HOLEMAKER Pro 35 Auto Operator's Manual

®

PRO 35 AUTO

DRILLING MACHINE

OPERATOR’S MANUAL

PART# HMPRO35AUTO

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

Serial #............................................ Date of Purchase............................

Ver: 1.1 07/10/2015

HOLEMAKER PRO 35 AUTO DRILLING MACHINE

PRODUCTS IMPORTED AND DISTRIBUTED NATIONALLY BY:

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST, YATALA QLD 4207

T: 07 3287 1114 E: sales@industrialtool.com.au

F: 07 3287 1115 W: www.industrialtool.com.au

WARRANTY TERMS

In addition to any warranties or conditions implied by applicable Statute or Regulations, Industrial

Tool & Machinery Sales warrants all of it’s products against defective workmanship and faulty

materials for a period of twelve (12) months from the date of purchase, unless otherwise stated.

At our option we will repair or replace, free of charge, any item on the condition that:

• The complete machine or tool is returned, freight prepaid to ITM or one of it’s authorised

service agents as directed by ITM, and is found to have a material or constructional defect.

• The machine or tool has not been subject to misuse, neglect or damage by accident.

• The fault is not a result of normal “wear and tear”.

• Written permission has been received from ITM prior to commencement of repair.

• Repairs, tampering or modification carried out by unauthorised personnel will void all warranty.

• Consumable items such as cutting tools, pilot pins, saw blades, grinding wheels etc. are NOT

covered by warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation for other

reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or

replaced if the goods fail to be of acceptable quality and the failure does not amount to a major

failure.

2

HOLEMAKER PRO 35 AUTO DRILLING MACHINE

TABLE OF CONTENTS

1. GENERAL INFORMATION - 4 -

1.1. Application - 4 -

1.2. Technical data - 4 -

1.3. Design - 5 -

1.4. Equipment included - 6 -

2. SAFETY INSTRUCTIONS - 6 -

3. START UP AND OPERATION - 8 -

3.1. Mounting and operating the annular cutter - 8 -

3.2. Mounting and dismounting the cooling system bottle - 10 -

3.3. Control system of the electromagnetic base holding force - 10 -

3.4. Preparing - 11 -

3.5. Drilling - 13 -

3.6. Replacing the motor brushes - 14 -

3

GENERAL INFORMATION

PRO 36 AUTO

PRO 36 AUTO

1. GENERAL INFORMATION

1.1. Application

The PRO 36 AUTO is a drilling machine with electromagnetic base designed to drill

holes with diameters of 12–36 mm (0.47–1.42’’) to the maximum depth of 51 mm (2’’)

through the use of annular cutters.

The electromagnetic base allows the drilling machine to be fixed to ferromagnetic

surfaces with a force that ensures user safety and proper machine operation. A safety

strap protects the machine from dropping in case of a power loss.

1.2. Technical data

1. GENERAL INFORMATION

1.1. Application

The PRO 35 AUTO is a drilling machine with electromagnetic base designed to drill holes

with diameters of 12–36 mm (0.47’’–1.42’’) to the maximum depth of 51 mm (2’’) through

the use of annular cutters.

The electromagnetic base allows the drilling machine to be xed to ferromagnetic

surfaces with a force that ensures user safety and proper machine operation. A safety

strap protects the machine from dropping in case of a power loss.

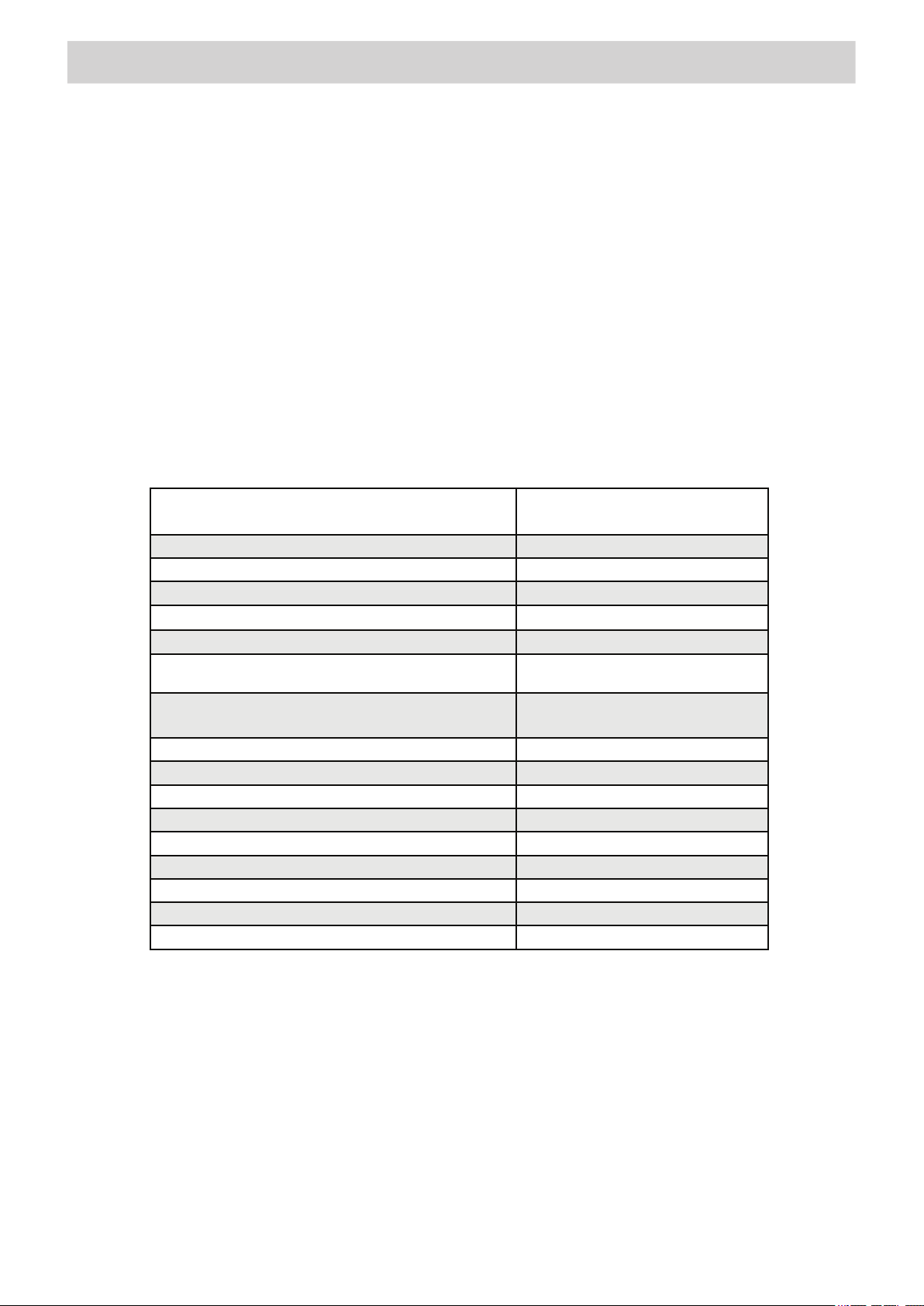

1.2. Technical data

Voltage

Total power 1000 W

Motor power 920 W

Cutter holder 19 mm Weldon (0.75’’)

Maximum drilling diameter 36 mm (1.42’’)

Maximum drilling depth 51 mm (2’’)

Electromagnetic base holding force

(surface with the thickness of 22 mm and roughness Ra = 1.25)

Electromagnetic base dimensions

Slider stroke 70 mm (2.8’’)

Rotational speed under load 350 rpm

Rotational speed without load 580 rpm

Minimum workpiece thickness 6 mm (0.23’’)

Protection class I

Noise level over 85 dB

Vibration level under 2.5 m/s

Required ambient temperature 0–40 °C (32–104 °F)

Weight 13.5 kg (30 lbs)

1~ 110–120 V, 50–60 Hz

1~ 220–240 V, 50–60 Hz

9 300 N

80 mm × 160 mm × 36.5 mm

3.1’’ × 6.3’’ × 1.4’’

2

(≤ 8.2 ft/s2)

4

GENERAL INFORMATION

PRO 36 AUTO

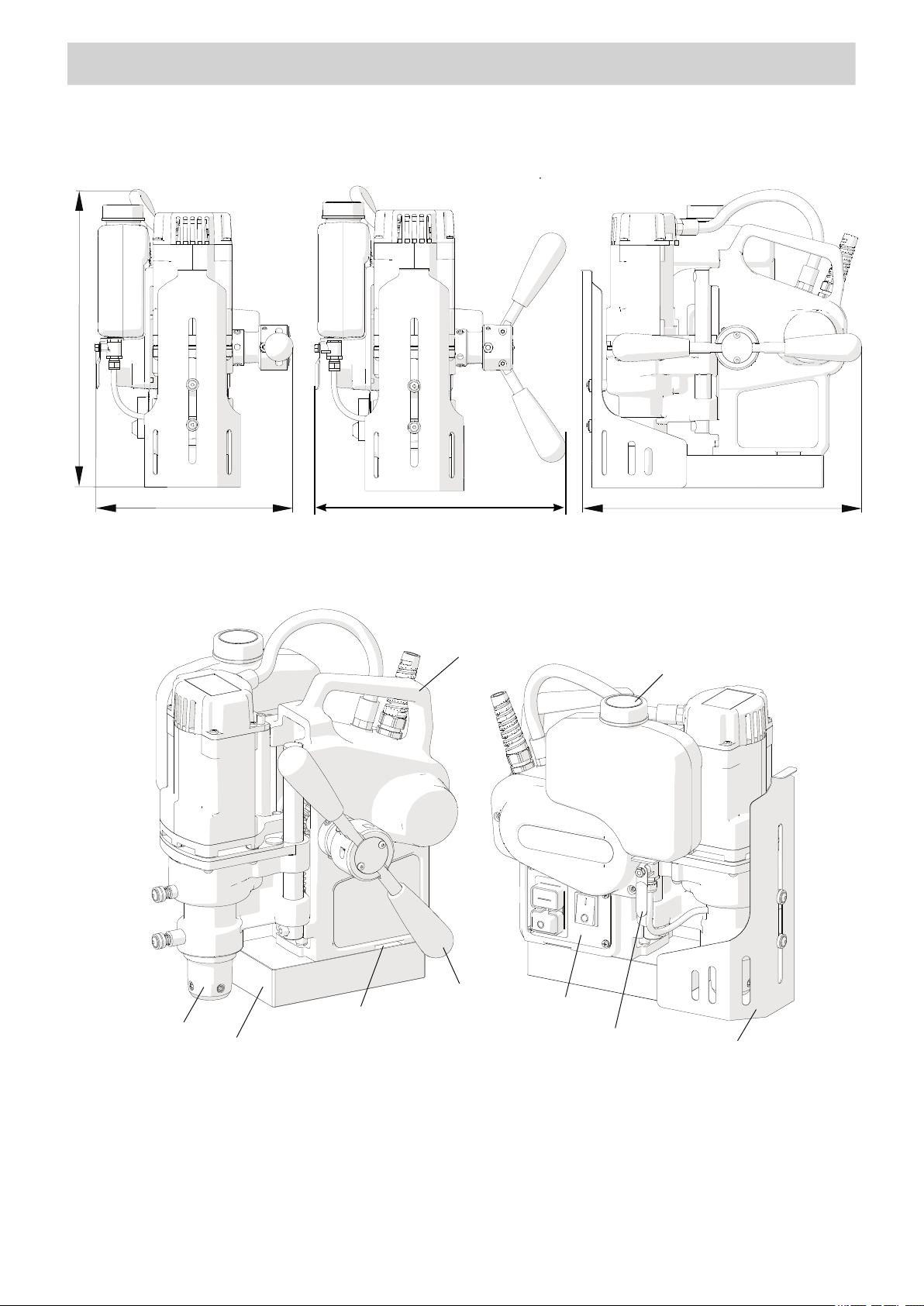

316 mm (12.4’’)

313 mm (12.3’’)

221 mm (8.7’’)

PRO 36 AUTO

Figure 7. Securing the drilling machine using the safety strap

When working in the position from Figure 7a, mount the cooling system bottle as

described before and

fill it with a cutting fluid. Do not use pure water as the cutting

fluid, however, using emulsions formed from mixing water and drilling oil is also

satisfactory. To check the operation of the cooling system, slightly loosen the bottle

cap, open the valve using the lever, and initially apply pressure on the pilot pin by

rotating the spoke handles counterclockwise. The fluid should fill the system and

should begin flowing from the inside of the cutter.

Enter into manual feed mode by positioning the spoke handles as shown in Figure 8a,

and

rotate them counterclockwise to place the tip of the pilot pin above the drilling

b)

The cooling system works by means of gravitation, therefore use

a cooling paste when working in horizontal or inverted positions

.

PRO 36 AUTO

313 mm (12.3’’)

PRO 36 AUTO

point.

316 mm (12.4’’)

221 mm (8.7’’)

261 mm

a)

313 mm (12.3’’)

1.3. Design

carrying handle

spoke handle

control panel

arbor

opening for safety strap

electromagnetic base

cooling system bottle

bottle valve lever

chip guard

5

Loading...

Loading...