Page 1

HLP-C100 Series Operating

Manual

Page 2

Introduction

Thank you for purchasing and using the minidrive of HLP-C100 series.

Please read caref ully the operation manual before putt ing the drive

to use so as to correctly install and operate the d rive, give f ull play to its

f unctions and ensu re the saf ety. Please keep the operation manual handy for

f utu re reference, maintenance, inspection and repair.

Due to the driveof a kind of powerelectronics product it must be

installed, tested a nd adjusted wit h specialized electr ical engineering workers.

Th e mar ks of

remind you of t he safety and prevention cautions dur ing the handling,

installation, running and inspection. Please follow these instr uctions to make

sure the safe use of t he drive. In case of a ny doubt please contact our local

agent f or consultation. Our professional persons are willing and ready to

ser ve you.

The ma nual is subject to change without notice.

(D ange r), (Caution)and other symbols in the manual

Page 3

HL P-C10 0 Ser ies

Index

Introduction I

Chapter 1 Sa fety Precautions - 1 -

1.1 Before Power-up -1 -

1.2 During the Power-up - 2 -

1.3 Duri ng the Operation - 3 -

1.4 After t he Power-off - 3 -

Chapter 2 Standards and Specicat ions - 4 -

2.1 Label Description - 4 -

2.2 Particular Specications - 5 -

2.3 Technical Specications - 5 -

2.4 Derat ing Specications - 7 -

2.5 Accessories - 7 -

Chapter 3 Mechanical and Electrical Installation - 8 -

3.1 Mechanical Installation - 8 -

3.1.1 Installat ion Environment Requirements - 8 -

3.1.2 External and Installation Dimensions - 8 -

3.1.3 Installation and Di rection - 9 -

3.1.4 Accessories I nstal lation - 11 -

3.2 Periphe ral Elect rical Devices - 14 -

3.2.1 Selection of MCCB/ Fuse/Contactor - 15 -

3.2.2 Selection of Braking Unit and Braking Resistor - 16 -

3.2.3 Selection of AC Input and Output Reactor - 17 -

3.2.4 Select ion of EMC Filter - 18 -

3.3 Descr iption of Mai n Circuit - 18 -

3.3.1 Schematic of Main Circuit Ter minals - 18 -

3.3.2 Main Circuit Terminal Screws and Wiri ng Recommended

Specications - 19 -

3.4 Description of Cont rol Circuit - 19 -

3.4.1 Schematic of Control Circuit Terminals - 19 -

3.4.2 Control Ter minals’ Screws and Wi ring Recommended

Specications - 20 -

3.4.3 Control Curcuit Wiring - 21 -

3.4.4 Digital Input Terminals Usage Specication - 21 -

3.5 EMC instructions - 22 -

3.5.1 Introduct ion to EMC Standard - 22 -

3.5.2 Noise Abatement - 23 -

3.5.3 Ground ing - 23 -

HLP-C100 Ser ies Operating Manual

Page 4

HL P-C10 0 Ser ies

3.5.4 Leakage Current Suppression - 23 -

3.5.5 Induction Voltage Suppression - 24 -

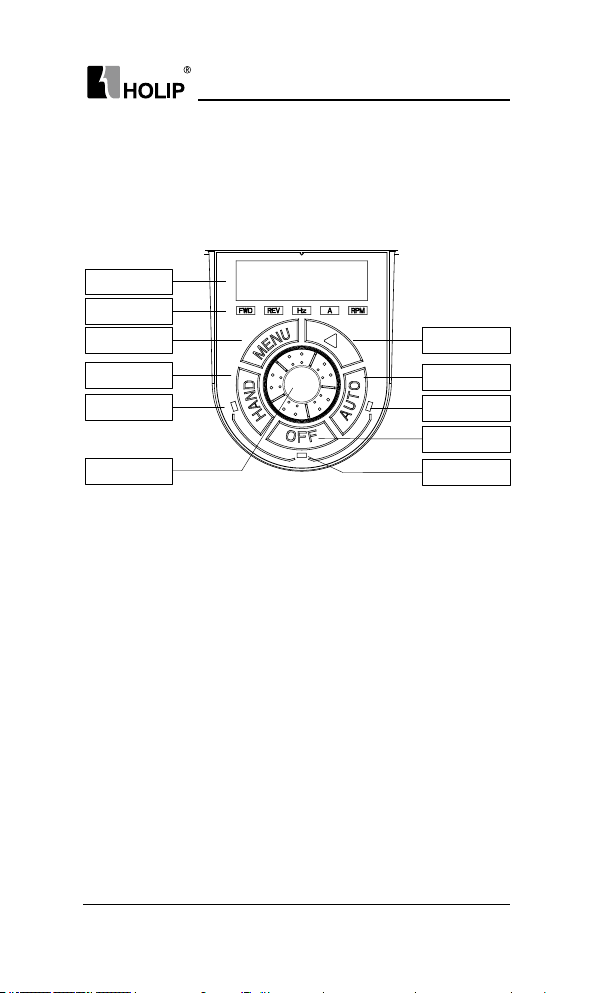

Chapter 4 Operation and Display Interface - 25 -

4.1 Local Control Panel - 25 -

4.2 Parameter Set ting - 26 -

4.3 FWD/REV Stat us - 28 -

4.4 Data Rea d-outs - 29 -

4.5 View Alar m Record - 30 -

4.6 View State Par ameter - 31 -

4.7 LED Display - 32 -

Chapter 5 Parameter Over view - 33 Chapter 6 Parameter Description - 43 -

6.1 Group 00: Ope ration /Display - 43 -

6.2 Group 01: Load and Motor - 45 -

6.3 Group 02: Brakes - 51 -

6.4 Group 03: Reference/Ramps - 53 -

6.5 Group 04: Limits/Warnings - 58 -

6.6 Group 05: Digital In/Out - 61 -

6.7 Group 06: Analog In/Out - 64 -

6.8 Group 07: Controllers - 67 -

6.9 Group 08: Communicat ion - 69 -

6.10 Group 14: Special Functions - 72 -

6.11 Group 15: Drive Inform ation - 76 -

6.12 Group 16: Data Readouts - 78 -

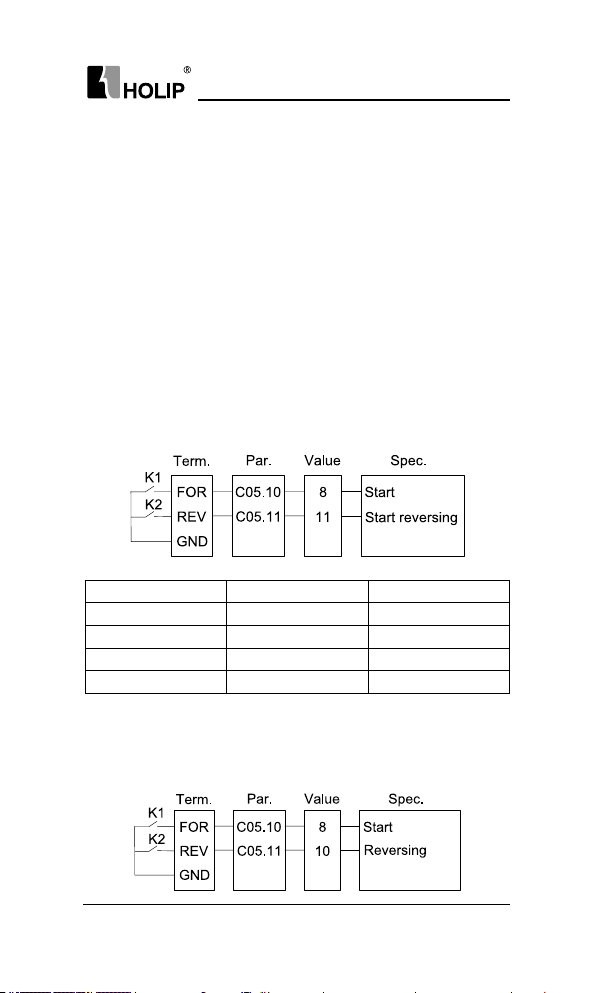

Chapter 7 Quick Application Guide - 81 -

7.1 Using LCP to Start/Stop the Drive - 81 -

7.2 Using Digital Input Terminals to Star t/Stop the Drive - 81 -

7.2.1 Two-line Mode 1 - 81 -

7.2.2 Two-line Mode 2 - 81 -

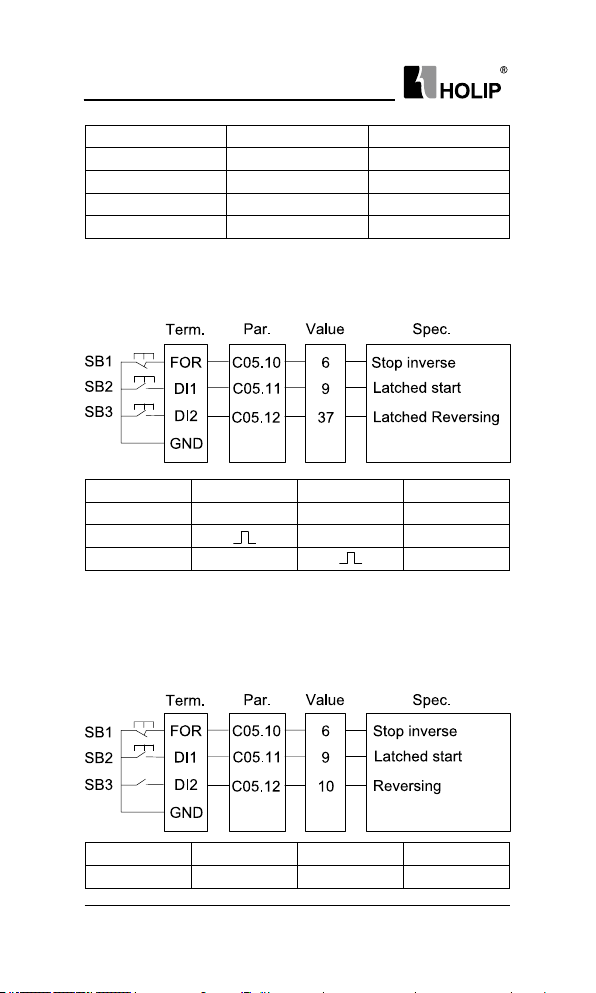

7.2.3 Th ree-line Mode 1 - 82 -

7.2.4 Th ree-li ne Mode 2 - 82 -

7.3 Multi-spee d - 83 -

7.4 Analog Input as the Frequency Source - 83 -

7.5 Speed up/down - 84 -

7.6 Parameter I nitialization - 84 -

Chapter 8 Faults and Solut ions - 85 -

8.1 Fault List - 85 -

Chapter 9 Maintenanc e - 88 -

9.1 Note - 88 -

9.2 Storage and Transpor t - 88 -

Appendix A Modbus Commun ication Specication - 89 -

Appendix B Copy Card Speci cation - 101 -

HLP-C100 Ser ies Operating Manual

Page 5

Chapter 1 Safety Precautions

HL P-C10 0 Ser ies

Caution

Danger

Indicates misu se may damage the inver ter or

mechanical system .

Indicates misuse may result in casualty.

1.1 Before Power-up

Caution

● Check to be sure that t he voltage of t he main circu it AC power

supply matches the input voltage of the d rive.

● Install the drive in a safe location, avoiding high temperat ure,

direct sunlight, humid air or wate r.

● The drive can only be used at the places accredited by our

company. Any u nauthor ized work ing envi ronment may have the

risks of re, gas explosion, electric shock and other incidents.

● If more tha n one d rive installed on the same control cabinet, make

additional cooli ng fan, so t hat the in side tempe rature is lower than

40

in order to prevent overheati ng or re occurs.

℃,

● It will affect the service life of the drive if a contactor is installed

on the input side to control the start a nd stop. Generally it is

requi red to cont rol it through terminal commands. Special

attention should be paid to its use in the case of the star t and stop

more frequently places.

● Do not install any switch component like circuit breaker or

contactor at the out put of the dr ive. If any of such components

must be installe d due process and other needs, it mu st be ensu red

that the drive has no output when the switch acts. In addition , it

is forbidden to install any capacitor for improvement of power

factor or any varistor against thunder at the out put. Otherwise

it will cause malf unctions, tripping protection and damage s of

compone nts of the dr ive.

● Please use an independent power supply for the d rive. Do avoid

using the common power supply with an electr ical welder and

other equipment with strong d isturbance. Ot herwise it will cause

the dr ive to protect or even dam age the dr ive.

● Do not make any high voltage test with any component inside the

drive. T hese semi-conductor parts are subject to the damage of

HLP-C100 Ser ies Operating Manual

- 1 -

Page 6

HL P-C10 0 Ser ies

high volt age.

● The IC board of the drive are suscept ible to the effect and damage

of static electricity. Don’t touch the mai n circuit board.

● Instal lation, commission ing and maintenance must be performed

by qualied professional per sonnel.

● Don’t carry the front cover of the d rive directly when handli ng.

It should be handled with the base t o prevent the front cover off

and avoid the d ropping of t he drive, which may possibly cause the

injur ies to people and the damages to the drive.

Danger

● Be su re to tu rn off t he power supply before wi ring.

● Mount the drive in the metal and other non-combu stible materials

to avoid the risk of re.

● Don’t install the drive in a space with explosive gas, otherwise,

they lead to explosion.

● R, S, T terminals are power input terminals, never mixed with

U.V.W term inals. Be su re that the wi ring of the main circuit is

correct. Othe rwise it will cause damages of the drive when the

power is appl ied to it.

● T he terminal of

connected toN-line. Otherw ise it will easily cause the protection

or errors of thedrive.

● Do not d issemble or modify any internal conne cting cord, wiring

or component of the dr ive by yourself.

● Never remodel it or exchange control board s a nd components by

yourself. It may expose you to an electrical shock or explosion,

etc.

● Keep the drivefrom the reach of children or pe rsons not concerned.

must be grounded separat ely and never

1.2 Duri ng the Power-up

Danger

● Do not plug the connectors of the drive during the power upto

avoid any surge into the main control board due to plugging,

which mig ht cause the damage of thedrive.

- 2 -

HLP-C100 Ser ies Operating Manual

Page 7

HL P-C10 0 Ser ies

1. 3 Dur in g t he Op era t ion

Caution

● Do not measu re the signals on circuit boards while the d rive is

run ning to avoid danger.

● The drive has been optimized before sold. Please make proper

adjust ments according to the desired functions.

● Do consider the vibration, noise and the speed limit of the motor

bearings and the mechan ical devices.

Danger

● Never connect or discon nect the motor set while thedrive is in

run ning. Otherw ise it will cause over-cu rrent t rip and even burn

up the main circuit of the drive.

● Do not come close to the machine when the ResetFunction is

used to avoid a nything unexpected. T he motor may automatically

recover f rom fault.

1.4 Af ter the Power-of f

Caution

● Even in the case of the main power, the other voltage inputs and

the share load (li nkage of DC i ntermediate ci rcuit) all have been

disconnected from the mains; the i nternal of the drive may still

have residu al energ y. Before touching any potentially live parts of

the dr ive, please wait at least 4 mi nutes. Ot herwise, it may expose

you to a risk of electrical shock.

HLP-C100 Ser ies Operating Manual

- 3 -

Page 8

HL P-C10 0 Ser ies

Chapter 2 Standards and Specications

2.1 La be l Des cr iption

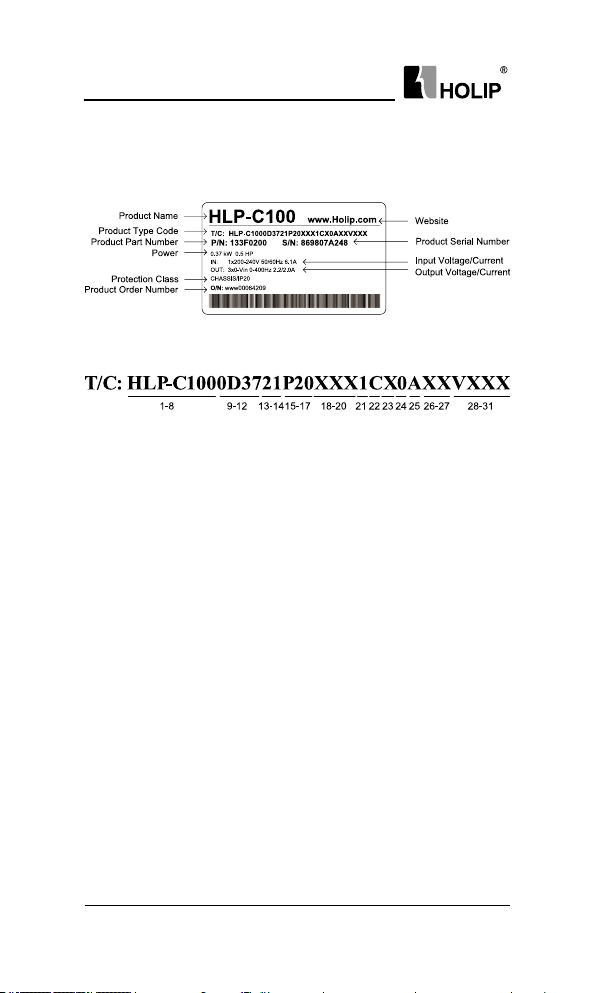

Signicance of the product type code:

1-8 H LP-C100 Indicate Produ ct Series

9-12 0D 37 I ndic ate 0.37KW

13-14 21 Indicate 1-Phase AC 220V

23 Indicate 3-Phase AC 220V

43 Indicate 3-Phase AC 380V

15-17 P20 IP rating is 20

18 X Without AC choke

A With AC choke

19 X Without Brake u nit

B Wit h Brake u nit

20 X Wit hout DC choke

B With DC choke

21 1 Control panel with LED display and potentiometer

22 C With coati ng on PCB

23 X R ese rved

24 0 Domestic sale

1 Overseas sale

25 A Without RS485

B Wi th RS 485

26-27 XX Re ser ved

28-31 VXX X Ind icate sof twa re version nu mber, such as

V235 means the version number is 2.35.

Note: Wit hout RS485 is sta ndard congu ration, Wit h RS485 is optional, please

specif y when ordering.

- 4 -

HLP-C100 Ser ies Operating Manual

Page 9

HL P-C10 0 Ser ies

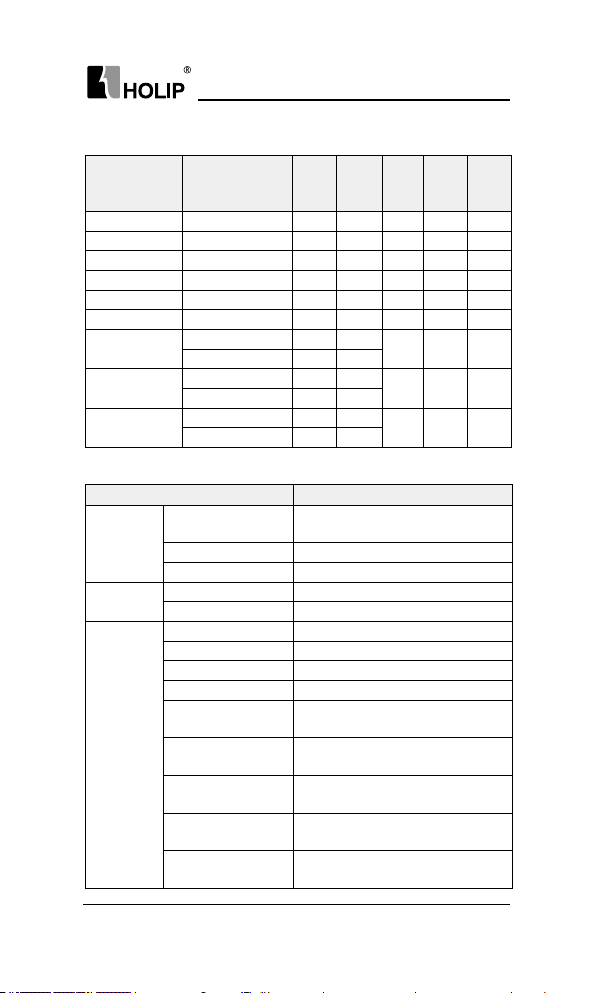

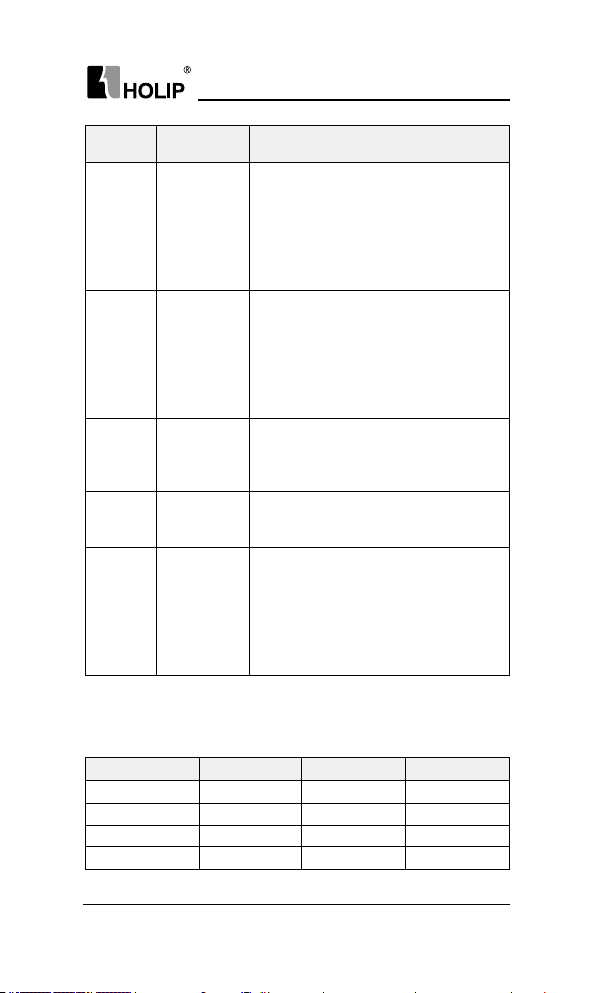

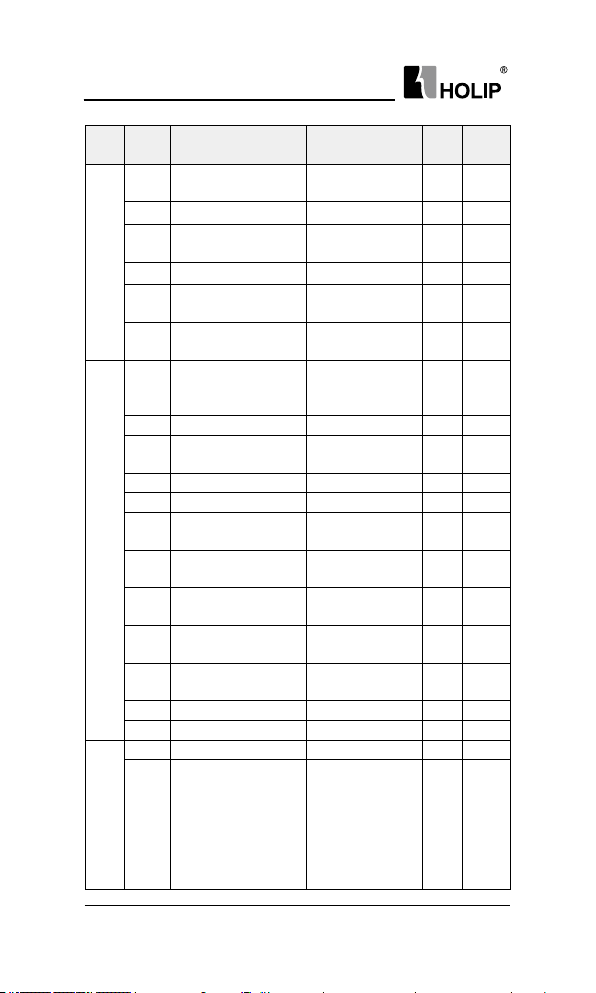

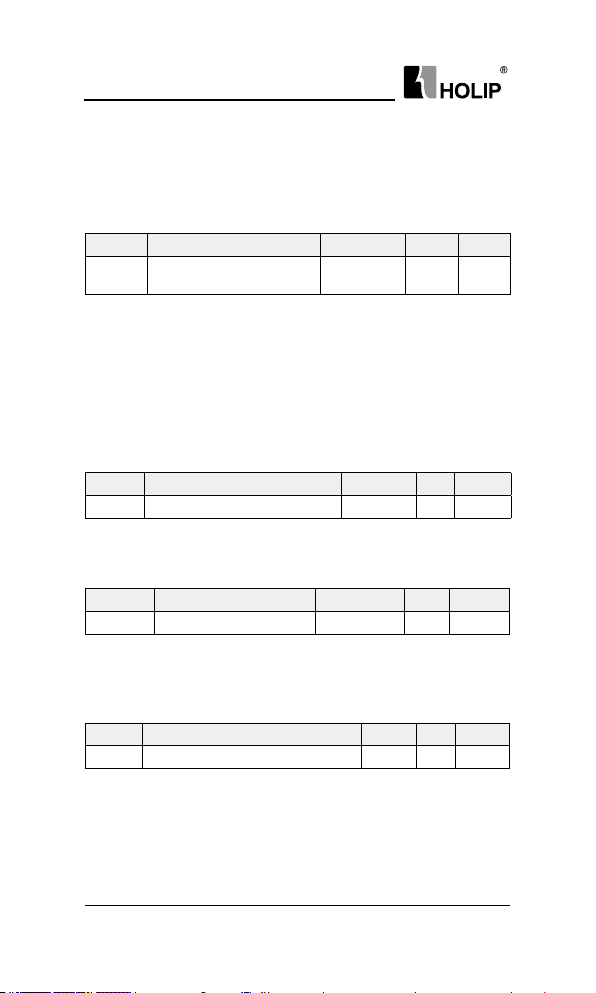

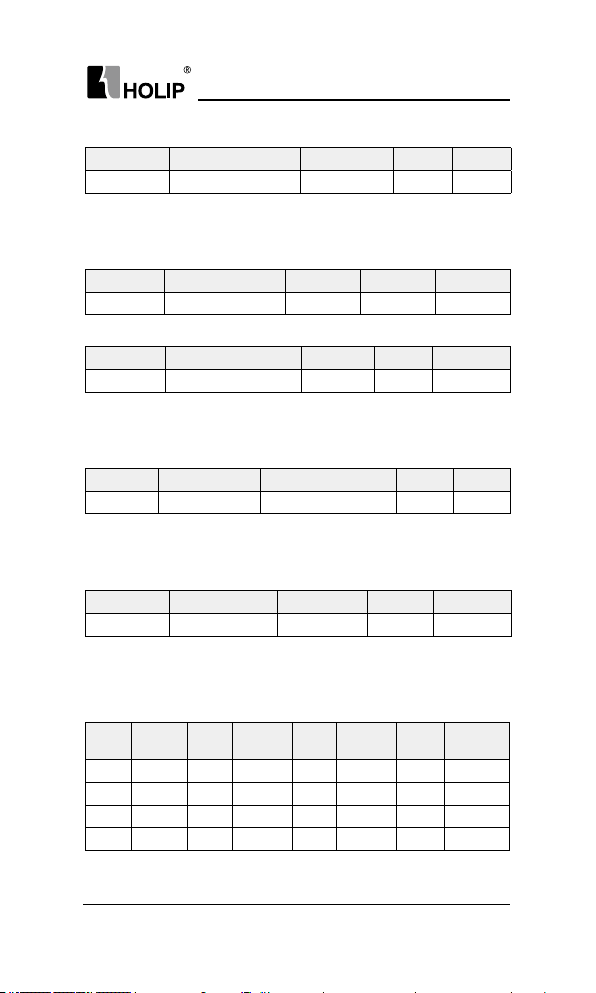

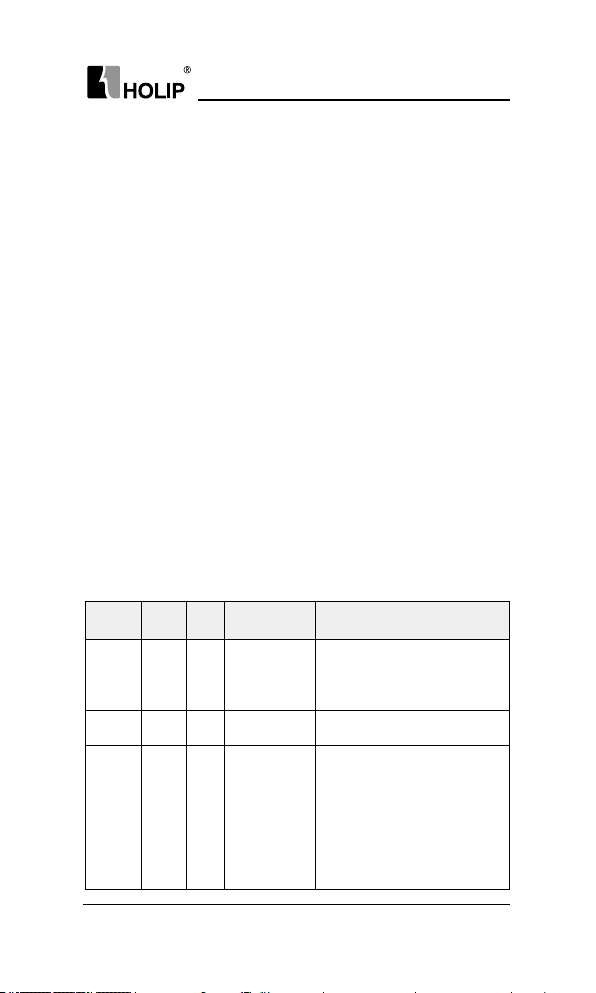

2.2 Particular Specications

Input

Output

Rated

Model

HLP-C1000D3721 1×200-240V50/60Hz 6.1 2.2 0.37 0.37 0.84

HLP-C1000D7521 1×200-240V50/60Hz 11. 6 4.2 0.75 0.75 0.8 4

HLP-C10001D521 1×200-240V50/60Hz 18.7 6.8 1. 5 1. 5 0.8 4

HLP-C1000D3723 3×200-240V50/60Hz 3. 5 2.2 0.37 0.37 0.84

HLP-C1000D7523 3×200-240V50/60Hz 6.7 4.2 0.75 0.75 0.84

HLP-C10001D523 3×200-240V50/60Hz 10. 9 6.8 1. 5 1. 5 0.84

HLP-C1000D7543

HLP-C10001D543

HLP-C10002D243

Input voltage

3×380-440V50/60Hz 3. 5 2.2

3×440-480V50/60Hz 3.0 2.1

3×380-440V50/60Hz 5.9 3.7

3×440-480V50/60Hz 5.1 3. 4

3×380-440V50/60Hz 8.5 5.3

3×440-480V50/60Hz 7.3 4.8

current/

A

current/

A

Suitable

power/

motor/

KW

KW

0.75 0.75 0.8 4

1. 5 1. 5 0.84

2.2 2.2 0.8 4

weight/

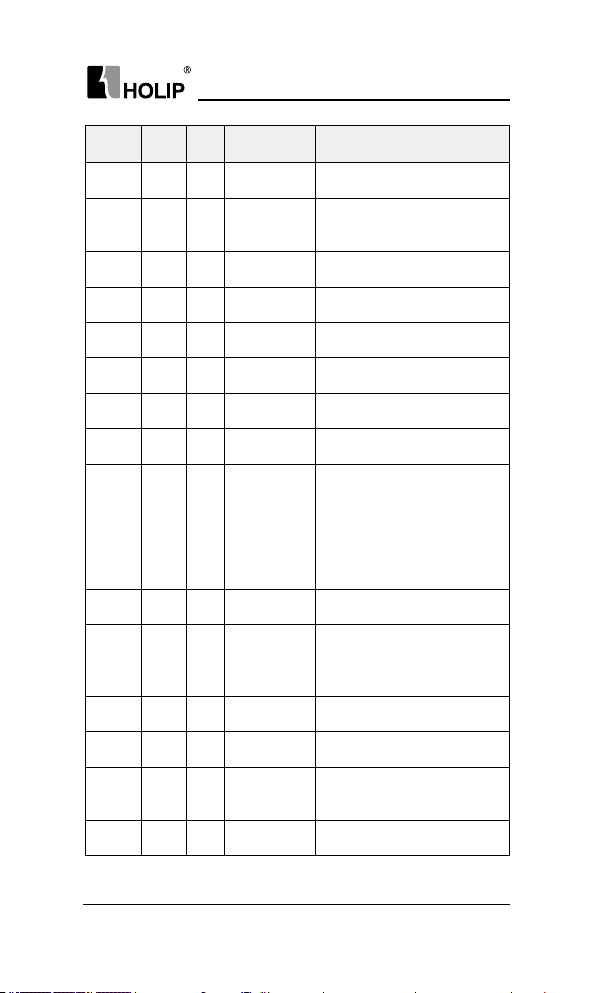

2.3 Technical Specications

Item Specication

Single/Three phase 200~240V -20%~+10%;

Th ree ph ase 380~480V -20%~ +10%;

Digi tal: 0.001Hz; A na logy: 0.5‰ of the

max. operating f requency ;

30~4000 rpm: tolerance±8 rpm;

LCP, digital ter minal, local bus;

LCP, analog, pu lse, local bus;

Selecta ble 8-speed steps ram p u p a nd

down times 0.05-300.00s;

Powe r su ppl y

Motor output

Mai n con trol

f unctions

Supply voltage

Freq uency 48~ 62Hz;

Ma x. imba lance 3%;

Output voltage Three phase 0-100% of supply voltage;

Output f requency 0- 400Hz;

Contr ol mod e V/ F, V VC+;

Sta rt torque 0.5H z 150%;

Overload ca pacity 150% 60s;

PWM switch fr equency 2 ~16 k H z;

Speed setting resolution

Speedope n-loop cont rol

accuracy

Con t r o l com m a n d

source

Frequency setting

source

Ra mp co ntr ol

Net

KG

HLP-C100 Ser ies Operating Manual

- 5 -

Page 10

HL P-C10 0 Ser ies

Speed O pen-loop Contr ol; Process Closed-loop Contr ol; Slip

Basic

Functions

Application

Functions

Protection

Functions

Contr ol

ter minals

Display

Environment

Compensation;Torq ue compensation;Automatic Voltage Regulation;

V/F Control, DC Bra ke; Speed Li mit; Cu rren t Limi t; Flyin gSta rt;

Reset Function;

Jogging; Mu lti-speed Control via Digital inp ut; Mecha nical

Br ak ing; UP/ DOW N; Cat ch u p/Slow dow n; Cou nte r.

Missi ng Motor Phase Protect ion; Low-volta ge Protectio n; Overvoltage Protection; Over-current Protection; Output Phase Loss

Protection; Out put Short Circuit Protection; Out put G rounding

Fault Protection;Live Zero Timeout Function;ButtonFreeze;

Du plicate Fails; LCP In valid; LCP Incompa tible; Par ameter Readonl y; Reference Out of Range; Inva lid While R un ning etc.

Input

Output 1 relay output;

Powe r su pply 1 +10V, max current output 10mA;

Comm un ication* RS+, RS-, max ba ud rate 38400bit/s;

8 segments, 5 numeric

displays

Indicator

Data read-outs

Enclosure IP 20;

Ambient temperature -10℃~50℃, derating use when over 40℃;

Humidit y 5%-85% (95% wi t ho ut con de nsa tio n);

Vibr at ion test 1.14g;

Max. altitude above sea

level

Motor cable length

DC choke N on e;

others

Braking unit ≥220/380V 1.5kWBuilt-in

Item Specication

5 digi tal i n pu ts;

1an alog in put, both can receive volt age

or cu rr ent si gna ls.

Display f req uenc y, war nings, status

and so on;

Light FWD, R EV, HZ, A, RPM display

various stat us of t he drive;

Frequency setti ng, output f requency,

feedback value, output cur rent, DC

link voltage, output voltage, output

power, input terminals state, output

terminals state, analogue input ,

analogue out put, 1-10 f ault records and

accumulated working time etc.;

1000m, derating use when more t han

1000 meters;

Shield cable: 5 meter s, unshield cable: 50

me te rs;

- 6 -

HLP-C100 Ser ies Operating Manual

Page 11

HL P-C10 0 Ser ies

2.4 Derating Specications

Derating f or ambient temperature: If the drive is operated over 40℃

ambient temperature, the continuous output current should be decreased.The

drive has been designed for operation at max 50℃ ambient temperationwith

one motor size smaller than nor mal.Continuous operation at f ull load at 50

ambient temperat ion will reduce t he lifeti me of the d rive.

Derating f or low air pressure: The cooling capability of air is decreased

at low air pressure. Below 1000m altitude no de-rating is necessar y but above

1000m the ambient temperature or the maximum output current should be

decreased. Dcrease the output by 1% per 100m altitude above 1000m or red uce

the max. a mbient t emperat ure by 1 degree per 200m.

℃

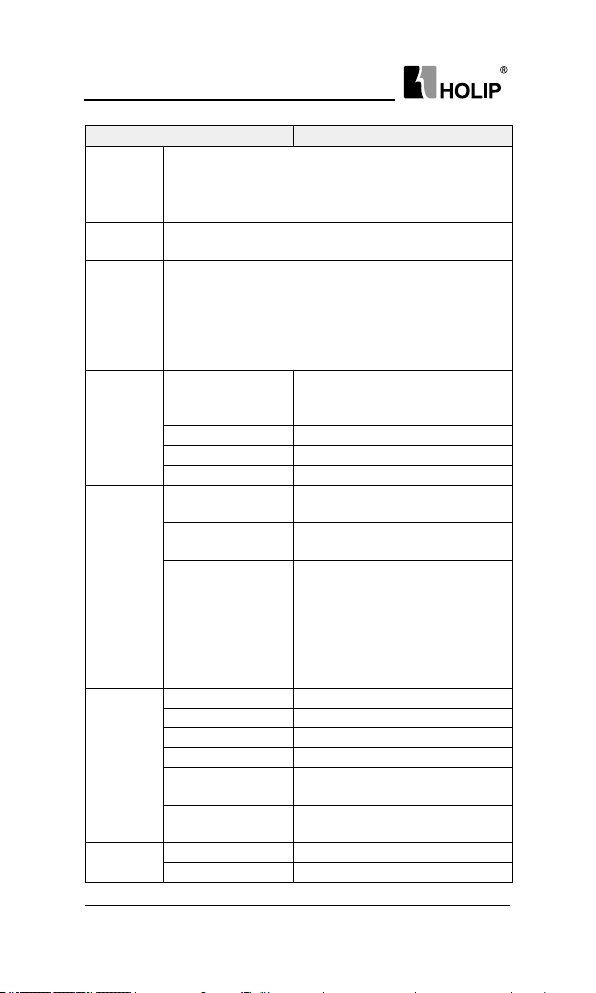

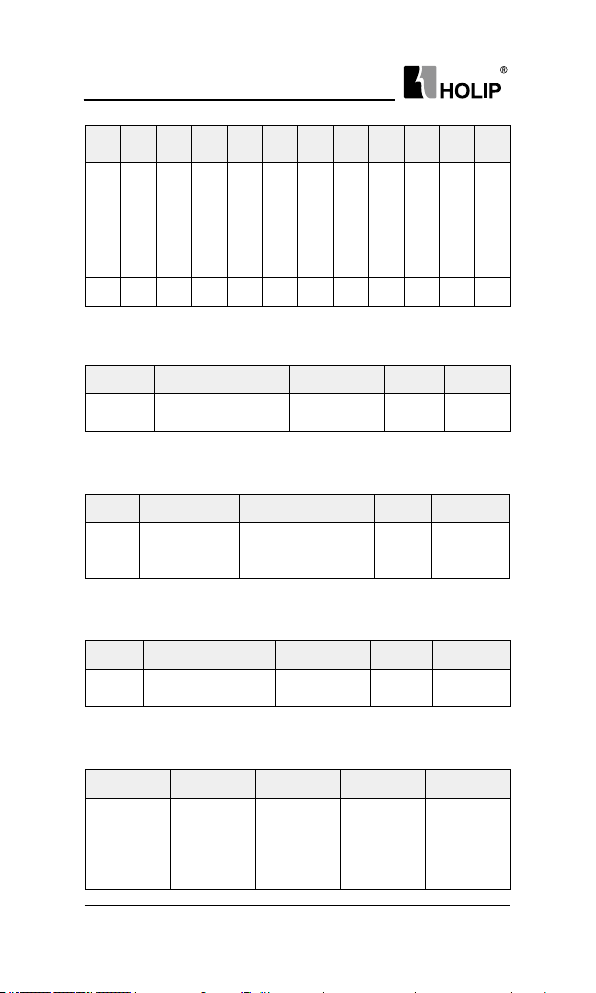

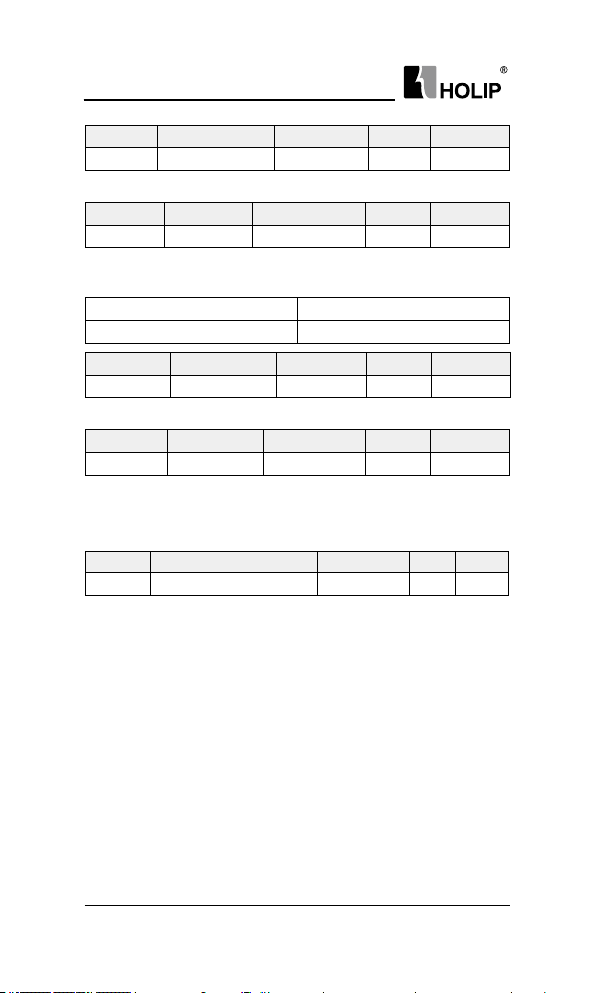

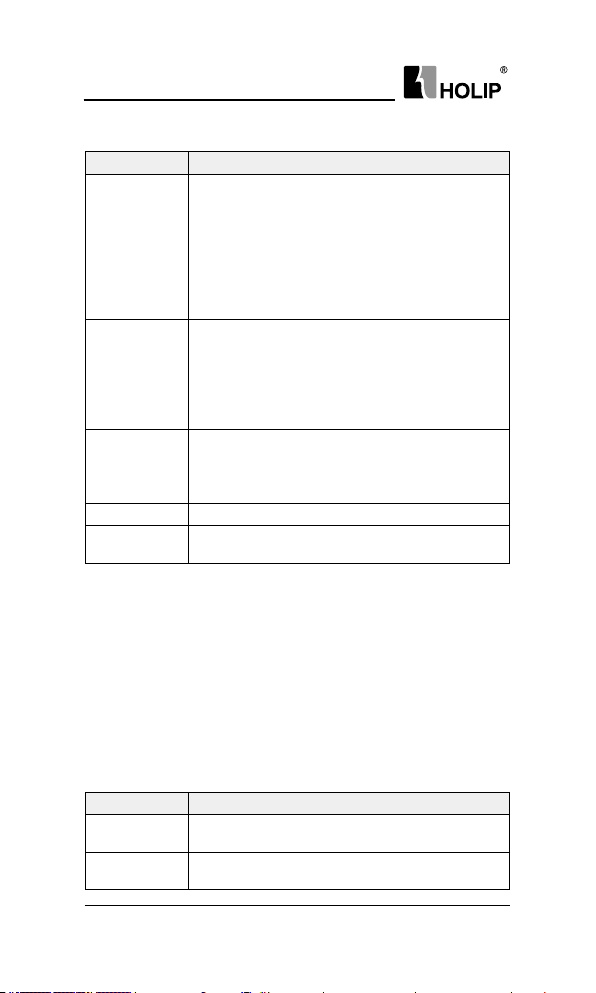

2.5 Accessories

C r ad l e - 01

Network Cable

CopyCard-01 LCP-03

Model Specication Remark

LCP-02

LCP-03

C r ad l e - 01 For LCP-02 installation.

CopyCard-01

Network

Cable

The standard length of

extension cable is 15 meters

when mounting LCP on control

cabi net.

LCP-03 has t he same installat ion

dimensions wit h HLP-A control

panel (OP-AB01).

Copy Card can copy parameters

f rom one drive to another.

Connect LCP to t he drive when

mounti ng LCP on control

cabi net.

HLP-C100 Ser ies Operating Manual

Op t iona l, ple ase s pecif y

when ordering

Op t iona l, ple ase s pecif y

when ordering

Op t iona l, ple ase s pecif y

when ordering

Op t iona l, ple ase s pecif y

when ordering

Do not of fer, self

procu reme nt

LCP-02

- 7 -

Page 12

HL P-C10 0 Ser ies

Chapter 3 Mechanical and Electrical Installation

3.1 Mechanical Installation

3.1.1 Installat ion Environment Requirements

1 Ambient temperature in the range of -10℃~ 50℃;

2 Drive should be in stalled on surfa ce of fla me retardant object, with

adequate sur roundi ngspace for heat dissipation;

3 Installation should be per formed where vibration is less t han 1.14g;

4 Avoid from moisture and direct su nlight;

5 Do not expose to a n atmosphere w ith fla mmable gases, corrosive

gases, explosive gasesor other harmf ul gases;

6 Protect the cooli ng fan by avoiding oil, dust a nd metal particles;

7 Prevent d rilling residues, wire ends and screws falli ng into drive;

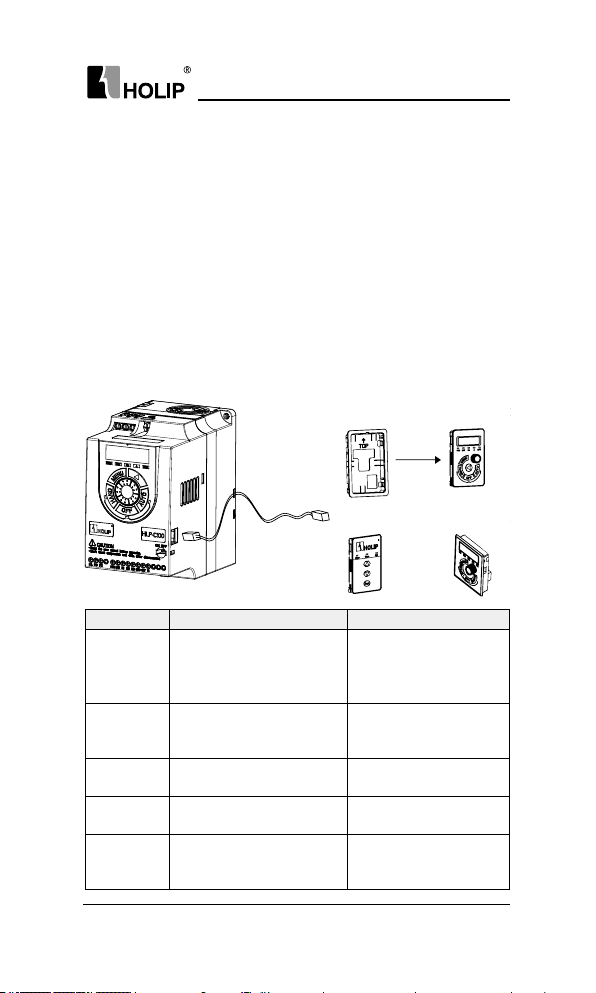

3.1.2 External and Instal lation Dimensions

B

A

CFD D

Single/t hree phase 220V 0.37~1.5kW and thre e phase 380V 0.75~2.2kW

- 8 -

HLP-C100 Ser ies Operating Manual

E

Page 13

HL P-C10 0 Ser ies

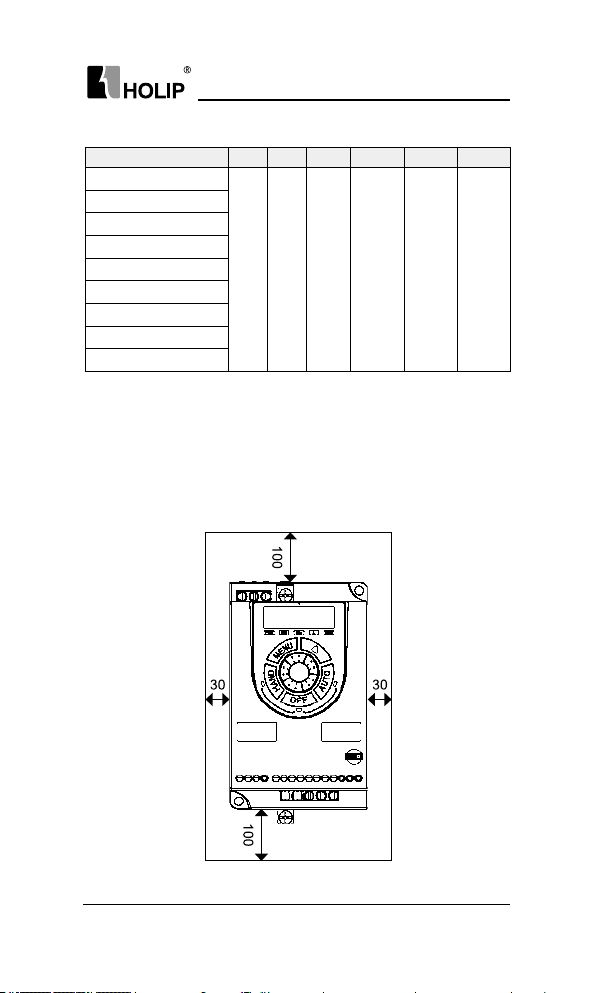

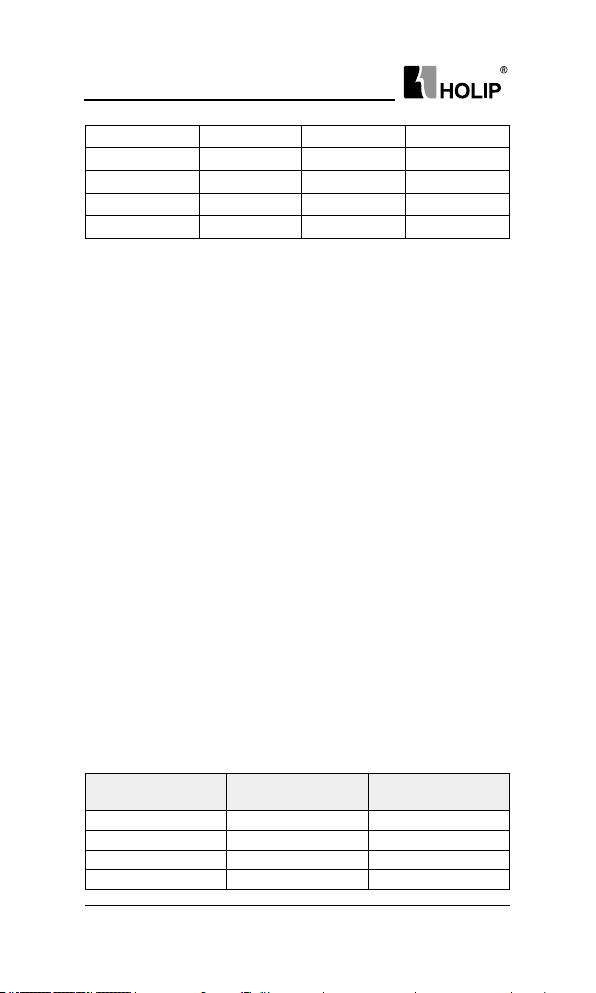

Exter nal and installation dimensions(unit: mm)

Model A B C D E F

HLP-C1000D3721

HLP-C1000D7521

HL P-C10 001D521

HLP-C1000D3723

HLP-C1000D7523

HL P-C10 001D523

HLP-C1000D7543

HL P-C10 001D543

HLP-C10002D243

74 85 130 140 127 5

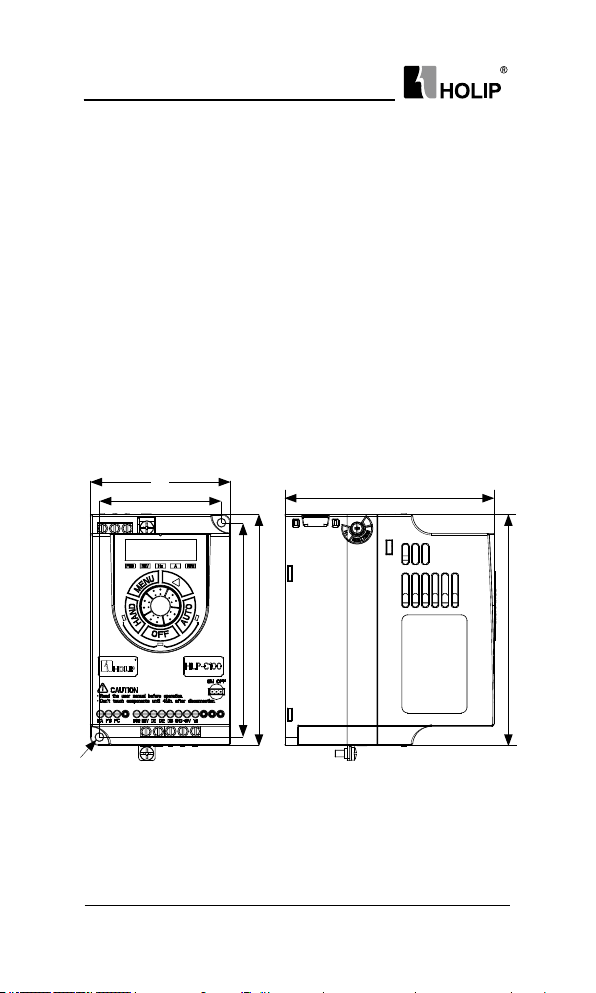

3.1.3 Installation and Direction

1. Single Installation

The dr ive must be in stalled vertically with smooth ventilation. Enough

space must be left around the drive to ensure good cooling, as show n

below (unit: m m):

HLP-C100 Ser ies Operating Manual

- 9 -

Page 14

HL P-C10 0 Ser ies

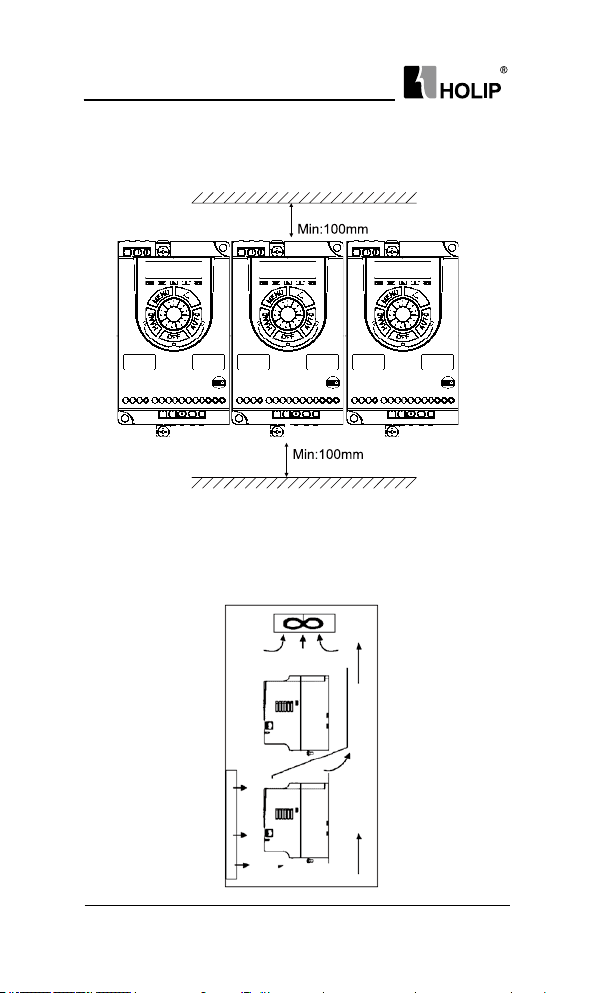

2. Side by Side Installation

The dr ive can be mou nted side by side, a minimum space must be

reser ved above and below the enclosu re, as show n below:

3.Upper and Lower Installation

If several drives need to be in stalled together i n one cabinet, upper a nd

lower installation can be adopted. Enough space mu st be reserved to

ensure effective cooling, as shown below:

- 10 -

HLP-C100 Ser ies Operating Manual

Page 15

HL P-C10 0 Ser ies

59.5

21.7

57.1

12.8

13.3

92.6

89.2

3.1.4 Accessories Installation

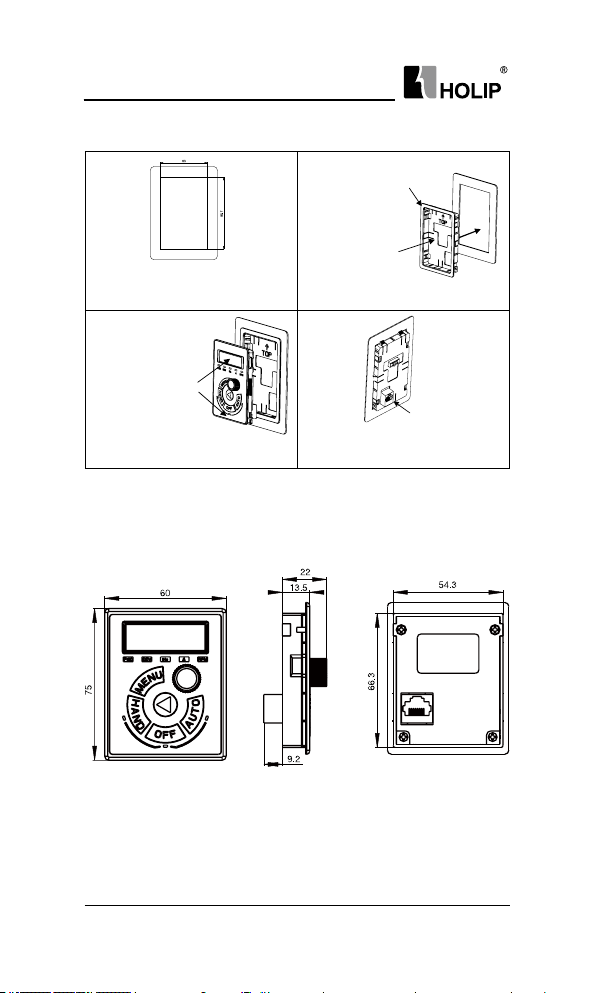

1. LCP-02 Installation

The external dimension s of LCP-02 are shown below (unit: mm):

When i nstalling LCP-02 outside, a cr adle is needed. The external

dimensions of the cr adle are shown below (unit: mm):

HLP-C100 Ser ies Operating Manual

- 11 -

Page 16

HL P-C10 0 Ser ies

The installat ion steps of LCP-02 are shown below:

Th is cra dle is sui ta ble f or 1.0 -2.0m m

th ickness s heet

meta l par ts

Press and hold

the snap roots whe n

installation, using

buckle deformation

Step1: Open a hole i n line with the size of

the con trol pa nel in t he position need to

install t he LCP, hole size, as shown:

Recommen ded

to install ver tical

mounti ng position

arrow, press with

unif orm for ce.

Step 3: The LCP is installed in the cr adle,

according to the dir ection of the arrow.

install sheet metal.

Step2: Install the LCP according to

the di rection of t he arrow.

Step 4: Install the external LCP communication

cable, insert into RJ45 ter minal from thebottom

of hole.

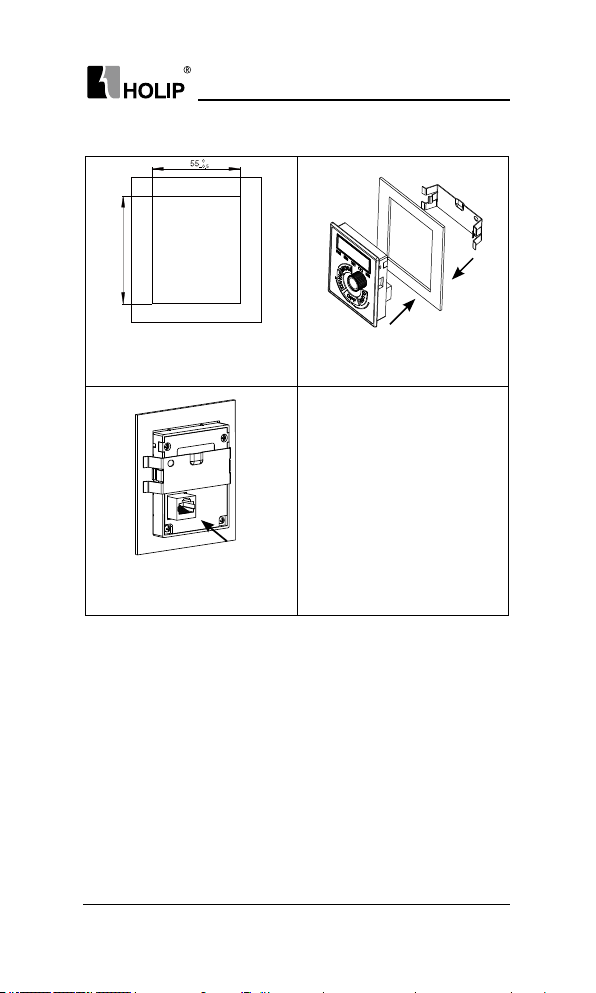

2. LCP-03 Installation

The external dimension s of LCP-03 are shown below (unit: mm):

- 12 -

HLP-C100 Ser ies Operating Manual

Page 17

The installat ion steps of LCP-03 are show n below:

Ste p 1: Open a h ole i n th e co ntrol pane l

where it is needed to ins tall LCP-01 or

LCP-02, the hole size is as shown.

Step 3: Inst all the LCP com mun-ication

cable, insert into RJ45 terminal f rom the

bot tom hole.

HL P-C10 0 Ser ies

HLP-C100 Ser ies Operating Manual

- 13 -

Page 18

HL P-C10 0 Ser ies

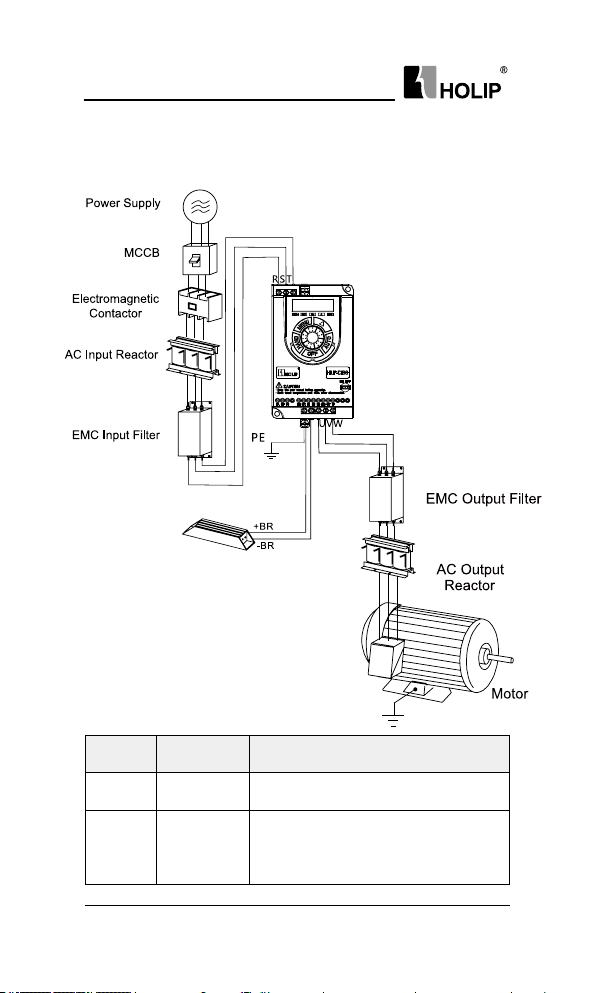

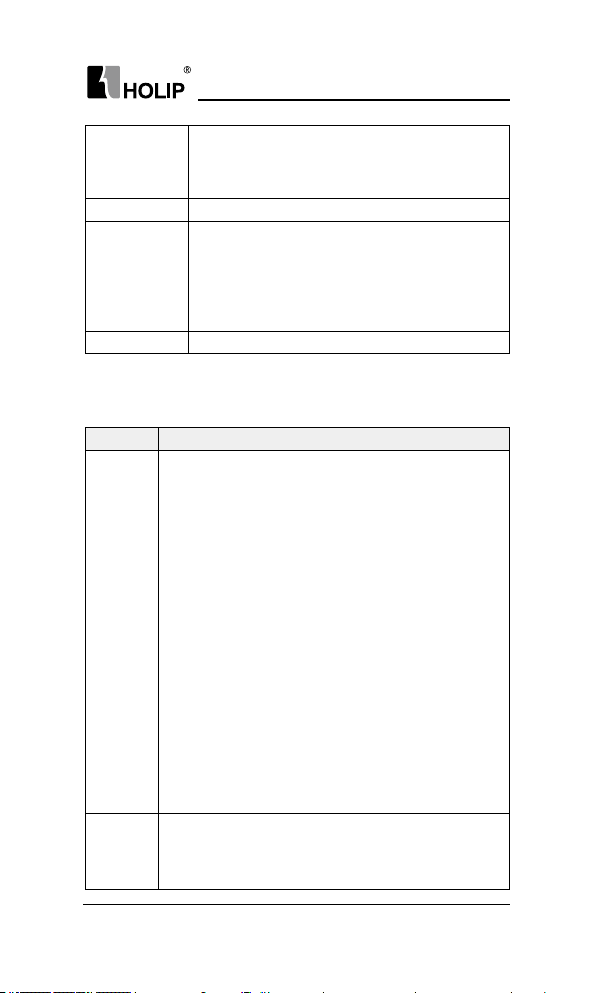

3.2 Peripheral Electrical Devices

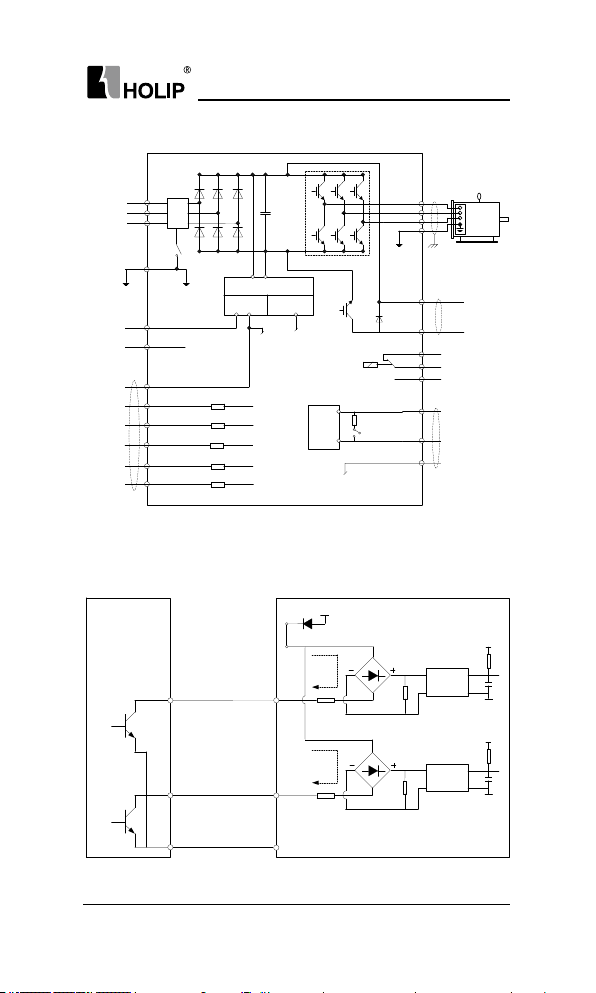

The per ipheral electrical devices of the drive a re shown below:

Part

MCCB

Contactor

- 14 -

Mounting

Location

Power

receiving side

Between

MCCB and

drive i nput

side

HLP-C100 Ser ies Operating Manual

Inter rupt t he power supply when

overcurrent occurs ondownstream devices.

Do not sta rt and st op the dr ive frequently

by switch ingthe contactor on and off (less

than t wice per m inute) noruse it to directly

star t the dr ive.

Function Description

Page 19

HL P-C10 0 Ser ies

Part

AC input

reactor

EMC input

lter

Braking

unit

Braking

resistor

EMC

output

lter

AC output

reactor

Mounting

Location

Drive input

side

Drive input

side

≥1.5kW

Braking unit

is standard

conguration

Drive out put

side

Betwee n the

drive

output side and

the

motor, close to

the

drive

Function Description

Improve the power factor of the input side;

Elimi nate the i nput cur rent unbalance due

to unbalancebet ween the power phases;

Elimi nate the h igher harmonics of the input

sideeffectively;

prevent ot her device s from bei ngdamaged

due to distortion of the voltage wavefor m;

Decrease the conduction interference

owing f rom the power e nd to the drive and

improve the antiinterference capacity of the

drive;

Reduce the exter nal conduction and

radiation

inter ference of the drive;

Consu me the motor feedback energy to

achieve rapid braking.

Reduce the exter nal conduction and

radiation

inter ference of the drive.

Degra de the motor insulation performance

and damage the motor in the long r un;

Generate large leakage current and cause

frequent ACdrive protection trips;

If the distance between the drive and the

motor isg reater than 100 m, install an AC

output reactor;

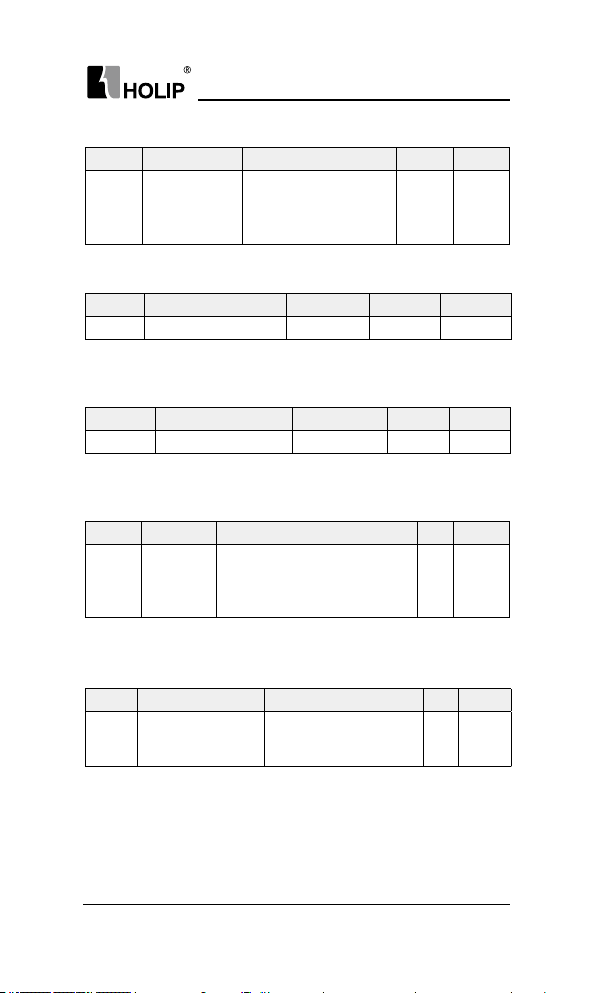

3.2.1 Selection of MCCB/Fuse/Contactor

Model MCCB (A) F use (A) Cont actor (A)

HLP-C1000D3721 10 10 10

HLP-C1000D7521 25 25 16

HL P-C10 001D521 32 32 25

HLP-C1000D3723 10 10 10

HLP-C100 Ser ies Operating Manual

- 15 -

Page 20

HL P-C10 0 Ser ies

HLP-C1000D7523 16 16 10

HL P-C10 001D523 25 25 16

HLP-C1000D7543 10 10 10

HL P-C10 001D543 10 10 10

HLP-C10002D243 16 16 10

3.2.2 Selection of Braking Unit and Braking Resistor

Users can select different braking resistor for different applicat ion,

it is calculated as follows. But the resistance should not be less than the

minimum recommended in the table, otherwise there is a risk of da mage

cau sed by the d rive, the p ower of brakin g resistor can b e greate r.the

gre ater system ine rtia, the shor t deceleration t ime , the more freque nt

bra king, the greater the power of the brak ing resistor, the sm alle r the

braking resistor value.

1. Selection of the Braki ng resistor value

The bra king resistor value:R = U

is the limit of the DC bus, generally it is 700V for 400V model ,

U

DH

400V for 200V model.

is rated motor power

P

MN

is br aking torqu e coefficient, it i s bet ween 0.8 to 2 .0. For

K

B

general machine, it is 1.0, for greateriner tia mach ine, it is 1.5 to 2.

;

DH×UDH

÷(KB×PMN)

2. Selection of the Braki ng resistor power

Braking power: Pb = U

Th eor et ica lly b ra ki ng resi sto r pow er and br ak ing powe r ca n

DH×UDH

÷ R

be t he same, Bu t in a ct ua l cho ice, it w il l be mult iplie d by a

correction factor, braking resistor power

Pr = a Pb

correction factor: a = 0.12~ 0.9

For not frequent accele ration and deceleration application, a can

be set as 0.12, for

frequent ac celeration and deceleration a pplication, it should be

increased.

3. Recommended selection

Model

Braking resistor

Recom mended Power

Braking resistor

Recommended value

HL P-C10 001D521 300W

HL P-C10 001D523 300W

HL P-C10 001D543 250W

HLP-C10002D243 500W

- 16 -

HLP-C100 Ser ies Operating Manual

≧

≧

≧

≧

50Ω

50Ω

200Ω

100 Ω

Page 21

HL P-C10 0 Ser ies

For the power less t han 0.75kW (including) models, the selection of

braking resistor depends on the selection of braking un it.

3.2.3 Selection of AC Input and Output Reactor

1. The guide of AC input reactor selection

Model

HLP-C1000D3721 6 9 11.6 4

HLP-C1000D7521 12 18 5.74

HL P-C10 001D521 19 28.5 2.87

HLP-C1000D3723 3.5 5.2 11.6 4

HLP-C1000D7523 7 10. 5 5.74

HL P-C10 001D523 11 16 .5 2.87

HLP-C1000D7543 3.5 5.2 16

HL P-C10 001D543 6 9 8

HLP-C10002D243 8.5 13 5.5

2. the guide of AC output reactor selection

Model

HLP-C1000D3721 2.5 5.3 9.78

HLP-C1000D7521 5 10.6 4.82

HL P-C10 001D521 7. 5 15.9 2. 41

HLP-C1000D3723 2.5 5.3 9.78

HLP-C1000D7523 5 10.6 4.82

HL P-C10 001D523 7. 5 15.9 2. 41

HLP-C1000D7543 2.3 4.8 14.39

HL P-C10 001D543 4 8.5 7.19

HLP-C10002D243 5.6 11 .9 4.9

Ratedcurrent

(A)

Rated current

(A)

Maximum

continuous

current(A)

Saturation

current (A)

Inductance (mH)

& 3% Impedance

Inductance (mH)

& 3% Impedance

HLP-C100 Ser ies Operating Manual

- 17 -

Page 22

HL P-C10 0 Ser ies

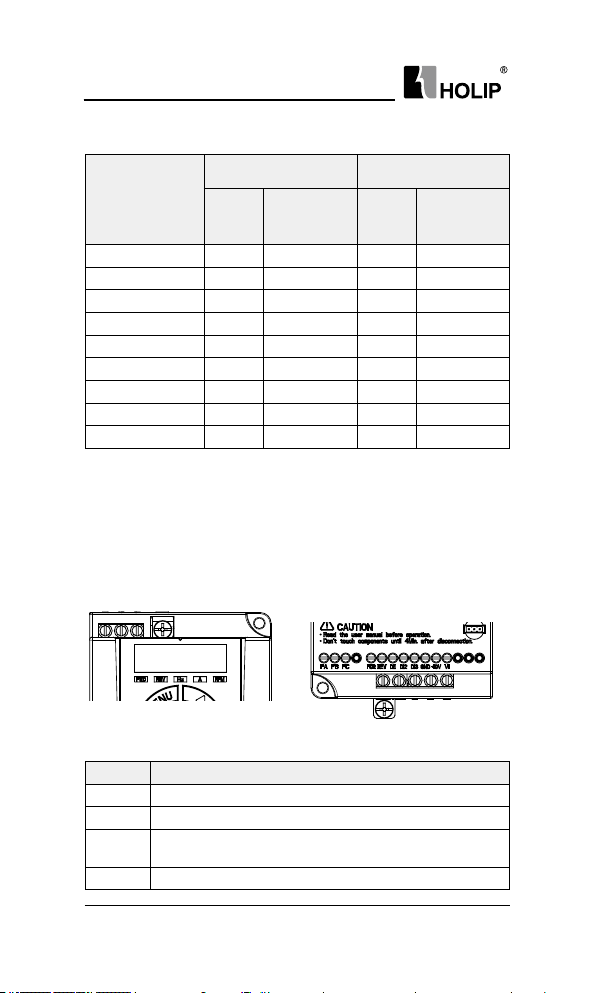

3.2.4 Selection of EMC Fi lter

EMC Input Filter EMC Output Filter

Model

HLP-C1000D3721 10 NFI- 010 5 NFO-005

HLP-C1000D7521 20 NFI-020 5 NFO-0 05

HL P-C10 001D521 20 NFI-020 10 NFO- 010

HLP-C1000D3723 5 NFI-005 5 NFO-005

HLP-C1000D7523 10 NF I- 010 5 NFO-005

HL P-C10 001D523 10 NF I- 010 10 N FO- 010

HLP-C1000D7543 5 NFI-005 5 NFO-005

HL P-C10 001D543 5 NFI-005 5 NFO-005

HLP-C10002D243 10 NFI- 010 10 N FO-010

* Recommended models is the Shanghai Eagtop Electronic Technology Co.,

Ltd. products, website:http://www.eagtop.com/

Rated

Current

(A)

Recommended

Model*

Rated

Current

(A)

Recommended

Model*

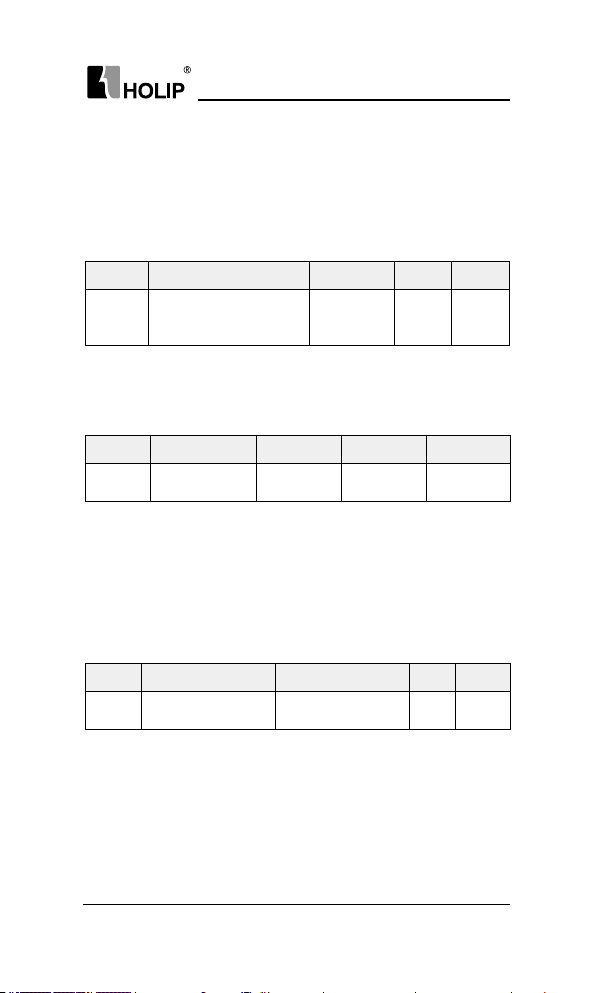

3.3 Description of Main Circuit

3.3.1 Schematic of Main Circuit Terminals

R S T PE

+BR-BR

Descr iption of mai n circuit terminals:

Symbol Function

R, S, T Power input, Single phase con nected to R, T

U, V, W Power output, connect t o the motor

+BR, -BR

PE Ground ter minal

- 18 -

Connect the brake resistor, make sure to set C02.10, C02.11

etc.

HLP-C100 Ser ies Operating Manual

PE

u v w

Page 23

HL P-C10 0 Ser ies

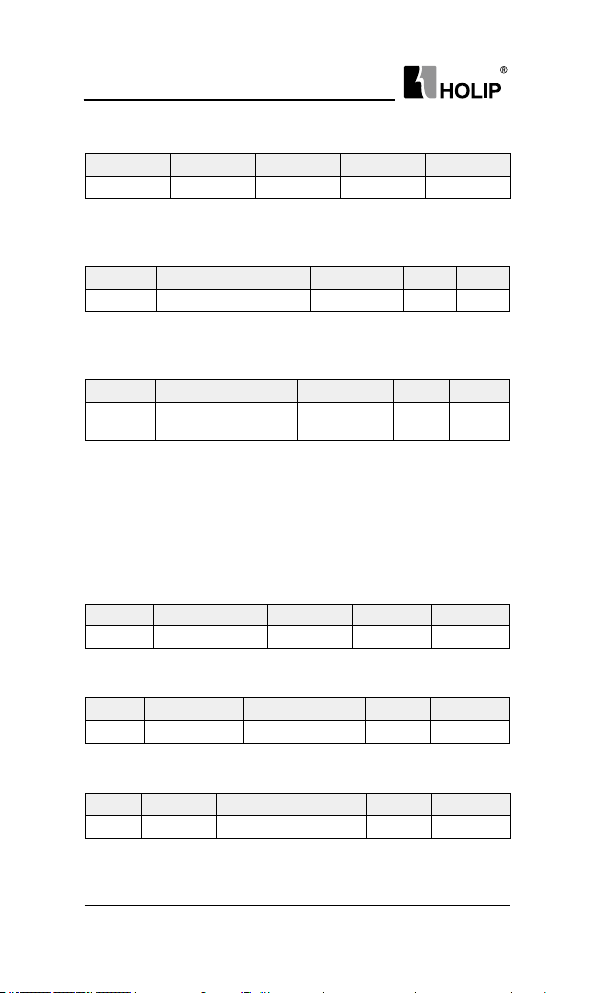

3.3.2 Main Circuit Terminal Screws and Wiring Recommended

Specications

Input and

Model

Input

Cable

(mm

Output

2

)

Cable

(mm

Te r mi na ls’

2

)

Output

Screws

Input and

Output

Te r mi na ls’

Torq ue

Ground

Te r m i nal

Screw

Ground

Te r m i nal

Torq ue

HLP-C1000D3721 1 1 M3.5 0.8 -1.0 M4 1.0-1. 2

HLP-C1000D7521 1.5 1 M3.5 0.8-1.0 M4 1.0-1. 2

HL P-C10 001D521 1. 5 1 M3.5 0 .8-1. 0 M4 1.0 -1.2

HLP-C1000D3723 1 1 M3.5 0.8-1.0 M4 1.0 -1.2

HLP-C1000D7523 1 1 M3.5 0.8-1.0 M4 1.0 -1.2

HL P-C10 001D523 1. 5 1 M3.5 0.8 -1.0 M4 1.0-1. 2

HLP-C1000D7543 1 1 M3.5 0.8-1.0 M4 1.0 -1.2

HL P-C10 001D543 1 1 M3.5 0.8-1.0 M4 1.0 -1.2

HLP-C10002D243 1 1 M3.5 0.8-1.0 M4 1.0 -1.2

Note: This specif ication is under using single-core line VV and 25℃, if use

other cables or under higher temperat ure environment, please refer to

electr ical manual.

3.4 Description of Control Circuit

3.4.1 Schematic of ControlCircuit Terminals

FA FB FC FOR FE V D11 D12 D13 GND +10V VI RS+ RS- COM

Terminals’ specication:

Symbol Descr ipt ion Specication

1. Resistive L oad: 250VAC 3A/30VDC

FA-FB-FC Relay output

FOR, REV,

DI1, DI2, DI3

Digital in put

3A;

2 . I n d u c t i v e L oa d : 2 50 VA C

0.2A/2 4V DC 0.1A (co sφ =0.4);

FA-FB: NC, F B-FC: NO

1. L og i c:

>DC 19V Logic:0;

<DC 14V Logic: 1;

2. Voltage: DC0~24v;

3. Input resistance: 5kΩ;

4. Inp ut volta ge Rang:Max ±30v;

J1

HLP-C100 Ser ies Operating Manual

- 19 -

Page 24

HL P-C10 0 Ser ies

ON

OFF

1 2 3

GND Digital/Analog Isolated f rom i nter nal COM.

+10 V 10Vpower supply

VI An alog i nput

J1

RS 485

communication

RS 485

termination

resisto r ju m per

switch

RS+, RS-

COM Digita l ground Isolated f rom internal GN D;

Maxload 10m A, wit h over load and

short circuit protection functions.

VI can be configurated to 0-20mA or

0-10Vby paramters:

1. Input Impedance: about 10kΩ;

2. Inpu t Impedence: ≤500Ω;

Max baud rate: 38400bit/s;

Jum per switch 1-2 connected: ON,

ter mination resistor con nected;

Ju mpe r sw it ch 2-3 connec ted: OFF,

termination resistor not connected,

default state;

3.4.2 ControlTerminals’Screws and Wiring Recommended

Specications

Cable ty pes

Shielded cables 0.4 0.4

Cable specications

(mm

2

)

Tor que (n∙m)

- 20 -

HLP-C100 Ser ies Operating Manual

Page 25

3.4.3 ControlCurcuit Wiring

Switch Mode

Power Supply

10VDC

10mA

24VDC

200mA

RS485

Interface

PE

R

T

S

Power

Supply

U

V

W

PE

+10V

VI

GND

FOR

REV

DI1

DI3

DI2

+BR

-BR

FA

FB

FC

RS+

RS-

COM

0-10V

/4-20mA

Braking

Resistor

RS485

Communication

Relay

Motor

RFI

RFI

Switch

Digital

Input

Terminal

Resistor

Jumper

Switch J1

24V (NPN)

24V (NPN)

24V (NPN)

24V (NPN)

24V (NPN)

2

3

1

Opto-

isolator

+24V

+3.3V

GND

Opto-

isolator

+3.3V

GND

DI1

DIn

GND

Drive

Y1

Yn

External

Controller

3.4.4 Digital Input Terminals UsageSpecication

Open collector NPN mode wiring

HL P-C10 0 Ser ies

HLP-C100 only supports this mode.

HLP-C100 Ser ies Operating Manual

- 21 -

Page 26

HL P-C10 0 Ser ies

3.5 EMC instructions

3.5.1 Introduction to EMC Standard

The HLP-C100 series satises t he requirements of stand ard IEC/E N61800-3:

2004 (Ad justable speed elect ricalpower drive systems part 3:EMC requirements

and specic test methods).

3.5.2 Noise Abatement

1. When peripheral equipment and the drive share the power supply

of one system, noise from the drive may be tra nsmitted to other

equipment in this system via power lines a nd result i n misoperation

and/or faults. In such a case, the following mea sures could be take n:

Mount input noise lter at input terminal of the drive;

a.

b. Mount power supply lter at power input terminal of af fected

equipment;

c. Use isolation t ra nsform er t o isolate the n oise tr ansmission path

2. As the wiring of peripheral equipment and the drive constitutes a

3. Sensitive equ ipment and sig nal lines shall be mounted as far away

4. Sig nal lines should be provided with shielded layer and reliably

5. Signal lines must orthogonally cross power lines if this cross

6. Motor cables shall be placed in thick protective screen like more than

7. Use 4 -core motor cables of which one is grou nded at close side of t he

8. I nput and out put ter minals of drive are respectively equippe d with

between other equipment and the drive.

circuit, the unavoidable ear thing leakage current of drive will cause

equipment misoperation and/or faults. Disconnect the grounding

connection of equipment may avoid th is misoperation a nd/or faults.

from drive as possible.

grounded. Alternatively, signal cable could be put into metallic

conduit s between which the distance shall be no less than 20c m, and

shall be kept as far away f rom drive and its per ipheral devices, cables

as possible. Never make signal lines in parallel with power li nes or

bundle t hem up.

inevitable.

2mm-t hick pipeli nes or bur ied cement groove, also, power lines can

be put into metallic conduit and grounded well with sh ielded cables.

drive and the other side is connected to motor enclosu re.

radio noise lter and linear noise lter. For example, ferrite common

mode choke ca n restr ain rad iation noise of power lines.

- 22 -

HLP-C100 Ser ies Operating Manual

Page 27

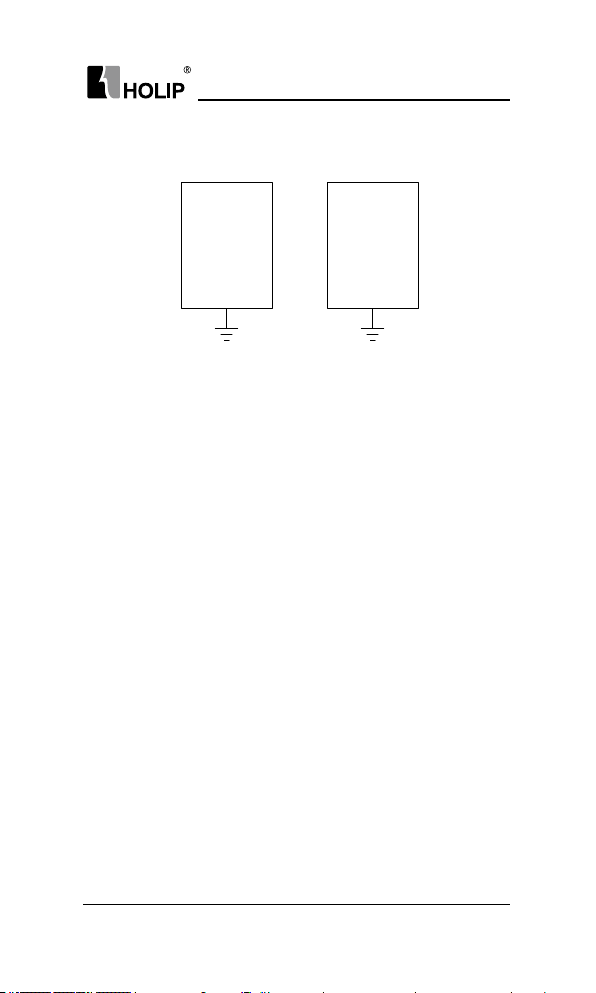

3.5.3 Grounding

Drive

Other

Devices

PE PE

Recommended ground electrode is shown in the gure below:

1. Use to the fullest extent the maxi mum standard size of grounding

cables to reduce the impedance of grounding system;

2. Grounding w ires should be as shor t as possible;

3. Grounding p oint shall be as close to the drive as possible;

4. One wire of 4 -core motor cables shall be grounded at the d rive side

and con nected to ground ing ter minal of motor at the other side.

Bette r effect will be achieved if motor and drive are provided with

dedicated ground electrodes;

5. When groundi ng termi nals of various parts of system are linked

togethe r, leakage current tu rns i nto a noise source that may inuence

other equipment in the system, thus, g roundi ng terminals of the drive

and othe r vulnerable equipment should be separated;

6. Grounding cable shall be kept away from input& output of noise-

sensitive equipment.

3.5.4 Leakage Current Suppression

Leakage current passes th rough the line-to-line and ground distributed

capacitors at input & output sides of drive, and its size is associated with the

capacitance of distributed capacitor and the carrier f requency. Leakage cur rent

is classied into grou nd leakage cu rrent and line-to-line leakage curr ent.

1. Ground leakage current not only circulates inside drive syst em, but

may also inuence other equipment via ground loop. Such a leakage

current may result in malf unction of RCD and other equipment.

The higher the car rier f requency of drive is, the bigger the g round

leakage current would be. The longer the motor cables and t he bigger

the par asitic capacitance are, the bigger the ground leakage current

would be. Therefore, the most immediate and effective method for

suppre ssion of grou nd leakage curre nt is to reduce carr ier frequency

HLP-C100 Ser ies Operating Manual

HL P-C10 0 Ser ies

- 23 -

Page 28

HL P-C10 0 Ser ies

and minimize the length of motor cables.

2. The h igher harmonics of line-to-line leakage cu rrent t hat passes

through between cables at out put side of dr ive will accel the aging

of cables and m ay bring about malf unction of other equipment. The

higher the carrier frequency of drive is, the bigger the line-to-line

leakage current would be. The longer the motor cables and t he bigger

the par asitic capacitance are, the big ger the line-to-line leakage

current would be. T herefore, the most immediate and effective

method for suppression of ground le akage cu rrent is to reduce

carrier requency and mi nimize the length of motor cable. Line-toline lea kage current can also be effectively suppressed by mou nting

additional output reactors.

3. For the HLP-C100 serials, it can remove RFI screw t o cut RFI lter

to reduce the leakage current;

3.5.5 Induction VoltageSuppression

The dr ive outpu ts pulse voltage which w ill for m induction voltage in t he

surface of the motor when the dr ive is not grounded. The induction voltage

can be reduced by connecting the drive's PE terminal to the motor and closing

RF I screws .

- 24 -

HLP-C100 Ser ies Operating Manual

Page 29

HL P-C10 0 Ser ies

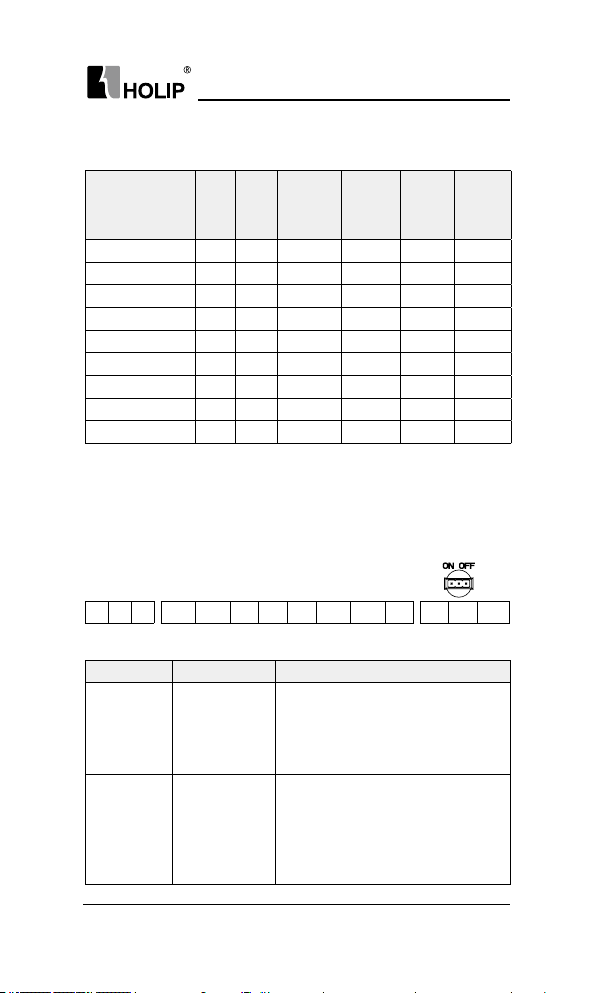

Chapter 4 Operation and Display Interface

4.1 Local Control Panel

Local Control Panel (LCP)can do the operat ion of paramet ers mod icat ions,

stat us monitori ng and dr ive control (sta rt, stop), its appearance is shown blow:

Screen

Functio LED

Menu key

Shift key

HAND key

HAND LE D

Incremental

potentiometer

AUTO key

AUTO LED

OFF key

OFF LED

1. StateLED

The drive has th ree operating states: HAND control state, AUTO cont rol

state and OFF sta te. The operating states are indicated by HA ND, AUTO and

OFF Led.

H A ND LE D: The drive is in the HA ND cont rol st ate w hen it is on. The

f requency can be changed by turning the incremental potentiometer. Push

“HA ND” key to set the drive in the HA ND state.

OF F Led: The drive is in the OFF state when it is on. Push “OFF” key to set

the dr ive in the HA ND state.

AU TO LE D: The d rive is in t he AUTO state when it is on. In the AUTO state,

the d rive is controlled by control termi nals or communication. Push “AUTO”

key to set the d rive in the AUTO state.

2. FunctionLed

FWD, REVLed: Indicates that the dr ive runs forwa rds or reverse.

Hz, A, RPM Led: Indicates the meaning of data displayed on the screen.

Local remote r un ni ng lig hts ru nning ligh ts, OFF LEDs, t hree LED lights

in dica te.

HLP-C100 Ser ies Operating Manual

- 25 -

Page 30

HL P-C10 0 Ser ies

3. Screen

There are 5 LED which can display reference, out put f requency,

monitoring data and warning/alarm code.

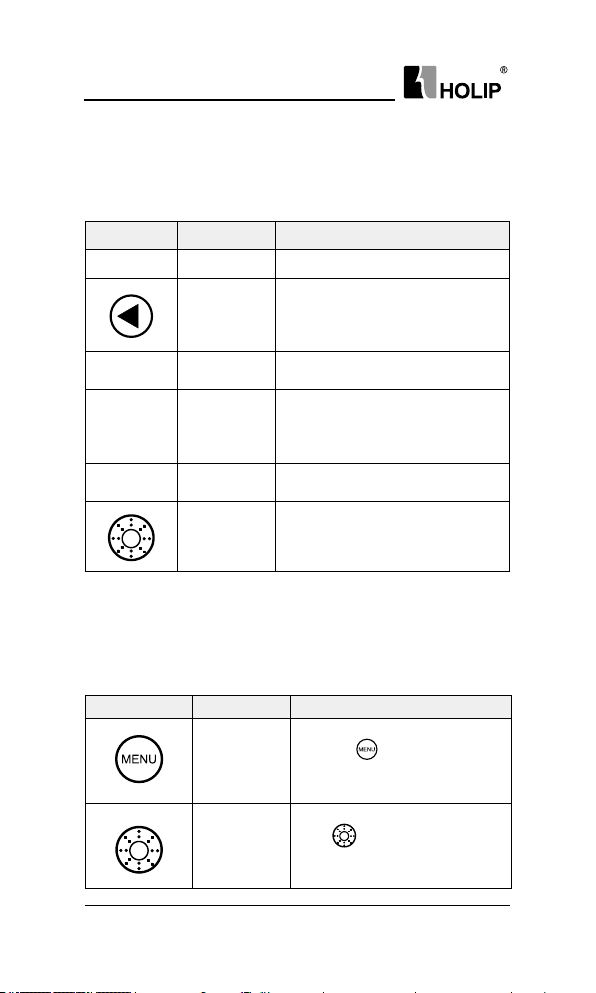

4. Keys

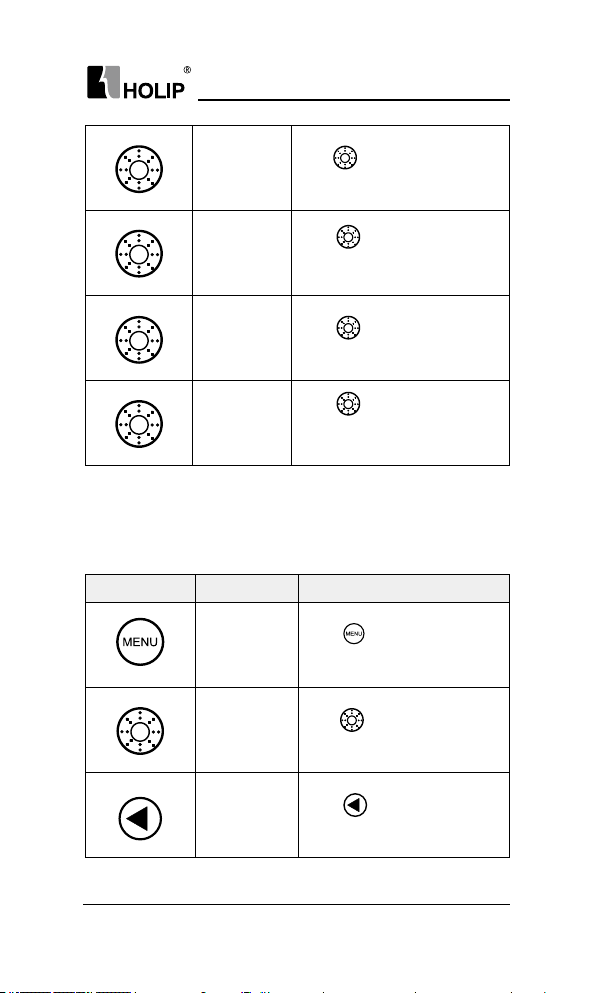

Symbol Name Function

MENU Programming Enter or exit menu.

Select the displayed pa ramete rs in

Shift

HAND Hand

OFF Off/Reset

AUTO Auto

Conrm

5. Incremental Potentiometer

Inc rease/decrease dat a or pa ra meter, clockwise to inc rease, cou nte rclockwise to decr ease.

tur n in the stop or running state;

Select the digit to be modied when

modifying parameters.

Push it to set the dr ive in the HAND

control state.

Stop the d rive when it is in the

run ning st ate and pe rform thereset

operation when it is in the fault

state.

Push it to set the dr ive in the AUTO

control state.

Push the incremental potentiometer.

Enter the menu or conrm the

parameter setting.

4.2 ParameterSetting

Example:Set C03.10 [0] to 20.5:

Key-press LCP Display Action Descr iption

- 26 -

C00.03

C03.00

HLP-C100 Ser ies Operating Manual

Presskey

basic C0 0.03

Turn

parameter groupC03

to display the rst

clockwise to select

Page 31

C03.00

C03.10

[0]

0000

000.5

000.5

020.5

HL P-C10 0 Ser ies

Press

key to shift to fractional

part

Turn

clockwise to select

parameterC03.10

Press

key show the rst

option of C03.10

key to show the value

Press

of the rst option of par ameter

C03.10

Turn

clockwise to change the

fractional part to 5

Press

key to shift to integral

part

Press

key to change the

integral par t to 20

Press

END

HLP-C100 Ser ies Operating Manual

key to accept the

change and save it as 20.5

- 27 -

Page 32

HL P-C10 0 Ser ies

4.3 FWD/REV Status

Conr m t he direct ion of the motor according to the set value, as shown in

t he f ollo wi ng t a ble:

Reference: R unning stat us Indicator Display

≥0 STOP

0 STOP

<

≥0 FWD

≥0 REV

0 FWD

<

0 REV

<

Note: A ash light denotes the stat us coming, Ligh t o n i ndica tes the cu rrent

state, and light of f means not in this state.

Example 1: The f irst line of the table indicates the drive is stop and the

reference is greater than or equal to 0, means the dir ve at some time in

the f uture will ru n for ward.

Example 2: The fou rt h line of t he table represents the cur rent d rive is reverse

ru nni ng, and the reference setting is greater than or eq ual to 0, it means

the d rive at some ti me in the f utu re will r un f orward.

- 28 -

HLP-C100 Ser ies Operating Manual

Page 33

HL P-C10 0 Ser ies

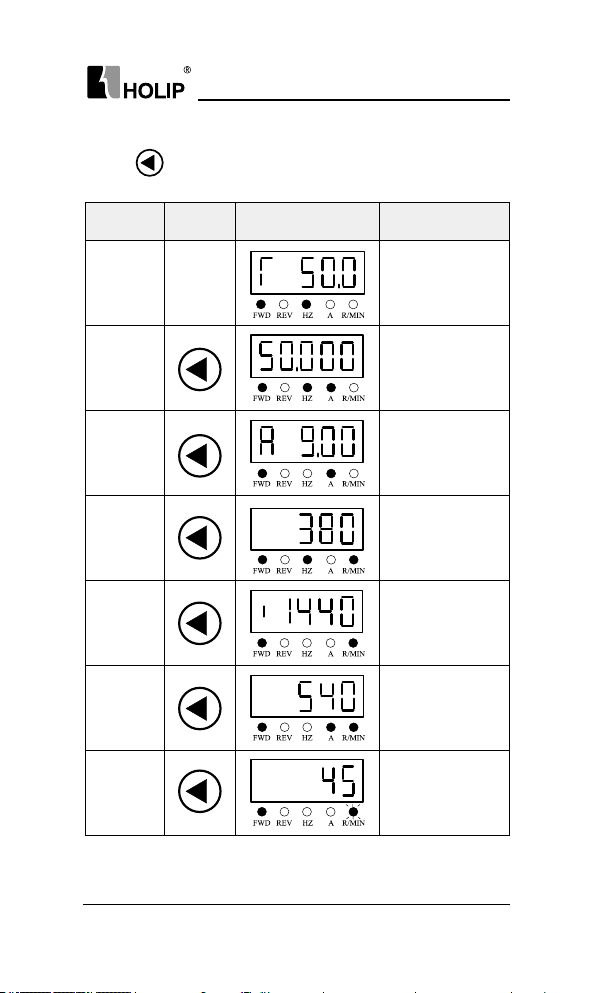

4.4 Data Read-outs

Press key to change the display items on LCP while displaying out put

f req ue ncy.

Display

Items

Output

Frequency

Reference

Motor

Current

Motor

Vol ta ge

Motor

Speed

DC Voltage

Drive

temperatu re

Key-press LCP Display Action Description

Show the out put

Initial

interface

frequency

C16.13is 50. 0H z,

display accuracy: 0.1

Show the reference

C16.01 is 50.00 0,

display accuracy:

0.0 01

Show the motor

cu r re nt C16.14

is 9.00A, display

accuracy: 0.01

Show the motor

voltage C16.12

is 380V, display

accuracy: 1

Show the motor

speed C16.05 is

1440rpm, display

accuracy:1

Show the DC

Voltage C16.30is

540V,display

accuracy: 1

Show the

drive temperature

C16.34 is45℃,

display accuracy:1

HLP-C100 Ser ies Operating Manual

- 29 -

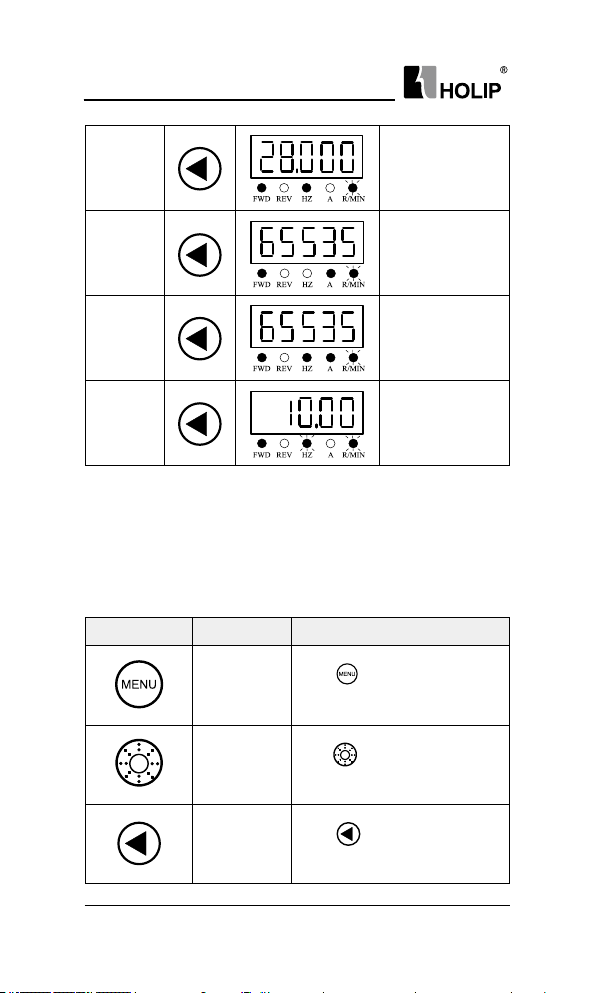

Page 34

HL P-C10 0 Ser ies

Feedback

Val ue

Counter A

Counter B

Analog i n

VI

Note: The drive only monitor output f requency, reference and output cur rent

reference by default. For monitoring other status (DC voltage, etc.),

please set the parameter C00.33 (refer to inst ructions).

Show the feedback

value C16.52

is28.000, display

accuracy: 0.001

Show counter A

C16.72 is 65535,

display accuracy:1

Show counter B

C16.72 is 65535,

diaplay accuracy: 1

Show analog i n VI

C16.62 is10.00V,

display accuracy:

0.01

4.5 View Alarm Record

If the drive trips, fault code will be showed to illustra te the reason,the drive

will save the last 10 trip record.

Key-press LCP Display Action Description

Press

C00.04

key to display the rst

basic C0 0.04.

- 30 -

Turn

C15.00

C15.00

HLP-C100 Ser ies Operating Manual

clockwise to select par.

group No.C15.

Press

to select parameter

num ber.

Page 35

HL P-C10 0 Ser ies

Turn

C15.30

[0]

**

[1]

clockwise to select

C15.30

Press

to show the rst option

of C15.30

Press

to show the rst fault

record.

Press

to show the second

fault record, it can d isplay up to

ten recent fault records in t urn.

4.6 View State Parameter

By viewing the group 16th parameters can lear n t he cur rent sta tus of the

drive. For example: C16.60 indicators the current state of digital input terminals.

Key-press LCP Display Action Description

Press

C00.04

to display the rst

basic parameterC00.04.

Turn

C16. 00

C16. 00

HLP-C100 Ser ies Operating Manual

clockwise to select

Par. group No. C16

Press

to select parameter

No.

- 31 -

Page 36

HL P-C10 0 Ser ies

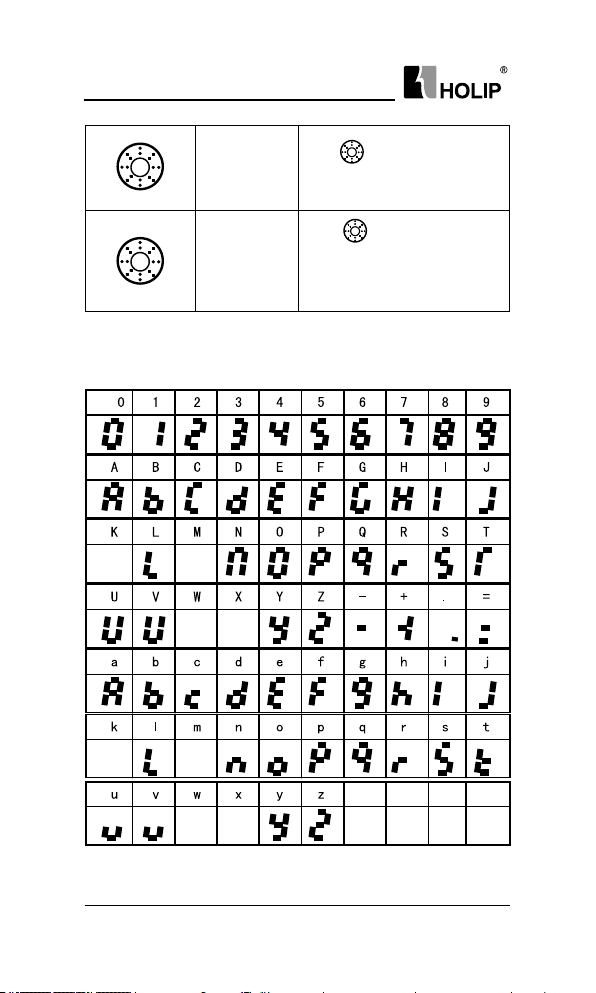

4.7 LED Display

C16. 60

2

Turn

clockwise to select

C16. 60

to view the value in

Press

C16.60, 2 indicates status of

FOR, DI1, DI2, DI3, DI4 is 0,

and status of REV is 1.

- 32 -

HLP-C100 Ser ies Operating Manual

Page 37

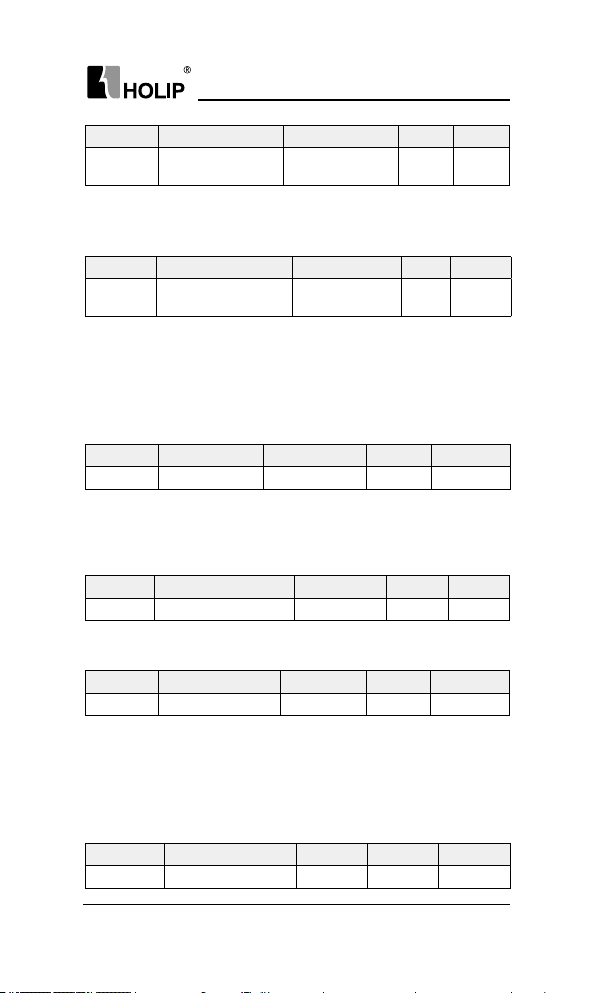

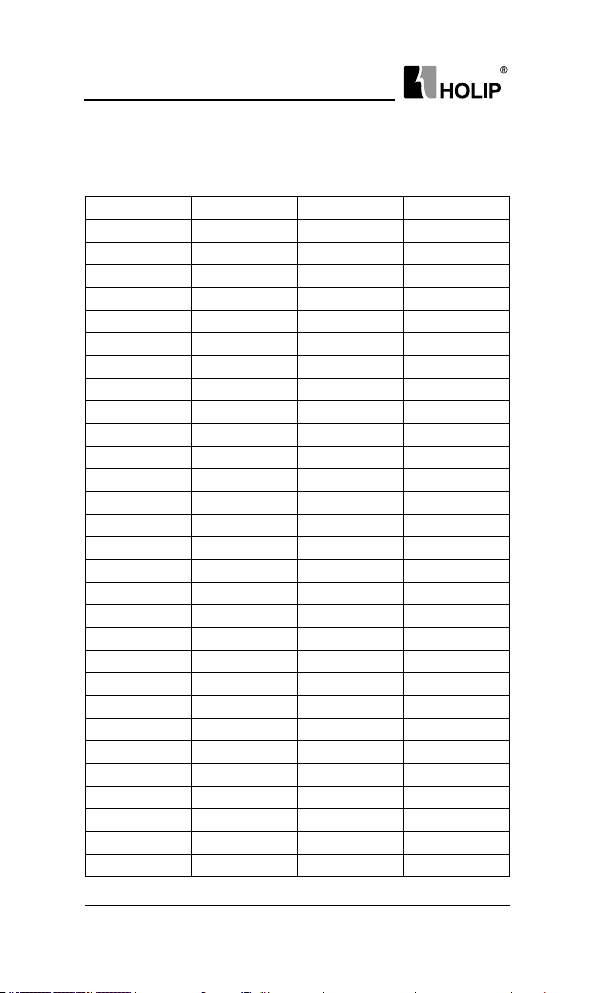

Chapter 5 Parameter Over view

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

Operating State at

C0 0.04

Powe r-u p

Custom Readout Min.

C 0 0 . 31

Val ue

Custom Readout Max.

C0 0.32

Val ue

C0 0.33 L CP Dis play Optio n 0 ~ 4095 0

0: R es u me

1: Forced stop,

ref =old

2: Forced stop, ref =0

0.00~9999.00 0.00

0.00~9999.00 0.00

HL P-C10 0 Ser ies

0

C0 0.40 H AND Key Option

C 0 0.41 OFF Ke y Opt ion

C0 0.42 AU TO Key Option

One Key Recover y

C0 0.46

Time

C0 0.47 LCP Potentiometer Step

C0 0.60 Set-up Locked

HLP-C100 Ser ies Operating Manual

0: Di sable d

1: E n a bl e d

0: Di sable d

1: E n a bl e d

2: E n a bl ed r es e t on ly

0: Di sable d

1: E n a bl e d

0: Di sable d

5: 5 s

10: 10 s

15: 15s

20: 20s

0: 0.1

1: 1

2: 10

0: Di sable d

1: E n a bl e d

0

1

1

1

1

0

- 33 -

Page 38

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

C 01.0 0 Conguration Mode

*C 01. 20 Mot or Powe r Motor dependant kW *

*C01.22 Motor Voltage 50~1000 V *

*C 01. 23 Motor Freq uenc y 20~400 Hz *

*C 01. 24 Motor Current Motor dependant A *

*C 01. 25 Motor Speed 100~9999 r pm *

*C 01. 26 Motor Torque 0.1~10000.0 N·m *

Par. Group01: Load / Motor

*C 01. 42 Moto r Ca ble Lengt h 0 ~15 0 m *

C 01.5 5 V/F Characteristic-V 0.0~999.9 V *

C 01.5 6 V/F Characteristic-F 0.0~ 400.0 Hz *

C 01.6 2 Slip Com pensation - 40 0~399 % 0

Slip Compensat ion Time

C 01.6 3

Constant

C 01.6 7 Torque Compen sation 0 ~200 % 0

C 01.71 Sta rt Delay 0.0~10.0 s 0.0

C 01.7 2 Start Function

*C 01.73 Fl ying St ar t

C 01.75 Min. Sta rt Frequenc y 0.00 ~10.00 Hz 0.00

C 01.7 6 Jum p Frequency 0.0 ~20.0 Hz 0.0

C 01.8 0 Function at Stop

Min Speed for Function

C 01.8 2

at Stop

C02.00 DC Hold Cu rren t 0 ~15 0 % 50

Par. Group 02: Brake Fu nction

C 0 2. 01 DC Bra ke Cur rent 0 ~150 % 50

C02.02 DC Bra king Ti me 0.0 ~60.0 s 10 .0

C02.04 DC Brake Cut in Speed 0.0 ~40 0.0 % 0.0

C 02 .10 Brake Function

C 0 2 .11 Brake Resistor 5 ~ 65535 Ω *

C 02 .17 Ove r-voltage Con trol

0: Speed open loop

3: Process closed loo p

4: Torque open loop

0.05~ 5.00 s 0.10

0: DC Hold

2: Coa st

0: Di sable d

1: E n a bl e d

0: Co ast

1: DC Hold

0.0~400.0 Hz 0.0

0: Of f

1: R e s i s t o r b r a k e

0: Di sable d

2: M od e 1

3: Mod e 2

0

2

0

0

0

0

- 34 -

HLP-C100 Ser ies Operating Manual

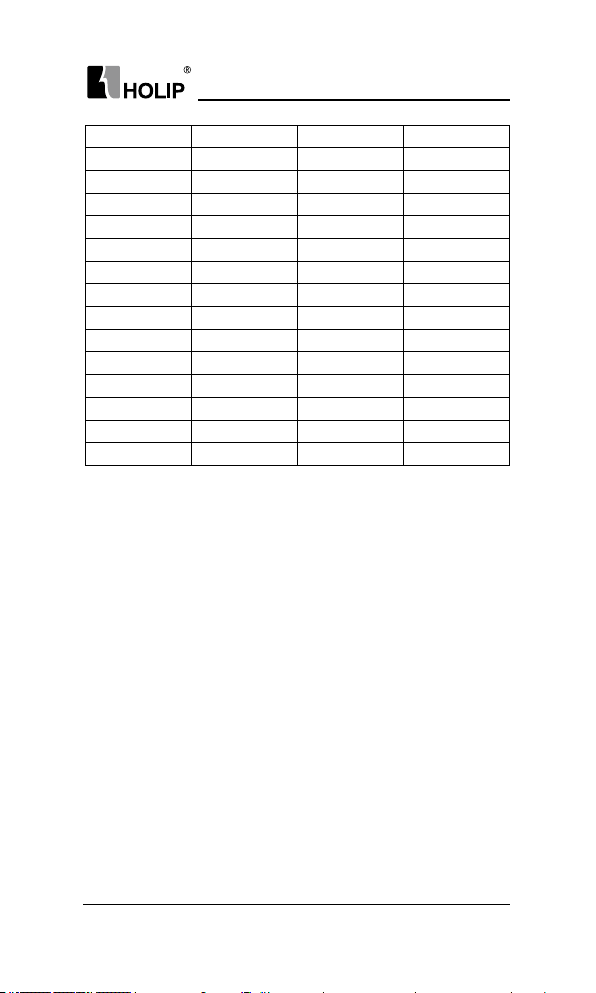

Page 39

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

C03.03 Maximum Reference 0.000~ 4999.000 50.000

Main Reference

C03. 07

Calculation

C 03.1 0 Preset Reference -100.00~100.00 % 0.0 0

C 0 3. 11 Jog s peed 0.0~ 400.0 Hz 0.0

Catch up/Slow down

C 03.1 2

Val ue

C 03.1 3 Speed Up/Down Value 0.01~50.0 0 Hz 0.10

C 03.1 5 Reference Source1

C 03.16 Reference Sou rce2 2

Par. Group 03: Reference / Ra mps

Relative Reference

C 03.18

Sou rce

Speed Up/Down Value

C 03.1 9

Stor e

C 0 3. 41 Ram p 1 Ram p U p Time 0.05~30 0.00 s *

Ram p 1 R amp Down

C03. 42

Time

C 03. 51 Ramp 2 Ramp Up Time 0.05 ~300.00 s *

Ramp 2 Ra mp Down

C03. 52

Time

C 03.61 Ramp 3 Ra mp Up Time 0.05~300.0 0 s *

Ram p 3 Ramp Down

C03.62

Time

C 03.71 Ra mp 4 Ra mp Up Time 0.05~300.00 s *

Ram p 4 Ram p Down

C03.7 2

Time

C03.80 Jog Ramp Ti me 0.05~300.0 0 s *

C03.85 Ramp 5 Ramp Up Time 0.05 ~300.0 0 s *

Ram p 5 Ramp Down

C03.86

Time

C03.88 Ramp 6 Ra mp Up Time 0.05~300.0 0 s *

0: Preset reference +

Reference source1, 2

1: Preset reference

priority

0.00~100.00 % 0.00

0: No f unction

1: Ter minal VI

11: Local bus

21: L C P

potentiometer

0: No f unction

1: Stop save

2: Power dow n save

0.05~ 300.0 0 s *

0.05~ 300.0 0 s *

0.05~ 300.0 0 s *

0.05~ 300.0 0 s *

0.05~ 300.0 0 s *

1

0

0

HLP-C100 Ser ies Operating Manual

- 35 -

Page 40

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

Par. Group 03: Reference / Ra mps

Par. Group 04: Limits / Warnings

Par. Group 05: Digital In /

Out

Ram p 6 Ramp Down

C03.89

Time

C 0 3.91 Ramp 7 Ramp Up Time 0.05~ 300.00 s *

Ram p 7 Ramp Down

C03.92

Time

C03.94 R amp 8 Ra mp Up Time 0.05 ~300.0 0 s *

Ram p 8 Ramp Down

C03.95

Time

Link preset reference

C03.96

and ramp time

*C 0 4.10 Motor Speed Direction

*C 0 4.12 Motor Speed Low Limit 0.0 ~ C 04.1 4 Hz 0.0

Motor Speed High

*C 0 4.14

Limit

C 04.18 Curre nt Limit 0 ~300 % 15 0

*C 0 4.19 Max Output Frequency 0.0~ 400.0 Hz 65.0

Counting Value of

C0 4.40

Counter A

Counting Value of

C 0 4. 41

Counter B

Warning Frequency

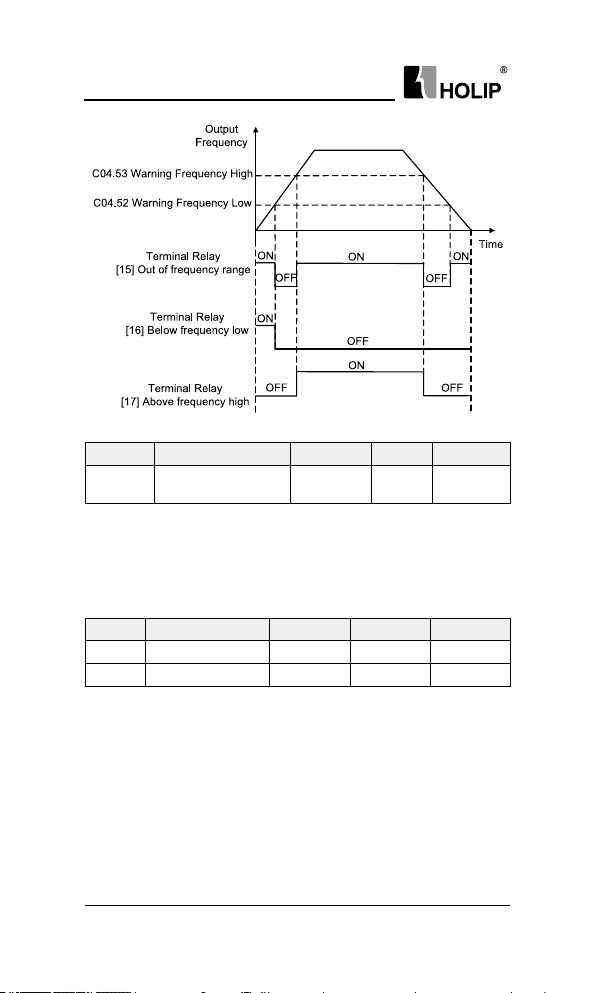

C0 4.52

Low

Warni ng

C0 4.53

FrequencyHigh

Missing Motor Phase

*C04.58

Function

C 0 4.61 By pass Speed Fr om 0.0 ~ 400.0 Hz 0.0

C0 4.63 By pass Speed to 0.0 ~4 00.0 Hz 0.0

C0 5.04 DI Filt er Ti me 2 ~16 ms 4

Function at External

C0 5.09

Alar m

0.05~ 300.0 0 s *

0.05~ 300.0 0 s *

0.05~ 300.0 0 s *

0: N o l i n k

1: L i n k

0: Clock wise

1: Cou nte r clock wise

2: Both directions

C 04 .12 ~ C 04.1 9 Hz 65.0

0~0x7FFFFFFFUL 0

0~0x7FFFFFFFUL 0

0.0~400.0 Hz 0.0

0.1~ 400.0 Hz 6 5.0

0: Di sable

1: E n a bl e

0: Of f

2: Stop and war ning

3: Jogging and

war ning

4: M a x. sp eeda nd

war ning

5: Stop and tr ip

0

2

1

0

- 36 -

HLP-C100 Ser ies Operating Manual

Page 41

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

C 05.10 Ter m i na l F OR

C 0 5. 11 Terminal REV 10

C 05.12 Te r mi n a l DI1 15

C 05.13 Ter mina l D I2 16

0: N o o pe ra t io n

1: Reset

2: Coa st i nve rs e

6: Stop inverse

8: S t a r t

9: Latched start

10: Reversing

11: Sta rt reversing

14: J og

Par. Group 05: Digital In / Out

C 05.14 Ter m i nal DI3 17

15: Preset ref. bit0

16: Preset ref. bit1

17: Preset ref. bit2

21: S p e e d u p

22: Sp ee d d ow n

28: Catch up

29: Slow dow n

34: Ra m p b it 0

35: R a m p bi t1

36: R am p b it2

37: Latched

Reversing

38: JogRever sing

42: Co ast

43: External Alar m

Input

46: St op

60: Counter A

62: Reset counter A

63: C ou n t er B

65: Reset counter B

8

HLP-C100 Ser ies Operating Manual

- 37 -

Page 42

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

0: N o o pe ra t io n

5: D r iv e r u n n i ng

8: Run on reference/

No war ning

9: A lar m

10: Al a r m o r

Par. Group 05: Digital In / Out

C0 5.40 Relay Function

Terminal VI Low

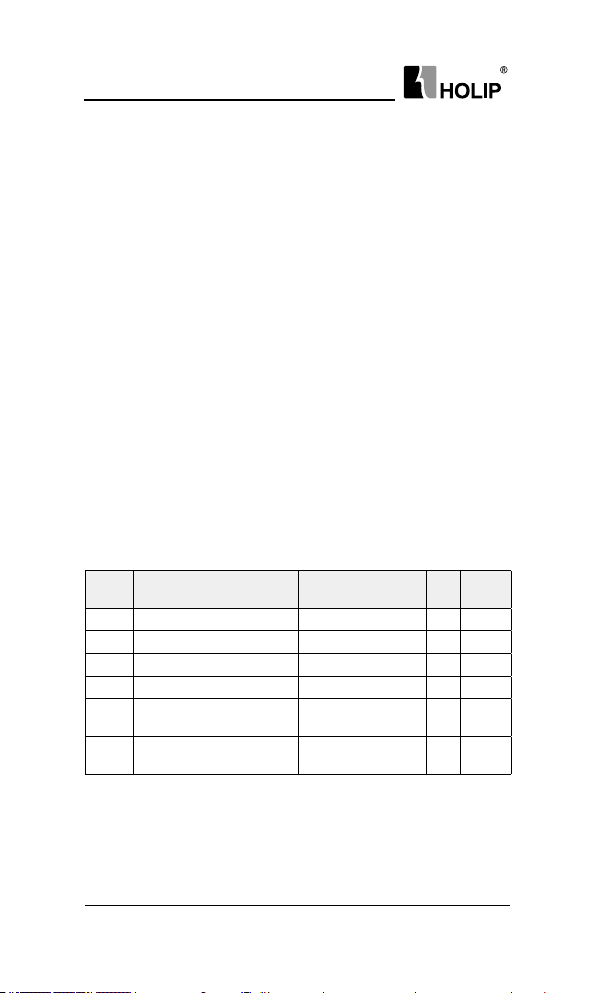

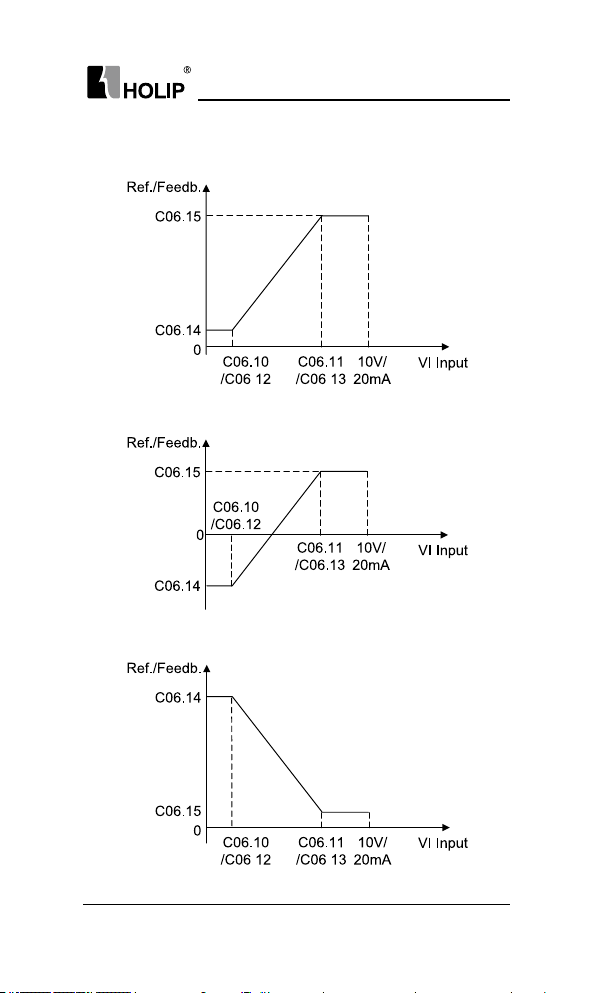

C 06 .10

Par. Group 06: Analog In / Out

Vol tage

Terminal VI High

C 0 6 .11

Vol tage

Terminal VI Low

C 06 .12

Current

Terminal VI High

C 06 .13

Current

Terminal VI Low Ref./

C 06 .14

Fee d b. Va lu e

Ter minal VI High Ref./

C 06 .15

Fee d b. Va lu e

C 06 .16 Terminal VI Filter Time 0.01~10.00 s 0 .01

war ning

15: Out of f requency

range

16: Below frequency

low

17: Ab o ve f r e q u e n c y

high

18: Out of feed back

range

21: Thermal war ning

24: Rea dy, v ol ta ge

OK

25: Reverse signal

26: Bu s OK

38: Counter A reach

39: Counter B reach

43: External alar m

55: R e v e r se

0 .0 0 ~ C 0 6 .11 V 0.07

C 0 6.10 ~10.0 0 V 10 .0 0

0.0 0 ~ C0 6.13 mA 0 .14

C 06 .12 ~2 0. 00 mA 20.0 0

-4999.000~ 4999.000 0.000

-4999.000~ 4999.000 50.000

5

- 38 -

HLP-C100 Ser ies Operating Manual

Page 43

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

Par. Group 06: Analog

In/ Out

Par. Grou p 07: Con trolle rs

Par. Group 08: Communiction

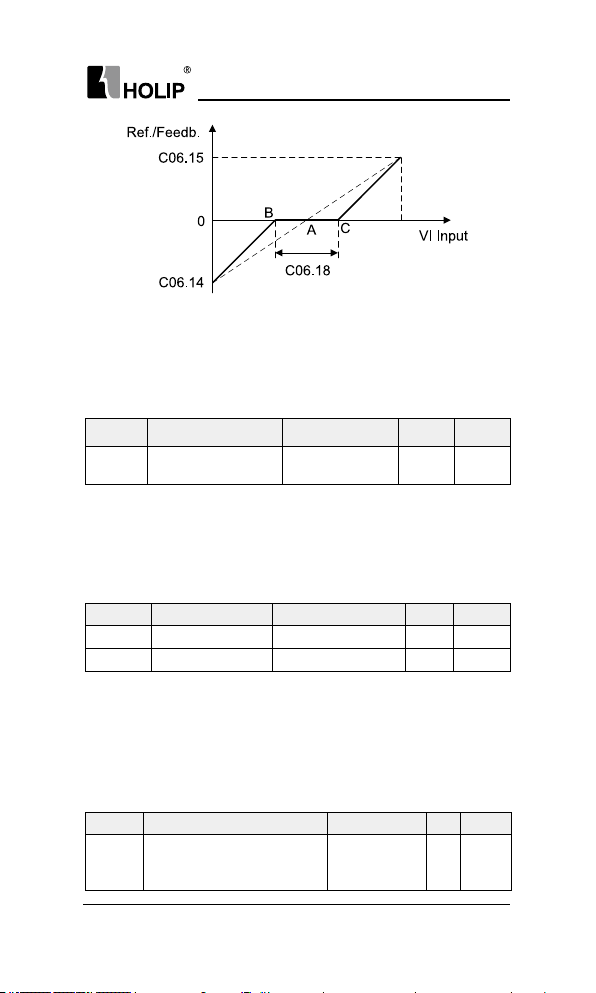

Terminal VI Zero Dead

C 06 .18

Ban d

C 06 .19 Terminal VI Mode

C 0 6 .81 LCP Pot.M in. R ef. -4999.000~4999.000 0.000

C0 6.82 LCP Pot.M ax. Ref. -4999.000~ 4999.000 50.000

Process PID Feedback

C 07. 20

Sou rce

Process PI D A nti

C 0 7. 31

Windup

Process PI D

C 07. 33

Proport ional Gain

Process PI D Int egr al

C 07. 34

Time

Pr oces s PI D Feed

C 07. 38

Forward Factor

On Reference

C 07. 39

Ban dw id th

Process PID Output

C 0 7. 41

Low

Process PID Output

C 07. 42

High

C 08 .01 Con trol Sit e

C08.02 Cont rol Word Selection

Control Word Timeout

C08.03

Time

Control Word Timeout

C08.04

Function

Reset Control Word

C08.06

Timeout

0.0~20.0 0 V/

0: Voltage mode

1: Current mode

0: No f unction

1: Ter minal VI

11: Local bus

0: Di sable

1: E n a bl e

0.00 ~10.00 0.01

0.10~9999.00

0~ 400

0~200

-10 0 ~10 0

-10 0 ~10 0

0: Digital and

control word

1: Digital only

2: Control word only

0: Di sable

1: E n a bl e

0.1~6500.0 s 1. 0

0: Of f

2: St op

3: Jog g in g

4: M a x. sp eed

5: Stop and tr ip

0: Do not reset

1: Do reset

mA

s 9999.00

% 0

% 0

% 0

% 10 0

0.00

0

0

0

0

1

0

0

HLP-C100 Ser ies Operating Manual

- 39 -

Page 44

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

Comm un ication Alarm

C08. 29

Mode

C 08.31 Address 0 ~247 1

C08.32 Baud Rat e

Par. Group 08: Communiction

C0 8.33 Parit y/Stop Bits

C08. 35 Min. Res ponse Delay 0.0 01~ 0.500 s 0.00 2

C0 8.36 Max. R espo nse Delay 0. 010~10. 00 0 s 5.000

C0 8.38 Message Response

Mod bus Parame ter

C0 8.39

Write Store

Par. Group 14: Special Functions

C14. 01 Switching Frequency

*C14 .03 Over modu lat ion

C14. 08 Dam ping Gain Factor 0~20 0 % 96

0: Bit mode

1: Code mode

0: 24 00

1: 4800

2: 96 00

3: 19 20 0

4: 38 40 0

0: Even parity (1 stop

bit)

1: Odd pa rity (1 stop

bit)

2: No parit y (1 stop

bit)

3: No par ity (2 stop

bit)

0: N or ma l

1: Only response

except ion message

2: N o t re sp ons e

0: Not saved at

power dow n

1: Saved at power

down

2~6: 2~6kHz

7: 8 k Hz

8: 10 k Hz

9: 12k H z

10: 16 k H z

0: Of f

1: O n

bit /s

kHz *

0

2

2

0

0

1

- 40 -

HLP-C100 Ser ies Operating Manual

Page 45

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

Function at Mains

C14 .12

Imbanlance

Automatic Voltage

C14 .17

Regulat ion

Delay Time of Auto

C14 .18

Par. Group 14: Special Functions

RestartWhen Power up

Again

C14. 20 Reset Mode

C14 .21 Automatic Restar t Time 0~ 600 s 10

C14. 22 Operation Mode

C14. 23 Tri p lock

Cur rent Controller 1

C14. 30

Proport ional Gain

Cur rent Controller

C1 4 . 31

1I nt eg r at i on Ti me

Current Controller Filter

C14. 32

Time

Cur rent Controller 2

C14. 33

Proport ional Gain

0: Tr ip (L ow

sensitivity)

1: W a r n i n g ( L o w

sensitivity)

2: D is ab le d

4: War ning (Mid dle

sensitivity)

5: Trip (M iddle

sensitivity)

6: Tr ip ( H ig h

sensitivity)

0: Di sable

1: E n a bl e

0.0~3600.0 s 0.0

0: Manu al rese t

1~10 : A u to r e s e t 1-10

times

11: Auto reset 15 times

12: A ut o r es e t 12

times

13: Innite auto reset

0: Normal operation

2: Initialization

3: Backup user

settings

4: Recover user

settings

0: Di sable

1: E n a bl e

0 ~300 % 10 0

0.005~2.000 s 0.020

2.0 ~100.0 ms 10 .0

0 ~300 % 0

0

1

0

0

0

HLP-C100 Ser ies Operating Manual

- 41 -

Page 46

HL P-C10 0 Ser ies

Pa r.

Pa r. No. Na me Range Unit Def au lt

Group

Par.Group 15: Drive Infor mation

Par. Group 16: Data Readouts

Note: Ref erence signed wit h “*”inPar. No. colum n means t his para meter can’t be

- 42 -

Cur rent Controller

C14. 34

2Integrat ion Time

*C14 .51 DC Link Compe nsation

C15. 0 0 Operating Days 0 ~9999 d

C15. 0 2 kWh Count er 0 ~65535 kWh

C15. 0 3 P ow e r Up’s 0 ~2147483647

C15. 0 6 Reset kWh Counter

C15. 30 Ala rm Code 0 ~255

C1 5. 31 Inter nal Fault Reason -32767~32767

C15. 38 Warni ng Code 0 ~255

C15. 43 Software Version

C16 .0 0 Control Word 0 ~6 5535

C16 .01 Reference -4999.000~ 4999.000

C16 .0 2 Reference -20 0.0~200.0 %

C16 .03 Sta tu s Wor d 0 ~ 65535

C16 .05 Motor Speed 0 ~9999 rpm

C16 .09 Custom Readout 0.00~9999.00

C16 .10 Output Power 0.000~1000.000 kW

C16 .12 Motor Voltage 0 ~6 5535 V

C16 .13 Output Frequency 0.0 ~ 400.0 Hz

C16 .14 Output Current 0. 00 ~ 655. 35 A

C16 .30 DC Li n k Volta ge 0 ~6 5535 V

C16 .34 IG BT Te mp era t u re 0 ~65535

C16.52 Fe ed back -4999.000~ 4999.000

C16 .60 Digital Input 0 ~6 5535

C16 .61 Terminal VI Setting

C16 .62 Analog Input VI 0.0 0 ~20.0 0 V/m A

C16 .71 Relay Output 0 ~ 65535

C16 .7 2 Cou nter A 0 ~2147483647

C16 .7 3 Counter B 0~2147483647

Comm un ication

C16 .8 6

Reference

modied when t he motor is running. In factory setting column, “*” means

the def ault setting for this parameter is determined by t he drive type.

HLP-C100 Ser ies Operating Manual

0.001~2.000 s 0.020

0: Of f

1: O n

0: Do not reset

1: Do reset

℃

0: 0 ~20m A

1: 0 ~1 0 V

-32768 ~32767

0

0

Page 47

HL P-C10 0 Ser ies

Chapter 6 Parameter Descr ipt ion

6.1 Group 00: Operation/Display

C00.0* Basic Setti ngs

Par. No. Name Range Unit Default

C00.04

Selects t he operating mode upon recon nection of the drive to mains

voltage after power dow n in Hand operation mode.

At tent ion: Th is parameter is only active in Hand operation mode.

C00.3*LCP Custom Readout

Par. No. Name Range Unit Default

C0 0.31 Custom Readout Mi n. Value 0.00~9999.00 0.00

C00.32 Custom Readout Max. Value 0.00~9999.00 0.00

Readout Value is linear proport ional to speed, it is stored in parameter

C16. 09.

Par. No. Name Range Un it Default

C00.33 LCP Display Option 0~4095 0

motor current (switch by ◄ key). This parameter is used to show another

11 basic operat ing states of the dr ive, each states cor respond s to a binary

code : “1” means display the item, “0” means does not display the item.

For example, if you want to display the states of the temperature and the

terminal VI on LCP. Transform the binary code to decimal digit,

Operating State at

Power-up

0: Resume, restarts the drive maintaining the same local reference a nd

the same start/stop settings as before the dr ive was powered down.

1: Forced stop, ref=old, restarts the dr ive with a saved local reference,

after mains voltage reappearsand after pressing HAND key.

2: Forced stop, ref =0, resets the local refere nce t o 0 upon resta rting

the drive.

It is pos sible t o cu stomi ze a r ea do ut va lu e in t he d ri ve. C us tom

The calculation of Cu stom Readout Value (C16.09) is shown below:

C16.09 = (C00.32 - C00.31) × C16.13 ÷ C04.14 + C00.31

Th e LCP i s fi xed to di spl ay the outpu t fr equen cy、reference and

HLP-C100 Ser ies Operating Manual

0: Resume

1: Forced stop, ref=old

2: Forced stop, ref=0

C00.33=1×23+1×27=136.

0

- 43 -

Page 48

HL P-C10 0 Ser ies

Bit11Bit

Custom Readout

0 0 0 0 1 0 0 0 1 0 0 0

C00.4*L CP Ke ypad

Par. No. Name Range Unit Default

C00.40 HAN D Key Option

Par. No. Name Range Unit Default

C0 0.41

Par. No. Name Ra nge Unit Default

C00.42 AUTO Key O ption

C00.46

Bit9 Bit8 Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

10

Reserved

Reserved

Reserved

VI

Counter B

Counter A

Feedback Value

Tem pera t ure

DC -Volt ag e

Motor Speed

Enable, disable individual keys on theLCP.

0: Disabled

1: Enabled

0: Disabled, No effect when HAN Dkey is pressed. Select [0] Disabled

to avoid accidental start of the d rive in Hand operat ion mode;

1: Enabled, HAND key is f unctional;

OFF Key

Option

0: Disabled, avoids accidental stop of the drive;

1: Enabled, OFF key stop signal and reset of any fault;

2: Enabled reset only, reset only (fault), stop (off) funct ion is disabled;

0: Disa bled, avoids accide ntal star t of the drive in AUTOop erat ion

mode;

1: Enabled, AUTO key is funct ional;

Par. No. Name Range Unit Default

One Key

Recover y

Time

0: Disabled

1: Enabled

2: Enabled reset only

0: Disabled

1: Enabled

0: Disabled

5: 5s

10: 10 s

15: 15s

20: 20s

1

Motor Voltage

0

1

1

- 44 -

HLP-C100 Ser ies Operating Manual

Page 49

HL P-C10 0 Ser ies

“One Key Recovery”is that u ser can press OFF key t o recover the

backup settings if the set tings have been back uped. If the settings have

not been backuped, this f unction is disabled .

One key Re cove ry Time is use d to de ter mi ne how man y sec ond s

should OFF key pressed to recover the backup settings, it is set to 0 to

disable one key recover y function.

Note: If an alarm happens, press OFF key will reset alarm rst.

Par. No. Name Range Unit Default

0: Disabled

1: Enabled

0: 0.1

1: 1

2: 10

1

0

C00.47 LCP Potentiometer Step

This parameter determines the reference value increa se or decrease

when the LCP potentiometer rotates.

C00.6*Protection

Par. No. Name Range Unit Default

C00.60 Set-up Locked

0: Disabled

1: Enabled, prevent unaut horized editing of parameters.

At tent ion: Th isfunction is only valid to LCP, not active to local bus.

6.2 Group 01: Load and Motor

C01.0* General Settings

Par. No. Name Range Unit Default

C01.0 0 Congu ration Mode

0: Speed open loop, Enables speed control (wit hout feedback signal

from mot or) with automatic slip compensation for almost constant

sp ee d at v ar y in g lo ad s. C om pe ns at io ns a re a ct iv e bu t ca n be

disabled in the Loa d/Motor par. group C01.0*;

3: Process closed loop, Enables the use of process cont rol in the drive.

The process control parameters are set in par. groups 7-2* and 7-3*.

At tent ion: If c onf ig uration mode is ch anged, C03.0 0, C0 3.03 will b e

restored to factory setting.

0: Speed open loop

3: Process closed loop

0

HLP-C100 Ser ies Operating Manual

- 45 -

Page 50

HL P-C10 0 Ser ies

C01.2* Motor Date

Par. No. Name Range Unit Default

*C01. 20 Motor Power Motordependant kW *

*C01. 22 Motor Voltage 50~1000 V *

*C01. 23 Motor Frequency 20~400 Hz *

*C01. 24 Motor Current Motordependant A *

*C01. 25 Motor Speed 100~9999 rpm *

*C01. 26 Motor Torque 0.1~10000.0 N·m *

Set the above paramet ers according to the motor nameplate.

C01. 4*Motor Cab le Len gt h

Par. No. Name Range Unit Default

*C01. 42 Mot or Cable Leng th 0 ~150 m *

Enter the motor cable length con nected between the motor and the drive.

Set correct cable length can suppress noises resulted from the motor.

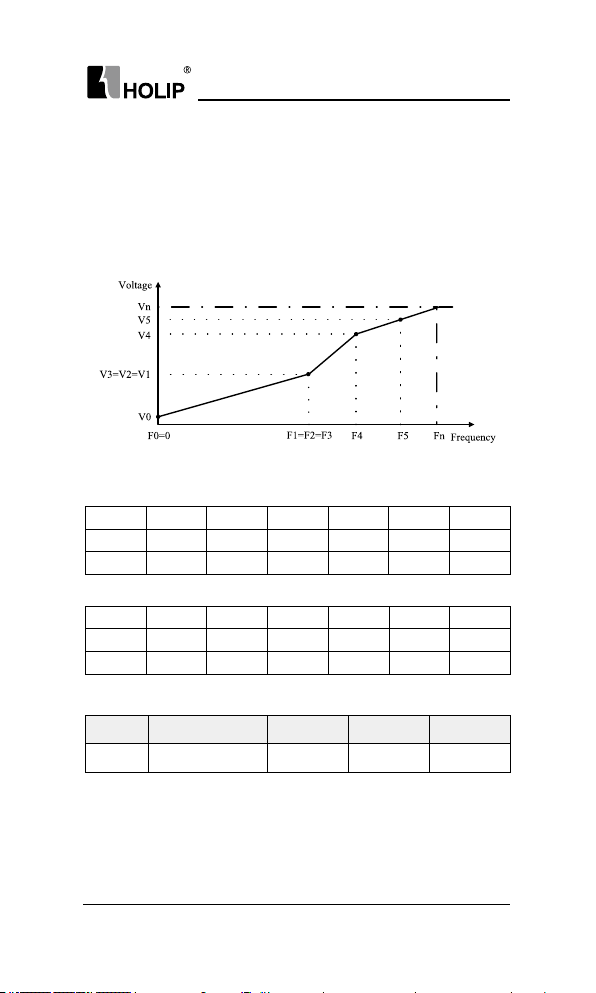

C01.5*Load Indep.Setting

Par. No. Name Range Unit Default

C01.55 V/F Characteristic-V 0.0~999.9 V *

C01.56 V/F Characteristic-F 0.0~ 400.0 Hz *

These parameters are array parameters [0-5], used to ma nually form a

V/F characteristic matching the motor. The f requency poi nts[F0-F5] are

dened in C01.56 V/F Charact eristic - F.The voltage at each point[V0-V5]

is defi ned in C01.55 V/F Characteristic - V.These paramet ers are

onlyaccessible when C01.01 Motor Control Principle is set to V/F.

- 46 -

HLP-C100 Ser ies Operating Manual

Page 51

HL P-C10 0 Ser ies

C01.55[0]~C01.55[5] is respective to V0~V5, C01.56[0]~C01.56[5] is

respective to F0~F5,Vn is motor rated voltage,Fn is the motor rated

frequency.

The set of C01.56 must met F0=0 and F1≤F2≤F3≤F4≤F5.

Simplif y V/F characteristicby merging 2 or more points (voltages and

frequencies), which respectively are set equal.

The slope (ratio of V/F) after point (F5, V5) must be equal to the slope

between point (F5, V5) and the previous point.

The defau lt setti ngs of V/F Characteristic are:

200V model:

[0] [1] [2] [3] [4] [5]

C01.55 0.0 7.0 230.0 230.0 230.0 230.0

C01.56 0.0 0.5 50.0 50.0 50.0 50.0

400V model

:

[0] [1] [2] [3] [4] [5]

C01.55 0.0 12 .0 400.0 400.0 400.0 400.0

C01.56 0.0 0.5 50.0 50.0 50.0 50.0

C01.6*Load Depen.Setting

Par. No. Name Range Unit Default

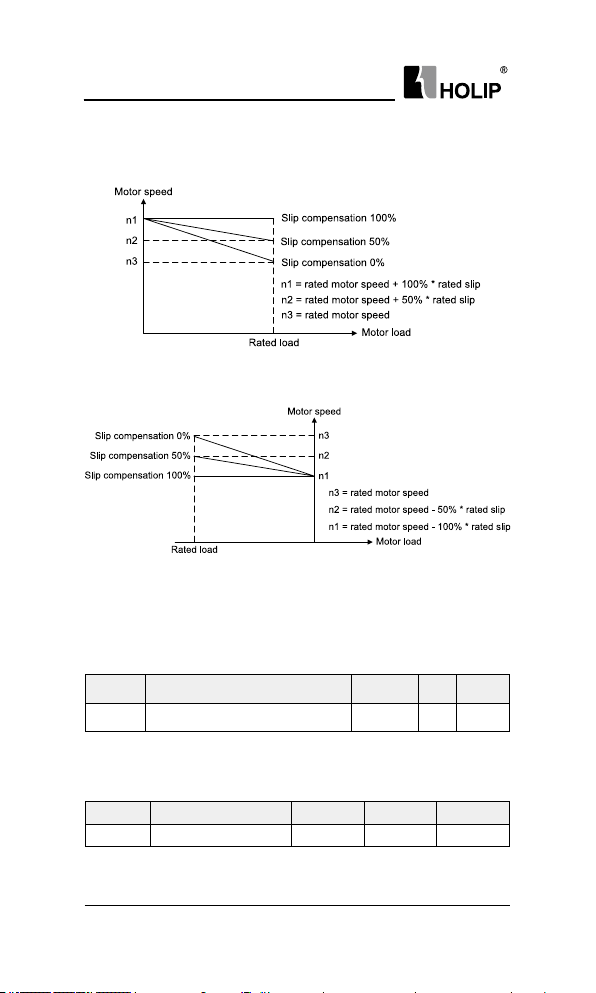

C01.62 Slip Compensation -40 0~39 9 % 100

When the motor is driving an electric-driven load, motor speed d ropswith

the increase of load. When the motor is dr iving a power generat ing load,

motor speed will i ncrease with the increase of load. Appropriate slip

compen sation can maintain const ant motor speed when the motor load is

changing.

If this pa rameter is set to 100%, it indicates that the compensation when

HLP-C100 Ser ies Operating Manual

- 47 -

Page 52

HL P-C10 0 Ser ies

the motor bears rated load is the rated motor slip.

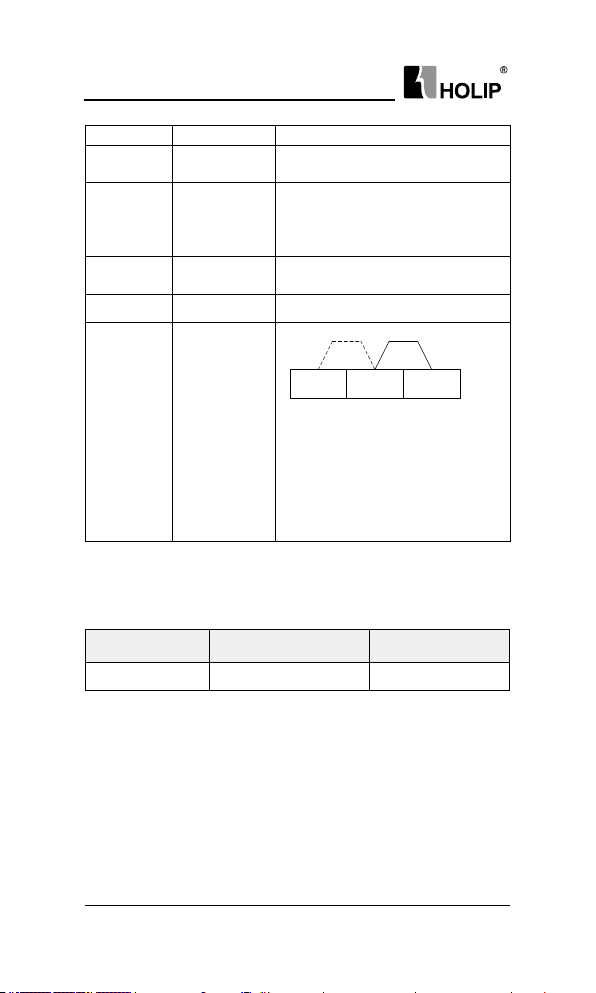

Diagram of slip compensat ion is shown below:

Slip compensation on electric driven load

Slip compensation on power generating load

When having more t han one motor on the same shaft the re is a need for

some kind of load share between t he drives controll ing the motors. This

has ty pically been made with two dr ives running i n speed open loop

mode and one with negat ive slip compe nsation.

Par. No. Name Range Unit Default

C01.6 3 Slip Compensation Time Constant 0.05~5.00 s 0.10

Enter the slip compensation reaction speed. A high value results in slow

react ion, and a low value results in quick reaction. If low-frequency

resona nce problems arise, use a longer ti me setting.

Par. No. Name Range Unit Defau lt

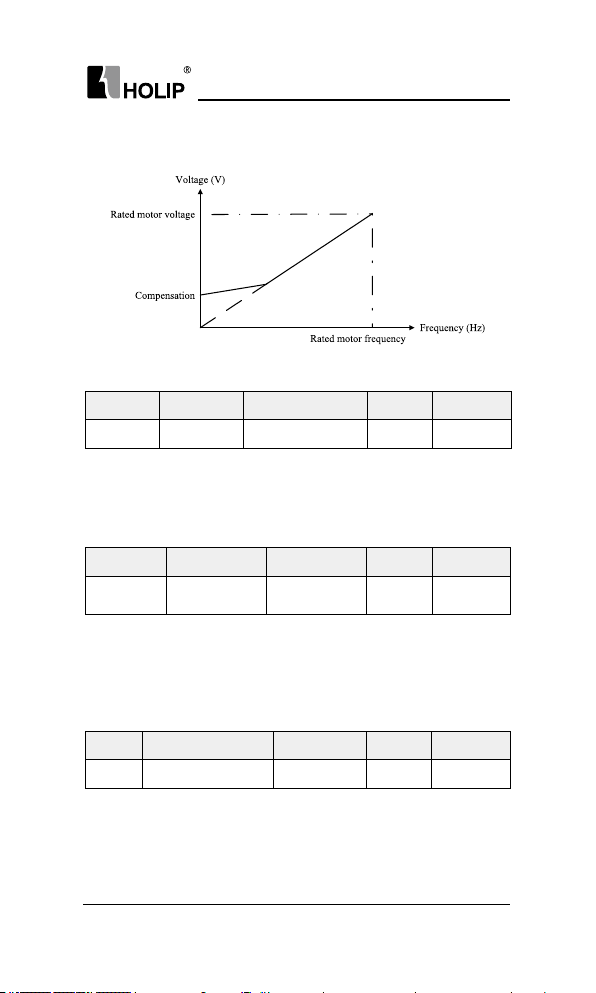

C01.67 Torque Compensation 0 ~200 % 0

Enter the % value to compensate voltage in relation to load when

the motor is runni ng at low speed. 100% corresponds to completely

- 48 -

HLP-C100 Ser ies Operating Manual

Page 53

HL P-C10 0 Ser ies

compen sate for the volt age drop caused by the stator resistance.

Diagr am of torque compensation is shown below:

C01.7*Start Adjustments

Par. No. Name Range Unit Default

C01.71 Start Delay 0.0 ~10.0 s 0.0

This parameter enables a delay of the star ting time. The drive begins

with the star t f unction selected in C01.72. Enter the time delay required

before com mencing accelerat ion.Setting start delay to 0.0 sec. disables

star t functionwhen st art command is g iven.

Par. No. Name Range Unit Default

C01.7 2 Star t Function

Select the start function duri ng star t delay. This parameter is linked to

C01.71 Start Delay.

0: DC Hold, Energizes motor with a DC holdi ng current (C02.00 DC

Hold Cur rent) during the start delay time;

2: Coast, Motor coasted duri ng the sta rt delay time (drive off );

0: DC Hold

2: Coast

2

Par. No. Name Range Unit Default

C01.75 Min. Start Frequency 0.00 ~10.00 Hz 0.00

If the drive f requency reference is less than C01.75 Min. Start Frequency,

the dr ive will not r un even the star t command is given (the st art command

will be shielded). Only the drive frequency reference is greater than or

equal C01.75, then the drive starts to run. The drive still accelerates from

0 to frequency reference using ramp ti me.

HLP-C100 Ser ies Operating Manual

- 49 -

Page 54

HL P-C10 0 Ser ies

Pa r. No. Na me R ange Unit Def ault

C 01.7 6 Jum p Freq uency 0.0 ~20.0 Hz 0.0

If the drive frequency reference’s absolute value (not zero, fre quency

reference maybe negative)is less than C01.76Jump Frequency, the drive

will r un at jump frequency (maybe reversing if the reference is negative).

For examp le:

Set C01.76 = 3. if the freque ncy reference is 2 , the d rive will run forward

at 3Hz; If the frequency reference is -2, the dr ive will r un reversing at

3Hz; If the f requency reference is 0, the dr ive will stop. If the frequency

reference is 20, the drive will r un at 3Hz immediately, then accele rates

from 3Hz to 20Hz using ramp time.

Note: it is not recom mended for using C01.75 and C01.76 toget her.

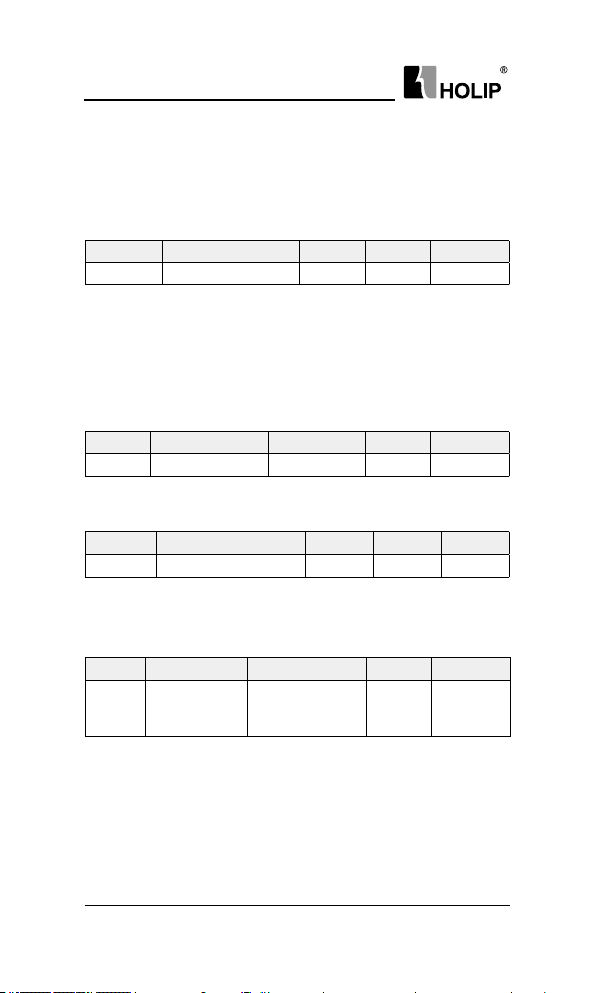

If C01.75 and C01.76 are used together, the following talbe is its

behaviour.

Freq. ref.

Par. setting

C 01.7 5 = 5.0 0

C 01.7 6 = 10. 0

C 01.7 5 = 10 .0 0

C 01.7 6 = 5. 0

At tent ion: When C01.76 Jump Frequency and C02.04 DC Br ake Cut i n Speed

are not zero, DC brake will only be active when C02.04 > C01.76.

3Hz 8Hz 15H z

Freq. ref<

C 01.75

the sta rt

command

is shielded,

the drive

st op.

Freq. ref<

C 01.75

the sta rt

command

is shielded,

the drive

st op.

Freq. ref >

C 01.75,

the sta rt

command is

given,

Freq. ref <

C 01.7 6

the drive

runs at

10. 0H z

Freq. ref<

C 01.75

the sta rt

command is

shield ed, t he

drive stop.

Freq. ref > C01.75,

the sta rt comma nd is

given,

Freq. ref > C01.76

the drive r uns a t 10Hz

imm edi at ely, the n

accelerates f rom 10Hz

to 15Hz using ramp

ti me.

Freq. ref > C01.75,

the sta rt comma nd is

given,

Freq. ref > C01.76

the dr ive runs at 5Hz

imm edi at ely, the n

accelerates from 5Hz

to 15Hz using ramp

ti me.

- 50 -

HLP-C100 Ser ies Operating Manual

Page 55

HL P-C10 0 Ser ies

C01.8*Stop Adjustments

Par. No. Name Range Unit Default

C01.8 0 Funct ion at Stop

Select the drive function after stop command is given or start com mand

is removed (standby), and output frequency is ramped down to C01.82

Min Speed for Funct ion at Stop.

0: Coast, Leaves motor i n free mode. the drive is off;

1: DC Hold, the motor is energi zed with a DC current. See C02.0 0 DC

Hold Cur rent for more i nformation;

Diagra m of Fu nction at Stop is shown below:

0: Coast

1: DC Hold

0

Par. No. Name Range Unit Default

C01.8 2 Min Speed for Function at Stop 0.0~40 0.0 Hz 0.0

Set the out put frequency at which to activate C01.80 Function at Stop.

6.3 Group 02: Brakes

C02.0*DC-Brake

Par. No. Name Range Unit Default

C02.00 DC Hold Current 0 ~150 % 50

HLP-C100 Ser ies Operating Manual

- 51 -

Page 56

HL P-C10 0 Ser ies

Enter a value for holding current as a percentage of the rated motor

current set i n C01.24 Motor Current. 100% DC holding current

corresponds to IM,N. This para meter either holds the motor (holding

torque) or pre-heats the motor. This parameter is act ive if DC Hold has

been selected in eit her C01.72 Start Function or C01.80 Funct ion at Stop.

At tent ion: Avoid 100% current too long a s it may overheat t he motor.

Par. No. Name Range Unit Default

C02.01 DC Brake Cur rent 0 ~150 % 50

Enter a value for cur rent as a percent age of the rated motor current IM,N,

see C01.24 Motor Current. 100% DC braking current corresponds to

IM,N.

DC brake curre nt is applied on a stop comm and, when the speed is lower

than the limit set in C02.04 DC Brake Cut I n Speed; or v ia the ser ial

commu nication p ort. The braking current is active during the time period

set in C02.02 DC Braking Time.

Par. No. Name Range Unit Default

C02.02 DC Braking Time 0.0 ~60.0 s 10 .0

This parameter defines DC brake current (C02.01) time during which

DC-brake current is applied to the motor.

Par. No. Na me Range Unit Default

C02.04 DC Bra ke Cut in Speed 0.0~400.0 % 0.0

Set the DC brake cut-in speed for act ivation of the DC braki ng current set

in C02.01 DC Brake Cur rent, upon a stop command.

C02.1*Brake Ener gy Funct .

Par. No. Name Range Unit Default

C02.10 Brake Function

0: Off;

1: Resisto r brake, u se the resistor brake to consu me sur plus energy

result ing from motor braking, and prevent the d rive to tr ip due to

over-voltage in the intermediate circuit;

2: AC brake, dissipate su rplus energy in the motor core, and prevent

the energy back into drive causing tr ips. It is important to keep in

mind that frequent use of this function will cause an inc rease i n

motor temperature;

0: Off

1: Resistor brake

2: AC brake

0

- 52 -

HLP-C100 Ser ies Operating Manual

Page 57

HL P-C10 0 Ser ies

Attention: Resistor brake is only f u nctional when the drive build-in braki ng

unit or external braking unit must be installed.

Par. No. Name Range Unit Default

C0 2.11 Brake Resistor 5~65535 Ω *

Set brake resistor value.This parameter is only active i n drives with

an integral brake unit.

Pa r. No. Na me Ra nge Unit Def ault

C 02 .17 Ove r-voltage Con tr ol

Over-voltage control (OVC) reduces the risk of t he dr ive tripping due

toan over volt age on the DC link caused by generative power from the

load.