Page 1

HOMELITE

RE-8E

•ip<^-'

® -’ v-'C. .

°'P<¿

py-!,--' «

^t.‘r>

;e.i

4^®

^"- ^4^v, S^~-"

“•/,*>

■* a

RE-8E, 8 H.P., SHUTTLE, ELECTRIC, W/30" MOWER, MFC. NO. 1690059

TRACTOR, 8 H.P., SHUTTLE MFC. NO. 1690058

Rotary Mower, 30-Inch, Mfg. No. 1651030

Grass Catcher, Rear Mounted, Mfg. No. 1600383

Counterweight, Mfg. No. 1600351

®-í?a»

’4'-

•fi'}’ •• 's'

at*,,.».«?» “

il'C-'"'' «

'y.r Ji.'J ' fl I'-'-

'A ^ 0^ s*

'^.•'«‘4^.- 8.'V

O f.ifl .1 .

W’»»' . ^ . Í

f,. S. *

,v f . •»

* •=“

■’i- ‘

Hv^’f 5 ^

-^¿>»•««1°«*®..®-«^' ¡I ..*»

»J* « 'is- » b'a«.í» "■ -

n‘<a^ ^ N

’.,®3

af=a9 — ;■ a'a'®'» «■.•'»••,;•.

‘=6‘*'=*i Ac'' ®

-I ^

FORM - 1651660

PRINTED IN U.S.A.

749

Page 2

SAFETY PRECAUTIONS TO PROTECT YOURSELF AND OTHERS

IMPORTANT

OPERATION

Know the controls and how to stop quickly. READ THE

OPERATOR'S MANUAL.

Do not allow children to operate vehicle. Do not allow adults

to operate it without proper instruction.

Do not carry passengers. KEEP CHILDREN AND PETS A

SAFE DISTANCE AWAY.

Clear work area of objects which might be picked up and

thrown.

Take all possible precautions when leaving vehicle unat

tended; such as disengaging power-take-off, lowering attach

ments, shifting into neutral, setting parking brake, stopping

engine and removing key.

Do not stop or start suddenly when going uphill or down

hill. Mow up and down the face of steep slopes; never across

the face.

Reduce speed on slopes and in sharp turns to prevent tipping

or loss of control. Exercise extreme caution when changing

direction on slopes.

Stay alert for holes in terrain and other hidden hazards.

Use care when pulling loads or using heavy equipment.

A. Use only approved drawbar hitch points.

B. Limit loads to those you can safely control.

C. Do not turn sharply. Use care when backing.

D. Use counterweight (s) or wheel weights when sug

gested in operator's manual.

Watch for traffic when crossing or near roadways.

Keep all nuts, bolts, and screws tight to be sure equipment

is in safe working condition.

Do not change engine governor settings or overspeed engine.

Do not operate equipment when barefoot or wearing open

sandals. Always wear substantial footwear.

FUEL AND FIRE HAZARDS

Handle gasoline with care - it is highly flammable.

A. Use approved gasoline container.

B. Never remove cap or add gasoline to a running or hot

engine or fill fuel tank indoors. Wipe up spilled gaso

line.

C. Open doors if engine is run in garage - exhaust fumes

aré dangerous. Do not run engine indoors.

Never store equipment with gasoline in the tank inside a

building where fumes may reach an open flame or spark.

Allow engine to cool before storing in any enclosure.

To reduce fire hazard keep engine free of grass, leaves or

excessive grease.

ATTACHMENTS

Disengage power to attachments and stop engine before

leaving operator position.

Disengage power to attachment (s) and stop engine before

making any repairs or adjustments.

Disengage power to attachments when transporting or not

in use.

When using any attachments never direct discharge of ma

terial toward bystanders or allow anyone near vehicle while

in operation.

Keep vehicle and attachments in good operating condition

and keep safety devices in place. Use guards as instructed in

operator's manual.

Vehicle and attachments should be stopped and inspected

for damage after striking a foreign object and the damage

should be repaired before restarting and operating the equip

ment.

When using vehicle with mower:

(1) Mow only in daylight or in good artificial light.

(2) Never make a cutting height adjustment while en

gine is running if operator must dismount to do so.

(3) Shut engine off when removing grass catcher and/or

unclogging chutes.

(4) Check blade mounting bolts for proper tightness at

frequent intervals.

Check grass catcher bags frequently for wear or deterioration.

Replace with new bags for safety protection.

Page 3

TABLE OF CONTENTS

Райе

SAFETY PRECAUTIONS ..........................................................................................Inside Cover

WARRANTY ..........................

ASSEMBLING ................................................................................................................................. 2

ACCESSORIES .................................................................................................................................. 2

OPERATION ....................................................................................................................................... 4

OPERATING ...................................................................................................................................... 6

ADJUSTMENTS

maintenance ....................................

OFF SEASON STORAGE

TROUBLESHOOTING ...................................................................................................................... 16

SPECIFICATIONS ....

PARTS LISTINGS

FRONT & REAR^TIRES ..............................................................................................................18

POWER TAKE OFF

FRONT FRAME & STEERING .................................................................................................. 20

TRANSMISSION & REAR AXLE _____________...........

CLUTCH & BRAKE

REAR FRAME SEAT &ENGINE

FILM & DECALS

ELECTRICAL STARTER ............................................................................................................ 28

; MOVVER HOUSING

MOWER CONTROL ................................................................................................................. 32

REAR MOUNTED GRASS CATCHER ........................................................................................34

.......................

..........

■■■■■••

........................................ . .

..

. .

...

.....................................................................................11

............

....................................................................................................15

.......

.....................................

...........

......................................................................................................... 19

...........

..................................... . . . . . . . . . .

.............

..........

........................................................................................ . .

.............

..........................................

......................................................................

.......................................................

. . ^ . . . .

................................................................................. 26

.......

..........................................

....

V . . . \ . . ............................ 30

..................................

.....................................

...

.............

1

7

\l

.22

24

27

WARRANTY

We warrant this HOMELITE product to be free from defects in material or workmanship under normal use and

service, except that we make no warranty, express or implied, with respect to tires, engines, generators or voltage

regulators (which usually are warranted by their respective manufacturers) nor.wjth respect to any unit which

after sale by HOMELITE hasbeen-altered in any way without HQMELITE'S express consent.Our obligation under

this warranty is limited to replacing, without charge any part which is proven defective within one year (30 days

if the unit is used for commercial, rental or municipal purposes) from date of purchase, if returned to us, with

transportation charges prepaid, at a HOMELITE branch office or to a dealer whom we have authorized to make

the replacement,

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, OF MERCHANT

ABILITY, FITNESS FOR A PARTICULAR PURPOSE, PERFORMANCE OR OTHERWISE AND IN NO EVENT

SHALL HOMELITE BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES.

HOMELITE

a division of Textron Inc.

Page 4

ASSEMBLING

The riding mower is shipped with mower attached to tractor.

Remove all shipping materials. The following preparation

is required:

REAR MOUNTED GRASS CATCHER

1. Place steering wheel on steering shaft and secure with

bolt and nut

NOTE

If rear mounted grass catcher is to be used with riding

mower avoid step number two (below). Deflector will

not be used with adapter.

2. Secure mower deflector to mower housing with bolts,

flat washers, lockwashers and nuts.

3. Using mower lift lever, raise mower.

4. Remove battery from mounting bracket. Fill each cell

with standard battery electrolyte to the level marks shown

on case. Charge' battery until specific gravity of electrolyte

is 1.260.

CAUTION

Use only a 12 volt charger at less than 1.5 ampere

charging rate. Any higher charging rate will damage

battery.

Place battery back on the mounting bracket with the ter

minals toward the center of tractor and secure in place

with rubber clamp.

If a rear mounted grass catcher is used, assemble and attach

it to vehicle as follows:

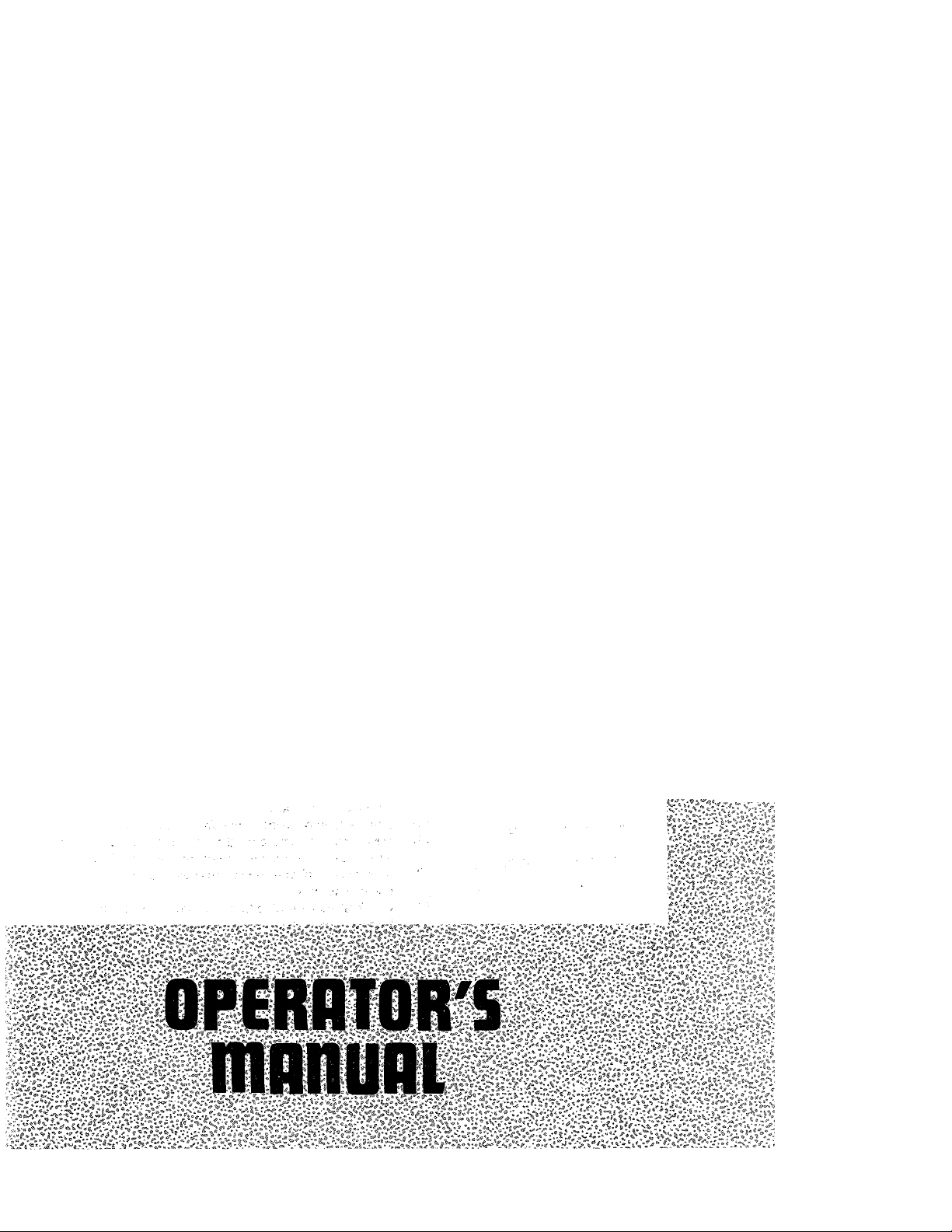

1. See Figure 1. Remove two 3/4-inch long carriage bolts,

flat washers, lockwashers, and nuts attaching deflector to

housing. Remove deflector from housing. Secure adapter

to housing with two 1-inch long carriage bolts (installed

from inside of adapter) and wing nut assemblies. Be sure

to replace discharge deflector, using wing nuts, whenever

adapter is removed.

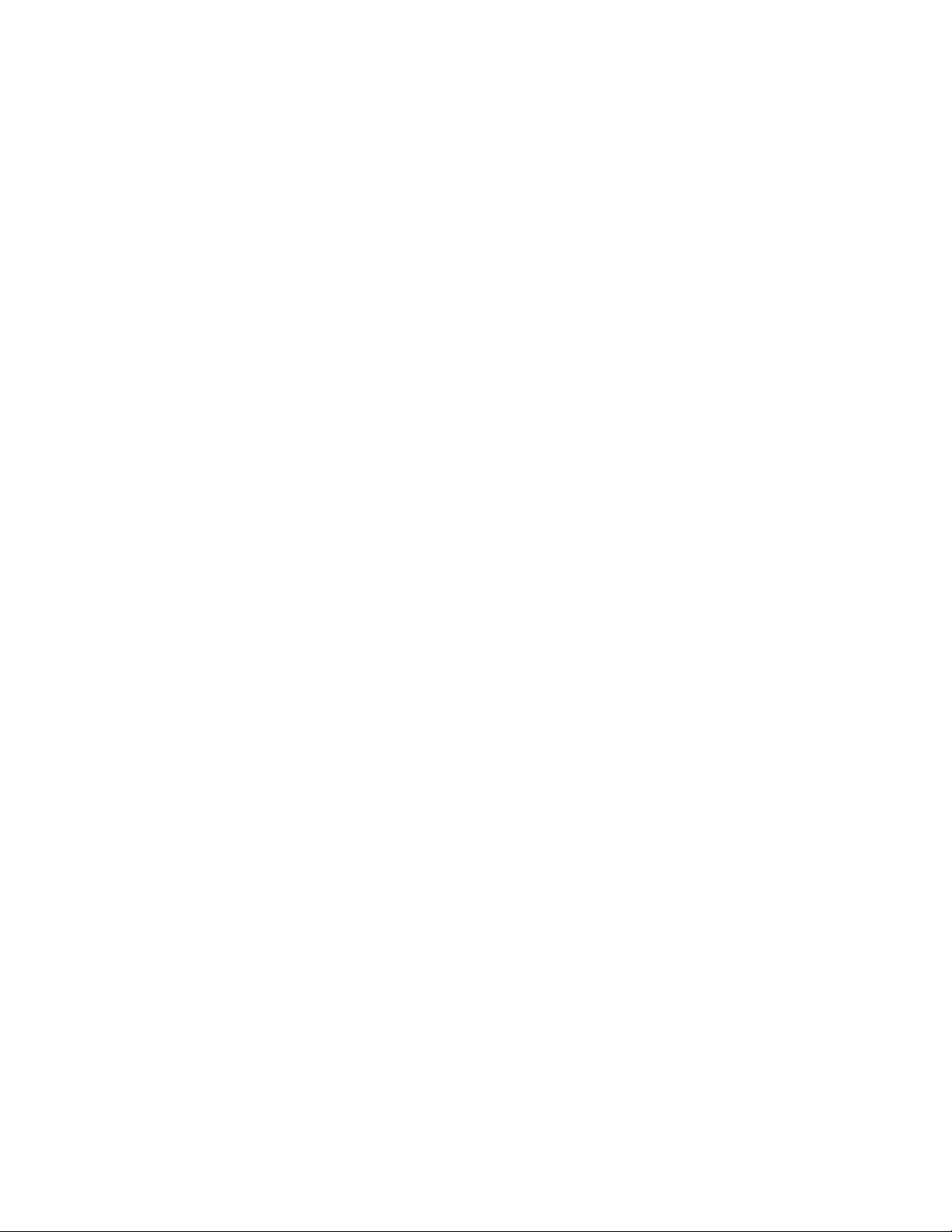

2. See Figure 2. Attach mower lift plates (bevel to inside

of housing) to mower blade with four capscrews and

locknuts.

ACCESSORIES

COUNTERWEIGHT

t. A: fronts cpu.rrterweighti, is recommended when using a

rear mounted grass catcher oh siopes of 15-30%. Mowing

slopes greater than 30% is not recommended.

2. See Figure A. Attach Counterweight assembly (1) with

two carriage bolts (2), lockwashers (3), and hex nuts (4).

Holes for weight are stamped in frame and are located under

rubber foot pads. After weight is installed, replace rubber

foot pads over the counterweight assembly.

Figure A

Figure 2.

Page 5

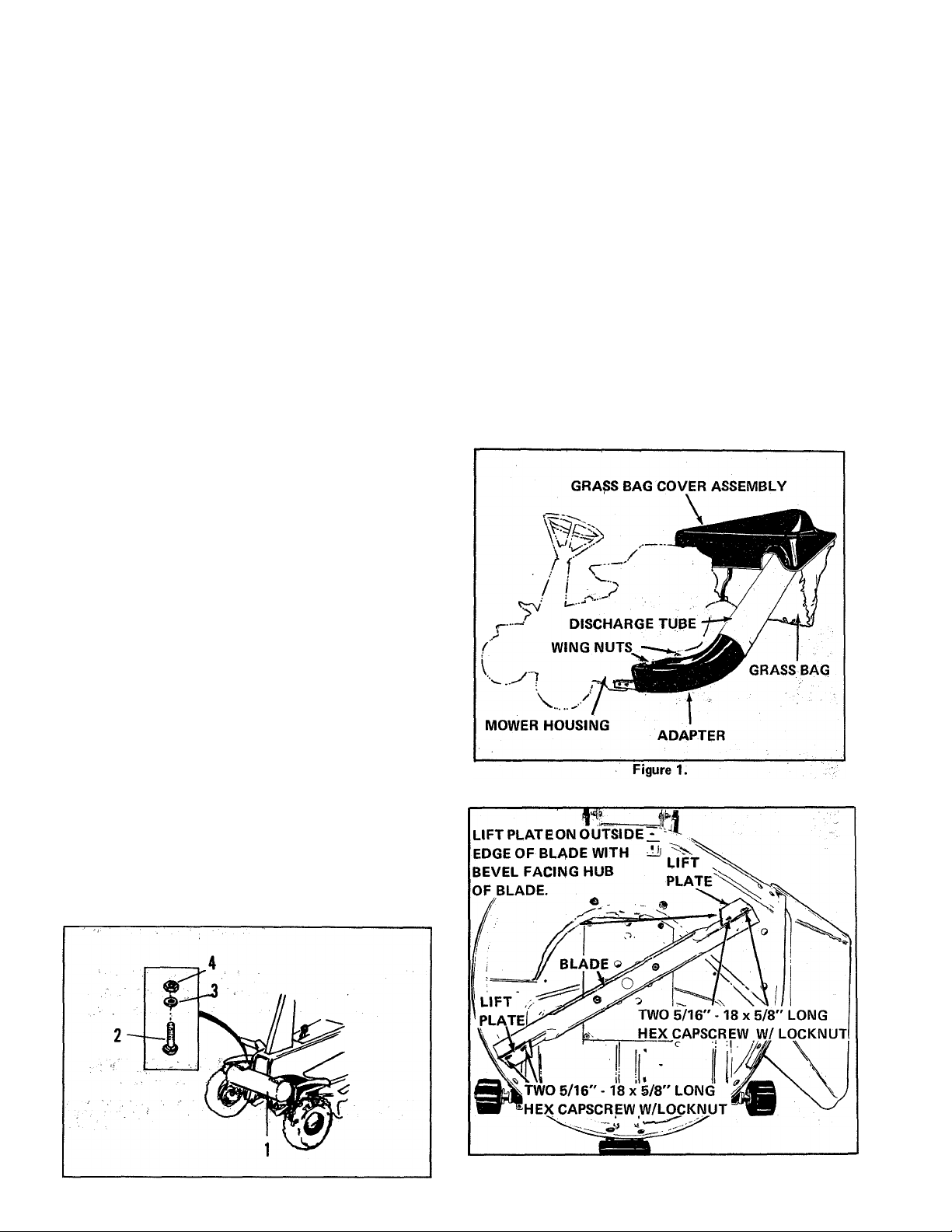

3. See Figure 3. Attach two vertical supports to rear of unit.

Holes are pre-starriped in tractor, frairie. Use two curved

head bolts, lockwashers, and nuts to fasten each vertical sup

port to unit.

5. See Figure 3. The grass bag tubular frame assembly, on

which the grass bag hangs, has two tubular supports welded

to its front side in position to fit over vertical supports. To

install bag on this frame, bag zipper must be completely

unzipped, allowing grass bag plastic top panel to unfold.

m

U

1

REAR GOVER

(OPEN)

Figure 3.

^^;iSe&9F.igure 4.- .^©'jEMschá^^^ is shipped as a flat

.plastic sheet. Roll it i%o a tube and hold in shape with

phillips-htead screws. InStaiFscrews from;inside with a flat

washer under head of screw. ; Place another fiat Washer bn

outside^of -tube followed.by a.lockwasher arid nut: install

discharge tube-on end of;, chapter as shown in Figure 1.

6. On front side of grass bag, opposite mesh panel, there

are two holes in plastic top panel. Insert two tubular sup

ports welded to grass bag frame down through these two

holes with cloth portion of bag toward inside of frame and

with plastic top panel on outside of frame.

7. Roll plastic top panel up and over frame tube and bring

two halves of zipper together on inside of frame. Connect

ends of zipper together at point "A". See Figure 4. Work

zipper handle counter-clockwise completely around frame.

8. See Figure 3. Install frame and bag assémbly in vertical

supports. Insert rear end of discharge tube in hole at left

front corner of grass bag. See Figure 4.

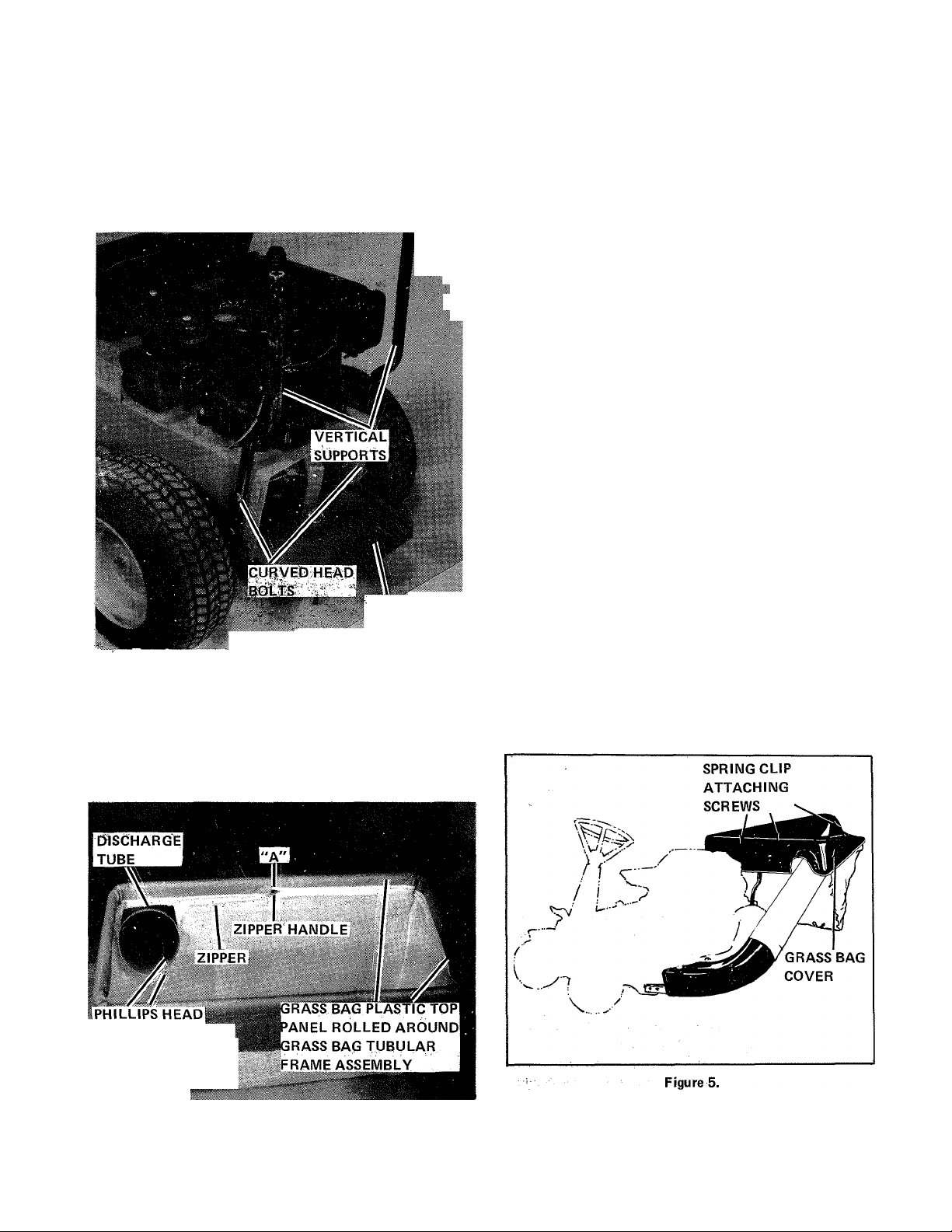

9. See Figure 5. To install grass bag cover, position it above

bag, align cutout on front side with discharge tube, and push

down firmly to snap spring clips over outside of bag frame,

and top panel.

WARNING

Before emptying grass bag, always stop tractor, dis

engage power take-off drive to mower, place trans

mission in neutral, apply parking brake, and stop

engine.

SCREWS

GRASSBAG '

MESH PANEL

Figure 4.

Page 6

10. To empty grass bag, pull up on cover to unsnap spring

clips and remove cover. Lift bag and frame straight up until

frame tubular supports come off of vertical supports. Turn

bag and frame over to dump grass clippings. Replace bag

tubular supports over vertical supports and lower in place,

slipping bag over discharge tube. Place grass bag cover over

bag frame and snap clips in place over bag frame.

NOTE: One front counterweight is recommended when

using grass catcher on slopes 15-30 percent. Mowing slopes

greater than 30% is not recommended.

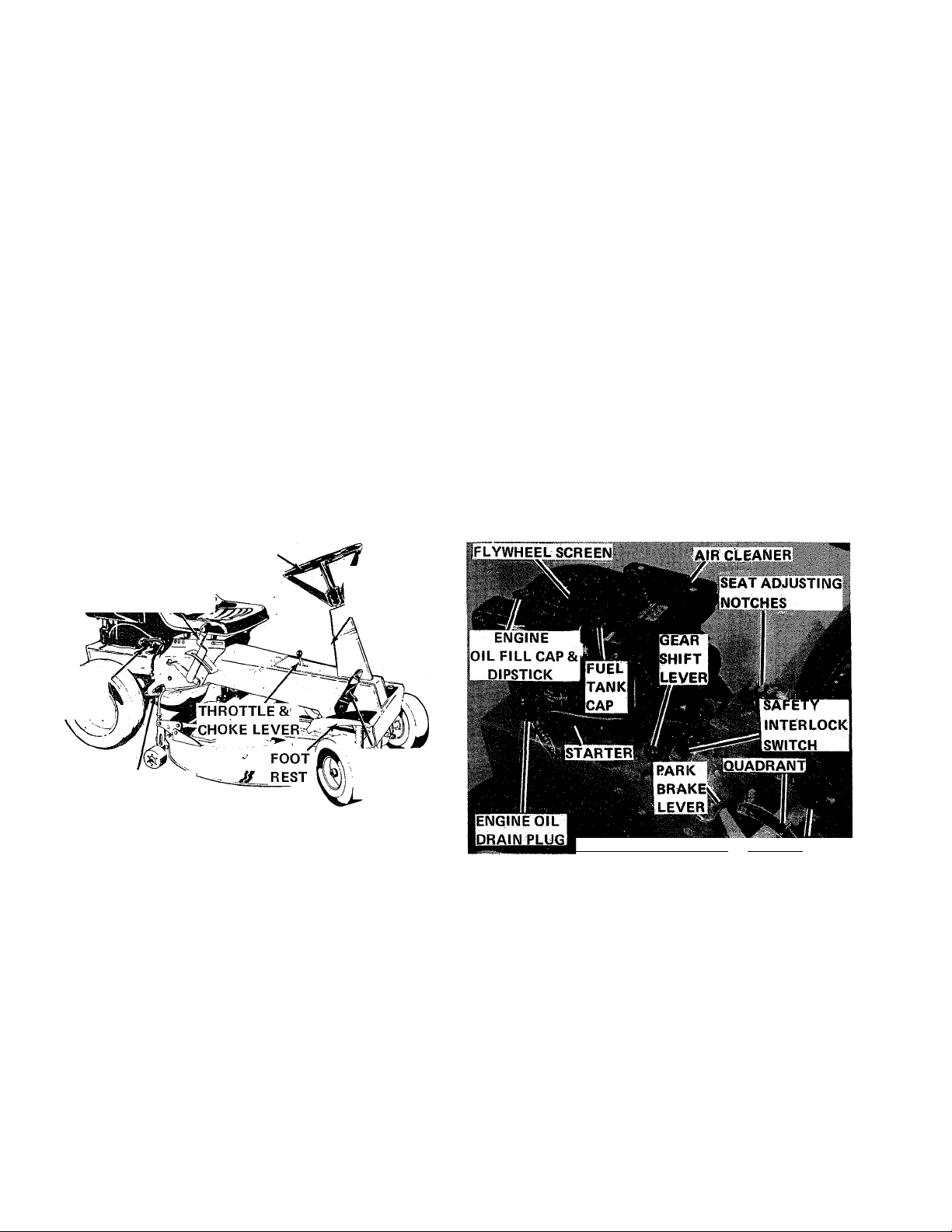

c. Gear Shift Lever

See Figure 6. Pulling up on gear shift lever places the trans

mission in low range. Pushing dovvn engages the high range

gearing. Shift lever must be placed in neutral midway be

tween high and low range to engage a safety interlock switch

to permit starting the engine (Figure 7|. To shift gears with

engine running, either the clutch-brake pedal must be fully

depressed, or the foryvard reverse contrbi lever must be

placed in neutral.

d. Forward-Reverse Control Lever

OPERATION

PREPARING

Controls

Before attempting to use the riding mower, acquaint your

self with all of the controls and how they operate.

STEERING

WHEEL

FORWARD-REVERSE i

CONTROL LEVER

GEAR ,

SHIFT

LEVER

MOWER HEIGHT

CONTROL CRANK

IGNITION

SWITCH &

KEY

CLUTCHBRAKE

PEDAL

See Figure 6. The forward-reverse control lever operates

the transmission shuttle clutch and perrriits starting and

stopping the tractor in either forward or reverse direction

without shifting gears or using the fbot clutch. The shuttle

clutch may be used for a short time to "inch" the tractor

forward or backward, and to start and stop motion smoothly.

IT MUST NOT be used as a speed change device. All con

tinuous operation MUST be done in either fully forward or

fully rearward position.

Figure 6.

a. Clutch Brake Pedal

See Figure 6. Pushing the clutch-brake pedal forward first,

loosens and disengages the transmission drive belts. Further

forward motion of the pedal applies the brakes.

b. Throttle and Choke Levet '’

See Figure 6. The throttle and choke lever controls the en

gine speed from idle to full speed. Moving the lever farther

forward past the "fast" position applies the choke for

starting the engine. As soon as engine starts the lever should

be pulled back to mid-range and engine allowed to warm up

a few minutes before applying a load. When operating at

full throttle be careful that the lever is not moved so far

forward that the choke is partially closed.

IFORWARD REVERSE CONTROL LEVER

Figure 7.

To operate in forward direction, select high or low gear

shift range. With engine running and clutch-brake pedal

fully up in engaged position, move forward-reverse control

lever smoothly, but firmly, forward and engage it in for

ward notch in quadrant. To stop, disengage lever from

forward notch and pull it smoothly, but firmly, to rear

arid place in neutral notch.

To operate in reverse for any appreciable distance, pull the

lever frorn neutral to the rear and of quadrant and hold

ifthere until you wish to stop rearward travel; at which time

it should be pushed forward to neutral notch. When oper

ating in reverse, the control lever will automatically be re

turned to neutral when clutch-brake pedal is depressed.

Page 7

e. Ignition Switch

ENGINE

See Figure 6. The ignition switch must be turned to the

"Start" position to actuate the starter. As soon as engine

starts; let go of key and it will automatically return to

"On". Turn key to "Off" to stop the engine,

f. Parking Brake Lever

See Figure 7. The parking brake lever, located under the

right side of the seat, is pushed down to engage brake. Brake

should be engaged when leaving the tractor unattended.

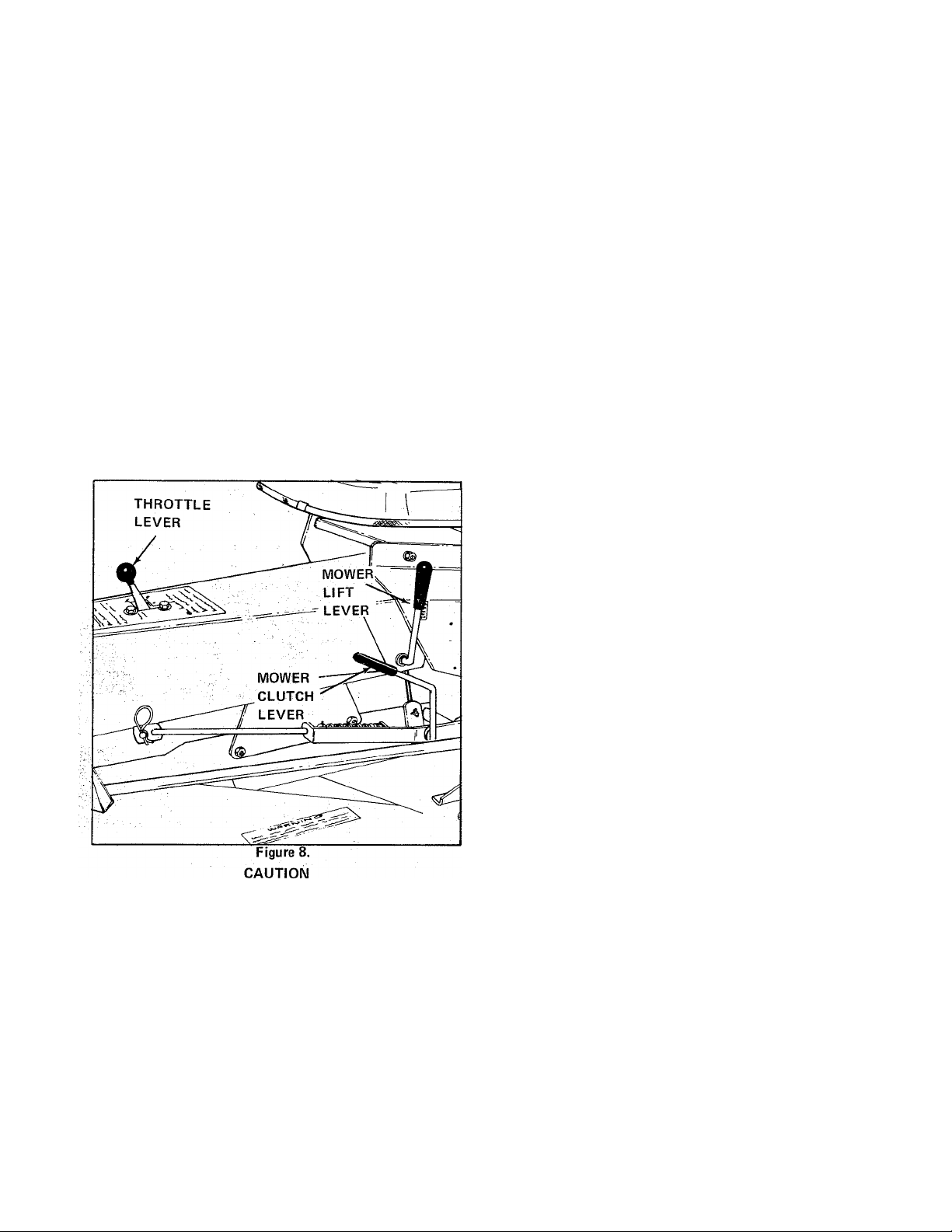

g. Mower P.T.O. Drive Clutch Lever

See Figure 8. The mower PTO drive is engaged by pushing

the mower drive clutch lever forward and down and is dis

engaged by pulling lever upward and back. A safety inter

lock switch requires that lever be in the disengaged position

to start engine.

CAUTION

Study the Safety Rules in this manual and follow all

of them when operating this riding mower.

a. Read the engine owner's manual thoroughly.

b. Check engine oil level, (Figure 7), and add oil as re

quired to maintain level up to full mark on dipstick.

NOTE: Use only a high quality detergent oil classified as

"SC", or "SD" or "MS". For summer operation, use SAE

30. If under 40 degrees, use .10W-30.

c. Fill the fuel tank (Figure 7) with a good grade of regular

gasoline. DO NOT use premium gasoline and DO NOT

mix oil with gasoline.

CAUTION

Gasoline is highly flammable. Avoid overfilling and

wipe up any spilled fuel. Allow no open flame,

smoking or matches near the area of refueling.

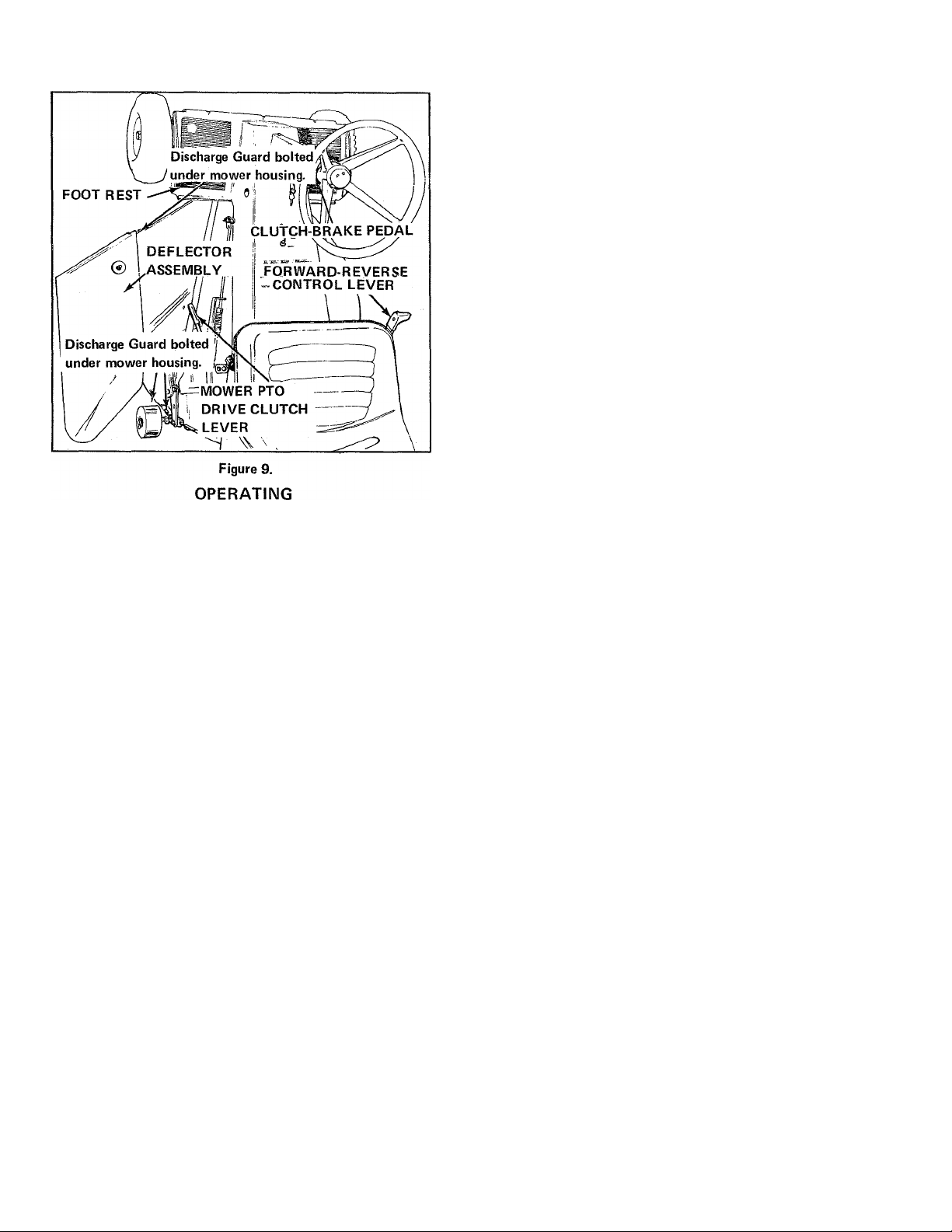

MOWER

Never leave the operators seat without disengaging

mower drive.

h. Mower Height Control Crank

See Figure 6. The cutting height of the; mower can be ad

justed from 1-1/2 to 3-1/2 inches by rotating the height con

trol crank. Turn clockwise to raise and counter-clockwise

to lower.

i. Mower Lift Lever

a. Be sure that you are familiar with the safety precautions,

controls and operating instructions given in this manual.

b. Check the mower carefully to be sure that it is properly

installed, leveled, and adjusted - (See Adjustments).

CAUTION

NEVER OPERATE THE MOWER unless the deflector

asserribly and discharge guard are securely bolted in

place, (See Figure 9).

c. Check the condition of mower blade. Keep it sharp and

in balance.

d. Clear the lawn of all sticks, stones, wire and other debris

which may be caught or thrown by the mower blade.

e. Determine the best method of mowing according to the

dimensions, terrain and obstructions of the lawn.

See Figure 8. Pull back to raise mower and push forward

and down to lower mower.

Page 8

STARTING (Figures 6, 7 and 8)

1. Place gear shift lever midway between "Hi" and "Lo".

Place forward-reverse control lever in the neutral notch in

quadrant and raise the mower PTO drive clutch lever to the

disengaged position to actuate the safety interlock switches.

2. Lock the parking brake.

3. Move the throttle lever forward into the "Choke" po

sition.

4. Turn the ignition switch to the "Start" position to

actuate starter. As soon as engine starts, let go of key and

pull throttle lever back to middle of its running range.

Allow engine to warm up. a few minutes before putting it

under load.

5. If the starter will not operate, turn ignition key to off

and check that both the gear shift lever and mower PTO

drive clutch are in neutral position and are actually actuating

the safety interlock switches (Figures 7 and 8).

6. If engine fails to start after being turned over 5 or 10

seconds with the safety interlock switches closed, the engine

may be flooded. If this is the case, pull throttle back to

middle of the range to disengage choke and turn engine

over several times to clear out excess fuel.

TRAVEL

1. With engine running, set engine throttle between 1/4 ano

1/2 open. Engine speed for mowing should be 3/4 to full

throttle. When grass is wet or oyer 3-inches high, full throttle

is best.

2. With forward-reverse lever in the neutral notch, move

the gear shift lever into "Lo" or "Hi" range. Transmission

gear could be placed in "Lo" range when mowing heavy or

Wet grass and when on rough or sloping terrain. Use "Hi"

range on dry, moderate sized grass on smooth terrain.' It is

necessary to place forward-reverse control lever in neutral

or depress the clutch brake pedal to stop tractor before

shifting gears.

NOTE; If there is any tendency for gear teeth to "clash"

when shifting, depress the clutch brake pedal fully. Release

clutch brake pedal slowly and remove foot from pedal.

CAUTION

When operating the tractor for first time put trans

mission in "Lo" gear until you become acquainted

with the controls and operation of the tractor.

3. Grasp steering wheel, straighten front wheels, and look

carefully around to make sure that the area in which you

plan to drive is clear of obstructions, people and pets.

4. Refer to "Forward-Reverse Control Lever" explanation

in the "Controls" section of this manual and engage forward

reverse control lever to start ground travel as instructed.

5. The forward-reverse control lever is not a speed control

device and for ail continuous operation it must be positioned

either fully forward or fully rearward. Practice starting,

stopping, steering, shifting gears, faster throttle settings,

operating in reverse, etc. until you can operate the riding

mower smoothly and easily.

STOPPING

1. Ground travel is normally stopped by placing the forward

reverse control lever in neutral position and moving gear

shift lever to neutral. This action will only stop forward or

reverse drive, it will not brake the vehicle to a stopped

position.

2. Ground travel can also be stopped quickly by fully de

pressing the clutch brake pedal. When forward-reverse con

trol lever is in reverse, depressing clutch brake pedal auto

matically overrides any position the shuttle control lever

would be in. When pedal is released vehicle will assume

operation in the position of the shuttle control lever.

NOTE: Do not keep foot on clutch brake pedal during

operation. To do so can result in "clutch riding" and ex

cessive slippage and wear on drive belts. Place foot on foot

rest.

3. To stop engine, turn the ignition key to the "Off" po

sition and remove key from ignition switch.

Before stopping engine that has been operating under load

allow engine to idle for a few minutes "cooling off" time.

Page 9

CAUTION

Never leave the tractor seat unless the power take off

is disengaged, transmission is in neutral and engine is

stopped. If leaving the tractor unattended, ALWAYS

remove ignition key.

MOWING PATTERN

1. For the first use of the mower choose a smooth level

area. Cut long straight strips overlapping slightly. After

becoming familiar with the operation proceed to inclined

or rougher ground.

2. The size and type of area to be mowed determines the

best mowing pattern to use. Obstructions such as trees,

fences and buildings must also be considered. In most cases,

making one or two passes in a counter-clockwise direction

around the outside of the area to be mowed is advisable to

keep cut grass off of fences, walks, etc. The remainder of

the mowing should normally be done in a clockwise di

rection so the clippings are dispersed on the cut area.

3. Always keep the right side of mower toward trees, posts,

or other obstacles on the first pass around obstacle.

CAUTION

4. On moderate size, frequently mowed lawns where grass

is light and dry it is sometimes practical to mow in a counter

clockwise direction so that clippings are thrown toward the

center of the lawn and concentrated for easy pickup and

removal.

5. Most lawns should be mowed to keep the grass approxi

mately two to three inches high. Best results are obtained

by cutting often and not too short. To keep a green lawn,

never mow more than one third off the height of the grass or

a maximum of one inch in one mowing. For extremely tall

grass, set the cutting height at maximum for first mowing,

then reset to the desired height and mow again. Allow the

grass to grow to three inches, then cut off only the top inch.

6. On thick or springy grass or soft ground, the mower rol

lers may sink into the ground giving too low a cut. Adjust

the cutting height to get the desired height of cut.

7. For best appearance, grass should be cut in the after

noon or evening when it is free of moisture.

8. Where possible change patterns occasionally to eliminate

matting, graining and a corrugated appearance. See diagrams

below.

DO NOT WORK around mower housing area until

you are certain that the mower blade has stopped

rotating.

Heed the CAUTION DECAL, the DANGER DECAL,

and the WARNING DECAL located on the mower

housing. Make certain the discharge guard and de

flector assembly are always in place before operating

mower.

ALWAYS disconnect the mower drive clutch and

stop engine before leaving the tractor seat. If leaving

the tractor and mower unattended, remove the ig

nition key.

Page 10

ADJUSTMENTS

IF VEHICLE IS PLACED ON END FOR OVER A

2 HOUR PERIOD, THE BATTERY MUST BE RE

MOVED AND THE FUEL TANK DRAINED.

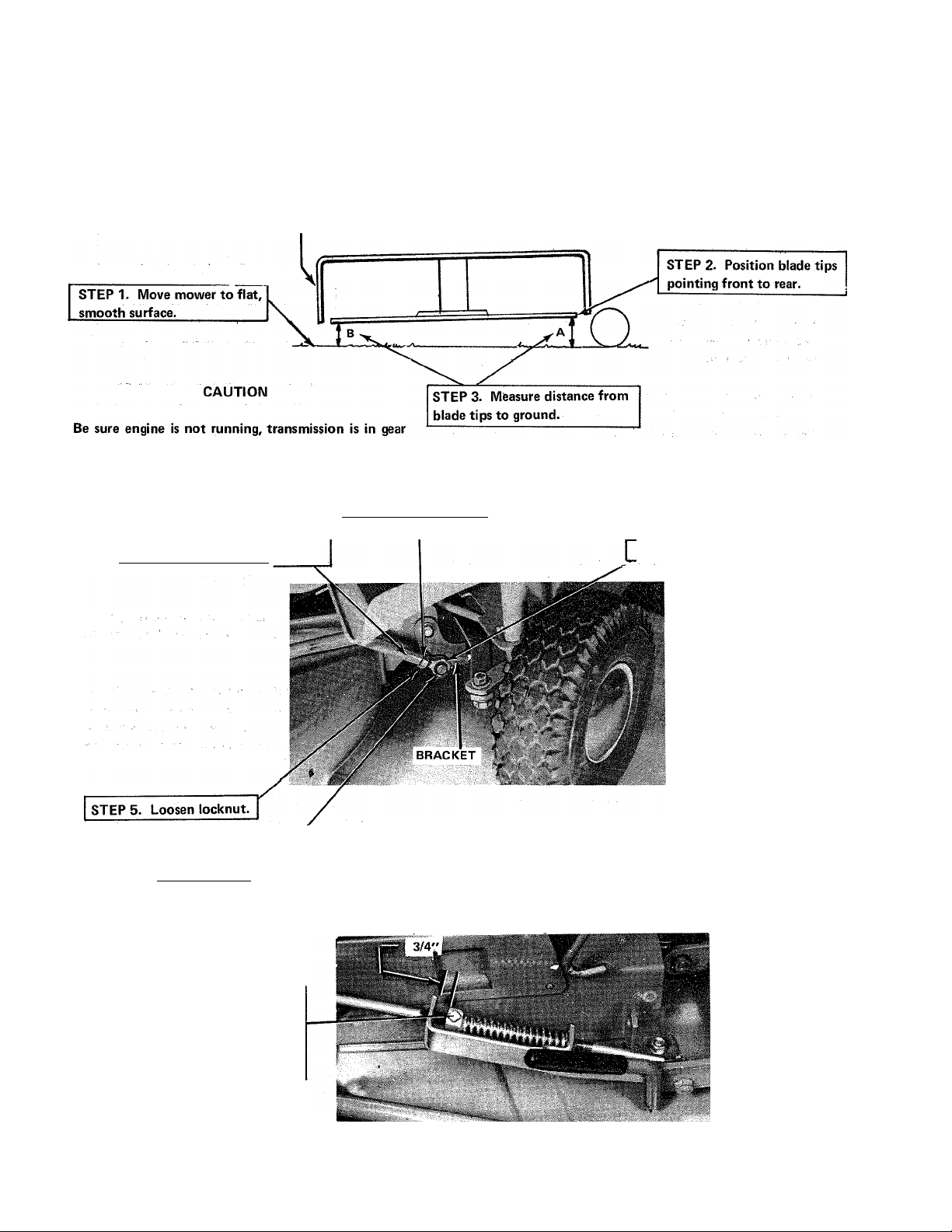

MOWER BLADE FRONT-TO-REAR PITCH

FRONT OF MOWER HOUSING

and mower drive is disengaged (clutch lever up). Block

the wheels, front and rear, to prevent rolling while

working on mower blade.

STEP 7. Tighten locknut.

STEP 6. Adjust turnbuckle until

blade is at desired setting

STEP 4. If distance "A" is not 1/8

to 1/4 inch greater than distance "B

remove eyebolt.

MOWER ENGAGEMENT

STEP 8. Secure eyebolt.

_________________

With clutch lever

engaged (lever down).

Loosen collar setscrew

and adjust to 3/4 inch

if necessary.

Page 11

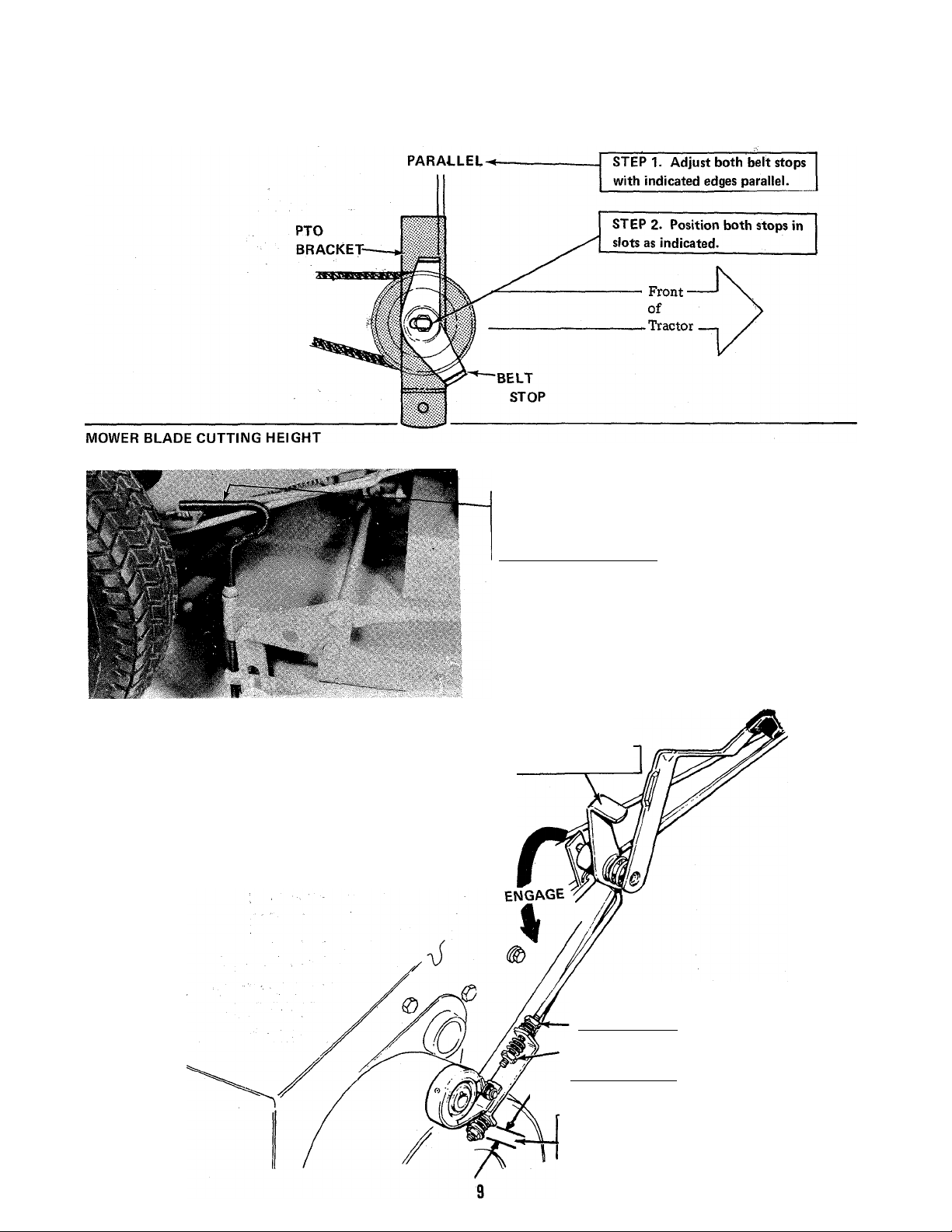

WIOWER BELT STOPS

Raise or lower entire

mower by turning

handle clockwise to raise

counter-clockwise to lower.

BRAKE MECHANISM

NOTE

Brake by either depressing clutch

pedal or engaging park brake lever.

When clutch pedal is depressed,

clutching and braking are at the

same time.

Suggested Cutting Height 2 inches.

STEP 2- Engage parking brake lever.

STEP 1. Turn nut to end of

threaded portion.

STEP 3. Tighten nut until spring is

compressed solid.

NOTE

__________

____________

STEP 4. Adjust nut to 1 to 1-1/4 inch

between washer and bracket.

Page 12

TRACTOR DRIVE MECHANISM

IDLE

BRACKET

SPRING

CAPSCREW

FLAT

WASHER

STEP 1. Place direction control

lever in "Neutral" position.

STEP 2. Open tractor rear cover.

STEP 3. Adjust nut until spring

is compressed 1-1/8 inches.

STEP 4. Turn elastic nut

snug against frame.

STEP 5. Close cover, place

tractor in upright position.

STEPS. Place reference mark.'

STEP 10. Place reference mark and

check indicated dimension.

STEP 7. Rotate shaft awgy from

you as far as possible.

STEP 9. Rotate shaft toward

you as far as possible.

STEP 12. Adjust shaft assembly by

raising or lowering to obtain indicated

dimension (Step 10).

_______________

STEP 11. If indicated dimension not

obtained, loosen four capscrews.

STEP 13. Secure capscrews to 15

foot-pounds torque.

10

Page 13

. BATTERY

*“ RUBBER

MOWER REMOVAL AND INSTALLATION

(Figure 16)

Remove mower as follows:

1. Lower mower to ground and remove lift link from raise

and lower lever.

2. Pull lock pin holding front of mower PTO drive clutch

rod to tractor and lay clutch rod on top of mower. Swing

PTO clutch lever forward for clearance.

3. Remove pins and lock pins holding mower link assembly

to axle attaching clips. Lower front of mower to ground.

.4. Raise rear end of belt cover and remove mower drive

belt from mower driven pulley.

Figure 15.

The maximum charge rate of this battery is 1.5 amps.

Any higher charging rate will damage battery.

AXLE ATTACHING

CLIP

MOWER INSPECTION

After each mowing clean the grass clippings and matérial

from the mower housing and inspect the blade for sharpness

and straightness.

Be sure that tractor engine is stopped, ignition key is

turned to “Off" and removed from switch, gear shift

lever is in neutral, forward-reverse control lever is in

neutral, mower drive clutch is disengaged and that

mower knife has stopped turning before attempting

to inspect or clean mower housing. .

if blade is bent, damaged or dull, the mower will have to be

removed from the tractor.

CAUTION

MOWER PTO DRIVE

CLUTCH LEVER

Figure 16.

WARNING

WARNING

5. Lift front end of tractor and push tractor backwards

until front wheels can be set on the ground back of mower.

. Install the mower as follows;

1. Position mower on ground with rear of mower in front

of tractor front wheels. Pick up front of tractor and pull

tractor forward on its rear wheels until front wheels can

be set down- on ground in front of mower.

2. Lift rear end of belt cover and install mower drive belt

over mower driven pulley. Lower belt cover to hold belt in

place.

3. Lift front end of mower and attach link assembly to

axle attaching clips with pins and lock pins.

4. Attach front end of mower PTO drive clutch rod to clutch

arm on trgctor yyith lock pin. Engage clutch and check that

belt is properly seated in the pulleys.

5. Attach lift link to. raise and lower lever and raise mower.

DO NOT try to remove or sharpen blade with mower

attached to tractor.

13

Page 14

BLADE REPLACEMENT

1. Remove the mower from tractor as outlined on preceding

pages and turn mower upside down.

2. Wedge a block of wood securely between the end of

blade and the mower housing to prevent blade turning

while loosening and tightening bolts. Remove the two

blade mounting bolts and the blade.

WARNING

ALWAYS handle blade with extreme care to avoid

injury.

3. If blade is bent, do not try to straighten it for reuse. Re

place it with a new blade.

4. If blade is straight and has nolarge nicks, you can sharpen

it yourself. Clamp blade securely in a vise and use a large

mill file along the original bevel. File to a sharp edge.

5. Place a small rod through the center hole of blade and

check for balance. File more metal off of heavy side until

blade does balance.

6. See Figure 17. Carefully clean blade and part of arbor

that blade fastens to. Install new or sharpened blade with

the lift tabs on blade end turned toward top of mower

housing. The blade mounting bolts should be tightened

to 30- foot -pounds of torque;

MOWER

iDLER PULLEY

FORWARD CONTROL

IDLER PULLEY

FORWARD IDLER

BELT

TRANSMISSION

DRIVE BELT

FORWARD

TRANSMISSION

IDLER PULLEY

REVERSE TRANSMISSION

IDLER PULLEY

MOWER DRIVE BELT

(ONE BELT)

UREVERSE CONTROL

IDLER PULLEY

REVERSE

IDLER BELT

TRANSMISSION

DRIVE PULLEY

MOWER DRIVE

PULLEY

ENGINE DRIVE

PULLEY

ENGINE IDLER

PULLEY

Figure 18.

BELT

STOP

7. Rotate blade slowly by hand to see that it clears the

housing all around and that the blade tips are running

in a true plane. If the tips of the blades move up and down

in relation to the mower housing as blade is turned, or if

blades are hard to rotate, the arbor shaft or housing may

be bent.

MOWER DRIVE BELT REPLACEMENT

NOTE: Refer to Figure 18 for location of pulleys and belts.

1. Remove mower as instructed in MOWER REMOVAL

AND INSTALLATION.

2. See Figure 19. Loosen belt stop and pulley mouhting

nuts and position belt stop so that stop fingers allow for

belt removal. Remove mower drive belt from mower idler

pulleys.

3. See Figure 20. Open rear cover of vehicle and pull

mower drive belt from drive pulley. Slowly guide belt

through vehicle and remove it through rear cover opening.

4. Install new mower drive belt in reverse order of removal.

Belt stops must be positioned in their slots with fingers

approximately 1/16-inch from belt. Adjust mower clutch

lever as instructed in ADJUSTMENTS section of this manual. 14

____^STOP

P.T.O. *

BRACKET

MOWER IDLER

PULLEY

I

MOWER DRIVE

BELT (ONE BELT)

Figure 19.

Figure 20.

Page 15

TRANSMISSION DRIVE BELT REPLACEMENT

NOTE: Refer to Figure 18 for location of pulleys and belts.

1. See Figure 20. Open rear cover of vehicle and push en

gine idler pulley in against spring until engine drive belt

can be slid from pulley. If spring does not allow sufficient

compression to allow belt removal, loosen outer adjusting

nut a few turns.

2. See Figure 18. Disengage engine drive belt from engine

drive pulley and remove from rear cover opening..

4. Install new forward and/or reverse idler belts in reverse

order of removal. Belt stops must be positioned 1/16-inch

from belt. Pivot-shaft assembly must be secured sufficiently

forward to allow controls to activate either forward or reverse

belt. Refer to complete ADJUSTMENTS procedure of this

manual for proper belt tension.

BELT CARE

1. Inspect belts frequently for proper alignments.

2. Keep belt tension properly adjusted.

NOTE: Engine drive belt is only one belt and it engages

transmission drive pulleys in opposite directions. The engine

drive pulley is smaller than its neighboring mower drive

pulley.

3. Working through rear cover opening, install new trans

mission drive belt on engine drive pulley. Carefully work

belt over outside transmission drive pulleys and; depress

engine idler pulley (Figure 20) enough to slip new engine

drive belt in place. Adjust drive belt as instructed in

ADJUSTMENTS section of this manual.

FORWARD AND REVERSE IDLER BELT

REPLACEMENT

NOTE: Refer to Figure 21 forlocationof pulleys and belts.

1. Remove transmission drive belt as instructed in TRANS

MISSION DRIVE BELT REPLACEMENT.

2. Loosen belt stop mounting bolts and slide them forward

enough to slide either or both idler belts from either or

both control idler pulleys.

3. Remove either or both idler belts from their respective

transmission idler pulleys.

3. Keep belt guides in right position.

4. Keep pulleys in alignment.

If oil should be spilled on a belt, wipe it off at once with

a cloth, then wash belt with warm, (not hot) water and a

detergent.

GENERAL REPAIRS

To prevent rusting, sand off and paint any parts or areas

which become chipped or damaged. Apply a good rust

preventive to all bare metal parts. Tighten all fasteners

and shields securely.

OFF SEASON STORAGE

1. Gasoline stored for several months can develop gum

deposits which clog carburetors. To prevent this, purchase

a good grade gasoline stabilizer from your dealer and follow

directions on the can to treat the gasoline in the tank and

in your gasoline container. Operate engine long enough to

make certain that engine is warm and that the treated gas

oline is in the carburetor..

FORWARD CONTROL IDLER

PULLEY AMD BELT

REVERSE CONTROL IDLER

PULLEY AND BELT

FORWARD TRANSMISSION

IDLER PULLEY

,0-1

PIVOT-SHAFT ASSEMBLY

CAPSCREW

FLAT WASHER

NUT

REVERSE

TRANSMISSION

IDLER PULLEY

Page 16

2. Stop engine, and drain and refill crankcase while engine

is warm. SEE MAINTENANCE section of this manual.

4. Mower PTO drive clutch lever must be up in the dis

engaged position to engage the safety interlock switch.

3. Remove spark plug, pour 1 oz. 10W-30oil into cylinder

through spark plug hole. Crank engine a few times to dis

tribute oil. Reinstall spark plug.

4. Clean dirt and chaff from cylinder head fins and engine

housing.

5. Apply grease to all fittings and light engine oil to all

points listed in "Grease Fittings and Oil Application".

SEE MAINTENANCE section of this manual.

6. When engine is cool, fill fuel tank full of stabilizer treated

gasoline to keep air out of tank which could cause con

densation.

7. Block the machine up off the wheels to relieve weight

and keep tires off a damp floor. Protect the tires from

prolonged exposure to direct sunlight.

8. Store the machine in a dry place outdoors.

STARTING AFTER STORAGE

1. Remove the spark plug and wipe it dry. Crank the en

gine a few times to blow the excess oil out of the spark

plug hole, then reinstall the spark plug.

2. If needed fill the fuel tank completely with fresh "Reg

ular" gasoline.

3. Service the air cleaner. (See "AIR CLEANER");

5. Forward-reverse control lever must be in neutral.

6. Spark plug cable must be securely connected.

IF BELT SLIPPAGE OCCURS, check the following:

1. Belts may be stretched or excessively worn.

2. Pulleys may be greasy or oily.

3. Insufficient belt tension due to a broken or worn tension

spring.

IF A BELT BREAKS, check the following:

1. Look for sharp edges or rough spots on pulleys.

2. Pulleys may be misaligned.

3. Belt tension may be too tight.

IF HANDLING IS DIFFICULT, check the following:

1. Controls or drive systems may be out of adjustment.

2. Tires under-inflated. Inflate rear tires to 10 pounds,

front tires to 24 pounds.

3. Wheels spinning on slopes. Wet grass is very slippery.

Mow in the late afternoon after it has dried.

4. Check the crankcase oil level and replenish if necessary.

(See "Engine Oil").

5. Start the engine and let it operate slowly. DO NOT

operate at high speed immediately after starting. Operate

the machine outdoors or in a well ventilated area.

6. Inflate the tires to operating pressure. 10 pounds rear,

24 pounds front.

TROUBLESHOOTING

IF ENGINE FAILS TO START, check the following:

1. Ignition switch must be "On".

2. Throttle lever should be forward in "Choke" position

unless engine is flooded. If flooded move throttle back to

mid-range.

3. Gear shift lever must be in neutral engaging the safety

interlock switch.

IF AN UNEVEN CUT RESULTS, check the following:

1. Mower may not be adjusted properly. See ADJUST

MENTS section of this manual.

2. Mower housing may be bent or damaged.

3. Blade arbor tube may be bent.

IF A POOR OR ROUGH LOOKING CUT RESULTS, check

the following:

1. Blade may need sharpening.

2. Grass may be too tall or gone to seed.

3. Drive belt may be slipping.

4. Mower may be out of adjustment.

5. Engine speed may be too slow. Run at 3/4 to full

throttle.

16

Page 17

CAUTION 2. Blade may be unbalanced or damaged.

IF VIBRATION OCCURS, stop tractor immediately. 3. Drive pulley may be bent or misaligned,

disengage mower drive clutch, stop engine and check

the following. Repair any damage and correct out of balance condition

before starting mower.

1. Arbor shaft or tube (or both) may be bent.

engine specifications

Make

.......................................

Model No

Type .........................................................

H.P.

Displacement

GOVERNOR

Type

Working Range

LUBRICATION

Type ......................................................................................Gear Impeller System

Capacity

STARTING

FUEL CAPACITY .......................................................................3 Quart

TRACTION DRIVE TYPE

Speeds @ 3400 RPM -Low

CLUTCH AND BRAKE ...............................................................Foot operated clutch-brake combination over-rides

FRAME TYPE

Front and Rear - U -Channel

DIMENSIONS

Width .............................................;

Length ................................................................... .57-3/4"

Wheel Base

Height ....................................................................................Top of steering wheel 36-1/4"

Tread Width .............................................................. .Front - 28", Rear - 28"

STEERING

Ratio

Turning Radius (Inside Rear Tire)

TIRE SIZE

Front ,...............................................; .

Rear ......................................................................................16 X 6.50 x 8 Turf Tread - 10 pounds pressure

ROTARY MOWER

Width of Cut .........................................................................30"

Mounting

Rear Support .........................................................................Three rollers, two adjustable for height and one fixed

Height Adjustment .................................................................Stepless screw, range 1-1/2" to 3-1/2"

Distance between mower blade and deck ...........................2-1/2" to 4-1/8" at chute

WEIGHT WITH MOWER

Weight Net .............................................................................346 pounds

Shipping Weight

ATTACHMENTS

Available as extra Equipment ................................................Hub Caps

...............................................................................

.....................

................................................................................... .Adjustable, mechanical

...............................................................................

.................................................................................. .Factory installed 12V electric with 3 amp alternator and

.............................................................. .3.81:1

...............................................................................

■ ■ . ■ ........................ .......................... .8 @ 3600 RPM (Engine Mfg. Rating)

.........

........................................................ . .19.44 cu. in.

.....................................................................

..........................................................

......

................................................................. .44-3/8"

....................................................................

• ■ ■

.................................

......

....................

..................................................

-High

................................................

..........

................................ . IHeavy gauge steel

........................

......................... .22"

...

...................... .410 X 3.50 X 4 Turf Tread - 24 pounds pressure

• ■ ■ ■ 40-1/4" with mower and safety shield in place

For instructions on removal and installation of mower

see MAINTENANCE section of this manual.

Briggs and Stratton

190707

0861-01

1800 - 3400 RPM for best mowing performance

2-3/4 Pints extended oil fill for ease of servicing

solid state rectifier.

Hand operated forward, neutral, reverse V-belt shuttle drive

to a two speed, all gear, fully enclosed transmission and

differential.

Forward - 2.52 MPH, Reverse - 2.52 MPH

Forward - 3.92 MPH, Reverse - 3.92 MPH

shuttle drive for emergency stops.

Full floating-attached to and tilts with front axle

406 pounds

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

17

Page 18

FRONTS REAR TIRES

FRONT

Ref.

No. Part No.

1

2

3

, 4

5

6

7

8

f-9

10

11

12

13

14

15

16

16

Qty.

171851 2

171850

159156

153038 2 TUBE

171270 2 CAP, Valve Stem

158433 2 BUTTON, Plug ^

118053 2 PIN Headed, drilléd

918451 2 PIN,Cotter, 1/8" X 3/4" Ig.

1608379

1608380

163108 2

163109 2 TUBE

163110

163111 4

928691

8021010

2 WHEEL ASSEMBLY

2

2 FRONT WHEEL & TIRE ASSY.

2

4 BEARING

2

2 COLLAR, Set

Description

REAR WHEEL & TIRE ASSY.

(Incl. Ref. Nos. 2 through 5)

TIRE, Tubeless

(Incl. Ref. Nos. 10 through 14)

WHEEL

TIRE

BEARING, Relief

SETSCREW, 5/16"-18x 5/16"'

18

Page 19

POWER TAKE OFF & THROTTLE CONTROL

Ref.

No.

1

2

3

4

5

6

7

Part No.

1652301

927375 1

930644

175954

157424

922606

923701

Qty.

Ref.

Description

1

1

2

4

1

1

PTO BRACKET ASSY.

BOLT, Carriage, 1/2"-

13 X 8"

LOCKNUT, 1/2"-13

PULLEY

WASHER, Special

CAPSCR EW, Hex, 3/8''-

16 X 1-3/4"

CAPSCREW, Hex, 3/8"-

16 X 2"

No.

8

9

10

11

12

13

14

15

16

Part No.

930645

928731

106681

1653116

176868

929000

176913 2

158499 2

176451

Qty.

2

1

1

1

1

2

1

Description

NUT, flange, 3/8"-26

LOCKNUT, 3/8"-16

SPRING

KNOB,Throttle

CONTROL, Throttle

SCREW, Taptite, 1/4"-

20 X 3/8"

GUIDE, Belt

STOP, Belt

BELT, "V"

19

Page 20

FRONT FRAME & STEERING

20

Page 21

Ref.

No.

Part No.

FRONT FRAME & STEERING

Qty.

Description

1

2

3

4

5

6

7

8 1652154

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

1652148

176440 4

176444

176441

1652150

1652152

157286 2

158578

108412

930645

1652156

154177

917642 2

916965

928726 2

916950 2

1652158

178490 1

176500 1

178489

175613 1

121210

920326 1

1652174

1652167

922122 3

930594

157077

926022

158223 1

176501 1

921977 1

923362

176809

176810

174664

1650149 1

1650893 1

930645 1

923471 1

930650 1

1

3

2

1

1

1

2

2

2

1

2

2

1

1

1

1

1

3

1

3

1

1

1

1

FRONT FRAME ASSEMBLY

BUSHING

BUSHING

BUSHING, Pivot

SPINDLE, LH.

SPINDLE, R.H.

RING, Retaining

ROD, Tie

SPRING

BOLT, Shoulder

NUT, Flange, 3/8-26

LINK, Drag

SPACER

WASHER, Plain, 5/16

LOCKWASHER, 3/8

CAPSCREW, Hex, 3/8-16 x 1-1/4 Ig.

NUT, Full, Hex, 3/8-16

GEAR, Steering

WASHER, Special

BUSHING

WASHER, Special

STEERING PINION ASSY.

WASHER

PIN, Cotter, 1/8 X 1-1/4 Ig.

SUPPORT, Steering

PANEL, Rear

SCREW, Self-Tapping, No. 10 x 1/2 Ig.

SCREW, Flange Head

BUSHING

NUT, Retainer

WASHER, (As Required)

WHEEL, Steering

CAPSCREW, Hex, 5/16

-18 X 1-1/4 Ig.

LOCKNUT, Full hex 5/16-18

PAD, Foot L.H.

PAD, Foot R.H.

HANDLE

KNOB

ARM ASSEMBLY

NUT, Flange Hex

CAPSCREW, Hex, 7/16-14 x 1-1/4

LOCKNUT, Flange, 7/16-14

21

Page 22

TRANSMISSION AND REAR AXLE

'59

Page 23

TRANSMISSION AND REAR AXLE

Ref.

No. Part No. Qty.

1

2

3

4

5

6 101042 2

7

8 1652511 1

9

10

11

12 165004

13

14

15

16 154262 1 BALL

17

18 930614 1

19 175270 1

20 156084 1 SEAL, Oil

21

22

23

24

25 156084

26

27

28

29

30

31

1652521

175330 1 CASE, Gear

918113 2 PIN, Roll, 3/8 X 1

163022

163050

917904 1 PIN, Roll

901653 1

930676 2 PLUG, Pipe, 3/4

8061048 1 RING, Retaining

918199

918213 1

171364 1

171456 1

156085

8061048 2 RING, Retaining

170453

156087 1

156089

165009

165010

165011 1 GEAR CLUSTER ASSY.

156292

1652445

1

1

1

1

1

2

1 KEY

1 SEAL, Oil

2

1

1

1

1

Description

GEAR CASE ASSY. (incl.

ref. nos. 2 through 8 33

and 62)

BUSHING

PLUG, Expansion 37

BUSHING, Ball, Half

SHIF.T ROD ASSY.

PLUG, Pipe, 3/8 41 156002 1 PLATE, Differential

SHAFT, shift, Rev.-Lo 44

LOCKWASHER,7/16

NUT, hex, full 7/16-14

FORK, Shift, Hi-Lo

SPRING

CAPSCREW, hex, 5/16"- 49

18 X 5/16" ref. nos. 50 through 53)

SHAFT, Pulley

WASHER

PINION ASSY., Hi-Lo 55

WASHER

SHAFT & GEAR ASSY.

(incl. ref. nos. 28-29-30)

SHAFT, Brake

PIN, Dowel 61

AXLE HOUSING ASSY.

(incl. ref. no. 32)

Ref.

No. Part No. Qty. Description

32 163021 2

163012

34 156099

35

36

38 175312

39

40 175314

42 175328

43

45 121084 2 SPACER

46 162085 2 SPRING

47

48 923428 4

50 1650305

51

52 163074 1

53

54 163012

56

57

58

59 172038

60

62 178051

161130

919357

916965 2

175311

121083

158579

921972

1652526

157679

163022

156103

907729

917356 10

930669

1651242

927428 2

1

1 SEAL, Oil

1

2

1

2 WASHER

1

10 CAPSCREW, Hex, 5/16"-

BUSHING

SEAL, Oil

CAPSCREW, Special

CAPSCREW, Hex, 3/8"-

16x7/8"

LOCKWASHER, 3/8"

R.H. AXLE ASSEMBLY

L.H. AXLE ASSEMBLY

1 DRIVE GEAR ASSY.

4 SPINDLE

4

4

1

PINION

CAPSCREW, Hex, 3/8"-

16x2-1/2"

LOCKNUT, 3/8-16

GEAR COVER ASSY. (incl.

1 COVER

2

2 BUSHING

BEARING, Roller

PLUG, Expansion

1 SEAL, Oil

1 GASKET

18 X 1-1/4"

LOCKWASHER, 5/16"

1

1

1

1 DEFLECTOR, Oil

KEY, 5/32" X 5/8"

KNOB

PLATE, Guide

SCREW, Thread-Forming,

1/4-20x3/8

23

Page 24

CLUTCH & BRAKE

24

Page 25

FILMS AND DECALS

MOWER

27

Page 26

16GABLK.W/

RED HASH MARKS

16 GA. BLACK

16 GA. W/ GREEISh

HASH MARKS

ELECTRICAL STARTER

ENGINE

ADAPTER

MAGNETO

ON ENGINE

NEUTRAL START

23

SWITCH

28

Page 27

ELECTRICAL STARTER

Ref.

No.

1

2

3 122234

4 Í22203 1

5

6

7

8 930647 3 NUT, Pal, 9/16-18

9

10 1650793

11 1652311 1 SUPPORT ASSEMBLY, 22

12

13

Part No. Qty.

178280

918906

154247

929000

177522

176833

172744

177981

1

1

1

1 CLAMP, Throttle cable

1

2

2 GROMMET 20 1651222

1 GROMMET

1 STRAP, Rubber

1 CABLE ASSEMBLY, 25

Description

SWITCH, Ignition

LOCKWASHER, int.,5/8

NUT, Special

KEY & RING ASSY. 16 174648 1

SCREW, Thread forming

SWITCH, Safety

Battery

battery to solenoid

Ref.

14

No. Part No. Qty. Description

176975 1

15

17

18 177982 1

19 1650862 1 WIRING HARNESS

21 178172

23 930612

24

177390

176912

178171

122216

929000 2

1 BATTERY & CLIP ASSY.

2

2

1

1 RESISTOR

CABLE ASSEMBLY,

BATTERY

CLIP, Wire

CABLE ASSEMBLY,

CONNECTOR, Body

WIRE ASSEMBLY

2

1

SCREW, Thread-forming

SOLENOID

SCREW, Thread-forming

neg. battery to ground

solenoid to starter

No. 16 GA. Black

Red Hash Marks

Battery Post

On Ignition

Switch

Start

Post (5)

On Ignition

Switch

Ground

Post (G)

On

Ignition

Switch

PTO

No. 16 GA.Black,

Green Hash Marks

WIRING HARNESS DIAGRAM

Solenoid

PTO

Safety

No. 16GA Black

No. 10 Stud

f6 GA Black

Green Hash Marks

Resistor

Neutral Start

Switch

Neutral Start

Switch

Magneto

On

Engine

29

Page 28

MOWER HOUSING

Page 29

Ref.

No.

30" ROTARY MOWER HOUSING

Part No. Qty.

Description

1 1608351

2 1651298 1

3 108202 2

4

5

6

7

8 108257

9 921158 6

10

11

176984

108182

108181

108472

921333

917356 8

12 917372 8

13 1651293 1

14

15 918312 1

16

17

18 177932 3

19

20

21

22

23

24 917642

25

26

27

28

29

30

31

32

33

34

35

36 8161199 2

37

38

1651295

1651404

1653600

1651297

922262

916965 2

922133

1611652

929001

928730

1611653

927428

1653132

920562

923700

917356

928698 2

917372 5

1611647

921133

1602446

1

1

1

1

2

30" HOUSING, Mower

ARBOR TUBE ASSY.

BEARINGS, Ball

SPACER

WASHER, Arbor

WASHER

WASHER

1

2

1

WASHER

BOLT, Carriage, 5/16-

18x 1"

CAPSCREW, Hex, 5/16"-

18 X 1"

LOCKWASHER, 5/16"

NUT, full hex, 5/16-18

ARBOR ASSEMBLY

SPACER

KEY, Woodruff, 3/16 X 5/8

1

1

1

2

1

1

2

HUB, Pulley

PULLEY

SCREW, Thread forming,

3/8"-16x3/4"

30" BLADE

CAPSCREW, Hex, 3/8"-

16x7/8"

LOCKWASHER, 3/8"

NUT, hex, jam, 3/4-16

LOWER COVER ASSY.

4 WASHER, Plain, 5/16

4

1

2

1

4

2

5

1

1

NUT, Flange, 5/16

CAPSCR EW, Hex, 3/8"-

16 X 1/2"

COVER, Upper

SCREW, Taptite

1/4-20 X 3/8

STONE GUARD ASSY.

BOLT, Carriage, 5/16-

18 X 3/4"

BOLT, Carriage, 5/16-

18X1/2"

LOCKWASHER, 5/16

LOCKNUT, jam, 5/16-18

NUT, full hex, 5/16^16

DEFLECTOR

WASHER, Special

FITTING, Grease

2

CLIP, Spring Anchor

Arbor to housing assembly 1653131 consists of ref. nos. 1,9,10,11,12,38 and arbor sub-assy. 1651034.

Arbor sub-assy. 1651034 consists of ref. nos. 5,6,7,8,10,13,14,15,22, and bearing and tube assy. 1651036.

Bearing and tube assy. 1651036 consists of ref. nos. 2,3, and 4.

31

Page 30

MOWER CONTROL

77 7a

32

Page 31

MOWER CONTROL

Ref.

No.

2

3

4

5 161100

6 930685

7

8

9

10

11

12

13

14

15

16

17

18

19

20 157215

21

22

23

24

25 923428

26

27

28 918430

29 916965

30 916950

31

32

33

34

35

36

37

38 176985

39 1602446

40 1653159 1 BRACKET, Pivot

41

42

43

44

Part No. Qty.

1

1653143

918111 2 PIN, Roll, 178 X 1

161105 1

1611091

917356 4

917372 4

1611118

930685 4 BOLT, Qarriage,

917356 4

917372 4

1611650

930591 2

927557 2 NUT, flange, 5/16-18

177351 4 WASHER

1653133

1653162 1 ARM, L.H. Adjusting

1653163 1

158399

919262 2

153081

921210

1611121 2

1602186

918458

1603206 2

108419 4

176775

108172 1 PIVOT

918448

1653599

921158 2 BOLT, Carriage,

917642 2

917356

917372 2 NUT, full hex, 5/16-18

1 CONTROL ARM ASSY.

1 BRACKET, L.H. Pivot

1 BRACKET, R.H. Pivot

4 BOLT, Carriage,

2 BR АСКЕТ, Rollersupport

1 BRACKET, Fr. Mower

1 ROCKER ARM ASSY.

2 EYEBOLT

2 RING, Retaining

4

4

4

4 BOLT, Shoulder

6

4

4

4

1 HANDLE

1 PI N, cotter, 3/32 x 1

1 ROD GUIDE ASSY.

1

2 ANCHOR, Spring

2 LOCKWASHER, 5/16

Description

GRIP, Handle

5/16-18 X 5/8 Ig.

LOCKWASHER, 5/16

NUT, full hex, 5/16-18

LOCKWASHER, 5/16

NUT, full hex, 5/16-18

SCREW, Whiz lock.

5/16-18 X 3/4 57

ARM, R.H. adjusting

NUT, hex jam, 1/2-20

SPACER

CAPSCREW, Hex,

3/8-16 X 1 Ig.

LOCKNUT, 3/8-16

ROLLER SUPP. ASSY.

WASHER, Plain, 7/16

LOCKWASHER, 3/8

NUT, full hex, 3/8-16

PIN, cotter, 3/16 x 1

ROLLER ASSEMBLY,

(incl. 2 of Ref. No. 33

BUSHING

GRIP, Handle

WASHER, Plain, 5/16

Ref.

No. Part No.

45

46 919318

47

48 917372 1

49

50

51

52 926267 1

53

54

55 916621

56

58

59 917378 4 WASHER, Flat, 3/8

60

61

62

63

64

65

66

67

68 105201

69 928804 1 SCREW, Set, 1/4-20X

70

71

72 106788 3 CLIP, Spring

73 930685

74

75

76 108431

77

78 108419

79 1603205

80 1002155

81 917378

82 1650645 1 ROD

83 922000

84

85 108199

86

87 923362 1 LOCKNUT, 5/16-18

1650140

017356

1653160

1653161

1610590

916080

917365 2

178547

178548 1 ROD GUIDE ASSY.

1611097

923428 1

1602894 2 SPRING

176743 1 ROD GUIDE ASSY.

153081

907731 1

923428

176874

162065

8161045 1 CLIP, Hairpin

156306 2

917356

917372 2

108178

106787 1 CLIP, Hairpin

917397

Qty.

1

1

1

1 BRAKE SUPPORT ASSY.

1

1 SHEAVE, Brake

1 SCREW, Rd., Hd. Mach.

2 NUT, hex. No. 10-24

1 ROD, Brake

1

1 SPACER

1

1 CLUTCH ROD ASSY.

1

1

2

2 LOCKWASHER, 5/16

1

1

1

Description

BRACKET

CAPSCREW, Hex,

5/16-18 x 5/8 Ig.

LOCKWASHER, 5/16

NUT, full hex,5/16-18

ANCHOR, Brake Rod

SCREW, flat hd. mach.

No. 10-24 x 5/8 Ig.

No. 10-24 x 1/2 ig.

LOCKWASHER, No. 10

BRACKET, Ctr. Roller

LOCKNUT, 3/8-16

CAPSCREW, Hex

3/8-16 X 1 Ig.

LOCKNUT, 3/8-16

SPRING

COLLAR, Set

3/8 Ig.

PIN

BOLT, Carriage,

5/16-18x5/8

NUT, Hex, 5/16-18

ROLLER ASSEMBLY

ROLLER

BUSHING

1 SHAFT, Ctr. Roller

2

1 WASHER, Flat, 3/8

1 PIN, cotter, 3/32 X 5/8

1

1 CAPSCREW, 5/16-18x3/4

RING, "E"

LINK

33

Page 32

REAR MOUNTED

GRASS CATCHER.

Page 33

REAR MOUNTED GRASS CATCHER

Ref.

No.

Part No.

Qty.

Description

1

2

3

4 177104 1

5

6 916955

7

8

9

10

11

12

13

14

15

16 909055

17

18

19

20

21

22

23

176871

123103

920563

930531

909055

917415

177086 1

1653266

1653265 1

177109 1

923362

930531

916955

917415

177096

177249 4

917356 4

917372 4

177243 2

925205 4

16

1

2

2

8

8

8

4

4

8

8

8

8

2

ADAPTER

NUT,ASSEMBLY

BOLT, Carriage,5/16-18x1

TUBE, Discharge

SCREW, Phillips hd.,

10-32 X 1/2

WASHERS, Plain, 3/16

LOCKWASHER, No. 10

NUT, full hex, 10-32

BAG, Grass

CLIPS

SUPPORT ASSEMBLY

COVER

LOCKNUT, full hex

5/16-18

SCREW, Phillips head.,

10-32 X 1/2

WASHERS, Plain, 3/16

LOCKWASHER, No. 10

NUT, full hex, 10-32

SUPPORT, Vertical

BOLT, Curved head

LOCKWASHER, 5/16

NUT, full hex, 5/16-18

PLATE, Lift

CAPSCREW, Hex,

5/16-18 X 5/8

COUNTERWEIGHT

Ref.

No.

1

2

3

4

Part No. Qty.

1653380

923232

916965

916950

-------------------------------

Description

COUNTERWEIGHT ASSY.

1

2

2

2

BOLT, Carriage, 3/8-16 x 1

LOCKWASHER, 3/8

NUT, Hex, 3/8-16

-

35

Page 34

Page 35

Page 36

Loading...

Loading...