Features

•

Operating voltage: 2.2V ~3.5V

•

Low power crystal oscillator control

–

512, 1200, or 2400 bps data rate operation

•

Decodes CCI R Radio-paging Code

No.1 (POCSAG Code)

•

2-bit random and optional 4-bit burst error

correction

•

Improved synchronization algorithm

•

Supports up to 6 independently programmable user addresses and 6 user frames

•

Three RF power on timing control pins

•

Single crystal for all available baud rate

(76.8kHz crystal)

•

Battery low indication (external detector)

•

Battery fail interrupt and data ready

interrupt

•

8K×16 program ROM

•

416×8 data RAM

General Description

The HT9480 is a high performance pager controller. The built-in single cycle instructions

(16-bit wide) and two-stage pipeline architecture of the HT9480 account for its high perform-

HT9480

Pager Controller

•

35×4 LCD display

•

7 input lines and 10 bidirectional I/O lines

•

8-bit programmable timer for R TC

interrupt

•

8-bit programmable timer/event counter

and overflow interrupt

•

8-bit programmable tone generator with

buzzer output

•

Watchdog timer

•

Halt function and wa ke-up feature reduce

power consumption

•

63 powerful instructions, most instructions

in one machine cycle

•

Eight-level subroutine nesting

•

Table read instruction

•

Inverted or non-inverted input signal

selection for decoder input

•

80-pin LQFP package

ance. The controller contains a full function

pager decoder (POCSAG code) at 512, 1200, or

2400 bits per second data rate and an LCD

display driver with a 35

×4 dot output.

1 23th Feb ’98

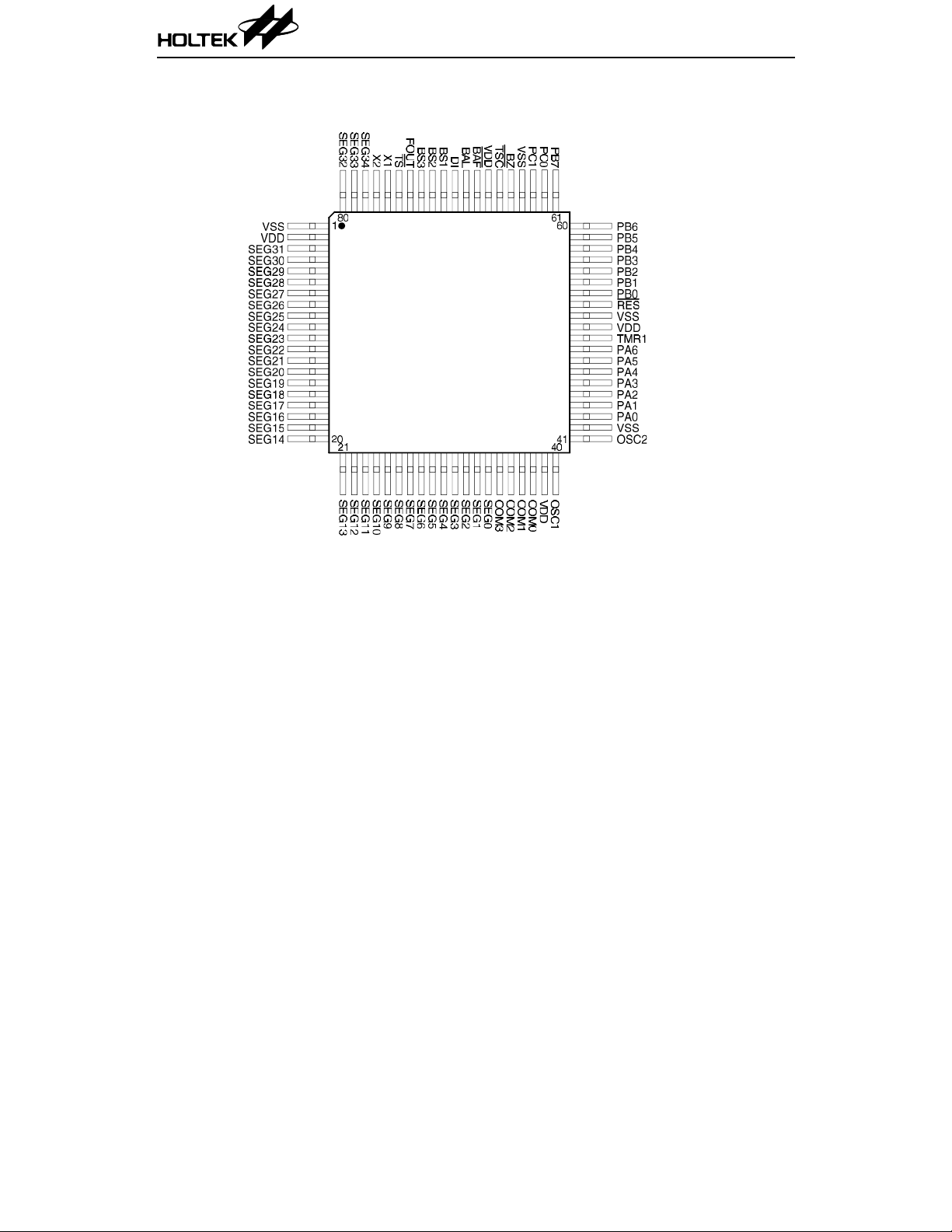

Pin Assignment

HT9480

2 23th Feb ’98

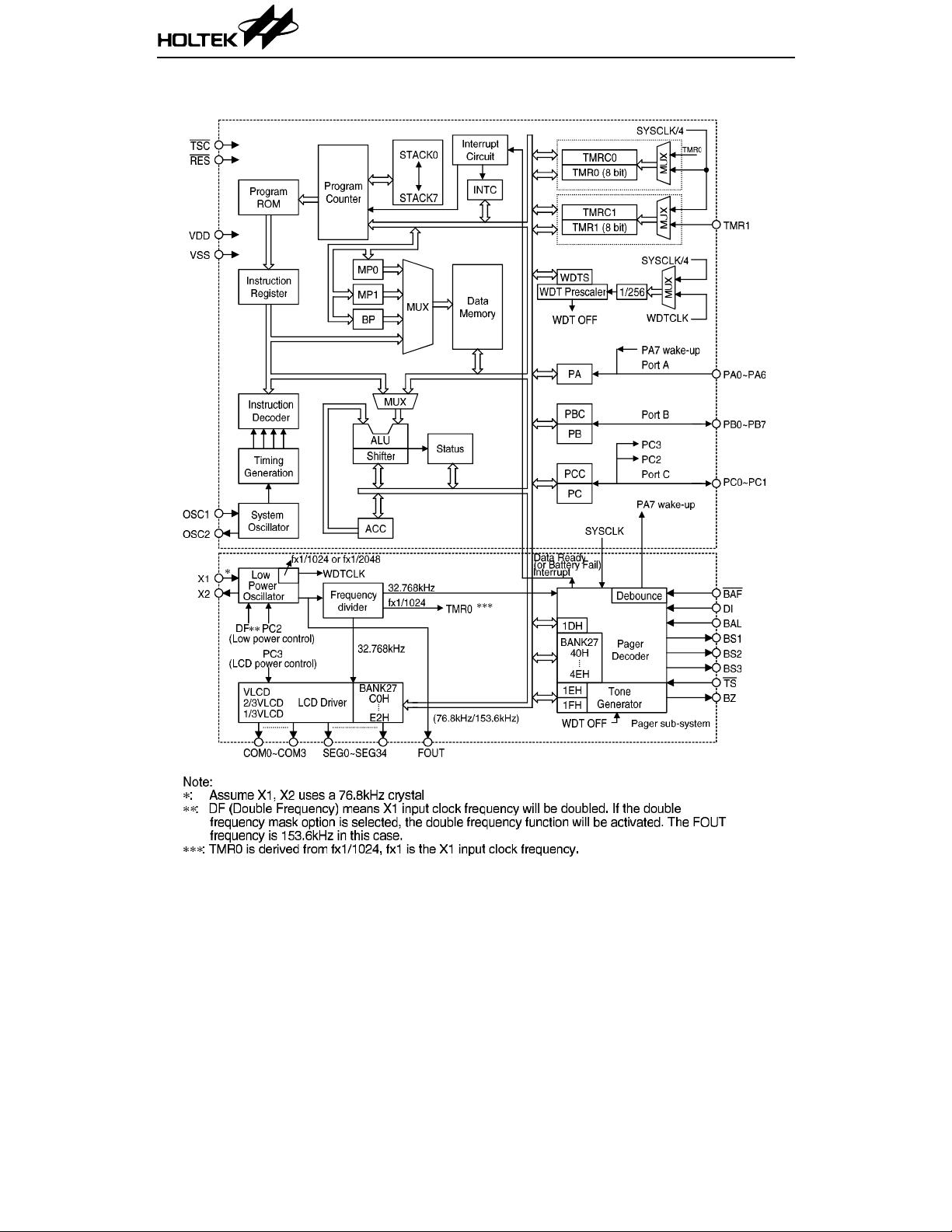

Block Diagram

HT9480

3 23th Feb ’98

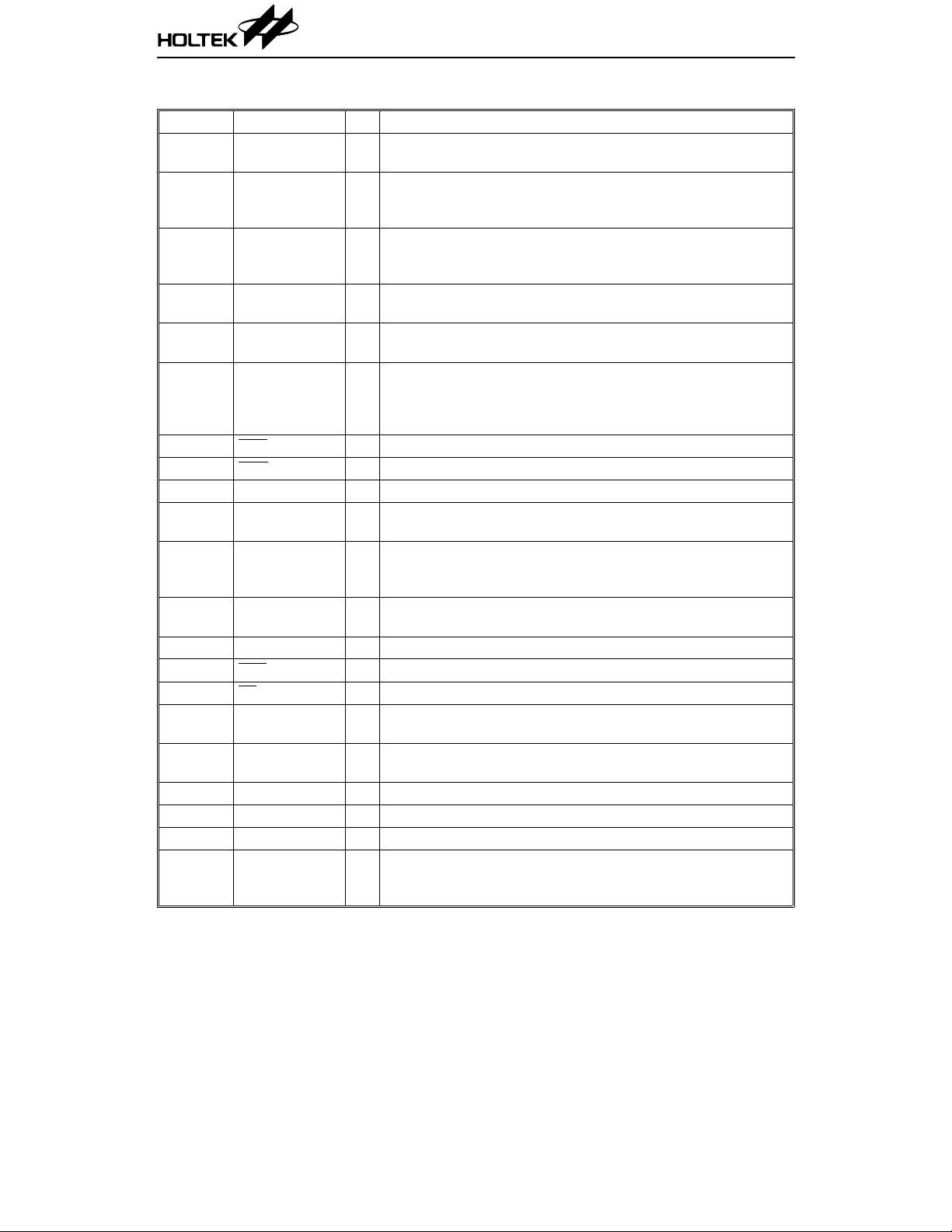

HT9480

Pin Description

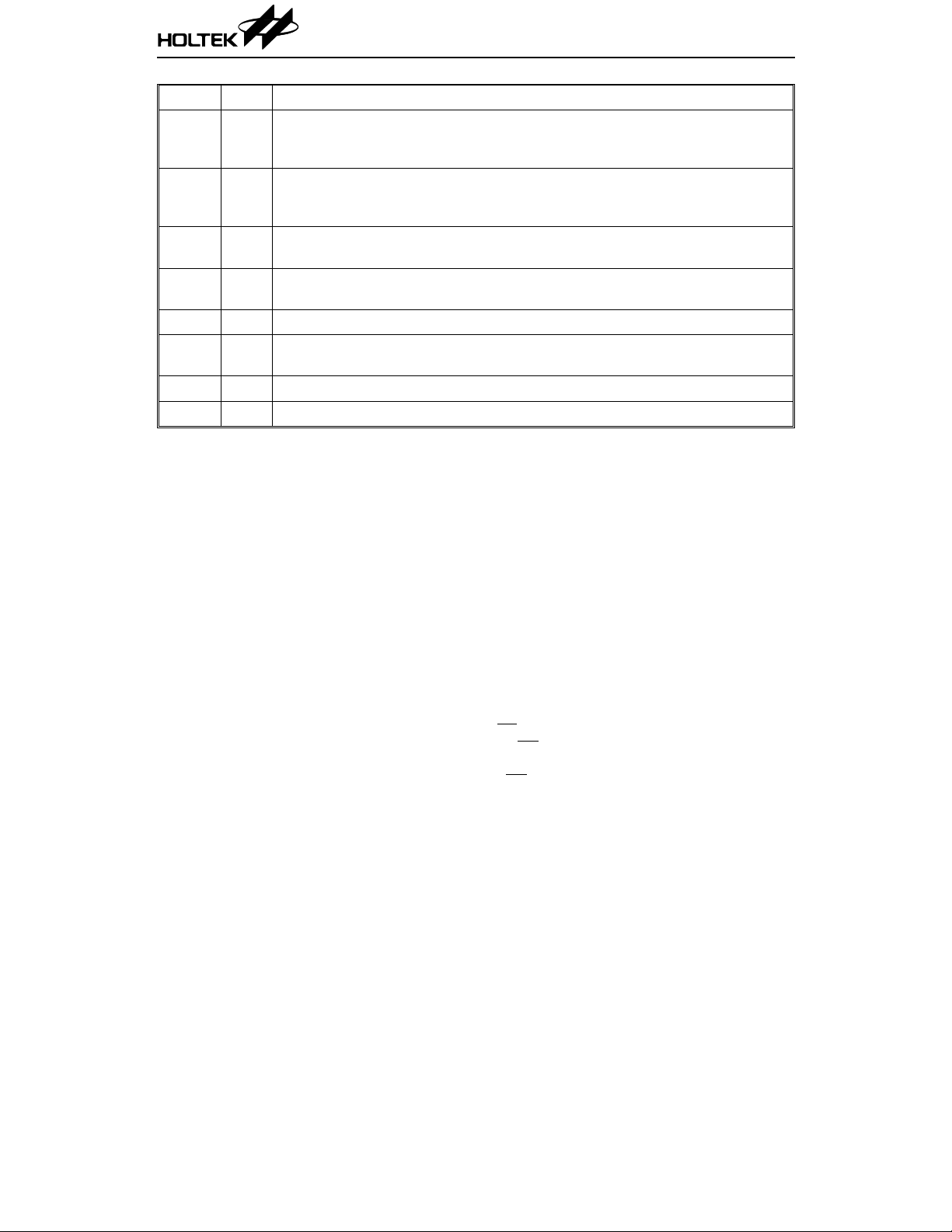

Pin No Pin Name I/O Function

43~49 PA0~PA6 I

54~61 PB0~PB7 I/O

62~63 PC0~PC1 I/O

1, 42,

52, 64

76

77

40

41

53

68

50 TMR1 I Schmitt trigger input for timer/event counter

2, 39, 51

67

65 BZ O

3~34

78~80

35~38 COM3~COM0 O Outputs for LCD panel common connections

66

75

69 BAL I

70 DI I

71 BS1 O Pager receiver power control enable output, CMOS output

72 BS2 O RF dc level adjustment pin, CMOS output

73 BS3 O PLL control pin, CMOS output

74 FOUT O

VSS Negative power supply (GND)

X1

X2

OSC1

OSC2

RES I Schmitt trigger reset input, active low

BAF I Battery fail interrupt with debounce circuit input

VDD Positive power supply

SEG31~SEG0

SEG34~SEG32

TSC I

TS I Decoder test mode input pin, active low with a pull-high resistor

7-bit input ports, with pull-high resistors

Each bit can be configured as a wake-up input by mask option.

Bidirectional 8-bit input/output ports, pull-high mask option

The output structures, whether tri-state or CMOS, are

determined by software instructions.

Bidirectional 2-bit input/output ports, pull-high mask option

The output structures, whether tri-state or CMOS, are

determined by software instructions.

IOX1 and X2 are connected to an external crystal to form an

internal low power oscillator clock.

OSC1 and OSC2 are connected to an RC network or a crystal

I

(determined by mask option) to form the system clock oscillator.

O

For RC operation , OSC2 is the output terminal of the system

clock.

Buzzer non-inverting BZ output

The BZ pin outputs “high” at buzzer off (by setting the value 00H

of 1DH)

O LCD driver outputs for LCD panel segments

µC test mode input pin, active low with pull-high resistor

Battery low indication input, active high without pull-high

resistor

POCSAG cod e input serial da ta (inverting o r non-inve rting as

determined by SPF32). CMOS input without pull-high resistor

Frequency reference output pin

The FOUT output pin produces a 76.8kHz/153.6kHz signal with

a 1/2 duty cycle reference frequency if a 76.8kHz crystal is used.

4 23th Feb ’98

HT9480

Absolute Maximum Ratings*

Supply Voltage.......... ................ ....–0.3V to 5.5V

Input Voltage..................V

–0.3V to VDD+0.3V

SS

*Note: Stresses above those listed under “Absolute Maximum Ratings” may cause permanent

damage to the device. The se are stress ratings on ly. Functional opera tion of this device at

these or any other conditions above those indicated in the operational sections of this

specification is not implied and exposure to absolute maximum rating conditions for extended

periods may affect device reliability.

Storage Temperature.................–50

Operating Temperature...............–25

°C to 125°C

°C to 85°C

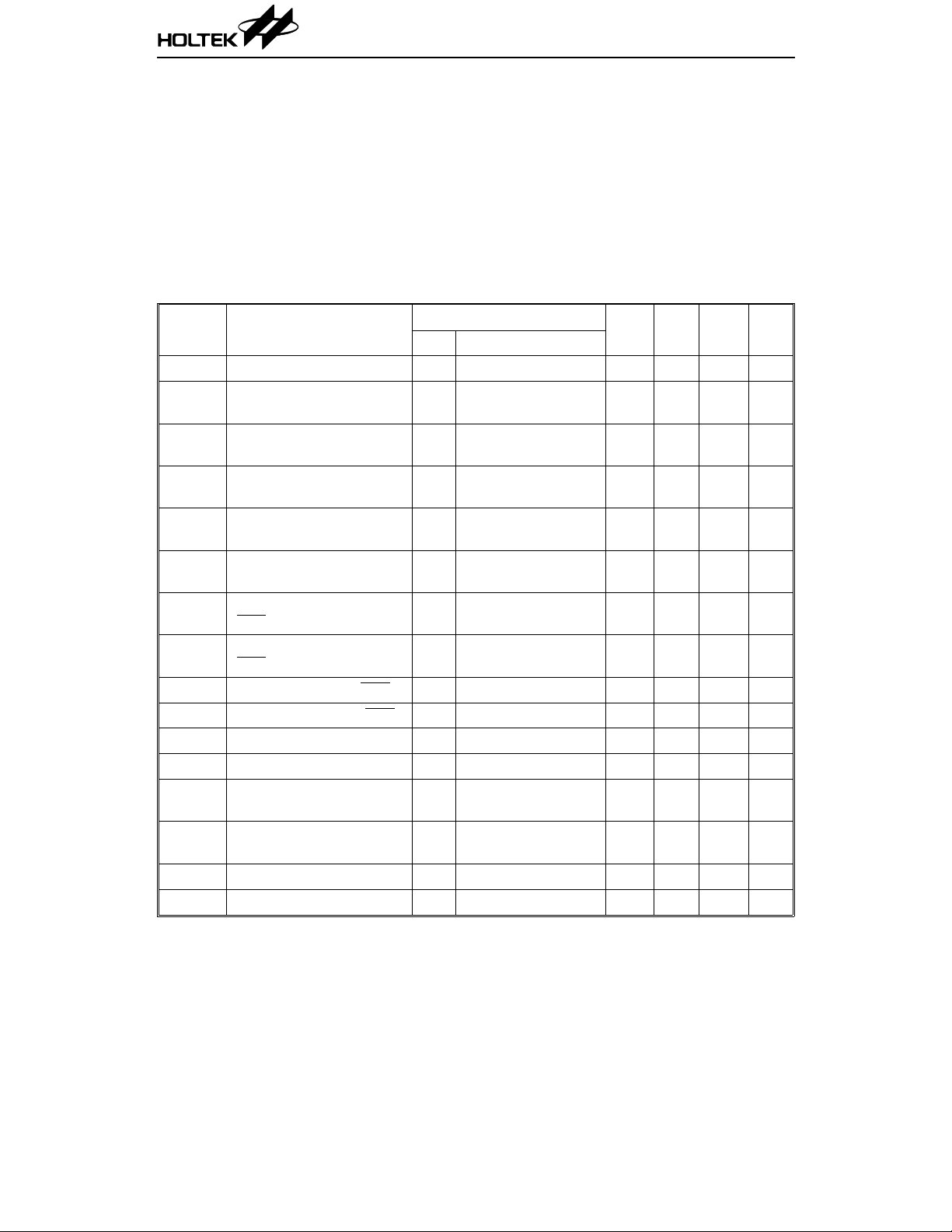

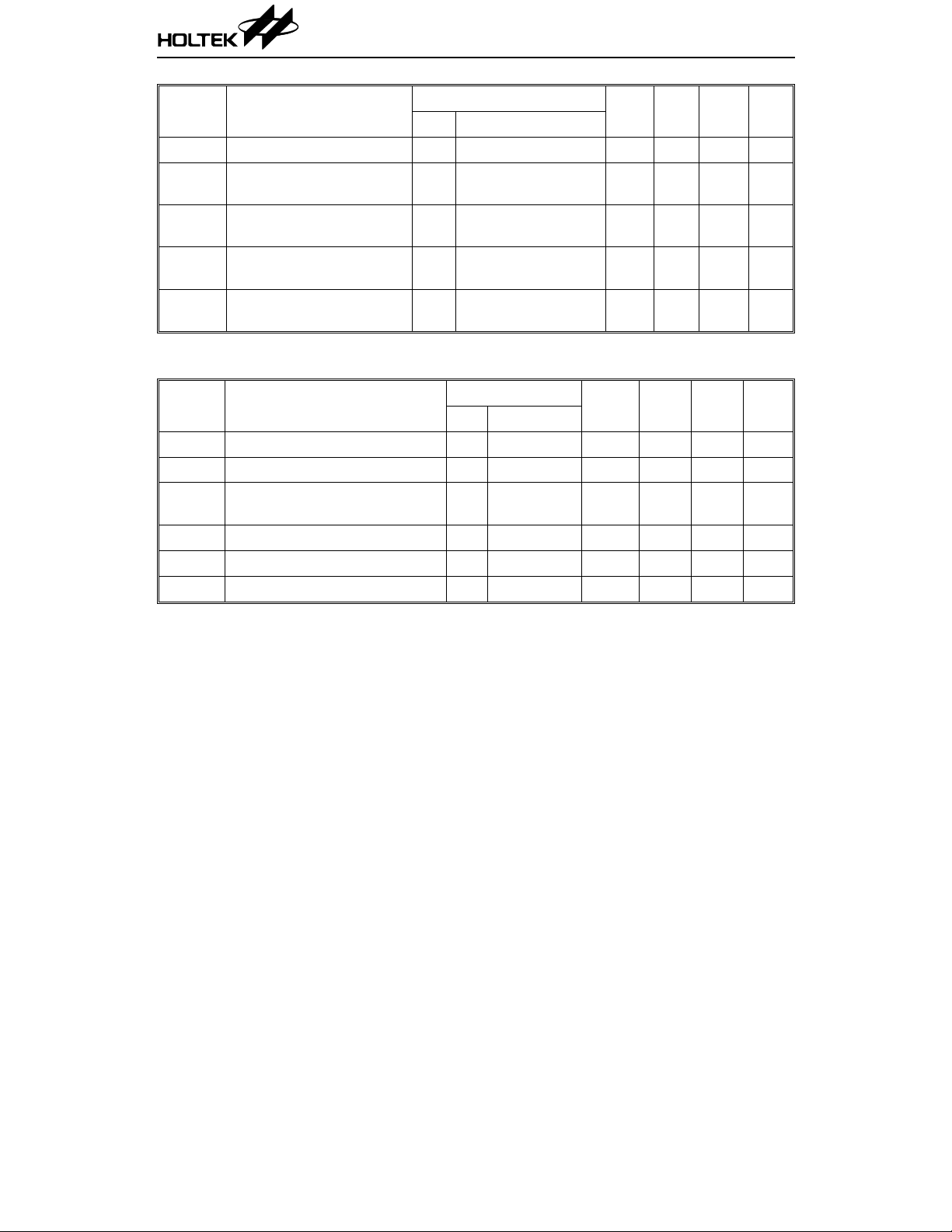

D.C. Characteristics

Symbol Parameter

V

DD

I

DD

I

STB1

I

STB2

V

IL

V

IH

V

IL1

V

IH1

V

IL2

V

IH2

I

OL

I

OH

I

OL

I

OH

I

OL

I

OH

Operating Voltage — 3V application 2.2 3.0 3.5 V

Operating Current 3V

Standby Current 1 3V

Standby Current 2 3V

Input Low Voltage for

Input Port and I/O Port

Input High Voltage for

Input Port and I/O Port

Input Low Voltage

(

RES,TMR1,BAL)

Input High Voltage

(

RES,TMR1,BAL)

Input Low Voltage (BAF) 3V — 0 — 0.9 V

Input High Voltage (BAF) 3V — 1.3 — 3 V

I/O Port Sink Current 3V VOL=0.3V 1.7 3.4 — mA

I/O Port Source Current 3V VOH=2.7V –1 –1.9 — mA

Segment 0-34 Output

Sink Current

Segment 0-34 Output

Source Current

BZ, Sink Current 3V VOL=0.3V 1 2.5 — mA

BZ, Source Current 3V VOH=2.7V –1 –2 — mA

(Ta=25°C)

Test Conditions

V

DD

Conditions

No load,

fsys=153.6kHz

No load, System

HALT (Watchdog ON)

No load, System

HALT (Watchdog OFF)

Min. Typ. Max. Unit

—300—

—200—

—— 1

3V — 0 — 1 V

3V — 2.2 — 3 V

3V — 0 — 1 V

3V — 2.2 — 3 V

3V V

3V V

=0.3V 20 44 —

OL

=2.7V –20 –38 —

OH

µA

µA

µA

µA

µA

5 23th Feb ’98

HT9480

Symbol Parameter

I

OL

I

OH

I

OL

I

OH

R

PH

PC0~PC1 Sink C urrent 3V VOL=0.3V 1.7 3.4 — mA

PC0~PC1 Source Current

if Pull-High Mask Option

BS1, BS2, BS3, FOUT Sink

Current

BS1, BS2, BS3, FOUT

Source Current

Pull-High I/O Port

Resistance

A.C. Characteristics

Symbol Parameter

f

SYS1

f

SYS2

f

SUBSYS

f

TIMER

t

RES

t

INT

System Clock (RC OSC) 3V — 76.8 256 1000 kHz

System Clock (Crystal OSC) 3V — 76.8 256 1000 kHz

Pager Subsystem Clock

(Crystal OSC)

Timer I/P Frequency (TMR1) 3V — 0 — 1000 kHz

External Reset Low Pulse Width — — 1 — —

Interrupt Pulse Width — — 1 — —

Test Conditions

V

DD

3V V

3V V

3V V

OH

=0.3V 350 — —

OL

OH

Conditions

=2.7V –1 –1.9 — mA

=2.7V –0.9 — — mA

Min. Typ. Max. Unit

3V — 100 200 500

Test Conditions

V

Conditions

DD

Min. Typ. Max. Unit

3V — 32.768 76.8 153.6 kHz

µA

Ω

k

(Ta=25°C)

µs

µs

* Note: t

SYS

=1/f

SYS

6 23th Feb ’98

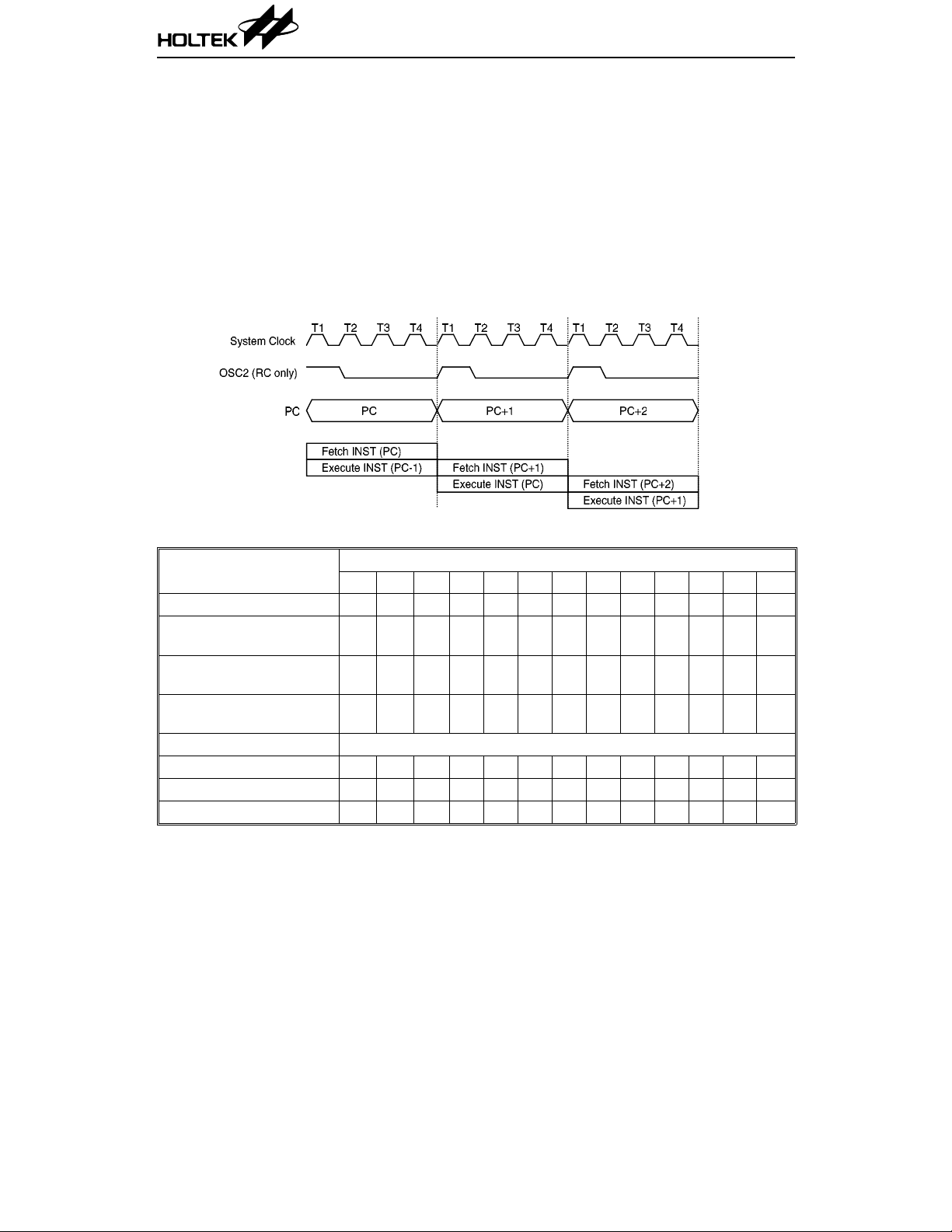

System Architecture

HT9480

Execution flow

The HT9480 system clock can be derived from

either a crystal or an RC o scillator. It is internally divided into four non-overlapping clocks

denoted by P1, P2, P3, and P4. Each instruction

cycle consists of T1 to T4.

Instruction fetching and execution are pipelined in such a way that a fetch takes an instruction cycle while decoding and execution

take the next instru ction cycle. The p ipelining

Execution flow

Mode

Initial reset 0000000000000

Data ready interrupt and

battery fail interrupt

Programmable timer

interrupt

Timer/event Counter

interrupt

Skip PC+2

Loading PCL *12 *11 *10 *9 *8 @7 @6 @5 @4 @3 @2 @1 @0

Jump, call branch #12#11#10#9#8#7#6#5#4#3#2#1#0

Return from subroutine S12 S11 S10 S9 S8 S7 S6 S5 S4 S3 S2 S1 S0

*12 *11 *10 *9 *8 *7 *6 *5 *4 *3 *2 *1 *0

0 000000000100

0 000000001000

0 000000001100

scheme causes each instruction to effectively

execute within a cycle. If an instruction changes

the content of the progra m counter two cycles

are required to complete the instruction.

Program counter – P C

The program cou nter (PC) is 13-bit wide and

controls the program ROM instruction sequence executi on. The contents of th e PC can

specify a of maximum 8192 addresses.

Program Counter

Notes:

*12~*0: Program counter bits

#12~#0: Instruction code bits

Program counter

S12~S0: Stack register bits

@7~@0: PCL bits

7 23th Feb ’98

The PC value is incremented by one after a

program memory word is accessed in order to

fetch an instruction code. The PC then points to

a memory word with the next instruction code.

The PC loads the address corresponding to each

instruction and then manipulates program

transfer while executing a jump instruction,

conditional skip execution, loading a PCL, a

register, a subroutine call, an i nitial reset, an

internal interrupt, an external interrupt, or returning from a subroutine.

The conditional skip is activated by instructions. Once the condi tion is satisfied, the next

instruction, fetched duri ng the current instruction execution, is discarded, and a dummy cycle

is replaced to get a proper instruction. Oth erwise it proceeds with the following instruction.

The low byte of the PC (PCL) is a readable and

writable register (06H). Moving data into the

PCL performs a sho rt ju mp. Th e des tin ation i s

within 256 locations.

If a control transfer takes pla ce, an additional

dummy cycle is required.

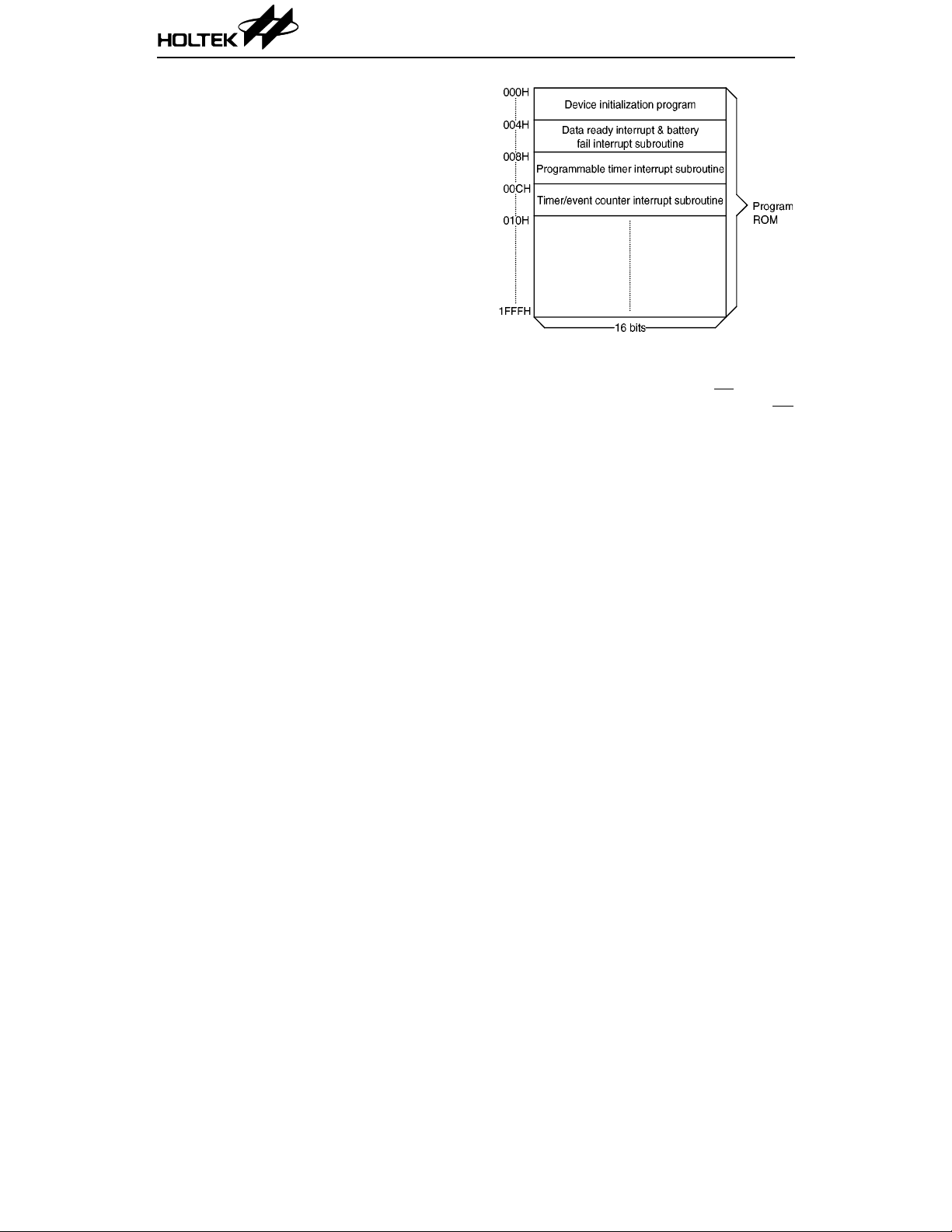

Program memory – ROM

The program memory (ROM) is used to store

the program instructions that are to be executed. It consists of data, table(s), and interrupt

entries, and is organized into 8192

×16 bits,

which are addressed by the PC and table pointer.

Certain location s in the ROM are reserved for

specific usage:

•

Location 0000H

Location 0000H is reserved for program in-

itialization. The progra m always begins execution at this lo cation each time the chip is

reset.

•

Location 0004H

Location 0004H is reserved for the data ready

interrupt and battery fail interrupt service

programs. If an interrupt results from a pager

decoder inte rrupt request or from a battery

fail interrupt request, and the interrupt is

enabled, and the stack is not full, the program

begins exe cution at location 0004 H. The occurrence of a data ready interrupt or a battery

HT9480

Program memory

fail interrupt is detected by checking the battery fail interrupt bit (1EH-bit 4,

the data ready inte rrupt bit (1EH-bit 7,

flag). The interrupt shou ld be carefu lly processed if both interrupt bits are active.

•

Location 0008H

Location 0008H is reserved fo r the program-

mable timer interru pt service program. If a n

interrupt results from a programmable timer

interrupt request (its source is from 256Hz

divided by N, where the value of N ranges

from 1 to 256.), and the in terrupt is enab led,

and the stack is no t full, the program begins

execution at location 0008H.

•

Location 000CH

Location 000CH is reserved for the timer/event

counter interrupt service program. If a timer

interrupt results from a timer/event counter

overflow, and the interrupt is enabled, and the

stack is not full, the program begins execution

at location 000CH.

•

Look-up tables XX00H~XXFFH

The ROM is composed of 32 groups (each

group contains 256 con tinuous words) whi ch

can be used as look–up tables. The instructions “TABRDC [m]” (the current table) and

“TABRDL [m]” (the last table) transfer the

contents of the low-order byte to the specified

data memory , and the contents of the high-order byte to TBLH (Table High-order Byte Reg-

BF flag) and

DR

8 23th Feb ’98

HT9480

ister) (08H). Only the destination of the loworder byte in the table is well-defined, the

other bits of the table word are all transferred

to the low portion of TBLH. TBLH is read only

while the table pointer (TBLP) is a readable/writable register (0 7H) used to indicate

the table location. Befo re accessing the tab le,

the location should be placed in TBLP. All of

the table related instructions require 2 cycles

to complete the operation. This feature is efficient only for the movement of the blocks,

which may functio n as look-u p tables o r as a

normal program memory depending upon the

requirements.

Stack register – STACK

The stack register is a special memory port used

to save the contents of the PC. It is divided into

8 levels. The stack register is neither part of the

data nor part of the program, and is neither

readable nor writable. The activated level of the

stack register is indexe d by the stack pointer

(SP), and is neither readable nor writable. At

the commen cement of a subroutine ca ll or an

interrupt acknowledge, the contents of the PC is

pushed onto the stack. At the end of the subroutine or the interrupt routine , as signaled by a

return instruction (RET or RETI), the content s

of the PC is restored to its previo us value from

the stack. After a chip reset, the SP will point to

the top of the stack.

If the stack is fu ll and a non-m aske d interrupt

occurs, the interrupt request flag is recorded

but acknowledging is inhibited unti l the value

of the SP is decremented (by RET or RETI),

allowing that interrupt to b e serviced. As this

feature can prevent a stack overflow, the use of

the structure becomes much easier. In a similar

case, if the stack is full, and a “CALL” is subsequently executed, a stack overflow occurs and

the first entry is lost (only the most recent eight

return addresses are stored).

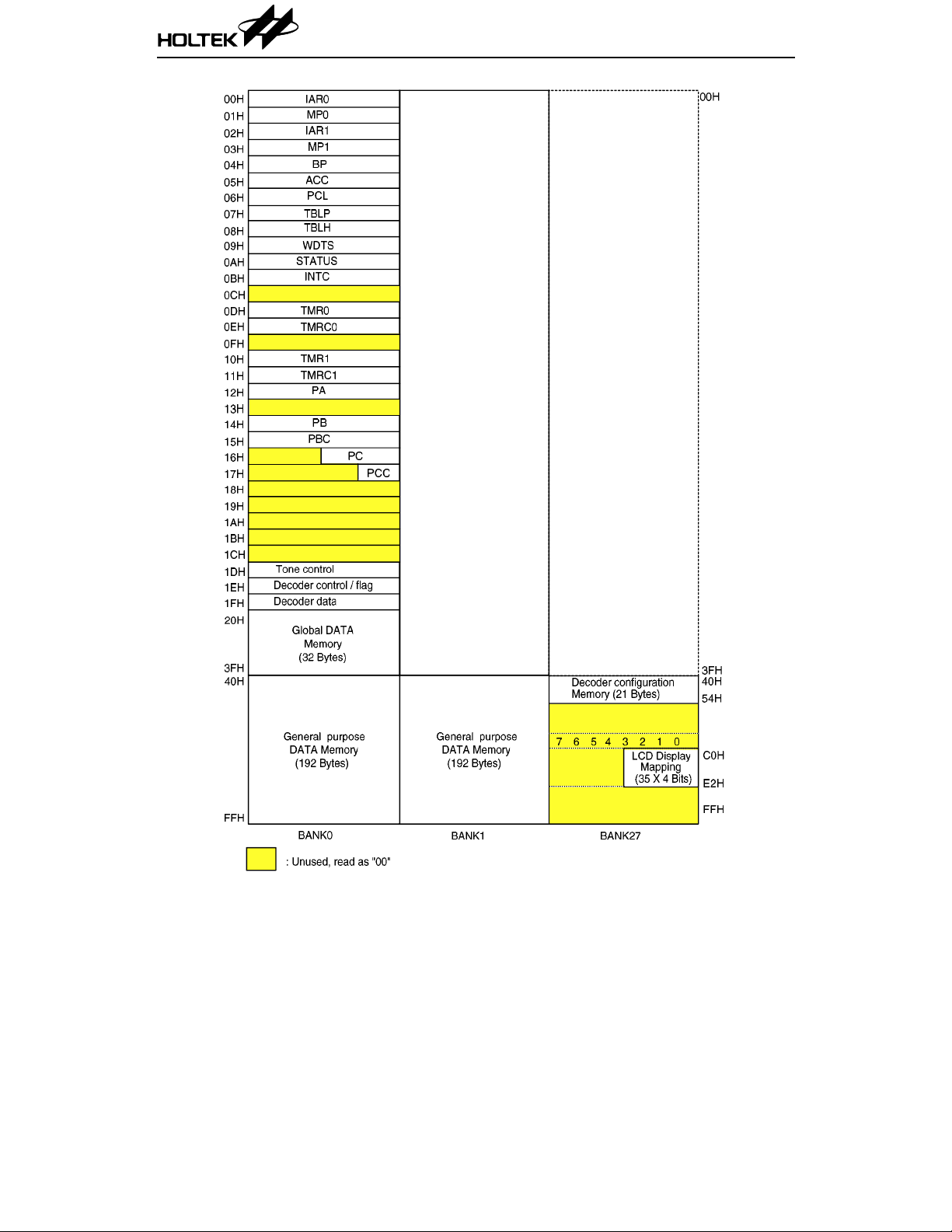

Data memory – RAM

The data memory (RAM) is designed in three

banks, i.e., bank 0, bank 1, and bank 27, and

comprised of four functional groups, namely

special function regis ters (of 22

1

×2 bit in bank0), data memory (of 416×8 bits;

224

×8 in bank 0; 19 2×8 in bank 1), LCD dis play

mapping memory (of 35

configuration RAM mapping m emory (of 21

bits). Most of the these groups are readable/writable but some are read only.

Of the four functional grou ps, the special function registers of ba nk 0 consist of an indirect

addressing registers (IAR0;00H, IAR1;02H),

memory pointer registers (MP0;01H,

MP1;03H), a memory bank pointer register

(BP;04H), an accumulator (ACC;05H), a program counter low byte register (PCL;06H), a

table pointer (TBLP;07H), a table high-order

part register (TBLH;08H), a watchdog timer

option setting register (WDTS;09H), a status

register (STATUS;0AH), an interrupt control

register (INTC;0BH), a programmable timer

counter (TMR0;0DH), a programmable timer

counter control register (TMRC0;0EH), a

timer/event counter (TMR1;10H), a timer/event

counter control register (TMRC1;11H), an input

port, two I/O ports (PA;12H, PB;14H, PC;16H),

two I/O control register (PBC;15H, PCC;17H), a

tone control register (1DH), a pager control register (1EH), and a page r data register (1FH).

The special fu nction regi sters are located from

00H to 1FH where as the 32 global data regi s-

×8 bits; 1×4 bit;

×4 bits), and decoder

×8

Instruction(s)

Table Location

*12*11*10*9*8*7*6*5*4*3*2*1*0

TABRDC [m] P12 P11 P10 P9 P8 @7 @6 @5 @4 @3 @2 @1 @0

TABRDL [m] 11111@7@6@5@4@3@2@1@0

Notes:

*12~*0: Table location bits

@7~@0: Table pointer bits

P12~P8: Current p rogram counter bits

9 23th Feb ’98

HT9480

RAM mapping

10 23th Feb ’98

HT9480

ters are from 20H to 3FH, where each bank

points to the same location. The other spaces ,

namely 0CH, 0FH, 13H, the high n ibble of 16H,

17H, and 18H~1CH, are all reserved for futu re

expansion usage; reading these locations will

get an “00H” value.

On the other hand, the general purpose data

memory, divi ded into thr ee banks (bank 0, bank

1, and bank 27), is used for data, control information, and LCD display control under instruction commands. The banks in the RAM are all

addressed from 40H to FFH, and are selected by

setting the value (“00H”: bank 0; “01H” : bank 1;

“1BH”: bank 27) of the bank pointer (BP;04H).

The bank27 memory is used for LCD display

mapping and the decoder configuration RAM

mapping. The spaces from 4FH to BFH and

from E3H to FFH, and the high nibble part from

C0H to E2H in bank 27 are all reserved for

future expansion usage; reading these locations

will derive “00H”.

The special regis ters, glob al data registe rs and

general data memory can directly perform

arithmetic, logic, increment, decrement, and rotate operations. Each bit in the RAM can be set

and reset by “SET [m].i” and “CLR [m].i”, and

can also be indirectly accessible through the

memory pointer registers (MP0;01H, MP1;03H).

Of the speci al a d dres se s, 1 DH an d 1F H ca nn ot

directly do all these operations, because they

are not read and write accessible addresses.

1DH is a write-only a ddress, 1FH a read-only

address, but these two a ddresses nam ely, 1DH

and 1FH can only perfo rm operatio ns by using

the “MOV” instruction.

Indirect addressing register

IARx (IAR0;00H, IAR1;02H) are indirect address registers that are not physically implemented. Any re ad/write operation of the IARx

accesses the data memory pointed to by MPx

(MP0;01H, MP1;03H). Reading the indirect addressing register itself will indirectly derive

00H, while writing the indirect addressing register indirectly will lead to no operations. (IAR0,

MP0) is indirectly addressable in bank 0, but

(IAR1, MP1) is available for all banks.

Accumulator – ACC

The accumulator (ACC) relates to the ALU operations. It is also mapped to location 05H of the data

memory and is capable of carrying out immediate

data operations. Data movement between these

two data memories has to pass t hrough t he ACC.

Arithmetic and logic unit – ALU

This circuit performs 8 -bit ari thm etic and logic

operations, and provides the following functions:

•

Arithmetic operation (ADD, ADC, SUB, SBC, DAA)

•

Logic operation (AND, OR, XOR, CPL)

•

Rotation (RL, RR, RLC, RRC)

•

Increment and decrement (INC, DEC)

•

Branch decision (SZ, SNZ, SIZ, SDZ, etc.)

The ALU not only saves the results of data

operation, but also changes th e contents of the

status register.

Status register – STATUS

The status register (0AH) is 8-bit wide. It contains

a zero flag (Z), a carry flag (C), an auxiliary carry

flag (AC), an over flow flag (O V), a powerdown flag

(PD), and a WDT time-out flag (TO). The status

register not only records the status information,

but also controls the operation sequence.

The status re gister, like most other regis ters,

can be altered by instructions except for the TO

and PD flags. Any d ata written into the status

register will not change TO or PD. It should be

noted that ope ration s re la ted to the statu s register may derive different results from those

intended. For exa mp l e, cleari ng th e statu s register CLR [0AH] has no effect on the TO and PD

flags, and the value of the zero flag is also “1”,

i.e., UU0100 is the data in the register, where

the value of U is an unchanged value.

The Z, OV, AC, and C flags generally reflect the

status of the latest operations.

On entering an interrupt sequence or executing

a subroutine call, the status register will not be

automatically pushed onto the stack. If the contents of the status is i mpo rtan t , and if the su broutine may corrupt the status register, the

programmer should take preca utions to sa ve it

properly.

11 23th Feb ’98

Labels Bits Function

C is set if the operation results in a carry out in additi on or if a borrow does not

C0

AC

Z2

OV

PD 4 PD is cleared during power up, and set by a “HALT” instruction.

TO 5

−

−

take place in s ubtraction; otherwis e C is cleared. C is also affected b y a rotate

through carry instructions.

AC is set if the operation results in a carry out of the low nibbles in addition or if

1

a borrow from the high nibble into the low nibble does not take place in

subtraction; otherwise AC is cleared.

Z is set if the resul t of an arith metic or a l ogic operati on is zero; o therwise Z is

cleared.

OV is set if the operation results in a carry into the high-order bit but not a carry

3

out of the high-order bit, or vice versa; otherwise OV is cleared.

TO is cleared during power up o r by a “CLR WDT” instruction and a “HALT”

instruction. TO is set by a current timer time-out.

6 Undefined, read as “0”

7 Undefined, read as “0”

STATUS register

HT9480

Interrupts

The HT9480 pr ovides an i nternal programm able timer inte rrupt, an internal d ata ready interrupt, timer/event counter interrupt, and a

battery fail interrupt. The inte rnal data ready

interrupt and the battery fail interrupt employ

the same jump location (04H). The interrupt

control register (INTC;0BH) contains interrupt

control bits to set no t only the enab le/disable

status but also the interrupt request flags.

Once an interrupt subro utine is serviced, the

other interrupts will all be blocked (by clearing

the EMI bit). This scheme may prevent any

further interrupt ne sting. Other interrupt requests may occur during this interval, but only

the interrupt re quest fla g is record ed. If a certain interrupt requires servicing within the

service routine, the EMI bit and the corresponding bit of the INTC register may be set to permit

interrupt nesting. W hen the stack is full, the

interrupt request will not be acknowledged

even if the related interrupt is enable d, until

the SP is decreme nted. If imme diate service i s

desired, the stack should be prevented from

becoming full.

All of these interrupts can support the wake-up

function. As an interrup t is serviced , a contro l

transfer occurs by pushing the contents of the

PC onto the stack, followed by a branch to a

subroutine at the specifi ed loca tion in the program memory. Only the contents of the PC is

pushed onto the stack. If the contents of the

register or of the status re gister (STATUS) is

altered by the interrupt service program which

corrupts the desire d control sequence, the contents should be saved in advance.

The data ready interrupt and battery fail interrupt share the same subroutine call location

04H. Checking the battery fail interrupt bit

(

BF;bit 4 of 1EH) and th e da ta re ady inte rrup t

bit (

DR; bit 7 of 1EH) can determine which kind

of interrupt has occurred. The value of 1EH-bit

7

DR is cleared “0” by the decoder data ready

interrupt signal, and is set to “1” when the

sets this bit high. Both interrupt bits are active

low.

The data ready inte rrupt is generated by the

pager decoder after a valid call is received, and

is initialized by setting the data ready interrupt

request flag (EIF; b it 4 of INTC) and th e data

µC

12 23th Feb ’98

HT9480

ready interrupt bit (DR; bit 7 of 1EH). Once the

data ready interru pt is triggered, the stack is

not full, and the EMI bit is set, a subroutine call

to location 04H will occur. The related interrupt

request flag (EIF) will, however, be reset, and

the EMI bit cleared to disable further interrupts. This interrup t sh ou ld be pro ces se d carefully if the battery fail interrupt is activated as

well.

The battery fail interrupt, on the other hand, is

triggered by a high to low transition on

When the battery fail interrupt is enabled, the

stack is not fu ll, an d th e interru pt requ es t fl ag

(EIF; bit 4 of INTC) is set, a subroutine call to

location 04H wil l occur. The related interrupt

request flag (EIF) will also be reset, and the

EMI bit be cleared to disable other interrupts.

The programmable timer interrupt is automatically triggered at a rate of 256Hz/N (where the

value of N ran ges from 1 to 256), and th en the

interrupt req uest flag (T0F; bit 5 of INTC) is

set. When the timer i nterrupt is enabled, the

stack is not full, and the programmable tim er

interrupt is activated, a subroutine call to location 08H will occur. Then, the related interrupt

BAF.

request flag (T0F) will be reset, and the EMI bit

cleared to disable other interrupts.

The timer/event counter interrupt is initialized

by setting the timer/event counter interrupt request flag (T1F; bit 6 of INTC), which is normally caused by a timer overflow. When the

interrupt is ena bled, the stack is not ful l, and

the T1F bit is set , a subroutine call to location

0CH will occur. The related interrupt request

flag (T1F) will be reset, and the EMI bit cleared

to disable further interrupts.

During the execution of an interrupt subroutine, other interrup t acknowledgments are all

held until the “RETI” instruction is executed, or

the EMI bit and the related interrupt control bit

are both set to 1 (if the stack is not full). To

return from the in terrupt subroutine, a “RET”

or “RETI” instruction may be invoked. RETI

will set the EMI bit to enable an interrupt service,

but RET will not.

The interrupts are serviced between the rising

edges of the two adja cent T2 clocks. In cas e of

simultaneous requests, the following table

shows the priority that is applied. These can be

masked by resetting the EMI bit.

Register Bit No. Label Function

Controls the master (global) interrupt

(1=enabled; 0=disabled)

Controls the data ready and battery fail interrupts

(1=enabled; 0=disabled)

Controls the programmable timer interrupt

(1=enabled; 0=disabled)

Controls the timer/event counter interrupt

(1=enabled, 0=disabled)

Internal data ready and battery fail interrupt request flag

(1=active; 0=inactive)

Internal programmable timer interrupt request flag

(1=active; 0=inactive)

Timer/event counter request flag

(1=active; 0=inactive)

INTC register

13 23th Feb ’98

INTC

(0BH)

0EMI

1 EEI

2ET0I

3ET1I

4EIF

5T0F

6T1F

7 -- Unused bit, read as “0”

NO. Interrupt Source Priority Vector

Data ready

interrupt and

a

battery fail

interrupt

Programmable

c

timer interrupt

Timer/event

d

counter overflow

The programmable timer interrupt request flag

(T0F), timer/event counter interrupt request

flag (T1F), data ready interrupt and battery fail

interrupt request flag (EIF), enable timer/event

counter bit (ET1I), enable data ready interrupt

bit (EEI), and ena ble programmable timer interrupt bit (ET0 I) make up the regi ster INTC

which is located at 0BH in the data memory.

The EEI, ET0I, ET1I, and EMI bits are all use d

to control the enable/disable status of the interrupts, preventing the requested interru pt from

being serviced. Once the interrupt request flags

(T0F, T1F, and EIF) are set, t hey wil l r emain in

the INTC register until the interrupts are serviced or cleared by a software instruction.

A “CALL subroutine ” in the interrupt subroutine should be u sed. This is beca use interrup ts

often occur in an unpredictable manner or need

to be immediately serviced in some applications. During this time, if only one stack is left,

and enabling the inte rrupt is not well controlled, the operation of a “CALL subroutine” in the

interrupt service routine is quite likely to upset

the original control sequence.

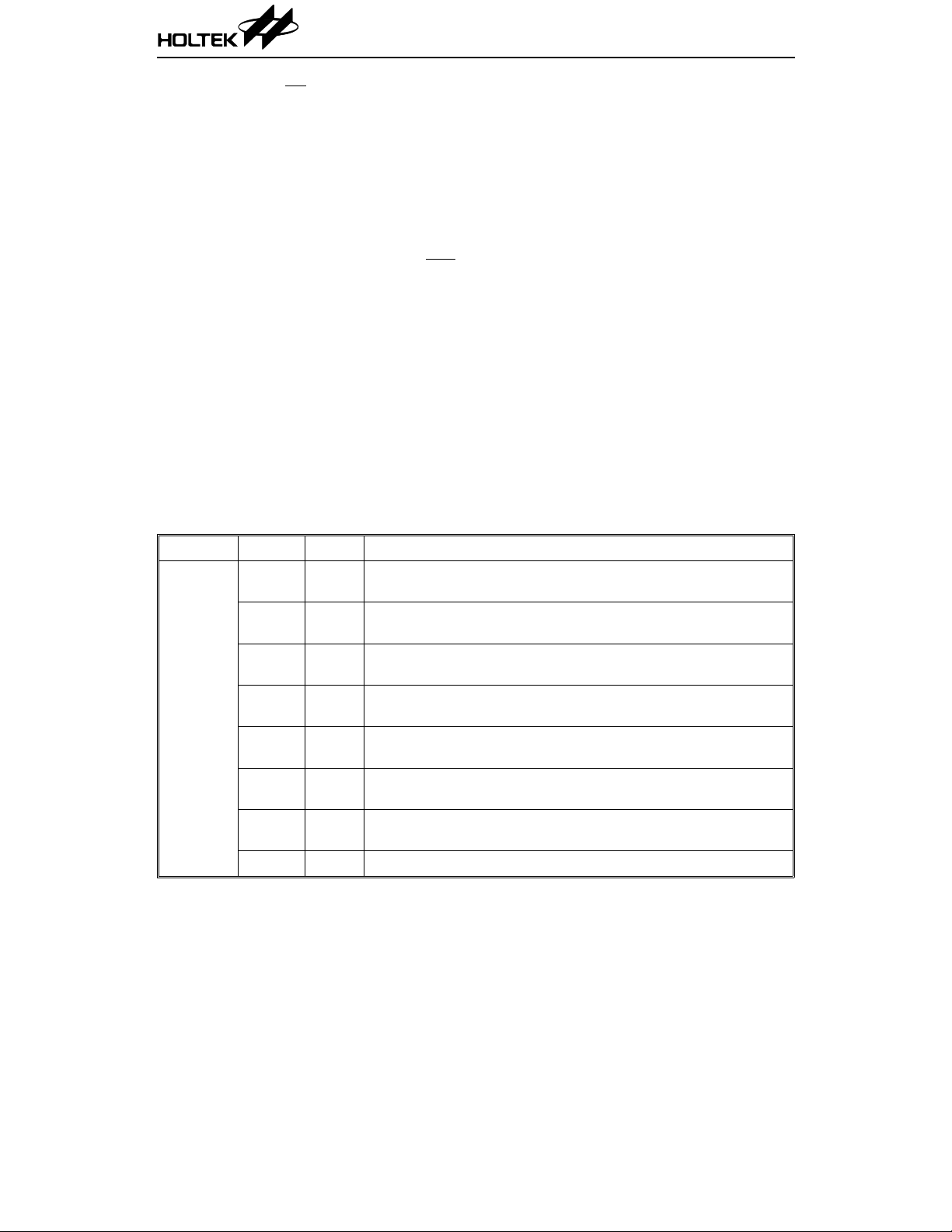

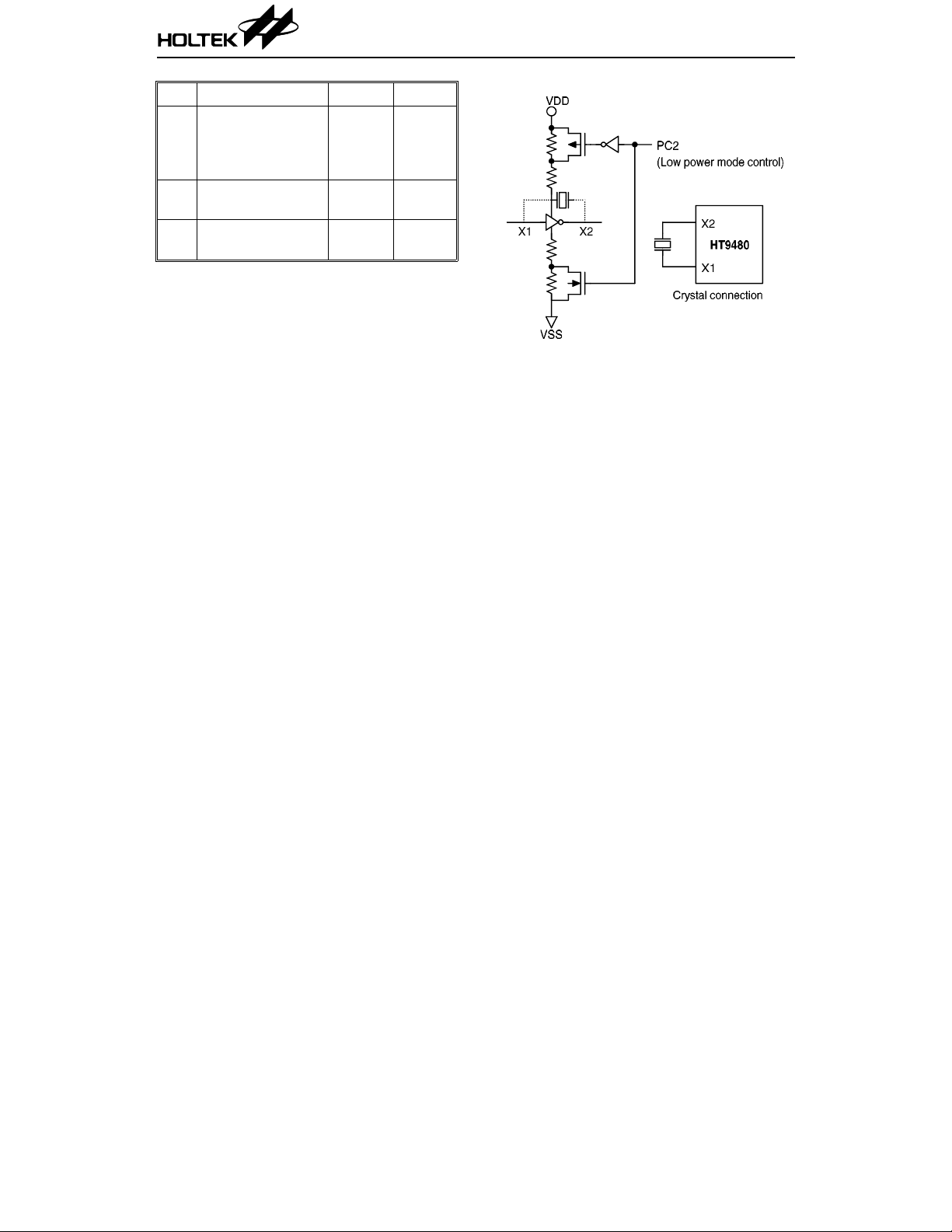

Oscillat or co nf iguration

The system core and the pager subsystem of the

HT9480 are clocked by different oscillators. The

system oscillato r can be either a crystal or an

RC type. The su bsystem low power osc illator , on

the other hand, is a crystal type which is designed with the power on start-up function to

reduce the stabili zation time of the oscillator.

This start-up function is enabled by PC2 which

is initially set high at power on reset, and

should be clea red so a s to en ab le th e low - power

oscillator functi on . T he oscil la tor co nfigura tio n

is running in the low power mode.

104H

208H

30CH

HT9480

Low power oscillator

The system oscillator can be configured as

either an RC or crystal type of oscillator , determined by mask option. No matte r what kind of

oscillator type is selected, the signal provides a

system clock. The system clock may also be

externally connected. The HALT mode stops

the system osci llator and igno res external signals to conserve power.

If the system oscillator is an RC type oscillator,

an external resistor between OSC1 and OSC2 is

required. The system clock is available on

OSC2, which can be used to syn chro nize e xternal logic. An RC oscillator provides the most

cost-effective solution. The frequency of oscillation may vary with power , temperature, and the

chip itself due to process variations. The RC

oscillator is, there fore, not suitable for timing

sensitive opera tions wh ere an accurate oscill ator frequency is desired.

On the other hand, if a crystal type oscillator is

used, a crystal across OSC1 and OSC2 is required to provide the feed back and phase shift

for oscillation, and no other external components are required. A ceramic resonator can

replace the crystal connected between OSC1

and OSC2 to derive a frequency reference. In

this case, two e xtern al ca paci tors at OSC 1 a nd

OSC2 are required.

14 23th Feb ’98

System clock oscillator

An external clock can also be applied to OSC1 .

In this application, the mask option for the

crystal type osci llator should be selected , and

OSC2 kept open.

The low power crystal oscillator is designed for

the pager subsystem and is used to clock the

frequency divider, pager decoder, and LCD

driver. When the system enters the powerdown

mode the crystal oscillator for the pager subsystem keeps running.

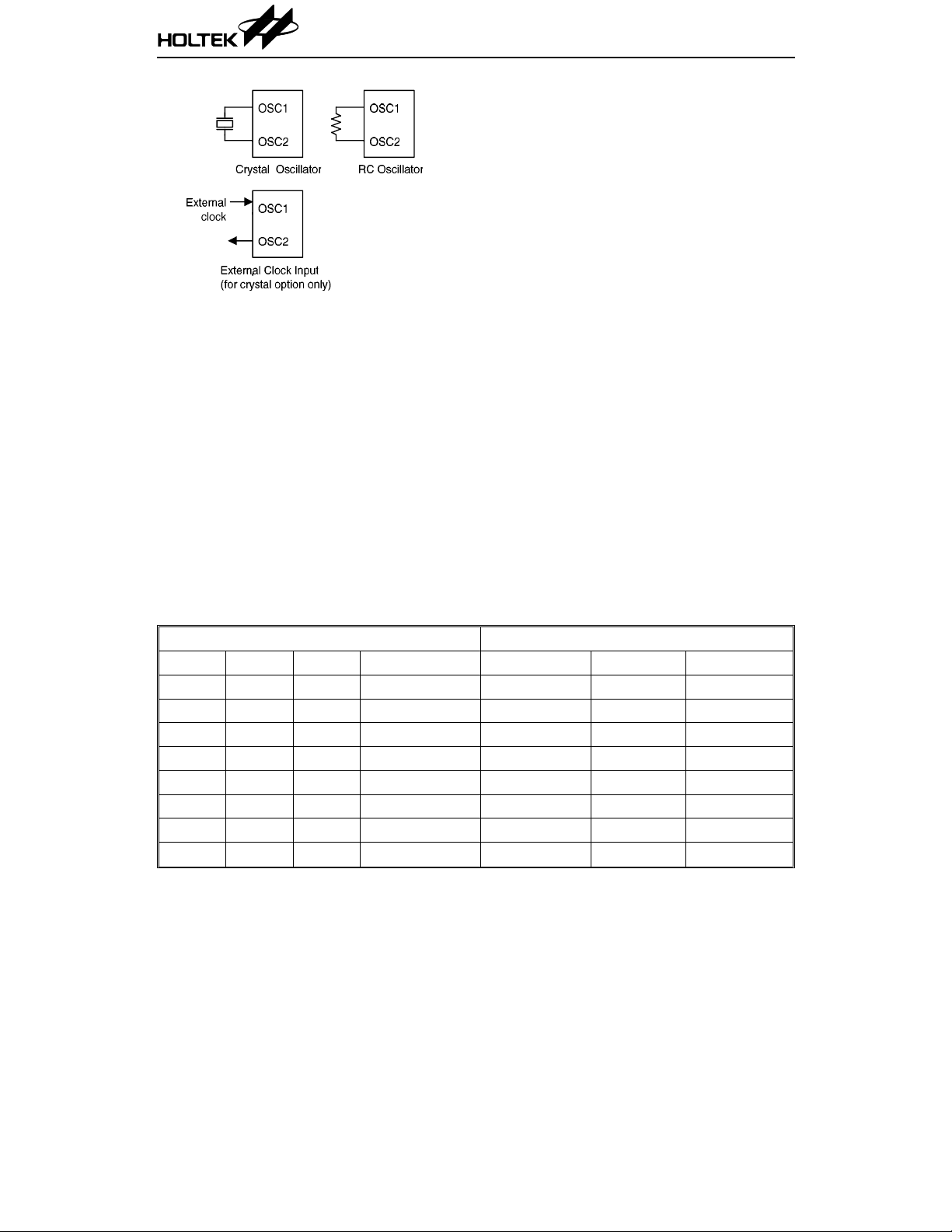

Watchdog timer – WDT

The clock source of the watchdog timer (WDT )

is implemented by a subsystem clock

(WDTCLK from the pager subsystem which remains running during a system halt) or by an

HT9480

instruction clock (the syste m clock divided by

4), that is deci ded by ma sk op ti on . Th e v a lu e of

WDTCLK can be set as 153.6kHz/1024 (or 2048),

76.8kHz/1024 (or 2048), or 32.768k Hz/1024 (or

2048), depending upon the different crystal

type. The WDT is the program designed to

avoid software m alfunctions or sequence from

jumping to an unknown location with unpredictable results. It can be disabled by mask

option. If the WDT is disabled, all the executions related to the WDT lead to no operations.

If the subsystem clock is selected, it is first

divided by 256 (8 stages) to get the nominal

time-out period. Longer tim e-outs can be realized by invoking the WDT prescaler. Writing

data to WS2, WS1, and WS0 (b its 2,1,0 of the

WDTS) can yie ld different time -out periods. If

the values of WS2, WS1, and WS0 are all equal

to 1, the division ratio is up to 1:128.

On the other hand, if th e instruction clock is

applied, the WDT operates in the same manner

as the case when the subsystem clock is chosen,

except that i n the HALT state the W DT stops

counting and lose its protection purpose. In this

situation, the WDT logic can be restarted by

external logic. The high nibble a nd bit 3 of the

WDTS is reserved for user defined flags, which

can be used to indicate some specified status.

The overflow of the WDT under normal ope ration not only initializes the “chip reset”, but sets

the status bit “TO”. An overflow in the HALT

Division Ratio Option Crystal Type and Time-Out Period

WS2 WS1 WS0 Division Ratio 153.6kHz 76.8kHz 32.768kHz

0 0 0 1:1 13.3ms 26.7ms 6 2.5ms

0 0 1 1:2 26.7ms 53.3ms 125ms

0 1 0 1:4 53.3ms 106.7ms 250ms

0 1 1 1:8 106.7ms 213.3m s 5 00ms

1 0 0 1:16 213.3ms 426.7ms 1000ms

1 0 1 1:32 426.7ms 853.3ms 2000ms

1 1 0 1:64 853.3ms 1706.7ms 4000ms

1 1 1 1:128 1706.7ms 3413.3ms 8000ms

WDTs register

15 23th Feb ’98

Watchdog timer

HT9480

mode initializes a “warm reset” only when the

PC and SP are reset to zero. To clear the contents of the WDT (including the WDT prescaler), there are three methods to be ado pted

namely, external reset (a low level to

software instruction(s) , and a “HALT” instruction. There are two typ es of software instructions, “CLR WDT” and “CLR WDT1”/“CLR

WDT2”. But only one of these two types of instructions can be active at a time depending on

the mask op tion

option”. If the “CLR WDT” is selected (i.e.,

CLRWDT times equal one), any execution of the

“CLR WDT” instruction clears the WDT. In the

case that “CLR WDT1” and “CLR WDT2” are

chosen (i.e ., CLRWDR times equal two), th ese

two instructions should be executed to clear the

WDT; otherwise, the WDT may reset the chip

due to a time-out.

Powerdown opera tion – HALT

The HALT mode is initialized by the “HALT”

instruction and results in the following.

The system tu rns o ff. The low power os cilla tor,

tone generator, LCD driver, pager decoder, and

WDT oscillator all keep running (if the WDT

oscillator is selected).

The contents of the on–chip RAM and of the

registers remain unchanged.

The WDT and th e WDT prescaler are cleared

and counted again (if the WDT clock is from the

WDT oscil lator).

All the I/O ports remain in their original status.

The PD flag is set but the TO flag is cleared.

The system can quit the HALT mode by an

− “CLR WDT tim es selection

RES),

external reset, an interrupt, an external falling

edge signal on port A, or a WDT overflow. An

external reset leads to device initialization and

the WDT overflow performs a “warm reset”.

After the TO an d PD flags are examined, the

reason for the chip reset is determined. The PD

flag that is cleared on power-up is set afte r the

“HALT” instruction is execute d. The TO fla g is

set when the WDT time-out occurs, which

causes a wake-up that resets only the PC and

SP, and leaves the others in their original status.

The port A wake-up and interrupt me thods can

be considered as a continuation of normal execution. Every bit in port A can be independently

selected to wake up the device by mask option .

Awakening from an I/O port stimulation, the

program resumes execution of the next instruction. However, if the program awakens from an

interrupt, two sequences may occur. The program will resume execution at the next instruction if the rela ted interrup t(s) is (are) di sabled

or the interrupt(s) is (are) enabled but the stack

is full. A regular interrupt response, on the

other hand, may tak e place if the interrupt is

enabled and the stack is not full.

If the wake-up event(s) occurs and the wake-up

results from an interrupt acknowledge, the actual

interrupt subroutine execution is delayed by one

or more cycles. On the oth er han d, if the wak eup brings about the following instruction execution, the actual interrupt subroutine is executed

immediately after the dummy period is completed.

To minimize power consumption, the I/O pins

should all be carefully managed before entering

the HALT status.

16 23th Feb ’98

Reset

There are five ways in which a reset can occur:

•

Power on reset (POR)

•

RES reset during normal operation

•

RES reset during HALT

•

WDT time-out reset during norma l oper ati on

•

WDT time-out reset during HALT

The WDT time-out during HALT is different

from other chip reset conditions, since it can

perform a “warm reset” that just resets the PC

and SP, leaving the other ci rcuits to ke ep their

state. Some registers remain unchanged during

other reset conditi ons. Most registers are reset

to the “initial condition ” when the reset conditions are met. By examining the PD and TO

flags, the program can distinguish between different “chip resets”.

TO PD RESET Conditions

0 0 Power on reset

uu

01

1u

RES reset during normal

operation

RES wake-up HALT

WDT time-out during normal

operation

1 1 WDT wake-up HAL T

Note:“u” means “unchanged”

HT9480

Reset configuration

If crystal mask option is selected , the

can be fed by X1, X2 decoder input clock (See

Application Circuit 2).

The functional un its ch ip res et sta tus is shown

in the following table.

PC 0000H

Interrupt Disabled

Prescaler Cleared

Cleared. After master

WDT

reset, WDT starts

counting.

Programmable

timer Counter

Timer/event

Counter

Programmable

Tone Generator

Off

Off

Off

Pager Decoder Off

Input/output Ports input mode

SP

Points to the top of the

stack

µC clock

Reset circuit

17 23th Feb ’98

HT9480

Programmable timer counter and

timer/event counter

The programmable timer co unter (TMR0) and

timer/event counter (TMR1) are constructed using the same structure. Both counters contain

an 8–bit programmable count-up counter,

whose clocks may come from an external

source or from the system clock divided by 4.

If the internal instruction clock is selected, only

one reference time-base is pro vided . The external clock input allows the user to count external

events, measure time intervals or pulse widths,

or generate an accurate time base. The clock of

the programmable timer counter should com e

from the external clock of the 75Hz for Real

Time Clock (RTC) if a 76.8kHz crystal is used.

There are two sets of regis ters related to the

programmable timer counter and to the

timer/event counter namely, TMR0 (0DH) and

TMRC0 (0EH) and TMR1 (10H) and TMRC1

(11H). There are also two physical registers

mapped to the TMR0 and TMR1 locations:

Writing to TMR0 and TMR1 puts the starting

value in the programmable tim er counter and

in the timer/event counter preload registers,

while reading them gets the contents of the two

counters. TMRC0 and TMRC1 are co ntrol registers used to define some timer options.

The TM0 and TM1 bits define the operation

mode. The event count mode is used to count

external events, which means that the clock

source may come from either a 256Hz generator

(for TMR0) or an external pin (for TMR1) . The

timer mode fu nctions as a normal timer, with

the clock source coming from the instruction

clock or from the outputs of the TMR1 prescaler

(TMR0 cannot be us ed i n th is mo de). The pulse

width measurement mode can be used to count

the high or low level duration of the exte rnal

signal TMR1, TMR0 is also disabled in this

mode. The counting is based on the system

clock.

In the event count or timer mode, once the

programmable timer counter or timer/event

counter starts counti ng, it will count from th e

current contents in the counter to FFH. Once an

overflow occurs, the counter is reloaded from its

counter preload register a nd generates an interrupt request flag (T0F; bit 5 of INTC and

T1F; bit 6 of INTC for programmable timer

counter and timer/event counter, respectively).

On the other hand, in the pulse width measurement mode with t he TON bit equa l to one, w hen

the TMR1 receives a transient from low to high

(or high to low depending upon the TE bit) it

will start counting until the TMR1 returns to

the original leve l and resets the TON as well.

Labels (TMRC0

and TMRC1)

— 0~2 Unused bits, read as “0”

TE 3

TON 4

−

TM0

TM1

Bits Function

To define the TMR0 and TMR1 active edge of programmable timer

counter and timer/event counter

(0=active on low to high; 1=active on high to low)

To enable/di sable timer count ing

(0=disable d; 1= en ab led)

5 Unused bits, read as “0”

To define the operation mode

01=Event count mode (external clock)

6

10=Timer mode (in ternal clock)

7

11=Pulse width measurement mo de

00=Unused

TMRC register

18 23th Feb ’98

HT9480

The states of the registers are summarized below.

Register

TMR0 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TMRC0 00-0 1--- 00-0 1--- 00-0 1--- 00-0 1--- uu-u u-TMR1 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TMRC1 00-0 1--- 00-0 1--- 00-0 1--- 00-0 1--- uu-u u-PC 0000H 0000H 0000H 0000H 0000H

MP0 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

MP1 xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

ACC xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TBLP xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

TBLH xxxx xxxx uuuu uuuu uuuu uuuu uuuu uuuu uuuu uuuu

STATUS --00 xxxx --1u uuuu --uu uuuu --01 uuuu --11 uuuu

INTC -000 0000 -000 0000 -000 0000 -000 0000 -uuu uuuu

WDTS 0000 0111 0000 0111 0000 0111 0000 0111 uuuu uuuu

PA 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PAC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PB 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PBC 1111 1111 1111 1111 1111 1111 1111 1111 uuuu uuuu

PC ---- 1111 ---- 1111 ---- 1111 ---- 1111 ---- uuuu

PCC ---- 1111 ---- 1111 ---- 1111 ---- 1111 ---- uuuu

Power-on

reset (POR)

WDT time-out

(normal

operation)

RES reset

(normal

operation)

RES reset

(HALT)

WDT time-

out (HALT)*

Note: “*” means “ warm reset”

“u” means “unchanged”

“x” means “unknown”

The measured result will remain in the

timer/event counter even when the activated

transient occurs again. In other words, only one

cycle measurement can be made until the TON

is set. The cycl e measuremen t will re-functio n

as long as further transient pulses are received.

Note that, in this operation mode, the

timer/event counter starts counting not according to the logic level but to the transient edges.

In the case of counting overflows, the counter is

re-loaded from its cou nter prel oa d regi ste r and

issues an interrupt request, similar to the other

two modes.

To enable the counting operation, the value of

the timer on bit (TON; bit 4 of TMRC0 and

TMRC1) is “1”. In the pulse width measurement

mode, the TON i s automatically cleared after

the measurement cycle is completed. In the

other two modes, namely the event count or

timer mode, the T ON can be reset only by instructions. The overflow of the programmable

timer counter and of the timer/event counter

can be configured as one of the wake-up

sources. No matter what type of operation mode

is chosen, writing a 0 to ET0I and ET1I disables

the interrupt service of the programmable

timer counter and the time r/event counter, respectively.

19 23th Feb ’98

Timer/event counter

Programmable tone generator

HT9480

In the case of the progra mm able tim er co unter

and a timer/event counter OFF condition, writing data to their preload registers also rel oads

that data to their counters. But if the programmable timer counter or the timer/event counter

is turned on, data written to the counter is kept

only in its preload register, and the counter still

goes on operating until an overflow occurs.

After the counter (rea ding TMR0 or TMR1) is

read, the clock is blocked to avoid errors. The

programmer should take clock blocking into

consideration, since this may result in timing

counting errors.

Programmable tone gene r at o r

The programmable tone generator is implemented in the HT9480. The programmable tone

generator contains an 8-stage programmable

frequency divider (mapping to the 1DH address

of the

µC), a 4-stage programm able frequency

prescaler (set by SPF 10 and SPF11), and a frequency source selector (set by SPF17). When

1DH=00H, the tone generator is disabled and

BZ outputs high. But when 1DH is of any value

greater than zero the generator is enabled. The

value of the frequency divider, ranging from

2~256, is always greater than the assigned

value by 1. The outp ut of the 8-sta ge divi der

divided

by 2 to generate an output of (1/2 or 1/4)

duty cycle on BZ. The 4-stage programmable

frequency prescaler is shown below.

SPF10 SPF11 Prescaler Divider Factor

00 1

01 2

10 4

11 8

The above setting of the prescaler divider factor

is designed for applications on melodies or

sound effects.

The frequency source selecto r is set by SPF17.

When SPF17=0, the value of the frequency

source selector is the system clock. On the other

hand, when SPF17=1, the va lue of the selector

turns out to be 32.768kHz. For i nstance, if the

20 23th Feb ’98

is

HT9480

desired output of BZ is 2.73kHz, the frequency

source is 32.768kHz, the values of SPF10 and

SPF11 are both set to 0, and the val ue of the

programmable frequency divider is set to 5.

Input/Output ports

There are 7 input lines, and 10 input/output

lines in the HT9480, which are labeled as PA,

and PB; PC (PC0, PC1). These are mapped to

[12H], and [14H]; [16H] of the data memory,

respectively. Port A is an input port only wh ile

Port B and Port C (PC0 and PC1) are bidirectional I/O ports. For input o peration, the ports

A, B, and C are non-latched, i.e., the inputs have

to be ready at the T2 rising edge of the instruction “MOV A, [m]” (m=12H, 14H, 16H). For

output opera tion, data is latched and then remains unchange d until the output latch is rewritten.

The PB and PC (PC0, PC1) I/O lines have their

own control registers (PBC, PCC) to control the

input/output configuration. These control registers, tri-state (control register=1) or CMOS

(control register=0) with pull-high (option)

structures can be reconfigured dynamically

(i.e., on-the-fly) by software control. To function

as an input, the corresponding I/O latch and

related bit of the control register should be written “1” to avoid external logical violation. These

control registers are mapped to location 15H,

and 17H (bit 0 and bit 1 of 17H).

After a chip reset, these input/output lines stay

at high levels or floating (by mask option). They

are defined as input types by writing “1” to the

control registers and as output types by writing

“0” to the control registers. Each bit of these

input/output latches can be set or cleared by

“SET [m].i” and “CLR [m].i” (m=14H only) instructions.

Some instructions first input data and then

follow the output operations. For example,

“SET [m].i”, “ CLR [m].i” , “CPL [m]”, “ CPLA [m]”

read the entire po rt states into the CPU, execute the defined operation (bit-ope ration), and

then write the results back to the latches or the

accumulator.

Each line of port A is capable of waking up the

device (when a falling edge occurs) and is determined by mask option. The highest four bits of

port C are not physically impl emented. Reading

them gets a “0”, but writing them leads to no

operation.

Bit 7 of port A connects a battery fal l i nterrup t

and a wake-up function. Bit 7 of port A wakes

up the

of port C is used for internal subsystem oscillator low-power function control (1: non-active; 0

: active). The value of bit 2 of port C is set as “1”

at an initial power on. Bit 3 of port C is used for

LCD power control (1: LCD turn-on; 0 : LCD

turn-off). The value of bit 3 of port C is also set

as “1” at the initial power on.

µC each time a battery is changed. Bit 2

Input/output ports

21 23th Feb ’98

Display memory

LCD disp lay

The LCD display memory is embedded in the

data memory (mapped to the addresses

C0H~E2H of bank 27). It can be read and written to as a normal data me mo ry. The following

figure illustrates the mapping between the display memory and the LCD pattern.

To turn the display on/off, the programmer

writes 1 or 0 to the corresponding bit of the

display memory. The LCD display module can

be of any form as long as the number of the

common doesn’t exceed 4 and the number of the

segment is not over 35.

The entire n um be r o f the L C D drive r ou tp ut is

35

×4. The LCD driver can directly drive an LCD

of 1/4 duty cycle and 1/3 bias. All of the LCD

segments are random at the initial clear mode.

The frequency of the LCD driving clock is fixed

at about 256Hz, an d cannot be cha nged. It is set

by HOLTEK according to the application.

The following is an example of an 8-segment

digit display, which shows a waveform of “5”.

HT9480

Pager decoder

The pager decoder is a POCSAG code pager

decoder at 512, 1200, or 2400 bps data rate,

compatible with CCIR radio paging Code No.1

(POCSAG Code). The decoder supports six user

addresses and six independently programmable user frames.

22 23th Feb ’98

LCD timing

HT9480

The operation of the decoder is contro lled by a

pager control address (1EH) in conjunction with

a pager data address (1FH). Upon rece ipt of a

valid call the data ready interrupt is generated.

•

The POCSAG paging code

The CCIR Radio paging Code No.1 (POCSAG

Code) is constructed accord ing to the following rules:

A transmission consists of a preamble followed by a batch of complete code words. Each

batch begins with a synchronization codeword

(SC). The format of the signal is illustrated in

the following Figure.

Each transmission begins with a preamble to

achieve bit syn chronization . The pre amble is

a pattern of one and zero; 10101010... repeated for a period of at least 576 b its.

Codewords are transmitted in batches. Each

batch consists of a syn chronizati on codeword

followed by 8 frames. Each frame consists of 2

codewords. The eight frames are nu mbere d 0

through 7. All pagers are similarly divided

into 8 groups. Each pager is assigned to one of

the 8 frames according to the 3 least signi ficant bits (LSB) of its 2 1-bit id e nti ty co de (ad dress). The 3 bits are called “Receiver Identity

Code” (RIC).

POCSAG code structure

23 23th Feb ’98

HT9480

A codeword is either an address or a message

codeword. Idle cod ewords are transm itted to

fill in empty batches or to separate messages.

An address codeword is coded as shown above.

Of the 21 bits of user addresses, 18 bits are

coded in the codeword itself (bits 2 to 19),

which is protected against transmission errors by a number of CRC checkbits (bits 22 to

31). Bit 32 is an overall even-parity bit.

The two functio n bits (bits 20 and 21) allow

dis ti n c ti o n o f fo u r di f f er e nt calls to one user address as shown in foll owing T a ble.

Bit 20

(MSB)

An idle codeword is a valid address codeword,

which cannot be allocated to the pager.

There is a total of 20 bits of caller information

to be put into a message codeword (bits 2 to 21),

which is protected by the CRC checkbits (bits 22 to

31).

•

Decoding of the POCSAG data stream

The POCSAG coded input data received from

RF module is first filtered by an internal digital filter in the decoder. From the filtered

data, a sampling clock synchronous to the

data rate is derived. The decoder supports

512, 1200, and 2400 bits per second data rate,

which in turn re sults in their correspond ing

sampling clock frequency.

Upon detection of a valid call, the decoder

performs several operations (refer to the following section of the Message Data Transfer).

Call termination is normally deemed when a

valid idle or another add ress codeword is received after a message code word.

Bit 21

(LSB)

0 0 Numeric 4-bits per digit

0 1 Alert only —

1 0 Alert only —

1 1 Alpha-numeric

Call Type Data Format

7-bits per ASCII

character

•

Erroneous codewords

Upon receipt of erroneous uncorrectable code-

words, call termination occurs according to

the conditions given below:

SPF08 SPF09 Call Termination Event

Any two consecutive

codewords or the

0X

1 0 Any single codeword in error

11

Error correction

codeword directly

following the address

codeword in error

Any two consecutive

codewords in error

Item Description

Preamble 4 random errors in 31 bits

Synchronization

code-word

Address

code-word

Message

code-word

In the HT94 80 error correction methods have

been implemented as shown in above Table.

Random error correction is defa ult for b oth address and message code-words. Burst error correction can be switched by SPF 15. Up to 4 bits

of burst errors can be corrected.

Decoder interface

The HT9480 has two interfaces available. One

is the pager control address (1EH), which controls the operation an d con figu ration of the decoder. The other is the pager data address

(1FH), which places the message data of calls in

the parallel mode.

2 random errors in 32 bits

2 random errors, or 4-bit

burst errors (optional)

2 random errors, or 4-bit

burst errors (optional)

24 23th Feb ’98

HT9480

•

Decoder control address

The decoder control address (1EH) contains a

data ready flag (

an out of range flag (

(

BF), a decoder standby flag (STB), a call

termination indication flag (

software reset (

control bit (

DR), a battery low flag (BL),

OR), a battery fail flag

CT), a decoder

RES), and a decoder on/off

ON). It not only records the status

information but contro ls the operati on of the

decoder.

Any data written to the decoder control address cannot change the

OR, BF, STB and CT

flags.

If the status of the b attery fail (

BF) changes

from “1” to “0”, the following conditions occur.

•

The pager controller generates an interrupt if

the value of the data ready interrupt flag is “1”.

•

The pager controller does not generate an

interrupt and no data is transmitted if the

value of the data ready interrupt flag is “0”.

On the other hand, if the status of the battery

fail (

BF) changes fro m “0” to “1”, the internal

node PA.7 of the pager controller will supply a

wake-up function.

After the decoder asserts the data transfer

request, the data ready interrupt is generated

and the

DR bit (bit 7 of 1EH) is cleared low;

then the data ready interrupt subroutine runs

to process the call data and resets the

DR bit

high.

Decoder interface

25 23th Feb ’98

HT9480

The function bits (ON, RES) and indication

bits (

CT, STB, BF, OR, BL and DR) are all

used to control the status of the decoder which

•

Pager data address

The pager data address (1FH) are the parall el

data lines for decoder data transfer.

is operated through the pager control address

as described in the following table.

Symbol Bit R/W Description

On/Off control bit

ON

0R/W

This bit selects the

0:

ON state

ON or STANDBY state of the decoder.

1: STANDBY state

Reset output for the decoder core

RES

1R/W

The

µC has to set the RES bit low and then high after the pager controller

is turned on.

Call termination indication bit

This bit decides the call termi nation status, when a valid code-word is

CT 2 R

received

0: End of code-word receive

1: Receiving message code-word

Standby indication bit

STB

3R

When the value of the ON bit is 1, the system goes into the STANDBY st ate.

The STANDBY stat e allows the

µC to execute the configuration RAM setting.

Battery fail indication bit

BF 4 R

Once the decoder detects that the battery fail interru pt is low, the BF bit

will be low but unlatched .

Out-of-range indication bit

Whenever the decoder detects an out-of-range condition, this bit is cleared

low after end of the programmed out-of-range hold of time that is selected

OR 5 R

by the configuration registers (SPF06 and SPF07). The out-of-range

indication may be tested for an out-of-range condition whenever the

interface enable of the deco der is active; otherwise the

high. The out-of-range i ndication is set high b y detection of a valid data

transmission or by switching the decoder to be in the STANDBY state.

Battery low indication bit

BL

6R/W

The battery low indication is periodically tested for a battery low condit ion.

If the decoder encounters a battery low condition the battery low indication

bit is cleared low. At this time, the

µC should set the BL bit high.

Data ready interrupt indication bit

DR 7 R/W

When a valid call is detected, data starts transfer. The

when the serial data is changed to pa rallel data (1FH). Afte r reading the

parallel data, the

µC software has to set the DR bit high.

OR is normally

DR bit becomes low

26 23th Feb ’98

HT9480

Message data transfe r

The decoder outputs a deformatted address

word and message words upon receipt of a valid

call. The message data to be transferre d is organized into 8-bit words and transferred

through the parallel pager data addres s (1FH)

byte by byte. When a ca ll word starts, the decoder generates a data ready interrupt simulta-

neously and runs the processing subroutine.

The subroutine should read out the word in the

pager data address (1FH) before the next call

word comes in, i.e., the word s hould be rea d in

4mS at 512/1200 bi t data rate a nd in 2m S at a

2400 bit data rate . Otherwi se , the da ta in 1F H

is overridden by the next word.

Numeric message data transfer

27 23th Feb ’98

HT9480

Alpha-Numeric Message Data Transfer

28 23th Feb ’98

HT9480

Termination word format

Successful call termination occurs by the reception of a valid address code-word with less than

2 bit errors on the deco der output register.

Unsuccessful termin ation occurs when sync is

not detected.

Termination word format:

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Error

Flag

Call data output format

The HT9480 automatically converts message

code-words received in numeric or alphanumeric format into ASC II form at. Depe nding o n

SPF09 and the fu nction bit setting in the received address code-word a conversion takes

place as shown in the following table.

SPF 09 Bit 20 Bit 21

0000100

Function Bits

Message

Format

0 X X numeric

100numeric

1 X 1 alpha -nu me ric

1 1 X alpha-numeric

When a conversio n from alphanumeric format

to ASCII takes place, the received message

code-words are split into message blocks, seven

bits in length. After addi ng the error flag they

are transferred as message words.

When a conversion from numeric format to ASCII

takes place, the received message code-words

are split into blocks, four bits in length. Each

four bit block is converted to a seven bit block as

shown in the fol lowing table. After adding the

error flag they are transferred as message

words. Refer to the “Numeric format to ASCII

conversion” table.

There is a new message packaging method after

receipt of message code-words. The new message packaging method is 4 bits packaging type.

Depending upon SP F20=1, m essage code -word

conversion takes place as show in the following

table.

Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Error

Flag

The received message code-words are split into

blocks, four bits in length. Each four bit block is

directly transferred to a four bit block. After

adding the error flag they are transferred as

message words.

000D3D2D1D0

29 23th Feb ’98

HT9480

Numeric format to ASCII conversion:

4-bit block Character 7-bit block

msb lsb msb lsb

0000 “0” 011000 0

0001 “1” 011000 1

0010 “2” 011001 0

0011 “3” 011001 1

0100 “4” 011010 0

0101 “5” 011010 1

0110 “6” 011011 0

0111 “7” 011011 1

1000 “8” 011100 0

1001 “9” 011100 1

1010 “*” 010101 0

1011 “U” 101010 1

1100 “ ” 010000 0

1101 “-” 010110 1

1110 “]” 101110 1

1111 “[” 101101 1

Synch word indication

The synch word recognized by HT9480 is the standard POCSAG synchronization code-word, as

shown in the following table.

Bit No.0123456789101112131415

Bit 0111110011010010

Bit No. 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Bit 0001010111011000

Idle word indication

The idle word reco gnized by the HT94 80 is the standard P OCSAG idle code-wo rd, as sho wn in the

following table.

Bit No.0123456789101112131415

Bit 0111101010001001

Bit No. 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Bit 1100000110010111

30 23th Feb ’98

HT9480

Error indication

After error correction, an y code-word containing more than two bits random error or four bits

burst error (option) in address or message codeword may be indicated from the error flag position.

Data transfer

Data transfer is initiated once the code-word is

already received. When the HT9480 is ready to

transfer the received call data, an external interrupt will be gen erated via outp ut

message data can be read by accessing the 1FH

address of the

bus.

The address word in dicates call a ddress, function bit setting, and decoder flags. The message

code-words are received and co ncatenated to a

valid call address word. The message words

derived from un-corrected message code-words.

Data transfer for a received call ends right after

the termination word is transferred.

Address word format

µC RAM map via the µC internal

INT. Any

Bit 7Bit6Bit5Bit4Bit 3Bit2Bit1Bit

0

Sync.

State

Bit 0: Bit 21 of the address code-word

Bit 1: Bit 20 of the address code-word

Bit 2=0 is to tell the diffe rence between term ination and add r ess word format

Bit 3=1 if a duplicate code-word.

Call

address

Dup.

Call

0

Function

code

Bit 6 Bit 5 Bit 4 Call Address

000 RIC A

001 RIC B

010 RIC C

011 RIC D

100 RIC E

101 RIC F

110 —

111 —

Bit 7= 1 if an address code-wo rd is received in

the data fail mode.

Interrupt indication

The HT9480 provides an internal data ready

interrupt and a battery fail interrup t. The internal data ready interrupt and battery fail

interrupt share the same pin connection.

Checking the battery fail interrupt bit (

4 of 1EH) and the data ready interrupt bit (

bit 7 of 1 EH ) will tell which typ e of interrup t

has occurred. Both interrupt bits are active

low.

Out-of-range indication

The out-of-range condition occurs when the

time interval defined by SPF06, SPF07 does not

receive any preamble or sync cod e word. This

signal will be used as “loss of RF signal” indicator.

BF; bit

DR;

31 23th Feb ’98

HT9480

Duplicate call suppression

The HT9480 provides a Duplicate Call Suppression with time-out facility, to identify duplicate

call reception. In display pager mode, duplicate

call indication is achieved only via the

face. A call is assumed to be duplicate if its

address and functi on bit se tting is equa l to the

latest received call, which initialized the call

address and function bit referen ce. The Duplicate Call suppression time-out is selected by

programming SPF06, SPF07 .

µC inter-

Address

Configuration RAM organization

The decoder contains a 2 1-byte RAM to store 6

user addresses, 6 independently programmable

frame numbers and specially programmed

function bits (SPF00~SPF23) for the decoder

application configu ration. The data me mory is

mapped to the a ddresses 40H~54H of bank 27.

Bit Definition

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

40H ENA A00 A01 A02 A03 A04 A05 A06

41H A07 A08 A09 A10 A11 A12 A13 A14

42H A15 A16 A17 FA2 FA1 FA0

43H

44H B07 B08 B09 B10 B11 B12 B13 B14

45H B15 B16 B17 FB2 FB1 FB0

46H

47H C07 C08 C09 C10 C11 C12 C13 C14

48H C15 C16 C17 FC2 FC1 FC0

49H

4AH D07 D08 D09 D10 D11 D12 D13 D14

4BH D15 D16 D17 FD2 FD1 FD0

4CH

4DH E07 E08 E09 E10 E11 E12 E13 E14

4EH E15 E16 E17 FE2 FE1 FE0

4FH

50H F07 F08 F09 F10 F11 F12 F13 F14

51H F15 F16 F17 FF2 FF1 FF0

52H SPF00 SPF01 SPF02 SPF03 SPF04 SPF05 SPF06 SPF07

53H SPF08 SPF09 SPF10 SPF11 SPF12 SPF13 SPF14 SPF15

54H SPF16 SPF17 SPF18 SPF19 SPF20 SPF21 SPF22 SPF23

ENB B00 B01 B02 B03 B04 B05 B06

ENC C00 C01 C02 C03 C04 C05 C06

END D00 D01 D02 D03 D04 D05 D06

ENE E00 E01 E02 E03 E04 E05 E05

ENF F00 F01 F02 F03 F04 F05 F05

32 23th Feb ’98

HT9480

User address format

A user address in the POCSAG code consists of

21 bits. Three of the 21 bits are coded in the

frame number and are therefore not explicitly

transmitted. In the decoder, the addresses A, B,

C, D, E and F can use 6 different frames respectively. Every address has to be explicitly enabled by resetting the associated enable bit.

Examples:

Address decimal value: RICA=10535

Binary equivalent(14 bits): 10100100100111

Binary equivalent(18+3 bits):

000000010100100100111

Register allocation:

A00 A01 A02 A03 A04 A05 A06 A07 A08

000000010

A09 A10 A11 A12 A13 A14 A15 A16 A17

100100100

FR12 FR11 FR10

111

Configuration

The program mode cha nges to the STANDBY

state by setting the

ON bit high at any time. Th e

configuration RAM can be programmed only

when the value of the STB flag is 1. After the

configuration RAM is programmed and the

ON

bit is set low, the system quits the program

mode and resumes normal operation.

•

BS1: Receiver enabled

Receiver establishment

time (t

BS1

)

Option

512 bps 1200/2400 bps SPF00 SPF01

7.81ms 53.33ms 0 0

15.63ms 6.67ms 0 1

31.25ms 13.33ms 1 0

62.50ms 26.67ms 1 1

•

BS2: Quick charge

RF dc level adjustment

time (t

BS2

)

Option

512 bps 1200/2400 bps SPF02 SPF03

7.81ms 1.67ms 0 0

11.71ms 6.67ms 0 1

15.63ms 11.67ms 1 0

19.53ms 13.33ms 1 1

•

BS3: PLL enabled

PLL establishment

time (t

BS3

)

Option

512 bps 1200/2400 bps SPF04 SPF05

0ms 0ms 0 0

31.25ms 26.67ms 0 1

46.87ms 40.00ms 1 0

62.50ms 53.33ms 1 1

Test mode

The test mode of the decoder is selected by

setting the

TS pin low at any time. In the test

mode, the RF con trol ou tp uts BS1 a nd B S3 are

set high constantly, but BS2 is set low.

After the

TS pin is set high the decoder exits the

test mode.

RF control

The HT9480 provides the BS1-BS3 signals for

RF control.

Timing

Timing

33 23th Feb ’98

HT9480

Description of the special

programmed function bits (SPF)

The following features can be selected by appropriate programming of the specially programmed function bi ts:

•

SPF00, SPF01

Receiver (BS1) establishment time (for the

BS2~BS3 options, refer to SPF2~SPF5)

00: 7.81ms/512 53.33ms/1200/2400

01: 15.63ms/512 6.67ms/1200/2400

10: 31.25ms/512 13.33ms/1200/2400

11: 62.50ms/512 26.67ms/1200/2400

•

SPF02, SPF03

RF dc level adjustment (BS2) enable time

00: 7.81ms/512 1.67ms/1200/2400

01: 11.71ms/512 6.67ms/1200/2400

10: 15.63ms/512 11.67ms/1200/2400

11: 19.53ms/512 13.33ms/1200/2400

•

SPF04, SPF05

PLL (BS3) establishment time

00: 0ms/512 0ms/1200/2400

01: 31.25ms/512 40.00ms/1200/2400

10: 46.87ms/512 40.00ms/1200/2400

11: 62.50ms/512 53.33ms/1200/2400

•

SPF06, SPF07

Duplicate the call suppress time-out and out-

of-range hold-off time-out

00: 30s/512/1200 15s/2400

01: 60s/512/1200 30s/2400

10: 120s/512/1200 60s/2400

11: 240s/512/1200 120s/2400

•

SPF08, SPF09

Call termination criteria combination method

and message data deformatting method

0x : Any two consecutive codewords or the

codeword directly following the address

codeword in error

10 : Any single codeword in error

11 : Any two consecutive codewords in error

x0 : Numeric data deformation

x1 : Numeric data deformation on function

code 00 only

•

SPF10, SPF11

Tone generation frequency prescaler divider

00: Prescaler factor 1

01: Prescaler factor 2

10: Prescaler factor 4

11: Prescaler factor 8

34 23th Feb ’98

Baud rate selection bits (SPF12, SPF13, SPF14)

SPF12 SPF13 SPF14 Connected Crystal (Hz) Baud Rate (Hz)

0 0 0 32768 512

0 0 1 76.8k 512

0 1 0 76.8k 1200

0 1 1 76.8k 2400

1 0 0 153.6k 512

1 0 1 153.6k 1200

1 1 0 153.6k 2400

HT9480

•

SPF15

1: 4-bit burst error correction fo r address and

message code-word

0: 2-bit random error correction for address

and message code-word

•

SPF16

1: Out-of-range Hold-off period according to

SPF06 and SPF07

0: Out-of-range Hold-off period is zero

regardless of SPF06 and SPF07

•

SPF17

Tone generatio n frequency source selector

0: System clock

1: 32.768kHz

•

SPF18

Tone generation frequency duty control

0: frequency duty cycle 1/2

1: frequency duty cycle 1/4

•

SPF19

Non-inversion or inversion data input selection

1: Inversion input selected for DI from RF

Circuit, referring to DI

0: Non-inversion in put selected for DI from

RF circuit

•

SPF20

Message code-word packaging method

1: 4 bits packaging mode

0: 7 bits A S CII mode

•

SPF21, SPF22, SPF23

Internal state status (for testing only)

35 23th Feb ’98

HT9480

Mask option

The following table ill ustrates n ine k inds of mask opti ons i n the H T9480 . All o f the opti ons sh ould

be defined to ensure proper system functioning.

No. Mask Option

HALT function selection . This opti on defin es the way o f enabling or disabling the H ALT

1

function.

WDT source selection. This option selects the WDT source, from either the subsystem clock,

2

or instruction clock, or disabling the WDT function.

CLRWDT times selection. This option defines the way of clearing the WDT by instruction.

3

“Once” means that the “CLR WDT” can clear the WDT and “Twice” implies that the “CLR

WDT1” and “CLR WDT2” should be executed before the time-out so as to clear the WDT.

Wake-up selection. T his option defin es the wake-up activity. Port A h as the capability of

4

waking-up the chip from HALT.

5 PB, PC0, and PC1 pull-high options

µC OSC type selectio n. This optio n is to de cide if an RC or Crystal oscillato r is chosen as

6

the system clock.

7 WDT prescaler selection. The prescaler can be set to 1/1024 or 1/2048

8 FOUT connection selection. The FOUT output can be connected to the OSC1 input or not.

9 Double frequency selection. The FOUT can be doubled from the X1 input clock.

36 23th Feb ’98

Application Circuit 1

HT9480

37 23th Feb ’98

Application Circuit 2

HT9480

38 23th Feb ’98

Instruction Set Summary

Mnemonic Description Flag Affected

Arithmetic

ADD A,[m]

ADDM A,[m]

ADD A,x

ADC A,[m]

ADCM A,[m]

SUB A,x

SUB A,[m]

SUBM A,[m]

SBC A,[m]

SBCM A,[m]

DAA [m]

Logic Operation

AND A,[m]

OR A,[m]

XOR A,[m]

ANDM A,[m]

ORM A,[m]

XORM A,[m]

AND A,x

OR A,x

XOR A,x

CPL [m]

CPLA [m]

Increment &

Decrement

INCA [m]

INC [m]

DECA [m]

DEC [m]

Rotate

RRA [m]

RR [m]

RRCA [m]

RRC [m]

RLA [m]

RL [m]

RLCA [m]

RLC [m]

Add data memory to ACC

Add ACC to data memory

Add immediate data to ACC

Add data memory to ACC with carry

Add ACC to register with carry

Subtract immediate data from A CC

Subtract data memory from ACC

Subtract data memory from ACC with result in data memory

Subtract data memory from ACC with carry

Subtract data memory from ACC with ca rry with result in

data memory

Decimal adjust ACC for addition with result in data memory

AND data memory to ACC

OR data memory to ACC

Exclusive-OR data memory to ACC

AND ACC to data memory

OR ACC to data memory

Exclusive-OR ACC to data memory

AND immediate data to ACC

OR immediate data to ACC

Exclusive-OR immediate data to ACC

Complement data memory

Complement data memory with result in ACC

Increment data memory with result in ACC

Increment data memory