HOLEMAKER HMPRO36AD Operator's Manual

HOLEMAKER HMPRO36AD

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

HOLEMAKER PRO 50

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

WARNING!

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

HOLEMAKER PRO 50

BEWARE OF

ROTATING

MACHINE PARTS

LINE VOLTAGE

PRESENT

NEVER PLACE

FINGERS NEAR

CUTTING AREA OR

MACHINE ARBOR

HEARING PROTECTION

REQUIRED

EYE PROTECTION

REQUIRED

OPERATOR’S MANUAL

PRO 36

PRO 36

AD

AD

DRILLING MACHINE

WITH ELECTROMAGNETIC BASE

Holemaker Portable Magnetic Drilling Machine

OPERATOR’S MANUAL

WARNING!

BEFORE USE, ENSURE EVERYONE USING THIS MACHINE READS AND UNDERSTANDS

ALL SAFETY AND OPERATING INSTRUCTIONS IN THIS MANUAL .

EYE PROTECTION

REQUIRED

HEARING PROTECTION

REQUIRED

NEVER PLACE

FINGERS NEAR

CUTTING AREA OR

MACHINE ARBOR

LINE VOLTAGE

PRESENT

BEWARE OF

ROTATING

MACHINE PARTS

esahcruP fo etaD # laireS

Ver: 1.01 31/07/2018

HMPRO36AD OPERATOR’S MANUAL

www.holemaker.com

LIMITED WARRANTY

Industrial Tool & Machinery Sales (hereinafter refered to as ITMS) will, within twelve (12)

months from the original date of purchase, repair or replace any goods found to be defective

in materials or workmanship.

This warranty is void if the item has been damaged by accident, neglect, improper service or

other causes not arising out of defects in materials or workmanship. This warranty does not

apply to machines and/or components which have been altered, changed, or modified in any

way, or subjected to overloading or use beyond recommended capacities and specifications.

Worn componentry due to normal wear and tear is not a warranty claim. Goods returned

defective shall be returned prepaid freight to ITMS or agreed repair agent, which shall be the

buyer’s sole and exclusive remedy for defective goods. ITMS accepts no additional liability

pursuant to this guarantee for the costs of travelling or transportation of the product or parts to

and from ITMS or the service agent or dealer, such costs are not included in this warranty.

Our goods come with guarantees which cannot be excluded under the Australian Consumer

Law. You are entitled to replacement or refund for a major failure and to compensation

for other reasonably foreseeable loss or damage. You are also entitled to have the goods

repaired or replaced if the goods fail to be of acceptable quality and the failure does not

amount to a major failure.

THE MANUFACTURER RESERVES THE RIGHT TO MAKE IMPROVEMENTS AND

MODIFICATIONS TO DESIGN WITHOUT PRIOR NOTICE.

PRODUCTS IMPORTED AND DISTRIBUTED NATIONALLY BY:

INDUSTRIAL TOOL & MACHINERY SALES

18 BUSINESS ST, YATALA QLD 4207

T: 07 3287 1114 E: sales@industrialtool.com.au

F: 07 3287 1115 W: www.industrialtool.com.au

CONTENTS

1. GENERAL INFORMATION 3

1.1. Application 3

1.2. Technical data 3

1.3. Equipment included 4

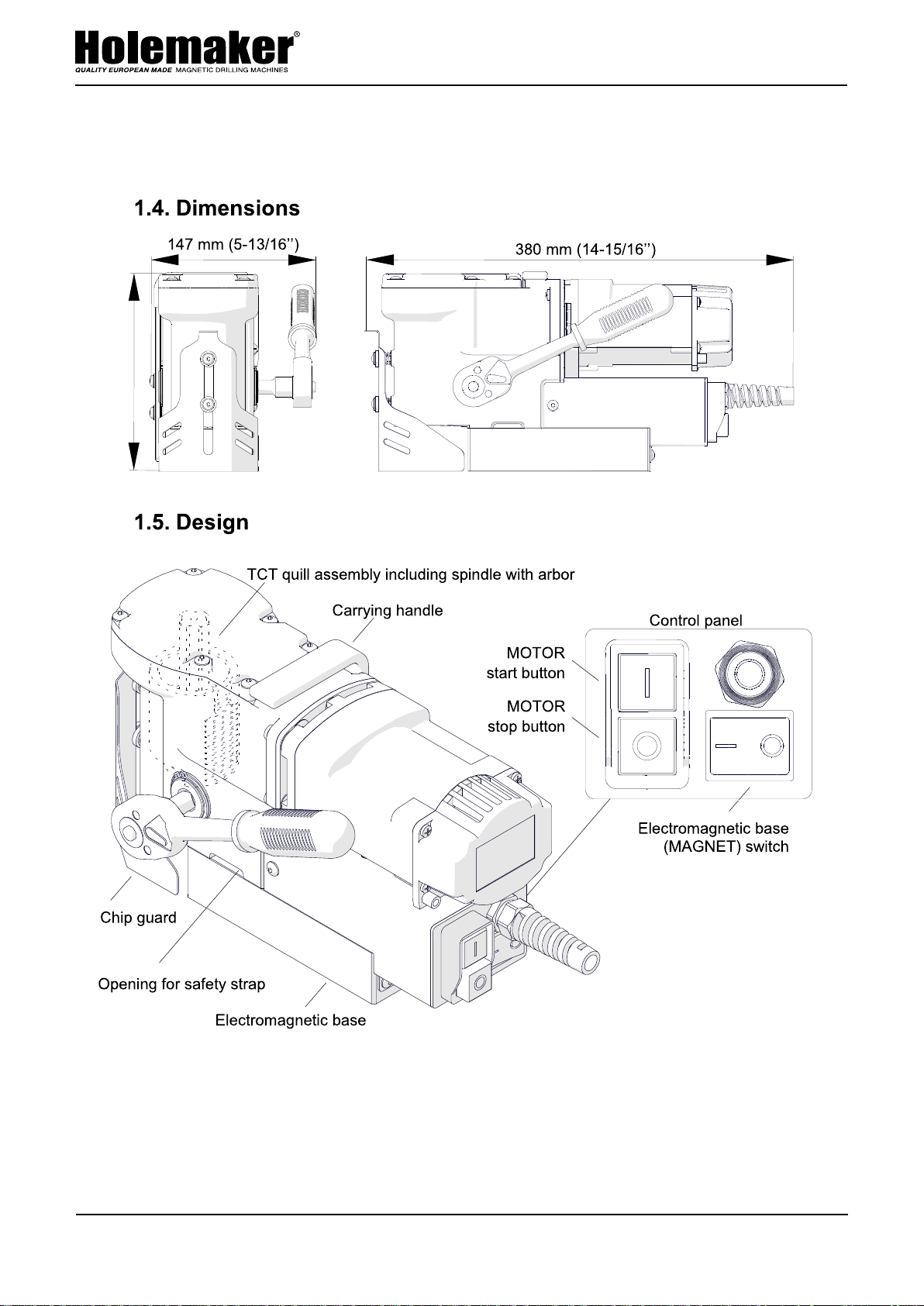

1.4. Dimensions 5

1.5. Design 5

2. SAFETY PRECAUTIONS 6

3. STARTUP AND OPERATION 7

3.1. Installing and removing the handle 7

3.2. Installing, removing, and operating the annular cutter 8

3.3. Preparing 10

3.4. Drilling 12

3.5. Replacing the motor brushes 13

4. WIRING DIAGRAM 15

2

HMPRO36AD OPERATOR’S MANUAL

www.holemaker.com

PRO 36 AD

1. GENERAL INFORMATION

1.1. Application

The PRO 36 AD is a drilling machine with electromagnetic base, designed to drill

holes with

diameters of up to 36 mm (1-7/16’’) either to a depth of up to 20 mm

(13/16’’) by using HSS annular cutters or to a depth of up to 30 mm (1-3/16’’) by using

TCT annular cutters. When using twist drill bits with a 19 mm (3/4’’) Weldon shank you

drill holes with diameters of up to 12 mm (1/2’’) to a depth of up to 20 mm

can

(13/16’’).

The electromagnetic base

allows the drilling machine to be fixed to ferromagnetic

surfaces with a force that ensures operator safety and proper machine operation.

A safety strap protects the machine from falling in case of a power loss.

With an optional HSS quill assembly you can drill holes to a depth of up to 25 mm

(1’’) by using HSS cutters or twist drill bits with a 19 mm Weldon shank.

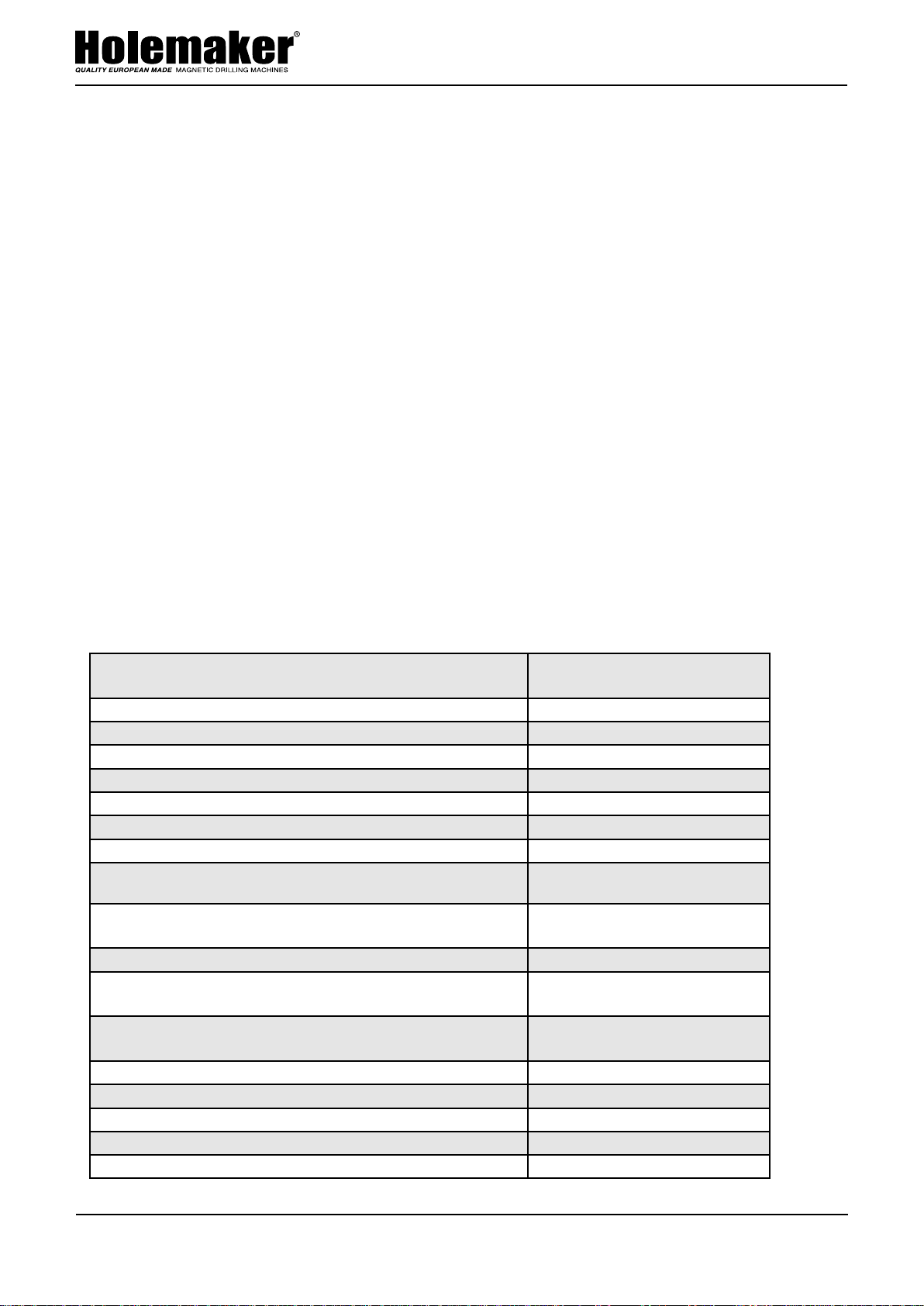

1.2. Technical data

Voltage

Total power 1000 W

Motor power 920 W

Tool holder 19 mm (3/4’’) Weldon

Maximum drilling diameter with annular cutter 36 mm (1-7/16’’)

Maximum drilling diameter with twist drill bit 12 mm (1/2’’)

Maximum drilling depth with HSS cutter or drill bit 20 mm (13/16’’)*

Maximum drilling depth with TCT cutter 30 mm (1-3/16’’)

Electromagnetic base holding force

(surface with the thickness of 25 mm and roughness Ra = 1.25)

Electromagnetic base dimensions

Stroke 39 mm (1-1/2’’)

Rotational speed without load

Rotational speed under load

Minimum workpiece thickness 6 mm (1/4’’)

Protection class I

Noise level More than 85 dB

Required ambient temperature 0–40°C (32–104°F)

Weight 9.5 kg (21 lbs)

* Up to 25 mm (1’’) when used with an optional HSS quill assembly (ZSP-0521-04-00-00-0).

1~ 110–120 V, 50–60 Hz

1~ 220–240 V, 50–60 Hz

8 900 N

90 mm × 180 mm × 38.5 mm

3-9/16’’ × 7-1/16’’ × 1-1/2’’

550 rpm (for 115 V)

580 rpm (for 230 V)

350 rpm (for 115 V)

370 rpm (for 230 V)

3

HMPRO36AD OPERATOR’S MANUAL

www.holemaker.com

PRO 36 AD

PRO 36 AD

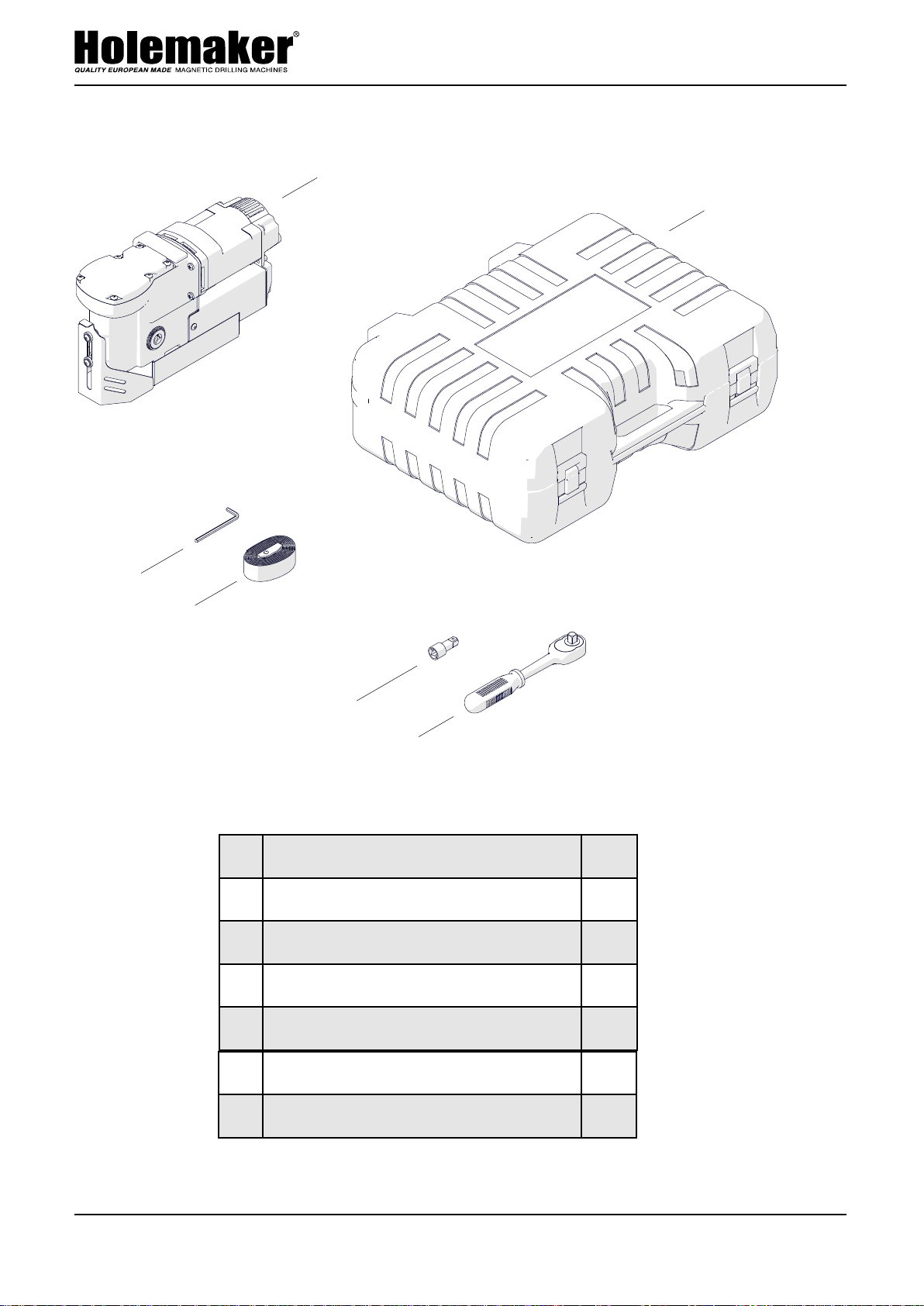

1.3. Equipment included

1

2

3

4

5

6

7

8

PRO 36 AD

1.3. Equipment included

1

2

3

4

5

6

7

8

PRO 36 AD

1.3. Equipment included

1 Drilling machine

1

unit

2 Plastic box

1

unit

3 Handle

1

unit

4 Handle adapter

1

unit

5 Pilot pin 7.98x85 for TCT cutters

1

unit

6 Pilot pin 6.34x74 for HSS cutters

1

unit

1

2

3

4

5

6

7

8

PRO 36 AD

1.3. Equipment included

1 Drilling machine

2 Plastic box

4

3 Handle

4 Handle adapter

7 Safety strap

8 4 mm hex wrench

– Operator’s Manual

1

unit

1

unit

1

unit

1

unit

1

unit

1

unit

1

unit

HMPRO36AD OPERATOR’S MANUAL

www.holemaker.com

"

G

176 mm (6-15/16’’)

5

HMPRO36AD OPERATOR’S MANUAL

www.holemaker.com

2. SAFETY PRECAUTIONS

CAUTION:

Drilling machine must not be used when:

1. The operator has not read the Operator’s Manual.

2. The work to be done is not in agreement with the recommendations in this Manual.

3. Drilling machine is not complete or has been repaired with non-original parts.

4. Power supply parameters do not conform to those stated on the motor’s plate.

5. Machines operator has not checked condition of the drilling machine, condition of air hose,

control panel or cutting tool.

6. Machine is not secured with safety chain as a protection from falling down especially when

used at heights or in vertical or upside-down positions.

7. Bystanders are present in the immediate vicinity of machine.

Important rules of safe use of drilling machine

1. Before attempting to work with the machine check condition of air hose and coupling.

2. Make sure that the drill is supplied with purified air and oiled.

3. Machine can be used outdoors, but is not weatherproof. Do not expose to rain, snow or

frost.

4. Machine should not be used on: rusty surfaces, steel plates covered with paint, uneven

surfaces, or steel plate which is being welded on.

5. Do not use the machine in explosion hazard zones.

6. Do not start work if the machine has excessive play on guide slides.

7. Always wear safety goggles and ear protection.

8. Do not remove metal chips with bare hands, always use gloves.

9. Do not touch the spindle and cutting tool during work.

10. Cutting Tools must be fastened firmly.

11. Do not drill with blunt of damaged cutting tools.

12. Do not use annular cutters without a pilot pin, and arbors without an ejection spring.

Do not touch or replace the cutting tool with power source on

13. After use, always clean drilling machine from metal chips and cutting fluid.

14. Any maintenance and repair should be performed only when the machine is disconnected

from the air supply.

15. Before each use the machine should be checked for the presence of damage. Check

whether any of the parts are broken and all the that all parts are fasten properly.

16. In the case that the machine falls on a hard surface, from a height, is wet or is subjected

to other unfortunate events that could affect its technical state - work should be terminated

immediately and the machine should be sent to service for inspection as soon as possible.

This machine is not recommended to be used to drill on steel thinner than 10mm (3/8”).

On thin steel less than 10mm (3/8”) magnet’s adhesive power would be significantly

reduced which can cause machines failure or personal injury.

6

HMPRO36AD OPERATOR’S MANUAL

www.holemaker.com

PRO 36 AD

3. STARTUP AND OPERATION

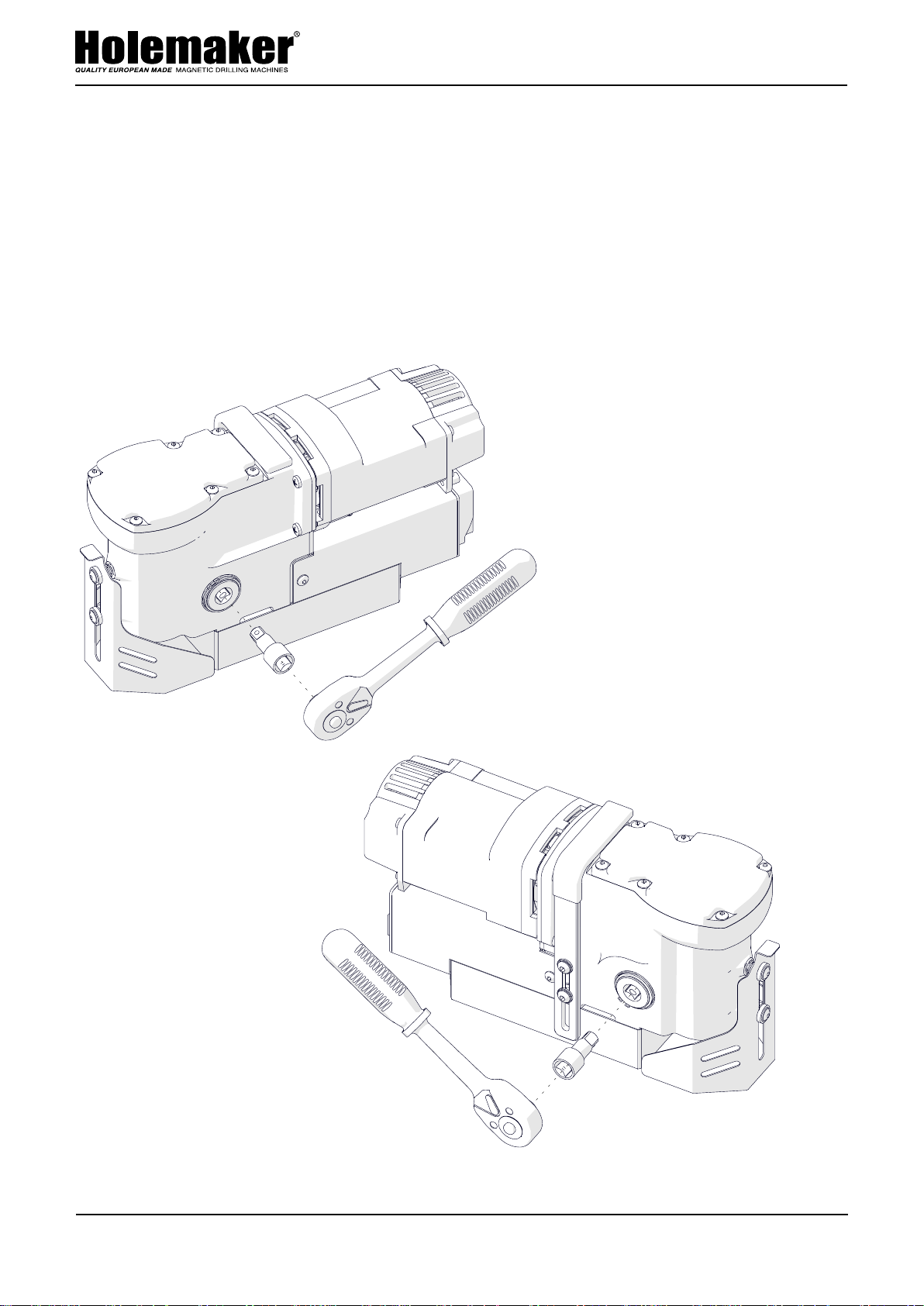

3.1. Installing and removing the handle

Install the handle by using the adapter as shown in Fig. 1. The handle can be installed

from the opposite side of the machine to allow working in places hard to reach or

using the machine by a left-handed person.

To remove the handle, pull it out.

Fig. 1. Installing the handle

7

Loading...

Loading...