Page 1

PARTS LIST

& INSTRUCTIONS

I io

38” LAWN REVITALIZER

HOMELITE'

DIVISION, PORT CHESTER, N-Y, 10573

textronl

Part No. 24683

Page 2

TABLE OF CONTENTS

INSTALLATION

....................................................................

OPERATION......................................................................... 4

DEPTH ADJUSTMENT.................................................... 4

PREPARATION FOR OPERATION

................................. 4

ENGAGING THE REVITALIZER ..................................... 4

TRAVEL SPEED AND DIRECTION

...............................

4

PREPARING A SEED BED.............................................. 5

REMOVING THE THATCH.............................................. 5

troubleshooting

...........................................................

ADJUSTMENTS ................................................................. 5

BELT TENSION ADJUSTMENT

BELT STOP ADJUSTMENT

DRIVE CHAIN ADJUSTMENT..

MAINTENANCE

..............

.....................................................

......................................

............................................

.....

.................................

AFTER EACH USE.......................................................... 7

AFTER 10 HOURS

ONCE EACH YEAR

BELT REPLACEMENT

..........................................................

.......................................................

....................................................

7

PROTECT YOURSELF AND OTHERS

1. Read and be familiar with the owners manual for your

tractor and the owners manual for the revitalizer before op

erating the revitalizer.

2. Do not allow anyone to use the revitalizer unless they have

been instructed in how to operate it safely.

3. Never attempt to adjust, repair or service the revitalizer

while the tractor engine is running.

4. Do not allow others near the revitalizer when it is operat

ing.

5. Stay clear of the drive belt, revitalizer knives and other

moving parts when the tractor engine is running.

3

5

5

5

6

^

7

^

f I

We warrant this HOME LITE product to be free from defects in material or workmanship under normal use and

service, except that we make no warranty, express or implied, with respect to tires, engines, generators or voltage

regulators (which usually are warranted by their respective manufacturers} nor with respect to any unit which

after sale by HOMELITE has been altered in any way without HOM ELITE'S express consent.Our obligation under

this warranty is limited to replacing, without charge any part which is proven defective within one year (30 days

if the unit is used for commercial, rental or municipal purposes) from date of purchase, if returned to us, with

transportation charges prepaid, at a HOMELITE branch office or to a dealer whom we have authorized to make

the replacement.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANT

ABILITY, FITNESS FOR A PARTICULAR PURPOSE, PERFORMANCE OR OTHERWISE AND IN NO EVENT

SHALL HOMELITE BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES.

REQUIRED ACCESSORIES

Rear Lift Kit No, LM-16001-61 for Tractor Models

T-10, T-12 & T-15.

WARRANTY

HOMELITE

a divisian tif Textron Inc.

RECOMMENDED ACCESSORIES

Electric Lift Kit No, LM-16 001-78 for Tractor Models

T-10, T-12 & T-15.

Page 3

INSTALLATION

I ;

CAUTION: DO NOT ATTEMPT TO INSTALL OR WORK

ON THE REVITALIZER WHEN THE TRACTOR ENGINE

IS RUNNING.

1, Position the revitalizer behind the tractor.

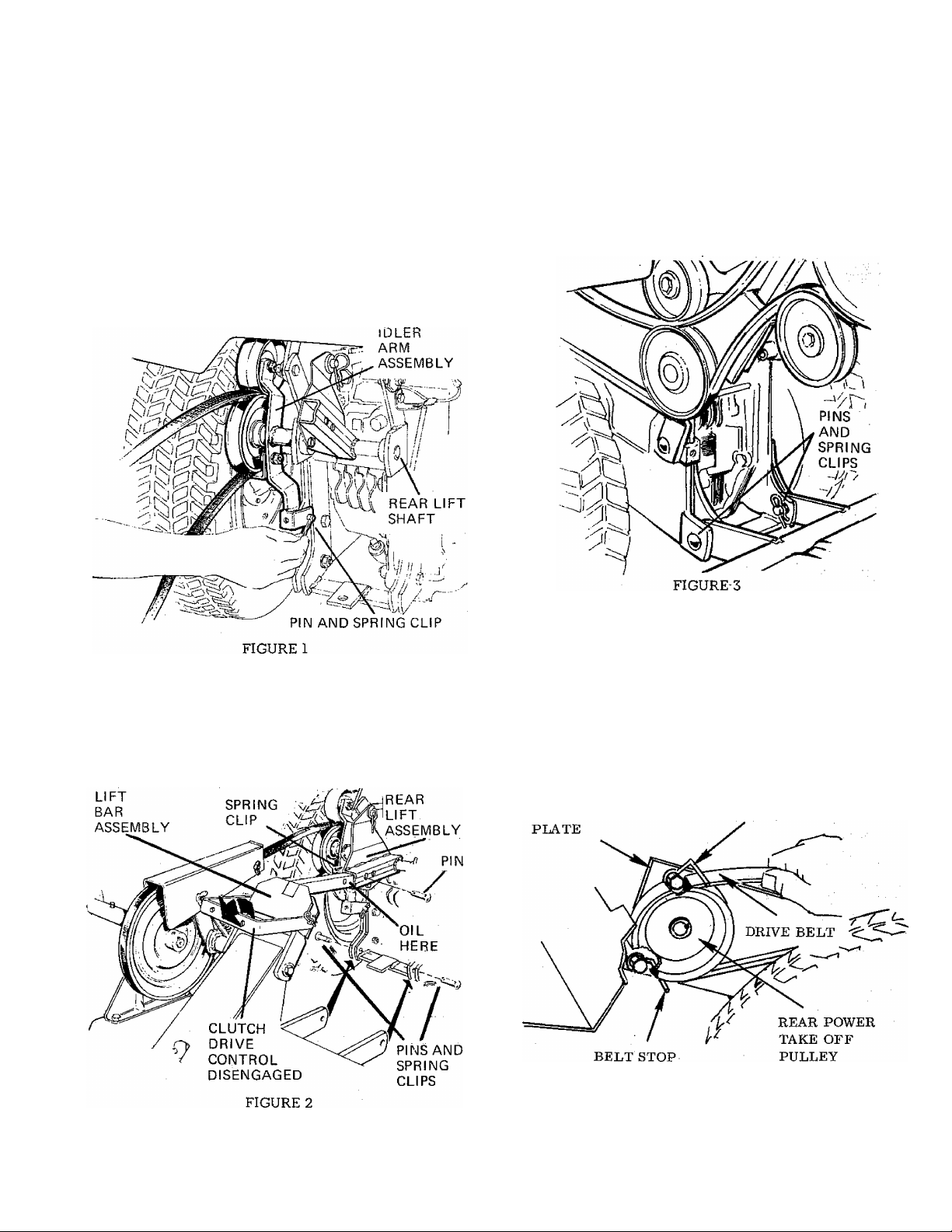

2. (See figure 1) Slide the idler arm assembly onto the left

end of the rear lift shaft. Attach the lower end of the idler

arm assembly to the hitch member with a pin and spring clip.

slide in place more easily. Fasten the lift bar in place with the

pin and spring clip provided.

4. (See figure 3) Move the tractor lift to the raised position.

Connect the revitalizer frame assembly to the tractor with 2

pins and spring dips.

3. (See figure 2) Lower the tractor lift unit and place the re

vitalizer lift bar assembly into the tube of the tractor rear lift

assembly. Placing a thin film of oil on the lift bar will make it

5. (See figure 2) Insure that the revitalizer drive dutch is

pushed all the way back in the disengaged position.

6. (See figure 4) Install the revitalizer drive belt over the rear

power-take-off pulley of the tractor. If-this pulley and the

belt'stops shown in figure 4 have not been previously installed

for use with the revitalizer or rotary tiller, see item (7) and

figure (12) of belt replacement in the Maintenance section of

this manual for proper positioning.

SIDE MOUNTING

BELT STOP

FIGURE 4

Page 4

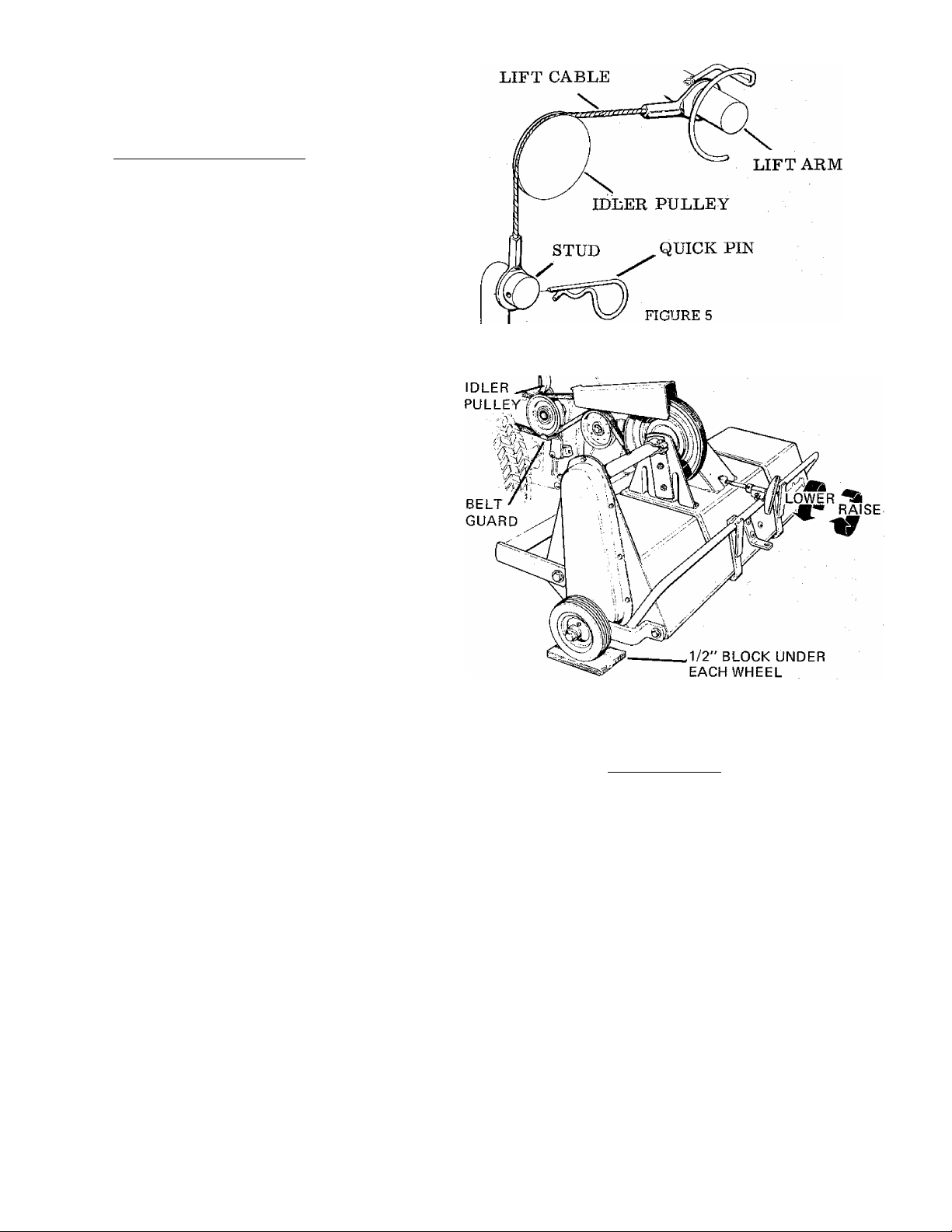

7. (See figure 5) If the mower is to be used with the revitalizer, remove the lift chain or cable from the tractor lift arm

when operating. This is especially beneficial in reducing lift

ing effort on tractors not equipped with power lift since the

revitalizer should be raised when turning to prevent excess

lawn damage. It is not advisable to raise the mower when

turning if the mower is engaged since operating the mower

in the raised position will reduce the life of the mower drive

belt.

8. Prior to first use or if the revitalizer has not been used re

cently, all adjustments listed in the Adjustments section of

this manual except the drive chain adjustment should be

checked before operating the revitalizer.

OPERATION

The HOMELITE Lawm Revitalizer is most effective if used in

the Spring and Fall of the year. In the Spring its use will lift

out thatch that harbors fungus and create a miniature irriga

tion system so that the water, fertilizer and air can reach the

grass roots. Use the Revitalizer pnce in the Spring between

the time the grass has started to grow vigorously and the time

when summer weather might be expected to slow grass

growth.

Used in the fall, the revitalizer will raise the summers accumu

lation of thatch and create a series of grooves which permit

frost to expand the soil for greater porosity. The grass roots

vrill have a better chance to expand during the next growing

season.

For best results the grass should be mowed to a length of

about 2 inches before the revitalizer is used. This will prevent

long grass from interfering with the revitalizing process.

Depth Adjustment

CAUTION; ALWAYS INSURE THE TRACTOR ENGINE

IS STOPPED BEFORE ATTEMPTING TO ADJUST OR

WORK AROUND THE REVITALIZER.

(See figure 6) Adjust the depth with the Revitalizer in the

lowered position. The cutting depth of the revitalizer knives

may be precisely adjusted by turning the T handle at the rear

of the revitalizer clockwise to raise the knives and counter

clockwise to lower them. For use in Spring and Fall as recom

mended, the knives should be set about 1/2 inch deep. The

1/2 inch depth may be set quite easily and accurately on a

level surface by placing a 1/2 inch block under each of the re

vitalizer guide wheels. BE SURE THE TRACTOR ENGINE

IS STOPPED. With the revitalizer clutch disengaged for ease

of turning, alternately rotate the drive pulley on the revital

izer and turn the depth adjusting handle until the ends of the

knives just hit the ground surface. The revitalizer should now

be set at 1/2 inch cutting depth. The grooves in the ground

may also be checked after operating a short distance to in

sure the correct depth setting.

Preparation for Operating

With the revitalizer (and mower if attached) disengaged and

in the raised position, move to the area to be revitalized. The

FIGURE 6

mower may be used with the revitalizer if the grass is notlong

or wet as to require full engine power for mowing. When

using the revitalizer it should be raised when turning to pre

vent excessive uprooting of grass, but it is neither advised nor

necessary to raise the mower. This may best be accomplished

by disconnecting the mower lift cable from the lift lever by

removing the spring clip and pin. See step 7 of Installation

instructions.

Engaging the Revitalizer

(See figure 7) The Revitalizer drive is engaged by pulling for

ward on the clutch lever mounted on the revitalizer. This can

be done from the tractor seat simply by reaching around and

pullir^ the clutch ahead. The revitalizer will be disengaged if

the lever is pushed back, away from the tractor.

Travel Speed and Direction

The revitalizer should be used with the tractor engine at

3/4 to full speed. Operating conditions will determine the

best ground speed. Under normal conditions where the

ground is smooth and soft a speed of 2 to 4 miles per hour’

should be satisfactory. This speed range will be approx

imated using 2nd gear, hi range on the dual| rangetrans-

Page 5

FIGURE 7

mission or 1/3 to 1/2 speed with the Hydrostatic Trans

mission, If the ground is hard, rocky or rough, a slower

speed may be advisable since the revitalizer will not be

as effective under these conditions.

Travel the long direction of the lawn to minimize turns. Be

fore turning, raise the revitalizer to prevent excessive uproot

ing of grass. On the second and successive passes, be sure to

drive so the revitalizer slightly overlaps that portion of the

lawn already revitalized.

NOTE: DO NOT MAKE SHARP TURNS WITH UNIT IN

GROUND, SINCE THIS WILL CAUSE LAWN DAMAGE.

If wire or other foreign material get caught in the revitalizer,

stop the tractor and disengage the clutch immediately. STOP

THE TRACTOR ENGINE BEFORE ATTEMPTING TO

WORK AROUND THE REVITALIZER.

Preparing a Seedbed

The revitalizer may be used to prepare a seedbed for reseed

ing a sparse area by making a second pass diagonally to the

first one at about a 45° angle. Use a depth setting of ap

proximately 1/2 inch.

Removing the Thatch

Dead g*ass and thatch should be removed after using the re

vitalizer. A HOMELiTE vacuum collector system is excellent

for this purpose. For best results allow the thatch and grass to

dry for a few hours before using the vacuum collector. A

sweeper will also work well in removing the thatch.

Trouble Shooting

If the thatch is not being lifted effectively:

1. Ground speed may be too fast - use a lower ground

speed.

2. Engine speed may be too slow - operate the engine at

3/4 to full throttle.

3. Long grass may be interfering - grass should be cut to

about 2” before revitalizing.

4. The revitalizer drive belt may be slipping - check the

belt tension to be sure it is set correctly, see Adjust

ments. Page 5.

If thatch removed is not uniform or an unusual amount of

green grass is being torn up:

1. Check to see if wire, sticks, etc. are caught on the

knives.

2. Check the depth of the grooves in the ground. A depth

of 1/2 inch is correct under most conditions.

If the drive belt will not stop turning when the revitalizer is

disengaged:

1. The belt stops may be out of adjustment. See “Ad

justments.” Page 5.

2. The belt tension adjustment at the revitalizer clutch

may be out of adjustment. See “Adjustments”. Page 5.

3. The belt may be of the wrong length or construction use only the correct belt.

O

ADJUSTMENTS.

Belt Tension Adjustment

(See figure 7) Tension on the revitalizer drive belt is regu

lated by the position of the set collar in the rod guide assem

bly of the revitalizer clutch. Belt tension is correct when there

is 5/8” to 3/4” clearance between the set collar and the lower

end of the rod guide assembly when the revitalizer clutch is

engaged. To increase belt tension, disengage the revitalizer

clutch and loosen the set screw in the collar. Move the rod

down slightly to reposition it under the set collar and re

tighten the set screw. Check the clearance by engaging the re

vitalizer clutch. Do not operate the revitalizer with more than

3/4 inch clearance between the set collar and rod guide as the

excessive tension may cause premature belt and bearing fail

ure.

Belt Stop Adjustment

If the revitalizer will not disengage properly or the back

side of the drive belt shows wear, the belt stops and guard

may need adjusting. Adjustments should be made as

follows.

CAUTION: DO NOT ATTEMPT TO MAKE ANY ADJUST

MENTS WITH THE TRACTOR ENGINE RUNNING.

(See Figure 8.) The belt stops are located above and be

low the drive pulley.

Page 6

I M— 16 0 6 0— 1 4

Pj,'

FIGURE 8

1. The belt stop located above the drive pulley is mounted

on the top mounting screw of the bevel gear case with

a special cap screw which replaces the original. This

belt stop should beadjusted to 1/4” clearance as shown

in Figure 8.

2. The belt stop located below the drive pulley is mounted

with a cap screw, flat washer, lock washer and hex nut

to the side mounting plate of the bevel gear case.

3. While holding the cap screw with a wrench so it will

not turn, loosen the nut located on the other side of the

mounting plate {see Figure 12) enough so the belt stop

can be moved. Adjust the belt stop so there is l/l6”

to 1/8” clearance between it and the revitalizer drive

belt.

4. To prevent the belt stops from moving, use a wrench

to hold the cap screw from turning while tightening the

nut inside the frame securely.

(See figure 7) The belt guard mounted over the revitalizer

drive belt should be adjusted so there is at least 1/8” clear

ance between the guard and the belt when the revitalizer

clutch is engaged to assure the backside of the belt does not

rub against the guard. If it is necessary to adjust the guard,

loosen the two wingnuts and reposition the guard correctly.

1. (See figure 9) With the chain cover removed so the chain

is visible, loosen, but do not remove the two bolts holding

each end of the bearing housing.

2. Pull upward on the bearing housing until, all slack is re

moved from the chain. Before tightening the bolts at each

end of the bearing housing, insure that the bearing housing is

parallel to the revitalizer housing. This may be easily and ac

curately done by measuring the distance from the bearing,

housing to the revitalizer housing at each end of the bearing

housing. When the two distances are equal, the bearing hous

ing is parallel to the revitalizer housing. (See figure 9).

After insuring all slack has been removed from the chain and

the bearing housing is parallel to the revitalizer housing,

tighten the two adjustment bolts at each end of the bearing

housing securely.

Put a liberal coating of automotive grease on the chain and

replace the chain cover.

GREASE

FITTING

LOOSEN HARDWARE

TO ADJUST CHAIN

BEARING HOUSING MUST

BE PARALLEL WITH

REVITALIZER HOUSING

CHAIN IS

CORRECTLY

ADJUSTED

WHEN ALL

SLACK HAS

BEEN

REMOVED

Drive Chain Adjustment

If inspection reveals that there is slack in the drive chain or it

must be replaced, use the following procedure to tighten the

chain:

GREASE FITTING

FIGURE 9

C

Page 7

0

CAUTION: ALWAYS BE SURE THE TRACTOR ENGINE

IS STOPPED BEFORE ATTEMPTING TO WORK AROUND

THE REVITALIZER.

After Each Use

Each time the revitalizer is used the knives should be checked

for wire or other material which may be caught in them.

Clean any foreign material away from the knives for best

operation. _

Every 10 Hours

There are five grease zerks located on the revitalizer which

should be lubricated with automotive grease after every 10

hours of use. They are located one on each of the two guide

wheels, one on each of the two tine shaft bearings and one on

the crossdrive housing. (See figure 9 and 10.) Lubricate each

zerk with 5 shots of grease or until grease is pushed out

around the bearings.

OIL

FIGURE 11

ON BOTH WHEELS

FIGURE 10

Lubricate all pivot points with engine oil to help prevent

wear. (See figure 11) Do not get oil on the drive belt OF the

pulleys.

Once Each Year

Once a year remove the chain cover on the left side of the re

vitalizer housing and inspect the chain. If the chain shows

excessive wear, it should be replaced. See your dealer for

the correct chain.

If the chain is loose it should be tightened until all slack is

removed. (See Adjustments).

Coat the chain liberally with automotive grease and replace

the cover.

Belt Replacement

If the revitalizer drive belt should become excessively frayed

or twisted or break and replacement is necessary, do the

following:

1. Be sure the tractor engine is not running.

2. Place the revitalizer clutch in the disengaged position.

3. (See figure 7) Remove the two wingnuts holding the belt

guard in place over the drive belt. Remove the belt guard.

4. (See figure 6) Remove the belt guard and idler pulley

from the reverse idler assembly and replace the damaged belt

with a new belt.

5. When replacing the belt guard, position it so the belt will

not rub against it when the revitalizer is operated.

6. (See figure 7) Place the new belt over the revitalizer pul

ley and replace the belt guard.

Page 8

7. (See Figure 12.) Check power-take-off pulley on the

tractor to be sure it is properly installed with the hub

facing in toward the tractor. Align the drive pulley with

the pulleys on the revitalizer, be sure that these pulleys

are in direct line. The key must be in place and the set

screw on the pulley hub tightened securely (see also

Figure 4).

Page 9

32

25

No.

1

2

3

Desciiption

SCREW-hex cap, 7/16-14 x l-^l/4

WASHER-flat, 3/8

SPACER

4 CLIP-spring

5

HANDLE-clutch-

6

NUT-hex jam, 7/16-14

WASHER-lock, '7/16

7

8

SCREW-set, 1/4-20 x 3/8

9

COLLAR-set

10 SPRING

11

ROD-clutch

12

GUIDE ASSEMBLY-rod

13 NUT-wing, 5/16-18

14 GUARD-belt

15

BOLT-carriage, 5/16-18 x 3/4

16

LEVER ASSEMBLY-clutch

17 NUT-hex, 3/8-16

18

WASHER-lock, 3/8

19

NUT-hex, 5/16-18

WASHER-flat, 5/16

20

21

SUPPORT-belt guard

22 SPACER-

Part No.

LM-09164-32

LM-09173-78

LM-01053-46

LM-01067-87

LM-01053-03

LM-09182-13

LM-09181-99

LM-0903S-07

LM-81910-22

LM-01620-65

LM-01053-43

LM-01584-06

LM-07180-06

LM-01053-26

LM-09205-62

LM-01052-95

LM-09169-50

LM-09169-65

LM-0923 3-62

LM-09176-42

LM-01053-59

LM-01053-39

ALWAYS FURNISH MGPEL AND SERIAL NUMBER WHEN ORDERING PARIS-

Qty.

1

3

2

6

1,

2

2

1

1 31 KEY LM-S0610-81

1

1

1

2

1

2'

1

4

4

1

3

1

1

No.

23 WASHER-flat, 7/16 LM-09J84-30 2

24 SCREW-hex cap, 7/16-14 x 3-1/2 LM-07150-93 1

25 KEY-Woodruff, #9.

26

27 SCREW-hex cap, 3/8-16 x 1-1/4 LM-,09174-00 2

28

29 BELT-"V", 12 hp.

30 STOP-belt

32

33

34

35

36 PULLEY-idler

37 PULLEY-idler

38 SCREW-hex cap, 3/8-16 x 7/8

39 GUARD-belt '

40

41 ARM ASSEMBLY-idler LM-01053-22

42

43

Description

PULLEY

PULLEY

SCREW-hex cap, 7/16-14 x 1-1/4 LM-09234-71

SCREW-hex cap, 3/8-16 x 1 LM-09077-31

STOP-belt

PULLEY LM-01642-02

PIN

BAR ASSEMBLY-lift

PIN

Part No.

Qty.

LM-09051-23 1

LM-010^3-02

LM-01053-06 1

LM-01053-40 1

LM-16060-14

LM-01670-32

LM-01053-80 1

LM-01640-83 1

LM-09193-57 1

LM-01053-51

LM-01563-06 1

LM-16074-25 1

LM-01180-53 i

1

1

1

1

1

1

1

1

1

Page 10

3

No. Description

1 CHAIN-drive

SHAFT ASSEMELY-drive LM-01723-40

2

3 WASHER

4

FITTING-grease (Hemite #1952) LM-07270-13

5 . HOUSING & BEARING ASSEMBLY

Includes:

6 BEARING-needle

7 ■ WASHER

8 WASHER-lock, 7/16

9 NUT-hex jam, 7/16-14

10

HOUSING ASSEME LY LM-01723-07

11 SCREW-hex cap, 5/16-18 x 5/8

12

SUPPORT-bearing

13

SUPPORT ASSEMBLY-clamp LM-01728-95

14 SCREW-hex cap, 5/16-18 x 1-1/2

15 BOLT-carriage, 7/16-14 x 1

16 WASHER-lock, 5/16

17 NUT-hex, 5/16-18

18 PLUG-button

19

SCREW-hex Taptite, 1/4-20 x 3/8

10

ALWAYS FURNfSH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Part No.

LM-01728-91

LM-01060-69

LM-01729-06

LM-01727-47

LM-01010-22

LM-09181-99

LM-09182-13

LM-09193-18

LM-01722-52

LM-09199-33

LM-07020-25

LM-09173-56

LM-09173-72

LM-01729-34

LM-09274-28

Qty. No.

1

1

1 22

1 23

1

2

1 27

4 28

4

1 30

2 31

1 32

2 33 SCREW-hex cap, 5/16-18 x 1/2

2

4

4

3

1

8

20

21

24

25

26

29

Accessories:

SPRAY CAN-blue, 14 oz. LM-16076-89 1

SPRAY CAN-black. 12 oz. 22772 1

Description Part No.

GUARD-chain

NUT-special, 5/16-18 LM-092 5 7-63 1

GUARD-trash

FLANGE-hearing

BEARING

FLANGE-bearing

WASHER-hex

SCREW-hex Taptite, 5/16-18 x 1/2

SHAFT ASSEMBLY-tine

TINE

SPACER

SPRING

WASHER

Qty.

LM-0172 9-83 1

LM-01728-74 2

LM-01729-73 2

LM-01723-47

LM-01729-72

LM-01723-32 4

LM-0924 8-56

LM-01723-38 1

LM-01703-33 14

LM-01703-37 12

LM-01704-17

LM-01231-44 1

LM-09193-17 1

2

2

6

1

Page 11

:W

HITCH AND HEIGHT ADJUSTMENT

1

No. Description

1 HITCH ASSEMBLY

2 ADJUSTER

3 PIVOT

4 WASHER-flat, 5/16

5 PIN-cotter, 3/32x3/4 LM-09184-47

Part No. Qty.

LM-16 074-44 1

LM-01722-71 1

LM-01081-72 1

LM-09176-42 1

1

6 COLLAR-set LM-01052-01 1

7 SCREW-set, 1/4-20 X 5/16

8

LENER-guide .LM-01211-75 1

9 GUIDE-rod LM-01520-50 1

10 WASHER-fiat, 3/8

11

SCREW ASSEMBLY-adjusting LM-01084-15 1

12

NUT-hex, 5/16-18

13

SCREW-hex cap, 5/16-18 x 1-1/4 LM-09077-29 1 30

14

BOLT-carriage, 5/16-18 x 3/4

15

REINFORCER-tow bar LM-01723-16 1

16

WASHER-lock, 5/16

17

NUT-hex, 5/16-18 LM-09173-72 4

LM-07135-05 1

LM-09173-78 3

LM-09233-62 1

LM-09194-14 3

LM-09173-56 4 ■

No. Description Part No.

18 BOLT-carriage, 5/16-18 x 1 LM^ 09211-58 1

19

BAR-tcw

20 NUT-hex, ,3/8-16

WASHER-lock, 3/8

21

22

SPACER LM-01183-35 2

SCREW-hex cap, 3/8-16 x 1-1/4

23

24 NUT-hex, 7/16-14 LM-07175-19 2

25 WHEEL & TIRE ASSEMBLY LM-16062-55

26

BOLT-wheel

27 NUT-hex, 1/2-13

28

WASHER-flat, 1/2 LM-09184-31 4

29 SPACER LM-01053-86 2

SCREW-hex cap, 1/2-13 x 1-1/4

31 PIN LM-01550-37

32 CLIP-spring LM-01067-87 2

DECAL-safety (not shown) LM-01030-31 1

LM-01723-17

LM-09169-50- 2

LM-09169-65 2

LM-09174-00 2

LM-01726-82 2

LM-07175-18

LM-09172-79 2

Qty.

1

2

2

2

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS;

11

Page 12

%

o

Printed in U. S, A.

HOMELITr

«text ran I

PORT CHESTER, NEW YORK, U.S.A. 10573

DIVISION

w'

E1271EZ

Loading...

Loading...