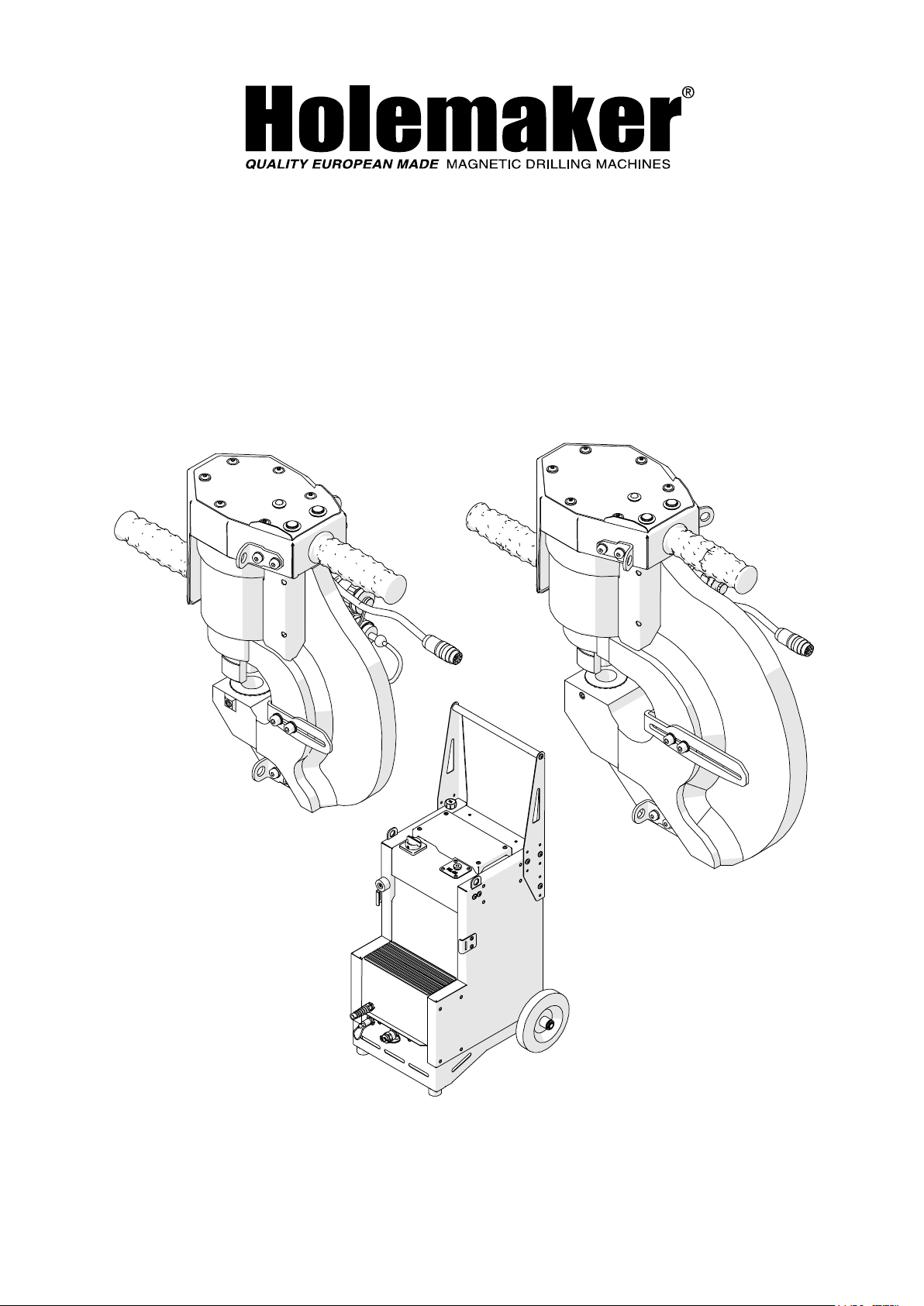

HOLEMAKER PRO 60 HP, PRO 110 HP, HPP 700/1.5 Operator's Manual

PUNCHER PRO 60 HP, PRO 110 HP

HYDRAULIC POWER PACK HPP 700/1.5

OPERATOR’S MANUAL

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

Serial #............................................ Date of Purchase............................

HOLEMAKER PRO 60 HP, PRO 110 HP & HPP 700/1.5

IMPORTED & DISTRIBUTED BY

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST

YATALA QLD 4207 AUSTRALIA

07 3287 1114

T

07 3287 1115

F

sales@industrialtool.com.au

E

www.industrialtool.com.au

W

WARRANTY TERMS

In addition to any warranties or conditions implied by applicable Statute or Regulations, Industrial

Tool & Machinery Sales warrants all of it’s products against defective workmanship and faulty

materials for a period of twelve (12) months from the date of purchase, unless otherwise stated.

At our option we will repair or replace, free of charge, any item on the condition that:

• The complete machine or tool is returned, freight prepaid to ITM or one of it’s authorised

service agents as directed by ITM, and is found to have a material or constructional defect.

• The machine or tool has not been subject to misuse, neglect or damage by accident.

• The fault is not a result of normal “wear and tear”.

• Written permission has been received from ITM prior to commencement of repair.

• Repairs, tampering or modification carried out by unauthorised personnel will void all warranty.

• Consumable items such as cutting tools, pilot pins, saw blades, grinding wheels etc. are NOT

covered by warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation for other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

2

HOLEMAKER PRO 60 HP, PRO 110 HP & HPP 700/1.5

TABLE OF CONTENTS

1. GENERAL INFORMATION - 4 -

1.1. Application - 4 -

1.2. Technical data - 4 -

1.3. Maximum plate thickness - 6 -

1.4. Selecting punches for the most common inch plates - 9 -

1.5. Allowed parameters of extension cords - 11 -

1.6. Design - 13 -

1.7. Equipment included - 14 -

1.5. Transportation - 14 -

2. SAFETY PRECAUTIONS - 15 -

3. START UP AND OPERATION - 16 -

3.1. Mounting the punch and die - 16 -

3.2. Connecting the hydraulic power pack - 17 -

3.3. Positioning - 18 -

3.4. Punching - 19 -

3.5. Replacing the die and punch - 19 -

3.6. Replacing the restrainer - 20 -

3.7. Troubleshooting - 21 -

4. ACCESSORIES - 23 -

4.1. Punches and dies - 23 -

4.2. Balancer - 24 -

4.3. Crane - 24 -

4.4. Stationary work set - 28 -

4.5. Guide - 30 -

4.6. Tool box - 32 -

5. WIRING DIAGRAM - 33 -

6. PARTS LIST - 34 -

6.1. PRO 60 HP Parts List - 34 -

6.2. PRO 110 HP Parts List - 38 -

6.3. HP 700 Parts List - 42 -

3

GENERAL INFORMATION

1.1. Application

The Puncher is designed to punch circular holes with diameters of 7–27 mm and oblong

holes in metal plates using a cylinder driven by the HPP 700/1.5 Hydraulic Power Pack.

1.2. Technical data

4

GENERAL INFORMATION

5

GENERAL INFORMATION

6

GENERAL INFORMATION

7

GENERAL INFORMATION

8

GENERAL INFORMATION

9

GENERAL INFORMATION

10

GENERAL INFORMATION

11

GENERAL INFORMATION

12

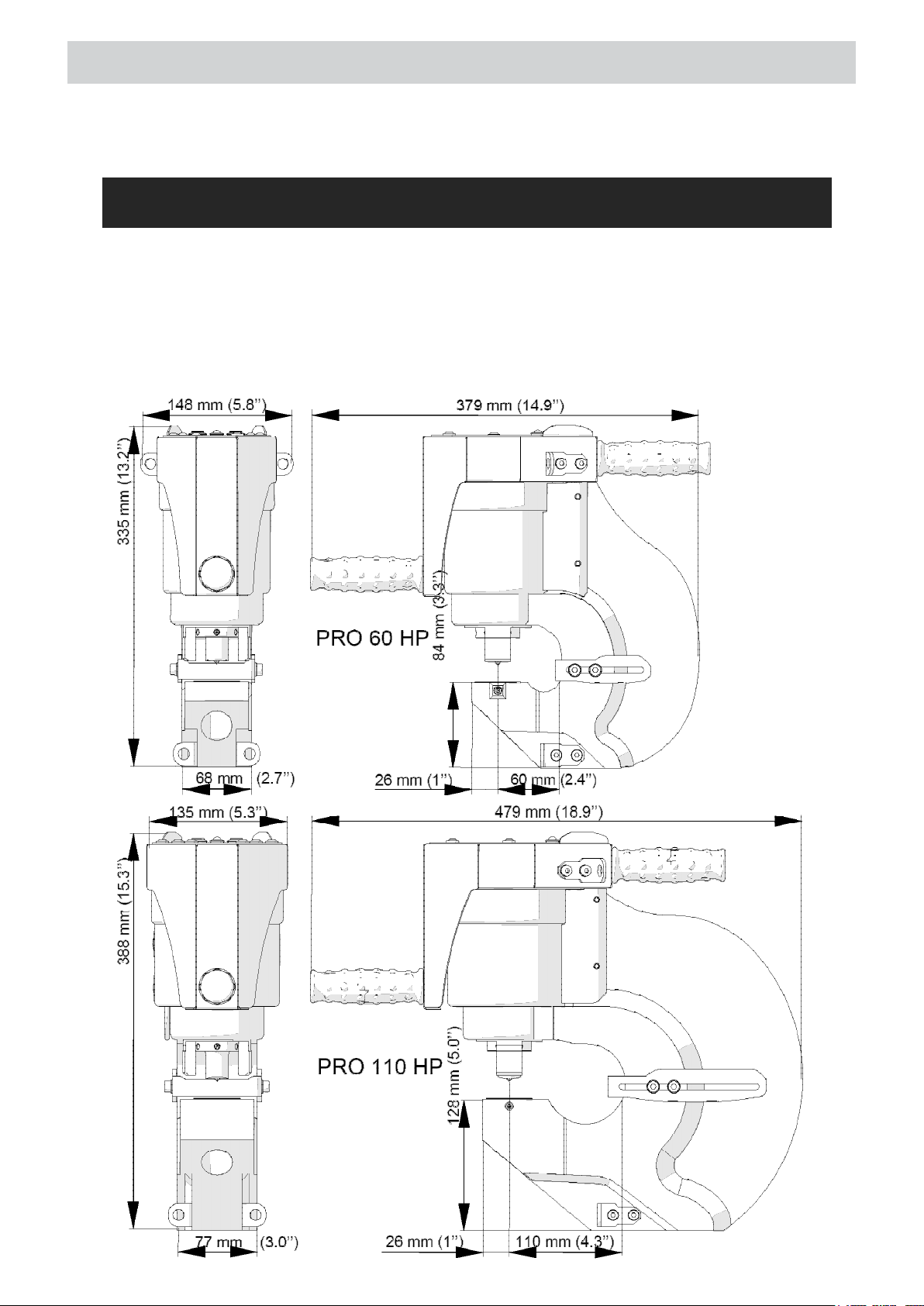

1.6. Design

GENERAL INFORMATION

13

SAFETY INSTRUCTIONS

1.7. Equipment included

1.8. Transportation

14

Loading...

Loading...