HOLZMANN MASCHINEN SB 3116RHN, SB 3116RMN User Manual

HOLZMANN-MASCHINEN GmbH

Marktplatz 4 · 4170 Haslach · Austria

Telefon +43.(0) 7289.71562 -0

Telefax +43.(0) 7289.71562 -4

Email info@holzmann-maschinen.at

www.holzmann-maschinen.at

Revision 1 / 12.12.2011

HOLZMANN SB 3116RHN / SB 3116RMN

Bedienungsanleitung Ständerbohrmaschine

User Manual drill press

www.holzmann-maschinen.at

Dear Customer!

This manual contains Information and important instructions for the installation and

correct use of the drill press SB 3116RHN.

This manual is part of the machine and

shall not be stored separately from the

machine. Save it for later reference and

if you let other persons use the machine,

add this instruction to the machine.

Please read and obey the security

instructions!

Before rst use read this manual carefully.

It eases the correct use of the machine

and prevents misunderstanding and damages of machine and the user’s health.

Due to constant advancements in product

design construction pictures and content

may diverse slightly. However, if you discover any errors, inform us please.

Technical specications are subject to

changes!

Copyright © 2011

This document is protected by international copyright law. Any unauthorized

duplication, translation or use of pictures,

illustrations or text of this manual will be

pursued by law – court of jurisdiction is

A-4020 Linz, Austria!

Contact adress:

HOLZMANN MASCHINEN GmbH

4170 Haslach

Marktplatz 4

Tel.: +43 (0) 7289 71562 0

Fax: +43 (0) 7289 71562 4

MO-FR 8:00-12 & 13:00-17:00 GMT +1

Sehr geehrter Kunde!

Diese Bedienungsanleitung enthält Informationen und wichtige Hinweise zur Inbetriebnahme und Handhabung der Ständerbohrmaschine SB 3116RHN . Die

Bedienungsanleitung ist Bestandteil der

Maschine und darf nicht entfernt werden.

Bewahren Sie sie für spätere Zwecke auf

und legen Sie diese Anleitung der Maschine bei, wenn sie an Dritte weitergegeben

wird!

Bitte beachten Sie die Sicherheitshinweise!

Lesen Sie vor Inbetriebnahme diese Anleitung aufmerksam durch. Der sachgemäße

Umgang wird Ihnen dadurch erleichtert,

Missverständnissen und etwaigen Schäden wird vorgebeugt. Halten Sie sich an

die Warn- und Sicherheitshinweise. Missachtung kann zu ernsten Verletzungen

führen.

Durch die ständige Weiterentwicklung unserer Produkte können Abbildungen und

Inhalte geringfügig abweichen. Sollten Sie

jedoch Fehler feststellen, informieren Sie

uns bitte.

Technische Änderungen und Irrtümer vorbehalten!

Urheberrecht © 2011

Diese Dokumentation ist urheberrechtlich

geschützt. Die dadurch verfassungsmäßigen Rechte bleiben vorbehalten! Insbesondere der Nachdruck, die Übersetzung

und die Entnahme von Fotos und Abbildungen werden gerichtlich verfolgt – Gerichtsstand ist A-4020 Linz, Austria!

Kontakt:

HOLZMANN MASCHINEN GmbH

4170 Haslach

Marktplatz 4

Tel.: +43 (0) 7289 71562 0

Fax: +43 (0) 7289 71562 4

MO-FR 8:00-12 & 13:00-17:00 GMT +1

ENGLISH

DEUTSCH

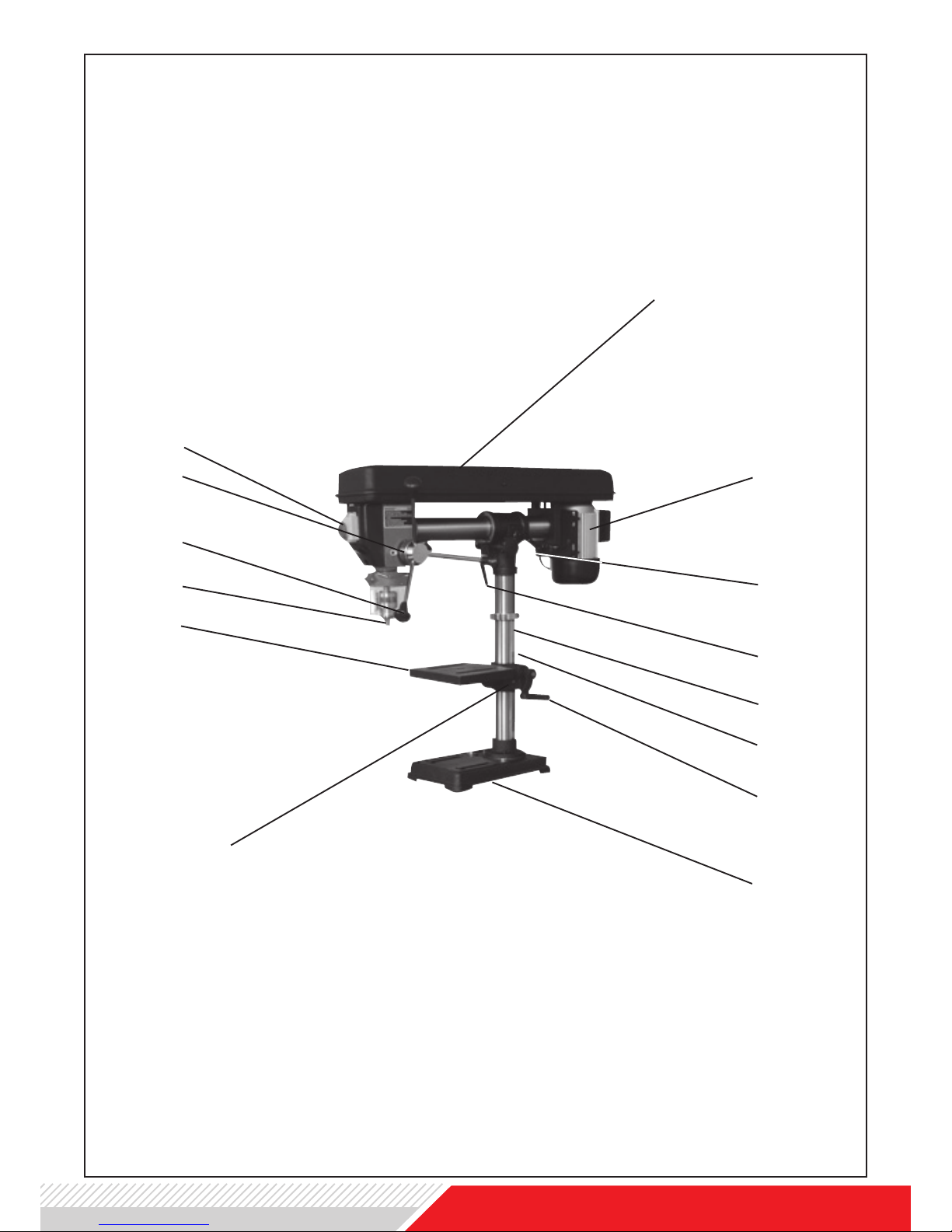

1

2

3

4

5

7

8

6

9

10

11

12

13

14

15

Abb. 1.1/Fig. 1.1

SB 3116RHN

www.holzmann-maschinen.at

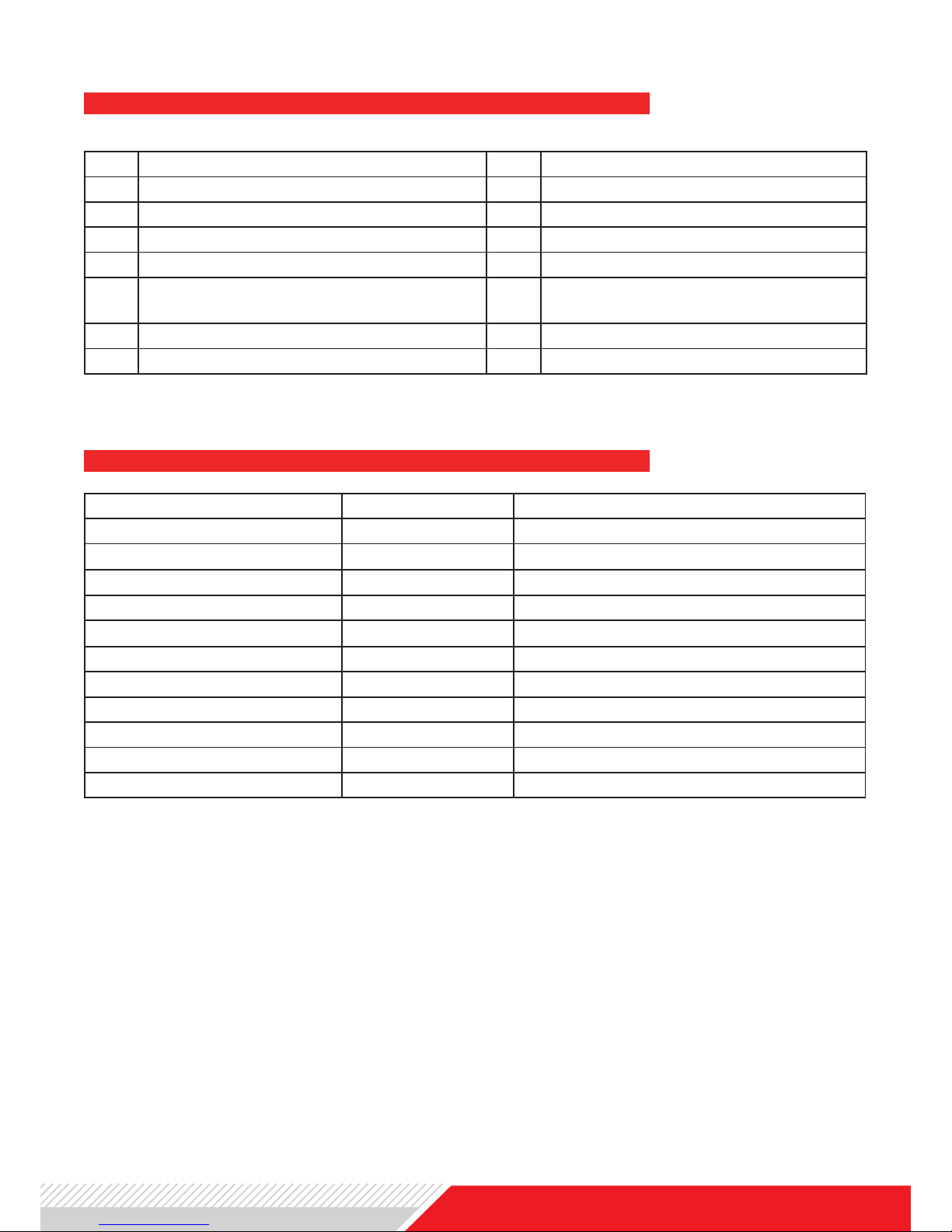

1

2

3

4

5

7

8

6

9

10

11

12

13

14

Abb. 1.2/Fig. 1.2

SB 3116RMN

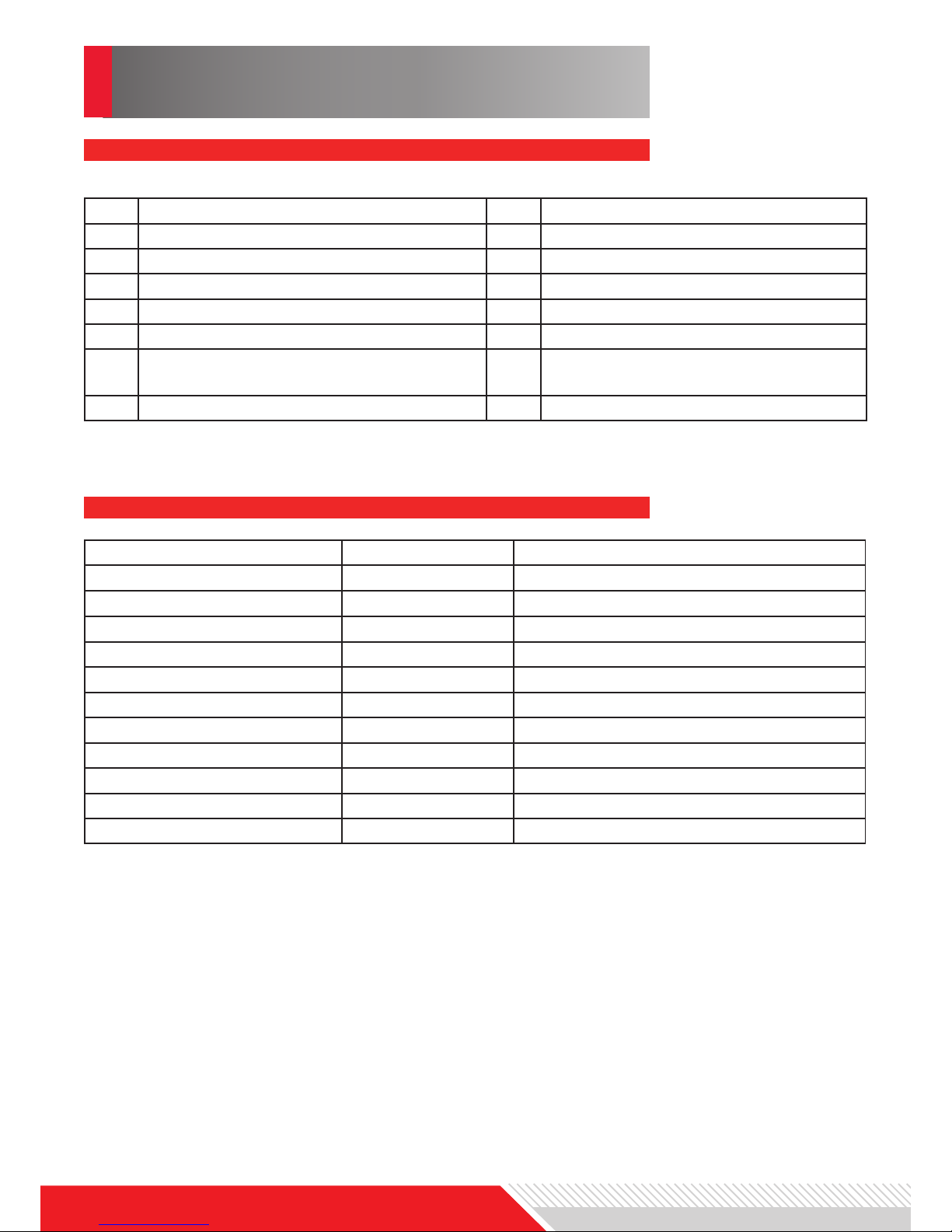

1. TECHNIQUE

Description to SB 3116RHN Fig. 1.1

Technical Details SB 3116RHN

max. drilling capacity

mm 16

spindle speeds

rpm (5) 500-2500

voltage

V 400 oder 230

distance spindle to column

mm 430

spindle holder

MT2

max. spindle travel

mm 80

max. distance chuck to table

mm 825

max. distance chuck to base

mm 1315

table dimensions

Ø300

base

mm 456x280

motor power S1(100%)

W 600

net weight

kg 58

1 pulley cover 9 table bracket

2 motor 10 clamping lever

3 clamping lever for radial adjustment 11 table

4 clamping lever 12 drill chuck

5 column 13 feed lever

6 rack 14 scale ring

7 handle 15 On/Off/ switch and emergency

stop

8 base

The SB 3116RHN is a very solid radial drill - due to various setting possibilities it can be

used for various tasks.

• Head can be moved around within 320mm back and forth.

• Head can be tilted 45° clockwise and 90° counterclockwise.

• Head can be turned round within 360°.

• It can be locked at any position within the adjustable angle.

• Speed can be changed at 5 levels

www.holzmann-maschinen.at

Description to Fig. 1.2 SB 3116RMN

Technical Details SB 3116RMN

max. drilling capacity

mm 16

spindle speeds

rpm (5) 500-2500

voltage

V 230 oder 400

distance spindle to column

mm 430

spindle holder

MT2

max. spindle travel

mm 80

max. distance chuck to table

mm 320

max. distance chuck to base

mm 475

table dimensions

mm

215x225

base

mm 350x215

motor power S1(100%)

W 600

net weight

kg 40

1 pulley cover 9 table bracket

2 motor 10 table

3 clamping lever for radial adjustment 11 drill chuck

4 clamping lever 12 feed lever

5 column 13 scale ring

6 rack 14 On/Off/ switch and emergency

stop

7 handle

8 base

The SB 3116RMN is a very solid table radial drill - due to various setting possibilities it

can be used for various tasks.

• Head can be moved around within 320mm back and forth.

• Head can be tilted 45° clockwise and 90° counterclockwise.

• Head can be turned round within 360°.

• It can be locked at any position within the adjustable angle.

• Speed can be changed at 5 levels

2. SAFETY

Read and understand the owner’s manual and labels afxed to

the machine. Learn the machines application eld and limitations as well as the specic potential hazards peculiar to it.

Keep working area and the ground clean and free of oil and other

materials!

Assure that the working area is sufciently lighted!

Don’t use the machine outside!

The use of the machine is forbidden if you are tired, not con-

centrated as well if you are under the inuence of medicaments,

alcohol and other drugs. Reduce distraction sources in the working area.

BEWARE: Routine leads to insufcient attention.

The machine shall be used only by trained persons wiht an age

of at least 18 years.

Non authorized personnel, especially children, shall be kept away

from the machine! Make your workshop childproof.

When working with the machine, don’t wear loose clothing, long

hair openly or loose jewellery like necklaces etc. Loose objects

might be catched by rotating parts and cause serious injuries.

Use proper safety clothing and devices when operating the machine (safety glasses, ear protectors)!

Assure yourself that your feeding current complies with the requirements of the motor - check the typeplate.

Electric checks and the electric installation of the machine may

only be performed by a qualied electrician.

DO NOT touch leading machine parts.

Prior to any Cleaning, checks, maintenance or tool change shut

the machine off and disconnect it from the power supply in order

to prevent unintended start up of the machine.

In the event of a malfunction or breakdown, grounding provides

a path of least resistance for electric current to reduce the risk of

electric shock. The plug must be plugged into a matching outlet

that is properly installed and grounded in accordance with all

local codes and ordinances. Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

Check with a qualied electrician whether the machine is grounded properly.

READ THE MANUAL

AVOID DANGEROUS CONDITIONS

OPERATOR

CLOTHING

SAFETY EQUIPMENT

ELECTRIC CONNECTION

GROUNDING

www.holzmann-maschinen.at

Form a habit of checking to see whether adjusting keys, wrenches and other objects are removed from the machine before turn-

ing it on.

It will do a better job when being used within its power range it

has been constructed for. Do not misuse the machine or parts of

it for jobs for which it was not intended.

Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one with sufcient cross-section to carry the current your machine will draw. An undersized

cord will cause a drop in the line voltage resulting in power loss

and overheating.

Use only accesories matching with the machines specications

and being suitable for the use with the machine. Especially important are the max. allowed revolution speeds for which the

accesory is allowed to be used. Use only Accesories whose max.

allowed revolution speed is higher than the max. speed of the

machine you intend them to use with.

Do not drill workpieces that are too small to be supported safely.

For smaller workpieces you should install a vice onto the working

table and support the workpiece with the vice.

SOME DUST CREATED by power sanding, sawing, grinding, drilling and other construction activities contains chemicals known to

cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead based paint

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber.

• Your risk from those exposures varies, depending on how of-

ten you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are

specically designed to lter out microscopic particles.

Finally obey all general working safety rules imperative when

operating a machine and follow all rules and regulations being

in power in your country regarding safety at work, accident pre-

vention, rst aid, re prevention.

DO NOT FORCE THE MACHINE

USE PROPER EXTENSION CORD

USE ONLY RECOMMENDED AND SAFE ACCESORIES

DRILL SAFETY

HAZARD FROM DUST

REMOVE ADJUSTING KEYS AND WRENCHES

WORK SAFETY RULES

Take care to remove the Chuck key from the drill chuck before

turning the machine on.

The drill bit shall not touch the workpiece when turning the machine on.

Especially workpieces with not even surface have to be clamped

by a vice.

Never change, remove, adjust workpiece while machine is running.

The work with a drill press always incorportates some remaining

risks which can never be eliminated entirely and the operator

should be aware of:

Hazard of severe injury when touching the rotating drill bit, drill

chuck or spindle.

Hazard of cutting injury caused by sharp drill edges or sharp

metal chips.

Hazard of injury through material or parts of the workpiece being catapulted away.

The drill press is equipped with an ON/OFF switch with a emergency OFF cap activating the red OFF button when being depressed.

The drill press has an automatic OFF switch which is activated as

long as the drive belt cover is not closed entirely

The drill press is equipped with a chip protection cover which

should be always used when performing drills.

REMAINING RISKS

SECURITY DEVICES

DRILL SPECIFIC SAFETY RULES

www.holzmann-maschinen.at

Unpack and separate all parts from packaging material and check if the delivery content

is complete. For checking refere to Fig. 3, Fig. 4 and Fig. 5 .

Please report eventual missing or damaged parts immediately to your reseller.

Later claims from transport damage cannot be accepted anymore.

DELIVERY CONTENT

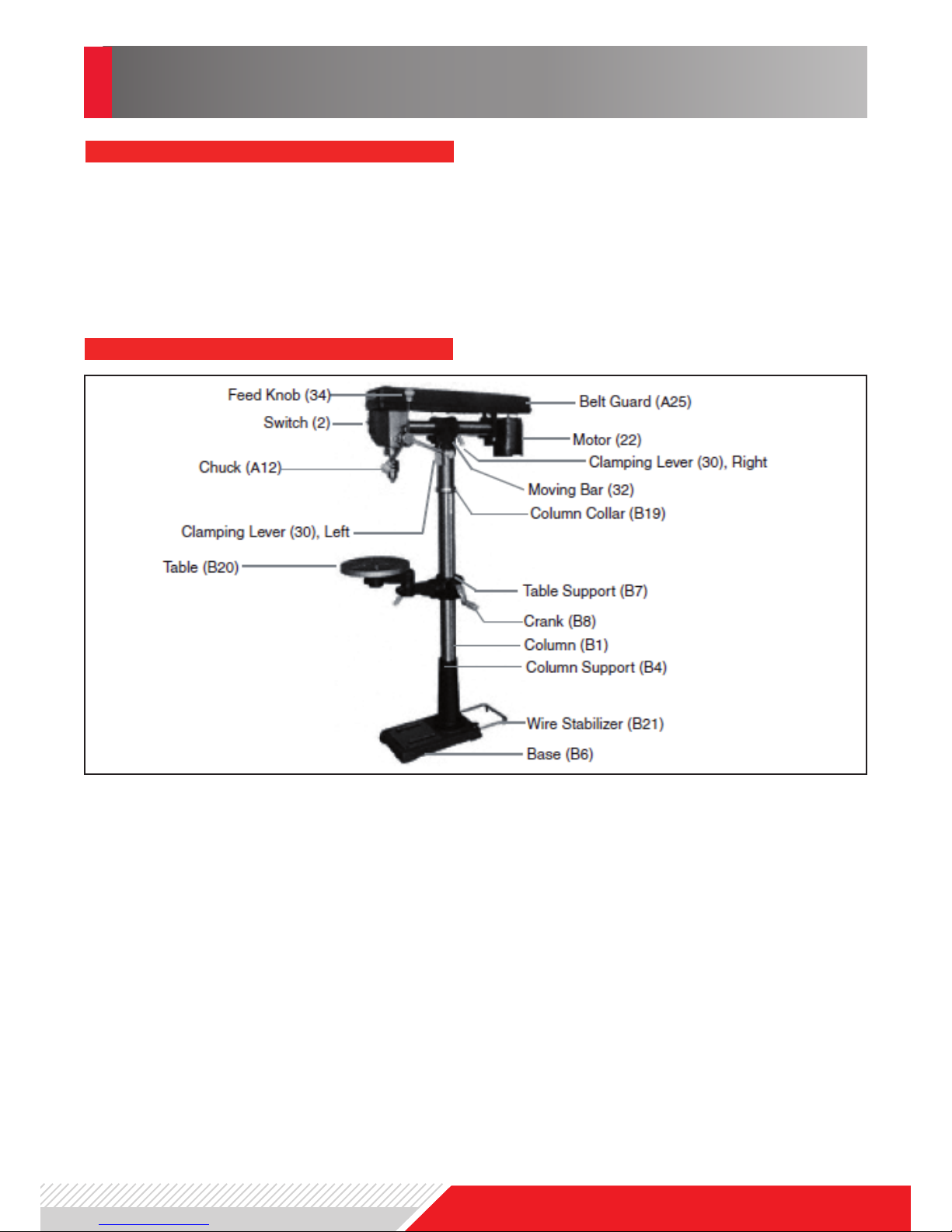

Assembly hardware is located in one box

and one bag. Each contains the necessary

parts for each assembly step. Remove all

packing and protective material from the

Drill Press components. To aid in assembly, refer to the Assembly Drawing Fig. 2

as well as to the parts drawings at the end

of this manual. The machine assembly is

shown on basis of the model SB 3116RHN.

1. Position the Base (B6) on a level and

sturdy oor for mounting.

Bolt the Base to the oor using appropri-

ate hardware (not supplied). Base holes

will accommodate 7/16 inch bolts. Pull out

the Wire Stabilizer (B21) rod from the rear

of the Base.

2. Place the Column Support (B4) on the

Base, aligning the mounting holes.

ASSEMBLY

3. SETUP

3. Insert four large Hex Screws (B5) into

the mounting holes and tighten with a

wrench.

4. Insert the Column (B1) into the Column

Support (B4) and secure with Screw (B3).

5. Install the Table Support (B7), with attached table Arm (B14), over the Column

(B1) and slide it down. Engage the gears onto the Rack (B2). Tighten the Table

Clamp (B13).

6. Slide the Column Collar (B19) over and

down the Column (B1) about 8 inches.

Tighten Screw (B11).

7. Place the Extend Arm (B15) into the

Arm (B14), and then the Table (B20) into

the opening in the Extend Arm.

Abb. 2/Fig. 2

CAUTION:

Avoid injuries. The next step involves

lifting the Head Assembly onto the

Column. The Head Assembly is heavy.

Have someone help you lift this assembly into place.

8. Using two people, lift the Head Assembly and insert the Column Guide (18) over

the Column (B1).

Slide it down on the Column Tube as far as

it will go. Align it so that it faces straight

forward, inline with the Base.

9. Insert one Locking Shoe (15) into place

inside the bottom of the Column Guide

(18), and the other on the outside of the

Column Guide. Tighten the Clamping Lever (30) into the Locking Shoe at the base

of the Column Guide.

10. Adjust V-Belt (A1) tension or change

speeds.

- Open the Belt Guard (A25) to expose the

V-Belt.

- Loosen the Thumb Nut (28) to relieve

the V-Belt tension.

- If necessary, move the Belt up or down

on the pulleys to change the drill speed.

- Push the Motor backward, tightening the

Belt on the pulleys, and hold in place.

- Turn the Thumb Nut (28) clockwise to

tighten the V-Belt in place.

- Refer to the chart inside the Guard lid to

select speed and belt locations.

Note: To test the proper belt tension, push

in on the center of each belt at its center.

It should move only 1/2 inch (in or out).

Caution: overtightening the belts can

cause the motor to bind, and not start.

It can also damage Motor bearings.

11. Locate the Feed Knobs (34) and Feed

Rods (35) and screw into the Hub (36).

12. Install the Chuck (A12).

- Thoroughly clean the tapered hole in the

Chuck and the Spindle (A15) shaft of all

dirt, grease, oil, and protective coatings

(paint thinner may be necessary).

- Slide the Chuck onto the Spindle shaft.

- Turn the Chuck sleeve clockwise and

open the jaws completely.

- Tap the nose of the Chuck lightly with a

piece of wood to securely set the Chuck.

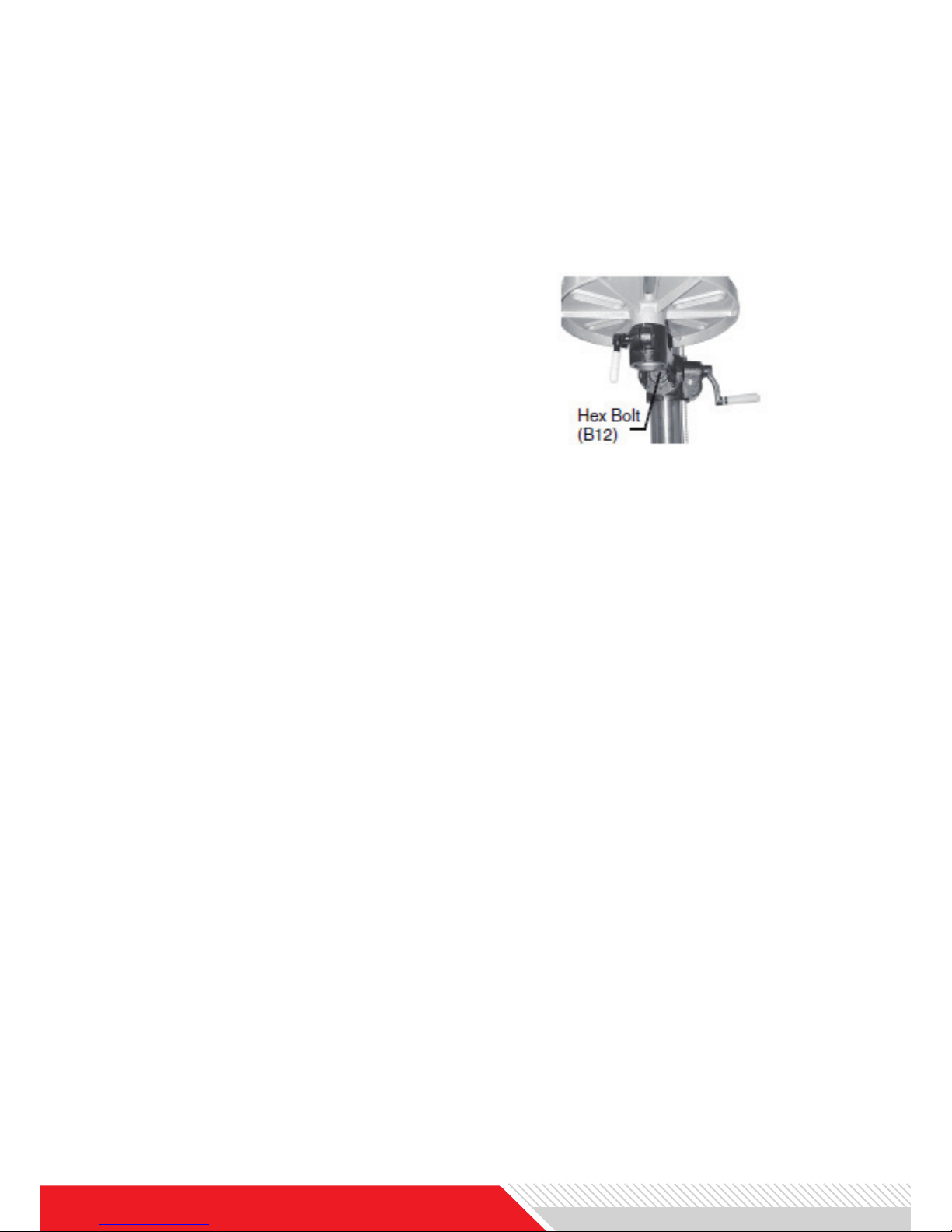

13. Verify that the Table (B20) is square

(90 degrees) to the Head Assembly and

drill bit.

- Raise the Table to within four inches of

the Chuck.

- Place the long side of a combination

square on the Table.

- Align the short side of the square to the

drill bit.

- If the Table is not square to the bit, loosen Hex Bolt (B12) with a wrench.

- Rotate the Table until it is square to the

bit.

- Retighten the Hex Bolt (B12).

Loading...

Loading...