Page 1

HOME LITE*

8H.P. TILLER

MFG. NO. 1600405 8 H.P: TILLER

TINE EXTENSION KIT MFG. 1^. 1600406

FURROW OPENER MFG. NO. 1600373

OPERATOR'S

RIHRURl

FORM - 1651767

PRINTED IN U.S.A.

749

Page 2

TABLE OF CONTENTS

Page

WARRANTY ........................................................................................................................ Inside Cover

SAFETY PRECAUTIONS ................................................................................................................ 1

ACCESSORIES ............................................................................................................................... 2

ASSEMBLING .................................................................................................................................. 2

OPERATION .................................................................................................................................... 4

ADJUSTMENTS ...............................................................................................................................5

MAINTENANCE ............................................................................................................................... 6

OFF-SEASON STORAGE ................................................................................................................8

TROUBLESHOOTING ..................................................................................................................... 8

SPECIFICATIONS ........................................................................................................................... 9

PARTS LISTINGS

PULLEY AND CONTROL GROUP

FRAME AND WHEELS ..............................................................................................................13

TINE EXTENSION KIT ...............................................................................................................14

FURROW OPENER .................................................................................................................. 14

DRIVE AND TINE GROUP ........................................................................................................15

DECALS .....................................................................................................................................17

...........................................................................................

11

CONGRATULATIONS!

This great new product is engineered with imagination and built with integrity to assure you maximum service and

performance for years to come. To completely understand the operation of your equipment and to take full

advantage of its many fine built-in features, study this instruction manual thoroughly before operating the machine.

The little time you spend reading now will repay you many times over in the time you save and the satisfaction you

gain in using your equipment properly and safely.

SAFETY PRECAUTIONS

i

Know the controls and how to stop quickly - READ THE

OWNER'S MANUAL.

Do not allow children to operate the Roticul. Do not allow

adults to operate it without proper instructions.

Clear the work area of objects which might be picked up and

thrown.

Keep all nuts, bolts and screws tight to be sure equipment is excessive grease,

in safe working condition.

Do not operate equipment when barefoot or wearing open

sandals. Always wear substantial footwear.

Handle gasoline with care - it is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running or

hot engine or fill the fuel tank indoors. Wipe up

spilled gasoline.

C. Open doors if the engine is run in a garage. Exhaust

fumes are dangerous. Do not run engine indoors.

Never store equipment with gasoline in the tank inside a

building where fumes may reach an open flame or spark.

Allow the engine to cool before storing in any enclosure.

To reduce fire hazard keep the engine free of grass, leaves or

Release the clutch lever and stop the engine before cleaning

the tines, removing obstacles, making adjustments, or when

leaving the operating position.

Never allow children or pets to cross your path, or cause dis

tractions in the area while operating.

Use caution to avoid slipping or falling, expecially when op

erating in reverse.

\

1

Page 3

ACCESSORIES

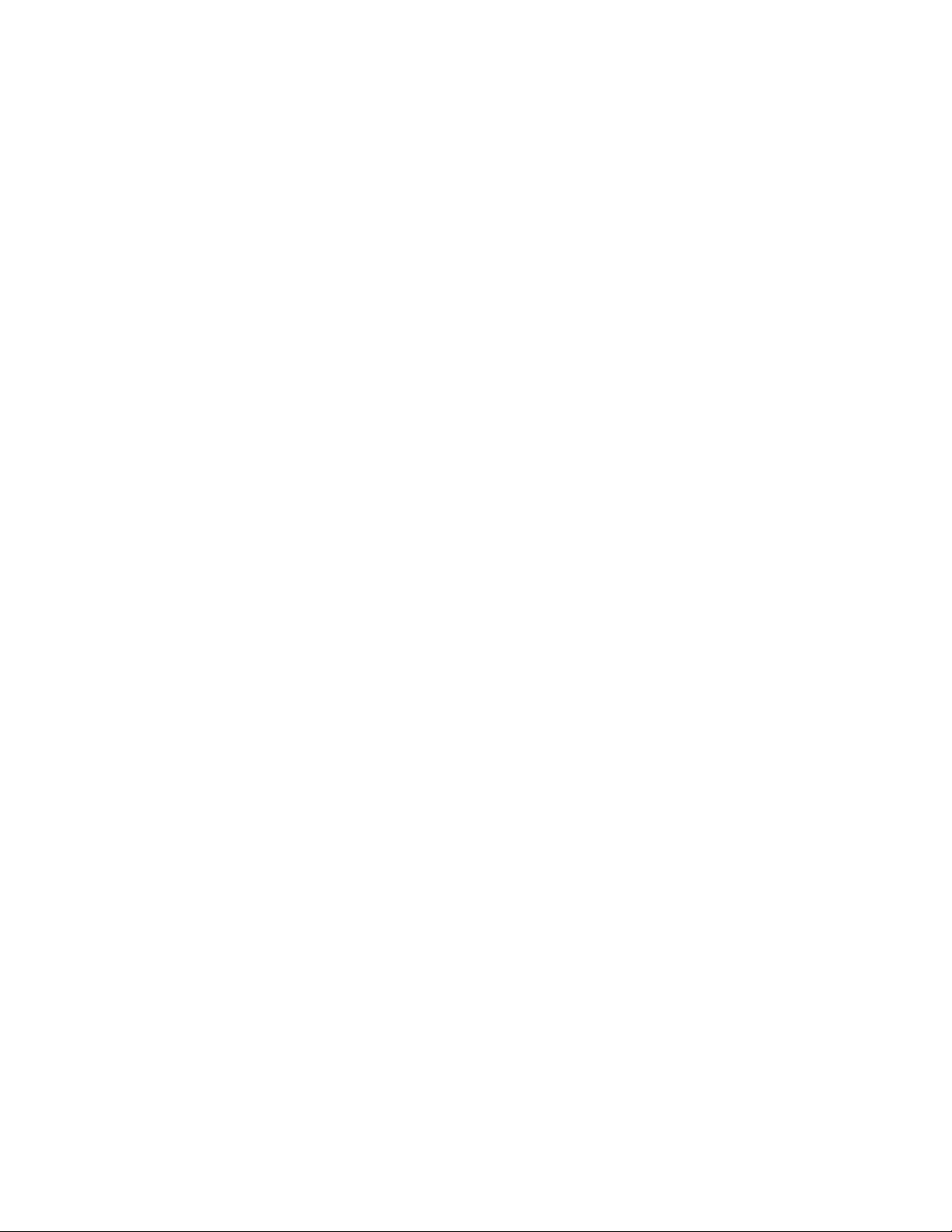

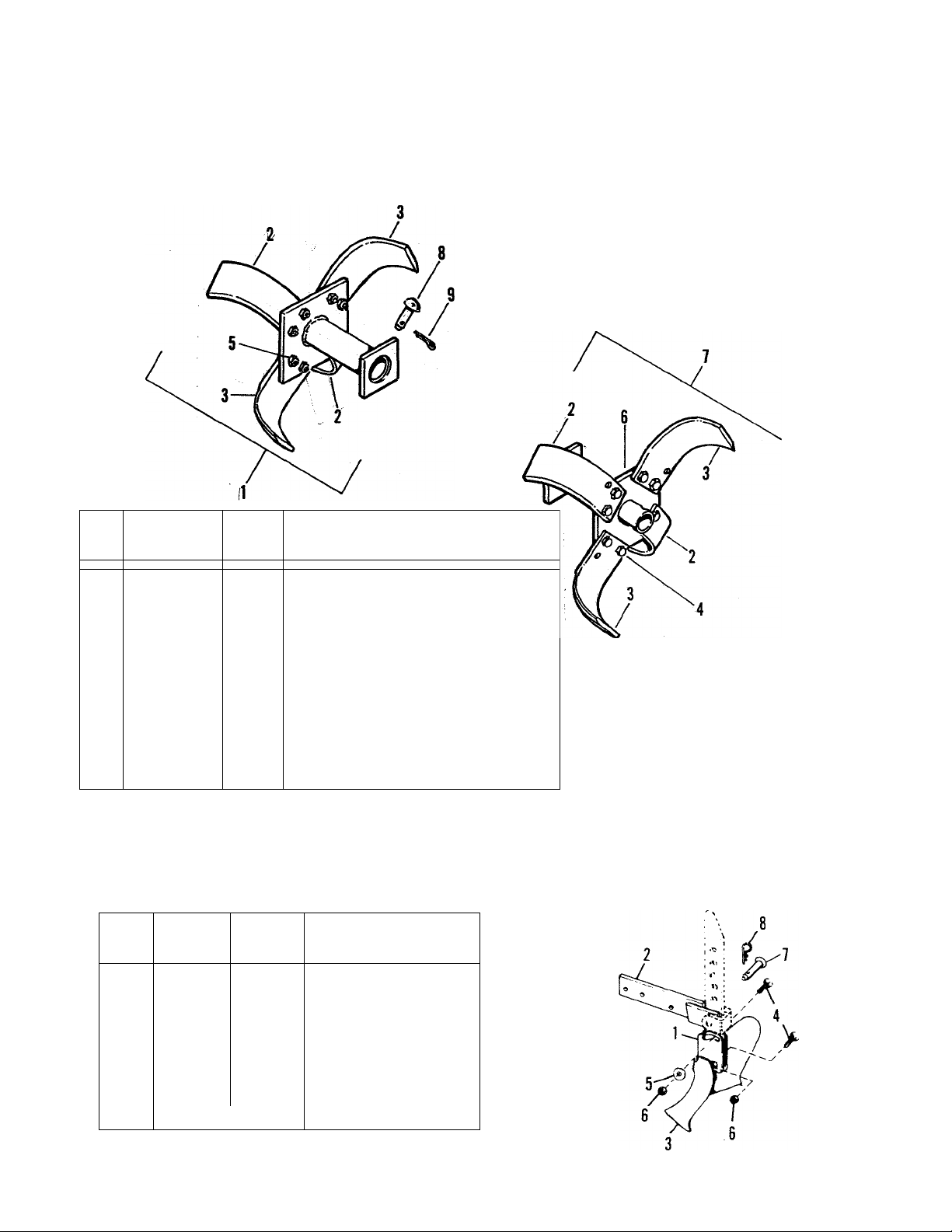

TINE EXTENSION SET (Mfg. No. 1600406)

See Figure 1. The extension set consists of a left and right

tine assemblies with mounting pins and cotter pins. Mount

long hub of extension over outside end of standard tine

assembly and secure assemblies together with pin and cotter

pin. Be sure sharpened edges of tines on top face forward.

The extension set increases effective tilling width to 35

inches.

ASSEMBLING

1. Remove all components of tiller from box and place them

in a clean, level area. Inspect each part for damage.

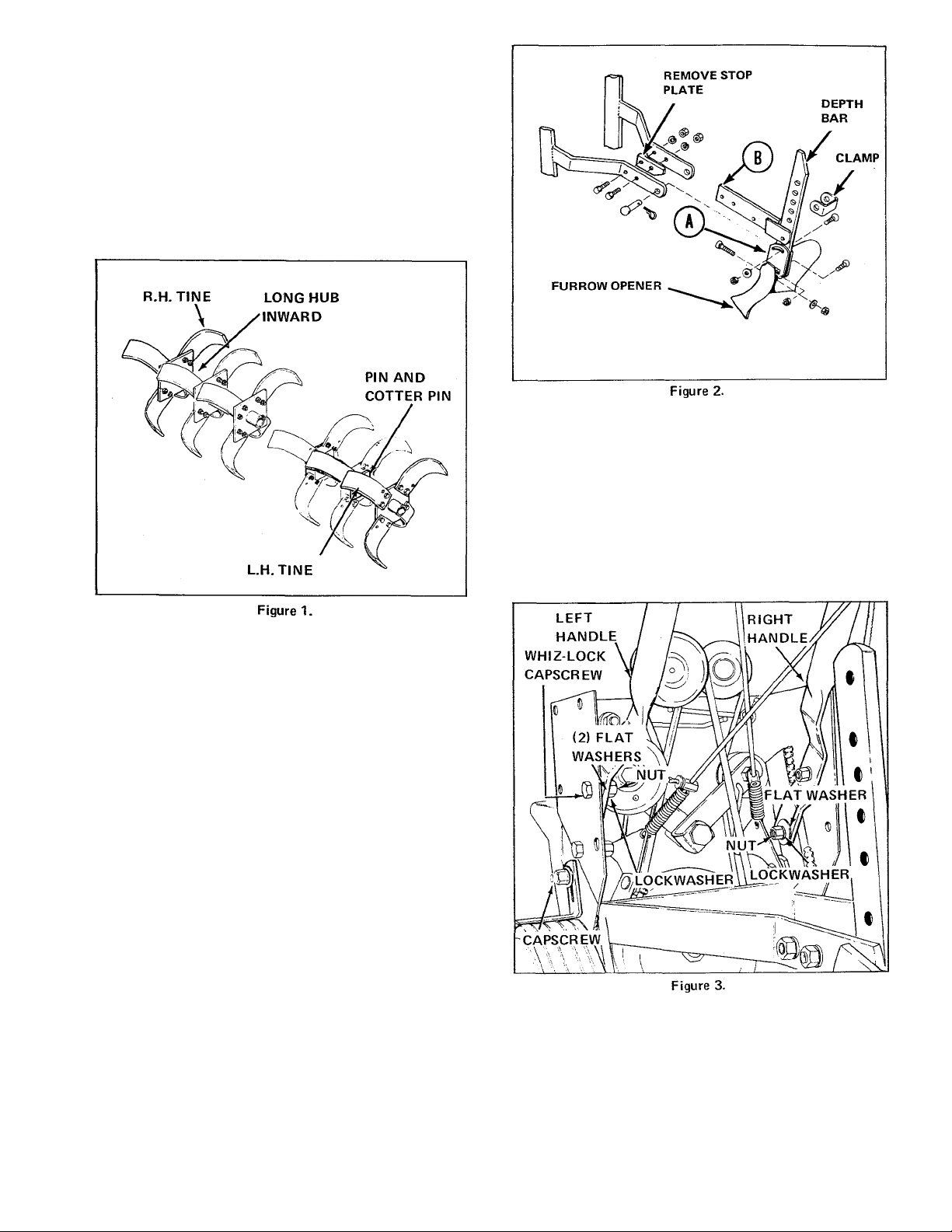

FURROW OPENER, 8-INCH (Mfg. No. 1600373)

See Figure 2. The furrow opener is intended for digging

furrows for crops which must be planted in rows. To install,

proceed as follows:

1. Remove the depth bar, turn it upside down and bolt it

to the tool holder (A) with the carriage bolts, washers and

nuts provided.

2. Remove the stop plate from between the frame supports

and install the extension support (B) with the old hardware.

3. Position the depth bar in the extension support and re

install the depth bar clamp using the pin and spring clip

provided. Bolt the furrow opener to the tool holder as

shown.

2. Remove belt cover.

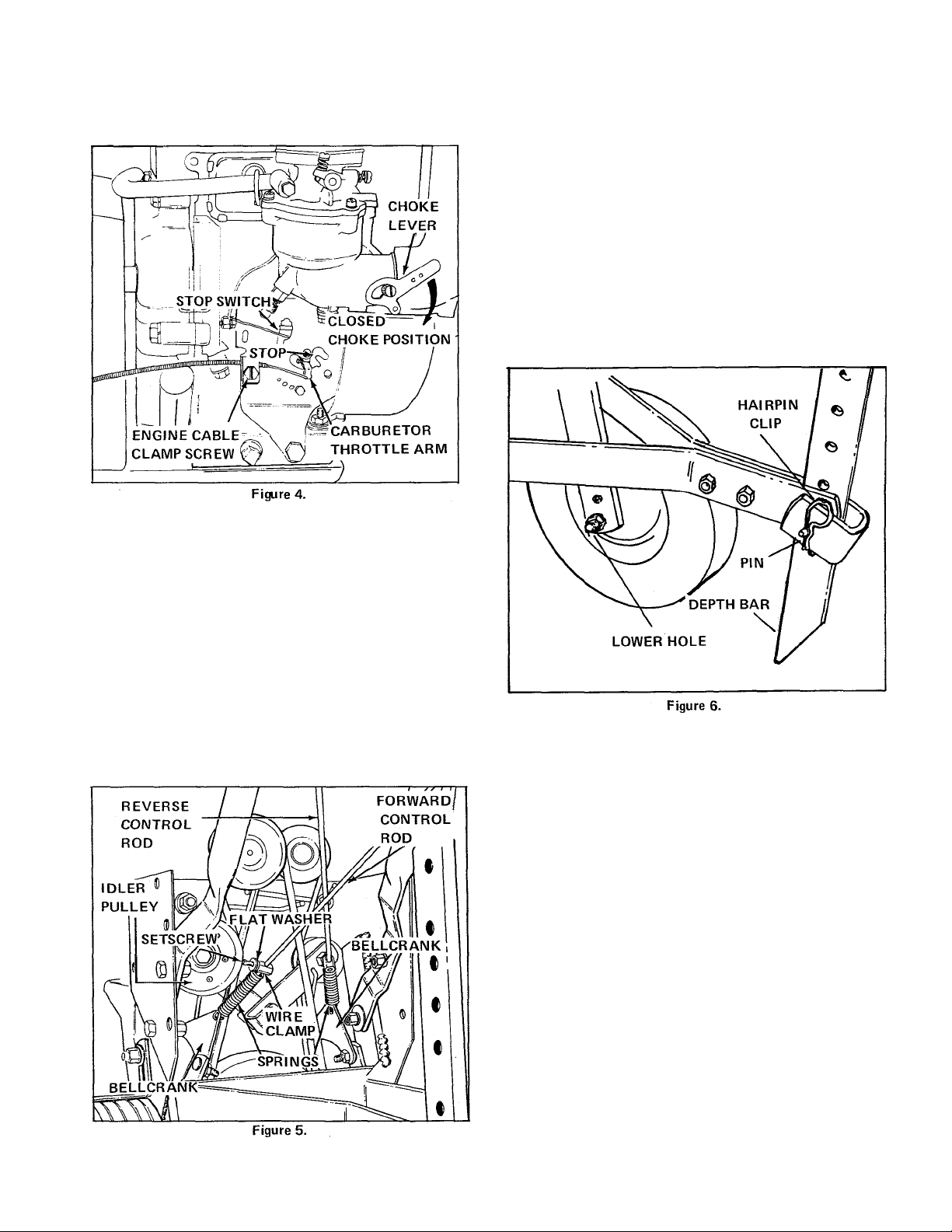

3. See Figure 3. Assemble left and right handles to frame as

shown. Note locations of flat washers.

SPECIAL WORM GEAR OIL

CAUTION

Damage to the worm gear drive which results from

use of any lubricant other than that specified, will

invalidate the warranty. (See back cover for special

Worm Gear Oil Part Number).

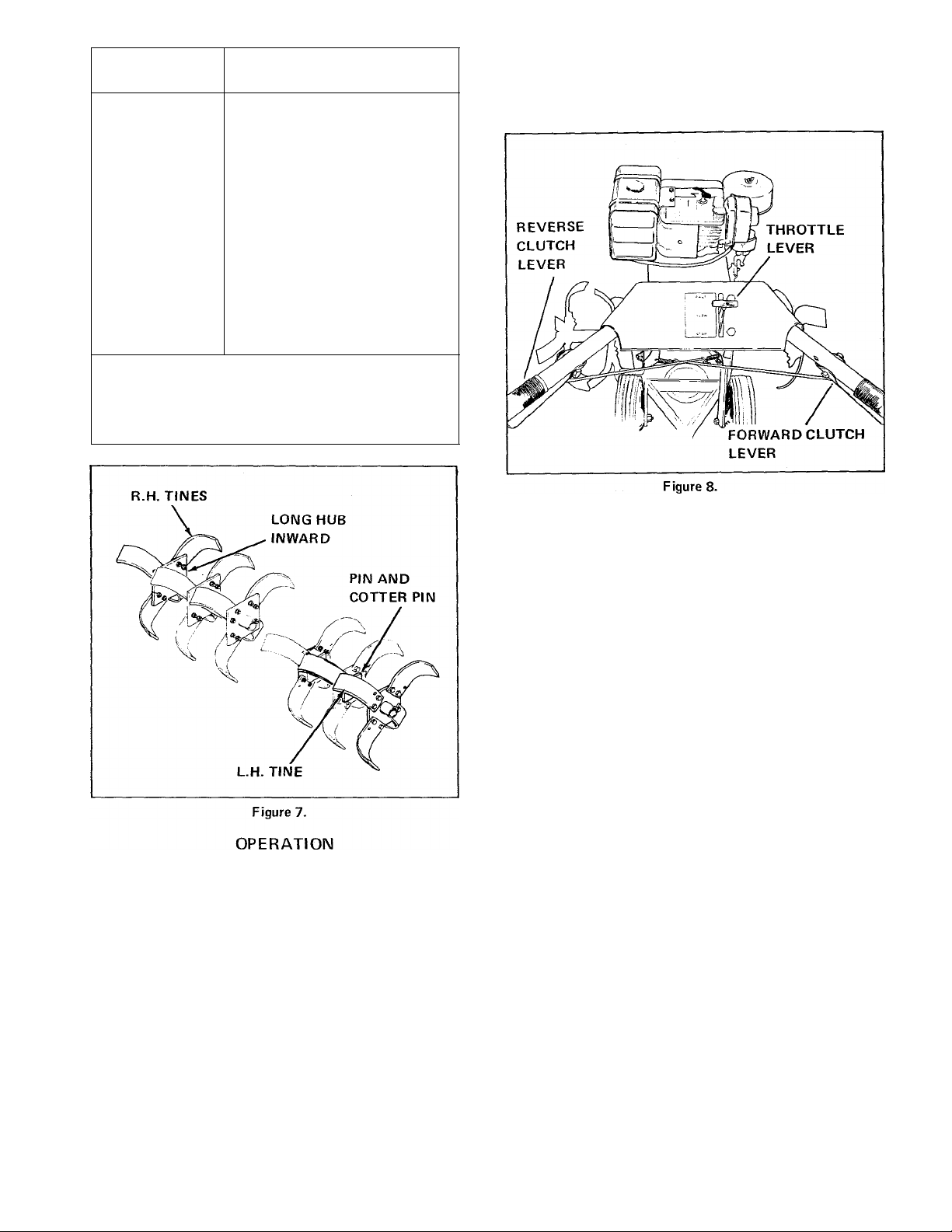

4. Connect throttle cable as follows:

a. See Figure 8. Move throttle control handle to FAST

position. Be sure throttle cable wire is securely attached

to throttle arm under control panel. From the throttle

Page 4

arm, the throttle cable must be secured to the right

handle with a clip. The cable must then pass outside the

right side of the cover and through a engine cable clamp.

Loosen engine cable clamp screw as required. See Figure

4.

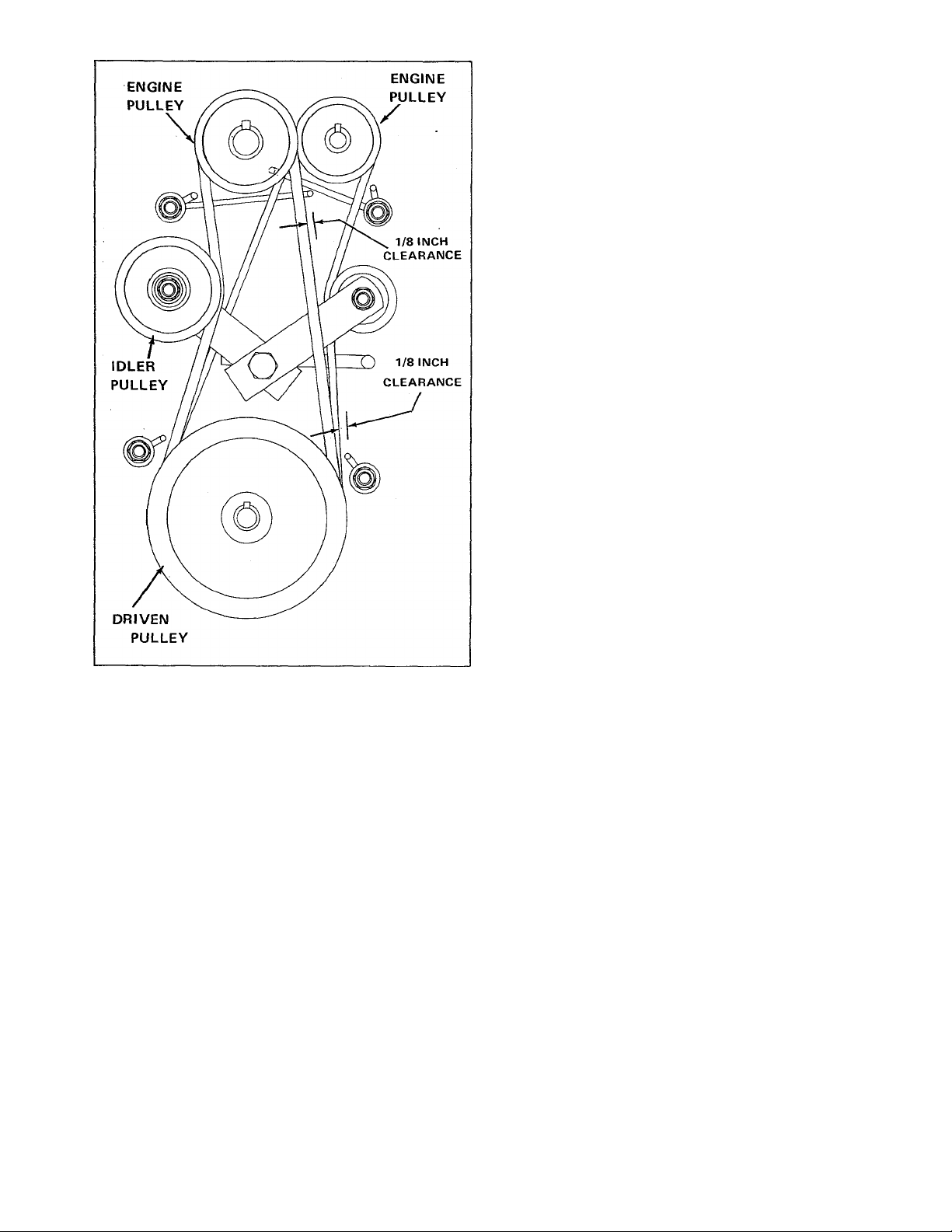

c. See Figure 5. Adjust spring tension by loosening clamp

setscrews and moving clamps on control rods. Idler

pulleys should be 1/4-inch from frame when clutch dis

engaged (handle released). Belt stops should be 1/8-inch

from belts when clutch engaged (handle compressed. See

Adjustments section of this manual for clutch adjustment

procedure.

d. Secure cover to frame with six self-tapping screws.

6. Install wheel assemblies as follows:

a. Tilt unit forward on engine.

b. See Figure 6. Secure each wheel assembly (bushing

inward) to frame through lower holes in frame support

with a 3-1/2-inch long shoulder bolt, lockwasher, and

hex nut. Tighten hex nut.

b. See Figure 4. Insert loose wire end of throttle cable

in carburetor throttle arm. Lever should be in forward

position against stop in slot. Tighten engine cable clamp

screw.

c. See Figure 8. Move throttle control handle to STOP

position. Be sure stop switch opens. See Figure 4.

5. Install forward and reverse control rods as follows:

a. See Figure 5. Attach reverse and forward control rod

springs to bellcranks.

b. See Figure 5. Slide reverse and forward control rods

through wire clamps inside springs. Loosely secure rods

in clamps with setscrews and flat washers. Hook loose

end of springs on setscrews between flat washers and

clamos.

7. See Figure 6. Secure depth bar and clamp to rear of

frame with pin and hairpin clip. Digging tip of bar should

be installed as shown.

NOTE: The depth bar setting determines the depth of

tilling. To till 4 to 6 inches deep, install bar mounting pin

in second or third hole from the top. The deeper depth bar

is set into soil, the deeper tines will dig.

8. Loosen each wheel scraper nut and adjust scraper to

clear wheel by 1/8-inch. Tighten scraper nut.

9. Depending upon what tilling width desired, install right

and left tine blade assemblies as follows. Use a pin and

hairpin clip for installation. See Figure 7 for right inner,

outer and extension tine installation.

Page 5

TILLING WIDTH

(INCHES)

8-3/4

TINES USED

^switched left and right inner

CAUTION

Never grip both forward and reverse clutch levers at

the same time.

12-7/8

19-3/8

** 23-1/2

35

*Switched denotes movina normal left or riaht blade assembly to opposite side. Be sure sharpened edges face

forward.

**Standard tine arrangement.

left and right inner

left and right inner

* switched left and right outer

left and right inner

left and right outer

left and right inner

left and right outer

left and right extension

2. Engine

a. MANUALS. Read the engine owner's manual and this

operator's manual thoroughly.

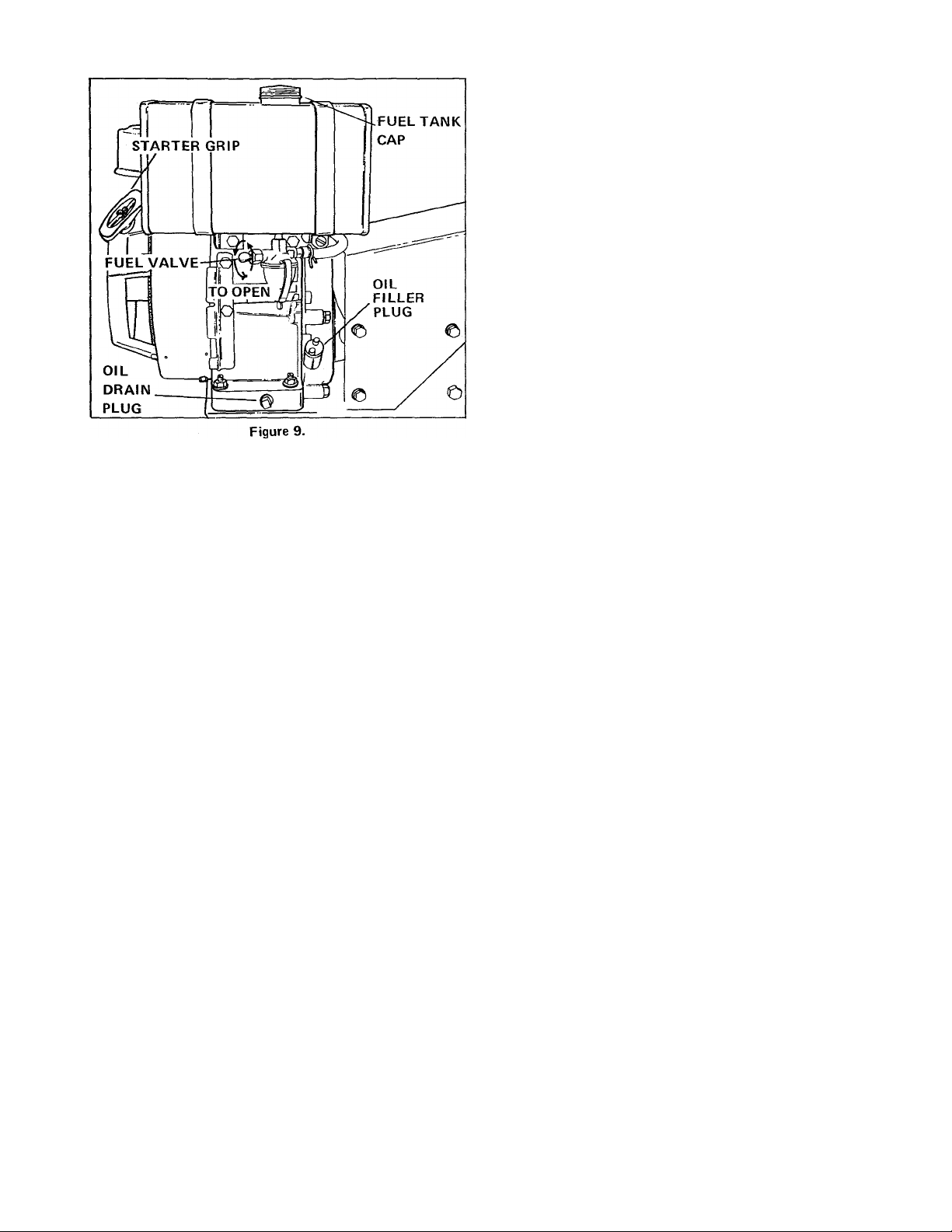

b. FUEL. See Figure 9. Have available sufficient quan

tities of clean, fresh (leaded or non-leaded), "regular"

automotive gEisoline. Remove fuel tank cap and fill

tank completely. Fuel capacity is 4 quarts.:

PREPARING

1. Controls

See Figure 8. Familiarize yourself with the following con

trols;

a. THROTTLE LEVER. Used to adjust ground speed or

to stop engine. See Figure 8 for throttle lever position

ing.

b. FORWARD AND REVERSE CLUTCH LEVERS.

Used to control forward or reverse action of the tiller.

Squeeze desired lever to engage and release to stop.

DO NOT MIX OIL WITH GASOLINE.

WARNING

Gasoline is highly inflammable. Avoid overfilling and

wipe up any spilled fuel. Allow no open flame, smok

ing or matches near the area when refueling.

Replace filler cap securely. Store gasoline only in small

quantities, prolonged storage produces gum and harmful

deposits. If it is necessary to store gasoline for long periods,

add a gasoline stabilizer. See Off-Season Storage section of

this manual.

c. OIL. See Figure 9. Have available sufficient quantitiesof engine crankcase oil, SAE 30 grade MS. Remove

dirt around engine filler plug. Remove engine filler plug

by turning counter-clockwise. Fill with oil until level

with top of neck. Crankcase capacity is 2-3/4 pints.

Reinstall filler plug securely. Check oil everytime fuel

is added.

Page 6

3. Depth Bar

See Adjustments section of this manual.

4. Wheels and Scraper.

f. If engine still fails to start, check fuel supply and

spark plug connections. Be sure engine stop switch is

closed (See Figure 4).

2. Operating

a. When operating the tiller for the first time, proceed

slowly and carefully to get the feel of the unit. Experi

ence will determine pressure and depth bar setting for

the operator.

b. Do not till when the soil is very wet. This causes

lumps which are difficult to work up. If the soil is ex

tremely hard and dry, it may be desireable to cross till an

area at shallow depth at first, then till in the direction

of planting rows on the second pass at the final depth.

Use reverse for working in tight areas and to dislodge

any rocks which may be caught between the tines and

worm gear housing.

c. Do not attempt to hold tiller back to cause the tines

to dig. Rather, adjust the depth bar so it will hold the

tiller back for you. When the tines have dug deep enough

in an area, raise up slightly on handles and the tiller will

move ahead. To stop the forward motion of the tiller,

put slight down pressure on the handles and the depth

bar will hold the tiller in place.

See Figure 6. Be sure wheels are mounted in the LOWER

holes of the frame support. If required, adjust wheel

scraper 1/8-inch above tire.

5. Tines

Be sure tines are installed securely with pin and cotter pin

Sharpened edges at the top must face forward. See As

sembly section of this manual for tine installation.

OPERATING

1. Starting

a. See Figure 8. Move throttle lever halfway between

SLOW and FAST position.

b. See Figure 4. Move choke lever to full CHOKE po

sition. If engine warm, use half choke. Choke arm should

be at right angles to exhaust tubing when in CLOSED

CHOKE position and parallel to tubing when in OPEN

CHOKE position,

c. See Figure 9. Be sure fuel valve is open.

d. To start engine, grasp starter grip (See Figure 9)

firmly in right hand and pull sharply straight out. Always

return grip by hand. Do not release the grip with rope

extended. Repeat if necessary with choke open slightly

(See Figure 4.) When engine starts, open choke grad

ually.

e. If engine fails to start after four or five pulls, it may

be flooded. Return choke to OPEN position and pull

out grip several times to clear excess fuel.

d. A furrow opener shovel is available for use in digging

furrows for crops which are planted in rows, such as po

tatoes. See Accessories section of this manual.

3. Stopping

a. Move the throttle lever (See Figure 8) to the STOP

position. The stop switch (See Figure 4) should open,

stopping the engine.

b. If the tiller has been operating under full load, allow

engine to idle for a minute to reduce engine temperature.

Stopping a hot engine suddenly may damage engine parts.

ADJUSTMENTS

BELT STOPS

All belt stops should be 1/8-inch from belts when clutch

engaged (handle compressed). To adjust, remove belt cover,

loosen stop mounting bolt, squeeze one clutch lever and

then the other, adjusting belt stop (sLas indicated in Figure

10. Tighten belt stop mounting bolt and replace cover.

NOTE: If tines will not stop turning after clutch lever is

released, belt stops may be too far from belts and not

braking belt as required when clutch handle released.

Page 7

DEPTH BAR

See Figure 6. The depth bar setting determines the depth

of tilling. To till 4 to 6 inches deep, install the bar mount

ing pind'n the second or third hole from the TOP. Pull out

the hairpin clip to change pin location. Be sure to install

the bar with the digging tip as shown. THE DEEPER THE

DEPTH BAR IS SET INTO THE SOIL, THE DEEPER

THE TINES WILL DIG.

CARBURETOR

Minor carburetor adjustments may be required to com

pensate for differences in fuel, temperature, altitude and

load. See your engine owner's manual for adjustment pro

cedures.

PULLEY ALIGNMENT

See Figure 10. Visually check alignment of engine, idler,

and driven pulleys. Pulleys must be aligned as closely as

possible or belts will be stretched and worn excessively.

Loosen engine and/or driven pulley setscrews and align

pulleys. Tighten setscrews securely.

Figure 10

CLUTCH

1. When clutch disengaged (handle released), idler pulleys

should be no closer than 1/4-inch from frame and all belt

stops must be firmly gripping the drive belts.

2. When clutch engaged (handle compressed), idler pulley

must press in on belt enough to remove belt from contact

with belt stops. Approximately 1/8-inch clearance between

belt stop and belt should be maintained. See Beit Stop

Adjustment.

3. See Figure 5. If clutch does not operate as described

above in steps 1 and 2, loosen wire clamp setscrew and ad

just wire clamp on forward or reverse control rod to obtain

required spring tension.

SCRAPERS

Loosen scraper mounting nut and adjust scraper in its slot

to 1/8-inch clearance above wheels. Tighten nut when

adjustment completed.

MAINTENANCE

Read the engine owner's manual thoroughly.

AFTER EACH USE

Grass, dirt, or chaff may clog engine cylinder head fins and

blower housing. Check for clogged condition and if nec

essary remove blower housing and clean.

CAUTION

Continued operation with a clogged cooling system

causes severe overheating and possible engine damage.

FIRST 5 HOURS OF OPERATION

See Figure 9. Change engine oil as follows:

a. Run engine for a few minutes to warm engine oil.

b. Remove oil drain plug and allow oil to completely

drain from engine.

c. Replace oil drain plug securely.

d. Remove dirt around engine oil filler plug.

e. Remove engine oil filler plug by turning counter

clockwise.

f. Fill with SAE 30 grade MS oil until level with top of

neck. Crankcase capacity is 2-3/4 pints.

g. Reinstall engine oil filler plug securely.

Page 8

EVERY 5 HOURS OF OPERATION

See Figure 11. Check and add worm drive housing gear oil

as follows:

a. Remove worm gear housing oil filler plug.

Worm Gear Oil Filler Plug

Figure 11.

CAUTION

There is a filter in a vent hole located at rear of worm

drive housing. Do not remove this filter for any reason.

a. Remove wing nut and cover.

b. Lift off foam element from base.

c. Push down foam element as shown and pull out air

cleaner cup.

d. Wash foam element in kerosene or liquid detergent

and water.

e. Wrap foam in cloth and squeeze dry.

f. Saturate foam in engine oil. Squeeze to remove excess

oil.

g. Put air cleaner cup inside element. Be sure sealing lip

is over top and bottom ends of cup.

h. Re-assemble air cleaner parts as shown. Screw wing

nut down securely.

b. Oil level should be level with plug hole when tines are

resting on ground.

c. If oil is required, tip tiller back until handles rest on

ground. Add a small amount of special worm gear oil

(See Back Cover for part number) through plug hole and

slowly lower tiller until tines rest on ground. Oil should

be level with plug hole, if not, repeat procedure. Do not

overfill.

CAUTION

Damage to the worm gear drive which results from use

of any other lubricant than that specified on back

cover, will automatically invalidate the warranty.

d. Tighten filler plug securely.

NOTE: The worm drive housing may become quite warm

while operating. This is completely normal and no harm to

gears will occur if the housing is kept filled as specified

with the special worm gear oil.

EVERY 25 HOURS OF OPERATION

1. Change engine oil. Refer to change procedure in FIRST

5 HOURS OF OPERATION.

2. See Figure 12. Clean air cleaner and re-oil element. The

capacity of the oil-foam air cleaner is adequate for a normal

full season's use without cleaning. However, under extremely

dusty conditions clean every few hours. Clean air cleaner

as follows;

Clean and reset spark plug gap at 0.030 of an inch. Plug

should be cleaned by scraping or wire brushing and washing

with a commercial solvent or gasoline. Grease the plug

threads before re-installing.

EVERY 200 HOURS OF OPERATION

See Figure 13. Clean fuel filter screen and bowl as follows:

WARNING

Do not remove fuel lines from fuel filter when engine

is hot.

1. Close fuel shutoff valve, loosen yoke, and remove bowl,

gasket, and screen.

2. Disgard gasket and replace it with new one.

3. Clean screen and bowl.

4. Using new gasket, assemble in reverse order of disassembly.

Be sure yoke is secure. Open fuel shutoff valve.

Page 9

LUBRICATION

1. See Figure 14. To reduce wear and assure free movement

of controls and tines, apply light motor oil occasionally at

points indicated. Be careful not to get oil on drive belts.

Use only small quantities of oil. Excess oil collects dirt and

causes extra wear.

Figure 13.

OFF-SEASON STORAGE

If tiller is to be stored over 30 days proceed as follows:

1. Glean fuel screen and bowl. See Maintenance section of

this manual.

2. Drain fuel tank and lines by placing suitable container

under fuel shutoff valve and opening valve. Store gasoline

in container using a gasoline stabilizer or additive. This ad

ditive can also be added to tanks instead of draining. This

additive prevents formation of gum and varnish for up to

one year.

3. Operate engine until gasoline in carburetor is completely

consumed.

4. While engine is still warm, drain oil from crankcase. See

Maintenance section of this manual. Refill with fresh oil.

5. Remove spark plug, pour one ounce (2 or 3 tablespoons)

of SAE-30 oil into cylinder and crank slowly to distribute

oil. Replace spark plug.

6. Clean dirt and chaff from cylinder head fins and blower

housing.

DO NOT OIL SELF-LUBRICATED WHEEL BEARINGS.

2. See Figure 15. Apply a light coat of grease or oil to in

side of tine: hubs and on tine shaft to prevent rust.

REPAIRS

----------------

TROUBLESHOOTING

IF ENGINE FAILS TO START

1. Fuel tank may be empty. See Figure 9.

2. Throttle lever is not set halfway between SLOW and

FAST position. See Figure 8.

3. Spark plug is not securely connected.

4. Choke lever is not in CLOSED CHOKE position or in

OPEN CHOKE position, if engine appears to be flooded.

See Figure 4. To clear a flooded engine, move choke lever

up to OPEN CHOKE position and pull starter rope several

times.

IF BELT SLIPPAGE OCCURS

1. Belts may be stretched or worn excessively. Replace belts.

2. Belts may be greasy or oils. If so, use cleaning fluid on a

rag to clean.

3. Pulleys may be misaligned. Refer to Pulley Alignment

in Adjustments section of this manual.

To prevent rust, sand off and paint any parts or areas which

become chipped or damaged. Tighten all bolts, nuts, and

fasteners securely.

4. Belt tension may be too loose. Refer to Clutch in

Adjustments section of this manual.

Page 10

SPECIFICATIONS

ENGINE

Make Briggs and Stratton

Model No. 190492

Type 0794-1

Cycles 4

Cylinders

Bore

Stroke

Displacement

Crankshaft Plane Horizontal

Starter

Choke

Governor Adjustable Mechanical

1 gnition Magneto

Lubrication Gear impeller system

Crankcase Capacity

Fuel Capacity

Air Cleaner

Muffler Lo-Tone, Side Discharge

1

3 1 nches

2-3/4 1 nches

19.44 Cu. In.

Manual, Easy spin

Manual

2-3/4 pints

4 Quarts

Sealed doing Housing, Reusable Oiled Foam Element

TR AKKMI QQIOM

Type Worm and Gear

Material Worm - Carburized Steel;Gear-Bronze

Bearings

Needle and Tapered Anti-Friction

Seals Double Lip - Dirt Excluding

Lubrication

Special Worm gear oil

Housing Cast Iron

Clutch

Hand Tensioning Belt Idler - Reverse and Forward

Page 11

SPECIFICATIONS (Cont'd)

TINES

Type Slashing, Self-sharpening

Material

Tilling Width 23-1/2 In. Standard, 35 In. With Tine Extensions

Tilling Depth

Attachments To shaft - Bolted

Depth Bar

Speed

nCDTU DAD

Attachment Pin and Spring Clip

Adjustment 0 to 8 Inches Tilling Depth

OUIM 1 KULo

Forged, High-Carbon Steel

0 to 8 Inches, Adjustable

Adjustable - 10 heights

116 RPM at Full Engine Speed

Location Forward Clutch - Right Handle,

Reverse Clutch - Left Handle

Throttle - Center

Rewind Starter and Choke - On Engine

UnAoolo

Frame

Tires

Heavy Duty, Electrically Welded with Cross Bracing

2.75 X 10 Heavy Duty, Semi-Pneumatic

Wheel Bearings Solid, Sintered Iron

OVERALL DllvlENSIONS

Length 53 Inches

Width

Height

Weight

26 Inches (Without Tine Extensions)

36 Inches (To top of handle)

164 Lbs. (net)

178 Lbs. (shipping)

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

10

Page 12

PULLEY AND CONTROL GROUP

Ref.

No. Part No.

1

2 118439

3 176328

175964 1

4 172668 1

5 118458

6

7 911712 2

8 1609352

9

10

11

12

13 916965 2

14

15 1609352

16

17 174870 1 SPACER

18

19

20

21

22 121073

23

24

25

26 922249

27 917642

28

29 916950

30 922249

31 176393

32 176917

910224

154534

118335

921971 1 CAPSCREW, Hex, 3/8,

917642 2 WASHER, Flat, 5/16

916950

118414 1

921969

1609295

171336

923362

106707

106346

106347

916965 8

Qty. Description

PULLEY, Driven

1 Key

1

1 PULLEY

1 KEY, Woodruff,

1

2 NUT, full hex, 3/8-16

PULLEY

KEY

5/32 X 5/8

SETSCREW, 5/16-18

x5/16lg.

LEVER, Idler

1

1

1 LEVER, Idler pulley

1 CAPSCREW, Hex, 3/8-16

2 BELLCRANK

1

1 LOCKNUT, Full hex,

1

1

3

1

2 BOLT, Carriage, 3/8 -16

6

4

2

1 BELT, "V" (reverse)

1

PULLEY, Idler

SPACER

-16x 1-3/4

LOCKWASHER, 3/8

PULLEY, Idler

x 1-1/2" Ig.

BOLT, Pivot

5/16- 18

STOP, Belt

STOP, Belt

STOP, Belt

STOP, Belt

x 1-1/4 " Ig.

WASHER, Flat, 5/16

LOCKWASHER, 3/8

NUT, Full Hex,

3/8- 16

BOLT, Carriage, 3/8"-

16 X 1" Ig.

BELT, "V" (forward)

Ref.

No.

33

34

35

36

37 161092

38

39

40

41

42

43

44

45

46

47

48

49 918240

50

51

52

53

54

55

56

57

58

59

60

Part No.

929001

1609299

923360

1609378

928722

118495

1609354

1609344

922611

916950

928728

930579

106558

118237

118298

916964

916622

1609383

925003

1605216

164191

1609343

927428

1609300

918240

923358

Qty.

2

2

4

2

2

2

2

1

1

4

4

2

2

2

1

1

4

4

4

1

2

1

1

1

6

2

2

2

Description

LOCKNUT, Flange

ROD, Link

PIN, Cotter, 1/16 X 3/4

ROD, Control

CLAMP, Wire

SETSCREW, Sq. Hd., 10-24

x5/8

SPRING

HANDLE, Left

HANDLE, Right

WASHER, Flat, 13/32 x

1-1/4

NUT, Hex, 3/8-16

SCREW, Hex, whiz-lock

fig, 3/8-16 X 1

CAPSCREW, Hex, 3/8-

16 X 1-1/4

GRIP

CONTROL HOUSING ASSY.

COVER, Upper handle

CAPSCREW, Hex, 1/4-20

X 1-1/2

LOCKWASHER, 1/4

NUT, Hex, 1/4-20

CONTROL ASSY.,Throttle

SCREW, washer head, hex,

1/4-20 X 1/2

CLIP, Cable

PLUG,' Button

COVER. Belt

SCREW, Self-tapping,

1/4 -20 X 3/8

GRIP, Clutch

CAPSCREW, Hex, 1/4-20

X 1-1/2

LOCKNUT, Hex, 1/4-20

12

Page 13

FRAMES WHEELS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

Part No. Qty.

177124

176196 2 BOLT, Shoulder

916966 2

916951

176364

922249 2

917642

916965

916950 2

118081 1

118371

105249 1 PIN

2

2

2

2

2

1

Description

WHEELS TIRE ASSY.

LOCKWASHER, 1/2

NUT, full hex, 1/2”-13

SCRAPER

BOLT, Carriage, 3/8"-

16 X 1"lg.

WASHER, Flat, 5/16"

LOCKWASHER, 3/8"

NUT, hex, 3/8"-16

BAR, Depth

CLAMP

Ref.

No.

13

14

15 118207 1 PLATE, Stop

16

17

18 916950

19 177123

20

21 917642

22

23 917372

Part No.

918196

1609342

919360 2

916965 2

917398

917356

Qty.

1 CLIP, Hairpin

1

2

1 ENGINE, 8 H.P.

4

4

4 -

4

13

Description

FRAME ASSEMBLY

CAPSCREW, Hex. 3/8"-

T6 x 1" Ig.

LOCKWASHER, 3/8"

NUT, full hex, 3/8"-16

CAPSCREW, Hex, 5/16-

18 X 1-3/4" Ig.

WASHER, Flat, 5/16"

LOCKWASHER, 5/16"

NUT, full hex,5/16"-18

Page 14

8 H.P. TILLER

MFG. NO. 1600406

TINE EXTENSION KIT

Ref.

No.

1

2

3

4

5

6

7

8

9

Part No.

1609387 1 TINE BLADE EXT. ASSY.,

172511 4 TINE, R.H.

172512 4 TINE, L.H.

925204

923428 16

1609386 2 TINE PLATE EXT. ASSY., Outer

1609388

118053 2

918451

Qty.

16

1

2 PIN, Cotter, 1/8X 3/4

Description

L.H. (Consists of Ref. No. 2 throygh 6)

CAPSCREW, Hex, 3/8" -16 x 1/2

LOCKNUT, Hex, 3/8-16

TINE BLADE EXT. ASSY., R.H.

Consists of Ref. no. ^ through 6

PIN

Ref.

No. Part No. Qty. Description

8 H.P. TILLER

MFG. NO. 1600373

FURROW OPENER

1

2

3

4

5

6

7

8

8271503 1

118287 1

103010 1 OPENER, Furrow, 8-Inch

922109 2

917378 1 WASHER, Flat, 3/8

916950

118053 1

918196

2 NUT, Hex, 3/8

L_J

_______

TOOL HOLDER ASSY.

SUPPORT ASSEMBLY

BOLT, 3/8-16 X 1-1/4

PIN

CLIP, Hairpin

14

Page 15

DRIVE AND TINE GROUP

Page 16

Ref.

No. Part No.

DRIVE & TINE GROUP

Qty.

Description

1

2

3

4 925204 32

5 923428

6

7 176467

8 1609387

9

10 1609388

11

12 118053 2

13 918451 2

14 175871 1 HOUSING, Worm Drive

15

16 118393

17

18 154393

19 118396

20

21

22 171762

23 176013

24

25

26 118399

27

28

29 154487

30 118020 2

31 118118

32

33 176011

34 930246

35

36 175872

37 175873

38 921959

39 916964

40 118403

41

176466

172511

172512 8

176225 2

1609386 2

917755

118462

154486

170888

170885

911171

118398

118396

118400 1 SHIELD

176724 1 SHAFT, Worm Gear

118315 2

901653

1

8

32

1 TINE BLADE ASSY., R.H. inner

1

1

2

1 PLUG, Vent

1 SEAL, Oil

2

2 CUP, Bearing

1

1 SHAFT, Worm

1 RING, Backing

1 RING, Backing

1 WORM., R.H.

1

1 SPACER

1 CUP

1

1 CAP, Hub

2

1

2

1

1

1 PLUG, Pipe

BLADE ASSY., L.H. inter,

(consists of ref Nos. 2 through 6)

TINE, R.H.

TINE, L.H.

CAPSCREW, Hex, 3/8"-16 x 1/2, gr 5

NUT, full hex, centerlock

PLATE ASSY., Inner Tine

(consists of ref. no. 2 through 6)

TINE BLADE EXT. ASSY., L.H.

(consists of ref no. 2 through 6)

TINE PLATE EXT ASSY., Outer

TINE BLADE EXT. ASSY., R.H.

(consists of ref no. 2 through 6)

KEY, woodruff, 1/4 X 3/4

PIN

PIN, Cotter, 1/8 X 3/4

CONE, Bearing

RING, Retaining

KEY

RING, Retaining

BEARING, Needle

SEAL, Oil

GEAR, Worm R.H.

KEY

WASHER, Thrust

GASKET

COVER

5

5

2 SHIELD

CAPSCREW, Hex, 1/4''-20

X 5/8" Ig.

LOCKWASHER, 1/4

1608999 Worm Drive Assy., consists of ref. nos. 14 through 41.

16

Page 17

FILMS & DECALS

1609429 - DECAL FORWARD

SIMPLICITY SPECIAL WORM GEAR OIL - 1600374

17

Loading...

Loading...