Page 1

Page 2

HLP-NV Series

Page 3

Page 4

HLP-NV Series

I. Introduction 2

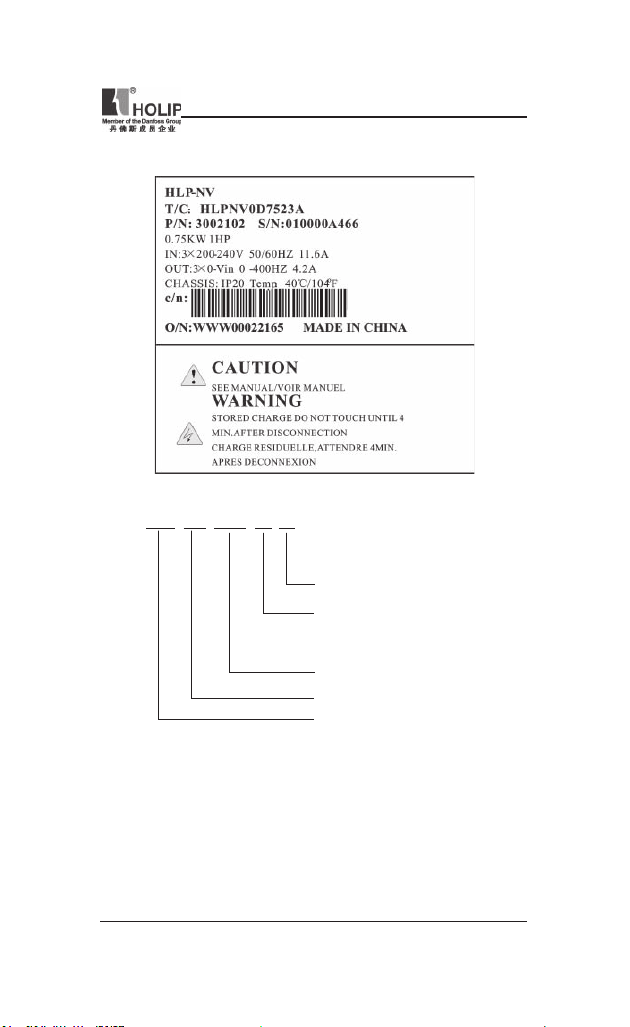

1. Checks upon Deliver y 3

2. Nameplate Desc ription of HLP-NV Series I nvert er 3

II. Safety Pre cautions 5

1. Before the Power-up 5

2. Dur ing the Power-up 6

3. Duri ng the Operat ion 6

4. Afte r the Power-off 7

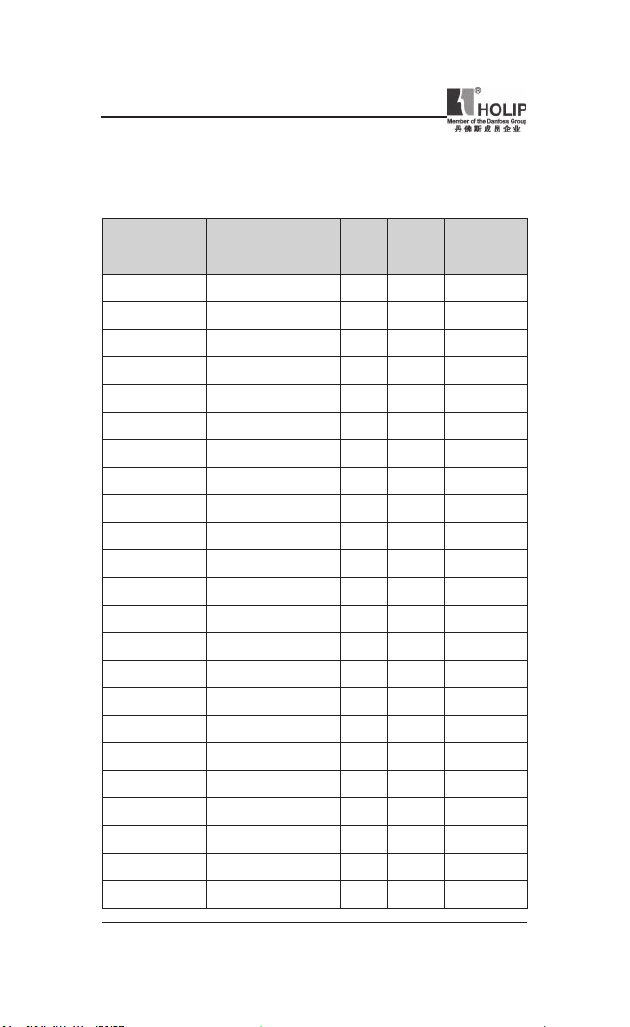

III. Standards and Specicat ions 8

1. Particular Specications 8

2. General Specications 9

IV. Storage and Instal lation 11

1. Storage 11

2. Inst allat ion Site and Environment 11

3. Insta llation and Direction 11

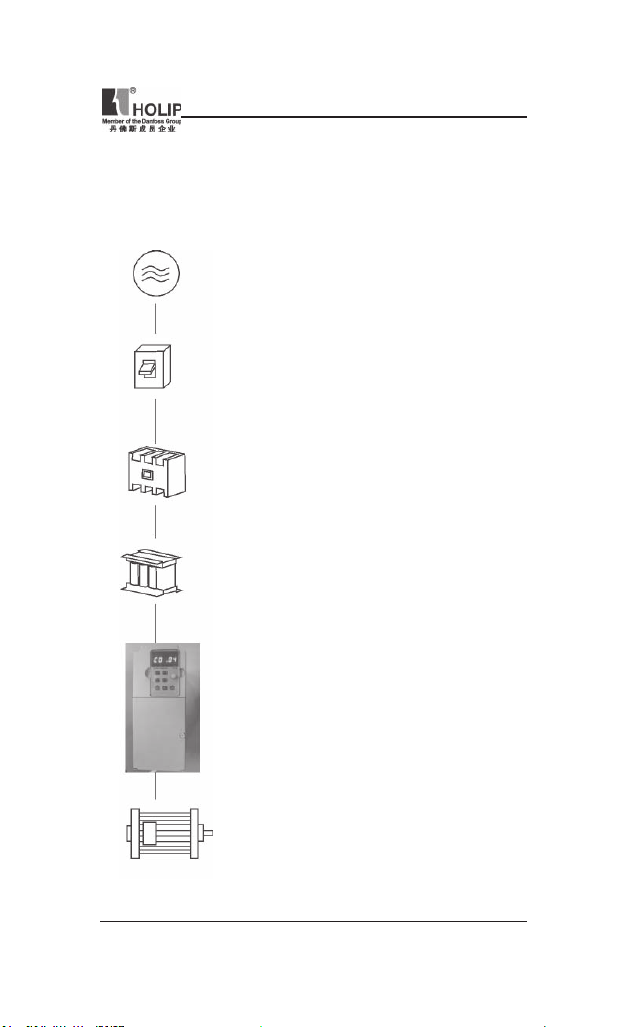

V. Wiring 12

1. Main Circuit Wiring Schematic Diagram 12

2. Description of Terminal Block 13

3. Basic Connection Diagram 15

4. Switches 15

5. Precaut ions on Wiring 16

VI. Instruc tion of the LCP Digital Operator 19

1. Description of the LCP Digital Operator 19

2. Programming with LCP 19

VII. Parameter Overv iew 25

VIII. Parameter Descriptions 37

IX. Ma intena nce, Fault I nformat ion and Trouble shooting 90

1. Precautions about Inspection and Maint enance 90

2. Periodical In spection and Ma inten ance items 90

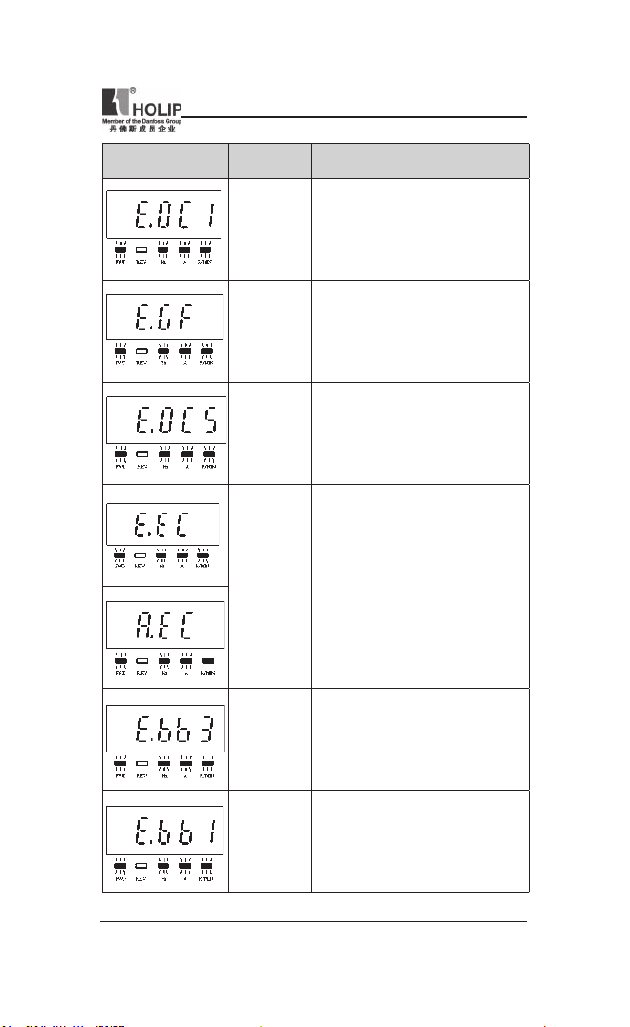

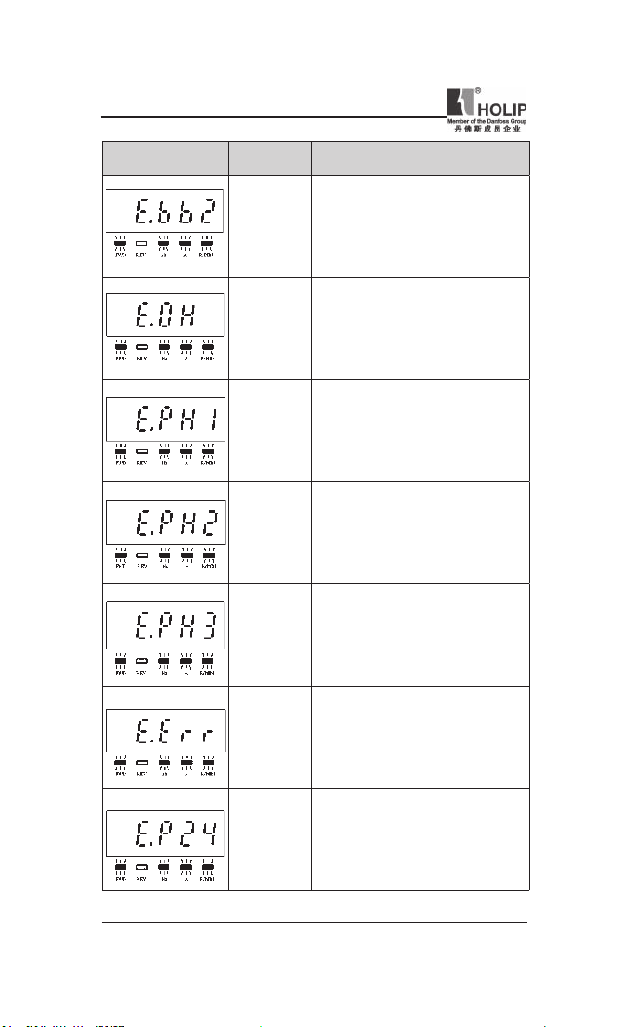

3. Fault Indication and Troubleshooting 91

3. Fault code descript ion and Analysis 92

HLP-NV Series

Page 5

HLP-NV Series

IX. Appendices 96

Append ix 1: Mounti ng Dime nsions of HOLI P NV inverters 96

Append ix 2: Mount ing Dimensions of LCP Digit al oper ator 98

Append ix 3. Braking Resistor Disposition 98

Append ix 4. Simple Example of Appl iaction 99

Append ix 5:User’s feedback 106

HLP-NV Series

Page 6

HLP-NV Series

I. Introduction

Than k you for purchas ing and using the gen eral- purp ose inver te r of

HLP-NV series of mu lti-functions and high performance.

Please read caref ully the operation m anual before putt ing the i nvert er to

use so as to correctly install and operate t he inverter, give f ull play to its

functions and ensure the safety. Please keep the operation manual handy

for future reference, maintenance, inspe ction and repai r.

Due to th e invert er of a k ind of ele ct rica l and elect ronic pr od uc t it

must be in sta lled, tested and adjust ed with parameters by specia lized

engineeri ng persons of motor s.

The ma rk s of

remind you of the s afet y and prevention caut ions d uring the handling,

inst allat ion, runn ing and inspection. Please follow t hese instructions to

make su re the safe use of the inver ter. In case of any doubt please contact

our local agent for consult ation. Our professional persons are w illing and

ready to serve you.

The manual is subject to change without notice.

Danger

Caution

and ot her sy mb ols in the ma nu al

Danger

Caution

indicates wrong use may k ill or injure people.

in di ca te s wro ng us e may damage the in ve rte r or

mechan ical system.

Danger

● Be sure to tur n off the input power supply before wiring.

● Do not touch any internal electrical circu it or component when the

charging lamp is sti ll on af ter t he AC power supply is disconnected,

which means the inver ter still has high voltage inside and it is very

dangerous.

● Do not check components and sig nals on the circuit boards dur ing

the operation.

● Do not dissemble or modify any internal con nect ing cord, wiring or

compone nt of the inverter by yourself.

● Be sure to make correct ground con nection of the earth terminal of

the inverter.

● Never remodel it or excha nge control boa rds and compon ent s by

yourself. It may expose you to an electrical shock or explosion, etc.

HLP-NV Series

- 1 -

Page 7

HLP-NV Series

● Mo t or ov er lo ad prote cti on is inc lu ded in the defau lt set tin gs.

Parameter C01.90 Motor thermal protection is set to value ET R trip.

● Do not ma ke any vol ta ge-withstand ing test with any co mpone nt

ins ide the inverter. These sem i-cond uct or parts are subj ect to th e

damage of high voltage.

● Ne ve r connect th e AC m ain ci rc ui t powe r supply to th e out put

terminals U.V W of the inver ter.

● The main electric circuit boards of CMOS and IC of the inverter are

subject to the ef fect and d amage of st atic electricity. Don’t touch the

main ci rcuit boards.

● Installation, t esting and maintenance must be perfor med by qu alied

professional personnel.

● The inverter should be discarded as industrial waste. It is forbidden

to bur n it.

1. Checks upon Delivery

Th e inver ter has bee n str ictl y and well pa ck ed befo re ex-wo rk . In

co ns id er atio n of var io us fa ctor s d u rin g the tra nsp or tat io n spe ci al

attention should be paid to the followi ng points before the assembly and

installation. If there is anything abnor mal please notify the dealer or the

relevant people of our company.

● Check if the i nver ter has got any damage or defor mat ion during t he

transpor tation and handling.

● Check if the re is one piece of HLP-N V ser ies inverter and one copy of

the instruction manual ava ilable when unpacking it.

● Check the inform atio n on the n ameplate to see if the spe cif icat ions

meet your order (Operating voltage and KVA value).

● Check i f there is somethi ng wrong with the i nne r par ts, wir ing and

circuit board.

● Check if each te rm inal is tightly locked an d if there is a ny foreign

article inside the inver ter.

● Check if t he operator buttons are all rig ht.

● Check if t he option al components you ordered are conta ined.

● Check if t here is a ce rti cate of qu alication and a warr anty card.

Caution

- 2 -

HLP-NV Series

Page 8

HLP-NV Series

2. Nameplate Description of HLP-NV Series Inverter

Model HLP N V 0D75 23 A

Software Version: A

Voltage Rating: 21:1-Phase AC 220V

23:3-Phase AC 220V

43:3-Phase AC 380V

Inverter Capacity:0 D 75 mean s 0.75KW

Serial No: NV mean s NV ser ies

Trade Mark: HOLIP

HLP-NV Series

- 3 -

Page 9

HLP-NV Series

II. Safety Precautions

1. Before the Power-up

● Check to be sure t hat the voltage of the main circuit AC power supply

matches the input voltage of the i nverter.

● The symbol

correct ground con nection of the earth terminals of the motor and the

inverter for safety.

● No conta ctor should be inst alled betwee n the power supply and the

inverter to be used for star ting or stopping of the i nvert er. Otherwise

it will affect the serv ice life of the inverter.

● R(L), S,T( N) ter mi nals are powe r input ter minal s, never mixed

with U.V.W t erm inals. Be sure that the wiri ng of the main circuit is

cor rec t. Other wise it will cau se damage s of the inve rt er when the

power is appl ied to it.

● The terminal of

to li ne zero. Otherw ise it will easily cause the prote ction or er rors of

the inverter.

, repr esents grou nd te rmi na ls . Be su re to ma ke

Danger

must be grou nded separately and never connect ed

Caution

● Do not ca rr y t he front cover of the inver ter directly when handling.

It should be hand led with the base to prevent the fall-off of the f ront

cover and avoid the dr opp ing of the inve rt er, which may pos sibly

cause the injur ies to pe ople and the damages to the i nvert er.

● Mount the i nver ter on a met al or other nonc ombustible mater ial to

avoid the risk of re.

● Insta ll the inverter in a safe loc ation, avoid ing hig h tempe rat ure,

direct sunlight, hu mid ai r or water.

● Kee p the inv erte r fro m th e re a ch of chi ldr e n or pe r so ns not

concer ned.

● The in ve r te r can only be use d at the pla ce s acc redit ed by our

com pa ny. Any unau th or iz ed work ing envi ronment may have th e

risks of re, gas explosion, ele ctric shock and other incidents.

● Install a he at sink or other cooling device when inst alling more than

one inverter in the same enclosure so that t he temperature in side t he

enclosu re be kept below 40℃ to avoid overheat or the risk of re.

Caution

- 4 -

HLP-NV Series

Page 10

HLP-NV Series

● Be su re to tu r n of f t h e po we r s up ply bef o re d i sse mbl i n g or

assembl ing the operation key panel a nd xing the front cover to avoid

bad cont act causing faults or non- display of the oper ator.

● Do not in stall the inverter in a space with explosive gas to avoid the

risk of explosion.

● If the i nvert er is used at or above 1000m above seal level, the cooli ng

efciency will be worse, so please run it by de-rating.

● Do not install any c ontactor and other comp onents of cap acit or or

var istor on the o utp ut side of the inverter. Other wise it will cau se

malfunctions and damages of components of the inverter.

● Do not ins tall any switch co mp on en t like ai r cir cu it brea ke r or

cont actor at t he output of the i nverter. If any of such components

mu st be ins t al led beca use of t he req uir e me nts of pro ces s and

others, it must be ensu red that the inverte r has no out put when the

swit ch acts. In addit ion, it is forbidden to install any c apacitor for

improvement of power factor or any varist or agai nst thunder at t he

output. Othe rwise it will cause malfunctions, tr ipping protection a nd

damages of components of the inverter. Please remove them as shown

in the below diagr am.

● It wi ll affect the service life of the inverter if a contact is connected

to the front end of input of the inver ter t o cont rol its starts and st ops.

Generally it is re qu ir ed to cont rol it thr ou gh Con trol term inal s.

Special attention should be p aid t o its use in the case of frequent

star ts and stops.

● Pleas e use an indep ende nt powe r supply for the i nver ter. D o avoid

using the common power supply with an electrical welder and other

equipme nt wi th st ro ng di st urbance. Ot herwise it wi ll ca us e the

protection or even d amage of t he inver ter.

HLP-NV Series

- 5 -

Page 11

HLP-NV Series

2. During the Power-up

● Do not plug the conne ctors of the inve rter du ri ng the power up to

avoid any surge i nto the main control board due to pluggi ng, which

might cause the damage of the inverter.

● Always have the protective cove r in place before the power up to

avoid electrical shock injur y.

Danger

3. During the Operation

● Never c onnect or discon nect the motor set while the inverter is in

run ning. O ther wise it will cause over-current trip and even bur n up

the mai n circu it of the inverter.

● Never rem ove th e fr ont cover of the inverter w hile the inve rt er is

powered up to avoid any inju ry of electric shock.

● Do not come close to the machine when the fault resta rt fu nction is

use d to avoid any thing unexp ect ed. The m otor may automa tic ally

resta rt af ter its stop.

● The f unction of STOP Swit ch is on ly valid af ter set ti ng, which is

different with the use of emergent stop switch. Please pay attention to

it when usi ng it.

Danger

● Do not touch the heat sink, braking resistor, or other heat elements.

Caution

These can become very hot.

● Be sure that the motor and m achine is withi n the applicable spe ed

ranges before sta rting operat ion because the inver ter is quite easy to

run f rom lower speed to higher sp eed.

● Do not check the sign al s on ci rcuit bo ar ds wh ile the inve rt er is

run ning to avoid danger.

● Be caref ul when changing the inver ter settings. The inverter has been

adju sted and set before ex-work . Do not a djust it wanton ly. Please

make proper adjustments according to the requ ired f unct ions.

● Do consider the vib ration, noise an d the speed limi t of the motor

bearings and the mechanical devices whe n the inverter is ru nni ng at

or above the f requency of 50Hz.

- 6 -

HLP-NV Series

Page 12

HLP-NV Series

4. After the Power-off

● Touching t he electrical parts may be fatal - even afte r the equipment

ha s been disco nn ec ted f rom mains. Also ma ke su re th at ot he r

voltage input s have been disconnected, (li nkage of DC intermediate

circuit).

● Be aware that there may be high volt age on the DC lin k even when

the LEDs a re tu rned of f.

● Before touching any potentially live parts of the VLT Micro, wait at

least as follows:

200 - 240 V, 0.4 – 1.5 kW: wait at lea st 4 minutes.

380 - 480 V,0.75 – 2.2 kW: wait at least 4 minutes.

Shor ter time is allowed only if indicated on the nameplate for t he

specic unit.

HLP-NV Series

- 7 -

Page 13

HLP-NV Series

III. Standards and Specications

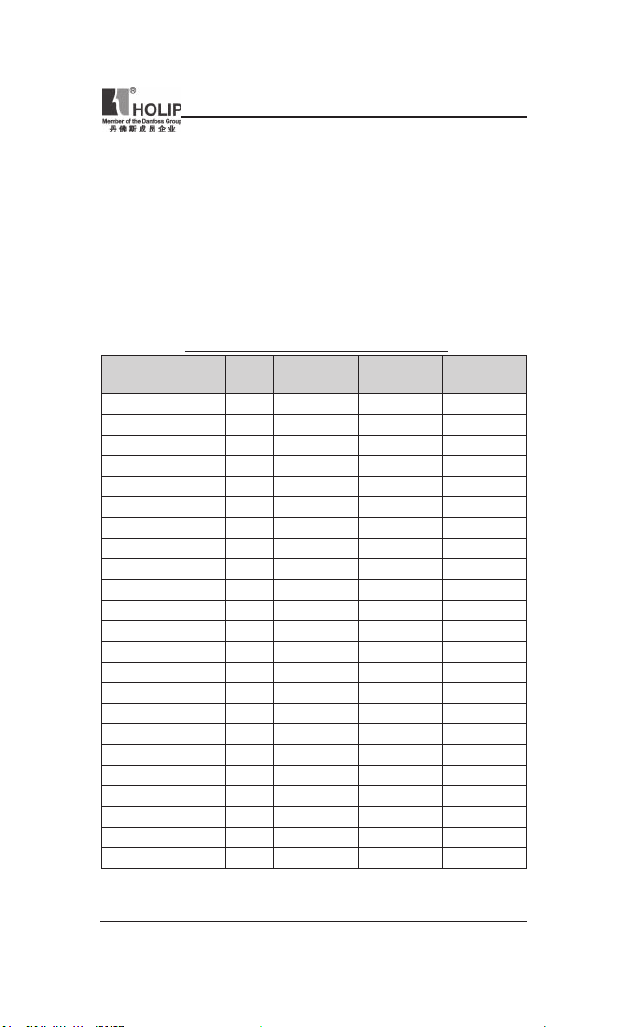

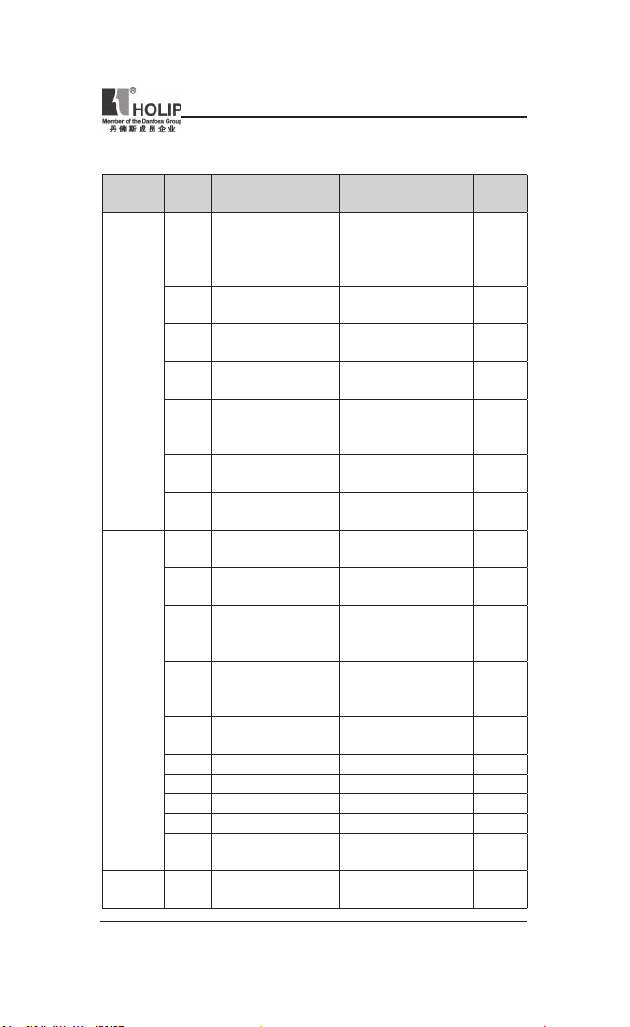

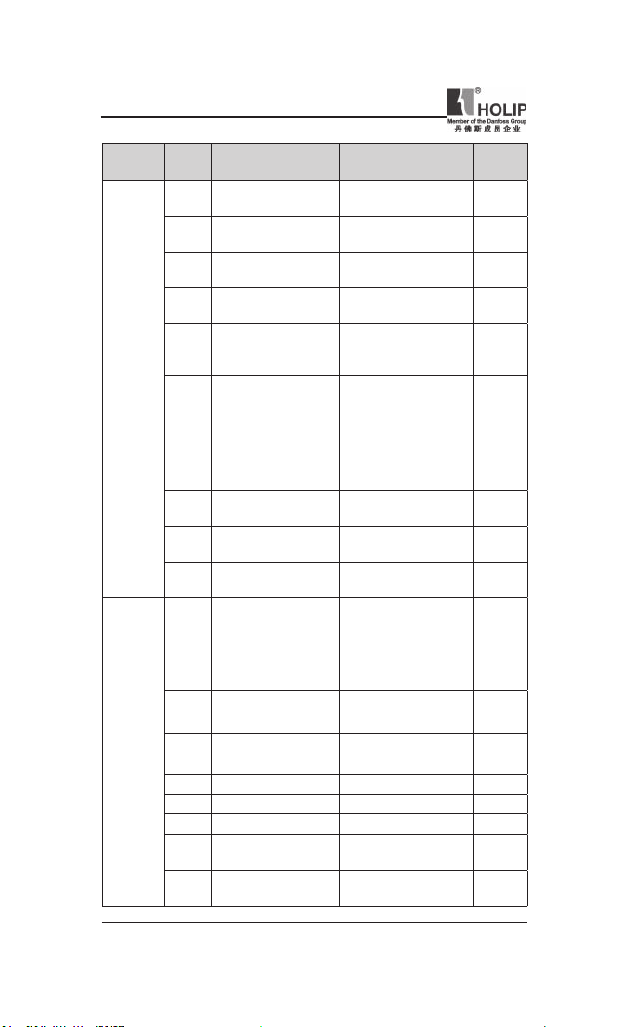

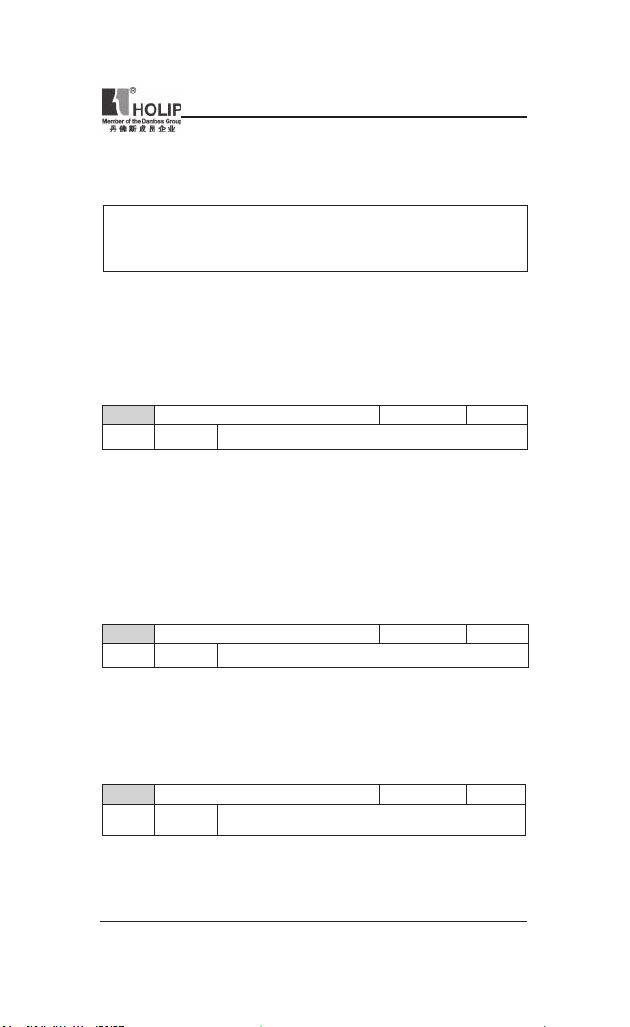

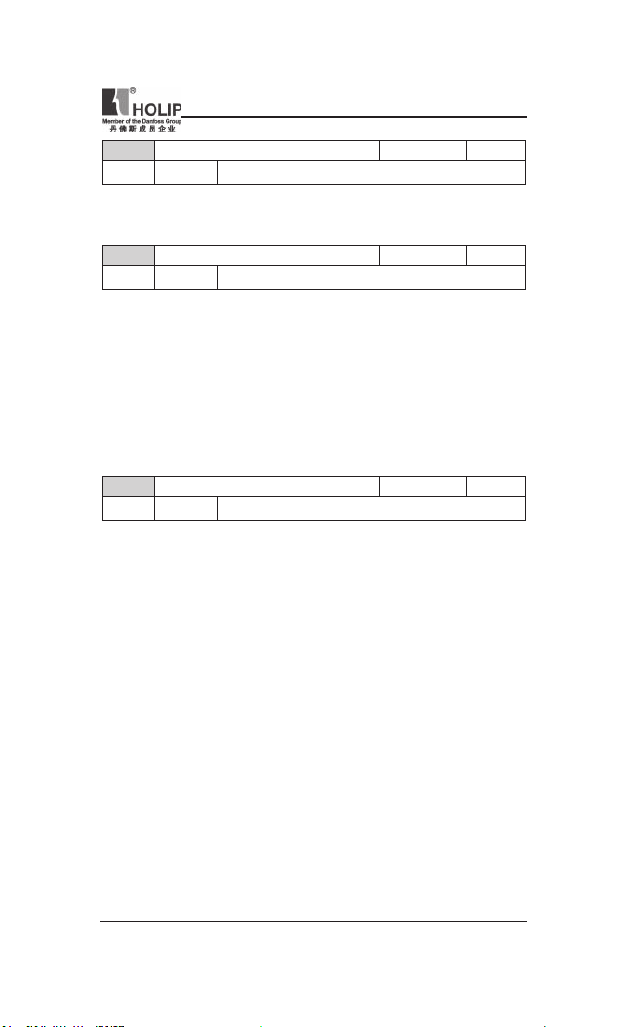

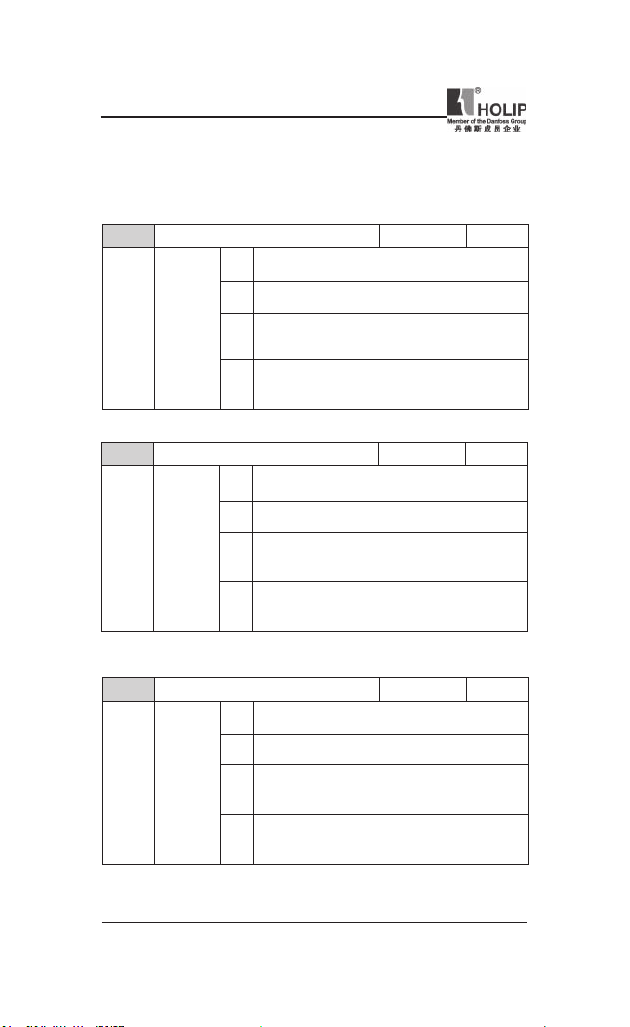

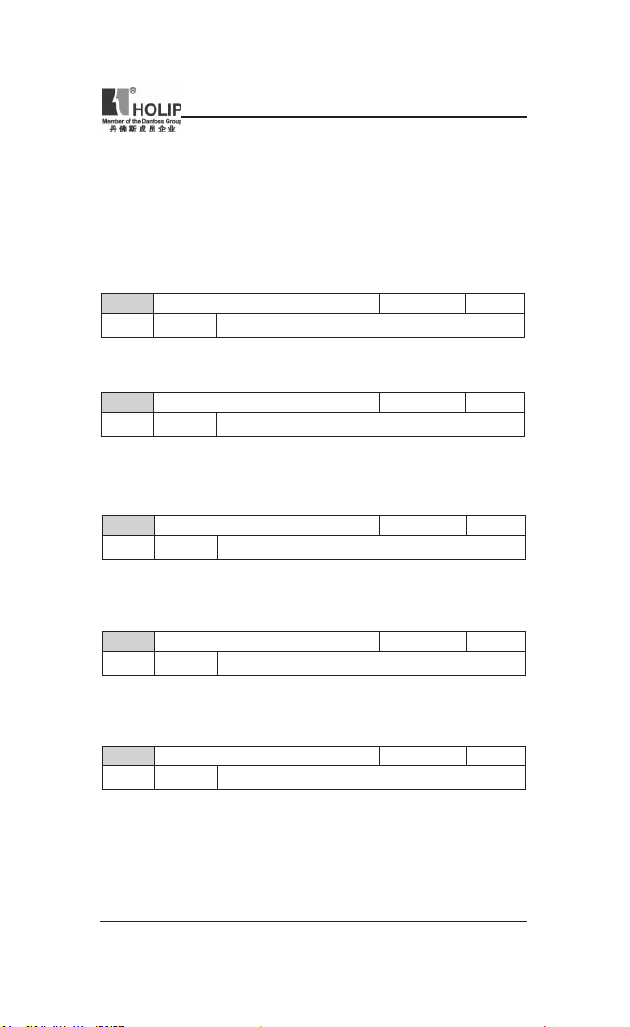

1. Particular Specications

Outp ut

Model Input Voltag e

HLPN V0D1821A 1×200-240V 50/60H z 0.18 1.2 0.18

HLPN V0D3721A 1×200-240V 50/6 0Hz 0.37 2.2 0.37

HLPN V0D7521A 1×200-240V 50/60 Hz 0.75 4.2 0.75

HLPN V01D521A 1×200-240V 50/60Hz 1.5 6.8 1.5

HLPN V02D221A 1×200-24 0V 50/60Hz 2.2 9.6 2.2

HLPN V0D2523A 3×200-240V 50/60Hz 0.25 1.5 0.25

HLPN V0D3723A 3×200-24 0V 50/60Hz 0.37 2.2 0.37

HLPN V0D7523A 3×200-24 0V 50/60Hz 0.75 4.2 0.75

HLPN V01D523A 3×200-240V 50 /60Hz 1.5 6.8 1.5

HLPN V02D223A 3×200 -240V 50/60Hz 2.2 9.6 2.2

HLPN V03D723A 3×200-24 0V 50/60Hz 3.7 15.2 3.7

HLPN V0D3743A 3×380-480V 50/60Hz 0. 37 1.2 0.37

HLPN V0D7543A 3×380-48 0V 50/60Hz 0.75 2.2 0.75

HLPN V01D543A 3×380-480V 50/60Hz 1.5 3.7 1.5

HLPN V02D243A 3×380- 480V 50/60Hz 2.2 5.3 2.2

HLPN V03D043A 3×380- 480V 50/60Hz 3.0 7.2 3.0

HLPN V04D043A 3×380- 480V 50/60H z 4.0 9.0 4.0

HLPN V05D543A 3×380-480V 50/60Hz 5.5 12 5.5

HLPN V07D543A 3×380- 480V 50/60Hz 7.5 15.5 7.5

HLPN V001143A 3×380-48 0V 50/60Hz 11 23.0 11

HLPN V001543A 3×380 -480V 50/60Hz 15 31.0 15

HLPN V18D543A 3×380-480V 50 /60Hz 18.5 37.0 18.5

HLPN V002243A 3×380-480V 50/60 Hz 22 43.0 22

Power

(KW)

Cur rent

(A)

Suitable

Motor

(KW)

- 8 -

HLP-NV Series

Page 14

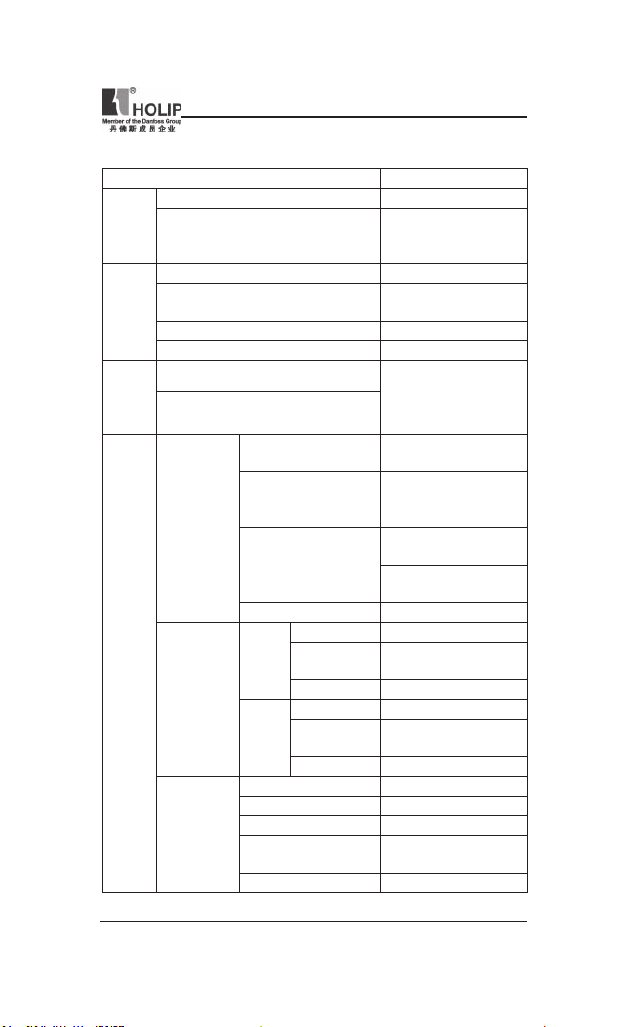

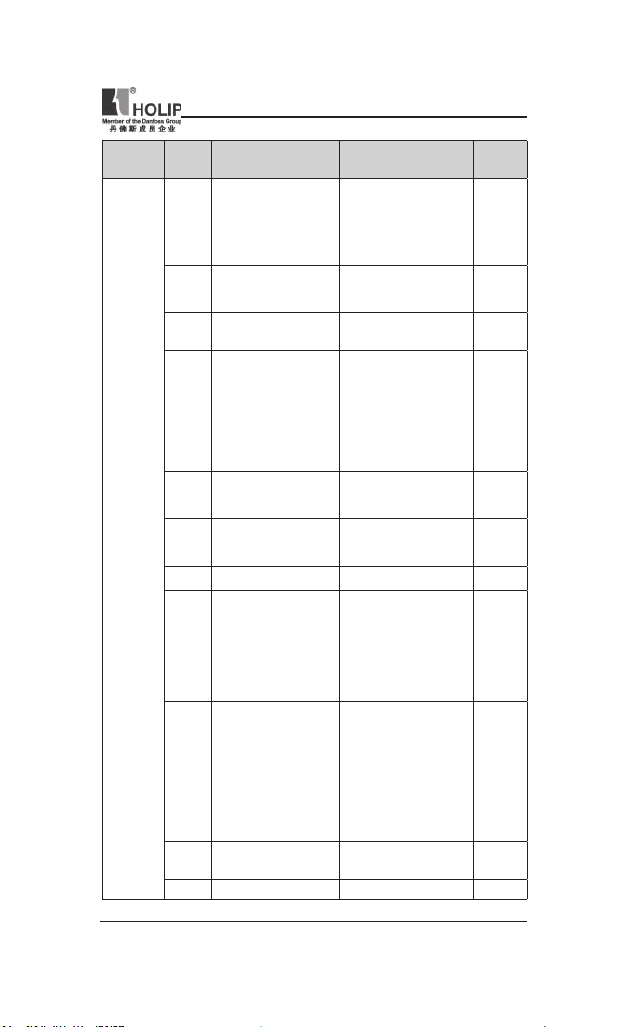

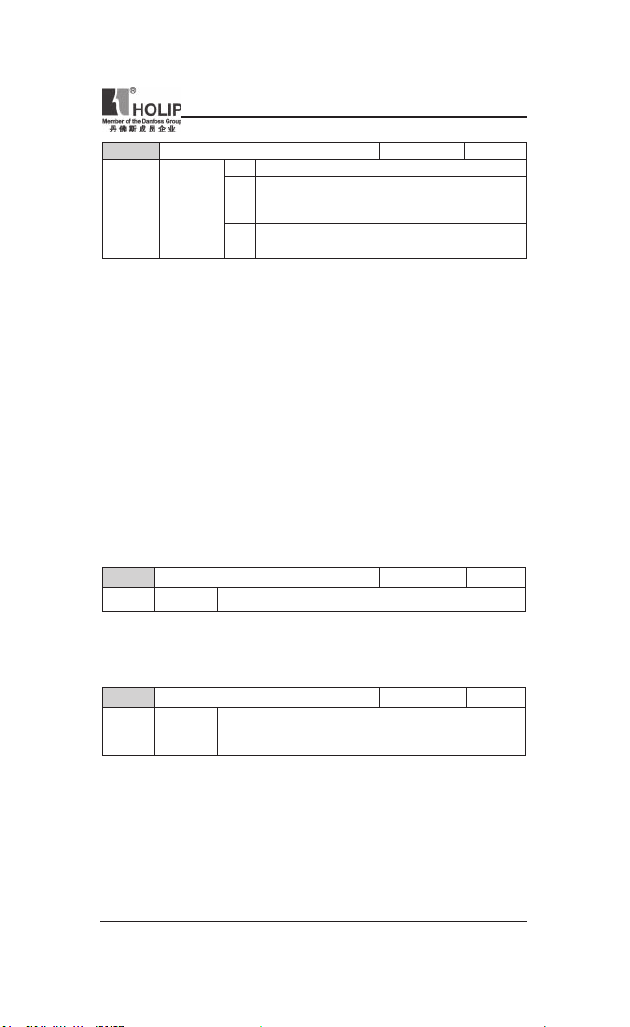

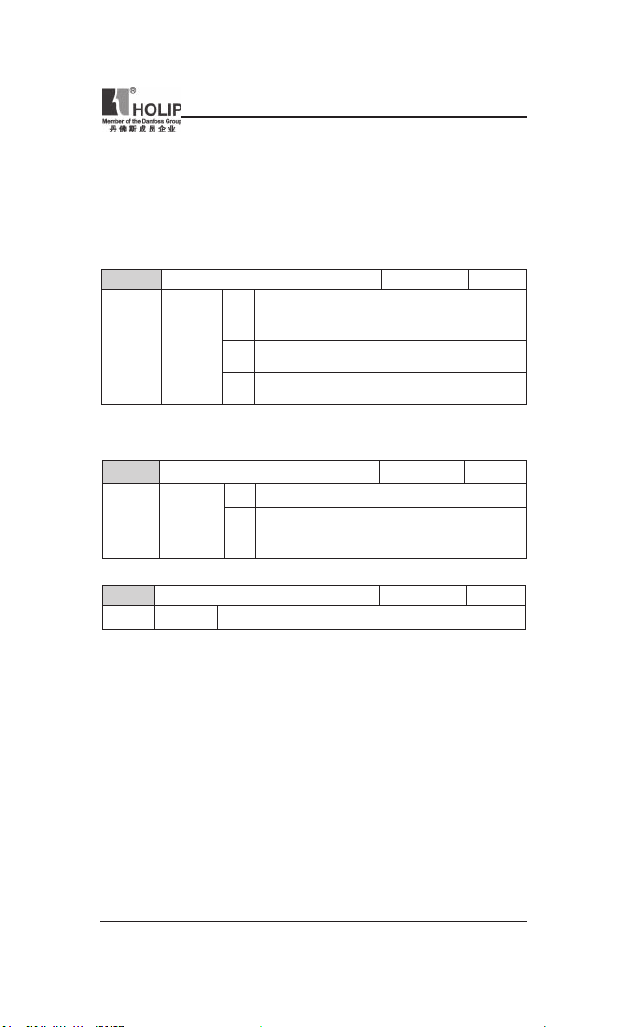

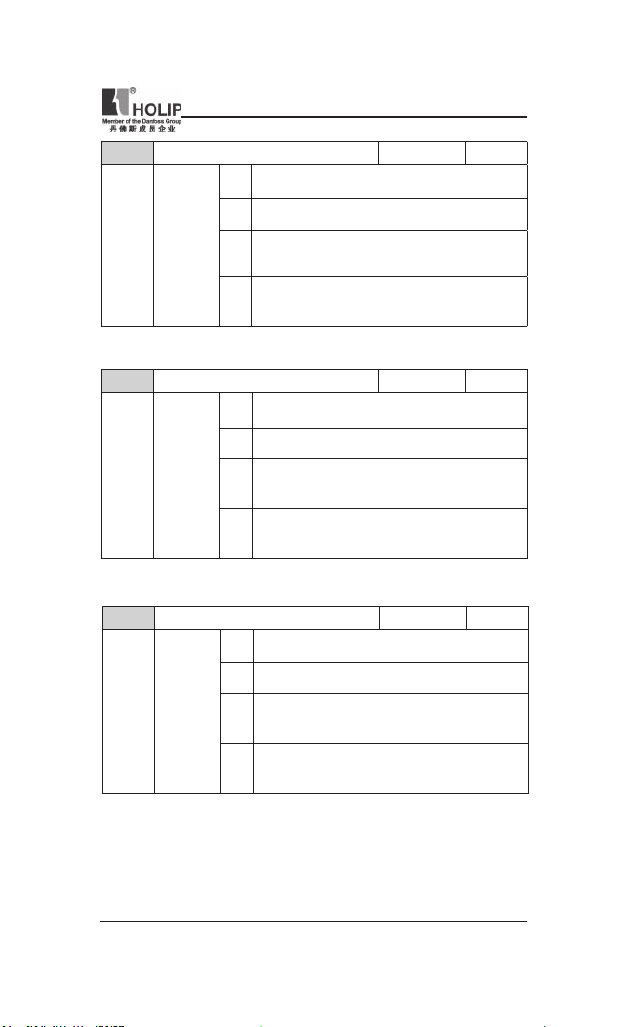

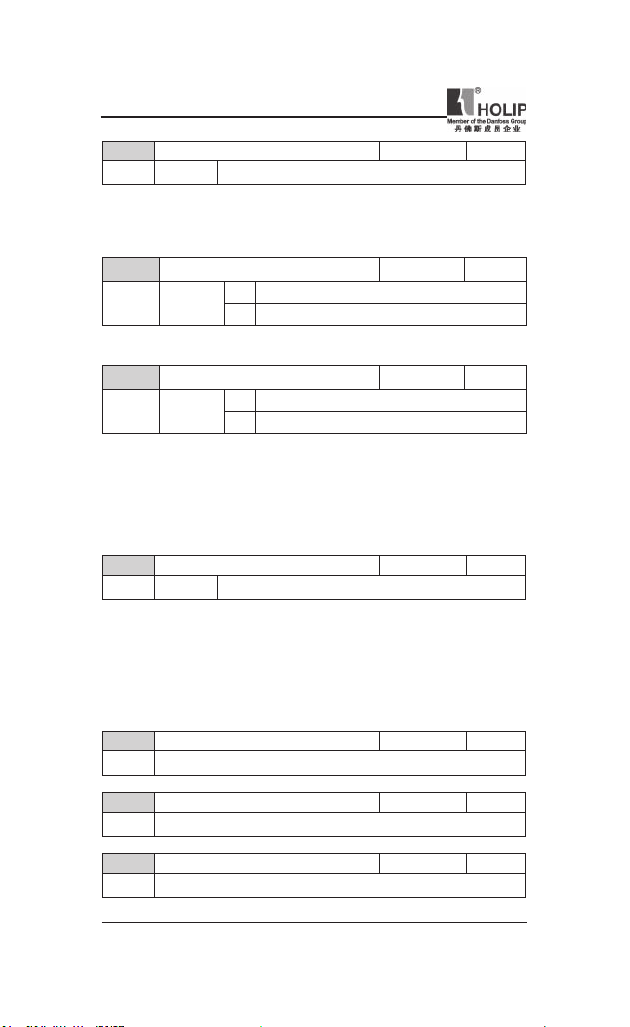

2. General Specications

Inverter Ser ies H LP-NV

Frequency 48~62HZ

Power

supply

Supply Voltage

Output voltage 0~100% of supply volt age

Output frequency

Motor

output

Over load 150% of rated cu rrent

Acc/De c time 0.05~3600s

Runn ing control

Control

Frequency sett ing

Number

Progr ammable

digital inputs

Control

terminals

Anology

inputs

Anology

output s

Voltage level

Logic Voltage level

Input resistance 4KΩ

Number 1;ter minal nos.: VI N

Voltage

Voltage level

Input resistance 10KΩ

Number 2; ter minal nos.: VI N,AIN

Cur rent

Cur rent ra nge

Input resistance 200 Ω

Number 1;Te rmi nal nos.: AO

Output Cur rent ra nge 0/4-20mA

Max.Load 500 Ω

Accuracy

Resolution 8bit

380~480V±10% for 380V

single/three phase

200~240V±10% for 220V

0-200H Z(V VC+),

0-400HZ(V/F)

LCP operate;

Multi input ter minals;

RS 485 ser ial

commu nication

5, term inal nos.: RUN

F/R,RST,JOG,EMS

0~24V DC (“PN P” OR

“NPN ”) ; Maximum

input: 28V DC

PNP: “0”<5VDC;

“1”>10VDC;

NPN: “0” >19VDC;

“1” <14VDC

0-10V DC ;

Maximum input 20V DC

0/4-20mA(scaleable);

Maximum input: 30mA

Max.er ror:0.5% of full

scale

HLP-NV Series

;

,

HLP-NV Series

- 9 -

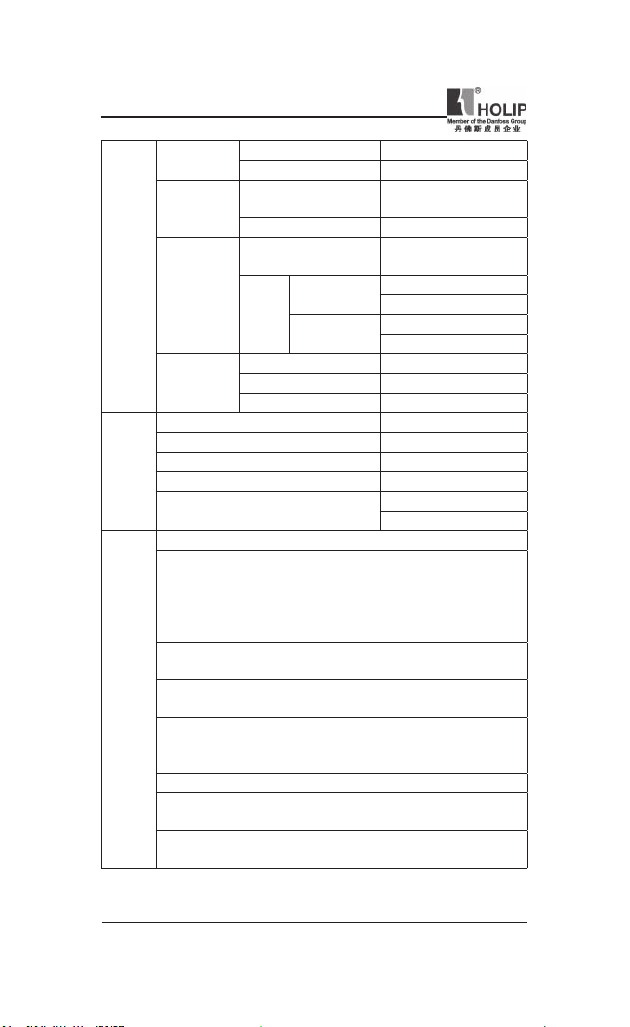

Page 15

HLP-NV Series

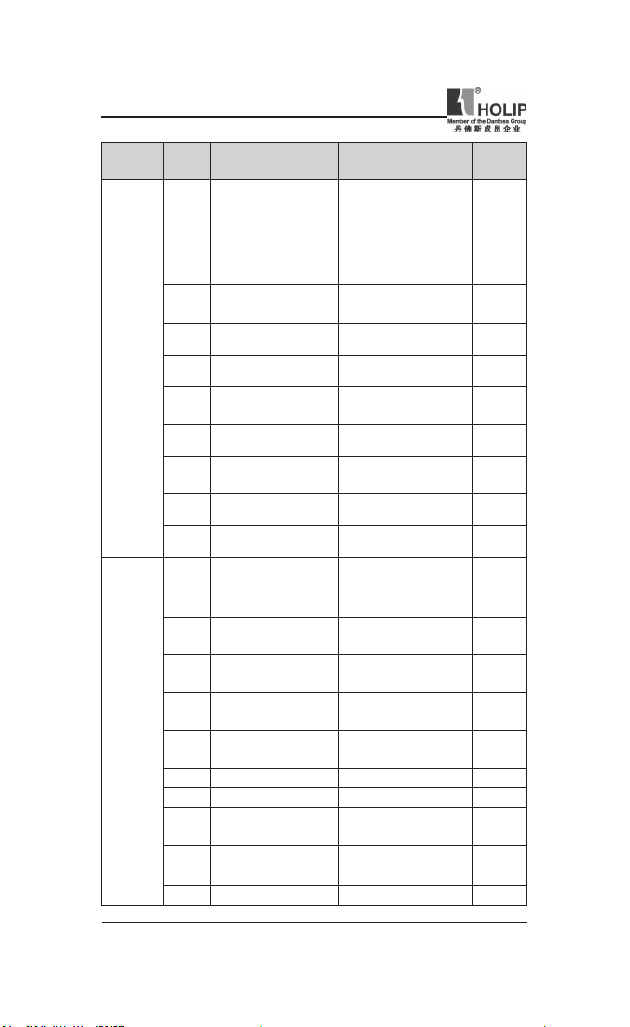

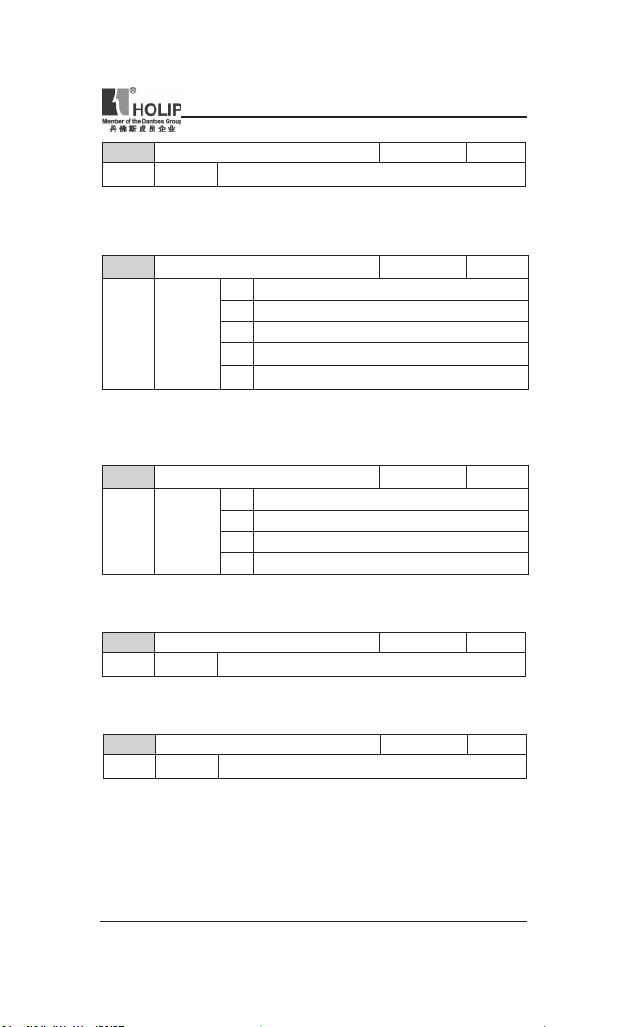

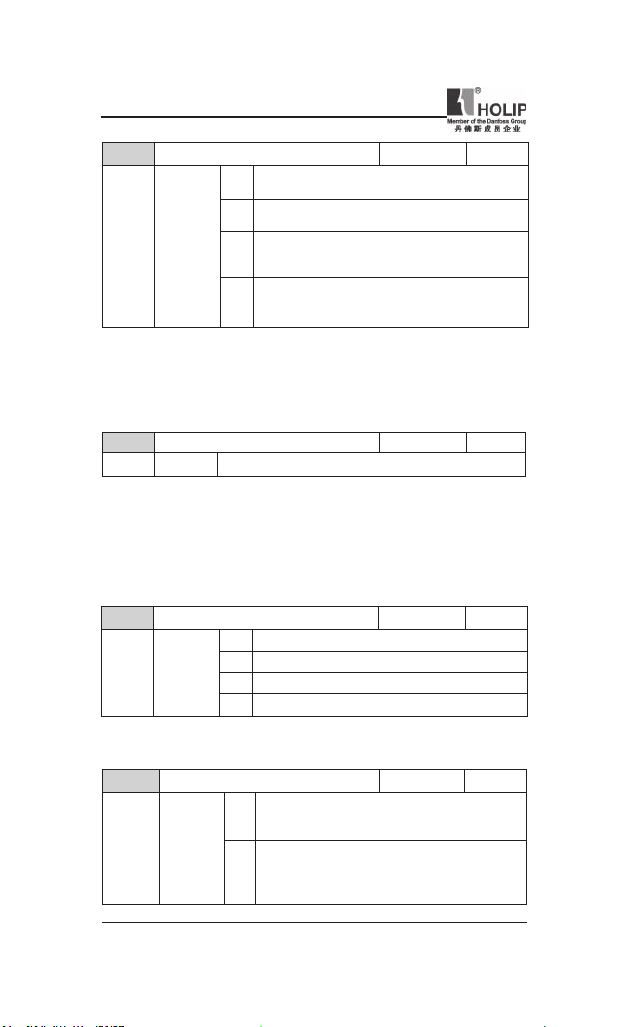

24V DC

RS 485

Control

terminals

Realy out pus

10V DC output

Enclosure IP20

Ambient temper ature -10℃~50

Max.relative hum idity 5%-95%

Surroundings

Vibration test 1.0g

Max.altitude above sea level

Electronic the rmal motor prot ection against overload.

Temperature monitoring of the heatsink ensures that the fre quency

converter tr ips if the temperatu re reaches 95 °C ± 5°C. An overload

temperatu re can not be reset until the temperature of t he heatsink

is below 70 °C ± 5°C (Guideline - these temperatures may vary for

different power si zes, enclosures etc.).

The frequency converter is protected against short-circuits on motor

terminals U, V, W.

The frequency converter is protected against ear th faults on motor

Protection

terminals U, V, W.

Functions

Monitor ing of the inter mediate circuit voltage ensures that t he

frequency conve rter trips if the intermediate circuit voltage is too low

or too hig h.

If a motor phase is missing, the frequency converter may tr ip.

If mains fault occurs, the frequency converter will ramp down to stop

and issues a war ning.

If a mains phase is missing, the frequency conver ter trips or issues a

warn ing (dependingon the load).

Terminal number EV

Max.load 200m A

Terminal number

Ground for RS485 COM

Terminal number

Resistive load

Max

load

Inductive load

Terminal number +10V

Output voltage 10.5±0.5V

Max.load 25mA

RS+(TX+,RX+),

RS- (T X-,RX-)

1,FA-FB(make),

FA-FC(break)

250V AC 2A

30V DC 2A

250V AC 0.2A

24V DC 0.1A

1000m

3000m(derati ng)

℃

- 10 -

HLP-NV Series

Page 16

HLP-NV Series

IV. Storage and Installation

1. Storage

The invert er mu st be kept in its or iginal package box before in stallation.

Pay at tention to the followings when keeping it in storage if the inver ter

is not used for the time being:

● It must be stored in a d ry pla ce without rubbish or dust.

● The suitable temperat ure for storage is between -20℃ and +65℃.

● The relative humidity required is 0-95% without condensation.

● There is no corrosive gas or l iquid in t he storage ambience.

● It’s better to lay the inverter on a rack and keep it in a proper package.

● It is better not to store the inverter for long time. Long t ime storage of

the inver ter wil l lead to the deterioration of electrolytic capacity. If it

needs to b e stored for a long ti me make sure t o power it up one time

withi n a year and t he power-up ti me should be at least above ve hours.

When powered up t he voltage must be increased slowly with a voltage

regulator to the rated volt age value.

2. Installation Site and Environment

The inverter should be instal led at the following location:

● Ambient temper ature -5℃ to 40℃ with good ventilation.

● No water d rop and low moisture.

● Free from direct sunshine, h igh temperat ure and heavy dust fall.

● Free from corrosive gas or liquid.

● Less dust, oil gas and metallic pa rticles

● Free from vibration and easy for ser vice and inspection.

● Free from the interference of elect romag netic noise.

Attention : The ambient condit ions of the invert er will aff ec t its

service life.

3. Installation and Direction

● Th er e mu st be en ou g h sp ace lef t ar ound the inv er te r for eas y

maintenance and cooling.

● The inverter must b e installed vertically wit h the smooth ventilation

HLP-NV Series

- 11 -

Page 17

HLP-NV Series

for effect ive cooling.

● If t here is a ny instabi lity when installi ng t he inverter, please put a at

board u nder the invert er bottom base and inst all it again. If the inverter

is installe d on a loose surfa ce, st ress may cause damage of part s in the

main ci rcuit so as to damage the inverter.

● The inverter should be in stalled on non-combustible mater ials, such as

iron plat e.

● If sever al inver ters are inst alled , up per an d lower, toget her in one

cabine t, pleas e add heat dissipation pla tes and lea ve enoug h space

between the inverters.

- 12 -

HLP-NV Series

Page 18

V. Wiring

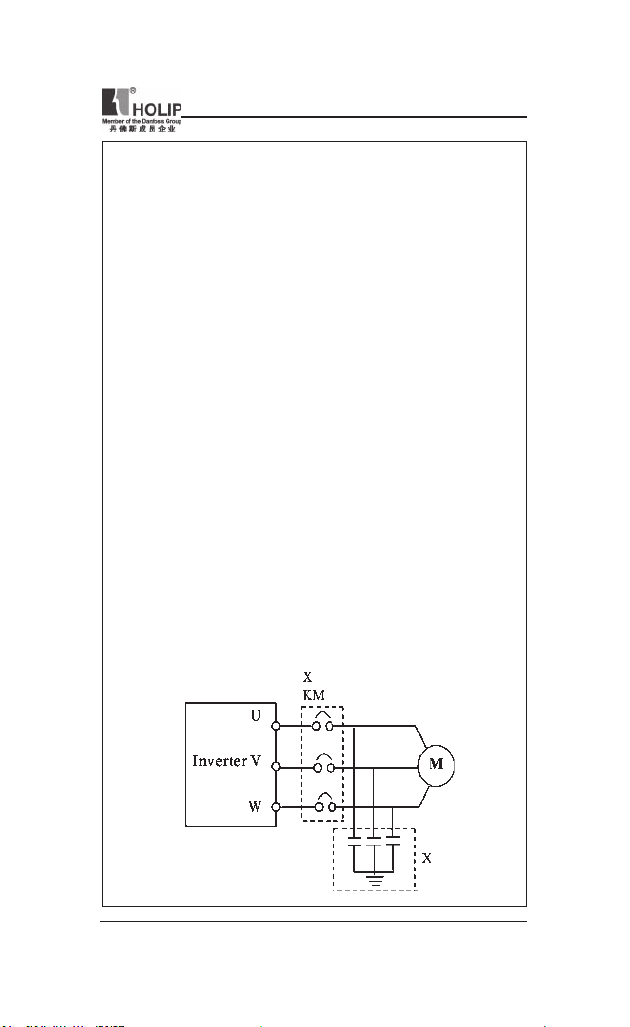

1. Main Circuit Wiring Schematic Diagram

Power supply:

● Verif y that the i nver te r’s r ate d volta ge coi ncid es

with AC p ower supply voltage to avoid a damage

of the inver ter.

No fuse breaker:

● Refer to the related list.

Ground fault circuit interrupter:

● Use one of anti-high harmonic.

Electromagnetic cont actor:

● Note: Do not use the electromagnetic contactor as

the on/off button of power supply for t he inver ter.

AC reactor:

● It is re commended to in st al l an AC reactor for

power factor improvement if the input capacit y is

more tha n 1000KVA.

Inverter:

● Be sur e to make correct c onnections of the main

ci rcu it wire s an d con t ro l sig nal wire s of the

inverter.

● Be s ure to make corre ct sett ing of para meters for

the inverter.

HLP-NV Series

HLP-NV Series

- 13 -

Page 19

HLP-NV Series

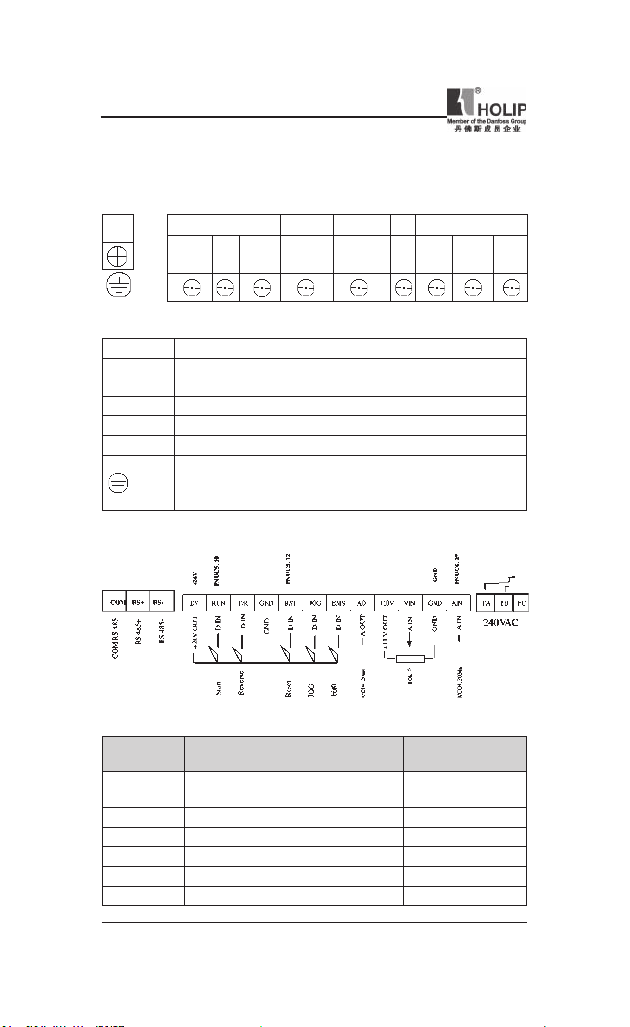

2. Description of Terminal Block

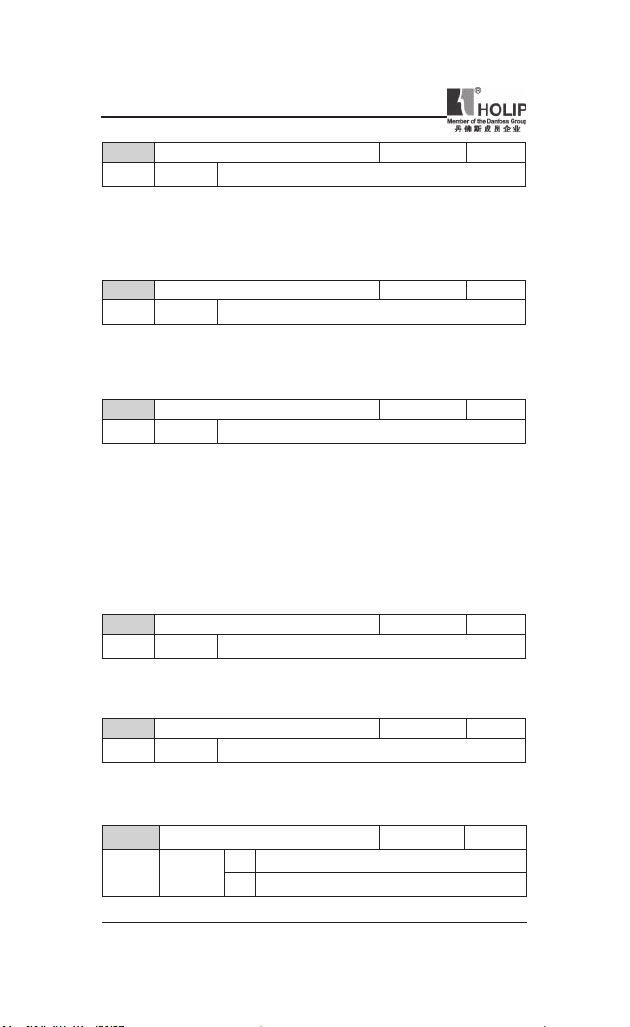

1)Arr angeme nt of Main ci rcuit Term inals

POWER MOTOR

R

L)

(

Function Description of Main circuit Terminals

Symbol Function Description

R S T

U.V.W Out put ter minal of the inve rter

+UDC BR Conne ctor for br aki ng resistor (optional).

-UDC Connector for DC reactor

2) Arra ngement of Control Circuit Terminals

In pu t ter min al of AC li ne power. (220V class:for bot h

single/three phase, si ngle phase connected to L and N)

Grou nd ter minal: the third method of g rounding for 220V

and special grou nding for 380 V of Electrical Engineering

Regulations.

T

S

-UDC +UDC BR U V W

(N)

Function Description of Control Ci rcuit Terminals

Symbol Function Descr iption

EV

RUN Multi- Dig ital Input Start

F/R Multi- Dig ital Input Reverse

GND Digital Ground (for 24V power)

RST Multi- Dig ital Input Reset

JOG Multi- Dig ital Input Jog

- 14 -

Common Terminal of Digital and

Control Signals ( +24V Power)

HLP-NV Series

Default setting

setting

Page 20

HLP-NV Series

Symbol Function Descr iption

EMS Multi- Digital Input Bit0

AO Multi- Analog Output 0/4-20m A

+10V Power Supply for Analog Setti ng +10V

VIN Multi- A nalog input Voltage

GND Analog Ground

AIN Multi- A nalog input 0/4~20mA

FA FB FC Multi- Dig ital Output (Relay)

COM RS+ RS -

RS485 Com munication port

Default setting

setting

FA-FC:break

FA-FB:make

COM:Common for

RS+ and RS -

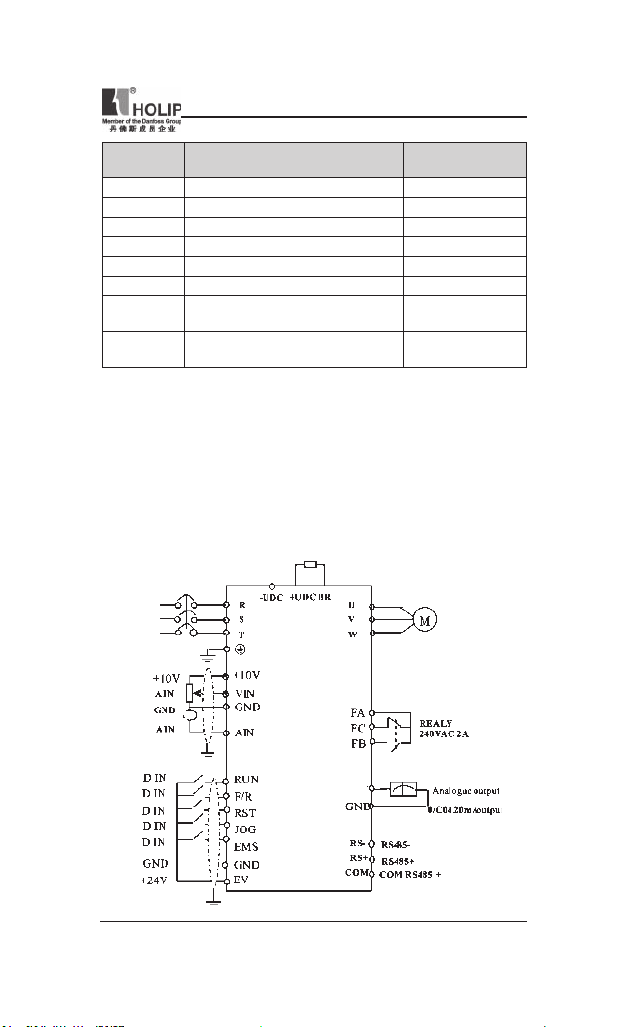

3. Basic Connection Diagram

The wiring of t he inver ter is d ivided i nto two parts, main circuit terminal

connectio ns an d cont rol ci rc uit te r mi na l connec tion s. The user can

see the m ai n ci rcuit terminal s an d th e contr ol circu it term in als af ter

remov in g the cover of encl os ur e. The ter mi nals must be co nnected

correctly as t he following wiring circuit diagrams.

The following diagram shows the Default setting standard con nection of

Model HLP-N V

HLP-NV Series

AO

- 15 -

Page 21

HLP-NV Series

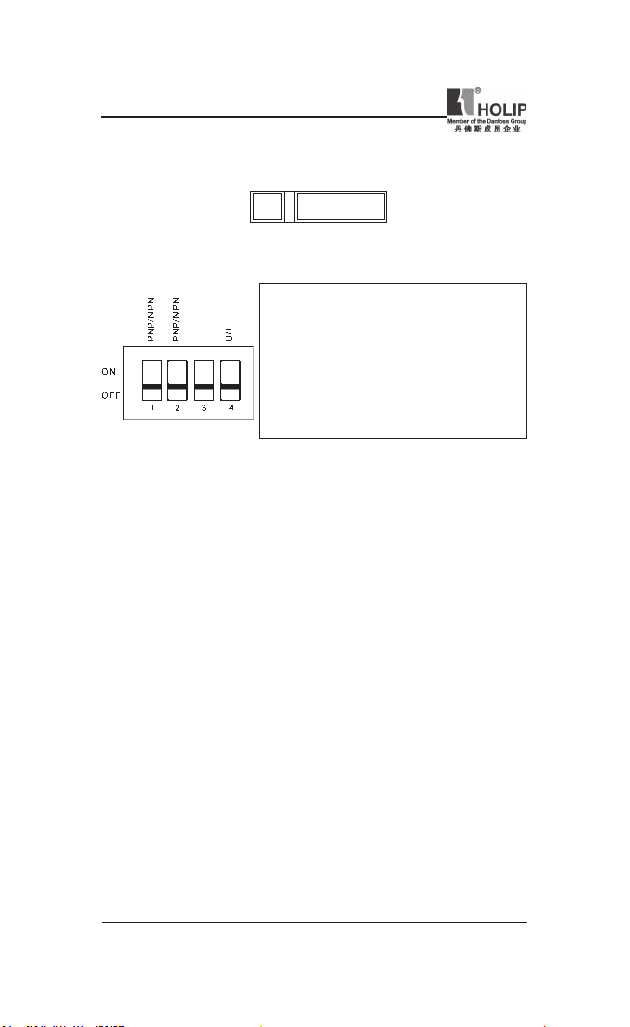

4. Switches

i. Bus ter mination:

OFF

Mark:Swit ch BUS TER enables termination of the RS485 port, term inals

RS+, RS-.

ii. Switches 1-4:

ATT EN TI ON: Para me te r C06.19 must be set acco rd in g to Switc h 4

position.

Warni ng: D o not oper ate swi tch es with pow er on the fr equ e nc y

converter.

BUS TER

ON

Switch 1: *OFF = PNP t erm inal JO G

ON = NPN te rmi nal JOG

Switch 2: *OFF = PNP t erm inals RUN,

F/R,R ST,EMS

ON = NPN te rmi nals RUN ,

F/R,R ST,EMS

Switch 3: No fun ction

Switch 4: *OFF = Termi nal VIN 0 - 10 V

ON = Termin al VI N 0/4 - 20 mA

* = default s etti ng

5. Precautions on Wiring

1) For the main circuit wiring:

● Wh ile wiring the sizes and specications of wires should be selected

an d the w iri ng sho ul d be exe cu t ed acc ord i ng to the elect ric al

engineeri ng regu lations to ensure the safety.

● It is better to use shielded wire or wire and conduit for power cord and

ground the shielded layer or t wo ends of wire conduit.

● Be sure to install a Non Fuse Breaker ( NFB) bet ween the power supply

and the in put te rminal s (L1.L2. L3). (If usin g grou nd fau lt circ ui t

inter rupter, please choose one corre sponding to high frequency)

● Ne ve r con ne ct AC powe r t o the outp ut ter min al ( U.V.W) of the

inverter.

● Outpu t wi res mus tn’t b e in tou ch of the metal part of t he inver ter

enclosu re, or it will result in ear th short-ci rcuit.

● Phase -s hift ing capacitors , LC, RC noise fi lte rs , etc, can never be

connected to t he output terminals of the inverter.

● The main ci rcuit wire must be enough far away from other control

equipments.

- 16 -

HLP-NV Series

Page 22

HLP-NV Series

● W hen th e wiring be tw ee n the invert er and the motor exc ee ds 15

meter s (shielded wire) or 50 meters (No shielded wire), much higher

dV/dT will be produced inside the coil of t he motor, which wi ll cause

the destr uction to the interlay or insulation of t he motor. Please use a

dedicated AC motor for the inver ter or add a react or at the inverter.

● Plea se lower the car rier frequ enc y whe n there is a longer di stance

bet ween the inverter a nd the motor. Beca use t he higher t he carr ier

frequency is t he bigger t he leak age cur rent of h igh-order ha rmon ics in

the cables will b e. The leakage current will have unfavorable effect on

the inverter a nd other equipme nt.

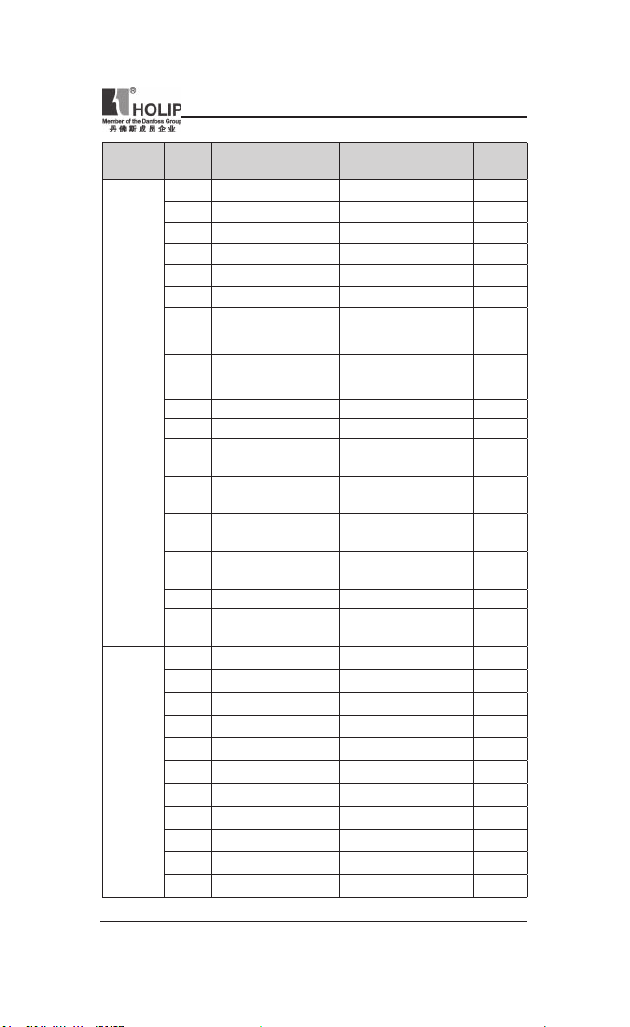

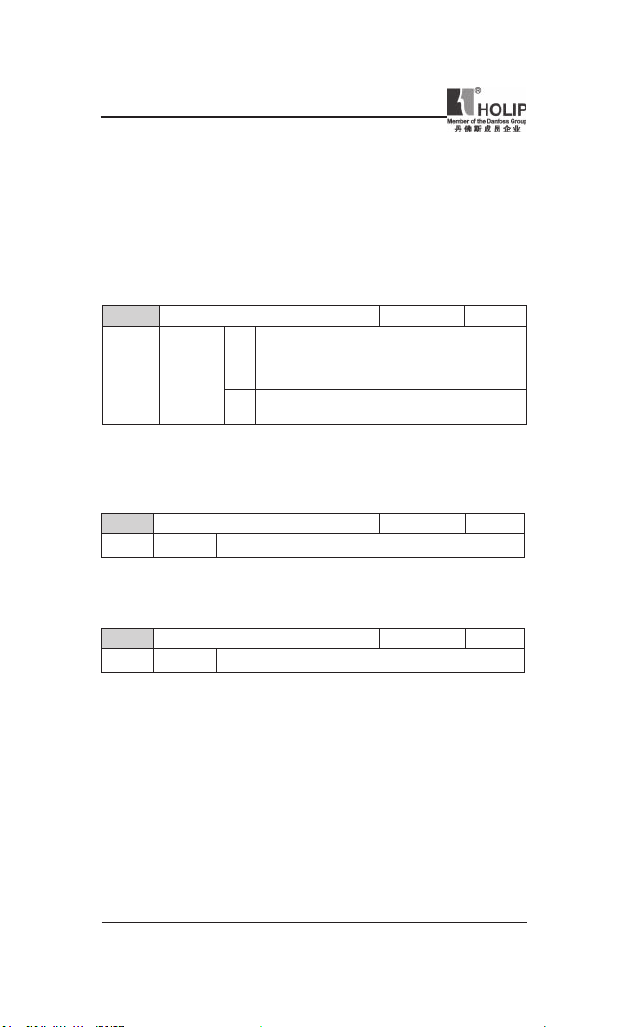

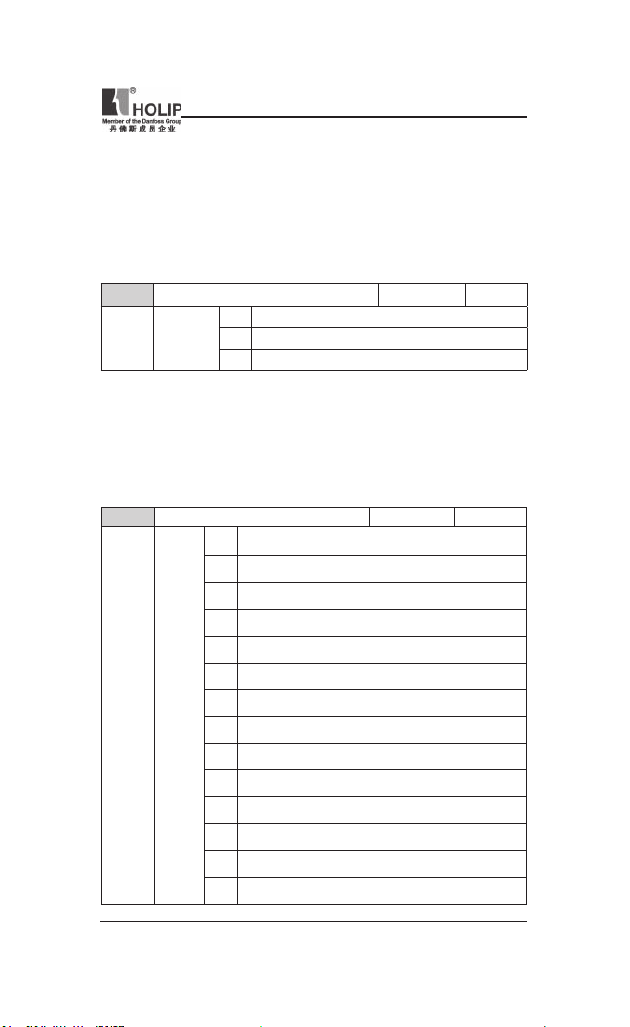

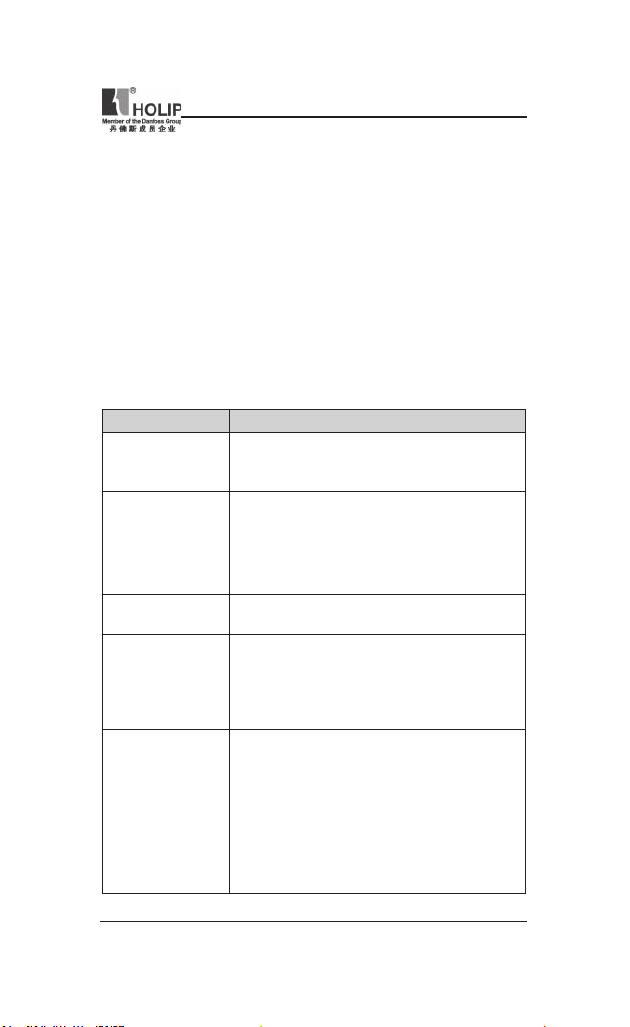

Specications of Non Fuse Breaker and Wire

Model

(A)

Input wire

mm

2

Output wire

2

mm

Control wire

2

mm

NFB

HLPNV0D1821A 16 2.5 2.5 0.5

HLPNV0D3721A 16 2.5 2.5 0.5

HLPNV0D7521A 16 2.5 2.5 0.5

HLPNV01D521A 16 2.5 2.5 0.5

HLPNV02D221A 32 4 4 0.5

HLPNV0D2523A 16 2.5 2.5 0.5

HLPNV0D3723A 16 2.5 2.5 0.5

HLPNV0D7523A 16 2.5 2.5 0.5

HLPNV01D523A 32 2.5 2.5 0.5

HLPNV02D223A 32 4 4 0.5

HLPNV03D723A 32 4 4 0.5

HLPNV0D3743A 16 2.5 2.5 0.5

HLPNV0D7543A 16 2.5 2.5 0.5

HLPNV01D543A 16 2.5 2.5 0.5

HLPNV02D243A 16 2.5 2.5 0.5

HLPNV03D043A 16 2.5 2.5 0.5

HLPNV04D043A 32 4 4 0.5

HLPNV05D543A 32 4 4 0.5

HLPNV07D543A 40 6 6 0.5

HLPNV001143A 63 6 6 0.5

HLPNV001543A 100 6 6 0.5

HLPNV18D543A 100 10 10 0.5

HLPNV002243A 100 16 16 0.5

Attention: The parameters i n the list are only for reference and should not

be regarded as st anda rd.

HLP-NV Series

- 17 -

Page 23

HLP-NV Series

2) For control circuit wi ring (signal line)

● The signal line should be separately laid in a different conduit with t he

main ci rcuit wire to avoid any possible i nterference.

● Please use the shielded cable wit h the size of 0.5-2mm2 for signal lines.

● Use the control terminals on the control panel correctly accor ding t o

your needs.

3) Grounding

● Grounding terminal E. Be sure to make cor rect g round ing

220V class: The third grounding method (Grou nding resistance should

be 100Ω or lower.)

380V class: The special third grounding met hod (Grounding resistance

should be 10Ω or lower.)

● Choose grounding w ires according to the basic length and siz e of the

technical require ments of the electric equipment.

● Do avoid shar ing ground ing wire with other large power equ ipment

such as el ec tr ic welder, power ma ch in e, et c. The gr ou nd in g wir e

should be kept away from the power supply wire s for la rge power

equipment.

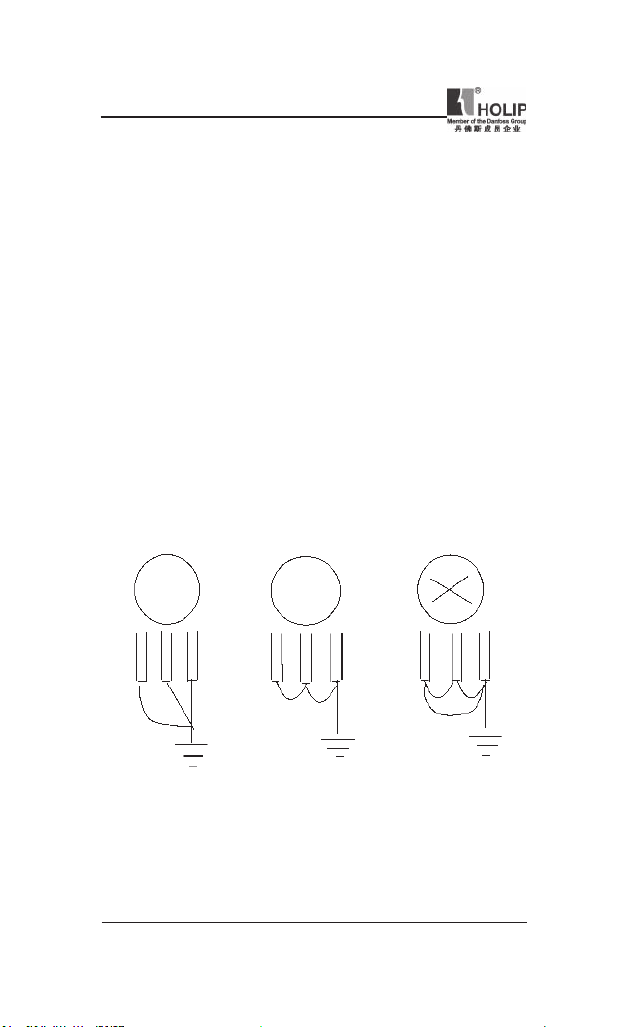

● The grounding method for several inverters together should be done as

the rst and sec ond diag rams below. Avoid the third loop.

● The groundi ng wire must be as short as p ossible.

(1) Good (2) Good (3) Not good

- 18 -

HLP-NV Series

Page 24

HLP-NV Series

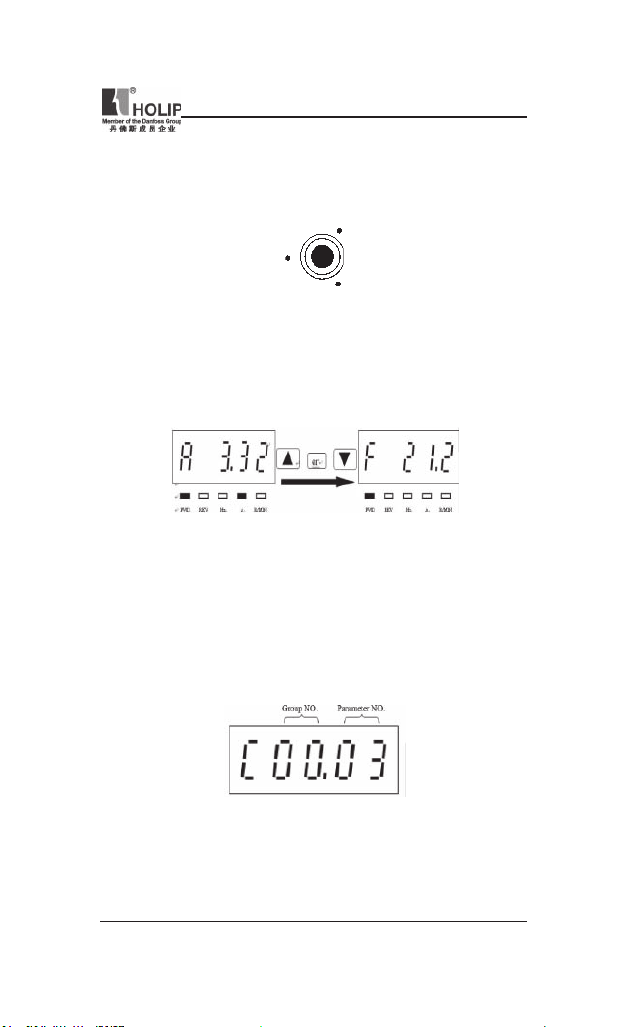

VI. Instruction of the LCP Digital Operator

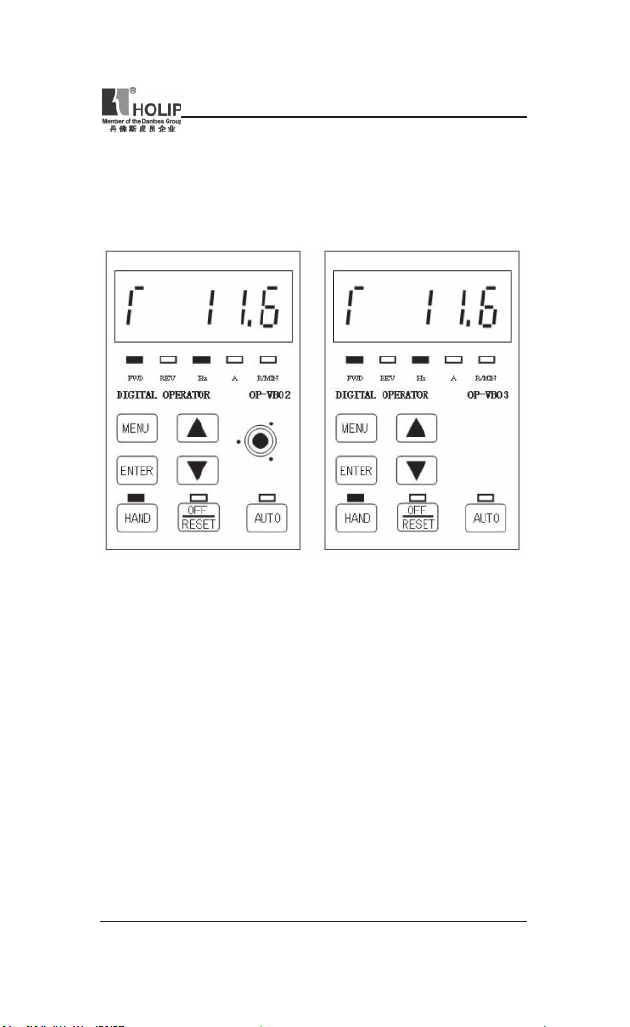

1. Description of the LCP Digital Operator

LCP with potentiometer

2. Programming with LCP

2.1. LCP introduction:

1. 5 numeric d isplays

2.

8 LEDs: FWD、REV、Hz、A、R/MIN、HAN D、OFF/RESET、AUTO

3. 7 keys: MENU、ENTER、▲、▼、HAN D、OFF/RESET、AUTO

4. 1 potent iometer (only for type OP-VB02).

LCP without potentiometer

HLP-NV Series

- 19 -

Page 25

HLP-NV Series

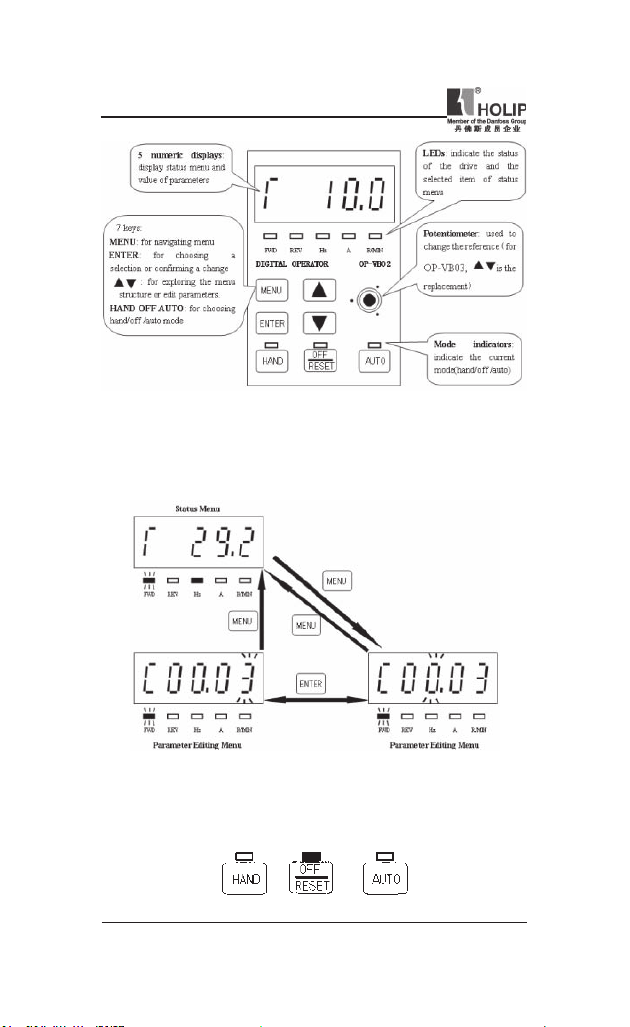

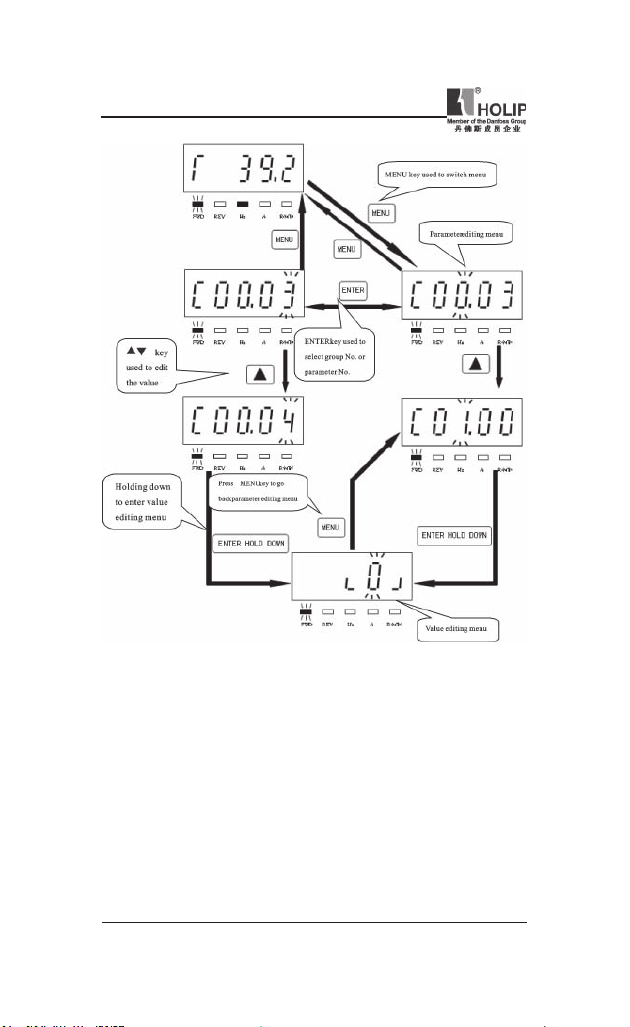

2.2

General Operation

.

The me nu syst em allows op er ators to nav igate th ro ug h hierarchica l

menus which contain related menu items. The top-level menu c onta ins

two menu items: statu s menu、parameter editing menu. These two items

can be explored by pressing MENU key:

2.3

Mode keys and potent iometer

.

Mode Keys are u sed to send Hand, OFF/Reset, Auto request to the dr ive.

It is related to the reference site selection ( Local or Remote).The yellow

LEDs ind icate the certain active mode.

- 20 -

HLP-NV Series

Page 26

HLP-NV Series

The HAND, OFF/RESET a nd AUTO key ca n be dis abled by chang ing

parameter(C00.40、C00.41、C00.42).

Potentiometer: used for set ting t he refere nce only.

The pot entiometer can be used in bot h hand and auto mode wit h different

functionality:

In Ha nd mode the potentio me te r will work as the arr ow key s – i .e.

controlli ng the local refere nce fr om 0 to max reference (C03.03). If the

LCP does not c ont ain a pot entiom ete r, the ar row keys ar e used to set

reference:

In auto mode the potentiometer will act a s an ext ra analog input to the

system. It is selected/deselected as the other analog input s (see C03.15 to

C03.18).

C06.81, C06.82 are used to scale the potentiometer input.

2.4 Parameter editing menu and st atus menu

2.4.1 Parameter editing menu:

HLP-NV Series

- 21 -

Page 27

HLP-NV Series

Parameter set ting example:

How to set C03.17 to 21

1. Pressing MENU key to let the display go to parameter ed iting menu.

2. Pressing▲▼key to select group No.(C03.00)

3. Pressing ENTER key t o edit par ameter No.,then p ressing▲▼key to

select paramet er No. (C03.17).

4. Hold in g down EN TER key to go to the va lue edtin g menu , then

pressi ng▲▼to edit the value of the parameter to 21,then holding down

ENTER key to conrm t he change till “END”was displayed.

- 22 -

HLP-NV Series

Page 28

HLP-NV Series

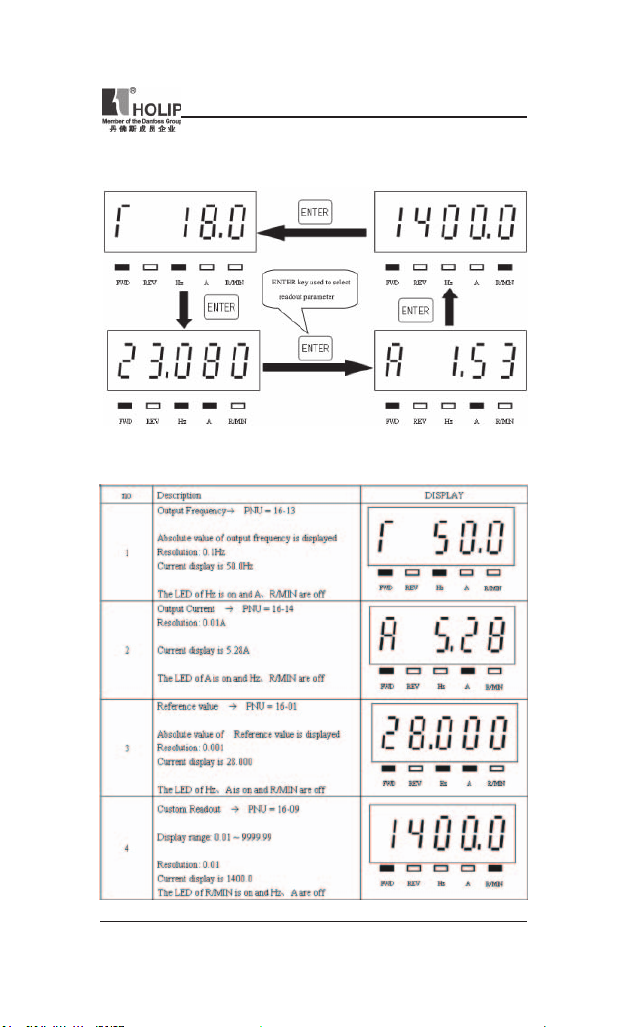

2.4.2 Readout and indicator:

The readout par amete rs toggled by pressing ENTER key:

The below table shows the screen of displayi ng every readout parameter

HLP-NV Series

- 23 -

Page 29

HLP-NV Series

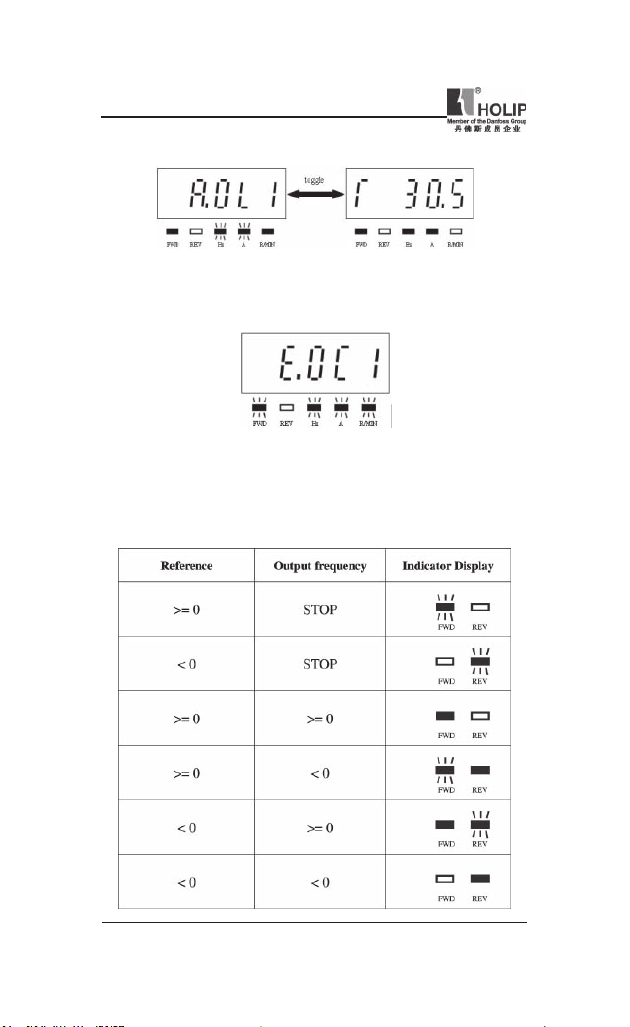

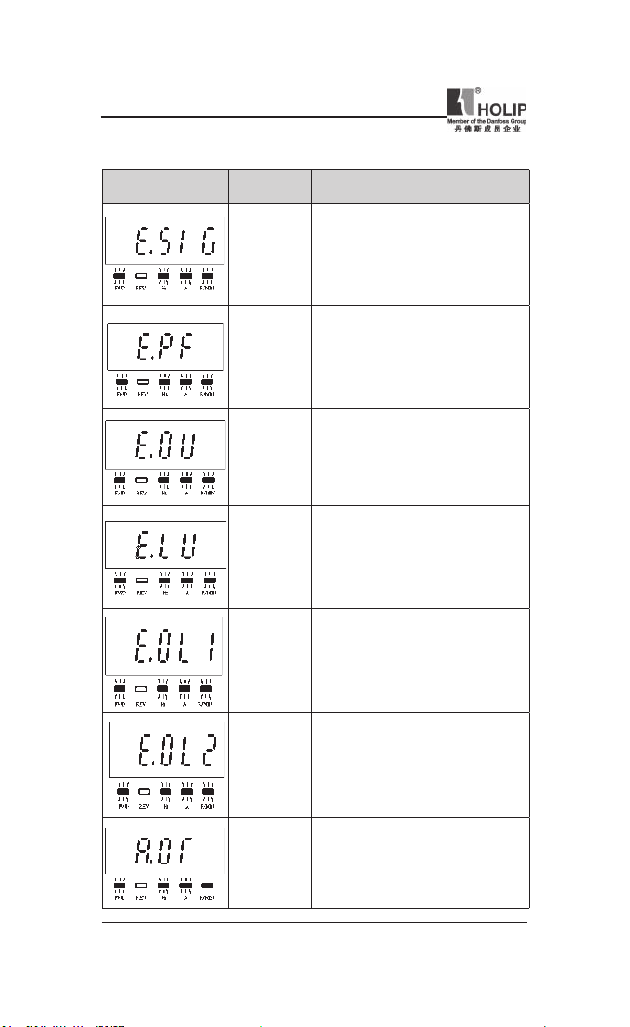

Warning descr iption:

when war ning o ccur red , the LEDs of Hz、A w ill ash a nd R/MIN will

be lit.

Alar m description:

when ala rm occur red, the LED s of Hz、A and R/ MIN will f lash,an d

the drive will trip. A trip ca n be cancelle d by pressing reset or, in some

cases, aut omatically. A locked trip ca nbe cancel led by cutting off mains

and restarting the drive.

The motor direction is indicated by the led s of FWD and REV:

- 24 -

HLP-NV Series

Page 30

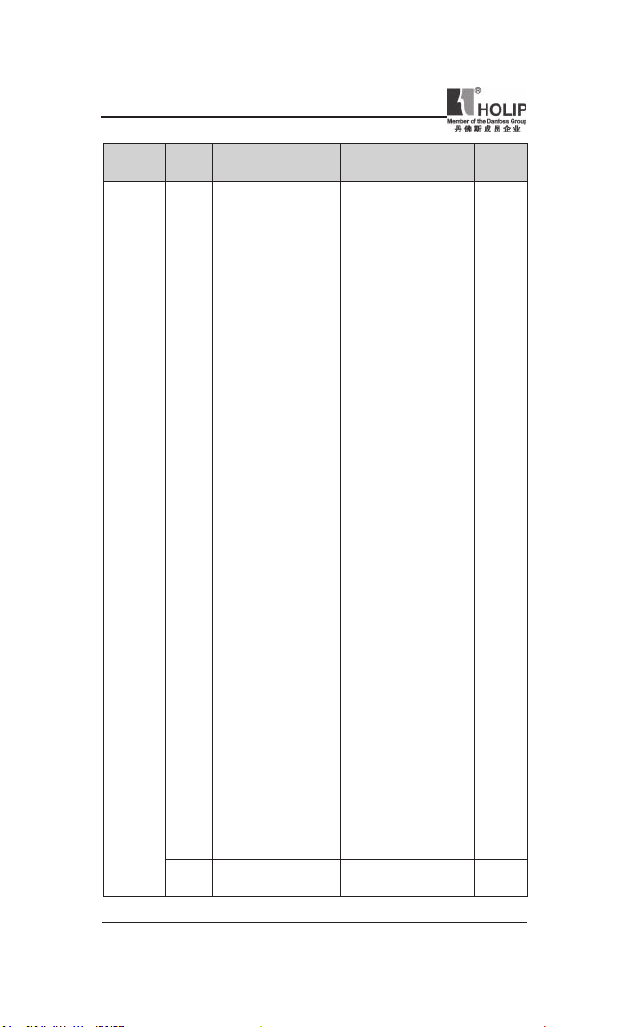

VII. Parameter Overview

Function

Item

Operation

/ Display

Load /

Motor

Fuction Description

Code

Op er. St at e at Power-

C00.04

up [Hand]

Cu st om Re ad ou t Min

C00.31

Scale

Custom Readout Max

C00.32

Scale

C00.40 [Hand on] Key on LCP

[Off / Re se t] Ke y on

C00.41

LCP

C00.42 [Auto on] Key on LCP

C00.60 Menu locked

C01.00 Conguration Mode

Motor Cont rol

C01.01

Principle

C01.03 Torque Character istics

Local Mode

C01.05

Cong urat ion

Motor Power

C01.20

[kW] [HP]

C01.22 Motor Voltage 50 - 999 V **

C01.23 Motor Frequency 20 - 400 Hz 50 Hz

C01.24 Motor Current 0.01 - 26.00 A **

C01.25 Motor Nom inal Sp eed 100 - 9999 r pm **

Automatic Motor

C01.29

Tuning (AMT )

C01.30 Stator Resistance (R s)

HLP-NV Series

Range&Function

explanation

[0] Resume

*[1] Forced sto p, ref =

old

[2] Forced stop, ref = 0

0.00 – 9999.00 0.00

0.00 – 9999.00 100.00

[0] Disabled

*[1] Enabled

[0] Disable All

*[1] Enable All

[2] Enable Reset O nly

[0] Disabled

*[1] Enabled

[0]Disabled

[1]Enabled

*[0] Speed open loop

[3] Process

[0] V/F

*[1] VVC+

*[0] Constant torque

[2] Automatic Energy

Optim.

[0] Speed Open Loop

*[2] As cong i n param.

C01.00

0.09 kW / 0.12 HP .... 11

kW / 15 HP

*[0] Off

[2] Enable AMT

[Ohm] * Dep. on mot or

data

Default

setting

1

1

1

1

0

0

1

0

2

**

0

**

HLP-NV Series

- 25 -

Page 31

HLP-NV Series

Function

Item

Load

/ Motor

Fuction Description

Code

Stator L eakage

C01.33

Reactance (X1)

C01.35 Main Reactance (X2)

Moto r Mag net is ation

C01.50

at 0 Speed

Min Speed Norm.

C01.52

Magnet. [Hz]

C01.55 V/F Character istic - V 0 - 999.9 V * 0.0 V 0V

C01.56 V/F Character istic - F 0 - 400 Hz 0H z

Low Speed Load

C01.60

Compen sation

High Speed Load

C01.61

Compen sation

C01.62 Slip Compensation -400 - 399 % 100%

Slip Compensation

C01.63

Time Constant

C01.71 St art Delay 0.0 - 10.0 s 0.0S

C01.72 Start Fu nction

C01.73 Flying Sta rt

C01.80 Function at Stop

Mi n Spee d for Fu nc t.

C01.82

at Stop [H z]

Motor The rmal

C01.90

Protection

C01.93 Ther mistor Resource

Range&Function

explanation

[Ohm] * Dep. on mot or

data

[Ohm] * Dep. on mot or

data

0 - 300 % 100%

0.0 - 10.0 Hz 0.0H z

0 - 199 % 100%

0 - 199 % 100%

0.05 - 5.00 s 0.10s

[0] DC hold / delay time

[1] DC brake / delay

time

*[2] Coast / delay time

*[0] Disabled

[1] Enabled

*[0] Coast

[1] DC hold

0.0 - 20.0 Hz 0.0Hz

*[0] No protection

[1] Te rmistor warning

[2] Therm istor t rip

[3] Etr warning 1

[4] Etr trip 1

*[0] None

[1] Analog Input V IN

[6] Digital I nput JOG

Default

setting

**

**

2

0

0

3

0

- 26 -

HLP-NV Series

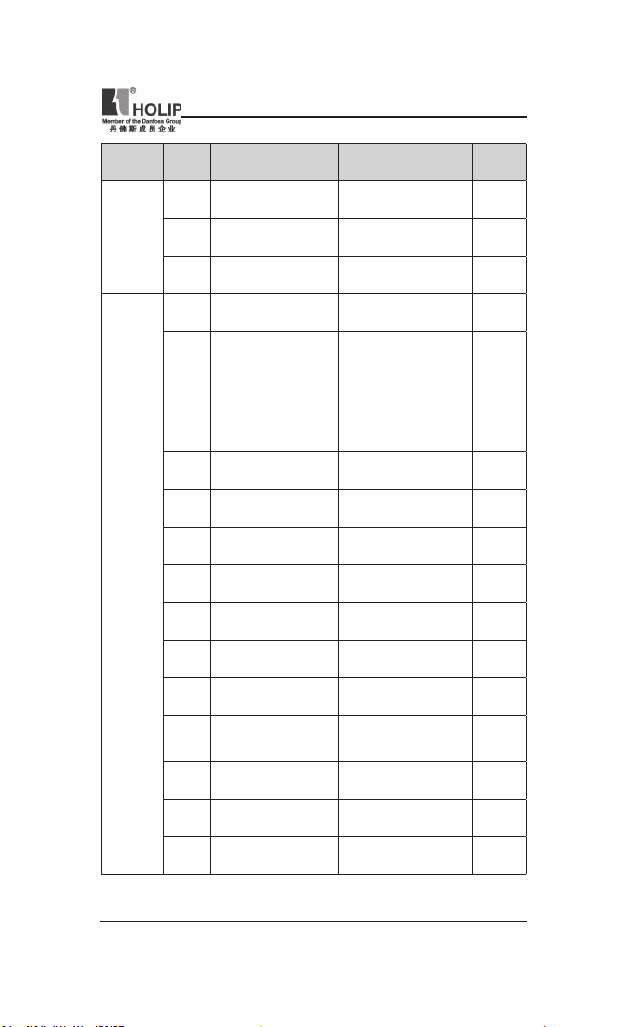

Page 32

HLP-NV Series

Item

Brakes

Reference

/ Ramps

Function

Fuction Description

Code

C02.00 DC Hold Current 0 - 100 % 50%

C02.01 DC Brake Cur rent 0 - 100 % 50%

C02.02 DC Br aki ng Time 0.0 - 60.0 10.0S

C02.04 DC Brake Cut In Speed 0.0 - 400.0 Hz 0.0Hz

C02.10 Brake Function

C02.11 Brake Resistor (ohm) 5 -5000Ω *

C02.16 AC Brake, Max current 0 - 400 % 100%

C02.17 Over-voltage Control

C02.20 Release Brake Cur rent 0.00 - 100.0 0 A 0.00A

Act iva te Brake Spe ed

C02.22

[Hz]

C03.00 Reference Range

C03.02 Minimum Reference -4999.000 - 4999.000 0.000

C03.03 Maximum Reference -4999.000 - 4999.000 50.000

C03.10 Preset Reference -100.00 - 100.00 % 0.00%

C03.11 Jog Speed [Hz] 0.0 - 400.0 H z 5.0Hz

Ca tch u p/sl ow Dow n

C03.12

Value

Preset Relative

C03.14

Reference

C03.15 Reference Resource 1

C03.16 Reference Resource 2

C03.17 Reference Resource 3 11

Range&Function

explanation

*[ 0] O ff [1] Re s istor

brake [2] AC brake

*[0] Disabled

[1] Enabled (not at stop)

[2] Enabled

0.0 - 400.0 Hz 0.0HZ

*[0] Min – Max

[1] -Max - +Max

0.00-100.00% 0.00%

-100.00%~100.00% 0.00%

[0] No function

*[1] Analog Input VIN

[2] Analog Input AIN

[8] Pulse input 33

[11] Local bus ref

[21] Lcp Potentiometer

[0] No function

[1] Analog Input V IN

[2] Ana lo g In pu t AI N

[11] Local bus ref

[21] Lcp Potentiometer

Default

setting

0

0

0

1

2

HLP-NV Series

- 27 -

Page 33

HLP-NV Series

Item

Reference

/ Ramps

Limits

/

Warnings

Function

Fuction Description

Code

Rel at iv e Scal i ng Ref .

C03.18

Resource

C03.40 Ramp 1 Type

C03.41 Ramp 1 R amp up Time 0.05~3600.00S

Ramp 1 Ramp Down Ti me

C03.42

C03.50 Ramp 2 Type

C03.51 Ramp 2 Ramp up Time 0.05~3600.00S

Ramp 2 Ramp down

C03.52

Time

C03.80 Jog Ramp Time 0.050~3600.000S

C03.81 Quick Stop Ramp Time 0.05~3600.00S

C04.10 Motor Speed Direction

Motor Speed Low

C04.12

imit [Hz]

Motor Speed High

C04.14

Limit [Hz]

Torque Limit Motor

C04.16

Mode

Torque Limit

C04.17

Generator Mode

C04.50 Warning Current Low 0.00~26.00A 0.00A

C04.51 Warn ing Cu rrent High 0.00 ~100.00A 100.00A

Missing Motor Phase

C04.58

Function

Bypass Speed From

C04.61

[Hz]

C04.63 Bypass Speed To [Hz] 0.0~ 400.0Hz 0.0Hz

Range&Function

explanation

*[0] No function

[1] Analog Input V IN

[2] Analog Input AIN

[8] Pulse input 33

[11] Local bus ref

[21] Lcp Potentiometer

*[0] Linear

[2] Sine2 ramp

0.05~3600.00S

*[0] Linear

[2] Sine 2 ramp

0.05~3600.00S

*[0] Clockwise

[1] CounterClockWise

[2] Both

0.0~400.0Hz 0.0Hz

0.0~400.0Hz 65.0Hz

0~400% 150%

0~400% 100%

[0] Off *[1] On 1

0.0~400.0Hz 0.0Hz

Default

setting

0

0

3.00/

15.00S

3.00/

30.00S

0

3.00/

15.00S

3.00/

30.00S

3.00/

15.00S

3.00/

30.00S

2

- 28 -

HLP-NV Series

Page 34

HLP-NV Series

Item

Digital

In / Out

Function

Fuction Description

Code

Termi nal RUN Digit al

C05.10

Input

Ter min al F/ R Dig it al

C05.11

Input

Term in al RST Digital

C05.12

Input

Term in al JOG Digital

C05.13

Input

Termi nal EMS Digital

C05.15

Input

Range&Function

explanation

[0] No function

[1] Reset

[2] Coast inverse

[3] Coast and reset inv.

[4] Quick stop inverse

[5] DC-brake inv.

[6] Stop inv

[8] Start

[9] Latched st art

[10] Reversing

[11] Start reversing

[12] Enable start forwa rd

[13] Enable start reverse

[14] Jog

[16] Preset ref bit 0

[17] Preset ref bit 1

[18] Preset ref bit 2

[19] Freeze reference

[20] Freeze out put

[21] Speed up

[22] Speed down

[23] Setup select bit 0

[26]Precise Stop Inve rse

(Only for C05.15)

[27] Start, Pr eci se Stop

(Only for C05.15)

[28] Catch up

[29] Slow down

[32] Pu ls e Input (Only

for C05.15)

[34] Ramp bit 0

[60] Counter A(up)

[61] Counter A(down)

[62] Reset counte r A

[63] Counter B(up)

[64] Counter B(down)

[65] ResetCou nterB

Default

setting

8

10

1

14

16

C05.40 Function Relay

HLP-NV Series

*[0] No opreation

[1] Control ready

[2] Drive ready

[3] Drive ready, Remote

[4] Enable / No warning

[5] Drive ru nning

[6] Running / No

warn ing

[7] Run in range / No

warn ing

- 29 -

Page 35

HLP-NV Series

Item

Digital

In / Out

Function

Fuction Description

Code

Te r mi n a l EM S Low

C05.55

Frequency

Range&Function

explanation

[8] R un o n r e f / N o

warn ing

[9] Alarm

[10] Alarm or war ning

[12] Out of current range

[13] Below current, low

[14] Above current, high

[21] Ther mal warning

[22] Rea dy, No thermal

warn ing

[23] Rem ot e read y, No

ther mal war ning

[24] Ready, Voltage ok

[25] Reverse

[26] Bus ok

[28] Brake,NoWarn

[ 29 ] B r a k e r e ad y /

NoFault

[30] BrakeFault (IGBT)

[32] Mech.brake control

[36] Control word bit 11

[51] Local ref. active

[52] Remote ref. active

[53] No alarm

[54] Start cmd active

[55] Running reverse

[56] Drive in hand mode

[57] Drive in auto mode

[60] Comparator 0

[61] Comparator 1

[62] Comparator 2

[63] Comparator 3

[70] Logic rule 1

[71] Logic rule 2

[72] Logic ru le 3

[80] SL digital output A

[81] SL digital output B

20~ 4999Hz 20

Default

setting

9

- 30 -

HLP-NV Series

Page 36

HLP-NV Series

Item

Analog I n

/ Out

Function

Fuction Description

Code

Ter mi nal EMS Hi g h

C05.56

Frequency

Term. E MS Low Ref./

C05.57

Feedb. Value

Term. EMS Hig h Ref./

C05.58

Feedb. Value

Li v e Ze ro T i me ou t

C06.00

Time

Live Zero

C06.01

TimeoutFunction

Te rm in al V I N Lo w

C06.10

Voltage

Te r m i nal V I N Hig h

C06.11

Voltage

Te rm in al V I N Lo w

C06.12

Cur rent

Te r m i nal V I N Hig h

C06.13

Cur rent

Term . VIN Low Ref./

C06.14

Feedb. Value

Term. V IN High Ref./

C06.15

Feedb. Value

Ter mi nal VI N Fi lte r

C06.16

Time Constant

C06.19 Terminal VI N mode

Te rm in al A I N Lo w

C06.22

Cur rent

Te r m i nal A I N Hig h

C06.23

Cur rent

Term . AIN Low Ref./

C06.24

Feedb. Value

Range&Function

explanation

21~5000Hz 5000

-4999.000~4999.000 0.000

-4999.000~4999.000 50.000

0~99S 10S

*[0] Off

[1] Freeze output

[2] Stop

[3] Jogging

[4] Max speed

[5] Stop and tr ip

0.00~9.99V 0.07V

0.10~10.00V 10.00V

0.00~19.99mA 0.14

0.10~20.00mA 20.00

-4999.000~4999.000 0.000

-4999.000~4999.000 50.000

0.01~10.00S 0.01

*[0] Voltage mode

[1] Current mode

0.00~19.99mA 0.14

0.10~20.00mA 20.00

-4999.000~4999.000 0.000

Default

setting

0

0

HLP-NV Series

- 31 -

Page 37

HLP-NV Series

Item

Analog I n

/ Out

Proess

PI

Contr-

olers

Function

Fuction Description

Code

Term. AIN High Ref.

C06.25

/Feedb. Value

Ter mi nal AI N Fi lte r

C06.26

Time Constant

LCP potm. Low Ref

C06.81

./Feedb. Value

LCP potm. High Ref.

C06.82

/Feedb. Value

C06.90 Terminal AON Mode

Terminal AON Analog

C06.91

Output

Termi nal AON Digital

C06.92

Output

Termi nal AON Output

C06.93

Min Scale

Termi nal AON Output

C06.94

Max Scale

Process CL Feedba ck 1

C07.20

Resource

Process PI Normal/

C07.30

Inverse Ctrl

Process PI Anti

C07.31

Windup

C07.32 Process PI Start Spee d 0.0~200.0 0.0

Process PI Proportion al Gain

C07.33

Process PI Integ ral Time

C07.34

Process PI Feed

C07.38

Forward Factor

On Reference

C07.39

Bandwidth

Range&Function

explanation

-4999.000~4999.000 50.000

0.01~10.00S 0.01

-4999.000~4999.000 0.000

-4999.000~4999.000 50.000

*[0] 0-20 Ma

[1] 4-20 mA

[2] Digital Output

*[0] No operation

[10] Output frequency

[11] Reference

[12] Feedback

[13] Motor Current

[16] Power

[20] BusCont rol

See par. C05.40 0

0.00-200.0 0% 0.00%

0.00-200.0 0% 100.00%

*[0] NoFunction

[1] Analog Input V IN

[2] Analog Input AIN

[8] PulseI nput33

[11] LocalBusRef

*[0] Normal

[1] Inverse

[0] Disable

*[1] Enable

0.0~10.00 0.01

0.01~9999.00S 9999.00

0-400% 0%

0-200% 5%

Default

setting

0

10

0

0

1

- 32 -

HLP-NV Series

Page 38

HLP-NV Series

Item

Comm-

unication

Function

Fuction Description

Code

C08.01 Cont rol Site

C08.02 Control Word Source

Control Word Timeout

C08.03

Time

Control Word Timeout

C08.04

Function

Re se t Co nt r ol Wor d

C08.06

Timeout

C08.30 Protocol

C08.31 Address 0~126 1

C08.32 FC Port Baud Rate

C08.33 FC Port Parit y

Mini mum Response

C08.35

Delay

C08.36 Max Response Delay 0.010~10.00S 5.000S

Range&Function

explanation

*[0] Digital and

ControlWord

[1] Digital only

[2] ControlWord only

[0] None

*[1] FC RS485

0.1~6500.0S 1.0S

*[0] Off

[1] Freeze Output

[2] Stop

[3] Jogging

[4] Max. Speed

[5] Stop and tr ip

*[0] No Function

[1] Do reset

*[0] FC

[2] Modbus

[0] 2400 Baud

[1] 4800 Baud

*[2] 9600 Baud

[3] 19200 Baud

[4] 38400 Baud

*[0] Even Parity, 1 Stop

Bit

[1] Odd Parity, 1 Stop

Bit

[2] No Parity, 1 Stop Bit

[3] No Parity, 2 Stop

Bits

0.001~0.500S 0.010S

Default

setting

0

1

0

0

0

2

0

HLP-NV Series

- 33 -

Page 39

HLP-NV Series

Item

Comm-

unication

Special

Function

Function

Fuction Description

Code

C08.50 Coasting Select

C08.51 Quick Stop Select 3

C08.52 DC Brake Select 3

C08.53 Sta rt Select 3

C08.54 Reversing Select 3

C08.55 Set-up Select 3

C08.56 Preset Reference Select 3

C08.94 Bus feedback 1 0x8000~ 0x7FF F 0

C14.01 Switchi ng Frequency

C14.03 Overmodulat ion [0] Off *[1] On 1

F u nc t io n a t m ai n s

C14.12

imbala nce

C14.20 Reset Mode

Automatic Resta rt

C14.21

Time

C14.22 Operation Mode

Action At Inverte r

C14.26

Fault

AEO Minimu m

C14.41

Magnetisation

Range&Function

explanation

[0] DigitalI nput

[1] Bus

[2] LogicAnd

*[3] LogicOr

[0] 2 kHz

*[1] 4 kHz

[2] 8 kHz

[4] 16 kHz

*[0] Trip

[1] Warning

[2] Disabled

*[0] Manual reset

[1] AutoReset 1

[2] AutoReset 2

[3] AutoReset 3

[4] AutoReset 4

[5] AutoReset 5

[6] AutoReset 6

[7] AutoReset 7

[8] AutoReset 8

[9] AutoReset 9

[10] AutoReset 10

[11] AutoReset 15

[12] AutoReset 20

[13] Innite auto reset

0~600S 10S

*[0] Normal Operation

[2] Initialisation

*[0] Trip [1] Warning 0

40~75% 66%

Default

setting

3

1

0

0

0

- 34 -

HLP-NV Series

Page 40

HLP-NV Series

Item

Drive

Infor ma-

tion

Data

Readout s

Function

Fuction Description

Code

C15.00 Operating Time 0 - 65535 0

C15.01 Running Hours 0~2147483647 0

C15.02 kWh Counter 0~65535 0

C15.03 Power Ups 0 ~2147483647 0

C15.04 Over Temps 0~65535 0

C15.05 Over Volts 0 ~65535 0

C15.06 Reset kWh Counter

Res et Ru nn ing Hour s

C15.07

Counter

C15.30 Fault Log: Er ror Code 0~255 0

C15.40 FC Type View FC type **

C15.41 Power Section

C15.42 Voltage

C15.43 Softwa re Version

Freq ue ncy Co nv ert er

C15.46

Order. No

C15.48 LCP Id No View LCP ID number **

Freq ue ncy Co nv ert er

C15.51

Serial No

C16.00 Control Word 0~65535 0

C16.01 Reference [Unit] -4999.000~4999.000 0.000

C16.02 Reference % -200.0~200.0% 0.0

C16.03 Status Word 0 ~65535 0

C16.05 Main Act ual Value [%] -100.00~100.00% 0.00

C16.09 Power [kW] 0.00~9999.00 0.0 0

C16.10 Power [ kW] 0~99KW 0KW

C16.11 Power [hp] 0~99HP 0HP

C16.12 Motor Voltage 0.0~999.9V 0.0

C16.13 Frequency 0.0~400.0Hz 0.0Hz

C16.14 Motor Cur rent 0.00 ~1856.00A 0.00A

Range&Function

explanation

*[0] Do not reset

[1] Reset counter

*[0] Do not reset

[1] Reset counter

View power section of

frequency conve rter

View voltage of

frequency conve rter

View power section of

frequency conve rter

View order ing number

for re-ordering

View frequency

converter ser ial number

Default

setting

**

**

**

**

**

0

0

HLP-NV Series

- 35 -

Page 41

HLP-NV Series

Item

Data

Readout s

Function

Fuction Description

Code

C16.15 Fre quency [%] -100.00~100.00% 0.0 0A

C16.18 Motor Ther mal 0 ~100% 0%

C16.30 DC Lin k Voltage 0~10000V 0%

C16.34 Heatsi nk Temp 0~255

C16.35 Inverter Thermal 0 ~100% 0%

C16.36 Inv. Nom. Cur rent 0.01~10000.00A 0.00A

C16.37 Inv. Max. Current 0.01~10000.00A 0.00A

C16.50 Exter nal Reference -200.0~200.0% 0.0%

C16.51 Pulse Reference -200.0~200.0% 0.0%

C16.52 Feedback [ Unit] -4999.000 ~4999.000 0.000

Dig ital In pu t RUN, F/

C16.60

R,RST,EMS

C16.61 D igital Input JOG 0~1 0

A na lo g I np ut VI N

C16.62

(volt)

A na lo g I np ut VI N

C16.63

(current)

C16.64 Analog Input AIN 0.00 ~20.00m A 0.00

Ana log Out put AO N

C16.65

[mA]

C16.68 Pulse Input 20~5000Hz 20Hz

C16.71 Relay Output [bin] 0~1 0

C16.72 Counter A

C16.73 Counter B

C16.86 FC Port REF 1 -200~200 0

C16.90 Alar m Word 0 ~0xFFFFFFFF 0

C16.92 Warning Word 0~ 0xFFFFF FFF 0

C16.94 Ext. Status Word 0~0xFF FFFF FF 0

Range&Function

explanation

℃

0~1111 0

0.00~10.00V 0.00

0.00~20.00 mA 0.00

0.00~20.00 mA 0.00

-2147483648~2147483647

-2147483648~2147483647

Default

setting

0

0

0

- 36 -

HLP-NV Series

Page 42

HLP-NV Series

VIII. Parameter Descriptions

1.Parameter group 0: Operation/Display

C00.04 Oper. State at Power-up (Hand) Default setting 1

Range [0] Resume Frequenc y co nverter star ts in same

Local referenc e is stor ed and used

[1] Forced Stop, Ref=Old

Fr equ enc y conver ter p ow er s up

Local referenc e is stor ed and used

[2] Forced Stop, Ref=0

Fr equ enc y conver ter p ow er s up

Lo cal refe re nc e is se t to 0. Thu s

● Func t ion: Thi s para mete r cont ro ls whe ther or not the frequency

conve rt er should star t ru nnin g the m otor when power in g up after a

power down i n Hand mode.

● ATT EN TION! If LC P wi th pot me te r is mou nt ed , reference is set

accord ing to actual potmeter value.

Hand or Off St ate as when powe red

off.

afte r power-up.

in Off Stat e mea ni ng that motori s

stopped after power up.

afte r power-up.

in Off Stat e mea ni ng that motori s

stopped after power up.

motor will not start ru nni ng b efore

local refe rence has been i ncrea sed.

C00.1* Set-up Handling

User def ined para meter s and miscella neous extern al input s (eg. bus,

LCP, analog /digital inputs, fe edba ck, etc.) cont rols the f unc tionalit y of

the frequency converter. A complete set of all parameters controll ing the

frequency converter is called a set-up. The Micro Drive FC 51 cont ains 2

set-ups, Set-up1 a nd Set-up 2. Furt hermore, a xed set of D efault setting

settings can be copied i nto one or more set-ups.

Some of the a dvantages of having more than one set-up in the frequency

converter are

● Run motor in one set-up (Active Set-up) wh ile updating parameters in

anothe r set-up (Edit Set-up)

HLP-NV Series

- 37 -

Page 43

HLP-NV Series

● Connect various motors (one at a time) to frequency conver ter. Motor

data for various motors can be placed in different set-ups.

● Rapidly change setti ngs of frequency conve rt er and/or moto r while

motor is running (eg. ramp time or preset references) via bus or digit al

inputs.

The Active Set-up can be set as Multi Se t-up wher e the active set-up is

select ed via input on a d igital input term inal a nd/or via the bus cont rol

word.

ATTENTION! Default settingSet-up cannot be used as Active Set-up.

C00.3* Custom Readout

C00.31 Custom Readout M in Scale Default setti ng 0.0 0

Range 0.0 0-9999.00: The value will b e shown at 0H z

● Function: Scale a rea dout parameter which can be read i n par. C16.09

C00.32 Custom Readout Max Scale Default sett ing 100

Range 0.0 0-9999.00: T he val ue will be sho wn at th e

● Function: Scale a rea dout parameter which can be read i n par. C16.09

f re qu enc y p ro gr a m med i n p ar.

C04.14.

C00.4* LCP Keypad

The frequency conver ter can operate in the following three modes: Ha nd,

Off and Auto.

Hand : The f requency convert er is locally oper ate d and does not allow

any remot e control. By activating Hand a sta rt signal is given.

OFF: The fre quency converter stops with a nor mal s top ramp. When

Off is chosen th e f reque ncy co nve rter ca n on ly be star ted by

pressi ng either Hand or Auto on the LCP.

Auto: In Auto-mode the freque ncy conve rter can be remote cont rolled

(bus/digital).

- 38 -

HLP-NV Series

Page 44

HLP-NV Series

C00.40 [Hand on] Key on LCP Default setti ng 1

Range [0] Disabled Hand-on key h as no fu nction.

[1] Enabled Hand- on key is f unct ional.

C00.41 [Off / Reset] Key on L CP Default set ting 1

Range [0] D isa bl e O ff/Re set Off /re set k ey has n o

[1] Enabl e Off /Re set Stop signal and reset of

[2] Enable Res et Only Reset only. Stop (Off)

C00.42 [Auto on] Key on LCP Defau lt sett ing 1

Range [0] Disabled Auto -on key h as no fu nction.

[1] Enabled Auto-on key is fu nction al.

C00.60 Menu Locke d Default sett ing 0

Range [0] Disable a l lo w fo r ch a ng i ng pa r a met er

[1] Enable parameter ca n be read,but can’t be

function.

any faults.

function is disabled.

values

edited

Parameter group 1: Load/Motor

C01.00 Cong urat ion Mode Default set ting 0

Range [0] S pe ed op en lo op For norm al sp eed con tr ol

[3] Proce ss Clos ed Loop Ena ble s proce ss c los ed

W he n r un ni ng in proce ss

● Funct ion: Use th is para meter for selec ti ng the ap pli cat ion con tr ol

principle to be used when a Remote Reference is act ive.

(Refere nces).

l o op co nt r ol . S ee pa r.

g ro up C07.3 * or f ur th er

i n f o r m a t i o n o n P I controller.

cl o se d loo p, pa r. C04.10

Motor Speed Direction must

be set to Clo ckwise [0]

HLP-NV Series

- 39 -

Page 45

HLP-NV Series

C01.01 Motor Cont rol Principle Defau lt sett ing 1

Range [0] V/F Is u sed for par allel connec te d mot ors

and/or special motor application s.

[1] VVC+ Nor mal r unni ng mod e, including slip-

and load c ompensation s.

● Function: The V/F settings are set in parameter s C01.55 and C01.56.

C01.03 Torque Chara cter istics Default setti ng 0

Range [0] Con stant Torque

Mot or sha ft out put pr ovide s consta nt

[2] Automat ic Energ y Opti m.

Th is funct ion automa tic ally o pti mi zes

torque u nder va riable speed control.

en erg y con sump tio n in c ent ri f ug al

pu mp and fan appl icat ions. See par.

14-41 AEO Mi nimu m Magnetisat ion.

● Function: With more t orque char acteri stic s it is pos sible to r un low

energ y consu ming, as well as high torque applications.

C01.05 Local Mode Cong uration Defa ult set ting 2

Range [0] Spe ed Ope n Loop

[2] As conguration in p ar. C01.00

● Funct ion: Th is paramet er is o nly relevant when parameter C01.00

Cong urat ion Mode is set to Process Closed Loop [3]. The parameter

is use d for det er min in g the reference or se tpoi nt ha nd lin g when

changing from Auto Mode to Hand Mode on the LCP.

■ 0: In Hand Mode the d rive always runs in Open Loop con gur ation

reg ar dless of sett ing in pa r. C01.00 Conf igur at ion Mode. Local

pot en tiometer (if pr esent) or Arr ow up/dow n determ ines out pu t

frequ enc y li mi ted by Motor Speed Hig h/Low Li mit (parame ters

C04.14 and C04.12).

■ 2: If par. C01.00 Conf igu rat ion Mode is set to Ope n Loo p [1]

fu nc ti on is as desc ri be d above . If pa r. C01.00 is se t to Pr oc es s

Closed Loop [3] chang ing from Auto mo de to Hand mode results in

a setpoint chan ge via local p otentiom eter or Ar row up/down. The

change is li mited by Referenc e Max /Min (para meters C03.02 and

C03.03)

- 40 -

HLP-NV Series

Page 46

HLP-NV Series

0-2* Motor Data

● Func tion: Enter the correct motor nameplate data (power, voltage,

frequency, cur rent and speed).

Run AMT, see par. C01.29. Default setting sett ings for advance d motor

data, par. C01.3*, are automatically calculated.

● ATTENTION! Parameters i n parameter g roup 1.2* cannot be adjusted

while motor runs.

C01.20 Motor Power [kW ] [HP] Default set ting **

Range [0.09 kW/0.12 HP -11 kW/15 HP]

Two sizes down, one size up from nominal VLT rati ng.

● Function: Enter motor power from nameplate data.

C01.22 Motor Voltage Default set ting **

Range [50.0 - 999.0 V]

● Function: Enter motor voltage f rom nameplate data.

C01.23 Motor Frequ ency Default setti ng 50

Range [20 -400 Hz]

● Function: Enter motor frequency f rom nameplate data.

● ATTENTION! Changing this parameter affects motor nominal speed

set in par. C01.25.

C01.24 Motor Current Def ault set ting **

Range [0.01 - 26.00 A]

● Function: Enter motor cur rent from name plate data.

C01.25 Motor Nomi nal Spe ed Default sett ing **

Range [100 - 9999 RPM]

● Function: Enter motor nominal speed from n ameplate data.

● ATTENTION! I f Motor Fre quency has been changed in par. C01.23,

Nominal Motor Spe ed is affe cted.

HLP-NV Series

- 41 -

Page 47

HLP-NV Series

C01.29 Automatic Motor Tuning (AMT) Default setti ng 0

Range [0] Of f A MT fu nctio n is disabled.

[2] Enable AMT

AMT f unction star ts run ning. This

may take up to 10 min. d epe ndi ng

on motor power rati ng.

● Function: Use AMT to optim ize motor performance.

● Stop VLT – make sure motor is at sta ndstill

● Choose [2] Enable AMT

● Apply start sig nal

■ Via LCP: P ress Ha nd On

■ Or in Remote On mode: Apply start signal on Terminal

RUN

● ATT ENTION! To gai n optimum tuning of frequency converter, run

AMT on a cold motor.

C01.3* Adv. Motor Data

Adjust advanced motor data using one of these methods:

1. Run AMT on cold motor. Fre quency conver ter measu res value f rom

motor.

2. Enter X1 value manually. Obtain value from motor supplier.

3. Use X1 defau lt set ting . Frequen cy conve rter es ta bli shes sett ing

based on motor nameplate data.

ATTENTION! This parameter can not be changed while motor r uns.

C01.30 Stator Re sista nce (R1s) Default set ting **

Range Depend ing on mot or data* [Ohm]

● Function: Set stat or resistance value.

- 42 -

HLP-NV Series

Page 48

HLP-NV Series

C01.33 Stator Leakage Reactance (X1) Default setting **

Range Depend ing on mot or data*[Ohm]

● Function: Set stat or leakage reactance of motor.

C01.35 Main Rea ctance (Xh) Default set ting **

Range Depend ing on mot or data*[Ohm]

● Function: Set motor main rea ctance.

1-5* Load Independent Setting

This parameter group is for set ting t he load independent motor settings.

C01.50 Motor Mag netisation at 0 Sp eed Default set ting 100%

Range [ 0 - 30 0%] Ente r a percentage of rated mag netizing

● Funct ion: This parameter enables diffe ren t th er mal loa d on motor

when running at low speed.

C01.52 Min Speed Norm. Magnet. [Hz] Default s etti ng 0.0HZ

Range [0.0 - 10.0 Hz]

● Fu nct ion: Us e t h is pa r a me ter al on g w it h p ar. C01. 50 , Mo tor

Magnetizi ng at Zero Speed.

Set fre quency required for nor mal magnetizing current. If frequency is

set lower than motor slip frequency, par. C01.50, Motor Magnetizing at

Zero Spe ed is inactive.

current. If setting is too low, motor shaft

torque m ay be reduced.

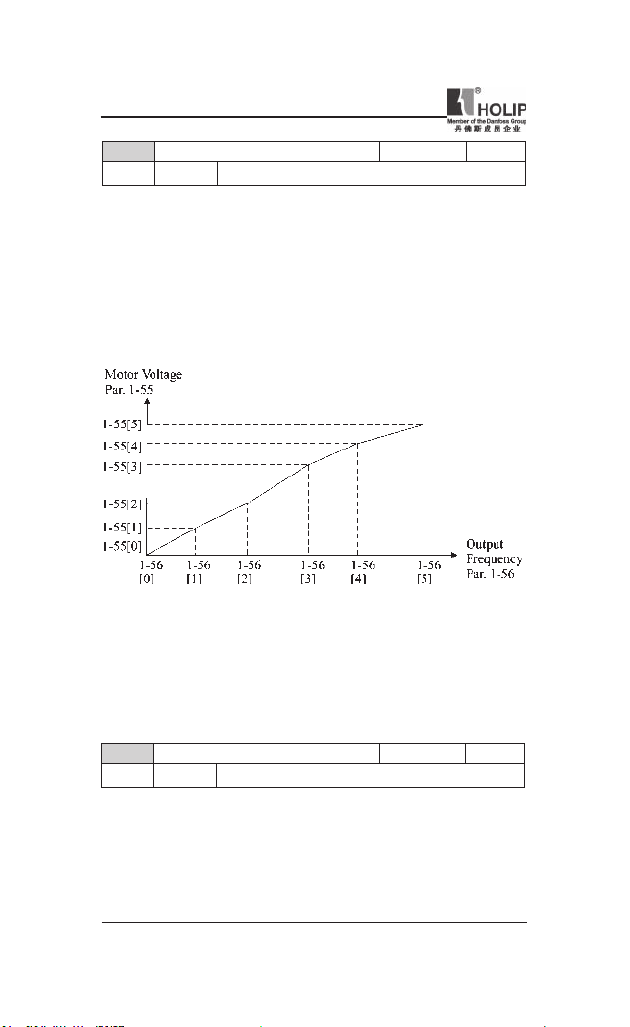

C01.55 V/F Chara cter istic - U Default setting 0V

Range [0 - 999 V]

● Fu nction: This pa ra me ter is an arr ay parame te r [0-5] and is only

functional when par. C01.01, Motor Control P rinciple is set to V/F [0].

En ter volt age at eac h fr e qu enc y poi nt to ma nu all y for m a V/F

character ist ic matching motor. Frequen cy poi nts are defin ed in pa r.

C01.56, V/F characteristics - F.

HLP-NV Series

- 43 -

Page 49

HLP-NV Series

C01.56 V/F Chara cter istic - F Default sett ing 0H Z

Range [0 - 40 0 Hz]

● Fu nc tion :Th is pa ra me te r is an ar ray para me te r [0-5] an d is on ly

functional when par. C01.01, Motor Control P rinciple is set to V/F [0].

En t er fr eq uen c y poin ts to ma nua lly for m a V/F cha rac ter ist ic

matching motor. Voltage at each point is de ned in pa r. C 01.55, V/F

Character istic - U.

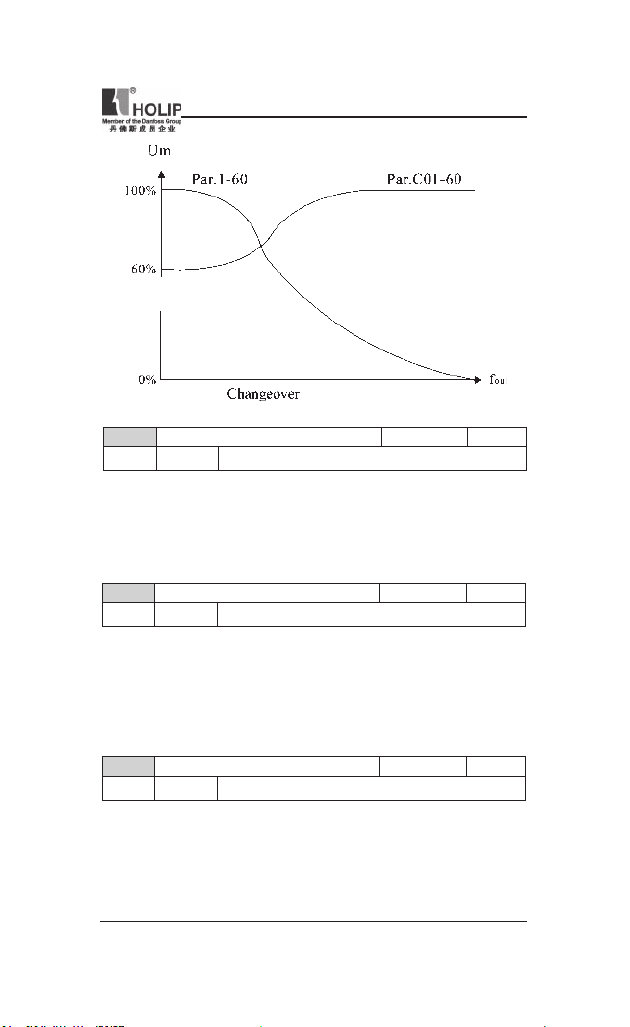

Ma ke a V/F cha rac teris tic base d on 6 def in abl e volt age s a nd

frequencies, see below gure.

Simplif y V/F character istics by merging 2 or more points (voltages and

frequencies), respectively, are set equal.

● ATTENTION! For par. C01.56 the followi ng applies [0]≤ [1] ≤ [2] ≤

[3] ≤ [4] ≤ [5]

C01.6* Load Dependent setting

Parameters for adjusting the load dependent motor settings.

C01.60 Low Speed L oad Compensation D efault setting 100%

Range [0 -199 %]

● Fun ct ion: Use this para met er to gai n optimum V/F chara cterist ic

when running at low speed.

Enter pe rcentage in relation to load when motor run s at low speed.

Change -over poi nt is automatically calculated based on motor size.

- 44 -

HLP-NV Series

Page 50

HLP-NV Series

C01.61 High Speed Load C ompensation Default setting 100%

Range [0 - 199 %]

● Func tion:Use this parame ter to obt ain opti mum load c ompensation

when running at hig h speed.

Enter percentage to compensate in relation to load when motor runs at

high speed.

Change -over poi nt is automatically calculated based on motor size.

C01.62 Slip Compe nsation Default se tti ng 100%

Range [- 400 - 399 %]

● Fu nct ion : C om pens ati on for loa d d epe nde nt moto r sl ip. Sli p

compen sation is calculated automatically based on rate d motor s peed,

nM,N.

● ATTE N TI ON ! T his fun cti on is only act iv e whe n par . C01.0 0,

Con fi gu ration Mod e, is s et to Speed Open Loop [0],and when par.

C01.01, Motor Cont rol Principle, is set to VVC+ [1].

C01.63 Slip Compe nsation Time Con stant Default setting 0.10 s

Range [0.05 - 5.00 s]

● Funct ion: 0.10 s [0.05 - 5.00 s] Enter slip compensation reaction speed.

A high value result s in slow reaction whereas a low value r esu lts in

quick rea ction.

If low-frequency resonance problems arise, use longer time setting.

HLP-NV Series

- 45 -

Page 51

HLP-NV Series

1-7* Start Adjustments

Considering t he need for various sta rt functions in d ifferent applications,

it is possible to select a nu mber of functions in this par amete r group.

C01.71 Star t Delay Default setting 0.0S

Range [0.0 - 10.0 s]

● Func tion: The st art dela y def ine s the ti me to pas s fro m a st art

comma nd is given until t he motor starts accele rati ng.

Setting sta rt delay to 0.0 sec. disables Start Function, [C01.72], when

star t command is given.

Ente r the time delay requir ed before commencing acceleration. Par.

C01.72 Star t Function is active dur ing Start delay time .

C01.72 Star t Funct ion Default set ting 2

Range [0] DC Hold/ Dela y Time Motor is ene rgi zed with

[1] DC Brake/ Delay Time Motor is energized with

[2] Coast /Delay Time I n v er t e r i s c oa st e d

C01.73 Flying St art Default setti ng 0

Range [0] Disabled Flying star t is not re quired.

[1] Enabled F re que nc y co nv er ter e na bled to

● Funct ion: Use ying start to cat ch a spin ni ng motor afte r eg. mai ns

dropout.

● Warning: T his function is not suitable for hoisting applications.

● ATTENTION! W hen ying st art is enabled par. C01.71, Start Delay,

and par. C01.72, Star t Funct ion, have no f unct ion.

DC hold ing current ( par.

C02.0 0) du ri ng s ta rt

delay time.

DC bra king cur rent ( par.

C 0 2 .0 1) d u r in g st ar t

delay time.

du ri ng s ta rt delay ti me

(inver ter off ).

catch spi nni ng motor.

- 46 -

HLP-NV Series

Page 52

HLP-NV Series

C01.8* Stop Adjustments

To meet the need for various stop fu nctions in d ifferent appl ication these

parameters offer some special stop features for t he motor.

C01.80 Function at Stop Default setti ng 0

Range [0] Coa st The inve rter i s coast ed.

[1] DC hold T he motor is ene rgi zed with a DC

cur rent. See par. C02.0 0 DC Hold

Current for more information.

● Fun c tio n: T he sele cte d fu nct io n at st op is act ive in followi ng

situations:

■ Stop command is given and ou tput speed is ramp ed down t o Min.

Speed for Activati ng Funct ions at Stop.

■ Start command is removed (standby), and output speed is ramped

down to Min. Speed for Activating Functions at Stop.

■ DC-brake command is g iven, and DC-bra ke time has passed

■ While running a nd calculated out put speed is below Min. Speed for

Activating Functions at Stop.

C01.82 Min Speed for Func t. at Stop [ Hz] Defau lt sett ing 0.0HZ

Range [0.0 - 20.0 H z]

● F unct ion: Set the speed at which to activate par. C01.80 Function at

Stop.

C01.9* Motor Temperature

With an estimated motor temperature monitor the f reque ncy conve rter is

able to estimate mot or tempe ratu re without having a thermistor mounted.

It is thus possible to receive a war ning or an alarm, if motor temperature

exceeds upper operational limit.

HLP-NV Series

- 47 -

Page 53

HLP-NV Series

C01.90 Motor The rmal P rotec tion Default setti ng 3

Range [0] No Pr otect ion

Disa bles temp erat ure mon itoring.

[1] Ther mistor Warni ng

A therm is to r conn ec te d to eit her

wa rnin g if upp er lim it of mo to r

[2] Ther mistor Trip

A therm is to r conn ec te d to eit her

an alar m and makes the frequency

lim it of motor temperatur e range

[3] ETR Warn ing

If calcu lat ed upper lim it of mo tor

[4] ETR Trip If calcu lat ed upper l im it of motor

digital or analog input gives a

tempe ratu re ra nge is exceeded , (see

par. C01.93, Ther mistor Resour ce).

digital or analog input gives

conver ter tr ip if upp er

is exceed ed, (see pa r. C01.93,

Ther mistor Resource.

tempe ratu re r ange is exc ee ded, a

warn ing occurs.

te mpe rat ure r ang e is ex cee ded ,

an a la rm occ urs and fr equ enc y

conver ter tr ips.

● Fu nc tion : Us ing ETR (Ele c t ro nic Ter m ina l Re l ay ) th e mo tor

temperatu re is calculated based on frequency, speed and time. Danfoss

recom mends using The ETR fu nction, if a ther mistor is not present.

● ATTENTIO N! ETR c alculat ion is based on motor data from group

C01.2*.

C01.93 Ther mistor Resour ce Defau lt sett ing 0

Range [0] None

No thermis tor is con nect ed.

[1] Analog I nput VIN

Con nect thermistor to analog input

[6] Digita l Input JOG

Con nect thermis tor to digit al input

W hi le t h i s in put f u nc t ion s as

Terminal VIN.

Terminal JOG.

t he rm i s t or i np ut , i t wi l l no t

res pon d to the fu nction chos en in

pa r. C0 5.13, Di git al Inp ut JO G.

The val ue of p ar. C05.13 remains

howe ver un chang ed i n parame te r

database whi le fun ction is i nact ive.

- 48 -

HLP-NV Series

Page 54

HLP-NV Series

● Function: Select t he ther mist or input t erm inal.

● ATTE NTION! A na lo g Inp ut V IN can no t be sele cted for oth er

purposes whe n selected as thermistor resource.

Input Dig ital/Analog Supply Voltage Th reshold C ut-out Values

Digital 10 V <800 oh m - >2.9k ohm

Analog 10 V <800 ohm - >2.9k ohm

Parameter group 2: Brakes

C02.0* DC-Brake

Th e pur pose of DC -b rake fun ct io n is to br ake a r ot ati ng mo to r by

applying DC-current to the motor.

C02.00 DC Hold Cur rent Defau lt sett ing 50%

Range [0 - 100%]

● Funct ion: This par ameter eit her holds t he motor (holding torque) or

preheat s the motor.

■ The pa rameter is active if DC Hold has been selected in either par.

C01.72 Star t Function or par. C01.80 Function at Stop.

■ Ente r a value for holdi ng cu rrent as a percentage of the rated motor

current set in par. C01.24 Motor Cur rent. 100% DC holding current

corresponds to I

● ATTENTION! Avoid 100% c ur rent too long as it may overheat the

motor.

C02.01 DC Brake C urrent D efault settin g 50%

Range [0 - 100%]

● Function: Set DC-cur rent needed to brake rot ating motor.

Activate DC-brake in one of the four following ways:

■ DC-brake command, see par. C05.1* choice [5]

■ DC Cut-in f unction, see par. C02.04

■ DC-brake selected as start f unct ion, see par. C01.72

■ DC-brake in connect ion with Flying St art , par. C01.73.

C02.02 DC Brak ing Time Defa ult setting 10.0S

Range [0.0 - 60 s] S et the time DC-bra ki ng c ur rent,

● Function:DC-braking time de nes the period dur ing which DC-br ake

current is applied to the motor.

● ATTENTION! If DC-brake is activated as star t function, DC-brake

time is dened by star t delay time.

.

M,N

set in pa r. C02.01, must be applied.

HLP-NV Series

- 49 -

Page 55

HLP-NV Series

C02.04 DC Brake C ut In Speed Default set ting 0.0HZ

Range [0.0 - 40 0.0 Hz]

● Function: Set DC-brake cut-in speed t o a ctivat e DC braking cur rent,

set in par. C02.01, when rampi ng down.

When set to 0 the f unction is off.

C02.1* Brake Energy Function

Us e th e pa ram e te rs in thi s gro up for selec t ing dyn ami c bra king

parameters.

C02.10 Brake Function Default set ting 0

Range [0] Of f No brake func tion.

[1] Resisto r Brake Resistor br ake is ac tive.

[2] AC Brake AC brake is act ive.

● Function:

■ Resistor Brake:

The resistor bra ke li mit s voltage in t he inter med iate circuit when

the motor acts as generat or. Without brake resistor, t he fr equency

converter event ually trips.

The resistor brake consume s surplu s energy resulting from motor

braking. A f reque ncy convert er wit h brake stops a motor faste r

than without a brake, wh ich is u sed in many applications. Requires

connection of external brake resistor. An alte rnative to the resistor

brake is t he AC brake.

■ AC Brake:

The AC brake consumes surplus energy by cre ating power loss i n

the motor.

It is important to keep in m ind that a n inc rease in power loss causes

motor temperature t o rise.

● ATTENT ION ! Re sis to r brake is on ly funct io na l in fr eq ue nc y

converters w ith integrated dy namic brake. An ext ernal resistor must

be connected.

C02.11 Brake Resistor (ohm) Default sett ing *Ω

Range [5 - 500 0 Ω]

● Function: Set brake resistor value.

C02.16 AC Brake, Max c urr ent Default setting 100%

Range [0 - 40 0 %]

● Fun ct ion: Enter max. pe rm issible current for AC-braking to avoid

overheating of motor.

100% equals motor cu rrent set in pa r. C01.24.

- 50 -

HLP-NV Series

Page 56

HLP-NV Series

C02.17 Over-voltage Control D efault setting 0

Range [0] Disabled The OVC is not active/requ ired.

[1] Enabled , not at stop

OVC is run ning u nless a stop sign al

[2] Enabled OVC is run ni ng, also when a st op

is active.

signal i s active.

● Funct ion: Use Over-voltage Control (OVC) to reduce the risk of the

fre que ncy converter t ripping due t o an over voltage on the D C link

cau sed by ge ner at ive power from the loa d. An over-volt age occu rs

eg. if the ramp dow n time is set too shor t compared to the actual load

iner tia.

● ATT ENTIO N! If Resistor Brake ha s be en cho se n in pa r. C02.10

Bra ke Functio n th e OVC is not acti ve even th oug h enabled in this

parameter.

2-2* Mechanical Brake

For hoist ing ap pli cat ions an ele ct ro-ma gn et ic brake is requ ir ed. Th e

brake is c ontrolled by a relay, which releases t he brake when activated.

The brake act ivate s if frequency conver ter trips or a coast c ommand is

given. Fu rthermore, it act ivates when motor speed is ramped down below

the speed set in par. C02.22, Active Bra ke Speed.

C02.20 Release Br ake Current Default sett ing 0.00A

Range [0.00 - 100 A]

● Funct ion: Select motor current at which mechanical brake releases.

● Warn ing: If star t delay time has passed, and motor cu rrent is below

Release br ake current, frequency converter trips.

C02.22 Activate Brake Spe ed [Hz] D efault setting 0

Range [0 - 40 0 Hz] S el ec t m ot or s p e e d at wh ic h

ramping down.

mechanical br ake act ivates when

● Funct ion: If the motor is stop ped using ramp, the mechanical bra ke is

activated when motor speed is less than Active Brake Spe ed.

Motor is ra mped dow n to stop i n the following situations:

■ A star t command is removed (stand by)

■ A stop com mand is activated

■ Quick-stop is activated (Q-stop ramp is used)

● Mechan ical bra ke automat ically activates if frequency converter trips

or repor ts an alarm.

HLP-NV Series

- 51 -

Page 57

HLP-NV Series

Parameter group 3: Reference/Ramps

Pa ram ete r s for refe ren ce han dli ng, def init io n of li mi t at ions, a nd

cong urat ion of the frequency

converter's reaction t o changes

3-0* Reference Limits

Parameters for setti ng the refe rence u nit, limits a nd ranges.

C03.00 Reference Range Default setting 0

Range [0] Mi n - Max Reference set point ranges can h ave

Se le ct thi s i f run ning in Pr oc es s

[1] -Max-+Max Ranges can h ave both p ositive and

● Funct ion: Select t he range of reference and fee dback signals. Values