HOMELITE

3H.P.

TILLER

3H.P. TILLER MFG. NO. 1600399

TINE EXTENSION KIT MFG. NO. 1600407

FURROW OPENER MFG. NO. 1600373

OPERIITOR'S

mnnuRi

FORM - 1651763

PRINTED IN U.S.A

748

WARRANTY

We warrant this HOMELITE product to be free from defects in material or workmanship under normal use and

service, except that we make no warranty, express or implied, with respect to tires, engines, generators or voltage

regulators {which usually are warranted by their respective manufacturers) nor with respect to any unit which

after sale by HOME LITE has been altered m any way without HOME LITE'S express consent.Our obligation under

this warranty is limited to replacing, without charge any part which is proven defective within one year {30 days

if the unit IS used for commercial, rental or municipal purposes) from date of purchase, if returned to us. with

transportation charges prepaid, at a HOMELITE branch office or to a dealer whom we have authorized to make

the replacement.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES. EXPRESS OR IMPLIED, OF MERCHANT

ABILITY. FITNESS FOR A PARTICULAR PURPOSE. PERFORMANCE OR OTHERWISE AND IN NO EVENT

SHALL HOMELITE BE LIABLE FOR ANY INCIDENTAL. SPECIAL OR CONSEQUENTIAL DAMAGES.

HOIVIELITE

a division ot Teitron Inc.

TINE WARRANTY

HOMELITE warrants rotary tiller tines against breakage for the period not to exceed

the normal life of the roUiry tiller; and will replace broken tines directly to the customer

at no diarge, [¡rovided broken tines are returned prepaid to the nearest HOMELITE

district office.

HOMELITE

a division of Teitron Inc

/ i/ I..’

ACCESSORIES

TINE EXTENSION SET (Mfg. NO. 1600407)

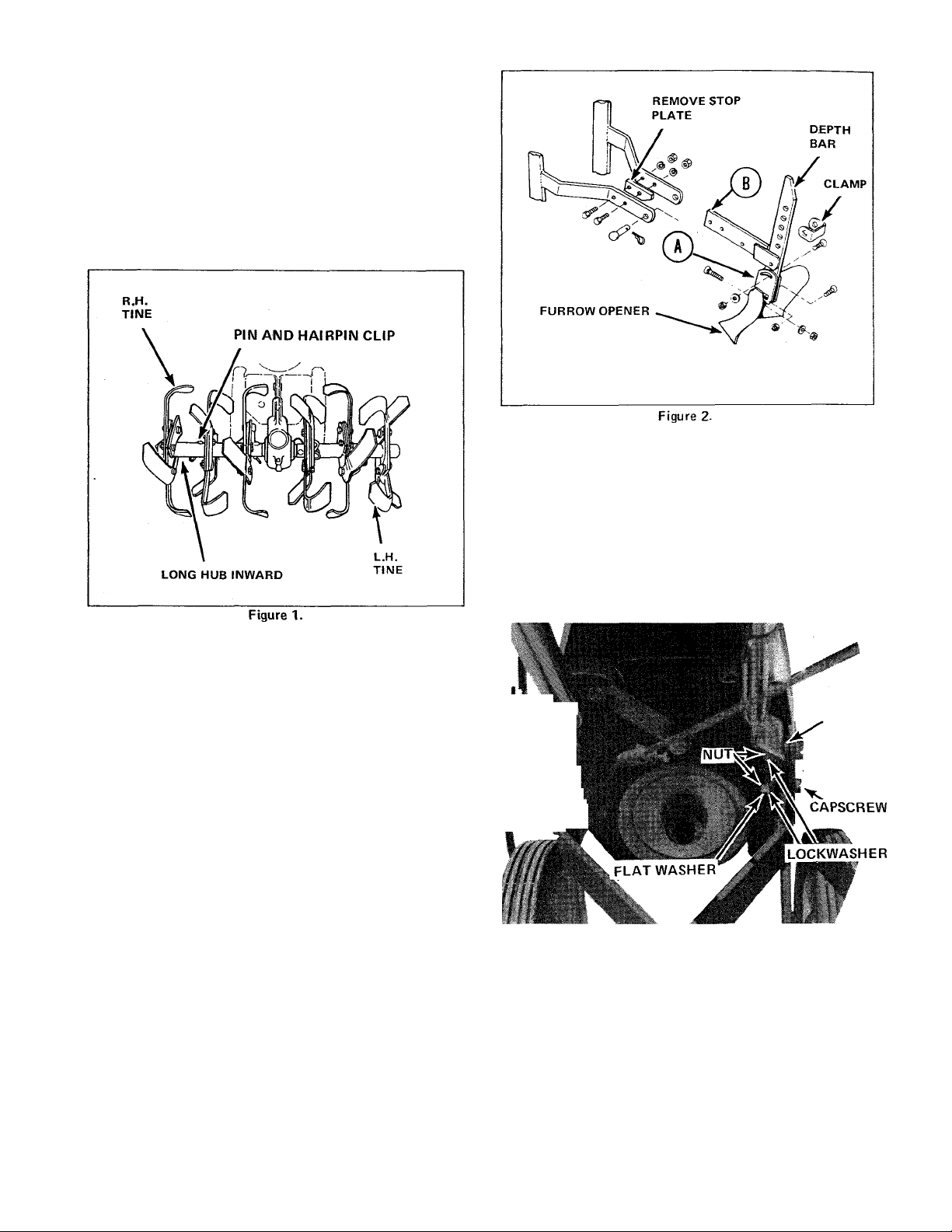

See Figure 1. The extension set consists of a left and right

tine assemblies with mounting pins and hairpin clips. Mount

long hub of extension over outside end of standard tine as

sembly and secure assemblies together with pin and hairpin

clip. Be sure sharpened edges of tines on top face forward.

The extension set increases effective tilling width to 31-1/4-

inches.

ASSEMBLING

1. Remove all components of tiller from box and place

them in a clean, level area. Inspect each part for damage.

FURROW OPENER, 8-INCH (Mfg. No. 1600373)

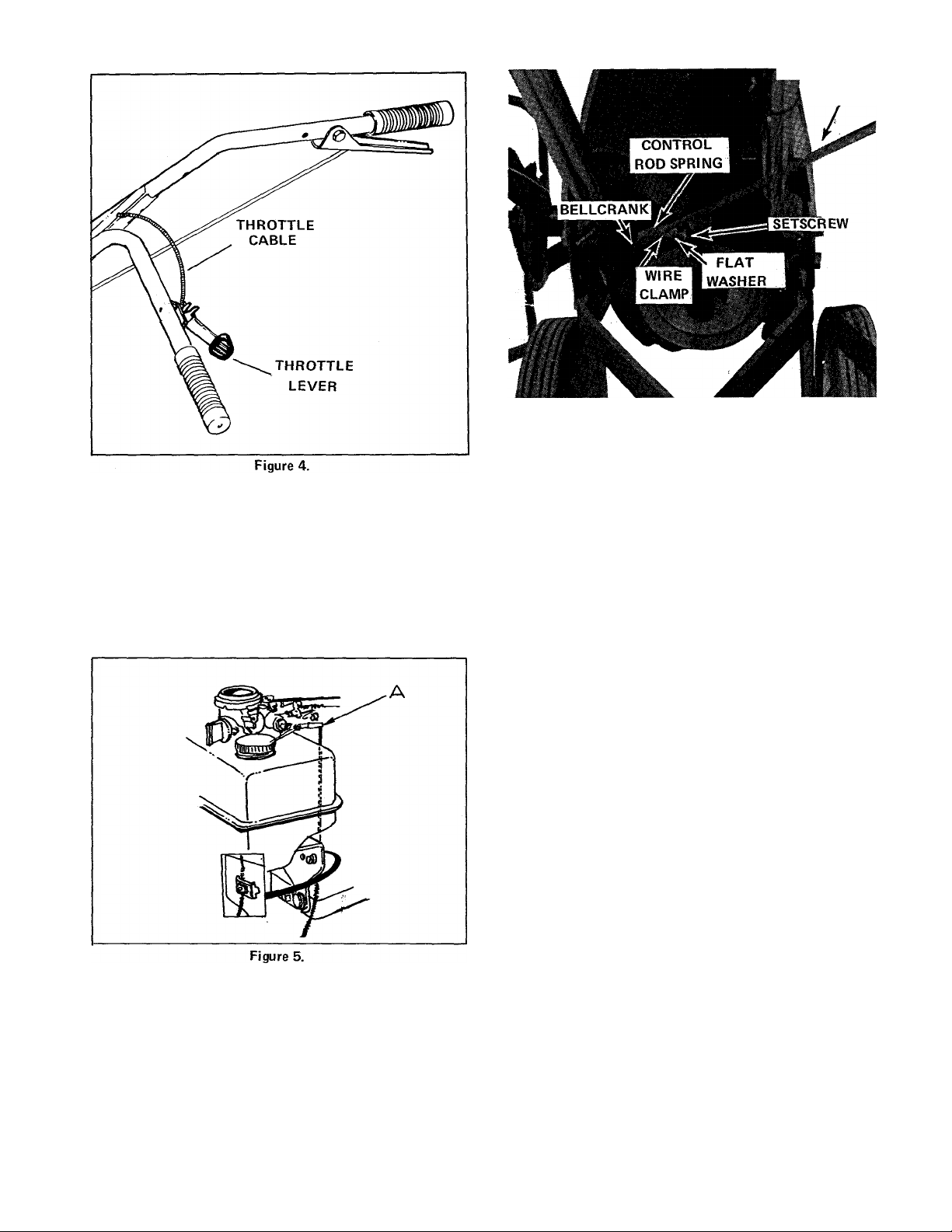

See Figure 2. The furrow opener is intended for digging

furrows for crops which must be planted in rows. To install,

proceed as follows.

1. Remove the depth bar, turn it upside down and bolt it to

the tool holder (A) with the carriage bolts, washers and nuts

provided.

2. Remove the stop plate from between the frame supports

and install the extension support (B) with the old hardware.

3. Position the depth bar in the extension support and re

install the depth bar clamp using the pin and spring clip pro

vided. Bolt the furrow opener to the tool holder as shown.

SPECIAL WORM GEAR OIL

2. Remove belt cover.

3. See Figure 3. Assemble left and right handles to frame

as shown. Note locations of flat washers.

FLAT

iV

VmLi. m.

Figure 3.

4. Connect throttle cable as follows:

WASHERS (2)

CAPSCREW,

WHIZ-LOCK

CAUTION

Damage to the worm gear drive which results from

use of any lubricant other than that specified will

invalidate the warranty. (See back cover for special

Worm Gear Oil Part Number).

a. Place throttle control lever in SLOW position.

TABLE OF CONTENTS

Page

WARRANTY ........................................................................................................................Inside Cover

SAFETY PRECAUTIONS ............................................................................................................... 1

ACCESSORIES ............................................................................................................................... 2

ASSEMBLING ................................................................................................................................. 2

OPERATION

ADJUSTMENTS .............................................................................................................................. 5

MAINTENANCE .............................................................................................................................. S

OFF-SEASON STORAGE .............................................................................................................. ^

TROUBLESHOOTING .................................................................................................................... 8

SPECIFICATIONS ........................................................................................................................... 9

...................................................................................................................................

4

PARTS LISTINGS

FRAME, HANDLES & WHEELS ....................................................................................................10

ENGINE PULLEY & CONTROL GROUP ......................................................................................11

DRIVE & TINE GROUP .................................................................................................................12

FURROW OPENER .......................................................................................................................13

TINE EXTENSION KIT .................................................................................................................. 13

DECAL LOCATION ........................................................................................................................14

CONGRATULATIONS!

This great new product is engineered with imagination and built with integrity to assure you maximum service and

performance for years to come. To completely understand the operation of your equipment and to take full advantage

of its many fine built-in features, study this instruction manual thoroughly before operating the machine. The little time you

spend reading now will repay you many times over in the time you save and the satisfaction you gain in using your equipment

properly and safely.

SAFETY PRECAUTIONS

Know the controls and how to stop quickly - READ THE

OPERATOR'S MANUAL.

Do not allow children to operate the Tiller. Do not allow

adults to operate it without proper instructions.

Clear the work area of objects which might be picked up and

thrown.

Keep all nuts, bolts and screws tight to be sure equipment is

in safe working condition.

Do not operate equipment when barefoot or wearing open

sandals. Always wear substantial footwear.

Handle gasoline with care - it is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running or hot

engine or fill the fuel tank indoors. Wipe up spilled

gasoline.

C. Open doors if the engine is run in a garage. Exhaust

fumes are dangerous. Do not run engine indoors.

Never store equipment with gasoline in the tank inside a

building where fumes may reach an open flame or spark.

Allow the engine to cool before storing in any enclosure.

To reduce fire hazard keep the engine free of grass, leaves or

excessive grease.

Release the clutch lever and stop the engine before cleaning

the tines, removing obstacles, making adjustments, or when

leaving the operating position.

Never allow children or pets to cross your path, or cause dis

tractions in the area while operating.

b. Be sure throttle control cable is secured along right

handle with a cable clip.

c. See Figure 5. Route cable under right side of belt

cover, along right side of engine, and up between fuel

tank bracket and starter. Install control wire on throttle

control lever (A).Throttle control lever must be down and

the governor spring relaxed.

d. Loosen clamp screw on fuel tank bracket and install

throttle cable in clamp. Tighten clamp screw.

■ S CONTROL

ROD

Figure 6.

c See Figure 6. Adjust spring tension by loosening

clamp setscrew and moving clamp on control rod. Idler

pulley should be 1/4-inch from frame when clutch dis

engaged (handle released). See Adjustments section of

this manual for clutch adjustment procedure.

d. Secure belt cover to frame with two self-tapping

screws. Tighten two whiz-lock screws attaching part of

handles.

6. Install wheel assemblies as follows;

a. Tilt unit forward on engine.

b. See Figure 7. Secure each wheel assembly (bushing

inward) to frame through lower holes in frame support

with a 3-1/2-inch long capscrew, a lockwasher, and hex

nut. Tighten hex nut.

5. Install forward control rod as follows:

a. See Figure 6. Attach forward control rod springs to

bellcrank.

b. See Figure 6. Slide forward control rod through wire

clamp and inside spring. Loosely secure rod in clamp

with setscrew and flat washer. Hook loose end of spring

between flat washer and clamp.

Figure 7.

7. See Figure 7. Secure depth bar and clamp to rear of

frame with pin and hairpin clip. Digging tip of bar should be

installed as shown.

NOTE: The depth bar setting determines the depth of

tilling. To till 4 to 6 inches deep, install bar mounting pin

in second or third hole from the top. The deeper depth bar

is set into soil, the deeper tines will dig.

8. Loosen each wheel scraper nut and adjust scraper to clear

wheel by 1/8-inch. Tighten scraper nut.

9. Depending upon what tilling width desired, install right

and left tine blade assemblies as follows. Use a pin and

cotter pin for installation. See Figure 8 for right inner,

outer, and extension tine installation.

TILLING WIDTH

INCHES

TINES USED

WARNING

Gasoline is highly inflammable. Avoid overfilling and

wipe up any spilled fuel. Allow no open flame,

smoking, or matches near the area when refueling.

Replace filler cap securely. Store gasoline only in small

quantities. Prolonged storage produces gum and harmful

deposits. If it is necessary to store gasoline for long periods,

add a gasoline stabilizer. See Off-Season Storage section of

this manual.

8-1/2

12

16

** 21-1/2

31-1/4

"denotes moving normal left or right blade assembly to op

posite side. Be sure sharpened'edges face forward.

""denotes standard tine arrangement.

"switched left and right inner

left and right inner

left and right inner

"switched left and right outer

left and right inner

left and right outer

left and right inner

left and right outer

left and right extension

Figure 8.

OPERATION

PREPARING

1. Controls

Figure 9.

c. OIL. See Figure 10. Have available sufficient quan

tities of engine crankcase oil, SAE 30 grade MS. Remove

dirt around engine filler plug. Remove engine filler plug

by turning counter-clockwise. Fill with oil until level

with top of neck. Crankcase capacity is 1-1/4 pints.

Reinstall filler plug securely. Check oil everytime fuel is

added.

See Figure 4. Familiarize yourself with the following

controls:

a. THROTTLE LEVER. Used to adjust engine speed.

b. FORWARD CLUTCH LEVER. Used to control

rotation of tines. Squeeze lever to engage and release

to disengage.

2. Engine

a. MANUALS. Read the engine owner's manual and

this operator's manual thoroughly.

b. FUEL. See Figure 9. Have available sufficient quan

tities of clean, fresh (leaded or non-leaded), "regular"

automotive gasoline. Remove fuel tank cap and fill

tank completely. Fuel capacity is 2 quarts. DO NOT

MIX OIL WITH GASOLINE.

OIL FILLER

PLUG

OIL DRAIN

PLUG

Figure 10.

3. Depth Ваг

See Adjustments section of this manual.

d. A Furrow Opener blade is available for use in digging

furrows for crops which are planted in rows, such as po

tatoes. See Accessories section of this manual.

4. Wheels

See Figure 7. Be sure wheels are mounted in the LOWER

holes of the frame support.

5. Tines

Be sure tines are installed securely with pin and cotter pin.

Sharpened edges must face forward. See Assembly section

of this manual for tine installation.

OPERATION

1. Starting

a. See Figure 4. Move throttle lever halfway between

SLOW and FAST position.

b. See Figure 11. Move stop switch away from spark plug.

c. See Figure 11. Pull choke plunger out to full CFIOKE

position. If engine warm, use half choke.

c. To start engine, grasp starter grip (See Figure 9) firm

ly in right hand and pull sharply straight out. Always

return grip by hand to original position. Do not release

grip with rope extended. When engine starts, push choke

plunger in gradually until it is firmly seated in carburetor

throat.

e. If engine fails to start after four or five pulls, it may

be flooded. Push choke plunger in completely and pull

grip out several times to clear excess fuel.

f. See Figure 11. If engine still fails to start, check fuel

supply and spark plug connections. Be sure engine stop

switch is away from spark plug.

2. Operating

a. When operating the tiller for the first time, proceed

slowly and carefully to get the feel of the unit. Experi

ence will determine pressure and depth bar setting for the

operator.

b. Do not attempt to hold tiller back to cause the tines to

dig deeper. Instead, adjust the depth bar so it will hold

the tiller back. When the tines have dug deep enough in

an area, raise UP slightly on handles and the tiller will

move ahead. To stop the forward motion of the tiller

and cause the tines to raise, put a slight DOWN pressure

on the handles and the depth bar will hold the tiller in

place.

c. Do not till when the soil is very wet. This causes clods,

which are difficult to work up. If the soil is extremely

hard and dry, it may be desirable to cross till an area at

shallow depth first, then till in the direction of planting

rows on the second pass at the final depth.

3. Stopping

a. See Figure 11. Push stop switch against end of spark

plug.

b. If tiller has been operating under full load, allow en

gine to idle for a minute to reduce engine temperature.

Stopping a hot engine suddenly may cause damage to en

gine parts.

STOP ^PLUG

SWITCH

SPARK

CHOKE

PLUNGER

PULL OUT!

TO CHOKE*’

Figure 11.

ADJUSTMENTS

BELT STOPS

Belt stops should be 1/8-inch from belt when clutch engaged

(handle compressed). To adjust, remove belt cover, loosen

stop capscrew, squeeze clutch lever and adjust belt stops as

indicated in Figure 12. Tighten belt stop capscrew and re

place cover.

NOTE: If tines will not stop turning after clutch lever is

released, belt stops may be too far from belt and not braking

belt as required when clutch handle released.

1/8-INCH —

CLEARANCE

ENGINE

PULLEY"

IDLER

PULLEY

DRIVEN

PULLEY

Figure 12.

BELT

STOP

CAPSCREW

1/8-INCH

CLEARNACE

5

CLUTCH

FIRST 5 HOURS OF OPERATION

1. When clutch disengaged (handle released), idler pulley

should be no closer than 1/4-inch from frame and all belt

stops must be firmly gripping the drive belt.

2. When clutch engaged (handle compressed), idler pulley

must press in on belt enough to remove belt from contact

with belt stops. Approximately 1/8-inch clearance between

belt stop and belt should be maintained (See Belt Stop

Adjustment).

3. See Figure 6. If clutch does not operate as described

above in steps 1 and 2, loosen wire clamp setscrew and adjust

wire clamp on control rod to obtain required spring tension.

DEPTH BAR

See Figure 7. The depth bar setting determines the depth

of tilling. To till 4 to 6 inches deep, install the bar moun

ting pin in the second or third hole from the top. Pull out

the hairpin clip to change pin location. Be sure to install

the bar with the digging tip as shown. THE DEEPER

THE DEPTH BAR IS SET INTO THE SOIL, THE DEEP

ER THE TINES WILL DIG.

See Figure 10. Change engine oil as follows:

a. Run engine for a few minutes to warm engine oil.

b. Remove oil drain plug and allow oil to completely

drain from engine.

c. Replace oil drain plug securely.

d. Remove dirt around engine oil filler plug.

e. Remove engine oil filler plug by turning counter

clockwise.

f. Fill with SAE 30 grade MS oil until level with top of

neck. Crankcase capacity is 1-1/4 pints.

g. Reinstall engine oil filler plug securely.

EVERY 5 HOURS OF OPERATION

See Figure 13. Check and add worm drive housing gear oil

as follows:

a. Remove worm gear housing oil filler plug.

CARBURETOR

Minor carburetor adjustments may be required to com

pensate for differences in fuel, temperature, altitude and

load. See your engine owners manual for adjustment pro

cedure.

PULLEY ALIGNMENT

See Figure 12. Visually check alignment of engine, idler,

and driven pulleys. Pulleys must be aligned as closely as

possible or belts will be stretched and worn excessively.

Loosen engine and/or driven pulley setscrews and align

pulleys. Tighten setscrews securely.

MAINTENANCE

Read the engine owner's manual thoroughly.

AFTER EACH USE

Grass, dirt, or chaff may clog engine cylinder head fins and

blower housing. Check for clogged condition and if neces

sary, remove blower housing and clean.

CAUTION

WORM GEAR HOUSING

OIL-FILLER PLUG

Figure 13.

CAUTION

There is a filter in a vent hole located at rear of worm

drive housing. Do not remove this filter for any

reason.

b. Oil level should be level with plug hole when tines

are resting on ground.

c. If oil is required, tip tiller back until handles rest on

ground. Add a small amount of special worm gear oil

through plug hole and slowly lower tiller until tines rest on

ground. Oil should be level with plug hole, if not, repeat

procedure. Do not overfill.

Continued operation with a clogged cooling system

causes severe overheating and possible engine damage.

CAUTION

EVERY 100 HOURS OF OPERATION

DAMAGE TO THE WORM GEAR DRIVE WHICH

RESULTS FROM USE OF ANY LUBRICANT OTH

ER THAN A SPECIAL WORM GEAR OIL WILL

AUTOMATICALLY INVALIDATE THE WARRAN

TY. (See back cover for Special Work Gear Oil Part

Number).

d. Tighten filler plug securely.

NOTE: The worm drive housing may become quite warm

while operating. This is completely normal and no harm

to gears will occur if the housing is kept filled as specified

with the special worm gear oil. .

EVERY 25 HOURS OF OPERATION

1. Change engine oil. Refer to change procedure in FIRST

5 HOURS OF OPERATION.

2. See Figure 14. Clean air cleaner and re-oil element. The

air cleaner normally need not be cleaned for a full season

unless tilling is done under extremely dusty conditions.

Clean every few hours under extremely dusty conditions.

Clean air cleaner as follows:

Clean and reset spark plug gap at 0.030 of an inch. Plug

should be cleaned by scraping or wire brushing and washing

with a commercial solvent or gasoline. Grease the plug

threads before re-installing.

CAUTION

DO NOT BLAST CLEAN PLUG.

LUBRICATION

See Figure 15. To reduce wear and assure free movement

of controls, apply light motor oil occasionally at points in

dicated. Be careful not to get oil on drive belts. Use only

small quantities of oil- Excess oil collects dirt and causes

extra wear. DO NOT OIL SELF-LUBRICATED WHEEL

BEARINGS.

a. Remove screw attaching air cleaner assembly to car

buretor.

b. Remove air cleaner assembly carefully from carburetor

so as to prevent dirt from entering carburetor.

c. Disassemble air cleaner assembly.

d. Wash foam element in kerosene or liquid detergent

and water to remove dirt.

e. Wrap foam in cloth and squeeze dry.

f. Saturate foam in engine oil. Squeeze to remove excess

oil.

g. Assemble parts and secure air cleaner assembly to

carburetor with screwr

To prevent rust, sand off and paint any parts or areas which

become chipped or damaged. Tighten all bolts, capscrews,

nuts, and fasteners securely.

OFF-SEASON STORAGE

If tiller is to be stored over 30 days proceed as follows:

1. Clean fuel screen and bowl. See Maintenance section of

this manual.

2. Drain fuel tank and lines by placing suitable container

under fuel shut-off valve and opening valve. Store gasoline

in container using a gasoline stabilizer or additive. This

additive prevents formation of gum and varnish for up to

one year.

3. Operate engine until gasoline in carburetor is completely

consumed.

4. While engine is still warm, drain oil from crankcase. See

Maintenance section of this manual. Refill with fresh oil.

5. Remove spark plug, pour one ounce (2 or 3 tablespoons)

of SAE 30 oil into cylinder and crank slowly to distribute

oil. Replace spark plug.

6. Clean dirt and chaff from cylinder head fins and blower

housing.

4. See Figure 11. Choke plunger is not pulled out to full

CHOKE position or, if engine appears flooded, pushed

in, to clear excess fuel. To clear a flooded engine, push

choke plunger completely in and pull starter rope several

times.

IF BELT SLIPPAGE OCCURS

1. Belt may be stretched or worn excessively. Replace belt.

TROUBLESHOOTING

IF ENGINE FAILS TO START

1. See Figure 9. Fuel tank may be empty.

2. See Figure 4. Throttle lever is not set halfway between

SLOW and FAST position.

3. Spark plug is not securely connected.

2. Belt may be greasy or oily. If so, use cleaning fluid on a

rag to clean.

3. Pulleys may be misaligned. Refer to Pulley Adjustment

in Adjustments section of this manual.

4. Belt tension may be too loose. Refer to Clutch in

Adjustments section of this manual.

SPECIFICATIONS

ENGINE

TRANSMISSION

TINES

DEPTH

BAR

CONTROLS

CHASSIS

OVERALL

DIMENSIONS

MAKE:

BRIGGS &

STRATTON

STARTER

CHOKE Manual

GOVERNOR

IGNITION

LUBRICATION

FUEL CAPACITY 2 Ouarts

AIR CLEANER Sealed Joint Housing, Reusable Oiled Foam Element

MUFFLER Quiet, Low Back Pressure Type, Side Discharge

TYPE

MATERIAL

BEARINGS

SEALS

LUBRICATION

HOUSING

CLUTCH

TYPE Self-sharpening, non-winding

MATERIAL

TILLING WIDTH 21-1/2 In. Standard, 31-1/4 In. with Tine Extensions

TILLING DEPTH

ATTACHMENTS

DRIVE

SPEED

ATTACHMENT Pin and Hairpin Clip

ADJUSTMENT

LOCATION

FRAME

TIRES

WHEEL BEARINGS

LENGTH

WIDTH

HEIGHT

WEIGHT

■ MODEL NO: 80200 ■ STROKE: 1-3/4 Inches

■ CYCLES: 4 ■ DISPLACEMENT: 7.75 Cu. In.

■ CYLINDERS; 1 ■ CRANKSHAFT

■ BORE: 2-3/8 Inches PLANE: Horizontal

TYPE NO.: 0252-01 _

Manual Rewind, easy spin

Adjustable Mechanical, 1800 - 4000 RPM

Magneto

Gear Impeller System - 40% Slope Operation

CRANKCASE CAPACITY: 1-1/4 Pints

Worm and Gear

WORM: Carburized Steel

GEAR: Bronze

FRONT: Tapered Roller Bearing

REAR: Tapered Roller Bearing

DOUBLE LIP: Dirt Excluding

Special Worm Gear Oil (See back cover).

Cast Iron

Touch-O-Matic V-Belt

Forged, High-Carbon Steel

0 to 7 Inches, Adjustable

TO HUB: Bolted

TO SHAFT: Pin and Cotter Pin

INNER: Pin Type Floating Drive

OUTER: Pin and Torsion Plate Floatinq\Drive

75 RPM at Full Engine Speed

0 to 7 Inches Tilling Depth

FORWARD CLUTCH: Right Handle, Top

THROTTLE: Left Handle

REWIND STARTER AND CHOKE: On Engine

Heavy-Duty, Electrically Welded with Cross-Bracing

8x1.75 Solid Rubber

Solid, Sintered Iron

51 Inches

26 Inches (Without Tine Extensions)

TO TOP OF HANDLE; 38-1/4 Inches

TO TOP OF ENGINE: 27-3/4 Inches

NET (DRY); 113 Lbs.

SHIPPING (DRY): 123 Lbs.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

3H.P. TILLER

ENGINE PULLEY & CONTROL GROUP

Ref.

No. Part No. Qty. Description

1

2

3

4

5

6

7

8 118027

9

10

11

12

118464 1

919354

917642

917356

917372

118463 6 SHIM

118470

905850

928691

118312

154534

4 CAPSCREW, Hex, 5/16

8 WASHER, Flat, 5/16

4 LOCKWASHER, 5/16

4

1 PULLEY, Driven

1

1

1

1

1 PULLEY, Idler

ENGINE

18x 2

NUT, Hex, 5/16-18

PULLEY, Engine

KEY, Square

SETSCREW, Cup

BELT, "V"

Ref.

No.

13

14

15 921971 1

16 916965 1 LOCKWASHER, 3/8

17

18 1609352 1

19

20 923362 1 LOCKNUT. Hex, 5/16

21 106545 1

22 118037 1

23

24

Part No.

118335 1

917642 1

916950

171337

909589

921370

Qty. Description

SPACER

WASHER. Flat, 5/16

CAPSCREW. Hex, 3/8-

16 X 1-3/4

1 NUT, Hex, 3/8

LEVER, Idler pulley

1 BOLT, Pivot

STOP, Belt

STOP, Beit

1

1 CAPSCREW, Hex, 1/2-

LOCKWASHER, 1/2

20 X 1

11

3H.P. TILLER

Ref.

No.

1

2

3

4

5

6

7

8 911171

9

10

n

12

13

14

15

16

17

18

19

20

21

22*

22*

23

Worm Drive Assy.

* Selective fit due

Part No.

118400

118393

118396 2

154393

154486

170888 1

118439 1

118399 1

118392

118462 1

901653 1

118492

118398

154487

118021 1

118403

118118

118020

118315

118022

170885

171762

118024

Qty.

1

1

2

2

1

1

1

1

1

2

2

2

2

1

1

1

1

consists of Ref. IMos. 1 through 27.

to machining of components^

Description

SHIELD

SEAL, Oil

RING, Retaining

CUP, Bearing

CONE, Bearing

SHAFT, Worm

KEY

KEY, 3/16x7/8

CUP

HOUSING, Worm drive

PLUG, Vent

PIPE, Plug 3/8

WORM, R.H.

SPACER

CAP, Hub

SHAFT, Worm gear

SHIELD

SEAL, Oil

BEARING, Needle

WASHER, Thrust

GEAR, Worm R.H.

RING, Backing

RING, Backing

GASKET

Ref.

No. Part No.

24 118402

25

26

27

28

29 8152001

30

31 920488 32

32

33

34

35 1609339

36

37

38

39 918451

921959

916964

930246

1609337

8152002

928867 32

1609332 2

1609338

1609334

1609340

118053 4

12

Qty. Description

1

4

4

1

COVER

CAPSCREW, Hex hd., 1/4-

20 N.C. X 5/8

LOCKWASHER, 1/4

1, KEY, Woodruff,474 x

3/4

BLADE ASSY., L.H. Inner,

Tine

8

8

1

1

2

1

BLADE, L.H. Tine

BLADE, R.H. Tine

CAPSCREW, Hex, 7/16,

20 X 1-1/4

NUT, full hex, 7/16-20

PLATE ASSY., inner tine

BLADE ASSEMBLY,

R.H. Inner Tine

BLADE ASSEMBLY, L.H.,

Tine, Outer

PLATE ASSY., Tine,

Extension Outer

BLADE ASSEMBLY, R.H.,

Tine Outer

PIN

PIN, Cotter, 1/8 X 3/4

4

Ref.

No. Part No.

3H.P. TILLER

MFG. NO. 1600373

FURROW OPENER

Qty. Description

1

2

3

4

5

6

7

8

8271503 1 TOOL HOLDER ASSY.

118287 1

103010 1

922109

917378 1

916950

118053 1 PIN

918196

2 BOLT, 3/8-16 X 1-1/4

2 NUT, Hex, 3/8

1

SUPPORT ASSEMBLY

OPENER, Furrow, 8-Inch

WASHER, Flat, 3/8

CLIP, Hairpin

3 H.P. TILLER

MFG. NO. 1600407

TINE EXTENSION KIT

Ref.

No.

Part No. Qty.

Description

1

2

3

4

5

6

7

8

9

1609339 1 BLADE ASSY., Tine left

1609334 2

1609340 1 BLADE ASSY., Tine right

118053

918196 2 CLIP, Hairpin

8152001

8152002

920488

928867

2

4

4

8 CAPSCREW, hex, 7/16-20 x 1-1/4

8 LOCKNUT, hex, 7/16-20

HUB & PLATE ASSY.

PIN

BLADE, Tine, left

BLADE, Tine, right

13

LIMITED WARRANTY

New SIMPLICITY products sold by Simplicity Manufacturing Company are warranted by Allis-Chalmers

Corporation (the Company) to be merchantable and free of defects in workmanship and material at the

time of shipment from the Company’s factory. THERE ARE NO WARRANTIES WHICH EXTEND

BEYOND THOSE EXPRESSLY STATED HEREIN.

No warranty of any kind, statutory, implied or otherwise, is made or shall be imposed upon the Com

pany with respect to (1) new products which have been subject to operation in excess of recommended

capacities, misuse, negligence, or accident, or have been altered or repaired in any manner not authorized

by the Company, or (2) tires, engines, generators, voltage regulators or accessories that are warranted

separately by their respective manufacturers except that the Company agrees to make available to the

first user whatever warranty benefits may be made available to the Company by such manufacturer.

The Company will repair or replace, without charge, any part which under normal use and service fails

to conform to this warranty, provided that such parts shall be returned to the Company’s authorized

Dealer, transportation charges prepaid, within 12 months from the date of delivery of such new

product to the first user.

Parts installed by an authorized Dealer, including parts furnished under this warranty, are warranted to

be free from defects in workmanship and material for a period of 90 days from the date of installation of

such parts or to the expiration of the original warranty, whichever is later. The Company will repair

or replace, without charge, any part not conforming to this warranty.

THE COMPANY’S LIABILITY ARISING OUT OF WARRANTIES, REPRESENTATIONS, INSTRUC

TIONS, OR DEFECTS FROM ANY CAUSE, SHALL BE LIMITED EXCLUSIVELY TO REPAIR OR

REPLACING PARTS UNDER THE CONDITIONS AS AFORESAID, AND IN NO EVENT WILL THE

COMPANY BE LIABLE FOR CONSEQUENTIAL DAMAGES.

Service under the terms of this warranty must be obtained at an authorized Simplicity Dealer.

Rotary tiller tines are warranted against breakage for the normal life of the rotary tiller. Simply return

any broken tine to an authorized Simplicity Dealer, and the broken tine will be replaced at no charge.

Loading...

Loading...