Page 1

DISCOVERY

™

QDR® Series

FAN BEAM X-RAY BONE DENSITOMETER

TECHNICAL MANUAL

Hologic, Inc.

35 Crosby Drive

Bedford, MA 01730

USA

Phone in US: 800-321-4659

Fax (Domestic): 781-280-0670

Fax (International): 781-280-0671

Document 080-1085

Revision 008

Page 2

Discovery QDR Series Technical Manual

December 2010

Notice

The information contained in this manual is confidential and proprietary to Hologic, Inc.

This information is provided only to authorized representatives of Hologic's customers

solely for the purpose of facilitating the use of Hologic's products. No information

contained herein may be disclosed to any unauthorized person for any purpose whatsoever

without the prior written consent of Hologic, Inc.

The procedures described in this document are intended for use by direct employees of

Hologic, Inc., or authorized Hologic Equipment Resellers and their trained field

engineers. Any unauthorized or untrained persons performing these procedures may affect

the warranty of the Discovery QDR Series.

Exercise proper caution when servicing the system. There are dangerous and potentially

lethal voltages accessible within the Discovery system. To avoid exposure to shock

hazards, the Main Circuit Breaker should be switched off, and the power cord removed,

before working inside any part of the system.

The Discovery QDR Series Fan Beam X-ray Bone Densitometer produces ionizing

radiation in the form of X-rays. It may be dangerous to the patient, operator or field

engineer unless safe exposure factors and operating instructions are observed. To avoid

unsafe exposure, do not attempt to service the equipment unless you are a Hologic, Inc.,

certified field engineers. Exercise proper caution when servicing the system. A dosimeter

(film badge) should always be worn while on site. Dose and scatter measurements must be

taken after each service call to ensure that the parameters are still within specifications.

Hologic, Inc., has made all effort to ensure that the information in this manual is accurate

and complete. Hologic, Inc., shall not, however, be liable for any technical or editorial

errors or omissions contained herein, or for incidental, special or consequential dangers in

connection with the furnishing or use of this manual. The information in this manual is

subject to change without notice.

Discovery and the Hologic logo are registered trademarks of Hologic, Inc. All other

products and company names used in this manual are trademarks and registered

trademarks of other manufactures.

Printed in U.S.A.

Copyright© 2003-2010 by Hologic, Inc., All rights reserved

ii

Page 3

Discovery QDR Series Technical Manual

Chapter 1 -

INTRODUCTION

1.1 System Overview ............................................................................................... 1-1

1.1.1 X-Ray Scanning Principles ....................................................................... 1-2

1.2 Functional Overview .......................................................................................... 1-4

1.3 Product Specifications ..................................................................................... 1-10

1.3.1 Exam Mode(s) Performance ................................................................... 1-12

1.3.2 Duty Cycle: ............................................................................................. 1-13

1.3.3 Leakage Technique Factors .................................................................... 1-13

1.3.4 Minimum Beam Filtration ...................................................................... 1-13

1.3.5 Measured Half Value Layer (HVL) At Different Operating Potentials . 1-13

1.3.6 Line Voltage and Maximum Line Current ............................................. 1-13

1.3.7 Technique Factors for Maximum Line Current ...................................... 1-13

1.3.8 Maximum Deviation ............................................................................... 1-14

1.3.9 Measurement Criteria for Technique Factors ......................................... 1-14

Chapter 2 -

FUNCTIONAL DESCRIPTION

2.1 Computer ........................................................................................................... 2-1

2.2 PCI Communications Controller Board ............................................................. 2-1

2.2.1 Interface Connections ............................................................................... 2-1

2.3 Distribution Board ............................................................................................. 2-3

2.3.1 Power ........................................................................................................ 2-3

2.3.2 Interface Connections ............................................................................... 2-4

2.4 Motor Controller Board ..................................................................................... 2-5

2.4.1 Power ........................................................................................................ 2-5

2.4.2 Interface Connections ............................................................................... 2-6

2.5 TZ Drive Board (A and SL Only) ...................................................................... 2-6

2.5.1 Service Switches ....................................................................................... 2-7

2.5.2 Power ........................................................................................................ 2-7

2.5.3 Interface Connections ............................................................................... 2-8

2.6 Control Panel Controller Board ....................................................................... 2-10

2.6.1 Power ...................................................................................................... 2-10

2.6.2 Interface Connections ............................................................................. 2-10

2.7 C-Arm Interface Board .................................................................................... 2-12

2.7.1 Continuity Daisy Chain .......................................................................... 2-13

2.7.2 Power ...................................................................................................... 2-13

2.7.3 Interface Connections ............................................................................. 2-13

2.8 X-Ray Controller Assembly (P/N 010-1273) .................................................. 2-16

2.8.1 Interface .................................................................................................. 2-16

Table of Contents iii

Page 4

Discovery QDR Series Technical Manual

2.8.2 X-Ray Controller Board .......................................................................... 2-18

2.9 X-Ray Source Unit ........................................................................................... 2-19

2.10 Data Acquisition System (C, W, and SL) ..................................................... 2-20

2.10.1 Solid State Detector ............................................................................. 2-20

2.10.2 Integrator/Multiplexor Subsection ........................................................ 2-20

2.10.3 Analog To Digital Board ...................................................................... 2-21

2.10.4 Power .................................................................................................... 2-21

2.10.5 Interface Connections ........................................................................... 2-21

2.11 Data Acquisition System (A Model only) ..................................................... 2-23

2.11.1 Solid State Detector ............................................................................. 2-23

2.11.2 Power .................................................................................................... 2-23

2.11.3 Interface Connections ........................................................................... 2-23

2.12 Integrator/Multiplexor Board ......................................................................... 2-24

2.12.1 Power .................................................................................................... 2-25

2.12.2 Interface Connections ........................................................................... 2-25

2.13 Analog To Digital Board (A Model Only) .................................................... 2-27

2.13.1 Power .................................................................................................... 2-27

2.13.2 Interface Connections ........................................................................... 2-27

2.14 Torroid Power Module and DIN Rail ............................................................ 2-29

Chapter 3 -

INSTALLATION

3.1 Pre-Installation Requirements ............................................................................ 3-1

3.1.1 Required Tools .......................................................................................... 3-1

3.1.2 Required Documentation .......................................................................... 3-1

3.1.3 Room and Doorway Size .......................................................................... 3-2

3.1.4 Arrange For Help ...................................................................................... 3-6

3.2 Uncrate and Move to Destination ...................................................................... 3-6

3.2.1 Inspect For Shipping Damage ................................................................... 3-6

3.2.2 Uncrate Unit .............................................................................................. 3-7

3.2.3 Take Inventory .......................................................................................... 3-8

3.2.4 Measure Path To Final Destination .......................................................... 3-8

3.2.5 Remove Tabletop (If Necessary) .............................................................. 3-9

3.2.6 Remove Discovery A or SL Lower C-Arm Assembly (If Necessary) ... 3-10

3.2.7 Prepare the Tabletop for Moving (A, W,Wi) .......................................... 3-12

3.2.8 Move Unit To Destination ...................................................................... 3-12

3.2.9 Set Up the Unit ....................................................................................... 3-16

3.3 Install the System ............................................................................................. 3-18

3.3.1 Install Cables ........................................................................................... 3-18

3.3.2 Check Power Line Voltage ..................................................................... 3-23

3.3.3 Install Computer ..................................................................................... 3-24

iv Table of Contents

Page 5

Discovery QDR Series Technical Manual

3.3.4 Start QDR Software in Service Mode ..................................................... 3-24

3.3.5 Check Table Alignment .......................................................................... 3-25

3.3.6 Perform C-Arm Parallelism Adjustment (A and SL systems only) ........ 3-27

3.4 Calibrate and Test the System ......................................................................... 3-28

3.4.1 Check Tube kV Peak Potential ............................................................... 3-28

3.4.2 Check Tube Current ............................................................................... 3-30

3.4.3 Adjust Belt Tension ................................................................................ 3-32

3.4.4 Calibrate Motors ..................................................................................... 3-33

3.4.5 X-Ray Beam Alignment ........................................................................ 3-47

3.4.6 Calibrate Aperture (Cannot be run on Ci and Wi models) ..................... 3-53

3.4.7 Check Laser Positioning Offset .............................................................. 3-54

3.5 A/D Gain Control Adjustment ......................................................................... 3-54

3.5.1 Check and Verify the A/D Gain ............................................................. 3-54

3.5.2 Adjust the A/D Gain ............................................................................... 3-55

3.5.3 Perform Detector Flattening .................................................................. 3-55

3.5.4 Perform Lateral Alignment Test (A and SL) .......................................... 3-56

3.5.5 Check HVPS/S (Tank) For Radiation Leakage ...................................... 3-58

3.5.6 Calibrate For Area, BMD And BMC ...................................................... 3-60

3.5.7 Scan Thickness Measurement & Calibration (C and W) ........................ 3-61

3.5.8 Scan Thickness Measurement & Calibration (A and SL) ....................... 3-61

3.5.9 Calibration of Area and BMC, for Array Scan Modes ........................... 3-62

3.5.10 RECALYZE and Add Array AP Scans to the QC Database ................ 3-63

3.5.11 Install Software Options ....................................................................... 3-64

3.5.12 Test Scan Modes ................................................................................... 3-64

3.5.13 Finish Assembling Unit ........................................................................ 3-66

3.5.14 Measure X-Ray Dose To Patient .......................................................... 3-66

3.5.15 Measure X-Ray Scatter From Phantom ................................................ 3-67

3.5.16 Perform QC ........................................................................................... 3-67

3.5.17 Run Reproducibility Test ...................................................................... 3-67

3.5.18 Table Top Radiographic Uniformity (A, W and Wi) ........................... 3-68

3.5.19 Instruments using Body Composition Analysis (BCA) ........................ 3-69

3.5.20 Instruments using BMD Whole Body Analysis ................................... 3-70

3.6 The Radiation Measurement Report ................................................................ 3-70

Chapter 4 -

ALIGNMENT AND CALIBRATION

4.1 Check Table Alignment ..................................................................................... 4-1

4.2 Align the Table .................................................................................................. 4-1

4.2.1 Table Edge to T-Rail (“A” Dimension) Adjustment ................................ 4-1

4.2.2 Front to Back T-Rail and Table Edge/Rail Gap Adjustment .................... 4-3

4.3 C-Arm Parallelism Adjustment ........................................................................ 4-3

4.4 X-Ray Beam Alignment ................................................................................... 4-4

4.5 Aperture Calibration ......................................................................................... 4-9

Table of Contents v

Page 6

Discovery QDR Series Technical Manual

4.6 Motor Calibration ............................................................................................ 4-10

4.7 Laser Positioning Offset Adjustment ............................................................... 4-26

4.8 A/D Gain Control Adjustment ......................................................................... 4-26

4.8.1 Check and Verify the A/D Gain ............................................................. 4-27

4.8.2 Adjust the A/D Gain ............................................................................... 4-27

4.9 Filter Drum Encoder Alignment ...................................................................... 4-28

4.10 Detector Flattening ....................................................................................... 4-29

4.11 Lateral Alignment Test (QDR 4500A and SL) .............................................. 4-30

4.12 Table Top Radiographic Uniformity ............................................................. 4-32

4.12.1 Instruments using Body Composition Analysis (BCA) ........................ 4-33

4.12.2 Instruments using BMD Whole Body Analysis ................................... 4-33

4.13 Check Phantom values ................................................................................... 4-34

4.14 Area, BMD, and BMC Calibration ................................................................ 4-34

4.14.1 Scan Thickness Measurement & Calibration (C and W) ...................... 4-35

4.14.2 Scan Thickness Measurement & Calibration (A and SL) ..................... 4-36

4.14.3 Calibration of Area and BMC, for Array Scan Modes ......................... 4-37

4.14.4 RECALYZE and Add Array AP Scans to the QC Database ................ 4-38

Chapter 5 -

REMOVE AND REPLACE PROCEDURES

5.1 Recommended Tools ......................................................................................... 5-1

5.2 Electronics Tray FRUS ...................................................................................... 5-1

5.2.1 Electronics Tray Printed Circuit Boards ................................................... 5-2

5.2.2 C-Arm Y Motor or Gearcase .................................................................... 5-3

5.2.3 C-Arm Y Encoder ..................................................................................... 5-4

5.3 Table Y FRUs (A, W and Wi Only) .................................................................. 5-4

5.3.1 Control Panel (All models) ....................................................................... 5-5

5.3.2 PCBs Under Right-Side of the Table ........................................................ 5-5

5.3.3 Table Y Belt .............................................................................................. 5-6

5.3.4 Table Y Motor or Gearcase ...................................................................... 5-7

5.3.5 Table Y Encoder ....................................................................................... 5-7

5.4 Table X FRUS ................................................................................................... 5-8

5.4.1 Table X Motor Controller PCB ................................................................ 5-9

5.4.2 Table X Belt ............................................................................................ 5-10

5.4.3 Table X Motor or Gearcase .................................................................... 5-10

5.4.4 Table X Encoder ..................................................................................... 5-11

5.5 Table Z FRUs (A and SL only) ...................................................................... 5-12

5.5.1 Pedestal ................................................................................................... 5-12

5.5.2 The Linear Rotary String (Encoder) ....................................................... 5-14

5.6 Lower C-Arm FRUS ........................................................................................ 5-16

vi Table of Contents

Page 7

Discovery QDR Series Technical Manual

5.6.1 C-Arm Interface Board ........................................................................... 5-17

5.6.2 X-Ray Controller Assembly ................................................................... 5-18

5.6.3 Filter Drum Assembly ............................................................................ 5-18

5.6.4 Tank Assembly ....................................................................................... 5-19

5.6.5 Arm R FRUS (A and SL only) ............................................................... 5-21

5.6.6 Motor Controller Board ......................................................................... 5-23

5.6.7 Arm R Belt .............................................................................................. 5-23

5.6.8 Arm R Motor, Gearcase, Encoder or Encoder Belt ................................ 5-24

5.6.9 Gas Spring ............................................................................................... 5-25

5.7 Upper C-Arm FRUS ........................................................................................ 5-25

5.7.1 Detector Assembly A, SL, W, C Systems .............................................. 5-26

5.7.2 Detector Assembly C1 and Wi Systems ................................................. 5-27

5.7.3 Laser Assembly ....................................................................................... 5-29

5.7.4 Analog to Digital Converter Board (A Model only) ............................... 5-30

5.8 Aperture Assembly FRUS ............................................................................... 5-31

5.8.1 Aperture Stepper Motor .......................................................................... 5-31

5.8.2 Aperture Motor PCB ............................................................................... 5-32

5.8.3 Aperture Position Belt ............................................................................ 5-32

5.8.4 Rotary Potentiometer .............................................................................. 5-33

5.9 Drum Assembly FRUS .................................................................................... 5-34

5.9.1 Drum Encoder PCB ................................................................................ 5-34

5.9.2 Drum Belts .............................................................................................. 5-36

5.9.3 Stepper Motor Assembly ........................................................................ 5-37

5.9.4 Drum Bearings ........................................................................................ 5-37

5.10 Replacing EMI Cables ................................................................................... 5-40

5.11 FRU Lists ....................................................................................................... 5-41

Chapter 6 -

FAULT ISOLATION

6.1 Before Starting ................................................................................................... 6-1

6.2 Software Configuration ...................................................................................... 6-1

6.3 Hardware Configuration .................................................................................... 6-1

6.4 Power Problems ................................................................................................. 6-1

6.5 Motion Problems ................................................................................................ 6-2

6.6 Control Panel Problems ..................................................................................... 6-5

6.7 Display Problems ............................................................................................... 6-5

6.7.1 Vertical Stripe ........................................................................................... 6-5

6.7.2 Horizontal Stripe ....................................................................................... 6-6

6.7.3 Noise ......................................................................................................... 6-7

6.7.4 No Display ................................................................................................ 6-7

6.8 Targeting/Laser Problems .................................................................................. 6-8

Table of Contents vii

Page 8

Discovery QDR Series Technical Manual

6.9 Data Communications Problems ....................................................................... 6-8

6.10 Area/BMD/BMC/CV Specification Problems ................................................. 6-9

6.11 X-Ray Problems ............................................................................................... 6-9

6.11.1 No X-Rays .............................................................................................. 6-9

6.12 X-Ray Alignment Problems ............................................................................. 6-9

6.12.1 X-Ray beam does not align properly ...................................................... 6-9

6.12.2 System Fails X-Ray Beam Alignment Verification ............................. 6-10

6.13 Detector Flattening Problems ........................................................................ 6-10

6.13.1 System Consistently Fails the Detector Flattening Procedure .............. 6-10

6.14 Laser Problems .............................................................................................. 6-11

6.15 Oil leakage ..................................................................................................... 6-12

6.15.1 The Torque Specifications .................................................................... 6-12

6.15.2 Tank Top Cover Components and Screw Location .............................. 6-12

6.15.3 Tightening the Lexan Cup Screws ........................................................ 6-13

6.15.4 Tightening the Bladder Gasket Screws ................................................. 6-13

6.15.5 Tightening the Transformer Seal Screws .............................................. 6-14

6.15.6 Tightening the Tank Cover Gasket Screws .......................................... 6-14

6.16 Miscellaneous Problems ................................................................................ 6-15

Chapter 7 -

PREVENTIVE MAINTENANCE

7.1 Customer Preventive Maintenance .................................................................... 7-1

7.2 Field Service Preventive Maintenance .............................................................. 7-1

7.2.1 Guide Rail and Bearing Maintenance ....................................................... 7-3

Chapter 8 -

PCB SUMMARY INFORMATION

Chapter 9 -

SOFTWARE TOOLS

9.1 X-Ray Survey .................................................................................................... 9-1

9.1.1 Invoking X-Ray Survey ............................................................................ 9-1

9.1.2 The Main Display ..................................................................................... 9-2

9.1.3 The Display Controls ................................................................................ 9-3

9.2 SQDRIVER ....................................................................................................... 9-9

9.3 SQVERIFY ...................................................................................................... 9-10

9.4 SQKEYPAD .................................................................................................... 9-10

Appendix A -

ERROR MESSAGES

viii Table of Contents

Page 9

Section 1

INTRODUCTION

1.1 System Overview

The Hologic Discovery® X-ray Bone Densitometer (Discovery-C and -W is shown in Figure 1-1

on Page 1-2; Discovery-A and -SL is shown in Figure 1-2 on Page 1-2) estimates the bone

mineral content (BMC) and bone mineral density (BMD) of selected areas of the body or of the

entire skeleton. It does so using X-rays of two different energy levels. This dual-energy scheme

allows soft tissue within the selected area to be subtracted out leaving only bone to be scanned

and estimated.

This manual uses "Discovery" to refer to all models in the Discovery series of systems.

Information presented in this manual that applies only to a particular model, or models, will be

noted as such.

The patient lies face up on the table and, with the aid of a cross-hair laser, the operator positions

the scanning arm over the region of interest. After entering patient data and selecting the type and

size of scan desired, the operator initiates the scan with a single keystroke.

The operator is not required to select technique factors as tube current and voltage are preselected and fixed. Since testing is performed by fan beam method, rather than by flooding the

area as in conventional radiography, the scanning time is a function of the dimensions of the area

to be measured, the desired resolution, and the desired precision.

BMC results are expressed in grams of calcium hydroxyapatite and BMD is reported in grams/

cm2 of the same compound.

In most cases, no additional shielding is necessary for patient, operator, or room. The Discovery

system can be placed in any convenient non-shielded examination room. Contact your state

regulatory agency for details about additional shielding requirements, if any.

The Discovery system employs a patented Automatic Internal Reference System, which

continuously calibrates the machine to eliminate the effects of variations in temperature, tube

flux, etc. No daily calibration is required. The daily scanning of a quality control phantom is

required to provide assurance that the system is functioning correctly and to aid in the detection of

any long-term drift.

The X-ray scans produced by the Discovery, and displayed on the monitor, are intended only to

locate anatomical sites for measurement and to assure the operator that the machine is operating

properly. They are not intended as a substitute for conventional film-based diagnostic scans.

1-1

Page 10

Discovery QDR Series Technical Manual

Figure 1-1. Discovery®-C and -W System

Figure 1-2. Discovery®-A and -SL System

1.1.1 X-Ray Scanning Principles

An X-ray source, consisting of a high voltage generator and X-ray tube in a common,

shielded enclosure, is mounted beneath the patient on the C-Arm. It generates a narrow,

tightly collimated, fan-shaped beam of X-rays which alternate, at power line frequency,

between 100kVp and 140kVp. At the other end of the C-Arm, above the patient, is a

crystal/solid state detector array. During a scan, the C-arm and table move, under

computer control, to guide the beam over the desired scan area.

1-2

Page 11

Discovery QDR Series Technical Manual

Before passing through the patient, the beam is filtered through a rotating drum in which

alternating segments having radio-opacities equivalent to tissue, bone and air are located.

When finally intercepted by the detector, the beam contains information about the X-ray

absorbing characteristics of both the patient and the calibration materials in the filter

drum. An A/D converter, fed by the detectors, supplies a complex digital signal to the

computer, which uses that signal both to construct the screen display, and as the basis for

its computations of BMC and BMD.

The Discovery computer algorithm is based on the principle that bone attenuates the X-ray

beam differently at high and low energies. The bone mineral content of any sample point

can be computed from:

Q= L - kH

where L and H are the logarithms of the sample attenuation at high (140kVp) and low

(100kVp) energies, respectively. The constant k depends on the tissue attenuation

characteristics of the beam. In the Discovery, k is continuously measured using the

“tissue” segment in the filter wheel.

The program works in the following manner:

1. Load preliminary scan and obtain regions of interest from operator.

2. Estimate k as an average value of:

k = [L

where L

tissue

interposed by the filter drum, and L

Note: The subscript "

- L

tissue

] / [H

air

tissue

- H

air

]

indicates a low-energy me as ureme nt with tissue -equi vale nt m aterial

, H

air

" designates the filter drum segment that is empty (i.e., contains

air

tissue

and H

are similarly defined.

air

neither bone- nor tissue-equivalent material).

3. Using this value of k, calculate Q for each point scanned using the formula given

above (Q = L - kH). This array of Q values constitutes a "Q scan". Displays the Q

scan.

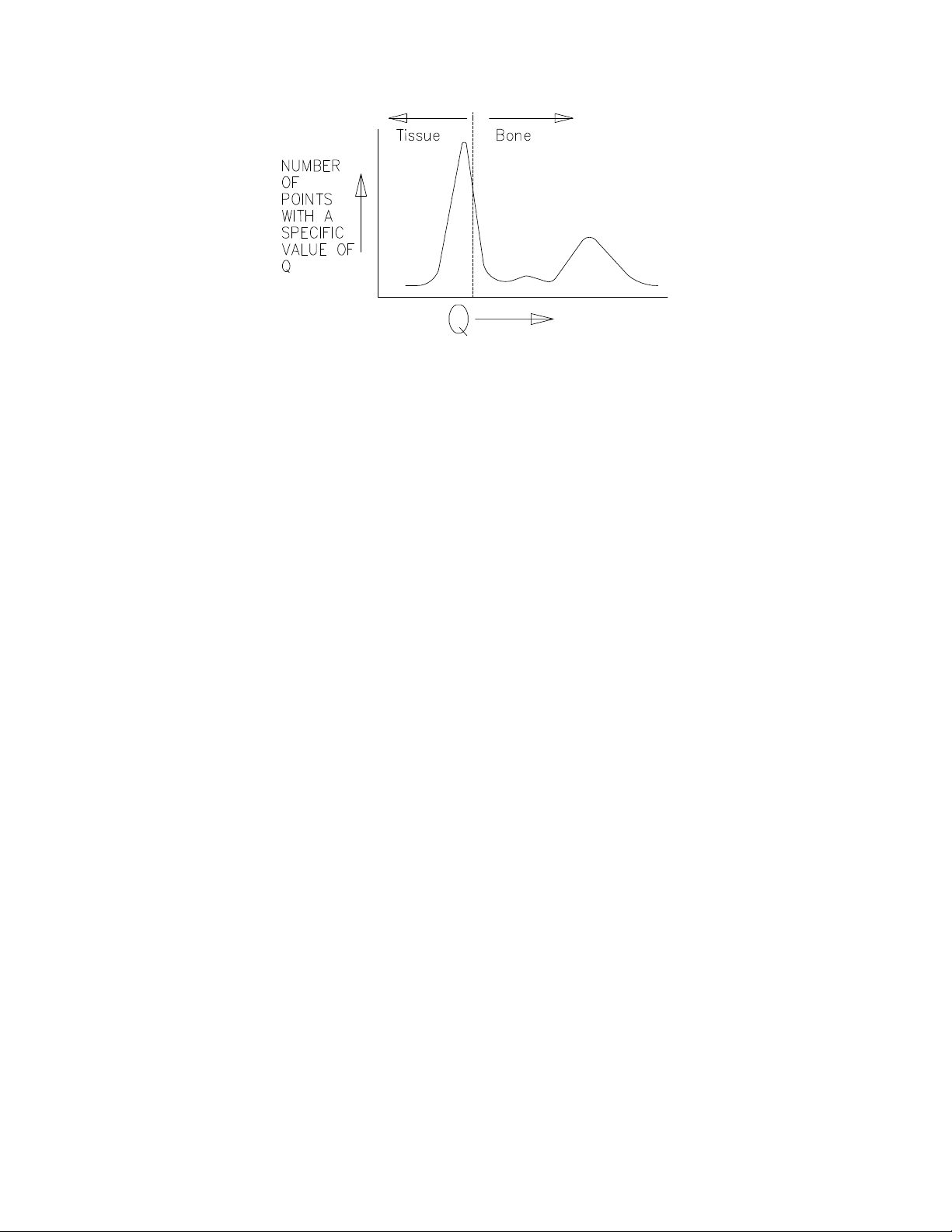

4. Compile a histogram of the Q values. Because a large portion of the scan con-

tains soft tissue only, this histogram will have a large peak. Choose a threshold

value just above this peak, and apply that value to discriminate, point by point in

the Q scan, between "bone" points (whose Q is above the threshold) and "nonbone" points (whose Q is below the threshold).

1-3

Page 12

Discovery QDR Series Technical Manual

Figure 1-3. Q Scan Plot

5. Use the "non-bone" points to calculate a baseline value for each scan line. Using

these points, form a new histogram and repeat steps 4 and 5 until the results con

verge.

6. Smooth the segment boundaries to eliminate isolated noise-generated "bone"

points.

-

7. Display the "bone" and "non-bone" points for operator approval.

8. Determine the constant of proportionality (d0) that relates the Q values to actual

BMC (grams). This constant is determined by measuring how much Q shifts

when bone-equivalent material is interposed by the filter drum.

9. Calculate the total bone mineral values by adding up the Q values for all "bone"

points in each region of interest (e.g., each vertebra), and multiplying by d0.

10. Determine the bone areas by counting the number of "bone" points in each region

of interest.

11. Calculate bone mineral density as:

BMD = BMC / area

12. Display the calculated results and print the report.

1.2 Functional Overview

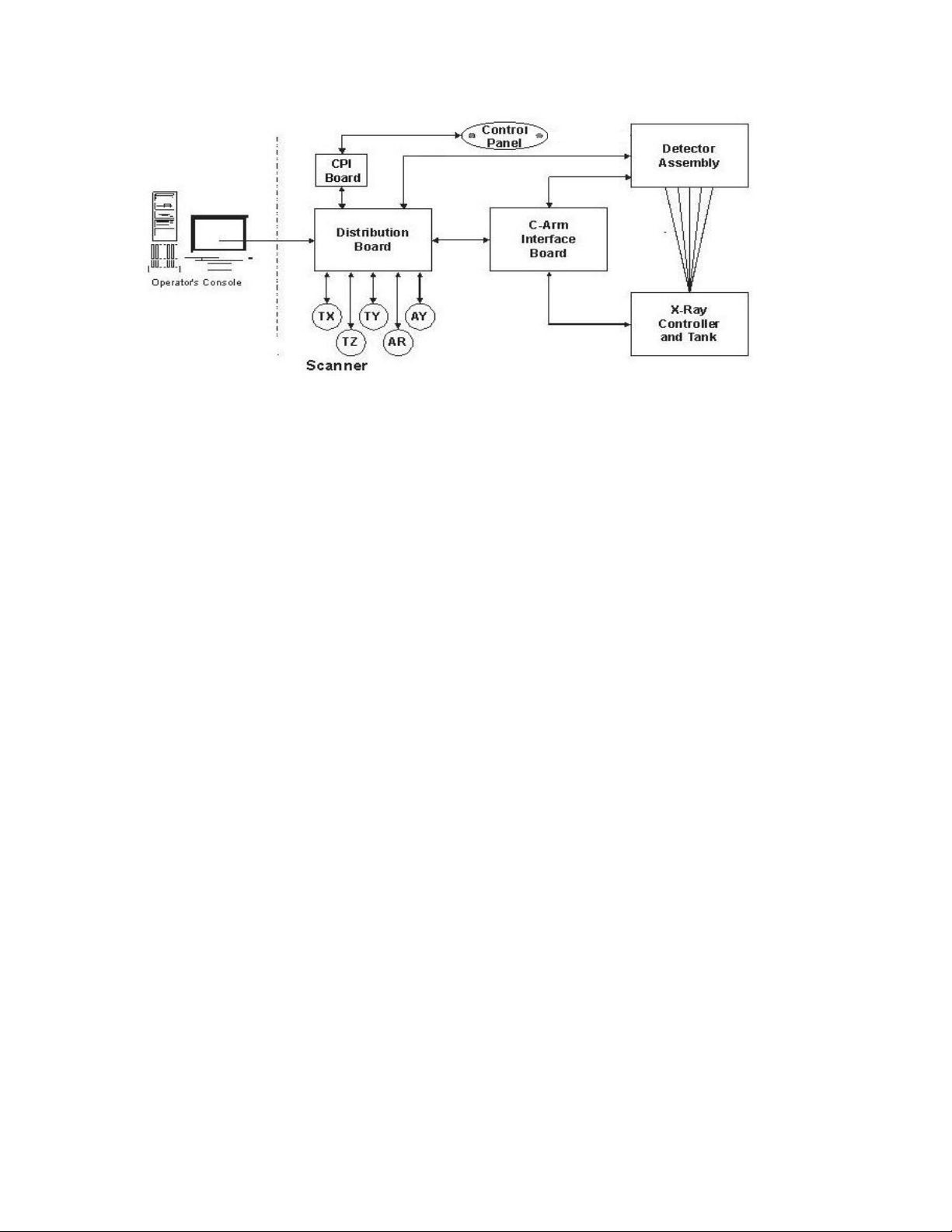

This section provides block diagrams of the Discovery system along with a brief

functional overview of each diagram and block. A detailed functional description along

with interconnection diagrams and interconnection descriptions is provided in Section 2 of

this manual.

1-4

Page 13

Discovery QDR Series Technical Manual

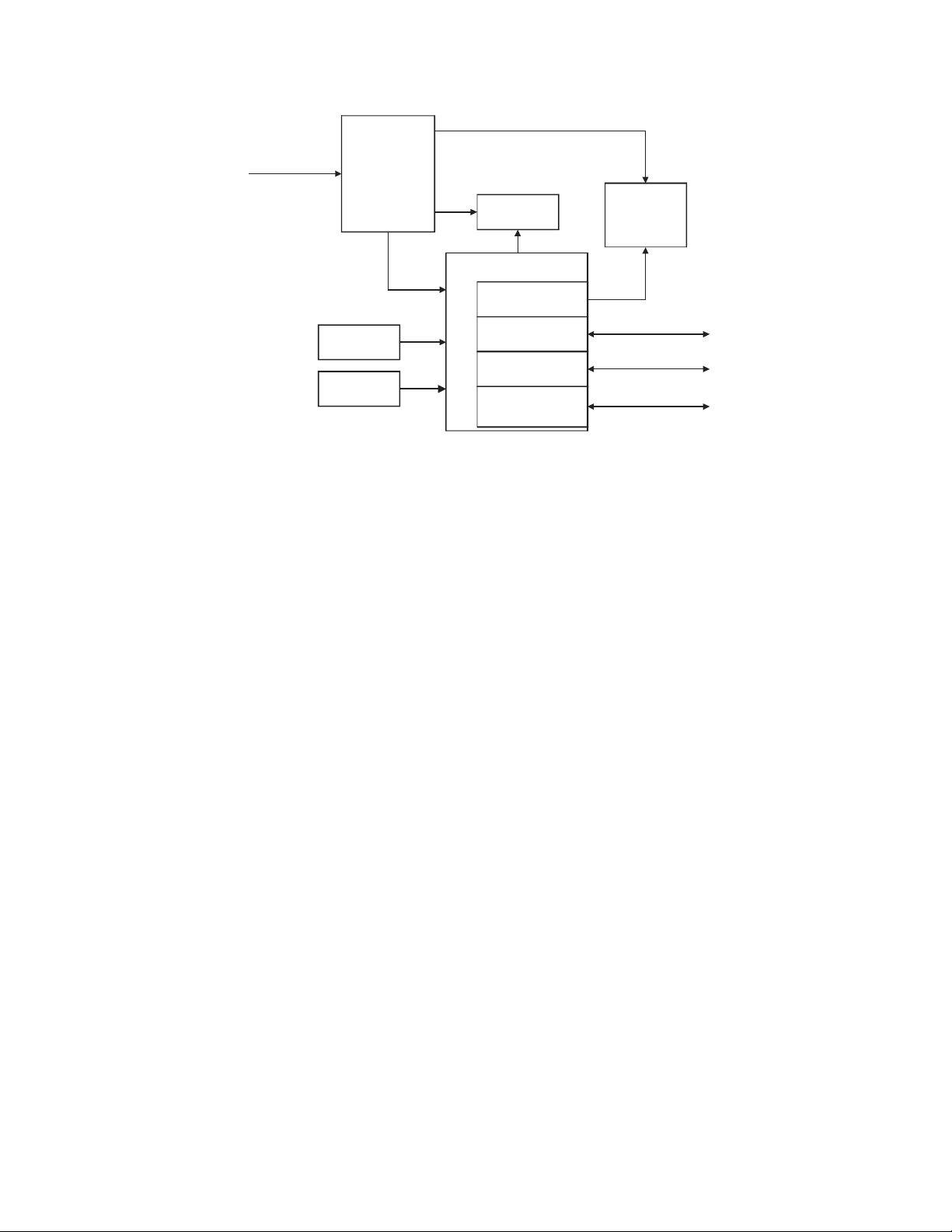

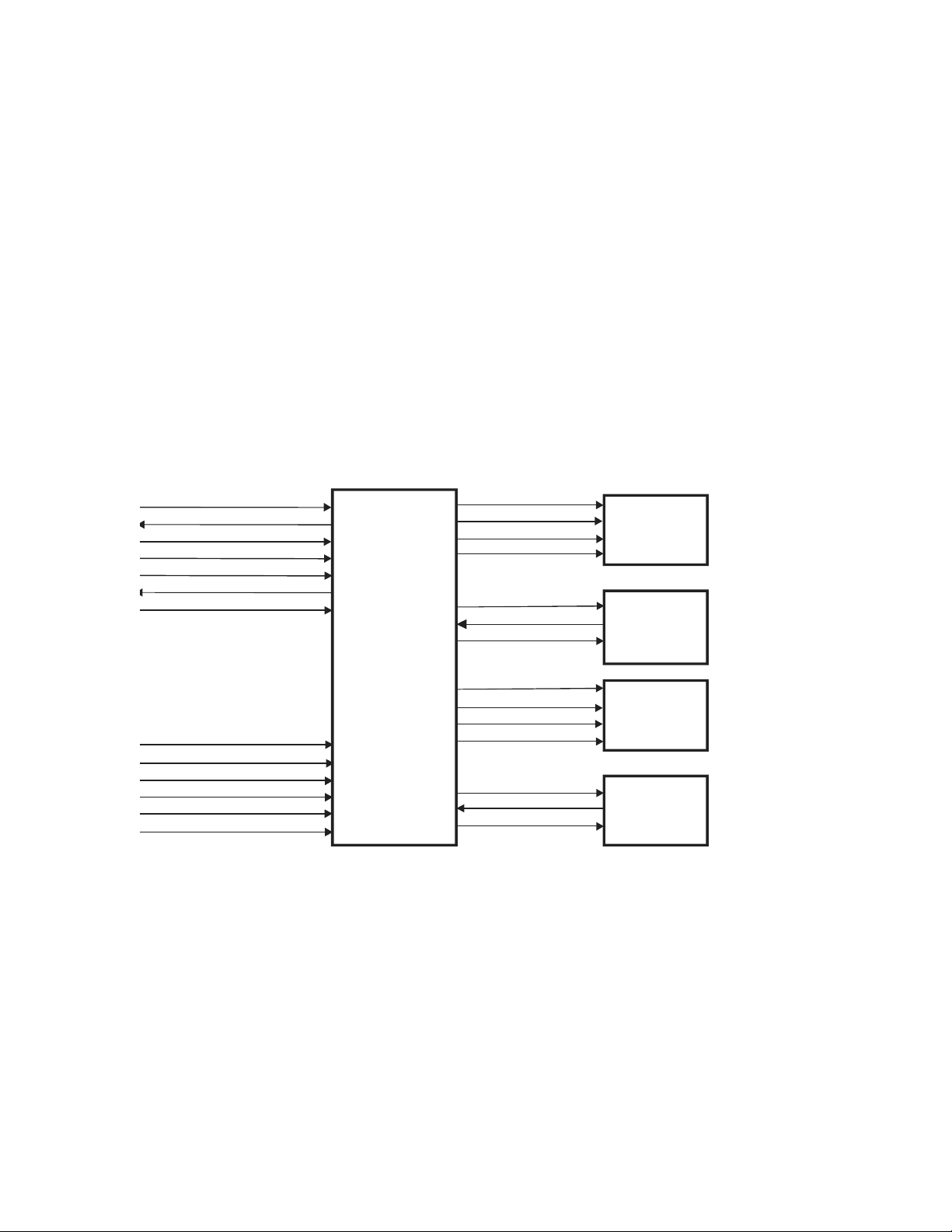

Figure 1-4. Discovery System Block Diagram

The Hologic Discovery consists of essentially three conceptual subsystems. These

subsystems are the Operator’s Console, Motor Control Subsystem, and C-Arm

Subsystem.

The Operator’s Console is the input/output subsystem of the instrument and consists of a

PC running the Discovery system software under Windows XP® and the PCI

Communications Controller Board manufactured by Hologic. The software communicates

with the scanner sending out arm and table motion commands, X-Ray commands, and Xray detection commands. The software also checks to see that commands have been

completed and issues an appropriate error message when a command fails.

The Motor Control subsystem of the scanner is controlled by the Distribution Board. All

motor movement commands are routed through the Distribution Board to the individual

Motor Drivers. There is one Motor Driver for each motor: Arm Y direction (A Y), Table X

direction (TX), T able Y directio n (TY) (A and W models only), and Arm Rotation (AR)(A

and SL models only). The Distribution Board also distributes the DC power throughout

the scanner. Circuit breakers for each Motor Driver can be found on the Distribution

Board.

The C-Arm subsystem controls the generation and detection of X-rays. It processes the

commands received from the Distribution Board and passes them to the X-Ray Controller

or the Detector Assembly. The X-Ray Controller, as its name implies, controls the

generation of the X-Rays by the X-Ray Source or “Tank”. The X-Rays pass through the

patient and are sensed by the Detector Assembly.

1-5

Page 14

Discovery QDR Series Technical Manual

Power

Strip

Keyboard

Mouse

Modem

Network I/F Card

Printer

Monitor

Phone

Jack

AC

AC

AC

Network

Jack

Discovery

Scanner

Video

Computer

AC from

DIN Rail

(Scanner)

AC

PCI

Communications

Controller

Figure 1-5. Discovery Operator's Console Block Diagram

The Discovery Operator’s Console consists of a Pentium PC on a convenient, roll-around

computer cart designed specifically for the Discovery PC. AC power from the scanner is

fed to the Operator’s Console via a power strip attached to the PC cart.

The Pentium PC contains the video controller board to drive the monitor and the PCI

Communications Controller Board to interface the PC to the Scanner. A modem card is

provided for remote communications with other PCs. A Network Interface Card (NIC) is

installed to control communications with the Hologic QDRNet® or a DICOM® network.

The mouse gives the operator easy control over the Windows XP-based Discovery

software and the keyboard is used for data input to the Discovery software. A color inkjet

printer is provided with the PC. An optional laser printer can be substituted for the inkjet

printer.

1-6

Page 15

Discovery QDR Series Technical Manual

TY Stepper

Motor Driver

TX Stepper

Motor Driver

AY Stepper

Motor Driver

TY

Motor

TY

Encdr

TX

Motor

TX

Encdr

AY

Motor

AY

Encdr

Signal

Distribution

Board

To/From C-Arm Interface

To/From Control Panel Interface

To/From

Communications

Controller

+/-15V

JP1

+24V

From DIN

Rail

and LVPS

AR Stepper

Motor Driver

AR

Motor

AR

Encdr

TZ Stepper

Motor Driver

TZ

Motors

TZ

Encdrs

AC

JP4

JP5

JP7

JP11

JP8

JP6

JP10

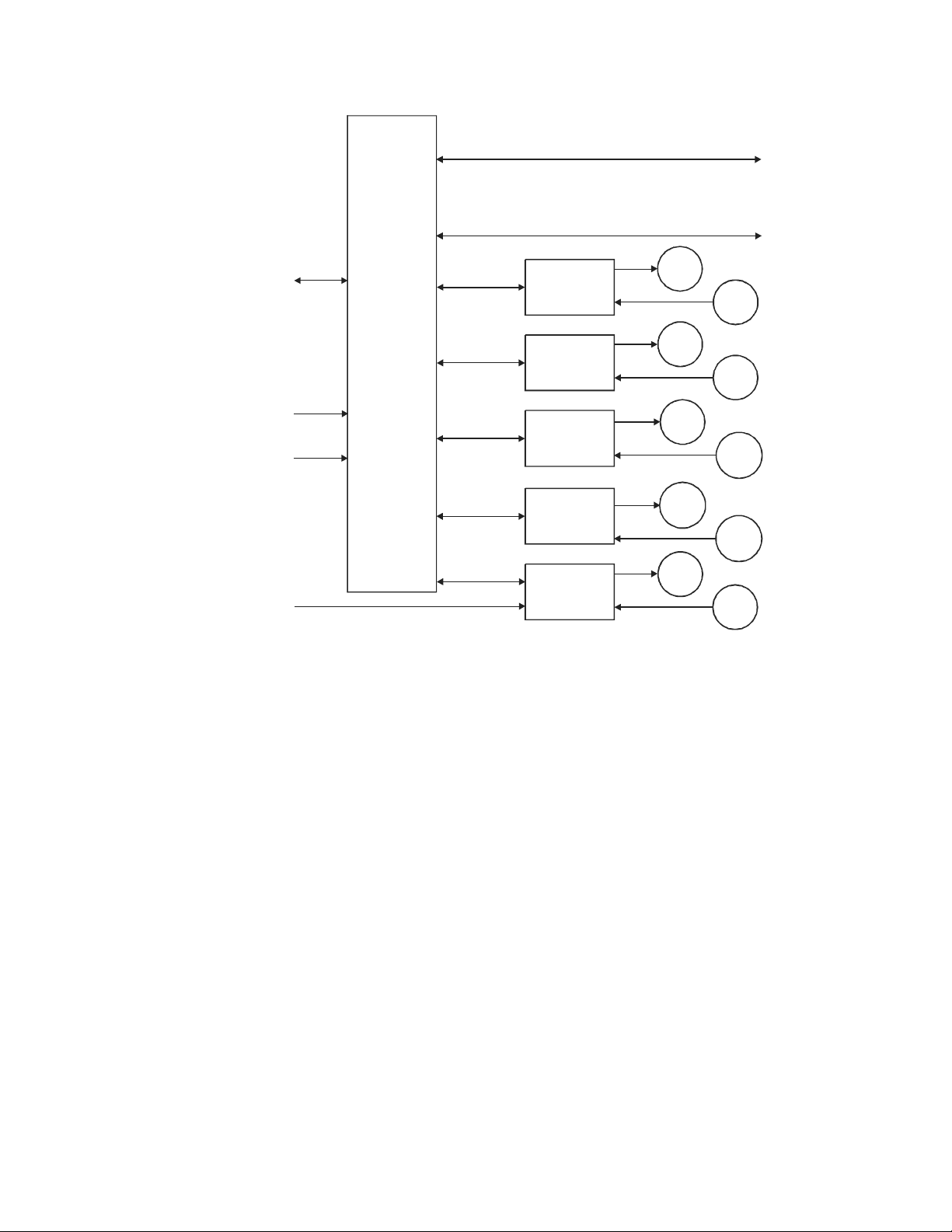

Figure 1-6.Discovery Distribution and Motor Control Block Diagram

The heart of the Discovery Scanner is the Distribution Board. This board interfaces the PC

to the different subsections of the Scanner, distributes control signals to the table and CArm, and distributes DC power throughout the Scanner. The Distribution Board receives

command inputs from the PCI Communications Controller Board in the PC and voltages

from the DIN rail and Low Voltage Power Supply. Commands and voltages dealing with

the generation of X-Rays or the acquisition of scan data are transferred to the C-Arm

Interface Board, which controls both functions. The Distribution Board also receives

Table and C-Arm motion commands from the PCI Communications Controller Board in

the PC.

When a motion command is received, the Distribution Board routes the command along

with a board address to the Motor Driver Boards. The addressed Motor Driver Board

converts these digital commands into analog signals that are strong enough to drive the

motors. A Position Encoder attached to the idler pulley moved by the motor, senses

changes in the position of the arm or table. This device provides a voltage feedback to the

Motor Driver Board that is translated into a motor position, which in turn, is fed back to

software in the Operator’s Console PC.

The Discovery Control Panel is located at the head end of the table and communicates

with the Distribution Board via the Control Panel Interface Board. The Control Panel

provides the operator with a means to issue manual commands to move table and arm

1-7

Page 16

Discovery QDR Series Technical Manual

C-Arm

Interface

Board

Detector Board

(Detectors, Muxes,

and A/D Converter)

Aperture Motor

and

Position Sensor

Filter Drum Motor

and

Position Sensor

Laser

Assembly

Detector Assembly

X-Ray

Controller

X-Ray

Source

(Tank)

To/From

Distribution

Board

From

DIN

Rail

motors, turn power to the instrument on or off, and an indicator showing when X-rays are

being generated.

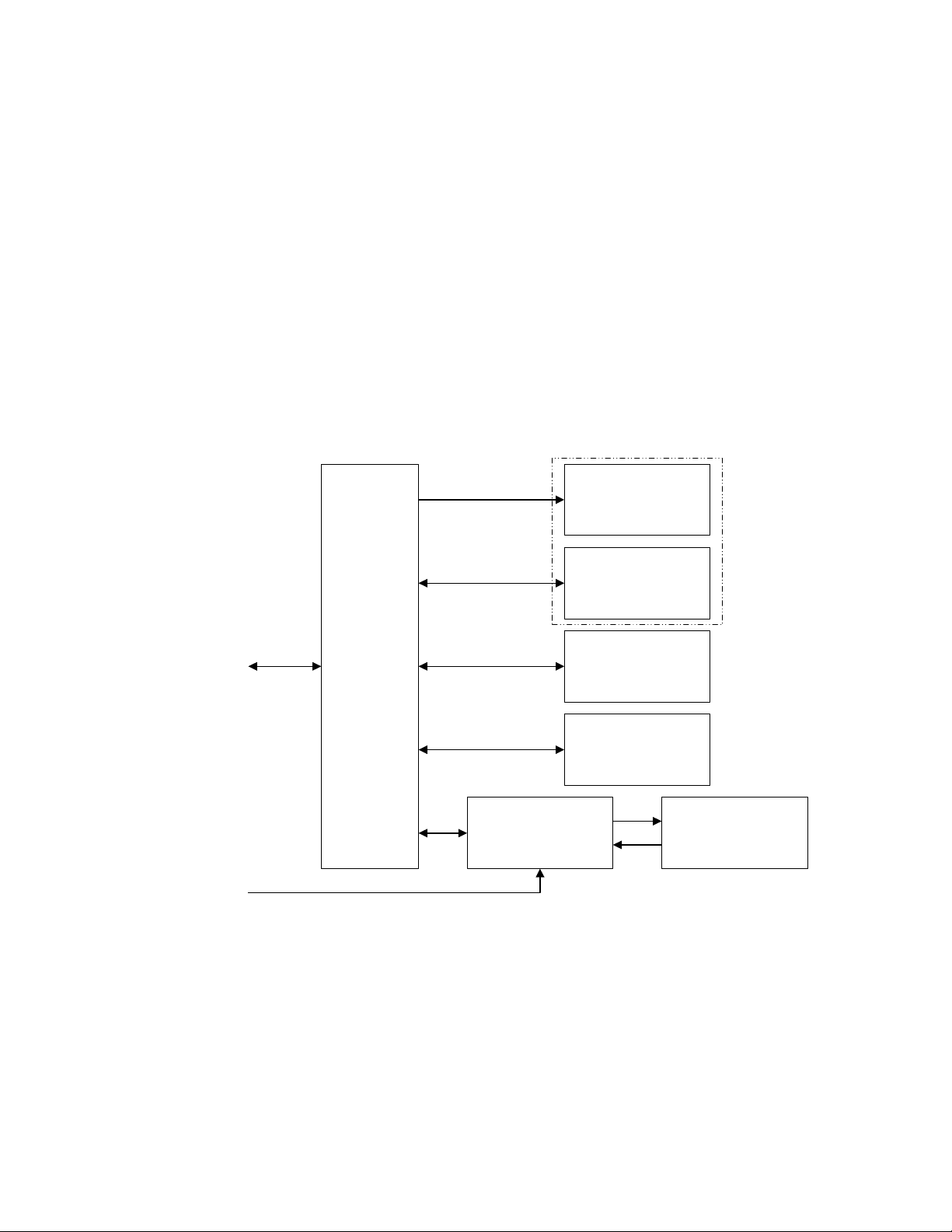

The C-Arm Interface Board controls the C-Arm Subsystem. Commands to the subsystem

arrive from the Distribution Board. The commands processed by the C-Arm Interface

Board are sent to the Positioning Laser, the X-Ray Control ler (XRC ), the Ape rture M otor,

the Detector assembly, or the Filter Drum Assembly. The commands sent to the

Positioning Laser are simple on/of f commands. Commands sent to the XRC tell it when to

produce X-rays, which power level of pulse to produce, and the pulse mode to be used.

These commands will subsequently control the way the X-Ray Source (Tank) is driven by

the XRC. Instructions to the Aperture Motor are for selecting the aperture to be used for

the scan. The commands to the Filter Drum Assembly turn the Filter Drum on or off and

synchronize the filter drum with the AC line waveform. The last set of command signals is

sent to the Detector Assembly to synchronize the acquisition of data with the production

of the X-rays from the source (Tank).

The C-Arm Interface Board collects data from most of the circuits mentioned above for

transmission back to the Distribution Board and, finally, the Discovery software. The

Figure 1-7. Discovery C-Arm Block Diagram

Aperture Motor Assembly sends back position information indicating which of the

aperture slits is in position. The Filter Drum Assembly sends back filter and reference

phase information. The XRC sends back information concerning fault conditions, beam

conditions, and an AC Line signal for generating AC Line Interrupts to the software. The

Detector Board sends data collected from scans back to the software through the C-Arm

1-8

Page 17

Discovery QDR Series Technical Manual

Interface Board and the Distribution Board. Mathematical algorithms applied to this data

produce the scans seen by the operator and to calculate the BMD, BMC, and area of the

bone matter scanned.

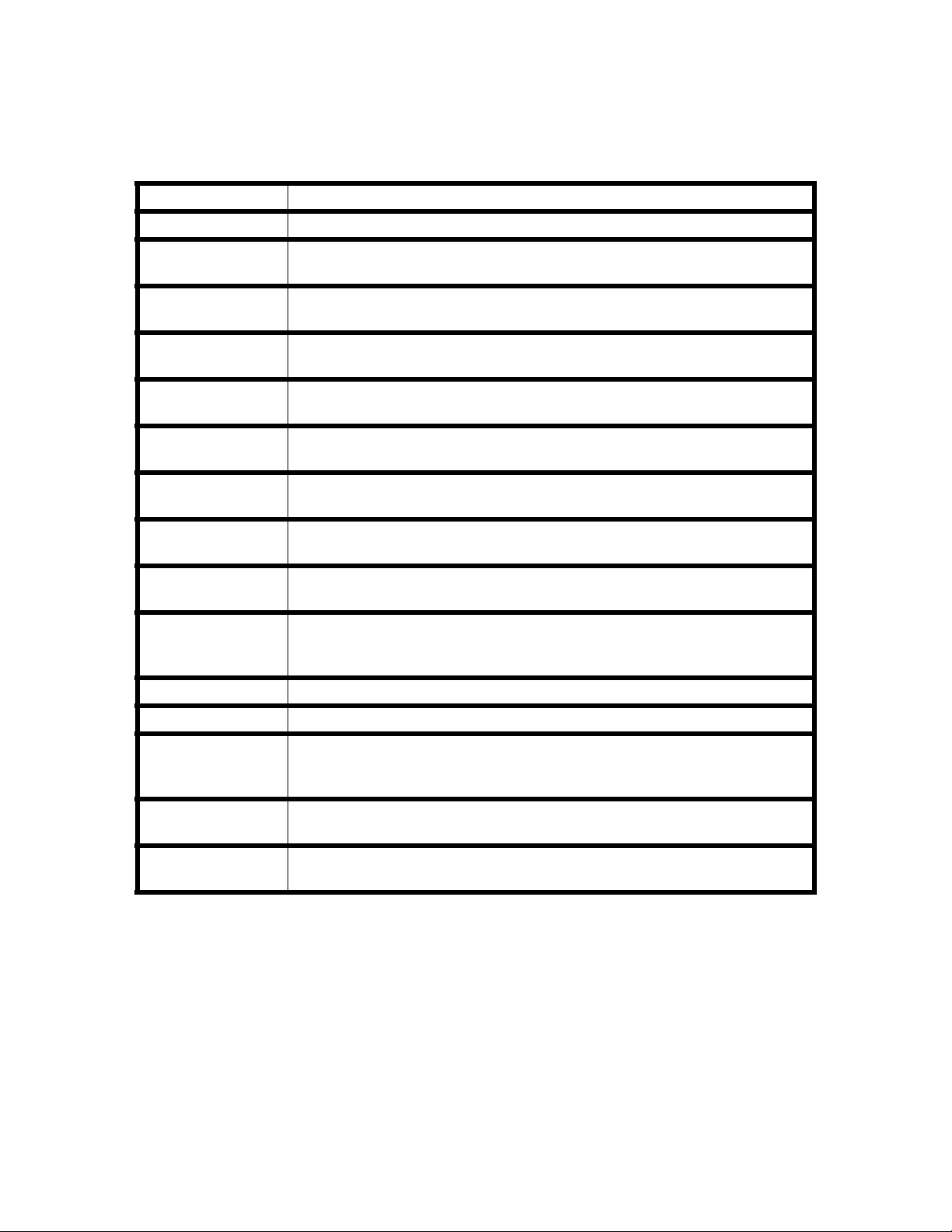

Block Description

Computer Controls and commands all Discovery hardware modules.

PCI Communications

Controller Board

Distributi on Board Provides the interconnections between the Discovery Operator's Console and the

Control Panel Provides switches for manually moving the C-Arm and Patient Table. Also

TX Stepper Motor

Driver

TY Stepper Motor

Driver

TZ Stepper Motor

Driver

AR Stepper M otor

Driver

AY Stepper Motor

Driver

C-Arm Interface Controls the Aperture and Filter Drum motors, generates timing and control signals

X-Ray Controller Controls the operation of the X-ray Source.

Controls the flow of commands to and from the Scanner modules via the

communications bus.

Scanner and distributes DC voltages.

provides Emergency Stop and Instrument On/Off switches.

Controls the motion of the Patient Table in and out motor and monitors table

position information from the encoder.

Controls the motion of the Patient Table left to right motor and monitors table

position information from the encoder (A and W only).

Controls the motion of the Patient Table left and right pedestal motor and monitors

table position information from the string encoders (A and SL only).

Controls the rotational motion of the C-Arm and m onitors C-arm position

information from the encoder (A and SL only).

Controls the motion of the C-Arm left and right motor and monitors C-Arm

position information from the encoder.

for the X-Ray Controller and the Data Acquisition System, monitors the tape

switches, and provides power to the Positioning Laser.

X-Ray Source Unit Generates the X-ray beam.

Detector Board Converts the X-rays into electrical signals. Integrates the signals from the Solid

State Detectors and converts them to a digital value in the Analog-to-Di git a l

converter circuitry.

Control Panel Provides the operator with a means to reposition the table, C-Arm, and to turn on

the laser.

Positioning Laser Provides a laser crosshair beam to assist in positioning the patient on the Patient

Table.

1-9

Page 18

Discovery QDR Series Technical Manual

1.3 Product Specifications

SPECIFICATION MODEL DEFINITION

Scanning Me t hod All Multi-detector array, indexing table, and motorized C-arm

X-ray System All Switched Pulse Dual-Energy X-ray tube, operating at 100 and

140kV, 5mA avg. at 50% duty cycle, 2.5mA avg. at 25% duty

cycle (30sec. maximum), Tungsten target

Detector System A 216 multi-channel detector consisting of CdWO4 scintillators

coupled to silicon diodes

SL/C/ W 128 multi-channel detector consisting of CdWO4 scintillators

coupled to silicon diodes

Scanning Sites A Lumbar spine (in AP and lateral projections), proximal femur

(hip) forearm, IVA Spine, and whole body

SL Lumbar spine (in AP and lateral projections), proximal femur

(hip), IVA Spine, and forearm

W Lumbar spine (in AP and decubitus lateral projections),

proximal femur (hip), forearm, IVA spine (AP only) and whole

body

C Lumbar spine (in AP and decubitus lateral projections),

proximal femur (hip), forearm, and IVA spine (AP only)

Scan Region A 1.95m (76.77 in.) x.65m (25.59 in.) maximum

SL 96cm (38 in.) x .65m (25.59 in.) maximum

W 1.97m (77.5 in.) x.65m (25.59 in.) maximum

C .96m (38 in.) x.51m (20 in.) maximum

Scatter Radiation All Less than 10µGy/h (1mrad/h) at 2m (79 in.) from the center of

the X-ray beam for all scans

Leakage Radiation All The Discovery meets the requirements of 21 CFR 1020.30(k)

for leakage from the X-ray source

External Shielding

Requirement

Calibration All Self Calibrating using Hologic Automatic Internal Reference

All Contact state regulatory agency.

System. Operator calibration NOT required.

1-10

Page 19

Discovery QDR Series Technical Manual

SPECIFICATION MODEL DEFINITION

System Weight

installed

A & SL 327kg 720lb 34.1kg 75lb

C & W 295kg 650lb

System Weight

shipping

Operating

Temperature

Humidity All 20 – 80% relative Humidity, non-condensing

Storage

Temperature

Humidity All 20 – 80% relative Humidity, non-condensing

Footprint Length Width

T ab le extended A & W 3.02 119 1.50

T ab le not exte nded A & W 2.02 79.5 1.22

Average Heat Load ALL 1000w (3400 BTU/hr)

A & SL 659kg 1450lb

C & W 568kg 1250lb

All

All

C & SL 2.02 79.5 1.40

Scanner Console

System

15o – 32o C (59o - 90o F)

15o – 32o C (59o - 90o F)

m inches m

inches m inches

59 1.42 56

48 1.42 56

55 1.42 56

Height

Patient Table

Height

Positioning Laser All Diode laser (<1mW) cross hair, with emergency mechanical shutter

X-Ray Collimation All Dual movable aperture with 0.5mm and 1.0mm slits

Leakage Current All Normal <75µA Single Fault <400µA

Resolution All 0.5 line pair/mm approximately 1.0mm

A & SL Adjustable, 71cm (28 in.) from floor when scanning in AP mode

86.4cm (34 in.) at maximum elevation

C & W 71cm (28 in.) +/- 25mm (1 in.)

1-11

Page 20

Discovery QDR Series Technical Manual

1.3.1 Exam Mode(s) Performance

Exam Type Model Default

Scan

Length (in.)

AP Spine High

Def

AP Spine Array All 8.0 82 L1, L2, L3, L4 0.20 1.0

AP Spine Fast All 8.0 41 L1, L2, L3, L4 0.10 1.0

AP Spine Turbo All 8.0 21 L1, L2, L3, L4 0.05 1.0

Express Scan All 8.0 10 L1, L2, L3, L4 0.07 1.0

Decubitus Lateral

Spine Fast

Lat Spine High

Def

Lat Spine Array A & SL 8.0 240 L1, L2, L3, L4 0.70 1.0

Lat Spine Fast A & SL 6.0 120 L1, L2, L3, L4 0.35 1.0

Hip High Def All 6.0 123 Femur (Total) 0.20 1.0

Hip Array All 6.0 62 Femur (Total) 0.20 1.0

Hip Fast All 6.0 31 Femur (Total) 0.10 1.0

All 8.0 163 L1, L2, L3, L4 0.20 1.0

C & W 8.0 160 L2, L3, L4 0.40 1.0

A & SL 8.0 240 L1, L2, L3, L4 0.35 1.0

D u r a tion(s)

@ Default

Length

Scan Site Dose

mGy

max

in vivo

Precision

(%)

Hip Turbo All 6.0 16 Femur (Total) 0.05 1.0

Dual Hip All 6.0 2X Scan Mode Left & Right

Femur

Whole Body W 77.0 402 Whole Body 0.015 1.0

A 77.0 180 Whole Body 0.01 1.0

Forearm All 6.0 31 Forearm

(Radius &

Ulna) (Total)

IVA SE AP

Imaging

IVA SE R/L

Lateral

IVA DE R/L

Imaging

Small Animal

Spine and Femur

Small Animal

Whole Body

All 16.1 10 Spine T5-L4 0.07 NA

All 16.1 10 Spine T5-L4 0.07 NA

All 13.6 511 Spine T5-L4 0.35 NA

A 2/3 149 Spine & Femur NA NA

A 12.0 122 Whole Body NA NA

Selecte

d Scan

Mode

0.10 1.0

Selected

Scan

Mode

1-12

Page 21

Discovery QDR Series Technical Manual

1.3.2 Duty Cycle:

C, W and SL IVA 12%

All Others 50%

A Whole Body 100%

IVA 12%

All Others 50%

1.3.3 Leakage Technique Factors

The leakage technique factors for all models of Discovery are the same. It is the maximum

continuous current at the maximum peak potential. This is X-ray mode #3. Peak potential

100/140kVp (dual energy), current 10mA peak 25% duty cycle or 2.5mA average.

1.3.4 Minimum Beam Filtration

The minimum filtration permanently in the beam is 3.7mm Al equivalent @80kV.

1.3.5 Measured Half Value Layer (HVL) At Different Operating Potentials

Measured operating potential Measured Half Value Layer

Discovery All

80kV 3.7mm Al equivalent

100kV 5.0mm Al equivalent

140kV 6.5mm Al equivalent

1.3.6 Line Voltage and Maximum Line Current

Power

Requirements:

All 100VAC 16A 50/60Hz, Max apparent resistance = 0.32 ohm

120VAC 14A 50/60Hz, Max apparent resistance = 0.32 ohm

230VAC 8A 50/60Hz, Max apparent resistance = 1.28 ohm

1.3.7 Technique Factors for Maximum Line Current

Peak Potential 140kVp

Tube Current 10mA peak, 50% duty factor or 5mA average.

1-13

Page 22

Discovery QDR Series Technical Manual

1.3.8 Maximum Deviation

The maximum deviation from the preindication given by labeled technique factor control

settings or indicators are as follows:

Peak Potential: +/- 15%

Current: +/- 40%

Time: +/- 10%

1.3.9 Measurement Criteria for Technique Factors

The measurement criteria of the technique factors is as follows:

Peak Potential: The voltage peak is measured with an oscilloscope. Voltage is a squarewave pulse.

Peak is defined as the peak voltage of the 4 millisecond pulse, discounting any initial

overshoot.

Current: Current is measu red with an oscilloscope on the last millisecond of the 4 millisecond

pulse.

Time: Time of each pulse is measured with an oscilloscope and defined as the time between

50% rise and fall times of the peak potential pulse. Time of the scan is measured by

counting the number of AC line pulses from the start to the end. X-ray pulses are

synchronous with the AC line.

1-14

Page 23

Section 2

FUNCTIONAL DESCRIPTION

This section provides a detailed functional description along with interconnection diagrams and

descriptions of the Hologic Discovery. Refer to Section 1 for a block diagram and a brief

functional description of each block.

2.1 Computer

The Discovery Scanner is interfaced to a PCI Communications Controller Board/ISA Bus

computer which controls table and C-arm movement, X-ray generation, performs all necessary

calculations, and manages both the patient and QC database information.

The computer is a Pentium III-based (or higher) PC that comes equipped with floppy disk drive,

hard disk drive, keyboard, mouse, 17” color monitor, and CDROM R/W for archiving scans and

backups of the system database. For details pertaining to the computer and its associated

components, please refer to the documentation shipped with each unit.

2.2 PCI Communications Controller Board

The PCI Communications Controller Board handles all the communications between the

Computer and the Scanner C-Arm and Table assemblies. The board resides in one of the computer

internal ISA slots and communicates with the computer via the computer's I/O bus. It connects to

the Distribution Board in the Scanner through a 50-conductor ribbon cable. This cable contains

two independent communications links (one synchronous and one asynchronous) and additional

system control signals. Each signal requires a pair of conductors for differential (RS422) noise

immunity.

The asynchronous link communicates with the Motor Controller Boards (TX, TY, AR, and AY),

the TZ Drive Board, the C-Arm Interface Board, and the Control Panel Controller section of the

Detector Board (or the Control Panel Interface on A and SL models). The synchronous link

communicates with the Data Acquisition System (DAS).

2.2.1 Interface Connections

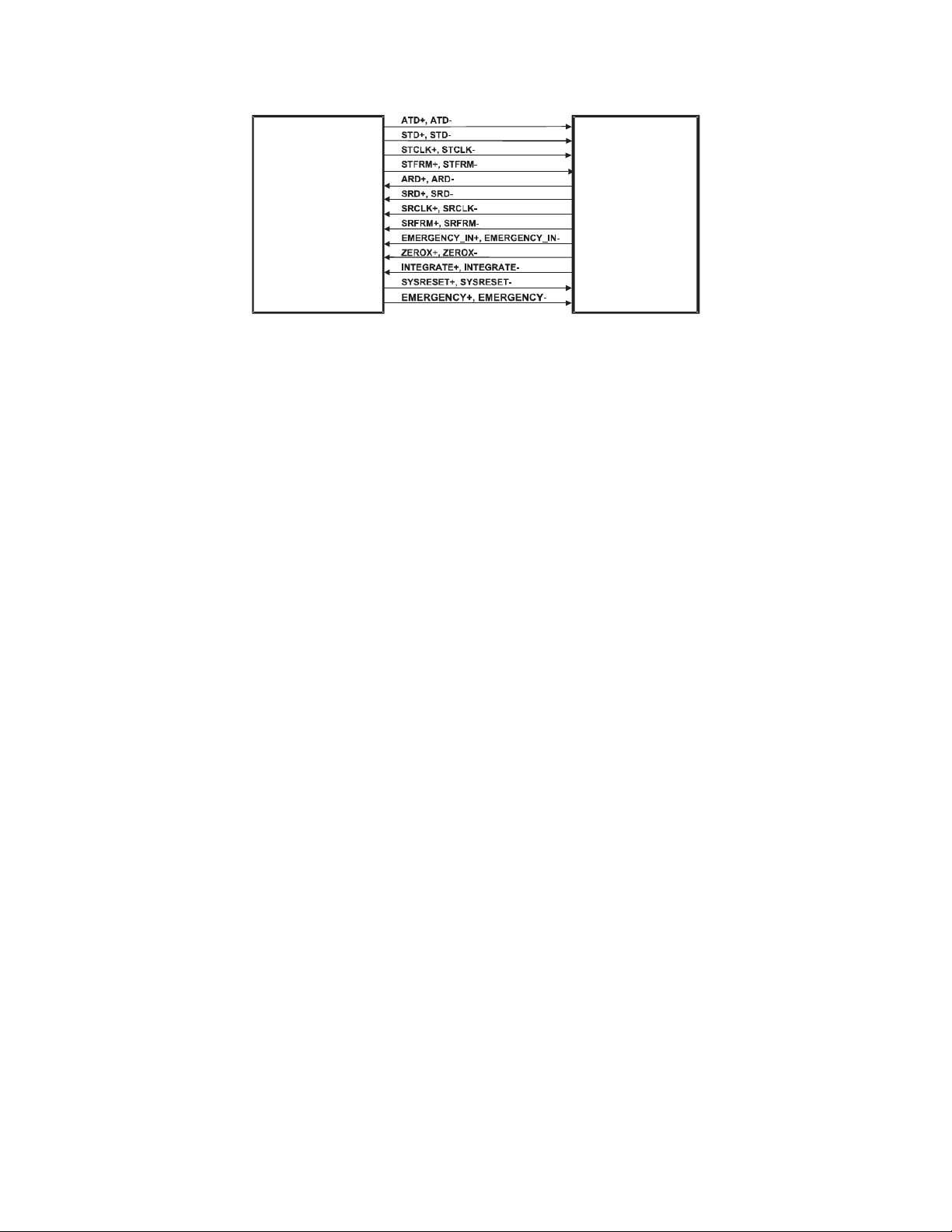

Figure 2-1 on page 2-3 describes the interconnections between the PCI Communications

Controller Board and the Distribution Board. The table also identifies the connectors and their pin

assignments.

2-1

Page 24

Discovery QDR Series Technical Manual

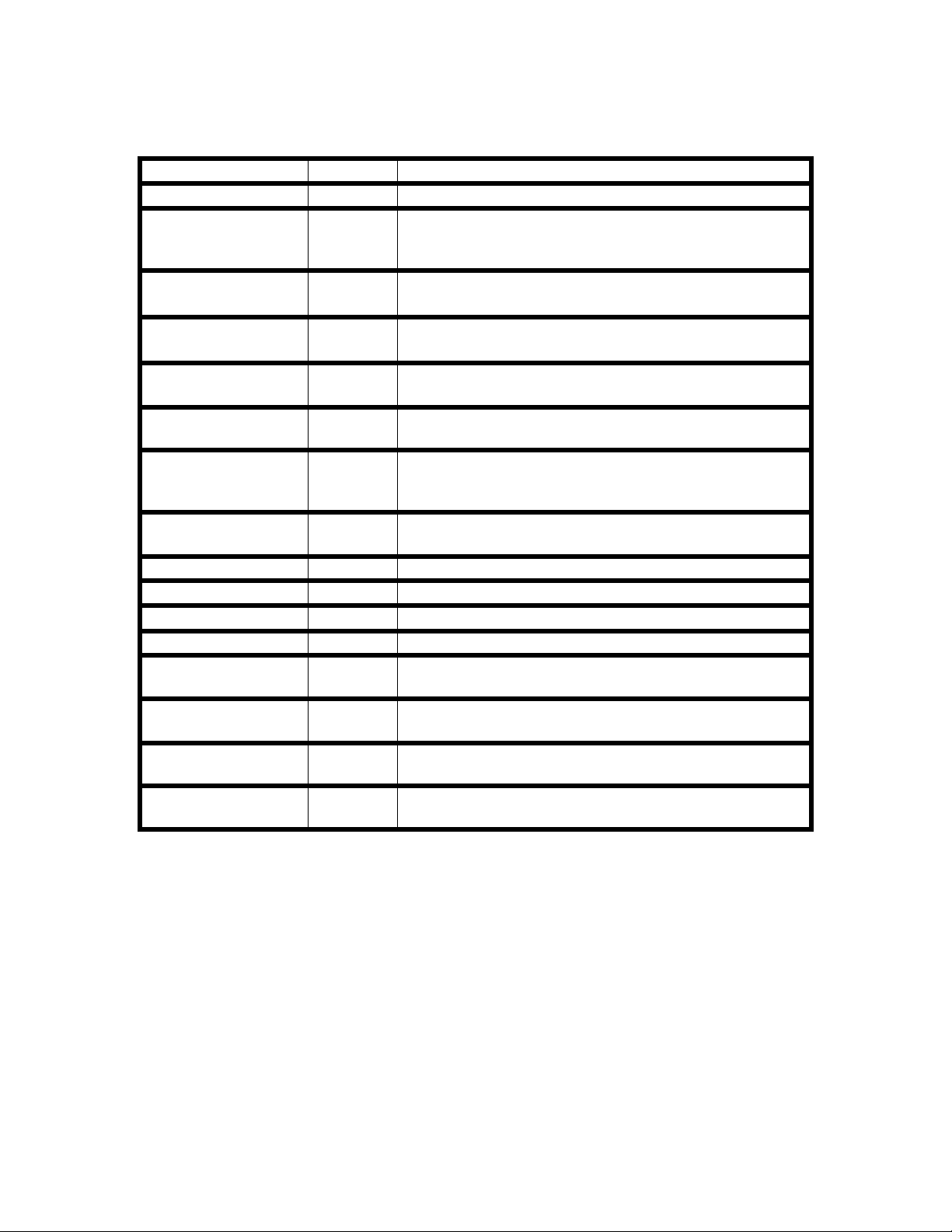

Table 2-1. PCI Communications Controller Board/Distribution Board

Interconnection Descri ptio ns

.

Signal Pair Description

ATD+

ATD-

STD+

STD-

STCLK+

STCLK-

STFRM+

STFRM-

ARD+

ARD-

SRD+

SRD-

SRCLK+

SRCLK-

SRFRM+

SRFRM-

EMERGENCY_IN+

EMERGENCY_IN-

Asynchronous data to the Scanner. JP1-2

Synchronous data to the Scanner. JP1-28

Synchronous data clock from PCI Communications

Controller Board to Distribution Board. Synchronizes

data to the Scanner.

Synchronous data frame from PCI Communication

Command Board to Distribution Board.

Asynchronous Data from the Scanner. JP1-8

Synchronous Data from the Scanner. JP1-34

Synchronous data clock from PCI Communication

Command Board to Distribution Board. Synchronizes

data from the Scanner.

Synchronous data frame from Distribution Board to

PCI Communication Command Board.

Signals an emergency condition. Generated by the CArm Interface Board.

PCI1 Pin Dist2 Pin

JP10-3

JP1-27

JP1-4

JP1-5

JP1-30

JP1-31

JP1-7

JJP1-33

JP1-10

JP1-11

JP1-36

JP1-37

JP1-13

JP1-14

JP1-39

JP10-4

JP10-6

JP10-7

JP10-9

JP10-10

JP10-12

JP10-13

JP10-15

JP10-16

JP10-18

JP10-19

JP10-21

JP10-22

JP10-24

JP10-25

JP10-27

JP10-28

ZEROX+

ZEROX-

INTEGRATE+

INTERGATE-

SYSRESET+

SYSRESET-

EMERGENCY+

EMERGENCY-

AC line zero-crossing signal used for system wide

synchronization. Generated by the C-Arm Interface

Board.

Synchronous signal for Detector Integrate period.

Generated by the C-Arm Interface Board.

Resets the Scanner controllers. JP1-20

Removes power from the Scanner motor drivers and

the X-ray system

Note: 1 PCI = PCI Communication Controller Board

2 Dist = Distribution Board

JP1-40

JP1-16

JP1-17

JP1-42

JP1-45

JP1-49

JP1-25

JP10-30

JP10-31

JP10-33

JP10-34

JP10-39

JP10-40

JP10-48

JP10-49

2-2

Page 25

Discovery QDR Series Technical Manual

KP1085_004-0201

PCI

Communication

Command

Board

DISTRIBUTION

BOARD

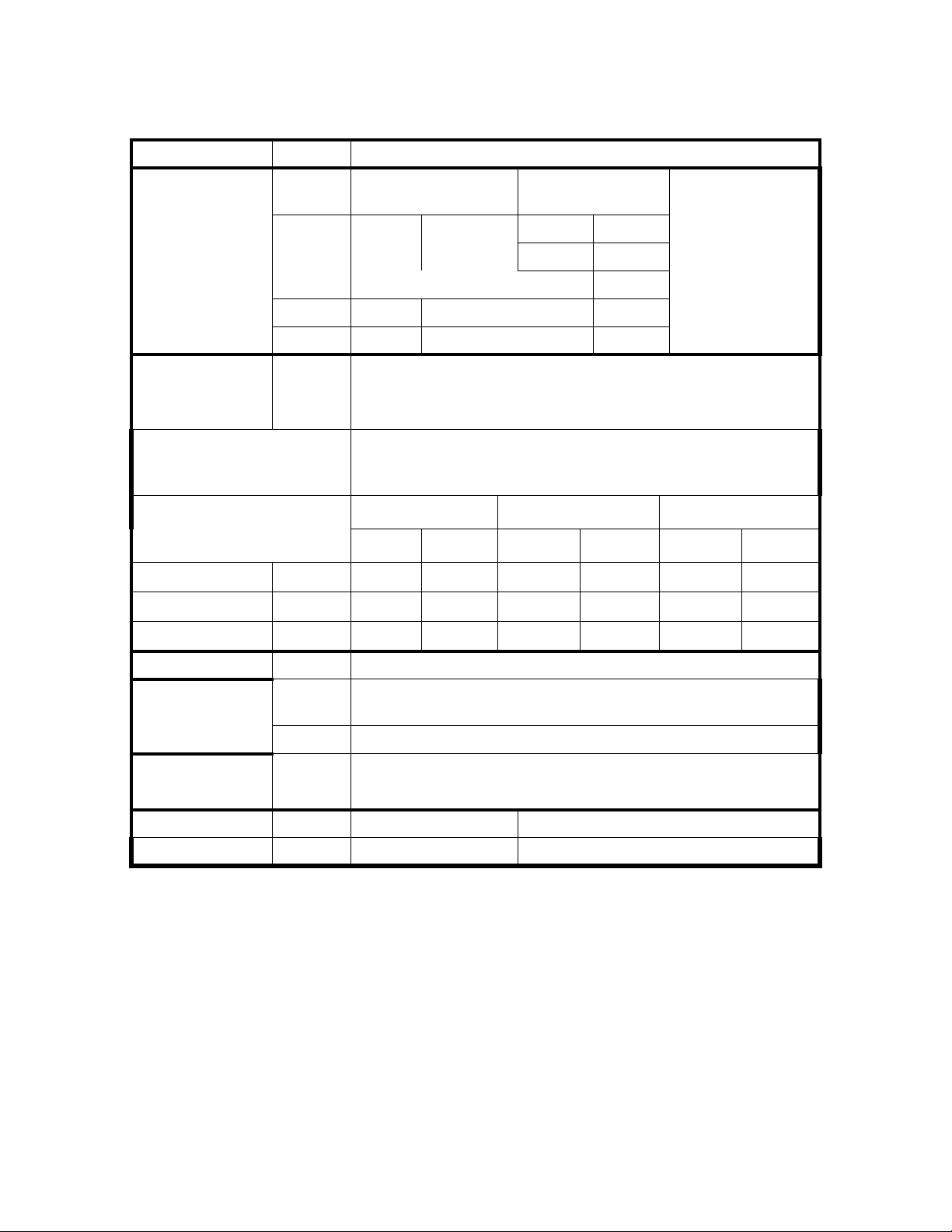

Figure 2-1. PCI Communication Command Board/Distribution Board

Interconnection Diagram

2.3 Distribution Board

The Distribution Board provides interconnections between the Discovery Operator's

Console (PC) and the Scanner. It passes several signal lines from the Operator's Console

and power lines from the DIN rail directly to the C-Arm Interface module. It also provides

buffering and individual drivers and receivers for various signal lines to and from

individual Scanner modules and the PCI Communication Command Board. The

Distribution Board is located in the Electronics Tray in the base of the Scanner.

One cable connects the Operator's Console (PC) communications bus to the Distribution

Board. One cable connects to the Distribution Board from the DIN rail. This cable brings

DC power to the Distribution Board and connects the X-Ray On and Emergency signal

lines to the Power Module.

Up to eight cables connect the Distribution Board to the various Scanner boards

depending on instrument model. Four cables connect to the four Motor Controller Boards

(Table X, Table Y, Arm R, and Arm Y). A single cable connects to the TZ Drive Board.

T wo cables (one signal and one power) connect to the C-Arm Interface Board. In addition,

one cable connects to the scanner Control Panel Interface Board. In the C and W models,

this board is a separate section of the Detector Board. In the A and SL versions, the

Control Panel Interface Board is a separate board located under the table.

The Distribution Board has provision for three jumpers that can be installed to override

the EMERGENCY signal lines when troubleshooting.

2.3.1 Power

The Distribution Board receives +24 and +/-15VDC from the Multi-voltage DC Switching

Power Module. The +24VDC is applied through four individual circuit breakers to the

Table X, Table Y, Arm R, and Arm Y Motor Controller Boards. The +24 and +/-15VDC

are passed to the C-Arm Interface Board. The +24 VDC is also reduced to +7 and +5VDC

by regulators to power op-amps and analog switches located on this board. The +7VDC is

passed to the Control Panel Controller Board. The +5VDC powers the digital section of

2-3

Page 26

Discovery QDR Series Technical Manual

COMMUNICATIONS

CONTROLLER

BOARD

OPERATOR’S

CONSOLE

COMPUTER

INSTRUMENT

ELECTRONICS

TRAY

the Distribution Board. The +24VDC power supply is not closely regulated and its outputs

may range from +24V to +35V under normal conditions.

Note: +7VDC may measure anywhere from +6.25VDC to +7.25VDC. This is true

everywhere +7VDC is shown in this manual.

Limits for +/- 15VDC

Six green LEDs indicate the status of the +28 (on QDR-4500s, +24 on Discovery), +24,

+15, -15, +7 and +5VDC (ON indicates the respective voltage is present). Five red LEDs

indicate the status of the five circuit breakers applying voltage to the motor drivers/

controller. ON indicates the circuit breaker has been tripped by an over-current condition.

2.3.2 Interface Connections

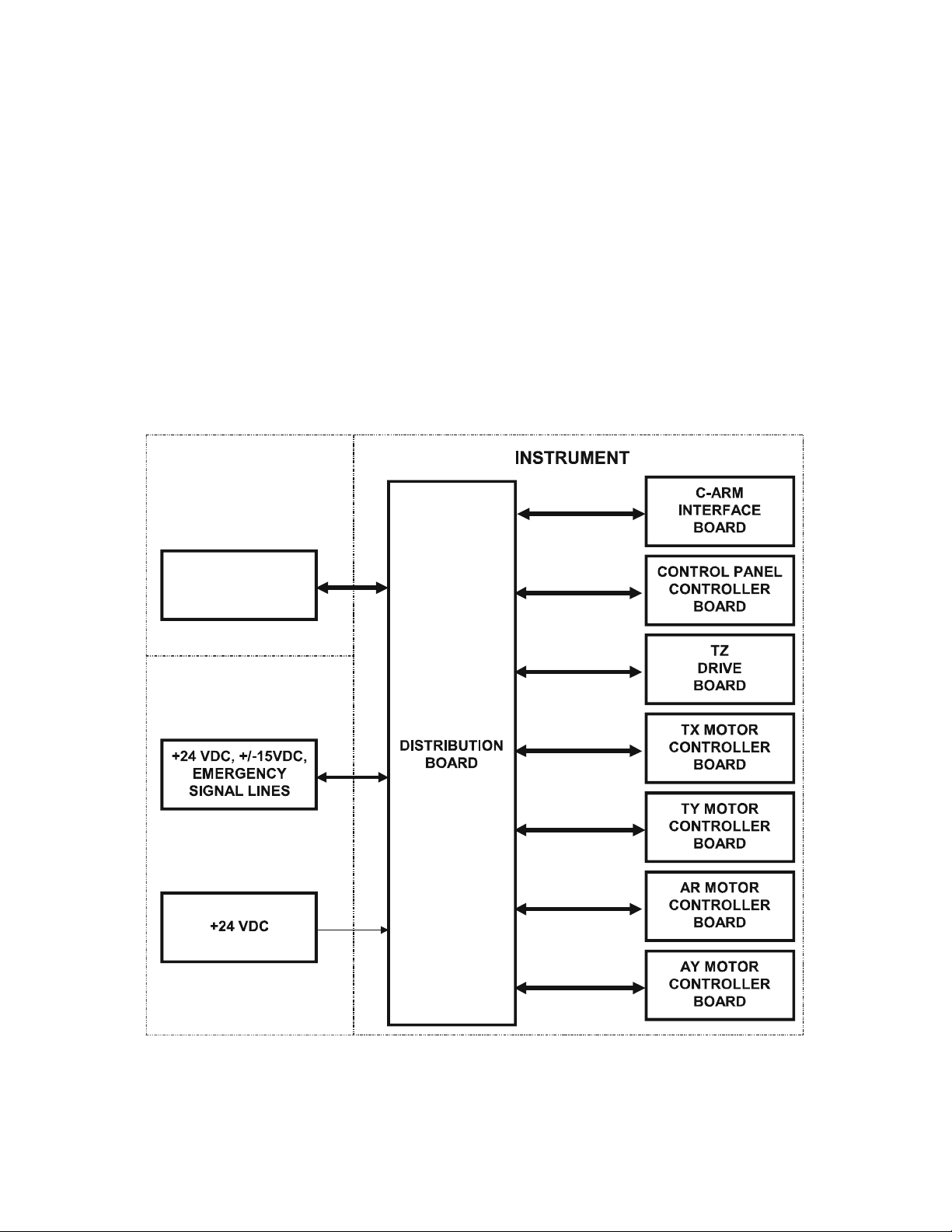

Figure 2-2 shows connections to/from the Distribution Board.

Figure 2-2. Distribution Board High Level Interconnection Diagram

2-4

Page 27

Discovery QDR Series Technical Manual

2.4 Motor Controller Boar d

The Motor Controller Board is a microprocessor controlled power driver circuit for use

with a two-coil bipolar stepper motor. It receives high-level commands through the

Distribution Board from the host computer, and applies 24-volt pulses to the stepper motor

windings. The Discovery uses four identical Motor Controller Boards to control and drive

the Table X (Table In/Out), Table Y (Table Left/Right), C-Arm Y (C-Arm Left/Right), CArm R (Arm rotation, A/SL only) stepper motors. The motor windings are driven by two

integrated H-bridges. These integrated circuits provide internal level conversion and

power limiting. Their logic level control inputs are driven from a stepper motor control

microcircuit that receives commands from the microprocessor. The control circuit senses

the current in the motor windings and adjusts the duty cycle of the applied voltage in such

a way as to limit the maximum motor current. The maximum value is determined by an 8bit control word at a Digital to Analog Converter.

Each Motor Controller Board monitors the position of its respective mechanism using a

voltage received from an associated Position Encoder connected to the mechanism. The

Position Encoder is a precision potentiometer that divides a +/-3V reference source. The

output voltage is fed to a sense amplifier in proportion to the position of the mechanism

driven by the motor. The sense amplifier output is converted to digital value that provides

position feedback to the microprocessor.

The Motor Controller Boards receive movement commands from the Discovery computer

via the communications bus. Each Motor Controller Board contains an ID switch and four

status indicators (LEDs). The ID switch is a 16-position rotary encoded switch (SW1) that

is read during system initialization to determine the Motor Controller Board address for

communicating with the Discovery computer. ID switch settings for the Motor Controller

Boards are as follows:

Table X drive 4

Table Y drive 5

C-Arm Rotation 6

C-Arm Y drive 7

The four red status LEDs provide visual indications of motor drive power on, Stepper

CPU active, motor drive direction, and motor step pulses.

The Motor Controller Board also has provision (JP2) for connecting limit switches to

inhibit motor operation when the mechanism goes beyond established mechanical limits.

This feature is not used in the Discovery and, therefore, no cable is connected to JP2.

2.4.1 Power

Power input to the Motor Controller Board is +24VDC. This voltage provides the motor

drive power and is converted down to +5VDC for use by logic circuits on the board. The

+5VDC is also converted to -5VDC. Two green LEDs provide a visual indication of the

power present on the Motor Controller Board.

2-5

Page 28

Discovery QDR Series Technical Manual

ARD+, ARDATD+, ATDSYSRESET+, SYSRESET+28V

28V_RET

(⎯)

(⎯)

(⎯)

(⎯)

+REF

(⎯)

-REF

MOTOR

CONTROLLER

STEPPER

MOTOR

To/From

Distribution Board

POSITION

ENCODER

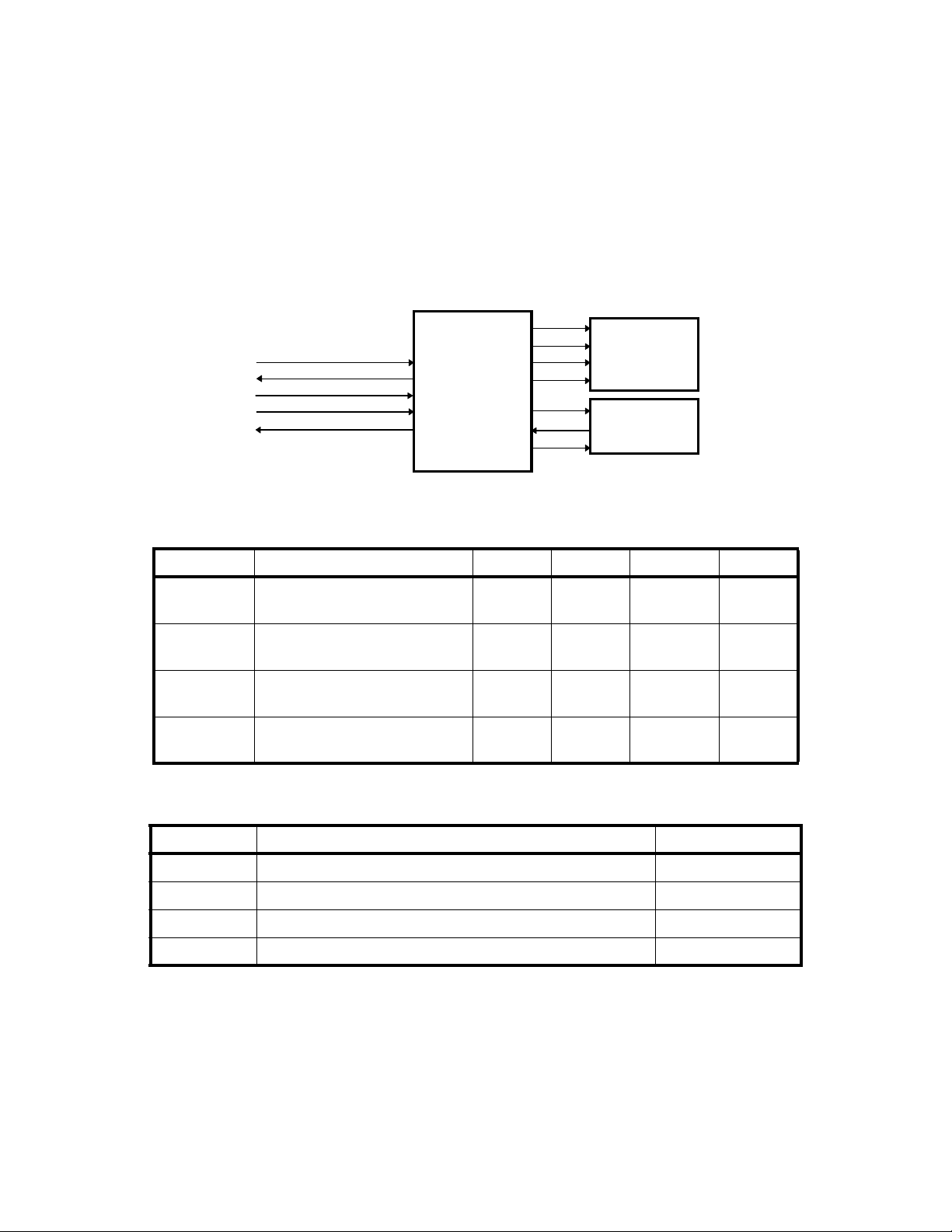

2.4.2 Interface Connections

Figure 2-3 shows the typical interconnections between the Distribution Board, the Motor

Controller Board, the Stepper Motor, and the Position Encoder. Figure 2-1 describes the

interconnections between the Distribution Board and the Motor Controller. Table 2-3

describes the interconnections between each Motor Controller and its respective stepper

motor and position encoder. The tables also identify the connectors and their pin

assignments.

Figure 2-3. Distribution Board/Motor Controller Board Interconnection Diagram

Table 2-2.Distribution Board/Motor Controller Board Interconnection Descriptions

Signal Description Table X Table Y C-Arm Y Pin(s)

ARD+

ARD-

ATD+

ATD-

SYSRST+

SYSRST-

28V

28V_RET

Asynchronous Receive Data. JP7 JP5 JP11 11

12

Asynchronous Transmit Data. JP7 JP5 JP11 14

15

System Reset. Resets the Motor

Controller Board.

DC power for the Motor

Controller Board.

JP7 JP5 JP11 17

18

JP7 JP5 JP11 2,3,4,5

1,6,7,8

Table 2-3. Motor Controller Board/Stepper Motor and Position Encoder

Interconnection Descriptions

Signal Description Pin

(No label) Motor drive signals (4). JP5-1 - JP5-4

+REF (+3V) Precision posit ive v oltage to position potentiometer. JP3-1

(No label) Position encoder wiper return voltage. JP3-3

-REF (-3V) Precision negative voltage to position poten tiome ter. JP3-5

2.5 TZ Drive Board (A and SL Only)

The TZ Drive Board is a microprocessor-controlled power driver circuit for the two AC

pedestal motors, which raise and lower the patient table of the Discovery A and SL. This

2-6

Page 29

Discovery QDR Series Technical Manual

board is located in the Electronics Tray in the rear of the bottom of the Scanner base

assembly.

The TZ Drive Board communicates with the PCI Board, via the Distribution Board, to

drive the pedestal motors under computer control. Manual repositioning of the pedestal

may be required in case of an emergency . In this case, manual control is provided through

the Table switches of the Scanner’s Operator Control Panel.

The TZ Drive board monitors the position of both pedestals using signals received from an

associated Position Encoder connected to the respective pedestal.

2.5.1 Service Switches

The TZ Drive board contains four service switches used during replacement of a defective

pedestal or Position Encoder. Table 2-4 describes these switches and their respective

functions.

Caution: The TZ drive motors are designed to run at a 5% duty cycle. If the motors

overheat, the built-in thermal cutouts may trip and cause the motors to stop

functioning. If this occurs, you must wait about 20 minutes before

functionality is restored.

The TZ drive motors are designed to run at a 5% duty cycle. If the motors overheat, the

built-in thermal cutouts may trip and cause the motors to stop functioning. If this occurs,

you must wait about 20 minutes before functionality is restored.

Table 2-4.TZ Drive Service Switches

Switch Function

Mode (Normal/Service) Determines whether the TZ Drive is in Normal or Service

operation.

Direction (Up/Down) When the TZ drive is in Service mode, determines the

direction of pedestal movement (not active in normal

mode).

Left When the TZ drive is in Service mode, moves the left

pedestal in the direction specified by the Direction switch

(not active in normal mode).

Right When the TZ drive is in Service mode, moves the right

pedestal in the direction specified by the Direction switch

(not active in normal mode).

Reset Resets the board after manual operation. The TZ Drive

board must be reset after any manual operation.

2.5.2 Power

Power input to the TZ Drive Board is +24VDC from the Distribution Board and 240VAC

from the DIN Rail. The +24VDC powers circuitry located on this board and is reduced to

2-7

Page 30

Discovery QDR Series Technical Manual

ARD+, ARD-

ATD+ , ATDSYSRESET+,

EMERGENCY+,

MAN_UP*, MAN_UP_RET

MAN_DOWN*, MAN_DOWN_RET

+24V

120V(A)_UP_LEFT

120V(A)_DWN_LEFT

120V(B)_LEFT

GND_PED

+3.0VREF

(Position Signal)

-3.0VREF

120V(A)_UP_RIGHT

120V(A)_DWN_RIGHT

120V(B)_RIGHT

GND_PED

+3.0VREF

(Position Signal)

-3.0VREF

TZ

DRIVE

BOARD

LEFT

PEDESTA L

MOTOR

To/From

Distribution Board

To/From

DIN Rail

Assembly

LEFT

PEDESTAL

POSITION

ENCODER

RIGHT

PEDESTAL

MOTOR

RIGHT

PEDESTAL

POSITION

ENCODER

120V(A)_RIGHT

120V(B)_RIGHT

GND_PED

120V(A)_LEFT

120V(B)_LEFT

GND_PED

+5VDC. The +5VDC is converted to -5VDC and +/-3VDC. The +/-5VDC powers logic

circuitry on this board, while the +/- 3VDC provides the reference voltage for the position

sensors. Two green LEDs provide visual indication of the +24 and +5VDC status (ON

indicates the respective voltage is present).

The 240VAC power is connected through control relays to the pedestal motors.

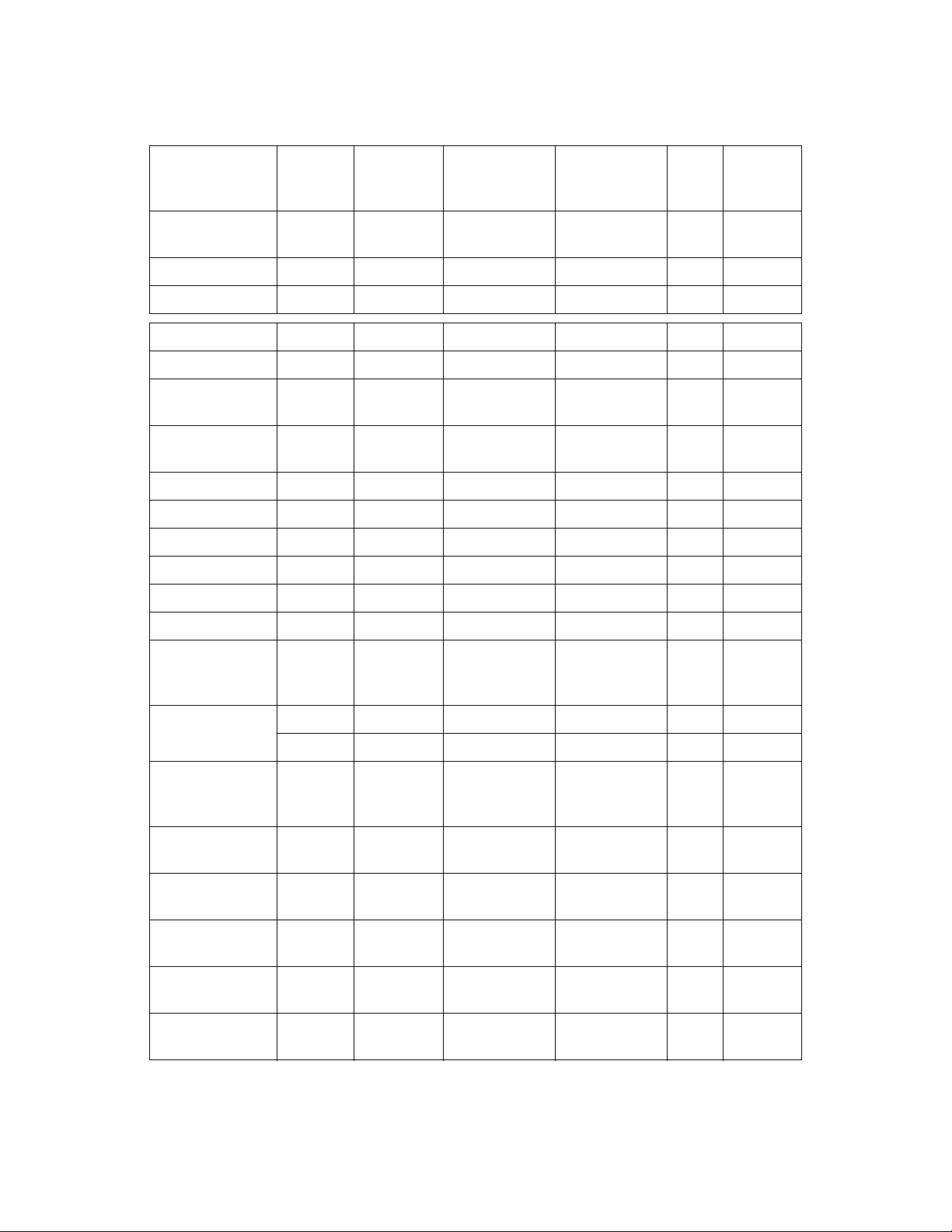

2.5.3 Interface Connections

Figure 2-4 shows the interconnections between the Distribution Board, the TZ Drive

Board, the Pedestal Motors, and the Pedestal Position Encoders. Table 2-5 describes the

interconnections between the Distribution Board and the TZ Drive Board. Table 2-6

describes the line voltage (240VAC, line to line) between the DIN Rail Assembly and the

TZ Drive Board. Table 2-7 describes the interconnections between the TZ Drive Board

and the two pedestal motors and their respective position encoders. The tables also

identify the interconnection connector and pin assignments.

Table 2-4 shows the interconnections between the Distribution Board, the TZ Drive

Board, the Pedestal Motors, and the Pedestal Position Encoder, Table 2-5 describes the

interconnections between the Distribution Board and the TZ Drive Board. Table 2-6

describes the line voltage (240VAC line to line) between the DIN Rail Assembly and the

TZ Drive Board. Table 2-7 describes the interconnection between the TZ Drive Board and

the two pedestal motors and their respective position encode rs. The tabl es also iden tify the

interconnection connectors and pin assignments.

2-8

Figure 2-4. Distribution Board/TZ Drive Board Interconnection Diagram

Page 31

Discovery QDR Series Technical Manual

Table 2-5. Distribution Board/TZ Drive Board Interconnection Descriptions

Signal Description Pin(s)

ARD+

ARD-

ATD+

ATD-

SYSRST+

SYSRST-

EMERGENCY+

EMERGENCY-

MAN_UP*

MAN_UP_RET

MAN_DWN*

MAN_DWN_RET

+24V DC power for the Motor Controller board. JP1-5, JP1-6

+6.5V Not used. JP1-2, JP1-3

Asynchronous Receive Data. JP1-11

JP1-12

Asynchronous Transmit Data. JP1-14

JP1-15

System Reset. Resets the TZ Drive board. JP1-17

JP1-18

Enables manual operation of the pedestals in the case

of an emergency (under control of the Control Panel

Table switch on the Patient Table).

Raises the Patient Table in the case of an emergency. JP1-23

Lowers the Patient Table in the case of an emergency. JP1-26

JP1-20

JP1-21

JP1-24

JP1-27

Table 2-6. DIN Rail Assembly/TZ Drive Board Interface Descriptions

Signal Description Pin

120V(A)_LEFT AC voltage (120) to drive the Left Pedestal motor. JP6-4

120V(B)_LEFT AC voltage (120) to drive the Left Pedestal motor. JP6-5

120V(A)_RIGHT AC voltage (120) to drive the Right Pedestal motor. JP6-1

120V(B)_RIGHT AC voltag e (12 0) to driv e the R ig ht Pede stal motor. JP6-2

GND_PED Ground line to the Left/Right Pedestal motor. JP6-3/JP6-

6

Table 2-7. TZ Drive Board/Pedestal Motors and Position Encoders

Interconnection Descriptions

Signal Description Pin

120V(A)_UP_LEFT AC v ol tage to th e Left Pedestal motor to move the left

end of the Patient Table up.

120V(A)_DWN_LEFT AC voltage to the Left Pedestal motor to move the left

end of the Patient Table down.

120V(B)_LEFT AC line to the Left Pedestal m otor. JP5-3

GND_PED Ground line to the Left Pedestal motor. JP5-4

120V(A)_UP_RIGHT AC voltage to the Right Pedestal motor to move the

right end of the Patient Table up.

120V(A)_DWN_RIGHT AC voltage to the Right Pedestal motor to mo ve the

right end of the Patient Table down.

120V(B)_RIGHT AC line to the Right Pedestal motor. JP4-3

GND_PED Ground line to the Ri gh t Pedestal motor. JP4-4

JP5-1

JP5-2

JP4-1

JP4-2

2-9

Page 32

Discovery QDR Series Technical Manual

Signal Description Pin

+3.0VREF Precision positive voltage to Left/Right Pedestal

position encoder potentiometer.

(Position Signal) Left/Right pedestal position encoder wiper return

voltage.

-3.0VREF Precision negative voltage to Left/Right Pedestal

position encoder potentiometer.

JP3-1/JP2-1

JP3-3/JP2-3

JP3-4/JP2-4

2.6 Control Panel Controller Board

The Control Panel Controller Board on the Discovery is a separate board under the table.

Its function is to interface the Scanner Operator Control Panel to the computer allowing

the software to determine the state of the Operator Control Panel switches, to define the

state of the various Operator Control Panel LEDs, and to control motor movement. The

board is located under the table at the head end of the scanner.

The Control Panel Controller communicates with the Operator's Console computer using

the asynchronous communications signals ARD and ATD of the communications buss and

the system control signals SYSRESET, XRAY_LIGHT, and EMERGENCY.

2.6.1 Power

The Control Panel Controller Board receives +7VDC from the Distribution Board. The +7

is reduced to +5VDC to power the circuitry on this board and is applied to the Operator

Control Panel to power the LEDs. A green LED, on this board, provides a visual

indication of the +5VDC power (ON indicates the voltage is present).

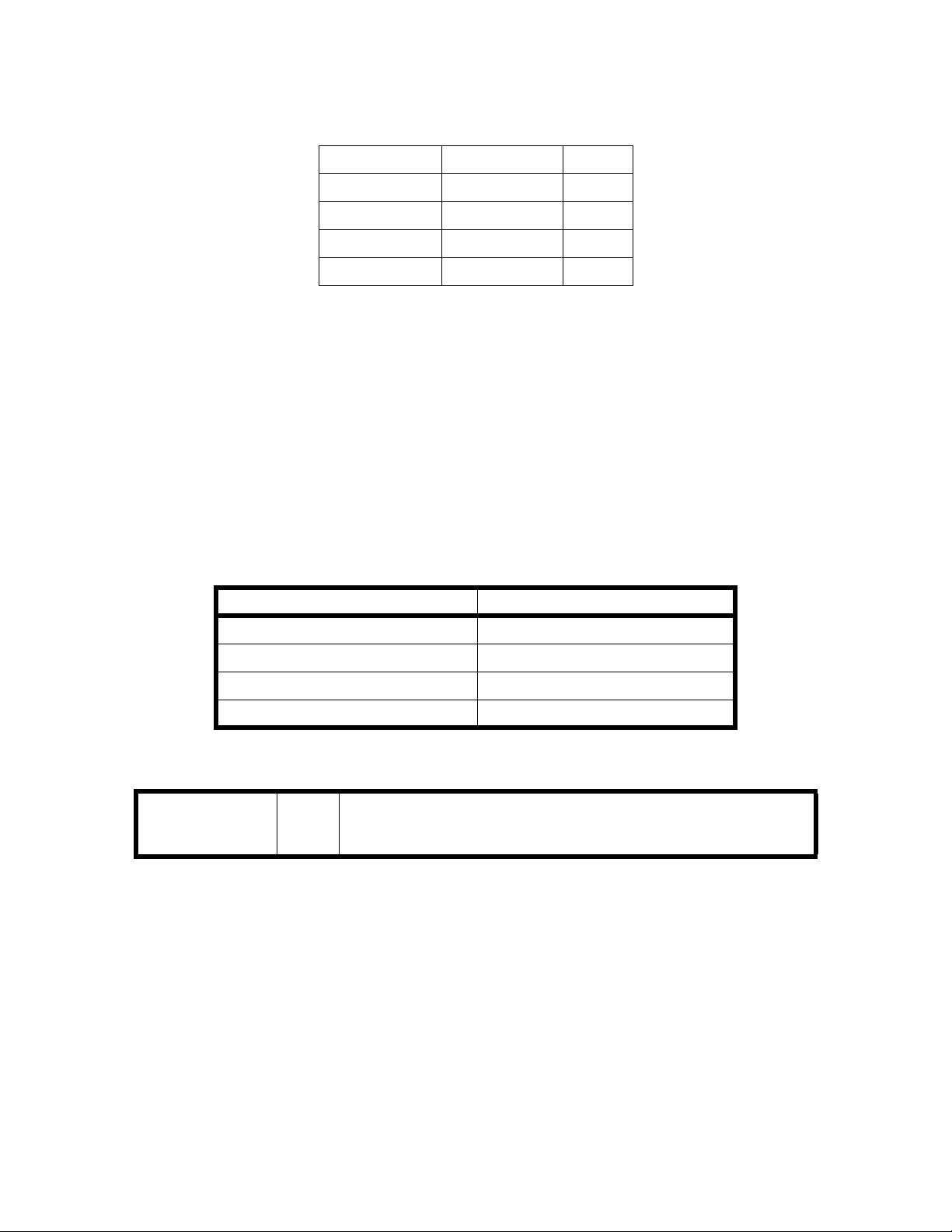

2.6.2 Interface Connections

Figure 2-5 shows the interconnections between the Distribution Board, Control Panel

Controller Board, and the Operator Control Panel.

Table 2-8 describes the interconnections between the Distribution Board and the Control

Panel Controller. Table 2-10 describes the interconnections between the Control Panel

Controller and the Operator Control Panel. The tables also identify the connectors and

their pin assignments.

2-10

Page 33

Discovery QDR Series Technical Manual

ARD+, ARDATD+, ATD-

SYSRES ET+, SYSRESETEMERGEN CY+, EMERGE NCY-

XRAY_LIGHT+, XRAY_LIGHTMAN_TZ_UP

MAN_TZ_UP_RET

MAN_TZ_DOWN

MAN_TZ_DOWN_RET

EMERBENCY_PANEL

HW_EMERGENCY_RET

+7V

L0_PWR* - L7_PWR*

TZ_PWR*

XRAY_LIGHT_PWR*

SW0 - SW2

SR0 - SR2

MAN_TZ_UP

MAN_TZ_UP_RET

MAN_TZ_DOWN

MAN_TZ_DOWN_RET

EMERGENCY_PANEL

HW_EMERGENCY_RET

+5V

CONTROL

PANEL

CONTROLLER

OPERATOR

CONTROL

PANEL

To/From

Distribution Board

TILT_A

TILT_B

To/From

C-Arm

Tilt Switch

(A/SL)

Table 2-8. Distribution Board/Control Panel Controller Interconnection Descriptions

Signal Description Pin

ARD+

ARD-

ATD+

ATD-

SYSRESET+

SYSRESET-

EMERGENCY+

EMERGENCY-

XRAY_LIGHT+

XRAY_LIGHT-

EMERGENCY_CPANEL

HW_EMERGENCY_RET

+7V DC power for the Control Panel Controller

Figure 2-5. Control Panel Controller Interconnection Diagram

Asynchronous Receive Data from the PCI

Communication Command Board via the

Distribution Board.

Asynchronous Transmit Data to the PCI

Communication Command Board via the

Distribution Board

System Reset from the PCI Communication

Command Board via the Distribution Board.

Resets the Control Panel Controller.

Emergency TZ drive indicator from the PCI

Communication Command Board via the

Distribution Board.

X-Ray Light from the X-Ray Controller via

the C-Arm Interface and Distribution Boards.

State of the STOP switch and of the collision sensor.

(Part of the safety daisy chain.)

Board

JP2-4

JP2-5

JP2-7

JP2-8

JP2-10

JP2-11

JP2-13

JP2-14

JP2-16

JP2-17

JP2-19

JP2-20

JP2-2

2-11

Page 34

Discovery QDR Series Technical Manual

Table 2-9. Control Panel Controller/Control Panel Interconnection Descriptions

Signal Description

L0_PWR* Turns on the ENABLE switch LED. JP6-11 JP1-11

L1_PWR* Turns on the HOME switch LED. JP6-12 JP1-12

L2_PWR* Turns on the LOAD switch LED. JP6-13 JP1-13

L3_PWR* Turns on the TABLE switch IN/OUT LED. JP6-14 JP1-14

L4_PWR* Not used. JP6-15 JP1-15

L5_PWR* Turns on the C-ARM switch RIGHT/LEFT

LED.

L6_PWR* Not used. JP6-17 JP1-17

L7_PWR* Turns on the Laser LED. JP6-18 JP1-18

XRAY_LIGHT_PWR* Turns on the X_RAY LED JP6-19 JP1-19

SW0 Control signal to determine the state of the

C-ARM and LASER switches.

SW1 Control signal to determine the state of the

TABLE IN/OUT switches.

SW2 Control signal to determine the state of the

LOAD, HOME and ENABLE switches.

SR0 Returns the state of the C-ARM switch LEFT

position when SW0 is active. Signals the

state of the TABLE switch IN position when

SW1 is active. Signals the state of the LOAD

switch when SW2 is active.

SR1 Returns the state of the C-ARM switch