Honda Power Equipment GVX340 User Manual

OWNER’S MANUAL

GXV340•GXV390

Gasoline or LPG Fueled Engines

.

WARNING:

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects or

other reproductive harm.

31Z1G740

00X31-Z1G-7400

CONTENTS

EM3

GXV340K2•GXV390K1

POM52355F

IPC

3,000.2004.01

PRINTED IN U.S.A.

INTRODUCTION

Thank you for purchasing a Honda engine. We want to help you to get

the best results from your new engine and to operate it safely. This

manual contains information on how to do that; please read it carefully

before operating the engine. If a problem should arise, or if you have

any questions about your engine, consult an authorized Honda

servicing dealer.

All information in this publication is based on the latest product

information available at the time of printing. American Honda Motor

Co., Inc. reserves the right to make changes at any time without notice

and without incurring any obligation. No part of this publication may be

reproduced without written permission.

This manual should be considered a permanent part of the engine and

should remain with the engine if resold.

Review the instructions provided with the equipment powered by this

engine for any additional information regarding engine startup,

shutdown, operation, adjustments or any special maintenance

instructions.

SAFETY MESSAGES

Your safety and the safety of others is very important. We have

provided important safety messages in this manual and on the engine.

Please read these messages carefully. A safety message alerts you to

potential hazards that could hurt you or others. Each safety message

is preceded by a safety alert symbol

DANGER, WARNING, or CAUTION.

These signal words mean:

DANGER

WARNING

and one of three words,

You WILL be KILLED or SERIOUSLY

HURT if you don't follow instructions.

You CAN be KILLED or SERIOUSLY

HURT if you don't follow instructions.

INTRODUCTION . . . . . . . . . . . . . . 1

Safety Messages . . . . . . . . . . . 1

Damage Prevention

Messages . . . . . . . . . . . . . . . . . . 1

Safety Information. . . . . . . . . . . 1

COMPONENT & CONTROL

LOCATION . . . . . . . . . . . . . . . . . . 2

Throttle Cable Connection . . . . 2

LPG Connection . . . . . . . . . . . . 2

Battery Connection . . . . . . . . . . 2

BEFORE OPERATION

CHECKS . . . . . . . . . . . . . . . . . . . . 3

Is Your Engine

Ready To Go . . . . . . . . . . . . . . . 3

OPERATION . . . . . . . . . . . . . . . . . 3

Safe Operating Precautions . . . 3

Starting the Engine . . . . . . . . . 3

Setting Engine Speed . . . . . . . . 3

Stopping the Engine . . . . . . . . . 4

SERVICING YOUR ENGINE . . . . . 4

The Importance of

Maintenance. . . . . . . . . . . . . . . . 4

Maintenance Safety . . . . . . . . . 4

Safety Precautions . . . . . . . . . . 4

Maintenance Schedule . . . . . . . 4

Refueling . . . . . . . . . . . . . . . . . . 5

Fuel Recommendations . . . . . . 5

Engine Oil . . . . . . . . . . . . . . . . . 5

Air Cleaner . . . . . . . . . . . . . . . . 6

Spark Plug . . . . . . . . . . . . . . . . . 6

Spark Arrester . . . . . . . . . . . . . 7

© 2000 - 2004 American Honda Motor Co., Inc.—All Rights Reserved

HELPFUL TIPS &

SUGGESTIONS. . . . . . . . . . . . . . . 7

Storing Your Engine . . . . . . . . . 7

Adding A Gasoline

Stabilizer To Extend Fuel

Storage Life . . . . . . . . . . . . . . . . 7

Draing The Fuel Tank And

Carburetor . . . . . . . . . . . . . . . . . 8

Transporting . . . . . . . . . . . . . . . 8

TAKING CARE OF UNEXPECTED

PROBLEMS. . . . . . . . . . . . . . . . . . 8

TECHNICAL & CONSUMER

INFORMATION . . . . . . . . . . . . . . . 8

Technical Information . . . . . . . 8

Serial Number Location . . . . . . 8

High Altitude Operation . . . . . . 9

Oxygenated Fuels . . . . . . . . . . . 9

Emission Control System

Information. . . . . . . . . . . . . . . . . 9

Air Index . . . . . . . . . . . . . . . . . . 10

Specifications . . . . . . . . . . . . . 10

Tuneup Specifications . . . . . . 10

Consumer Information . . . . . . 10

Honda Publications. . . . . . . . . 10

Wiring Diagram . . . . . . . . . . . . 10

Distributor’s Limited

Warranty. . . . . . . . . . . . . . . . . . 11

Emission Control System

Warranty. . . . . . . . . . . . . . . . . . 11

Distributor/Dealer Locator

Information. . . . . . . . . . . . . . . . 12

Customer Service

Information. . . . . . . . . . . . . . . . 12

CAUTION

instructions.

Each message tells you what the hazard is, what can happen, and

what you can do to avoid or reduce injury.

DAMAGE PREVENTION MESSAGES

You CAN be HURT if you don't follow

You will also see other important messages that are preceded by the

word NOTICE. This word means:

NOTICE

Your engine or other property can be

damaged if you don’t follow instructions.

The purpose of these messages is to help prevent damage to your

engine, other property, or the environment.

SAFETY INFORMATION

• Understand the operation of all controls and learn how to stop the

engine quickly in case of emergency. Make sure the operator

receives adequate instruction before operating the equipment.

• Your engine’s exhaust contains poisonous carbon monoxide. Do not

run the engine without adequate ventilation, and never run the

engine indoors.

• The engine and exhaust become very hot during operation. Keep

the engine at least 3 feet (1 meter) away from buildings and other

equipment during operation. Keep flammable materials away, and

do not place anything on the engine while it is running.

Text surrounded by a box is additional information specifically for

LPG model engines ONLY. Disregard this information if your engine

is operating on gasoline.

1

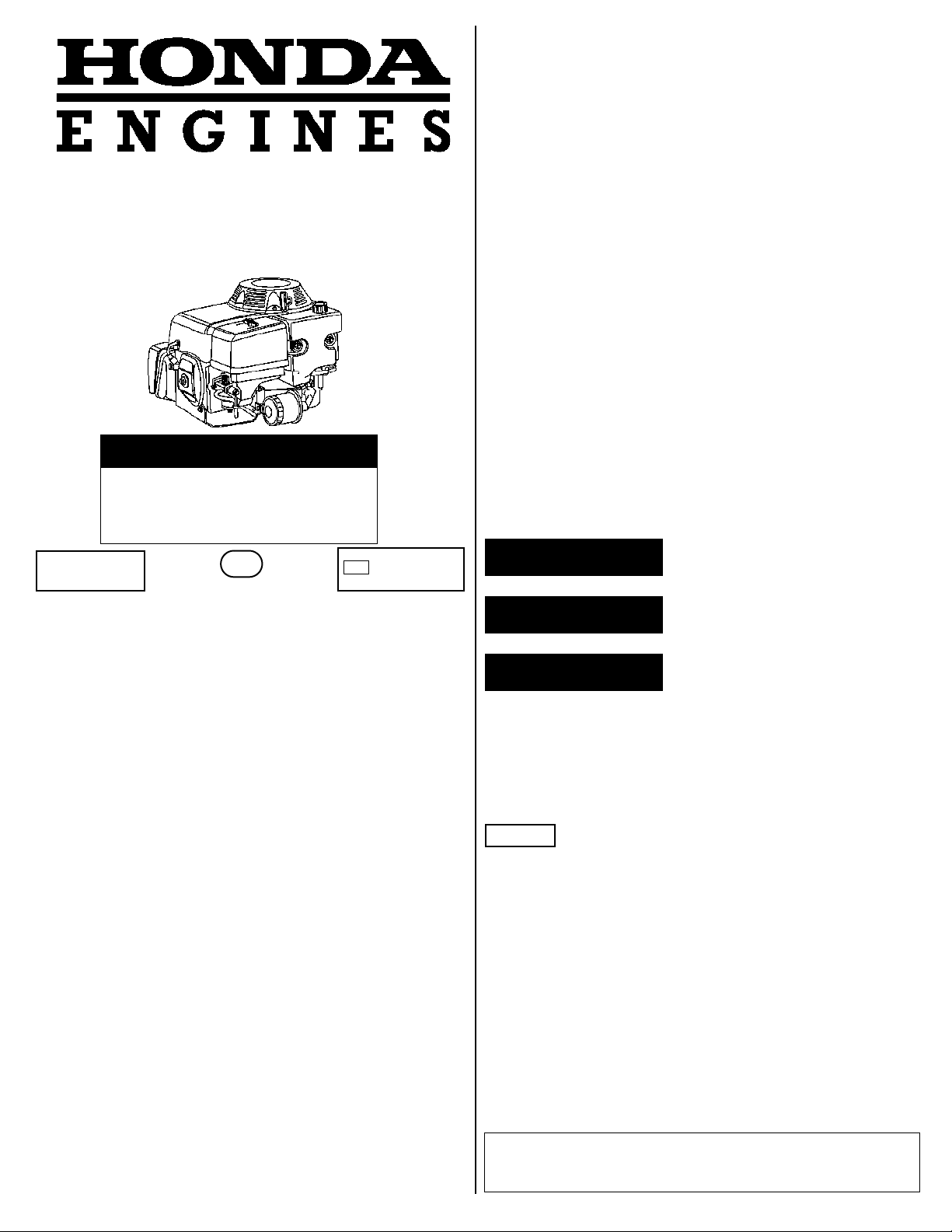

COMPONENT & CONTROL LOCATION

COOLING AIR FILTER

(LPG MODELS)

AIR FILTER

SPARK PLUG CAP

FUEL TANK CAP

OIL FILTER

THROTTLE

CONTROL

OIL FILLER CAP/

DIPSTICK

RECOIL

STARTER

GRIP

STARTER

SOLENOID

MUFFLER

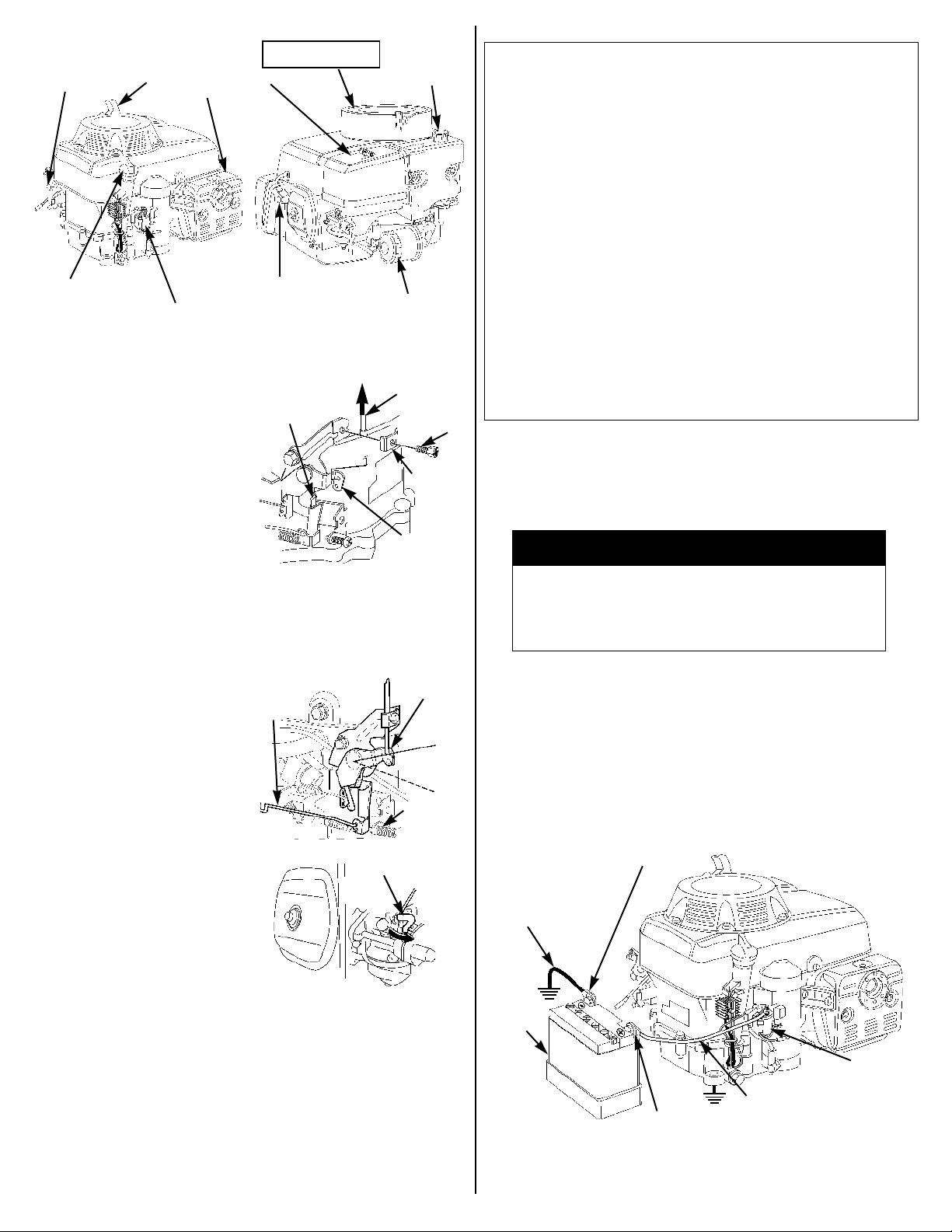

THROTTLE CABLE CONNECTION

CHOKE

THROTTLE

CABLE

5 mm

SCREW

CABLE

HOLDER

THROTTLE

LEVER

THROTTLE

LEVER

CHOKE

FAST

CHOKE

ADJUSTING

SCREW

The throttle lever is provided with

holes for attaching a solid wire

throttle cable.

CHOKE

ARM

PULL

1. Remove the 5 mm screw and

the cable holder. Hook the solid

wire cable end into the throttle

lever as shown.

2. Move the throttle cable control

(located on equipment) into the

FAST (or HIGH) throttle

position.

3. Move the throttle lever by pulling

the throttle cable until the

throttle lever just contacts the

choke arm. Install the cable

holder securing the throttle

cable and tighten it securely.

4. Move the throttle control

(located on equipment) to move

CHOKE

ROD

the throttle lever to the CHOKE

position. Verify the engine

choke rod moves the carburetor

choke fully closed. Adjust the

adjusting screw until it just

contacts the choke arm.

5. Start the engine and move the

throttle lever to the FAST (or

HIGH) position. Using a

tachometer, check the engine

speed. Loosen the cable holder

bolt and move the throttle cable

to obtain the top no load engine

speed specified by the

equipment manufacturer.

Tighten the cable holder bolt

securely.

6. Move the throttle cable control lever to the STOP position and

confirm that the engine stops.

LPG CONNECTIONS

This engine is certified to comply with U.S. EPA and California ARB

emission regulations using the Impco Beam regulator specified in the

installation instructions (see below). Honda used this regulator and

other specific parts and adjustments to demonstrate compliance with

the emission regulations. Adjustable fuel system parts must have

U.S. EPA and California ARB approved tamper resistant features to

limit the available adjustment after the fuel system is correctly

installed. If an equipment manufacturer did not install your engine in a

product you will need the installation instructions for the Honda

certified system (see below). If you choose not to use the Honda fuel

system you must use a system that has been certified by the fuel

system manufacturer to be used on this Honda engine. Or if you use

a fuel system that is not already certified you must have certification

test data satisfactory to the U.S. EPA or the California ARB. The test

data must prove that the system will meet the emission standard both

when the engine is new and at the end of its emission durability

period (250 hours).

To obtain a copy of the installation instructions for this engine, contact

an independent Honda engine distributor, or our Customer Service

Department (page 12).

BATTERY CONNECTIONS

Use a 12 volt battery with an ampere-hour rating of at least 18 AH.

Coat the terminals and cable ends with grease. Be careful not to

connect the battery in reverse polarity, as this will short circuit the

battery charging system.

WARNING

A battery can explode if you do not follow the correct

procedure, seriously injuring anyone nearby.

Keep all sparks, open flames, and smoking materials away

from the battery.

1. Connect the battery positive (+) cable to the starter solenoid

terminal as shown.

2. Connect the battery negative (-) cable to an engine mounting bolt,

frame bolt, or other good engine ground connection.

3. Connect the battery positive (+) cable to the battery positive (+)

terminal as shown.

4. Connect the battery negative (-) cable to the battery negative (-)

terminal as shown.

BATTERY NEGATIVE (-)

TERMINAL

BATTERY

NEGATIVE (-)

CABLE

BATTERY

STARTER

SOLENOID

BATTERY POSITIVE (+)

BATTERY POSITIVE

(+) TERMINAL

CABLE

2

BEFORE OPERATION CHECKS

IS YOUR ENGINE READY TO GO?

For your safety, and to maximize the service life of your equipment, it

is very important to take a few moments before you operate the engine

to check its condition. Be sure to take care of any problem you find, or

have your servicing dealer correct it, before you operate the engine.

WARNING

Improperly maintaining this engine, or failure to correct a

problem before operation, can cause a malfunction in

which you can be seriously hurt or killed. Always perform a

preoperation inspection before each operation, and correct

any problem.

Before beginning your preoperation checks, be sure the engine is level

and the throttle lever is in the STOP position. Always check the

following items before you start the engine:

1. Fuel level (see page 5).

2. Oil level (see page 5).

3. Air cleaner (see page 6).

4. LPG models: cooling air filter (see page 6).

5. General inspection: Check for fluid leaks and loose or damaged

parts.

6. Check the equipment powered by this engine.

Review the instructions provided with the equipment powered by

this engine for any precautions and procedures that should be

followed before engine startup.

LPG EQUIPMENT

Carefully follow the installation and operating instructions of the LPG

equipment manufacturer.

OPERATION

SAFE OPERATING PRECAUTIONS

Before operating the engine for the first time, please review the

SAFETY INFORMATION section on page 1 and the BEFORE

OPERATION CHECKS section above.

WARNING

Carbon monoxide gas is toxic. Breathing it can cause

unconsciousness and even kill you. Avoid any areas or

actions that expose you to carbon monoxide.

Review the instructions provided with the equipment powered by this

engine for any safety precautions that should be observed with engine

startup, shutdown, or operation.

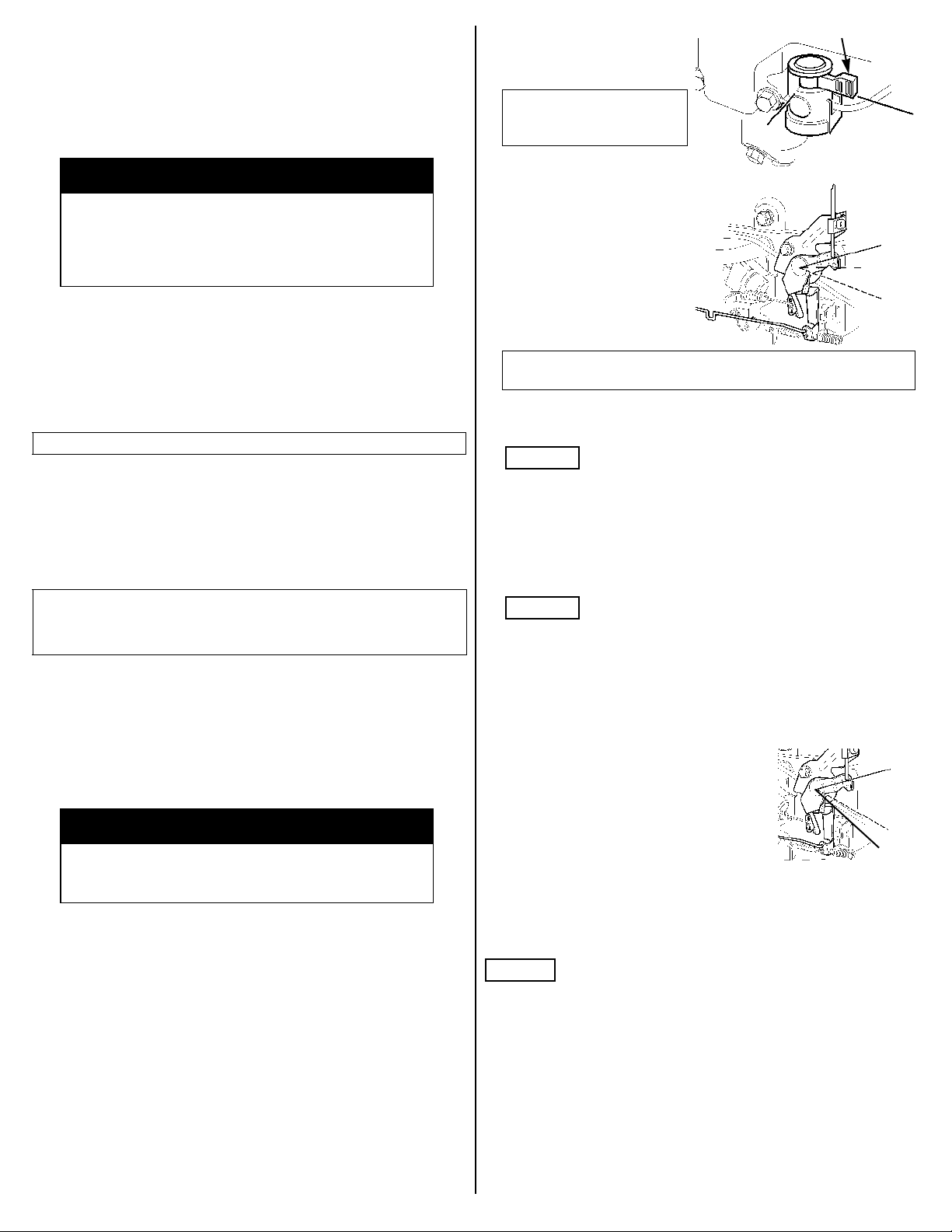

STARTING THE ENGINE

1. Turn the fuel valve to the ON

position.

LPG Models:

Turn the fuel valve on at the

source.

2. STARTING A COLD

ENGINE:

Move the throttle control to

the CHOKE position.

STARTING A WARM

ENGINE:

Do not use the CHOKE

position when the engine is

warm. Move the throttle

control slightly past the

SLOW position.

LPG Models:

Always use the CHOKE position when starting the engine.

3. Recoil Start Models

Pull the starter grip lightly until resistance is felt, then pull briskly.

NOTICE

Do not allow the starter grip to snap back against the engine.

Return it gently to prevent damage to the starter.

4. Electric Start Models

Turn the engine switch to the START position, and hold it there until

the engine starts. When the engine starts, allow the engine switch

to return to the ON position.

NOTICE

Do not use the starter for more than 5 seconds or starter motor

damage may occur. If the engine fails to start, release the switch

and wait 10 seconds before operating the starter again.

5. If the choke was used to start the engine, move the throttle to the

FAST (or HIGH) position as soon as the engine warms up enough

to run smoothly without use of the choke.

SETTING ENGINE SPEED

Position the throttle control for the desired

engine speed. For best engine performance, it

is recommended the engine be operated with

the throttle in the FAST (or high) position.

OIL ALERT® BUZZER

FUEL VALVE LEVER

ON

CHOKE

FAST

SLOW

FAST

SLOW

OFF

(oil alert type only)

The OIL ALERT buzzer will warn you before the engine oil level falls

below the safe operating limit. If the buzzer sounds, stop the engine

immediately and add oil (see page 5).

NOTICE

The buzzer indicates insufficient oil. Running the engine with

insufficient oil can cause serious engine damage.

3

STOPPING THE ENGINE

1. Recoil Start Models

Move the throttle control to the

SLOW position.

2. Move the throttle control to the

stop position.

Electric Start Models

SLOW

OFF

Move the throttle control to the

slow position, then turn the

engine switch to the OFF or

STOP position.

3. Turn the fuel valve lever to the

FUEL VALVE LEVER

OFF position if you do not

intend to restart the engine

soon.

LPG Models:

Turn the fuel valve OFF at

the source.

OFF

SERVICING YOUR ENGINE

THE IMPORTANCE OF MAINTENANCE

Good maintenance is essential for safe, economical and trouble-free

operation. It will also help reduce pollution.

WARNING

Improper maintenance, or failure to correct a problem

before operation, can cause a malfunction in which you

can be seriously hurt or killed. Always follow the inspection

and maintenance recommendations and schedules in this

owner’s manual.

To help you properly care for your engine, the following pages include

a maintenance schedule, routine inspection procedures, and simple

maintenance procedures using basic hand tools. Other service tasks

that are more difficult, or require special tools, are best handled by

professionals and are normally performed by a Honda technician or

other qualified mechanic.

The maintenance schedule applies to normal operating conditions. If

you operate your engine under severe conditions, such as sustained

high-load or high-temperature operation, or use in unusually wet or

dusty conditions, consult your servicing dealer for recommendations

applicable to your individual needs and use.

Maintenance, replacement, or repair of the emission control

devices and systems may be performed by any engine repair

establishment or individual, using parts that are “certified” to

EPA standards.

MAINTENANCE SAFETY

Some of the most important safety precautions follow. However, we

cannot warn you of every conceivable hazard that can arise in

performing maintenance. Only you can decide whether or not you

should perform a given task.

SAFETY PRECAUTIONS

• Make sure the engine is off before you begin any maintenance or

repairs. This will eliminate several potential hazards:

– Carbon monoxide poisoning from engine exhaust.

Be sure there is adequate ventilation whenever you operate

the engine.

– Burns from hot parts.

Let the engine and exhaust system cool before touching.

– Injury from moving parts.

Do not run the engine unless instructed to do so.

• Read the instructions before you begin, and make sure you have

the tools and skills required.

• To reduce the possibility of fire or explosion, be careful when

working around gasoline. Use only a nonflammable solvent, not

gasoline, to clean parts. Keep cigarettes, sparks and flames away

from all fuel related parts.

Remember that an authorized Honda servicing dealer knows your

engine best and is fully equipped to maintain and repair it.

To ensure the best quality and reliability, use only new genuine Honda

parts or their equivalents for repair and replacement.

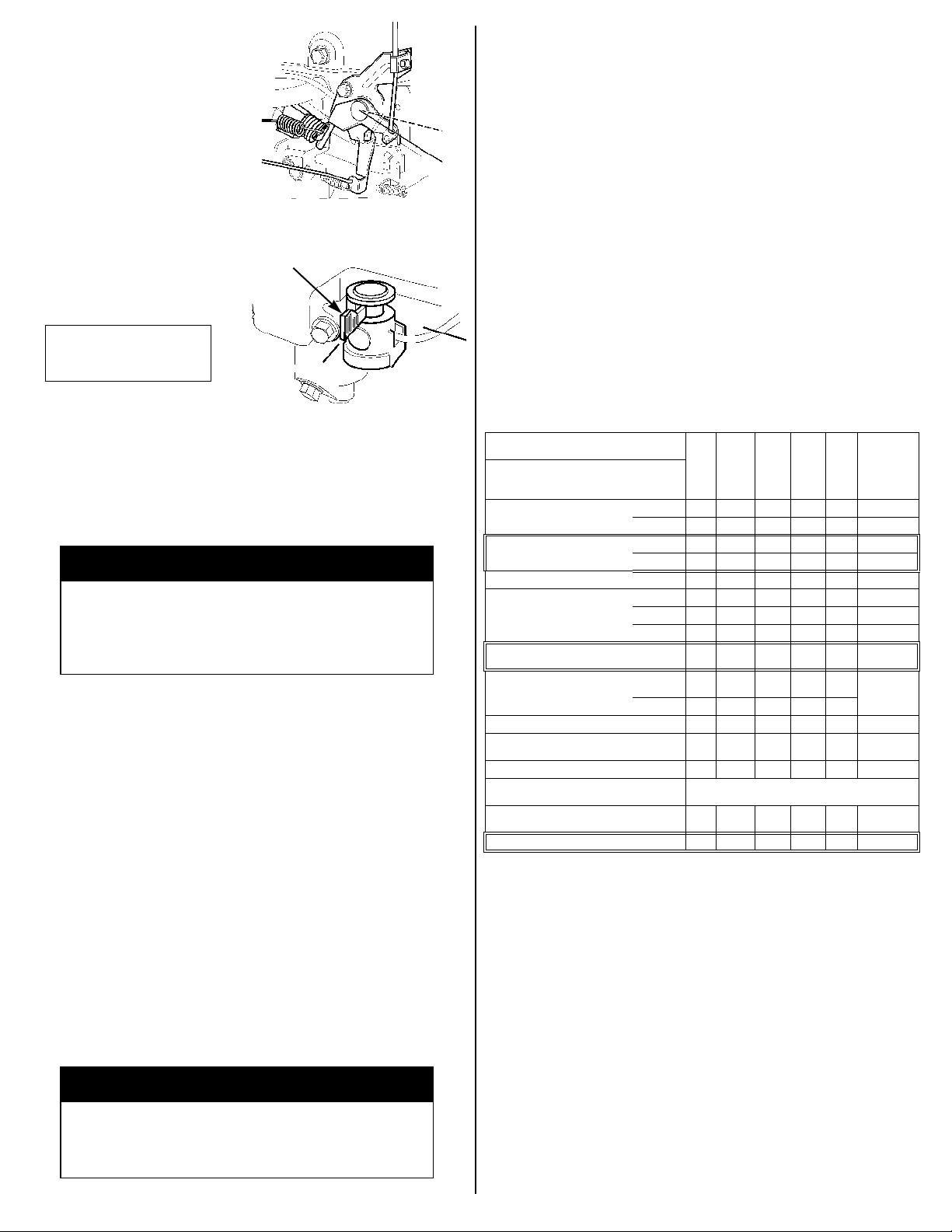

MAINTENANCE SCHEDULE

Every

Every 6

REGULAR SERVICE

ITEM

Perform at every indicated month or operating

hour interval, whichever comes first.

Engine oil Check

Engine oil

(LPG models)

Engine oil filter Replace

Air filter Check

Cooling air filter

(LPG models)

Spark plug Check-

Spark arrester (optional part) Clean

Idle speed Check-

Fuel tank and filter Clean

Fuel line Check Every 2 years

Valve clearance Check-

Fuel hose (LPG models) Check

PERIOD (3)

Replace

Check level

Change

Clean

Replace

Clean

adjust

Replace

adjust

adjust

Each

Use

O5

O5

O6

O (1) 6

O-

(1) Service more frequently when used in dusty areas.

(2) Change engine oil every 25 hours when used under heavy load or

in high ambient temperatures.

(3) These items should be serviced by an authorized Honda servicing

dealer, unless you have the proper tools and are mechanically

proficient. Refer to the Honda shop manual for service

procedures.

(4) For commercial use, log hours of operation to determine proper

maintenance intervals.

Every 3

First

Months

Month

or

or

50 Hrs

20 Hrs

OO 5

OO 5

O (1) 6

(Replace if necessary)

Year

Months

or

100 Hrs

O

O7

O(3) -

O(2) -

O(2) -

Page

or

300

Hrs

O6

O6

O

6

WARNING

Failure to properly follow maintenance instructions and

precautions can cause you to be seriously hurt or killed.

Always follow the procedures and precautions in this

owner’s manual.

4

REFUELING

Use unleaded gasoline with a pump octane rating of 86 or higher. This

engine is certified to operate on unleaded gasoline. Unleaded gasoline

produces fewer engine and spark plug deposits and extends exhaust

system life.

WARNING

Gasoline is highly flammable and explosive, and you can

be burned or seriously injured when refueling.

• Stop engine and keep heat, sparks, and flame away.

• Refuel only outdoors.

• Wipe up spills immediately.

NOTICE

Fuel can damage paint and some types of plastic. Be careful not to

spill fuel when filling your fuel tank. Damage caused by spilled fuel is

not covered under the Distributor’s Limited Warranty (see page 11).

Never use stale or contaminated

gasoline or oil/gasoline mixture.

Avoid getting dirt or water in the

fuel tank.

Adding Fuel

1. Remove the fuel tank cap.

2. Add fuel to the bottom of the

fuel level limit in the neck of

the fuel tank. Do not overfill.

Wipe up spilled fuel before

starting the engine.

Fuel tank capacity: 0.61 US gal (2.3 )

3. Reinstall the fuel tank cap.

ENGINE OIL

Recommended Oil

Use 4-stroke motor oil that meets

or exceeds the requirements for

API service classification SH, SJ,

or equivalent. Always check the

API service label on the oil

container to be sure it includes the

letters SH, SJ, or equivalent.

SAE 10W-30 is recommended for general use. Other viscosities

shown in the chart may be used when the average temperature in your

area is within the indicated range.

FUEL TANK CAP

FUEL

LEVEL

LIMIT

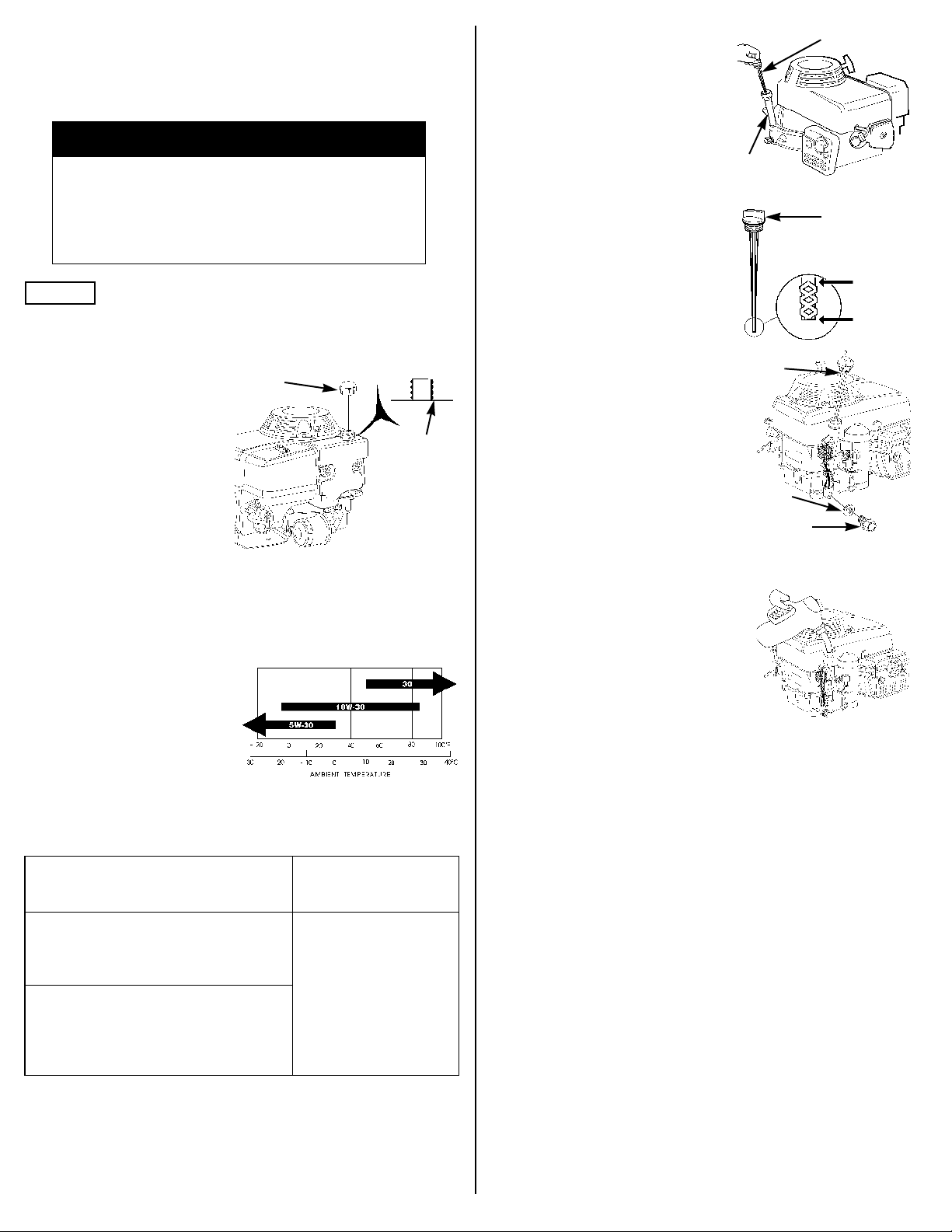

Oil Level Check

OIL FILLER CAP/DIPSTICK

1. Check the oil with the engine

stopped and level.

2. Remove the oil filler cap/dipstick and

wipe it clean.

3. Insert the oil filler cap/dipstick into

the oil filler neck as shown. Do not

screw it in, then remove it to check

OIL FILLER

NECK

the oil level.

4. If the oil level is near or below the

lower limit mark on the dipstick,

OIL FILLER

CAP/DIPSTICK

remove the oil filler cap/dipstick, and

fill with the recommended oil to the

upper limit mark. Do not overfill.

5. Reinstall the oil filler cap/dipstick.

Oil Change

Drain the engine oil when the engine is

warm. Warm oil drains quickly and

completely.

OIL FILLER

CAP/

DIPSTICK

UPPER

LIMIT

LOWER

LIMIT

1. Place a suitable container next to the

oil drain bolt.

2. Wipe the oil filter area clean, then

remove the oil filler cap/dipstick.

3. Remove the oil drain bolt and sealing

washer and allow the oil to drain into

a suitable container. After draining,

SEALING

WASHER

DRAIN BOLT

install the drain bolt with the sealing

washer and tighten it securely.

4. Fill with the recommended oil. Do not

overfill. Measure the oil level as shown

above.

Engine Oil Capacity: 1.16 US qt (1.1 )

with oil filter: 1.48 US qt (1.4 )

Please dispose of used motor oil and the oil containers in a manner

that is compatible with the environment. We suggest you take used oil

in a sealed container to your local recycling center or service station

for reclamation. Do not throw it in the trash or pour it on the ground or

down a drain.

Recommended Oil

(LPG models)

Use 4-stroke motor oil that is designed for

engines operating on LPG fuel. Use one

of the recommended oils that meet

Honda’s requirements.

For operation in temperatures below 32°F

(0°C), 5W-30 synthetic oil may be used

for easier starting. Do not use 5W-30

when the air temperature is above 32°F

(0°C).

Use SAE 30, API

service classification

SG minimum

Pennzoil HD 30

Valvoline HPO 30

Castrol HD 30

5

Loading...

Loading...