Honda Power Equipment GXI 60, GXI 20 User Manual

Click SAVE to save this manual to your computer. Thank you for choosing Honda.

Thank you for purchasing a Honda engine.

the

This manual covers

eng~ines and is based on GXI

electric and manual starting; other types are equipped for manual starting

onl$. All information in this publication

mation available

Horjda Motor Co., Ltd. reserves the right to make changes

without notice and without incurring any obligation.

No part of this publication may be reproduced without written permission.

at

operation and maintenance

60

engine. The QXE type is equipped for both

is

based on the latest product infor-

the time of printing.

of

GXI

20

and GXI

at

60

any time

This manual should be considered

should remain with the engine if

It

is^

illegal in some areas to operate

spa~rk arrester; check local laws and regulations. An optional spark arrester

for this engine is available from any dealership displaying the Honda Power

Equipment Engines sign.

READ

these symbols and any instructions that follow:

-1

NOTE: Gives helpful information.

,

~

THIS

OWNER’S

-Indicates serious injury or death

-Indicates a strong possibility that serious injury or

-Indicates a possibility that minor injury can result if

-Indicates that equipment or property damage can

MANUAL

instructions are not followed.

death could result if instructions are not followed.

instructions are not followed.

result if instructions are not followed.

a

permanent part of the engine and

it

is resold.

an

engine without a U.S.D.A. qualified

CAREFULLY.

Pay special attention to

WILL

result if

If alproblem should arise, or if you have any questions about your engine,

consult your Honda engine dealer.

CONTENTS

1

.

ENGINE SAFETY

2

.

COMPONENT IDENTIFICATION

3

.

BATTERY CONNECTIONS (for electric starter)

4

.

REMOTE CONTROL LINKAGE

5 .

PRE-OPERATION CHECK

1

.

ENGINE

2

.

REDUCTION GEAR

3

.

AIR CLEANER

4

.

FUEL

GASOLINE CONTAINING ALCOHOL

6

.

STARTING THE ENGINE

7

.

OPERATION

Oil Alert System

.

STOPPING THE ENGINE

8

High altitude operation

9

.

MAINTENANCE

1

.

Oil change

.

Air cleaner service

2

3

.

Sediment cup cleaning

4

.

Spark plug service

5 .

Spark arrester maintenance

6

.

Carburetor adjustment

10

.

TRANSPORTING/STORAGE

I1

.

TROUBLESHOOTING

.

SPECIFICATIONS

12

.

WIRING DIAGRAM

13

14

.

WARRANTY SERVICE

OIL

.............................................................................

.................................................................

.............................................

................................................

......................................................

....................................................................

OIL

.....................................................

.................................................................

.......................................................

.......................................................................

..............................................................

.......................................................

.....................................................

..................................................................

......................................................................

...........................................................

.....................................................

...........................................................

...............................................

.....................................................

..................................................

...........................................................

................................................................

..............................................................

..........................................................

.........................

...................................

3

4

5

6

7

7

8

9

11

12

13

16

17

18

19

20

21

22

25

26

28

29

30

31

33

34

36

2

I.

ENGINE

SAFETY

eonda engines are designed to give safe and dependable service

ated according to instructions. Read and understand this Owner’s

Manual before operating the engine. Failure to do

sonal injury or equipment damage.

To

prevent fire hazards and to provide adequate ventilation, keep the

engine at least

ment during operation.

engine.

Children and pets must be kept away from the area of operation due to

a

possibility of burns from hot engine components or injury from any

equipment the engine may be used to operate.

Know how to stop the engine quickly, and understand the operation of

all controls. Never permit anyone to operate the engine without proper

instructions.

Gasoline is extremely flammable and is explosive under certain

conditions.

Refuel

or allow flames or sparks

stored.

Do

closed properly and securely.

Be careful not to spill fuel when refueling. Fuel vapor or spilled fuel may

i,gnite.

engine.

Never run the engine

poisonous carbon monoxide gas; exposure may cause

sciousness and may lead to death.

The muffler becomes very hot during operation and remains hot for a

while after stopping the engine. Be careful not to touch the muffler

while

before transporting

in

a well-ventilated area

not overfill the fuel tank. After refueling, make sure the tank cap is

If

any fuel is spilled, make sure the area is dry before starting the

it

is hot.

1

meter

To

avoid severe burns or fire hazards, let the engine cool

(3

feet) away from buildings and other equip-

Do

not place flammable objects close to the

with

the engine stopped.

in

the refueling area or where gasoline is

in

an enclosed or confined area. Exhaust contains

it

or

storing

it

indoors.

so

could result

Do

if

oper-

in

not smoke

loss

of con-

per-

3

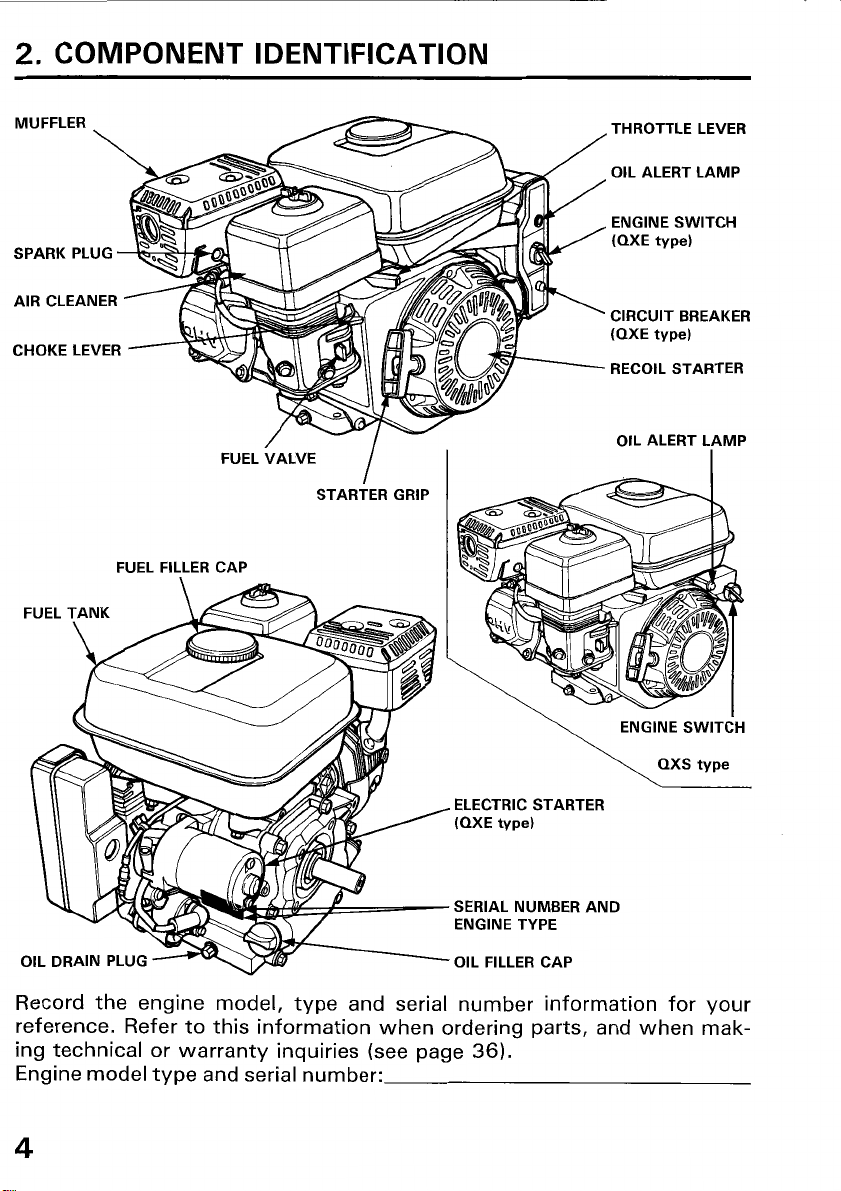

2.

COMPONENT IDENTIFICATION

MUFFLER

SPARK PLUG

AIR CLEANER

CHOKE LEVER

FUEL

FUEL FILLER CAP

THROTTLE LEVER

OIL ALERT LAMP

ENGINE SWITCH

(QXE type)

CIRCUIT BREAKER

(QXE type)

RECOIL STARTER

OIL ALERT LAMP

VALVE

I

STARTER GRIP

ENGINE

,

ELECTRIC STARTER

(QXE type)

SERIAL NUMBER AND

ENGINE TYPE

OIL DRAIN PLUG OIL FILLER CAP

Record the engine model, type and serial number information for your

reference. Refer to this information when ordering parts,

ing technical or warranty inquiries (see page

36).

and

when mak-

Engine model type and serial number:

4

SWITCH

QXS type

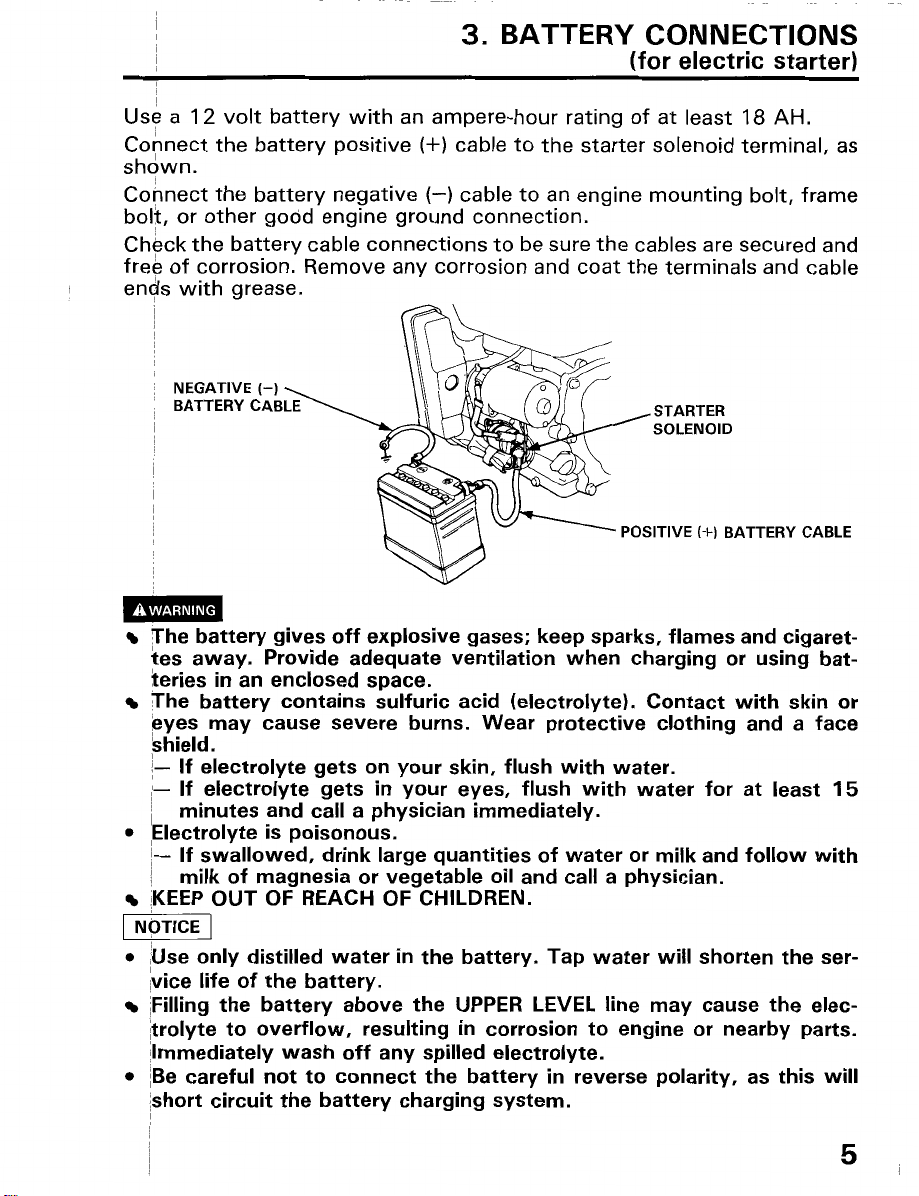

3.

BATTERY CONNECTIONS

(for

electric

Use

a

12

volt battery

Connect the battery positive

shown.

Connect the battery negative

bolt, or other good engine ground connection.

Check the battery cable connections to be sure the cables are secured and

free

of

corrosion. Remove any corrosion

l

ends

with

grease.

with

an ampere-hour rating

(+)

cable to the starter solenoid terminal, as

(-1

cable to an engine mounting bolt, frame

of

at least

and

coat the terminals and cable

,STARTER

SOLENOID

starter)

18

AH.

'

the battery gives off explosive gases; keep sparks, flames and cigarettes away. Provide adequate ventilation when charging or using batkeries

The battery contains sulfuric acid (electrolyte). Contact

pyes may cause severe burns. Wear protective clothing and a face

Fhield.

!-

~-

~

0

Electrolyte is poisonous.

~-

I

!KEEP OUT

I

NOTICE

0

use

vice

filling

~trolyte to overflow, resulting

~lmmediately wash off any spilled electrolyte.

0

be

;short circuit the battery charging system.

in

an enclosed space.

If

electrolyte gets on your skin, flush

If

electrolyte gets

minutes and call a physician immediately.

If

swallowed, drink large quantities of water or milk and follow

milk

of magnesia or vegetable oil and call a physician.

OF

REACH

in

your eyes, flush

OF

CHILDREN.

with

I

only distilled water

life of the battery.

the battery above the UPPER LEVEL line may cause the elec-

careful not to connect the battery

in

the battery. Tap water

in

corrosion to engine or nearby parts.

in

POSITIVE

water.

with

water for at least

reverse polarity, as this

(+I

BATTERY

with

will

shorten the ser-

skin

CABLE

or

15

with

will

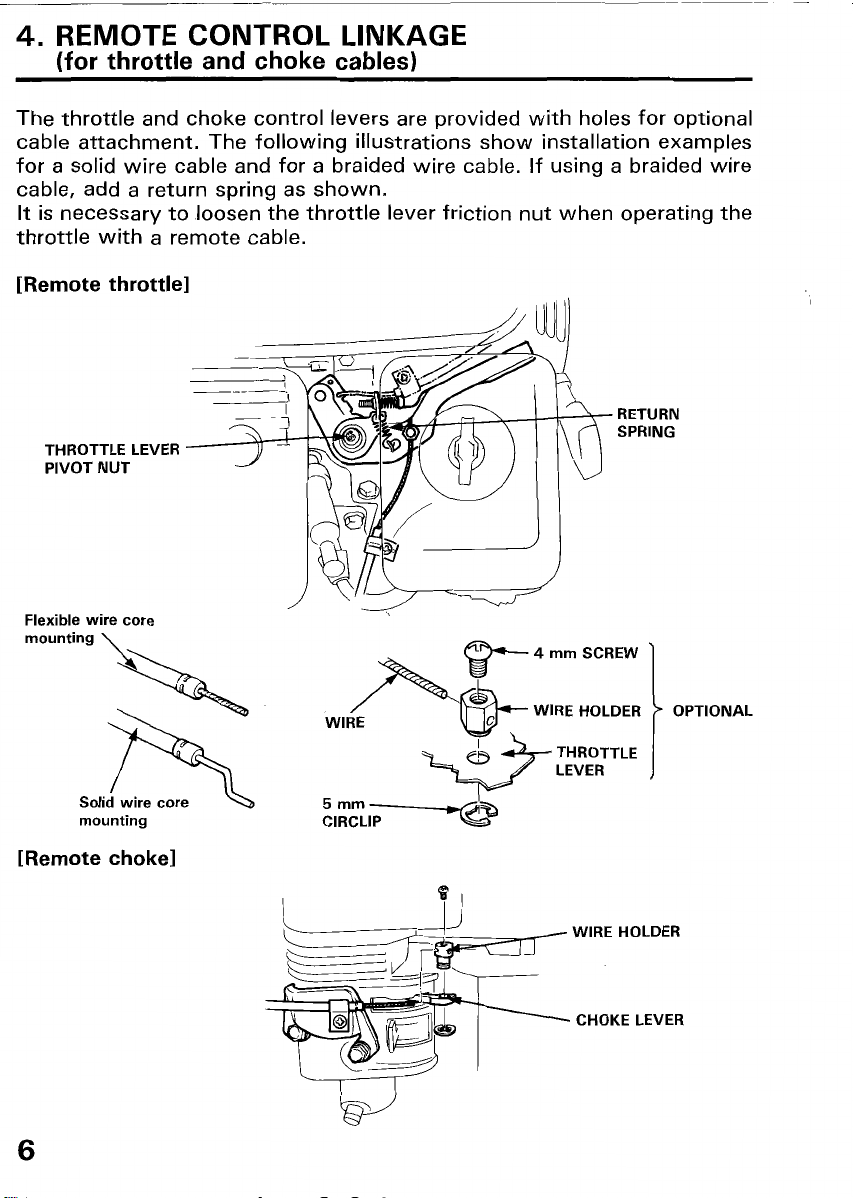

4.

REMOTE

(for

throttle

CONTROL

and

choke

LINKAGE

cables)

The throttle and choke control levers are provided

with

holes for optional

cable attachment. The following illustrations show installation examples

for a solid wire cable and for a braided wire cable.

If

using a braided wire

cable, add a return spring as shown.

It

is necessary to loosen the throttle lever friction

throttle

with

a remote cable.

nut

when operating the

[Remote throttle]

THROTTLE LEVER

PIVOT NUT

Flexible wire core

Y

4

mm SCREW

mounting

[Remote choke1

6

WIRE

WIRE HOLDER

THROTTLE

LEVER

WIRE HOLDER

.

CHOKE LEVER

’

OPTIONAL

5.

PRE-OPERATION CHECK

I.

ENGINE

I

NOTICE

OIL

1

Engine oil is a major factor affecting engine performance and service

life. Non-detergent oils and vegetable oils are not recommended.

Be sure to check the engine on a level surface with the engine stopped.

i

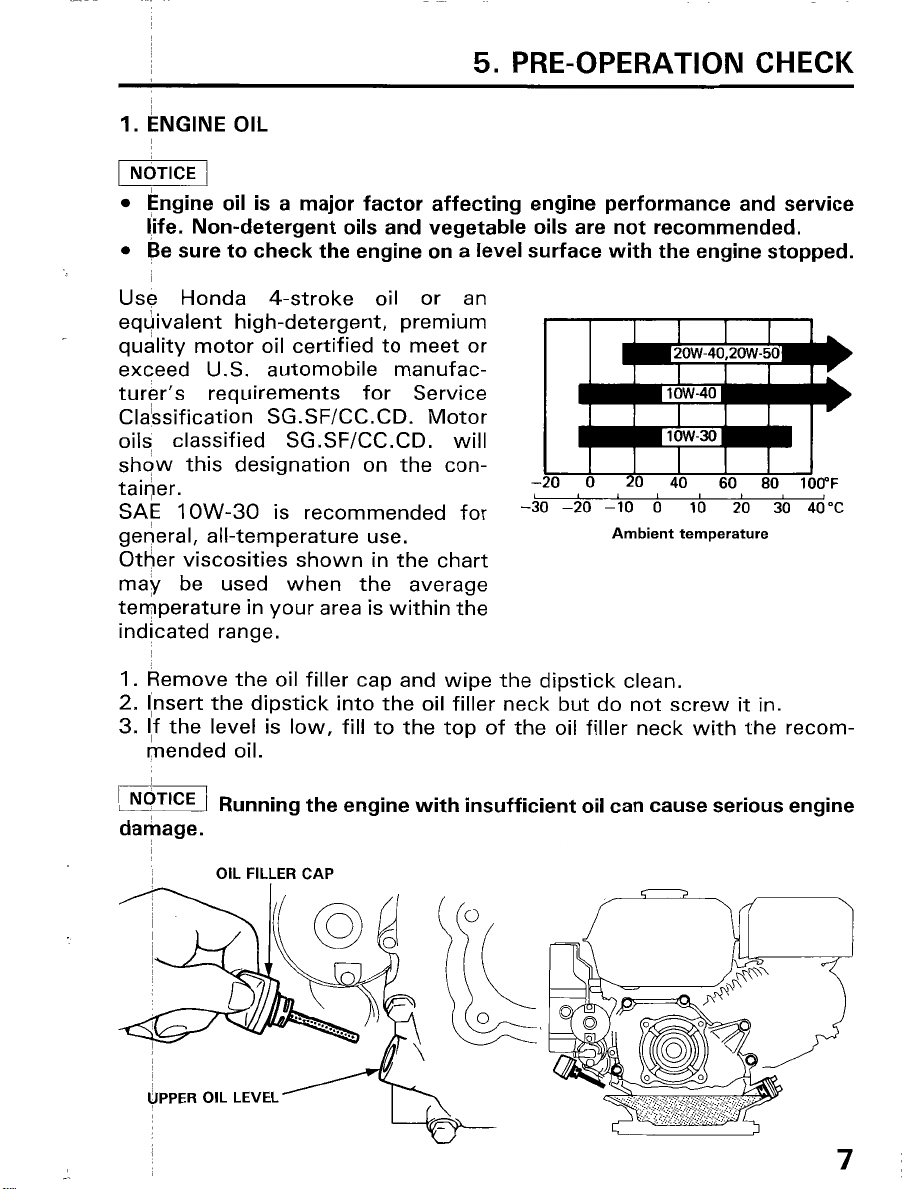

Use Honda 4-stroke oil or an

equivalent high-detergent, premium

quality motor oil certified to meet or

exceed U.S. automobile manufac-

I

2OW-40.2OW-56

I

1

I

turer's requirements for Service

Cla'ssification SG.SF/CC.CD. Motor

oils classified SG.SF/CC.CD. will

show this designation on the contairjer.

SAE

IOW-30

is recommended for

general, all-temperature use.

Other viscosities shown

in

the chart

-20

I

-30

I

-20

0

20

40

lo

60 80

2o

30

1

-lo

Ambient temperature

may be used when the average

temperature

your area is

within

the

in

indicated range.

I

100°F

I

40"c

1.

Remove the oil filler cap and wipe the dipstick clean.

2.

l~nsert the dipstick into the oil filler neck

3.

Iif

the level is

low,

fill to the top of the oil filler neck

but

do not screw

mended oil.

Running the engine with insufficient oil can cause serious engine

damage.

OIL

FILLER

CAP

with

it

in.

the recom-

7

2.

REDUCTION GEAR

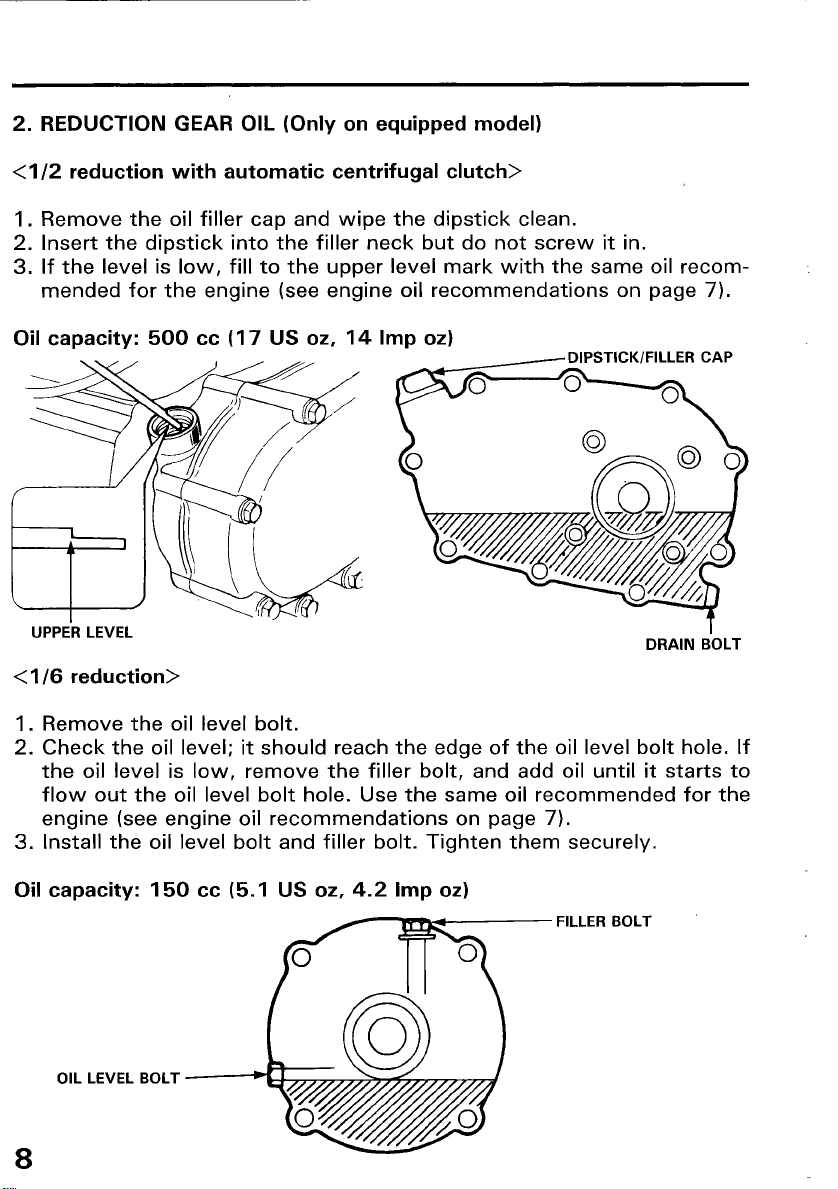

<I

/2

reduction with automatic centrifugal clutch>

1.

Remove the oil filler cap and wipe the dipstick clean.

2.

Insert the dipstick into the filler neck but do not screw

3.

If

the level is

mended

low,

for

the engine (see engine oil recommendations on page

OIL

(Only on equipped model)

fill to the upper level mark

it

in.

with

the same oil recom-

7).

Oil capacity:

500

cc

(1

7

US

02,

14

ImD

02)

DIPSTICK/FILLER

p=-y

UPPER

LEVEL

<

1

/6

reduction>

1.

Remove the oil level bolt.

2.

Check the oil level;

the oil level is low, remove the filler bolt, and add

flow out the

engine (see engine oil recommendations on page

3.

Install the oil level bolt and filler bolt. Tighten them securely.

Oil capacity:

oil

150

it

should reach the edge of the oil level bolt hole. If

oil

level bolt hole. Use the same oil recommended for

7).

cc

(5.1

US

02,

4.2

Imp

02)

FILLER

until

BOLT

DRAIN

it

starts to

CAP

BOLT

the

OIL LEVEL

BOLT

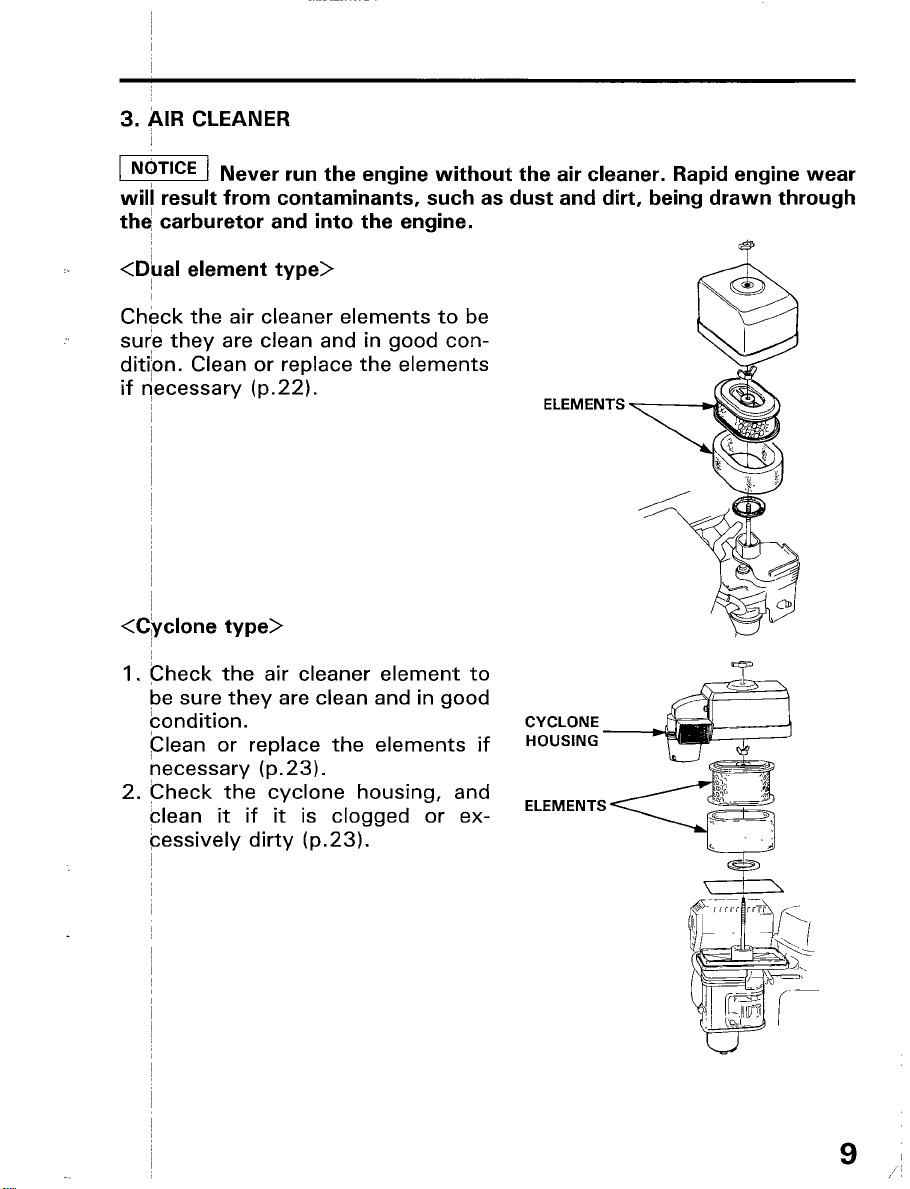

3.

AIR

CLEANER

Never run the engine without the air cleaner. Rapid engine wear

will result from contaminants, such as dust and dirt, being drawn through

the: carburetor and into the engine.

'I

<Dual element type>

Check the air cleaner elements to be

..'

sur~e they are clean and

in

good conditi~on. Clean or replace the elements

if necessary (p.22).

ELEMENTS

<Cbclone type>

Check the air cleaner element to

1.

be sure they are clean and

condition.

Flean or replace the elements

in

good

if

CYCLONE

HOUSING

-

necessary (p.23).

Check the cyclone housing, and

2.

clean

it

if

it

is

clogged or ex-

ELEMENTS

cessively dirty (p.23).

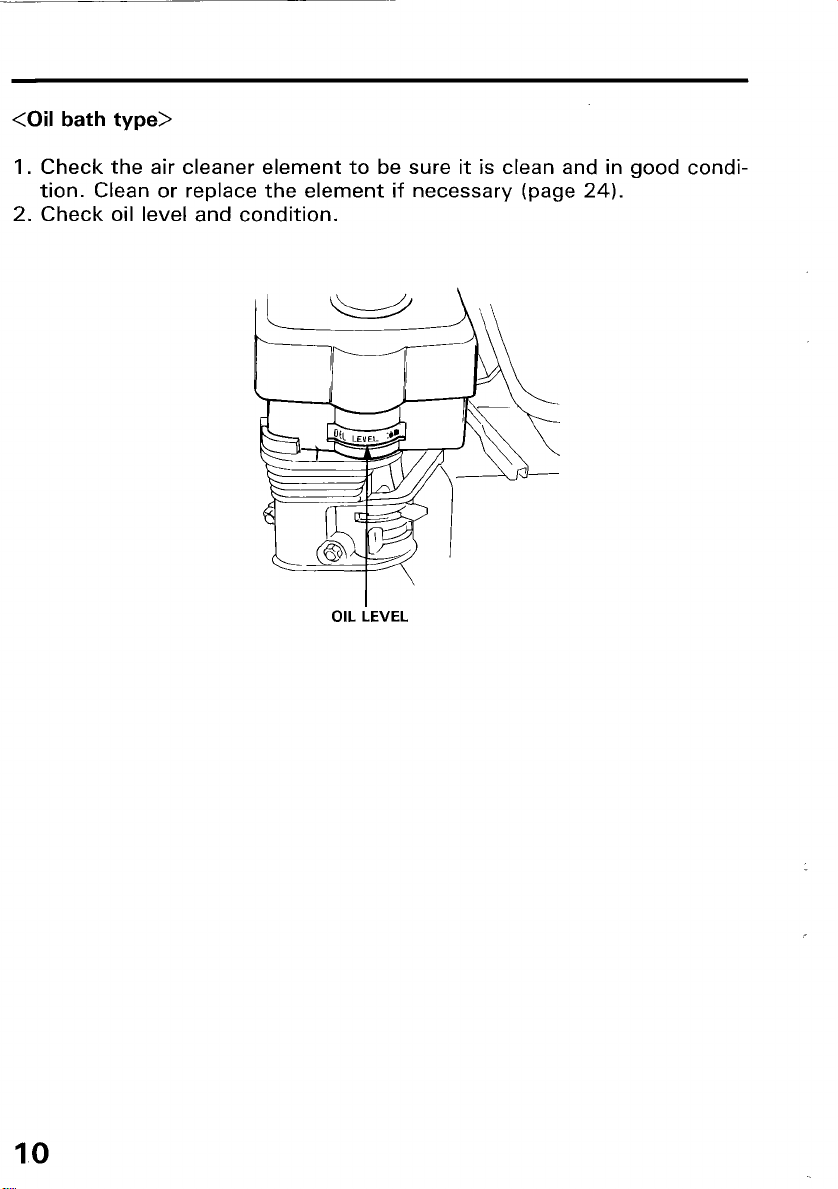

<Oil

bath

type>

1.

Check the air cleaner element to be sure

or

tion. Clean

2.

Check oil level and condition.

replace the element if necessary (page

OIL LEVEL

it

is clean and

in

good condi-

24).

10

Loading...

Loading...