Honda Power Equipment GX35 user guide

Honda GX35 Gas Pack

Back Pack & Hand Held

Operator/Service Manual

Hours of Operation

8:00AM to 4:30PM Mon. – Fri. Eastern Standard Time

277 North Main Street Phone: 419.524.1000

PO Box 367 www.minnich-mfg.com Toll Free: 800.524.1033

Mansfield, OH 44902 e-mail: sales@minnich-mfg.com Fax: 419.524.4000

Form: LIT-019 Revised 7/1/2007

TABLE OF CONTENTS

Section Page #

Warranty ------------------------------------------------------------------------------------------------------------------------------------------3

GENERAL SAFETY RULES

Work Area -----------------------------------------------------------------------------------------------------------------------------------------5

Personal Safety ----------------------------------------------------------------------------------------------------------------------------------5

Tool Use and Care ------------------------------------------------------------------------------------------------------------------------------5

Service ---------------------------------------------------------------------------------------------------------------------------------------------5

Back Pack Specifications -------------------------------------------------------------------------------------------------------------------6

Hand Held Specifications-------------------------------------------------------------------------------------------------------------------- 7

Warranty ------------------------------------------------------------------------------------------------------------------------------------------8

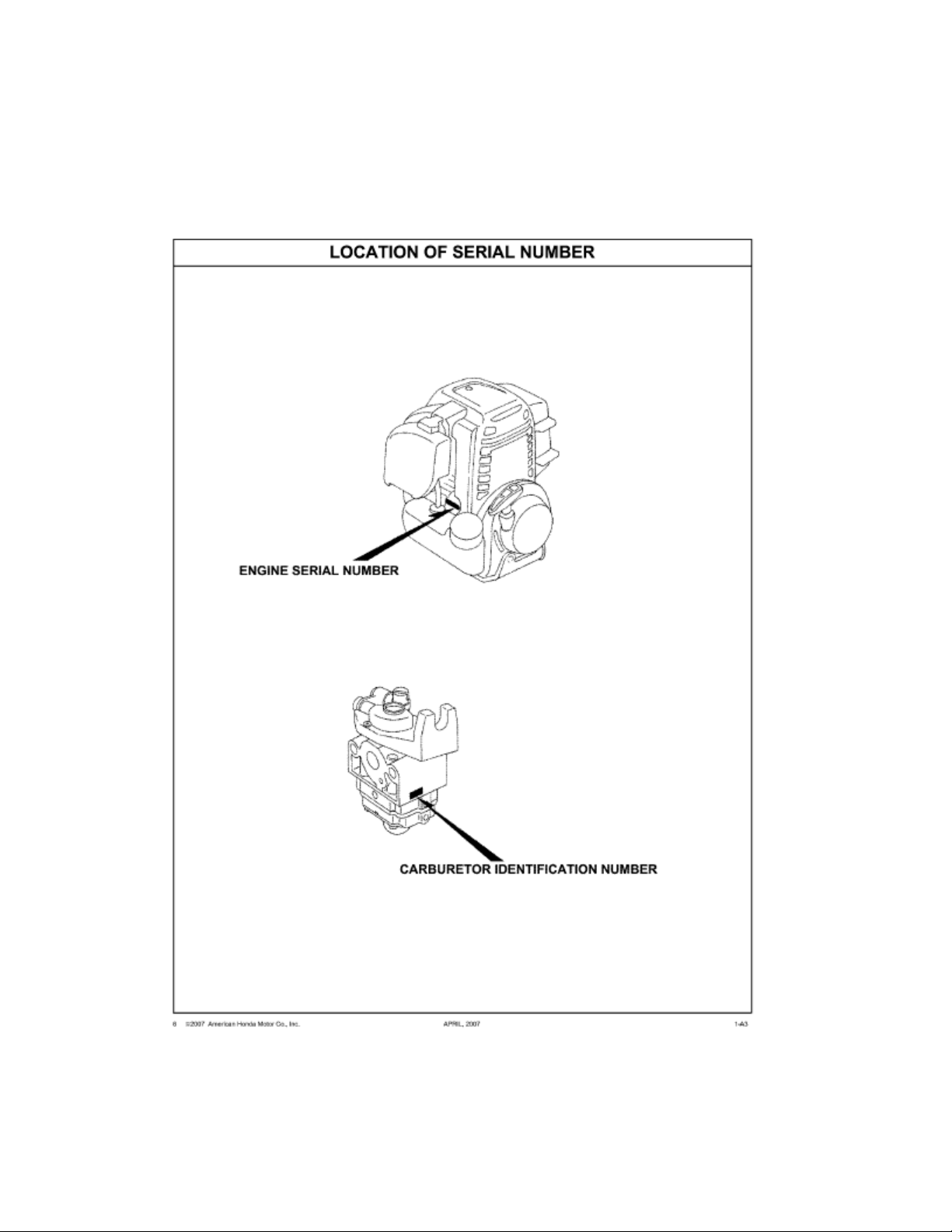

Serial Number Location----------------------------------------------------------------------------------------------------------------------9

Part Breakdowns

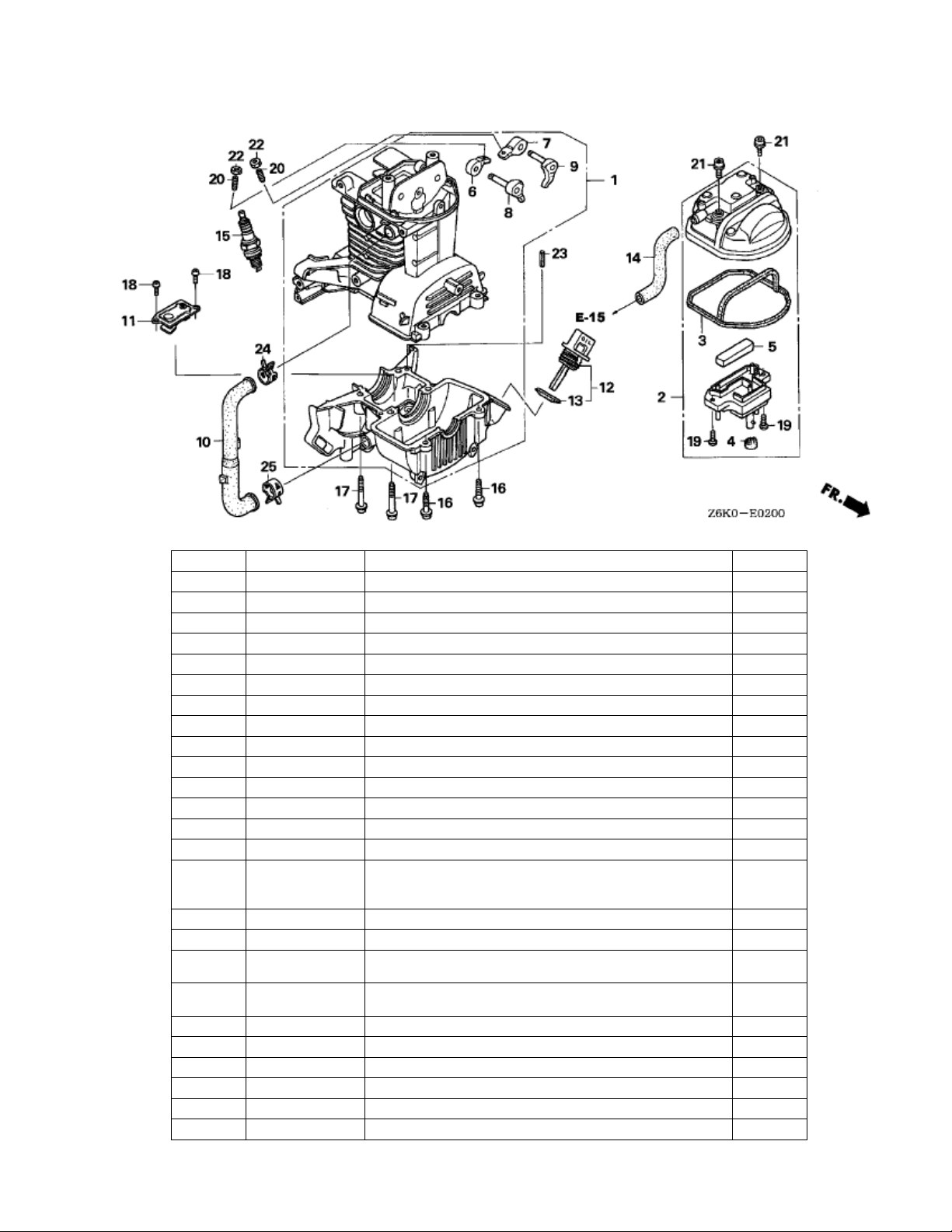

E-2 Crankcase Set --------------------------------------------------------------------------------------------------------------------------- 10

E-7 Crankshaft/Piston ---------------------------------------------------------------------------------------------------------------------- 11

E-10 Cam Pulley ------------------------------------------------------------------------------------------------------------------------------ 12

E-11 Recoil Starter--------------------------------------------------------------------------------------------------------------------------- 13

E-12 Fan Cover/Clutch---------------------------------------------------------------------------------------------------------------------- 14

E-14 Carburetor------------------------------------------------------------------------------------------------------------------------------- 15

E-15 Air Cleaner ------------------------------------------------------------------------------------------------------------------------------ 16

E-16 Muffler ------------------------------------------------------------------------------------------------------------------------------------ 17

E-17 Fuel Tank -------------------------------------------------------------------------------------------------------------------------------- 18

E-19 Flywheel---------------------------------------------------------------------------------------------------------------------------------- 19

E-27 Top Cover-------------------------------------------------------------------------------------------------------------------------------- 20

E-28 Label -------------------------------------------------------------------------------------------------------------------------------------- 21

E-29 Tool---------------------------------------------------------------------------------------------------------------------------------------- 22

Throttle Assembly --------------------------------------------------------------------------------------------------------------------------- 23

Engine Assembly (Hand Held)----------------------------------------------------------------------------------------------------------- 24

Engine Assembly (Back Pack)----------------------------------------------------------------------------------------------------------- 25

Frame Assembly (Back Pack)------------------------------------------------------------------------------------------------------------ 26

Shaft Assembly------------------------------------------------------------------------------------------------------------------------------- 27

Vibrator Heads and Shafts Maintenance

Vibrator Head Parts Breakdown--------------------------------------------------------------------------------------------------------- 28

Head and Shaft Assembly----------------------------------------------------------------------------------------------------------------- 28

Flexible Shaft Maintenance--------------------------------------------------------------------------------------------------------------- 29

Vibrator Head Maintenance--------------------------------------------------------------------------------------------------------------- 29

- 2 -

MINNICH MANUFACTURING CO.

WARRANTY AND SERVICE AGREEMENT

Minnich Manufacturing Co. warrants to the original purchaser that, if any part of the product proves defective in material or

workmanship within one year from purchase, and is returned to Minnich Manufacturing Co. within 90 days after the defect

is discovered, Minnich Manufacturing Co. will at its option repair or replace said part. Product shipped to Minnich

Manufacturing Co. freight prepaid will be returned freight prepaid. Product shipped to Minnich Manufacturing Co. freight

collect will be returned freight collect.

LIMITATIONS:

Warranty does not apply to repairs that are required because of normal wear or tear, parts or products that are damaged

as a result of misuse, neglect, accident or fire, or of lightning, flooding or other acts of God, or by improper installation or

maintenance, of which Minnich Manufacturing Co. will be the sole judge. Warranty does not apply to parts or products

that have been modified by an unauthorized party that has in Minnich Manufacturing Co.’s judgment affected their

performance or reliability. Warranty does not apply if the part or product substantially fulfills the performance

specifications.

Minnich Manufacturing Co. shall not in any event be liable for the cost of any special, indirect, or consequential damages

as a result of this product.

SERVICE:

Out of warranty service is available through Minnich Manufacturing Co.

- 3 -

GENERAL SAFETY RULES

This manual contains NOTES, CAUTIONS, and WARNINGS. These MUST be followed to

prevent the possibility of improper use, incorrect servicing, damaging the equipment, or

personal injury. Read and comply with all NOTES, CAUTIONS and WARNINGS included in

these instructions.

NOTE: Notes contain additional information important to the operation of

the equipment.

CAUTION: Cautions provide important information to prevent mistakes

that could result in damage to the equipment.

WARNING: Warnings alert one to practices or conditions that could

lead to personal injury or death!

WARNING

Read and understand all instructions.

Failure to follow all instructions listed below may result in one or all of the following;

electric shock, fire, and serious injury.

WARNING

DO NOT USE TOOL IF IT IS IN NEED OF SERVICE!

SAVE THESE INSTRUCTIONS

- 4 -

- WORK AREA –

Keep your work area clean and well lit.

Cluttered and dark areas invite accidents.

DO NOT operate power tools in explosive atmospheres, such as, in the presence of flammable liquids, gases, or

dust.

Power tools create sparks that may ignite the dust or fumes.

Keep bystanders, children, and visitors away while operating a power tool.

Distractions can cause you to lose control.

- PERSONAL SAFETY -

Stay alert, watch what you are doing and use common sense when operating a power tool. DO NOT use tool

while tired or under influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious personal injury.

Dress properly. DO NOT wear loose clothing, or jewelry. Tie up long hair. Keep your hair, clothing, and gloves

away from moving parts.

Loose clothes, jewelry, or long hair can be caught in moving parts.

Avoid accidental starting. Be sure switch is off before plugging in.

Carrying tools with your finger on the switch or plugging in tools that have switches on invites accidents.

DO NOT overreach. Keep proper footing and balance at all times.

Proper footing and balance enables better control of the tool in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing protection must be used for appropriate conditions.

- TOOL USE AND CARE -

DO NOT force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for which it is designed.

DO NOT use tool if switch does not turn it on or off.

Any tool that cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing acces sories, or storing the

tool.

Such preventive safety measures reduce the risk of starting the tool accidentally.

Store tools out of the reach of children and other untrained persons.

Tools are dangerous in the hands of untrained users.

Maintain tools with care. Keep tools clean.

Properly maintained tools are less likely to bind and are easier to control.

Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect

the tools operation. If damaged, have the tool serviced before using.

Many accidents are caused by poorly maintained tools.

Use only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may become hazardous when used on another tool.

- SERVICE

Tool service must be performed only by qualified repair personnel.

Service or maintenance performed by unqualified personnel could result in a risk of injury.

When servicing a tool, use only identical replacement parts. Follow instructions in the maintenance section of

this manual.

Use of unauthorized parts or failure to follow maintenance instructions may create a risk of injury.

-

- 5 -

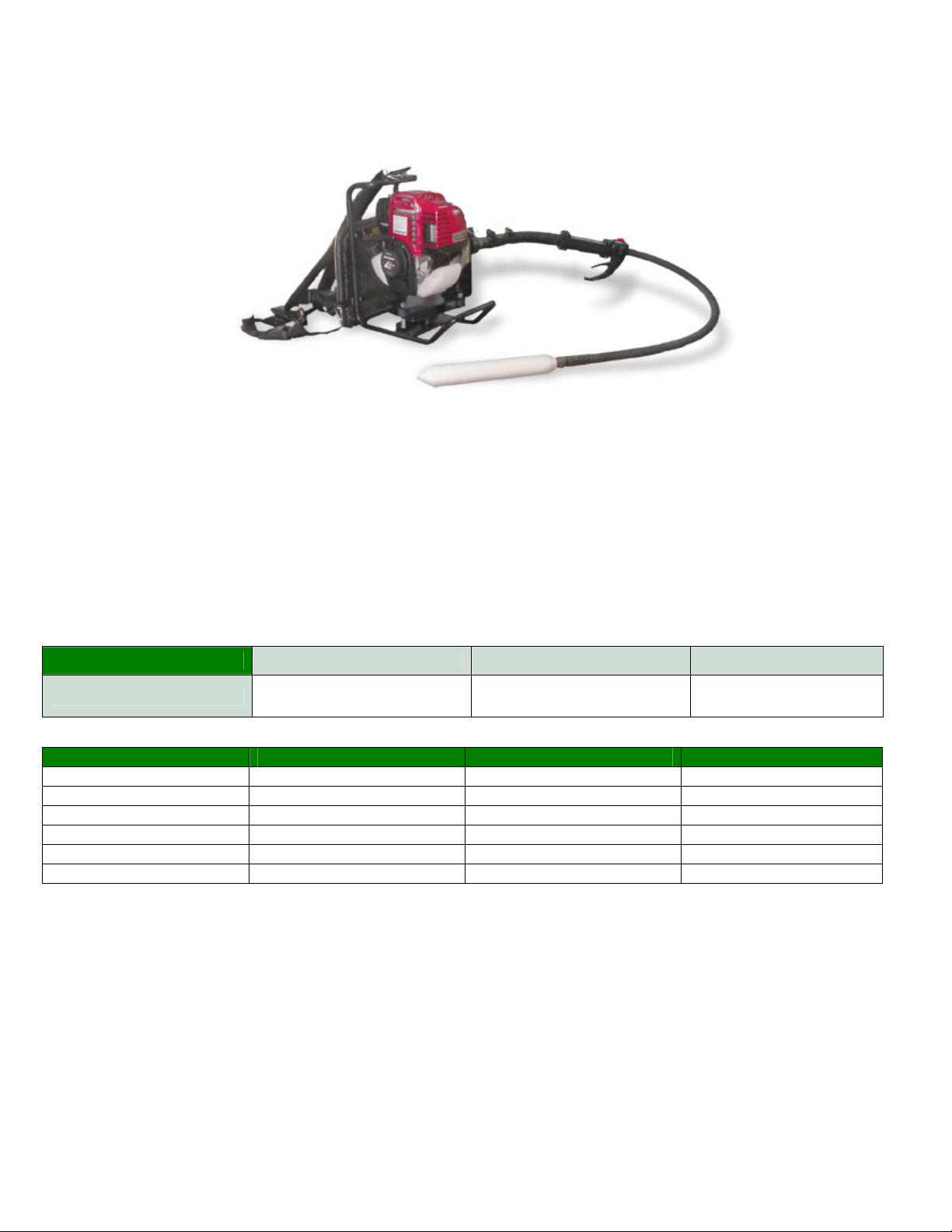

Back Pack Flex Shaft Specs.

ENGINE------------------------------------------------------------------------------- HONDA GX35 MINI 4-STROKE

POWER------------------------------------------------------------------------------------------------------ 1.3HP (1.0kw)

RPM (ENGINE/HEAD) ---------------------------------------------------------------------------------------- 8000-9000

DISPLACEMENT------------------------------------------------------------------------------------------------------35CC

FUEL CAPACITY -------------------------------------------------------------------------------------- 20 FL OZ, (.59 l)

CLUTCH----------------------------------------------------------------------------------------2 SHOE CENTRIFUGAL

IGNITION---------------------------------------------------------------------------------------------------------ELECTRIC

CARBURETOR-------------------------------- ALL POSITION DIAPHRAGM/PRIMER FOR EASY START

MOUNT ------------------------------------------------------------------------------------------------- ANTI-VIBRATION

SHAFT ------------------------------------------------------------------------------------- 7/8” (22.2mm) OD CASING

WEIGHT --------------------------------------------------------------------------------------------------19.5lbs. (8.84kg)

Recommended Shaft Length 7’ (2.1mm) 10’ (3.0m) 14’ (4.3m)

Recommended Head Sizes

Head Diameter Centrifugal Force Amplitude Diameter of Influence

3/4” (19mm) 105lbs. (467N) .050” (1.27mm) 4”-6” (101mm-152mm)

1” (25mm) 150lbs. (671N) .056” (1.42mm) 5”-7”- (127mm-177mm)

1-3/8” (35mm) 424lbs. (1886N) .070” (1.77mm) 8”-14” (203mm-355mm)

1-3/4” (45mm) 795lbs. (3536N) .102” (2.59mm) 16”-20” (406mm-508mm)

2” (50mm) 1000lbs. (4448N) .090” (2.28mm) 20”-124” (2508mm-609mm)

2-3/8” (60mm) 1186lbs. (5275N) .092” (2.33mm) 23”-27” (584mm-685mm)

3/4”, 1”, 1-3/8”,

1-3/4”, 2”, 2-3/8”

3/4”, 1”,

1-3/8”, 1-3/4”

3/4”, 1”, 1-3/8”

See Honda Engines Owners Manual for use and care of GX35 Engine

Specifications are nominal values and will vary depending on the size and range of aggregate, and the slump of the concrete.

Specifications taken at 10,500VPM.

- 6 -

Hand Held Flex Shaft Specs.

ENGINE--------------------------------------------------------------------------------HONDA GX35 MINI 4-STROKE

POWER-------------------------------------------------------------------------------------------------------1.3HP (1.0kw)

RPM (ENGINE/HEAD)-----------------------------------------------------------------------------------------8000-9000

DISPLACEMENT------------------------------------------------------------------------------------------------------ 35CC

FUEL CAPACITY ----------------------------------------------------------------------------------------20 FL OZ (.59 l)

CLUTCH----------------------------------------------------------------------------------------2 SHOE CENTRIFUGAL

IGNITION---------------------------------------------------------------------------------------------------------ELECTRIC

CARBURETOR---------------------------------ALL POSITION DIAPHRAGM/PRIMER FOR EASY START

MOUNT--------------------------------------------------------------------------------------------------ANTI-VIBRATION

SHAFT--------------------------------------------------------------------------------------7/8” (22.2mm) OD CASING

WEIGHT --------------------------------------------------------------------------------------------------19.5lbs. (8.84kg)

Recommended Shaft Length 3’ straight-rigid with 2’ flex 3’ bent-rigid with 2’ flex 2’ straight-rigid with 5’flex

Head Diameter Centrifugal Force Amplitude Diameter of Influence

3/4” (19mm) 105lbs. (467N) .050” (1.27mm) 4”-6” (101mm-152mm)

1” (25mm) 150lbs. (671N) .056” (1.42mm) 5”-7”- (127mm-177mm)

1-3/8” (35mm) 424lbs. (1886N) .070” (1.77mm) 8”-14” (203mm-355mm)

1-3/4” (45mm) 795lbs. (3536N) .102” (2.59mm) 16”-20” (406mm-508mm)

2” (50mm) 1000lbs. (4448N) .090” (2.28mm) 20”-124” (2508mm-609mm)

2-3/8” (60mm) 1186lbs. (5275N) .092” (2.33mm) 23”-27” (584mm-685mm)

See Honda Engines Owners Manual for use and care of GX35 Engine

Specifications are nominal values and will vary depending on the size and range of aggregate, and the slump of the concrete.

Specifications taken at 10,500VPM.

- 7 -

- 8 -

E-2 Crankcase Set

FIG # PART # DESCRIPTION QTY

1 012120-00001 CRANKCASE SET 1

2 012120-00002 COVER, CYLINDER HEAD 1

3 012120-00003 SEAL, HEAD COVER 1

4 012120-00004 GROMMET, HEAD COVER 1

5 012120-00005 FILTER, BREATHER 1

6 012120-00006 ARM, INTERNAL VALVE ROCKER 1

7 012120-00007 ARM, EXTERNAL VALVE ROCKER 1

8 012120-00008 LIFTER COMP., INTERNAL VAVLE 1

9 012120-00009 LIFTER COMP., EXTERNAL VALVE 1

10 012120-00010 TUBE, OIL 1

11 012120-00011 PLATE ASSEMBLY, OIL OUTLET VALVE 1

12 012120-00012 CAP ASSEMBLY, OIL FILLER 1

13 012120-00013 PACKING, OIL FILLER CAP 1

14 012120-00014 TUBE, BREATHER 1

012120-0015A

15

16 012120-00016 BOLT, SOCKET, 5 X 20 2

17 012120-00017 BOLT, SOCKET, 5 X 32 4

18

19

20 012120-00020 SCREW, TAPPET ADJUSTING 2

21 012120-00021 BOLT, SOCKET, 5 X 12 2

22 012120-00022 NUT, TAPPET ADJUSTING 2

23 012120-00023 PIN, SPRING, 4 X 10 1

24 012120-00024 CLAMP, TUBE (D12) 1

25 012120-00025 CLAMP, TUBE (D13) 1

012120-0015B

012120-0015C

012120-00018

012120-0018A

012120-00019

012120-0019A

PLUG, SPARK (CMR4H)(NGK) OPTIONAL

PLUG, SPARK (CRM5H)(NGK)

PLUG, SPARK (CRM6H)(NGK) OPTIONAL

SCREW, PAN, 4 X 8 (UP TO SERIAL # 1002284)

SCREW, PAN, 4 X 8 (FROM SERIAL # 1002285 & UP)

SCREW, PAN, 4 X 8 (UP TO SERIAL # 1002284)

SCREW, PAN, 4 X 8 (FROM SERIAL # 1002285 & UP)

(1)

1

(1)

2

2

2

2

- 9 -

Loading...

Loading...