Page 1

dummyheaddummyhead

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

A Few Words About Safety

Service Information

The service and repair information contained in this manual is intended for use by qualified, professional te chnicians. Attempting

service or repairs without the proper training, tools, and equipment could cause injury to you or others. It could also damage the

vehicle or create an unsafe condition.

This manual describes the proper methods and procedures for performing service, maintenan ce and repairs. Some procedures

require the use of specially designed tool s and dedicated equipment. Any person who intends to use a replacement part, service

procedure or a tool that is not recommended by Honda, must determine the risks to their personal safe ty and the safe operation of

the vehicle.

If you need to replace a part, use genuine Honda parts with the correct part number or an equivalent part. We strongly recommend

that you do not use replacement parts of inferior quality.

For Your Customer’s Safety

Proper service and maintenance are essential to the customer’s safety and the reliability of the vehicle. Any error or oversight while

servicing a vehicle can result in faulty operation, damage to the vehicle, or injury to others.

Improper service or repairs can create an unsafe

condition that can cause your customer or others to

be seriously hurt or killed.

Follow the procedures and precautions in this

manual and other service materials carefully.

For Your Safety

Because this manual is intended for the professional service technician, we do no t provide warnings about many basic shop safety

practices (e.g., Hot parts–wear gloves). If you have not received shop safety training or do not feel confident about your knowledge

of safe servicing practice, we recommend that you do not attempt to perform the procedures described in this manual.

Some of the most important general service safety precautions are given below. However, we cannot warn you of every

conceivable hazard that can arise in performing service and repair procedu res. Only you can decide whether or not you should

perform a given task.

Failure to properly follow instructions and

precautions can cause you to be seriously hurt or

killed.

Follow the procedures and precautions in this

manual carefully.

Important Safety Precautions

Make sure you have a clear understanding of all basic shop safety p ractices and that you are wearing appropriate clothing and

using safety equipment. When performing any service task, be especially careful of the following:

• Read all of the instructions before you begin, and make sure you have the tools, the rep lacement or repair parts, and the skills

required to perform the tasks safely and completely.

• Protect your eyes by using proper safety glasses, goggl es or face shields any ti me you hammer, drill, gri nd, pry or wo rk arou nd

pressurized air or liquids, and springs or other stored-energy components. If there is any doubt, put on eye protection.

• Use other protective wear when necessary, for example gloves or safety shoes. Handling hot or sharp parts can cause severe

burns or cuts. Before you grab something that looks like it can hurt you, stop and put on gloves.

• Protect yourself and others whenever you have the vehicle up in the air. Any time you lift the vehicle, either with a hoist or a jack,

make sure that it is always securely supported. Use jack stands.

Make sure the engine is off before you begin any servicing procedu res, unless the instruction tells you to do otherwise. This will

help eliminate several potential hazards:

• Carbon monoxide poisoning from engine exhaust. Be sure there is adequate ventilation whenever you run the engine

• Burns from hot parts or coolant. Let the engine and exhaust system cool before working in those areas.

• Injury from moving parts. If the instruction tells you to run the engine, be sure your hands, fingers and clothing are out of the way.

Gasoline vapors and hydrogen gases from batteries are explosive. To reduce the po ssibility of a fire or ex plosion, be ca reful w hen

working around gasoline or batteries.

• Use only a nonflammable solvent, not gasoline, to clean parts.

• Never drain or store gasoline in an open container.

• Keep all cigarettes, sparks and flames away from the battery and all fuel-related parts.

0-1

Page 2

dummyheaddummyhead

HOW TO USE THIS MANUAL

How To Use This Manual

This manual describes the service procedures for the NC700X/XA/XD/S/SA/SD-C.

Sections 1, 2 and 3 apply to the whole motorcycle. Section 2 illustrates procedures for removal/installation of components that may

be required to perform service described in the following sections.

Section 4 through 23 describe parts of the motorcycle, grouped according to location.

If you are not familiar with this motorcycle, read Technical Feature in Section 1.

Follow the Maintenance Schedule recommendations to ensure that the motorcycle is in peak operating condition.

Performing the first scheduled maintenance is very important. It compensates for the initial wear that occurs during the break-in

period.

Find the section you want on this page, then turn to the table of contents on the first page of the section.

Most sections start with an assembly or system illustration, service information and troubleshooting for the section. The subsequent

pages give detailed procedure.

Refer to the troubleshooting in each section according to the malfunction or symptom. In case of an engine trouble, refer to PGM-FI

section troubleshooting first.

Your safety, and the safety of others, is very important. To help you make informed decisions we have provided safety

messages and other information throughout this manual. Of course, it is not practical or possible to warn you about all the

hazards associated with servicing this vehicle.

You must use your own good judgement.

You will find important safety information in a variety of forms including:

• Safety Labels – on the vehicle

• Safety Messages – preceded by a safety alert symbol and one of three signal words, DANGER, WARNING, or CAUTION.

These signal words mean:

You WILL be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be KILLED or SERIOUSLY HURT if you don’t follow instructions.

You CAN be HURT if you don’t follow instructions.

• Instructions – how to service this vehicle correctly and safely.

As you read this manual, you will find information that is preceded by a symbol. The purpose of this message is to help

prevent damage to your vehicle, other property, or the environment.

ALL INFORMATION, ILLUSTRATIONS, DIRECTIONS AND SPECIFICATIONS INCLUDED IN THIS PUBLICATION ARE

BASED ON THE LATEST PRODUCT INFORMATION AVAILABLE AT THE TIME OF APPROVAL FOR PRINTING. Honda

Motor Co., Ltd. RESERVES THE RIGHT TO MAKE CHANGES AT ANY TIME WITHOUT NOTICE AND WITHOUT

INCURRING ANY OBLIGATION WHATSOEVER. NO PART OF THIS PUBLICATION MAY BE REPRODUCED WITHOUT

WRITTEN PERMISSION. THIS MANUAL IS WRITTEN FOR PERSONS WHO HAVE ACQUIRED BASIC KNOWLEDGE OF

MAINTENANCE ON Honda MOTORCYCLES, MOTOR SCOOTERS OR ATVS.

© Honda Motor Co., Ltd.

SERVICE PUBLICATION OFFICE

Date of Issue: February 2012

0-2

Page 3

dummyheaddummyhead

HOW TO USE THIS MANUAL

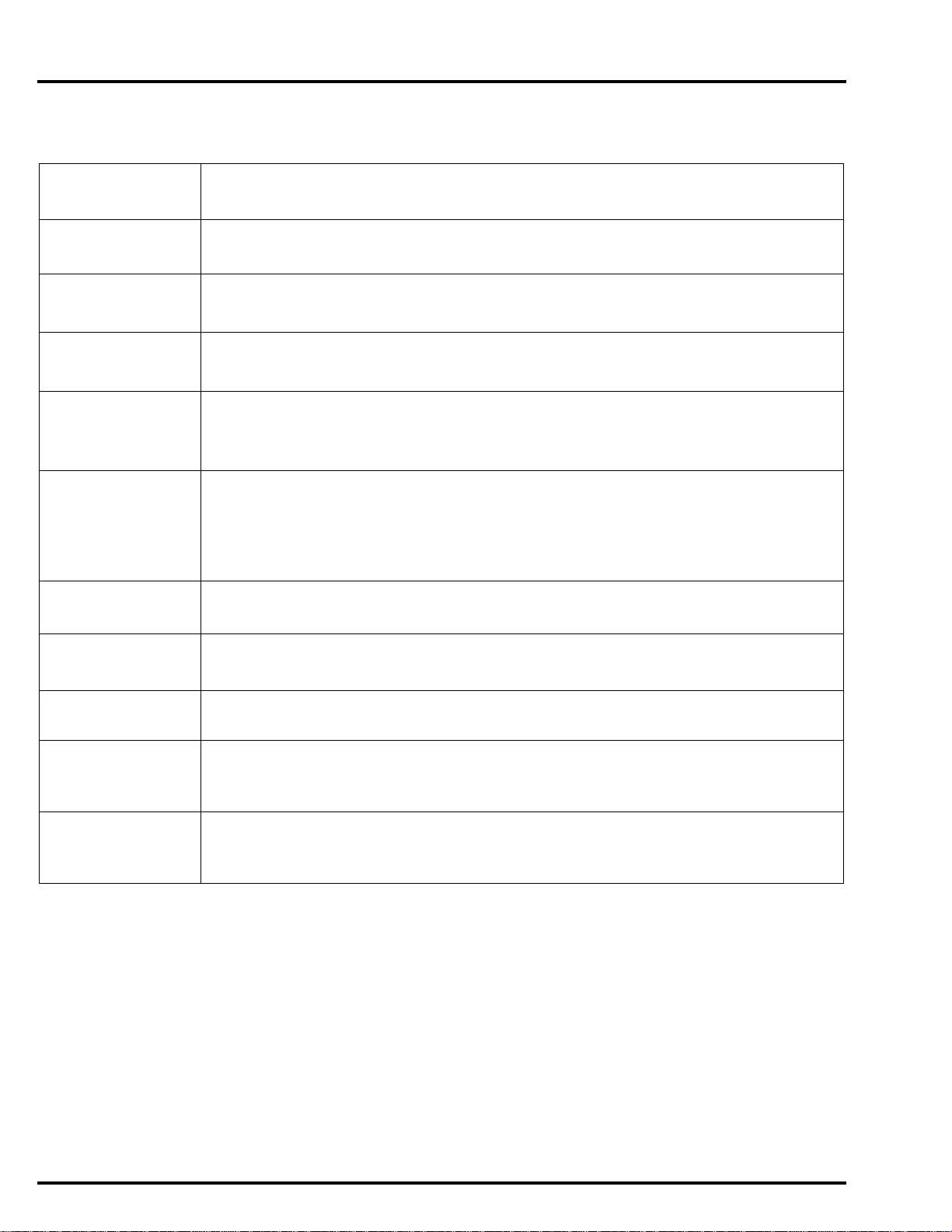

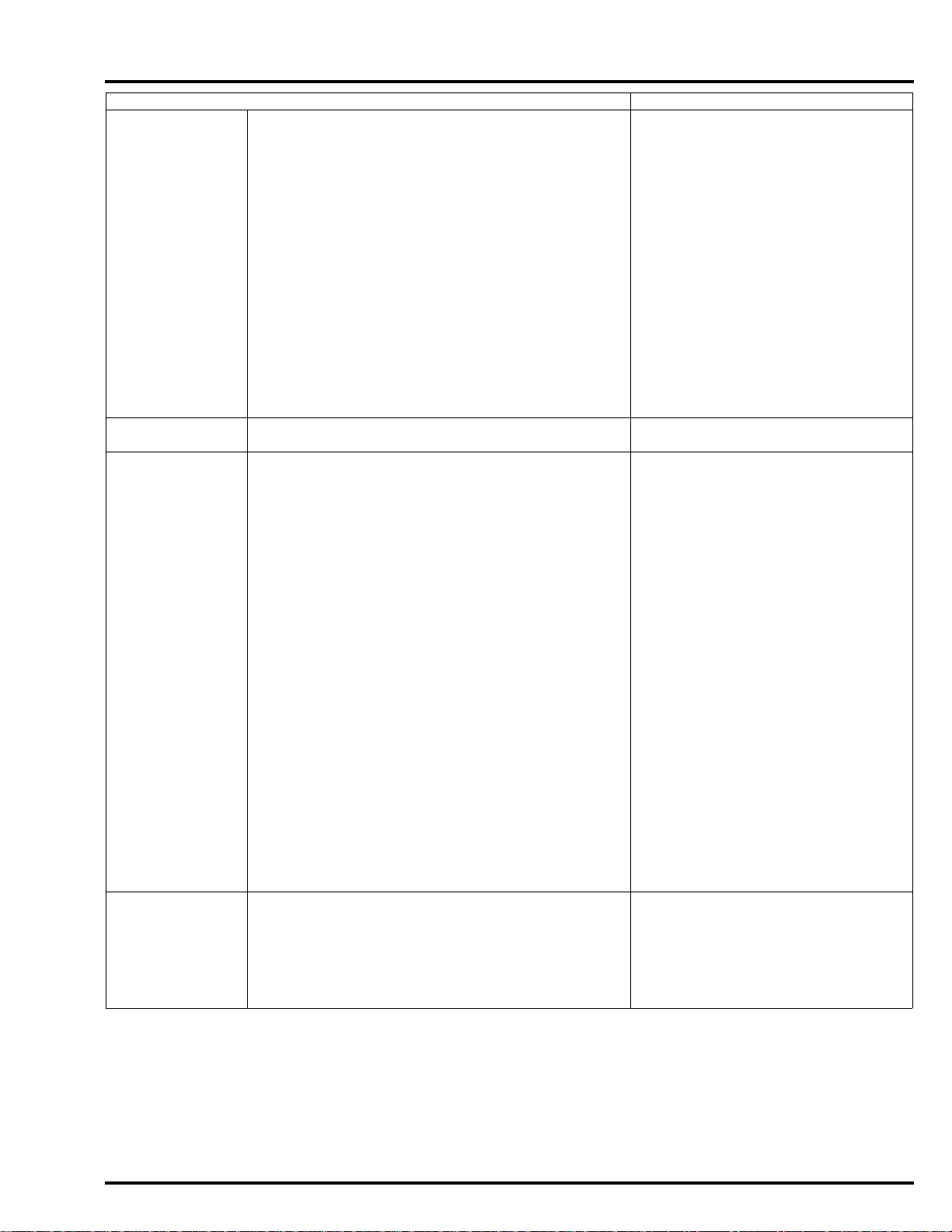

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplement ary info rmatio n is requi red p ertainin g to

these symbols, it would be explained specifically in the text without the use of the symbols.

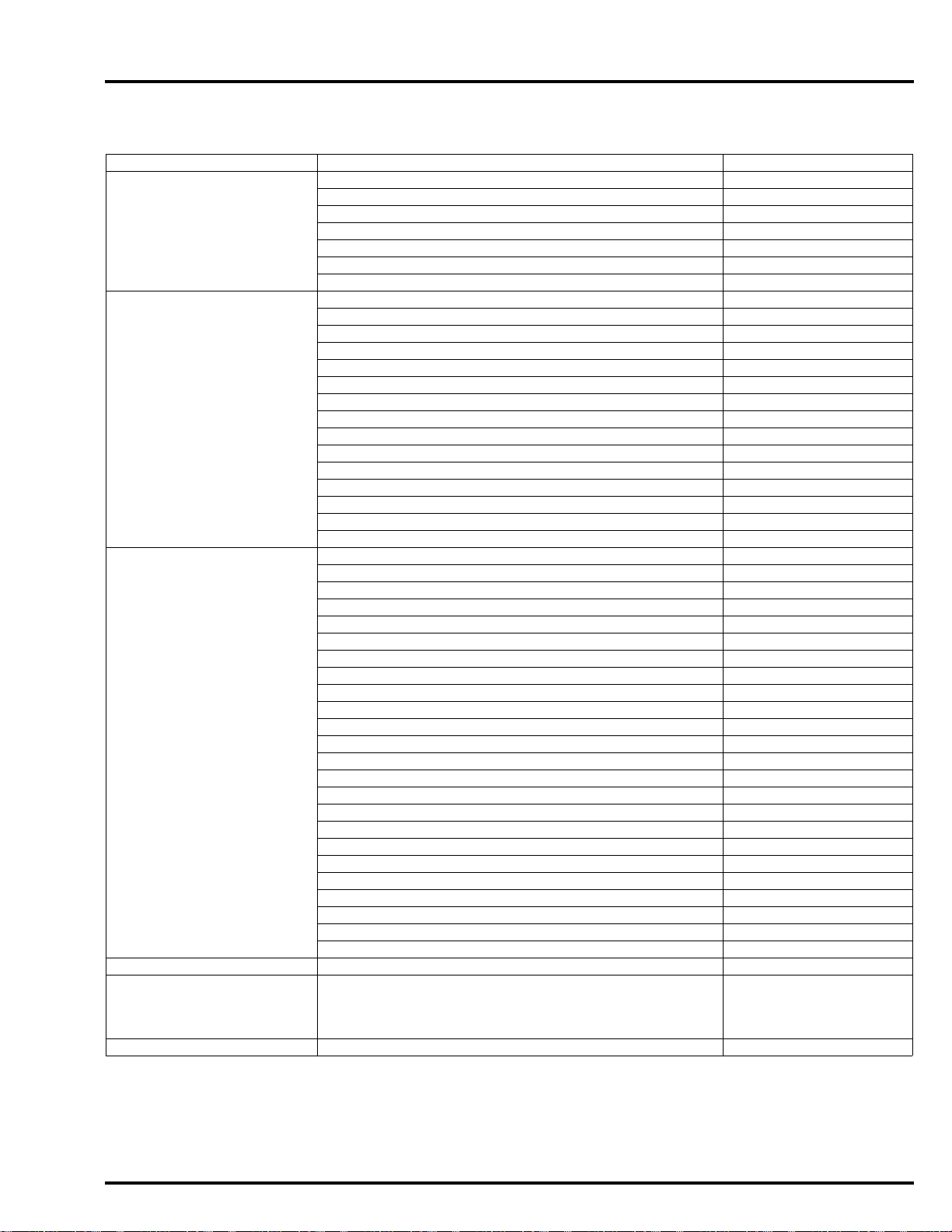

Replace the part(s) with new one(s) before assembly.

Use the recommended engine oil, unless otherwise specified.

Use molybdenum oil solution (mixture of the engine oil and molybdenum grease in a ratio of 1:1).

Use multi-purpose grease (lithium based multi-purpose grease NLGI #2 or equivalent).

Use molybdenum disulfide grease (containing more than 3% molybdenum disulfide, NLGI #2 or

equivalent).

Example:

• Molykote® BR-2 plus manufactured by Dow Corning U.S.A.

• Multi-purpose M-2 manufactured by Mitsubishi Oil, Japan

Use molybdenum disulfide paste (containing more than 40% molybdenum disulfide, NLGI #2 or

equivalent).

Example:

• Molykote® G-n Paste manufactured by Dow Corning U.S.A.

• Honda Moly 60 (U.S.A. only)

• Rocol ASP manufactured by Rocol Limited, U.K.

• Rocol Paste manufactured by Sumico Lubricant, Japan

Use silicone grease.

Apply locking agent. Use a medium strength locking agent unless otherwise sp ecified.

Apply sealant.

Use DOT 4 brake fluid. Use the recommended brake fluid unless otherwise specified.

Use fork or suspension fluid.

0-3

Page 4

dummyheaddummyhead

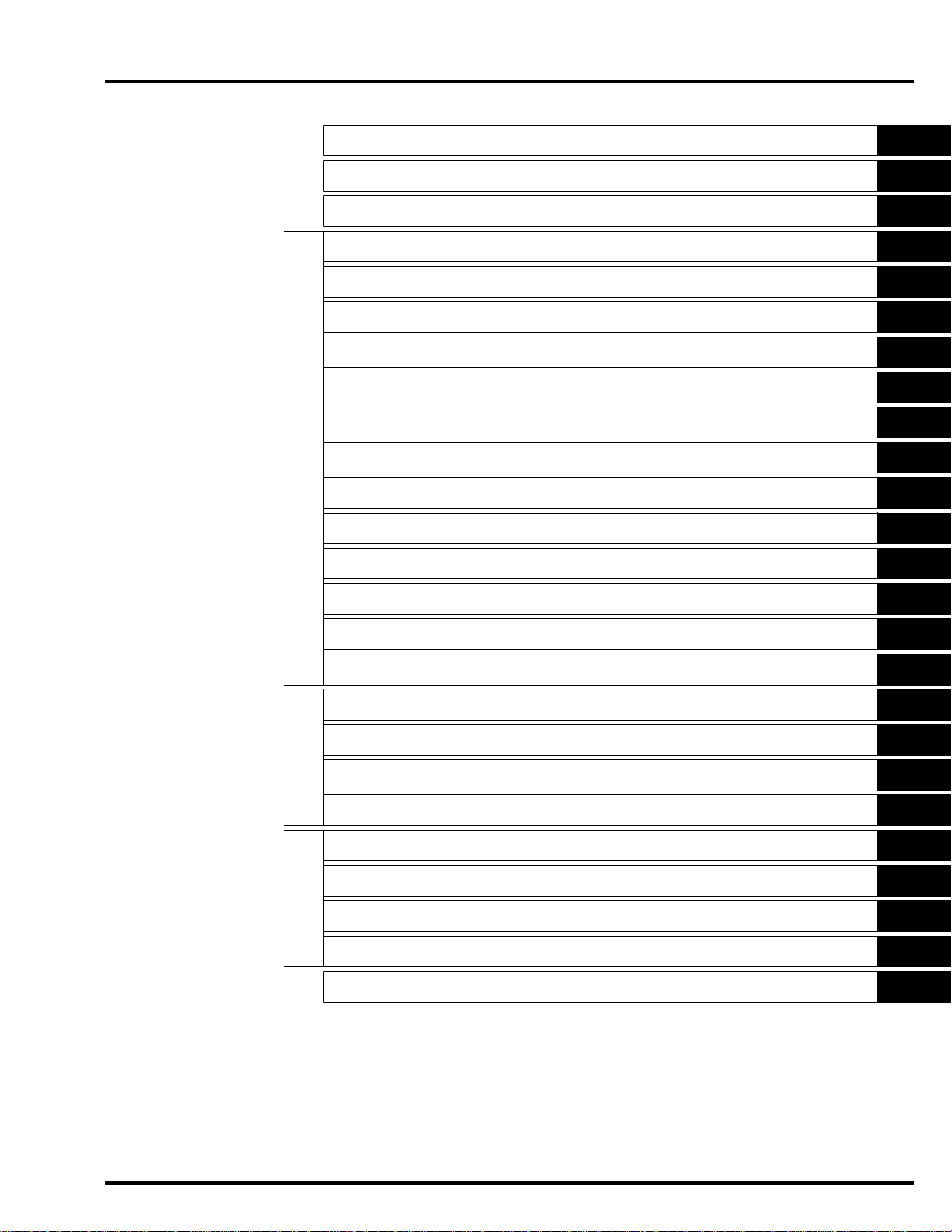

CONTENTS

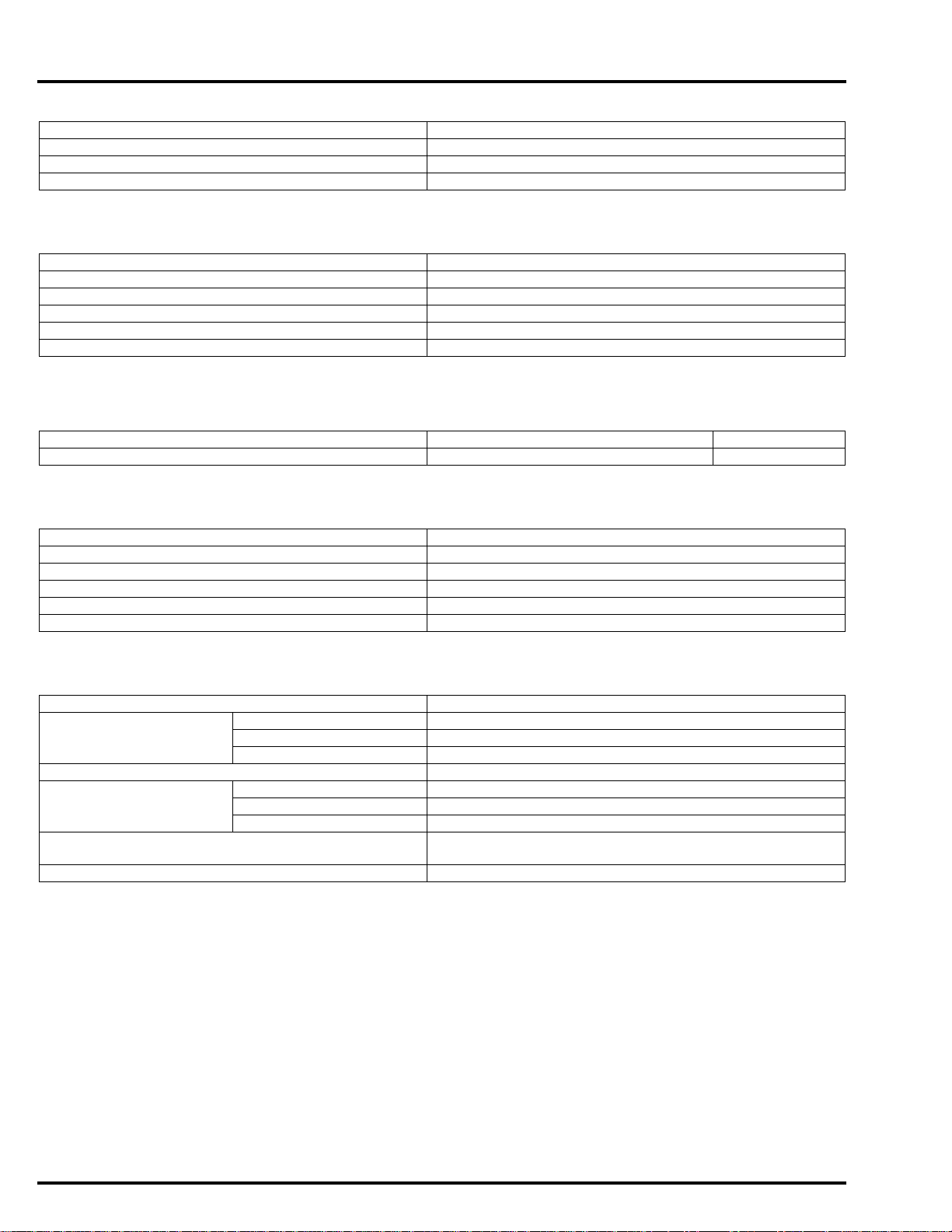

GENERAL INFORMATION

FRAME/BODY PANELS/EXHAUST SYSTEM

MAINTENANCE

PGM-FI SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

FUEL SYSTEM

COOLING SYSTEM

LUBRICATION SYSTEM

CYLINDER HEAD/VALVES

CLUTCH/GEARSHIFT LINKAGE (NC700X/XA/S/SA)

DUAL CLUTCH TRANSMISSION (DCT) (NC700XD/SD)

ALTERNATOR/STARTER CLUTCH

1

2

3

4

5

6

7

8

9

10

11

12

13

CRANKCASE/TRANSMISSION/BALANCER

ENGINE/DRIVE TRAIN ELECTRICAL

CRANKSHAFT/PISTON/CYLINDER

ENGINE REMOVAL/INSTALLATION

FRONT WHEEL/SUSPENSION/STEERING

REAR WHEEL/SUSPENSION

HYDRAULIC BRAKE

CHASSIS

ANTI-LOCK BRAKE SYSTEM (ABS)

BATTERY/CHARGING SYSTEM

LIGHTS/METERS/SWITCHES

FRAME

IMMOBILIZER SYSTEM (HISS)

ELECTRICAL

WIRING DIAGRAM

INDEX

14

15

16

17

18

19

20

21

22

23

24

Page 5

dummyheaddummyhead

MEMO

Page 6

dummytext

1. GENERAL INFORMATION

1

SERVICE RULES··········································1-2

MODEL IDENTIFICATION ····························1-3

SPECIFICATIONS·········································1-6

TORQUE VALUES······································1-15

LUBRICATION & SEAL POINTS ···············1-23

CABLE & HARNESS ROUTING·················1-25

EMISSION CONTROL SYSTEMS ··············1-86

TECHNICAL FEATURES····························1-87

1-1

Page 7

dummyheaddummyhead

GENERAL INFORMATION

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommende d parts and lubricants or their equivalents. Parts that don't meet Honda's desi gn

specifications may cause damage to the motorcycle.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the motorcycle. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

4. Install new gaskets, O-rings, cotter pins, and lock plates when reassembling.

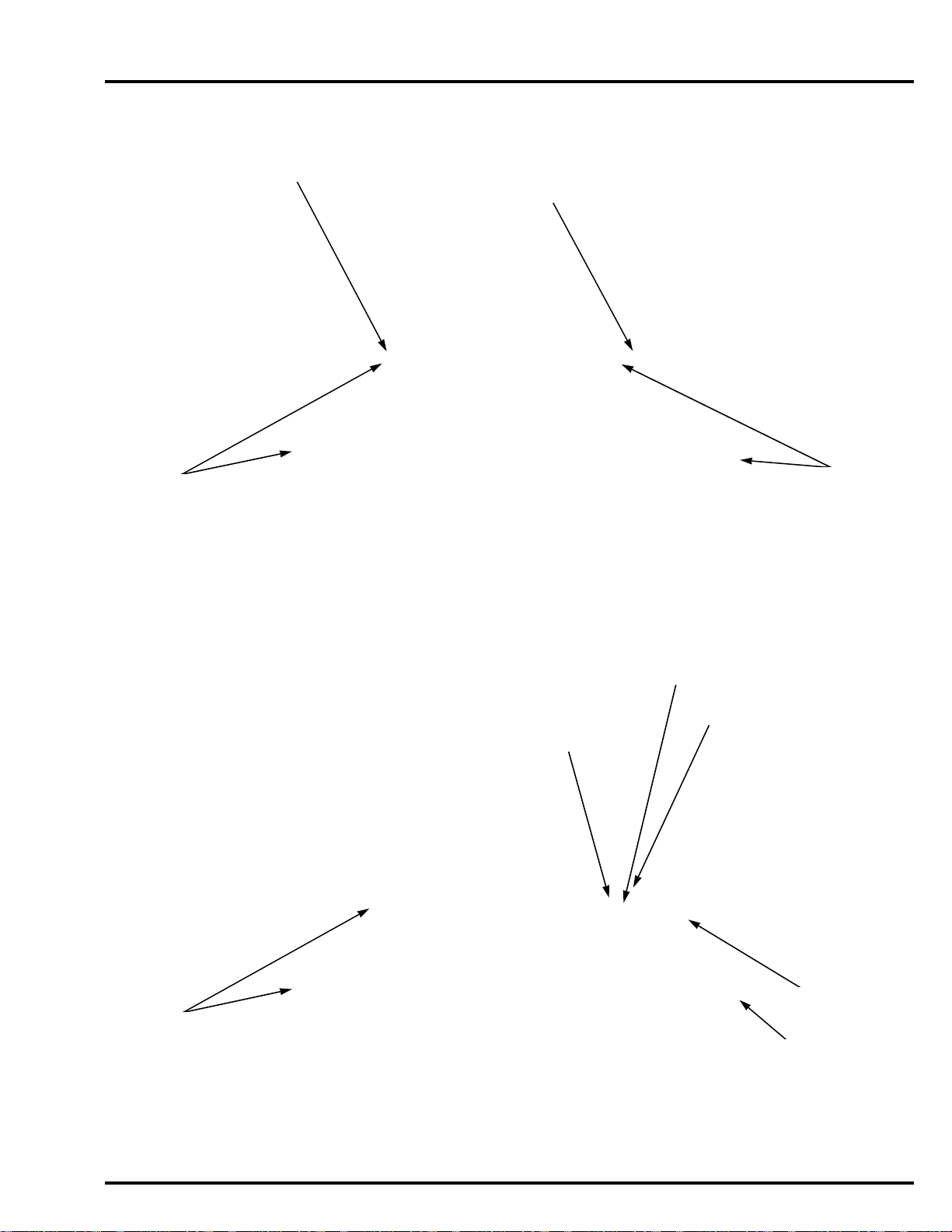

5. When tightening bolts or nuts, begin with the larger diameter or inner bolt first. Then tighten to the specified torque diagonally in

incremental steps unless a particular sequence is specified.

6. Clean parts in cleaning solvent upon disassembly. Lubricate any slid ing surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Route all electrical wires as show in the Cable and Harness Routing (page 1-25).

9. Do not bend or twist control cables. Damaged control cables will no t operate smoothly and may stick or bind.

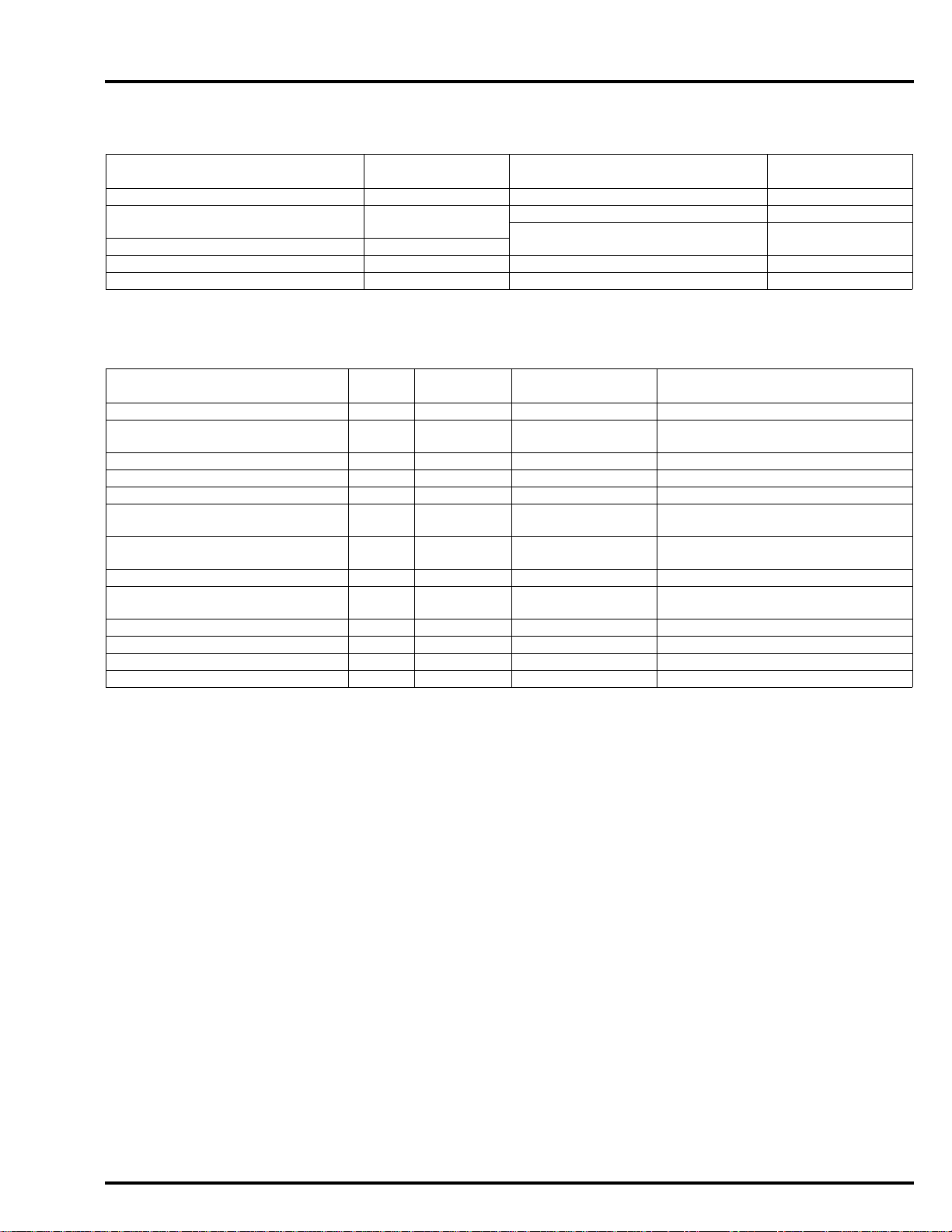

ABBREVIATION

Throughout this manual, the following abbreviations are used to iden tify the respective parts or systems.

Abbrev. term Full term

ABS (NC700XA/XD/SA/SD) Anti-lock Brake System

CKP sensor Crankshaft Position sensor

DCT (NC700XD/SD) Dual Clutch Transmission

DLC Data Link Connector

DTC Diagnostic Trouble Code

ECM (NC700X/XA/S/SA) Engine Control Module

ECT sensor Engine Coolant Temperature sensor

EEPROM Electrically Erasable Programmable Read Only Memory

EOP sensor (NC700XD/SD) Engine Oil Pressure sensor

EOP switch Engine Oil Pressure switch

EOT sensor (NC700XD/SD) Engine Oil Temperature sensor

HDS Honda Diagnostic System

HISS Honda Ignition Security System

IACV Idle Air Control Valve

IAT sensor Intake Air Temperature sensor

MAP sensor Manifold Absolute Pressure sensor

MIL Malfunction Indicator Lamp

2 sensor Oxygen sensor

O

PCM (NC700XD/SD) Power Control Module

PCV Proportional Co ntrol Valve

PGM-FI Programmed Fuel Injection

SCS connector Service Check Short connector

TP sensor Throttle Position sensor

TR sensor (NC700XD/SD) Transmission Range Sensor

VS sensor Vehicle Speed sensor

DESTINATION CODE

Throughout this manual, the following codes are used to identify individual types for each region.

DESTINATION CODE REGION

EU.K.

III E U.K. type III

ED EUROPEAN DIRECT SALES

II ED EUROPEAN DIRECT SALES type II

FFrance

II F France type II

KO Korea

RU Russia

U Australia, New Zealand

1-2

Page 8

dummyheaddummyhead

MODEL IDENTIFICATION

NC700XA shown:

GENERAL INFORMATION

NC700SA shown:

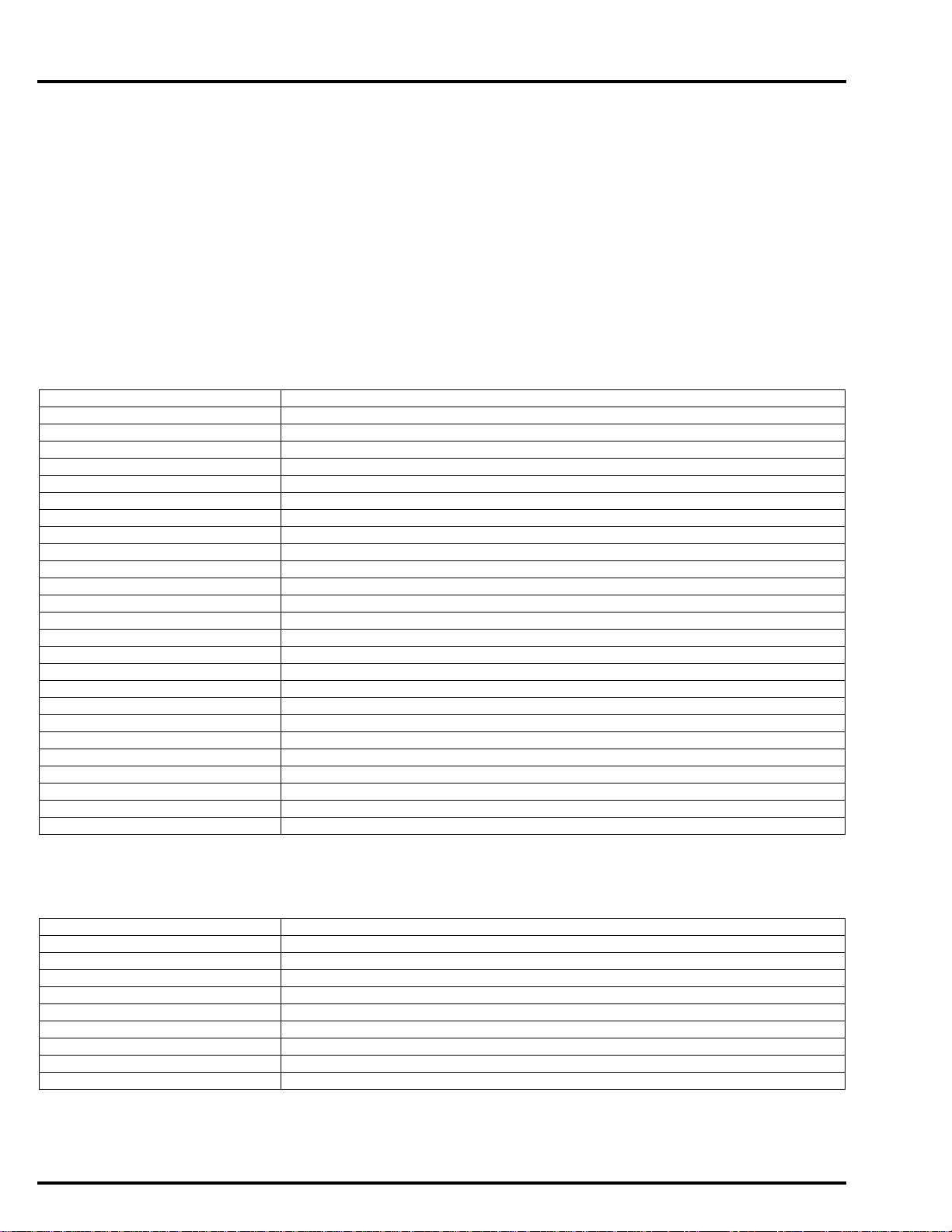

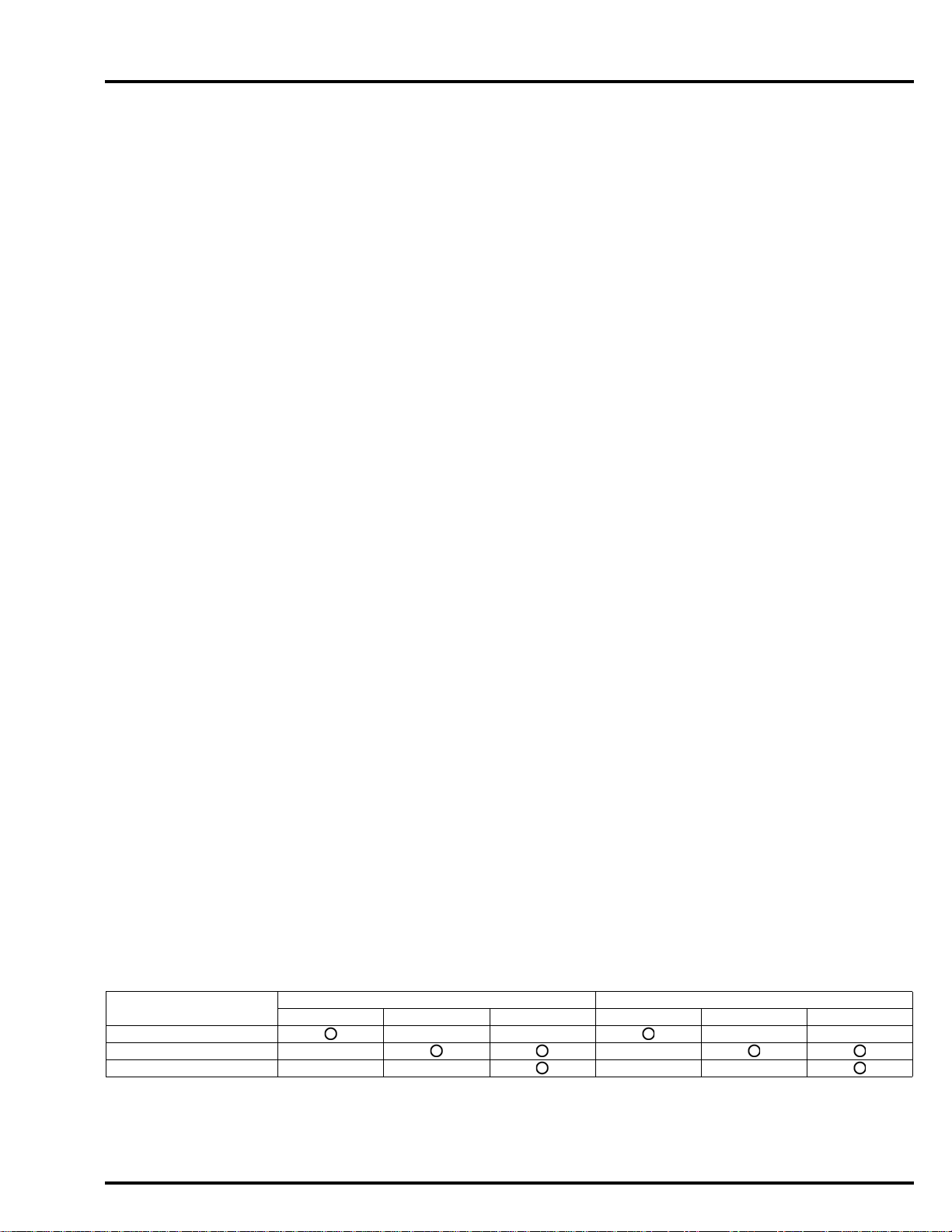

This manual covers following types of NC700 models:

TYPE

Standard brake – – – –

ABS – –

DCT –– ––

NC700X NC700XA NC700XD NC700S NC700SA NC700SD

NC700X NC700S

Be sure to refer to the procedure for the appropriate version of the NC700.

1-3

Page 9

dummyheaddummyhead

[1]

[1]

[1]

[1]

GENERAL INFORMATION

SERIAL NUMBERS

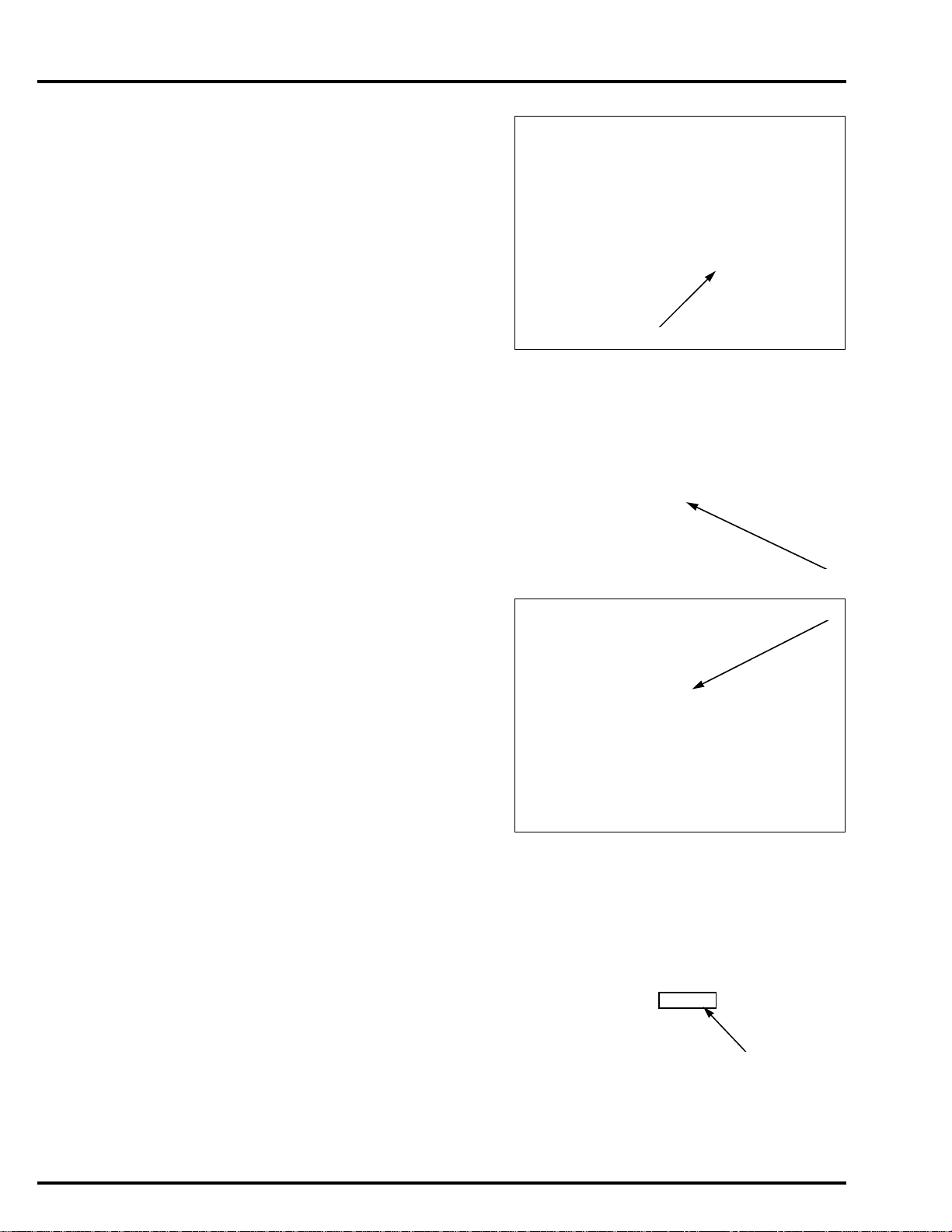

The Vehicle Identification Number (V.I.N) [1] is stamped on the right side of

the steering head.

The registered number plate (E, F, ED, RU types) [1] and compliance plate

(U type only) is attached on the left side of the steering head.

The engine serial number [1] is stamped on the lower right side of the

crankcase.

The throttle body identification number [1] is stamped on the lower left side

of the throttle body as shown.

1-4

Page 10

dummyheaddummyhead

[1]

[1]

[1]

LABELS

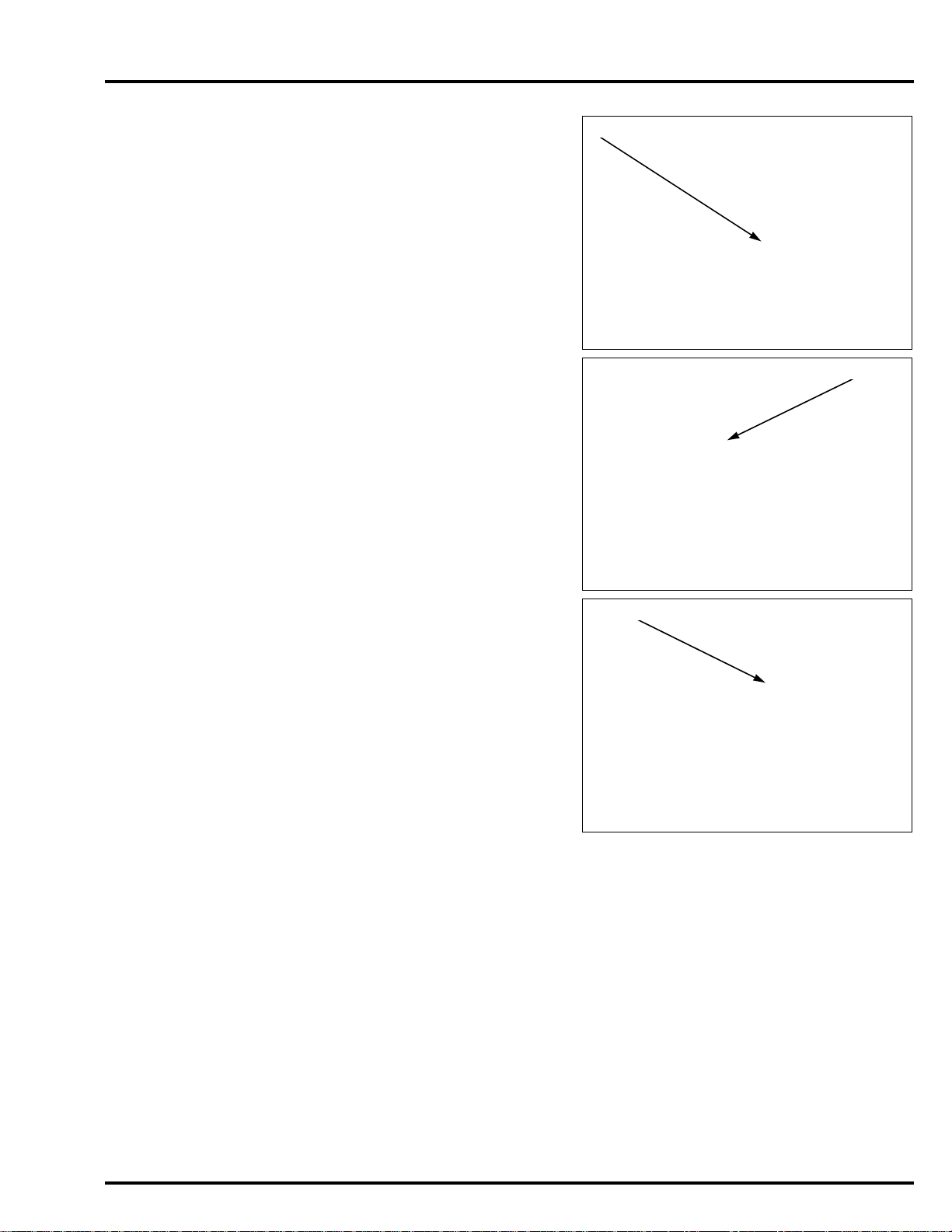

The color label [1] is attached on the right side of the rear frame. When

ordering color-coded parts, always specify the designated color code.

The Safety Certification Label (KO type) [1] is located on the left side of the

rear frame.

GENERAL INFORMATION

The Emission Control Information Label (KO type) [2] is located on the left

side of the rear frame.

1-5

Page 11

dummyheaddummyhead

GENERAL INFORMATION

SPECIFICATIONS

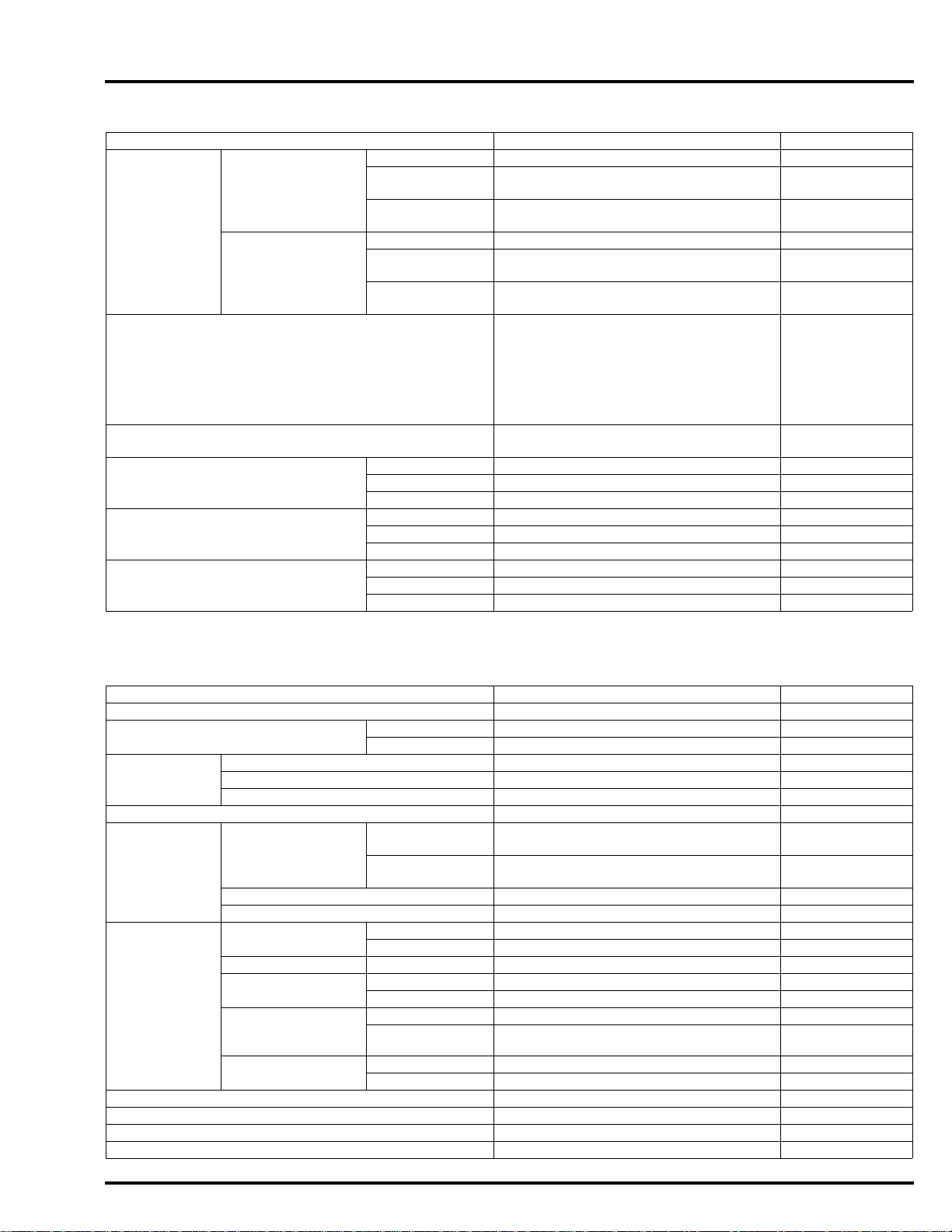

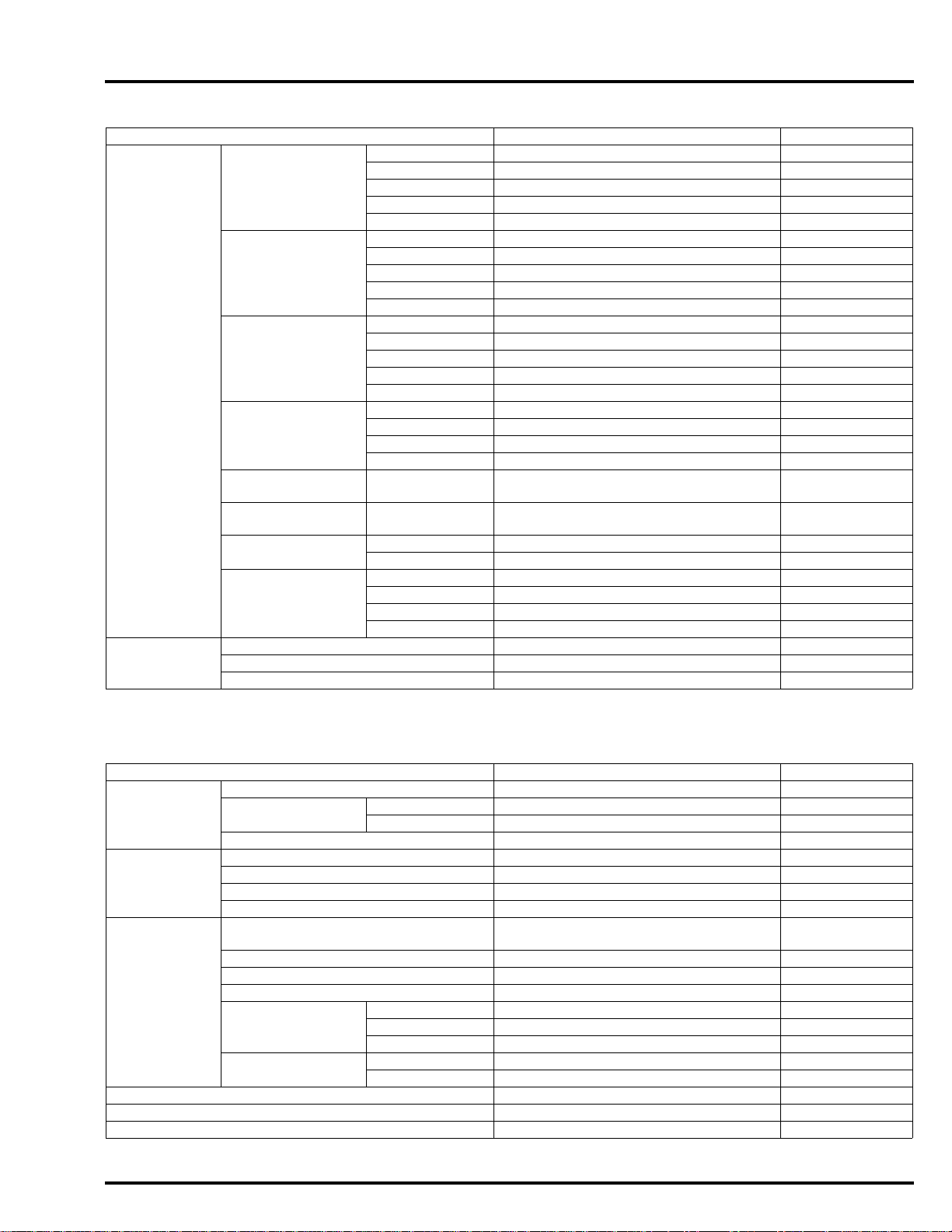

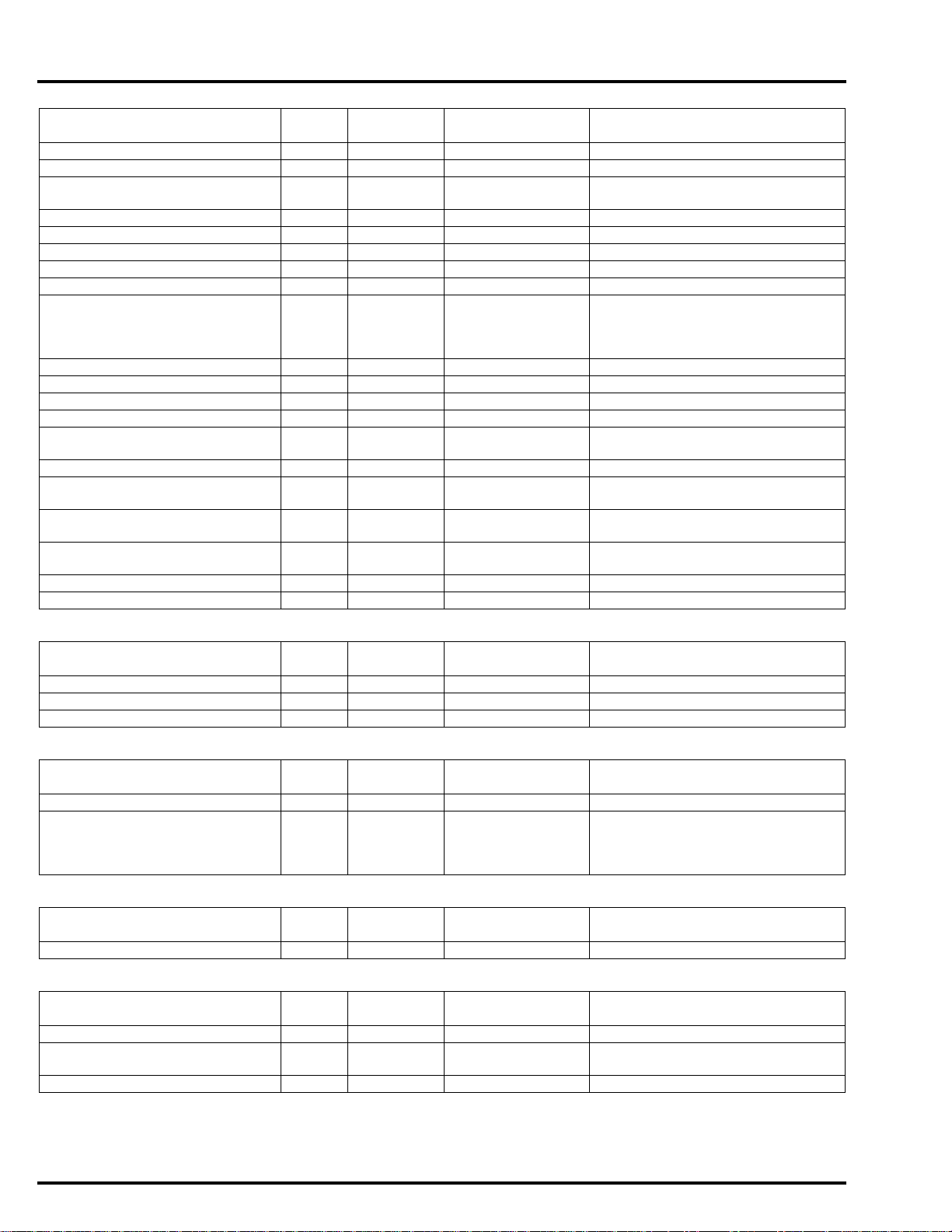

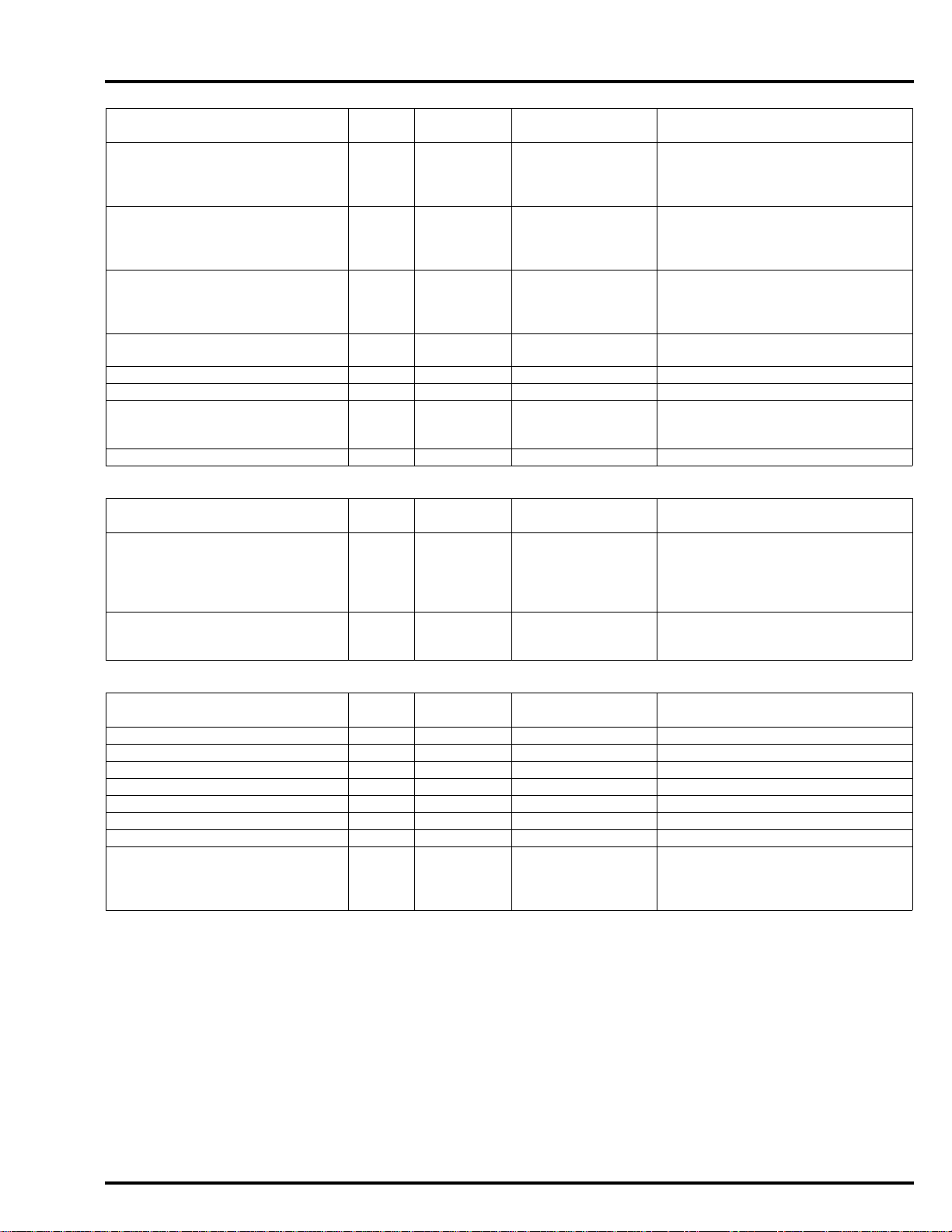

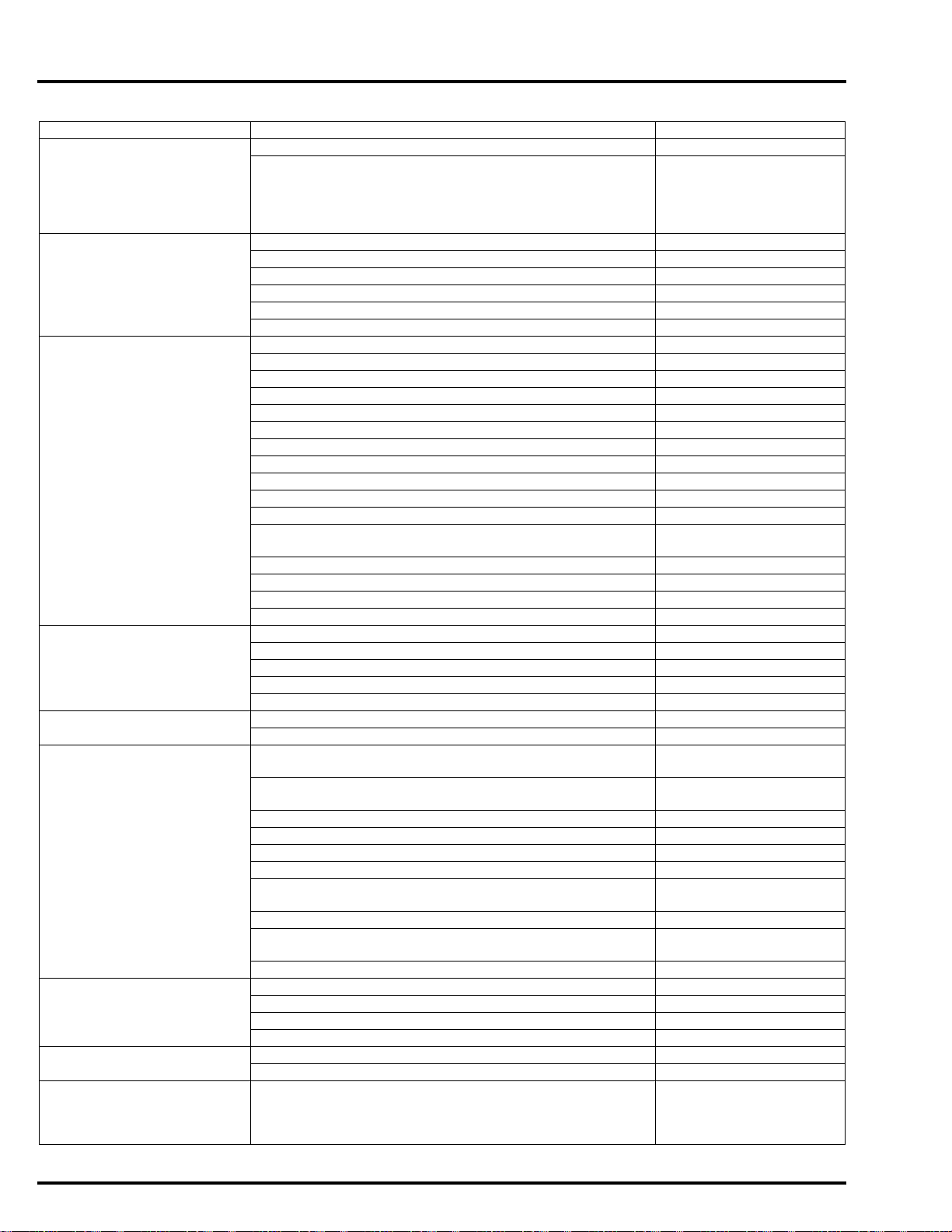

GENERAL SPECIFICATIONS

ITEM SPECIFICATIONS

DIMENSIONS Overall length NC700X/XA/XD 2,210 mm (87.0 in)

NC700S/SA/SD 2,195 mm (86.4 in)

Overall width E, ED, F,

RU, U type

KO type NC700XA 825 mm (32.5 in)

Overall height NC700X/XA/XD 1,285 mm (50.6 in)

Wheelbase NC700X/XA/XD 1,540 mm (60.6 in)

Seat height NC700X/XA/XD 830 mm (32.7 in)

Footpeg height NC700X/XA/XD 341 mm (13.4 in)

Ground clearance NC700X/XA/XD 165 mm (6.5 in)

Curb weight E, ED, F,

RU, U type

KO type NC700XA 220 kg (485 lbs)

Maximum weight capacity E, ED, F, RU, U type 209 kg (461 lbs)

FRAME Frame type Diamond

Front suspension Telescopic fork

Front axle travel NC700X/XA/XD 137 mm (5.4 in)

Rear suspension Swingarm

Rear axle travel NC700X/XA/XD 150 mm (5.9 in)

Front tire size 120/70ZR17M/C (58W)

Rear tire size 160/60ZR17M/C (69W)

Front tire brand BRIDGESTONE BT023F G

Rear tire brand BRIDGESTONE BT023R G

Front brake Hydraulic single disc

Rear brake Hydraulic single disc

Caster angle 27°

Trail length 110 mm (4.3 in)

Fuel tank capacity 14.1 liters (3.73 US gal, 3.1 Imp gal)

NC700X/XA/XD 830 mm (32.7 in)

NC700S/SA/SD 760 mm (29.9 in)

NC700S/SA/SD 1,130 mm (44.5 in)

NC700S/SA/SD 1,525 mm (60.0 in)

NC700S/SA/SD 790 mm (31.1 in)

NC700S/SA/SD 310 mm (12.2 in)

NC700S/SA/SD 140 mm (5.5 in)

NC700X 214 kg (472 lbs)

NC700XA 218 kg (481 lbs)

NC700XD 228 kg (503 lbs)

NC700S 211 kg (465 lbs)

NC700SA 215 kg (474 lbs)

NC700SD 225 kg (496 lbs)

KO type 189 kg (417 lbs)

NC700S/SA/SD 107 mm (4.2 in)

NC700S/SA/SD 120 mm (4.7 in)

METZELER ROADTEC Z8 INTERACT E

METZELER ROADTEC Z8 INTERACT

1-6

Page 12

dummyheaddummyhead

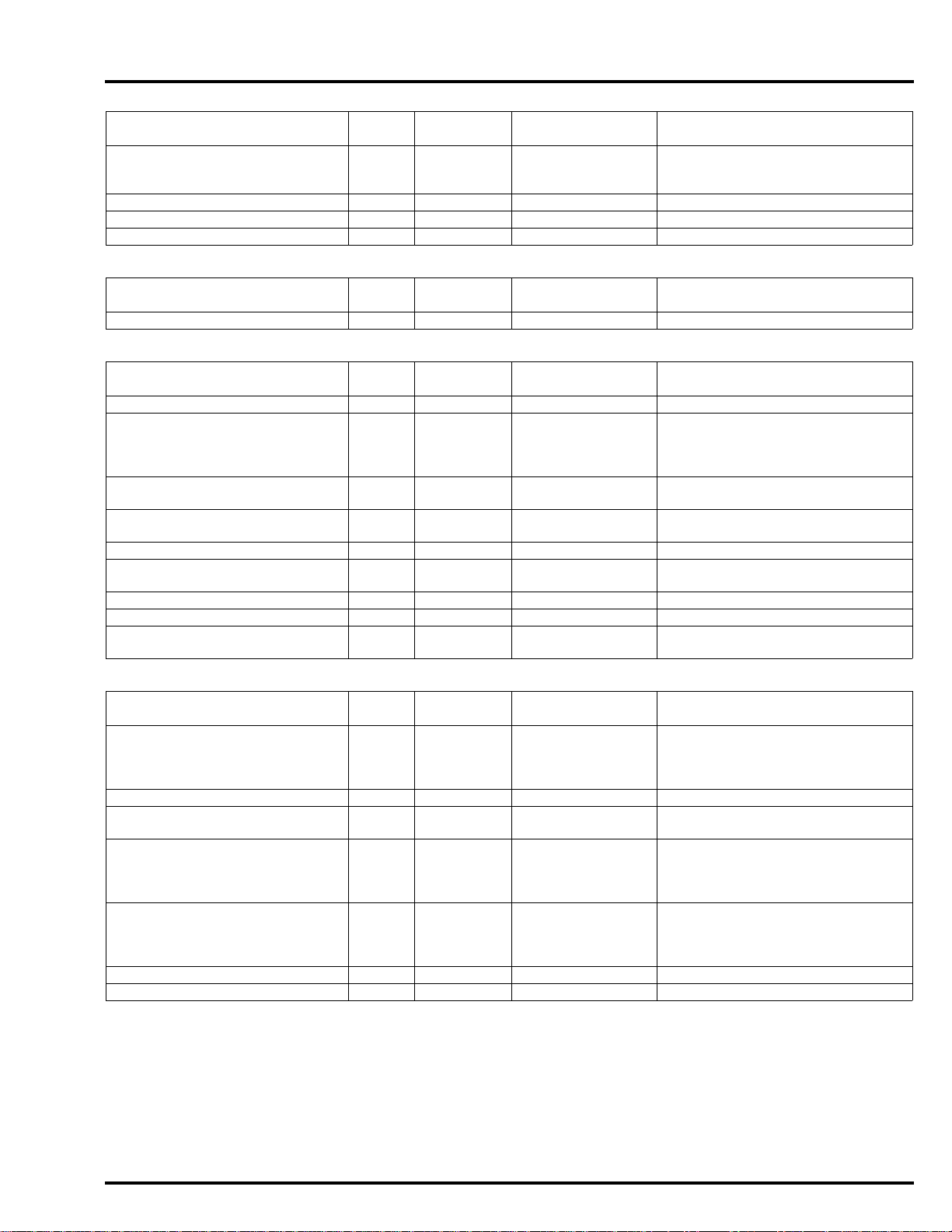

GENERAL INFORMATION

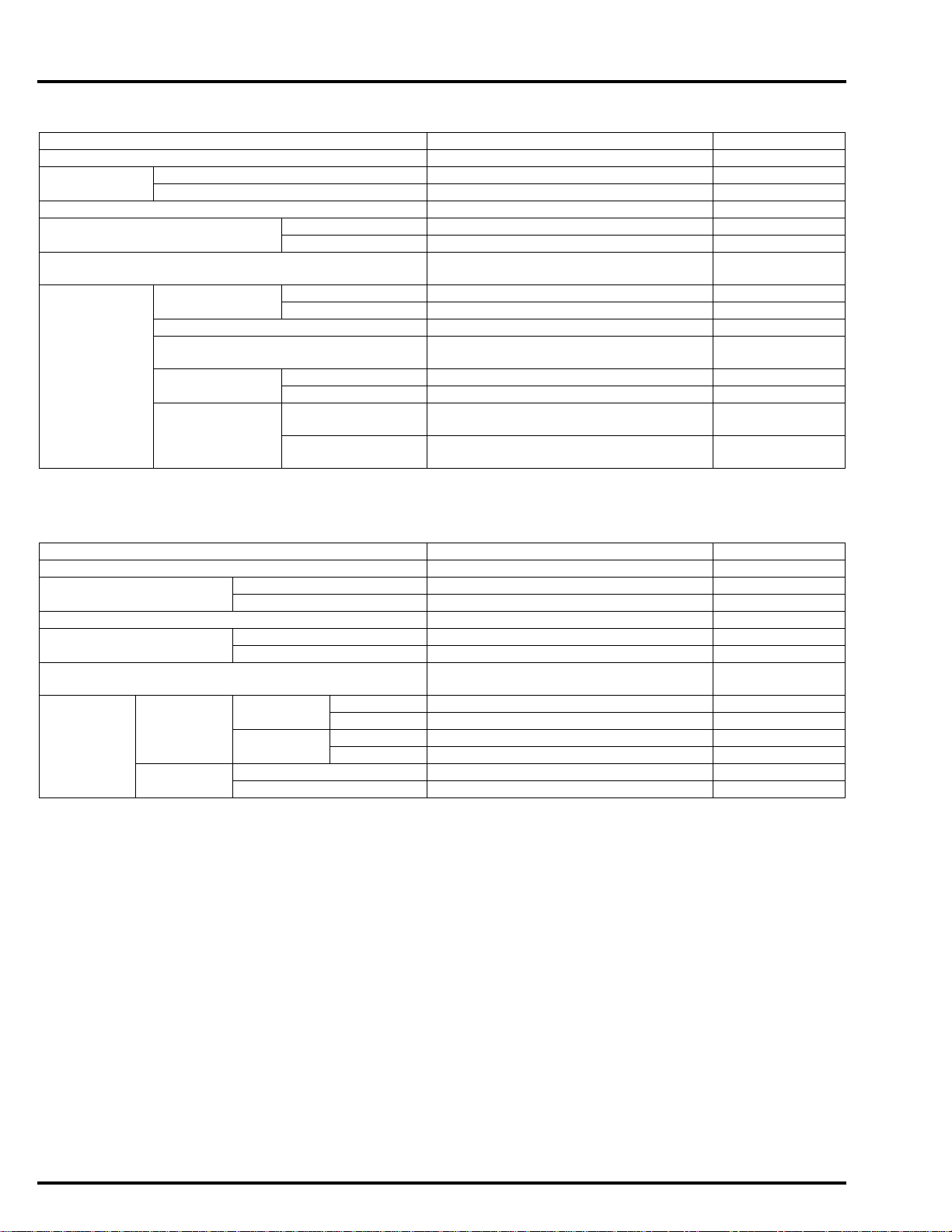

ITEM SPECIFICATIONS

ENGINE Cylinder arrangement 2 cylinders in-line, slant angle 55°

Bore and stroke 73.0 x 80.0 mm (2.87 x 3.15 in)

Displacement 670 cm3 (40.9 cu-in)

Compression ratio 10.7:1

Valve train Chain driven, OHC with rocker arm

Intake valve opens at 1 mm (0.04 in) lift No.1: – 20° BTDC

No.2: – 25° BTDC

closes at 1 mm (0.04 in) lift 27° ABDC

Exhaust valve opens at 1 mm (0.04 in) lift 30° BBDC

closes at 1 mm (0.04 in) lift No.1: – 15° ATDC

No.2: – 20° ATDC

Lubrication system Forced pressure and wet sump

Oil pump type Trochoid

Cooling system Liquid cooled

Air filtration Paper element

Engine dry weight NC700X/XA/S/SA 60.5 kg (133.4 lbs)

NC700XD/SD 67.3 kg (148.4 lbs)

Firing order 1 - 2

FUEL DELIVERY

SYSTEM

DRIVE TRAIN Clutch system NC700X/XA/S/SA Multi-plate, wet

ELECTRICAL Ignition system Computer-controlled digital

Type PGM-FI (Programmed Fuel Injection)

Throttle bore 36 mm (1.4 in)

NC700XD/SD 2 Multi-plate wet clutches

Clutch operation system NC700X/XA/S/SA Cable operating

NC700XD/SD Automatic

Transmission Constant mesh, 6-speeds

Primary reduction NC700X/XA/S/SA 1.731 (71/41)

NC700XD/SD 1.921 (73/38)

Final reduction NC700X/XA/S/SA 2.687 (43/16)

NC700XD/SD 2.437 (39/16)

Gear ratio NC700X/XA/S/SA 1st 2.812 (45/16)

2nd 1.894 (36/19)

3rd 1.454 (32/22)

4th 1.200 (30/25)

5th 1.033 (31/30)

6th 0.837 (31/37)

NC700XD/SD 1st 2.666 (40/15)

2nd 1.904 (40/21)

3rd 1.454 (32/22)

4th 1.200 (30/25)

5th 1.033 (31/30)

6th 0.837 (31/37)

Gearshift pattern NC700X/XA/S/SA Left foot operated return system,

1 - N - 2 - 3 - 4 - 5 - 6

NC700XD/SD Automatic and electric shift (left hand

operated) return system,

N - 1 - 2 - 3 - 4 - 5 - 6

transistorized with electric advance

Starting system Electr ic starter motor

Charging system Triple phase output alternator

Regulator/rectifier FET shorted/triple phase full wave

rectification

Lighting system Battery

1-7

Page 13

dummyheaddummyhead

GENERAL INFORMATION

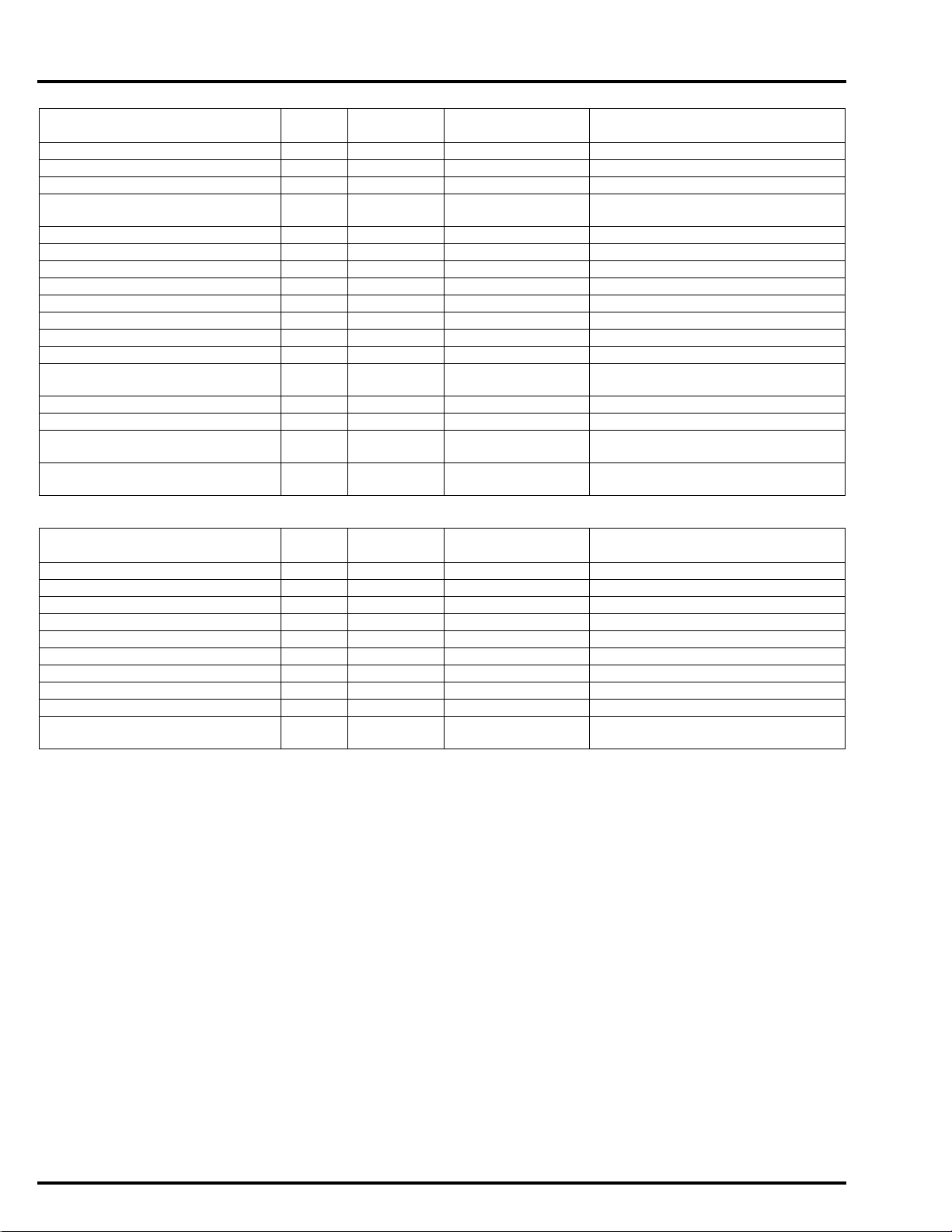

PGM-FI SPECIFICATIONS

ITEM SPECIFICATIONS

IAT sensor resistance (at 20°C/68°F) 2.2 – 2.7 k

ECT sensor resistance (at 40°C/104°F) 1.0 – 1.3 k

Injector resistance (at 20°C/68°F) 11 – 13

IGNITION SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Spark plug (Iridium) IFR6G-11K (NGK)

Spark plug gap 1.0 – 1.1 mm (0.039 – 0.043 in)

Ignition coil peak voltage 100 V minimum

CKP sensor peak voltage (at 20°C/68°F) 0.7 V minimum

Ignition timing ("F" mark) 12° BTDC at idle

ELECTRIC STARTER SPECIFICATION

ITEM STANDARD SERVICE LIMIT

Starter motor brush length 12.0 – 13.0 (0.47 – 0.51) 6.5 (0.26)

Unit: mm (in)

FUEL SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Throttle body identification number GQ3UA

Idle speed 1,200 ± 100 min

Throttle grip freeplay 2 – 6 mm (1/16 – 1/4 in)

Fuel pressure at idle 343 kPa (3.5 kgf/cm

Fuel pump flow (at 12 V) 230 cm3 (7.8 US oz, 8.1 Imp oz) minimum/10 seconds

-1

(rpm)

2

, 50 psi)

COOLING SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Coolant capacity Radiator and engine 1.69 liters (1.79 US qt, 1.49 Imp qt)

At draining 1.41 liters (1.49 US qt, 1.24 Imp qt)

Reserve tank 0.13 liter (0.14 US qt, 0.11 Imp qt)

Radiator cap relief pressure 108 – 137 kPa (1.1 – 1.4 kgf/cm

Thermostat Begin to open 80 – 84°C (176 – 183°F)

Fully open 95°C (203°F)

Valve lift 8 mm (0.3 in) minimum

Recommended antifreeze High quality ethylene glycol antifreeze containing silicate-free

corrosion inhibitors

Standard coolant concentration 1:1 (mixture with distilled water)

2

, 16 – 20 psi)

1-8

Page 14

dummyheaddummyhead

GENERAL INFORMATION

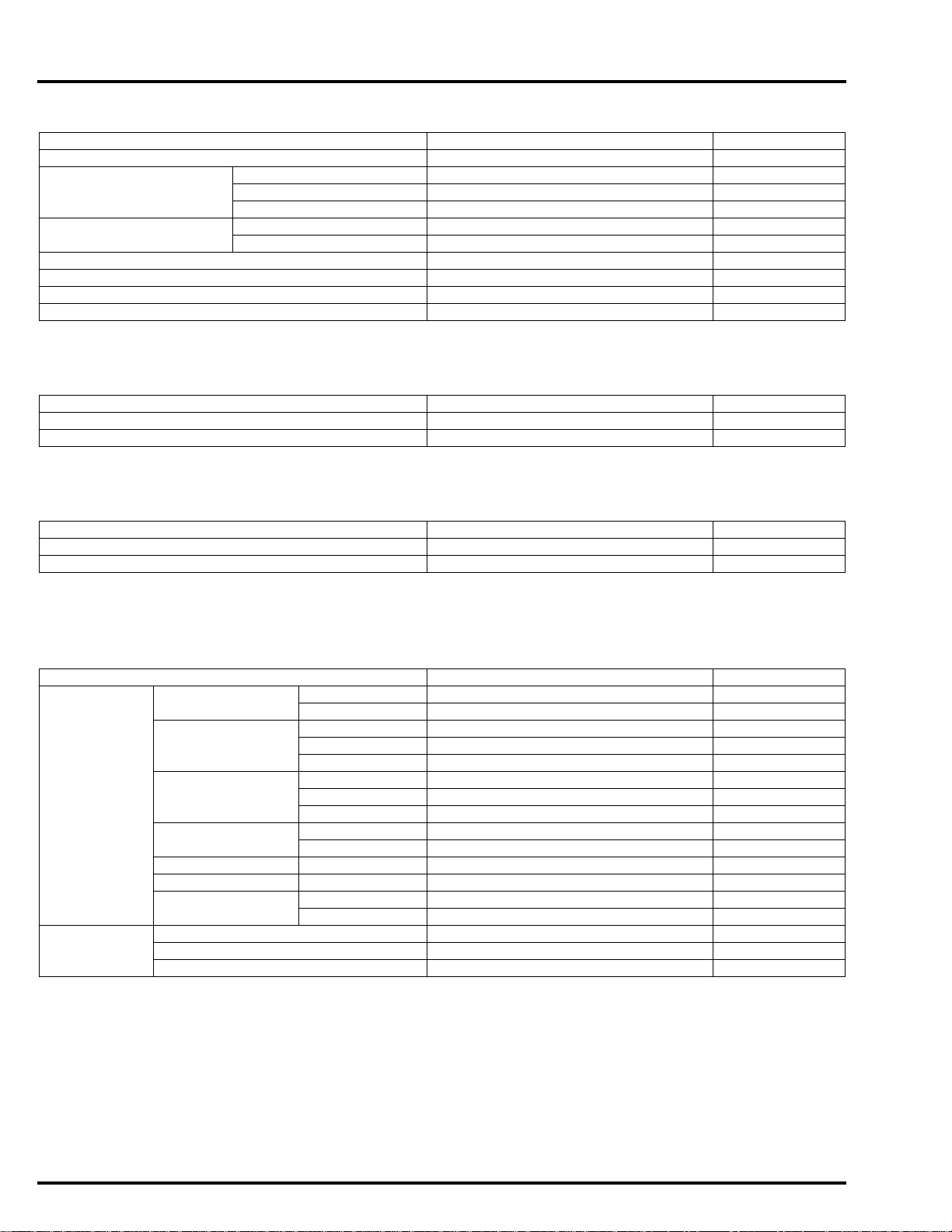

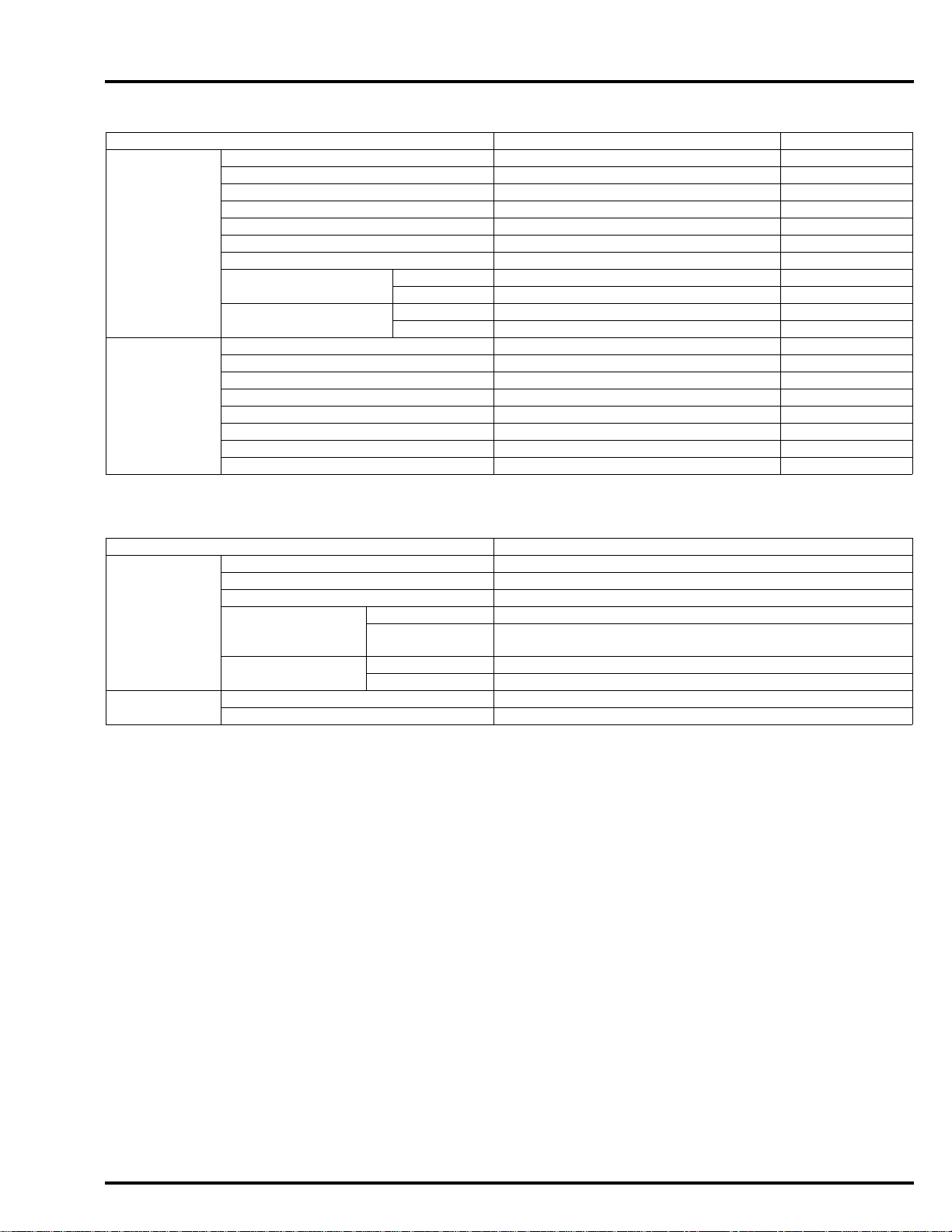

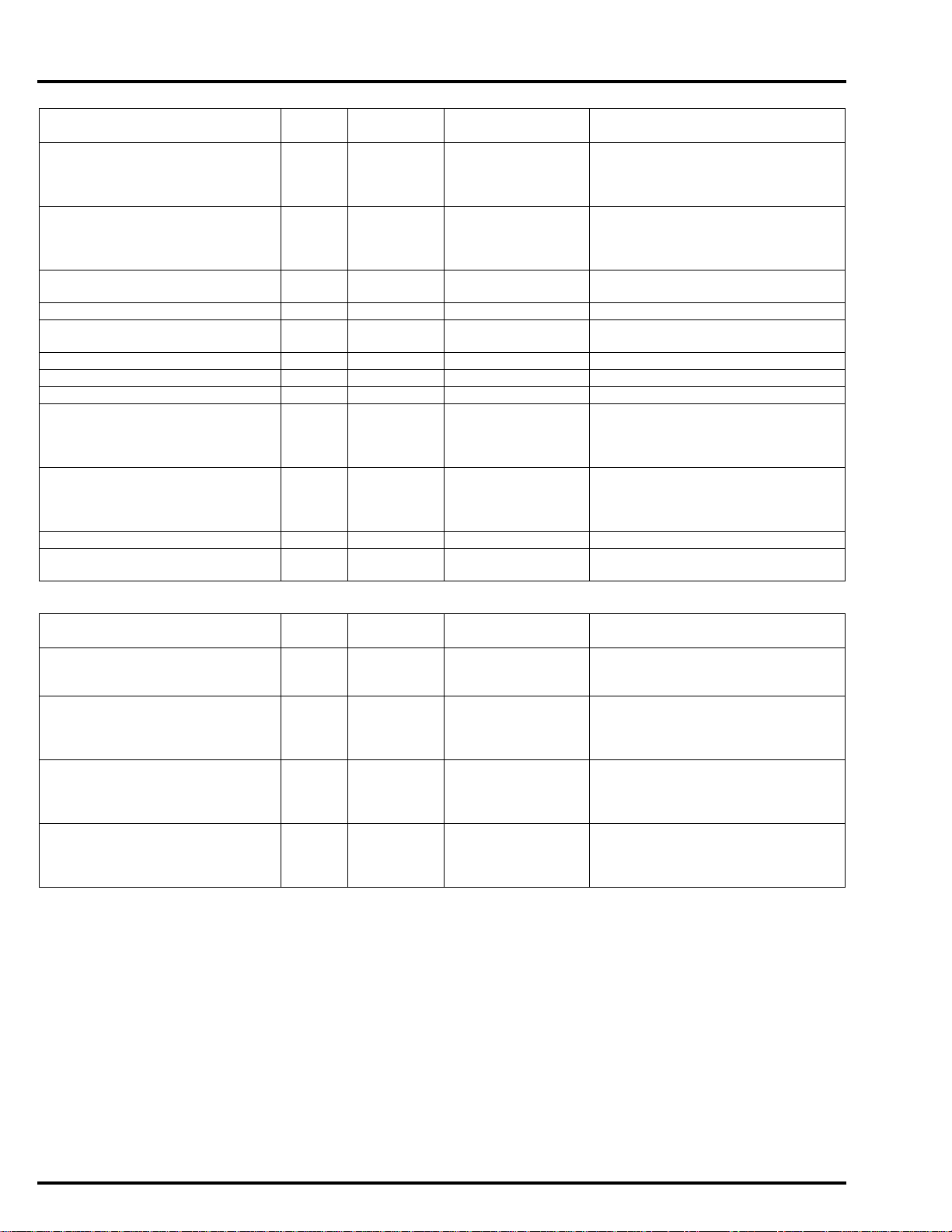

LUBRICATION SYSTEM SPECIFICATIONS

ITEM ST ANDARD SERVICE LIMIT

Engine oil

capacity

Recommended engine oil Honda "4-stroke motorcycle oil" or an

Oil pressure at engine oil filter 470 kPa (4.8 kgf/cm

Oil pump rotor (NC700X/XA/S/SA) Tip clearance 0.15 (0.006) 0.20 (0.008)

Engine oil pump rotor (NC700XD/SD) Tip clearance 0.15 (0.006) 0.20 (0.008)

Clutch oil pump rotor (NC700XD/SD) Tip clearance 0.15 (0.006) –

NC700X/XA/S/SA After draining 3.1 liters (3.3 US qt, 2.7 Imp qt) –

After draining/

filter change

After

disassembly

NC700XD/SD After draining 3.2 liters (3.4 US qt, 2.8 Imp qt) –

After draining/

filter change

After

disassembly

Body clearance 0.15 – 0.21 (0.006 – 0.008) 0.35 (0.014)

Side clearance 0.04 – 0.09 (0.002 – 0.004) 0.12 (0.005)

Body clearance 0.15 – 0.21 (0.006 – 0.008) 0.35 (0.014)

Side clearance 0.04 – 0.09 (0.002 – 0.004) 0.12 (0.005)

Body clearance 0.15 – 0.21 (0.006 – 0.008) –

Side clearance 0.04 – 0.09 (0.002 – 0.004) –

3.4 liters (3.6 US qt, 3.0 Imp qt) –

3.7 liters (3.9 US qt, 3.3 Imp qt) –

3.4 liters (3.6 US qt, 3.0 Imp qt) –

4.1 liters (4.3 US qt, 3.6 Imp qt) –

equivalent

API service classification: SG or higher

(except oils labeled as energy conserving

on the circular API service label)

Viscosity: SAE 10W-30

JASO T 903 standard: MA

at 5,000 min

-1

2

, 68 psi)

(rpm)/(80°C/176°F)

Unit: mm (in)

–

–

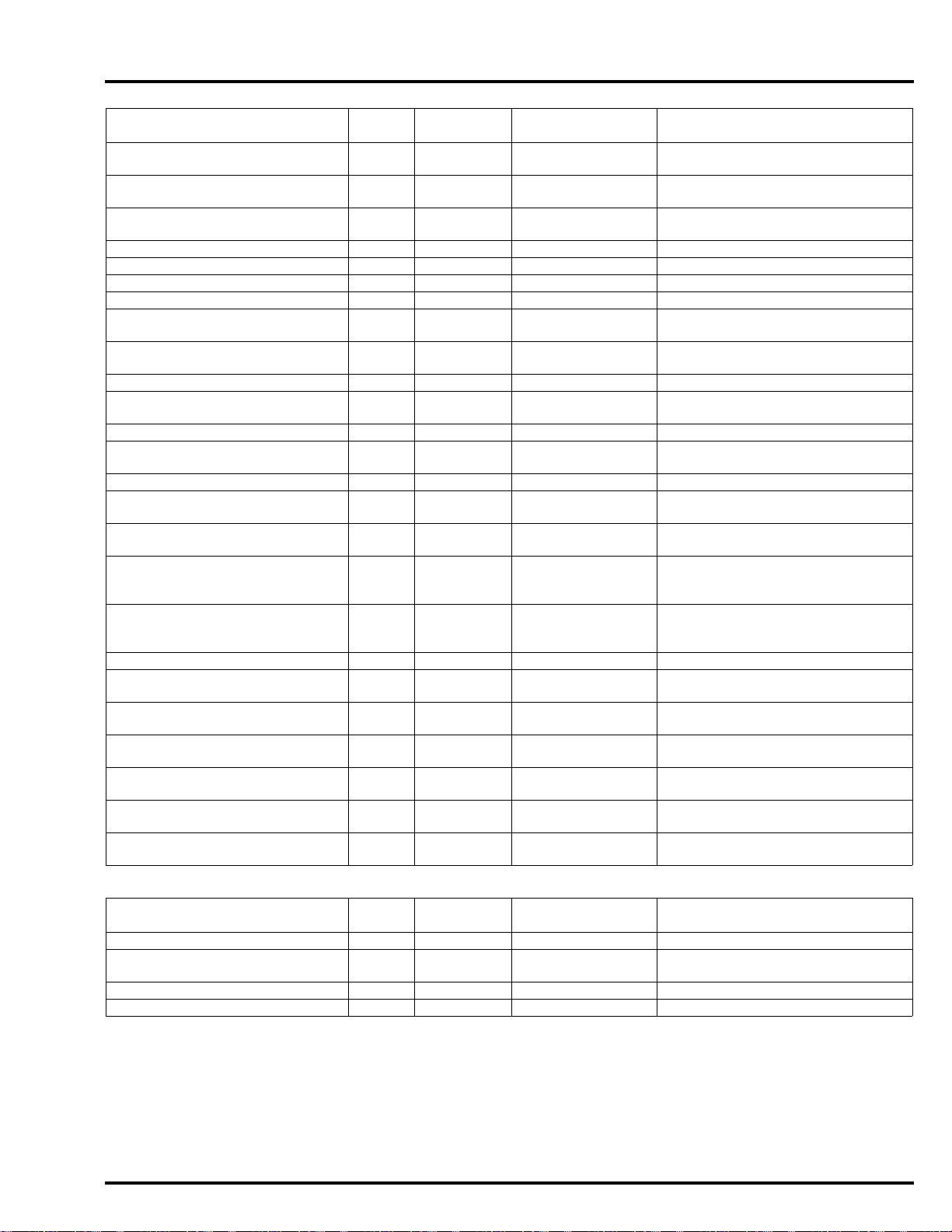

CYLINDER HEAD/VALVES SPECIFICATIONS

Unit: mm (in)

ITEM ST ANDARD SERVICE LIMIT

Cylinder compression at 470 min-1(rpm) 1,775 kPa (18.1 kgf/cm2, 257 psi) –

Valve clearance IN 0.17 ± 0.02 (0.007 ± 0.001) –

EX 0.28 ± 0.02 (0.011 ± 0.001) –

Rocker arm,

rocker arm

shaft

Cam chain tensioner wedge B length – 6.0 (0.24)

Camshaft Cam lobe height

Valve, valve

guide

Valve spring free length 49.07 (1.932) 48.1 (1.89)

Cylinder head warpage – 0.10 (0.004)

Cylinder head camshaft journal I.D. 41.995 – 42.019 (1.6533 – 1.6543) 42.027 (1.6546)

Cylinder head-to-camshaft clearance 0.045 – 0.084 (0.0018 – 0.0033) 0.10 (0.004)

Rocker arm I.D. 20.012 – 20.030 (0.7879 – 0.7886) 20.041 (0.7890)

Rocker arm shaft O.D. 1 9.972 – 19.993 (0.7863 – 0.7871) 19.961 (0.7859)

Rocker arm-to-shaft clearance 0.019 – 0.058 (0.0007 – 0.0023) 0.08 (0.003)

IN 34.7897 – 35.0297 (1.36967 – 1.37912)

EX 34.9227 – 35.1627 (1.37491 – 1.38436)

Runout – 0.04 (0.002)

Camshaft journal O.D. 41.935 – 41.950 (1.6510 – 1.6516) 41.927 (1.6507)

Valve stem O.D. IN 4.975 – 4.990 (0.1959 – 0.1965) 4.965 (0.1955)

EX 4 .965 – 4.980 (0.1955 – 0.1961) 4.955 (0.1951)

Valve guide I.D. IN/EX 5.000 – 5.012 (0.1969 – 0.1973) 5.04 (0.198)

Stem-to-guide

clearance

Valve guide

projection above

cylinder head

Valve seat width IN 0.90 – 1.10 (0.035 – 0.043) 1.5 (0.06)

IN 0.010 – 0.037 (0.0004 – 0.0015) 0.075 (0.0030)

EX 0 .020 – 0.047 (0.0008 – 0.0019) 0.085 (0.0033)

IN 17.7 – 18.0 (0. 70 – 0.71) –

EX 19.6 – 19.9 (0.77 – 0.78) –

EX 1.30 – 1.50 (0.051 – 0.059) 1.9 (0.07)

34.7697

(1.36888)

34.9027

(1.37412)

1-9

Page 15

dummyheaddummyhead

GENERAL INFORMATION

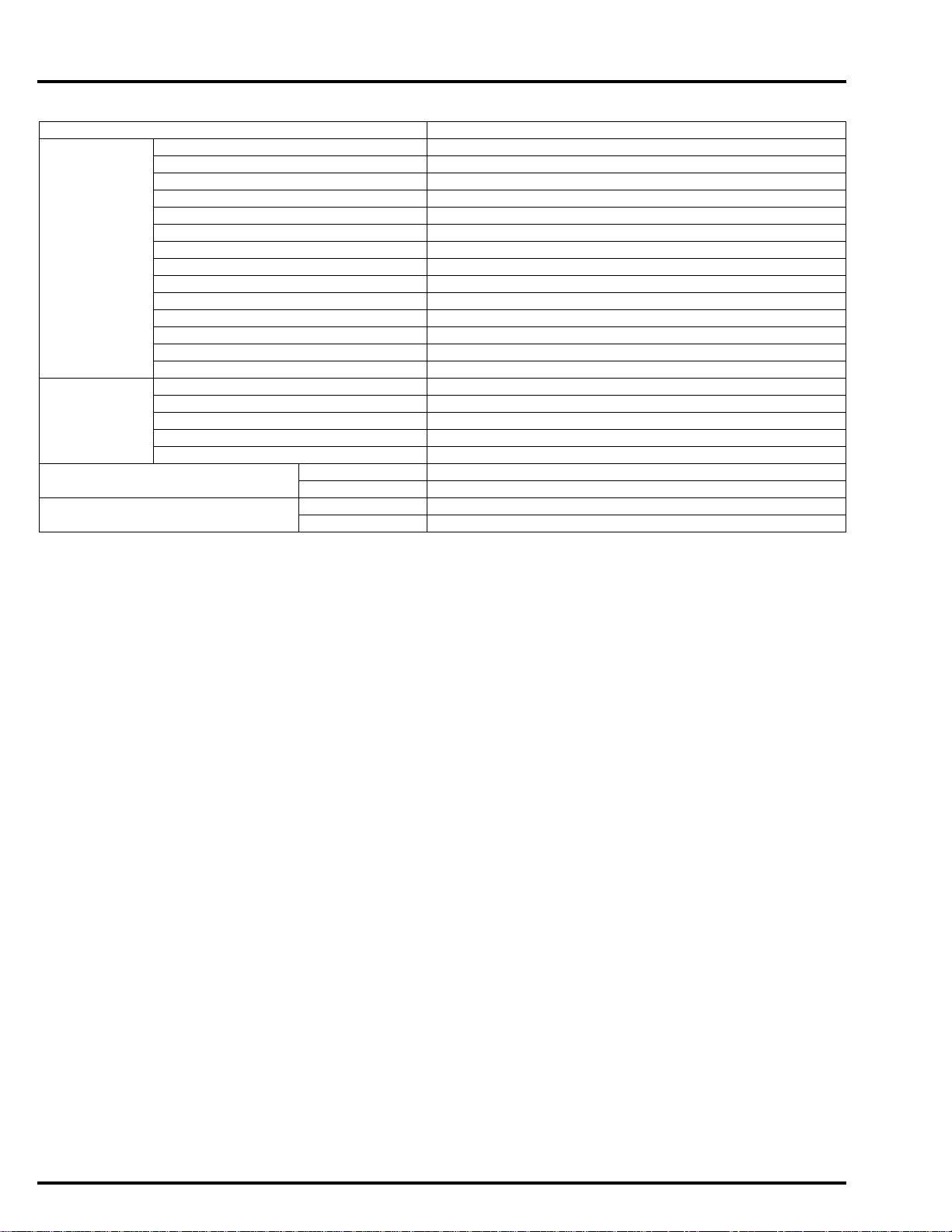

CLUTCH/GEARSHIFT LINKAGE SPECIFICATIONS (NC700X/XA/S/SA)

Unit: mm (in)

ITEM ST ANDARD SERVICE LIMIT

Clutch lever freeplay 10 – 20 (3/8 – 13/16) –

Clutch Spring free length 43.2 (1.70) 41.7 (1.64)

Disc thickness 2.62 – 2.78 (0.103 – 0.109) 2.3 (0.09)

Plate warpage – 0.30 (0.012)

Clutch outer guide I.D. 21.991 – 22.016 (0.8658 – 0.8668) 22.03 (0.867)

O.D. 31.959 – 31.975 (1.2582 – 1.2589) 31.92 (1.257)

Mainshaft O.D. at clutch outer guide 21.967 – 21.980 (0.8648 – 0.8654) 21.95 (0.864)

Clutch outer guide-to-mainshaft clearance 0.011 – 0.049 (0.0004 – 0.0019) 0.08 (0.003)

Primary driven gear I.D. 32.000 – 32.025 (1.2598 – 1.2608) 32.09 (1.263)

Primary driven gear-to-clutch outer guide clearance 0.025 – 0.066 (0.0010 – 0.0026) 0.10 (0.004)

DUAL CLUTCH TRANSMISSION SPECIFICATIONS (NC700XD/SD)

Unit: mm (in)

ITEM ST ANDARD SERVICE LIMIT

Clutch clearance 0.9 – 1.1 (0.035 – 0.043 ) 2.0 (0.08)

EOT sensor resistance (20°C/68°F) 2.5 – 2.8 k –

ALTERNATOR/STARTER CLUTCH SPECIFICATIONS

Unit: mm (in)

ITEM STANDARD SERVICE LIMIT

Starter driven gear boss O.D. 57.749 – 57.768 (2.2736 – 2.2743) 57.73 (2.273)

Starter clutch outer I.D. 74.412 – 74.442 (2.9296 – 2.9308) 74.46 (2.931)

CRANKCASE/TRANSMISSION/BALANCER SPECIFICATIONS

NC700X/XA/S/SA

Unit: mm (in)

ITEM ST ANDARD SERVICE LIMIT

Transmission Gear I.D. M5, M6, C1 28.000 – 28.021 (1.1024 – 1.1032) 28.04 (1.104)

C2, C3, C4 31.000 – 31.025 (1.2205 – 1.2215) 31.04 (1.222)

Shift fork,

fork shaft

Gear bushing

O.D.

Gear-to-bushing

clearance

Gear bushing I.D. M5 25.000 – 25.021 (0.9843 – 0.9851) 25.04 (0.986)

Mainshaft O.D. At M5 bushing 24.972 – 24.993 (0.9831 – 0.9840) 24.95 (0.982)

Countershaft O.D. At C2 bushing 27.967 – 27.980 (1.1011 – 1.1016) 27.95 (1.100)

Bushing-to-shaft

clearance

Fork I.D. 12.000 – 12.018 (0.4724 – 0.4731) 12.03 (0.474)

Claw thickness 5.93 – 6.00 (0.233 – 0.236) 5.9 (0.23)

Shift fork shaft O.D. 11.957 – 11.968 (0.4707 – 0.4712) 11.95 (0.470)

M5, M6 27.959 – 27.980 (1.1007 – 1.1016) 27.94 (1.100)

C2 30.955 – 30.980 (1.2187 – 1.2197) 30.93 (1.218)

C3, C4 30.950 – 30.975 (1.2185 – 1.2195) 30.93 (1.218)

M5, M6 0.020 – 0.062 (0.0008 – 0.0024) 0.08 (0.003)

C2 0.020 – 0.070 (0.0008 – 0.0028) 0.10 (0.004)

C3, C4 0.025 – 0.075 (0.0010 – 0.0030) 0.11 (0.004)

C2 27.985 – 28.006 (1.1018 – 1.1026) 28.02 (1.103)

M5 0.007 – 0.049 (0.0003 – 0.0020) 0.09 (0.004)

C2 0.005 – 0.039 (0.0002 – 0.0015) 0.06 (0.002)

1-10

Page 16

dummyheaddummyhead

GENERAL INFORMATION

NC700XD/SD

ITEM ST ANDARD SERVICE LIMIT

Transmission Gear I.D. M5 33.000 – 33.025 (1.2992 – 1.3002) 33.04 (1.301)

M6 43.000 – 43.025 (1.6929 – 1.6939) 43.04 (1.694)

C1 31.010 – 31.035 (1.2209 – 1.2218) 31.06 (1.223)

C2 25.000 – 25.021 (0.9843 – 0.9851) 25.03 (0.985)

C3, C4 31.000 – 31.025 (1.2205 – 1.2215) 31.04 (1.222)

Shift fork,

fork shaft

Gear bushing

O.D.

Gear-to-bushing

clearance

Gear bushing I.D. M5 29.985 – 30.006 (1.1805 – 1.1813) 30.03 (1.182)

Inner mainshaft

O.D.

Outer mainshaft

O.D.

Countershaft O.D. At C1 bushing 27.967 – 27.980 (1.1011 – 1.1016) 27.95 (1.100)

Bushing-to-shaft

clearance

Fork I.D. 12.000 – 12.018 (0.4724 – 0.4731) 12.03 (0.474)

Claw thickness 5.93 – 6.00 (0.233 – 0.236) 5.9 (0.23)

Shift fork shaft O.D. 11.957 – 11.968 (0.4707 – 0.4712) 11.95 (0.470)

M5 32.955 – 32.980 (1.2974 – 1.2984) 32.93 (1.296)

M6 42.950 – 42.975 (1.6909 – 1.6919) 42.93 (1.690)

C1 30.970 – 30.995 (1.2193 – 1.2203) 30.94 (1.218)

C2 24.959 – 24.980 (0.9826 – 0.9835) 24.94 (0.982)

C3, C4 30.950 – 30.975 (1.2185 – 1.2195) 30.93 (1.218)

M5 0.020 – 0.070 (0.0008 – 0.0028) 0.10 (0.004)

M6 0.025 – 0.075 (0.0010 – 0.0030) 0.11 (0.004)

C1 0.015 – 0.065 (0.0006 – 0.0026) 0.10 (0.004)

C2 0.020 – 0.062 (0.0008 – 0.0024) 0.09 (0.004)

C3, C4 0.025 – 0.075 (0.0010 – 0.0030) 0.11 (0.004)

M6 40.007 – 40.028 (1.5751 – 1.5759) 40.038 (1.5763)

C1 28.000 – 28.021 (1.1024 – 1.1032) 28.04 (1.104)

C2 21.985 – 22.006 (0.8655 – 0.8664) 22.02 (0.867)

At M5 bushing 29.957 – 29.970 (1.1794 – 1.1799) 29.93 (1.178)

At M6 bushing 39.975 – 39.991 (1.5738 – 1.5744) 39.965 (1.5734)

At C2 bushing 21.952 – 21.965 (0.8643 – 0.8648) 21.94 (0.864)

M5 0.015 – 0.049 (0.0006 – 0.0019) 0.09 (0.004)

M6 0.016 – 0.053 (0.0006 – 0.0021) 0.10 (0.004)

C1 0.020 – 0.054 (0.0008 – 0.0021) 0.08 (0.003)

C2 0.020 – 0.054 (0.0008 – 0.0021) 0.08 (0.003)

Unit: mm (in)

CRANKSHAFT/PISTON/CYLINDER SPECIFICATIONS

Unit: mm (in)

ITEM ST ANDARD SERVICE LIMIT

Crankshaft Connecting rod side clearance 0.15 – 0.35 (0.006 – 0.014) 0.45 (0.018)

Runout Right side – 0.03 (0.001)

Left side – 0.03 (0.001)

Main journal bearing oil clearance 0.019 – 0.037 (0.0007 – 0.0015) 0.05 (0.002)

Cylinder I.D. 73.000 – 73.015 (2.8740 – 2.8746) 73.07 (2.877)

Out-of-round – 0.10 (0.004)

Taper – 0.10 (0.004)

Warpage – 0.10 (0.004)

Piston, piston

rings

Cylinder-to-piston clearance 0.010 – 0.039 (0.0004 – 0.0015) 0.05 (0.002)

Connecting rod small end I.D. 17.964 – 17.977 (0.7072 – 0.7078) 17.985 (0.7081)

Crankpin bearing oil clearance 0.026 – 0.044 (0.0010 – 0.0017 ) 0.05 (0.002)

Piston O.D. at 13 mm (0.5 in) from

bottom

Piston pin bore I.D. 18.010 – 18.013 (0.7091 – 0.7092) 18.023 (0.7096)

Piston pin O.D. 17.996 – 18.000 (0.7 085 – 0.7087) 17.988 (0.7082)

Piston-to-piston pin clearance 0.010 – 0.017 (0.0004 – 0.0007) 0.035 (0.0014)

Piston ring end

gap

Piston ring-to-ring

groove clearance

Top 0.15 – 0.30 (0.006 – 0.012) 0.6 (0.02)

Second 0.30 – 0.42 (0.012 – 0.017) 0.6 (0.02)

Oil (side rail) 0.20 – 0.70 (0.008 – 0.028) 0.8 (0.03)

Top 0.035 – 0.080 (0.0014 – 0.0032) 0.15 (0.006)

Second 0.030 – 0.055 (0.0012 – 0.0022) 0.13 (0.005)

72.976 – 72.990 (2.8731 – 2.8736) 72.970 (2.8728)

1-11

Page 17

dummyheaddummyhead

GENERAL INFORMATION

FRONT WHEEL/SUSPENSION/STEERING SPECIFICATIONS

ITEM ST ANDARD SERVICE LIMIT

Minimum tire tread depth – 1.5 (0.06)

Cold tire

pressure

Axle runout – 0.2 (0.01)

Wheel rim runout Radial – 2.0 (0.08)

Wheel balance weight

Fork Spring free

Driver only 250 kPa (2.50 kgf/cm

Driver and passenger 250 kPa (2.50 kgf/cm2, 36 psi) –

Axial – 2.0 (0.08)

length

Tube runout – 0.20 (0.008)

Recommended fork fluid Honda ULTRA CUSHION OIL SS-47

Fluid level NC700X/XA/XD 104 (4.1) –

Fluid capacity

NC700X/XA/XD 394.9 (15.55) 387.0 (15.24)

NC700S/SA/SD 357.0 (14.06) 349.9 (13.78)

(10W) or equivalent

NC700S/SA/SD 103 (4.1) –

NC700X/XA/XD

NC700S/SA/SD

514 ± 2.5 cm

0.09 Imp oz)

518 ± 2.5 cm

0.09 Imp oz)

3

(17.4 ± 0.08 US oz, 18.1 ±

3

(17.5 ± 0.08 US oz, 18.2 ±

2

, 36 psi) –

–

60 g (2.1 oz)

max.

Unit: mm (in)

–

–

–

REAR WHEEL/SUSPENSION SPECIFICATIONS

ITEM ST ANDARD SERVICE LIMIT

Minimum tire tread depth – 2.0 (0.08)

Cold tire pressure Driver only 290 kPa (2.90 kgf/cm

Driver and passenger 290 kPa (2.90 kgf/cm2, 42 psi) –

Axle runout – 0.2 (0.01)

Wheel rim runout Radial – 2.0 (0.08)

Axial – 2.0 (0.08)

Wheel balance weight

Drive

chain

Size/link NC700X/

XA/S/SA

NC700XD

/SD

Slack NC700X/XA/XD 30 – 40 (1.2 – 1.6) –

NC700S/SA/SD 25 – 35 (1.0 – 1.4) –

DID DID520V0-114LE –

RK RK520MKO-114LE –

DID DID520V0-112LE –

RK RK520MKO-112LE –

2

, 42 psi) –

–

60 g (2.1 oz)

max.

Unit: mm (in)

1-12

Page 18

dummyheaddummyhead

GENERAL INFORMATION

HYDRAULIC BRAKE SPECIFICATIONS

ITEM ST ANDARD SERVICE LIMIT

Front Specified brake fluid DOT 4 –

Brake disc thickness 4.8 – 5.2 (0.19 – 0.20) 4.0 (0.16)

Brake disc warpage – 0.30 (0.012)

Master cylinder I.D. 11.000 – 11.043 (0.4331 – 0.4348) 11.055 (0.43 52)

Master piston O.D. 10.957 – 10.984 (0.4314 – 0.4324) 10.945 (0.4309)

Caliper cylinder I.D. (NC700X/S) 27.000 – 27.050 (1.0630 – 1.0650) 27.060 (1.0654)

Caliper piston O.D. (NC700X/S) 26.918 – 26.968 (1.0598 – 1.0617) 26.91 (1.059)

Caliper cylinder I.D.

(NC700XA/XD/SA/SD)

Caliper piston O.D.

(NC700XA/XD/SA/SD)

Rear Specified brake fluid DOT 4 –

Brake disc thickness 4.8 – 5.2 (0.19 – 0.20) 4.0 (0.16)

Brake disc warpage – 0.30 (0.012)

Master cylinder I.D. 14.000 – 14.043 (0.5512 – 0.5529) 14.055 (0.55 33)

Master piston O.D. 13.957 – 13.984 (0.5495 – 0.5506) 13.945 (0.5490)

Caliper cylinder I.D. 38.18 – 38.23 (1.503 – 1.505) 38.24 (1.506)

Caliper piston O.D. 38.098 – 38.148 (1.4999 – 1.5019) 38.09 (1.500)

Brake pedal height 85.0 – 87.0 (3.35 – 3.43) –

Cylinder A 22.650 – 22.700 (0.8917 – 0.8937) 22.712 (0.8941)

Cylinder B 27.000 – 27.050 (1.0630 – 1.0650) 27.060 (1.0654)

Piston A 22.585 – 22.618 (0.8892 – 0.8905) 22.56 (0.888)

Piston B 26.918 – 26.968 (1.0598 – 1.0617) 26.91 (1.059)

Unit: mm (in)

BATTERY/CHARGING SYSTEM SPECIFICATIONS

ITEM SPECIFICATIONS

Battery Type YTZ12S

Capacity 12 V – 11 Ah

Current leakage 1.2 mA maximum

Voltage

(20°C/68°F)

Charging current Normal 1.1 A/5 – 10 h

Alternator Capacity 0.42 kW/5,000 min

Charging coil resistance (20°C/68°F) 0.1 – 0.5

Fully charged 13.0 – 13.2 V

Needs

charging

Quick 5.5 A/1 h

Below 12.4 V

-1

(rpm)

1-13

Page 19

dummyheaddummyhead

GENERAL INFORMATION

LIGHTS/METERS/SWITCHES SPECIFICATIONS

ITEM SPECIFICATIONS

Bulbs Headlight 12 V – 60/55 W

Position light 12 V – 5 W

Brake/tail/license light 12 V – 21/5 W

Turn signal light 12 V – 21 W x 4

Instrument light LED

Turn signal indicator LED

High beam indicator LED

Neutral indicator LED

Engine oil pressure indicator LED

High coolant temperature indicator LED

MIL LED

HISS indicator LED

ABS indicator (NC700XA/XD/SA/SD) LED

Parking brake indicator (NC700XD/SD) LED

Fuse Main fuse 30 A

PGM-FI fuse 15 A

Sub fuse 15 A x 2, 7.5 A x 4

ABS fuse (NC700XA/XD/SA/SD) 30 A x 2, 7.5 A

DCT fuse (NC700XD/SD) 30 A, 7.5 A

ECT sensor resistance 40°C (104°F ) 1.0 – 1.3 k

100°C (212°F) 0.1 – 0.2 k

Fuel level sensor resistance Full 4 – 6

Empty 80 – 83

1-14

Page 20

dummyheaddummyhead

TORQUE VALUES

STANDARD TORQUE VALUES

GENERAL INFORMATION

FASTENER TYPE

5 mm bolt and nut 5.2 (0.5, 3.8) 5 mm screw 4.2 (0.4, 3.1)

6 mm bolt (Include SH flange bolt)

and nut

8 mm bolt and nut 22 (2.2, 16)

10 mm bolt and nut 34 (3.5, 25) 8 mm flange bolt and nut 27 (2.8, 20)

12 mm bolt and nut 54 (5.5, 40) 10 mm flange bolt and nut 39 (4.0, 29)

TORQUE

N·m (kgf·m, lbf·ft) N·m (kgf·m, lbf·ft)

10 (1.0, 7) 6 mm screw 9.0 (0.9, 6.6)

6 mm flange bolt (Include NSHF) and

nut

FASTENER TYPE

TORQUE

12 (1.2, 9)

ENGINE & FRAME TORQUE VALUES

FRAME BODY PANELS/EXHAUST SYSTEM

ITEM Q'TY

Seat cowl assembly screw 2 4 0.9 (0.1, 0.7)

Brake/tail/license light mounting

socket bolt

Reflector mounting nut 1 5 1.7 (0.2, 1.3)

Turn signal light mounting screw 4 6 2.5 (0.3, 1.8)

Luggage box lid assembly screw 9 4 0.9 (0.1, 0.7)

Luggage box lid lock plate

mounting screw

Luggage box lid mounting socket

bolt

Luggage box lid hinge nut 1 6 12 (1.2, 9) U-nut

Gearshift arm pinch bolt

(NC700X/XA/S/SA)

Muffler cover socket bolt 1 6 10 (1.0, 7)

Muffler band bolt 1 8 17.5 (1.8, 13)

Exhaust pipe joint nut 3 8 28 (2.9, 21) See page 2-34

Exhaust pipe stud bolt 3 8 – See page 2-35

1 6 10 (1.0, 7)

2 6 4.0 (0.4, 3.0)

3 6 12 (1.2, 9)

1 6 12 (1.2, 9) ALOC bolt; replace with a new one.

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

1-15

Page 21

dummyheaddummyhead

GENERAL INFORMATION

MAINTENANCE

ITEM Q'TY

Air cleaner housing cover screw 6 5 1.1 (0.1, 0.8)

Spark plug 2 14 22 (2.2, 16)

Valve adjusting screw lock nut 8 7 14 (1.4, 10) Apply engine oil to the threads and

Camshaft maintenance cap 1 36 4.0 (0.4, 3.0) See page 3-12

Timing hole cap 1 14 10 (1.0, 7) Apply grease to the threads.

Crankshaft hole cap 1 30 15 (1.5, 11) Apply grease to the threads.

Engine oil drain bolt 1 12 30 (3.1, 22)

Engine oil filter cartridge 1 20 26 (2.7, 19) Apply engine oil to the threads.

Oil filter boss 1 20 – See page 3-14

Rear axle nut 1 18 98 (10.0, 72) U-nut

Drive chain adjuster lock nut 2 8 21 (2.1, 15)

Drive sprocket bolt 1 10 54 (5.5, 40)

Driven sprocket nut 5 12 108 (11.0, 80) U-nut

Master cylinder reservoir cover

screw

Rear brake reservoir mounting bolt 1 6 10 (1.0, 7)

Rear master cylinder push rod lock

nut

Parking brake adjuster bolt lock

nut (NC700XD/SD)

Sidestand pivot bolt 1 10 – See page 3-27

Sidestand pivot nut 1 10 39 (4.0, 29) U-nut

Sidestand switch bolt 1 6 10 (1.0, 7) ALOC bolt; replace with a new one.

4 4 1.5 (0.2, 1.1)

1 8 17 (1.7, 13)

1 8 17 (1.7, 13)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

seating surface.

Apply locking agent to the threads.

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) from tip

Apply grease to the sliding surface.

PGM-FI SYSTEM

ITEM Q'TY

ECT sensor 1 10 12 (1.2, 9)

Bank angle sensor mounting bolt 2 6 10 (1.0, 7)

O2 sensor 1 12 24.5 (2.5, 18)

IGNITION SYSTEM

ITEM Q'TY

Timing hole cap 1 14 10 (1.0, 7) Apply grease to the threads.

Right crankcase cover wire clamp

bolt (NC700XD/SD)

ELECTRIC STARTER

ITEM Q'TY

Starter motor terminal nut 1 6 10 (1.0, 7)

FUEL SYSTEM

ITEM Q'TY

Fuel pump mounting nut 6 6 12 (1.2, 9) For tightening sequence (page 7-14)

Air cleaner connecting hose band

screw

Insulator band screw 2 5 – See page 7-18

2 6 12 (1.2, 9) Apply locking agent to the threads.

1 4 1.5 (0.2, 1.1)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

REMARKS

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

REMARKS

REMARKS

1-16

Page 22

dummyheaddummyhead

GENERAL INFORMATION

COOLING SYSTEM

ITEM Q'TY

Water hose band screw 6 – – See page 8-9

Fan motor shroud mounting bolt 3 6 8.4 (0.9, 6.2)

Fan motor mounting screw 3 4 2.7 (0.3, 2.0)

Cooling fan mounting nut 1 3 1.0 (0.1, 0.7) Apply locking agent to the threads.

LUBRICATION SYSTEM

ITEM Q'TY

Engine oil filter cartridge 1 20 26 (2.7, 19) Apply engine oil to the threads.

CYLINDER HEAD/VALVES

ITEM Q'TY

Cylinder head cover socket bolt 3 6 10 (1.0, 7)

Breather plate mounting bolt 8 6 12 (1.2, 9) Apply locking agent to the threads.

Rocker arm shaft bolt 3 8 29 (3.0 , 21) Apply engine oil to the threads and

Camshaft maintenance cap 1 36 4.0 (0.4 , 3.0) See page 10-11

Cam chain tensioner bolt 2 6 12 (1.2, 9)

Cam sprocket bolt 1 10 56 (5.7, 41) Apply engine oil to the threads and

Water hose band screw 6 – – See page 10-16

Insulator band screw 1 5 – See page 10-25

Cylinder head special bolt 6 9 44 (4.5, 32) Apply molybdenum oil solution to the

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

See page 8-10

See page 8-14

REMARKS

REMARKS

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

seating surface.

See page 10-28

seating surface.

threads and seating surface.

CLUTCH/GEARSHIFT LINKAGE (NC700X/XA/S/SA)

ITEM Q'TY

Clutch center lock nut 1 18 128 (13.1, 94) Apply engine oil to the threads and

Clutch lifter plate bolt 4 6 12 (1.2, 9)

Primary drive gear mounting bolt 1 10 93 (9.5, 69) Apply engine oil to the threads and

Shift drum stopper arm pivot bolt 1 6 12 (1.2, 9) Apply locking agent to the threads.

Shift drum center socket bolt 1 8 23 (2.3, 17) Apply locking agent to the threads.

Gearshift pedal adjuster lock nut 2 6 10 (1.0, 7)

Gearshift pedal pivot bolt 1 8 27 (2.8, 20)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

seating surface.

Lock nut; replace with a new one and

stake.

seating surface.

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

1-17

Page 23

dummyheaddummyhead

GENERAL INFORMATION

DUAL CLUTCH TRANSMISSION (DCT) (NC700XD/SD)

ITEM Q'TY

Solenoid valve stopper plate bolt 1 6 12 (1.2, 9) Apply locking agent to the threads.

Right crankcase cover wire clamp

bolt

Linear solenoid valve body

mounting bolt

Shift spindle angle sensor bolt 1 6 12 (1.2, 9)

Primary drive gear mounting bolt 1 10 93 (9.5, 69) Apply engine oil to the threads and

Reduction gear cover bolt 3 6 14 (1.4, 10)

TR sensor bolt 1 6 12 (1.2, 9)

Shift control motor bolt 3 6 14 (1.4, 10)

Shift drum center bolt 1 8 23 (2.3, 17) Apply locking agent to the threads.

Drum shifter guide plate bolt 2 6 12 (1.2, 9) Apply locking agent to the threads.

Clutch line EOP sensor 3 10 19.6 (2.0, 14)

EOT sensor 1 10 14 (1.4, 10) Apply engine oil to the threads and

2 6 12 (1.2, 9) Apply locking agent to the threads.

6 6 – For tightening sequence (page 12-

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

Coating width: 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width: 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

101)

seating surface.

Coating width: 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width: 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

seating surface.

ALTERNATOR/STARTER CLUTCH

ITEM Q'TY

Flywheel mounting bolt 1 12 157 (16.0, 116) Left hand thread

Starter clutch socket bolt 6 8 30 (3.1, 22) Apply locking agent to the threads.

Alternator stator mounting bolt 4 6 10 (1.0, 7) Apply locking agent to the threads.

Alternator wire clamp bolt 1 6 10 (1.0, 7) Apply locking agent to the threads.

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

Apply engine oil to the threads and

seating surface.

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

1-18

Page 24

dummyheaddummyhead

GENERAL INFORMATION

CRANKCASE/TRANSMISSION/BALANCER

ITEM Q'TY

Mainshaft bearing set plate bolt 3 6 12 (1.2, 9) Apply locking agent to the threads.

Shift drum bearing set plate bolt 2 6 12 (1.2, 9) Apply locking agent to the threads.

Balancer shaft bearing set plate

bolt

Crankcase main journal bolt (new) 6 9 20 (2.0, 15) + 150° See page 14-30

Crankcase 10 mm bolt 1 10 39 (4.0, 29)

Crankcase 8 mm bolt 3 8 24 (2.4, 18)

Crankcase 8 x 45 mm bolt 1 8 24 (2.4, 18) Apply locking agent to the threads.

Crankcase 6 mm bolt 8 6 12 (1.2, 9)

3 6 12 (1.2, 9) Apply locking agent to the threads.

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

Replace with a new one.

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) from tip

CRANKSHAFT/PISTON/CYLINDER

ITEM Q'TY

Crankpin bearing cap bolt 4 6 10 (1.0, 7) + 90° See page 15-7

Crankcase main journal bolt

(retightening)

ENGINE REMOVAL/INSTALLATION

ITEM Q'TY

Rear lower engine hunger nut 1 12 59 (6.0, 44)

Front lower engine hunger bolt 2 12 54 (5.5, 40 )

Upper engine hunger bolt 2 12 54 (5.5, 40)

Rear upper engine hunger nut 1 12 54 (5.5, 40)

Step holder mounting socket bolt 4 8 32 (3.3, 24)

Drive sprocket bolt 1 10 54 (5.5, 40)

Starter motor terminal nut 1 6 10 (1.0, 7)

Water hose band screw 2 – – See page 16-18

6 9 20 (2.0, 15) + 120° See page 15-9

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

See page 15-12

Replace with a new one.

Apply engine oil to the threads and

seating surface.

Apply engine oil to the threads and

seating surface.

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

See page 16-19

See page 16-24

See page 16-25

REMARKS

REMARKS

1-19

Page 25

dummyheaddummyhead

GENERAL INFORMATION

FRONT WHEEL/SUSPENSION/STEERING

ITEM Q'TY

Handlebar holder bolt 4 8 22 (2.2, 16)

Handlebar switch housing screw 4 5 2.5 (0.3, 1.8)

Front master cylinder holder bolt 2 6 12 (1.2, 9)

Handlebar weight mounting screw 2 6 10 (1.0, 7) ALOC screw; replace with a new

Front brake disc mounting bolt 5 8 42 (4.3, 31) ALOC bolt; replace with a new one.

Front axle 1 18 74 (7.5, 55) Apply grease to the sliding surface.

Front axle pinch bolt 1 8 22 (2.2, 16)

Fork socket bolt 2 8 20 (2.0, 15) Apply locking agent to the threads.

Bottom bridge pinch bolt 2 10 39 (4.0, 29)

Fork cap 2 37 22 (2.2, 16)

Top bridge pinch bolt 2 8 22 (2.2, 16)

Front brake caliper mounting bolt 2 8 30 (3.1, 22) ALOC bolt; replace with a new one.

Steering stem adjusting nut 1 26 23 (2.3, 17) See page 17-38

Steering stem adjusting lock nut 1 26 – See page 17-38

Steering stem nut 1 24 103 (10.5, 76) See page 17-38

Clutch lever pivot bolt

(NC700X/XA/S/SA)

Clutch lever pivot nut

(NC700X/XA/S/SA)

1 6 1.0 (0.1, 0.7) Apply grease to the slidin g surface.

1 6 6.0 (0.6, 4.4)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

one.

Apply engine oil to the threads.

REAR WHEEL/SUSPENSION

ITEM Q'TY

Driven sprocket nut 5 12 108 (11.0, 80) U-nut

Rear brake disc mounting bolt 5 8 42 (4.3, 31) ALOC bolt; replace with a new one.

Rear axle nut 1 18 98 (10.0, 72) U-nut

Shock absorber mounting nut 2 10 44 (4.5, 32) U-nut

Shock arm nut 1 10 44 (4.5, 32) U-nut

Shock link nut 2 10 44 (4.5, 32) U-nut

Drive chain slider mounting screw 2 5 5.9 (0.6, 4.4)

Swingarm pivot nut 1 18 98 (10.0, 72) U-nut

Step holder mounting socket bolt 4 8 32 (3.3, 24)

Gearshift arm pinch bolt

(NC700X/XA/S/SA)

1 6 12 (1.2, 9) ALOC bolt; replace with a new one.

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

1-20

Page 26

dummyheaddummyhead

GENERAL INFORMATION

HYDRAULIC BRAKE

ITEM Q'TY

Brake caliper bleed valve

(NC700X/S)

Brake caliper bleed valve

(NC700XA/XD/SA/SD)

Master cylinder reservoir cover

screw

Rear brake reservoir mounting bolt 1 6 10 (1.0, 7)

Brake pad pin 2 10 17 (1.7, 13)

Rear brake caliper mounting bolt 1 8 22 (2.2, 16) ALOC bolt; replace with a new one.

Front master cylinder holder bolt 2 6 12 (1.2, 9)

Brake hose oil bolt

(NC700X/S)

Brake hose oil bolt

(NC700XA/XD/SA/SD)

Front brake light switch screw 1 4 1.2 (0.1, 0.9)

Front brake lever pivot bolt 1 6 1.0 (0.1, 0.7) Apply 0.10 g (0.004 oz) silicone

Front brake lever pivot nut 1 6 5.9 (0.6, 4.4)

Rear master cylinder mounting

bolt

Step holder mounting socket bolt 4 8 32 (3.3, 24)

Rear master cylinder hose joint

screw

Rear master cylinder push rod lock

nut

Front brake caliper pin 1 8 22 (2.2, 16) Apply locking agent to the threads.

Front brake caliper bracket pin 1 8 12 (1.2, 9) Apply locking agent to the threads.

Front brake caliper mounting bolt 2 8 30 (3.1, 22) ALOC bolt; replace with a new one.

Rear brake caliper pin 1 12 27 (2.8, 20) Ap ply 0.4 g (0.01 oz) silicone grease

Parking brake caliper mounting

bolt (NC700XD/SD)

Parking brake caliper pin bolt

(NC700XD/SD)

Parking brake pad pin

(NC700XD/SD)

Parking brake adjuster bolt lock

nut (NC700XD/SD)

Parking brake cable mounting nut

(NC700XD/SD)

2 8 5.4 (0.6, 4.0)

3 8 5.4 (0.6, 4.0)

4 4 1.5 (0.2, 1.1)

4 10 34 (3.5, 25)

5 10 34 (3.5, 25)

2 6 12 (1.2, 9)

1 4 1.5 (0.2, 1.1) Apply lockin g agent to the threads.

1 8 17 (1.7, 13)

2 8 31 (3.2, 23) ALOC bolt; replace with a new one.

1 8 22 (2.2, 16) A pply locking agent to the threads.

2 8 17 (1.7, 13) ALOC bolt; replace with a new one.

1 8 17 (1.7, 13)

1 10 10 (1.0, 7)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

grease to the sliding surface.

Apply 0.4 g (0.01 oz) silicone grease

to the sliding surface.

Apply 0.4 g (0.01 oz) silicone grease

to the sliding surface.

to the sliding surface.

ANTI-LOCK BRAKE SYSTEM (ABS) (NC700XA/XD/SA/SD)

ITEM Q'TY

Step holder mounting socket bolt 4 8 32 (3.3, 24)

Brake pipe joint nut 14 10 14 (1.4, 10) Apply brake fluid to the threads and

PCV mounting bolt 2 6 12 (1.2, 9)

Delay valve mounting bolt 2 6 12 (1.2, 9)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

sliding surface.

1-21

Page 27

dummyheaddummyhead

GENERAL INFORMATION

LIGHTS/METERS/SWITCHES

ITEM Q'TY

Turn signal light mounting screw 4 6 2.5 (0.3, 1.8)

Combination meter mounting

screw

Combination meter back cover

mounting screw (NC700S/SA/SD)

EOP switch 1 PT 1/8 18 (1.8, 13) Apply sealant to the threads.

Ignition switch mounting bolt 2 8 25 (2.5, 18) One way bolt; replac e with a new

Neutral switch 1 10 12 (1.2, 9)

Parking brake switch screw

(NC700XD/SD)

OTHERS

ITEM Q'TY

Cam chain tensioner set plate bolt 1 6 12 (1.2, 9) Apply locking agent to the threads.

Camshaft cap 1 20 30 (3.1, 22)

Gearshift spindle return spring pin 1 8 23 (2.3, 17)

Main step rubber mounting bolt 2 5 5.1 (0.5, 3.8) ALOC bolt; replace with a new one.

Main step cap bolt 2 6 12 (1.2, 9)

3 5 1.0 (0.1, 0.7)

4 3 0.3 (0.03, 0.2)

1 4 1.2 (0.1, 0.9)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

THREAD TORQUE

DIA. (mm) N·m (kgf·m, lbf·ft)

REMARKS

one.

REMARKS

Coating width; 6.5 ± 1.0 mm (0.26 ±

0.04 in) except 2.0 ± 1.0 mm (0.08 ±

0.04 in) from tip

1-22

Page 28

dummyheaddummyhead

GENERAL INFORMATION

LUBRICATION & SEAL POINTS

ENGINE

MA TERIAL LOCA TION REMARKS

Liquid sealant

(Three Bond 1207B or

equivalent)

Molybdenum oil solution

(a mixture of 1/2 engine oil

and 1/2 molybdenum

disulfide grease)

Engine oil Oil filter cartridge O-ring

Multi-purpose grease Each oil seal lips

Locking agent CKP sensor mounting bolt threads Coating width; 6.5 ± 1.0

Templex N3 grease (ESSO) Electric shift reduction gear teeth and journal (NC700XD/SD) 2 – 4 g (0.07 – 0.14 oz)

Oil pan mating surface See page 9-12

Right crankcase cover mating surface See page 11-6

CKP sensor wire grommet

Linear solenoid valve wire grommet (NC700XD/SD)

Alternator wire grommet

Alternator cover mating surface See page 13-7

Crankcase mating surface See page 14-28

Rocker arm sliding surface

Rocker arm shaft outer surface

Camshaft lobes, journals and thrust surface

Valve stem (valve guide sliding surface) and stem end

Clutch outer guide sliding surface (NC700X/XA/S/SA)

Starter reduction and idle gear shaft outer surface

M3/4, C5, C6 gear (shift fork grooves) (NC700X/XA/S/SA)

M3, M4, C5, C6 gear (shift fork grooves) (NC700XD/SD)

Each transmission spline collar outer surface

Each transmission collar inner and outer surface

Shift fork guide area and guide pin

Shift fork shaft outer surface

Main journal bearing sliding surface

Crankpin bearing sliding surface

Crankshaft thrust surface

Oil filler cap O-ring

Timing hole cap O-ring

Crankshaft hole cap O-ring

Clutch oil filter cover O-ring (NC700XD/SD)

Oil joint pipe O-ring (NC700XD/SD)

Clutch oil guide collar O-rings (NC700XD/SD)

Oil strainer seal ring

Starter motor O-ring

Injector seal ring

Water pump large O-ring

Valve stem seal

Clutch disc entire surface (NC700X/XA/S/SA)

Clutch lifter rod A sliding surface (NC700X/XA/S/SA)

Clutch lifter rod B sliding surface (NC700X/XA/S/SA)

Mainshaft seal rings (NC700XD/SD)

Starter one-way clutch

Piston sliding surface

Piston ring sliding surface

Piston pin outer surface

Each bearing

Each gear teeth and rotating surface

Each O-ring (except water sealing)

Other rotating area and sliding surface

mm (0.26 ± 0.04 in)

except 2.0 ± 1.0 mm (0.08

± 0.04 in) from tip

1-23

Page 29

dummyheaddummyhead

GENERAL INFORMATION

FRAME

MA TERIAL LOCATION REMARKS

Urea based multi-purpose

grease with extreme

pressure

(example: Kyodo Yushi

EXCELITE EP2, Shell

Stamina EP2 or equivalent)

Molybdenum disulfide grease Shock arm needle bearings

Multi-purpose grease Seat catch hook sliding area

Cable lubricant Seat lock cable inside

Honda bond A, Cemedine

#540 or equivalent

Silicone grease Front brake lever sliding surface and lever-to-master piston

DOT 4 brake fluid Brake caliper piston and piston seals

Fork fluid Fork cap O-ring

Drive chain lubricant

designed specifically for use

with O-ring chains, #80 – 90

gear oil or equivalent

Steering head bearing sliding surface 3 – 5 g (0.1 – 0.2 oz)

Steering head dust seal lips

Rear shock absorber needle bearing

Rear shock absorber dust seal lips

Swingarm pivot needle bearings

Swingarm pivot ball bearing

Swingarm pivot dust seal lips

Luggage box lid catch sliding area

Gearshift pedal pivot and dust seal lips (NC700X/XA/S/SA)

Gearshift pedal tie-rod ball joint area (NC700X/XA/S/SA)

Throttle cable end and throttle grip pipe flange groove

Front wheel dust seal lips

Rear wheel hub O-ring

Rear wheel dust seal lips

Rear axle sliding surface

Swingarm pivot sliding surface

Rear brake pedal pivot sliding area

Parking brake ratchet A, B teeth and sliding surface

(NC700XD/SD)

Parking brake lever, washer sliding surface (NC700XD/SD)

Parking brake switch spring sliding surface (NC700XD/SD)

Main step sliding area

Pillion step sliding area

Luggage box lid lock cable inside

Throttle cable A, B inside

Clutch cable inside (NC700X/XA/S/SA)

Parking brake cable inside (NC700XD/SD)

Handlebar grip rubber inside

Brake pad retainer mating surface

contacting area

Rear brake master cylinder push rod sliding surface and boot

fitting area

Brake caliper dust seals

Rear brake caliper boot inside 0.4 g (0.01 oz)

Brake pad pin stopper ring

Parking brake shaft outer surface (NC700XD/SD) 0.4 g (0.01 oz) minimum

Parking brake adjuster bolt threads and caliper piston sliding

surface (NC700XD/SD)

Parking brake shaft boot lips (NC700XD/SD) 0.4 g (0.01 oz) minimum

Parking brake caliper bracket pin sliding surface (NC700XD/

SD)

Parking brake caliper sleeve sliding surface (NC700XD/SD) 0.4 g (0.01 oz) minimum

Brake master piston and cups

Brake master cylinder inside

Rear master cylinder reservoir hose joint O-ring

Fork dust seal and oil seal lips

Drive chain whole surface

0.10 g (0.004 oz)

0.4 g (0.01 oz) minimum

0.4 g (0.01 oz) minimum

1-24

Page 30

dummyheaddummyhead

RIGHT HANDLEBAR

SWITCH WIRE

LEFT HANDLEBAR

SWITCH WIRE

CLUTCH SWITCH WIRE

BRAKE LIGHT SWITCH

CONNECTOR

RIGHT HANDLEBAR

SWITCH WIRE

LEFT HANDLEBAR

SWITCH WIRE

BRAKE LIGHT SWITCH

CONNECTOR

RIGHT HANDLEBAR

SWITCH WIRE

THROTTLE CABLE B

THROTTLE CABLE A

CABLE & HARNESS ROUTING

NC700X/XA:

GENERAL INFORMATION

NC700XD:

1-25

Page 31

dummyheaddummyhead

RIGHT HANDLEBAR

SWITCH WIRE

LEFT HANDLEBAR

SWITCH WIRE

CLUTCH SWITCH WIRE

BRAKE LIGHT SWITCH

CONNECTOR

RIGHT HANDLEBAR

SWITCH WIRE

LEFT HANDLEBAR

SWITCH WIRE

BRAKE LIGHT SWITCH

CONNECTOR

RIGHT HANDLEBAR

SWITCH WIRE

THROTTLE CABLE A

THROTTLE CABLE B

GENERAL INFORMATION

NC700S/SA:

NC700SD:

1-26

Page 32

dummyheaddummyhead

FRONT SUB HARNESS

FRONT LEFT TURN SIGNAL LIGHT

3P (ORANGE) CONNECTOR

FRONT RIGHT TURN SIGNAL LIGHT

3P (BLUE) CONNECTOR

POSITION

LIGHT WIRE

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

FRONT SUB HARNESS

FRONT LEFT TURN SIGNAL LIGHT

3P (ORANGE) CONNECTOR

FRONT RIGHT TURN SIGNAL LIGHT

3P (BLUE) CONNECTOR

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

POSITION

LIGHT WIRES

NC700X/XA/XD:

GENERAL INFORMATION

NC700S/SA/SD:

1-27

Page 33

dummyheaddummyhead

CLUTCH CABLE

LEFT HANDLEBAR

SWITCH WIRE

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

HEADLIGHT

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

THROTTLE CABLES

IMMOBILIZER

RECEIVER WIRE

RIGHT HANDLEBAR

SWITCH WIRE

BRAKE HOSE

MAIN WIRE HARNESS

Front

side

MAIN WIRE HARNESS

Front

side

COMBINATION METER

16P (GRAY) CONNECTOR

GENERAL INFORMATION

NC700X:

1-28

Page 34

dummyheaddummyhead

CLUTCH CABLE

LEFT HANDLEBAR

SWITCH WIRE

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

HEADLIGHT

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

THROTTLE CABLES

IMMOBILIZER

RECEIVER WIRE

RIGHT HANDLEBAR

SWITCH WIRE

FRONT BRAKE HOSE A

(to ABS MODULATOR)

MAIN WIRE HARNESS

Front

side

MAIN WIRE HARNESS

Front

side

COMBINATION METER

16P (GRAY) CONNECTOR

NC700XA:

GENERAL INFORMATION

1-29

Page 35

dummyheaddummyhead

PARKING BRAKE CABLE

LEFT HANDLEBAR

SWITCH WIRE

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

HEADLIGHT

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

3P (BLACK) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

THROTTLE CABLES

IMMOBILIZER

RECEIVER WIRE

RIGHT HANDLEBAR

SWITCH WIRE

FRONT BRAKE HOSE A

(to ABS MODULATOR)

Front

side

MAIN WIRE HARNESS

Front

side

COMBINATION METER

16P (GRAY) CONNECTOR

MAIN WIRE HARNESS

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

GENERAL INFORMATION

NC700XD:

1-30

Page 36

dummyheaddummyhead

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

HEADLIGHT

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

MAIN WIRE HARNESS

IMMOBILIZER RECEIVER

4P (BLACK) CONNECTOR

RIGHT HANDLEBAR SWITCH

8P (BLUE) CONNECTOR

BRAKE HOSE

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

HEADLIGHT

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

MAIN WIRE HARNESS

IMMOBILIZER RECEIVER

4P (BLACK) CONNECTOR

RIGHT HANDLEBAR SWITCH

8P (BLUE) CONNECTOR

FRONT WHEEL SPEED

SENSOR WIRE

FRONT BRAKE HOSE D

(from ABS MODULATOR)

BRAKE SUB HOSE C

(from DELAY VALVE)

NC700S:

GENERAL INFORMATION

NC700SA:

1-31

Page 37

dummyheaddummyhead

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

HEADLIGHT

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

MAIN WIRE HARNESS

IMMOBILIZER RECEIVER

4P (BLACK) CONNECTOR

RIGHT HANDLEBAR SWITCH

8P (BLUE) CONNECTOR

FRONT WHEEL SPEED

SENSOR WIRE

FRONT BRAKE HOSE D

(from ABS MODULATOR)

BRAKE SUB HOSE C

(from DELAY VALVE)

RIGHT HANDLEBAR SWITCH

7P (GREEN) CONNECTOR

LEFT HANDLEBAR SWITCH

7P (GREEN) CONNECTOR

RIGHT HANDLEBAR

SWITCH WIRE

IMMOBILIZER

RECEIVER WIRE

CLUTCH CABLE

THROTTLE CABLE A

THROTTLE CABLE B

FRONT BRAKE HOSE

LEFT HANDLEBAR

SWITCH WIRE

IGNITION SWITCH WIRE

CLUTCH SWITCH

CONNECTORS

GENERAL INFORMATION

NC700SD:

NC700S:

1-32

Page 38

dummyheaddummyhead

RIGHT HANDLEBAR

SWITCH WIRE

IMMOBILIZER

RECEIVER WIRE

CLUTCH CABLE

THROTTLE CABLE A

THROTTLE CABLE B

FRONT BRAKE HOSE A

(to ABS MODULATOR)

LEFT HANDLEBAR

SWITCH WIRE

IGNITION SWITCH WIRE

CLUTCH SWITCH

CONNECTORS

RIGHT HANDLEBAR

SWITCH WIRE

IMMOBILIZER

RECEIVER WIRE

PARKING BRAKE CABLE

THROTTLE CABLE A

THROTTLE CABLE B

FRONT BRAKE HOSE A

(to ABS MODULATOR)

LEFT HANDLEBAR

SWITCH WIRE

IGNITION SWITCH WIRE

NC700SA:

GENERAL INFORMATION

NC700SD:

1-33

Page 39

dummyheaddummyhead

CLUTCH CABLE

LEFT HANDLEBAR

SWITCH WIRE

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

IGNITION SWITCH WIRE

LEFT HANDLEBAR

SWITCH WIRE

COMBINATION METER

16P (GRAY) CONNECTOR

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

GENERAL INFORMATION

NC700X/XA:

1-34

Page 40

dummyheaddummyhead

LEFT HANDLEBAR

SWITCH WIRE

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

IGNITION SWITCH

2P (BROWN) CONNECTOR

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

IGNITION SWITCH WIRE

LEFT HANDLEBAR

SWITCH WIRE

COMBINATION METER

16P (GRAY) CONNECTOR

FRONT SUB HARNESS

6P (BROWN) CONNECTOR

PARKING BRAKE CABLE

LEFT HANDLEBAR SWITCH

3P (BLACK) CONNECTOR

NC700XD:

GENERAL INFORMATION

1-35

Page 41

dummyheaddummyhead

CLUTCH CABLE

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

No.2 IGNITION COIL

No.1 SPARK PLUG WIRE

BATTERY BOX DRAIN HOSE

IAT SENSOR

2P (BLACK) CONNECTOR

MAIN WIRE HARNESS

GENERAL INFORMATION

NC700S/SA:

1-36

Page 42

dummyheaddummyhead

PARKING BRAKE CABLE

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

No.2 IGNITION COIL

No.1 SPARK PLUG WIRE

BATTERY BOX DRAIN HOSE

IAT SENSOR

2P (BLACK) CONNECTOR

MAIN WIRE HARNESS

NC700SD:

GENERAL INFORMATION

1-37

Page 43

dummyheaddummyhead

THROTTLE CABLE B

RIGHT HANDLEBAR

SWITCH WIRE

BRAKE HOSE

IMMOBILIZER RECEIVER

4P (BLACK) CONNECTOR

RIGHT HANDLEBAR SWITCH

8P (BLUE) CONNECTOR

IMMOBILIZER

RECEIVER WIRE

RIGHT HANDLEBAR

SWITCH WIRE

CLUTCH CABLE

THROTTLE CABLE A

THROTTLE CABLE A

THROTTLE CABLE A

THROTTLE CABLE B

THROTTLE CABLE B

BRAKE HOSE

GENERAL INFORMATION

NC700X:

1-38

Page 44

dummyheaddummyhead

RIGHT HANDLEBAR

SWITCH WIRE

FRONT WHEEL SPEED

SENSOR WIRE

IMMOBILIZER RECEIVER

4P (BLACK) CONNECTOR

RIGHT HANDLEBAR SWITCH

8P (BLUE) CONNECTOR

FRONT WHEEL SPEED

SENSOR WIRE

IMMOBILIZER

RECEIVER WIRE

RIGHT HANDLEBAR

SWITCH WIRE

CLUTCH CABLE

FRONT BRAKE HOSE D

(from ABS MODULATOR)

BRAKE SUB HOSE C

(from DELAY VALVE)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

FRONT WHEEL SPEED SENSOR

2P (BLUE) CONNECTOR

THROTTLE CABLE B

THROTTLE

CABLE A

THROTTLE CABLE A

THROTTLE CABLE A

THROTTLE CABLE B

THROTTLE

CABLE B

FRONT WHEEL SPEED

SENSOR WIRE

FRONT BRAKE HOSE D

(from ABS MODULATOR)

BRAKE SUB HOSE C

(from DELAY VALVE)

NC700XA:

GENERAL INFORMATION

1-39

Page 45

dummyheaddummyhead

RIGHT HANDLEBAR

SWITCH WIRE

FRONT WHEEL SPEED

SENSOR WIRE

IMMOBILIZER RECEIVER

4P (BLACK) CONNECTOR

RIGHT HANDLEBAR SWITCH

8P (BLUE) CONNECTOR

FRONT WHEEL SPEED

SENSOR WIRE

IMMOBILIZER

RECEIVER WIRE

RIGHT HANDLEBAR

SWITCH WIRE

PARKING BRAKE CABLE

FRONT BRAKE HOSE D

(from ABS MODULATOR)

BRAKE SUB HOSE C

(from DELAY VALVE)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

FRONT WHEEL SPEED SENSOR

2P (BLUE) CONNECTOR

THROTTLE CABLE B

THROTTLE

CABLE A

THROTTLE CABLE A

THROTTLE CABLE A

THROTTLE CABLE B

THROTTLE

CABLE B

FRONT WHEEL SPEED

SENSOR WIRE

FRONT BRAKE HOSE D

(from ABS MODULATOR)

BRAKE SUB HOSE C

(from DELAY VALVE)

RIGHT HANDLEBAR SWITCH

6P (BLACK) CONNECTOR

GENERAL INFORMATION

NC700XD:

1-40

Page 46

dummyheaddummyhead

CLUTCH CABLE

BRAKE HOSE

NC700X:

GENERAL INFORMATION

1-41

Page 47

dummyheaddummyhead

FRONT BRAKE HOSE D

(from ABS MODULATOR)

FRONT WHEEL SPEED

SENSOR WIRE

CLUTCH CABLE

BRAKE SUB HOSE C

(from DELAY VALVE)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

Parallel

GENERAL INFORMATION

NC700XA:

1-42

Page 48

dummyheaddummyhead

FRONT BRAKE HOSE D

(from ABS MODULATOR)

FRONT WHEEL SPEED

SENSOR WIRE

BRAKE SUB HOSE C

(from DELAY VALVE)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

PARKING BRAKE CABLE

Parallel

NC700XD:

GENERAL INFORMATION

1-43

Page 49

dummyheaddummyhead

CLUTCH CABLE

BRAKE HOSE

THROTTLE CABLE B

THROTTLE CABLE A

SIPHON HOSE

RESERVE TANK

OVERFLOW HOSE

HORN WIRES

O2 SENSOR

1P (BLACK) CONNECTOR

No.2 IGNITION COIL

IGNITION COIL

PRIMARY WIRES

LEFT HANDLEBAR

SWITCH WIRE

CLUTCH SWITCH WIRE

GENERAL INFORMATION

NC700S:

1-44

Page 50

dummyheaddummyhead

THROTTLE CABLE B

THROTTLE CABLE A

SIPHON HOSE

RESERVE TANK

OVERFLOW HOSE

No.2 IGNITION COIL

IGNITION COIL

PRIMARY WIRES

FRONT BRAKE HOSE D

(from ABS MODULATOR)

FRONT WHEEL SPEED

SENSOR WIRE

BRAKE SUB HOSE C

(from DELAY VALVE)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

CLUTCH CABLE

LEFT HANDLEBAR

SWITCH WIRE

CLUTCH SWITCH WIRE

FRONT WHEEL SPEED SENSOR

2P (BLUE) CONNECTOR

Parallel

NC700SA:

GENERAL INFORMATION

1-45

Page 51

dummyheaddummyhead

THROTTLE CABLE B

THROTTLE CABLE A

SIPHON HOSE

RESERVE TANK

OVERFLOW HOSE

No.2 IGNITION COIL

IGNITION COIL

PRIMARY WIRES

FRONT BRAKE HOSE D

(from ABS MODULATOR)

FRONT WHEEL SPEED

SENSOR WIRE

BRAKE SUB HOSE C

(from DELAY VALVE)

FRONT BRAKE HOSE A

(to ABS MODULATOR)

PARKING BRAKE CABLE

FRONT WHEEL SPEED SENSOR

2P (BLUE) CONNECTOR

Parallel

GENERAL INFORMATION

NC700SD:

1-46

Page 52

dummyheaddummyhead

SEAT LOCK CABLE

LUGGAGE BOX LID LOCK CABLE

SEAT LOCK CABLE

TURN SIGNAL/HAZARD RELAY

IGNITION COIL

PRIMARY WIRE

No.1 IGNITION COIL

TURN SIGNAL/HAZARD RELAY

4P CONNECTOR

NC700X/XA/XD:

GENERAL INFORMATION

NC700X/XA/XD:

1-47

Page 53

dummyheaddummyhead

LUGGAGE BOX LID LOCK CABLE

No.2 IGNITION COIL

SEAT LOCK CABLE

SIDESTAND SWITCH

3P (GREEN) CONNECTOR

FUEL PUMP

1P (BLACK) CONNECTOR

LUGGAGE BOX LID LOCK CABLE

GENERAL INFORMATION

NC700S/SA/SD:

NC700S/SA/SD:

1-48

Page 54

dummyheaddummyhead

LUGGAGE BOX LID LOCK CABLE

DLC

JUNCTION B

14P (ORANGE) CONNECTOR

JUNCTION G

14P (ORANGE) CONNECTOR

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

No.2 IGNITION COIL

NC700S/SA/SD:

GENERAL INFORMATION

1-49

Page 55

dummyheaddummyhead

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

IAT SENSOR

2P (BLACK) CONNECTOR

IGNITION COIL

PRIMARY WIRES

IGNITION SWITCH

2P (BROWN) CONNECTOR

DLC

JUNCTION B

14P (ORANGE) CONNECTOR

JUNCTION G

14P (ORANGE) CONNECTOR

No.2 IGNITION COIL

IGNITION COIL

PRIMARY WIRES

MAIN WIRE HARNESS

CKP SENSOR

2P (RED) CONNECTOR

STARTER MOTOR CABLE

GROUND CABLE

FUEL FEED HOSE

STARTER RELAY

SWITCH

FUSE BOX

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

GENERAL INFORMATION

NC700X/XA:

1-50

Page 56

dummyheaddummyhead

TURN SIGNAL/HAZARD RELAY

No.1 IGNITION COIL

IAT SENSOR

2P (BLACK) CONNECTOR

IGNITION COIL

PRIMARY WIRES

IGNITION SWITCH

2P (BROWN) CONNECTOR

DLC

JUNCTION B

14P (ORANGE) CONNECTOR

JUNCTION G

14P (ORANGE) CONNECTOR

No.2 IGNITION COIL

IGNITION COIL

PRIMARY WIRES

MAIN WIRE HARNESS

CKP SENSOR

2P (RED) CONNECTOR

STARTER MOTOR CABLE

GROUND CABLE

FUEL FEED HOSE

STARTER RELAY

SWITCH

FUSE BOX

LEFT HANDLEBAR SWITCH

3P (BLACK) CONNECTOR

LEFT HANDLEBAR SWITCH

10P (GRAY) CONNECTOR

NC700XD:

GENERAL INFORMATION

1-51

Page 57

dummyheaddummyhead

FUEL FEED HOSE

BATTERY BOX DRAIN HOSE

No.1 SPARK PLUG WIRE

AIR CLEANER HOUSING

DRAIN HOSE

RADIATOR LOWER

WATER HOSE

FAN MOTOR

3P (GRAY) CONNECTOR

GENERAL INFORMATION

NC700X/XA/S/SA:

1-52

Page 58

dummyheaddummyhead

FUEL FEED HOSE

BATTERY BOX DRAIN HOSE

No.1 SPARK PLUG WIRE

AIR CLEANER HOUSING

DRAIN HOSE

RADIATOR LOWER

WATER HOSE

FAN MOTOR

3P (GRAY) CONNECTOR

SHIFT PEDAL ANGLE SENSOR

3P (BLACK) CONNECTOR (Opt ional)

NC700XD/SD:

GENERAL INFORMATION

1-53

Page 59

dummyheaddummyhead

CLUTCH CABLE

No.2 SPARK PLUG WIRE

RADIATOR UPPER

WATER HOSE

SIPHON HOSE

O2 SENSOR WIRE

O2 SENSOR

1P (BLACK) CONNECTOR

HORN WIRES

RESERVE TANK

OVERFLOW HOSE

ECT SENSOR

2P CONNECTOR

FUEL FEED HOSE

EOP SWITCH

1P (GRAY) CONNECTOR

EOP SWITCH

1P (GRAY) CONNECTOR

GENERAL INFORMATION

NC700X/XA:

1-54

Page 60

dummyheaddummyhead

No.2 SPARK PLUG WIRE

RADIATOR UPPER

WATER HOSE

SIPHON HOSE

O2 SENSOR WIRE

O2 SENSOR

1P (BLACK) CONNECTOR

HORN WIRES

RESERVE TANK

OVERFLOW HOSE

ECT SENSOR

2P CONNECTOR

FUEL FEED HOSE

EOP SWITCH

1P (GRAY) CONNECTOR

EOP SWITCH

1P (GRAY) CONNECTOR

PARKING BRAKE CABLE

NC700XD:

GENERAL INFORMATION

1-55

Page 61

dummyheaddummyhead

No.2 SPARK PLUG WIRE

RADIATOR UPPER

WATER HOSE

SIPHON HOSE

O2 SENSOR WIRE

O2 SENSOR

1P (BLACK) CONNECTOR

HORN WIRES

RESERVE TANK

OVERFLOW HOSE

ECT SENSOR

2P CONNECTOR

FUEL FEED HOSE

EOP SWITCH

1P (GRAY) CONNECTOR

EOP SWITCH

1P (GRAY) CONNECTOR

CLUTCH CABLE

Upper

side

GENERAL INFORMATION

NC700S/SA:

1-56

Page 62

dummyheaddummyhead

No.2 SPARK PLUG WIRE

RADIATOR UPPER

WATER HOSE

SIPHON HOSE

O2 SENSOR WIRE

O2 SENSOR

1P (BLACK) CONNECTOR

HORN WIRES

RESERVE TANK

OVERFLOW HOSE

ECT SENSOR

2P CONNECTOR

FUEL FEED HOSE

EOP SWITCH

1P (GRAY) CONNECTOR

EOP SWITCH

1P (GRAY) CONNECTOR

PARKING BRAKE CABLE

Upper

side

NC700SD:

GENERAL INFORMATION

1-57

Page 63

dummyheaddummyhead

MAIN WIRE HARNESS

MAIN WIRE HARNESS

SHIFT SPINDLE ANGLE SENSOR WIRE

CLUTCH LINE EOP SENSOR

3P (BLACK) CONNECTOR

No.1 CLUTCH EOP SENSOR

3P (GRAY) CONNECTOR

No.2 CLUTCH EOP SENSOR

3P (GRAY) CONNECTOR

GENERAL INFORMATION

NC700XD/SD:

1-58

Page 64

dummyheaddummyhead

BATTERY BOX DRAIN HOSE

FUEL TANK DRAIN HOSE B

SIDESTAND SWITCH WIRE

NEUTRAL SWITCH CONNECTOR

ALTERNATOR WIRE

VS SENSOR

3P (BLACK) CONNECTOR

OPTION

6P CONNECTOR

NEUTRAL SWITCH WIRE

SIDESTAND

SWITCH WIRE

NEUTRAL

SWITCH WIRE

SIDESTAND

SWITCH WIRE

FUEL TANK

DRAIN HOSE B

NC700X/XA:

GENERAL INFORMATION

1-59

Page 65

dummyheaddummyhead

BATTERY BOX DRAIN HOSE

FUEL TANK DRAIN HOSE B

SIDESTAND SWITCH WIRE

TR SENSOR WIRE

NEUTRAL SWITCH

SIDESTAND

SWITCH WIRE

BATTERY BOX DRAIN HOSE

MAIN WIRE HARNESS

Upper

side

MAIN WIRE HARNESS

TR SENSOR

SHIFT CONTROL MOTOR

2P (BLACK) CONNECTOR

FUEL TANK DRAIN HOSE B

TR SENSOR WIRE

SIDESTAND

SWITCH WIRE

MAIN WIRE HARNESS

SHIFT PEDAL ANGLE SENSOR

3P (BLACK) CONNECTOR (Optional)

GENERAL INFORMATION

NC700XD/SD:

1-60

Page 66

dummyheaddummyhead

IACV

4P (BLACK) CONNECTOR

STARTER MOTOR CABLE

GROUND CABLE

THROTTLE CABLES

ECT SENSOR

2P CONNECTOR

FUEL FEED HOSE

INJECTOR

2P (GRAY) CONNECTORS

BATTERY BOX

DRAIN HOSE

SENSOR UNIT

5P (BLACK) CONNECTOR

No.2 SPARK PLUG WIRE

No.1 SPARK PLUG WIRE

CRANKCASE BREATHER HOSE

WATER BYPASS HOSE

Left

side

Right

side

Upper

side

Upper

side

NC700X:

GENERAL INFORMATION

1-61

Page 67

dummyheaddummyhead

IACV

4P (BLACK) CONNECTOR