Honda Power Equipment EW171 User Manual

I -

t

.

m The aenerator is a potential source of electrical shock

if misused. Do notexpose the generator to moisture, rain or snow. Do

not let the generator get wet, and do not operate it with wet hands.

Thank you for purchasing a Honda generator/welder. We want to help you get

the best results from your new generator/welder and to operate it safely. This

manual contains the information on how to do that; please read it carefully.

This owner’s manual describes the operation and maintenance of the EWI 71

Honda generator/welder. All information in this publication is based on the

latest product information available at the time of printing. Honda Motor Co.,

Ltd. reserves the right to make changes at any time without notice and without

incurring any obligation. No part of this publication may be reproduced without

written permission.

This manual should be considered a permanent part of the generator/welder

and should remain with it if it is resold.

Safety Messages

Your safety and the safety of others is very important. We have provided

important safety messages in this manual and on the generator/welder.

Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others.

Each safety message is preceded by a safety alert symbol Band one of three

words: DANGER, WARNING, or CAUTION.

These mean

.

D ’

m You WILL be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

A -

!

m You CAN be KILLED or SERIOUSLY HURT if you don’t

follow instructions.

* L

m You CAN be HURT if you don’t follow instructions.

.

0

Each message tells you what the hazard is, what can happen, and what you

can do to avoid or reduce injury.

Damage Prevention Messages

You will also see other important messages that are preceded by the word

NOTICE.

This word means:

(1

you don’t follow instructions.

The purpose of these messages is to help prevent damage to your generator/

welder, other property, or the environment.

Your generator/welders or other property could be damaged if

1

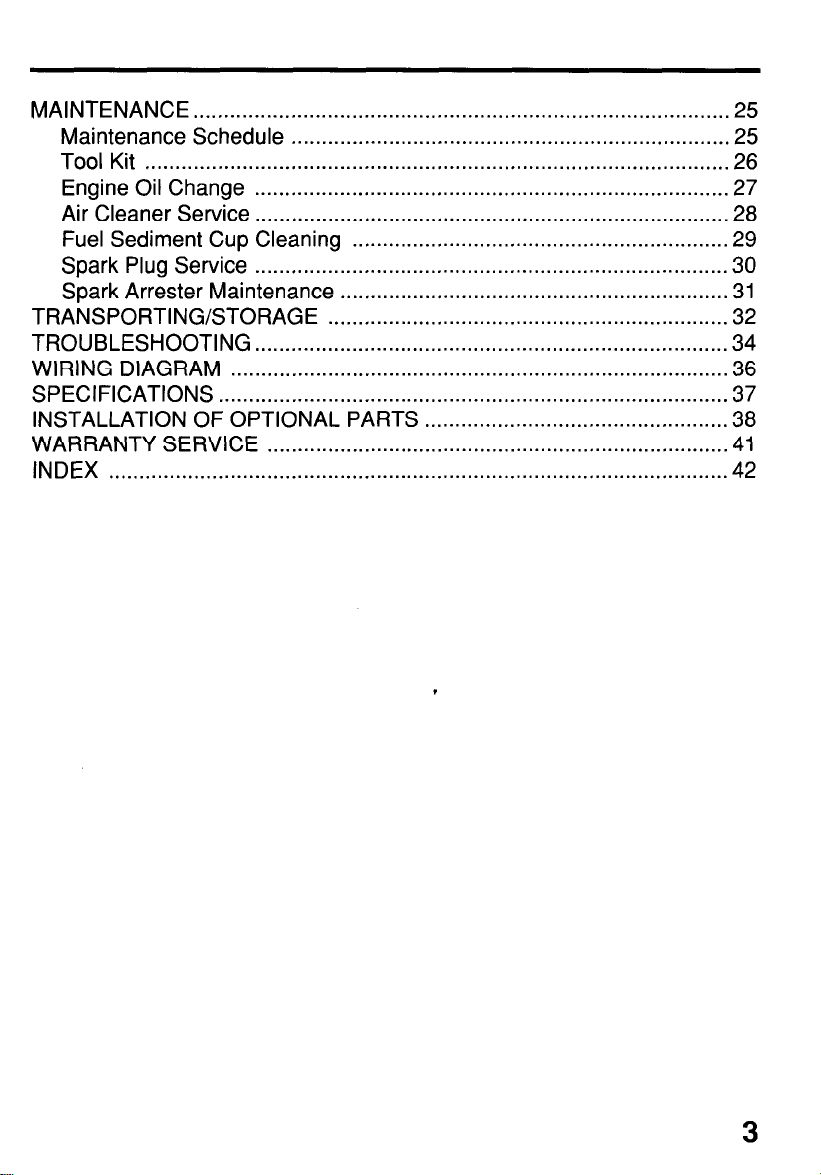

CONTENTS

SAFETY

Safety

Safety Information

COMPONENT IDENTIFICATION

CONTROLS

Engine Switch

Recoil

Fuel Valve

Choke

Circuit

Oil Alert System

Auto-throttle system

AC/DC (Weld) Selector Switch

Welding

Welding Current Adjust System

GENERATOR USE

Connections to a Building’s Electrical System

AC

Welding

Selecting the Correct Welding Current

Welding

Welding

Polarity Selection

High Altitude Operation

Auto-throttle System

PREOPERATION

Engine Oil

Fuel

STARTING THE

......................................................................................................

Label Locations

..............................................................................................

......................................................................................

Starter ......................................................................................

............................................................................................

..........................................................................................

Rod

Breaker ....................................................................................

..................................................................................

Cable Terminal

..................................................................................

Operation

................................................................................................

Cable Selection

Duty Cycle..

Recommendation

......................................................................................

CHECK..

............................................................................................

ENGINE/STOPPING THE

..........................................................................

..................................................................................

..............................................................

............................................................................

..i ......................................................

...

......................................................................

..........................................................

......................................................................

............................................................................

................................................................................

........................................................................

............................................................................

......................................................................

........................................................................

....................................

................................................

ENGINE

..............................

4

4

6

8

10

10

10

11

11

12

12

13

13

14

14

15

15

16

17

17

18

18

19

19

20

21

21

22

24

2

MAINTENANCE..

Maintenance

Tool Kit

Engine Oil Change

Air Cleaner

Fuel Sediment Cup Cleaning

Spark Plug

Spark Arrester

TRANSPORTING/STORAGE

TROUBLESHOOTING..

WIRING

SPECIFICATIONS

INSTALLATION OF OPTIONAL PARTS

WARRANTY

INDEX

................................................................................................

DIAGRAM

......................................................................................................

......................................................................................

Schedule

Service

Service

Maintenance

....................................................................................

SERVICE

........................................................................

..............................................................................

..............................................................................

..............................................................

..............................................................................

................................................................

..................................................................

............................................................................

..................................................................................

............................................................................

..................................................

25

25

26

27

28

29

30

31

32

34

36

37

38

41

42

3

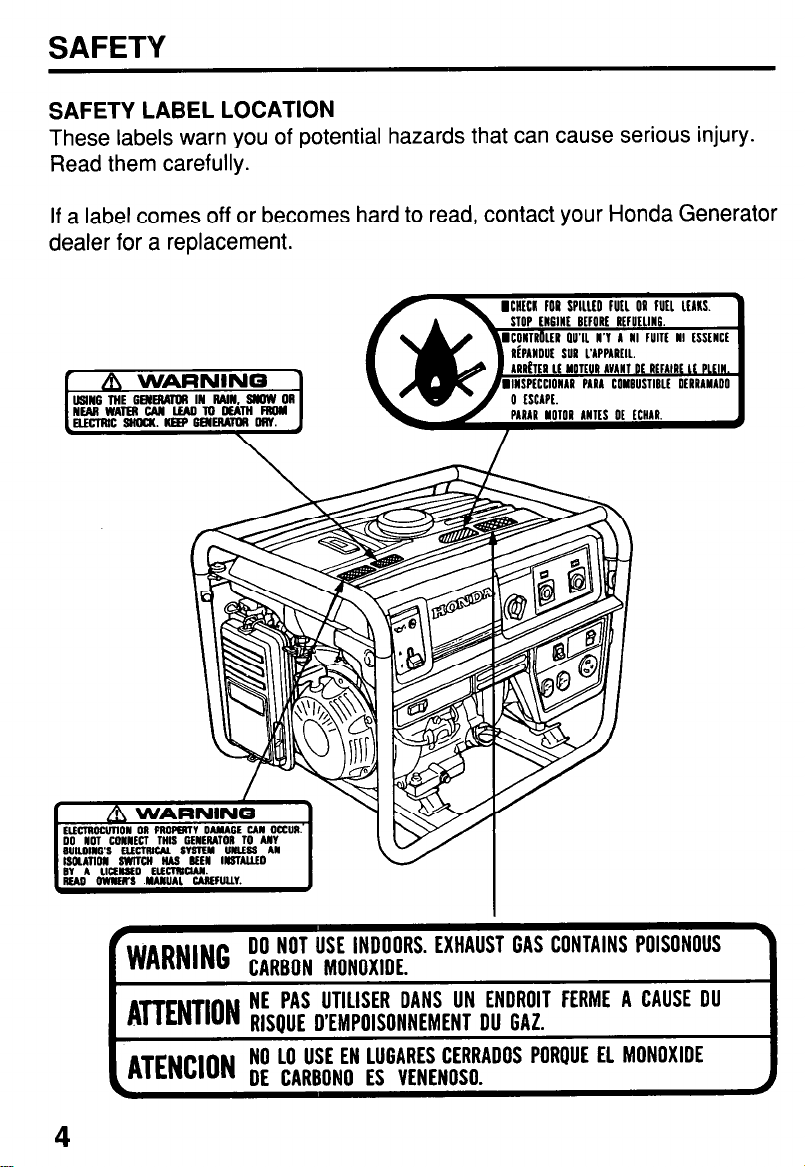

SAFETY

SAFETY LABEL LOCATION

These labels warn you of potential hazards that can cause serious injury.

Read them carefully.

If a label comes off or becomes hard to read, contact your Honda Generator

dealer for a replacement.

STOP fR61llf BffORf RffUflll6.

NconrRolfu au’tt 1’1 A WI fllllf ill fSSfnct

r

\ niPAllolJf sun L’APPARfIL.

ARRhfR Lt YOTtUR WI Of RflAlRI Ii PL

0 fSCAPf.

PARAR NOTOR ANIfS Of fCHAR.

/

PARA CONRUSTlBLt UfRRANAOO

I

‘WARNING

ATTENTION NE PAS UTILISER DANS UN ENOROIT FERME A CAUSE DU

4

DO NOT USE INDOORS. EXHAUST GAS CONTAINS POISONOUS

h

CARBON MONOXIDE.

RISQUE D’EMPOISONNEMENT DU GAZ.

NO LO USE EN LUGARES CERRADOS PORDUE EL MONOXIDE

DE CARBON0 ES VENENOSO.

”

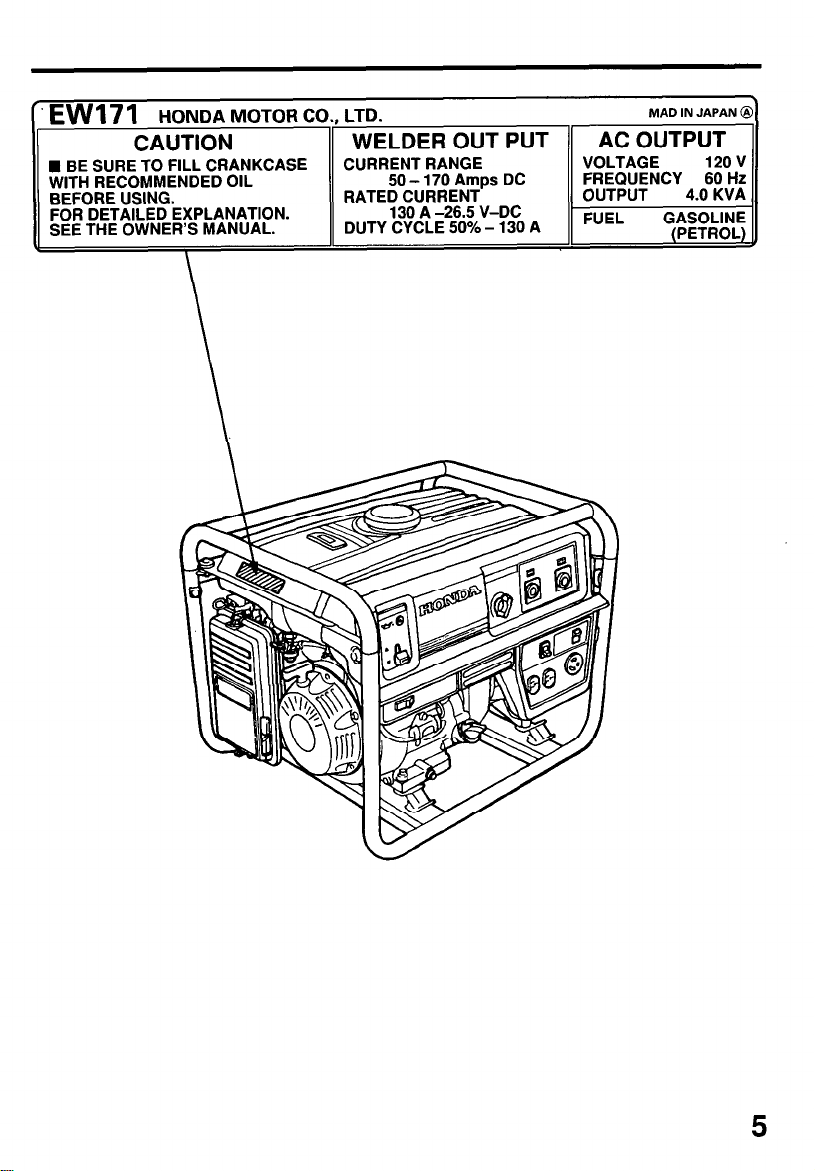

EW 17 1

HONDA MOTOR CO., LTD.

CAUTION

n

BE SURE TO FILL CRANKCASE

WITH RECOMMENDED OIL

BEFORE USING.

FOR DETAILED EXPLANATION.

SEE THE OWNER’S MANUAL.

\

CURRENT RANGE

50 - 170 Amps DC

RATED CURRENT

130 A -26.5 V-DC

MAD IN JAPAN @

AC OUTPUT

>

5

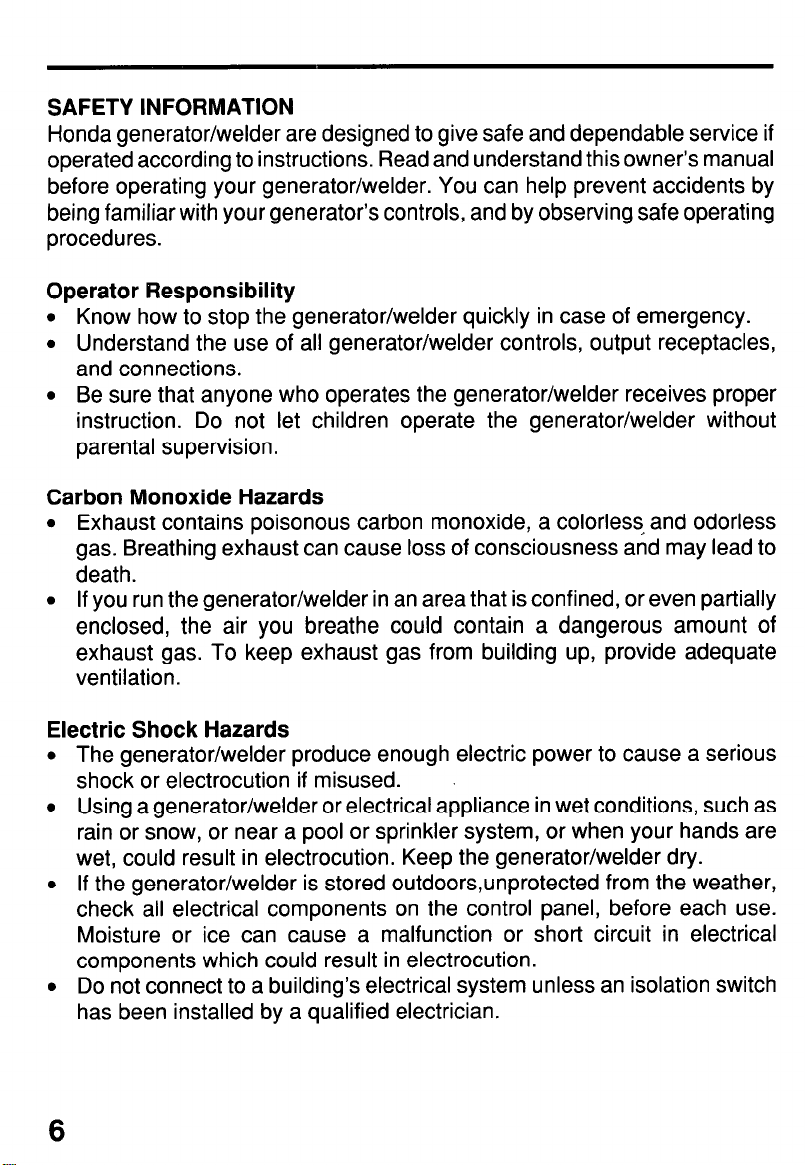

SAFETY INFORMATION

Honda generator/welder are designed to give safe and dependable service if

operated according to instructions. Read and understand this owner’s manual

before operating your generator/welder. You can help prevent accidents by

being familiar with your generator’s controls, and by observing safe operating

procedures.

Operator Responsibility

l

Know how to stop the generator/welder quickly in case of emergency.

l

Understand the use of all generator/welder controls, output receptacles,

and connections.

l

Be sure that anyone who operates the generator/welder receives proper

instruction. Do not let children operate the generator/welder without

parental supervision.

Carbon Monoxide Hazards

l

Exhaust contains poisonous carbon monoxide, a colorless and odorless

gas. Breathing exhaust can cause loss of consciousness and may lead to

death.

l

If you run the generator/welder in an area that is confined, or even partially

enclosed, the air you breathe could contain a dangerous amount of

exhaust gas. To keep exhaust gas from building up, provide adequate

ventilation.

Electric Shock Hazards

The generator/welder produce enough electric power to cause a serious

shock or electrocution if misused.

Using a generator/welder or electrical appliance in wet conditions, such as

rain or snow, or near a pool or sprinkler system, or when your hands are

wet, could result in electrocution. Keep the generator/welder dry.

If the generator/welder is stored outdoors,unprotected from the weather,

check all electrical components on the control panel, before each use.

Moisture or ice can cause a malfunction or short circuit in electrical

components which could result in electrocution.

Do not connect to a building’s electrical system unless an isolation switch

has been installed by a qualified electrician.

6

Fire and Burn Hazards

The exhaust system gets hot enough to ignite some materials.

- Keep the generator/welder at least 1 mater (3 feet) away from buildings

and other equipment during operation.

- Do not enclose the generator/welder in any structure.

- Keep flammable materials away from the generator/welder.

The muffler becomes very hot during operation and remains hot for a while

after stopping the engine. Be careful not to touch the muffler while it is hot.

Let the engine cool before storing the generator/welder indoors.

Gasoline is extremely flammable and is explosive under certain conditions.

Do not smoke or allow flames or sparks where the generator/welder is

refueled or where gasoline is stored. Refuel in a well-ventilated area with

the engine stopped.

Fuel vapors are extremely flammable and may ignite after the engine has

started. Make sure that any spilled fuel has been wiped up before starting

the generator/welder.

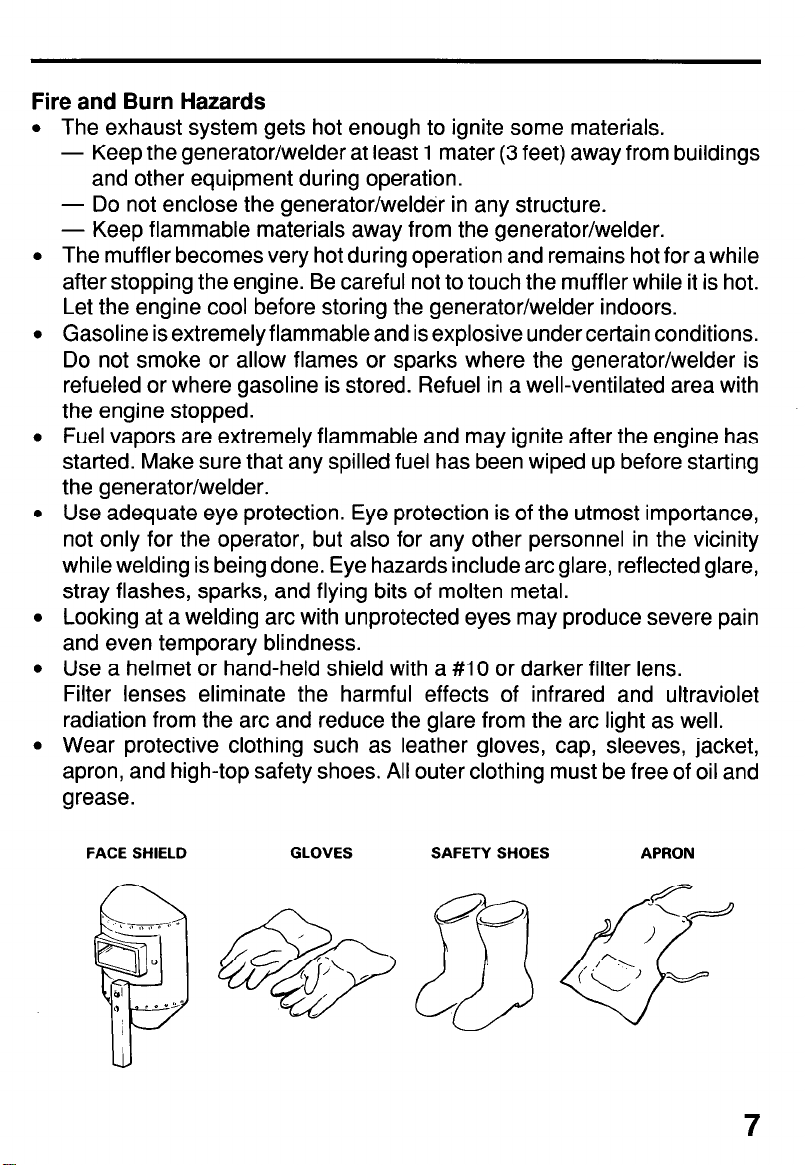

Use adequate eye protection. Eye protection is of the utmost importance,

not only for the operator, but also for any other personnel in the vicinity

while welding is being done. Eye hazards include arc glare, reflected glare,

stray flashes, sparks, and flying bits of molten metal.

Looking at a welding arc with unprotected eyes may produce severe pain

and even temporary blindness.

Use a helmet or hand-held shield with a #I 0 or darker filter lens.

Filter lenses eliminate the harmful effects of infrared and ultraviolet

radiation from the arc and reduce the glare from the arc light as well.

Wear protective clothing such as leather gloves, cap, sleeves, jacket,

apron, and high-top safety shoes. All outer clothing must be free of oil and

grease.

FACE SHIELD GLOVES SAFETY SHOES APRON

7

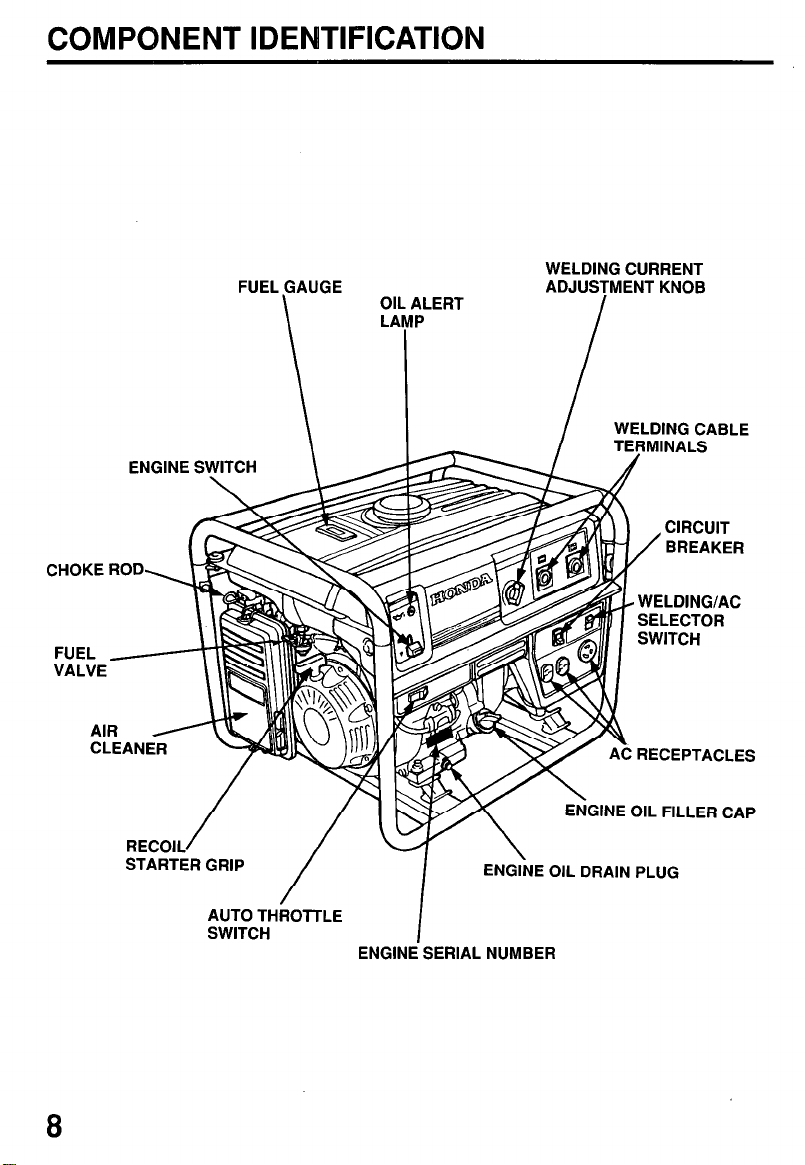

COMPONENT IDENTIFICATION

FUEL GAUGE

ENGINE SWITCH

CHOKE ROD

WELDING CURRENT

ADJUSTMENT KNOB

/ WELDING CABLE

FUEL

VALVE

AIR

CLEANER

3

-3c

/

RECOIL

STARTER GRIP

B

AUTO THkOlTLE

SWITCH

I

ENGINE SERIAL NUMBER

‘ITCH

Ai2 RECEPTACLES

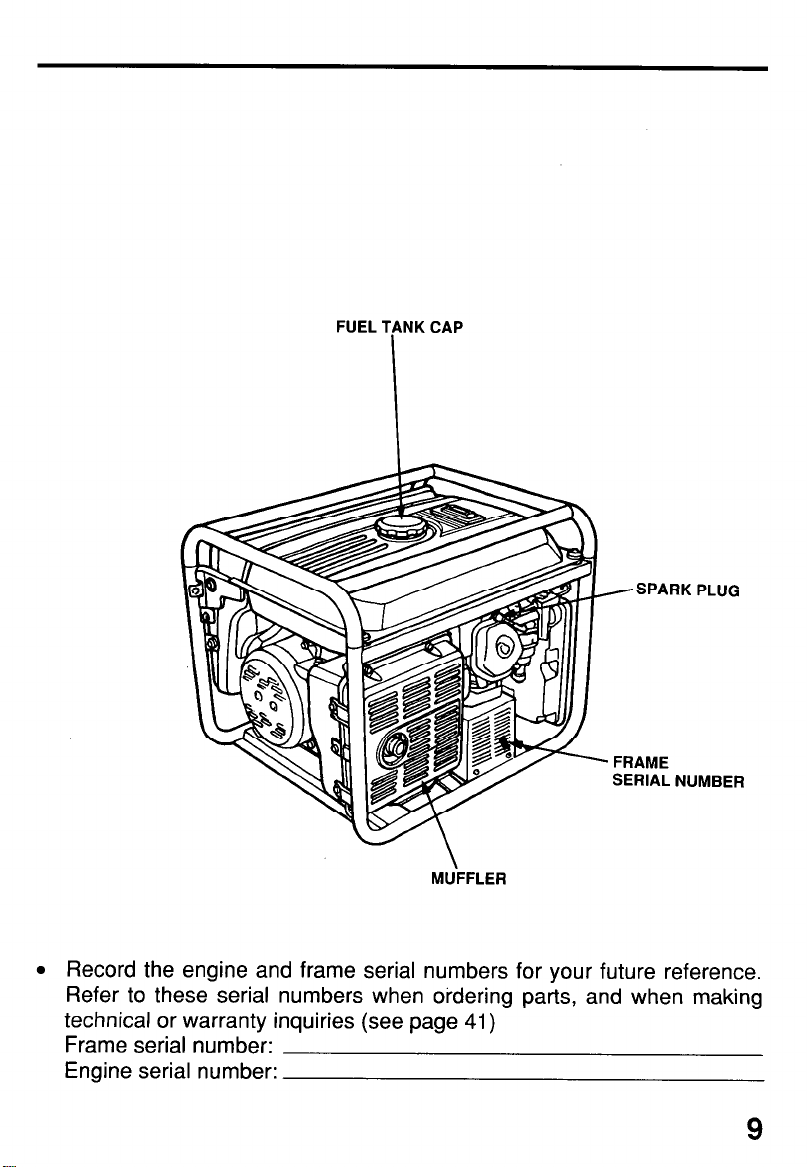

FUEL TANK CAP

MU\FFLER

SERIAL NUMBER

l

Record the engine and frame serial numbers for your future reference.

Refer to these serial numbers when oidering parts, and when making

technical or warranty inquiries (see page 41)

Frame serial number:

Engine serial number:

9

CONTROLS

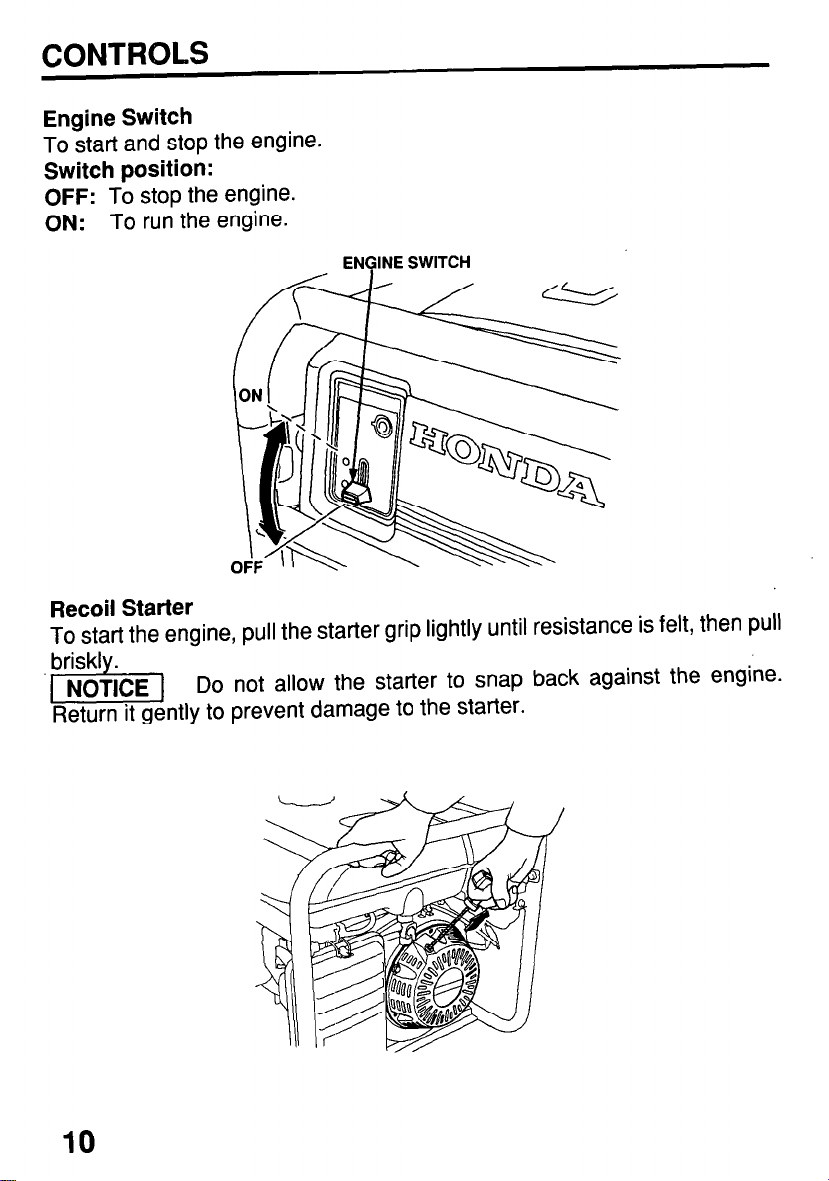

Engine Switch

To start and stop the engine.

Switch position:

OFF:

ON:

To stop the engine.

To run the engine.

ENGINE SWITCH

Recoil Starter

To start the engine, pull the starter grip lightly until resistance is felt, then pull

Do not allow the starter to snap back against the engine.

Return it gently to prevent damage to the starter.

10

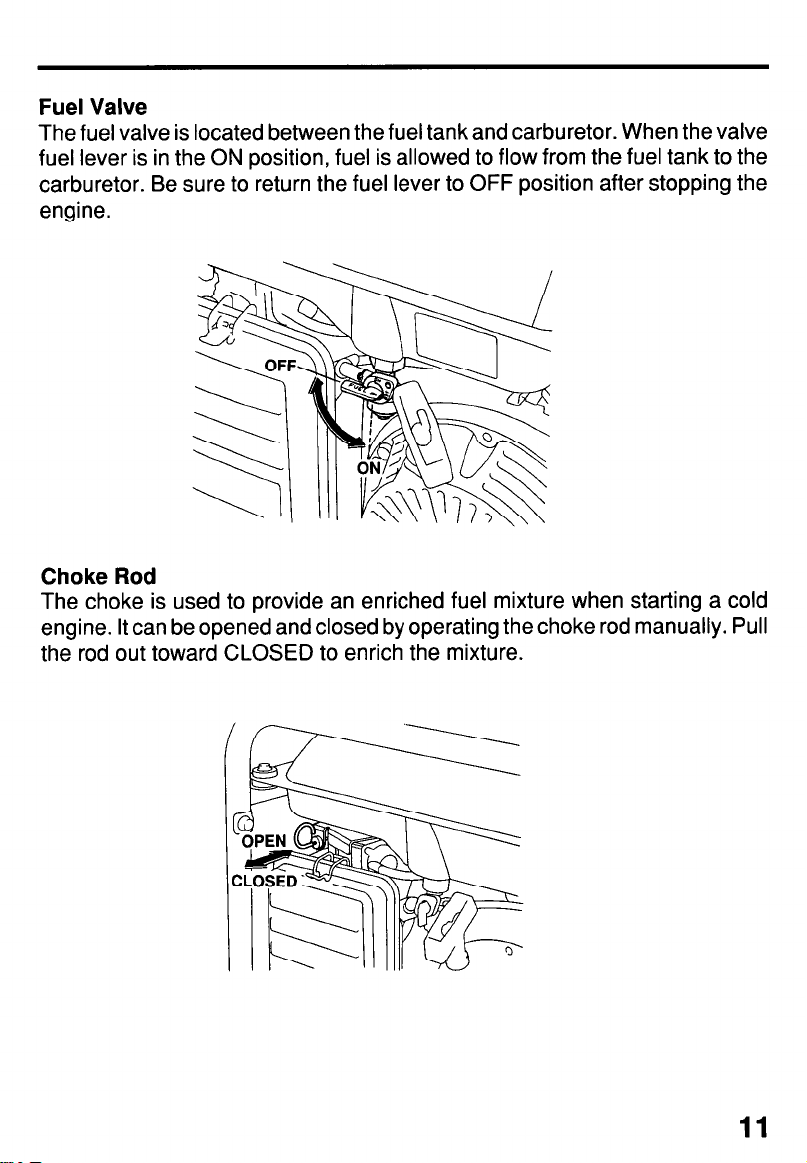

Fuel Valve

The fuel valve is located between the fuel tank and carburetor. When the valve

fuel lever is in the ON position, fuel is allowed to flow from the fuel tank to the

carburetor. Be sure to return the fuel lever to OFF position after stopping the

engine.

Choke Rod

The choke is used to provide an enriched fuel mixture when starting a cold

engine. It can be opened and closed by operating the choke rod manually. Pull

the rod out toward CLOSED to enrich the mixture.

11

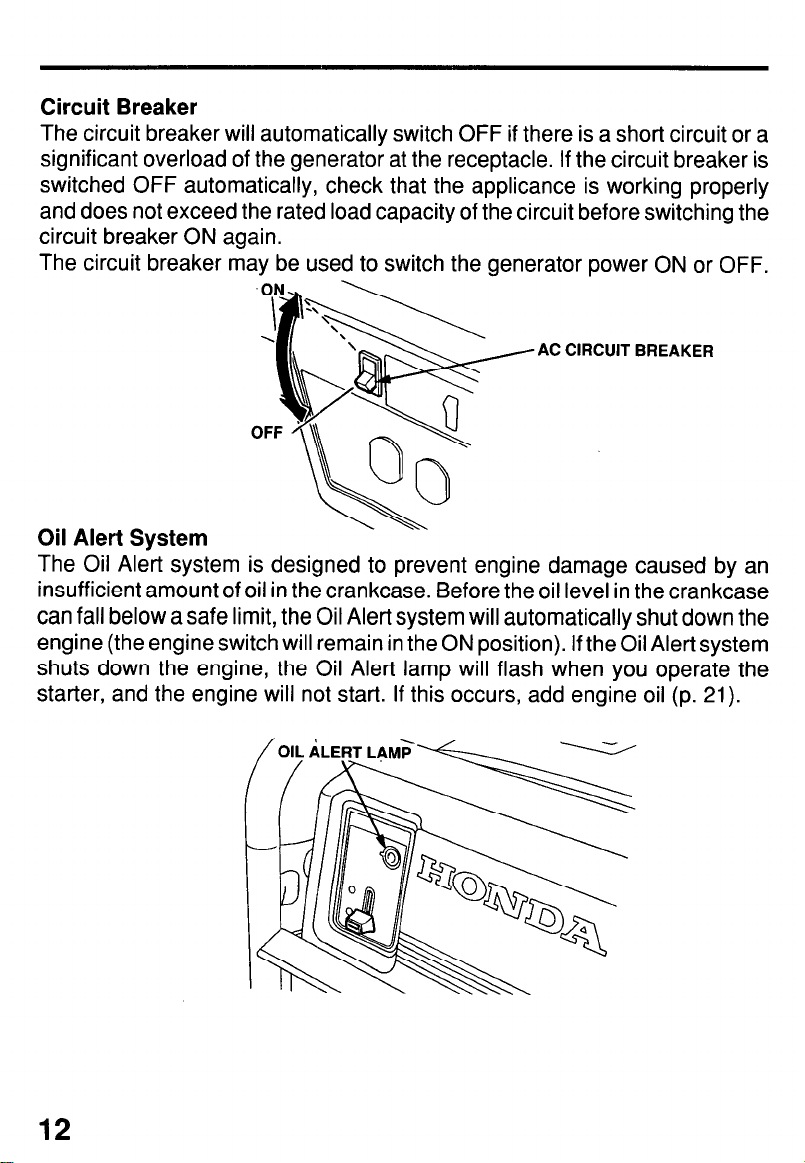

Circuit Breaker

The circuit breaker will automatically switch OFF if there is a short circuit or a

significant overload of the generator at the receptacle. If the circuit breaker is

switched OFF automatically, check that the applicance is working properly

and does not exceed the rated load capacity of the circuit before switching the

circuit breaker ON again.

The circuit breaker may be used to switch the generator power ON or OFF.

AC CIRCUIT BREAKER

Oil Alert System

The Oil Alert system is designed to prevent engine damage caused by an

insufficient amount of oil in the crankcase. Before the oil level in the crankcase

can fall below a safe limit, the Oil Alert system will automatically shut down the

engine (the engine switch will remain in the ON position). If the Oil Alert system

shuts down the engine, the Oil Alert lamp will flash when you operate the

starter, and the engine will not start. If this occurs, add engine oil (p. 21).

12

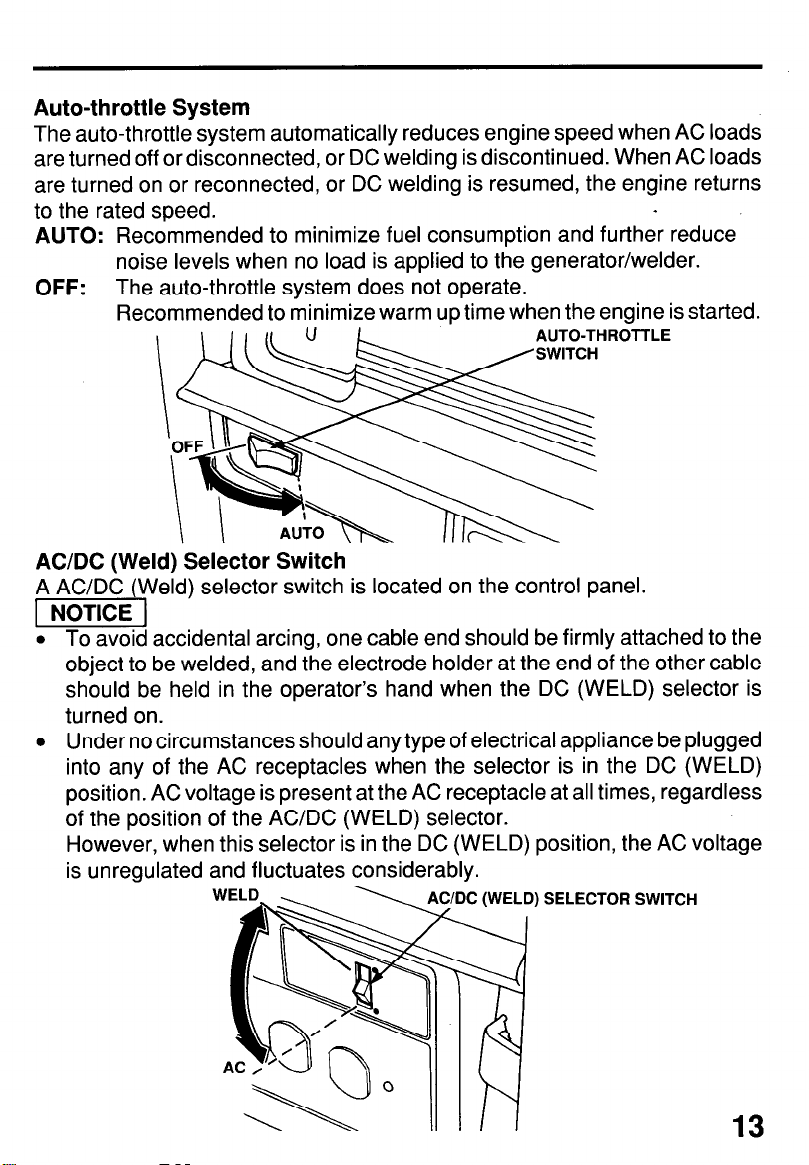

Auto-throttle System

The auto-throttle system automatically reduces engine speed when AC loads

are turned off or disconnected, or DC welding is discontinued. When AC loads

are turned on or reconnected, or DC welding is resumed, the engine returns

to the rated speed.

AUTO:

Recommended to minimize fuel consumption and further reduce

noise levels when no load is applied to the generator/welder.

OFF:

The auto-throttle system does not operate.

Recommended to minimize warm up time when the engine is started.

AUTO-THROTTLE

:

AC/DC (Weld) Selector Switch

A AC/DC (Weld) selector switch is located on the control panel.

psieq

l

To avoid accidental arcing, one cable end should be firmly attached to the

object to be welded, and the electrode holder at the end of the other cable

should be held in the operator’s hand when the DC (WELD) selector is

turned on.

l

Under no circumstances should any type of electrical appliance be plugged

into any of the AC receptacles when the selector is in the DC (WELD)

position. AC voltage is present at the AC receptacle at all times, regardless

of the position of the AC/DC (WELD) selector.

However, when this selector is in the DC (WELD) position, the AC voltage

is unregulated and fluctuates considerably.

C (WELD) SELECTOR SWITCH

13

Loading...

Loading...