Honda goldwing clarion type ii Installation Manual

Accessory

TYPE 11

AM/FM RADIO

Application

GL1100

Publications No.

HP 190 8112

Issue Date

DECEMBER

PREFACE

Congratulations on purchasing this quality

Type 11 Honda Motorcycle Audio system.

This booklet is your guide to the installation

of your new Type II Honda Motorcycle

Radio. Please take the time to read the

booklet carefully. (Your authorized Honda

dealer will be glad to provide further information or assistance and is equipped to handle

your further service needs.)

TOOLS REQUIRED

• Ratchet and 12" extension

• 7 and 10 mm sockets

• 8, 10, and 14 mm box wrenches

• Drill

• 1/8", 7/32", 3/16", and 1/4" Bits

• 2.5, 4, 8 mm hex wrench

• #1 and #2 Phillips screwdrivers

• Sharp knife or Razor blade

• Hammer

• Center punch

• Masking tape

• 17 mm open-end wrench

HONDA MOTOR CO., LTD. 1981•All Rights Reserved 08118-MB910-95 Printed in Japan

28 4-3 60 2-0 0

2 of 1 1

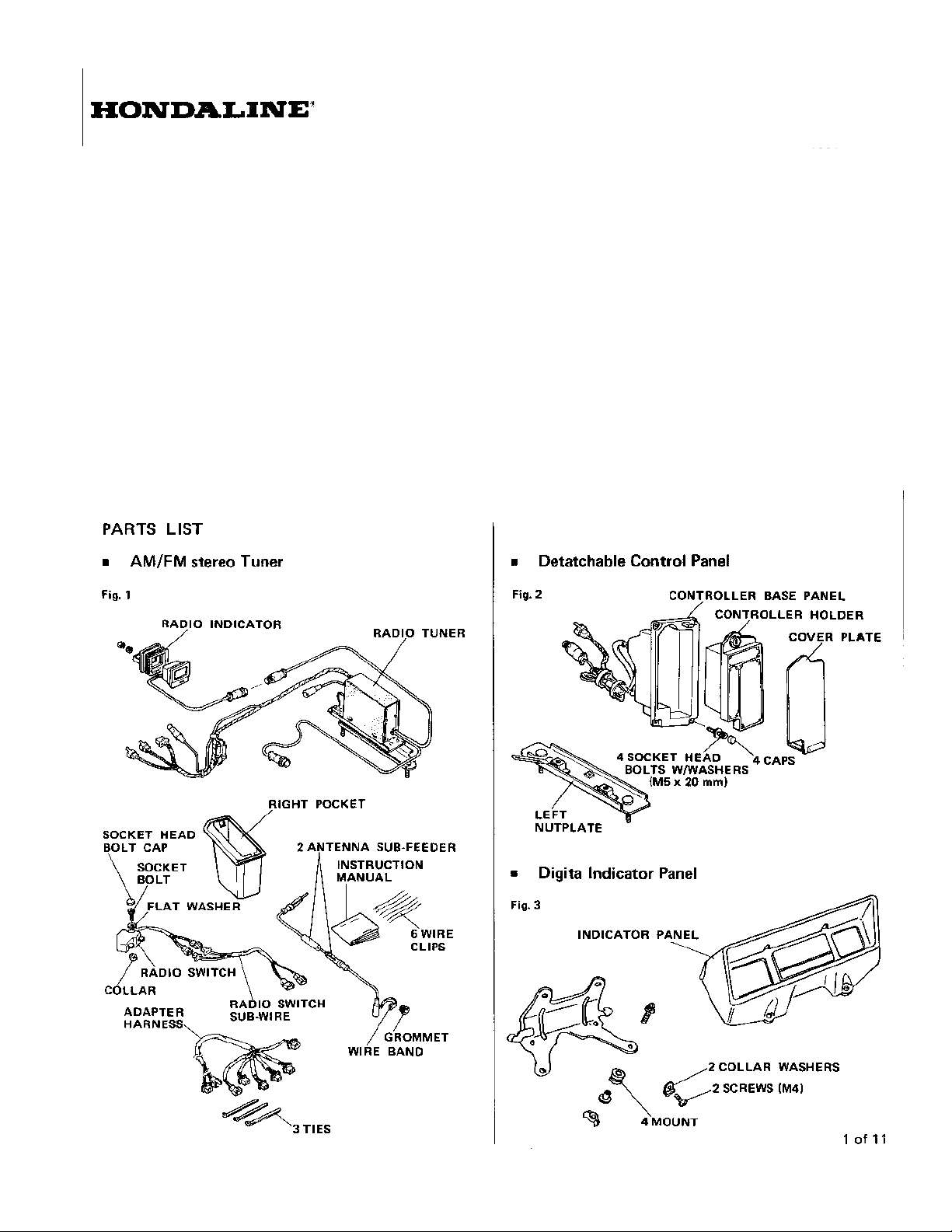

OVERALL LAYOUT

Fig. 9

INSTALLATION

■ Outline Procedures

This section gives general information needed

for mounting the individual radio components

on and in the fairing.

A) Fairing

1) Install radio on fairing before mounting

fairing on motorcycle. (Remove fairing

from your motorcycle when already

mounted).

2) Remove fairing parts.

3) Drill unit mount holes.

4) Install six wire clips.

5) Install windshield on fairing before install-

ing speakers.

6) Install radio indicator I on indicator panel

II , then install indicator panel on fairing.

7) Install speakers III.

8) Install nutplate IV.

9) Install Power Amplifier in fairing.

10) Install radio funer VI.

11) Install the radio controller VII.

12) Install controller base panel VIII

13) Install radio switch sub-wire.

14) Connect adapter harness and wires inside

fairing by working through left turn

signal lens hole.

B) Motorcycle frame and handlebar

1) Remove travel trunk and seat. Unscrew

four shelter bolts (M6, one on each side

at front and rear) to route antenna feeder.

2) Install antenna mount and antenna IX.

3) Route antenna feeder along the frame

tube.

4) Install radio switch X on left handlebar

3 of 11

C) Fairing installation

1) Install fairing on motorcycle.

2) Connect motorcycle wire harness 9-P

coupler to fairing wire 9-P coupler.

3) Connect radio switch wire to switch sub-

wire.

4) Connect antenna feeder.

5) Confirm that radio operates properly.

Reinstall parts removed in step 2 or (A)

and in step 1 of (B).

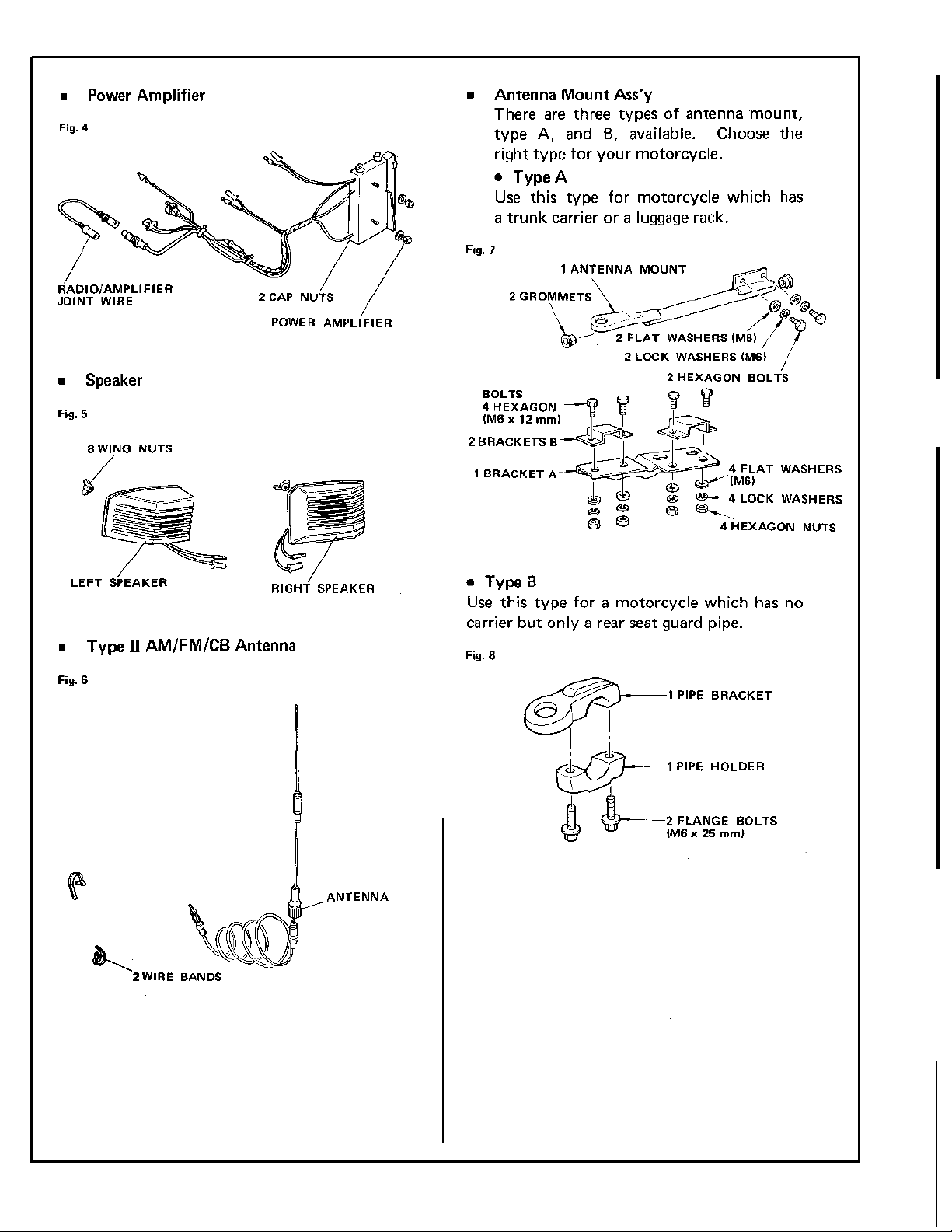

REWORKING

■ Remove Fairing and Fairing Parts (Fig.10)

1) Install radio on fairing before mounting

fairing on motorcycle. (Remove fairing

from your motorcycle when already

mounted).

2) Remove right and left fairing pockets,

right and left turn signal lenses, right and

left nutplates, left hole cover and indicator base panel from fairing. (Fig.10)

Fig. 10

LEI-1 NU I PLATE

4 of 11

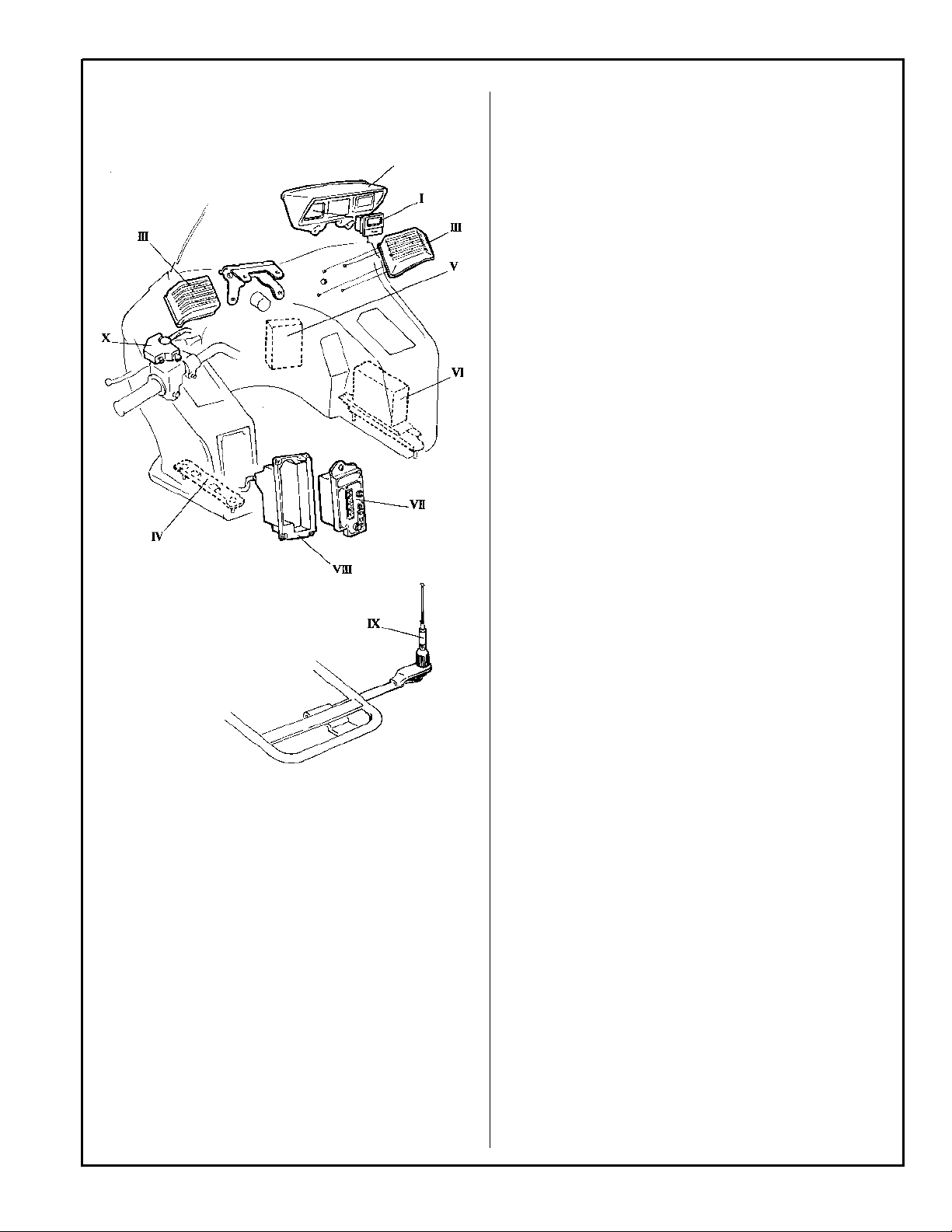

■ Reworking on Fairing —

Speaker mounting holes-

1) Remove 18 mm grommet.

2) Lightly roll template so that it will follow

contour of fairing snugly.

3) Position template on fairing with its upper

and outer edges aligned with those of

fairing as indicated by arrows.

4) Attach template to fairing using adhesive

tape where shown.

5) Punch mark centers of four holes with a

drift and hammer.

6) Drill 6 mm holes through marked centers.

To obtain a more balanced response with

richer, deeper bases, drill two 50 mm holes in

the fairing so as to link the speaker box with

the inside of the fairing.

Fig. 11-1

—Power amplifier mounting holes-

7) Drill two 5.5 mm holes through concaves

in fairing.

Fig. 11-2

RIGHT HAND SHOWN, LEFT

SIMILAR

ADHESIVE

TAPE

TEMPLATE

—Indicator panel mounting holes-

8) Drill four 15 mm holes through fairing at

the marked locations, and 40 mm holes as

shown.

Fig. 11-3

INSTALLATION ON FAIRING

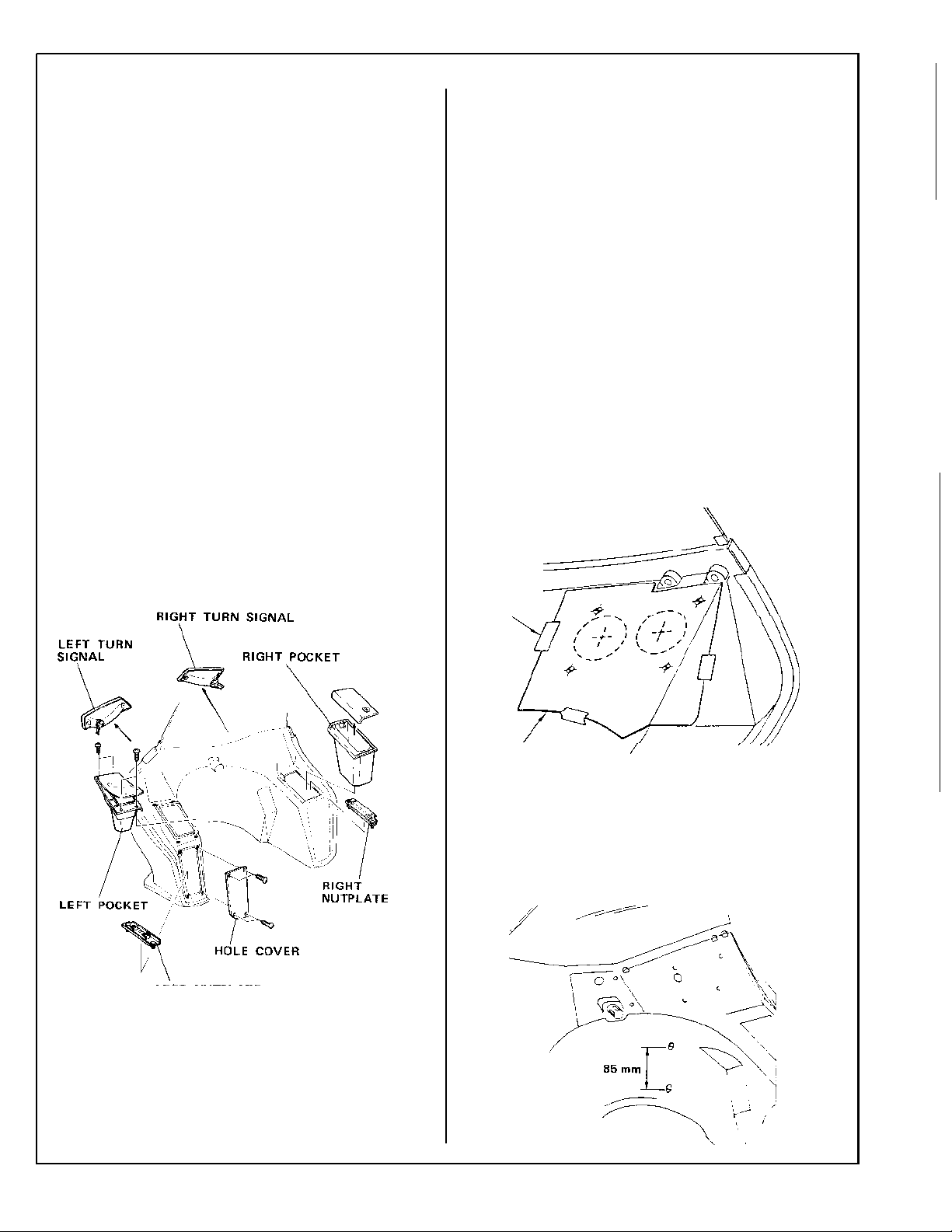

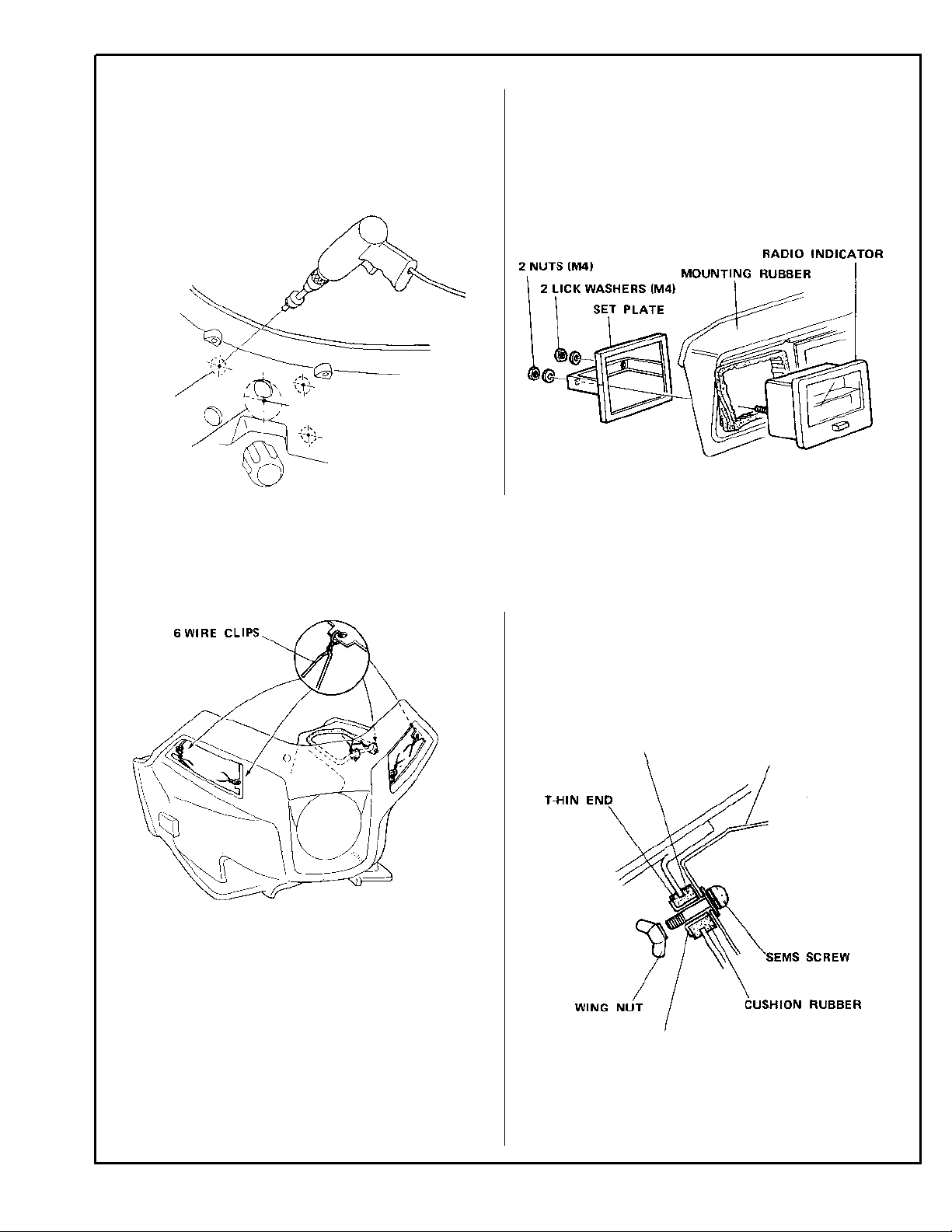

■ Radio Indicator Installation (Fig. 12, 13,

14)

1) Install radio indicator in indicator panel as

shown.

15 mm HOLE

40 mm HOLE

Fig. 12

9) Install six wire clips to temporarily secure

wires as shown.

Fig. 11-4

6 WIRE CLIPS

2) Insert the cushion rubbers into the holes

with the thick ends facing out.

3) Slide special washers into cushion rubbers

from inside fairing.

4) Attach the top of the base bracket to fair-

ing using two screw-washer combinations

and wing nuts. Tighten wing nuts with

pliers while holding the screws with

screwdriver.

Fig. 13

THICK END

SPECIAL WASHER

BASE BRACKET

CUSHION RUBBER

5 of 11

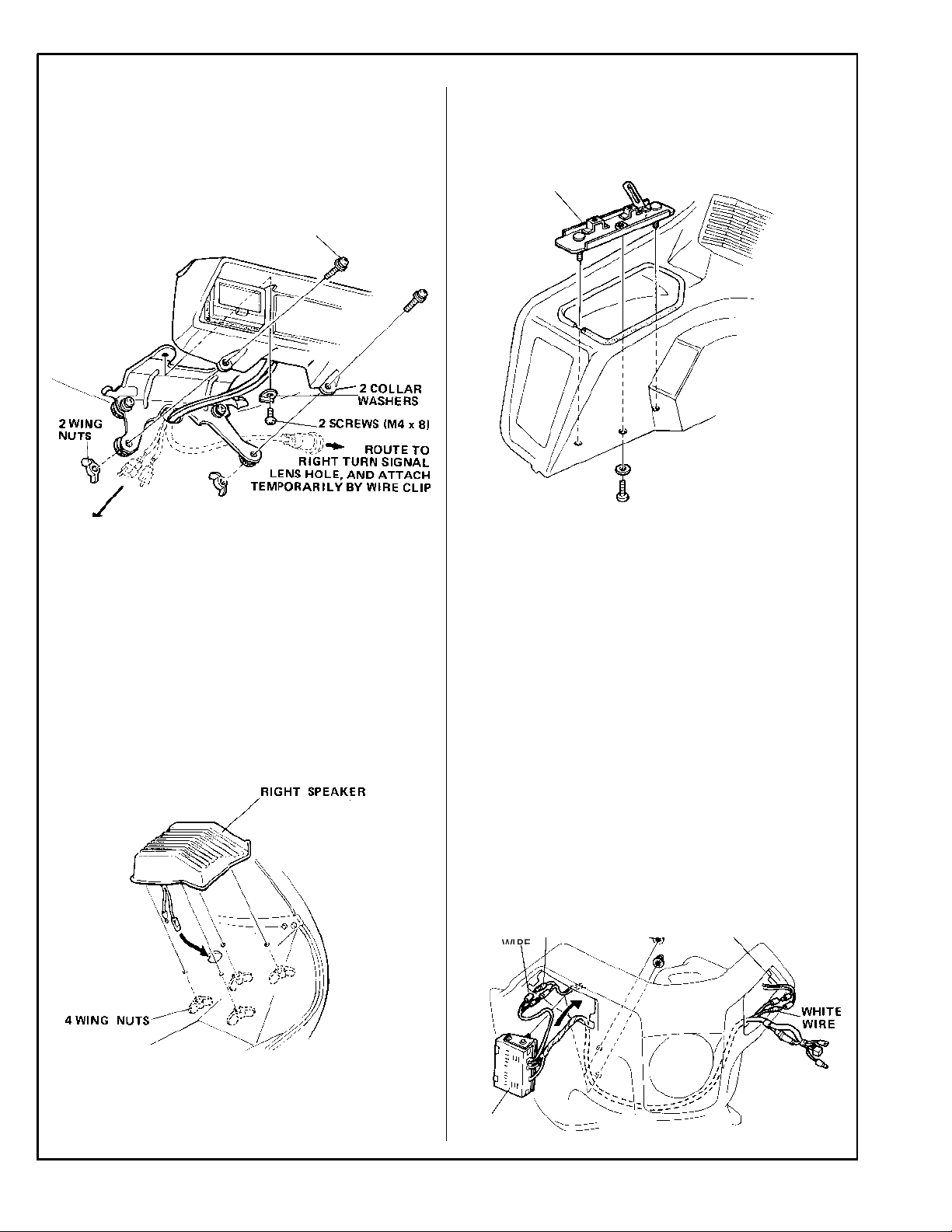

5) Install indicator panel on base bracket.

6) Route indicator wire out through right

turn signal lens hole and sub-wire harness

G out -through left turn signal lens hole.

Temporarily secure wires with wire clips.

Fig. 14

2 SEMS SCREWS

ROUTE TO LEFT TURN SIGNAL LENS HOLE

AND

ATTACH TEMPORARILY BY WIRE CLIP

■

Speaker Installation (Fig. 15)

1) Route speaker wires through holes in fairing and position each speaker in fairing

align studs with holes in fairing.

2) Reaching through the turn signal lens

holes, install wing nuts on studs and

tighten securely.

Fig. 15

RIGHT SPEAKER SHOWN LEFT SIMILAR

6 of 11

■ Left Nutplate Installation (Fig. 16)

1) Install left nutplate as shown.

Fig. 16

■ Power Booster Installation (Fig. 17)

1) Insert booster into fairing through right

turn signal lens hole.

2) Insert booster studs into holes in fairing

and install using a cap nut on each stud.

Tighten securely.

3) Route the gray wire out to right turn

signal lens hole and connect to wire from

right speaker.

4) Route wires bundled with yellow tape

under headlight and out through left turn

signal lens hole.

5) Remove yellow tape from wires and

connect white wire to left speaker wire.

Temporarily secure other wires with wire

clips.

LEFT NUTPLATE

Fig. 17

WIRE FROM RIGHT SPEAKER

I 2 CAP NUTS -

POWER

AMPLIFIER

WIRE FROM LEFT

SPEAKER

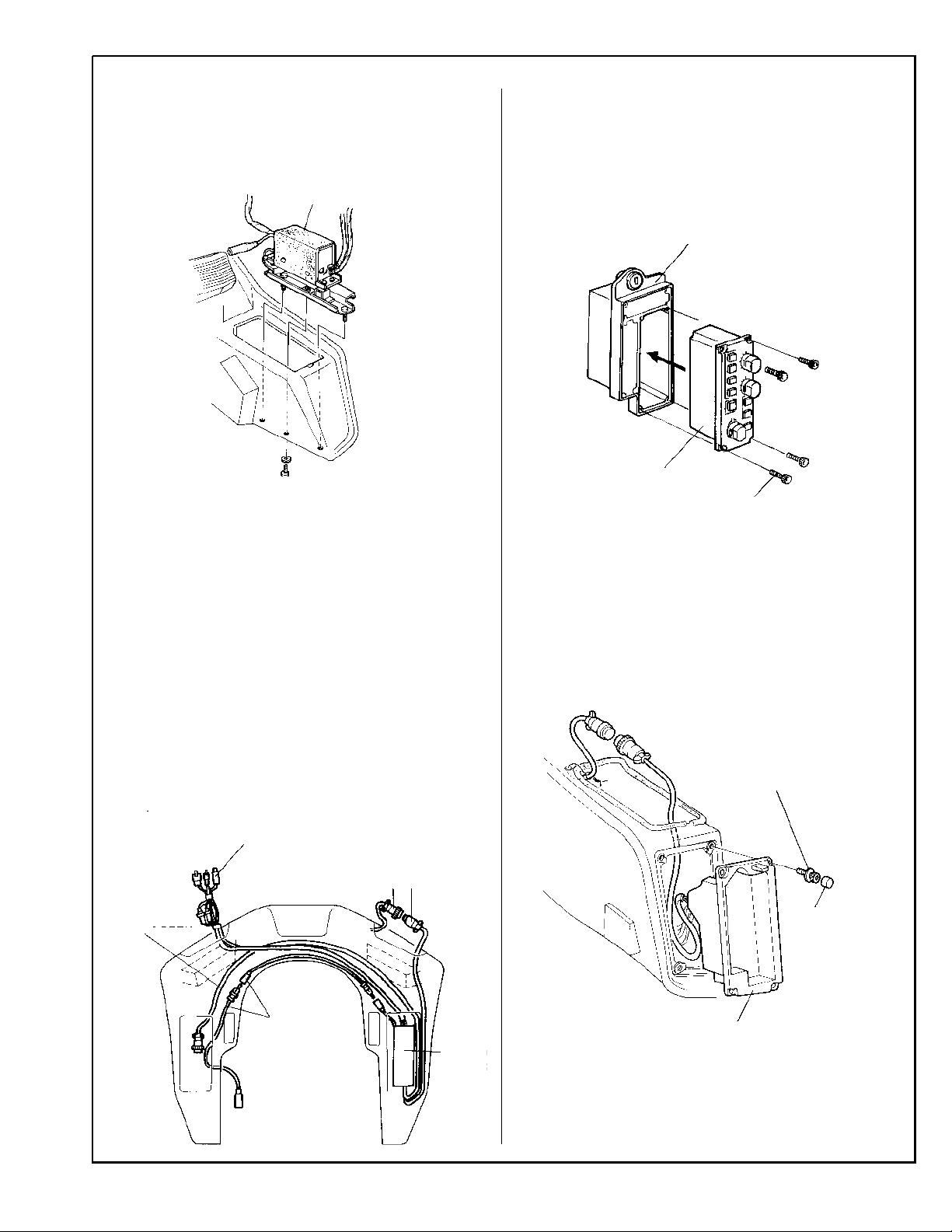

■ Radio Tuner Installation (Fig. 18, 19)

1) Attach right nutplate with radio to fairing.

Fig. 18

2) Route wires bundled with green tape

under headlight towards left and out

through left turn signal lens hole. Temporarily secure wires with wire clip.

3) Route wire to radio controller under

headlight towards left side and out

through left pocket hole. Secure wire

with wire clip temporarily.

4) Pass indicator wire out through right turn

signal lens hole and connect it to wire

from indicator.

5) Connect two antenna feeders to radio and

route them out through hole above 9-P

connector.

■ Radio Controller Installation (Fig. 20)

Remove radio controller blind lid from

controller holder. Slide the radio controller into the holder and install using

four hex socket bolts.

Fig. 20

CONTROLLER HOLDER

4 SOCKET HEAD BOLTS

■ Controller Base Panel Installation (

Fig. 21, 22)

1)

Slide controller base plate into fairing and

install using four socket head bolts. Place

caps over heads of socket bolts.

Fig. 21

CONTROLLER

BASE PLATE

7 of 11

RADIO TUNER

Fig. 19

WIRES BUNDLED WITH YELLOW TAPE

INDICATOR WIRE

FROM INDICATOR

CONTROLLER

WIRE

ANTENNA

FEEDER

EXTENSION

RADIO

TUNER

RADIO CONTROLLER

4 SOCKET HEAD BOLT

W/WASHERS

(M5 x 20

mm)

4 CAPS

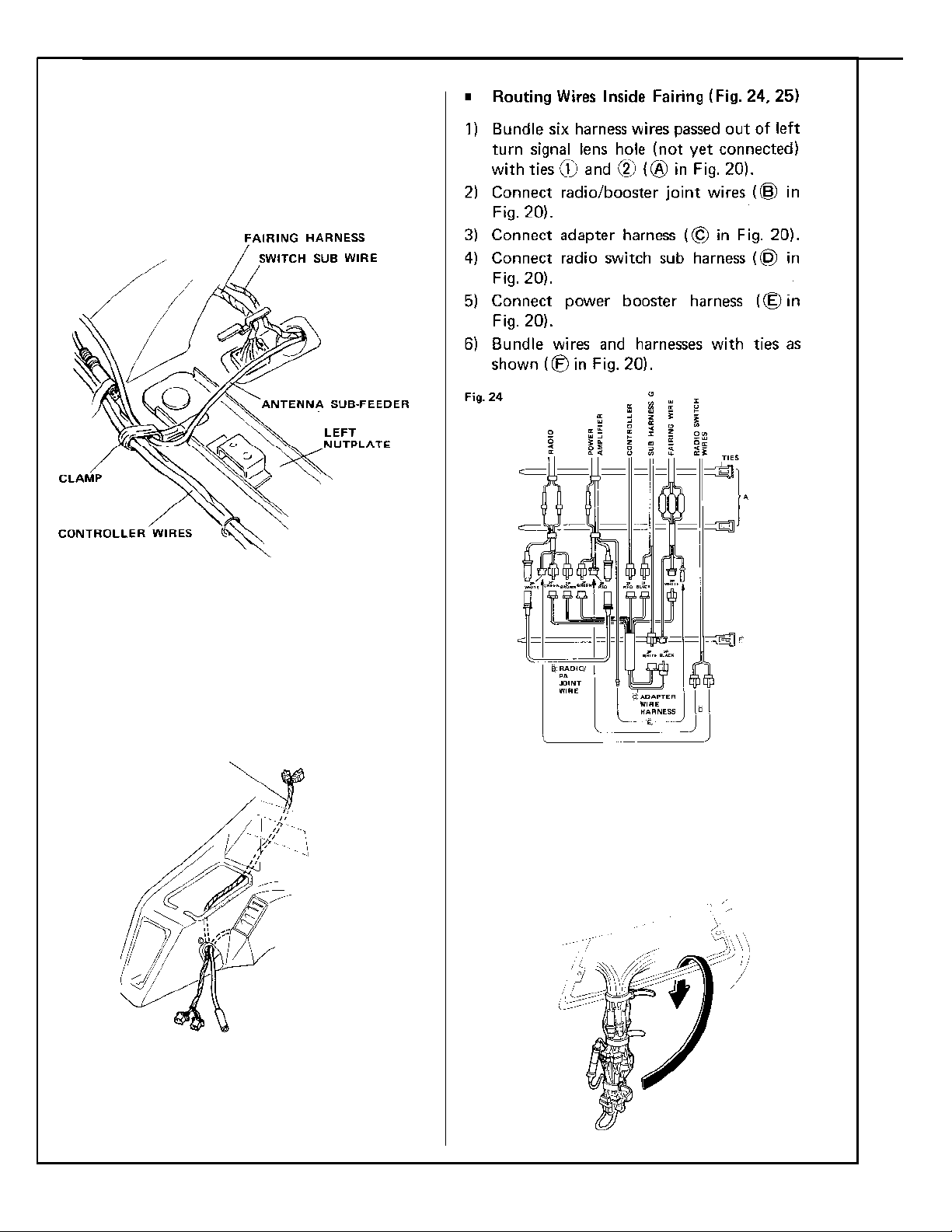

7) Press all bundled wires and wire harness

into fairing through left turn signal lens

hole.

Fig. 25

2) Route radio wires out through left pocket

hole and connect them to wires from

radio. Insert wires into fairing. Secure

wires and antenna feeder with wire clamp

on nutplate.

Fig. 22

■

Radio Switch Sub-wire Routing (Fig. 23)

1)

Route radio switch sub wire out through

left turn signal lens hole and secure with

wire clip as shown.

Fig. 23

RADIO SWITCH SUB-WIRE

8 of 11

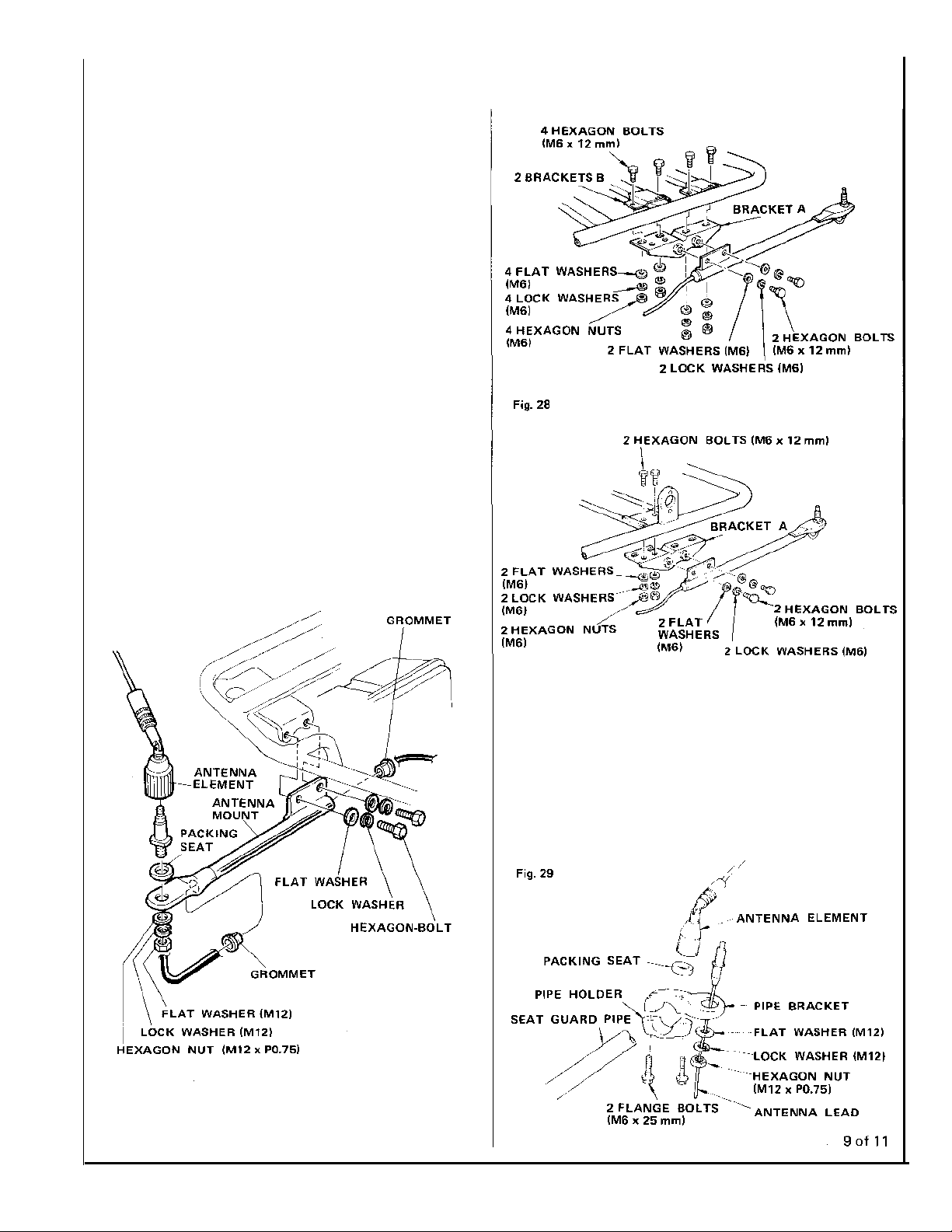

■ Antenna Installation (Fig. 26, 27, 28, 29)

1) Remove seat by removing hex socket

bolts (one on each side) and pulling it

backward.

2) Remove the top compartment by remov-

ing four bolts (M6) (one on each side at

front and rear) and pulling it upward. See

Motorcycle Service Manual.

3) Install antenna on antenna mount and

route antenna feeder through mount.

Antenna is collapsible. Install the antenna

so it folds along the frame. This is for

convenience when covering the motorcycle, or putting the motorcycle in a

garage.

4-1 Press grommets into holes at ends of

mount. Position antenna mount on rear

trunk stay and install using bolts

w/washers.

• Tighten nuts (M12) to 0.1 kg-m torque.

• Tighten hexagon bolt (M6 x 12 mm) to 0.8-

1.2 kg/m (6-9 ft/lb) torque.

Fig. 26

Fig. 27

4-2 Position antenna base on seat guard pipe

and install using bracket, holder and two

flange bolts (M6 x 25 mm).

• Tighten the flange bolt (M6 x 25 mm)

to 0.8-1.2 kg/m (6-9 ft/lb) torque.

• Tighten the hexagon nut (M12) to

0.1 kg/m torque.

Loading...

Loading...