREVENTION MESSAGES

You will also see other important messages that are preceded by

the word NOTICE.

This word means:

Your engine or other property can be damaged if you

don’t follow instructions.

The purpose of these messages is to help prevent damage to your

engine, other property, or the environment.

CONTENTS

.......................INTRODUCTION .1

................SAFETYMESSAGES .1

..........SAFETYINFORMATION .2

COMPONENT& CONTROL

................................LOCATION .2

................................FEATURES .3

BEFORE OPERATION

....................................CHECKS .3

..............................OPERATION .4

SAFE OPERATING

.....................PRECAUTIONS .4

THE IMPORTANCE OF

....................MAINTENANCE .7

MAINTENANCE

............................SCHEDULE .7

...........................REFUELING .8

...........................ENGINE OIL .8

............RecommendedOil .8

..................Oil Level Check .9

.........................Oil Change .9

......................AIR CLEANER .10

........................Inspection .10

..........................Cleaning .10

.....SAFETYLABEL LOCATION .2

......STARTINGTHE ENGINE .4

......STOPPINGTHE ENGINE .5

.....SETTINGENGINE SPEED .6

.....SERVICING YOUR ENGINE .7

......MAINTENANCE SAFETY .7

.......SAFETYPRECAUTIONS .7

......................SPARK PLUG .10

.............SPARK ARRESTER .11

HELPFUL TIPS &

......................SUGGESTIONS .11

...STORING YOUR ENGINE .11

................TRANSPORTING .13

TAKING CARE OF

....UNEXPECTED PROBLEMS .13

TECHNICAL& CONSUMER

.......................INFORMATION .14

.....Serial Number Location .14

Battery Connections for

....................Electric Starter .14

.....Remote Control Linkage .14

Carburetor Modifications for

.....High AltitudeOperation .14

...............OxygenatedFuels .15

Emission Control System

.........................Information .15

..............................Air Index .16

.....................Specifications .16

........Tuneup Specifications .16

Quick Reference

.........................Information .17

................Wiring Diagrams .17

.CONSUMER INFORMATION .18

Distributor/DealerLocator

.........................Information .18

CustomerService

.........................Information .18

2005 Honda Motor Co., Ltd. All Rights Reserved

32Z5N600

00X32-Z5N-6000

−

GXV340UT2·GXV390UT1

ENGLISH

1

05/04/12 20:09:12 32Z5N600_002

Understand the operation of all controls and learn how to stop

the engine quickly in case of emergency. Make sure the operator

receives adequate instruction before operating the equipment.

Do not allow children to operate the engine. Keep children and

pets away from the area of operation.

Your engine’s exhaust contains poisonous carbon monoxide.

Do not run the engine without adequate ventilation, and never

run the engine indoors.

The engine and exhaust become very hot during operation.

Keep the engine at least 1 meter (3 feet) away from buildings

and other equipment during operation. Keep flammable

materials away, and do not place anything on the engine while it

is running.

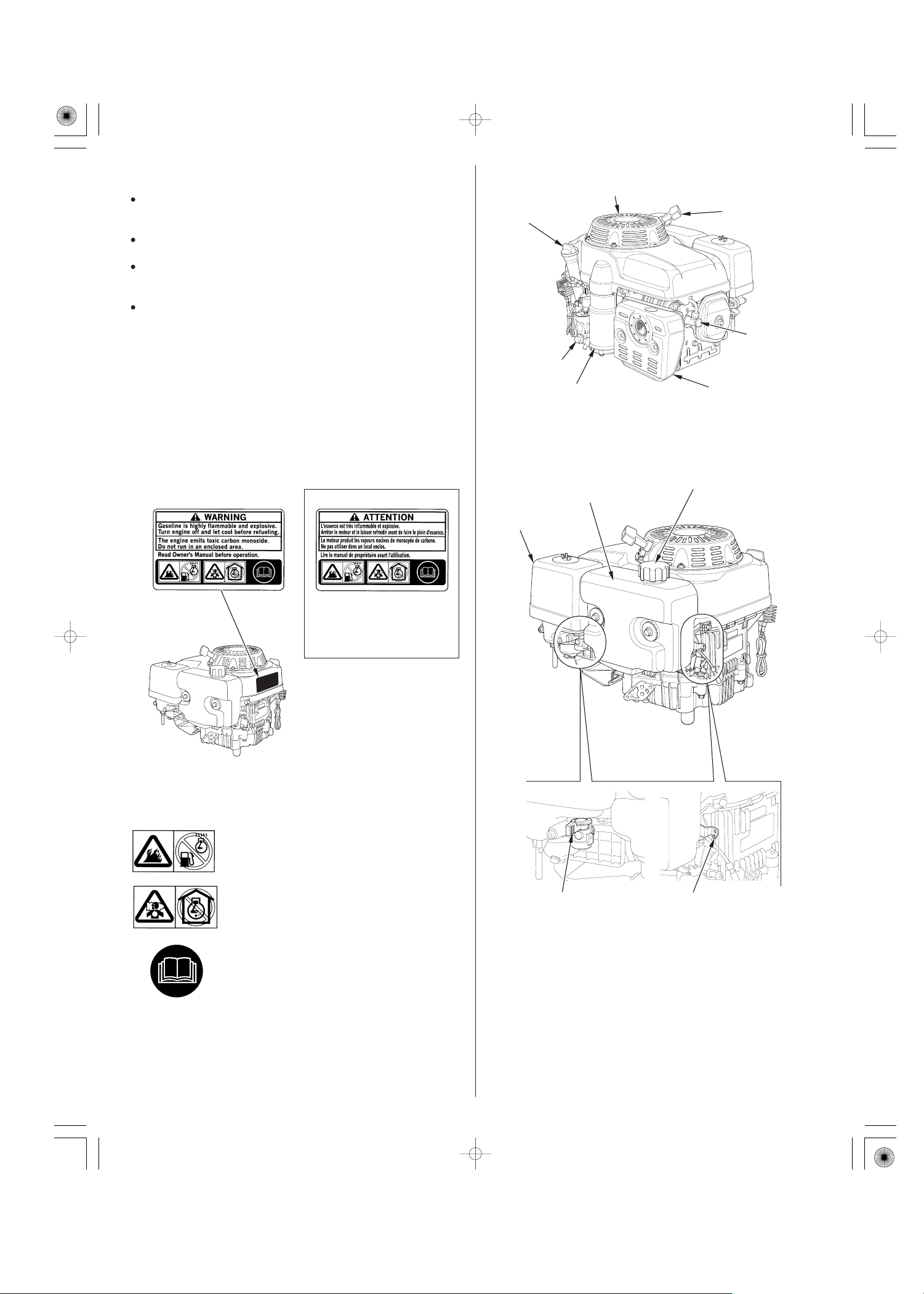

COMPONENT & CONTROL LOCATIONSAFETY INFORMATION

OIL FILLER CAP/

DIPSTICK

OIL DRAIN PLUG

RECOIL STARTER

STARTER GRIP

SPARK PLUG

SAFETY LABEL LOCATION

This label warns you of potential hazards that can cause serious

injury. Read it carefully.

If the label comes off or becomes hard to read, contact your Honda

dealer for replacement.

For Canadian types only:

French label comes with

the engine.

ELECTRIC STARTER

(applicable types)

FUEL TANK

AIR CLEANER

MUFFLER

FUEL FILLER CAP

ENGINE CONTROL

Gasoline is highly flammable and explosive.

Turn engine off and let cool before refueling.

The engine emits toxic poisonous carbon

FUEL VALVE LEVER

CONTROL LEVER

monoxide gas. Do not run in an enclosed area.

Read Owner’s Manual before operation.

2

ENGLISH

05/04/12 20:09:28 32Z5N600_003

BEFORE OPERATION CHECKSFEATURES

OIL ALERT SYSTEM (applicable types)

The Oil Alert

system is designed to prevent engine damage

caused by an insufficient amount of oil in the crankcase. Before

the oil level in the crankcase can fall below a safe limit, the Oil

Alert

system will sound a buzzer, warning you that oil needs to be

added to the engine.

The Oil Alert

system is not designed to be used in place of

checking the oil. Check the oil level prior to each use.

The ‘‘Oil Alert

’’ buzzer will arm you when engine oil needs to be

added to the crankcase. If the buzzer sounds, stop the engine and

add oil (see page ).

9

The buzzer indicates insufficient oil. Running the engine with

insufficient oil can cause serious engine damage.

IS YOUR ENGINE READY TO GO?

For your safety, and to maximize the service life of your

equipment, it is very important to take a few moments before you

operate the engine to check its condition. Be sure to take care of

any problem you find, or have your servicing dealer correct it,

before you operate the engine.

Improperly maintaining this engine, or failure to

correct a problem before operation, can cause a

malfunction in which you can be seriously hurt or

killed.

Always perform a preoperation inspection before

each operation, and correct any problem.

Before beginning your preoperation checks, be sure the engine is

level and the engine switch is in the OFF position.

Always check the following items before you start the engine:

Check the General Condition of the Engine

1.

Look around and underneath the engine for signs of oil or

gasolineleaks.

Remove any excessive dirt or debris, especially around the

2.

muffler and recoil starter.

Look for signs of damage.

3.

Check that all shields and covers are in place, and all nuts, bolts,

4.

and screws are tightened.

Check the Engine

Check the fuel level (see page ).Startingwith a full tank will

1.

8

help to eliminate or reduce operating interruptions for refueling.

Check the engine oil level (see page ). Running the engine

2.

9

with a low oil level can cause engine damage.

The ‘‘Oil Alert ’’ buzzer (applicable types) will warn you when

engine oil needs to be added to the crankcase. If the buzzer

sounds, stop the engine and add oil.

3.

Check the air filter element (see page ). A dirty air filter

10

element will restrict air flow to the carburetor, reducing engine

performance.

Check the equipment powered by this engine.

4.

Review the instructions provided with the equipment powered

by this engine for any precautions and procedures that should

be followed before engine startup.

ENGLISH

3

05/04/12 20:09:46 32Z5N600_004

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION

OPERATIONCHECKS

section on page and the

on page .

3

Carbon monoxide gas is toxic. Breathing it can cause

unconsciousness and even kill you.

Avoid any areas or actions that expose you to carbon

monoxide.

Review the instructions provided with the equipment powered by

this engine for any safety precautions that should be observed

with engine startup, shutdown or operation.

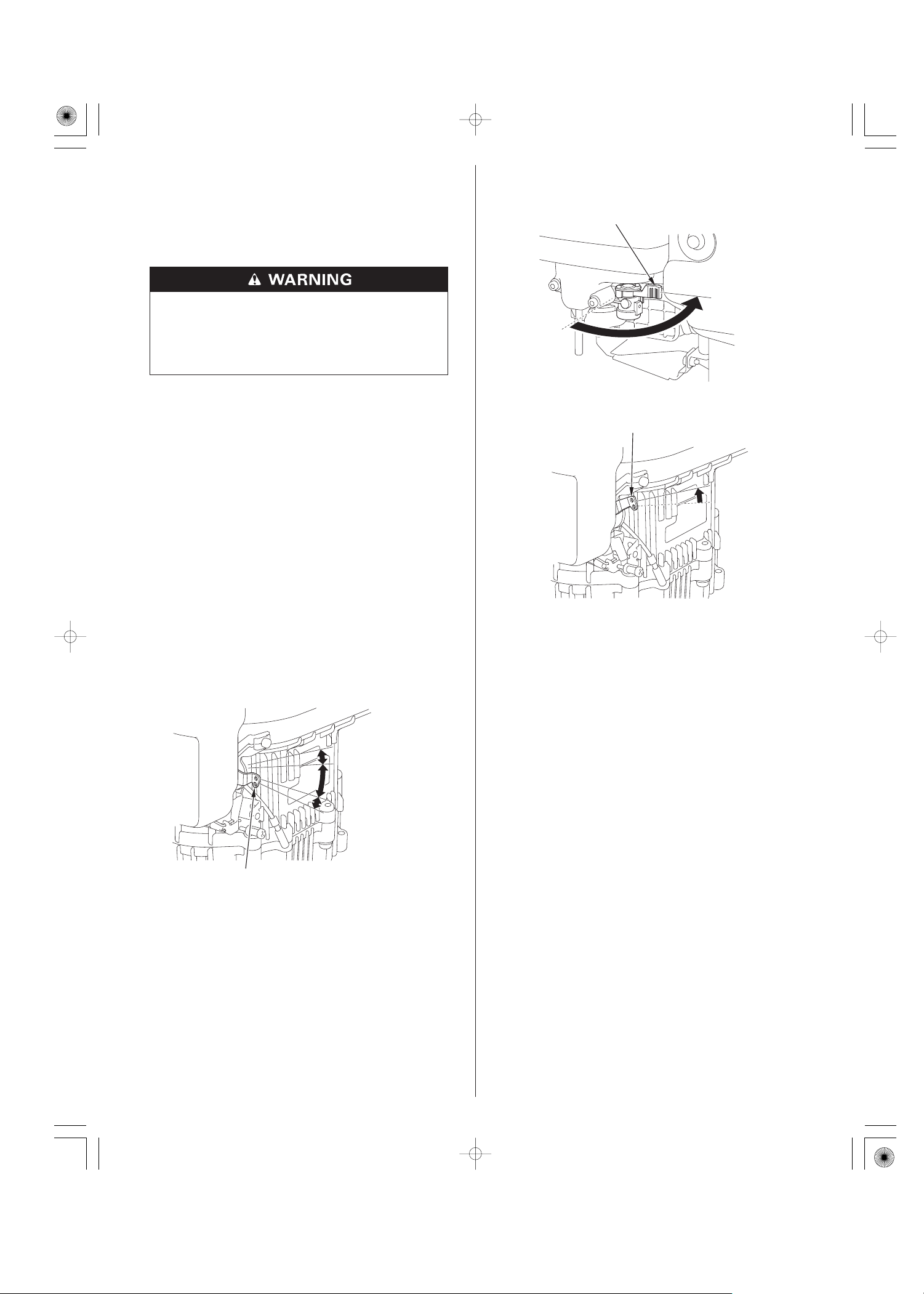

Control Lever

The control lever operates the engine switch, throttle, and choke.

OFF

––––––––

Stop the engine by switching off the ignition system.

All other control lever positions leave the ignition

system switched on.

2

BEFORE

STARTING THE ENGINE

1.

Move the fuel valve lever to the ON position.

FUEL VALVE LEVER

ON

2.

To start a cold engine, move the control lever to the CHOKE

position.

CONTROL LEVER

CHOKE

MAX.

MIN.

MAX.

–––––––

For running the engine at idle speed.

––––––

For restarting a warm engine, and for running the

engine at maxinum speed.

Enriches the fuel mixture for starting a cold engine.

CHOKE

–––––

The control lever shown here will be connected to a remote

control on the equipment powered by this engine. Refer to the

instructions provided with that equipment for remote control

information.

CHOKE

MAX.

MMIINN..

OOFFFF

CONTROL LEVER

To restart a warm engine, leave the control lever in the MAX.

position.

The control lever shown here will be connected to a remote

control on the equipment powered by this engine. Refer to the

instructions provided with that equipment for remote control

information.

3.

Turn the engine switch to the ON position.

There may be a remote engine switch mounted on the

equipment powered by this engine. Refer to the instructions

provided with the equipment for remote control information.

4

ENGLISH

05/04/12 20:10:02 32Z5N600_005

4.

Operate the starter.

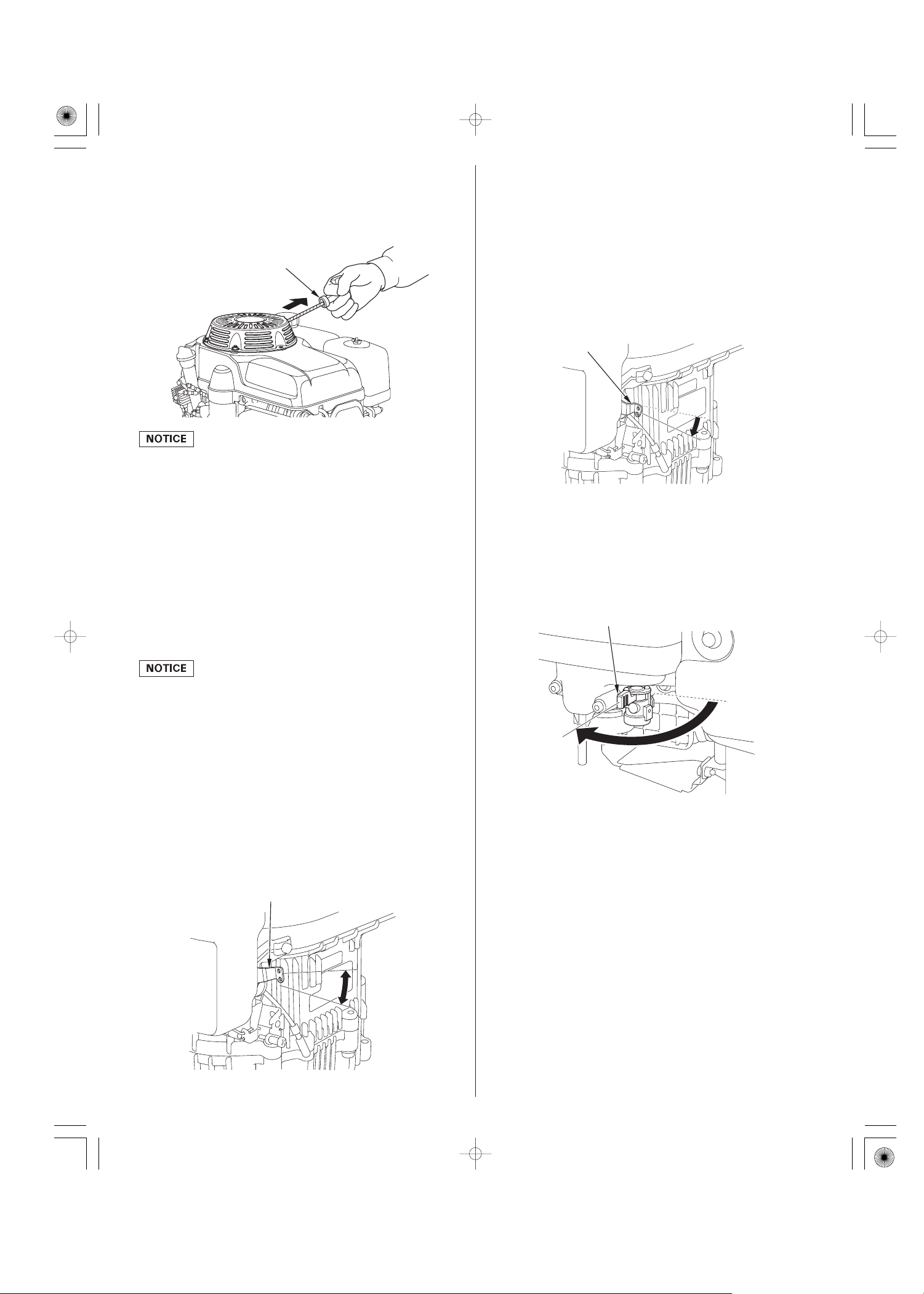

RECOIL STARTER

Pull the starter grip lightly until you feel resistance, then pull

briskly. Return the starter grip gently.

SSTTAARRTTEERR GGRRIIPP

Do not allow the starter grip to snap back against the engine.

Return it gently to prevent damage to the starter.

ELECTRIC STARTER (applicable types):

The electric starter will be connected to a remote control on the

equipment powered by this engine. Refer to the instructions

provided with the equipment for remote control information.

Turn the engine switch key to the START position, and hold it

there until the engine starts.

STOPPING THE ENGINE

To stop the engine in an emergency, simply move the control

lever to the OFF position. Under normal conditions, use the

following procedure.

1.

Move the control lever to the OFF position.

The control lever shown here will be connected to a remote

control on the equipment powered by this engine. Refer to the

instructions provided with the equipment for remote control

information.

CONTROL LEVER

OOFFFF

2.

Turn the engine switch to the OFF position.

There may be a remote engine switch mounted on the

equipment powered by this engine. Refer to the instructions

provided with the equipment for remote control information.

3.

Turn the fuel valve lever to the OFF position.

If the engine fails to start within 5 seconds, release the engine

switch key, and wait at least 10 seconds before operating the

starter again.

Using the electric starter for more than 5 seconds at a time will

overheat the starter motor and can damage it.

When the engine starts, release the engine switch key, allowing

it to return to the ON position.

5.

If the control lever was moved to the CHOKE positionto start the

engine, gradually move it to the MAX. or MIN. position as the

engine warms up.

The control lever shown here will be connected to a remote

control on the equipment powered by this engine. Refer to the

instructions provided with that equipment for remote control

information.

CONTROL LEVER

MAX.

FUEL VALVE LEVER

OOFFFF

MMIINN..

ENGLISH

5

05/04/12 20:10:07 32Z5N600_006

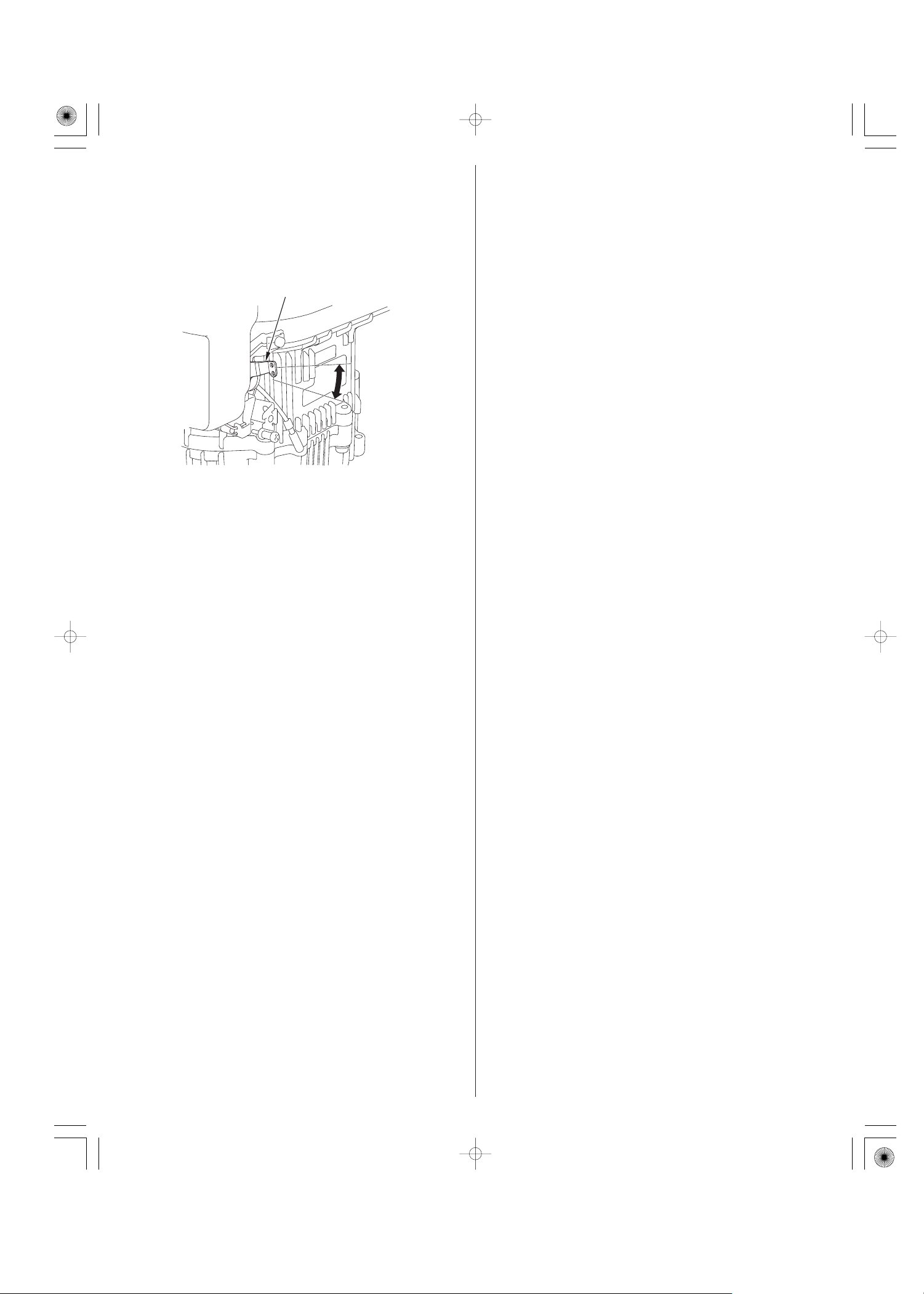

SETTING ENGINE SPEED

Positionthe control lever for the desired engine speed.

The control lever shown here will be connected to a remote

control on the equipment powered by this engine. Refer to the

instructions provided with that equipment for remote control

information and engine speed recommendations.

CONTROL LEVER

MMAAXX..

MMIINN..

6

ENGLISH

Loading...

Loading...