Page 1

TITLE

DOCUMENT NUMBER

REV

TEXT, IFU, AQUILEX FLUID

MANAGEMENT SYSTEM, 4320

AW-07059-4320

009

ARTWORK

SIZE A

SHEET 1 OF 1

REV AUTHORED BY

DATE

K BUJOLD

4/29/16

REV DRAFTED BY

DATE

K BUJOLD

4/29/16

PROPRIETARY: This document contains

proprietary data of Hologic, Inc. No

disclosure, reproduction or use of any

part thereof may be made except by

written permission from Hologic.

REV. RELEASE DATE:

05/16/2016

File Name

Description

AW-07059-4320_009_02.pdf

View File

Artwork consists of:

302 8.26 inch x 11.69 inch (A4) sheets attached.

Artwork contains the following file(s):

Artwork is black and white.

Form ENG-0034-T03, Rev. 004

Page 2

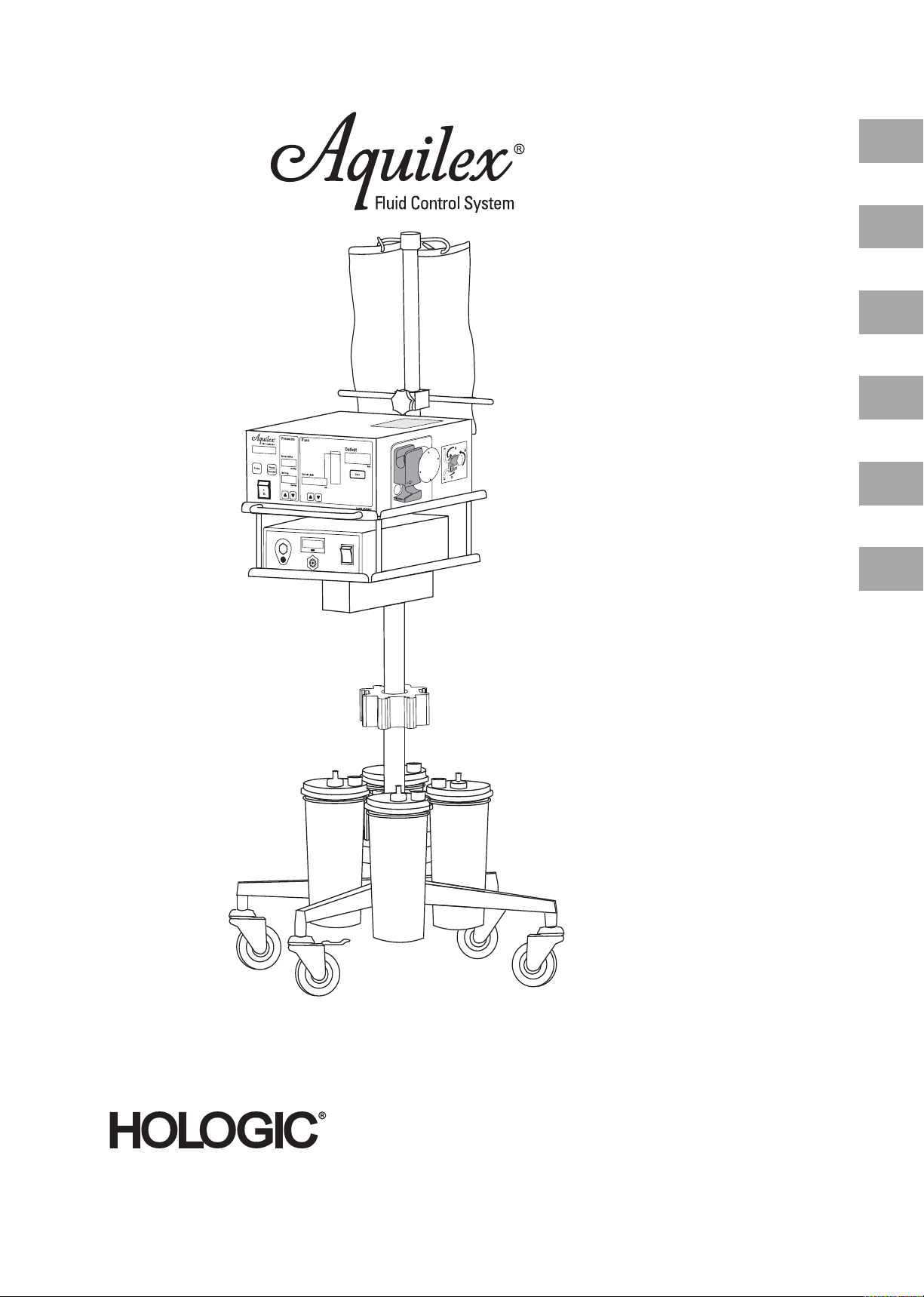

Instructions for Use and Fluid

Control System Operator’s Manual

Gebrauchs- und Bedienungsanweisungen für Fluid Control System

EN

DE

Manuel d‘instruction et d‘utilisation du

Fluid Control System

Manual de Instrucciones y de Utilización

del Fluid Control System

Istruzioni per l'uso e istruzioni operative

del Fluid Control System

Gebruiks- en bedieningsinstructies voor

Fluid Control System

FR

ES

IT

NL

Page 3

Hologic and MyoSure are registered trademarks of Hologic,

ENDEFRESIT

NL

Inc. and its subsidiaries in the United States and other countries. Aquilex is a trademark of Hologic, Inc. and its subsidiaries

in the United States and other countries. All other trademarks,

their respective owners.

zeichen, eingetragene Warenzeichen und Produktnamen sind Eigentum der

jeweiligen Inhaber.

spectifs.

ductos son propiedad de sus respectivos dueños.

registered trademarks, and product names are the property of

Hologic und MyoSure sind eingetragene Warenzeichen der Hologic, Inc. und ihrer Tochtergesellschaften in den Vereinigten

Staaten und anderen Ländern. Aquilex ist ein Warenzeichen

der Hologic, Inc. und ihrer Tochtergesellschaften in den Vereinigten Staaten und anderen Ländern. Alle anderen Waren-

Hologic et MyoSure sont des marques déposées de Hologic

Inc., de ses filiales aux États-Unis et d'autres pays. Aquilex est

une marque de Hologic Inc., de ses filiales aux États-Unis et

d'autres pays. Toutes les autres marques, marques déposées,

et noms de produits sont la propriété de leurs propriétaires re-

Hologic y MyoSure son marcas comerciales registradas de Hologic, Inc. y sus subsidiarias en los Estados Unidos y otros países.

Aquilex es una marca comercial de Hologic, Inc. y sus subsidiarias en los Estados Unidos y otros países. Todas las demás marcas

comerciales, marcas comerciales registradas y nombres de pro-

Hologic e MyoSure sono marchi registrati di Hologic, Inc. e relative società affiliate negli Stati Uniti e in altri paesi. Aquilex è

un marchio registrato di Hologic, Inc. e relative società affiliate

negli Stati Uniti e in altri paesi. Tutti gli altri marchi commer-

rispettivo proprietario.

gedeponeerde handelsmerken en productnamen zijn eigendom van de desbetreffende houders.

ciali, marchi registrati e nomi di prodotti sono di proprietà del

Hologic en MyoSure zijn gedeponeerde handelsmerken van

Hologic, Inc. en haar dochtermaatschappijen in de Verenigde

Staten en andere landen. Aquilex is een handelsmerk van Hologic, Inc. en haar dochtermaatschappijen in de Verenigde Staten en andere landen. Alle andere handelsmerken,

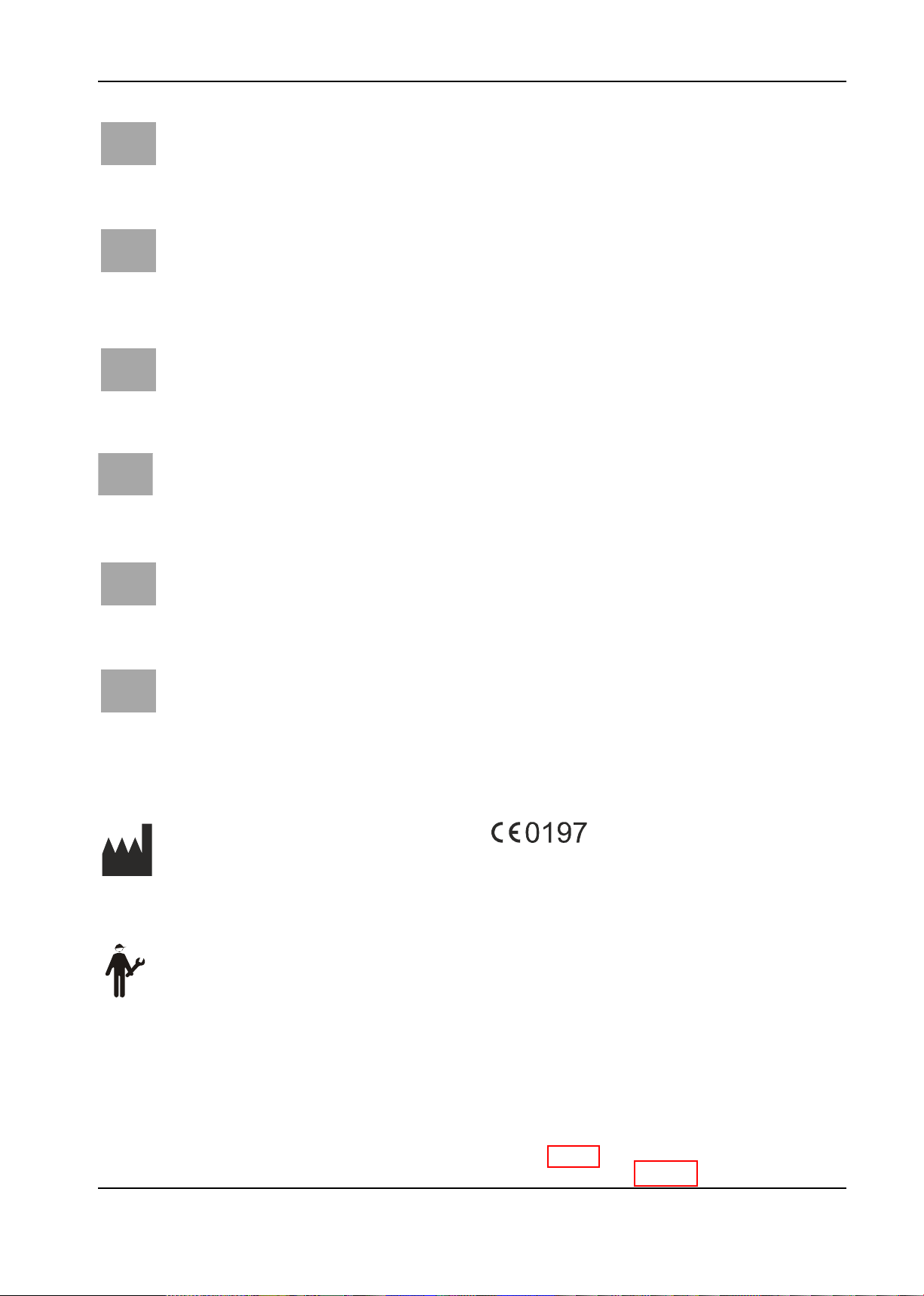

Manufacturer/Hersteller/Fabricant/Fabricante/

Fabbricante/Fabrikant:

W.O.M. WORLD OF MEDICINE GmbH

Salzufer 8

10587 Berlin, Germany

Phone: +49 30 39981-550

Fax: +49 30 39981-545

E-mail: info.berlin@womcorp.com

W.O.M. WORLD OF MEDICINE GmbH

Alte Poststraße 11

96337 Ludwigsstadt, Germany

Phone: +49 9263 877-0

Fax: +49 9263 877-152

E-mail: info.ludwigsstadt@womcorp.com

CE marking according to Directive 93/42/EEC

CE-Kennzeichnung gemäß Richtlinie 93/42/CEE

Marquage CE conforme à la directive 93/42/CEE

Identificación CE conforme a la directiva 93/42/CEE

Marchio CE conforme alla direttiva 93/42/CEE

EG-markering conform Richtlijn 93/42/EEG

Distributor/Vertreiber/Distributeur/Distribuidor/

Distributore/Distributeur:

HOLOGIC, INC.

250 Campus Drive,

Marlborough

MA 01752 USA

1.800.442.9892 (US Toll Free)

1.508.263.2900

MAN-02570-4320 Rev.009

Model: H112/1201048/10000011593 07/2016-04/endefresitnl/marik

Page 4

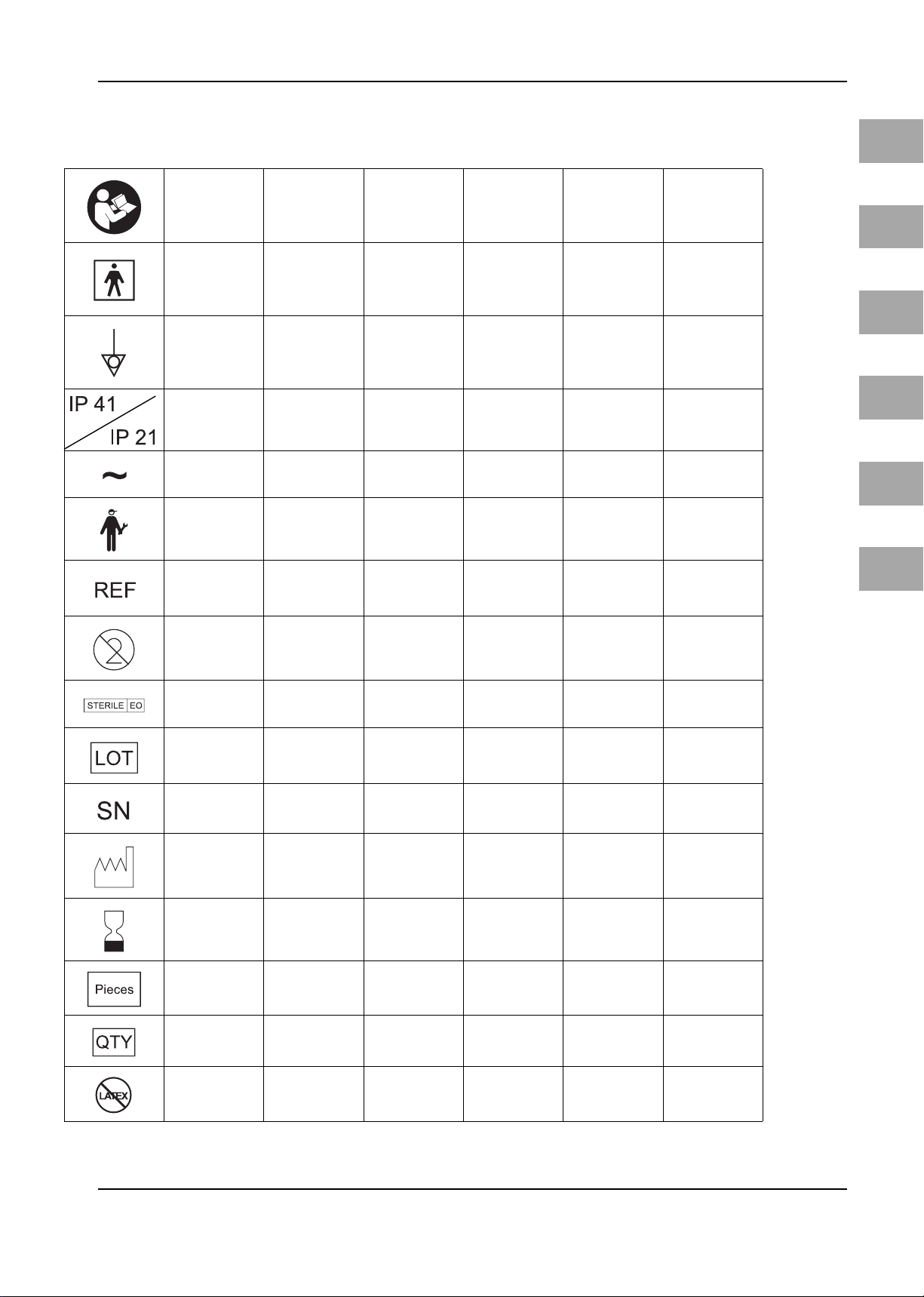

Symbols/Bildzeichen/Symboles/Símbolos/Simboli/Symbolen

EN

Read Instructions

Before Use

BF Type Equipment

Symbol for Poten-

tial Equalization

Degrees of Protec-

tion Provided by

Enclosures (IP-

Code)

Alternating Current

Service Service

Order Number

Bedienungsanlei-

tung befolgen

System des Typs BF

Symbol für Potenti-

alausgleich

Gehäuseschutz-

klasse (IP-Code)

Wechselstrom

Bestellnummer

Lire la documenta-

tion jointe !

Système de type BF

Symbole pour la

fiche équipoten-

tielle

Degrés de protec-

tion procurés parles

enveloppes (Code

IP)

Courant alternatif Corriente alterna Corrente alternata Wisselstroom

Service Servicio Servizio Service

Numéro de

commande

Observe la docu-

mentación adjunta

Sistema del tipo BF Sistema tipo BF

Símbolo para la

conexión equipo-

tencial

Grado de protec-

ción proporcio-

nado por los

envolventes

(Código IP)

Número de pedido

Leggere la docu-

mentazione alle-

gata

Simbolo per il colle-

gamento equipo-

tenziale

Grado di prote-

zione degli involu-

cri (Codice IP)

Numero di ordina-

zione

Lees de begelei-

dende documenta-

tie

Syteem van het

type BF

Symbool voor de

potentiaalvereffe-

ning

Beschermings-

klasse (IP-code)

behuizing

Bestelnummer

DE

FR

ES

IT

NL

Do not Reuse

Sterilized using

Ethylene Oxide

Lot Number

Serial Number

Date of Manufac-

ture

Expiration Date

Pieces

Quantity

Not Made with

Natural Rubber

Latex

Nicht zur Wieder-

verwendung

Sterilisiert mit

Ethylenoxid

Chargenbezeich-

nung

Seriennummer

Herstellungsdatum

Ver wendb ar bis

Stück

Menge

Nicht aus Natur-

kautschuklatex

hergestellt

Usage unique No reutilizable Non riutilizzabile

Stérilisés à l’éthy-

lène oxide

Numéro de lot Número de lote Numero di lotto Chargenummer

Numéro de série Número de serie Numero di serie Serienummer

Date de fabrication

Date limite

d’utilisation

Unités Unidades Pezzi Eenheden

Quantité Cantidad Quantità Hoeveelheid

Ce produit ne con-

tient pas de latex

de caoutchouc

naturel

Esterilizado con

óxido de etileno

Fecha de fabrica-

ción

Utilizable hasta

Producto no produ-

cido con látex de

caucho natural

Sterilizzato con

ossido di etilene

Data di produzione Fabricagedatum

Da utilizzarsi entro

il

Non prodotto in lat-

tice di caucciù

naturale

Niet voor herge-

bruik

Sterilisatie met

ethyleenoxide

Te gebruiken tot

Niet vervaardigd

van natuurlijke rub-

berlatex

Page 5

Symbols/Bildzeichen/Symboles/Símbolos/Simboli/Symbolen

NON

STERILE

FR

ES

IT

EN

DE

Not Made with

Phthalates

Made with Phthala-

tes

Do Not Get Wet

Top-Bottom

Fragile

Waste Manage-

ment

Reset Deficit

Button

Dieses Produkt enthält kein Diethylhe-

xylphthalat (DEHP)

Dieses Produkt ent-

hält Diethylhe-

xylphthalat (DEHP)

Vor Nässe schützen

Oben-Unten

Zerbrechlich

Entsorgung

Tas te Res et D ef ici t

Ce produit ne con-

tient pas du

diethylhexyl phta-

late (DEHP)

Ce produit contient

du diethylhexyl

phtalate (DEHP)

Protéger de l’humi-

dité

Haut-bas Arriba-abajo Alto - basso Boven-Beneden

Fragile Frágil Fragile Breekbaar

Élimination des

déchets

Touche de remise à

zéro du déficit

Este producto no

contiene dietilhe-

xilftalato (DEHP)

Este producto con-

tiene dietilhexilfta-

lato (DEHP)

Proteger contra la

humedad

Gestión de residuos Smaltimento Verwijdering

Tecla de reseteo del

déficit

Questo prodotto

non contiene

diethylhexylftalato

(DEHP)

Questo prodotto

contiene

diethylhexylftalato

(DEHP)

Proteggere

dall'umidità

Tasto di reset per

deficit

Dit product bevat

geen di-ethylftalaat

Dit product bevat

di-ethylftalaat

Beschermen tegen

Resettoets voor

(DEHP)

(DEHP

vocht

deficit

NL

Prime Button Taste Prime Touche Prime Tecla Prime Tasto Prime Toets Prime

Pause/Resume

Button

Increase

Decrease Verringern Décroissant Disminución Decrescente Verlagen

Fluid Bags Flüssigkeitsbeutel Poche de liquide Bolsa de líquido Sacche di liquido Vloeistofzak

Non-Sterile Nicht steril Non stérile No estéril Non è sterile Niet steriel

Connection for

Canister Scale

Data Transfer Datenübertragung

Tas t e

Pause/Resume

Erhöhen

Anschluss Contai-

newaage

Touche Pause/

Resum e

Croissant Aumento Crescente Verhogen

Raccord pour unité

de pesage à

container

Tra nsm iss ion d e

données

Tecla Pause/

Resum e

Conexión para la

balanza de cubetas

Transmisión de

datos

Tasto Pause/

Resume

Attacco per unità di

pesatura conteni-

tori

Trasmissione dati Datatransmissie

Aansluiting reservoirweegsysteem

Toets Pause/

Resume

Do not push! Schieben verboten Interdit de pousser! ¡No empujar! Non spingere! Duwen verboden

General Warning

Sign

SGS USTC Certifica-

tion Mark

Warnzeichen für

allgemeine Gefahr

SGS USTC Produkt-

zertifizierung

Signalisation

générale de danger

Marque de certifi-

cation SGS USTC

Señal de adverten-

cia general

Marca de certifica-

ción SGS USTC

Segnale generale di

pericolo

Marquio de certifi-

cazione SGS USTC

Waarschuwingsteken voor algemeen

gevaar

Kwaliteitsmerk SGS

USTC

Page 6

Table of contents

1 Important User Notes......................................................................................................................................................... 3

2 Safety Information.............................................................................................................................................................. 4

3 Purpose of the System ........................................................................................................................................................ 5

3.1 Warnings and Precautions .................................................................................................................................................... 5

3.1.1 Warnings .................................................................................................................................................................................... 5

3.1.2 Precautions................................................................................................................................................................................. 9

3.2 Description of the Aquilex Fluid Control System ............................................................................................................ 10

4 Initial System Set-up........................................................................................................................................................... 11

4.1 Preparing the System For Use............................................................................................................................................... 11

4.2 System Set-up............................................................................................................................................................................ 12

5 System Operation ............................................................................................................................................................... 13

5.1 Front of Pump............................................................................................................................................................................ 13

5.2 Rear of Pump.............................................................................................................................................................................. 13

5.3 Cart/scale.................................................................................................................................................................................... 14

5.3.1 Scale Set-up................................................................................................................................................................................ 15

5.3.2 Connecting the Vacuum Tubing........................................................................................................................................... 16

5.4 Turning On the Aquilex System............................................................................................................................................ 17

5.5 Hanging the Fluid Bags........................................................................................................................................................... 18

5.6 Using Tube Sets......................................................................................................................................................................... 18

5.7 Tubing Overview....................................................................................................................................................................... 19

5.8 Connecting the Outflow Tubing .......................................................................................................................................... 19

5.8.1 MyoSure® Outflow Connection............................................................................................................................................ 20

5.9 Inserting the Inflow Tube Set................................................................................................................................................ 21

5.10 Presetting the Intrauterine Pressure .................................................................................................................................. 22

5.11 Setting the Deficit Limit ......................................................................................................................................................... 22

5.12 Using the Pump during Operation...................................................................................................................................... 23

5.13 Changing Canisters during Procedure ............................................................................................................................... 23

5.14 Total Volume Displayed .......................................................................................................................................................... 24

5.15 Turning System Off.................................................................................................................................................................. 24

6 Safety functions .................................................................................................................................................................. 25

7 Care and Maintenance........................................................................................................................................................ 26

7.1 Cleaning the System................................................................................................................................................................ 26

7.2 Authorized Service Technician Maintenance................................................................................................................... 26

7.3 Replacing the Fuse ................................................................................................................................................................... 26

8 Annual Inspection............................................................................................................................................................... 28

8.1 Safety Test................................................................................................................................................................................... 28

8.2 Basic Function Tests................................................................................................................................................................. 28

8.3 Scale Test..................................................................................................................................................................................... 28

8.4 Flow Rate Test............................................................................................................................................................................ 29

8.5 Pressure Measuring Test ........................................................................................................................................................ 30

8.6 Fluid Deficit Measurement Test ........................................................................................................................................... 31

8.7 Vacuum Pump Operational Test........................................................................................................................................... 32

9 Error and Warning Messages.............................................................................................................................................. 33

10 Technical Data..................................................................................................................................................................... 35

11 Guidelines and manufacturer's statement - electromagnetic compatibility .................................................................... 37

11.1 Impact of Mobile and Portable HF Communication Devices....................................................................................... 37

11.2 Electrical Connections............................................................................................................................................................. 37

11.3 Guidelines and Manufacturer’s Statement – Electromagnetic Emissions.............................................................. 38

11.4 Guidelines and Manufacturer's Statement - Electromagnetic Interference Immunity....................................... 39

11.5 Guidelines and Manufacturer's Statement - Electromagnetic Interference Immunity....................................... 40

11.6 Recommended safety distances between portable and mobile HF telecommunications devices and the

Aquilex Fluid Control System................................................................................................................................................ 41

12 Accessory List ...................................................................................................................................................................... 42

13 Warranty Information ........................................................................................................................................................ 43

14 Glossary............................................................................................................................................................................... 45

15 Appendix ............................................................................................................................................................................. 46

15.1 Test Log........................................................................................................................................................................................ 46

Index.................................................................................................................................................................................... 47

EN

1

Page 7

Page 8

1Important User Notes

Read the manual carefully and become familiar with the operation and function

of the Aquilex® Fluid Control System (Aquilex System) and the accessories before

use during surgical procedures. Non-observance of the instructions listed in this

manual can lead to:

• life-threatening injuries to the patient,

• severe injuries of the surgical team, nursing staff or service personnel, or

• damage or malfunction of the system and/or accessories.

technical data of the product through continued development of the product.

sections with special attention.

WARNING!

Warnings indicate risks to the safety of the patient or user. Failure to follow

warnings may result in injury to the patient or user.

CAUTION!

Warnings indicate risks to the equipment. Failure to follow cautions may result

in damage to the system.

Important User Notes

EN

Subject to technical changesThe manufacturer reserves the right to modify the appearance, graphics, and

Please noteThe words WARNING, CAUTION, and NOTE carry special meanings. Read these

NOTE!

Notes provide special information to clarify instructions or present additional in-

formation.

3

Page 9

EN

Safety Information

2 Safety Information

Federal Law (only for U.S. market) Caution: Federal law restricts this device to sale by or on the order of a physician.

Exclusion of liability Hologic is not liable for direct or consequential damage and the warranty is null

and void if:

• the system and/or the accessories are improperly used, prepared, or maintained,

• the instructions in the manual are not adhered to,

• non-authorized persons perform repairs, adjustments, or alterations on or to

the system or accessories,

• non-authorized persons open the pump housing,

• the prescribed inspection and maintenance schedules are not adhered to.

Receipt of technical documentation from Hologic does not authorize individuals

to perform repairs, adjustments, or alterations on or to the system or accessories.

Authorized service technician Only an authorized service technician may perform repairs, adjustments, or al-

terations on the system or accessories. Any violation will void the manufacturer's

warranty. Authorized service technicians are trained and certified only by the

manufacturer.

Intended use The system may be used only as intended.

Care and maintenance The service and maintenance of the system and its accessories has to be carried

out as per instructions to ensure its safe operation. For the protection of the patient and the operating team, check that the system is complete and functional

before each use.

Waste management In the European Community, this symbol indicates that the waste of electrical

and electronic equipment must not be disposed of as unsorted municipal waste

and must be collected separately instead. Please contact Hologic or an accordingly authorized disposal or waste management company for further information.

4

Page 10

3 Purpose of the System

us during diagnostic and operative hysteroscopy, and to monitor the volume differential between the irrigation fluid flowing into and out of the uterus.

py is contraindicated. See the operators manual of your hysteroscope for absolute and relative contraindications.

Relative contraindications to endometrial ablation:

Hysteroscopic endometrial ablation, whether by laser or electrosurgery, should

not be undertaken before adequate training, preceptorship, and clinical experience. Additionally, tissue sampling is required prior to destruction of the endometrium. The following are clinical conditions that can significantly complicate

hysteroscopic endometrial ablation:

• Adenomatous endometrial hyperplasia

•Uterine leiomyoma

• Severe adenomyosis

• Pelvic pain (subtle PID)

• Uterine anomalies

• Surgical skill (see above)

• Severe anemia

• Inability to circumnavigate the myoma (re: myoma size) - predominantly intramural myomas with small submucous components.

Purpose of the System

Indication for useAquilex® Fluid Control System is intended to provide liquid distension of the uter-

ContraindicationsThe system may not be used to introduce fluids into the uterus when hysterosco-

EN

3.1 Warnings and Precautions

3.1.1 Warnings

WARNING!

When performing monopolar hysteroscopic electrosurgery, the distension medium must be electrically non-conductive. Examples include glycine, sorbitol and

mannitol. Isotonic saline irrigation fluids may only be used when performing bipolar electrosurgical resective procedures.

WARNING!

The pressure should be kept as low as possible to allow for a sufficient intrauter-

ine distension and to reduce the forces that could allow fluid, ambient air, and/

or gas to enter the circulatory system.

WARNING!

Intrauterine distention is usually possible with pressure values between 35 to

70 mmHg. A pressure above 75 to 80 mmHg is required only in rare cases or if the

patient has an excessively high blood pressure.

WARNING!

When using the cart/scale, follow the exact operating instructions in this manu-

al.

WARNING!

Fluid overload

There is a risk of irrigation fluid reaching the circulatory system of the patient's

soft tissue by passing through the uterus. This can be affected by distention pres-

sure, flow rate, perforation of the uterine cavity and duration of the hystero-

5

Page 11

EN

Purpose of the System

scopic surgery. It is critical to closely monitor the input and outflow of the

distending liquid at all times.

WARNING!

Fluid deficit

The fluid left in the patient must be monitored. The deficit is the total amount of

fluid left in the patient or unaccounted for otherwise. Take notice of the measurement tolerance of the system (see Chapter 10, Technical Data). Estimating

the fluid volume remaining in the patient is the physician’s responsibility.

WARNING!

Fluid intake and output surveillance

Strict fluid intake and output surveillance should be maintained. If a low viscos-

ity liquid distention medium is used, intrauterine instillation exceeding 2 liters

should be followed with great care due to the possibility of fluid overload. If a

high viscosity fluid (e. g. Hyskon) is used, the use of more than 500 ml should be

followed with great care. See labeling for Hyskon for additional information.

WARNING!

Serum sodium concentration

It is also necessary to monitor the concentration of sodium in the blood of the pa-

tient to prevent electrolyte disturbances. Monitoring of the concentration of sodium in the blood must be performed by the physician and is not performed or

supported by the system.

WARNING!

The deficit display value is lost in case of a power loss or “brownout.”

WARNING!

Hyponatremia

Some distension fluids may lead to fluid overload and, consequently, hyponatre-

mia with its attending sequelae. This can be affected by the distending pressure,

flow rate, and duration of hysteroscopic procedure. It is critical to closely monitor the input and outflow of the distending liquid at all times.

WARNING!

Pulmonary edema

Hysteroscopic surgery is associated with a risk of developing pulmonary edema

resulting from fluid overload with isotonic fluids. It is critical to closely monitor

the input and outflow of the distending liquid at all times.

6

Page 12

Purpose of the System

WARNING!

Cerebral edema

Hysteroscopic surgery is associated with a risk of developing cerebral edema re-

sulting from fluid overload and electrolyte disturbances with hypoosmolar (nonionic) fluids such as glycine 1.5% and sorbitol 3.0%. It is critical to closely monitor

the input and outflow of the distending liquid at all times.

WARNING!

Idiosyncratic reactions

In rare cases, idiosyncratic reactions, including:

• intravascular coagulopathy

• allergic reaction including anaphylaxis

may occur while performing hysteroscopy if a liquid distention medium is used.

Specifically, idiosynatric anaphylactoid reactions have been reported when using Hyskon as an irrigation fluid during hysteroscopy. These should be managed

like any allergic reaction.

WARNING!

Hypothermia (monitoring body temperature)

Continuous flow of distention fluids can lead to a lowering of the patient's body

temperature during hysteroscopic surgery. Lower body temperatures can cause

coronary and cardiovascular problems. Always monitor the patient's body temperature during the entire surgery. Make especially sure that the following, hypothermia promoting, operation conditions are avoided as best as possible:

• longer operating times

• use of cold irrigation fluid.

EN

WARNING!

Rupture of the fallopian tube secondary to tubal obstruction

Distention of the uterus may lead to a tear of the fallopian tube should there be

an obstruction or permanent occlusion. The rupture could lead to irrigation fluid

flowing into the patient's peritoneal cavity, resulting in a fluid overload. It is critical to closely monitor the input and outflow of the distending liquid at all times.

WARNING!

An air embolism can be the result of air contained in the tube set or connected

instrument reaching the patient. Ensure there is always fluid in the bag to prevent air from being pumped into the patient.

WARNING!

The system is only intended for use with flexible fluid containers. Do not use

glass containers as they might break. With rigid containers, fluid cannot flow

quickly enough due to the vacuum being generated inside of the containers. Risk

of implosion with rigid containers.

WARNING!

Filling the tubing with irrigation fluid and resetting the deficit display to zero are

to be done at the physician’s discretion.

7

Page 13

EN

Purpose of the System

WARNING!

Place the system in such a way as to allow for easy visualization of the display

values, system functions, and access to the control elements.

WARNING!

Do not use this system if a defect is suspected or detected during the function

check. This also applies to obvious defects, especially defects and damage to the

power plug and power cord.

WARNING!

Pressing the ON/OFF switch does not disconnect the system from the wall power

outlet. This requires pulling the power cord located in the rear of the system.

WARNING!

Technique and procedures

Only the physician can evaluate the clinical factors involved with each patient

and determine if the use of this system is indicated. The physician must determine the specific technique and procedure that will accomplish the desired clinical outcome.

WARNING!

Check all factory settings.

Factory settings are not mandatory settings for the physician. The physician is responsible for all settings affecting the surgical procedure.

WARNING!

Original accessories

For your own safety and that of your patient, use only Aquilex accessories.

WARNING!

Not explosion-proof

The system is not explosion-proof. Do not use in an area where flammable anesthetic gases are present.

WARNING!

No modification of this equipment is allowed.

WARNING!

To avoid risk of electric shock, this equipment must only be connected to a sup-

ply mains with protective earth.

8

Page 14

WARNING!

Professional qualification

This manual does not include descriptions or instructions for surgical proce-

dures/techniques. It is also not suitable for training physicians in the use of surgical techniques. Medical instruments and systems may be used only by

physicians or medical assistants with the appropriate technical/medical qualification working under the direction and supervision of a physician.

WARNING!

Sterile media and accessories

Always work exclusively with sterile substances and media, sterile fluids, and

sterile accessories, if so indicated.

WARNING!

Replacement system and accessories

In case the system or any of the accessories fail during a procedure, an alterna-

tive system and replacement accessories should be kept within easy reach to be

able to finish the operation with the replacement components.

Purpose of the System

EN

WARNING!

Cleaning the system

Do not sterilize the system.

WARNING!

Condensation / Water penetration

Protect system from moisture. Do not use if moisture has penetrated the system.

WARNING!

System defect

If a system defect is suspected or confirmed, do not use the system. Ensure the

system will no longer be used until a qualified service technician conducts the

appropriate tests and repairs.

WARNING!

Replacing fuse

Replace the fuse only with a fuse of the same type and rating (see Chapter 10,

Technical Data).

WARNING!

Equipment should be positioned such that power cord can be easily disconnect-

ed.

3.1.2 Precautions

CAUTION!

Federal Law (only for U.S. market)

Federal law restricts this device to sale by or on the order of a physician.

9

Page 15

EN

Purpose of the System

CAUTION!

When using the Aquilex System with MyoSure® or other morcellation systems,

the combination of low set pressures and high vacuum pressures may result in a

significant loss of intrauterine distension pressure which has the potential to affect the visibility of the surgical field. Conversely, when employing high distension pressures, the deactivation of the MyoSure® or other morcellator system

can lead to pressure spikes that can exceed 150 mmHg. These situations may occur for a short time as the system automatically adjusts the flow rate to return

to the set intrauterine pressure.

CAUTION!

The system may only be connected with hysteroscopes designed for and featur-

ing the technical specification permitting such a combined use. Any utilized hysteroscopes must comply with the most recent versions of EC 60601-2-18 and

ISO 8600.

CAUTION!

Electrical Interference: (See Chapter 11, Guidelines and manufacturer's state-

ment - electromagnetic compatibility). Electrical interference with other devices

or instruments was practically eliminated when developing this system and

none was detected during testing. However, if you still detect or suspect such interference, please follow these suggestions:

• Move the Aquilex System, the other device, or both devices to a different location

• Increase distance between devices used

• Consult an electro-medical expert

CAUTION!

Check to ensure the available wall outlet voltage matches the data listed on the

label attached to the back of the pump. Incorrect voltage can cause errors and

malfunctions and may destroy the system.

3.2 Description of the Aquilex Fluid Control System

Technical application scope of the system The intrauterine pressure can be adjusted on the front of the pump. It can be pre-

set to a range between 40 and 150 mmHg. The maximun inflow rate is 800 ml/

min and is reduced automatically by the pump once the pre-set intrauterine

pressure setting has been reached.

The system has been designed to provide both fluid and vacuum systems that

maximize the performance of the MyoSure® Tissue Removal System.

Suggested distension media The Aquilex Fluid Control System can be used with hypotonic, electrolyte-free

media (e.g., glycine 1.5% and sorbitol 3.0%) and isotonic, electrolyte containing

media (e.g., saline 0.9% and Lactated Ringer's).

Pressure measuring and regulating The system operates with a completely non-contact pressure measurement of

the irrigation medium. The contact-free pressure measurement is achieved by integrating the pressure chamber into the tubing system. The pressure chamber

transmits the irrigation fluid pressure to the electronics of the device via a pressure sensor. The pressure control circuit continuously compares the desired preset intrauterine pressure with the actual intrauterine pressure. The function of

this algorithm is to maintain the pre-set intrauterine pressure. Check for possible

leaks if the pre-set intrauterine pressure cannot be achieved.

10

Page 16

4 Initial System Set-up

Always check all parts and accessories of the system when performing initial setup. If the system should show obvious defects, contact Hologic Technical Support

(Chapter 13, Warranty Information).

temperature and humidity must meet the requirements mentioned in Chapter

10, Technical Data.

WARNING!

Equipment should be positioned such that power cord can be easily disconnected.

4.1 Preparing the System For Use

CAUTION!

Check to ensure the available wall outlet voltage matches the data listed on the

label attached to the back of the system. Incorrect voltage can cause errors and

malfunctions and may destroy the system.

Initial System Set-up

EN

Initial system set-upPlace the system on a level surface and install in a dry environment. The ambient

Connection to the wall outlet

Ensure the connection data and technical specifications of the power supply

comply with DIN VDE or national requirements. The wall outlet power supply

cord must be plugged into a properly installed safety wall plug (see DIN VDE

0107). Read the device label located in rear of pump to determine the operating

voltage of the system.

The power connection must be equipped with a grounding contact. Use the Aquilex power cord to establish a connection between the wall outlet and the power

cord connection located in the rear of the system.

3 leads. The plug connectors must comply with NEMA 5-15 or IEC 320/CEE22.

Grounding will only be reliable if the equipment is connected to a corresponding

hospital grade outlet.

safety rules and regulations.

electromagnetic compatibility (hereafter abbreviated as EMC).

This system is to be used only for the purposes described in the manual and has

to be installed, set up, and operated in compliance with the EMC notes and instructions.

Grounding contact

Only for U.S. operatorsUse only a certified (UL-listed), removable power cord, type SJT, minimal 18 AWG,

Potential equalizationIntegrate the system into the potential equalization system as specified by local

Precautionary measuresMedical devices are subject to special safety and protective measures concerning

11

Page 17

EN

(10)

(5)

(7)

(8)

(11)

(1)

(9)

(12)

(4)

(2)

(3)

(6)

Initial System Set-up

4.2 System Set-up

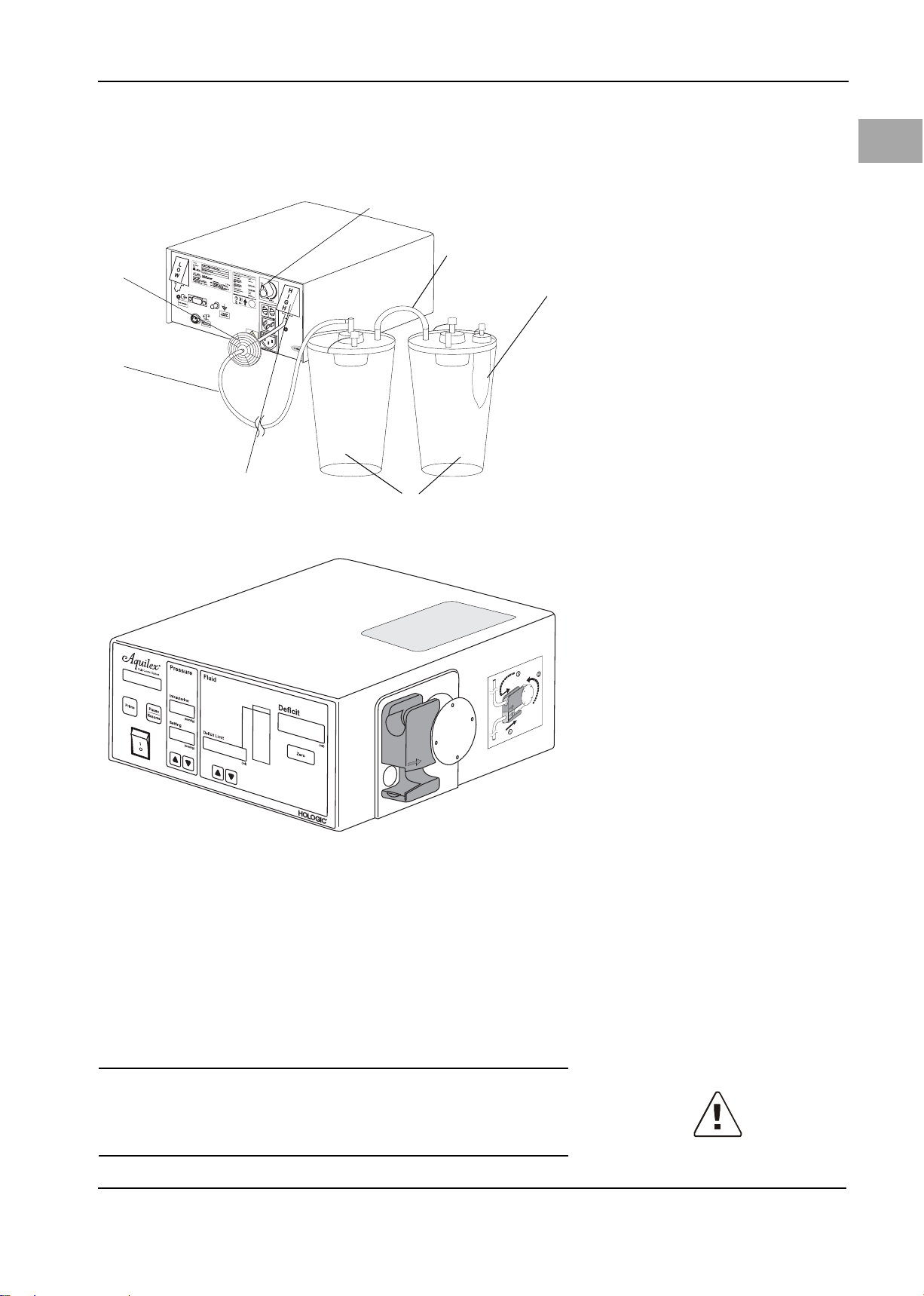

Figure 4-1 Set-up of Aquilex Fluid Control

System

(1) Cart

(2) Bag holder

(3) Pump

(4) Fluid bag

(5) Tr ay s

(6) Scale cable

(7) MyoSure® Control Unit

(8) Scale

(9) Canister holders

(10) Canister

(11) Roller base

(12) Locking foot brake

The Aquilex Fluid Control System is divided into two separate boxes for shipping.

Box 1 contains:

•Pump

•Manual

• Wall power cord

• Aquilex vacuum tube set (low and high vacuum)

• MyoSure® Control Unit power cord

Box 2 contains:

• Cart/scale

• Canister rings

12

Page 18

5System Operation

(11)

(1)

(2)

(3)

(7)(4)

(5)

(6)

(8)

(9)

(10)

(13)

(16)

(17)

(15)

(14)

(12)

(6)

(5)

(4)

(9)

(1)

(2)

(3)

(7)

(8)

(10)

(11)

(12)

(12)

5.1 Front of Pump

Please familiarize yourself with the layout of the individual elements on the front

of the pump.

5.2 Rear of Pump

System Operation

EN

Fig. 5-1 Front of Pump

(1) Pump display

(2) Intrauterine pressure display

(3) Fluid deficit limit display

(4) Deficit meter

(5) Deficit display

(6) Inflow tube holder

(7) Roller wheel

(8) Pressure sensor

(9) Reset deficit button (Zero)

(10) Decrease deficit limit

(11) Increase deficit limit

(12) Decrease intrauterine pressure set-

ting

(13) Increase intrauterine pressure set-

ting

(14) Intrauterine pressure setting dis-

play

(15) ON/OFF switch

(16) Pause/Resume button

(17) Prime button

Please familiarize yourself with the layout of the individual elements at the rear

of the pump.

CAUTION!

Any devices to be connected via the interface have to comply with EN 60950.

Figure 5-2 Rear of Pump

(1) Low vacuum port (white)

(2) Product ID label

(3) Device performance data

(4) Adjustment dial for high vacuum

(5) High vacuum port (green)

(6) Fuse holder(s)

(7) Power cord connection

(8) MyoSure® Control Unit Power Con-

nection

(9) Potential equalization connector

(10) Service interface

(11) Scale connection

(12) Exhaust ports

13

Page 19

EN

(1)

(3)

(6)

(7)

(4)

(8)

(5)

(9)

(2)

System Operation

5.3 Cart/scale

Figure 5-3 Cart/Scale

(1) Fluid bag

(2) Scale cable

(3) Scale

(4) Pole with bag hooks

(5) Bag deflector

(6) Canister

(7) Upper canister holder (Serres,

Medela, Baxter, Baxter flex)

(8) Lower canister holder (Abbott,

Bemis, Medi-Vac, DeRoyal)

(9) Roller base

The cart/scale consists of a weighing scale for the canisters, a pole with hooks for

irrigation fluid bags, and a roller base.

1. Remove the cart/scale from the cardboard shipper box.

2. Extend the pole to stop position.

3. Extend the bag deflector to stop position.

4. Remove the pump and the power cords from the first cardboard box.

5. Install canister rings (included in the second box) on upper (7) or lower (8)

canister holders, in accordance with type of canister.

6. Connect the wall power cord to the male outlet at the rear of the pump ((7)

Figure 5-2, Rear of Pump, page 13) and a grounded safety wall outlet.

7. Connect the scale to the pump by connecting the scale cable ((2) Figure 5-3,

Cart/Scale) to the scale connection ((11) Figure 5-2, Rear of Pump).

8. Use the enclosed MyoSure Control Unit power cord to connect the pump ((8)

Figure 5-2, Rear of Pump) with the MyoSure® Control Unit.

WARNING!

Scale error

Ensure that nothing weighs down the scale during system start-up. Doing so

may result in an inaccurate deficit value.

WARNING!

Fluid deficit

The fluid left in the patient must be monitored. The deficit is the total amount of

fluid left in the patient or unaccounted for otherwise. Take notice of the measurement tolerance of the system (see Chapter 10, Technical Data). Estimating

the fluid volume remaining in the patient is the physician’s responsibility.

14

Page 20

WARNING!

Serum sodium concentration

It is also necessary to monitor the concentration of sodium in the blood of the pa-

tient to prevent electrolyte disturbances. Monitoring of the concentration of sodium in the blood must be performed by the physician and is not performed or

supported by the system.

to achieve the most exact deficit value possible.

value triggers the Scale Overloaded/Check Scale message. Three audible warning

tones are emitted (See Chapter 9, Error and Warning Messages.)

CAUTION!

Ensure canisters hang freely and are not supported or in contact with anything;

otherwise, the deficit calculated is inaccurate.

NOTE!

Connect the scale to the pump before turning the system on to ensure the sys-

tem recognizes the scale.

System Operation

EN

Precise balancingTry to collect all the fluid running out of the uterine cavity during the procedure

Scale capacityThe scale can be loaded with a weight of up to 65 lbs (~30 kg). Weight above this

5.3.1 Scale Set-up

The scale can be equipped with different makes of canisters.

Bemis®3 liters DeRoyal®

Abbott 2 liters Serres 2 & 3 liters

Medi-Vac® 3 liters Medela 3 liters

15

Page 21

System Operation

(3)

(4)

(2)

(1)

(5)

EN

Medi-Vac Flex Advantage

3000 cc

NOTE!

Ensure canisters are positioned properly in the respective holders.

NOTE!

Only use canisters with overflow protection.

5.3.2 Connecting the Vacuum Tubing

CAUTION!

When using the Aquilex System with MyoSure® or other morcellation systems,

the combination of low set pressures and high vacuum pressures may result in a

significant loss of intrauterine distension pressure which has the potential to affect the visibility of the surgical field. Conversely, when employing high distension pressures, the deactivation of the MyoSure® or other morcellator system

can lead to pressure spikes that can exceed 150 mmHg. These situations may occur for a short time as the system automatically adjusts the flow rate to return

to the set intrauterine pressure.

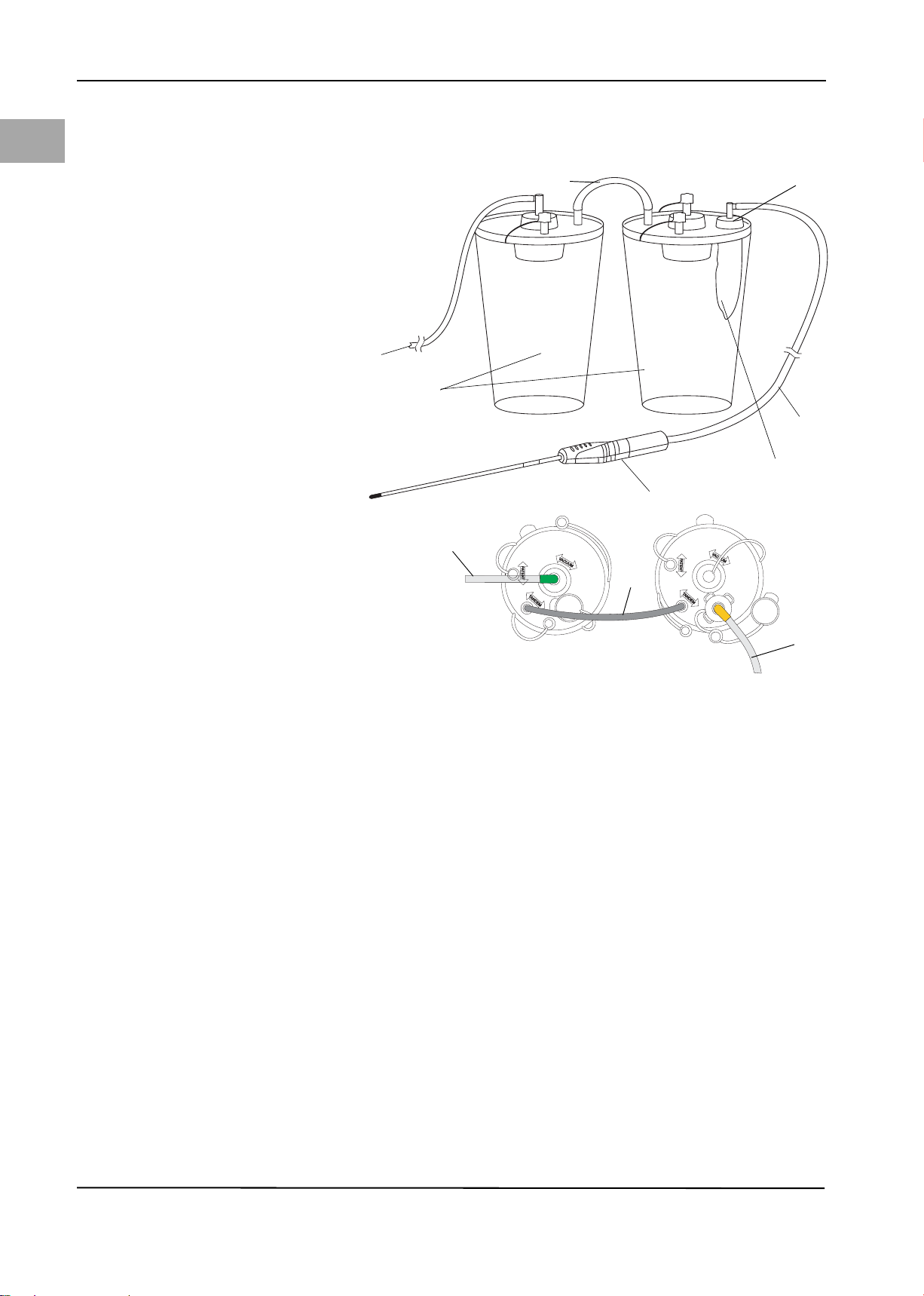

Figure 5-4 Low vacuum tube

(1) Low vacuum port (white)

(2) Hygiene filter

(3) Vacuum tube

(4) Canisters

(5) Tandem tu be

1. Connect vacuum to the suction containers (using vacuum tube with hygiene

filter). This is done once during the initial set-up of the system, not prior to

each procedure.

• Low Vacuum Side (White)

· Connect vacuum tube with white connectors to low vacuum port (1) Fig-

ure 5-4. This vacuum pump has a fixed vacuum pressure (~ 225 mmHg).

· Use tandem tube ((5) Figure 5-4, Low vacuum tube) when two canisters

are serially connected to the same vacuum port.

• High Vacuum Side (Green)

· Connect vacuum tube set with the green connectors to the high vacuum

port (green)

(8) in Figure 5-5. This vacuum can be adjusted to a maximum

16

Page 22

500 mmHg using adjustment dial.

(7)

(8)

(9)

(6)

(10)

(11)

(12)

· Use tandem tube ((12) Figure 5-5, High vacuum tube) when two canisters

are serially connected to the same vacuum port.

System Operation

EN

Figure 5-5 High vacuum tube

(6) Hygiene filter

(7) Vacuum tube (green connectors)

(8) High vacuum port (green)

(9) Canisters

(10) Tissue trap (MyoSure® procedures)

(11) Adjustment dial

(12) Tan dem tube

5.4 Turning On the Aquilex System

1. Press the ON/OFF switch. The displays and indicators light up and system

turns on.

2. The system now performs a self-diagnostic test.

3. If a tube set is in the inflow tube holder when the pump switches on, the

pump display (Fig. 5-1, Front of Pump (1)) shows Remove Tube Set. The selftest resumes once the tube set is removed from the roller wheel.

If the system self-test is unsuccessful, the corresponding error messages are

displayed. (See Chapter 9, Error and Warning Messages).

The system has successfully completed the self-diagnostic test when a single audible tone is heard. The message System OK is displayed for 5 secs followed by

the message Insert Tube Set.

WARNING!

Do not use this system if a defect is suspected or detected during the function

check. This also applies to any obvious defects, especially defects on the power

plug and power cord.

17

Page 23

EN

(2)

(1)

(3)

System Operation

5.5 Hanging the Fluid Bags

Figure 5-6 Fluid bag suspension

(1) Fluid bags

(2) Pole with bag hooks

(3) Bag deflector

WARNING!

When performing monopolar hysteroscopic electrosurgery, the distension medium must be electrically non-conductive. Examples include glycine, sorbitol and

mannitol. Isotonic saline irrigation fluids may only be used when performing bipolar electrosurgical resective procedures.

Hang one or two fluid bags with distension media appropriate for procedure. (A

MyoSure® procedure utilizes one or two 3000 cc saline bags.)

WARNING!

The system is only intended for use with flexible fluid containers. Do not use

glass containers as they might break. With rigid containers, fluid cannot flow

quickly enough due to the vacuum being generated inside of the containers. Risk

of implosion with rigid containers.

5.6 Using Tube Sets

The Aquilex Fluid Control System is designed for use with disposable inflow and

outflow tube sets.

Tube set recognition technology Each inflow tube set is equipped with tube set recognition technology. An RFID

transponder detects the type of tubing, whether it has been used, and its reliability automatically. The pump display indicates this information. This eliminates

accidental reuse of tubing on more than one patient (see Chapter 5.7, Tubing

Overview).

WARNING!

Reprocessing of sterile disposable products

Reuse of inflow or outflow tubing can cause an infection hazard for patients

and/or users as well as impair of product functionality. Contamination and/or

impaired functionality of the system can cause risk of injury, illness, or death. Do

not re-process single-use inflow or outflow tubing.

18

NOTE!

Comply with hygiene rules when disposing of tubing, fluid collected, and the

canisters.

Page 24

5.7 Tubing Overview

(2)

(6)

(3)

(4)

(5)

(1)

(7)

(5)

(3)

(1)

Three different tube sets are necessary to operate the system. The following table lists each type of tube set and its application.

Part Number Description

AQL-110 Aquilex Fluid Control System Inflow Tube Set

AQL-111 Aquilex Fluid Control System Outflow Tube Set

AQL-112 Complete tube set (Inflow and Outflow) disposable, sterile

AQL-114 Aquilex Fluid Control System High and Low Vacuum Tube

Set: re-usable, non-sterile

Table 5- 1

5.8 Connecting the Outflow Tubing

CAUTION!

When using the Aquilex System with MyoSure® or other morcellation systems,

the combination of low set pressures and high vacuum pressures may result in a

significant loss of intrauterine distension pressure which has the potential to affect the visibility of the surgical field. Conversely, when employing high distension pressures, the deactivation of the MyoSure® or other morcellator system

can lead to pressure spikes that can exceed 150 mmHg. These situations may occur for a short time as the system automatically adjusts the flow rate to return

to the set intrauterine pressure.

System Operation

EN

Figure 5-7 Outflow Tubing

(1) To low vacuum port (white)

(2) Canisters

(3) Tande m tube

(4) Patient port

(5) Outflow tube set

(6) Drape

(7) Removable Outflow Channel (Myo-

Sure®) or hysteroscope outflow

sheath stopcock

Using Low Vacuum configuration of Figure 5-4, connect outflow tubing (Y-tube)

to patient port (4) of second canister. Yellow flexible connector attaches to

drape (6). Yellow luer fitting connects to stopcock (7) of Removable Outflow

19

Page 25

System Operation

(7)

(6)

(3)

(4)

(5)

(1)

(2)

(6)

(3)

(1)

Channel (MyoSure®) or hysteroscope outflow sheath.

EN

5.8.1 MyoSure® Outflow Connection

Figure 5-8 MyoSure®Connection

(1) To High Vacuum port (green)

(2) Canisters

(3) Tande m tube

(4) Specimen tissue port

(5) Tissue trap

(6) MyoSure® vacuum tube

(7) MyoSure® Tissue Removal Device

(TRD)

If intrauterine pathology is identified, the MyoSure® TRD can be connected to the

Aquilex System as shown in Figure 5-8. The MyoSure® vacuum tube (6) is connected to the tissue trap (5) located in the second canister.

20

Page 26

5.9 Inserting the Inflow Tube Set

(7)

(5)

(8)

(1)

(2)

(4)

(3)

(9)

(6)

(10)

1

2

3

(9)

(8)

(3)

(2)

(5)

(7)

(1)

(6)

System Operation

EN

Figure 5-9 Tube set elements

(1) Protective caps

(2) Bag spikes

(3) Tubing clamps

(4) Y-connector

(5) Inflow section

(6) Roller wheel section

(7) Pressure chamber with membrane

and RFID transponder

(8) Hysteroscope section

(9) Luer lock connector (blue)

(10) Roller wheel connector

(See Figure 5-9, Tube set elements) The inflow tube set consists of three tube sections, a Y-connector (4) and two bag spikes (2). The three tube sections are: roller wheel section (6), inflow section (5), and hysteroscope section (8).The bag

spikes (2) are used to connect the tube sections to the bags.

The Luer lock connector (9) connects the hysteroscope tube with the hysteroscope.

Figure 5-10 Inserting the tube set

(1) Bag spikes

(2) Fluid bags

(3) Bag clamps

(5) Inflow tube

(6) Roller wheel tube

(7) Pressure chamber with mem-

brane and RFID transponder

(8) Hysteroscope tube

(9) Luer lock connector (blue)

Open outer packaging of the inflow tube set.

A sterile nurse then removes the inner tube set package and opens it.

Keep the blue Luer lock connector (9) in the sterile area and hand the tube

end with the bag spikes (1) to the non-sterile nurse.

Open outer packaging1. Inflow tube set - To be carried out by non-sterile nurse:

Connect to hysteroscope2. To be carried out by sterile nurse:

21

Page 27

EN

(5)

(6)

(7)

(11)

(8)

(12)

(13)

System Operation

Connect the blue Luer lock connector (9) with the hysteroscope inflow stop-

cock. Open stopcock.

Insert tube set 3. To be carried out by non-sterile nurse:

Ensure system is turned on.

Close the clamps (3) on the inflow tubing below the bag spikes (1).

Insert the inflow tube set into the inflow tube holder.

Insertion of the roller wheel tube is depicted in Figure 5-11, Positioning the

roller wheel tube.

Carefully insert the pressure chamber (7) into the lower notch of the inflow

tube holder (12) until you feel resistance. Align pressure chamber and inflow

tube holder using arrows (see Figure 5-11, Positioning the roller wheel tube).

When inserting the roller wheel tube, ensure not to damage the membrane

of the pressure chamber. Insert the pressure chamber (7) only if chamber is

not pressurized.

Place the roller wheel tube (6) around the roller wheel (11).

Connect the fluid bags

Figure 5-11 Positioning the roller wheel

tube

(5) Irrigation tube

(6) Roller wheel tube

(7) Pressure chamber

(8) Hysteroscope tube

(11) Roller wheel

(12) Inflow tube holder

(13) Alignment arrows

When connecting or removing the tube to or from the irrigation fluid bags,

grasp the bag spike at the provided handle. Observe aseptic technique when

inserting the spike(s) into the fluid bag(s). The surgeon must select a distension fluid suitable for the type of procedure.

5.10 Presetting the Intrauterine Pressure

Intrauterine pressure setting The intrauterine pressure setting can be adjusted while the system is in opera-

tion. Use the º and » buttons (Fig. 5-1, Front of Pump). The pressure setting can

be adjusted to between 40 to 150 mmHg in steps of 5 mmHg. The intrauterine

pressure is shown on the intrauterine pressure display (2).

Safety threshold When scrolling with the º button (Fig. 5-1, Front of Pump) if the safety threshold

of 100 mmHg is reached, an audible tone is emitted. Release the º button for one

second and scroll again to set higher values up to 150 mmHg.

CAUTION!

If the intrauterine pressure does not react to an increase in the pressure setting

during the procedure, a perforation of the uterine cavity might be the cause. This

results in an increased risk of intravasation. Examine the uterine cavity for injuries.

5.11 Setting the Deficit Limit

Deficit limit setting The deficit limit can be adjusted while the system is in operation. Use the º and

» buttons (Fig. 5-1, Front of Pump). The deficit limit can be adjusted to between

600 to 2500 ml in increments of 100 ml. The deficit limit is shown on the deficit

limit display (3). The deficit meter is designed to help the user track the deficit

volume. The color of the deficit meter changes as the deficit limit is approached.

The user set deficit limit is marked with a red LED on the top of the deficit meter.

22

Page 28

During the operation as the actual deficit climbs, the LEDs will light up sequentially representing the actual deficit volume until the deficit limit is reached. (See

Section Deficit Limit in Chapter 6, Safety functions).

5.12 Using the Pump during Operation

Open bag clamps ((3) Figure 5-10).

Fully open hysteroscope inflow stopcock.

Press the Prime button ((17) Fig. 5-1).

Pump will run for approximately 20 seconds to purge air from tubing and

run the Automatic Lumen Calibration.

Pump will display Calibration Running.

system determines the flow resistance of the hysteroscope. This resistance is

used to calculate the pump pressure necessary to maintain the pre-set intrauterine pressure. In order to overcome this resistance the pump allows pressure of up

to 80 mmHg during calibration. This is indicated in the Intrauterine Pressure display. In case calibration fails due to high resistance it will be repeated allowing

pressure of up to 150 mmHg. If it still cannot be completed the pump will show

Prime Fail -Open Stopcock, Clamps.

The automatic lumen calibration starts once the Prime button is pressed.

Once Automatic Lumen Calibration is completed, pump will beep three

times. The pump display will show Prime Successful Close Stopcock for 5 secs

followed by System Operating.

Close hysteroscope inflow stopcock to stop fluid flow. Once all fluid has been

removed from the drape, zero the deficit display.

System Operation

EN

Automatic lumen calibrationThe pump is equipped with an automatic lumen calibration functionality. The

NOTE!

The pump continues to operate after automatic lumen calibration is complete.

The pump should be stopped by closing hysteroscope inflow stopcock.

NOTE!

Automatic lumen calibration has to be performed each time a different hysteroscope is used during the procedure by pressing the Prime button.

Open stopcock and guide the hysteroscope with fluid flowing into the uter-

us.

Adjust intrauterine pressure setting as necessary to obtain adequate disten-

sion and visualization.

Wait until the entire fluid volume in the under-buttock drape and the tube

set has been has been collected into the canisters.

Press the Pause/Resume button.

Record the deficit volume on the deficit display. This is the total fluid volume

that was absorbed by the patient.

WARNING!

Device error: Do not use the Aquilex System if a defect is suspected or detected

during the function check. This also applies to obvious and visible defects, espe-

cially defects and damage of the power plug and power cord.

System Operation

Completing System Operation After system operation is complete, close the hysteroscope inflow stopcock.

5.13 Changing Canisters during Procedure

This locks the fluid deficit display number.

Remove desired canisters and install new canisters.

Changing canisters during the procedure Pause the pump by pressing Pause/Resume button.

23

Page 29

EN

System Operation

Reconnect canister tubing.

Press Pause/Resume button to resume procedure.

CAUTION!

If a filled canister is removed from scale without activating the " Pause/Resume"

button, the message "Container Change, Press Resume" will appear, the pump

will stop immediately and the deficit display locked to insure an accurate deficit

count is maintained. Once the canister exchange is completed, the System is restarted by pressing "Pause/Resume" button.

5.14 Total Volume Displayed

Total volume displayed If a manual check of fluid deficit is desired, the total fluid volume can be obtained

by simultaneously pressing and holding both the up and down arrows ((10) &

(11) in Fig. 5-1, Front of Pump) underneath the Fluid Deficit Limit display ((3) in

Fig. 5-1, Front of Pump). The number in the Deficit Display is the total fluid volume in ml. Once one or both of these buttons is released, the Deficit Display will

return to the Fluid Deficit value.

5.15 Turning System Off

Shut down Press the ON/OFF switch to tu rn pu mp of f. The d ispl ays and indicat ors are no lo n-

ger illuminated.

WARNING!

Pressing the ON/OFF switch does not disconnect the system from the wall power

outlet. This requires pulling the power cord located in the rear of the system.

24

Page 30

6 Safety functions

The electronic components continuously monitor the proper function of the system. System malfunctions are indicated with audible warning tones, error messages, and/or the blocking of system functions. A table listing a summary of

possible error and warning messages is provided in Chapter 9, Error and Warning

Messages.

Safety functions

EN

If the intrauterine pressure exceeds the intrauterine pressure setting by

10 mmHg for longer than 5 seconds, the pressure reduction function is activated.

The roller wheel will move forward or backward a few times during the pressure

reduction process. If the pressure cannot be reduced, the message Overpressure/

Open Stopcock is displayed and three audible tones are emitted.

tones once the intrauterine pressure exceeds 150 mmHg. The maximum permissible pressure has now been reached.

roller wheel stops and the message Overpressure/Check Stopcock is displayed.

Three short continuous audible warning tones are continuously emitted until the

pressure is reduced. Once the intrauterine pressure falls below 200 mmHg, the

audible alarm stops and the pump wheel resumes turning automatically.

Prime button results in a short audible tone and Check Tube Set Installation is

displayed. The roller wheel does not start to turn.

ror is displayed and five short audible tones are emitted. The roller wheel stops

turning.

tinuous audible tone is emitted and Scale Overloaded Check Scale is displayed.

The warning stops once the excess weight is removed from the scale.

Intrauterine pressure 10 mmHg above preset intrauterine pressure setting

Intrauterine pressure > 150 mmHgThe message Maximum Pressure is displayed and the pump will emit 3 audible

Intrauterine pressure > 200 mmHgIf the intrauterine pressure exceeds 200 mmHg for longer than 5 seconds, the

Check Tube Set InstallationIf the inflow tube set is not inserted properly over the roller wheel, pressing the

Errors of the pressure measuring systemIf a malfunction is detected in the pressure measurement electronics, Sensor Er-

Scale overloadIf the maximum permissible weight of the scale is exceeded (65 lbs/30 kg), a con-

short continuous warning tones are emitted and Container Change, Press Resume is displayed. The audible warning tone stops once the initial status is re-

stored or the Pause/Resume button is pressed

ue is reset to the default value of 80 mmHg.

triggers 3 audible warning tones that are repeated while the pump continues to

operate. The message Deficit Limit Exceeded is displayed.

ted and the message High Fluid Loss Check Leakage is displayed. If no obvious

source of high fluid loss can be identified, an assessment of potential cervical or

uterine perforation should be made.

that errors can occur in the start up sequence prior to the enabling of the Pump

Display. In this situation, the Pump Display will remain blank.

Loading/unloading scale while in operationIf a container is removed from the scale while the pump is being operated, three

Pressure setting at restartIf the last pre-set intrauterine pressure setting is greater than 80 mmHg, this val-

Deficit limitEach additional deficit increase by 100 ml above the selected deficit threshold

Deficit rate >300 ml/minWhen the deficit rate exceeds 300 ml/min, three audible warning tones are emit-

Serious system defectFive short audible tones are emitted and Motor Error is displayed. It is possible

25

Page 31

EN

Care and Maintenance

7 Care and Maintenance

Care and maintenance The service and maintenance of the system and its accessories has to be carried

out as per instructions to ensure the safe operation of the system. For the protection of the patient and the operating team, check that the system is complete

and functional before each use.

Special care is necessary when servicing, maintaining, and storing the system

and its accessories to maintain the functionality of the equipment and any attached devices.

7.1 Cleaning the System

1. Use the ON/OFF switch to turn off the system.

2. Remove the power cord.

3. Wipe the surface of the system with a soft cloth moistened with a disinfectant (for example, Meliseptol® rapid). The concentration of the used disinfectant depends on the information provided by the manufacturer of the

disinfectant. Make sure moisture does not enter the system.

NOTE!

Do not sterilize the system.

7.2 Authorized Service Technician Maintenance

Two-year maintenance interval It is recommended that an authorized service technician inspects and services

the system at appropriate intervals to ensure safety and functionality. The minimum service interval is two years, depending on frequency and duration of use.

If this interval is not maintained, the manufacturer does not assume any liability

for the functional safety of the system. A sticker located on the rear panel of the

system contains the latest date for the next service or maintenance check.

Certification Ask the service technician for a certificate after he or she has inspected the sys-

tem or performed any service tasks. This certificate must list:

• type and scope of service,

• date of service,

• name of company performing service

• as well as signature.

7.3 Replacing the Fuse

CAUTION!

Before replacing the fuse, check the values of the fuse to be inserted according

to Chapter 10, Technical Data.

The fuse may be defective and is in need of replacement if:

• one or more of the pump displays does not light up,

• the system does not function.

26

Check whether

• the power cord is properly connected to the power cord connection (Figure 5.2)

and to a grounded safety wall outlet,

• the wall outlet has power.

WARNING!

Unplug the power cord from the system before checking the fuse.

The system does not have to be opened to replace the fuse.

Page 32

1. Turn system off.

2. Disconnect system from wall power outlet.

3. The fuse holder is located on the back of the pump, next to the male connection.

4. Remove both fuse holders as depicted in Figure 7-1, using small flathead

screwdriver.

5. Pull out the fuse holders.

6. Check the fuses.

7. Insert new fuses. Use only the specified type of fuse (see Chapter 10, Technical Data).

8. Insert the fuse holders.

9. Reconnect the power cord and connect the pump to the wall outlet.

Care and Maintenance

EN

Figure 7-1 Opening the fuse holder

27

Page 33

EN

Annual Inspection

8 Annual Inspection

Manufacturer’s specification The manufacturer stipulates that qualified personnel or biomedical technicians

must regularly test the system to assess its functionality and technical safety.

These inspections must be carried out annually. Regular inspections will assist in

early detection of possible malfunctions. This helps maintain the system and increases its safety and service life.

Inspection tests The following tests are designed specifically for trained personnel or a biomedi-

cal technicians. System operation, functionality, and serviceability are easily

checked. Each test conducted must be documented by signing and dating the

test log.

WARNING!

If the specified parameters and tolerances are exceeded, the system must be returned to Hologic for evaluation.

8.1 Safety Test

1. Perform a visual inspection. Ensure:

• the fuse corresponds with the specifications indicated by the manufacturer,

• labels and stickers on system are legible,

• the mechanical condition of the system allows for its safe use,

• the system is clean to ensure proper and safe functionality.

2. Perform the measurement of the ground leakage current (max. 500 μA) and

contact current (max. 100 μA in normal state and max. 500 μA on first error)

according to IEC 60601-1 / EN 60601-1.

3. Measure protective conductor resistance according to IEC 60601-1 / EN

60601-1. The protective conductor resistance is measured while the system

is connected to the power supply. The max. value is 0.2 Ω.

As an alternative, perform safety test according to DIN EN 62353.

8.2 Basic Function Tests

The basic function tests check displays, buttons, and general performance of the

system. For this test, you will need:

• Aquilex inflow tube set

• Fluid bags

• Measuring container with marked scale (1 Liter)

• Stop-watch

• Precision weight (e.g., Ohaus 1 kg 49016-11 or 41000-00 or equivalent).

8.3 Scale Test

1. Turn the system on.

2. Once the message Insert Tube Set appears, press the Pause/Resume button

and the Zero button simultaneously.

3. Scale Test is shown on the pump display.

4. Place a precision weight on the scale (500 g - 2000 g)

5. The fluid deficit limit display will display the weight.

6. The acceptable tolerance is ±20 g.

7. If a greater difference is detected, a service technician has to re-calibrate the

scale.

8. Remove weight from scale.

9. Press the Pause/Resume button to conclude this test.

28

Record results in the test log in Section 15.1. Test is successful if results fall within

acceptable tolerance limits.

Page 34

8.4 Flow Rate Test

Annual Inspection

EN

Figure 8-1 Flow rate test

1. Turn the system on. (See 5.4, Turning On the Aquilex System)

2. Insert the tube set into pump and close bag clamps.

3. Hang the fluid bags onto the hooks of the bag holder.

4. Spike bags and open bag clamps.

5. Insert hysteroscope tube into measuring container.

6. Set intrauterine pump pressure to 150 mmHg.

7. Press the Prime button.

8. The roller wheel starts to turn to purge air from tubing and complete automatic lumen calibration.

9. Once automatic lumen calibration finishes (

button.

10. Empty measuring container.

11. Re-Insert hysteroscope tube into measuring container.

12. Press the Pause/Resume button.

13. After one minute, press the Pause/Resume button. The measuring container

should contain approximately 800 ml of fluid.

14. The acceptable tolerance is ±25 ml/min.

Record results in the test log in Section 15.1. Test is successful if results fall within

acceptable tolerance limits.

20 sec), press Pause/Resume

~

Performing flow rate testThe test set-up is depicted in Figure 8-1, Flow rate test.

29

Page 35

EN

Annual Inspection

8.5 Pressure Measuring Test

The test set-up is depicted in Figure 8-2, Set-up of pressure measuring test.

Figure 8-2 Set-up of pressure measuring

test

h Height of the water line

The pressure test checks the pressure chamber, pressure sensor, and accurate

measurement of pressure to ensure all elements are functioning properly. This

test requires an inflow tube set and a canister filled with water. The height of the

water column (hydrostatic pressure) is used to test the pressure transducer.

1. Place the inflow tube end with the bag spikes into a canister filled with water.

2. Fill

the end of the

the

Prime

button. Let the pump run until the calibration sequence is completed.

Press the

sure display displays 0 mmHg.

3. Close the hysteroscope end of the tube (use finger on luer connector tip).

4. Hold the water level of the end of the hysteroscope tube (h) 12 in [30 cm]

above the pressure chamber. The water column provides a hydrostatic pressure load onto the pressure transducer.

5. Release the finger covering the luer connector end of the hysteroscope tube.

6. The intrauterine pressure display should be 20 mmHg (±5 mmHg).

7. Change the water column height. The value of the intrauterine pressure display should change accordingly.

Record results in the test log in Section 15.1. Test is successful if results fall within

acceptable tolerance limits.

Pause/Resume

tube set completely with water by starting the pump using

button to stop the roller wheel. The Intrauterine Pres-

30

Page 36

8.6 Fluid Deficit Measurement Test

The test setup is depicted in Fig. 8-3, page 31. It is critical that the collection canister be placed on the scale as shown in Fig. 8-3.

1. If Basic Function Tests 8.3 to 8.5 have been conducted, skip to step 2. If not,

see Basic Function Tests 8.4 steps 1 to 11.

2. "Zero" the fluid deficit display by pressing the Zero button (see Fig. 5-1 Item

(9)).

3. Press the Pause/Resume button.

4. Let system run for 1 minute. The canister should have ~800 ml of fluid but the

fluid deficit display should stay at ~0.

5. The acceptable tolerance is ±50.

Record results in the test log in Section 15.1. Test is successful if results fall within

acceptable tolerance limits.

Annual Inspection

EN

Fig. 8-3 Fluid deficit measurement test

setup

31

Page 37

EN

(1)

(1)

Annual Inspection

8.7 Vacuum Pump Operational Test

This test is not designed as a performance test to measure the vacuum pressure

but only to assess if vacuum pumps are operational.

1. If Basic Function Tests 8.3 to 8.5 have been conducted, skip to step 2. If not,

see Basic Function Tests 8.4 steps 1 to 9.

2. Check canisters to be sure at least one port is open.

3. Press the Pause/Resume button.

4. Place a finger adjacent to one or both of the gold exhaust ports (Fig. 8-4, (1))

on the back of the pump and feel for air flow.