Page 1

INSTRUCTDNS

& PARTS LIST

HOMELITE

■ ■ ■■■

®

O

56 ROTARY

TILLER

II*

PART NO. 24666

Page 2

Read the Owner's Manual carefully. Be thoroughly

familiar with the controls and proper use of the

equipment.

Never allow children to operate the unit.

■ Disengage power to attachments when transporting or

not in use.

■ Do not change engine governor settings or overspeed

engine.

Keep the area of operation clear of all persons, particu

larly small children, and pets.

Thoroughly inspect the area where the equipment is to

be used and remove all stones, wire, bones and other

foreign objects.

Do not operate equipment when barefoot or wearing

open sandals. Always wear substantial footwear.

Check fuel before starting engine. Do not fill gasoline

tank indoors, when engine is running, or while engine is

still hot. Wipe off any spilled gasoline before starting

engine.

TINE WARRANTY

■ Do not put hands or feet near or under rotating parts.

■ Stop tines when crossing gravel drive, walks or roads.

■ Vehicle and attachments should be stopped and inspected

for damage after striking a foreign object and the damage

should be repaired before restarting and operating the

equipment.

■ If the equipment should start to vibrate abnormally, stop

the engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

vT’'n"^S

HOMELITE warrants rotary tiller tines against breakage for the period not to exceed

the normal life of the rotary tiller: and will replace broken tines directly to the customer

at no charge, provided broken tines are returned prepaid to the nearest HOMELITE

district office.

HOMELITE

a division of Textron Inc.

CONTENTS

SAFETY............................................................................................................................... 2

HOMELITE

A tgXtfOnI DIVISION, POUT CHESTER. N.T. !OS73

//

36 R OT A RY TI L LE R

WARRANTY..................................................................................................................... 2

INSTRUCTIONS.............................................................................................................. 3

LUBRICATION ............................................................................................................... 3

BELT ADJUSTMENT...................................................................................................... 3

PARTS

HOUSING GROUP........................................................................................................ 4

DEFLECTOR & TINE GROUP..................................................................................... 6

TILLER DRIVE GROUP................................................................................................. 8

TINE EXTENSION GROUP..................................................................................... 10

PARTS LIST.................................................................................................................... 11

Page 3

ASSEMBLY INSTRUCTIONS BELT ADJUSTMENT

1. Position tiller at the rear of the tractor. Place the lift

lever in the fully back position. Put the tiller lift assem

bly into the tractor lift assembly and secure with clevis

pin and quick pin.

fe(

2. Place tractor lift lever in forward position. Secure the

tiller frame assembly to tractor with the two clevis pins

and two quick pins supplied.

The belt that transmits power from the bevelgear box to the

tiller drive shaft is designed to provide long and satisfactory

service. Because of the special design of this belt, it is

urged that it is only replaced with genuine replacement

ordered from your dealer.

Adjustment of belt tension is controlled by the set collar on

the rodguide assembly. The tensionshould be correct when

there is about 1-1/4" clearance between the collar and the

bracket of the rod guide assembly with the tiller clutch lever

engaged. To increase the tension, release the tiller clutch

lever and loosen the setscrew in the collar. Slide the collar

up toward the spring and retighten the set screw. Check

the tension by engaging the tiller clutch lever. Avoid ex

cessive tension as it will cause premature belt failure.

3. Slide idler arm assembly onto rear lift shaft.

4. Attach lower end of idler arm assembly to hitch member

with clevis pin and quick pin.

5. Assemble pulley to power take-off (PTO) shaft on bevel

gear housing. Using existing cap screw, washers, and

nut, secure belt stop to tractor.

6. Position belt dh pulleys and check that the belt is seated

properly in the pulleys, and that the pulleys are properly

aligned.

LUBRICATION

There are grease fittings on each housing bearing and two

90° grease fittings are on the right hand side of the housing.

These fittings should be lubricated every three hours of

operation. Use a good grade of general purpose automotive

type grease applied with a standard grease gun. (Fittings

should be wiped clean before applying any grease.) Also

apply a few drops of lubricating oil to the moving linkages

of the tiller drive assembly occasionally.

Before starting the tractor engine, place the tiller clutch

lever in the disengaged position, and raise the tiller above

the surface of the ground. With the tractor engine running,

engage the tiller clutch and lower the tiller into contact

with the ground. As the tiller works into the soil, slowly

release the tractor clutch and move ahead. When coming

to the end of a row, raise the tiller free of the ground be

fore turning around.

Effective operation of the tiller will depend in a large degree

upon the operator. For example; when intending to till a

sod area into a seed bed for gardening, it obviously will re

quire several passes over the same path to break the sod

and ground into fine particles suitable for a seed bed. De

pending on the nature of the soil, it will be desirable to altar

the depth settings for the tiller on succeeding passes until

the desired depth is reached. When tilling in soil that has

been previously worked, it may be possible to till to the de

sired depth from the start.

The depth of tilling is regulated by the ground speed of the

tractor. The slower the ground speed the deeper the tilling

action.

NOTE: When using the rotary tiller on a tractor

equipped with the power lift attachment,

the power lift attachment must be in the

float position. Operating the tiller in the

hold position will cause the tiller tines to

propel the tractor at a dangerous speed .

Page 4

HOUSING GROUP

I

Page 5

No.

Description Part No. Qtj

FITTING-grease

1

2

BOLT-(R. H. side)

WASHER-lock, 1/2

3

SIDE BAR

4

NUT-full hex, 5/16-18

5

WASHER-lock, 5/16

6

BEARING

7

LCXiKNUT-full hex, 5/16-18

8

9

HALF CASE ASSEMBLY (R. H.)

NUT-full hex, 1/2-13

10

WASHER-flat, 1/2 LM-09184-31

11

SCREW-thread forming,

12

3/8-16 X 1-1/2

13

BEARING

14

SEAL

15 UPPER BEARING PLATE

ASSEMBLY

Includes: (each assembly)

16

17

SCREW-hex cap, 5/16-18 x 1-1/2

SEAL

18 PLATE-reinforcing

19 NUT-hex lock, jam, 3/8-16

20

SPACER

21 BEARING-roller

22

RING - r eta ining

23

WASHER

24 PULLEY SHAFT ASSEMBLY

SPACER-intermediate

25

26

SPROCKET ASSEMBLY

27

CHAIN

28 TINE SHAFT ASSEMBLY

29

30

CHAIN

SPROCKET ASSEMBLY

31 SPACER-intermediate

SCREW-hex cap, 5/16-18 x 5/8

32

33 SCREW-hex cap, (L. H.)

1/2-20 X 1-1/4

34 SCREW-hex cap, 1/2-13 x 4

HALF CASE ASSEMBLY (L. H.)

35

36

GASKET

GREASE CAP

LM-09150-19

LM-01051-32

LM-09169-66

LM-01053-20

LM-09173-72

LM-09173-56

LM-01053-11

LM-09233-62

LM-01053-66

LM-09169-51

LM-07150-91

LM-01053-09

LM-01053-65

LM-01053-13

LM-09212-21

LM-01053-57

LM-01053-07

LM-09287-31

LM-01053-60

LM-01051-95

LM-01051-94

LM-82810-14

LM-01052-98

LM-01051-92

LM-01053-01

LM-01053-45

LM-01052-97

LM-01053-36

LM-01052-91

LM-01052-92

LM-09193-18

LM-07060-22

LM-07050-68

LM-01053-67

LM-01053-73

LM-01053-63

2

2

5

2

4

4

2

14

1

1

2

6

2

2

2

2

2

2

6

2

4

4

4

1

1

1

1

1

2

1

1

14

2

1

1

1

2

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Page 6

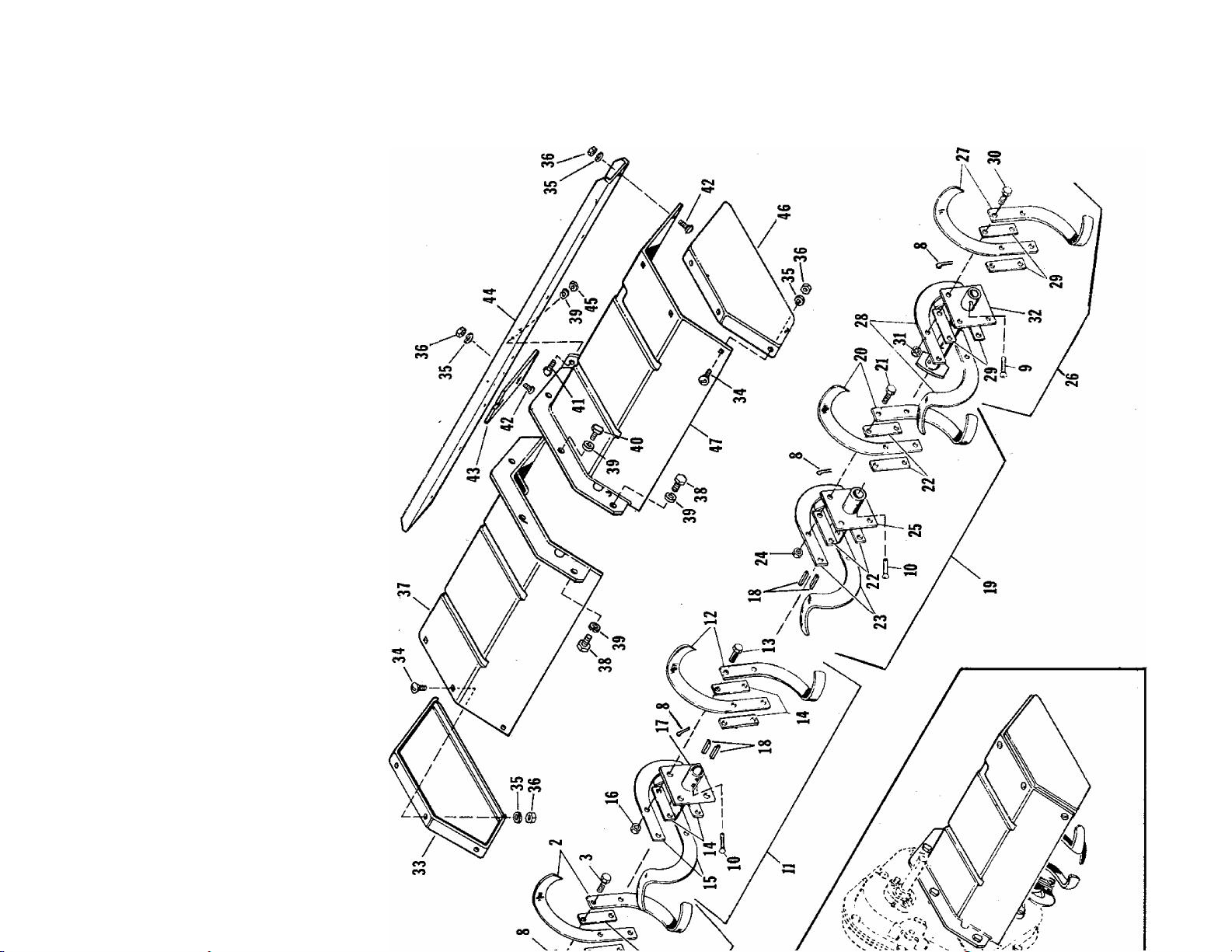

DEFLECTOR & TINE GROUP

Page 7

No.

Description Part No.

Qty.

Kj

1 BIADE ASSEMBLY (R. H,)

Includes:

2

3

TINE-blade (left hand)

SCREW-hex cap, 7/16-20 x 2

4 SPACER

5

6

7

8

9

10

11

TINE BLADE (right hand)

NUT-hexlock, 7/16-20

PLATE-tine

PIN-cotter, 1/8 X 3/4

PIN

PIN-inner

BLADE ASSEMBLY-inner (R. H.)

Includes:

12

TINE-blade (left hand)

13 SCREW-hex cap, 7/16-20 x 2

14

15

16

SPACER

TINE-blade (right hand)

NUT-hex lock, 7/16-20

17 HUB-attachment

18 KEY

BLADE ASSEMBLY-inner (L. H.)

19

Includes:

20 TINE-blade (left hand)

21

22

23

24

25

26

SCREW-hex cap. 7/16-20 x 2

SPACER

TINE-blade (right hand)

NUT-hex lock, 7/16-20

HUB-attachment

BLADE ASSEMBLY (L. H.)

Includes:

27

28

29

30

31

32

33

34

35

TINE-blade (left hand)

TINE-blade (right hand)

SPACER

SCREW-hex cap, 7/16-20 x 2

NUT-hex lock

PLATE-tine

PLATE-end, deflector (right hand)

BOLT-carriage, 5/16-18 x 1/2

WASHER-lock, 5/16

36 NUT-hex, 5/16-18

DEFLECTOR-right hand

37

SCREW-hex cap, 3/8-16 x 1

38

WASHER-lock, 3/8

39

SCREW-hex cap, 3/8-16 x 5/8

40

SCREW-hex cap, 3/8-16 x 7/8

41

BOLT-carriage, 5/16-18 x 3/4

42

SHIELD

43

CHANNEL-reinforced

44

NUT-hex, 3/8-16

45

PLATE-end, deflector (left hand) LM-01052-73

46

DEFLECTOR-left hand

47

DECAL-safety

LM-01053-90 1

LM-01053-75

LM-07150-95 4

LM-01053-77 4

LM-01053-76 2

LM-09148-80 4

LM-01053-84 1

LM-09184-51 4

LM-01180-53 2

LM-01052-49 2

LM-01053-87

LM-01053-75 2

LM-07150-95 4

LM-01053-77 4

LM-01053-76 2

LM-09148-80 4

LM-01053-81

LM-01053-37 4

LM-01053-88 1

LM-01053-75 2

LM-07150-95 4

LM-01053-77 4

LM-01053-76 2

LM-09148-80 4

LM-01053-81

LM-01053-89

LM-01053-75 2

LM-01053-76 2

LM-01053-77 4

LM-07150-95 4

LM-09148-80 4

LM-01053-84

LM-01052-74 1

LM-07030-11

LM-09173-56 15

LM-09173-72 15

LM-01053-69 1

LM-09212-10 5

LM-09169-65 8

LM-07150-24 1

LM-09193-57 2

LM-09194-14

LM-01053-54 1

LM-01053-30 1

LM-09169-50 2

LM-01053-70 1

LM-01030-31 1

2

1

1

1

1

1

8

7

1

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Page 8

TILLER DRIVE GROUP

TORQUE TO 75 FT, LBS.

32

B

36 54

28

Page 9

No. Description

Part No.

Qty

1 HANDLE-clutch

2

CLIP-spring

WASHER-flat, 3/8

3

4

SCREW-hex cap, 7/16-14 x 1-1/4

5 SPACER

6 PIN

NUT-hex lock, 7/16-14

7

SPACER

8

9 LEVER-clutch

10 NUT-hex, 3/8-16

11 WASHER-lock, 3/8

NUT-whiz lock, 5/16-18

12

13 SUPPORT-rear belt guard

14 WASHER-flat, 7/16

SCREW-hex cap, 7/16-14 x 3-1/2

15

16 GUARD-belt

BOLT-carriage, 5/16-18 x 1/2

17

18 KEY

19 PULLEY

20 PULLEY

SCREW-hex cap, 3/8-16 x 1-1/4

21

22 WASHER-flat, 5/16

23 PULLEY-idler

24 PULLEY-idler

25 BELT-V

26 KEY

27 PULLEY

WASHER-flat, 1/2

28

29

SPACER

30

SCREW-hex cap, 1/2-13 x 5

LM-01053-03

LM-01067-87

LM-09173-78

LM-09206-77 1

LM-01053-46 2

LM-01180-53

LM-07175-19

LM-01053-39

LM-01052-95 1

LM-09169-50 4

LM-09169-65

LM-09257-63

LM-01053-59

LM-09184-30 ■ 2

LM-07150-93

LM-01053-26

LM-07030-11 2

LM-01574-27 1

LM-01053-02 1

LM-01053-06

■ LM-09174-00 2

LM-09176-42 2

LM-01640-83

LM-01053-80 1

LM-01053-40

LM-80610-81 1

LM-01642-02 1

LM-09184-31 4

LM-01053-86 - 2

LM-07150-97 1

31 SCREW-hex cap, 3/8-16 x 4-1/2 LM-09220-48 1

32 PIN LM-01550-37

33

CLIP-spring

34 FRAME

LM-01067-88 2

LM-16074-26

35 NUT-hex lock, 3/8-16 LM-09234-28

36

NUT-hex lock, 1/2-13

LM-07175-18 1

37 STOP-belt LM-01670-32 1

38

PIN

39 GUARD-belt

40

SCREW-hex cap, 3/8-16 x 7/8

LM-01563-06

LM-01053-51 1

LM-09193-57 1

41 BRACKET-depth limit LM-01726-39

42

CHAIN LM-01070-31

43 CLIP-spring LM-81610-4 5 2

44 CLIP-chain LM-01082-00 1

NUT-hex lock, 5/16-18

45

GUIDE-rod LM-01584-06 1

46

LM-09233-62 1

47 ROD-clutch LM-01053-43 1

48 SPRING LM-81910-45 1

50 SCREW-set, 1/4-20 x 3/8 LM-09038-07

51 BAR-lift LM-16074-25 1

52

IDLER-arm

LM-01053-22

53 STOP-belt LM-16060-14 1

SCREW-hex, 3/8-16 x 1

54

LM-09077-31

55 SCREW-hex, 7/16-14 x 1-1/4 LM-09234-71

56 WASHER-lock, 7/16

LM-09181-99

1

5

3

1

2

1

4

2

1

1

1

1

1

1

2

1

1

3

1

1

1

1

1

1

1

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Page 10

TINE EXTENSION GROUP

ALTERNATE METHOD OF ASSEMBLY

FOR MAXIMUM WIDTH.

No. Description Part No.

BLADE ASSEMBLY (L. H.)

Includes:

1

2

3

4

5 PLATE ASSEMBLY-tine ext. LM-01052-21 1

6

7 CLIP-spring LM-S1610-45 2

8 DEFLECTOR-extension(right hand)

9 DEFLECTOR-extension (left hand) LM-01052-76

10

11 WASHER-lock, 5/16 LM-09173-56 10

12

13 TINE-blade (left hand) LM-81520-01 2

14 TINE-blade (right hand) LM-81520-02 2

15 SCREW-hex cap, 7/16-20 x 1-1/4 LM-09204-88 4

16

17

TINE-blade (left hand) LM-81520-01 2

TINE-blade (right hand)

SCREW-hex cap, 7/16-20 x 1-1/4

NUT-hex lock, 7/16-20

PIN LM-01180-53 2

BOLT-carriage, 5/16-18 x 1/2

NUT-hex, 5/16-18

BLADE ASSEMBLY (R. H.)

Includes:

NUT-hex lock, 7/16-20

PLATE ASSEMBLY-tine ext.

LM-01052-22

LM-81520-02 2

LM-09204-88 4

LM-09148-80 4

LM-01052-75 1

LM-09237-00

LM-09173-72 10

LM-01052-23 1

LM-09148-80 4

LM-01052-21 1

Qtj

1

1

10

10

ALWAYS FURNISH MODEL AND SERIAL NUMBER WHEN ORDERING PARTS.

Page 11

Part No.

Description

Qty.

Part No. Description

Qty,

I ^

LM 01030 31 Decal-safety

LM 01051 32 Bolt-(right hand side) 2

LM 01051 92

LM 01051 94 Ring-retaining 4

LM 01051 96 Bearing-roller 4

LM 01052 21 Plate Assembly 2

LM 01052 22

LM 01052 23 Blade Assembly (R. H.)

LM 01052 49

LM 01052 73

LM 01052 74

LM 01052 75 Deflector Ext. (R. H.)

LM 01052 76

LM 01052 91

LM 01052 92 Spacer-intermediate

LM 01052 95 Lever-clutch

LM 01052 97

LM 01052 98

LM 01053 01

LM 01053 02

LM 01053 03

LM 01053 06 Pulley

LM 01053 07 Plate-re inforc ing

LM 01053 09

LM 01053 11

LM 01053 13 Plate Assembly

LM 01053 20

LM 01053 22

LM 01053 26

LM 01053 30

LM 01053 36

LM 01053 37

LM 01053 39

LM 01053 40

LM 01053 43

LM 01053 45

LM 01053 46

LM 01053 51

LM 01053 54

LM 01053 57

LM 01053 59

LM 01053 60

LM 01053 63

LM 01053 65

LM 01053 66

LM 01053 67

LM 01053 69

LM 01053 70

LM 01053 73

LM 01053 75

LM 01053 76 Tine-blade {R.H.)

LM 01053 77

LM 01053 80

LM 01053 81

LM 01053 84

LM 01053 86 Spacer

LM 01053 87

LM 01053 88 Blade Assembly (L. H.)

LM 01053 89 Blade Assembly (L. H.)

LM 01053 90 Blade Assembly (R. H.)

LM 01067 87

LM 01067 88

LM 01070 31

Spacer- inter mediate

Blade Assembly (L. H.)

Pin-inner

Plate-deflector (L. H.)

Plate-deflector (R. H.)

Deflector Ext. (L. H.)

■Sprocket Assembly

Shaft Assembly-tine

Shaft-pulley

Sprocket Assembly

Pulley

Handle-clutch

Bearing

Bearing

Bar-side

Arm Assembly-idler

Guard-belt

Channel Reinforcing

Chain

Key

Spacer

Belt-V, 12 hp.

Rod-clutch

Chain

Spacer

Guard -belt

Shield

Seal

Support-belt guard

Spacer

Grease Cap

Seal

Case-half (R. H.)

Case-half (L. H.)

Deflector- (R. H.)

Deflector Assembly (L. H.)

Gasket

Tine-blade (L. H.)

Spacer

Pulley-idler

Hub-attach assembly

Plate Assembly-tine

Blade Assembly (R. H.)

Clip-spring

Clip-hairpin

Chain

16

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

1

1

1

2

4

1

1

1

1

2

1

1

2

1

2

2

2

1

1

1

1

1

8

8

1

2

2

2

1

1

1

1

5

2

1

LM 01082 00 Clip-chain

LM 01180 53

LM 01550 37 Pin-rd.hd.

LM 01563 06

LM 01574 27 Key-parallel

LM 01584 06

LM 01640 83 Pulley-idler

LM 01642 02 Pulley-P. T. O.

LM 01670 32 Stop-belt

LM 01726 39

LM 09150 19

LM 16060 14 Stop-belt

LM 16074 25

LM 16074 26

LM 80610 81

LM 81520 01 Blade-tine (L. H.)

LM 81520 02 Blade-tine {R. H.)

LM 81610 45

LM 81910 22 Collar-set

LM 81910 45 Spring

FASTENING PARTS

LM 07030 11

LM 07050 68

LM 07-060 22 1/2-20 X 1-1/4

LM'-07150 24

LM 07150 91

LM 07150 93

LM 07150 95 7/16-20 X 2

LM 07150 97

LM 07175 18

LM 07175 19

LM 09038 07

LM 09077 31

LM 09148 80

LM 09169 50

LM 09169 51

LM 09169 65

LM 09169 66 Washer-lock, 1/2

LM 09173 56 Washer-lock, 5/16

LM 09173 72

LM 09173 78

LM 09174 00

LM 09176 42

LM 09181 99

LM 09184 30

LM 09184 31

LM 09184 51

LM 09193 18

LM 09193 57

LM 09194 14

LM 09204 88

LM 09206 77

LM 09212 10

LM 09212 21

LM 09233 62 Nut-hex, 5/16-18

LM 09220 48

LM 09234 28

LM 09234 71 7/16-14 x 1-1/4

LM 09237 00

LM 09257 63

LM 09287 31

LM 82810 14

Pin-tine shaft 5

Pin-rd.hd.

Guide Assembly-rod

Bracket Assembly

Fitting-grease 2

Lift Bar Assembly

Frame Assembly

Key

Clip-spring

Bolt-carriage

1/2-13 X 4

3/8-16 X 5/8

3/8-16 X 1-1/2

7/16-14 X 3-1/2

1/2-13 X 5

Nut-hex, 1/2-13

Nut-hex, 7/16-14

1/4-20 X 3/8

3/8-16 X 1

Nut-hex cap

Nut-hex, 3/8-16

Nut-hex, 1/2-13

Washer-lock, 3/8

Nut-hex, 5/16-18

Washer-flat, 3/8

3/8-16 X 1-1/4

Washer-flat, 5/16

Washer-lock, 7/16

Washer-flat, 7/16

Washer-flat, 1/2

Pin-cotter, 1/8 X 3/4

5/16-18 X 5/8

3/8-16 X 7/8

Bolt-5/16-18 X 3/4 7

7/16-20 X 1-1/4

7/16-14 X 1-1/4

3/8-16 X 1 5

5/16-18 X 1-1/2

3/8-16 X 4-1/2

Nut-hex, 3/8-16

Bolt-5/16-18 X 1/2

Nut-5/16-18

Nut-hex, 3/8-16

Washer

1

2

3

1

1

1

1

1

1

1

1

1

1

4

4

4

1

1

10

1

2

1

6

1

16

1

1

2

1

1

24

6

1

12

5

29

29

3

2

2

1

2

6

4

14

1

8

1

2

15

1

1

1

10

2

6

4

n

Page 12

PRINTED IN U. S.A.

HOMELITr

* textronl

PORT CHESTER, NEW YORK, U.S.A. 10573

DIVISION

E1272EZ

Loading...

Loading...