Page 1

-r-S

PARTS LIST &

INSTRUCTIONS

SNOW THROWER

77

32

PART NO. 24659

Page 2

Safety.

Read over carefully the owners manual for your tractor and

rotary snow thrower before attempting to operate snow

thrower.

Do not make any adjustments, repairs or service the snow

thrower while engine is running.

Always be sure area is clear of all bystanders before oper

ating.

Stay clear of the auger and discharge spout when the engine

is running.

Be sure the snow thrower auger has stopped turning before

attempting any repairs or adjustments to the snow thrower.

Clear the work area of any object which could possibly be

picked up and thrown by snow thrower or cause damage to it.

Disengage the power take-off and stop the engine before

leaving operators position.

Operate the snow thrower only in daylight or good artificial

light.

Use caution when operating on sloping surfaces.

When operating the snow thrower, never direct the discharge

spout toward or near any bystanders or allow anyone near

snow thrower when in operation.

CAUTION: The auger may continue to rotate a few seconds

after the clutch has been disengaged and the

engine shut off.

TABLE OF CONTENTS

SAFETY.............................................................................2

ASSEMBLY.......................................................................3

ADJUSTMENTS...............................................................4

OPERATION

MAINTENANCE..............................................................6

TROUBLESHOOTING...................................................7

PARTS LIST

....................................................................

.....................................................................

4

8

Page 3

ASSEMBLY

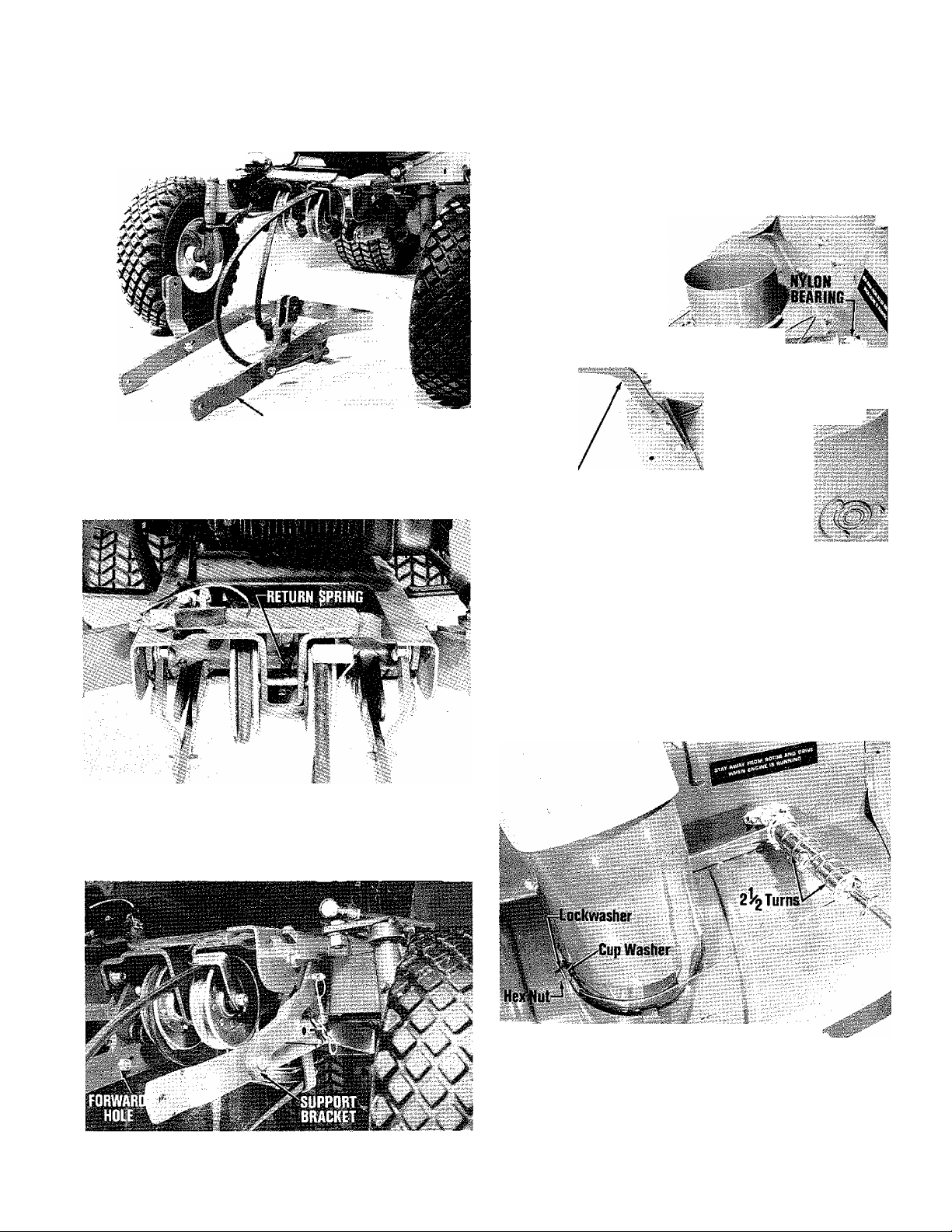

1. Disconnect the return spring between PTO idler pulleys.

Place belt around rotor drivepulley on the hitch assem

bly. Position hitch assembly under tractor (see photo).

■ c,

4. Secure rod guide support to body using the 3/8-16 x 1

hex head bolts, 3/8" lockwashers, and 3/8-16 hex nuts

supplied. Insert spout control rod into spout control

tube and secure with 1" cotter pin. Now insert spout

control rod assembly into nylon bearing on right side of

body and secure with two 3/4" cotter pins. Attach rod

guide and nylon liner to control rod and secure to rod

guide support arm with the hex head bolt, lockwasher and

hex nut (see photo).

Si

ROD GUIDE and

NYLDNLINER

4.

HITCH ASSEMBLY

Pass the belt over PTO idle pulleys through cutout in

crossmember and around lower engine pulley. Replace

the return spring previously removed and pull forward

all slack to left side of unit (see photo).

2. Secure hitch to tractor using clevis pins and quick pins.

Be sure to mount rear of hitch to the rear most holes in

the hitch support brackets. Check to insure support arm

assembly is mounted in the foward holes in hitch assem

bly (see photo).

X2 COTTER PINS

ROD GUIDE

SUPPORf

5. Lower spout over neck of discharge spout on body and

line up with slot in rear of spout neck. Rotate spout until

it faces forward and connect spout extension with carriage

bolt, hex cup washer and wing nut. Position -control rod

tube so that cable clamp faces side of discharge spout.

Loop wire cable on most forward part 2-1/2 coils counter

clockwise passing over the top of guide tube and secure

to stud on spout. Coil 2-1/2 times on rear of tube clock

wise passing under tube to spout and secure with special

cup washer, lockwasher and hex nut (sec photo).

3. Attach skidshoes to bodyusing the3/8-16 x 3/4carriage

bolts, 3/8" flat washers, 3/8" lockwashers and 3/8" full

hex nuts.

NOTE: HOOD REMOVED FOR

PHOTOGRAPHIC PURPOSES

Page 4

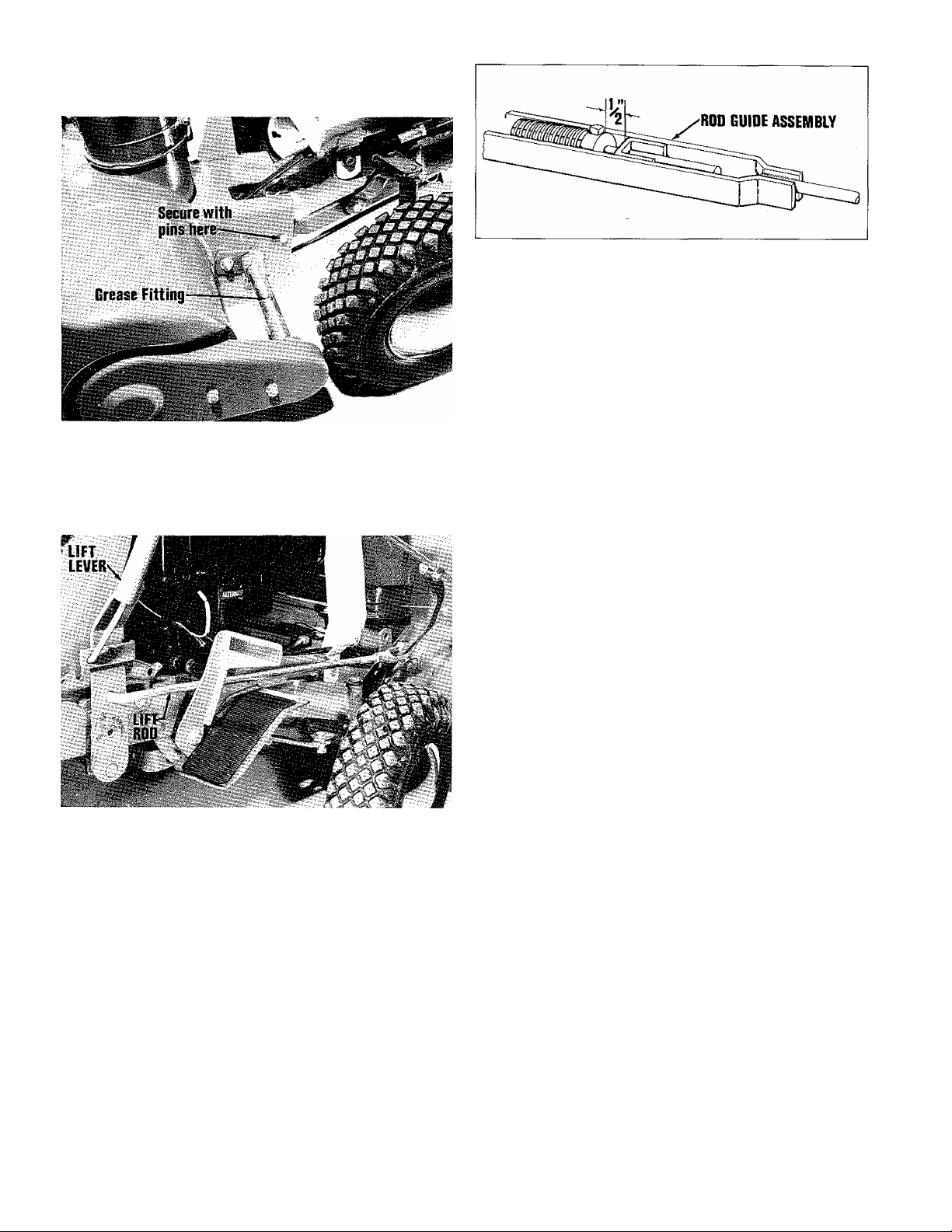

6. Position the snow thrower in front of^the tractor lining

up hitch with mounting holes in body and secure with

clevis pin and quick pin (see photo).

Place lift control handle in forward most position. In

sert lift rod into upper hole on lift control and secure

with quick pin. Loosen the lock nut and adjust clevis to

line up with mounting hole in rod guide support. Secure

with clevis pin and quick pin and tighten locknut (see

photo).

OPERATION

CHUTE DEFLECTOR POSITION

The chute deflector can be adjusted by loosening the wing

nuts and moving the deflector up or down. Be sure to tighten

both wing nuts after positioning the deflector. The chute

deflector position supplements the engine speed control to

control throwing distance. The highest position provides

the greatest throwing distance. Most snow moving can be

done with the deflector all the way up by using the engine

speed lever to control the throwing distance. Hold the rear

of the deflector down while tightening the wing nuts to make

sure all of the snow goes out the chute.

.f"'v

% -p.'

BELT ADJUSTMENT

The lower pulley on the hitch assembly may be moved for

ward or backward in the slotted hole for belt adjustment

purposes. Adjust this pulley so there is sufficient beltslack

for proper idling of the snow thrower.

Once proper belt slack for idling has been obtained, the PTO

spring must be checked and adjusted to give the proper belt

tension during operation. Proceed as follows:

1. Engage the PTO lever.

2. Measure the distance from the set collar to the rod guide

assembly. There should be 1/2” spacing between these

points. (See Figure)

It may be necessary to adjust the set collar to obtain the

1/2”. Be sure to disengage PTO lever first. Loosen the

set screw on the collar and reposition the rod in the collar.

Engage PTO lever and check again. Repeat this procedure

until the 1/2” is obtained.

SKID SHOE ADJUSTMENT

Gravel Surface Use Adjustment

The two skid shoes located on each side of the snow thrower

housing, should be lowered all the way down when operating

on a gravel surface. To adjust the skid shoes, raise the

snow thrower housing a couple of inches off the ground.

Loosen the two nuts and drop the skid shoes to the lowered

position. Set the bottom surface of the skid shoes so they

are level or slightly (maximum of 1/8”) higher in the front

and tighten nuts securely. Both skid shoes should be posi

tioned the same. The snow thrower will now be supported

on the skid shoes so the scraper bar can skim the snow from

the surface without picking up and throwing stones.

Hard Surface Use Adjustment

Loosen the two skid shoe mounting nuts and rest the snow

thrower on a hard level surface. The snow thrower should

now be supported by the tractor and the skid shoes with the

scraper bar resting on the ground surface. Tighten the nuts

on both skid shoes taking care that their position doesn’t

change while the nuts are tightened. The full width scraper

bar on your snow thrower will now get down to the ground

surface and scrape it clean.

OPERATING THE TRACTOR AND SNOW THROWER

Determining Snow Removal Pattern

Before beginning to remove snow from any area, the opera

tor should determine the best snow removal pattern. The

size, shape, terrain and obstructions of the area to be cleared

should be considered. Usually it is best to drive back and

forth the long direction of the area to minimize turning.

CAUTION: ALWAYS RAISE THE SNOW THROWER BEFORE

TURNING OR BACKING TO PREVENT DAMAGE TO IT.

Page 5

TRANSPORTING THE SNOW THROWER

Transport the snow thrower in the raised position with the

power take off control in the disengaged position. Ground

speed should be adjusted according to the type and condition

of the road surface. CAUTION: WITH THE SNOWTHROWER

INSTALLED ON THE TRACTOR, WEIGHT ON THE FRONT

WHEELS WILL BE SUBSTANTIALLY INCREASED MAKING

TURNING MORE DIFFICULT UNDER SOME CONDITIONS.

ENGINE SPEED

The tractor engine should normally be operated at 3/4 to

full speed when using the snow thrower. Operate it at full

speed when throwing deep or heavy snow. Less than 3/4

speed may be used in light snow if a short throwing distance

is desirable.

ENGAGING SNOW THROWER DRIVE

The tractor engine should be operating at 1/2 to 3/4 throttle

when the snow thrower is engaged. To engage the snow

thrower drive, push forward and down on power take off

lever. CAUTION: IF THE SNOW THROWER DRIVE

SHOULD BEGIN TO SLIP WHILE THE POWER TAKE

OFF IS ENGAGED, DISENGAGE THE POWER TAKE OFF

CLUTCH IMMEDIATELY TO PREVENT DAMAGE TO THE

SNOW THROWER DRIVE BELT OR POWER TAKE OFF

CLUTCH.

RAISING AND LOWERING THE SNOW THROWER

The snow thrower should be raised and lowered using the

tractor lift lever.

CONTROLLING GROUND SPEED

The best ground speed will vary greatly with the type and

amount of snow being thrown. For most conditions one to

two MPH will be a good starting speed. Refer to the opera

tion chart in your tractor owner's manual for speed control

settings to achieve the desired speed. Firstgear is normally

used for snow throwing.

THROWING DISTANCE

The snow should be deposited beyond the surface you want

to clear if at all possible. Start with the deflector all the

way up and adjust engine speed so that the thrown snow is

deposited just beyond the far side of the area to be cleared .

If the snow is only a couple of inches deep, it may be nec

essary to go over the ground quite rapidly to feed snow into

the auger. In this situation the deflector should be lowered

and the engine speed increased. CAUTION: STOP THE

ENGINE AND PLACE PTOIN NEUTRAL WHILE CHANGING

THE DEFLECTOR ADJUSTMENT.

THROWING DIRECTION

The spout control handle is used to rotate the snow thrower

spout to the left and right to control the throwing direction.

Whenever possible, begin snow removal on the upwind side

of the sidewalk or driveway so it is not necessary to blow

snow over an area already cleared.

The chute should be rotated to discharge the snow downwind,

not into it. Always adjust the spout and extension so that

you are well out of the path of the snow stream. CAUTION:

CONSTANT INHALATION OF COLD, WET VAPOR IS EX

TREMELY DANGEROUS. ON WINDY DAYS, HAVE YOUR

NOSE AND MOUTH COVERED UNLESS YOUR TRACTOR

IS EQUIPPED WITH A SNOW CAB.

MOVING THE SNOW

Light Snow

Snow up to 8” deep can usually be cleared in one pass the

full width of the machine. Face the snow thrower into the

snow, set the throttle at 1/2 speed or more and engage the

tractor power take off completely. When the auger drive is

fully engaged, readjust the engine speed as described under

Throwing Distance. Select the proper gear or transmission

speed control lever setting to give the speeds suggested

under Controlling Ground Speed. Drive the tractor and

snow thrower slowly into the snow. When you have come

to the end of a pass, raise the snow thrower and turn the

tractor around to make the next pass along side of the cleared

area. Allow about 2" of overlap into the cleared area.

Lower the snowthrower, rotate thechuteso thesnowstream

goes downwind, and engage the tractor drive for the second

pass. Repeat these steps until the area is cleared.

HEAVY DEEP SNOW

With very dense snow or snow deeper than the center of the

auger, a different method is necessary.

First Pass

Lower the deflector about 1/2 way and run the engine at full

speed. Raise the snow thrower until the top of the auger

housing is above the top of the snow whenever possible.

Engage the tractor drive gently, drive slowly through the

snow. Readjust the deflector if necessary to obtain the

desired throwing distance. Renieiiiber to stop the engine

before adjusting the deflector. At the end of the pass, turn

around as described under light snow, except go over the

same path with the snowthrower in the lowered position.

In some cases it may be better to back up every few feet

and clear the snow down to the ground surface, so the tractor

tires are not running in deep snow.

Subsequent Passes

Use the same procedure as for light snow, but substantially

increase the overlap into the cleared area. In other words,

take a narrower slice of snow than the width of the auger

housing. Judge how wide a slice to take by watching the

snow stream. It should continue to flow freely from the

chute. If it does not, slow the tractor ground speed or take

a narrower slice of snow. Any time snow stops flowing

freely from the spout, use reverse to back away until the

snow thrower clears itself and then inch slowly into the

snow. You will soon get the feel of how fast to go, and how

wide a slice to take.

FOREIGN OBJECT IN THE AUGER OR PLUGGED CHUTE

If the auger stalls or the chute plugs, disengage the tractor

power take off control immediately. Stop the engine, set

the parking brake and remove the foreign object or clear

the spout. Always stop the engine before working near or

on the auger or spout.

Page 6

STORING THE SNOW THROWER

After the clearing job is finished, the tractor should be

transported to a sheltered area,. When transporting the

snow thrower, always disengage the power take off, and

lift the snow thrower to the raised position. Place the

transmission and power take off control in the neutral po

sition and run the engine at slow speed for 5 minutes to

melt and dry up the snow in hidden areas to prevent icing.

ORDERING REPLACEMENT PARTS

Replacement parts required for maintenance services or

repair work should be purchased from your HOME LITE

dealer. When ordering parts, always furnish model and

serial number to dealer.

ACCESSORIES

MAINTENANCE

After Each Use

With the engine stopped and the PTO in "Neutral", inspect

the snow thrower for loose or missing bolts, pins and worn

or damaged parts. Check for any buildup of ice in the thrower

housing and around pulleys which may cause damage when

unit is started. Make any necessary repairs before using

the snow thrower again.

Every 15 Hours of Operation

There is one giease fitting located on the cross shaft. Wipe

off fitting and lubricate with a general purpose automotive

type grease. Apply a coating of grease on the chain every

15 hours of operation.

An occasional application of light motor oil should be applied

on all moving parts.

NOTE: Do not get oil or grease on belts or pulleys.

Once Each Year

Once each year or more often if the snow thrower is used

commercially, the drive chain should be inspected for wear

and adjustment. Proceed as follows:

1. Remove the two hex nuts and drive chain cover.

The following accessories can be purchased through your

HOMELITE dealer.

1. Four rear wheel weights.

2. Two front wheel weights.

3. 'Tire chains.

CHAIN

BEAR Stud

C0VER\^

HEX NUTS

LOCK WASHERS

2. Inspect the chain for wear and excessive slack. Replace

if worn.

To Adjust Chain:

1. Loosen the rear stud on the chain side plate.

2. Pull back on the crosspiece until all slack is taken out of

the chain.

3. Tighten stud and replace chain guard.

To remove and replace chain loosen rear stud and push for

ward on crosspiece until chain can be removed from smaller

sprocket. Install new chain and follow procedures for adjust

ing chain.

Page 7

TROUBLE

SHOOTING

TROUBLE

AUGER DOES NOT ROTATE

AUGER ROTATES BUT DOES

NOT THROW SNOW FAR

ENOUGH

SCRAPER BAR DOES NOT

CLEAN DOWN TO HARD

SURFACES

SNOW THROWER PICKS UP

AND THROWS STONES

WHEN USED ON GRAVEL

SURFACE.

TRACTOR DOES NOT HAVE

SUFFICIENT TRACTION

POSSIBLE SOLUTION

• PTO NOT ENGAGED.

• DRIVE BELT SLIPPING.

• ENGINE SPEED TO LOW.

• GROUND SPEED TOO FAST.

• CLOGGED DISCHARGE SPOUT,

• SKID SHOES NOT PROPERLY

ADJUSTED.

SKID SHOES NOT PROPERLY

ADJUSTED.

• ADD WHEEL WEIGHTS AND

TIRE CHAINS.

TRACTOR NOT STABLE ON

SLOPING SURFACES

HOMELIXr

PORT CHESTER, NEW YORK, U.S.A. 10573

• REDUCE GROUND SPEED.

• ADD WHEEL WEIGHTS

CHECK FOR CORRECT TIRE

INFLATION (OWNER’S MANUAL).

*laxtront

DIVISION

Page 8

BODY, ROTOR & DRIVE ASSEMBLY

No. Description

1

KEY-hi-pro

SCREW-hex cap, 5/16‘-18 x 5/8

2

ROTOR

S

DEFLECTOR

4

5 NUT-hex, 5/1G-18

WASHER-lock, 5/16

6

7

BODY

SCREW-set, 5/16-18 x 5/lG

8

KEY-Woodruff #9

9

10 PULLEY-drive

SCREW-hex cap, 3/8-16 x i

11

WASHER-flat, 3/8

12

SCREW-hex cap, 5/16-18 x 1-1/2

13

CLAMP-support assembly

14

15 BEARING-ncedle

WASHER

l(j

17 HOUSING-bearing

WASHER-lock, 3/8

18

NUT-hex, 3/8-16

19

FITTING-grease

20

8

Part No.

LM-01510-40

LM-09193-18

LM-01068-47

LM-01067-74

LM-09173-72

LM-0917 3-56

LM-01611-98

LM-09117-12

LM-09051-23

LM-01064-85

LM-09077-31

LM-09173-78

LM-09199-33

LM-01064-76

LM-01542-58

LM-80610-12

LM-0106 8-54

LM-09169-65

LM-09169-50

LM-09128-08

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Qty.

1

4

1

1

12

12

1

2

1

1

1

4

2

2

2

1

1

7

7

1

N9.

'21

22

23

24

25

26

27 PLATE-side

28 NUT-hex lock, 3/8-16

29

30

31

32

33

34

35 WASHER-lock, 1/4

36 NUT-hex lock, 5/16-lS

37

38

39

40

Description

NUT-Range, 3/S-16

SKID

BOLT-carriage, 3/8-16 x 3/4

SHAFT

CHAIN

STUD

GUARD- chain

SPROCKET-rotor

SCREW-hex cap, 5/16-18x3/4

CARTRIDGE-bearing w/setscrew

FLANGE-bearing

NUT-hex. 1/4-20

SCREW-hex cap, 5/16-18 x 5/8

SCREW-hex cap, 1/4-20 x 5/8

SCRAPER-body

WASHER-1/2

Part No.

LM-09283-52

LM-01067-47

LM-09221-10

LM-01068-51

LM-01060-58

LM-01067-71

LM-01707-54

LM-09234-28

LM-01708-65

LM-01066-53

LM-09173-97

LM-01067-32

LM-01610-69

LM-09166-22

LM-09169-64 6

LM-09233-62 2

LM-09252-05

LM-09219-59

LM-01068-53

LM-09173-77

Qty.

2

2

4

1

1

2

1

2

1

1

6

2

4

6

2

6

1

2

Page 9

HITCH ASSEMBLY

1 PIN-yoke LM-01543 “OS 1

2 PIN-quick LM-09181-96 8

3 YOKE-end adjusting LM-0157 6-31 1

4 NUT-hex, 1/2-20 LM-09194-23 1

5 SCREW-hex cap, 3/8-16 x 3/4 LM-09081-27 1

6 PULLEY LM-01010-96 1

7 BELT-"V” LM-OiO82-09 1

8 WASHER-flat, 3/8 LM-09173-78 2

9 SPACER LM-01541-77 1

10 ARM-support LM-16072-22 2

11 PIN LM-01563-OG 6

12 SCREW-hex cap, 3/8-16 x 1 LM-09077-31 2

13 ROD-lift LM-16075-61 1

14 WASHER-loek, 3/8 LM-09169-65 1

15 NUT-hex, 3/8-16 LM-09169-50 ■ 1

16 ARM-push LM-16072-24 1

17 NUT-hex lock, 3/8-16 LM-09234-28 2

18 DEFLECTOR-heat LM-01612-96 1

19 FILM-shield LM-01702-52 1

DECAL-safety LM-01612-47 1

20 SCREW-hex cap, 3/8-16 x 1 LM-09077-31 2

21 NUT-hex, 3/8-16 LM-09169-50 2

22 WASHER-lock, 3/8 LM-09169-65 2

23 SUPPORT-spout adj. rod LM-16075-62 1

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Page 10

24

/1

2»

SPOUT ASSEMBLY

'6 '®I4l3

No,

1 NUT-hex, 5/16-18 LM-09173-72 1

2 WASHER-lock, 5/16

3 WASHER-cup

4

5 WASHER-flat, 3/8

6 NUT-wing, 5A6-18

7

WASHER-lock, shakeproof, 3/8

8

BOLT-carriage, 5/16-18 x 3/4

SPOUT

9

10 CLAMP-cable

11

CABLE

12

NUT-hex, 1/4-20

13 WASHER-lock, 1/4 LM-09169-64 2

14

BEARING

15 SCREW-hex cap, 1/4-20 x5/8

PIN-cotter, 3/32 x 3/4

16

17

SCREW-Taptite, 1/4-20 x 3/8

18 TUBE-spout control

19 NUT-hex lock, 5/16-18

20 GUIDE-rod LM-01520-50

21 LINER-guide

22 SCREW-hex cap, 5/16-18 x 1-1/2 LM-09199-33 1

PIN-cotter, 5/32 x 1

23

24

HANDLE

Description

EXTENSION-spout

Part No.

LM-09173-56 1

LM-01713-79

LM-01067-60 1

LM-09173-78 2

LM-01062-29

LM-09287-10 2

LM-09205-62 2

LM-01067-62 1

LM-01713-82 1

LM-01713-62 1

LM-09166-22 2

LM-01064-91 1

LM-09077-27

LM-09184-47 2

LM-09274-28 1

LM-01068-09 1

LM-09233-62

LM-01211-75 1

LM-09184-55 1

LM-01066-06 1

Qty.

1

2

2

1

1

\s#'

10

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Page 11

NUMERICAL PARTS LIST

Part No.

LM 01010 96

LM 01060 58 Chain w/conn, link

LM 01064 76

LM 01064 85

LM 01064 91

LM 01066 06 Handle Assembly

LM 01066 53

LM 01067 32 Bearing Cartridge

LM 01067 47

LM 01067 60

LM 01067 62 Spout Assembly

LM 01067 71

LM 01067 74 Deflector

LM 01068 09

LM 01068 47

LM 01068 51

LM 01068 53 Scraper-body

LM 01068 54

LM 01082 09 Belt-"V”

LM 01211 75

LM 01510 40 Key-hi pro

LM 01520 50

LM 01541 77

LM 01542 58

LM 01543 05

LM 01563 06

LM 01576 31

LM 01610 69 Flange -bearing

LM 01611 98 Body Assembly

LM 01612 47

LM 01612 96

LM 01702 52

LM 01707 54

LM 01708 65

LM 01713 62

LM 01713 82

LM 09051 23 Key-Woodruff #9

Description

Pulley-idler

Clamp-support

Pulley-drive

Bearing

Spro cket-rotor

Skid 2

Extension-spout

Stud 2 LM 09081 27

Tube Assembly

Rotor Assembly

Shaft Assembly

Housing-bearing

Liner-guide

Guide-rod

Spacer

Bearing-needle

Pin-yoke

Pin-rd.hd.-3/8X 1-1/2

Yoke-rod end

Decal-safety

Deflector-heat

Film-shield

Plate-side

Guard-chain

Cable Assembly

Clamp

Qty.

1

1

2

1

1

1

1 FASTENING PARTS

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

6 LM 09194 23

1

4

1

1

1

1

1

1

1

1

2 LM 8Ó610 12

Part No.

LM 09128 08

LM 09181 96

LM 16072 22

LM 16072 24

LM 16075 61

LM 16075 62

LM 01062 29

LM 01713 79

LM 09077 27

LM 09077 31

LM 09117 12

LM 09166 22

LM 09169 50

LM 09169 64

LM 09169 65

LM 09173 56

LM 09173 72

LM 09173 77

LM 09173 78

LM 09173 97

LM 09184 47

LM 09184 55

LM 09193 18

LM 09199 33

LM 09205 62

LM 09219 59

LM 09221 10

LM 09233 62

LM 09234 28

LM 09252 05

LM 09274 28

LM 09283 52

LM 09287 10

Description

Fitting-grease

Pin-quick

Arm Assembly-support 2

Arm Assembly-push 1

Rod-lift

Support-spout adj. rod

Nut-wing, 5/16-18

Washer-cup

1/4-20 X 5/8

3/8-16 X 1 5

3/8-16 X 3/4

5/16-18 X 5/16

Nut-1/4-20

Nut-3/8-16

Washer-lock, 1/4

Washer-lock, 3/8

Washer-lock, 5/16

Nut-5/16-18

Washer-flat, 1/4

Washer-fiat, 3/8

5/16-18 X 3/4

Pin-cotter, 3/32 X 3/4 2

Pin-cotter, 5/32 x 1

5/16-18 X 5/8

Nut-hex, 1/2-20

5/16-18 X 1-1/2 3

Bolt-5/16-18 X 3/4

1/4-20 X 5/8

BoU-3/8-16 X 3/4

Nut-hex, 5/16-18

Nut-hex, 3/8-16

5/16-18 X 5/8

1/4-20 X 3/8

Nut-flange, 3/8-16

Washer-lock, 3/8

Washer

Qty.

1

8

1

1

2

1

2

1

2

8

10

8

10

13

13

2

8

6

1

4

1

2

6

4

3

4

2

1

2

2 .

7

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

11

Page 12

\ ,

PRINTED IN U.S.A,

HOMELITT

* tMttronI

PORT CHESTER, NEW YORK, U.S.A. 10573

DIVISION

E1271EZ

Loading...

Loading...