Page 1

Page 2

HLP-A100 Series Operating

Manual

Page 3

Page 4

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

Index

Introduction 1

Chapter 1 Safty Precautions 1

1.1 Before power-up 1

1.2 During the power-up 3

1.3 During the operation 3

1.4 After the power-off 4

Chapter 2 Standards and Specications 5

2.1 Label Description 5

2.2 Particular Specications 6

2.3 Technical Specications 7

Chapter 3 Installation and wiring 11

3.1 Checks before Installation 11

3.2 Installation Dimensions 11

3.2.1 Dimensions of LCP 11

3.2.2 Dimensions of the inverter 12

3.3 Installation and Wiring 13

3.3.1 Electrical Installation in General 13

3.3.2 Fuse and Main Circuit Terminals Specications 13

3.3.3 Installation and Direction 14

3.3.4 Wiring terminal 15

3.3.5 Wiring 19

Chapter 4 Operation and Display Interface 21

4.1 LCP Digital Operator 21

4.2 Quick to set parameters 21

4.2.1 Preset reference by LCP 21

4.2.2 FWD/REV Status 22

4.2.3 Data read-outs 23

4.2.4 View alarm record 25

4.2.5 View state parameter 26

4.2.6 LED Display 27

Chapter 5 Parameter Overview 28

Chapter 6 Parameter Description 54

6.1 Parameter Group 00: Operation/Display 54

6.2 Parameter Group 01: Load and Motor 59

6.3 Parameter Group 02: Brakes 69

6.4 Parameter Group 03: Reference/Ramps 72

6.5 Parameter Group 04: Limits/warnings 81

6.6 Parameter Group 05: Digital Input/Output 86

Page 5

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

6.7 Parameter Group 06: Analog In/Out 95

6.8 Parameter Group 07: Controller 103

6.9 Parameter Group 08: Comm. and Options 106

6.10 Parameter Group 13: Simple PLC 110

6.11 Parameter Group 14: Special Functions 118

6.12 Parameter Group 15: Drive Information 123

6.13 Parameter Group 16: Data Readouts 127

6.14 Parameter Group 25: App. Functions Cascade 136

6.15 Parameter Group 30: App. Functions Wobble 145

Chapter 7 Quick Application Guide 150

7.1 Motor Parameter Adaption 150

7.2 Using LCP to control the drive [HAND] 150

7.3 Using digital in terminals to control the drive [AUTO] 151

7.4 Set-up selection 151

7.5 Potentiometer reference 152

7.6 Connect two-wire transductor to terminal AI 152

7.7 Reference for pulse input 153

7.8 Multi-speed 153

7.9 Speed up/down 154

7.10 Pulse start/stop 155

7.11 Digital speed up/down 155

7.12 Conguration Mode 156

7.13 Simple PLC 158

7.13.1 Order Execution 158

7.13.2 Parallel Execution 160

Chapter 8 Accessory Specication 161

8.1 Braking Resistor 161

8.2 Remote Mounting Kit 162

Chapter 9 EMC 163

9.1 EMC–Correct Installation 163

Chapter 10 Warnings/Alarms and Fault Handling 164

10.1 Fault List 164

10.2 Fault Indication and Trouble Shooting 168

Chapter 11 Maintenance 170

11.1 Note 170

11.2 Storage and Transport 170

Chapter 12 Communication protocol 171

12.1 Format specication 171

12.2 Coil addressing 171

12.3 Read Coil Status 173

12.4 Read Holding Registers 174

12.5 Force Single Coil 175

Page 6

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 5 -

12.6 Preset Single Register 175

12.7 Force Multiple Coils 176

12.8 Preset Multiple Regs 177

12.9 Read/Write array 178

12.10 Exception code 179

Page 7

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 6 -

Page 8

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 1 -

Caution

● Check to be sure that the voltage of the main circuit AC power

supply matches the input voltage of the inverter.

● Install the inverter in a safe location, avoiding high temperature,

direct sunlight, humid air or water.

● The inverter can only be used at the places accredited by our

company. Any unauthorized working environment may have the

risks of re, gas explosion, electric shock and other incidents.

● If more than one drive installed on the same control cabinet, make

additional cooling fan, so that the inside temperature is lower than

40

℃

,

in order to prevent overheating or re occurs.

● It will affect the service life of the inverter if a contactor is

Introduction

Thank you f or purchasing and using the general-purpose vector

inverter of HLP-A100 series.

Please read caref ully the operation manual before putting the inver ter

to use so as to correctly install and operate the inverter, give f ull play to its

f unctions and ensure the safet y. Please keep the operation manual handy for

f uture reference, maintenance, inspection and repair.

Due to the inverter of a kind of power electronics product it must be

installed, tested and ad justed with specialized electrical engineering workers.

The ma r ks of

(Da nger)

、

(Caution) a nd other symbols in

the manual remind you of the safety and prevention cautions during

the handling, installation, running and inspection. Please follow these

instr uctions to make su re the safe use of the inverter. In case of any doubt

please contact our local agent f or consultation. Our professional persons are

willing and ready to serve you.

The manual is subject to change without notice.

Chapter 1 Safet y Precautions

1.1 Before power-up

Caution

Indicates misuse may damage the inverter or

mechanical system .

Danger

Misuse may result in casualty.

Page 9

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 2 -

Danger

● Be sure to turn off the power supply before wiring.

● Mount the drive in the metal and other non-combustible materials

to avoid the risk of re.

● Don’t install the drive in a space with explosive gas, otherwise,

they lead to explosion.

● R, S, T terminals are power input terminals, never mixed with

U.V.W terminals. Be sure that the wiring of the main circuit is

installed on the input side to control the start and stop. Generally

it is required to control it through terminal commands. Special

attention should be paid to its use in the case of the start and stop

more frequently places.

● Do not install any switch component like circuit breaker or

contactor at the output of the inverter. If any of such components

must be installed due process and other needs, it must be ensured

that the inverter has no output when the switch acts. In addition,

it is forbidden to install any capacitor for improvement of power

factor or any varistor against thunder at the output. Otherwise

it will cause malfunctions, tripping protection and damages of

components of the inverter.

● Please use an independent power supply for the inverter. Do avoid

using the common power supply with an electrical welder and

other equipment with strong disturbance. Otherwise it will cause

the drive to protect or even damage the drive.

● Motor overload protection is not included in the default settings. If

this function is desired, set C01.09 (motor thermal protection) to

date value ETR trip or date value ETR warning.

● Do not make any high voltage test with any component inside the

inverter. These semi-conductor parts are subject to the damage of

high voltage.

● The IC board of the inverter are susceptible to the effect and

damage of static electricity. Don’t touch the main circuit board.

● Installation, commissioning and maintenance must be performed

by qualied professional personnel.

● Don’t carry the front cover of the inverter directly when handling.

It should be handled with the base to prevent the front cover off

and avoid the dropping of the inverter, which may possibly cause

the injuries to people and the damages to the inverter.

Page 10

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 3 -

correct. Otherwise it will cause damages of the inverter when the

power is applied to it.

● The terminal of

must be grounded separately and never

connected to N-line. Otherwise it will easily cause the protection

or errors of the inverter.

● Do not dissemble or modify any internal connecting cord, wiring

or component of the inverter by yourself.

● Never remodel it or exchange control boards and components by

yourself. It may expose you to an electrical shock or explosion,

etc.

● Keep the inverter from the reach of children or persons not

concerned.

Caution

● Do not measure the signals on circuit boards while the inverter is

running to avoid danger.

● The drive has been optimized before sold. Please make proper

adjustments according to the desired functions.

● Do consider the vibration, noise and the speed limit of the motor

bearings and the mechanical devices.

Danger

● Do not plug the connectors of the inverter during the power up

to avoid any surge into the main control board due to plugging,

which might cause the damage of the inverter.

● Always have the protective cover in place before the power up to

avoid electrical shock injury.

Danger

● Never connect or disconnect the motor set while the inverter is in

running. Otherwise it will cause over-current trip and even burn

up the main circuit of the inverter.

1.2 During the power-up

1.3 During the operation

Page 11

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 4 -

Caution

● Even in the case of the main power, the other voltage inputs and

the share load (linkage of DC intermediate circuit) all have been

disconnected from the mains, the internal of the drive still have

residual energy. Before touching any potentially live parts of the

inverter, please wait at least 4 minutes for the drives of less than

22KW (including 22KW), and wait at least 15 minutes for the

drives of more than 30kW (including 30kW). Otherwise, it will

expose you to a risk of electrical shock.

The user must strictly follow the instruction to operate and make

wire connection. Otherwise HOLIP will not responsible for the

damages due to wrong operation. The user will responsible for the

damages themselves.

● Never remove the front cover of the inverter while the inverter is

powered up to avoid any injury of electric shock.

● Do not come close to the machine when the Reset Function is

used to avoid anything unexpected. The motor may automatically

recover from fault.

1.4 Af ter the power-off

Page 12

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 5 -

Chapter 2 Standards and Specications

2.1 La be l Descr i pt ion

Signicance of the type code:

1-8 HLP-A100 Indicate Product Series

9-12 0075 I n dica te 75K W

13-14 21 Indicate 1-Phase AC 220V

23 Indicate 3-Phase AC 220V

43 Indicate 3-Phase AC 380V

15-17 P20 IP rating is 20

18 X Without AC choke

A With AC choke

19 X Without Brake unit

B With Brake unit

20 X Without DC choke

D With DC choke

21 1 Control panel with LED display and potentiometer

22 C Wit h coating on PCB

23 X Reser ved

24 0 Domestic sale

1 Overseas sale

25-27 XX Reser ved

28-31 VXXX Indicate sof tware version number,

such as V235 means the version number is 2.35 .

Page 13

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 6 -

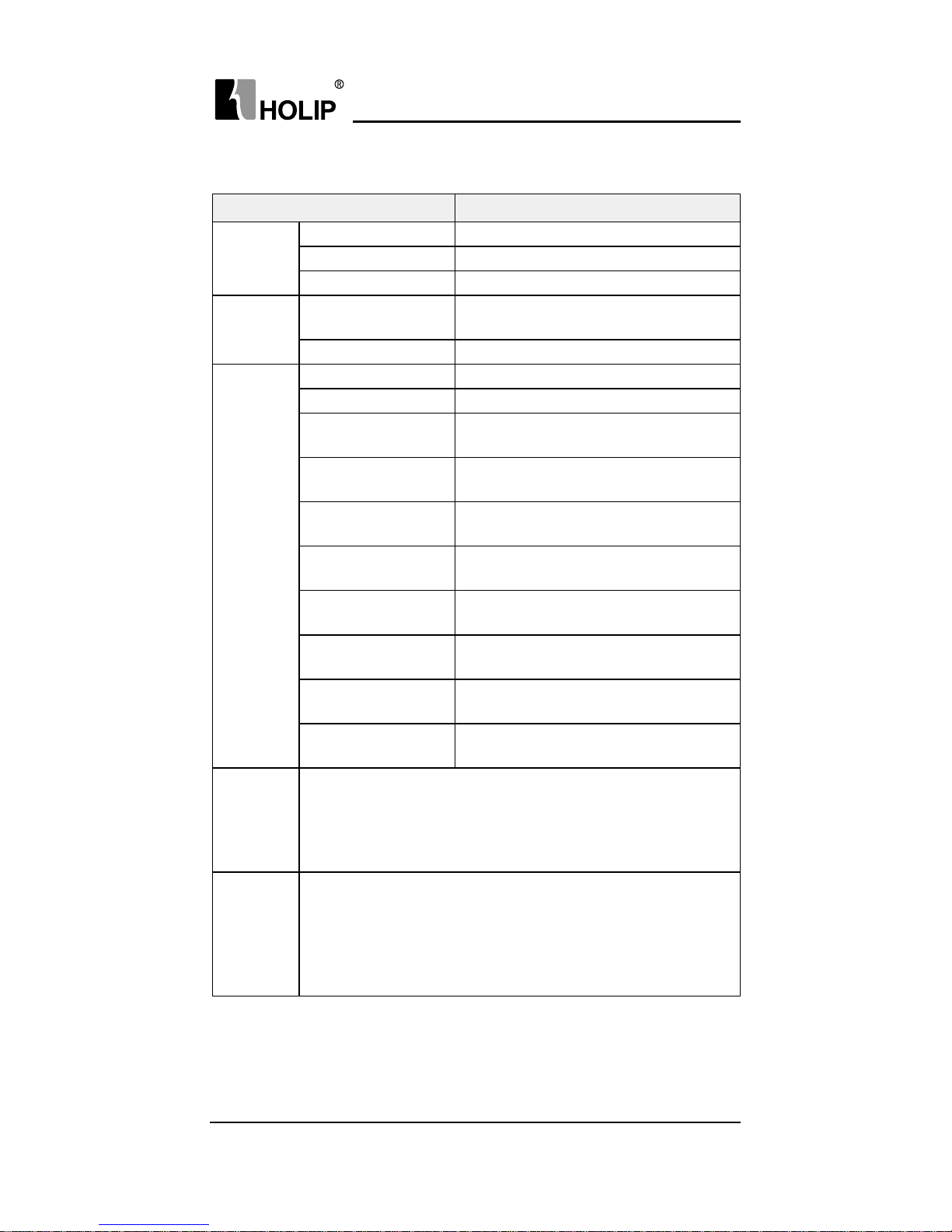

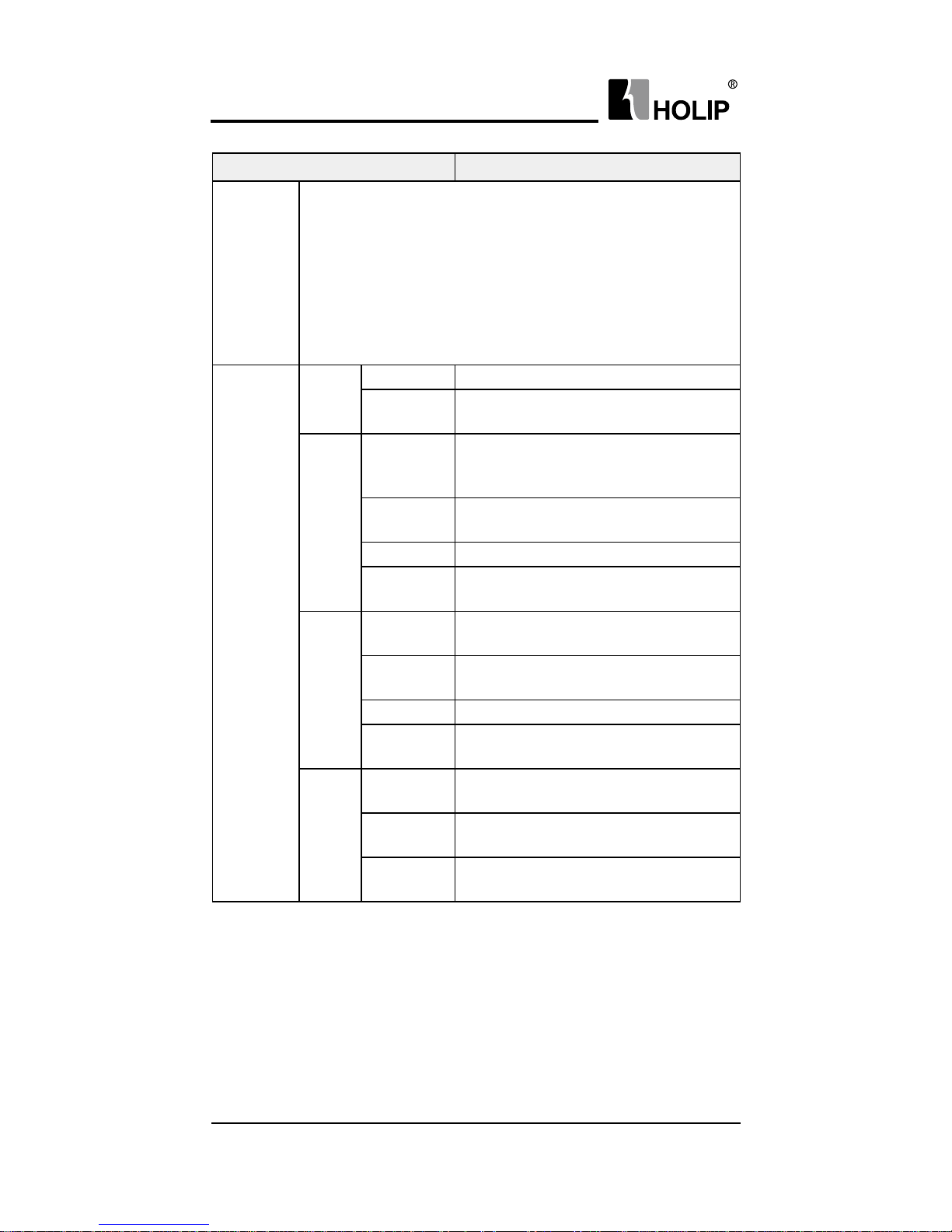

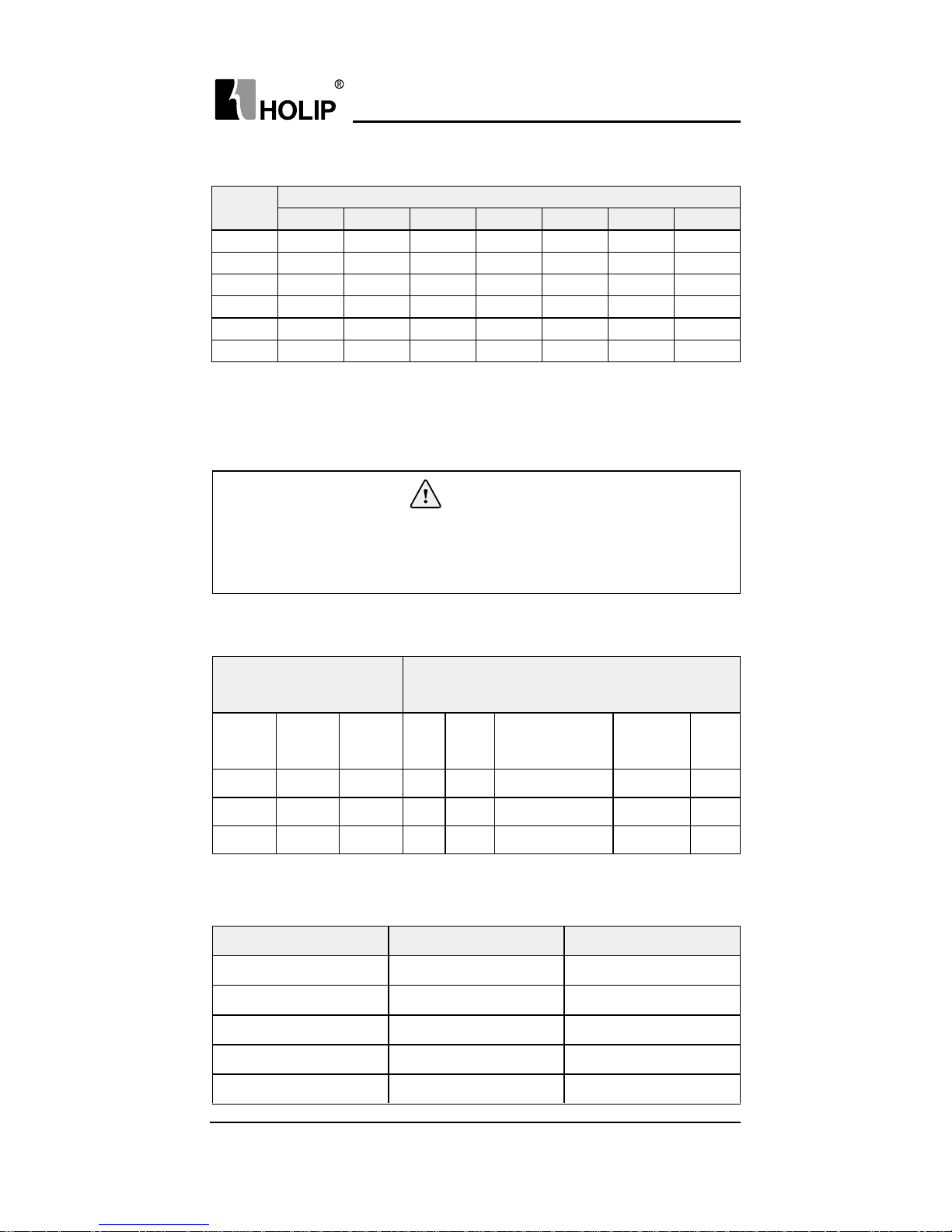

2.2 Particular Specications

Model Inpu t voltage

Input

current/

A

Output

current/

A

Rated

power/

KW

Suitable

motor/

KW

Net

weight /

KG

HLP-A100001143

3×380 - 4 40 V 5 0 /6 0 H z 35.9 25

11 11 5.8

3×4 4 0 - 48 0 V50 /6 0 Hz 31. 4 22.7

HLP-A100001543

3×380 - 4 40 V 5 0 /6 0 H z 43. 4 32

15 15 5.8

3×4 4 0 - 48 0 V50 /6 0 Hz 38.8 29.1

H L P- A10 018 D 5 43

3×380 - 4 40 V 5 0 /6 0 H z 51.5 38

18. 5 18. 5 8

3×4 4 0 - 48 0 V50 /6 0 Hz 4 6.1 34.5

HLP-A100002243

3×380 - 4 40 V 5 0 /6 0 H z 61.0 45

22 22 8

3×4 4 0 - 48 0 V50 /6 0 Hz 54.5 4 0.9

HLP-A100003043

3×380 - 4 40 V 5 0 /6 0 H z 57 61

30 30 25. 4

3×4 4 0 - 48 0 V50 /6 0 Hz 46 52

HLP-A100003743

3×380 - 4 40 V 5 0 /6 0 H z 70 73

37 37 2 5.4

3×4 4 0 - 48 0 V50 /6 0 Hz 57 65

HLP-A100004543

3×380 - 4 40 V 5 0 /6 0 H z 84 90

45 45 50

3×4 4 0 - 48 0 V50 /6 0 Hz 68 80

HLP-A100005543

3×380 - 4 40 V 5 0 /6 0 H z 103 10 6

55 55 50

3×4 4 0 - 48 0 V50 /6 0 Hz 83 105

HLP-A100007543

3×380 - 4 40 V 5 0 /6 0 H z 14 0 147

75 75 50

3×4 4 0 - 48 0 V50 /6 0 Hz 113 130

HLP-A100009043

3×380 - 4 40 V 5 0 /6 0 H z 175 18 0

90 90 60

3×4 4 0 - 48 0 V50 /6 0 Hz 15 4 16 0

H L P- A10 0 0110 43

3×380 - 4 40 V 5 0 /6 0 H z 206 215

110 11 0 60

3×4 4 0 - 48 0 V50 /6 0 Hz 18 3 19 0

HLP-A100013243

3×380 - 4 40 V 5 0 /6 0 H z 2 51 260

132 132 60

3×4 4 0 - 48 0 V50 /6 0 Hz 2 31 240

HLP-A100016043

3×380 - 4 40 V 5 0 /6 0 H z 304 315

16 0 16 0 99

3×4 4 0 - 48 0 V50 /6 0 Hz 2 91 302

HLP-A100018543

3×380 - 4 40 V 5 0 /6 0 H z 350 365

185 185 99

3×4 4 0 - 48 0 V50 /6 0 Hz 320 335

HLP-A100020043

3×380 - 4 40 V 5 0 /6 0 H z 381 395

200 200 99

3×4 4 0 - 48 0 V50 /6 0 Hz 348 361

HLP-A100022043

3×380 - 4 40 V 5 0 /6 0 H z 420 435

220 220 99

3×4 4 0 - 48 0 V50 /6 0 Hz 383 398

Page 14

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 7 -

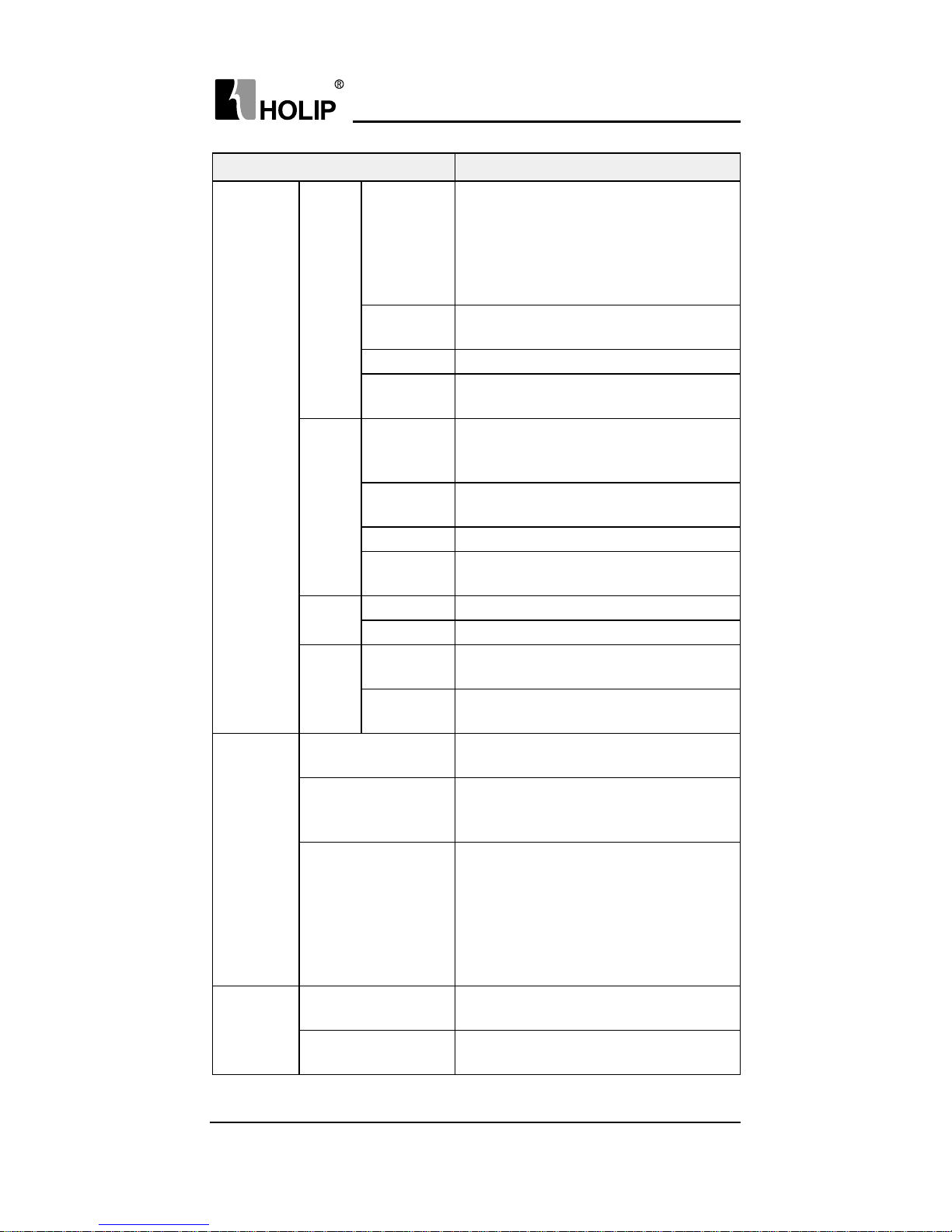

2.3 Technical Specications

Item Specif ication

Power

su pply

Supply voltage three phase 380-480V -20%-+10%;

Frequency 48-62Hz;

Max. imbalance 3%;

Motor

output

Output voltage

three phase 0-100% of supply

volt a ge;

Output f requency V/F : 0-400Hz , VVC+: 0-200Hz;

Main

con t rol

f unctions

Cont rol mode V/ F, V VC+;

Sta rt torque 1H z 150 %;

Overload capacity

150% rated output current (60s),

200% rated output current(1s);

PWM switch

f requency

2 K-16 K H z ;

Speed setting

resolution

Dig i t al: 0.001Hz; a nalog y: 0.5‰ of t h e

max. operating f requency ;

Speed open-loop

cont rol accuracy

30 - 4000 r pm: tolerance±8 rpm;

Speed closed-loop

cont rol accuracy

0 - 6000 rpm: tolerance±0.15 r pm;

Cont rol com ma nd

source

LCP , digital terminal, local bus;

Frequency setting

source

LCP , analog, pulse, local bus;

Ramp control

Selectable 4-speed steps ramp up and

down times 0.05-3600.00s;

Basic

Functions

AMA Function; Motor Magnetisation; Slip Compensation;

Torque compensation; Automatic Voltage Regulation; V/

F Control, DC Brake; AC brake; Speed Limit; Cu r rent

Limit; Flying Star t; Reset Function; Cou nter; Timer; PI

Controller.

Application

Functions

Speed Open-loop Control; Process Closed-loop Cont rol;

Wobble Function; Cascade controller; Winder; Jogging

; Multi-speed Control via Digital input; Multi-speed

Control via Reference; SLC ( including Order Control

、

Parallel Control ) ; Mechanical Braking;UP/DOWN;Catch

up /Slow down; Relative Scaling Reference etc.

Page 15

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 8 -

Item Specif ication

Protection

Functions

Missing Motor Phase Protection; Low-voltage Protection;

Over-voltage Protection; Over-current Protection; Output

Phase Loss Protection; Output Short Circuit Protection;

Output Grounding Fault Protection; Motor Thermal

Protection; Live Zero Timeout Function; AMA Fails;

CPU Fault; EEPROM Faults; Button freeze; Duplicate

Fails; LCP Invalid; LCP Incompat ible; Parameter Readonly; Reference Out of Range; Invalid While Running;

Password Er ror etc.

Cont rol

Te r mi na ls

Digital

input

Number 6 d igital i n pu ts.

Scan ni ng

time

1ms;

Analog

input

Numbe r of

input

2 analog inputs ( VI 、 AI ) , both

can receive voltage or cur rent

signals.

Input

accuracy

Max.er ror: 0.5% of f ul l scale

Resolution 11 b i t ;

Scan ni ng

time

1ms;

Pulse

input

Input

nu mber

1 pulse input ( DI4 ) , pulse

range:1Hz-100K Hz;

Input

accuracy

Max.er ror:0.5% of f ul l scale;

Resolution 11 b i t ;

Scan ni ng

time

16 m s ;

Digital

output

Output

nu mber

2 digital out puts ( DO1 、 DO2 )

Relay

output

2 relay outputs ( KA-KB 、 FA- F BFC ) ;

Scan ni ng

time

1ms;

Page 16

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 9 -

Item Specif ication

Cont rol

Te r mi na ls

Analog

output

Output

nu mber

2 analog outputs ( VO 、 AO ) , VO

can be selected to the current output

or voltage output via jumper switch

in the control board. AO can only be

selected as cu r rent output . Up to 11

dif ferent f eatures can be selected;

Output

accuracy

Max. error: 4‰ of f ull scale;

Resolution 11 b i t ;

Scan ni ng

time

16 m s ;

Pulse

output

Output

nu mber

1 pulse output (DO1), range: 1Hz-

2KHz (range f rom 1Hz-100KHz is

optional);

Output

accuracy

Max.er ror: 0.5% of f ul l scale;

Resolution 11 b i t ;

Scan ni ng

time

16 m s ;

Power

su pply

VDD 24VDC power supply;

+10 V 10 V D C p o w e r s u p p l y ;

RS485

serial

commu-

nication

Te r mi na l

nu mber

1, RS+(TX+,RX+), RS- (TX-, RX-);

Ground for

RS485

GN D;

Display

8 segments, 5

numeric displays

Display f requency, wa r nings, status

and so on;

Indicator

Light FWD 、 REV 、 HZ 、 A 、 R/

MIN display various status of the

inverter;

Data read-outs

Frequency setting, output f requency,

feedback value, out put current, DC

link voltage, output voltage, output

power, input terminals state, output

terminals state, analogue input ,

analogue output, 1-10 fault records

and accumulated working time etc.;

Accessor y

Remote mounting

kit

Available when the control panel f or

external use;

Copy card

Copy parameters f rom one inverter

to another ;

Page 17

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 10 -

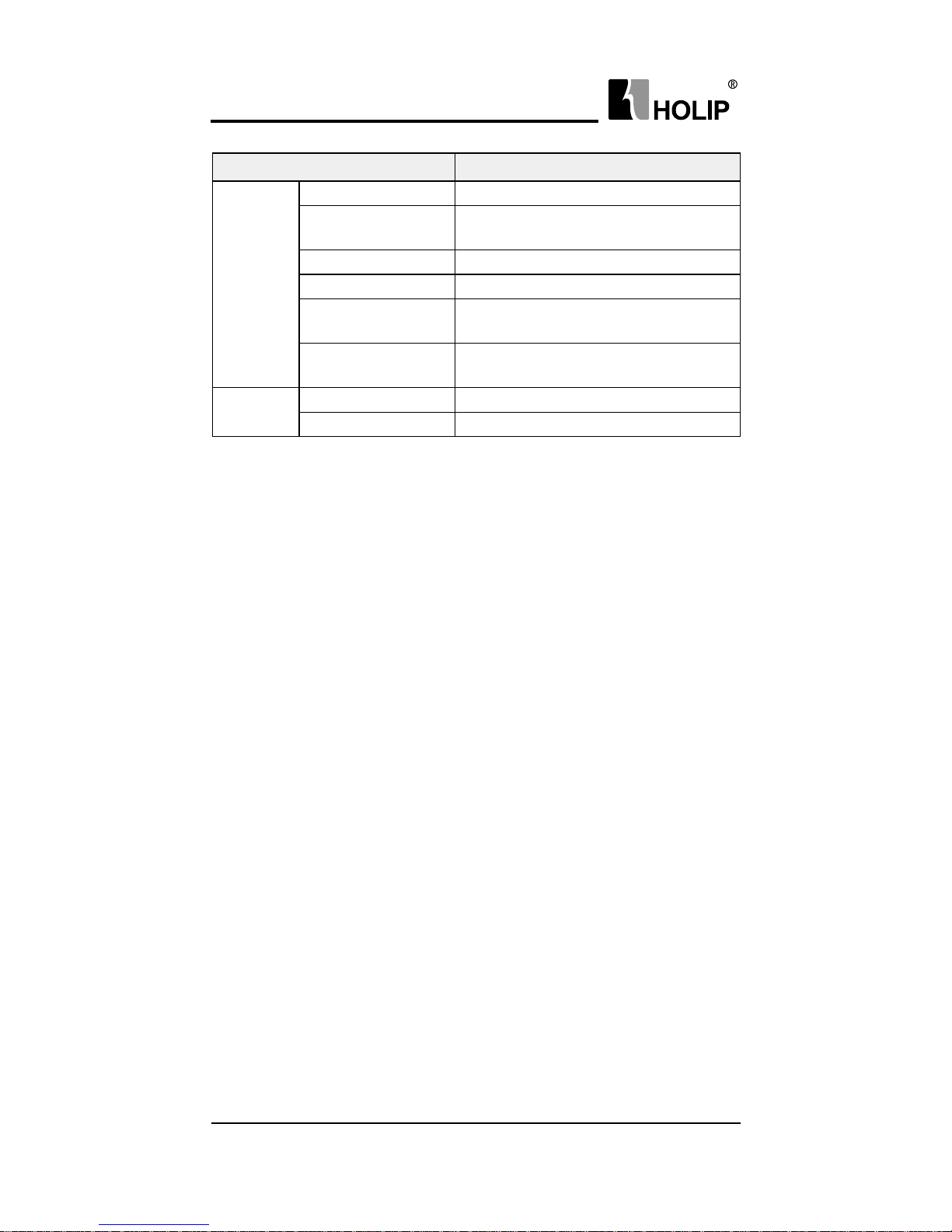

Item Specif ication

Environment

Enclosure IP 20;

Ambient

temperat u re

-10℃ - 40℃ ;

Humidity 5%-85% ( 95% wi t hou t conde nsa tion);

Vibration test ≤ 75K W:1.14g;90 - 2 2 0K W:0.7g;

Max. altitude above

sea level

1000m, derating use when more than

1000 meters;

Motor ca ble length

Shield ca ble: 50 meters, u nshield

cable: 100 meters;

Others

DC Choke ≥30kW with DC choke;

Brake Unit ≤22KW with Brake Unit;

Attention: Inverter under special environment (derating

)

:

● Derating for ambient temperature: If the f requency converter is

operated over 40

℃

ambient temperature, the continuous output

current should be decreased. The f requency converter has been

designed for operation at max 50

℃

ambient temperation with one

motor size smaller than normal. Continuous operation at full load at

50

℃

ambient temperation will reduce the lifetime of the f requency

converter.

● Derating for low air pressure: The cooling capability of air is

decreased at low air pressure. Below 1000m altitude no de-rating is

necessary but above 1000m the ambient temperature or the maximum

output current should be decreased. Dcrease the output by 1% per

100m altitude above 1000m or reduce the max. ambient temperature

by 1 degree per 200m.

Page 18

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 11 -

Chapter 3 Installation and wiring

3.1 Checks before Installation

3.2 Installation Dimensions

3.2.1 Dimensions of LCP

The inverter has been strictly and well packed before sold. In

consideration of various factors during the transportation special attention

should be paid to the following points before installation. If there is anything

abnor mal please notif y the dealer or the relevant people of our company.

● Check if the inverter has got any damage or deformation during the

transportation and handling;

● Check if there is one piece of HLP-A100 series inverter and one copy

of the instruction manual available when unpacking it;

● Check the information on the label to see if the specications meet

your order (Operating voltage and KW value);

● Check if the optional components you ordered are contained;

● Check if there is a certicate of qualication and a warrant y card.

Dimensions of the LCP are shown below (unit: mm):

Page 19

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 12 -

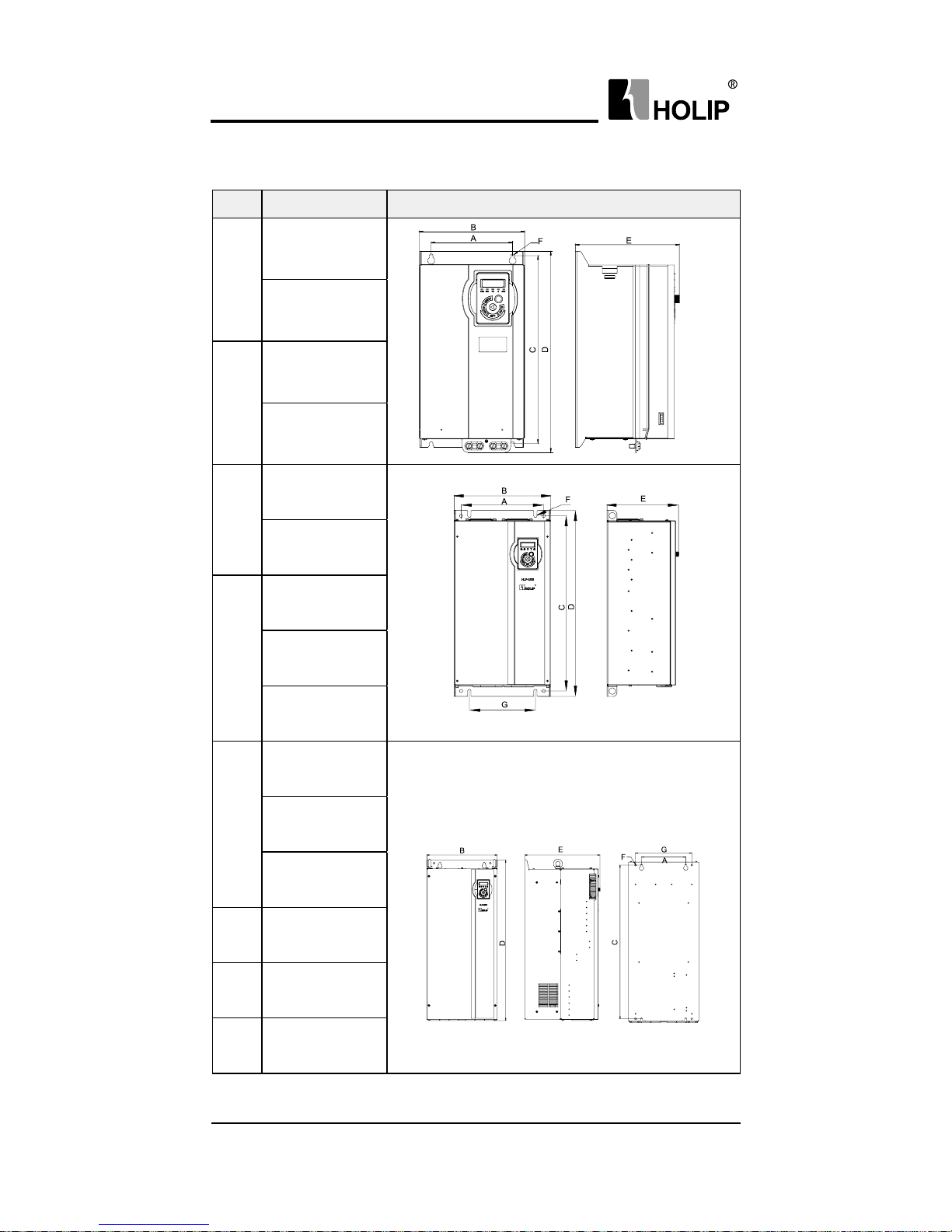

3.2.2 Dimensions of the inverter

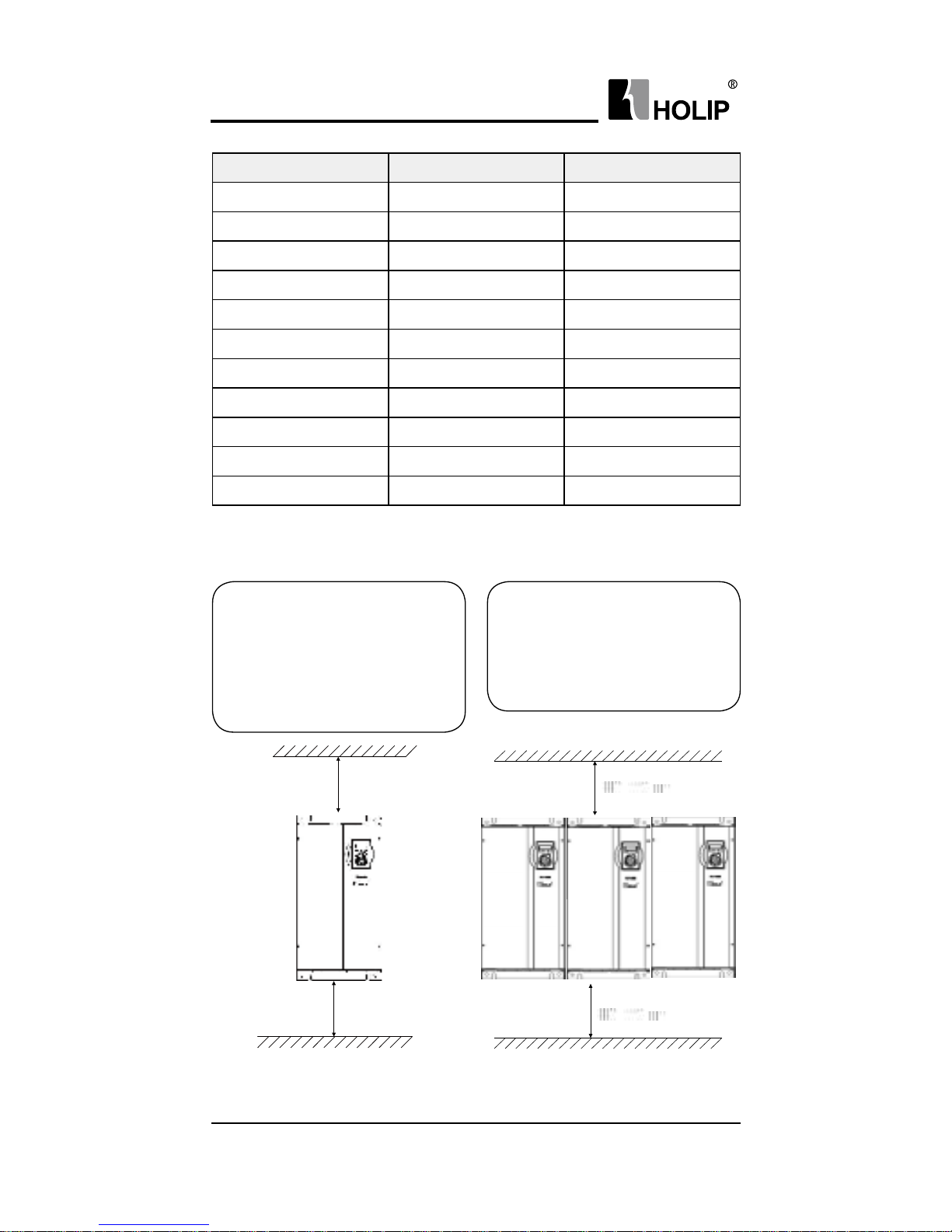

Item Model Frame size and Installation Dimension

A3

HLP-A100001143

HLP-A100001543

A4

H L P - A10 018 D5 4 3

HLP-A100002243

A5

HLP-A100003043

HLP-A100003743

A6

HLP-A100004543

HLP-A100005543

HLP-A100007543

A7

HLP-A100009043

H L P- A10 0 0110 4 3

HLP-A100013243

A8 HLP-A100016043

HLP-A100018543

HLP-A100020043

Page 20

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 13 -

Installation dimensions of the inverter:

Details of terminal tightening torques:

3.3 Installation and Wiring

3.3.1 Electrical Installation in General

Caution

● All cabling must comply with national and local regulations on

cable cross-sections and ambient temperature. Copper conductors

required.

Power ( KW ) a nd Volt age

levels

Tor qu e ( Nm )

1× 2 0 0 -

240V

3×20 0 -

240V

3×380 -

480V

Line Motor

DC connection/

Bra ke

Cont rol

terminals

Relay

11- 2 2 1. 2 1. 2 1. 2 0.15-0.4 0.4

30-75 8 8 8 0.15-0.4 0.4

90-220 16 16 16 0.15-0.4 0.4

Item

Dime nsion(mm)

A(mm) B(mm) C(mm) D(m m) E (mm) F(mm) G(mm)

A3 148 192 340 365 189 6.5 -

A4 150 214 395 420 194 6.5 -

A5 250 292 530 563 216.5 10 200

A6 280 330 680 720 308 10.5 215

A7 220 350 765 799 375 10.5 280

A8 345 486 863 900 390 10.5 410

3.3.2 Fuse and Main Circuit Terminals Specications

Model Fuse(Rated current/A) Main Circuit Terminals

HLP-A100001143 63 M4

HLP-A100001543 80 M4

H L P - A10 018 D5 4 3 80 M5

HLP-A100002243 10 0 M5

HLP-A100003043 10 0 M8

Page 21

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 14 -

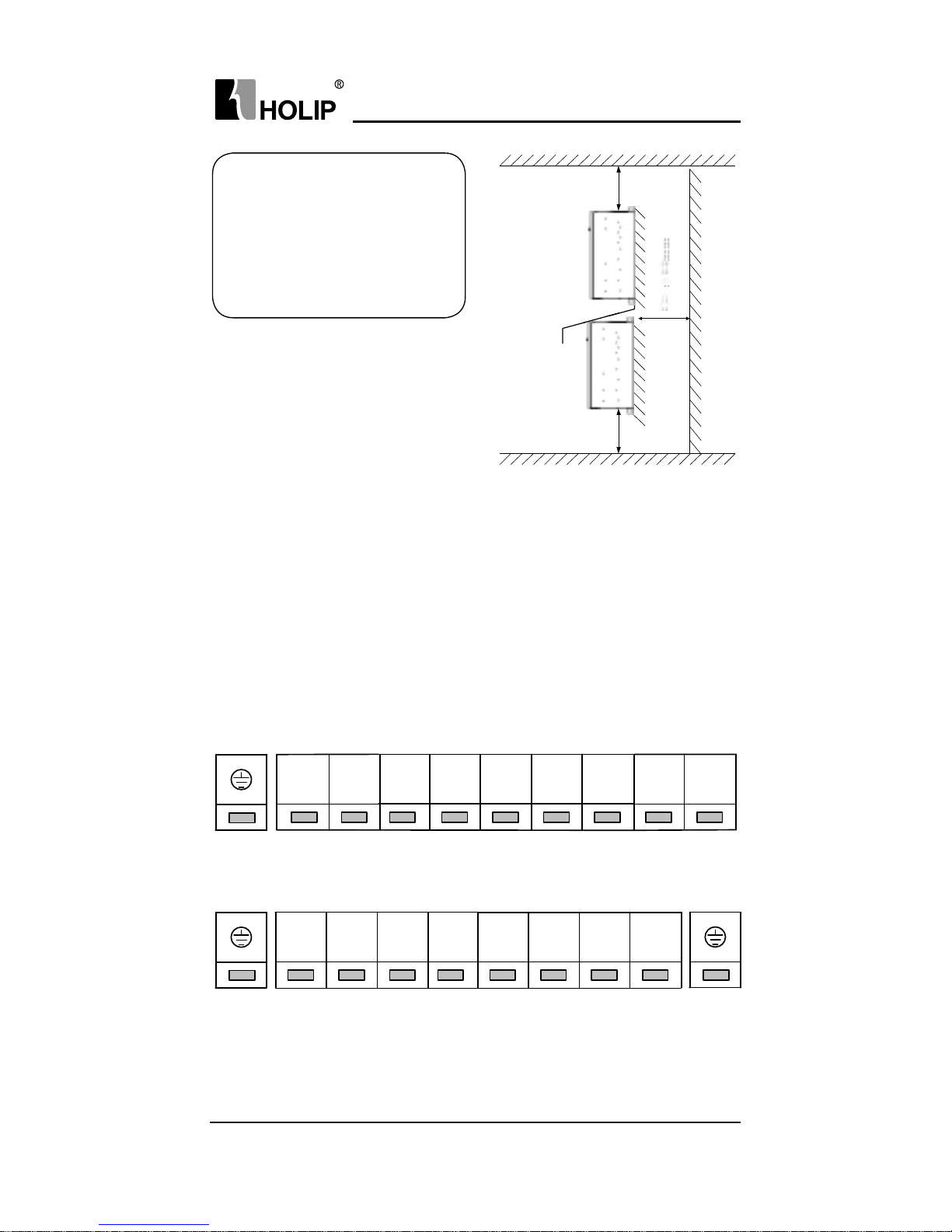

3.3.3 Installation and Direction

Single Installation

The inverter must be installed

vertically with smooth ventilation.

Enough space must be lef t around

the inverter to ensure good cooling,

as show n below:

Min:100mm

Min:100mm

Side by Side Instal lation

HLP-A100 series inverter can be

mou nted side by side, a minimum

space must be reserved above and

below the enclosure, as shown below:

Fig.1 Single installation

Fig.2 Side by side installation

Model Fuse(Rated current/A) Main Circuit Terminals

HLP-A100003743 12 5 M8

HLP-A100004543 16 0 M8

HLP-A100005543 16 0 M8

HLP-A100007543 224 M8

HLP-A100009043 300 M10

H L P- A10 0 0110 4 3 350 M10

HLP-A100013243 400 M10

HLP-A100016043 500 M12*1 ( M10*2)

HLP-A100018543 630 M12*1 ( M10*2)

HLP-A100020043 630 M12*1 ( M10*2)

HLP-A100022043 800 M12*1 ( M10*2)

Page 22

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 15 -

Fig. 3 Upper and Lower installation

Upper and Lower Installation

If several inverters need to be

installed together in one cabinet,

upper and lower installation can

be adopted. Enough space must be

reserved to ensure effective cooling,

as shown right:

Note: Install the unit and make sure that it is f ree f rom high moisture 、 high

temperat u re 、 heavy dust 、 metal f ragments and high oil mist.

3.3.4 Wiring terminal

Min:100mm

Min:100mm

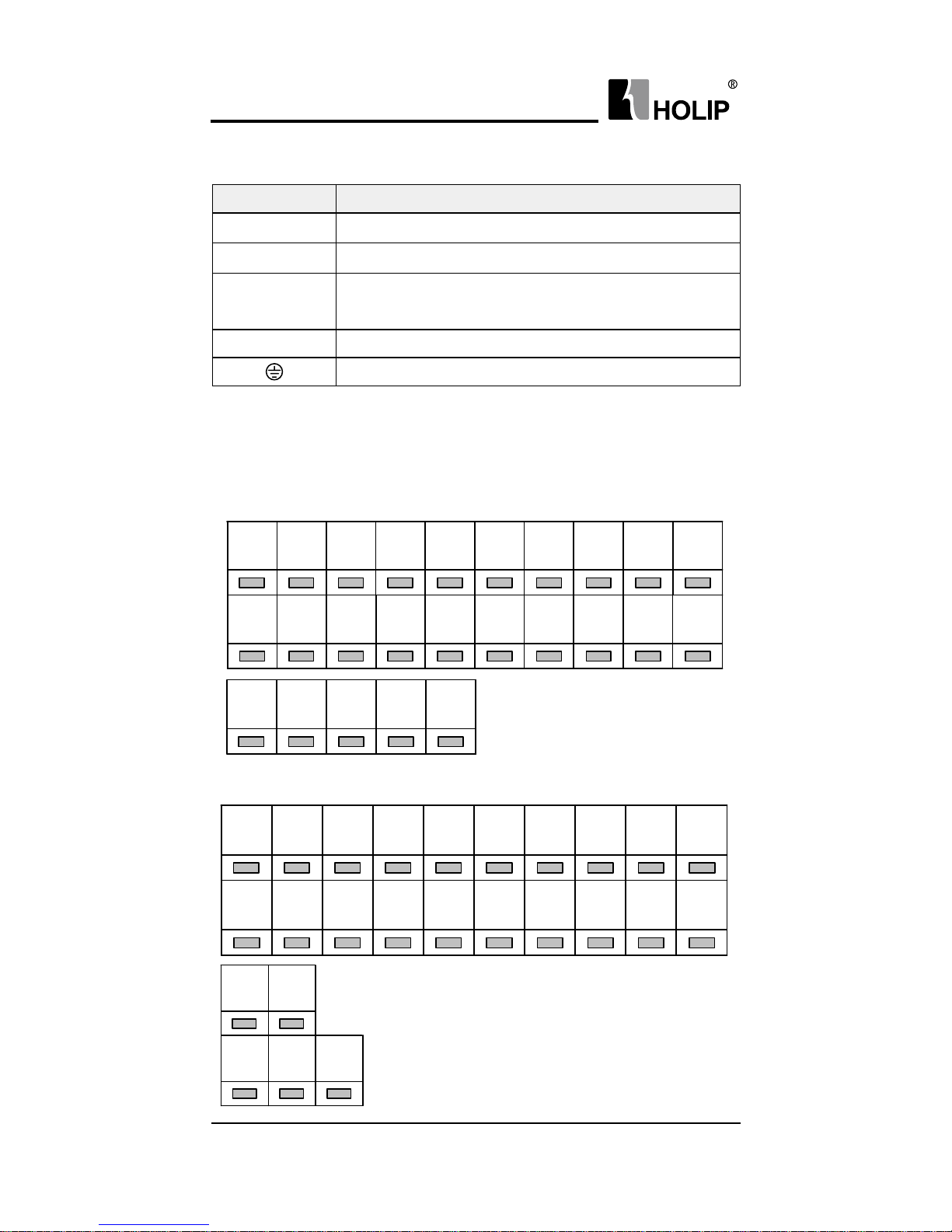

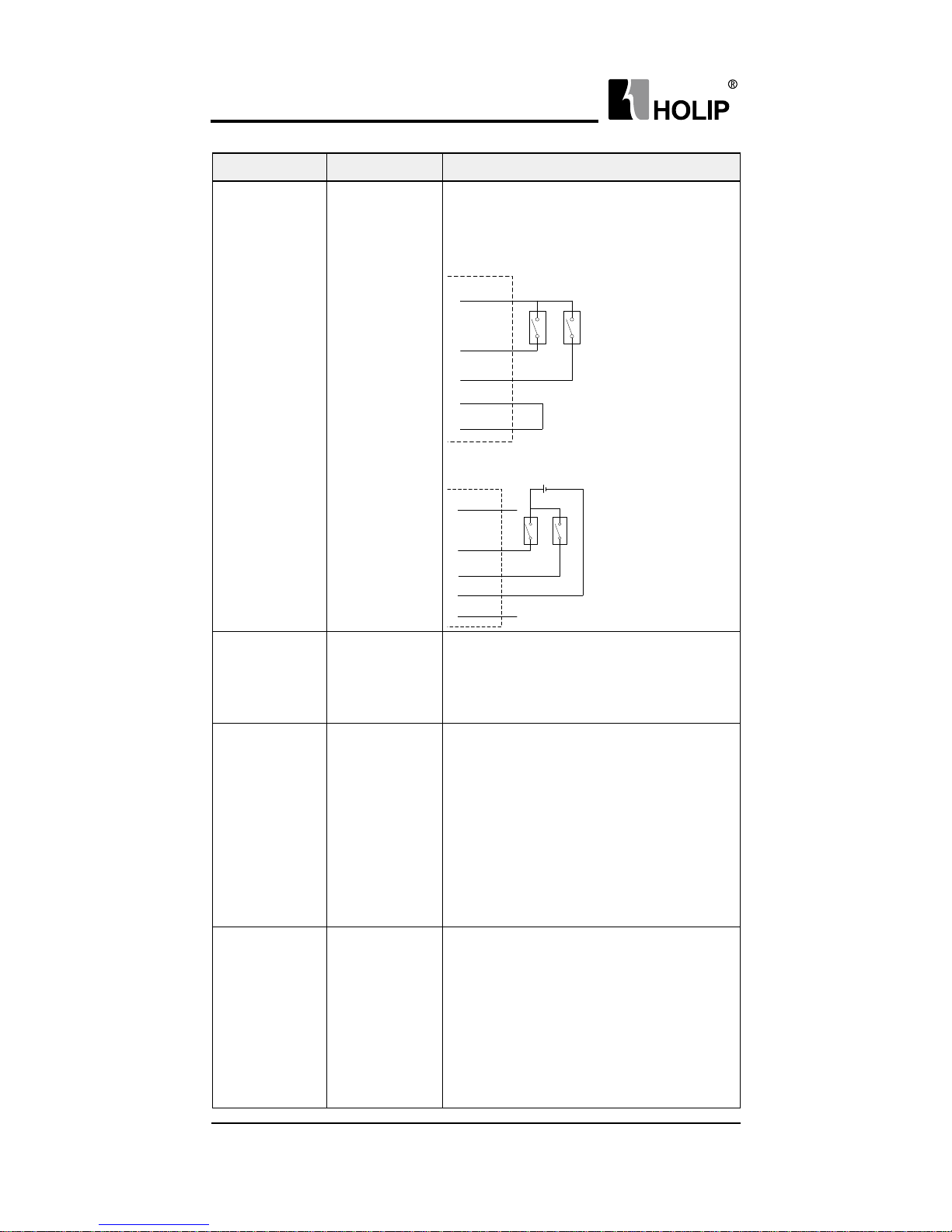

3.3.4.1 Main Circuit Terminals

Terminals of the main circuit:

11- 22k W:

30 - 22 0 K W:

R S

T

VU

W

-UDC

+UDC

-UDC

+UDC/

+BR

TS

U

-BR

R

V

W

Page 23

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 16 -

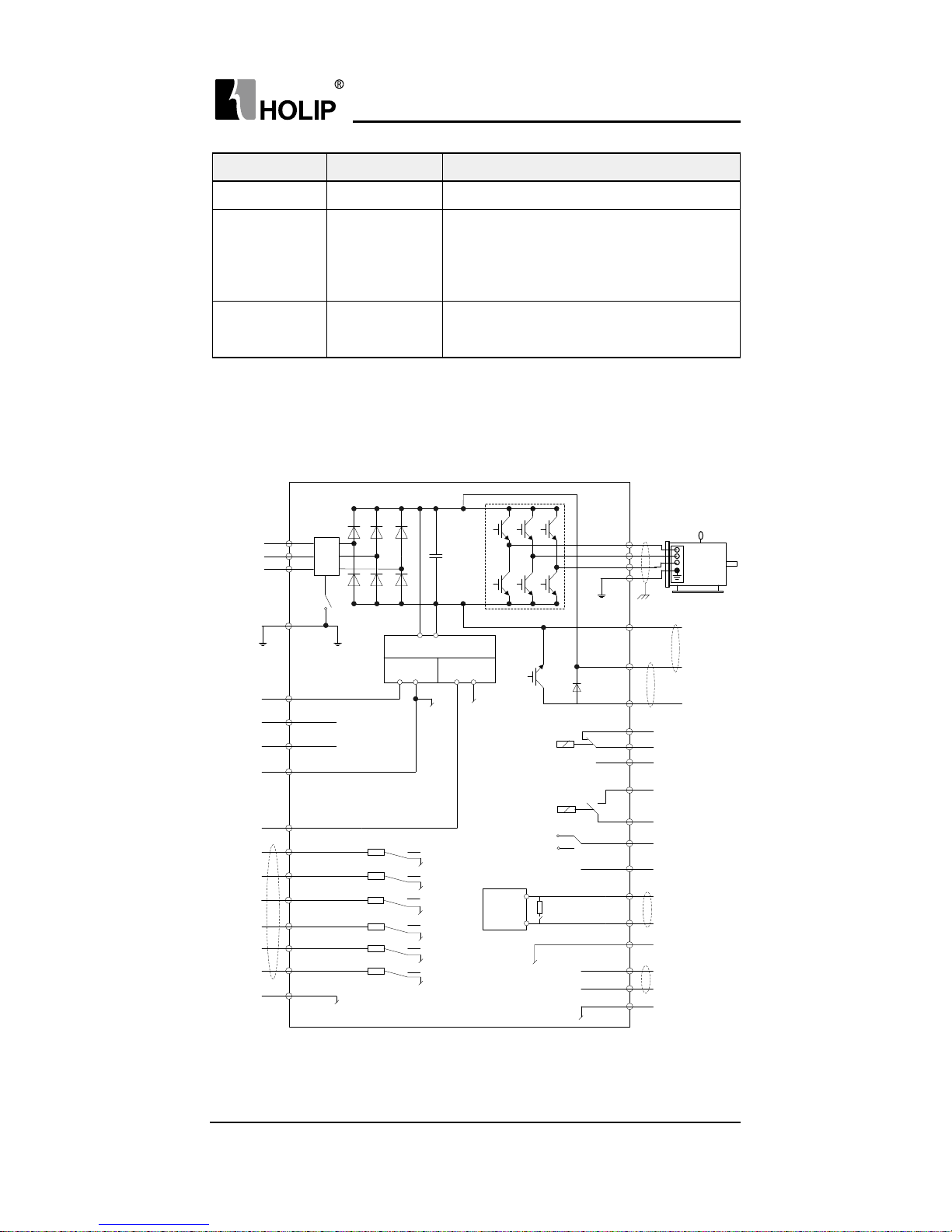

3.3.4.2 I/O Control Terminals

Description of main circuit terminals:

30-75kW Control and Relay Terminals:

Symbol Function

R 、 S 、 T Power input

U 、 V 、 W Power output, connect to the motor

-BR 、 +BR

Connect the brake resistor, make sure to set C02.10

、

C 0 2 .11 e t c .

+UDC 、 -UDC DC bus

Ground terminal

11-22kW & 90-220kW Control and Relay Terminals:

RS+ RS-

FORCOM VDDREV

VI

AI

+10V

DI2 DI3 GNDDI4 DO2DO1 VO AODCM

GND

DI1

FA FB

KA FC KB

RS+ RS-

AIVI REVFOR

VDD

DO1

DI1

AO +10V DI2GND DI4DI3 DCM COMCOM

DO2

VO

KA KB

FB FCFA

Page 24

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 17 -

Description of I/O control terminals:

Symbol Description Specication

VDD

24Vpower

su pply

Max.load 200m A, with over load and

short circuit protection f unctions;

+10 V

10 V po w e r

su pply

Max.load 10 mA, with over load and

short circuit protection f unctions;

Digital input

(FOR、 REV

、

DI1、 DI2、 DI3

、

DI4)

Digital cont rol

terminals

1 、 Log ic:

PNP <DC5V logic ‘0’;

>DC10V logic ‘1’;

NPN >DC19V logic ‘0’;

<DC14V logic ‘1’;

2 、 Vol t age: DC 0 -2 4 V;

3 、 Input resistance: 5KΩ;

4 、 Input voltage rang: max ±28V;

5 、 Switch PNP and NPN model by

Ju mper switch.

Analog input

(VI、 AI)

Analog setting/

Fee d ba ck

Set by the related pa rameter, analog input

channel can be congurated to 0-20mA

o r 0 -10 V:

Vol t age in put:

1 、 Input impedance: about 10 KΩ;

2 、 Maximum withstand voltage is 20V,

duration of 2 seconds, the maximum

reverse

voltage is -15V , du ration of 2seconds.

Current input:

1 、 Input impedence≤500Ω;

2 、 Maximum withstand cur rent is 29

mA duration of 2 seconds.

Analog

、

communication

(GN D)

Analog

、

communication

ground

Isolated f rom inter nal digital

grou n d(COM)

Pulse input DI4

Pulse setting/

Fee d ba ck

1 、 Pulse input: 0.001-100.000KHz;

2 、 Voltage range: 24V ± 20%;

3 、 Input duty ratio: 40%-60%;

Page 25

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 18 -

Symbol Description Specication

Digital output

( D O1 、 DO2)

Digital output

1 、 Open collector output;

2 、 Output current range: 0-50mA;

3 、 Max voltage 30V;

4、 Two different way to connect relay:

VD D

DO1

DO2

D CM

COM

R e la y 1 R e la y 2

Note: DCM and COM must be connected.

VD D

DO1

DO2

D CM

COM

+ +

Supply

R e la y 1 R e la y 2

Digital output

common

terminal

(DCM)

Digital output

common

terminal

Connect COM as Digital output reference

grou nd wh ile use.

Analog output

(VO 、 AO)

Analog output

VO can be selected to the current output

or voltage output via jumper switch

in the control board. AO can only be

selected as cur rent out put:

1 、 Output mode: 0-20mA or 0-10V;

2 、 Voltage output: Load larger tha n

500Ω;

3 、 Current output: Load larger than

500Ω;

Pulse output

D O1

Pulse output

DO1 can also be congu red as pulse

output channels:

1 、 Pulse output range: 0.001-5.000KHz

(r ange f r o m 0.001-100.000K Hz is opt iona l );

2 、 Voltage range: 0-24V;

3 、 Duty ratio: 40%-60%;

4 、 Resistive load >1kΩ, capacitive load <

10 n F;

Page 26

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 19 -

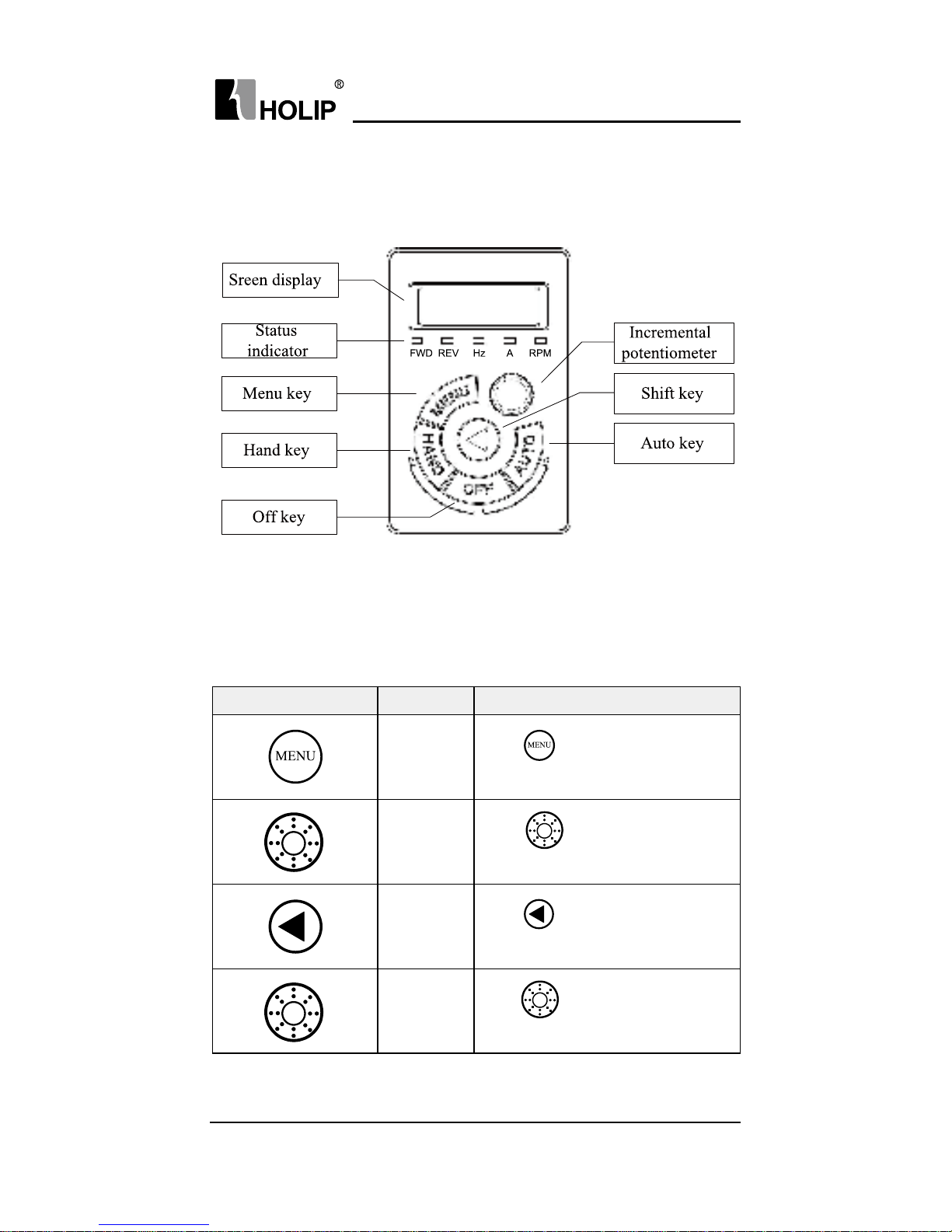

3.3.5 Wiring

Basic Connection Diagram of HLP-A100 series inverter:

Symbol Description Specication

COM Digital ground Isolated f rom internal GND;

Relay output

(K A-K B, FA-

FB-FC)

Relay output

1 、 Resistive load: 250VAC 3A/30VDC

3A;

2 、 Inductive load: 250VAC 0.2A /24VDC

0.1A(cosφ= 0.4);

RS+、 RS-

RS485 com m-

unication

Max baud rate: 115200bit/s;

10VD C

10Ma

24VD C

200Ma

24V +NpN+

0V +pNp+

24V +NpN+

0V +pNp+

24V +NpN+

0V +pNp+

24V +NpN+

0V +pNp+

24V +NpN+

0V +pNp+

24V +NpN+

0V +pNp+

RS485

I N te Rf a C e

pe

R

t

S

p Ow e R

INp ut

u

V

w

pe

+10V

VI

aI

GND

VD D

fOR

ReV

DI1

DO2

DI3

DI2

DI4

COM

+uDC

+uD C++BR

+BR

fa

fB

fC

Ka

KB

RS+

RS+

GND

0+10VD C

+4+20Ma

0+10VD C

+4+20Ma

0+10VD C

+4+20Ma

D C B uS

B RaKe

R e SIStOR

RS485

C O M M uN ICa tION

R e la y 1

R e la y 2

M OtOR

2

1

3

JuM p e R

S w I tC h

RfI

RfI

S w I tC h

D CM

VOltaGe O up ut

VO

aO

4+20Ma

DO1

D IGIta l

INp ut

D IGIta l

O utp ut

t e RM IN al R e SIS tO R

S w I tC h M O D e

pOweR Supply

CuRRe Nt O uput

J u M p e R S w I tCh

Page 27

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 20 -

Precautions for the main circuit wiring:

● Note: The drives of more than 30kW (including 30kW) do not have +BR

and –BR terminals.

● While wiring the sizes and specications of wires should be selected

and the wiring should be executed according to the electrical

engineering regulations to ensure the safety.

● It is better to use shielded wire or wire conduit for power cord and

ground the shielded layer or two ends of wire conduit.

● Be sure to install a circuit Breaker between the power supply and the

in put ter minals (R.S.T). (If using RCD, please choose B ty pe)

● Phase-shif ting capacitors, LC, RC noise f ilters etc, can never be

connected to the output terminals of the inverter.

● Please lower the inverter switching f requency when there is a longer

distance between the inverter and the motor.

● Drive ea r t h leakage cu r rent is greater more than 3.5 mA. According

to the requirments of IEC 61800-5-1 , must use the f ollowing ways to

enhance the protection of ground: minimum 10mm2 cross sectional

area of copper, or additional PE line, its cross sectional area and the

main power cable should be the same, must be separate grounded.

● Make sure reliable ground of the inverter in accordance with IEC

618 0 0 -5 -1.

● Please refer to 9.2 for the use of RFI SWITCH.

Page 28

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 21 -

Key-press LCP Display Action Descr iption

C0 0.0 4

Press

key to display the rst

basic C00.03

C0 3.0 0

Tu r n

clockwise to select

pa ra meter grou p C03

C0 3.0 0

Press

key to shif t to f ractional

part

C 0 3.10

Tu r n

clockwise to select

p a r a m e t e r C0 3.10

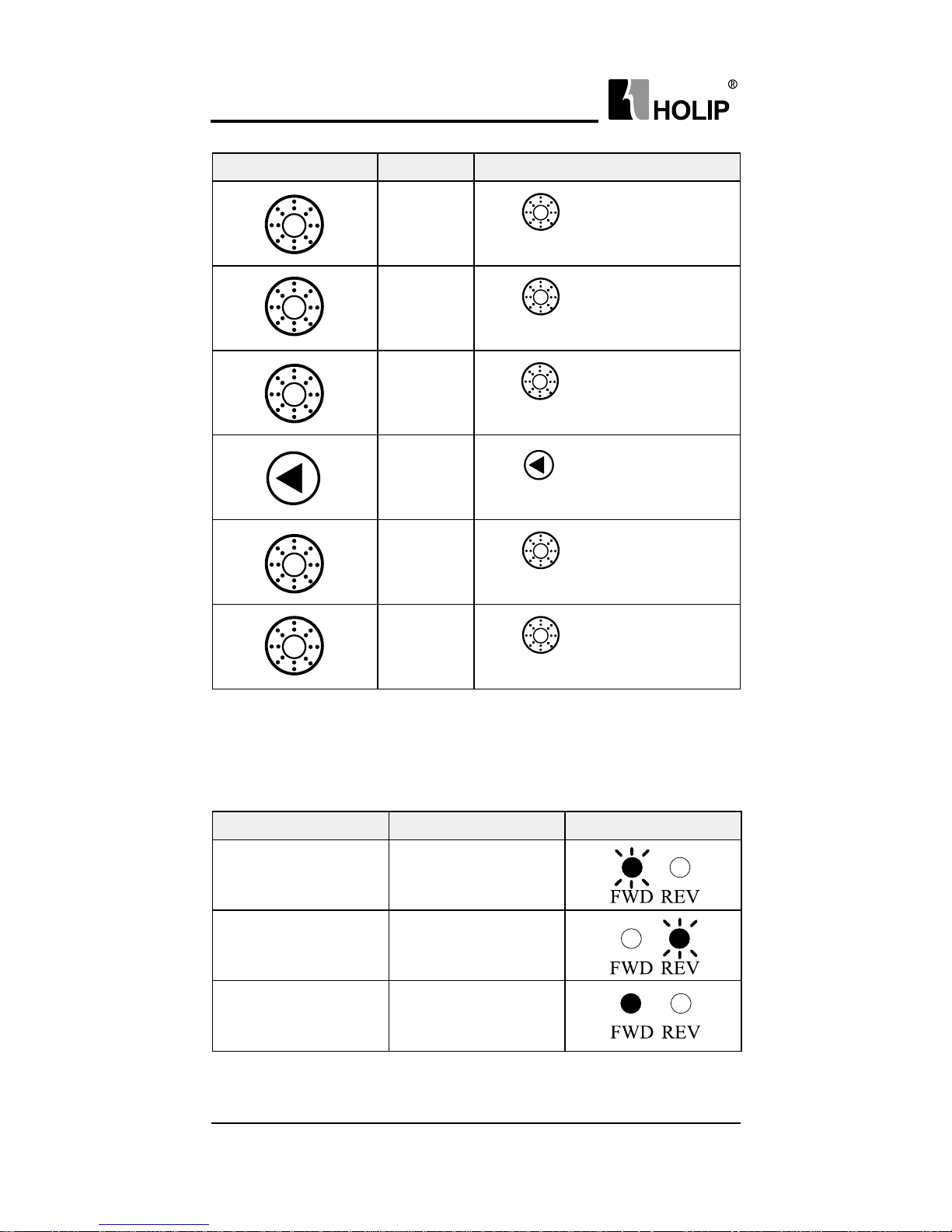

Chapter 4 Operation and Display Interface

4.1 LCP Digital Operator

4.2 Quick to set parameters

4.2.1 Preset reference by LCP

Example: Set C03.10[0] to 20.5:

Page 29

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 22 -

Key-press LCP Display Action Description

[0]

Press

key show the rst option

o f C 03.10

0000

Press

key to show the value of

the rst option of parameter C03.10

000.5

Tu r n

clockwise to change the

f ractional pa r t to 5

000.5

Press

key to shif t to integral

part

020.5

Press

key to change the

integ ral par t to 20

END

Press

key to accept the change

and save it as 20.5

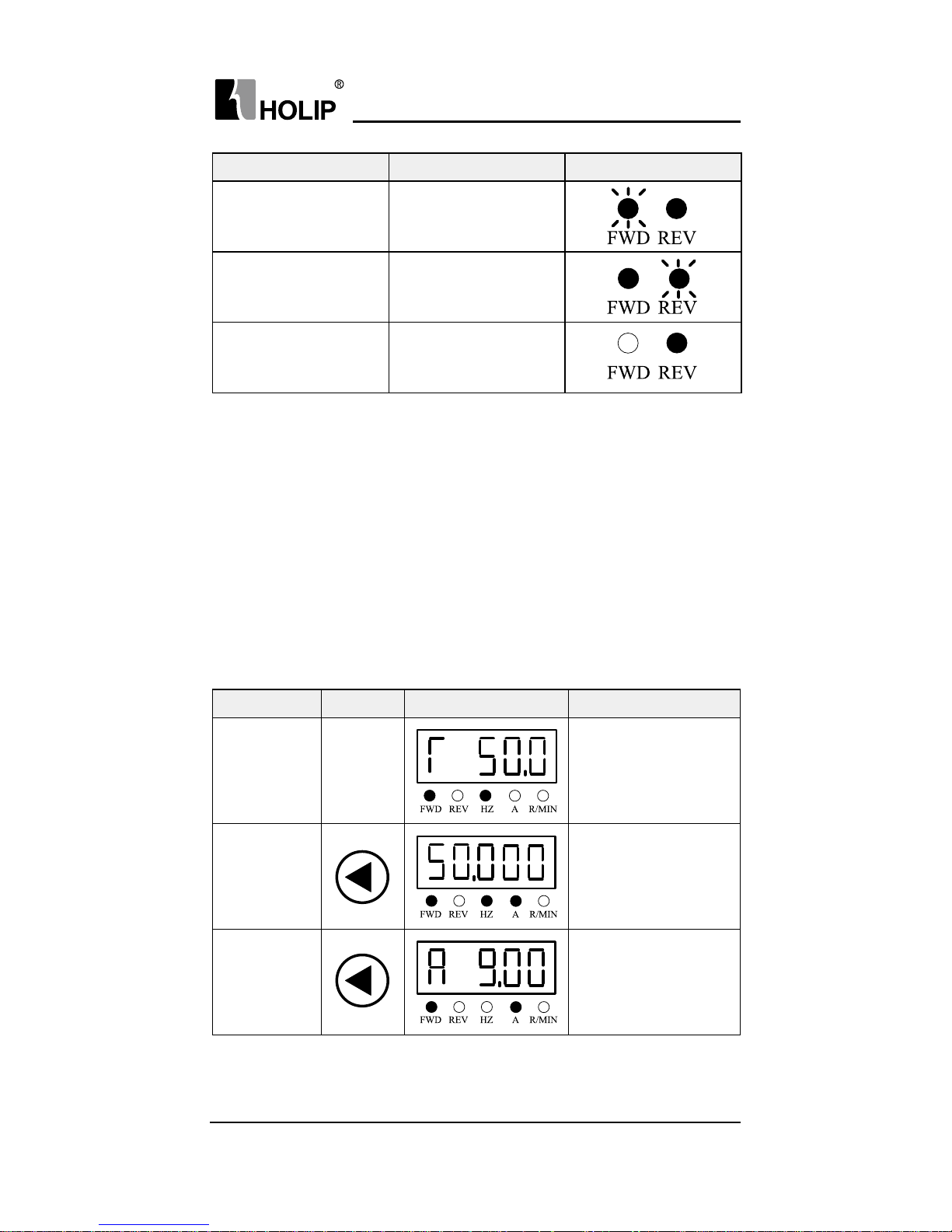

4.2.2 FWD/R EV Status

Conrm the direction of the motor according to the set value, as shown

in the following table:

Reference Running status Indicator Display

≥0 STOP

<

0 STOP

≥0 FWD

Page 30

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 23 -

Reference Running status Indicator Display

≥0 REV

<

0 FWD

<

0 REV

Note: A ash light denotes the status coming, Light on indicates the current

state, and light off means not in this state.

Example 1: The f irst line of the table indicates the drive is stop and the

reference is greater than or equal to 0, means the dir ve at some

time in the f uture will r un forward.

Example 2: The fourth line of the table represents the cur rent drive is

reverse r unning, and the reference setting is greater than or

equal to 0, it means the drive at some time in the f uture will run

for ward.

4.2.3 Data Read-outs

Display Items Key-press LCP Display Action Descr iption

Output

Frequency

Initial

interf ace

Show the output

f requency (C16.13)

is 50.0Hz, display

accuracy : 0.1

Reference (%)

Show the preset

reference (C16.01) is

50%, display accuracy:

0.0 01

Motor Current

Show the motor

current (C16.14) is

9.00A, display

accuracy: 0.01

Page 31

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 24 -

Display Items Key-press LCP Display Action Descr iption

Mo t or Volt a ge

Show the motor

voltage (C16.12)

is 380.0V, display

accuracy: 0.1

Motor Speed

Show the motor speed

( C16. 05 ) i s 14 4 0 r p m ,

display accuracy:1

DC Volt age

Show the DC

v o l t a ge (C16 . 30 ) i s

540.0 V, d i s p la y

accuracy: 0.1

Inverter

temperat u re

Show the inverter

temperat u re

( p a r C16 . 34 ) i s 45℃,

display accuracy:1

Fee d ba ck

Value

Show the f eedback

value(C16.52) is 28.000,

display accuracy: 0.001

Counter A

Show value of counter

A is (C16.72) 65535,

display accuracy : 1

Counter B

Show counter B(C16.72)

is 65535, d ia pl a y

accuracy : 1

Analog in VI

Show analog in VI

(C16.62) is 10.00V,

display accuracy: 0.01

Page 32

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 25 -

Key-press LCP Display Action Description

C0 0.0 4

Press

key to display the rst

basic C00.03.

C15. 0 0

Tu r n

clockwise to select par.

g r o u p N o. C15.

C15. 0 0

Press

to select pa rameter

nu m ber.

C15. 30

Tu r n

clockwise to select C15.30

Display Items Key-press LCP Display Action Descr iption

Analog in AI

Show Analog in AI

(C16.63) is 20.00mA,

display accuracy: 0.01

Pulse Input

Show pulse in put

(C16.68) is 50000Hz,

display accuracy:1

Pulse Output

Show pulse output

(C16.69) is 50000Hz,

display accuracy: 1

Note: Press key to cha nge the display items on control panel, however,

C00.33 must be activated (see C00.33).

4.2.4 View alarm record

If the drive trips, fault code will be showed to illust rate the reason, all the

trip record will be saved.

Page 33

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 26 -

Key-press LCP Display Action Description

[0]

Press

to show the rst option

of C15.30

**

Press

to show the rst fault

record.

[1]

Press

to show the second f ault

record, it can display up to ten recent

fault records in t urn.

Key-press LCP Display Action Description

C0 0.03

Press

to display the rst basic

pa r a m e te r C 0 0.0 3.

C16 .0 0

Tu r n

clockwise to select Par.

g r o u p N o. C16

C16 .0 0 Press

to select pa r ame t er No.

C16 .01 Press

select C16.01

0

Tu r n

clock wise to nish browse

v a l u e o f C16 . 01.

4.2.5 View state parameter

View the status of input terminal, reference, feedback value, output

f requency, output current, output voltage, and the power etc.

Page 34

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 27 -

Key-press LCP Display Action Description

C16 .6 0 Press

to select C16.60.

0000

Press

to view the value in

C16.60, 0100 indicates stat us of FOR

、

DI1 、 DI2 is 0, and stat us of REV is 1.

4.2.6 LED Display

Page 35

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 28 -

Chapter 5 Parameter Overview

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 00: Operation/Display

*C0 0.03

Regional

Settings

0: 50 Hz; 1: 60 Hz; 0 54

C0 0.0 4

Operating

State at

Power-u p

0: Resu me;1: Forced

stop ref erence=old;

2: Forced stop

reference=0;

1 54

*C0 0.06 G rid Ty pe 0 -132 * 55

C 0 0 .10 Active Set-up

1: Set-up1; 2: Set-up2;

9: Multi set-up;

1 55

C 0 0 .11 Edit Set-up 1: Set-up1; 2: Set-up2; 1 56

*C 0 0 .12 Link Set-up

0: N o t li n ke d ;

20: Li n ked;

20 56

C 0 0 . 31

Custom

Readout Min

Value

0.00-9999.00 0.00 56

C00.32

Custom

Readout Max

Value

0.00-9999.00 100.00 57

C0 0.33

LCP Display

Option

0-2047 0 57

C0 0.40

[H AND ON]

key on LCP

0: Disa bled;

1: E n a b l e d ;

1 57

C 0 0 .41

[OFF/ R ESET]

key on LCP

0: Disa ble A ll;

1: E n a b l e A l l ;

2: Enable Reset Only;

1 58

C0 0.42

[AUTO] key

on LCP

0: Disa bled;

1: E n a b l e d ;

1 58

*C 0 0 .51 Set-up Copy

0: No co py; 1: Copy

f rom set-up1; 2: Copy

f ro m se t-u p2; 9: Cop y

f rom factory set-up;

0 58

C0 0.60

Menu

Password

0: Disa bled;

1: E n a b l e d ;

0 58

C 01. 0 0

Conguration

Mode

0: Speed open loop;

3: Process closed loop;

4: To rq u e Op e n l o op;

0 59

Page 36

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 29 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group01: Load/motor

*C 01.01

Motor Control

Pr i nciple

0: U/ F; 1: VCC+; 1 59

*C 01.0 3

Tor qu e

Characteristics

0: Constant torque;

1: Muta t ive; 3: Energy

optim;

0 59

*C 01.0 7

Application

Conguration

Mode

0: No Function;

1: Wobble Function;

2: Cascade Cont rol;

3: Winder Function;

0 60

*C 01. 2 0

Motor Power

[ kW ][ H P]

De p.on m o t or da ta kW * 60

*C01.22

Mo t or Volt a ge

(Um.n)

50~1000 V * 60

*C 01. 2 3

Motor

Frequency

(f m.n)

20~400 Hz * 61

*C 01. 2 4

Motor

Cu r rent(Im.n)

De p.on m o t or da ta A * 61

*C 01. 25

Motor

Nominal

Speed(nm.n)

100 ~9999 rpm * 61

*C 01. 29

Automatic

Motor

Adaptation

(AMA)

0: Of f ; 1: Enabled

Complete AMA;

2: Enable Reduced

AMA;

0 61

*C 01.3 0

Stator

Resista nce

(Rs)

De p.on m o t or da ta Ω * 62

*C 01.3 3

Stator

Leakage

Reactance

(XI)

De p.on m o t or da ta Ω * 62

*C 01.35

Main

Reactance

(X h)

De p.on m o t or da ta Ω * 62

*C 01.3 9 Motor poles 2 ~10 0 P 4 62

*C 01. 4 2

Motor Cable

Length

0 ~150 m 50 62

Page 37

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 30 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group01: Load/motor

C 01. 50

Motor

Magnetisation

at Zero Speed

0 ~300 % 10 0 63

C 01. 52

Min Speed

Normal

Magnetising

[Hz]

0.0~10.0 Hz 0.0 63

C 01. 55

U/F Characteristic-U

0~999 V 63

C 01. 56

U/F Characte-

ristic-F

0~ 400 Hz 64

C 01. 6 0

Low Speed

Load

Compensation

0 ~19 9 % 10 0 64

C 01. 61

High Speed

Load

Compensation

0 ~19 9 % 10 0 65

C 01. 6 2

Slip

Compensation

- 4 00 ~399 % 10 0 65

C 01. 6 3

Slip

Compensation

Time

Constant

0.05~5.00 s 0 .10 66

C 01. 6 4

Resonance

Dampening

0~50 0 % 50 66

C 01. 65

Resonance

Dampening

Time

Constant

0.005~ 0.050 s 0.0 05 66

C 01.71 Sta r t Delay 0.0 ~10.0 s 0.0 66

C 01.7 2 Start Function

0: DC hold/delay

time; 2: Coast/Delay

ti me;

2 66

*C 01.7 3 Flying sta r t

0: Disa bled;

1: E n a b l e d ;

0 67

C 01. 8 0

Function at

Stop

0: Coast; 1: DC Hold; 0 67

Page 38

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 31 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

C 01. 8 2

Min Speed for

Function at

Stop [Hz]

0.0~20.0 Hz 0.0 68

C 01. 9 0

Motor

Ther mal

Protection

0: No Protection;

1: Ther mister

War ning;

2: Termister Trip;

3: E T R w a r n i n g;

4: ETR trip;

0 68

*C 01.9 3

Thermister

Resou rce

0: None; 1: A na log

input VI; 6: Digital

input DI4;

0 68

Parameter Group 02: Brake Function

C02.0 0

DC Hold

Current

0 ~150 % 50 69

C 0 2 . 01

DC Brake

Current

0 ~150 % 50 69

C02.02

DC Braking

Time

0.0~ 60.0 s 10. 0 70

C02.0 4

DC Brake Cut

In Frequency

0.0~ 400.0 Hz 0.0 70

C02.08

Demagnatizing

Rate

0 ~10 0 % 10 0

C 0 2 .10

Bra ke

Function

0: Of f ; 1: Resist or

bra ke; 2: AC bra ke;

0 70

C 0 2 .11

Brake Resistor

(ohm)

De p.on m o t or da ta Ω * 70

C 0 2 .16

AC Brake,

Max current

0 ~150 % 10 0 70

C 0 2 .17

Over-voltage

Cont rol

0: Disa bled;

2: E na ble d;

0 71

C02.20

Release Brake

Current

0.00~100.00 A 0.00 71

C02.22

Activate

Bra ke Speed

[Hz]

0.0~ 400.0 Hz 0.0 71

C0 3.0 0

Reference

Ra nge

0: Min-Max; 1: -Max-

+Ma x;

0 72

C0 3.0 2

Minimum

Reference

-4999.000~ 4999.000 0.000 72

Page 39

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 32 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 03: Reference/Ramps

C03.03

Maximum

Reference

-4999.000~ 4999.000 50.000 72

C0 3.0 7

Main

reference

calculation

0: Preset reference +

Ref erence source 1,2

1: Preset ref erence

priority

0

C 0 3.10

Preset

Reference

-100.00~100.00 % 0.00 73

C 0 3 .11 Jog Speed [Hz] 0.0 ~ 400.0 Hz 5.0 74

C 0 3.12

Catch up/slow

Dow n Val u e

0.00~100.00 % 0.0 0 74

C 0 3.13

SpeedUp/

Dow n Val u e

0.01~50.00 Hz 0.10 74

C 0 3.14

Preset

Relative

Reference

-100.00~100.00 % 0.00 75

C 0 3.15

Reference

Resou rce 1

0: No function;

1: Analog input VI;

2: Analog Input AI;

8: P u ls e i n p u t;

11: Local bus ref;

21: L C P

potentiometer;

1 75

C 0 3.16

Reference

Resou rce 2

2 75

C 0 3.17

Reference

Resou rce 3

11 75

C 0 3.18

Relative

Scali ng

Reference

Resou rce

0 76

C 0 3.19

Save Speed

Up/Down

Value

0: No function;

1: Stopsa ve; 2: Power

dow n sa ve;

0 76

C0 3. 40 R a mp 1 Ty p e

0: Linear; 2: Sine2

ra m p;

0 76

C 03. 41

Ramp 1 Ramp

up Time

0.05~3600.00 s * 77

C0 3. 42

Ramp 1 Ramp

Down Time

0.05~3600.00 s * 78

C0 3. 50 Ra m p 2 Ty pe

0: Linear; 2: Sine2

ra m p;

0 78

Page 40

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 33 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 03: Reference/Ramps

C 0 3. 51

Ramp 2 Ramp

up Time

0.05~3600.00 s * 78

C0 3. 52

Ramp 2

Ramp down

Time

0.05~3600.00 s * 79

C0 3.6 0 Ra mp 3 Ty pe

0: Linear; 2: Sine2

ra m p;

0 79

C 03. 61

Ramp 3 Ramp

up Time

0.05~3600.00 s * 79

C0 3.6 2

Ramp 3 Ramp

dow n Time

0.05~3600.00 s * 79

C0 3.70 Ramp 4 Type

0: Linear; 2: Sine2

ra m p;

0 80

C 0 3.71

Ramp 4 Ramp

up Time

0.05~3600.00 s * 80

C0 3.72

Ramp 4

Ramp down

Time

0.05~3600.00 s * 80

C0 3.80

Jog Ramp

Time

0.05~3600.00 s * 80

C 03.81

Quick Stop

Ramp Time

0.05~3600.00 s * 80

Parameter Group 04: Limits/War nings

*C 0 4.10

Motor Speed

Direction

0: Clockwise;

1: Counterclock wise;

2: Bo t h;

2 81

*C 0 4.12

Motor Speed

Low Limit

[Hz]

0.0~ 400.0 Hz 0.0 81

*C 0 4.14

Motor Speed

High Limit

[Hz]

0.0~ 400.0 Hz 65.0 81

C 0 4.18 Cu r rent Limit 0~300 % 150 81

*C 0 4.19

Max. Output

Frenquency

0.0~ 400.0 Hz 65.0 82

C 0 4. 21

Max Output

Frequency

Resou rce

0 ~21 1

Page 41

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 34 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 04: Limits/War nings

C0 4.30

Motor

Feedback Loss

f unction

0: No function;

1: Freeze output;

3: Jog; 4: Max. Speed;

5: Stop and trip;

11: Switch to open

loo p;

4 82

C 0 4 . 31

Motor

Fee d ba ck

Speed Er ror

0~600 rpm 300 82

C04.32

Motor

Feedback Loss

Timeout

0.00~ 60.00 s 0.05 82

C0 4.50

War ning

Cur rent Low

0.00~ I ma x A 0.00 83

C 0 4 .51

War ning

Cu r rent High

0.00~ I ma x A 83

C0 4.52

War ning

Speed Low

0.0~ 400.0 Hz 0.0 83

C04.53

War ning

Speed High

0.1~ 400.0 Hz 65.0 83

C0 4.54

War ning

Reference

Low

-4999.000~ 4999.000 0.000 83

C0 4.55

War ning

Reference

High

-4999.000~ 4999.000 50.000 84

C0 4.56

War ning

Fee d ba ck Low

-4999.000~ 4999.000 0.000 84

C04.57

War ning

Fee d ba ck

High

-4999.000~ 4999.000 50.000 84

*C0 4.58

Missi ng

Motor Phase

Function

0: Of f ; 1: On; 1 84

C 0 4.61

Bypass Speed

From [Hz]

0.0~ 400.0 Hz 0.0 84

C0 4.63

Bypass Speed

To [H Z]

0.0~ 400.0 Hz 0.0 85

Page 42

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 35 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

*C 05.0 2

Digital Output

DO Mode

0: PNP; 1: N PN; 0 86

C 0 5.10

Te r mi na l FOR

Digital Input

0: N o ope ra tion;

1: Reset; 2: Coast

i n v e r se ; 3: C o a s t a n d

reset inverse;

4: Quick stop inverse;

5: D C - b r a ke i n v e r s e;

6: Stop inverse;

8: St a rt; 9: Latched

star t; 10: Reversing;

11: Start reversing;

12: Enable star t

f o r w a r d ; 13: E n a bl e

star t reverse; 14: Jog;

15: Preset ref bit0;

16: Preset ref bit1;

17: Preset ref bit2;

18: Preset ref bit3;

19: Freeze reference;

20: Freeze output;

21: S p e e d u p;

22: Sp e ed dow n;

23: Set-up select;

28: Ca t ch u p; 29: Slow

down; 32: Pulse input

(only available with

terminal DI4 digital

i n p u t ) ; 34: R a mp

bit0; 35: Ramp bit1;

60: CounterA (up);

62: Reset counterA;

63: CounterB (up);

65: Reset counterB;

70: Wobble start

c o m m a n d ; 71: Wo b b l e

r e s et; 72: Wo b ble

initialization;

90: Low water level;

91: H i g h w a t e r l e v e l ;

8 86

C 0 5 .11

Te r mi na l

REV Digital

Input

10 86

C 0 5.12

Te r m i n a l DI1

Dgital Input

15 86

C 0 5.13

Te r mi na l DI 2

Digital Input

16 86

C 0 5.14

Te r mi na l DI3

Digital Input

17 86

Page 43

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 36 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

C 0 5.15

Te r mi na l DI4

Digital or

Pulse Input

92: Scarcity water

level; 93: Over r un

water level;

18 86

Parameter Group 05: Digital In/Out

C05.30

Te r mi na l

D O1 D ig i t a l

Output

0: N o ope ra tion;

1: Control ready;

2: D r ive rea d y;

3: D r i v e r e a d y /

Remote control;

4: E na ble / N o

w a r n i n g; 5: D r iv e

running; 6: Running

/ No wa r ning;

7: Run in rang/ No

warning; 8: Run on

ref /No wa r ni ng;

9: Ala r m; 10: A lar m

or Warning; 12: Out

of cur rent ra ng;

13: Below current,

low; 14: Above

current,high; 15: Out

of f req uency rang;

16: Below f requency,

low; 17: Above

f re q uency, high;

18: Out of feedback

r a ng ; 19: Be l o w f e e d

back, low;

20: Above feedback,

high; 21: Thermal

warning; 22: Ready,

no t her mal wa r n i ng;

23: Remote ready, no

ther mal wa rn i ng;2 4:

R e a d y, v ol t ag e ok ; 25:

Reverse;

26: Bus ok; 28: Br ake,

no brake warning;

29: Br a ke rea d y, no

fault; 30: Brake fault

(IGBT); 32: Mech

br a ke cont rol;

0 88

C 0 5. 31

Te r mi na l

DO2 Digital

Output

0 88

Page 44

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 37 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 05: Digital In/Out

C05.4 0

Relay

Function

(K A-K B,FA-

FB 、 FB-FC)

36: Control word bit

11; 37: Control word

bit12; 40: Out of

ref erence rang;

41: Below ref, low;

42: Above ref , high;

51: Local ref , active;

52: Re mo t e r ef ,

active; 53: No alarm;

54: Start command

active; 55: Running

reverse; 56: Drive in

ha n d mod e;

57: D r iv e i n a u to

mod e;

60-63: Comparator

0-3; 70~73: Logic r ule

0-3; 80: SLC digital

output 1;

81: S L C d i g i t a l

output2; 82: SLC

relay 1; 83: SLC relay

2; 84: SL C di g it a l

output 3; 85: SLC

digital output 4;

90: Upto wobble

limit; 91: Upto wobble

ref .; 100: Start pu mp1;

101: Star t pump2;

102: Below water

level, low; 103: Above

water level, high;

104: Low water

w a r n i n g ; 10 5: H ig h

water warning;

106: Low voltage

w a r n i n g ; 10 7: O v e r

voltage war ni ng;

108: sl e e p;

5,9 88

Page 45

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 38 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 05: Digital In/Out

C05.55

Te r mi na l

DI4 Low

Frequency

0.020~49.999

KHz

0.020 91

C05.56

Te r mi na l

DI4 High

Frequency

0.021~50.0 00

KHz

50.000 91

C05.57

Te r mi na l DI4

Low Ref./

Feed b. Va l ue

-4999.000~ 4999.000 0.000 91

C05.58

Te r mi na l DI4

High Ref./

Fe e d b.V a l u e

-4999.000~ 4999.000 50.000 92

C05.59

Te r mi na l DI4

Filter Time

Constant

1~1000 ms 10 0 92

C05.60

Te r m i na l DO1

Pulse Output

Va r ia ble

0: Dgital output;

10: Output frequency;

11: Reference;

12: Feedback;

13: Motor current;

16: Power; 17: Speed;

18: Motor voltage;

20: Bus con t rol;

21: P u l s e i n p u t ;

22: Terminal VI

input; 23: Terminal

AI input;

0 92

C 05. 61

Pulse Output

Min Freq

0.020~49.999

KHz

0.020 93

C05.62

Pulse Output

Max Freq

0.021~50.0 00

KHz

50.000 93

C05.63

Pulse Output

Mi n Scale

0.00~200.00 % 0.00 93

C05.6 4

Pulse Output

Max Scale

0.00~200.00 % 100.00 93

C06.00

Live Zero

Timeout Time

1~ 9 9 s 10 94

Page 46

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 39 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 05: Digital In/Out

C 0 6.01

Live Zero

Timeout

Function

0: Of f ; 1: Freeze

out put; 2: Stop;

3: Joggi ng; 4: Max.

speed; 5: Stop and

Tr i p;

0 94

C 0 6.10

Te r mi na l V I

Low Volt a ge

0.0 0 ~ 9.9 9 V 0.07 95

C 0 6 .11

Te r mi na l V I

High Volt age

0.10 ~10 . 0 0 V 10 . 0 0 95

C 0 6.12

Te r mi na l V I

Low Current

0.0 0 ~19.99 mA 0 .14 95

C 0 6.13

Te r mi na l V I

High cur rent

0.01~20.00 mA 20.00 95

C 0 6.14

Te r mi na l V I

Low Ref./

Fe e d b.V a l u e

-4999.000~ 4999.000 0.000 95

C 0 6.15

Te r mi na l V I

High Ref./

Fe e d b.V a l u e

-4999.000~ 4999.000 50.000 96

C 0 6.16

Te r mi na l V I

Filter Time

Constant

0.01~10.00 s 0. 01 96

C 0 6 .18

Te r mi na l V I

Zero dead

band

0.00~20.0 0

V/

mA

0.00 96

C 0 6.19

Te r mi na l V I

Mode

0: Votage mode;

1: Current mode;

0 97

C06.20

Te r mi na l A I

Low Volt a ge

0.0 0 ~ 9.9 9 V 0.07 97

C 06 . 21

Te r mi na l A I

Hig h voltage

0.01~10.00 V 10. 0 0 97

C06.22

Te r mi na l A I

Low Current

0.0 0 ~19.99 mA 0 .14 97

C06.23

Te r mi na l A I

High Cur rent

0.01~20.00 mA 20.00 98

C06.24

Te r mi na l A I

Low Ref./

Fe e d b.V a l u e

-4999.000~ 4999.000 0.000 98

Page 47

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 40 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 05: Digital In/Out

C06.25

Te r mi na l A I

High Ref./

Fe e d b.V a l u e

-4999.000~ 4999.000 50.000 98

C06.26

Te r mi na l

AI Filter

Constant

0.01~10.00 s 0.01 98

C06.28

Te r mi na l A I

Zero dead

band

0.00~20.0 0

V/

mA

0.00 98

C06.29

Te r mi na l A I

Mode

0: Voltage mode;

1: Current mode;

1 99

C06.70

Te r mi na l VO

Mode

0: 0-20 m A;

1: 4-20m A; 3: 0-10V;

3 99

C 0 6.71

Te r mi na l

VOAnalog

Output

0: N o ope ra tion;

10: Output frequency;

11: Ref erence;

12: Feedback;

13: Motor current;

16: Power; 17: Speed;

18: Motor voltage;

20: Bus con t rol;

21: P u l s e i n p u t ;

22: Terminal VI;

2 3: Te r m i n a l A I;

0 99

C06.73

Te r mi na l VO

Output Min

Scale

0.00~200.00 % 0.0 0 10 0

C06.74

Te r mi na l VO

Output Max

Scale

0.00~200.00 % 100.00 10 0

C 0 6 .81

LCP Pot meter

Low Ref.

-4999.000~ 4999.000 0.000 10 0

C06.82

LCP Pot meter

High Ref.

-4999.000~ 4999.000 50.000 101

C06.90

Te r mi na l AO

Mode

0: 0 ~ 20 m A;

1: 4 ~ 2 0 m A ;

0 101

C 06 .91

Te r mi na l

AO A nalog

output

See also C06.71. 0 101

Page 48

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 41 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

C06.93

Te r mi na l AO

Output Min

Scale

0.00~200.00 % 0.0 0 101

C06.9 4

Te r mia n l AO

Max Scale

0.00~200.00 % 100.00 10 2

Parameter Grou p07: Controllers

C 0 7.12

Tor qu e PI

Proportional

Gain

0~50 0 % 10 0

C 0 7.13

Tor qu e PI

Integration

Time

0.002 ~2 S 0.02

C 0 7.2 0

Process CL

Fee d ba ck

Resou rce

0: No Function;

1: A n a l o g i n V I ;

2: Analog in AI;

8: P u ls e i n p u t;

11: Local bus;

0 103

C 0 7.30

Process PI

Normal/

Inverse

Cont rol

0: Normal; 1: In verse 0 10 3

C 0 7. 31

Process PI

Anti Windup

0: Disa bled;

1: E n a b l e d ;

1 10 4

C 0 7.32

Process PI

Sta rt Speed

0.0~20 0.0 Hz 0.0 10 4

C 0 7.33

Process PI

Proportional

Gain

0.0~10.00 0.01 10 5

C 0 7.34

Process PI

Integ ral time

0.10~9999.00 s 9999.00 105

C 0 7.38

Process PI

Feed Forward

Factor

0~ 400 % 0 10 5

C 0 7.39

On Reference

Bandwidt h

0~200 % 5 10 5

C 07. 41

Process PI

Output Low

-10 0 -10 0 % 0 105

C 0 7.42

Process PI

Output High

-10 0 -10 0 % 10 0 10 6

Page 49

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 42 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 08: FC Port Settings

C 0 8.01 Cont rol Site

0: Digital and ctrl.

word; 1: Digital only;

2: Control Word

only;

0 10 6

C08.02

Control Word

Sou rce

0: None; 1: FC RS485; 1 10 6

C08.03

Control Word

Timeout Time

0.1~6500.0 s 1. 0 10 6

C08.0 4

Control Word

Timeout

Function

0: Of f ; 1: Freeze

out put; 2: Stop;

3: Joggi ng; 4: Max.

speed; 5: Stop and

t ri p;

0 10 6

C08.06

Reset Control

Word

Timeout

0: No Fu nction; 1: Do

Reset;

0 10 7

C08.30 Protocol

0: FC; 2: MODBUS

RTU; 6: MODBUS

ASCI I;

0 10 7

C 0 8. 31 Address

F C (1 ~1 2 6 ) ; M O D B U S

R T U (1~ 247 );

1 10 7

C08.32

FC Por t Baud

Rate

0: 2400; 1: 4800;

2: 9600; 3: 19200;

4: 38400; 5: Rese r ved;

6: R ese r ve d;

7: R es e r ve d;

8: R e se r ved ;

9: R es e r ved ;

2 10 7

C08.33 FC Por t Parit y

0: E v e n P a r i t y ,1S t o p

bit; 1: Odd Parity,1stop

bit; 2: No Parity,1Stop

bit; 3: No Parity,2

St o p bits;

0 10 8

C08.35

Minimum

Response

Delay

0.001~0.500 s 0.010 108

C08.36

Max.

Response

Delay

0.010 ~10.0 0 0 s 5.000 10 8

Page 50

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 43 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 08: FC Port Settings

C08.50

Coasting

Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 10 8

C 0 8.51

Quick Stop

Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 10 8

C08.52

DC Brake

Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 10 9

C08.53 Star t Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 10 9

C08.54

Reversing

Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 10 9

C08.55 Set-up Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 10 9

C08.56

Preset

Reference

Select

0: Digital input;

1: Bus; 2: Logic A ND;

3: Logic OR;

3 110

C08.94

Bu s Feed back

1

-32768~32767 0 11 0

Parameter Group 13: Simple PLC

C13.0 0

Sample PLC

Mode

0: Of f ; 1: Or der

execution; 2: Parallel

execution;

0 11 0

C13.01 St a r t Event 0 ~54 39 111

C13.0 2 Stop Event 0~54 40 11 2

C13.03

Reset Sample

PLC

0: Do not reset;

1: Reset Sample PLC;

0 11 2

C13.10

Comparator

Opera nd

0 ~ 31 0 11 3

C1 3.11

Comparator

Operator

0~2 1 11 3

C13.12

Comparator

Value

-9999.0~9999.0 0.0 11 4

C13. 2 0

SL Controller

Timer

0.0 ~36 0 0 s 0.0 11 4

Page 51

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 44 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 13: Simple PLC

C13.4 0

Logic Rule

Boolea n 1

0~64 0.0 11 4

C13.41

Logic Rule

Operator 1

0~8 0 114

C13.4 2

Logic Rule

Boolean 2

Same to C13.40 0 11 5

C13.4 3

Logic Rule

Operator 2

0~8 0 11 5

C13.4 4

Logic Rule

Boolean 3

Same to C13.40 0 11 6

C13. 51

SL Controller

Event

Same to C13.40 0 11 6

C13.52

SL Controller

Action

0~69 0 116

Parameter Group 14: Special Functions

C14.01

Switching

Frequency

2~6: 2kHz~6kHz;

7: 8k Hz; 8: 10 kHz;

9: 12k Hz; 10: 16 k Hz;

4 118

*C14.0 3

Over

modulation

0: Of f ; 1: On; 1 118

C14.0 8

Damping

Gain Factor

0~200 % 96 118

C14 .12

Function

at Mains

Imbalance

0: Trip; 1: Warning;

2: D i sa bl e d;

0 11 9

C14 .16

Low Volt a ge

Mode

0: Disabled; 1:

Ena ble;

0

C14. 2 0 Reset Mode

0: Ma n u al r es e t; 1~10:

Automatic reset x

1~10; 11: Automatic

r e s e t x 15;

12: Automatic reset x

20;

13: Innite auto reset;

0 11 9

C14 . 21

Automatic

Restart Time

0~600 s 10 11 9

C14. 2 2

Operation

Mode

0: Normal Operation;

2: Initialisation;

3: Backup user

settings;4: Recover

user settings;

0 11 9

Page 52

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 45 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 14: Special Functions

C14. 2 3 Trip Lock

0: Disable, Trip lock

fault reset do not

need power of f;

1: enable, Trip lock

fault reset need

power of f;

1

C14. 2 7

Action At

Inverter Fault

0: Tr i p; 1: Wa r ning; 0 120

C14.30

Current

Limit Cont rol,

Proportional

Gain

0~50 0 10 0

C14 . 31

Current

Limit Cont rol,

Integration

Time

0~2 0.02

C14.32

Current Limit

Cont r ol, Filter

Time

1~10 0 1

*C14. 4 0 VT Level 40-90 % 90 120

*C14 .41

AEO

Minimum

Magnetisation

40 ~75 % 66 120

C14.50

R FI Filter

Switch

0: Off 1:On

2:R ese r ved

1

*C14 .51

DC-Link

Vol t age

Compensation

0: Of f ; 1: On; 1 120

C14.52 Fa n Con t rol

0: Auto; 4:Run in

low temperature;

5-8: R es e r ve d;

0

*C14.55 Output Filter

0: Of f ; 1: Sine-Wave

Fi lt e r ; 3: Si n e -W a v e

Filter with feedback;

0 121

*C14.63

Min Switch

Frequency

2~6: 2kHz~6kHz;

7: 8k Hz; 8: 10 kHz;

9: 12k Hz; 10: 16 k Hz;

2 121

Page 53

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 46 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 15: Drive Information

C15. 0 0

Operating

Days

0~9999 d 121

C15. 01

Running

Hours

0~60000 h 121

C15. 0 2 KWh Counter 0 ~ 6 5535 121

C15. 03 P o w e r u p’s 0~21474836 47 122

C15. 0 4 O v e r Te m p’s 0 ~ 65535 122

C15. 05 Over Volt’s 0 ~ 65535 122

C15. 06

Reset KWh

Counter

0: Do not reset;

1: Reset Counter;

122

C15. 07

Reset

Running

Hours

Counter

0: Do not reset;

1: Reset Counter;

122

C15. 30

Fau l t Log:

Er ror Code

0 ~255 122

C15 . 31

In t er nal Fa u lt

Reason

-32767~32767 123

C15. 4 0 FC Ty pe View FC t y pe 12 3

C15.41 Power Sect ion

View power size of

the d rive

123

C15. 4 2 Volt a ge

View Mains Voltage

of the d r ive

123

C15. 43

Sof twa r e

Ver sion

View the sof tware

version

123

C15. 4 4

Orde r ed Type

Code

View the ordered

type code of the

drive

123

C15. 4 6

Frequency

converter

or de r i ng NO.

View f requency

converter ordering

NO.

123

C15. 47

Power Card

Or de r ing NO.

View power ca rd

orde ri n g No. of the

drive

124

C15. 48 LCP I D NO. View LCP ID NO. 124

C15. 49

Sof twa re ID

Control Card

View sof t ware ID

control card

124

Page 54

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 47 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

C15. 50

Sof twa re ID

Power Card

View sof t ware ID

Power card

124

C15. 51

Frequency

Converter

Serial

Number

View f requency

converter No.

124

C15. 53

Power Card

Serial number

View power ca rd

serial number

124

C15. 92

Parameter

List

View parameter list

of the d r ive

124

Parameter Group 16: Data Readouts

C16 .0 0 Control Word 0 ~ 65535 125

C16 .01

Reference

[Unit]

-4999.000~ 4999.000 125

C16 .0 2 Reference % -200.0 ~20 0.0 % 126

C16 .0 3 Stat us Word 0 ~ 65535 126

C16 .0 4 Active Set-up 0~2 126

C16 .0 5

Motor Speed

[R PM]

0~9999 Hz 127

C16 .0 9

Custom

Readout

0.00~9999.00 127

C16 .10 Powe r[K W] 0.000~1000.000 kW 127

C1 6 .11 Power[h p] 0.000~1000.000 Hp 127

C16 .12 Motor Volt age 0.0 ~ 65535 V 127

C16 .13 Frequency 0.0~ 400.0 Hz 127

C16 .14

Motor

Current

0.0 0 ~ 655.35 A 127

C16 .15

Frequency

(%)

0.0~20 0.0 % 128

C16.18

Motor

Ther mal

0 ~10 0 % 128

C16 .30

DC Link

Vol t age

0 ~ 65535 V 128

C16 .3 4

Heat sink

Tem p.

0 ~255

℃

128

C16 .35

Inverter

Ther mal

0 ~255 % 128

C16 .36

Inv. Nom.

Current

0.0 0 ~ 655.35 A 128

Page 55

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 48 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 16: Data Readouts

C16 .37

Inv. Max.

Current

0.0 0 ~ 655.35 A 128

C16 .38

SLC

Controller

State

0 ~255 128

C16 .4 0

Wobble

Length

0.000~60.000 Km 129

C16.50

External

Reference

-200.0~200.0 % 129

C16.51

Pulse

Reference

-200.0~200.0 % 129

C16.52

Fee d ba ck #

[Unit]

-4999.000~ 4999.000 129

C16 .6 0 Digital In put 0 ~65535 129

C16 .61

Te r mi na l V I

Setting

0: 0-10V; 1: 0-20m A; 130

C16 .6 2

Analog Input

VI

0.000-20.000

V/

mA

130

C16 .6 3

Te r mi na l A I

Setting

0: 0-10V; 1: 0-20m A; 130

C16 .6 4

Analog Input

AI

0.000~20.000

V/

mA

130

C16 .6 5

Analog

Output AO

0.000~20.000

V/

mA

130

C16 .6 6

Digital Output

DO

0 ~255 130

C16 .6 7 Encoder Input -9999.000~9999.000

KHz

131

C16 .6 8

Pulse Input

DI4

0.020 ~50.000

KHz

131

C16 .6 9

Pulse Output

DO

0.020 ~50.000

KHz

131

C16 .71

Relay Output

[bin]

0 ~ 65535 131

C16 .7 2 Counter A 0 ~2147483647 131

C16 .7 3 Counter B 0~2147483647 131

C16 .7 8

Analog

Output AO

0.00~20.0 0 mA 131

C16 .86 FC Por t R EF -32768 ~32767 132

Page 56

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 49 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

C16 .9 0 A la rm Word 0~0xFFFFFFFFUL 132

C16 .91

Ala r m Word

2

0~0xFFFFFFFFUL 133

C16 .9 2

War ning

Word

0~0x7FFFFFFFUL 133

C16 .9 3

War ning

Word 2

0~0x7FFFFFFFUL 134

Parameter Group 25: App. f unctions Cascade

C25.00 Cascade Mode

0: Normal cascade;

1: W a t e r l e v e l c o n t r o l ;

0 13 4

C25.03

Fixed Speed

Pump

Number

0~2 0 13 4

C 2 5.10

Multi Pressure

Select ion

0: Disa ble; 1: Ena ble; 0 134

C 2 5 .11 Present Time 0.0 0 ~ 2 3.59 h 0.00 134

C 2 5.12

Multi Pressure

Time

0.0 0 ~ 2 3.59 h 0.00 135

C25.2 0

Cascade Low

Frequency

0.000~400.000 Hz 20.000 135

C 25.21

Low

Frequency

Delay Time

0.0~3600.0 s 20.0 135

C25.25

Cascade High

Frequency

0.000~400.000 Hz 50.000 136

C25.26

High

Frequency

Delay Time

0.0~3600.0 s 20.0 136

C25.30

Low Pressure

War ning

Level

0.000~99.999 kg 3.000 136

C 25 . 31

Low Pressure

War ning

Delay Time

0.0~3600.0 s 10.0 136

C25.32

Recover y

Low Pressure

Level

0.000~99.999 kg 4.000 136

Page 57

HLP-A100 Series Operating Manual

HLP-A10 0 Ser ies

- 50 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.

Parameter Group 25: App. f unctions Cascade

C25.33

Recover y

Low Pressure

Level Delay

Time

0.0~3600.0 s 10.0 137

C25.34

Over Pressure

War ning

Level

0.000~99.999 kg 7.000 137

C25.35

Over Pressure

War ning

Level Delay

Time

0.0~3600.0 s 10.0 137

C25.36

Recover y

High Pressure

Level

0.000~99.999 kg 5.000 137

C25.37

Recover y

High Pressure

Level Delay

Time

0.0~3600.0 s 10.0 137

C25.4 0

Pump

Interlock

Time

0.0~3600.0 s 5.0 138

C 25.41

Pump

Continuous

Run Time

0.0~3600.0 h 12.0 138

C25.50 Slee p Ti me 0: Disa ble; 1: Ena ble; 1 138

C 2 5. 51

Sleep Pressure

Level

0 ~150.0 % 95 138

C25.52

Sleep Pressure

Delay Time

0.0~300.0 s 20.0 139

C25.53

Sleep

Frequency

0.0~ 400.0 Hz 20.0 139

C25.54

Sleep

Frequency

Delay Time

0.0~300.0 s 20.0 139

C25.57 Awake Level 0.0~150.0 % 80 139

C25.60

Pu mp Ty pe

Select ion

0: Fe e d pu m p;

1: D r a i n p u m p ;

0 14 0

Page 58

HLP-A10 0 Ser ies

HLP-A100 Series Operating Manual

- 51 -

Item

Parameter

No.

Function

Descr iption

Setting range Unit

Def ault

setting

Page

No.