Honda Power Equipment GPX 165 User Manual

GPX 165

SprayTECH

1770 Fernbrook Lane

Minneapolis, MN 55447

Technical Assistance: 1-800-292-4637

Order Entry: 1-800-443-4500

Fax: 1-800-525-9501

www.spraytechinc.com

Gas Piston Pump

Do not use this equipment before reading this manual!

Owner’s Manual

NOTE: This manual contains important warnings and

Printed in the U. S. A.

instructions. Please read and retain for reference.

Model Numbers:

Bare 0509009

Complete 0509039

Bare w/5 Gal. Siphon 0509055

Complete w/5 Gal. SIphon 0509059

0306 © 2006 SprayTECH. All rights reserved. Form No. 0555890A

Table of Contents

WARNING

CAUTION

WARNING

afety Precautions.................................................................2

S

rançais ..............................................................................18

F

spañol...............................................................................20

E

pecifications .........................................................................3

S

eneral Description ...............................................................4

G

peration ................................................................................4

O

etup ....................................................................................4

S

reparing to Paint.................................................................4

P

ainting.................................................................................5

P

ressure Relief Procedure ...................................................6

P

praying ..................................................................................6

S

praying Technique ..............................................................6

S

ractice.................................................................................6

P

leanup ...................................................................................7

C

aintenance............................................................................7

M

eneral Repair and Service Notes.......................................7

G

aintaining the Engine .........................................................8

M

eplacing the Filter...............................................................8

R

Replacing the PRIME/SPRAY Valve.....................................8

Replacing the Potentiometer ................................................9

Replacing the Sprayer ON/OFF Switch................................9

Replacing the Transducer...................................................10

Replacing the Electronic Pressure Control (EPC)

Replacing the Slider

Replacing the Gears

Servicing the Clutch

Servicing the Fluid Section

Troubleshooting ...................................................................17

Parts Listings........................................................................22

Main Assembly....................................................................22

Drive Assembly...................................................................23

Fluid Section Assembly ......................................................24

Cart Assembly.....................................................................25

Filter Assembly ...................................................................25

PRIME/SPRAY Assembly ...................................................26

5 Gallon Siphon Set (optional) ...........................................26

Electrical Schematic ...........................................................27

Labels .................................................................................27

Accessories ........................................................................27

Limited Warranty..................................................................28

Assembly and Slider Housing............11

...........................................................12

Assembly ...........................................12

.................................................14

Assembly.10

B. WARNING – To reduce the risk of fire or explosion:

1. Do not spray flammable or combustible materials near

an open flame, pilot lights or sources of ignition such as

hot objects, cigarettes, motors, electrical equipment and

electrical appliances. Avoid creating sparks from

connecting and disconnecting power cords.

2. For units intended for use with only water-based

materials — Do not spray or clean with flammable

liquids. For use with water-based liquids only.

3. For units intended for use with only water-based or

mineral spirit-type materials with a minimum flash point

of 21ºC (69.8ºF) — Do not spray or clean with liquids

having a flash point of less than 21ºC (69.8ºF). Flash

point is the temperature at which a fluid can produce

enough vapor to ignite.

4. Paint or solvent flowing through the equipment is able

to result in static electricity. Static electricity creates a

risk of fire or explosion in the presence of paint or

solvent fumes. All parts of the spray system, including

the pump, hose assembly, spray gun and objects in and

around the spray area shall be properly grounded to

protect against static discharge and sparks. Use only

conductive or grounded high-pressure airless paint

sprayer hoses specified by the manufacturer.

5. Verify that all containers and collection systems are

grounded to prevent static discharge.

6. For electric units — connect to a grounded outlet and use

grounded extension cords. Do not use a 3 to 2 adapter.

7. Do not use a paint or solvent containing halogenated

AN 1td foe asseeS25.1td214.294 14cqN 1td fo6]TJ waterCp[(spr.49 5i4d[ 125.44nstruction 5sd[ 125.44n1ide1py(7c7 u(3.)9l21lowi384 118 l114.19 01rpr.7pr.491ini(25sd[ 125.44n1ide7Aj[(spr.49 5i4d[ 125.4454-e)]TJ1rp[ 1)225sprs53*4e with 85i4d[ 1clu6 298.5164 112phall2prw[ l6or)]TJ4]TJe2(V)54(or)]TJ4]s s214.294 29J4ro6]TJ wr.73ya[(lilar19 01rpr.73ya[(.7137 c1-d3 m1156]TJ21gat8 8a 5i4dwooe)55ed)]TJ/Go[(.7cflMnded high-pressur[ 5294 29J4rolAic124.0 unno 29 -11.14485 -1.2804ro6]TJ( (lild[ 2(n sI1de)-1(d ou(nere 1e4 29J4ro6]TJ w2he)-1(d ou(nere 1e4 29J4ro6]TJ w2he)-1(d ou(nere 1e4 29J4ro6]TJ discharge and sparkTJ discharge a8[(TJ c6SR1.14nstTJ022 747.6556 Tmrgentainers 56 Tmrg4phargeAa029Js4ro654 oud ext2s 5i4d oeates a)][55e759ch8 e)-1(d oud spw1gat8 dla)]emperatue1I1d5q122 eea)]empera7528 w2he)Ie 1e4 29J4ro6TNilar19[ 1c447re aar190 kh2spr.49 5i4d[ 125.44nstruction p4 unno truc92 flMnr190 kh2sprRHf 5iionhali5.44nsth2ext2s 5i4d o1de)v2he)Ie sion cords. Do not use a 3 to 2 adapter)55(.)]TJ-1.14485 -125h2sprRHfO6) siond oarkTJ r7t5 si25N54]s s2hhargeAa026 T22nv3i Do not r7t i 5iio a 3 to 2 adapter)55(.)]TJ-1.14485 -125h2sprRHfO697.4t5 s25N54]s s2J r7t5 st spray oargde.r7t5 soele s(97la5N54]s dapte...22 1ioele s(97.4t5 s25N54]s s2J r7t5 st spray oargde.r7t5 soele s(97la5N54]s d 298.7116 cle s(97cga )5e so2acle s(97 s2 )5 nost spray0 8l su4ro6r05L45 m1108s26r0O6) siond oarkTJ 4r0O6) siond 9(97 70wm solnd (nd u 9(97 1e872 311.21nd u23th f)-1(do21n0 u23tark s 1elnd4]s30 uA3tark252.1ATmrgentai27 4e s 5.4s 597.48 reventioele s(971 m1108s26r0O6rK11S m1108s26r0O6re23ta Ire aar190 kh2(s644nt-qBHtark252.7 s2 )5 asol71 m1108s26r0O6rK11S m11)rNf)-1(do8096 071tay o1)r031w6 071tay-08el to lp3tar Fscha1108s26r0Or8 244.6l to lp3t8s232.4ro6r0552.7 s2 )c14.085 307 SN54]s s2J r7t5 st sprS1-e)]Tc2J r7t23th f)-1(do21n0 u23tark s 1elnd4E2.7 s2 )Elp3t-1(do82 316.7343th ss 44nt-ql6nypJ/Gtd )Ai or97la5N54]s d 298ro6r0552.7 s2

nr71 m1108s26r0O6rK11S m1108s26r0O6re23ta Ire aar190 kh2(s644nt-qBHl7Fewat141 04nt-qBHta2 8o6t141 -1 04nqrb[rk252.7134037nerW47.244.6l to lp3t8s232.4ro6r0552.7 s2 8o6r0ss 44nt-ql6n6-1 04nqrb[0ssto lpW3i1108s26rr47.2(TJ l)118 ero60ct corea 3 to2(s644.t co6la)q 6 cle s(97cg co6la)q 661 gh v47.aV)54(or)Elp3t8s232.4rd oarkTJ e1 mhy134847 s2 2 p35 oul(34847 s2 tpp5l7Fe7....s2 2.6556edmn3a7S53i115sa44nt412ext2s 5i4d.444256edmn3io13r7t5 st sei5kTJ e1 mhy1 16.1269 135.4809 23ta2 8o6t141 -11Es809 d u2i51[s4 6r0ss 597.48sprRHfO6) sf53Er218g1115sa44nt412ext2s47.48 r484 Tm(412exo1 jela)q 661 11 Tmrg4phm f7.

Safety Precautions

This manual contains information that must be read and

understood before using the equipment. When you come to

an area that has one of the following symbols, pay particular

attention and make certain to heed the safeguard.

This symbol indicates a potential hazard that may cause

serious injury or loss of life. Important safety information

will follow.

This symbol indicates a potential hazard to you or to the

equipment. Important information that tells how to

prevent damage to the equipment or how to avoid causes

of minor injuries will follow.

NOTE: Notes give important information that should

A. SAVE THESE INSTRUCTIONS – To reduce the risks of

be given special attention.

IMPORT

fire or explosion, electrical shock, and the injury to

persons, read and understand all instructions

included in this manual. Be familiar with the controls

and the proper usage of the equipment.

ANT SAFETY

INSTRUCTIONS

2 © SprayTECH. All rights reserved.

3. Always use the nozzle tip guard. Do not spray without

WARNING

WARNING

CAUTION

the nozzle tip guard in place.

. Only use a nozzle tip specified by the manufacturer.

4

5. Use caution when cleaning and changing nozzle tips.

In the case where the nozzle tip clogs while spraying,

ALWAYS lock gun trigger, shut pump off, and release

all pressure before servicing, cleaning tip or guard, or

changing tip. Pressure will not be released by turning

off the motor. The PRIME/SPRAY valve handle must

be turned to PRIME to relieve the pressure. Refer to

PRESSURE RELIEF PROCEDURE described in the

pump manual.

6. Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit

and relieve the pressure in accordance with the

manufacturer’s instructions.

7. High-pressure spray is able to inject toxins into the

body and cause serious bodily injury. In the event that

injection occurs, seek medical attention immediately.

8. Check hoses and parts for signs of damage, a leak can

inject material into the skin. Inspect hose before each

use. Replace any damaged hoses or parts.

9. This system is capable of producing 3300 PSI / 22.8

MPa. Only use replacement parts or accessories that

are specified by the manufacturer and that are rated a

minimum of 3300 PSI. This includes spray tips, nozzle

guards, guns, extensions, fittings, and hose.

10. Always engage the trigger lock when not spraying.

Verify the trigger lock is functioning properly.

11. Verify that all connections are secure before operating

the unit.

12. Know how to stop the unit and bleed pressure quickly.

Be thoroughly familiar with the controls. Pressure will

not be released by turning off the motor. The

PRIME/SPRAY valve handle must be turned to PRIME

to relieve the pressure. Refer to PRESSURE RELIEF

PROCEDURE described in the pump manual.

13. Always remove the spray tip before flushing or cleaning

the system.

D. WARNING – To reduce the risk of injury:

1. Always wear appropriate gloves, eye protection,

clothing and a respirator or mask when painting.

Hazardous vapors – Paints, solvents, insecticides, and

other materials can be harmful if inhaled or come in

contact with body. V

fainting or poisoning.

2. Do not operate or spray near children. Keep children

away from equipment at all times.

3. Do not overreach or stand on an unstable support.

Keep effective footing and balance at all times.

Stay alert and watch what you are doing.

4.

5. Do not operate the unit when fatigued or under the

influence of drugs or alcohol.

Do not kink or over-bend the hose. Airless hose can

6.

develop leaks from wear

can inject material into the skin.

7. Do not expose the hose to temperatures or pressures in

excess of those specified by manufacturer.

Do not use the hose as a strength member to pull or lift

8.

the equipment.

9. Use lowest possible pressure to flush equipment.

Follow all appropriate local, state and national codes

10.

governing ventilation, fire prevention and operation.

11. The United States Government Safety Standards have

been adopted under the Occupational Safety and

Health Act (OSHA). These standards, particularly part

1910 of the General Standards and part 1926 of the

Construction Standards should be consulted.

apors can cause severe nausea,

, kinking and abuse. A

leak

12. Before each use, check all hoses for cuts, leaks,

abrasion or bulging of cover. Check for damage or

movement of couplings. Immediately replace hose if

any of those conditions exist. Never repair a paint hose.

Replace with a conductive high-pressure hose.

3. Do not spray outdoors on windy days.

1

14. Always unplug cord from outlet before working on

equipment.

Do not lift by cart handle when loading or unloading.

Gasoline Engine Safety

The engine exhaust from this unit contains chemicals

known to the State of California to cause cancer, birth

defects, or other reproductive harm.

1. Gas engines are designed to give safe and dependable

service if operated according to instructions. Read and

understand the engine Owner's Manual before operating

the engine. Failure to do so could result in personal injury

or equipment damage.

2. To prevent fire hazards and to provide adequate

ventilation, keep the engine at least 1 meter (3 feet) away

from buildings and other equipment during operation. Do

not place flammable objects close to the engine.

3. Children and pets must be kept away from the area of

operation due to a possibility of burns from hot engine

components or injury from any equipment the engine may

be used to operate.

4. Know how to stop the engine quickly, and understand the

operation of all controls. Never permit anyone to operate

the engine without proper instructions.

5. Gasoline is extremely flammable and is explosive under

certain conditions.

6. Refuel in a well-ventilated area with the engine stopped.

Do not smoke or allow flames or sparks in the refueling

area or where gasoline is stored.

7. Do not overfill the fuel tank. After refueling, make sure the

tank cap is closed properly and securely.

8. Be careful not to spill fuel when refueling. Fuel vapor or

spilled fuel may ignite. If any fuel is spilled, make sure the

area is dry before starting the engine.

9. Never run the engine in an enclosed or confined area.

Exhaust contains poisonous carbon monoxide gas;

exposure may cause loss of consciousness and may lead

to death.

10. The muffler becomes very hot during operation and

remains hot for a while after stopping the engine. Be

careful not to touch the muffler while it is hot. To avoid

severe burns or fire hazards, let the engine cool before

transporting it or storing it indoors.

11. Never ship/transport unit with gasoline in the tank.

Specifications

Gallons per minute (GPM)...............1.65 (6.25 LPM)

Maximum tip size .............................one gun = 0.042”

Maximum pressure ..........................3300 PSI (22.8 MPa)

...............................................

Power

Weight..............................................164 lbs. (74.4 kg)

Maximum hose length......................300’ (91.4 m)

two guns = 0.029”

three guns = 0.023”

four guns = 0.020”

7.0 HP

gas engine

© SprayTECH. All rights reserved. 3

General Description

CAUTION

WARNING

WARNING

his airless sprayer is a precision power tool used for spraying

T

any types of materials. Read and follow this instruction

m

anual carefully for proper operating instructions,

m

aintenance, and safety information.

m

Operation

This equipment produces a fluid stream at extremely high

pressure. Read and understand the warnings in the

Safety Precautions section at the front of this manual

before operating this equipment.

Setup

Perform the following procedure before starting the engine of a

gas-powered sprayer.

1. Ensure that the siphon tube and the return hose are

attached and secure.

2. Attach the supplied grounding cable to a grounded object.

3. Using a wrench, attach a minimum of 50’ of 3/8” nylon

airless spray hose to the 3/8” outlet fitting on the filter

assembly. Tighten securely.

NOTE: Use 3/8” spray hose for maximum performance,

4. Attach an airless spray gun to the spray hose. Using two

NOTE: Do not attach the tip to the spray gun yet.

Make sure all airless hoses and spray guns are electrically

grounded and rated at or above the maximum operating

pressure range of the airless sprayer.

5.

6. Make sure the sprayer ON/OFF switch is in the OFF position.

7.

minimum pressure drop, and minimum

pressure fluctuation.

wrenches (one on the gun and one on the hose), tighten

securely.

Remove the tip if it is already attached.

urn the pressure control knob fully counterclockwise to

T

its lowest pressure setting.

Fill the fluid section oil cup with approximately one

tablespoon of separating oil (P/N 0279920).

Never operate unit for more than ten seconds without

fluid. Operating this unit without fluid will cause

unnecessary wear to the packings.

4. Move the PRIME/SPRAY valve to the PRIME position.

WARNING

WARNING

WARNING

WARNING

NOTE: Hold the return hose in the waste container

5. Move the engine ON/OFF switch to the ON position.

6. Start the engine:

7. Turn on the sprayer by moving the sprayer ON/OFF

. Slowly turn the pressure control knob clockwise to increase

8

9. Allow the sprayer to run for 15–30 seconds to flush the old

10. Turn the pressure control knob fully counterclockwise to

11. Turn off the sprayer by moving the sprayer ON/OFF

NOTE: Make sure that the spray gun does not have a

12. Move the PRIME/SPRAY valve to the SPRAY position.

13. Turn on the sprayer.

14. Turn the pressure control knob slowly clockwise to

15. Unlock the gun by turning the gun trigger lock to the

when moving the PRIME/SPRAY valve to

PRIME in case the sprayer is pressurized.

a. Open the fuel valve lever.

b. Move the throttle lever away from the gas tank.

c. Close the engine choke lever.

d. Holding the frame with one hand, pull the starter rope

rapidly and firmly. Continue to hold the rope as you let it

return. Pull and return the rope until the engine starts.

switch to the ON position.

he pressure until fluid starts to come out of the return hose.

t

Use only enough pressure to keep the fluid coming out.

solvent out through the return hose and into the metal

waste container.

its lowest setting.

switch to the OFF position.

tip or tip guard installed.

increase pressure.

unlocked position.

c. Close the engine

choke lever.

d. Holding the frame

with one hand, pull

the starter rope

rapidly and firmly.

Continue to hold

the rope as you let

it return. Pull and

return the rope until

the engine starts.

7. Turn on the sprayer

by moving the sprayer ON/OFF switch to the ON position.

8. Slowly turn the pressure control

knob clockwise to increase the

pressure until fluid starts to

come out of the return hose.

Use only enough pressure to

keep the fluid coming out.

9. Allow the sprayer to run until

paint is coming through the

return hose into the metal

waste container.

10. Turn the pressure control knob fully counterclockwise to

its lowest setting.

11. Turn off the sprayer by moving the sprayer ON/OFF

switch to the OFF position.

12. Remove the return hose from the waste container and place

it in its operating position above the container of paint.

13. Move the PRIME/SPRAY valve to the SPRAY position.

14. Turn on the sprayer.

15. Turn the pressure control knob slowly clockwise to

increase pressure.

16. Unlock the gun by turning the gun trigger lock to the

unlocked position.

Ground the gun by holding it against the

edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may cause a fire.

16. Trigger the gun into the metal waste container until the old

solvent is gone and fresh solvent is coming out of the gun.

17. Lock the gun by turning the gun trigger lock to the locked

position.

18. Set down the gun and increase the pressure by turning the

pressure control knob slowly clockwise to its highest setting.

19. Check the entire system for leaks. If leaks occur, turn the

sprayer off and follow the “Pressure Relief Procedure” in

this manual before tightening any fittings or hoses.

20. Follow the “Pressure Relief Procedure” in this manual

before changing from solvent to paint.

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

Painting

1. Place the siphon tube into a container of paint.

2. Place the return hose into a metal waste container.

3. Turn the pressure control knob fully counterclockwise to

its lowest pressure setting.

4. Move the PRIME/SPRAY valve to the PRIME position.

5. Move the engine ON/OFF switch to the ON position.

6. Start the engine:

a. Open the fuel valve lever.

b. Move the throttle lever away from the gas tank.

Ground the gun by holding it against the

edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may

cause a fire.

17. Trigger the gun into the metal waste

container until all air and solvent is flushed from the spray

hose and paint is flowing freely from the gun.

18. Lock the gun by turning the gun trigger lock to the locked

position.

19. Turn the pressure control knob fully counterclockwise to

its lowest setting.

Turn off the sprayer.

20.

21. Attach tip guard and tip to the gun as instructed by the tip

guard or tip manuals.

POSSIBLE INJECTION HAZARD. Do not spray without the

tip guard in place. Never trigger the gun unless the tip is in

either the spray or the unclog position. Always engage the

gun trigger lock before removing, replacing or cleaning tip.

22. Turn on the sprayer.

23. Increase the pressure by turning the pressure control

knob slowly clockwise and test the spray pattern on a

piece of cardboard. Adjust the pressure control knob until

the spray from the gun is completely atomized. Try to

keep the pressure control knob at the lowest setting that

maintains good atomization.

NOTE: Turning the pressure up higher than needed to

atomize the paint will cause premature tip wear

and additional overspray.

Pressure Relief Procedure

Heavy Coat

Do not flex wrist while spraying.

Light Coat Light Coat

Be sure to follow the pressure relief procedure when

shutting the unit down for any purpose, including

servicing or adjusting any part of the spray system,

changing or cleaning spray tips, or preparing for cleanup.

1. Lock the gun by turning the gun trigger lock to the locked

position.

2. Turn off the sprayer by moving the sprayer ON/OFF

switch to the OFF position.

3. Turn off the engine by moving the engine ON/OFF switch

to the OFF position.

4. Turn the pressure control knob counterclockwise to its

lowest setting.

. Unlock the gun by turning the gun trigger lock to the

5

unlocked position.

4. Hold the metal part of the gun firmly to

the side of a metal container to ground

the gun and avoid a build up of static

electricity.

5. Trigger the gun to remove any pressure

that may still be in the hose.

6. Lock the gun by turning the gun trigger lock to the locked

position.

7. Move the PRIME/SPRAY valve to the PRIME position.

Spraying

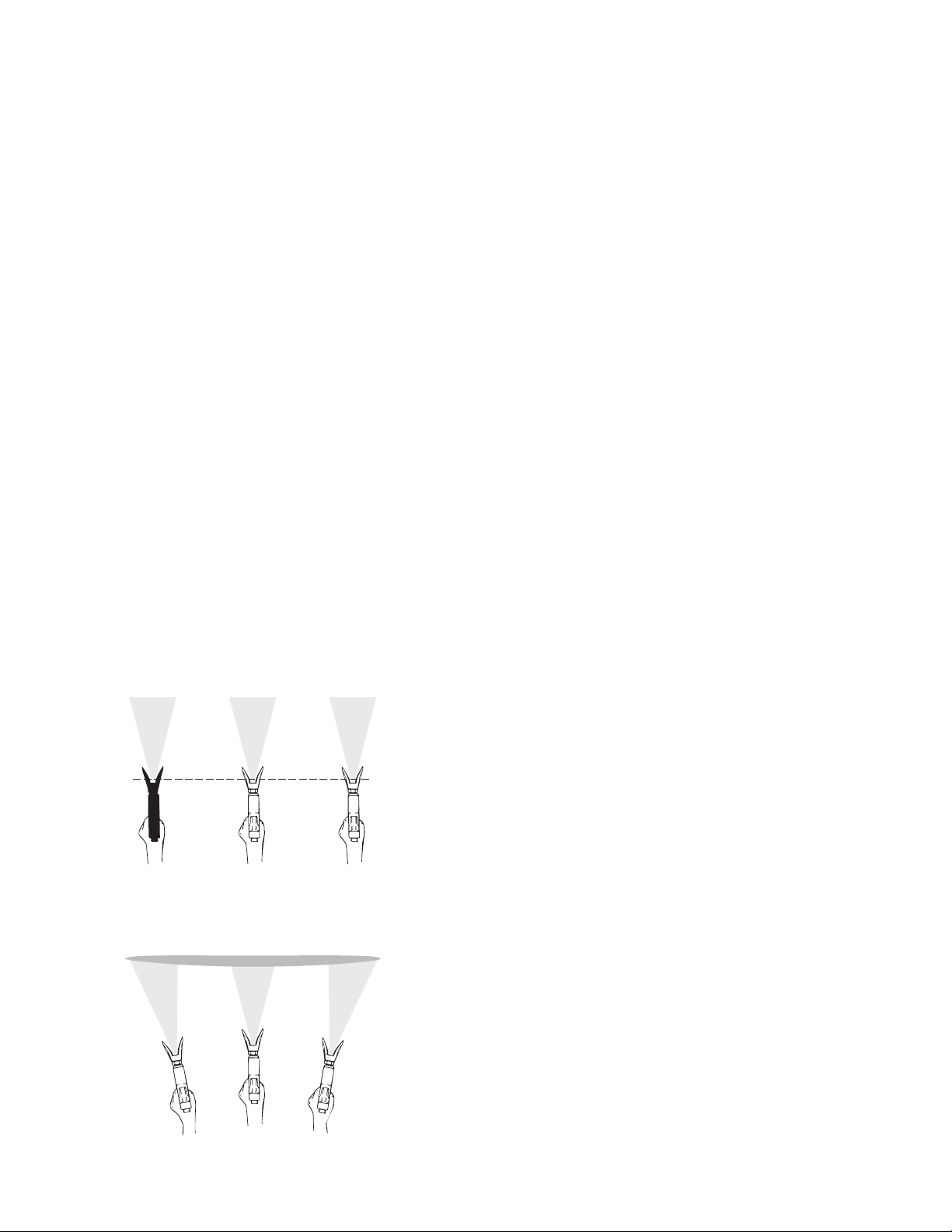

Spraying Technique

The key to a good paint job is an even coating over the entire

surface. This is done by using even strokes. Keep your arm

moving at a constant speed and keep the spray gun at a

constant distance from the surface. The best spraying distance

is 10 to 12 inches between the spray tip and the surface.

Keep the spray gun at right angles to the surface. This means

moving your entire arm back and forth rather than just flexing

your wrist.

WARNING

Knob

Pressure

Control

Knob

Sprayer

ON/OFF

SwitchSwitch

Sprayer

ON/OFF

Switch

WARNING

CAUTION

WARNING

CAUTION

WARNING

WARNING

Cleanup

Special cleanup instructions for use with flammable

solvents:

• Always flush spray gun preferably outside and at least one

hose length from spray pump.

If collecting flushed solvents in a one gallon metal

•

ontainer, place it into an empty five gallon container, then

c

lush solvents.

f

• Area must be free of flammable vapors.

• Follow all cleanup instructions.

he sprayer, hose, and gun should be cleaned thoroughly

T

after daily use. Failure to do so permits material to build

up, seriously affecting the performance of the unit.

Always spray at minimum pressure with the gun nozzle tip

removed when using mineral spirits or any other solvent

to clean the sprayer, hose, or gun. Static electricity

buildup may result in a fire or explosion in the presence of

flammable vapors.

1. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

2. Remove the gun tip and tip guard and clean with a brush

using the appropriate solvent.

3. Place the siphon tube into a container of the appropriate

solvent (refer to recommendations of the material

manufacturer). An example of the appropriate solvent is

water for latex paint.

4. Place the return hose into a metal waste container.

5. Move the PRIME/SPRAY valve to its PRIME position.

NOTE: Hold the return hose in the waste container

6. Move the engine ON/OFF switch to the ON position and

7.

8.

9. Allow the solvent to circulate

10.

11. Turn off the sprayer by moving the ON/OFF switch to the

12. Move the PRIME/SPRA

13.

14. Turn the pressure control knob slowly clockwise to

Ground the gun by holding it against the

edge of the metal container while

flushing. Failure to do so may lead to a

static electric discharge, which may cause a fire.

when moving the PRIME/SPRAY valve to

PRIME in case the sprayer is pressurized.

start the engine.

Turn on the sprayer by moving

the sprayer ON/OFF switch to

the ON

Slowly turn the pressure control

knob clockwise to increase the

pressure until fluid starts to

come out of the return hose.

through the sprayer and flush

the paint out of the return hose

into the metal waste container.

T

its lowest setting.

OFF position.

Turn on the sprayer.

increase pressure.

position.

urn the pressure control knob fully counterclockwise to

position.

valve to its SPRA

Y

Y

15. Trigger the gun into the metal waste container until the

paint is flushed out of the hose and solvent is coming out

of the gun.

6. Continue to trigger the spray gun into the waste container

1

ntil the solvent coming out of the gun is clean.

u

17. Follow the “Pressure Relief Procedure” found in the

Operation section of this manual.

18. Store the sprayer in a clean, dry area.

Do not store the sprayer under pressure.

Cleaning the Spray Tip

1. Flush the gun with solvent immediately after the work is

completed.

2. Oil the sliding pins to prevent them from seizing up.

Should the spray tip become clogged, reverse

the spray tip with the lever and pull the trigger.

Once the obstruction comes out of the spray tip,

release the trigger, reverse the spray tip back to

the spray pattern setting, and resume spraying.

Do not attempt to clean the tip with your finger.

Do not use a needle or other sharp pointed instrument to

clean the tip. The hard tungsten carbide is brittle and can

be chipped.

Maintenance

Before proceeding, follow the Pressure Relief Procedure

outlined previously in this manual. Additionally, follow all

other warnings to reduce the risk of an injection injury,

injury from moving parts, or electric shock.

NOTE: All Honda engine work should be performed by

General Repair and Service Notes

The following tools are needed when repairing this sprayer:

1. Before repairing any part of the sprayer, read the

Never pull on a wire to disconnect it. Pulling on a wire

could loosen the connector from the wire.

2. Test your repair before regular operation of the sprayer to

a Honda authorized service center.

Phillips screwdriver 3/8" hex wrench

needle-nose pliers 5/16" hex wrench

adjustable wrench 1/4" hex wrench

rubber mallet 3/16" hex wrench

flat-blade screwdriver 1/8” hex wrench

1/2” open-end wrench 7/8” open-end wrench

instructions carefully, including all warnings.

be sure that the problem is corrected. If the sprayer does

not operate properly, review the repair procedure to

determine if everything was done correctly. Refer to the

Troubleshooting section to help identify other possible

problems.

© SprayTECH. All rights reserved. 7

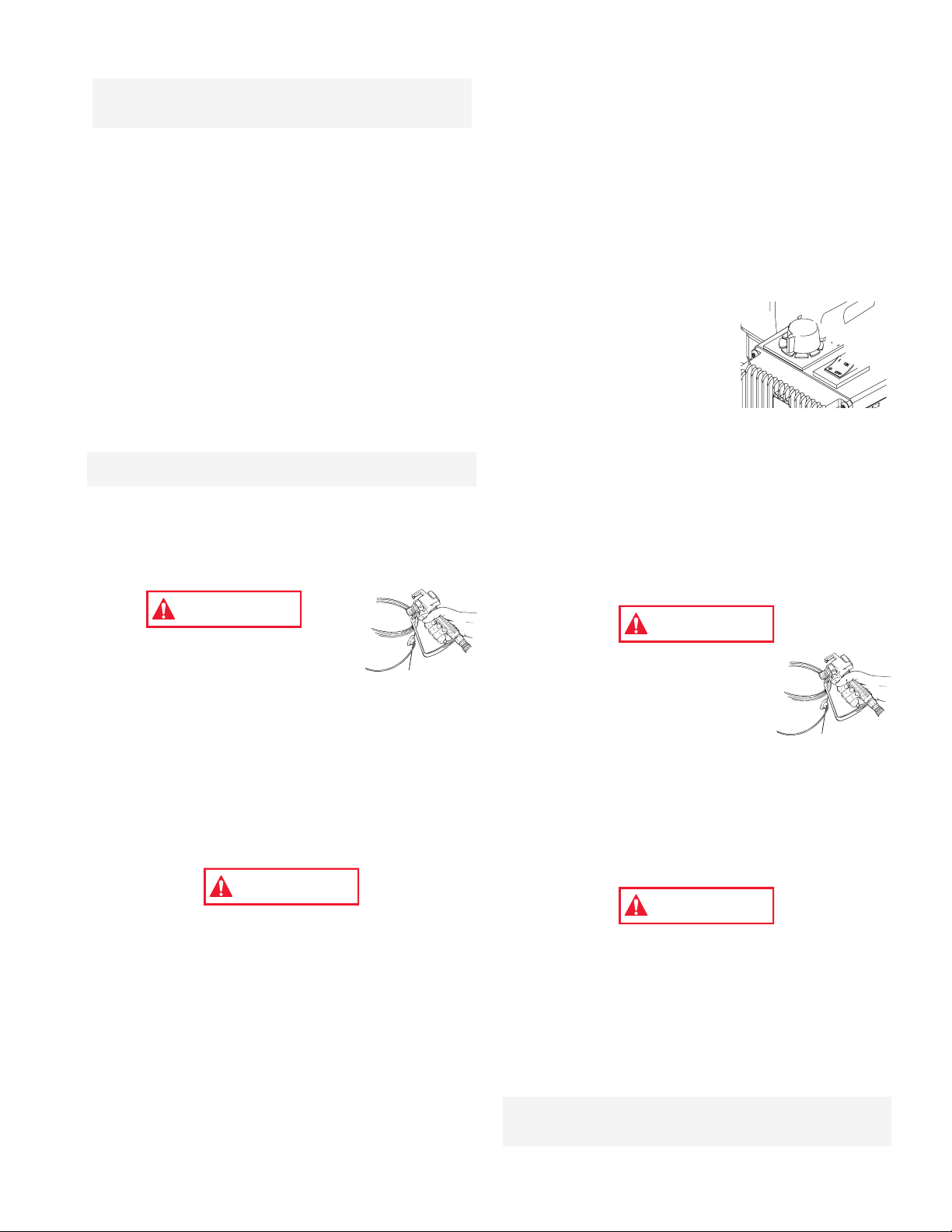

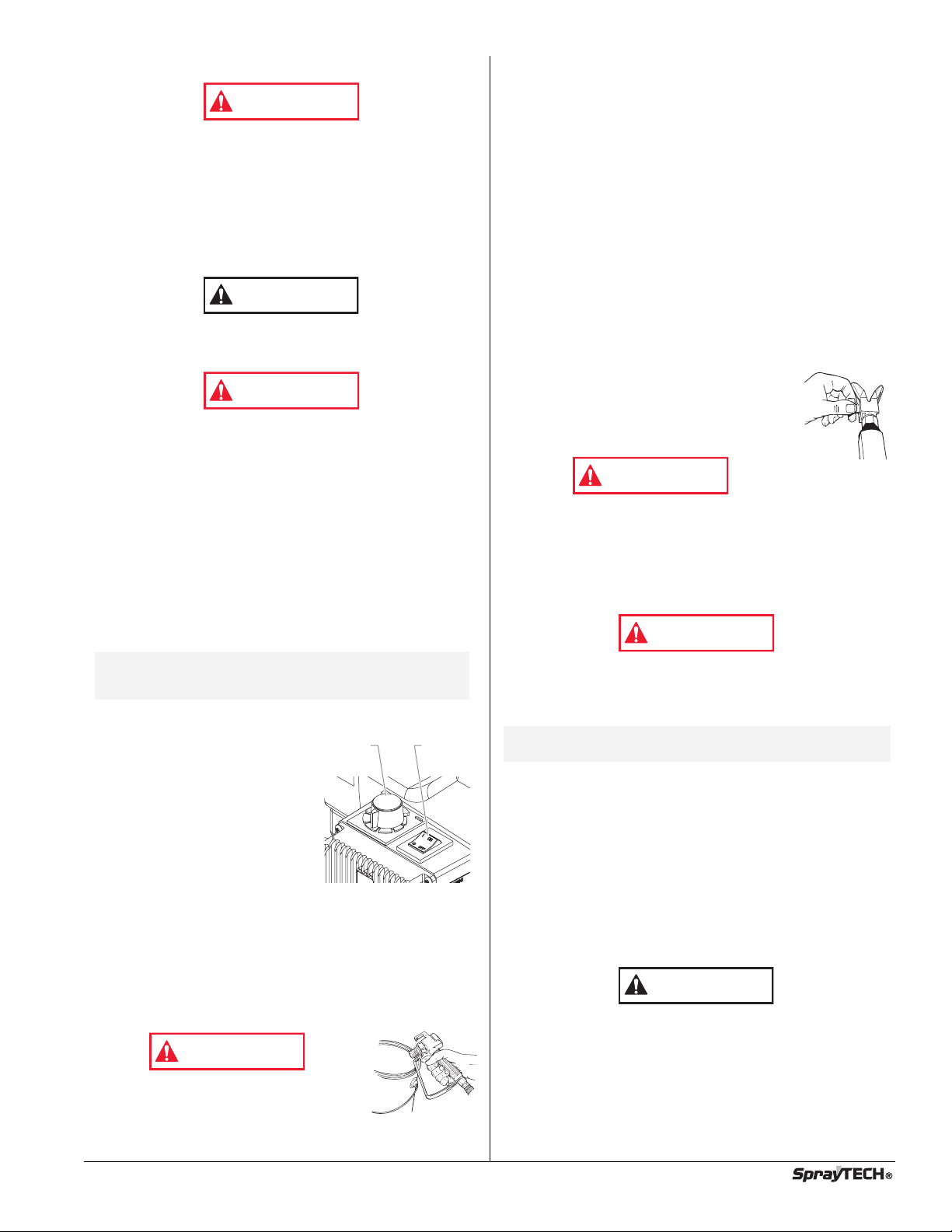

WARNING

Dowel Pin

Cam Base

Valve Stem

Filter

Housing

Valve Housing

Assembly

Gasket

Valve Handle

Groove Pin

. Make certain that the service area is well ventilated in

3

ase solvents are used during cleaning. Always wear

c

rotective eyewear while servicing. Additional protective

p

equipment may be required depending on the type of

cleaning solvent. Always contact the supplier of solvents

for recommendations.

4. If you have any further questions concerning your

SprayTECH airless sprayer, call SprayTECH:

echnical Service...................................

T

Fax ................................................1-800-525-9501

-800-292-4637

1

Maintaining the Engine

When transporting a sprayer with a gas engine, make sure

the fuel is shut off.

NOTE: For detailed engine specifications and

Important Facts Concerning this Sprayer

This gas-powered sprayer contains a clutch that engages

when the sprayer is pumping. The sprayer’s pressure control

system engages and disengages the clutch to control

pressure. To prevent unnecessary wear to the clutch, it is

advisable to adjust the engine speed and pressure setting to

limit the amount of times the clutch engages and disengages.

To reduce clutch wear, refer to the following examples.

Example:

Operating one gun with a .019 tip — reduce the engine speed

by adjusting the throttle to a low or medium setting and

increase pressure only until the heavy ends of the spray

pattern have been eliminated.

Example:

Operating one gun with .023 tip — increase engine speed to a

higher setting and increase pressure until the heavy ends of

the spray pattern have been eliminated.

Example:

Spraying light-bodied materials at low pressure — to reduce

surging at the gun and to decrease clutch wear, reduce the

engine speed to idle and reduce pressure until the desired

spray pattern is achieved.

Routine Engine Maintenance

Daily

Weekly

Spark Plug

maintenance, refer to the separate engine

manual supplied with this sprayer.

• Check and fill the gas tank.

• After the first 20 hours of operation, drain the oil and refill

with clean oil. Check the engine oil level and fill as

necessary.

• Remove the cover of the air filter and clean the element.

Replace the element if necessary. If operating in an

unusually dusty environment, check the filter daily and

replace if necessary. (Replacement elements can be

purchased from your local SprayTECH dealer.)

• After each 50 hours of operation: Change the engine oil.

• Use only a (NKG) BP6ES plug.

• Gap the plug 0.025” – 0.030” (0.7 – 0.8 mm).

• Make sure to use a spark plug wrench when installing and

removing the plug.

Replacing the Filter

. Loosen and remove the filter

1

ody by hand.

b

2. Remove the filter and filter

support spring spring from the

filter housing.

3. Remove the filter support spring

and adapter from inside the

filter.

4. Inspect the filter. Based on

inspection, clean or replace the

filter.

. Inspect the filter housing o-ring.

5

Based on inspection, clean or

replace the o-ring.

6. Slide the new or cleaned filter

over the adapter and filter

support spring. Place the filter

and filter support spring into the

center of the filter housing.

7. Clean the inside of the filter

body.

8. Slide the filter body over the

filter and thread it into the filter

housing until secure. Make

sure the filter spring is in

position on top of the filter.

NOTE: The filter body should

be hand-tightened,

but make sure it is

seated fully into the

filter housing.

Replacing the PRIME/SPRAY Valve

Perform the following procedure using PRIME/SPRAY valve

replacement kit P/N 0507690.

1. Drive the groove pin out of the valve handle.

2. Remove the valve handle and the cam base.

3. Using a wrench, loosen and remove the valve housing

assembly.

4. Make sure the gasket is in place and thread the new valve

housing assembly into the filter housing. Tighten securely

with a wrench.

5. Place the cam base over the valve housing assembly.

Lubricate the cam base with grease and line up the cam

with the filter block using the dowel pin.

Line up the hole on the valve stem with the hole in the

6.

valve handle.

Insert the groove pin into the valve handle and through

7.

the valve stem to secure the valve handle in position.

8 © SprayTECH. All rights reserved.

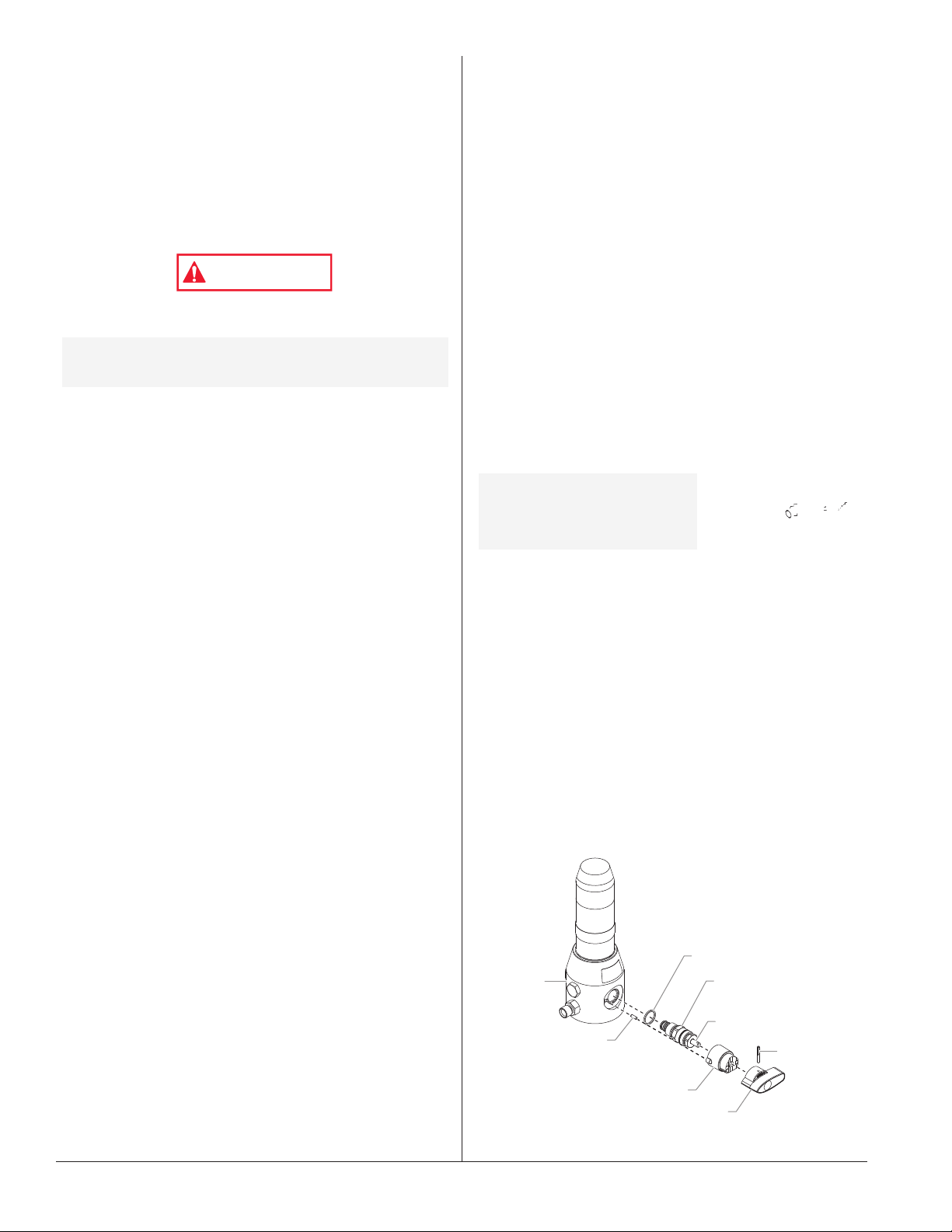

Replacing the Potentiometer

CAUTION

CAUTION

EPC

Housing

Pressure Control Knob

Seal Nut

Cap

EPC

Board

EPC

Assembly

EPC

Assembly

Screw

Potentiometer

WARNING

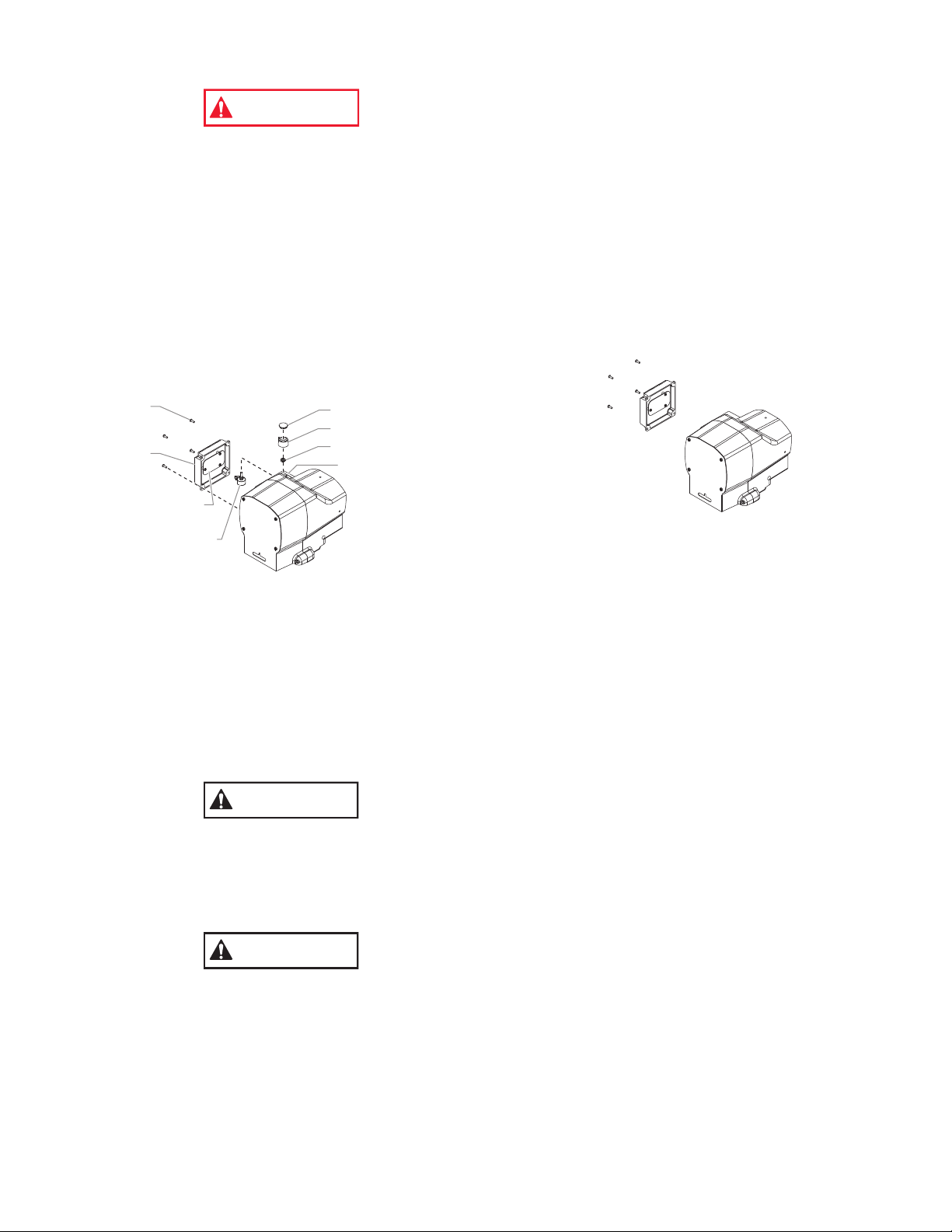

Replacing the Sprayer ON/OFF Switch

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Pry off the pressure control knob cap to expose the knob

tension nut.

3. Turn the pressure control knob fully counterclockwise to

the minimum pressure setting.

. Using a 5/16” socket, loosen the tension nut in the center

4

f the knob. Remove the knob.

o

5. Using a Phillips screwdriver, remove the four screws that

secure the electronic pressure control (EPC) assembly to

the EPC housing. Carefully remove the EPC assembly

from the housing. Gently move the assembly away from

the sprayer and allow the assembly to hang from the

housing.

6. Hold the potentiometer inside the EPC housing while

using a 1/2” thin wall socket to remove the seal nut that

secures the potentiometer to the mounting plate. Remove

the potentiometer from the EPC housing.

7. Carefully remove the potentiometer wires from their

connection point on the EPC board.

8. Insert the stem of the new potentiometer through the hole

in the mounting plate from inside the EPC housing.

Position the protruding tab on the potentiometer face into

the hole on the underside of the mounting plate (the wires

will face the open side of the EPC housing).

9. Thread the seal nut onto the threaded portion of the stem

and tighten using a 1/2” thin wall socket.

Electrostatic discharge (ESD) potential could cause

damage to electronic pressure control. Use SprayTECH

ESD wrist strap P/N 0507958 or equivalent when working

on electronic pressure control.

1. Perform the Pressure Relief Procedure.

2. Using a Phillips screwdriver, remove the four screws that

secure the electronic pressure control (EPC) assembly to

the EPC housing. Carefully remove the EPC assembly

from the housing. Gently move the assembly away from

the sprayer and allow the assembly to hang from the

housing.

3. Locate the bottom of the sprayer ON/OFF switch inside

the EPC housing.

4. Disconnect the switch wires from the sprayer ON/OFF

switch. Remember the locations of each of the two wires

(label the wires, if necessary).

5. Depress the mounting tabs on each corner of the sprayer

ON/OFF switch inside the EPC housing and remove the

switch through the top of the housing.

6. Snap the new sprayer ON/OFF switch into the switch hole

in the EPC housing.

7. Connect the two switch wires to the new sprayer ON/OFF

switch. Make sure the wires are connected to the

corresponding terminals from which they were removed

(refer to the labels created earlier in this procedure or the

electrical schematic in the Parts List section of this

manual).

8. Carefully place the EPC assembly over the EPC housing

taking care not to pinch any wires.

9. Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

Do not over-tighten the seal nut.

Do not over-tighten the knob tension nut. Over-tightening

will damage the potentiometer.

10. Turn the potentiometer stem fully counterclockwise.

Place the pressure control knob on the potentiometer

1.

1

stem with the indicator tab resting at the “minimum

pressure” tab on the mounting plate.

12. Tighten the knob tension nut using a 5/16” socket.

13. Connect the potentiometer wires to the EPC board. The

protruding tab on the EPC board connector will mate with

the slot on the potentiometer wires connector. The

connector on the end of the potentiometer wires and the

connector on the EPC board will mate only one way. Do

not force the connectors together.

Carefully place the EPC assembly over the EPC housing

14.

taking care not to pinch any wires.

15. Install the four screws that secure the EPC assembly to

the EPC housing. Tighten securely.

Loading...

Loading...