HOLEMAKER SM3X3 Operator's Manual

HOLEMAKER SM3X3

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

Serial #............................................ Date of Purchase............................................

Important Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 -4

Power Supply Requirement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Special Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Contents of Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Machine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Basic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Machine Parts Breakdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 - 17

Holemaker SM3X3 Portable Magnetic Drilling Machine

2

WARRANTY TERMS

In addition to any warranties or conditions implied by applicable Statute or Regulations,

Industrial Tool & Machinery Sales warrants all of it’s products against defective workmanship

and faulty materials for a period of twelve (12) months from the date of purchase, unless otherwise stated. At our option we will repair or replace, free of charge, any item on the condition that:

- The complete machine or tool is returned, freight prepaid to ITM or one of it’s authorised

service agents as directed by ITM, and is found to have a material or constructional defect.

- The machine or tool has not been subject to misuse, neglect or damage by accident.

- The fault is not a result of normal “wear and tear”.

- Written permission has been received from ITM prior to commencement of repair.

- Repairs, tampering or modification carried out by unauthorised personnel will void all warranty.

- Consumable items such as cutting tools, pilot pins, saw blades, grinding wheels etc. are

NOT covered by warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation

for other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

IMPORTED & DISTRIBUTED BY

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST

YATALA QLD 4207 AUSTRALIA

T

F

E

W

07 3287 1114

07 3287 1115

sales@industrialtool.com.au

www.industrialtool.com.au

TABLE OF CONTENTS

WHEN USING EL ECTRICAL TOOLS, BASIC SAFETY PRECAUTIONS SHOULD ALWAYS BE FOLLOWED

TO REDUCE RISK OF FIRE, ELECTRIC SHOCK AND PERSONAL INJURY .

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE REFERENCE.

1. Keep Work Area Clean

• Cluttered areas and benches increase risk of injuries.

2. Consider Work Area Environment

• Do not expose power tools to rain.

• Do not use power tools in damp or wet locations.

• Keep work area well lit.

• Do not use tool in presence of flammable liquids or gases.

3. Guard Against Electric Shock

• Prevent body contact with grounded surfaces. For example: pipes, radiators, ranges and refrigerator

enclosures

.

4. Keep Children Away

• Do not let visitors contact tool or extension cord.

• All visitors should be kept away from work area.

5. Store Idle Tools

• When not in use, tools should be stored in a dry, high and locked-up place, out of reach of children.

6. Do Not Force Tool

• It will do the job better and safer at the rate for which it was intended.

7. Use Right Tool

• Do not force a small tool or attachment to do the job of a heavy-duty tool.

• Do not use tool for unintended purpose. For example: Do not use a circular saw for cutting tree limbs or logs.

8. Dress Properly

• Do not wear loose clothing or jewellery. They can be caught in moving parts.

• Rubber gloves and non-skid footwear are recommended when working outdoors.

• Wear protective hair covering to contain long hair.

• Always wear safety glasses

• Use face or dust mask if necessary

• Use hearing protection

9. Do Not Abuse Electrical Cord

• Never carry tool by cord or yank it to disconnect from receptacle.

• Keep cord away from heat, oil and sharp edges.

10. Secure Work

• Use clamps or a vise to hold work. It’s safer than using your hand and it frees both hands to operate tool.

11. Do Not Overreach

• Keep proper footing and balance at all times.

IMPORTANT SAFETY INSTRUCTIONS

3

12. Maintain Tools With Care

• Keep tools sharp and clean for better and safer performance.

• Follow instructions for lubricating and changing accessories.

• Inspect tool cords periodically and if damaged, have repaired by authorized service facility.

• Inspect extension cords periodically and replace if damaged.

• Keep handles dry, clean, and free from oil and grease.

13. Disconnect Tools

• Unplug when not in use, before servicing, and when changing accessories, such as cutters.

14. Remove Adjusting Keys And Wrenches

• Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

15. Avoid Unintentional Starting

• Do not carry a plugged-in tool. Always disconnect from power source before moving.

• Be sure switches are off before connecting to a power source.

16. Outdoor Use Of Extension Cords

• When tool is used outdoors, use only extension cords intended for use outdoors and so marked.

17. Stay Alert

• Watch what you are doing. Use common sense. Do not operate tool when you are tired.

• Do not use when taking medications that may cause drowsiness.

18. Check Damaged Parts

• Before further use of the tool, any damaged parts should be repaired and performance verified prior to operation.

• Check alignment of moving parts, binding of parts, breakage of parts, mounting, and any other conditions

that may affect its operation. Any part that is damaged should be properly repaired or replaced by an authorized

service center.

• Do not use this tool if switches do not turn it on and off. Have defective switches replaced by authorized service

center.

19. Use Cutter Guard

• Always use cutter guard supplied with machine to reduce the risk of injury. (refer fig. 1)

fig. 1

IMPORTANT SAFETY INSTRUCTIONS

MP

ORTANT SAFETY INSTRUCTIONS

4

Prior to use check condition of the power cord, which has to be free of any cuts, or similar damages.

Attention!: This unit has a class one of insulation and

absolutely requires the power source

to be equipped with a protection circuit.

Power source should be protected with the difference-current circuit cut-out and protected with a 10A fuse - for 230V.

At building sites, power should be supplied from a separation transformer such as Type AVM, with minimum power of

2000 VA and with second class protection.

GROUNDING INSTRUCTIONS

Improperly connecting the grounding wire can result in the risk of electrical shock.

Check with a qualified electrician if you are in doubt as to whether the outlet

is properly grounded. Do not modify the plug provided with tool. Never remove

the grounding prong from the plug. If the cord or plug is damaged, have it

repaired before using. If the plug will not fit the outlet, have a proper outlet

installed by a qualified electrician. The Holemaker must be plugged into an

appropriate outlet, properly installed and grounded in accordance with all codes

and ordinances. The plug and outlet should look similar to those in Figure A.

If in doubt of proper grounding, call a qualified electrician.

DO NOT USE HOLEMAKER DRILLING MACHINES ON SURFACES OR MATERIALS BEING

WELDED. DOING SO CAN RESULT IN DAMAGE TO THE DRILLING MACHINE.

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that accept the

tool’s plug. Replace or repair damaged cords. Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of power and overheating. See table for the correct size to use

depending on cord length and nameplate amperage rating. If in doubt, use the next heavier gauge. The smaller the

gauge number, the heavier the cord.

DRIP LOOP: To help prevent cutting fluids from traveling

along power cord and contacting power source, tie a drip

loop in power cord as shown in Figure C.

MINIMUM GUAGE FOR EXTENTION CORDS

VOLTS TOTAL LENGTH OF CORD IN METRES

240V 0-15 15-30 30-60 60-90

0-6 18 16

16 14

6-10 18 16

14 12

10-12 16 16

14 12

12-16 14 12

NOT RECOMMENDED

RECOMMENDED WIRE GUAGE

Speed Recommendations

for cutting Mild Steel

POWER SUPPLY REQUIREMENTS

WER SUPPLY

REQUIREMENTS

5

Supply voltage: ………………………………… 220-240V/ 50-60 Hz.

Motor power ……………………………………………………. 1460 W

Total power …………………………………………………….. 1570 W

Machine speeds (under load): ……...…............ Gear 1: 80-160rpm

Gear2: 160-320rpm

Insulation class ………………………………………………….. First

Arbor bore ………………………………………………………. MT 3

Tool holder …………………………………. (3/4” Weldon) 19.05 mm

Capacities: max. Holemaker cutter diameter …………......... 75mm

max.drilling depth with standard arbor ……....... 75mm

Magnet Dead Lift (on 25 mm plate) ………....................... 19500 N

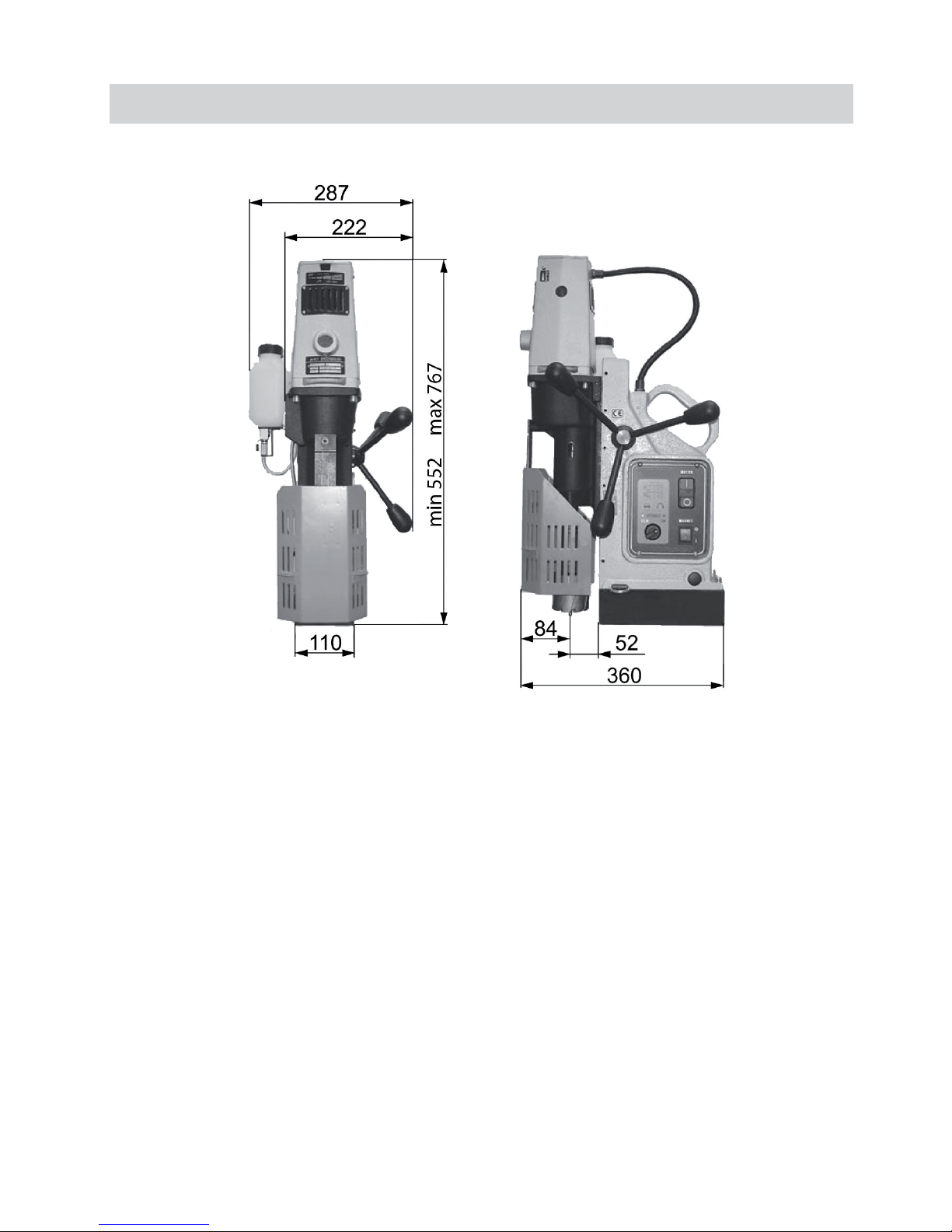

Dimensions:

electromagnetic base ….............................................. 110x224 mm

Length of the power cord ……………………............................... 3 m

Total weight ………………………………...…..................... 28.0 kg

Noise level ……………………………………………...…...…….. 85 dB

TECHNICAL DATA

6

Loading...

Loading...