HOLZMANN MASCHINEN SB4132SM, SB4132LR User Manual

HOLZMANN-MASCHINEN GmbH

Marktplatz 4 · 4170 Haslach · Austria

Telefon +43.(0) 7289. 71562- 0

Telefax +43.(0)7289.71562 -4

Email info@holzmann-maschinen.at

HOLZMANN SB 4132SM / SB 4132LR

Návod k použití Stojanová vrtčka

User Manual drill press

www.holzmann-maschinen.at

Revision 1 / 07.10.14

ENGLISH

1

ČESKY

Dear Customer!

This manual contains Information and im-

portant instructions for the installation and

correct use of the drill press SB 4132SM.

This manual is part of the machine and

shall not be stored separately from the

machine. Save it for later reference and

if you let other persons use the machine,

add this instruction to the machine.

Please read and obey the security

instructions!

Before rst use read this manual carefully.

It eases the correct use of the machine

and prevents misunderstanding and damages of machine and the user’s health.

Due to constant advancements in product

design construction pictures and content

may diverse slightly. However, if you discover any errors, inform us please.

Technical specications are subject to

changes!

Copyright © 2011

This document is protected by interna-

tional copyright law. Any unauthorized

duplication, translation or use of pictures,

illustrations or text of this manual will be

pursued by law – court of jurisdiction is

A-4020 Linz, Austria!

Contact adress:

HOLZMANN MASCHINEN GmbH

4170 Haslach

Marktplatz 4

Tel.: +43 (0) 7289 71562 0

Fax: +43 (0) 7289 71562 4

MO-FR 8:00-12 & 13:00-17:00 GMT +1

Vážený zákazníku!

Tento návod k použití obsahuje důležité

informace a pokyny k uvedení do provozu

a používání stojanové vrtačky SB 4132SM.

Návod k použití je nedílnou součástí stroje

a nesmí od něj být odstraněn. Pokud stroj

předáváte někomu třetímu, návod vždy

přiložte!

Dbejte bezpečnostních pokynů!

Před uvedením stroje do provozu

si pozorně přečtěte návod. Usnadníte tím používání stroje a vyhnete

se omylům, škodám a zraněním.

Vlivem stálého zlepšování našeho výrobku se mohou vyobrazení a obsah návodu

lehce odlišovat od skutečnosti. Pokud

narazíte na chybu, uvědomte nás o ní!

Technické změny vyhrazeny!

Autorské právo © 2011

Tato dokumentace je chráněna autor-

ským právem. Všechna práva vyhrazena!

Obzvláště kopírování, přetisk, překlady

nebo použití fotograí a vyobrazení budou

trestně stíhány – soudní místo je Linz, Rakousko!

Kontakt:

HOLZMANN MASCHINEN GmbH

4170 Haslach

Marktplatz 4

Tel.: +43 (0) 7289 71562 0

Fax: +43 (0) 7289 71562 4

MO-FR 8:00-12 & 13:00-17:00 GMT +1

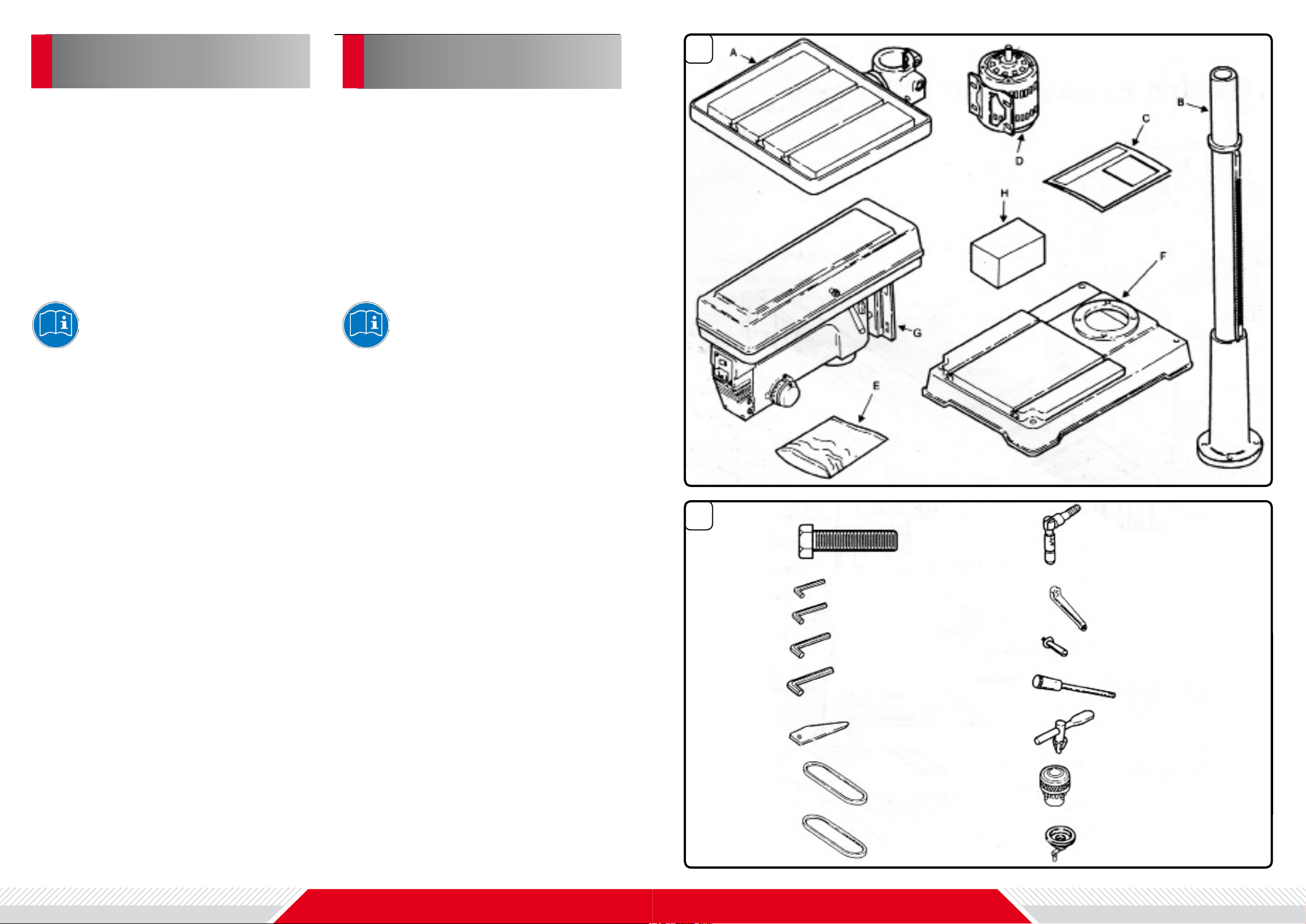

2

4x

1x

1x

1x

1x

1x

1x

1x

S1

M3

M4

M5

M6

K

V-A29

V-A33

1x

1x

1x

3x

1x

1x

1x

L

N1

N2

Z

CH1

CH2

W

www.holzmann-maschinen.at

3

1. SAFETY

READ THE MANUAL

Read and understand the owner’s manual and labels axed to

the machine. Learn the machines application eld and limitations as well as the specic potential hazards peculiar to it.

AVOID DANGEROUS CONDITIONS

Keep working area and the ground clean and free of oil and other

materials!

Assure that the working area is suciently lighted!

Don’t use the machine outside!

The use of the machine is forbidden if you are tired, not concentrated as well if you are under the inuence of medicaments,

alcohol and other drugs. Reduce distraction sources in the working area.

BEWARE: Routine leads to insucient attention.

OPERATOR

The machine shall be used only by trained persons wiht an age

of at least 18 years.

Non authorized personnel, especially children, shall be kept away

from the machine! Make your workshop childproof.

CLOTHING

When working with the machine, don’t wear loose clothing, long

hair openly or loose jewellery like necklaces etc. Loose objects

might be catched by rotating parts and cause serious injuries.

SAFETY EQUIPMENT

Use proper safety clothing and devices when operating the machine (safety glasses, ear protectors)!

ELECTRIC CONNECTION

Assure yourself that your feeding current complies with the requirements of the motor - check the typeplate.

Electric checks and the electric installation of the machine may

only be performed by a qualied electrician.

DO NOT touch leading machine parts.

www.holzmann-maschinen.at

Prior to any Cleaning, checks, maintenance or tool change shut

the machine o and disconnect it from the power supply in order

to prevent unintended start up of the machine.

GROUNDING

In the event of a malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of

electric shock. The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all

local codes and ordinances. Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualied electrician whether the machine is grounded properly.

REMOVE ADJUSTING KEYS AND WRENCHES

DRILL SPECIFIC SAFETY RULES

Form a habit of checking to see whether adjusting keys, wrenches and other objects are removed from the machine before turning it on.

DO NOT FORCE THE MACHINE

It will do a better job when being used within its power range it

has been constructed for. Do not misuse the machine or parts of

it for jobs for which it was not intended.

USE PROPER EXTENSION CORD

Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one with sucient cross-section to carry the current your machine will draw. An undersized

cord will cause a drop in the line voltage resulting in power loss

and overheating.

USE ONLY RECOMMENDED AND SAFE ACCESORIES

Use only accesories matching with the machines specications

and being suitable for the use with the machine. Especially important are the max. allowed revolution speeds for which the

accesory is allowed to be used. Use only Accesories whose max.

allowed revolution speed is higher than the max. speed of the

machine you intend them to use with.

DRILL SAFETY

Do not drill workpieces that are too small to be supported safely.

For smaller workpieces you should install a vice onto the working

table and support the workpiece with the vice.

HAZARD FROM DUST

SOME DUST CREATED by power sanding, sawing, grinding, drilling and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

• Your risk from those exposures varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are

specically designed to lter out microscopic particles.

WORK SAFETY RULES

Take care to remove the Chuck key from the drill chuck before

turning the machine on.

The drill bit shall not touch the workpiece when turning the machine on.

Especially workpieces with not even surface have to be clamped

by a vice.

Never change, remove, adjust workpiece while machine is running.

INTENDED USE

This vertical drill press is designed for performing vertical drills

with max. diameter of 20mm and max. drilling depth of 100mm

into suitable materials under the premise to use the correct combination of drill bits, spindle speed and feed rate.

Stainless steel can be drilled up to a diameter of 16mm

The intended use incorporates sucient knowledge of the opera-

tor regarding the work with drill presses and regarding accident

prevention rules, sucient material knowledge as well as sufcient maintenance.

Any manipulation of the machine is a misuse, in this case HOLZMANN-Maschinen and its sales partners cannot be made liable

for ANY direct or indirect damage.

It is imperative to obey all safety rules as well as assembly, operation and maintenance instructions to keep alive your guarantee rights.

REMAINING RISKS

The work with a drill press always incorportates some remaining

risks which can never be eliminated entirely and the operator

should be aware of:

Hazard of severe injury when touching the rotating drill bit, drill

chuck or spindle.

Hazard of cutting injury caused by sharp drill edges or sharp

metal chips.

Hazard of injury through material or parts of the workpiece being catapulted away.

SECURITY DEVICES

The drill press is equipped with an ON/OFF switch with a emergency OFF cap activating the red OFF button when being depressed.

The drill press has an automatic OFF switch which is activated as

long as the drive belt cover is not closed entirely

Finally obey all general working safety rules imperative when

operating a machine and follow all rules and regulations being

in power in your country regarding safety at work, accident prevention, rst aid, re prevention.

www.holzmann-maschinen.at

The drill press is equipped with a chip protection cover which

should be always used when performing drills.

2. SETUP

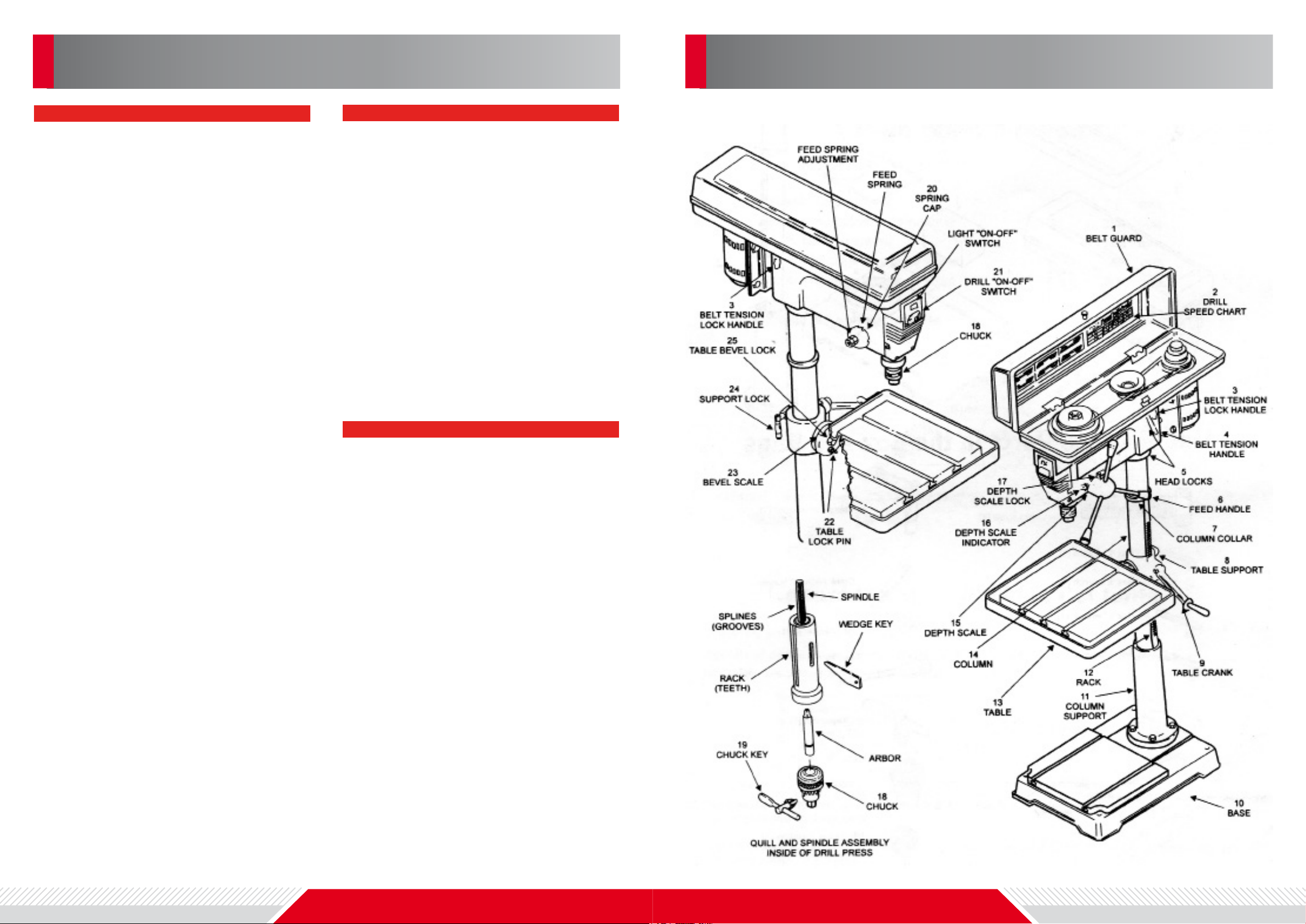

3. MACHINE DESCRIPTION

DELIVERY CONTENT

Unpack and separate all parts from packaging material and check with gure 1 and

2 the delivery content for completeness

before discarding any packing material.

Please report eventual missing or damaged parts immediately to your reseller.

Later claims from transport damage cannot be accepted anymore.

SEE FIGURE 1

A Working Table

B Column

C User Manual

D Motor

E Bag of Loose parts

F Base Stand

G Head Assembly

H Box of Loose parts

SEE FIGURE 2

MAIN SPECIFICATION

Chuck capacity 20mm

Distance Spindle to column 254mm

max. spindle travel 120mm

max. distance chuck to table 595mm

max. distance chuck to base 1075mm

Net weight 144kg

Spindle speeds at

motor speed 1400rpm 700rpm

120 60

200 100

250 120

360 180

400 200

450 220

950 470

1280 640

1520 760

1840 920

2440 1220

3480 1740

ASSEMBLY

The bag (E) and box (H) of loose parts

contain:

S1 4x M12x1.75-40 Hex head screw

M3 1x M3 Hex L type hex wrench

M4 1x M4 Hex L type hex wrench

M5 1x M5 Hex L type hex wrench

M6 1x M6 Hex L type hex wrench

K 1x Key-drift

V-A29 1x V-type drive belt A29

V-A33 1x V-type drive belt A33

L 1x Clamp-column lock

N1 1x Crank (with set screw)

N2 1x Handle for Crank N1

Z 3x Feed Handle

CH1 1x Drill Chuck

CH2 2x Key for Drill Chuck CH1

W 1x idler pullex assembly

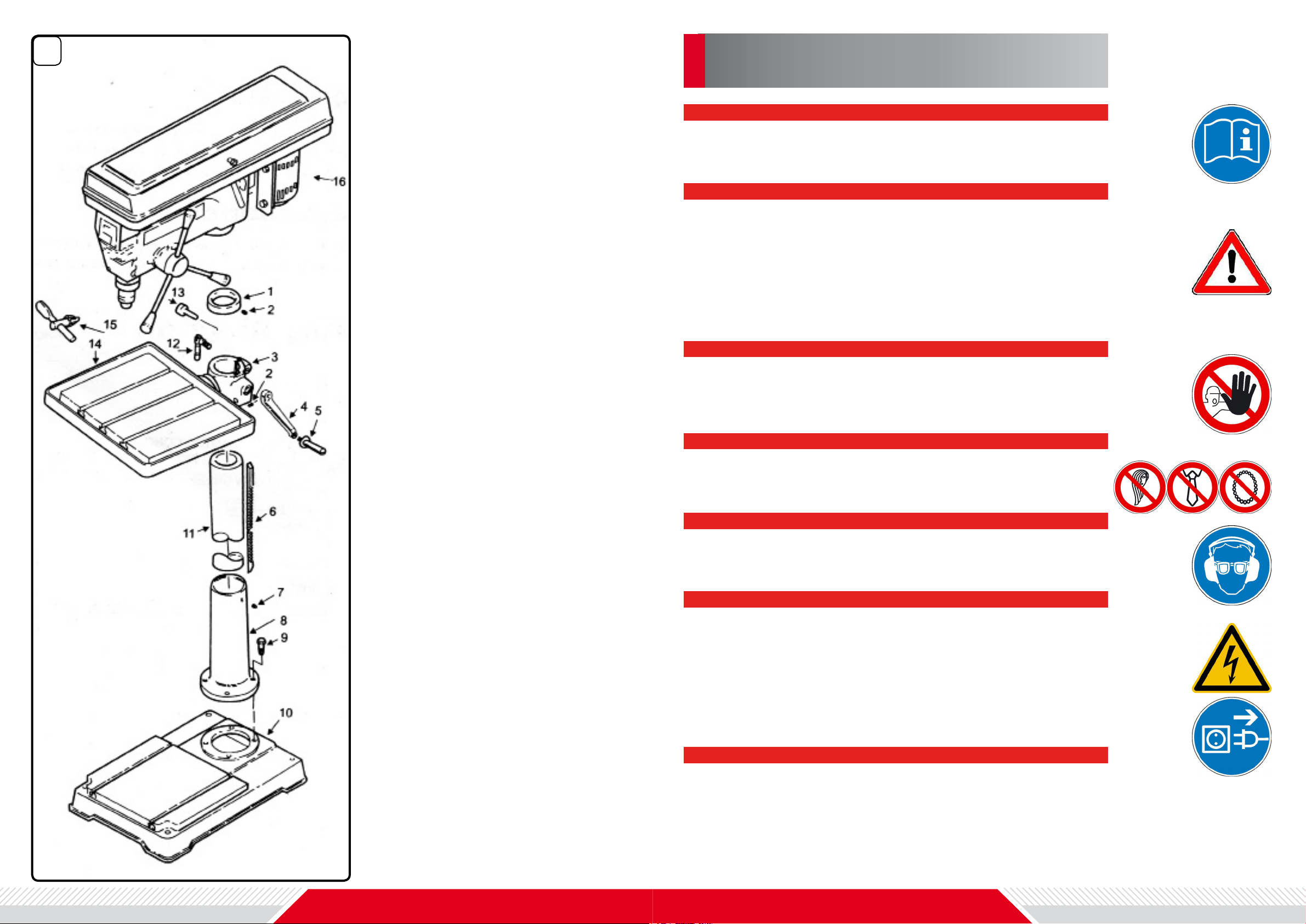

REFER TO FIGURE 3 to install all parts correctly.

Assembly procedure is in short:

complete Head Assembly (G + W + Z

+D)

connect Base to Column & rack

Table onto column with rack

nished Head assembly to column

Be sure to tighten all screws and bolts se-

curely.

1 Collar Rack

2 Screw Hex soc set M6x1.0-10

3 Table support

4 Crank

5 Crank Handle

6 Rack

7 Hex Screw M10x1.5-12

8 Column Support

9 Hex Head screw M12x1.75-40

10 Base

11 Column

12 Table Lock

www.holzmann-maschinen.at

Loading...

Loading...