Homelite 150 Owner's Manual

HOMELITE'

HCDiITLITE

ol.J4

O9ML-,r

---:

Dl.l''ll|lg

0!,6 O@

dLd

q\,*

n@ O@

6e

it will

pay

you

to familiarize

yourself

with

the

saw

and

a

few simple

operating

and maintenance

principles.

Top

performance

and long

life

ol

this saw depends

on

using

it

correctly

right from

the

start,

This

manual

tells

you

how

to do

lhis, and also how

to mainlain lhe saw.

NEW SAW

WARRANTY

AND SAW

REGISTRATION

Be sure

to record

the saw

model and serial

numbers,

name of dealer,

date of

purchase

and

invoice number so

DEALER'S

COPY

FILL OUT

AND MAIL

THIS CARD

you

can

refer

to

them

whenever

necessary.

Our

FtOueufe

warranty

is

printed

on

page

23

of

this man-

ual.

HOMELTTE

will repair

or replace

HOMELITE

SAW

CHATN

free of

charge

if it is

lound delective either

in

material

or workmanship.

Fill out

the

two-part

registration

card as completely

as

possible.

One

part

should

be

given

to

your

dealer.

The

bther

part

is a

questionnaire

to be mailed

to HOMELITE

as

sodn as

possible.

We

study

your

comments

on lhis

card.

lt

is one way

we have

of

improving ourproducts,

and

part

of our

research to

develop

better

products.

CONTENTS

PREPARATION

SECTION

NEW

SAWWARRANTY

AND REGISTRATION

. .. . ...

2

LISTOFSAFE

OPERATINGRULES

. .. ....

... 3

PREPARINGYOURNEWSAW

........3

OiltoUseandHowOftentoFillUp

.........

3

TestingChainOiletOutput

.....

'..3

FuelingtheSaw

......4

FuelGaplsValved

..'.4

FuelandHowtoPreparelt.....

.....4

RecommendedOilsandGasolines

... ............

4

GuideBarandChainAssembly

......5

Pre-SoakChaininOil

...

.....5

DirectionofChainRotation

.........5

MountingChainonGuideBar

.......5

Engaging

Tensigning

Pinin BarHole

. . .

.. .. 5

ChainTensionAdiustment.....

.....5

MaintainingTensionDuringBreak-ln

....... 5

DailyAltentionto

Chain

and

Guide Bar . .

. .. . . .... 6

Lubricationof

SprocketNose

Bars

. .. . .

.. .. 6

OPERATITVG

SECT'OIV

LOCATIONOFSAWCONTROLS

.....,6

HOWTO

START,

STOPAND

HOLD

THE

SAW .

.. .. .

. 6

SgnceandGrip

DuringCranking

. . . ..

.. ...

7

Gripand

Balance

When SawlsRunning

. .'

.. .

"..

7

StartingandStoppinS....

.........7

MakingContactwiththeWood.

....

'7

CARBURETOR

ADJUSTMENT

..

..,...

8

AdjustmentlsNota"Cure-all"

..... 8

Adjustment

Range

..........8

FineAdjustmentofCarburetor.

.....8

Adjustment

to Stop Chain

from Turning

' . ' . . I

AIR FILTER

REQUIRES

FREQUENT

CLEANING

. ..

.. 8

Filter

Eventually

Should

Be

Replaced

. ....

. 8

WOODCUTTING

INSTRUCTIONS

.....9

GlossaryolTerms

..

'.. 9

Equipment

.....9

Personal

Protective

Equipment

I

WARRANTY

.

Work

Area Precautions

Basic Sawing

Techniques

.10

Overbucking

and

Underbucking

.

.........

10

NotchingandFellingTrees.

......10

ProtectingAgainstKick-Backof

Saw

....

'.

11

BoringwiththeNose.

'....'

11

Stressed

Log and

Limb Situations

....

....

11

MAINTENANCE

AND ADJUSTMENT

SECT'ON

HOMELITE

SAW CHAIN

.. ..12

HowtoFileCutters

.........12

FilingDepthGaugeClearance

.....13

GUIDE

BAR

AND SPROCKET

MAINTENANCE

. . . 13

Installing

Sprocket

Kit in Sprocket

Nose

Bar .

. . . . .13

FUELTANKANDFUELFILTER

.......1'

IGNITION,

COOLING

AND

EXHAUST

SYSTEM

MAINTENANCE

. .

,. ... 1'I

SparkPlugTypeandGap..

.......14

Conditionof

PlugTellsaStory.

....14

TestingforlgnitionSpark.

........

15

CleaningtheGoolingSystem

.....15

STORINGTHESAW

....15

REPAIR

SECT'ON

HOMELITE

ALL-TEMP

REMOVAL

OF

POWER

AND

REASSEMBLY

.

Multi-Purpose

GREASE

. . . .

16

HEAD

FROM ENGINE

COVER

STARTER

REPAIRS

To Re-tension

Starter

To Replace

Starter

. .

To

Replace

Starter

SPring

To Replace

Starter

RoPe .

EXPLODED

VIEW

ASSEMBLY

DRAWING

OF

SAW

. .

TOOLS

&

ACCESSORIES

.

MAINTENANCE

SCHEDULE

. . .

Rope .

16

17

17

17

17

17

18

20

22

23

FOR

YOUR

SAFETY

Although

this

bookret

rater

on

telrs

you

how

to

use

the

saw

safery

and

correcily,

here

are

some

or

rhe

importinip6iriis-to

o-Jkbi

il:r";iriin

mino:

O

Pgl"g_"-11_ting,

sready

the

saw

with

the

side

of

your

Knee

agatnst

the

rear

handle

and

hold

saw

Aown

tiim-

ly^on

the

ground

with

one

trana

on

ifre

ironrr,andie

Dar.

3

Alway_s

keep

both

hands

on

the

saw

when

it

is

run-

ning.

Be

sure

to

use

the

ptopei

grip

inlhe

nanOle

bar

(9ee

page

7)

and

mainriin

voui

6iliiiie

and

conrrol

ol

the

saw.

1

Never

let

the

chain_

contact

any

obstacle

other

than

lhe

work

at

hand.

Never

tet

il cbniacioiier

timbs

or

louch

lhe

ground.

1

Helpers

and

bystanders

must

be

kept

a

safe

distance

from

lhe

operator

and

the

cuttinl

chlin.

--

O Keep

clear

of

a

moving,chain.

Do

not

touch

it.

Shut

engine

off

before

making

anv

Jaw

i6piirs

or

ad-

justments.

O

Afler

completing

a

cut,

don.t

move

away

until

chain

stops.

Shrir

or

ihe

"n6tne

oeloi"-"1'rrling

rhe

saw

between

cuts.

put

a sdaobaro

ovliitrti'olaoe

wten

transporting

the

saw.

3

Select a path

of safe

retreat

before

making

a felling

cul

O

Ecrrre

of falling

limbs.

Wear

a

,,hard

hat,,

in

the

Fdr.nd

ourin!'relins

oiiiise'ire;;:

-'

j

lf

there

is

anything-wrong

with

the

saw,

get

it

fixed

betore

rurrheiuse.ieep

ifie

ilijin

!-niipL;a

il;fi;;;

tensioned.

A

dull,

misfiied

or

loose

ctrtn

wili

ctr'attei

and

buck,

and

can

cause

saw

to

ficfbicf.

3

Keep

fuel

in clearly

-labeled

safety

type

cans.

Fuel

your

saw_over

ground

that

presents

nd

hazard

of

lire.

Move

at teast

i0 teet

awayi

from

fueiintlpot

uefore

starting

up

the

saw.

1

Avoid.spitlagg

of

fue_|,

.and

wipe

saw

down

if fuel

is

spilled

on

it-

Do

not

bring

tuei

wtrJre

itrere

is

fire

oi

any

kind.

3

Keep-the

saw

clean

and

free

of

leaves,

sawdust,

pitch

and

oil.

j

Do

not

operate

with

fuet

cap

loose

or

muffter

or

lilters

removed.

Use

spark

arreiters

unoei-:;lry

woods,l

conditions

and

always

where

requiieC'Oy

iaw.

3

Use.only

lhe

correct

fuel

mixtures

made

from

the

in-

gredients

recommended

in

rhii

m;;;;i.

'

1

Keep

a

fire

extinguisher

handy.

j

For

15

minutes

after

stopping

work,

check

the

area

lo

be sure

rhere

are no_

snidroeitns;.,biiJ.'p"r

ouiirii

ftres

and

lgpol!

rhem,

tisring

ia-uiijJir

iirlwn,

ro

the

proper

authorities.

t

$Am;"offiil?.tn"

rarr

or

a tree

or

prevent

.

fj:il":lJ."ill1lt?,rf

rearn

rhe

besr

and

saresr

ways

ro

PE,AHNGYOUN

NEW

SAW

Study

the

anblv

instructions

and

lamiliarize

yourself

with

the-bacc

consrruction-oi*ii-i"ii.'fnis

saw

is

a

high-performance

righrweigrti

m-6Jeilngi;eered

to

at-

l?H":f

owner

to

m-ake

ir,t

iriiiolitvtiyrino,

repairs

CHAIN

OIL

SYSTEM

The

cha_in

oil

filler

cap

is

located

on

top

of the

saw

to

the

lelt

of

the guide

bar'mounting-p;

1.

J|T

qF.OtL:

HOMEL|TEo

Bar

and

Chain

Oit

shoutd

be

used

just

as

it

gom.es

trom

tfre

c6iitlin"r,

as

it

is

formulated

to

ftow

freely

even_

at

betowzero

tempera_

g1r19s.

n1v

brand

of

m.oior;ii

i;;,rJiffieprocessed

moror

oit

mav

be

u::d-3"

"

"rdltitujd.'Tire

weighr

of

the

oil

to

be-used

rito;;4d"-F:ff

;iE.i'ffi

!f#!'",'l;fi

'""?:!illi:i

ro

sA

E-

1 0

or

eve n

.

a.

I is

rr

te

i

-ridiJrril'J'r

rli

nii"iiiiv

add

kerosene

to

whatevl,

*"ighTJil'y-ou'i,"n"

until

it

flows

freety.

No

dirty

or

useO

oiiCn6ufi'Ol

put

inro

the

chain

oiteras

it

may

aam"G

th;;i;L;;.

2.

!.OW

OFTEN

TO

FTLLTHE_

CHATN

OtL

RESERVOTR:

The

reservoir

shoutd

te

riiled-iliiib''il'li

rhe

srarr.

The

votume

of

oit

discharsla

ogf!1{aI'Li.!n"

ensine

speed.

However,

atw.ays

tiit

up-ttri-ita-ii

bir

reservoir

every

time

you

fuel

th-e

saw.

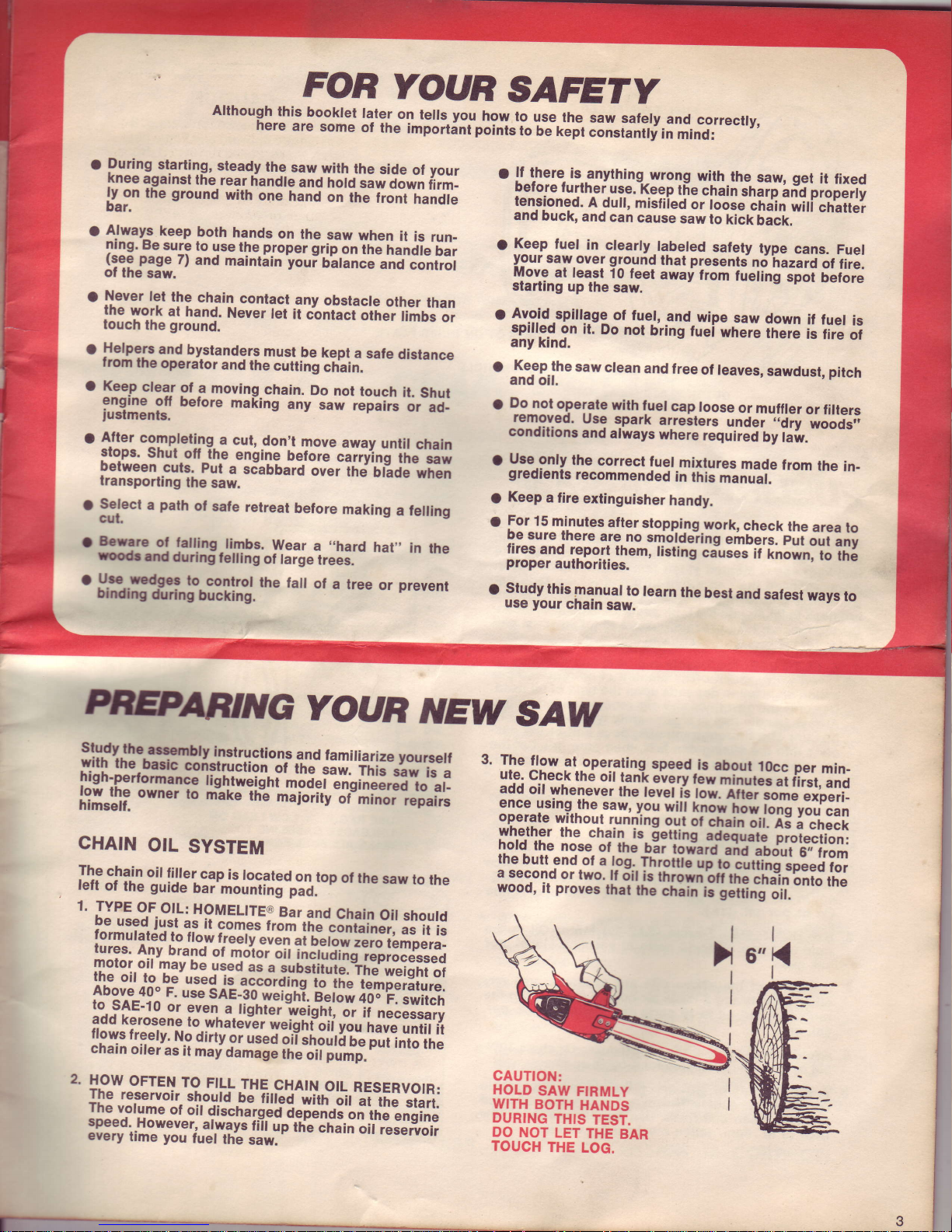

3.

The

flow

at

ooerating

speed_is

about

10cc

per

min-

ute.

Check

rh6

oit

rarit<

e-verv

Gw-iiririrel'at

tirsr,

ana

add

oit

whenever

rhe

tevet

isj";.;iG;me

experi-

9199_ysin-S.Jhe

saw, you

wiil

tnow

tiii

t-ong you

"an

operate

without

running

out

ot

chain

6irji

i

crrecii

!'vh_ether

rhe

chain

is.

leiling

;i"di;

prorecrion:

hotd

rhe

nose

ot

rhe

glr

roJaraiio

i-Udur

0,,

trom

the

buil

end

of

a

tos..

ThrotriJ

r-p

r.i

i-rrii,i!

speed

tor

a second

or

rwo.

tt;itis

rh6un:rril;iiia=in

onto

t

e

wood,

ir

proves

rhat

rhe

crrain

ii-idir'l,id'lir.

6"!

CAUTION:

HOLD

SAW

FTRMLY

WITH

BOTH

HANDS

DURING

THIS

TEST.

DO

NOT

LET

THE

BAR

TOUCH

THE

LOG.

h

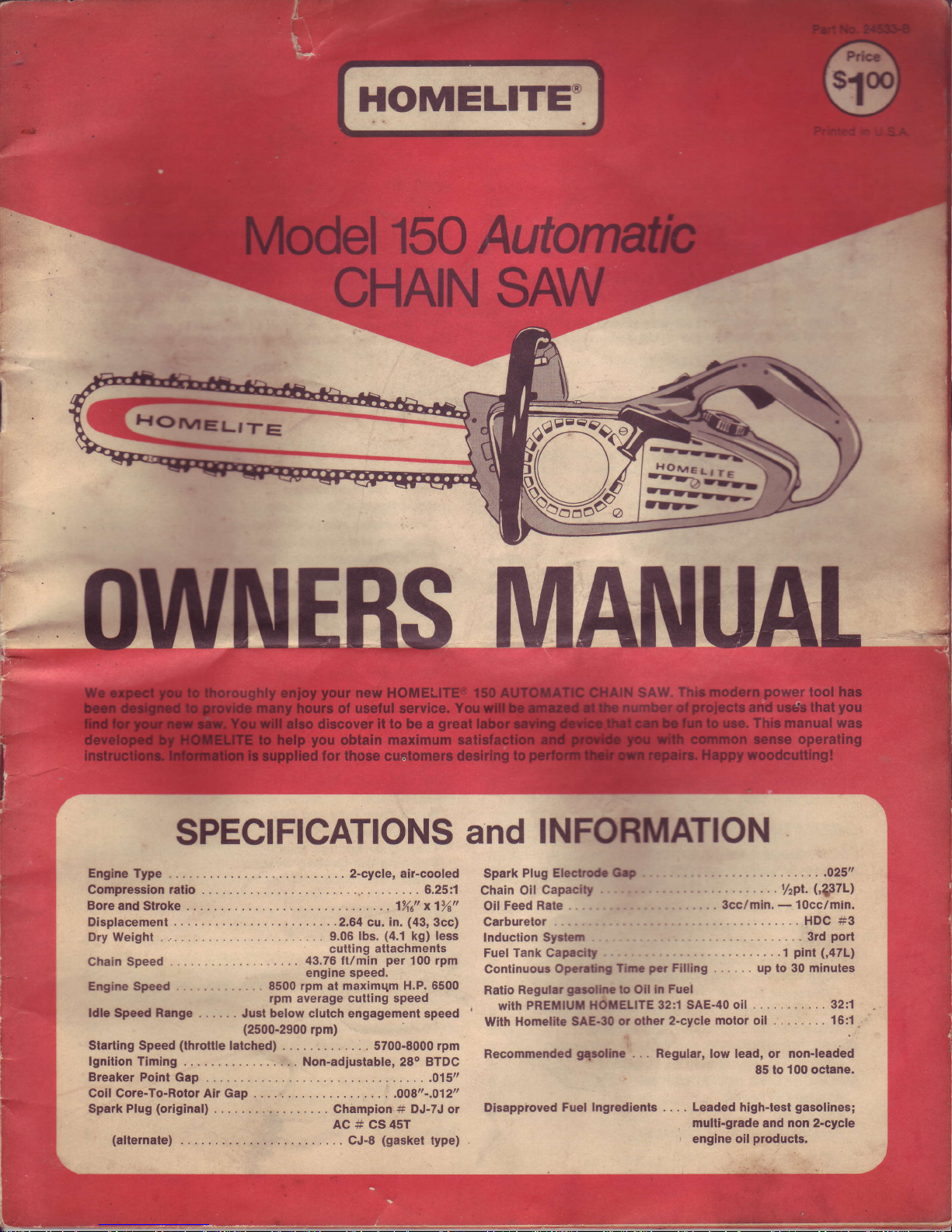

FUEL

TANK

FILLER CAP

,a

CHAIN

OIL

FILLER

CAP

OIL

SLOT ON

INNER PLATE

CHAIN

OIL

DISCHARGE

HOLE

FUEL'NG

T'IE

SAW

I

fUEL

RESERVOIR:

The

fuel

tank holds

one

pint

of fuel,

i enouqh

lor up

to 30

minutes

of

continuous

running.

The

i

fuel tiiler

cad

is located

at

lelt

rear of

the engine

cover.

I

nlways

loos'en

the cap

a

half-turn

and

let the

tank de-

I

presdurize

before

you

unscrew

the

cap

further.

This cap

I

is valved to

let air

ihtc

the

tank

and

should

be

kept clean;

'

During

fuelilg,faka

;i.'

'tautions

nof to

let sawdust

and

the

luel

tanx or'dair.valve.

1.

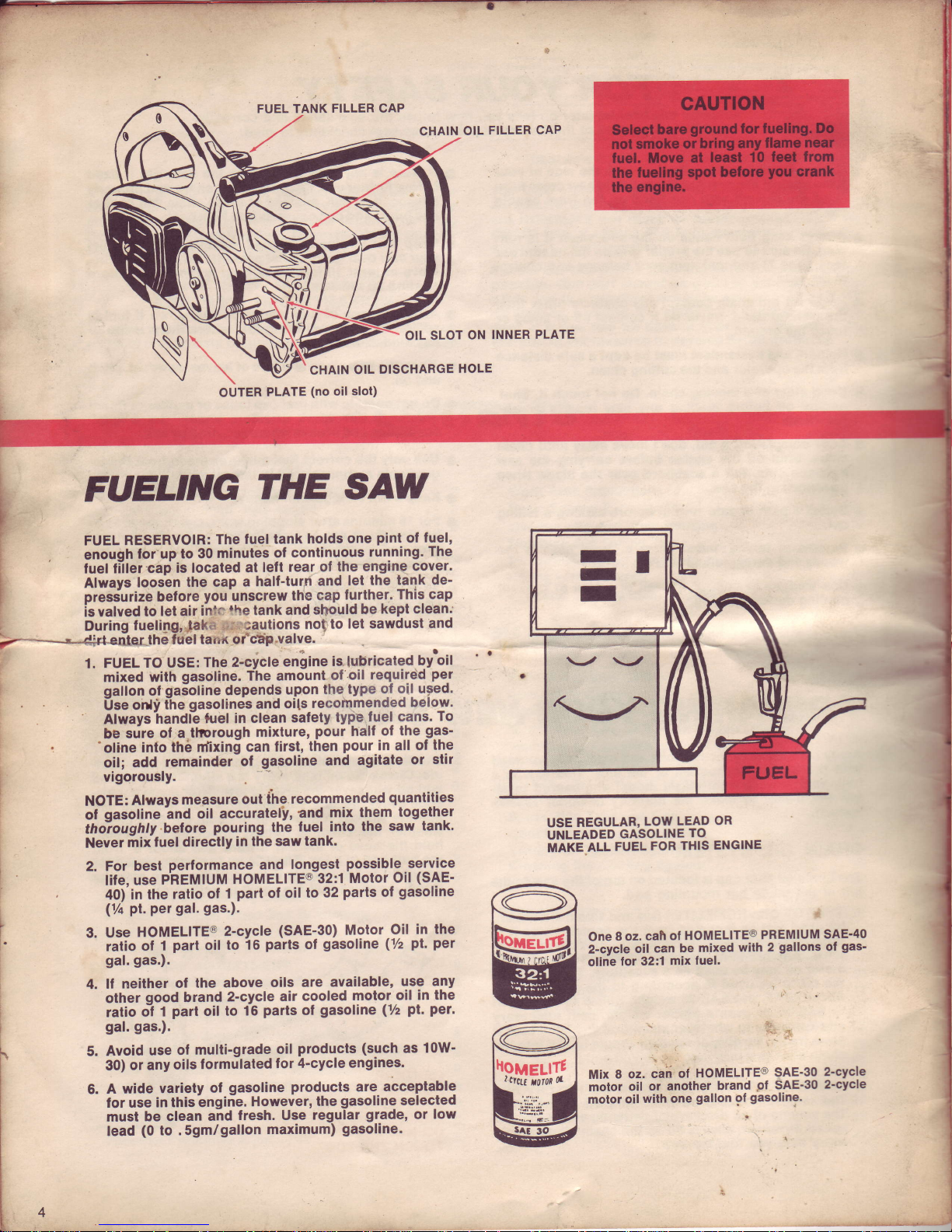

FUEL

TO USE:

The

2-cycle

"niin"

is

lubricated

by'oil

mixed

with

gasoline.

The

amount

of

'oil

required

per

gallon

of

ga5oline

depends

upon

the

type

of oil u.sed'

Use

olti

ihe

qasolines

and

oils

recommended

below'

Always

handte

luel in

clean

safety

type

fuel cans.

To

be srire

of a

tlrcrough

mixture,

pour

hall

of

the

gas-

"oline

into

th6

nfixing

can first,

then

pour

in all

of

lhe

oil;

add

remainder-ol

gasoline and

agitate

or

slir

vigorously.

NOTE:

Always

measure

out

ihe recommended

quantities

of

qasoline

-and

oil accuratel'y,

and

mix them

logether

thoioughty

before

pouring

the

fuel into

the

saw tank'

Never

mixfuel

directly

in the

saw

tank.

2. For

best

performance

and

longest

possible

service

life.

use

PhEMluM

HOMELITE@

32:1

Motor

oil

(sAE'

40)'in

the

ratio

of 1

part

of oil

to 32

parts

of

gasoline

(1/q

pl. pet

gal' gas.).

3.

Use

HOMELITE@

2-cycle

(SAE-30)

Motor

Oil

in the

ratio

ot 1

part

oil

to 16

parts

of

gasoline

(Vz

pl.per

gal.

gas.).

4. lf

neither

of

the above

oils

are

available'

use any

other

good

brand

2-cycle

air

cooled

motor

oil in

the

ratio

o-i

1

part

oil

to 16

parts

ol

gasoline

(1/2

Pl.

per.

gal.

gas.).

5. Avoid

use

of multi-grade

oil

products

(such

as

10W-

30)

or any

oils

formulated

lor 4'cycle

engines.

6.

A wide

variety

of

gasoline

products

are

acceptable

for use

in this'engine.

However,

the

gasoline

selected

must

be clean

and

fresh. Use

regular

grade,

or low

lead

(0

to .Sgm/gallon

maximum)

gasoline.

USE

REGULAR,

LOW

LEAD

OR

UNLEADED

GASOLINE

TO

MAKE

ALL

FUEL

FOR

THIS

ENG]NE

@

w

/;^\

lv1

lhoueutT, I

ru;

W

One

8 oz.

cah

of HOMELITE@

PREMIUM

SAE-40

2-cycle

oil

can

be mixed

with

2

gallons

of

gas-

oline tor

32:1

mix fuel.

Mix

8 oz.

caii

of

HOMELITE@

SAE-30

2-cycle

motor

oil or

anolher

brand

gl

SAE-30

2-cycle

motor

oil

with

one

gallon

ol

gasoline'

OUTER

PLATE

(no

oil

slot)

CLUTCH

DRUM

AND

SPROCKET

,i

OUTER

PLATE

ouo,

"os

MOUNTING

BOLTS

o.-

CHAIN

ROTATION

@el

NUTS

TENSIONING

PIN

DR]VEGASE COVER

HOLE IN

BAR

FOR TENSIONING

PIN

TENSION

ADJUSTING

SCREW

CHAIN

PRE.SOAK

CHAIN

IN LIGHT. OIL

of

the'bar.

in.place

with

the

two

nuts

-

finger

tight to

adfustment

of

the chain

tension.

GT''DEBA,R

AND

CHAIN

ASSEMBD.

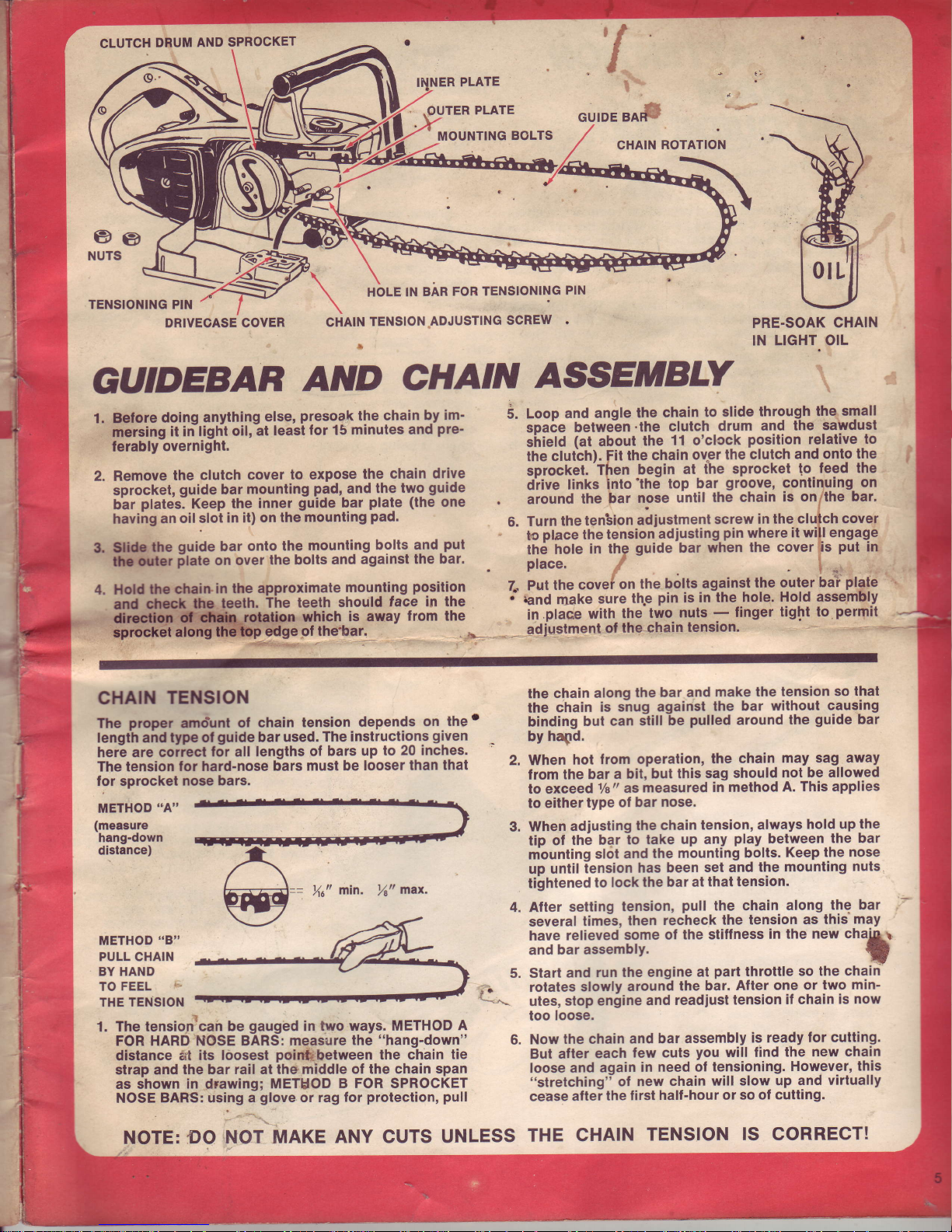

1.

Belore

doing anything

else,

presoak

the chain

by

im'

mersing

it in ligh-t

oil,

at least

for 15

minutes and

pre-

ferably

overnight.

2. Remove

the

clutch

cover to expose

lhe

chain

drive

sprocket,

guide

bar

mounting

pad,

and

the

two

guide

b-ar

platesl

Keep

the inner

guide

bat

plate (the

one

having

an

oil slot

in it)

on the

mounling

pad.

&

Slb

the

guide

bar

onto

the

mounting

bolts

and-put

f,ltrler

Flate

on

over

the bolts

and

against

the bar.

4. Hold lhe

cfrainin

the approximate

mounting

posilion

The

teeth

should

face

in the

which

is auvay

from the

'

,Ir-.

6.

toop and

anqle

the

chain

to

slide lhrough

the

small

soaie

between'the

clutch

drum

and the

sawdust

sirlela

(at

about

the

11 o'clcck

position

relative

to

the clutbh).

Fit

the

chain

ovpr

the clutch

and onto

the

sprocket.-Then

begin

at the

sprocket

!o

feed the

d'rive

links into'the

top

bar

groove'

continuing

on

.

around

the

bar

nose

until

the chain

is

onllhe bar'

6.

Turn

the

tenbion

adiustment

screw

in

the clufch cover

tc

place

the

tension-adiusting

pin

where

it wift engage

tn6

hole

in

thg

guide

bar when

the

cover

ris

put

in

t

l';ffi"

.ou"{onthe

b6tts asainst

tt " out"rL#plate

"

''

€nd make

sure

tlle

pin

is in the

hole.

Hold assembly

in.place

with

the

two

nuts

-

finger

tigl-tt to

permit

CHAIN

TEttlSlON

The

proper

amoiunt

ol chain

tension

depends

on

the'

length and type ol

guide

bar used.

The instructions

given

here are

correct

for all

lengths

of bars

up to

20 inches.

The lension

for hard-nose

bars

must be

looser than

that

for sprocket

nose bars.

the

chain

along

the bar and

make the

tension so

that

the

chain

is

snug against

the bar

without

causing

binding

bul

can still

be

pulled

around

the

guide

bar

by hapd.

When

hot

from operation,

the

chain

may sag away

from

the bar

a bit,

but this

sag should

not be allowed

to exceed Va"

as

measured

in

method

A. This applies

to either

type

of

bar nose.

When

adjusting

the chain

tension,

always

hold

up the

tip of

the bar

lo

take up any

play

between

the bar

mounting

slot

and

the

mounting bolts.

Keep

the

nose

up until

iension

has been

set and

the

mounting

nuls

tightened

to lock

the bar

at that

tension.

After

setting

tension,

pull

the chain

along

the

bar

several

time-s,

then

reiheck

the tension

as this"may

have

relieved

some of

the stiffness

in

the new

chaial

and

bar assembly.

t

Start

and

run

the engine

at

part

throttle

so the

chain

rotates

slowly

around

the

bar. Alter

one

or two

min-

utes,

stop engine

and

readiust

tension

if chain

is

now

too

loose.

Now

the

chain

and bar

assembly

is ready

for culting'

But after

each

few cuts

you

will find

the

new chain

loose and

again

in

need of tensioning.

However,

this

"stretching'i

of new

chain

will slow

up and

virtually

cease

aftei

the first

half-hour

or so of

cutting.

THE CHAIN

TENSION

IS CORRECT!

2.

METHOD

"A''

(measure

hang-down

distance)

==

l(rt,

min'.

r/a,,max,

METHOD

"B''

PULL CHAIN

BY HAND

TO

FEEL

THE TENSION

1. The tension'cah

be

gauged

in

two ways. METHOD

A

FOR HARD'NOSE BARS:

measure

the

"hang-down"

6.

distance

&t its loosest

pointbetween

the chain

tie

strap and

the bar rail at the

middle ol the chain

span

as shown

in

drawing;

METHOD

B FOR SPROCKET

NOSE BARS: using a

glove

or rag

lor

protection, pull

NOTE: DO

NOT MAKE

ANY CUTS UNLESS

l'

I

r

E

t

h.'.

F.

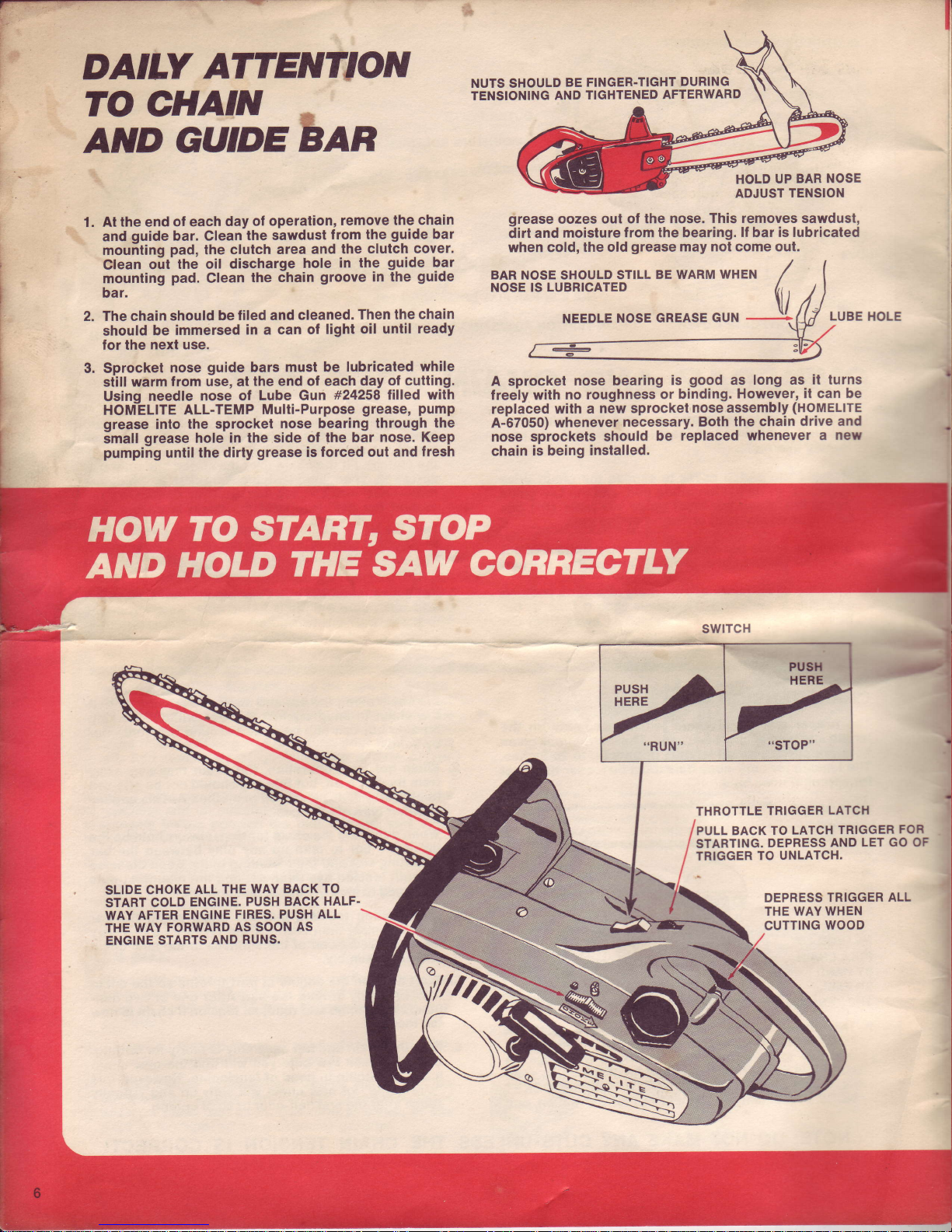

DAILY

ATTENTTON

n?Ki!;,ban

At the end

of each

day

ol operation,

remove

the chain

and

guide

bar. Clean

the sawdust

from the

guide

bar

mounting

pad,

the

clutch area

and

the clutch

cover.

Clean

out'the

oil discharge

hole

in the

guide

bar

mounting

pad.

Clean

the

Chain

groove

in the

guide

bar.

The chain

should

be liled and

cleaned.

Then the

chain

should

be immersed

in a can

of light

oil until

ready

for the

next use.

Sprocket

nose

guide

bars

must be

lubricated while

siill warm

lrom use, at

the end of each

day of

cutting.

Using

needle

nose of

Lube Gun

#24258

filled

with

HOMELITE

ALL-TEMP

Multi-Purpose

grease'

pump

grease

into the

sprocket

nose bearing

through_ the

-mall

grease

hole

in the side of

the bar

nose. Keep

pumping

until the

dirty

grease

is forced out

and

fresh

1.

grease

oozes out

of the nose,

This removes sawdust,

dirt and

moisture

trom the bearing.

ll

bar

is lubricated

when cold,

the old

grease

may not come out.

BAR NosE sHouLD stLL

BE *ARM

*HEN

/

NOSE IS

LUBRICATED

1,,

[/

\,

3.

LUBE

HOLE

swlTcH

THROTTLE

TRIGGER

LATCH

PULL BACK

TO

LATCH

TRIGGER

FOR

STARTING.

DEPRESS

AND

LET GO

OF

TR]GGER

TO

UNLATCH,

DEPRESS

TRIGGER

ALL

THE WAY WHEN

CUTTING

WOOD

A sprocket

nose

bearing

is

good

as

long as it

turns

freeiy with

no roughness

or binding.

However, it can be

replaced

with a

new sprocket

nose assembly

(Ho[,lELlTE

A--67050)

whenever

necessary. Both

the chain

drive and

nose sprockets

should

be

replaced

whenever a

neu

chain

is being installed.

NUTS SHOULD

BE FINGER.TIGHT

DURING

TENSIONING

AND

TIGHTENED

AFTERWARD

HOLD

UP

BAR NOSE

ADJUST

TENSION

SLIDE

CHOKE

ALL

THE WAY

BACK

TO

START

COLD

ENGINE.

PUSH BACK

HALF.

WAY AFTER

ENGINE

FIRES. PUSH ALL

THE

WAY

FORWARD

AS SOON

AS

ENGINE

STARTS

AND RUNS.

r

I

I

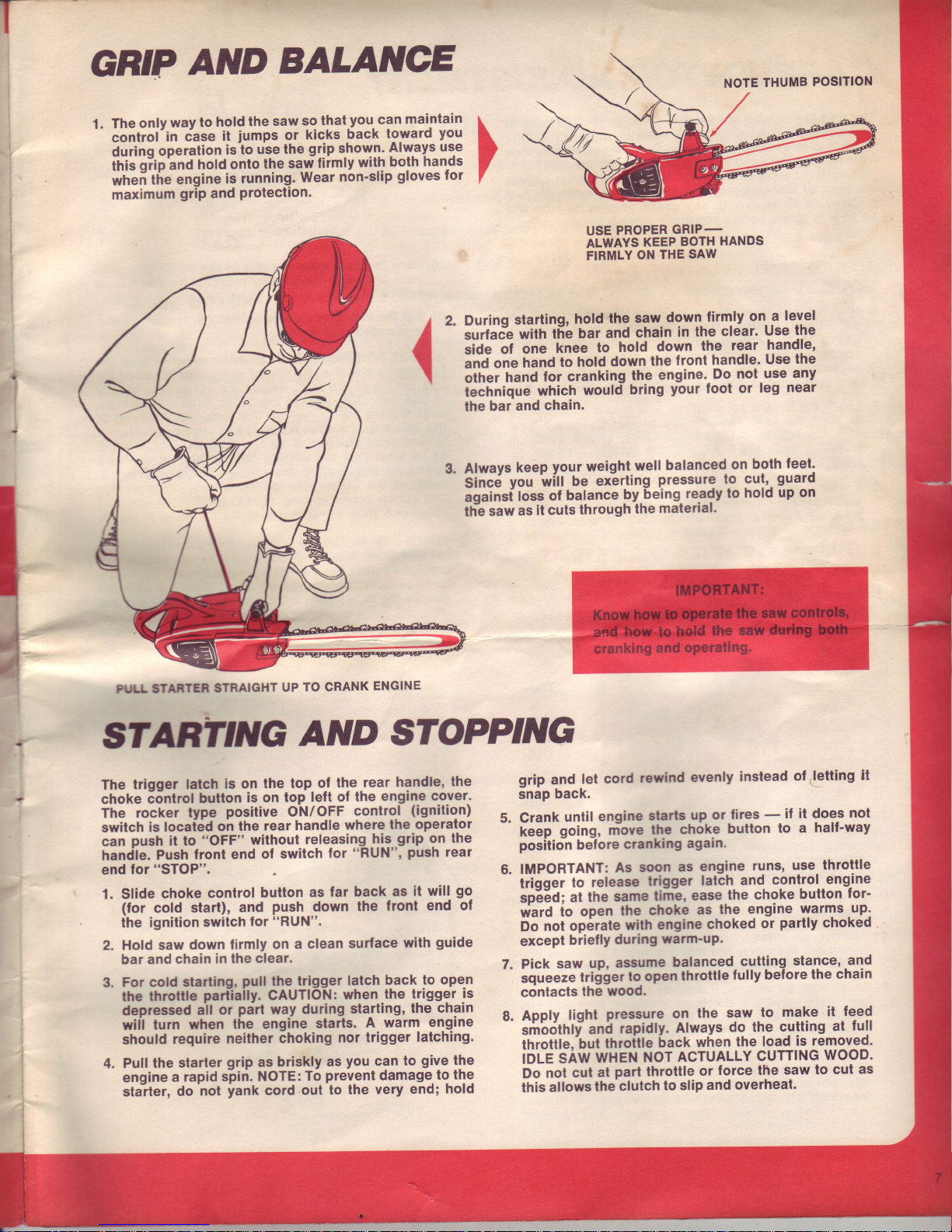

Gmp

AND

BALANoE

1.

The

only

way

to

hold

the

saw

so

that

you-

can

maintain

'-

control'in

iase

it

jumps

or

kicks

back

toward

you

durinq

operation

isio

u-se

the

grip

shown'

Always

us-e

ilriJqiip

ina

hold

onto

the

saw

tiimly

with

both

hands

*nei

tfie engine

is running.

Wear

non'slip

gloves for

maximum

griP

and

Protection.

']

USE

PROPER

GRIP-

ALWAYS

KEEP

BOTH

HANDS

FIRMLY

ON

THE

SAW

Durinq

startinq,

hold

the

saw

down

lirmly

on a

level

Jurfic.e

with

t66

bar

and

chain

in

the

clear.

Use

the

iiCe

of

one

knee

to

hotd

down

the

rear

handle,

ana

one

hand

to hold

down

the

front

handle.

Use

the

other

hand

for

cranking

the

engine'

Do

not,use

any

technique

which

would

bring

your

foot

or

leg

near

the

bar and

chain.

Always

keep

your

weight

well

balanced

on

both

feet'

CinC,i vou

wi'll

oe

ex-eriing

pressure to cut,-

guard

ioainsf

loss

ol

balance

by

being

ready

to

hold

up

on

th-e

saw

as

it

cuts

through

the

material.

3.

.+

PTTT

ATARTER

STRAIGHT

UP

TO CRANK

ENGINE

1

START'NG

AND

STOPPTNG

The

triqqer latch

is

on

the top

of

the rear

handle,

the

choke

d6ntrol

bulton

is

on top

lelt of

the

engine

cover.

The

rocker

type

positive

ON/OFF

control

(ignition)

6

switch

is loca[dd

oh

the

rear

handle

where

the

operator

can

push

it lo

"OFF"

without

releasing-his..grip

on

the

handle.

Push

front

end of

switch

for

"RUN",

push

rear

end

for

"STOP".

-

6.

1. Slide

choke

control button

as

far back

as it

will

go

(for

cold

start),

and

push

down

the

front end

of

the

ignition

switch

tor

"RUN".

2.

Hold saw

down

firmty

on a

clean

surface

with

guide

bar and

chain

in

the

clear.

7.

3.

For cold

starling,

pull

the

trigger

latch

back

to ope.n

the

throtlte

part-iaily.

CAUTION:

when-the

trigger

is

depressed

ail

or

pdrt

way

during

starting,

the chain

a

wiil

turn when

the engine

starts.

A

warm

engine

should

require

neither

choking

nor trigger

latching.

4.

Pull the

starter

grip

as

briskly

as

you

can

to

give

the

engine

a

rapid

spii. XOte:

To

prevent

damage-to

the

stalter,

do-not

lank

cord

out

to the

very

end;

hold

grip

and

let

cord

rewind

evenly

instead

of

,letting

il

snap

back.

Crank

until

engine

starts

up or-fires

-

if

it does

not

ie-p

golng,

niove

thc

ch6ke

button

to a

half-way

position

belore

crankang

agaln.

IMPORTANT:

As

soon

as

engine

runs'

use

throttle

iriqqer

to

release

lrigger

latCh

and

control

engine

sp66A:

at

the

same

timl,

ease

the choke

button

for-

rriard

io open

the

choke

as

the

engine

warms

up'

do

not

op6rate

with

engine

choked

or

partly choked

except

brielly

during

warm'uP.

Pick

saw

up,

assume

balanced-

cytting

stance,

and

iqueeze

triller

to

open

throttle

lully

before

the

chain

contacts

the

wood.

Aoolv lioht

pressure

on

the

saw

to

make

it

leed

srhbdttrti

and

rapidly'

Always

do

the

cutting

at

full

throttle,'but

throitle

back

when

the

load

is

removed.

]DLE

SAW

WHEN

NOT

ACTUALLY

CUTTING

WOOD.

Do

not

cut

at

part

throttle

or

force the

saw

to cut

as

this

allows

the-clutch

to

slip and

overheat'

7

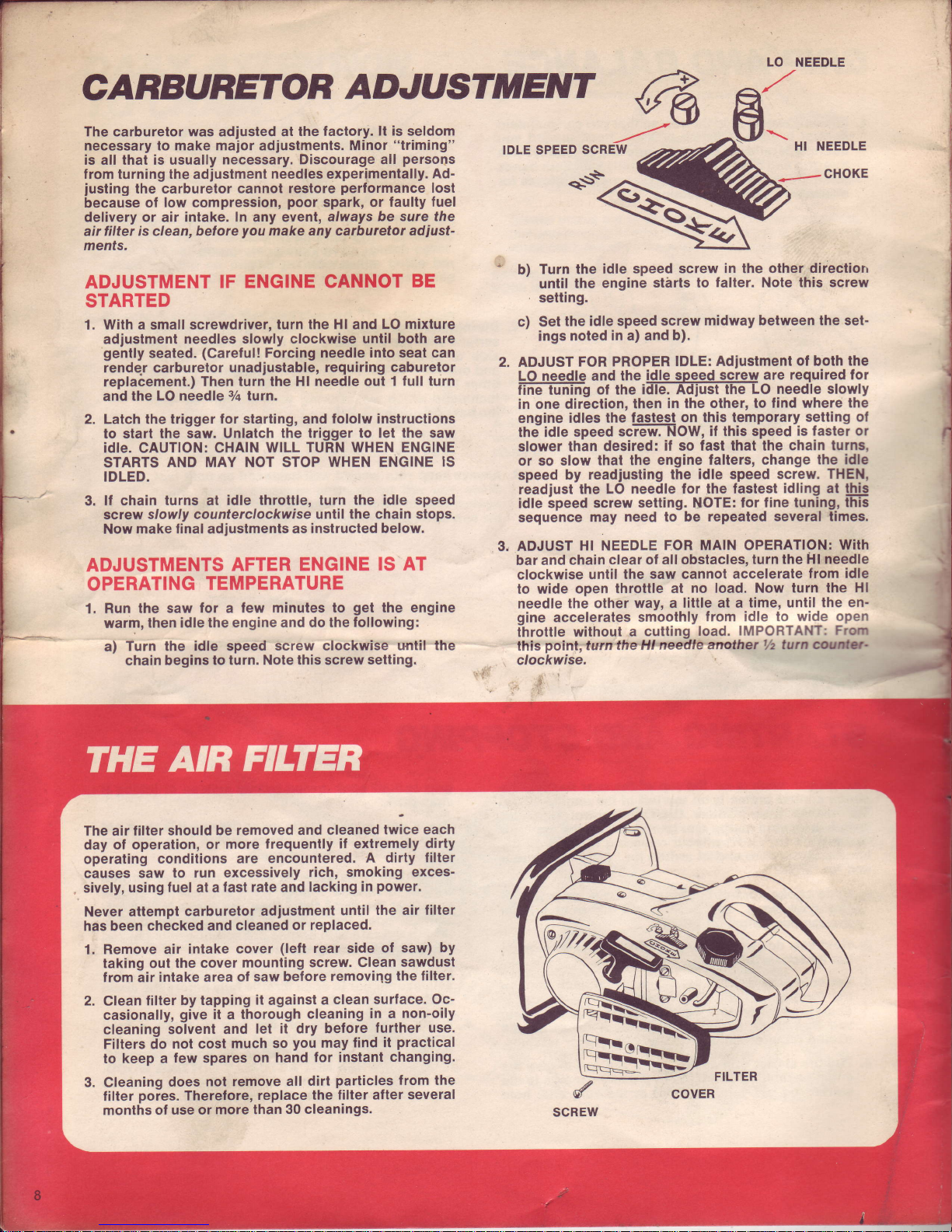

CARBURET

OR

ADJ U

STNilENT

fr

The carburetor was adjusted at

the factory.

lt is

seldom

necessary to make

major

adjustments.

Minor

"triming"

is all that is usually

necessary. Discourage all

persons

from

turning

the

adjustment

needles experimentally.

Ad-

justing

the carburetor

cannot restore

performance

lost

because

of

low compression,

poor

spark, or

faulty fuel

defivery or air intake. In any evenl,

always

be sure the

air

filter is clean,

belore

you

make any carburetor adiust-

ments.

ADJUSTMENT

IF

ENGINE

CANNOT

BE

STARTED

With a small screwdriver,

turn the Hl and

LO mixture

adjustment needles slowly

clockwise until

both

are

gently

seated.

(Careful!

Forcing

needle

into seat can

rende-r carburetor

unadjustable, requiring

caburetor

replaiement.)

Then turri the Ht

ireedle ou-i 1 full turn

and the

LO needle

3/+

lurn.

Latch the

trigger for starting, and

lololw instructions

lo start

the saw. Unlatch

the trigger to let

the

saw

idle. CAUTION: GHAIN

WILL TURN WHEN ENGINE

STARTS

AND MAY NOT STOP WHEN ENGINE

IS

IDLED.

3. lf chain

turns al idle throttle, turn

lhe idle speed

screw

slowly counterclockwise until

the chain stops.

Now

make linal adjustments as

instructed below.

ADJUSTMENTS

AFTER ENGINE

IS AT

OPERATING

TEMPERATURE

1.

Run the saw

for a few

minules to

get

the engine

warm,

then idle the engine

and do the lollowing:

a)

Turn the idle speed

sclew clockwise

until the

chain begins

to turn. Note

this

screw

setting.

+ts+

*

b)

Turn the

idle speed

screw in the

other

direction

until the

engine

starts to

falter.

Note

this screw

'

setting.

c) Set

the

idle speed

screw

midway between the set-

ings noted

in a) and b).

2. ADJUST

FOR PROPER

IDLE:

Adiustment

ol

both

the

LOrcedte

and

the

idle speed screw

are required for

iiFe tuning

of the

iiiiiltiir5TThEl,o

needie slowly

in one

direction,

then in the

other, to find where

the

engine

idles the

fastest on

this temporary setting

of

th;idle

speed

sciffiNOw,

il this speed-is

fastei or

slower

than

desired:

if so fast thal the

chain turns'

or so slow that

lhe

engine falters, change

the idle

speed

by readjusting

the idle speed

screw.

THEN,

readjust the

LO needle

for

lhe

fastest

idling at

!!!9

idte

speed screw

setting.

NOTE:

for

line tuning, lhis

sequence

may

need to be repeated

several limes.

3, ADJUST

Hl NEEDLE

FOR

MAIN OPERATION:

With

bar and

chain clear

of all obstacles,

turn the Hl needle

clockwise until

the saw cannot

accelerate

flom idle

to wide

open

throttle at

no

load. Now

turn the

Hl

needle

the other

way, a little at a

time, until the

en-

gine

accelerates

smoothly

lrom

idle

to wide open

throttle

without a

cutting

load.

IMPORTANT:

Frqn

this

point,turntheltffittanother

th

turn oo*s

clockwise.

IDLE

SPEED SCREW

1.

The air filter

should be removed

and cleaned

twice each

day

of operation, or

more

frequently if extremely

diriy

operating

condilions

are encountered.

A dirty lilter

causes

saw

to run excessively

rich,

smoking exces-

sively, using

luel at a

fast rate

and

lacking

in

power.

Never

attempt

carburetor

adiustment

until

the air filter

has

been checked

and cleaned

or replaced.

1.

Remove air

intake

cover

(left

rear side

of saw)

by

taking

out

the cover

mounting screw.

Glean sawdust

from air

intake area ol

saw belore

removing

the filter.

2. Clean

filter by

tapping

it

against

a

clean surface. Oc-

casionally,

give

it a

thorough

cleaning

in a

non'oily

cleaning

solvent and

let it dry befote

further use.

Filters do

not cost

much so

you

may

lind it

practical

to keep

a

few

spares

on

hand

lor instant

changing.

3.

Cleaning

does

not remove

all dirt

particles

lrom the

filter

pores.

Therefore,

replace

the lilter after

several

months of

use or

more than

30 cleanings'

Loading...

Loading...