Page 1

GAS FULL SIZE

_

_

COMPUTERIZED

CONVECTION OVEN

GCSF-ES

GCSF-EZ

Installation and

Operation

Instructions

2M-W741 Rev. C 2/8/08

GCSF_2

GCSF_1

1

Page 2

SAFETY SYMBOL

These symbols are intended to alert the user to the presence of important operating

and maintenance instructions in the manual accompanying the appliance.

FOR YOUR SAFTEY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINTIY OF THIS OR ANY OTHER APPLIANCE.

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE "ANSI Z223.1 - LATEST

EDITION" AND ALL LOCAL GAS COMPANY RULES AND REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/CGA-B149.1 NATURAL

GAS INST ALLATION CODE OR CAN/CGA-B149.2 PROP ANE INST ALLA TION CODE AND LOCAL CODES WHERE

APPLICABLE.

POST IN PROMINENT LOCATION

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT USER SMELLS GAS. THIS INFORMATION

SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS SUPPLIER. AS A MINIMUM, TURN

OFF THE GAS AND CALL YOUR GAS COMPANY AND YOUR AUTHORIZED SERVICE AGENT.

EVACUATE ALL PERSONNEL FROM THE AREA.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. REAT THE INSTALLATION, OPERATION

& MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

WARNING

RISK OF FIRE OR ELECTRIC SHOCK

DO NOT OPEN

WARNING, TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE

CONTROL PANEL. NO USER-SERVICABLE PARTS INSIDE.

REPAIRS SHOULD BE DONE BY AUTHORIZED SERVICE PERSONNEL ONLY.

NOTICE

Using any part other than genuine Lang factory supplied parts relieves the manufacturer of all liability.

Lang reserves the right to change speci¿ cations and product design without notice. Such

revisions do not entitle the buyer to corresponding changes, improvements, additions or

replacements for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies and regulations, the

specifications contained in this sheet are subject to change without notice. While Lang

Manufacturing exercises good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided or conclusions reached as a

result of using the speci¿ cations. By using the information provided, the user assumes all risks in con-

nection with such use.

MAINTENANCE AND REPAIRS

Contact your local dealer for service or required maintenance. Please record the model number, serial

number, voltage and purchase & Installation Information in the area below and have it ready when you

call to ensure a faster service.

Model No.:

Serial No.:

Voltage:

1-Phase or 3 Phase:

2

Purchased From:

Location:

Purchase Date:

Installed Date:

Page 3

PROBLEMS, QUESTIONS or CONCERNS

Before you proceed consult you authorized Lang service agent directory

or

Call the Lang Technical Service at 1-800-807-9054.

SPECIFICATIONS

Model Height x Width x Depth Clearance from Weight

combustible surface Installed Shipping Freight Class

GCSF_1 36” x 40” x 40” Side:0, Back: 1, Floor: 4 555 lbs. 620lbs 70

(91.4cm x 101.6cm x 101.6cm) (252 kg) (281 kg)

GCSF_2 74” x 40.4” x 40” Side:0, Back: 1, Floor: 4 1110 lbs. 1240 lbs 70

(188cm x 102.6cm x 101.6cm) (503 kg) (562 kg)

UTILITY REQUIREMENTS

Model Voltage Total kW Phase Amps/Line Total Gas Req. Gas W.C. Max.

GCSF_1 120V/60Hz 0.7 1 5.8` 3/8” NPT, 60,000 BTU/hr 12 W.C.

GCSF_2 120V/60Hz 1.4 3 11.6 3/8” NPT, 120,000 BTU/hr 12 W.C.

WATER QUALITY REQUIREMENTS

Waterline pressure and quality MUST meet Lang Manufacturing Specifi cations listed below.

Contact your local water equipment system provider to assist you in determining your

specifi c water quality, or contact Lang Technical support for assistance, 1-800-807-9054.

-IMPORTANT-

YOUR LOCAL WATER CONDITIONS MAY DAMAGE YOUR LANG EQUIPMENT.

FAILURE TO PROPERLY TREAT WATER MAY RESULT IN DAMAGE AND MAY VOID

SOME OR ALL OF THE WARRANTY.

WATER SPECIFICATIONS, after treatment the water must continuously be within the

following parameters.

Cold Water: 20 to 80 PSI, 3 GPH minimum capacity

pH: 6.8 to 7.6

Conductivity: <1/500,000 ohms per inch

Total dissolved solids: < 100 PPM

Hardness: 2 to 4 grains per gallon

Maximum Salinity Ion Content

Chlorine: < 0.5 PPM

•

Chlorides: < 30 PPM

•

Sulfates: < 40 PPM

•

Iron: < 0.1 PPM

•

Copper: < 0.05 PPM

•

Manganese: < 0.05 PPM

•

Chloramines: < 0.5 PPM

•

3

Page 4

THIS APPLIANCE MUST BE GROUNDED AT THE TERMINAL PROVIDED. FAILURE TO

GROUND THE APPLIANCE COULD RESULT IN ELECTROCUTION AND DEATH.

W ARNING

NOTICE

NOTICE

NOTICE

CAUTION

INSTALLATION OF THE UNIT MUST BE DONE BY PERSONNEL QUALIFIED TO WORK

WITH ELECTRICITY AND PLUMBING. IMPROPER INSTALLATION CAN CAUSE

INJURY TO PERSONNEL AND/OR DAMAGE TO EQUIPMENT. UNIT MUST BE

INSTALLED IN ACCORDANCE WITH ALL APPLICABLE CODES.

The data plate is located on the lower right side panel of the unit. The oven voltage,

wattage, serial number, and clearance specifi cations are on the data plate. This

information should be carefully read and understood before proceeding with the

installation.

The installation of this unit must conform to applicable national, state and locally

recognized installation standards.

The installation of any components such as a vent hood, grease extractors, fi re

extinguisher systems, must conform to their applicable National, State and locally

recognized installation standards.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS MEMBRANES AND

CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO WEAR RUBBER GLOVES,

GOGGLES OR FACE SHIELD AND PROTECTIVE CLOTHING. CAREFULLY READ THE

WARNING AND FOLLOW THE DIRECTIONS OF THE LABEL OF THE CLEANER TO BE

USED.

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR HOSE

CONTROL CONSOLE, ELECTRICAL CONNECTIONS, ETC.

W ARNING

W ARNING

NOTICE

NOTICE

BOTH HIGH AND LOW VOLTAGES ARE PRESENT INSIDE THE APPLIANCE WHEN

THE UNIT IS PLUGGED/WIRED INTO A LIVE RECEPTACLE. BEFORE REPLACING

ANY PARTS, DISCONNECT THE UNIT FROM THE ELECTRIC POWER SUPPLY.

The appliance is equipped with a 3-prong (grounded) plug for your protection against

shock hazard and must be plugged directly into a properly grounded 3-prong receptacle. DO NOT cut or remove this gronding prong from the plug.

Never use chlorine sanitizer in contact with stainless steel surfaces longer than 10

minutes. Longer contact can cause corrosion.

Service this, or any other Lang appliance must be performed by qualifi ed personnel

only. Consult your authorized service station directory or call the factory at

1-800-807-9054, or log onto www.STAR-MFG.com for the service agent nearest you.

4

Page 5

CAUTION

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and

experienced in its operation and is not sold for consumer use in and around the home nor for

use directly by the general public in food service locations.

Before using your new equipment, read and understand all the instructions & labels associated

with the unit prior to putting it into operation. Make sure all people associated with its use

understand the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both visible and concealed.

This unit has been tested and carefully packaged to insure delivery of your unit in perfect

condition. If equipment is received in damaged condition, either apparent or concealed, a claim

must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until after equipment is unpacked,

a request for inspection of concealed damage must be made with carrier within 15 days. Be

certain to retain all contents plus external and internal packaging materials for inspection. The

carrier will make an inspection and will supply necessary claim forms.

PURCHASER’S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the electric & gas services (12” WC max) for the oven are installed on site in

accordance with the manufacturer’s specifi cations.

2. To unload, uncrate, and install the oven in its proper location and in accordance with this

installation operation manual.

3. To see that electric services are connected properly by a qualifi ed installer of your

choice.

4. To see that there is a water purifi cation system supplying the oven that meets Lang

Manufacturing Specifi cations. All connections must be in accordance with applicable code

requirements.

5. To arrange for inspection and operation check-out by an authorized service technician.

5

Page 6

CAUTION

Cardboard

Micro-foam

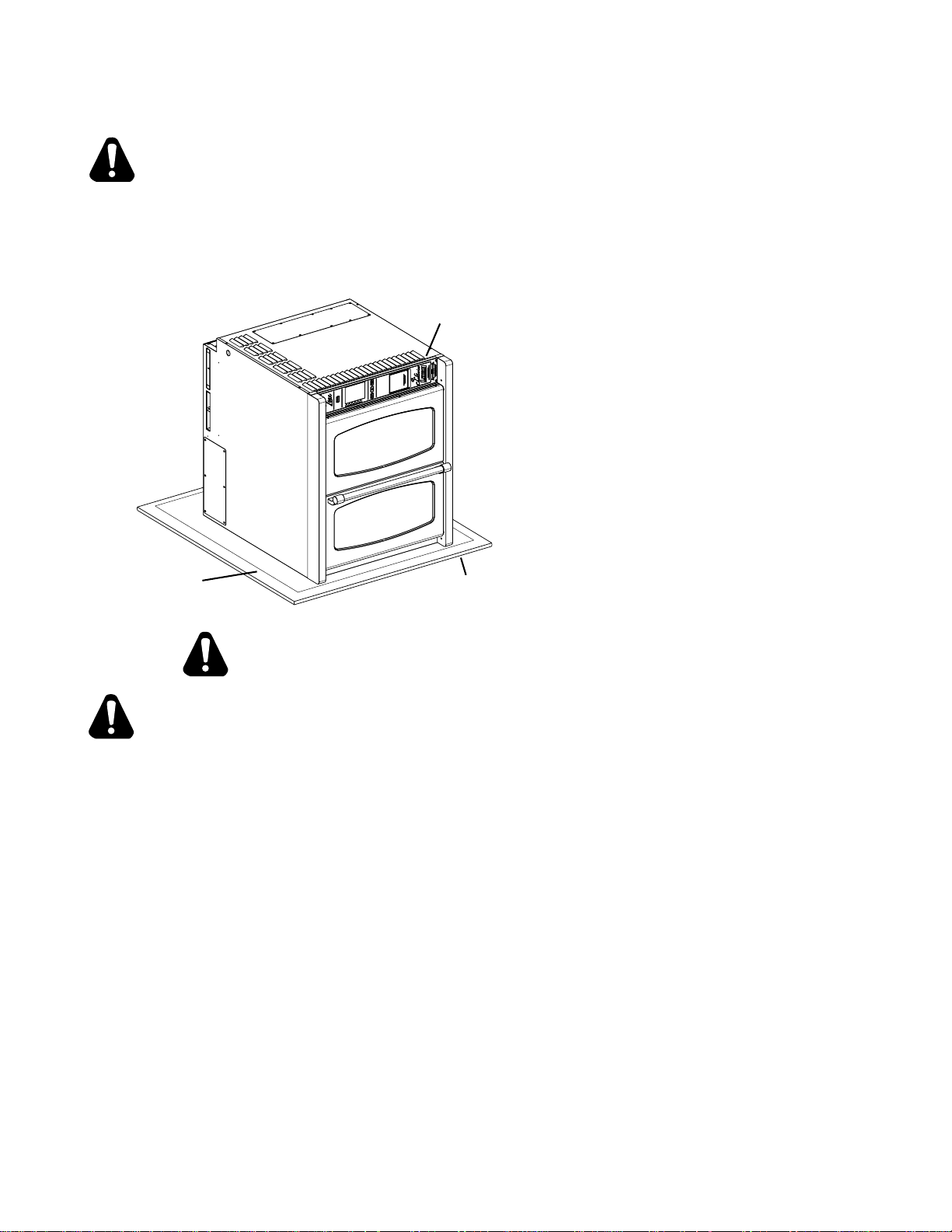

UNCRATING

The oven will arrive completely assembled inside a wood frame. Prior to uncrating move the

oven as close to its fi nal location as practical. This will protect it from damage associated with

moving (scratches, dings, dropping).

Some hardware, (i.e. casters, legs, stacking kits) may be shipped inside the oven.

Please remove any items before continuing.

It may be necessary during the installation to place the unit on its side (i.e. leg, caster installation,

fi t through doors, etc) follow these guidelines to lessen the risk of damage to the unit.

Control

Placing the unit onto its side:

1. Have oven completely uncrated and sitting

on its shipping crate.

2. When using a dolly, place a piece of plywood

on top of the dolly to distribute the weight

evenly. Also have a piece of cardboard or

micro-foam between plywood and oven to

protect the fi nish from scratches.

3. Carefully tilt the oven onto its LEFT SIDE

ONLY (or CONTROL SIDE UP)

NOTE: Turning the unit onto its right side

will damage the control panel.

4. Avoid sudden drops.

or

Panel

IL1214

Plywood

CAUTION

NEVER lay oven with the control side down, this will damage the controls.

THE OVEN WEIGHS 525 LBS (238KG). FOR SAFE HANDLING, INSTALLER SHOULD

OBTAIN HELP AS NEEDED, OR EMPLOY APPROPRIATE MATERIALS HANDLING

EQUIPMENT (SUCH AS A FORKLIFT, DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF INSTALLATION.

ANY STAND COUNTER OR OTHER DEVICE ON WHICH THE OVEN WILL BE LOCATED

MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE OVEN.

SHIPPING STRAPS ARE UNDER TENSION AND CAN SNAP BACK WHEN CUT.

6

Page 7

W ARNING

INSTALLATION

The oven is equipped for the voltage indicated on the nameplate mounted on the lower right

side panel of the oven. It will operate on alternating current (AC) only . For optimum performance

have a separate circuits breaker for each unit.

DO NOT CONNECT TO DIRECT CURRENT (DC).

The installation of the electric oven should conform to the:

NATIONAL ELECTRIC CODE AND ALL LOCAL ELECTRIC CODES AND

ORDINANCES AND THE LOCAL ELECTRIC COMPANY RULES AND

REGULATIONS.

INSTALLATION CHECK LIST

CHECK BEFORE

YOU GO!

VENTILATION & CLEARANCES

Local codes prevail. These are the “authority having jurisdiction” as stated by the National Fire

Protection Association, Inc. in NFPA 96-Latest Edition. For further ventilation information see

below.

□ Ventilation & Clearances

□ Air Supply

□ Legs & Caster Installation

□ Stacking Instructions (Double Ovens Only)

□ Draft Inducer Installation

□ Water Connection

□ Drain Connection

□ Electrical Connection

□ Gas Pressure Testing & Connection

CAUTION

A ventilation hood may be required to remove heat and cooking odors. The hood and HVAC

installation must meet local codes to gain approval by the authority having jurisdiction.

Requirements may vary throughout the country depending on the location by city , county, and

state. Obtain information from the authority having jurisdiction to determine the requirements for

your installation. Obtain information and review copies of codes or documents that will be used

to inspect and approve your installation. Your ventilation hood supplier and HVAC contractor

should be contacted to provide guidance.

Combustible clearances Non-Combustible clearances

0” from side • 1” from back, 4” from fl oor

1” from back • Without legs; 2” from back

4” from fl oor

DO NOT install oven closer than 1” on the control side, from another oven.

DO NOT install oven closer than 12” on the control side, from a uncontrolled heat source

(charbroiler, open fl ame, griddle, etc.), unless a Hi-Temperature Spacer is installed then

it can be reduced to 1”.

AIR SUPPLY

Make certain not to obstruct the fl ow of combustion (gas) and ventilation air. Provisions for

adequate air supply must be furnished.

7

Page 8

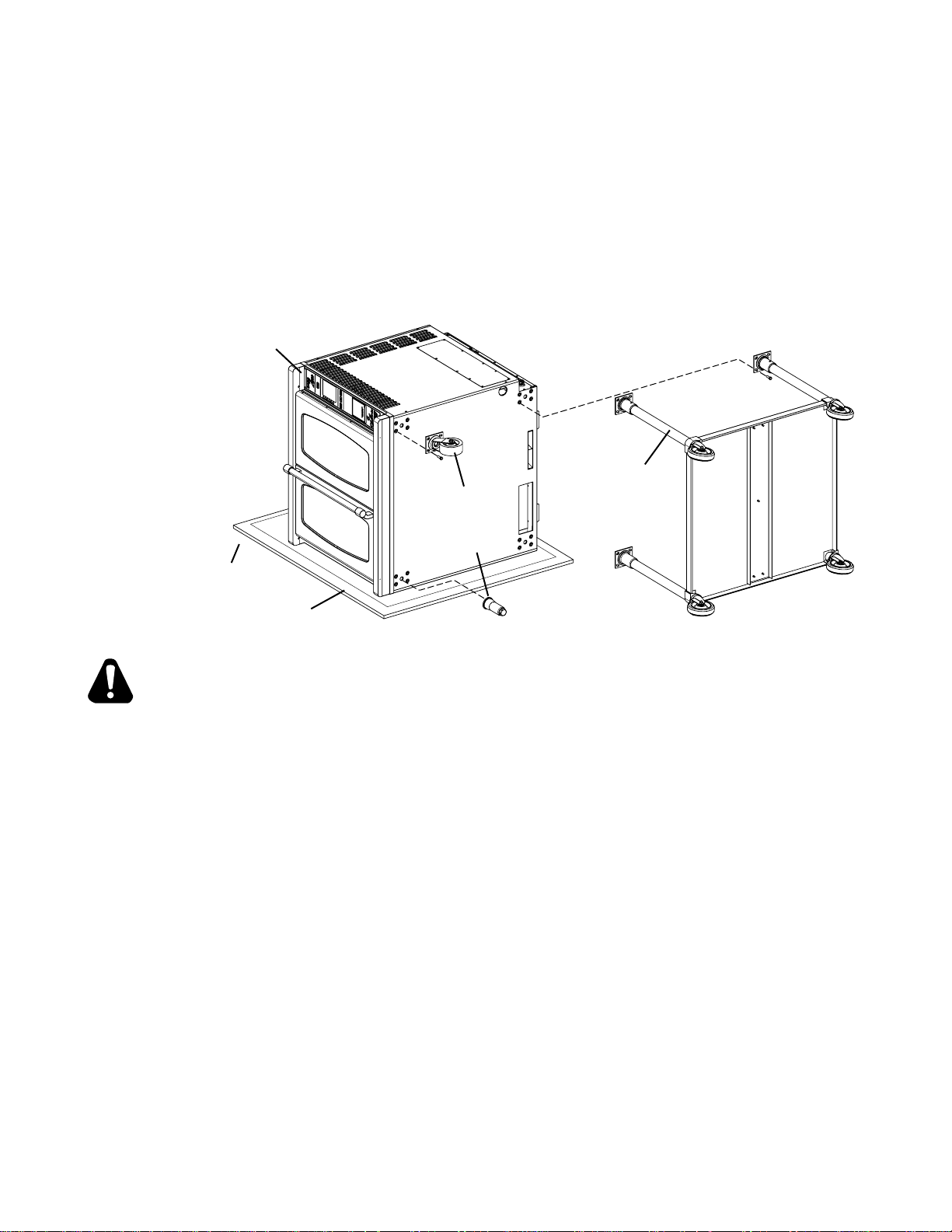

LEGS & CASTER INSTALLATION

The legs supplied with the unit must be installed, casters are an accessory and must be ordered

separately.

Legs are available for both the single and double deck installations.

SINGLE: require 27” legs or stands

DOUBLE: require 6” legs or casters.

To install the legs, place some cardboard on the fl oor and gently tip the oven onto its-back

or non-control side. Fasten all four legs to the oven’s corners using the sixteen 5/16” bolts

provided in the leg kit. Once legs securely in place, with assistance lift the unit upright, the

adjustable feet can adjusted to level the unit. A torpedo level placed on the oven rack will

assist in leveling the unit.

Control

Panel UP

27" Legs

Caster

or

Adj. Foot

CAUTION

Plywood

IL1215

Cardboard

These units may be placed on a curbed base.

CAREFULL Y TIL T OVEN ONT O ITS LEFT SIDE (CONTROL SIDE UP) WHEN INST ALLING

LEGS, FEET OR CASTERS. TURNING OVEN ONTO ITS RIGHT SIDE (CONTROL SIDE

DOWN) WILL DAMAGE THE CONTROL PANEL.

PROPER LEVELING IS ESSENTIAL TO PROPER BAKING PERFORMANCE.

CONVECTION OVENS INSTALLED WIHT CASTERS MUST HAVE THE FOLLOWING: A

CONNECTOR THA T COMPLIES WITH THE STANDARD FOR CONNECTORS FOR MOV ABLE

GAS APPLIANCES ANSI Z21.69 LATEST EDITION, A QUICK DISCONNECT THA T COMPLIES

WITH THE ST ANDARD FOR QUICK DISCONNECT DEVICES FOR USE WITH GAS FUEL,

ANSI Z21.141 LATEST EDITION, A TETHER OR OTHER MEANS TO LIMIT APPLIANCE

MOVEMENT WITH OUT RELIANCE ON THE GAS SUPPLY PIPING. SECURELY ATTACH

THE TETHER TO THE EYEBOLT PROVIDED AT THE REAR OF THE APPLIANCE.

BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST ALL JOINTS FOR

GAS LEAKS.

8

Page 9

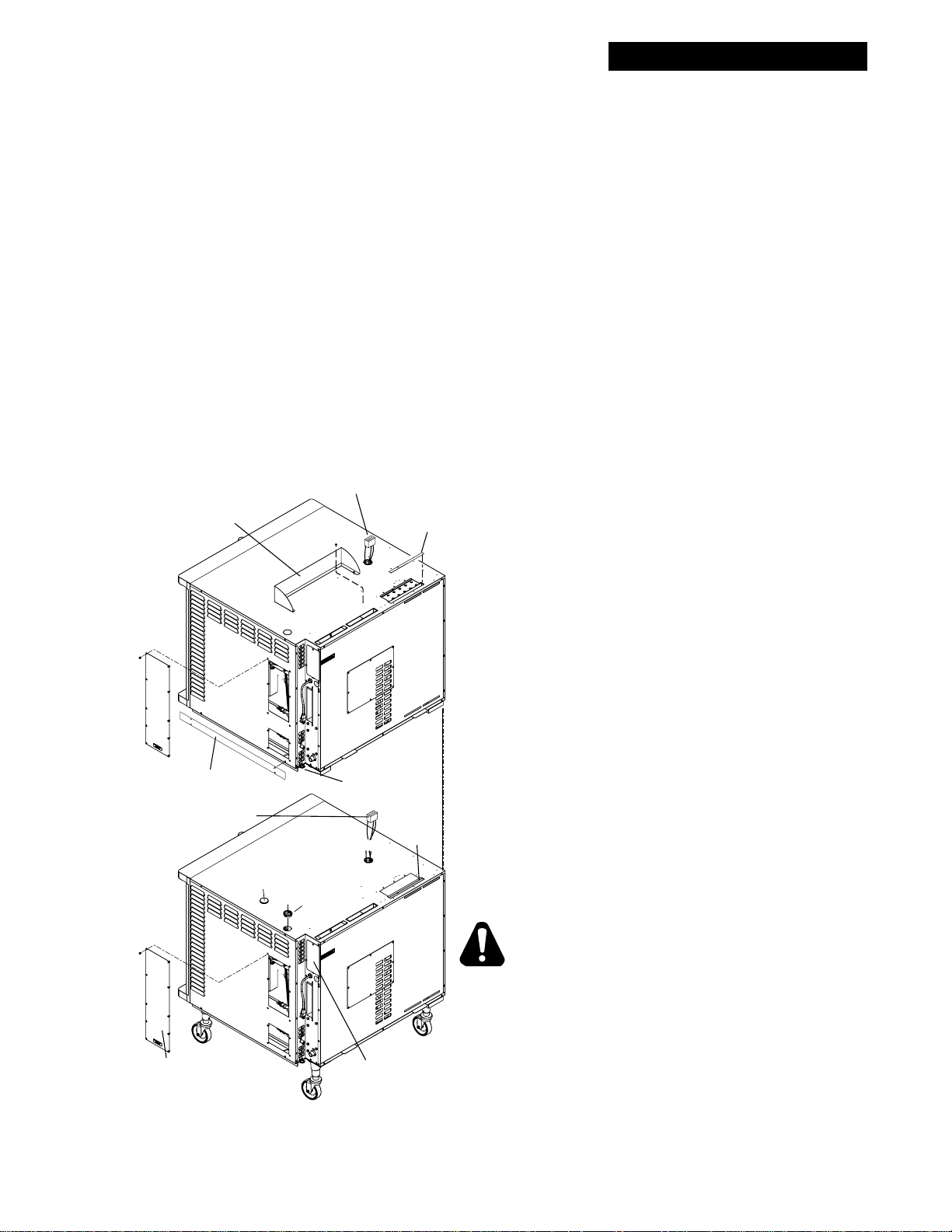

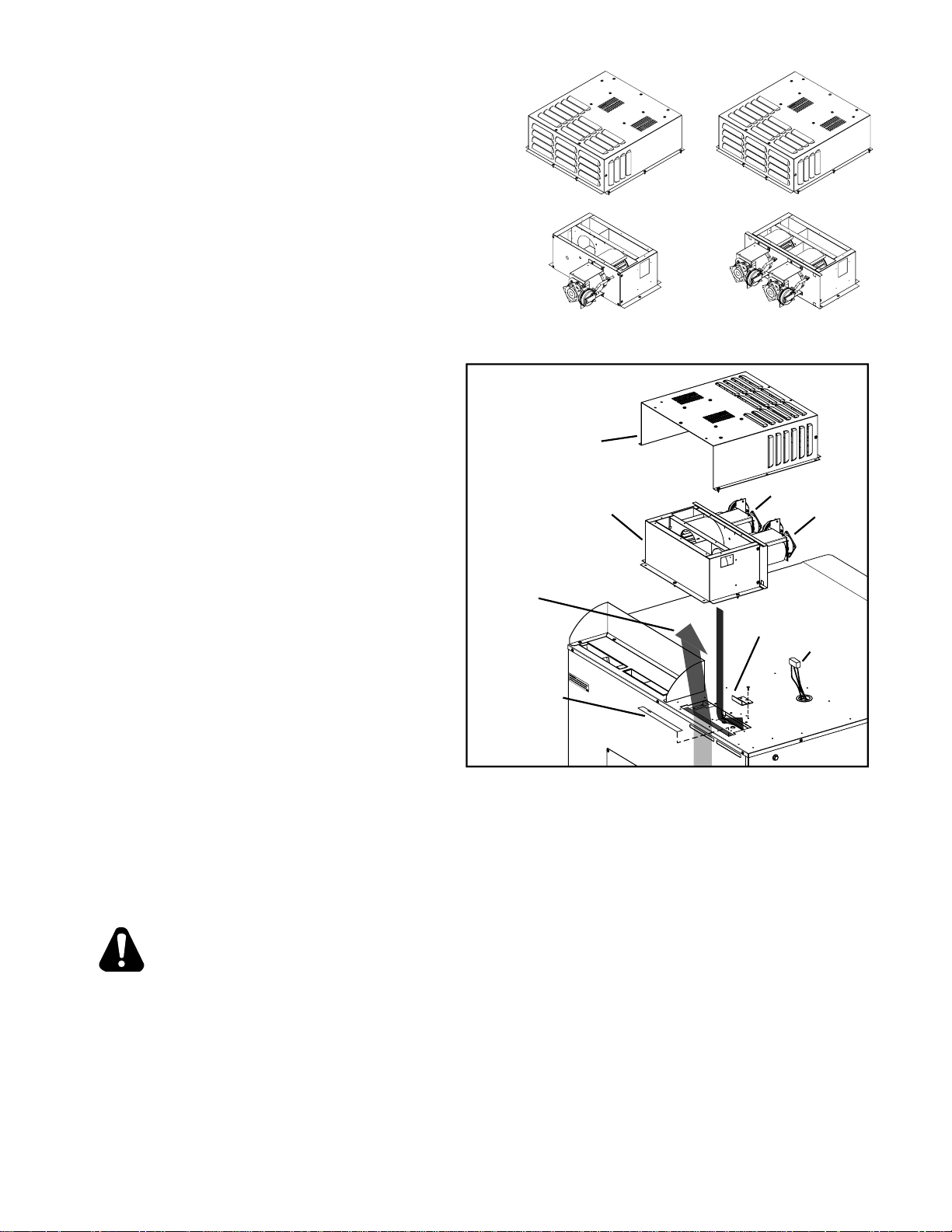

DOUBLE STACKED UNITS

STACKING INSTRUCTIONS, GCSF Oven

These stacking instructions apply when two units are being installed in a stacked arrangment only.

When an GCSF is in the top position, in a stacked assembly , the draft inducer wiring harness is needed

to power the inducer. The GCSF is the bottom position of a stacked assembly, must have the draft

inducer wiring harness removed.

When stacking an GCSF (gas) with a ECSF (electrical), put the GCSF on top to ensure proper venting

of combustion gasses.

1. Attach the feet or casters to the lower oven per the previous “Leg & Caster Installation” section.

2. Remove the Button Plug from the top right hand of the lower oven and replace it with the 1 3/4” plastic

electrical bushing provided in the stacking kit, see illustration.

3. Remove the LOWER OVEN, Draft Inducer Wiring Harness, this is not needed for the lower unit.

To accomplish this:

• Cut the 9 pin and the two single connectors coming through the top of the lower unit.

• Remove the Side Access Panel & the Terminal Block Access Panel on the lower oven.

• Disconnect the wires from the harness going to the terminal block.

• Locate the bundle of wires in the side access panel labeled “DRAFT INDUCER CONNECTION”,

disconnect the wires from the oven harness at the 6 pin connector.

• The draft inducer harness can now be removed from the unit by pulling the harness from the

control side through the fi rewall bushing

Upper Draft Inducer Harness

Vent Shroud

Upper

Oven

Strapping Plates

Lower Draft Inducer Harness

(9 pin connector)

Lower

Oven

Button Plug

(9 pin connector)

Eye Bolt

Bushing

REMOVE

Knockout

Do Not

Remove

Inducer

Knockout

4. REMOVE THE INDUCER KNOCKOUT on the right

rear of the UPPER UNIT ONLY, prior to placing it into

position. DO NOT remove the knockout for the lower

Inducer

unit, doing so will interupt proper gas venting from that

unit.

5. Using the Strapping Plates (see stacking kit) secure the

two ovens together, by mounting them into the existing

side panel, using existing screws on both sides of the

unit.

6. Install the vent shroud with 4 #10 sheet metal screws,

provided.

7. Remove the side access panel from the upper oven.

8. Locate the wire bundle labeled “Lower Oven Draft

Inducer Connection” in the upper oven. Pass this

connection through the plastic electrical bushing at the

bottom of the oven and into the lower oven.

EnviroZONE only: Install a 1 3/4” plastic electrical

bushing, replacing the knock-out directly behind the

control cooling fan of the lower oven.

9. In the lower oven, connect the 6 pin connector that was

passed through from the upper oven to the connection

marked “Draft Inducer Connection”

10. Replace the side access panels & attach the

earthquake strap (not included) to the eye bolt to the

upper oven, see illustration.

CAUTION

THE OVEN WEIGHS 520 LBS (238KG). FOR SAFE

HANDLING, INST ALLER SHOULD OBTAIN HELP AS

NEEDED, OR EMPLOY APPROPRIA TE MA TERIALS

IL1270

Side Access Panel

Terminal Block

Access Panel

ANY STAND, COUNTER OR OTHER DEVICE ON WHICH THE OVEN WILL BE LOCATED

MUST BE DESIGNED TO SUPPORT THE WEIGHT OF THE OVEN.

HANDLING EQUIPMENT (SUCH AS A FORKLIFT,

DOLLY, OR PALLET JACK) TO REMOVE THE UNIT

FROM THE SKID AND MOVE IT TO THE PLACE OF

INSTALLATION.

9

Page 10

DRAFT INDUCER INSTALLATION

d

y)

SINGLE UNIT

In single unit applications the oven must be

mounted to its cart before completing these

steps.

DOUBLE UNITS

When installing the draft inducer in a stacked

application, it must be completed only after

the previous “Stacking Instructions” have been

performed.

1. Install the bracket that came with the draft

inducer with three (3) of the #10 sheet metal

screws provided.

Single GCSF

One Motor

Double GCSF Stack

Two Motors

2. Make certain the knockout is

removed from the unit, top unit ONLY

in stacked situations. see illustration

shown here.

3. Place the draft inducer, without the

louvered cover, on top of the unit,

over the exhaust collector.

4. Slide the inducer forward until

secured under the attached bracket.

Using six (6) #10 sheet metal screws,

fasten this assembly onto the top of

Louvered

Cover

Draft Inducer

Lower Oven

Combustion

Exhaust Flow

Motor Top Unit

Motor Lower

Unit

the oven.

5. Connect the 9 pin and two single

electrical connections from the

Bracket

Inducer

Harness

draft inducer to the wiring harness

protuding from the top of the unit.

NOTE: There is no polarity

distinction between the single

Knockout

emove

TOP unit onl

connections.

6. Test the Inducer by plugging in the

120V connection to the oven (upper

Above: STACKED UNITS ONLY, Remove Knockout

before installing Draft Inducer.

oven on stacked assemblies) and

make sure the axial fan(s) on the draft inducer are turning. The fans will turn without the

controls being on.

IL1413

IL1272

7. Fasten the draft inducer cover to the top of the oven with the #10 sheet metal screws

provided.

IMPORTANT: IMPROPER DRAFT INDUCER INSTALLATION WILL ADVERSLY

AFFECT THE PERFORMANCE OF YOUR LANG EQUIPMENT.

EARTHQUAKE STRAPS

If the oven is to be installed with casters, it must be secured to the building structure. To do

this, attach an oven earthquake strap (not supplied) to the eye bolt (supplied) at the bottom

right corner of the oven. For stacked ovens, attach the strap to the eye bolt of the uppermost

oven. Connect the earthquake strap to the wall or other structure per instructions supplied

with the strap.

10

Page 11

UTILITY INSTALLATION

WATER CONNECTION

It is vital that the water supply line be thoroughly fl ushed with clean water before being connected

to the oven’s water manifold.

After your water has been tested and meets the minimum requirements (see water requirements).

Connect water supply to 3/8” NPTM fi tting located at right rear corner of the oven. Once the

water manifold and water supply are connected to the oven turn the oven ON and press the

1-shot steam button for 1 minute to remove the air and any impurities from the system.

The water must continuously be within the specifi cations (for this application) while this unit is

in service. Periodic testing may be needed to verify any changes in water conditions.

DRAIN CONNECTION

Attach drain plumbing to the ¾” NPTM oven drain fi tting located

at the lower rear right had corner of the oven.

Drains need to have a vent pipe attached. T ypical venting is

accommodated by using a “T” off the drain pipe with an 8” to

10” open pipe in the top part of the “T”. for stacking, the drains

can be manifolded together with only the top drain vented.

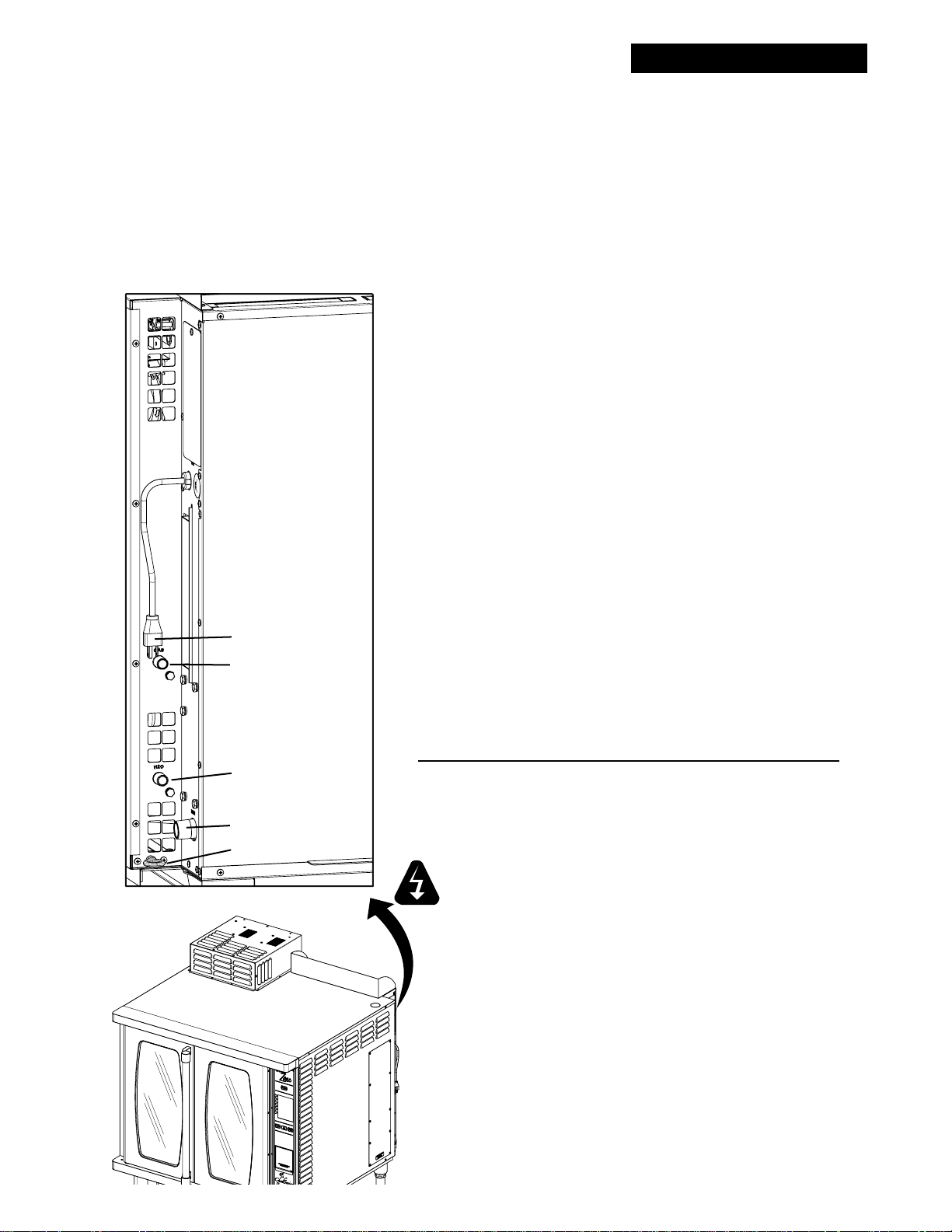

ELECTRICAL CONNECTION

All electrical connections must be made in accordance with

local codes or in the absence of local codes with NFPA No.

70 latest edition (in Canada use: CSA STD. C22.1)

Plug

Gas Connection

Water Connection

Drain

Eye Bolt

IL1276

- IMPORTANT -

IF A SINGLE POWER SOURCE IS TO BE CONNECTED TO

BOTH OVENS, REMOVE THE CONTROL SIDE PANELS

AND RUN THE INTERCONNECTION WIRES THROUGH

THE 1” PLASTIC ELECTRICAL BUSHING RUNNING

BETWEEN THE TWO OVENS.

The electrical service entrance is provided by several

knockouts in the top right rear corner of each oven. Line

current information can be found on the unit’s data plate.

Voltage Phase Total kW Amps/Line

Single 120V 1 0.7 5.8

Double 120V 1 1.4 11.6

Supply wire size must be large enough to carry the amperage

load for the number of ovens being installed.

WARNING

THIS APPLIANCE IS EQUIPPED WITH A

3-PRONG (GROUNDING) PLUG FOR YOUR

PROTECTION AGAINST SHOCK HAZARD AND

MUST BE PLUGGED DIRECTLY INTO A PROPERLY

GROUNDED 3-PRONG RECEPT ACLE. DO NOT CUT

OR REMOVE THIS GROUNDED PRONG FROM THE

PLUG.

11

Page 12

UTILITY INSTALLATION

GAS CONNECTION

Attach gas plumbing to the 3/8” NPTM fi tting located on the right hand rear corner of the

oven.

WARNING

CONVECTION OVENS INSTALLED WITH CASTERS MUST HAVE THE FOLLOWING:

A CONNECTOR THAT COMPLIES WITH THE STANDARD FOR CONNECTORS FOR

MOVABLE GAS APPLIANCES ANSI Z21.69 LATEST EDITION, A QUICK DISCONNECT

THA T COMPLIES WITH THE STANDARD FOR QUICK DISCONNECT DEVICES FOR USE

WITH GAS FUEL, ANSI Z21.141 LATEST EDITION, A TETHER OR OTHER MEANS TO

LIMIT APPLIANCES MOVEMENT WITH OUT RELIANCE ON THE GAS SUPPLY PIPING.

SECURELY ATTACHED THE TETHER TO THE EYEBOLT PROVIDED AT THE REAR OF

THE APPLIANCE.

BEFORE LIGHTING, USE A SOAP AND WATER SOLUTION TO TEST ALL JOINTS FOR

GAS LEAKS.

PRESSURE TESTING THE GAS SUPPLY LINE

During pressure testing note the following:

1. The oven and its individual manual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

Turn OFF main gas shut-off valve or main gas supply line.

2. The oven must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

3. If incoming pressure is over 12" water column, a separate regulator for the oven must be installed

before the gas supply to the oven.

To prevent damage to the control valve regulator during the initial turn-on of

gas, it is very important to open the manual shut-off valve very slowly . After the

initial gas turn-on, the manual shut-off valve must remain open except during

pressure testing as outlined in the above steps or when necessary during service

maintenance.

NOTE: The supplied regulator is evaluated for a maximum gas supply pressure of

14" water column (34.5 mBar). The recommended maximum gas supply pressure

is 12" water column (29.9 mBar).

PRESSURE TESTING THE GAS CONTROL VALVE

Determine the outlet pressure is 4” W.C. by applying power to the valve

and energizing both valve solenoids. Use the outlet pressure tap connection on the underside of the valve body to monitor the outlet

pressure. The outlet pressure tap is a bleed hole with a cast

spigot, sealed with a threaded brass needle screw.

To monitor the outlet pressure, turn the screw in a

counterclockwise direction one or two turns

and fi t a 9 mm diameter fl exible tube

over the cast spigot. After making all valve adjustments and

obtaining the desired outlet

pressure, remove the fl exible

tube. Tighten the needle screw

by turning it clockwise with a

slotted screwdriver until hand

tight, sealing the bleed hole.

Pilot Tube

Connection

IL1407

Outlet Pressure

Tap Connection

12

Page 13

INITIAL START-UP

Pre-Power ON

After the oven is installed and connected to power, prior to turning on, verify the following:

• The doors open and close freely.

• All racks are in the oven correctly.

• All packing materials have been removed from the inside of the oven.

• Power is applied to the oven.

• Water is connected and turned on.

• Drains are connected.

NOTICE

During the fi rst few hours of operation you may notice a small amount of smoke

coming from the oven, and a faint odor. This is normal for a new oven and will

disappear within a few hours of operation.

Enviro-STAR

Control Panel Defi nitions:

Power, - on/off button

Note: Fan remains on until oven cools down

to 250°F

1-Shot Steam - Provides single shot of steam

to the cooking chamber between 1 to 20 seconds. To adjust hold down button and turn

knob until desired time displays on LED.

Pulse Steam - Sends Steam Shots in

non-adjustable 1 second duration, to the

cooking chamber. Adjust the Pulse Steam

time between 1 to 120 minutes by holding

down the button and turning knob until the

desired time is displayed on the LED.

1-SHOT

STEAM

FAN

HI/LOW

POWER

PULSE STEAM

COOK-N-HOLD

LED TEMP

INDICATOR

TEMP KNOB

LED TIMER

SCREEN

TIMER KNOB

FAN - Fan has two speeds (L=LOW,

H=HIGH) Note: the fan will reverse directions

periodically during operations, this provides

for a more consistent bake.

COOK-N-HOLD - Once the cooking has

completed the unit will beep 5 times

(1-Shot Steam or Pulse Steam) this feature will

reduce the oven temperature to 150°F and

the cook-n-hold light will turn off. The oven

will remain at 150°F until the user begins

another cooking cycle or the unit is turned

off.

Note it may take as long as 1-hour for it to reach

150°F depending on the set cooking temperature.

This time must be taken into account when using

the Cook-N-Hold feature.

13

BACKUP CONTROL

ACCESS DOOR

Page 14

Enviro-STAR

Control Panel Defi nitions (Continued)

LED Temperature Indicator – Indicates the current temperature.

• V1.12 blinks with a call for heat,

• Solid means oven on set point.

Temperature Knob – Use to set oven temperature.

LED Timer Screen – Multifunctional digital readout.

• Reads out the time remain in the current cooking cycle.

• Reads out time when setting “Pulse Steam” interval time.

• Reads out time when setting “1 Shot Steam” duration.

Timer Knob – Sets cook time, Pulse Steam interval time and 1 Shot Steam duration.

Back UP Controls – Allows oven operation utilizing a completely separate set of manual

controls. Operation in Back-Up Mode is described in the “Operation with Back Up Controls”

section.

Initial Power On Test:

1. Follow these steps to verify the basic operation and temperature control capability of oven.

a) Turn Power On. Verify interior light and display comes on.

b) Set temperature to 300°F. Verify Temperature Indicator light is blinking.

c) Verify oven reaches set point & signals ‘Ready’ with an audible tone with in

12 Minutes. (starting with a cold oven)

d) Set timer to 10 Minutes and verify fan stops and reverses direction after

approximately 108 seconds. (complete reversing cycle takes 2 minutes.)

e) Open door and verify the Fan and Time Display stops then restarts when door is

closed.

f) Turn timer to zero, temp to zero.

g) Confi rm fan stays on until temp cools to below approximately 250°F.

For units with water hookup for Steam.

2. Identify water purifi cation system used: ________________________________________

(write “none” if no water treatment system is in use.)

3. Flush water system to clear tainted water from the install process. _____.

a) Put oven into Back-Up Mode and set temperature to approx. 400°F.

(Listen for contactor changing states)

b) Once up to temp, Use the steam bypass switch (spring loaded toggle switch in the

Back Up Access area) to fl ush the water through the oven for 1 minute.

c) Check water drain for proper operation.

14

Page 15

Enviro-ZONE

Control Panel Defi nitions:

Power – On/Off button. When switched on, the control will turn on the interior light and the

display. The fan is left off until there is a call for heat or a timer is started.

When the “Power” button is pushed to turn the oven off, the interior lights turn off, the front

display turn off.

Up – Allows you to scroll up.

Down – Allows you to scroll down.

Cancel – When scrolling through

menus this will allow you to back

up to the previous menu. In

program mode this will allow you

to back up to the previous step.

Function Keys – Keys are

active when a program option is

displayed on the display adjacent

to that key.

Back UP Controls – Allows oven

operation utilizing a completely

separate set of manual controls.

Operation in Back - Up Mode is

described in the “Operation with

Back Up Controls” section of this

manual.

BACKUP CONTROL

ACCESS DOOR

POWER

FUNCTION

KEYS

DOWN

UP

CANCEL

OPERATION WITH BACK UP CONTROLS

During Back-Up operation, the main control

panel is disabled by removing it’s power allowing

operator to utilize a completely separate set of

controls.

On both the Enviro-Zone & Enviro-Star models, the

back-up controls are located behind the Access

Door located just below the Control Panel. Inside

you will fi nd a Temperature Control Knob, a Back-

Up Control toggle switch and a spring loaded BackUp Steam toggle switch.

To enable Back-Up operation, throw the BackUp Control toggle switch to the ON position.

The oven’s convection fan will come on at High

speed / CCW and the heat can be controlled using the Temperature Knob. Steam may be applied

manually using the Back-Up Steam toggle switch.

Unlike normal operation, the Back-Up mode does

not employ energy saving processes or allow the

fan to reverse direction or change speeds.

Temperature Knob

Steam Toggle Switch

IL1218

15

Control Toggle Switch

OCE/OCG BACK-UP CONTROLS

Page 16

Enviro-ZONE

Initial Power On Test:

1) Energize Oven and verify the basic operation and temperature control capability of oven.

a. Turn Power On. Verify interior lights and the display comes on. _____

b. Install a Temperature Meter thermocouple in center of oven cavity.

c. Using ‘Run Oven’ / ‘Manual Program’, set temperature to 300°F. _____

d. Verify oven reaches set point & signals ‘Ready’ with an audible tone with in

12 Minutes. (starting with a cold oven) _____

e. Press Manual Program again. Using the enter key and up button, enter time 00:10:00,

Press ‘Accept’ and then select shelf “C”. Verify the shelf timer starts count down;

Verify the fan stops and reverses direction after approximately 108 seconds.

(complete reversing cycle takes 2 minutes.) _____

f. Verify the measured temperature at the transition point (when heat contactor changes

states.) matches the temperature on the display panel. _____

g. Open door and verify the Fan stops then restarts when door is closed. _____

h. Press Cancel several times to return to “Run Oven” menu.

i. Confi rm fan stays on until temp cools to below approximately 250°F. _____

For units with water hookup for Steam.

2) Identify water purifi cation system used: _________________________________________

(write “none” if no water treatment system is in use.)

3) Flush water system to clear tainted water from the install process. _____.

a. Put oven into Back-Up Mode and set temperature to approx. 400°F.

b. Once up to temp, Use the steam bypass switch (spring loaded toggle switch) to

fl ush the water through the oven for 1 minute.

c. Check water drain for proper operation.

16

Page 17

OPERATION

Enviro-STAR Typical Operation Sequence:

ACTION RESULT

Press the POWER button Front panel lights up.

Select Fan Speed HI or Fan Speed LO. Selected Fan Speed light will be lit.

Adjust to desired temperature between 125° F Fan and heat come on. Fan will reverse direction every 2

and 525°F. (Minimum suggested temperature minutes (approximately) through out cooking process.

for operation with Steam is 250°F.).

Set Pulse Steam by pressing and holding Pulse Pulse Steam light will stay on. Digital display will momentarily

Steam button and selecting between 1 and show selected interval between steam pulses.

120 minutes interval between pulses

Temperature reaches Set Point. Set point reached within 12 minutes and audible tone signals.

Load Product into Oven. See Hints & Suggestions – “Loading the Oven.”

Set Timer Knob to desired cook time. Time starts timing down on digital display. If Pulse

Steam has been enabled, a 1 second shot of steam will be

applied at the selected interval.

Set Cook n Hold (Optional) Cook n Hold light comes on to indicate feature is enabled.

Cooking timer times out. Audible tone signals cook time complete.

If Cook n Hold feature is enabled, the oven temperature will

drop no lower than 150°F with the 150° time light on solid until

the timer is reset. The Cook n Hold light will go out at end of

timer.

Unload Oven See Hints & Suggestions – “Unloading the Oven”

Enviro-ZONE Typical Operation Sequence:

ACTION RESULT

Press the “POWER” button Control Panel comes on, display says “LANG, Run Oven,

Time/Date/Program.

Select “RUN OVEN”. Display will show a list of product to choose.

Select Product button next to Icon desired. Display says “Preheating to xxx°F”.

Beeper sounds briefl y. Display says “Ready”.

Select Function to start. Display shows possible product selection for that temperature.

Select Function to start. Display says “Select Shelf”, Place Product in oven

on selected shelf.

Press Function Button next to desired shelf Display will show icon chosen and begin to count down.

Beeper sounds continuously. Display shows “DONE” press button and remove product

from that shelf.

Oven is ready for another program.

17

Page 18

MAINTENANCE

• Water fi lters and conditioners should be inspected and replaced per their manufacturers

recommendations.

• Oven interiors should be wiped down daily and thoroughly cleaned weekly using warm water

and mild detergent. DO NOT use caustic cleaners.

• The appliance should be thoroughly checked at six-monthly intervals by a qualifi ed

technician (heating unit, mechanical stability, corrosion...) with particular emphasis on all

control and safety devices.

CLEANING

• Always start with a cold oven.

• The stainless exterior can easily be cleaned using stainless steel cleaner.

• Always follow the cleaner manufacturer’s instructions when using any cleaner.

• Care should be taken to prevent caustic cleaning compounds from coming in contact with

the fan wheel.

• The oven racks, rack slides, may be cleaned outside the oven cavity using oven cleaner.

• Using any harsh chemicals will result in the removal of the ETC coating and etching of the

porcelain below it. The oven interior should only be cleaned using a mild soap and a non

metal scouring pad. DO NOT use caustic cleaners.

• Always apply stainless steel cleaners when the oven is cold and rub in the direction of the

metal’s grain.

W ARNING

CAUTION

KEEP WATER AND SOLUTIONS OUT OF CONTROLS. NEVER SPRAY OR

HOSE CONTROL CONSOLE.

MOST CLEANERS ARE HARMFUL TO THE SKIN, EYES, MUCOUS

MEMBRANES AND CLOTHING. PRECAUTIONS SHOULD BE TAKEN TO WEAR

RUBBER GLOVES, GOGGLES OR FACE SHIELD AND PROTECTIVE

CLOTHING.

CAREFULLY READ THE WARNING AND FOLLOW THE DIRECTIONS ON THE

LABEL OF THE CLEANER TO BE USED.

NEVER LEAVE A CHLORINE SANITIZER IN CONTACT WITH STAINLESS STEEL

SURFACES LONGER THAN 10 MINUTES. LONGER CONTACT CAN CAUSE

CORROSION.

18

Page 19

CONVECTION OVEN BAKING GUIDE

CONVECTION OVENS IN GENERAL

• Convection ovens constantly circulate air over the product. This strips away the thin layer of moisture laden air

from the top of the product allowing heat to penetrate more quickly. This allows cooking times to be shortened

and cooking temperatures reduced in convection ovens. Introducing Steam into the cooking process prevents

the bake from loosing moisture and allows for a better product.

• Applying steam to dough during fi rst 5 minutes, allows the yeast to work a little longer, allowing for better oven

spring and loaf volume keeping the outer layer fl exible and moist. Once the outside layer of the dough sets,

gases in the loaf can no longer expand to increase the loaf size.

• Steaming the dough as it bakes also gelatinizes starch on the outside layer, producing a bread with a crisp crust

and a brown crust color in varying degrees; too much steam results in an undesirable crust. Steam also helps

to prevent wild breaks in the loaves because it delays the setting of the bread’s crust, allowing it more time to

bake and brown. However, in contrast, during the last stages of baking, a dry oven is required when the crust is

browning; after the steam is removed, the gelatinized layer dries out forming a thick crunchy crust.

• The convection oven is an electro-mechanical piece of equipment and is designed to produce a consistent

result. Variations in results are therefore more likely due to differences in the preparation process.

DEFINITIONS

EnviroZone & EnviroStar

Cooking Time & Temperature: To convert standard deck oven recipes to convection oven recipes, start by

reducing the cooking temperature by 50 °F and the time by 25%.

Fan Speed Functions: The convection fan is programmable as either HI or LO speed. Most baking is done

with the fan speed set to high. Delicate products (i.e. Meringue pie) may require use of the low fan speed

setting.

EnviroZone

Cooking Curve: Cooking curve is a programmable function that adjusts the cooking time to

compensate for planned times when the oven temperature would be lower than the programmed temperature.

(i.e. temperature loses during loading and unloading). Cooking Curve 40%, is the most commonly used.

Cooking Curve settings from 0% (no time adjustment) to 100% (max time adjustment) are available. As a

general rule the longer the cooking time the lower the cooking curve, the shorter the cooking time the higher

the cooking curve.

Pulse Fan Function: A Fan Pulse Rate setting allows the fan to be programmed to cycle on and off at regular

intervals during the period in the cooking cycle when there is no heat applied. (The computer will not allow

the fan to be OFF whenever the heat is ON).

Steam Programming: (Optional) One Second shots of steam can be introduced at programmable intervals.

Steam is typically only used when wanting to maintain moisture or achieve a specifi c result.

Tier Cooking: “Tiered” programming is the ability to change the cooking temperature or fan

function while cooking. (i.e. some products may require high heat and the fan to be LO for the

fi rst half of the cooking cycle. Tier 1 would be programmed with the Heat up and the fan LO and Tier

2 would then be programmed with the heat lowered and the fan HI for the remainder of the cycle.)

Multiple shelf baking function is disabled when using Tier Baking programs.

Vent Programming: The vent can be programmed to be either open or closed. Most baking should be done

with the vent closed. Open the vent only with high moisture products to avoid seepage of condensed

moisture around the front of the door.

BAKING HINTS

• Always maintain a consistent cooking process. Establish a process that works for you, write it down and stick

to it. Consistency in your cooking processes is very important to the quality of your bake.

• Always weigh your product. This will give you a more consistent size, color and quality.

• Do not overload pans or space product unevenly in the pan as this will create a uneven bake.

• Bent or warped pans can greatly affect the evenness of the bake.

• Always use the oven lights to view the product through the oven door windows. Do not open the oven doors

during baking as this will change the baking characteristics and produce erratic results.

• If using baker’s parchment, be sure the parchment does not blow over the product or obstruct air fl ow in any

way. This will create a uneven bake. Never use aluminum foil in your convection oven.

• Use proper sheet pans for baking. i.e. Aluminum pans have better heat transference than steel pans and

therefore yield much better bake results.

19

Page 20

LOADING THE OVEN

• When loading the oven, stage products and racks so the oven doors are opened for the least amount

of time during the loading process to minimize the loss of heat inside the oven.

• Center each pan on the oven shelves. Spaces should be maintained equally between the pan edges

and the oven walls, front and back. This will allow for an even distribution of airfl ow. The better the

air fl ow around the product, the better and more consistent the bake.

• Load the pans on the shelves as close to equal distant apart as possible. Even vertical spacing of the

pans on shelves 1 thru 6 inside the oven is important to the proper circulation of air and therefore will

have an effect on the quality of your bake.

• When loading the oven randomly, (Different times for different shelves) load the oven from the

center shelf out with even vertical spacing.

• When loading multiple pans at the same time, load the shelves spaced as equal distant as possible with even vertical spacing.

UNLOADING THE OVEN

• Unload the top shelf before the bottom shelves. This is necessary because it is a characteristic of

all ovens that, after the fan shuts down, rising heat and the hot oven ceiling causes the top shelf to

bake quicker. This characteristic is more pronounced when baking at higher temperatures and/or for

prolonged periods of time.

• Always stage your product racks so that you can unload quickly with the door open for a minimal

amount of time. This is to preserve the temperature inside the oven cavity for your next round of

baking.

ALWAYS KEEP THE AREA NEAR THE UNIT FREE FROM COMBUSTIBLE MATERIALS.

CAUTION

KEEP FLOOR IN FRONT OF EQUIPMENT CLEAN AND DRY. IF SPILLS OCCUR,

CLEAN IMMEDIATELY TO AVOID THE DANGER OF SLIPS OF FALLS.

20

Page 21

EnviroZONE PROGRAMING

When using the EnviroZone Control Panel follow

these simple steps.

Function Keys: Are active when selecting an option

that is displayed on the LCD Screen.

Function Buttons:

Cancel: During Program Mode it will take you to

the next step, otherwise it will take you back to the

previous menu.

Up & Down: Will move you through the selections/

settings displayed on the LCD Screen which will be

used when programming your specifi c

requirements. (Example: access codes,

temperature settings, cooking time, curve , fan

speed etc.)

On/Off: Main Power Switch

Function

Keys

Function

Buttons

EnviroZONE PROGRAMING

LCD Screen

Cancel Up Down Light On/Off

IL1221

Programming Step Contents:

Step 7 Select Product Icon,

Step 8 Select Product Name,

Step 9 Select Product Temperature,

Step 10 Select Tier Cook Time,

Step 11 Select Cooking Curve,

Step 12 Select Fan Speed,

Step 13 Select Steam One Shot Seconds,

Step 14 Select Pulse Rate,

Step 15 Select Vent Start Minutes,

Step 16 Select Vent Open Minutes,

Step 18 Continue To Next Tier

Cooking Curve: Cooking curve is a programmable function that adjusts

the cooking time to compensate for planned times when the oven temperature would be lower than the programmed temperature.

(i.e. temperature loses during loading and unloading). Cooking Curve

40%, is the most commonly used. Cooking Curve settings from 0%

(no time adjustment) to 100% (max time adjustment) are available. As

a general rule the longer the cooking time the lower the cooking curve,

the shorter the cooking time the higher the cooking curve.

Pulse Fan Function: A Fan Pulse Rate setting allows the fan to be pro-

grammed to cycle on and off at regular intervals during the period in

the cooking cycle when there is no heat applied. (The computer will

not allow the fan to be OFF whenever the heat is ON).

Steam Programming: (Optional) One Second shots of steam can be in-

troduced at programmable intervals. Steam is typically only used when

wanting to maintain moisture or achieve a specifi c result.

Tier Cooking: “Tiered” programming is the ability to change the cooking

temperature or fan function while cooking. (i.e. some products may

require high heat and the fan to be LO for the fi rst half of the cooking

cycle. Tier 1 would be programmed with the Heat up and the fan LO

and Tier 2 would then be programmed with the heat lowered and the

fan HI for the remainder of the cycle.)

Multiple shelf baking function is disabled when using Tier Baking

programs.

Vent Programming: The vent can be programmed to be either open or

closed. Most baking should be done with the vent closed. Open the

vent only with high moisture products to avoid seepage of condensed

moisture around the front of the door.

21

Page 22

EnviroZONE PROGRAMING

◄ RUN OVEN

◄ TIME / DATE / PROGRAM

TIME DATE TEMP STATUS

12:00 01/01/01 325 STANDBY

Cancel Up Down Light On/Off

Step 1. Turn power switch on. If the oven

is on, press cancel until the above

screen is displayed.

Step 2. Select TIME/DATE/PROGRAM

◄ DISPLAY PRODUCT

◄ TIMER ONLY

◄ SET TIME / DATE

◄ PROGRAM COMPUTER

TIME DATE TEMP STATUS

12:00 01/01/01 325 STANDBY

Cancel Up Down Light On/Off

Step 3

Select PROGRAM COMPUTER

ENTER ACCESS CODE

A

USE ▲▼ KEYS TO SELECT

THEN PRESS ENTER

◄ ENTER

PRESS CANCEL TO QUIT

Cancel Up Down Light On/Off

Step 4 Using the ▲▼ arrows, enter

access code “A B C D E F”

hitting ENTER after each letter.

◄ PROGRAM PRODUCT

◄ EDIT READY ZONE

◄ EDIT ACCESS CODE

◄ ENABLE MANUAL PRODUCT

◄ CONFIGURE TIME OF DAY

Cancel Up Down Light On/Off

Step 5 Select PROGRAM PRODUCTS

then

Step 6 Select

CREATE NEW PRODUCTS

SELECT PRODUCT ICON

USE ▲▼ KEYS TO SELECT

THEN PRESS

ENTER TO ACCEPT

APPETIZER A

◄ ENTER

Cancel Up Down Light On/Off

Step 7 Select Product Icon,

This is the fi rst screen in creating a

product program. Press ▲▼ until

you fi nd a icon which resembles

your product.

Select ENTER to accept the icon

and move to the next screen.

SELECT PRODUCT NAME

APPETIZER A

USE ▲▼ KEYS TO SELECT

APPETIZER A

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 8 Select Product Name,

This is where you enter the name

of the product into the computer.

Using the ▲▼ keys type over the

default name, blank space is before

the A and after the 9.

Select ACCEPT to continue.

Note: Curser must be moved past the last

digit to save the entire entry.

22

Page 23

EnviroZONE PROGRAMING

SELECT PRODUCT TEMP

100

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 9 Select Product Temperature,

Press the ▲▼ to select the fi rst

digit, then press ENTER to move

to the next digit. It will

automatically move to the next

screen after the third digit.

SELECT TIER COOK TIME

00:45:00

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 10 Select Tier Cook Time,

Time is entered in

hours:minutes:seconds.

The maximum is 12:59:59.

Select ENTER to move the cursor

to the place you want to enter the

number.

Select ACCEPT to continue.

SELECT COOKING CURVE

000%

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 11 Select Cooking Curve,

press ▲▼ to select the numbers,

press the ENTER to move the

cursor to the next space.

Cooking Curve may be any

number between 0% and 100%.

Select ACCEPT to continue.

SELECT FAN SPEED

HIGH LOW

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

COOKING CURVE: 80%

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 12 Select Fan Speed,

Press the ▲▼ to move the curser

between the HIGH and LO

settings.

Press ENTER to make your

selection and move to the next

screen.

Steam One Shot Seconds

00

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

FAN: HI

CCURVE: 80%

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 13 Select Steam One Shot Seconds,

Press the ▲▼ to select the fi rst

digit, then press ENTER to move

to the next digit.

Select ACCEPT to continue.

23

SELECT PULSE RATE

100%

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

FAN: HI

CCURVE: 80%

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 14 Select Pulse Rate,

Press the ▲▼ to select the fi rst

digit, then press ENTER to move

to the next digit. It will automatically move to the next screen after

the third digit.

Page 24

EnviroZONE PROGRAMING

Select Vent Start Minutes

000

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

FAN: HI RATE: 100%

CCURVE: 80%

BOTH STEAM: 03, 050

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 15 Select Vent Start Minutes,

Press the ▲▼ to select the fi rst

digit, then press ENTER to move

to the next digit. It will automatically move to the next screen after

the third digit.

Select ACCEPT to continue.

Select Vent Open Minutes

000

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

FAN: HI RATE: 100%

CCURVE: 80% Vent: 4, 1,

BOTH STEAM: 03, 050

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 16 Select Vent Open Minutes,

Press the ▲▼ to select the fi rst

digit, then press ENTER to move

to the next digit. It will automatically move to the next screen after

the third digit.

Select ACCEPT to continue.

YES NO

CORRECT?

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

FAN: HI RATE: 100%

CCURVE: 80%

BOTH STEAM: 03, 050

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 17 Correct

The computer is asking if the

display is correct. If any part of

the program is incorrect press ▲▼

NO, and you will be taken back to

Step 7.

Selecting YES will advance the

screen.

CONTINUE TO NEXT TIER

YES NO

USE ▲▼ KEYS TO SELECT

APPLE

TIER 1

TEMP: 320°F TIME: 00:45:00

FAN: HI RATE: 100%

CCURVE: 80%

BOTH STEAM: 03, 050

◄ ACCEPT

◄ ENTER

Cancel Up Down Light On/Off

Step 18 Continue To Next Tier

The cursor automatically appears

on NO. Select ENTER or

ACCEPT to end programming

or

move the curser ▲▼ to YES.

This will allow your to enter another tier to this program, repeating steps 6 - 14 to program second

tier.

◄ CREATE NEW PROGRAM

◄ EDIT PRODUCT

◄ DELETE PROGRAM

◄ EDIT PROGRAM

Cancel Up Down Light On/Off

Step 19 After programing the last tier, the

computer will automatically advance the screen to program more

products. If no other products

need to be programmed, select

CANCEL three times to advance

screen to the boot up screen.

24

◄ RUN OVEN

◄ TIME / DATE / PROGRAM

TIME DATE TEMP STATUS

12:00 01/01/01 325 STANDBY

Cancel Up Down Light On/Off

Step 20 Boot-up Screen

You may now preheat the oven

for any product you have programmed.

Step 21 Select RUN OVEN

Page 25

AIR PROVING

SWITCH 1

L

K

J

I

1

37

FLAME

SENSOR

51

54

BURNER

DRAFT

INDUCER

MOTOR 1

DI2

N

IGNITER

2

AIR PROVING

SWITCH 2

51

37

54

TO OTHER OVEN

DRAFT

INDUCER

MOTOR 2

DI2

N

S1

52

L1

30

L2

S2

53

3

4

DRAFT

INDUCER

(MOUNTED ON

TOP OF OVEN)

NOTE: DRAFT INDUCER USED

FOR SINGLE AND DOUBLE OVENS.

THEREFORE, ON SINGLE OVEN

ONLY ONE DRAFT INDUCER AND AIR

PROVING SWITCH IS USED.

10

F1

51

F2

30

R

5

REV. DATE/ECO DESCRIPTION OF CHANGE DR

B 12/21/2006

C

D

6

12/5/2007

ECO# 6361

2/12/2008

ECO# 6582

REVISIONS

ADDED CAPACITOR P/N REF (AID

ADDED NOTE AND UPDATED T1 WIRING

ADDED R TERMINAL AND JUMPER TO

7

MANUFACTURE)

FOR CLARIFICATION

IGNITION CONTROL

GND

8

SN

L

LRC

LRC

120 VAC 1 PHASE

A

N

K

A

19

N

F7

15A

24

MR1

SC15

10

PUR

20

PUR

YEL

21

YEL

J

13

MR2

MR3

11

RED

Fan

Motor

N

WHT

BLK

D

12

LAMP1

CAPACITOR

(P/N 40704-14)

I

PS

54

123

C

LAMP2

LAMP3

LAMP4

N

4

T1

24 VAC CT

H

N

G

W

37

GAS

VALVE

H

55

34

37

55

34

MV1

GND

IGNITION

CONTROL

15

LR1

10

NOTE: ON TRANSFORMER T1,

CONNECT 1 (BLK) & 3 (BLK-RED)

TOGETHER TO WIRE 10. CONNECT

2 (BLK-YEL) & 4 (BLK-WHT)

30

G

34

TOGETHER TO WIRE N.

37

GND

SW2

46

F

BACK-UP SWITCH

31

32

F

BACK-UP SWITCH

35

30

36

E

CONTROL CIRCUIT BOARD

D

36

46

32

C

38

15 PIN OUTPUT CONNECTOR

PIN 1

PIN 2

PIN 3

10 PIN INPUT

CONNECTOR

PCB

PIN 1

PIN 2

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

PIN 9

PIN 10

30

39

36

35

41

42

36

43

PIN 11

BACK-UP T-STAT

SW4

47

BACK-UP

SW2

SWITCH

35

35

SW6

SW3

34

45

37

38

MR2

SW1

MR1

LR1

BACK-UP STEAM

SWITCH

SV1

OVER TEMP

SWITCH

MOTOR RELAY

- RUN

DOOR SWITCH

MOTOR RELAY FWD/REVERSE

LIGHT RELAY

WATER SOLENOID

E

D

C

B

A

Manufacturing

Company

RTD

1

DWN. BY :

DESCRIPTION:

CAD FILE :

HJP

146-799-11.SLDDRW

2

PIN 7

PIN 8

DWN. DATE : 8/10/05

WD GCSF ENVIROSTAR 120V

DWG. NO:

3

2M-146-799-11

PIN 12

PIN 13

PIN 14

PIN 15

4

SPARE

48

SPARE

SHEET

5

B

32

MR3

OF

1

REV:

1

C

6

HI/LOW SPEED

7

A

8

Page 26

AIR PROVING

SWITCH 1

L

1

DRAFT

INDUCER

MOTOR 1

DI2

2

AIR PROVING

SWITCH 2

DRAFT

INDUCER

MOTOR 2

DI2

3

DRAFT

INDUCER

(MOUNTED ON

TOP OF OVEN)

NOTE: DRAFT INDUCER USED

FOR SINGLE AND DOUBLE OVENS.

THEREFORE, ON SINGLE OVEN

ONLY ONE DRAFT INDUCER AND AIR

PROVING SWITCH IS USED.

4

5

REV. DATE/ECO DESCRIPTION OF CHANGE DR

D

6

2/6/2008

ECO# 6567

REVISIONS

REDRAWN & REVISED B/U SWITCH

WIRING; ADDED R AND 32 JUMPER

120 VAC 1 PHASE

A

N

7

GND

8

LRC

L

K

37

51

54 N

37

54

51

TO OTHER OVEN

N

COOLING FAN

A

24

CF1

19

N

K

F7

15A

SC-

MR1

15

20

J

I

H

FLAME

SENSOR

GAS

VALVE

BURNER

55

34

IGNITER

D

37

30

52

32

53

54

37

55

34

S1

L1

L2

S2

PS

W

MV1

GND

IGNITION

CONTROL

F1

F2

R

10

51

32

D

10

MR2

PUR

13

MR3

15

LR1

PUR

11

RED

BLK

12

LAMP1

LAMP2

LAMP3

LAMP4

Fan

Motor

21

YEL

YEL

N

WHT

CAPACITOR

(P/N 40704-14)

N

J

I

N

H

10

D

BACK-UP SWITCH

SW2

G

64

12

0 VAC

T1

24 VAC CT

F

60 46

62

30

12

0 VAC

T2

24 VAC CT

32

G

F

60

E

46

E

62

35

36

CO

46

D

NTROL CIRCUIT BOARD

BACK-UP

T-STAT

SW4

36

60

JP2

JP40

39

36

JP13

C

JP11

38

JP15

SW7

33

JP35

DOOR SWITCH #2

JP14

35

36

41

36

42

36

43

35

35

36

B

GP3

RTD

JP21

JP1

GP4

JP12

GP4

44

36

48

SW2

BACK-UP SWITCH

47

SW2

BACK-UP

SWITCH

SW6

34

GND

SW3

45

MR2

BACK-UP STEAM

SWITCH

37

SW1

MR1

LR1

SV1

VS1

MR3

OVER TEMP

SWITCH

MOTOR RELAY

- RUN

DOOR SWITCH #1

MOTOR RELAY FWD/REVERSE

LIGHT RELAY

WATER SOLENOID

VENT SOLENOID

32

HI/LOW SPEED

D

C

B

GP3

A

Manufacturing

Company

DWN. BY :

DESCRIPTION:

CAD FILE :

1

HJP

FROM SOLIDWORKS

DWN. DATE : 8/10/05

WD OCG ENVIRO ZONE 120V

DWG. NO:

2

3

146-799-13

GND

SHEET

4

5

OF

1

REV:

1

D

6

7

8

A

Page 27

Page 28

45

76

2

131

22

3

19

18

18

20

70

23

69

75

4

1

14

128

9

119

119

125

86

87

21

85

IL1313 Rev. - 3/28/07

MODEL:

GCSF Main Exterior Assy

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

Page 29

111

110

68

59

15

77

143

144

73 74

42

60

16

107

138

6261

63 64

Burner & Heat Exchanger

132

65

106

82

133

Circulation Fan

100

101

99

Interior Lights

89

90

Thermostat

11

11

12

109108

Temp Probe

IL1312 Rev. A 6/10/08

MODEL:

GCSF Main Interior Assy

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

Page 30

IL1316 Rev. - 3/28/07

MODEL:

GCSF-ES Control Panel Assy (EnviroSTAR)

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

129

117

30

115

24

104

79

35

37

38

39

130

40

33

34

26

93

137

98

140

40

95

94

71

31

113

Page 31

116

25

117

30

37

38

39

80

102

35

36

103

105

130

40

33

34

93

27

131

91

137

95

97

40

94

98

31

113

IL1315 Rev. - 3/28/07

MODEL:

GCSF-EZ Control Panel Assy (EnviroZONE)

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

Page 32

51

52

135

46

55

47

48

134

83

53

54

136

136

88

84

50

49

IL1317 Rev. - 3/27/07

MODEL:

GCSF Draft Inducer Assy

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

Page 33

72

44

43

109 108

139

17

119

119

123

123

118

126

10

120

124

121

78

66

122

13

96

92

67A

67

56

58

130

57

81

EnviroZone Only

29

114

32

28

127

EnviroZone Only

5

8

7

EnviroZone Only

6

7

EnviroStar Only

IL1319 Rev. - 3/28/07

MODEL:

GCSF Below Skin Level Assy

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L. INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

Page 34

Description

Per

Quantity

Part

Number

Fig

GCSF-ES, GCSF-EZ Gas Full Size Convection Oven Parts List

49 Q9-146-426-1 1 INDUCER MOTOR BRACKET ALL

50 Q9-146-426-2 1 INDUCER FAN ADAPTER PLATE ALL

No.

51 Q9-146-427-1 1 INDUCER COVER ALL

Description

52 Q9-146-428 1 INDUCER COVER FRONT ALL

53 Q9-146-430-1 1 INDUCER AIR FLOW SENSING ALL

54 Q9-146-431-1 1 AIR FLOW SENSING TUBE ALL

55 Q9-146-432 1 INDUCER HOLD DOWN CLIP ALL

56 Q9-146-490 1 CTRL PANEL COOLING FAN BRKT GCSF-EZ

57 Q9-146-491 1 CTRL PANEL COOLING FAN MOUNT GCSF-EZ

58 Q9-146-493 1 CTRL PANL FAN BTM DEFLECTOR GCSF-EZ

59 Q9-146-720-2 1 INTAKE COVER ASSY-OCG ALL

60 Q9-146-728 1 HEATR MODULE WELDMENT ASY ALL

61 Q9-146-729 1 BURNER ASSY-NATURAL GAS GCSF-NAT

62 Q9-146-729-2 1 BURNER ASSY - PROPANE GCSF-LP

63 Q9-146-730 1 SQ. ORIFICE TUBE ASY - NG GCSF-NAT

64 Q9-146-730-2 1 SQ. ORIFICE TUBE ASY - GCSF-LP

65 Q9-146-736 1 MOTOR BRACKET WELD ALL

66 Q9-146-737-1 2 WATER INLET ASSY ALL

67 Q9-146-738 1 WATER INLET ASSY ALL

67A 2K-70101-04 1 BRAS TBE ELBW 3/8NPTM-3/8 ALL

68 Q9-146-740 1 STEAMER ASSY ALL

69 Q9-146-745 1 DOOR ASSY LH ALL

70 Q9-146-750 1 DOOR ASSY RH ALL

71 Q9-146-762 1 BUZZER ASSY ALL

72 Q9-146-765 1 STACKING VENT ASSY ALL

73 Q9-146-775-11 1 DRAFT INDUCER ASSY SINGLE ALL

74 Q9-146-775-21 1 DRAFT INDUCER ASSY DOUBLE ALL

75 Q9-146-776 1 BODY SIDE ASSY RH W/AVK ALL

76 Q9-146-778 1 BODY BACK W/AVKS ALL

77 2C-20112-03 4 SCRW THUMB 1/4-20X1/2 SS ALL

78 2C-20119-01 1 EYEBLTFORGD/SHLDR1/4-20X1 ALL

79 2A-20501-05 4 SPCR FBR 1/4 OD #6 ID 1/4 ALL

80 2A-20504-02 4 SPACER NYLON #6 1/4 X 1 GCSF-EZ

Per

Quantity

81 2U-30200-45 1 MTR W/FAN AXIAL 115VAC70C GCSF-EZ

82 2U-30200-68 1 MOTOR OCG 120V ALL

83 2U-30200-70 1 MOTOR OCG VENT FAN ALL

84 2U-30200-71 1 FAN AXIAL 60MMX30MM 115V ALL

85 2E-30301-19 1 SWT MIN. LEVER ACTUAT ALL

86 2E-30303-16 1 SWT TOG ON-ON BLK MOM ALL

87 2E-30303-26 1 SWITCH 3PDT GCSF-ES

2E-30303-27 1 SWT TOGGLE ON-ON 4PDT GCSF-EZ

88 2E-30308-08 1 AIR SWITCH .1 WC ALL

NI = NOT ILLUSTRATED

Part

Number

Fig

No.

1 Q9-146-102-1 1 RIGHT REAR CORNER ALL

2 Q9-146-103-21 1 BODY TOP - OCG ALL

3 Q9-146-104 1 BODY LEFT SIDE ALL

4 Q9-146-105-01 1 RH SIDE ACCESS COVER ALL

6 Q9-146-126-1 1 BOTTOM POWER VENT E-S ALL

7 Q9-146-127 1 TOP POWER VENT ALL

9 Q9-146-149-1 1 BACKUP CONTROL BRACKET ALL

10 Q9-146-150 1 WATER SOLONOID BRACKET ALL

11 Q9-146-160 2 PROBE HOLDER ALL

12 Q9-146-161 1 PROBE CLAMP ALL

13 Q9-146-162 1 SERVICE ENTRANCE BOX ALL

14 Q9-146-163 1 SERVICE ENTRANCE COVER ALL

15 Q9-146-165-1 1 BURNER ACCESS COVER ALL

16 Q9-146-212 1 IGNITOR & SENSOR BRACKET ALL

17 Q9-146-230 1 GAS VALVE BRACKET ALL

18 Q9-146-316 2 DOOR GASKET SIDES ALL

19 Q9-146-317 1 DOOR GASKET TOP ALL

20 Q9-146-318 1 DOOR GASKET BOTTOM ALL

21 Q9-146-322 1 DOOR SWITCH BRACKET ALL

22 Q9-146-330 1 HINGE COVER TOP ALL

23 Q9-146-331 1 HINGE COVER BOTTOM ALL

24 Q9-146-350 1 CONTROL PANEL - ENVIROSTAR GCSF-ES

25 Q9-146-350-1 1 CONTROL PANEL - ENVIROZONE GCSF-EZ

26 Q9-146-351 1 COMPONENT MOUNT ENVIRO ALL

30 Q9-146-356 1 COVER CONTROL PANEL DOOR ALL

31 Q9-146-357 1 BACK UP DOOR HINGE ROD ALL

33 Q9-146-359 1 RELAY CLAMP ALL

34 Q9-146-360 1 RELAY CLAMP BASE ALL

35 Q9-146-361 1 PC BOARD HEAT SHIELD ALL

36 Q9-146-362 1 PC BOARD PROTECTOR ALL

37 Q9-146-363 1 COMPONENT WIRE COVER ALL

38 Q9-146-363-1 1 TRIMLOCK 8.750 ALL

39 Q9-146-363-2 1 TRIMLOCK 7.500 ALL

40 Q9-146-364 2 COMPONENT WIRE COVER CLIP ALL

41 Q9-146-404 2 STACKING CLIP ALL

42 Q9-146-405 1 VENT COVER ALL

43 Q9-146-408 1 VENT PASSTHROUGH UPPER ALL

44 Q9-146-409 1 REAR PANEL STANDOFF ANGLE ALL

45 Q9-146-413 1 ACCESS PANEL - MOTOR ALL

46 Q9-146-423-1 1 INDUCER INSULATION PLATE ALL

47 Q9-146-424-1 1 INDUCER INSULATION COVER ALL

48 Q9-146-425-1 1 INDUCER FAN BEZEL ALL

Rev. C 4/05/2010

Page 35

Description

Per

Quantity

Part

Number

Fig

GCSF-ES, GCSF-EZ Gas Full Size Convection Oven Parts List

126 2V-70403-05 1 SOLENOID WATER ALL

128 Y9-70701-17-1 1 KNOB 450o B PHANTOM ALL

No.

129 2R-70701-45-1 2 BKKNOB RED TOP 6MM W/D GCSF-ES

Description

130 2K-70801-04 3 SNAP BUSH 3/4 SB750-10 GCSF-ES

130 2K-70801-04 5 SNAP BUSH 3/4 SB750-10 GCSF-EZ

131 2K-70801-08 1 SNAP BUSH 1 3/4 SB1750-22 ALL

132 2U-71500-16 1 FAN - NCO 16 IN ALL

133 2U-71500-17 1 FAN - NCO 6 IN ALL

134 2U-71500-18 1 FAN - OCG COOLING FAN ALL

135 2U-71500-19 1 BLOWER WHEEL OCG INDUCER ALL

136 2C-71700-03 1 HOSE CLAMP 1/2 ALL

137 PS-SK-W1353 1 KIT, SERVICE GCSF MODULE ALL

138 2J-80302-13 1 IGNITER 1325-1425'C - OCG ALL

139 2V-80505-18 1 GAS VALVE - OCG ALL

140 Q9-EH-502-1 1 TRIMLOCK 4 ALL

141 9Q-GCSF-IK-1 1 INSTALL KIT-SINGLE OVEN ALL

142 9Q-GCSF-IK-2 1 INSTALL KIT-DOUBLE OVEN ALL

143 2C-20204-02 4 WASHER SS 1/4 SPLIT LOCK ALL

144 2C-20109-15 14 SCRW PHD MS SS 10-32X1/2 ALL

NI 2P-73000-09 1 SPROCKET 5/8 BORE NO/KEY ALL

NI 2E-30500-09 1 TRM BLOCK 3 POLE SMALL 95 ALL

NI 2J-40301-50 4 SOCKET CONTACT FEMALE ALL

NI Q9-146-727 1 HEATER MODULE-NATURAL GCSF-NAT

NI Q9-146-727-2 1 HEATER MODULE-PROPANE GCSF-LP

NI Q9-146-213 1 SQUARE ORFICE TUBE-NATURAL GCSF-NAT

NI Q9-146-213-2 1 SQUARE ORFICE TUEB-PROPANE GCSF-LP

INSTALLATION KIT

NI Q9-60101-96 1 SINGLE CONNECTION MANIFOLD KIT

NI PS-SK1463633 1 DRAFT INDUCER NOISE REDUCTION SERVICE KIT

NI PS-SK-W1352 1 GCSF SUBBERS / RELAY SERVICE KIT

Per

Quantity

NI = NOT ILLUSTRATED

Part

Number

Fig

No.

89 Q9-30401-30-2 1 SWT KIT STAT FXD 550 DEG ALL

91 2E-30500-08 1 TRM BLOCK 2 POLE SMALL 95 GCSF-EZ

92 2E-30500-09 1 TRM BLOCK 3 POLE SMALL 95 ALL

93 2E-30701-05 4 CONTC 2POLE 30A 24VAC P & ALL

94 2E-30900-10 2 FUSE 15AMP 300V (SC-15) ALL

95 2E-30901-12 1 FUSE HOLDER 600V 2 POLE ALL

96 2E-31200-02 1 LUG GROUNDING UL APPROVED ALL

98 2E-31400-34 1 XFORMR 120-240/25.2VAC CT ALL

99 2S-31602-08-2 4 LMP GLBE SP FR31602-08@09 ALL

100 2S-31602-09 4 LAMP FIXTURE RANGE W/130V ALL

101 2S-31602-09-1 4 130V BULB {FOR 31602-09} ALL

102 2J-40102-25 1 DSPLY 302X240 DB170-001 GCSF-EZ

103 2J-40102-51 1 CIRBD FILTER GCSF-EZ

104 2J-40102-W64 1 CONTROL - OCE/OCG GCSF-ES

105 Q9-40102-70 1 MAIN BOARD, OCE/OCG GCSF-EZ

106 2E-40704-14 1 CAP 7.5 MFD 370VAC ALL

107 2E-41100-36 1 SENSOR FLAME PROBE OCG ALL

108 2E-41100-38 1 SENSOR TEMP ECSF/GCSF GCSF-ES

2E-41100-41 1 SENSOR TEMP ECSF/GCSF GCSF-EZ

110 2B-50200-103 2 RACK SLIDE OCE/OCG ALL

111 2B-50200-20 6 RACK ECCO/GCCO OVEN ALL

112 Q9-50312-02-1 2 DOOR CHAIN AND TURNBCKL ALL

113 2P-51001-19 1 SPRING SWT DR HINGE EHS ALL

114 2P-51001-38 1 SPRING VENT ALL

115 2M-60301-162 1 LABEL PANEL OCE/G ENVIROSTAR GCSF-ES

116 2M-60301-166 1 LABEL PANEL OCE/G ENVIROZONE GCSF-EZ

117 2M-60301-169 1 LABEL OCE ACCESS DR W/BUP ALL

118 2K-70101-03 1 BRASTBEELBOW 1/4NPT-3/8CC ALL

119 2K-70101-12 1 BRAS TBE ELBW 3/8CC-1/2 ALL

120 2K-70101-54 1 BRAS TBE UNION 3/8CCX1/4 ALL

121 2K-70302-36-1 1 PIPE NIPPLE 3/4NPT X 8BLK ALL

122 2K-70302-53 1 PIPE COUPLING 3/8X1-3/16 ALL

123 2K-70303-03 1 PIPE COUPLING 1/4 NPT ALL

124 2K-70305-05 1 PIPE 90o ELBOW 3/4 BLK ALL

125 2V-70402-07 1 VALVE MANUAL GAS 1/2X1/2 ALL

Rev. C 4/05/2010

Page 36

STAR MANUFACTURING

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(800) 807-9054 (314) 781-2777

Parts & Service (800) 807-9054

www.star-mfg.com

Loading...

Loading...