Holder C 9700, C-Trac C 9.83 H, C-Trac C 9.88 H, C-Trac A4 VG 40 EP, C-Trac C 9.78 H User Manual

...Page 1

Operating Instructions

C-Trac

C 9700

C 9700 H

C 9800 H

C 9.72

C 9.72 H

C 9.83 H

C 9.78 H

C 9.88 H

Order No.: 145 052

Date of Issue: 23.10.2002

Page 2

C 9700 ... C 9.88 H

Operating Instructions

Foreword

We congratulate you for having chosen a product from

HOLDER. We would like you to be able to work safely with

your tractor and without malfunctions, and therefore we

recommend you follow the instructions in this operating

manual. You also ensure getting full value from your tractor,

save yourself trouble and maintain your warranty. The

operating manual provides you with the required information.

Development

Due to the continuous improvements made in the design

and equipment of our tractors, deviations between this

operating manual and your tractor may be possible.

Despite taking all care possible in the creation of this manual,

we cannot fully exclude mistakes. Please note that the

technical data, illustrations and descriptions contained in

this manual are not binding and no legal claims can be made

on the basis hereof.

This operating and maintenance manual is supplied with

each tractor. Keep this in a safe place where it is available

for the driver and owner at any time. If they should get lost,

the owner must get a replacement from the manufacturer.

The personnel concerned with the operation and maintenance

of the tractors must be made acquainted with the operating

and maintenance manual. The owner must ensure that every

operator has received, read and understood this manual.

We thank you for reading and observing this manual. In

case you still have any questions, suggestions for

improvements or discovered mistakes, please contact our

customer service.

General Notes on Service

Detach the warranty card, have it filled in by your dealer

and send the signed card to us.

Have the scheduled services carried out at the proper

intervals and have it confirmed with the dealer's stamp and

signature in this manual. Please note that warranty can only

be claimed if the regular services have been carried out as

scheduled.

Descriptions and illustrations can be related to special

equipment not installed in your tractor.

145 052 1

Page 3

Operating Instructions

Foreword

In case of questions regarding your tractor, please state the

following data:

Tractor Model ................................................ eg C 9800 H

Engine Serial Number .................................. eg 00542087

Chassis Serial Number................................. eg 52410101

Date of Sale, or Date of Complaint ............. eg 02.01.2003

Operating Hours ............................. eg 2860 service hours

Date of Issue and Manual Version

C 9700 ... C 9.88 H

Explanations of Terminology:

DANGER

Indicates procedures which must be observed

exactly to prevent danger to the life and limbs

of persons.

CAUTION

Indicates procedures which must be observed

exactly to prevent personal injuries.

November 2002

We wish you safe driving and troublefree working with your

HOLDER C-Trac.

Gebrüder Holder GmbH

Max-Holder-Straße 1

72555 Metzingen

Phone (Germany) 07123 966 - 0

Fax 07123 966 - 228

E-mail: info@holder-gmbh.com

www.holder-gmbh.com

2 145 052

ATTENTION

Indicates procedures which must be observed

exactly to prevent damage to and/or

destruction of objects and equipment.

NOTE

Indicates technical requirements requiring

special attention.

Page 4

C 9700 ... C 9.88 H

Table of Contents

Operating Instructions

Foreword

Chapter Page

Foreword ........................................................................ 1

Instructions for the Tractor ............................................ 5

Instructions for Operation .............................................. 7

Technical Data ..............................................................15

Description ................................................................... 28

Taking into Service .......................................................49

Operation ......................................................................63

Operating Implements ...................................................85

Other Activities ........................................................... 119

Taking out of Operation .............................................. 133

Trailers, Towing ..........................................................135

Transport, Loading, Towing ......................................... 139

Indicators, Adjustments .............................................. 141

Problems, Causes, Remedy .......................................143

General Notes on Maintenance ................................... 149

Chapter Page

Maintenance Schedule................................................157

Maintenance during the First Period of Operation ....... 161

Maintenance as Required ........................................... 163

Maintenance According to Intervals ............................ 169

Maintenance Every 125 Service Hours ....................... 169

Maintenance Every 500 Service Hours ....................... 177

Maintenance Every 1000 Service Hours ..................... 183

Maintenance Every 1500 Service Hours ..................... 187

Maintenance Every 3000 Service Hours ..................... 197

Maintenance Annually .................................................199

Maintenance Every 2 Years ....................................... 199

Laying Up ................................................................... 201

Recommended Oils and Fuels .................................... 203

Alphabetical Index ......................................................213

145 052 3

Page 5

Page 6

C 9700 ... C 9.88 H

Operating Instructions

Instructions for the Tractor

After the safety test, this tractor has received the operating

permit acc. to 74/150/EEC. The tractor conforms to the EMC

(Electromagnetic Compatibility) requirements of directive 89/

336/EEC. The regulations for exhaust gas identification and

the noise emissions are observed. The tractor must be

registered and the license plate must be attached at the

front and/or rear if applicable.

Approved Applications

The tractor can be used for towing trailers and for mounting

various attachments. The maximum trailer load, which must

not be exceeded, is stated on the identification plate. The

transport of persons is only allowed on the passenger seat.

The tractor is designed solely for the customary type of

operation in farming and forestry, the upkeep of municipal

facilities, including operation in winter. The tractor may only

be used as intended and described in this operating manual.

The intended use also includes the use following the specified

maintenance and repair recommendations. The tractor,

together with its attachments, may only be used, serviced

and repaired by persons familiar with this equipment and have

been warned of possible risks. The applicable safety

regulations must be strictly observed, along with all other

recognized rules regarding industrial health, safety at work

and the highway traffic code.

Site of Operation

The tractor must be used in the open. Its operation on public

roads is allowed. When using the public highway, respect

the high way code in your country.

Unintended Applications

Any use not intended as described as above is not

authorized. The Supplier HOLDER will not be responsible

for any hazard resulting from unintended applications. The

Supplier will also not be responsible for any resulting

damages, they shall be solely borne by the user. The tractor

may not be used for any other purposes than those described

in this manual. Do not carry persons on the loading area or

on attachments.

145 052 5

Page 7

Operating Instructions

Instructions for the Tractor

Residual Hazards and Risks

Despite all care being taken and in conformance with standards

and regulations, it is not possible to exclude all risks in the

handling of the tractor.

The tractor and all other system components conform to

currently applicable safety regulations. Nevertheless, a residual risk cannot be excluded even by authorized use of

the tractor and observation of all the safety notices given.

For this reason, persons standing in the area of the tractor

and attachments must exercise particular caution in order

to be able to be able to react directly in case of a malfunction,

an incident, a failure, etc.

CAUTION

All persons standing in the area of the tractor

and implements must be advised of the risks

which can result from their operation.

Furthermore, read and observe the other

safety rules and regulations contained in this

operating manual.

C 9700 ... C 9.88 H

The risks can include:

- Unexpected movements of the implements and

tractor.

- Escape of fuel and lubricants due to leaks, broken

lines and reservoirs, etc.

- Risk of accidents when driving, steering and braking

due to unfavourable ground conditions such as

slopes, icy roads, unevenness or poor visibility, etc.

- Falling, stumbling, etc. when moving on the tractor,

particularly when it is wet.

- Fire and explosion hazards due to the battery and

electric currents.

- Danger of poisoning through Diesel exhaust gases

- Danger of fire through Diesel fuel and oils

- Human errors due to non-observance of the safety

rules.

Note on Disposal of Tractor

Your tractor is made of different materials. Each material

should be disposed of/treated/recycled according to different regional/national regulations. We recommend contacting

a salvage company.

6 145 052

Page 8

Operating Instructions

C 9700 ... C 9.88 H

Instructions for Operation

Driver's license

For the operation of this vehicle you need a driver's license

dependent of the maximum speed and the permissible total

weight of the vehicle or the combination. See the tables

below. Please observe your national laws.

Driver's license classes (Germany only)

Tractors for farming and forestry (also with implements)

Maximum Speed

(dependent on type)

up to 32 km/h

over 32 km/h

145 052 7

Maximum Total Weight

no limitation B, L, T 1, 1a, 1b, 2, 3, 4, 5

up to 3.5 tons B

over 3.5 tons

to 7.5 tons

Driver's License Class

(Minimum Requirements)

T: 60 km/h, under 18 years

only 40 km/h

C1

T: 60 km/h, under 18 years

only 40 km/h

Former Driver's License

Class

2, 3

2, 3

Page 9

Operating Instructions

Instructions for Operation

Single-axle Trailers or Two-axle Trailers with an Axle Base of up to max. 1 m

C 9700 ... C 9.88 H

Maximum Total Weight

up to 750 kg trailer weight B, C1, C, T

over 750 kg trailer weight BE, C1E, CE, T

Driver's License Class

(Minimum Requirements)

25

L: only with additional

sign and maximum tractor

speed of 25 km/h

(depending on type)

B, C1, C: only up to

3.5 tons adm. total weight of

the combination and adm.

total weight of trailers

dead weight of tractor;

≤

otherwise:

C1E: only up to 12 tons adm.

total weight of combination

and adm. total weight of

trailer ≤ dead weight of

tractor; otherwise:

25

L:

25

Former Driver's License

Class

1, 1a, 1b, 2, 3, 4, 5

1, 1a, 1b, 2, 3, 4, 5

25

8 145 052

Page 10

Operating Instructions

C 9700 ... C 9.88 H

Multiple-axle Trailers and Two-axle Trailers with an Axle Base over 1 m

Instructions for Operation

Maximum Total Weight

up to 750 kg trailer weight B, C1, C, T

over 750 kg trailer weight

up to 3.5 tons Maximum Total

Weight

up to 12 tons Maximum Total

Weight

Driver's License Class

(Minimum Requirements)

25

L: only with additional

sign and maximum tractor

speed of 25 km/h

(depending on type)

BE, C1E, CE, T

B, C1, C: only up to

3.5 tons adm. total weight of

the combination and adm.

total weight of trailers

dead weight of tractor;

≤

otherwise:

C1E: only up to 12 tons adm.

total weight of combination

and adm. total weight of

trailer ≤ dead weight of

tractor; otherwise:

25

L:

25

25

Former Driver's License

Class

2, 3

2, 3

1, 1a, 1b, 4, 5:

in each case

25

145 052 9

Page 11

Operating Instructions

Instructions for Operation

Two Trailers behind Tractors for Farming and Forestry

C 9700 ... C 9.88 H

Maximum Total Weight

up to 3.5 Maximum Total

Weight

up to 12 Maximum Total

Weight

Driver's License Class

(Minimum Requirements)

BE, C1E, CE, T

B, C1, C

in each case only up to

3.5 tons adm. total weight of

the combination and adm.

total weight of trailers

dead weight of tractor;

≤

otherwise:

C1E:

only up to 12 tons adm. total

weight of combination and

adm. total weight of trailer

dead weight of tractor;

otherwise:

25

L:

25

≤

25

Former Driver's License

Class

2, 3

1, 1a, 1b, 4, 5,

25

10 145 052

Page 12

Operating Instructions

C 9700 ... C 9.88 H

Safety

General Notes on Safety

• Observe the VSG 3.1 (German regulations for safety

and health protection).

• Do not allow children under 16 to use the tractor.

• When using the public highway, respect the highway

code.

• Do not allow anyone to stand around where they might

get hurt.

• Do not run the engine in enclosed spaces.

• Exercise extreme caution when handling fuels - there

is a high risk of fire.

• Exercise extreme caution when handling fuels and

oils; these can be poisonous and caustic.

• To prevent the danger of fire, keep the tractor and

implements clean.

• Observe the warning notices and symbols on your

tractor.

Instructions for Operation

Working Clothes

• Only wear snugly fitting clothing when working with

the tractor.

• If necessary, wear suitable headwear to keep loose

hairs and pigtails from being caught in rotating parts.

• Do not wear any jewellery and similar objects, eg

rings, when working with the tractor.

Safety Notes for Later Installations

The tractor has electronic components whose proper

functioning can be influenced by the electromagnetic

emissions of other equipment. These influences can

endanger persons if the following notes on safety are not

observed.

• Have your equipment installed only by an authorized

workshop.

• Before the installation of electric or electronic equipment connected to the tractor's electrical system,

check if these installations can interfere with the

tractor's electronic system or other system components.

145 052 11

Page 13

Operating Instructions

Instructions for Operation

• The installed equipment must conform to the applicable EMC directive 89/336/EU and carry the CE

symbol.

• If you must install a mobile communications system

(or have it installed) (eg radio, mobile telephone), the

following requirements must be met:

- Only approved equipment (eg BTZ approval in Germany) may be installed.

- The equipment must be installed permanently.

- The operation of portable or mobile equipment inside

the vehicle is only allowed if connected to a permanently installed external antenna.

- The transmitting section must be installed away from

the tractor's electronic system.

- When installing the antenna, install it properly and

with a good connection vehicle ground.

- Do not exceed the maximum permissible current

rating of the wiring according to the installation instructions of the equipment manufacturer.

C 9700 ... C 9.88 H

Safety Instructions for Handling Fuels and

Oils

Gear Oil, Engine Oil, Diesel Fuel

Do not eat, drink or smoke when working with

the product. Prolonged intensive contact may

cause degreasing and irritation of the skin.

Wash skin with soap and water, use skin care

products. If required, wear protective gear.

Change soaked clothes and shoes immediately. If vapour or mist was inhaled, breathe

fresh air. Consult a doctor if the complaint

persists. After contact with the eyes, rinse

the eyes thoroughly with water (at least 10

minutes), then consult an eye doctor. If swallowed, do not force to vomit, but consult a

doctor. Danger of slipping on the spilled product, especially in connection with water.

Oils can contaminate water. Always keep

them in approved containers. Avoid spilling

oils. Remove spilled fluids at once with an oil

binding agent and dispose of in accordance

with laws and regulations. Discard drained

fluids as specified. Observe all applicable laws

and regulations. Oils are inflammable. Do not

12 145 052

Page 14

C 9700 ... C 9.88 H

let them come in contact with hot engine parts

as fire can result.

Hydraulic Oil, Brake Fluid

During tractor operation, these fluids are under

pressure and a health hazard. Do not spill these

fluids! Remove any spilled fluid at once with an

oil binding agent and discard as specified. Dispose of old fluids as specified and follow the

applicable laws and regulations. Do not allow

them to come in contact with hot engine parts

as fire can result. Danger of fire!

Avoid contact with the skin. Avoid the inhalation

of spray fog. The penetration of the fluids into

the skin is especially dangerous if the fluids

are under high pressure and escape from the

hydraulic system through leaks. Seek medical

aid at once in case of such injuries.

If injuries cannot be excluded, use suitable

protectors (for example, protective gloves,

glasses and skin protection and care creams).

Operating Instructions

Instructions for Operation

Battery Acid

Battery acid contains dissolved sulphuric

acid. This acid is poisonous and caustic. When

working with battery acid, always wear

protective clothing and eye protectors. Do not

allow acid to contact clothing, skin or eyes.

In case of contact, wash directly with ample

clean water. If personal injuries exist, seek

medical aid at once. Neutralize spilled battery

acid immediately.

Discard the old battery fluid as specified.

Observe laws and regulations.

Emissions

Exhaust Gases

During operation, the engine emits exhaust

gases into the environment. The exhaust gas

mainly consists of water vapour, carbon

dioxide (CO2), carbon monoxide (CO),

hydrocarbon (CH), nitrogen oxide (NOX) and

soot. The components CO, CH and NOX are

poisonous or hazardous to health and should

not be inhaled in high concentrations. Soot is

a carcinogenic material; particularly the

145 052 13

Page 15

Operating Instructions

Instructions for Operation

particles in the exhaust gases can cause

cancer. For this reason the engine may not

be operated in enclosed spaces.

Heat

The exhaust gases are very hot and can ignite

inflammable material. The exhaust gas pipe

should therefore be kept away from ignitable

material.

Battery

During charging, the battery produces a mixture of oxygen and hydrocarbon (detonating

gas). This mixture of gases is explosive and

may not be ignited. The risk of explosion can

be avoided with proper ventilation and keeping naked flames away. Observe the safety

rules when handling the battery.

C 9700 ... C 9.88 H

14 145 052

Page 16

Operating Instructions

C 9700 ... C 9.88 H

Technical Data

Model Variants

Model Transmission Type of Drive Type of Engine Engine Performance

C 9700

Mechanical Reversing

Gearbox

Mechanical BF4M1011 53.5 kW 72 HP (DIN)

C 9700 H Hydrostatic transmission Hydrostatic BF4M1011 53.5 kW 72 HP (DIN)

C 9800 H Hydrostatic transmission DUAL DRIVE* BF4M1011F 61 kW 83 HP (DIN)

C 9.72

Mechanical Reversing

Gearbox

Mechanical BF4M1011 53.5 kW 72 HP (DIN)

C 9.72 H Hydrostatic transmission Hydrostatic BF4M1011 53.5 kW 72 HP (DIN)

C 9.83 H Hydrostatic transmission DUAL DRIVE* BF4M1011F 61 kW 83 HP (DIN)

C 9.78 H Hydrostatic transmission Hydrostatic BF4M2011 57 kW 78 HP (DIN)

C 9.88 H Hydrostatic transmission DUAL DRIVE* BF4M2011F 65 kW 88 HP (DIN)

^

=

^

=

^

=

^

=

^

=

^

=

^

=

^

=

* mechanical + hydrostatic

145 052 15

Page 17

Technical data

Tractor Dimensions

Sketch

Operating Instructions

C 9700 ... C 9.88 H

(7,8")

200

(3,9")

100

a

b

c

970

1030

1110

(38,2")

(40,5")

(43,1")

e

f

1040-1160

(40,9-45,6")

1827

3900-4020

3980-4100

(72")

(153,5-158,3")

(156,5-161,4")

g

d

1090

(42,9")

(Cab for 1 person)

(49,3")

1250

(Cab for 2 persons)

Bild_194

Data in brackets are American dimensions

16 145 052

Page 18

C 9700 ... C 9.88 H

Table of Dimensions

Operating Instructions

Technical data

Trailer Coupling

Tires Type Overall Height Avg. Height of

Seat

a

mm (Inches)

10

5-18 MPT S

.

10

5-18 MPT

.

36x13

50-15

.

400/60-15

33x12,50-R15 524-31-7 2090 (82.2) 1020 (40.1) 190 (7.3) 535 (21.0) 935 (36.6) 1090 (42.9)

33/18LL-16.1 524-31-9 2090 (82.2) 1020 (40.1) 190 (7.3) 535 (21.0) 935 (36.6) 1090 (42.9)

33x12

50-15

.

50-15

33x15

.

31x15

50-15

.

145 052 17

524-31-6 2130 (83.8) 1050 (41.3) 230 (9) 575 (22.4) 975 (38.2) 1130 (44.5)

524-31-1 2130 (83.8) 1050 (41.3) 230 (9) 575 (22.4) 975 (38.2) 1130 (44.5)

524-31-8 2100 (82.5) 1020 (40.1) 200 (7.9) 545 (21.3) 945 (37.1) 1095 (43.1)

524-31-5 2095 (82.3) 1030 (40.5) 195 (7.5) 540 (21.2) 940 (37) 1095 (43.1)

5

.

524-31-4 2075 (81.4) 1010 (39.7) 180 (7) 525 (20.6) 925 (36.3) 1075 (42.3)

524-31-3 2075 (81.4) 1010 (39.7) 180 (7) 525 (20.6) 925 (36.3) 1075 (42.3)

524-31-2 2065 (81.1) 980 (38.6) 165 (6.4) 510 (20) 910 (35.8) 1060 (41.7)

b

mm (Inches)

Ground

Clearance

c

mm (Inches)

Lowest Position Highest Position Height of Body

d

mm (Inches)

d

mm (Inches)

g

mm (Inches)

Page 19

Operating Instructions

Technical data

Track Widths

Min. Turning

Radius to DIN

7020

(measured at

Tires

36x13.50-15

10.5-18 MPT S

10.5-18 MPT

400/60-15.5

33x12.50 R15

33x12.50-15

33x15.50-15

33/18LL-16.1

31x15.50-15

*Snow chains not possible

* With track spacer type 526-34-75 (15 mm per wheel)

outermost

point of

vehicle)

m

7.28 m

f. track w. 1084

7.10 m

f. track w. 960

7.14 m

f. track w. 1034

7.30 m

f. track w. 1070

7.15 m

f. track w. 1000

7.15 m

f. track w. 1000

7.24 m

f. track w. 1124

7.45 m

f. track w. 1164

7.30 m

f. track w. 1124

Normal Track Width

Flange size

(

Track Width e Overall Width f Track Width e Overall Width f Track Width e Overall Width f

min.-mmmax.-

mm

- 1084 - 1439 1090 1174 1445 1529 1160 1244 1515 1599

960 1124 1230 1394 1124 1140 1320 1484 1120 1284 1390 1554

1034 1050 1304 1320 1050 1214 1394 1410 1194 1210 1464

- 1070 - 1470 1106 1160 1506 1560 1176 1230 1576 1630

1000 1084 1320 1404 1090 1174 1410 1494 1160 1244 1480 1564

1000 1084 1320 1404 1090 1174 1410 1494 1160 1244 1480 1564

*• 992 1124 * 1382 1514 1052 1214 1442 1604 1122 1284 1512 1674

- 1164 - 1636 - 1254 - 1726 - - - -

*• 962 1124 * 1332 1494 1052 1214 1422 1584 1122 1284 1492 1654

min.

mm

)

1034

max.-mmmin.-mmmax.-

-

C 9700 ... C 9.88 H

With Hub Spacers

Type 5234-80= 45 mm Type 526-34-70= 80 mm

mm

min.

mm

max.-mmmin.-mmmax.-

-

mm

min.

mm

max.-

-

1480

mm

18 145 052

Page 20

C 9700 ... C 9.88 H

Weights

Operating Instructions

Technical data

All Tractors Weight in kg

Permissible total weight

Permissible load on front axle

Permissible load on rear axle

Permissible supporting load on

trailer hitch

* With 33x12.50 R15 tires

4500 kg (9920.6 LBS)

*

2660 kg - 2700 kg

(5864 LBS - 5952 LBS)

2660 kg - 2700 kg

*

(5864 LBS - 5952 LBS)

800 kg (1764 LBS)

Weights w/o loading platform and rear lift

Tires 36x13.5-15

C9700

C9700H

C9.72

C9800H

2430

1275

1155

C9.72H

C9.78H

C9.83H

C9.88H

2620

5776)

1390

(3064.4)

1230

(2711.6)

Empty weight (incl.

driver 75 kg)

Tot al: kg

Front: kg

Rear: kg

(5351)

(2810.8)

(2546.3)

10.5-18 MPT

400/60-15.5

C9700

C9.72

2440

(5319)

1280

(2821.8)

1160

(2551.3)

C9700H

C9800H

C9.72H

C9.78H

C9.83H

C9.88H

2630

(5198)

1395

3015)

1235

(2122.6)

Accessories Total Front Rear

Creep speed gear

Rear lift

Loading platform

33x12.50 R15 33x12.50-15

C9700

(2766.7)

C9.72

2390

(5269)

1255

1135

(2502)

C9700H

C9800H

C9.72H

C9.78H

C9.83H

C9.88H

2580

(5687.8)

1370

(3020.3)

1210

(2667.5)

C9700

C9.72

2380

(5246.9)

1250

(2755.7)

1130

(2491.2)

C9700H

C9800H

C9.72H

C9.78H

C9.83H

C9.88H

2570

(5665.8)

1365

(3009.3)

1205

(2656.5)

13 kg

(28.6 LBS)

77 kg

(169.7 LBS)

75 kg

(165.3 LBS)

31x15.50-15

33x15.50-15

C9700

C9.72

2410

(5313.1)

1265

(2788.8)

1145

(2524.3)

(22 LBS)

-25 kg

(-55 LBS)

0 k g

(0 LBS)

C9700H

C9800H

C9.72H

C9.78H

C9.83H

C9.88H

2600

(5732)

1380

(3042.3)

1220

(2689.6)

10 kg

(5445.4)

(2590.4)

3 kg

(6.6 LBS)

102 kg

(224.8 LBS)

75 kg

(165.3 LBS)

33/18LL-16.1

C9700

C9.72

2470

1295

(2855)

1175

C9700H

C9800H

C9.72H

C9.78H

C9.83H

C9.88H

2660

(5864.2)

1410

(3108.5)

1250

(2755.7)

145 052 19

Page 21

Operating Instructions

C 9700 ... C 9.88 H

Technical data

Tires

Type of Tire Ply Profile Tube Inflation Pressure Wheel Weights

Type Weight

10.5-18 MPT S 6 Cleat profile yes 1.5 bar (22 PSI) 524-34-1 approx. 45 kg (100 LBS)

10.5-18 MPT 6 Cleat profile yes 1.5 bar (22 PSI) 524-34-1 approx. 45 kg (100 LBS)

31x15.50-15 8 Profile no 2.0 bar (14-29 PSI) 524-34-1 approx. 45 kg (100 LBS)

33x15.50-15 4 Profile no 1.0 bar (14.7 PSI) 524-34-1 approx. 45 kg (100 LBS)

33x12.50-15 6/8 (M+S)/Profile no 1.4 bar (20 PSI) 524-34-1 approx. 45 kg (100 LBS)

33x12.50-R15 6 M + S no 1.6 bar (23 PSI) 524-34-1 approx. 45 kg (100 LBS)

36x13.50-15 4 Lawn no 1.0 bar (14.7 PSI) 524-34-1 approx. 45 kg (100 LBS)

400/60-15.5 6 Profile yes 1.8 bar (26 PSI) 524-34-1 approx. 45 kg (100 LBS)

33/18LL-16.1 10 Lawn no 1.2 bar (17 PSI) 524-34-1 approx. 45 kg (100 LBS)

NOTE: Observe prescribed inflation pressure with maximum axle load and when driving on roads.

20 145 052

Page 22

C 9700 ... C 9.88 H

Engine Specifications

Operating Instructions

Technical data

C 9700/9.72

C 9700/9.72H

Manufacturer Deutz AG Deutz AG Deutz AG Deutz AG

Type BF4M1011 BF4M1011F BF4M2011 BF4M2011

Mode of operation Four-stroke Diesel Four-stroke Diesel Four-stroke Diesel Four-stroke Diesel

Number of cylinders 4 4 4 4

Cubic capacity 2914 2914 3108 3108

Fuel consumption

Rated speed

Maximum idling speed 2600 rpm 2750 rpm

Minimum idling speed 900 rpm 900 rpm 900 rpm 900 rpm

Power at n=2800 rpm 53.5 KW (72 HP) 61 KW (83 HP) 57 KW (78 HP) 65 KW (88 HP)

223g/KW-h at

1500-1750 rpm

2500

rpm

C 9800/9.73H C 9.78H C 9.88H

222g/KW-h

at 1750-1850 rpm

2600 rpm

216g/KW-h

at 1750-1850 rpm

2500 rpm 2800 rpm

rpm

2750

216g/KW-h

at 1550-1650 rpm

3050 rpm

145 052 21

Page 23

Operating Instructions

Technical data

Theoretical Driving Speeds

C 9700 ... C 9.88 H

Transmission Unit Gearbox

Engine Output

Engine speed

Tires Type

36x13.50-15

10.5-18 MPT

400/60-15.5

33x12.50 R15

33x12.50-15

33x15.50-15

33/18LL-16.1

31x15.50-15

524-31-8 km/h 36.8 30.8 32.0 34.4 38.4 39.9 43.0

524-31-1/-6 km/h 35.9 30.1 31.3 33.7 37.6 39.1 42.1

524-31-5 km/h 34.1 28.6 29.7 32.0 35.7 37.1 40.0

524-31-7 km/h 33.3 27.9 29.0 31.2 34.8 36.2 39.0

524-31-4 km/h 32.4 27.2 28.3 30.4 33.9 35.3 38.0

524-31-3 km/h 32.4 27.2 28.3 30.4 33.9 35.3 38.0

524-31-9 km/h 31.8 26.7 27.8 29.9 33.3 34.7 37.3

524-31-2 km/h 30.5 25.1 26.1 28.1 31.3 32.6 35.1

kW 53.5

rpm 2500 2500 2600 2800 2500 2600 2800

Hydrosta-

tic Drive

53.5

57

Hydrosta-

tic Drive

61 65

Hydrosta-

tic Drive

Dual

Drive

53.5

57

Dual

Drive

61 65

Dual

Drive

22 145 052

Page 24

Operating Instructions

C 9700 ... C 9.88 H

Technical data

Technical Data/Filling Quantities

Assembly Suppl. Information Description

Mechanical gearbox

Hydrostatic drive

Power take-offs

- RPM, front 540 rpm at 2200 engine rpm, 1000 rpm at 2390 engine rpm

- RPM, rear 1000 rpm at 2360 engine rpm

- Wedge shaft profile 1 3/8 " (6) DIN 9611

PTO clutch Multiple disk wet clutch

Differential lock Acts simultaneously on front and rear axles

Fuel system

Fuel tank Diesel fuel 86 l (22.7 USGAL.)

16 forward gears/16 reverse gears with planetary axles

Infinitely variable driving speed, 2 mechanical speed ranges

2 PTOs (front and rear) Rotating Direction: clockwise when looking at

end of shaft

145 052 23

Page 25

Operating Instructions

C 9700 ... C 9.88 H

Technical data

Assembly Suppl. Information Description

Steering

- Type Hydrostatic with 2 double-acting steering rams

- Steering valve Orbitrol OSPC 125 LS

Brakes

- Service brake Multiple-disk brakes, wet, acting on all 4 wheels

- Activation Hydraulic

- Parking brake Multiple-disk brakes, wet, acting on all 4 wheels

- Activation Mechanical

Trai ler h itch

- Make Cramer, height-adjustable

Front lift

- Make 3-point, upper link adjustable

- Mounting Category I and II

- Lifting power 27000 N (measured at installation points)

- Cylinders 2 double-acting cylinders

24 145 052

Page 26

C 9700 ... C 9.88 H

Operating Instructions

Technical data

Assembly

Rear lift

- Model HOLDER 3-point standard

- Mounting Category I and II

- Lifting power 15700 N (at installation points)

- Cylinders 2 double-acting cylinders

Drive Hydraulics

Variable pump Hydromatik

- Model A11 VG 50 EP / A4 VG 40 EP

- Flow rate 160 l/min (42 GAL/MIN)

- Operating pressure 300 bar (4410) (max. 350 bar (5145)) / 380 bar (5586) (max. 430 bar (6320))

Vari able moto r Hydromat ik

- Model A6 VM 55 EP

- Displacement 26.1 - 55 cm

Hydraulic oil tank 19 l (5.02 GAL.)

Suppl.

Information

Description

3

/rev

145 052 25

Page 27

Operating Instructions

Technical data

Assembly Suppl. Information Description

Hydraulics for implements

(with steering)

Pump Sundstrand

- Make -

- Flow rate 17 cm

- Operating pressure 180 -190 bar

Hydraulic oil tank 22 l (5.8 GAL.)

Electrical System

- Operating voltage 12 VDC

- Battery 12 V / 88 Ah

- A/C alternator 14 V / 60 A

- Starter 12 V / 2.4 kW

3

/rev (42.5 l/min at 2500 engine rpm)

C 9700 ... C 9.88 H

Whole Vehicle

- Ambient temperature range - 30° to + 50°C

26 145 052

Page 28

Operating Instructions

C 9700 ... C 9.88 H

Technical data

Noise Level

The tractor emits the following noise level (measured at the

driver's ear) according to EU Standard 77/311/EEC;

measurement according to Appendix II.

Table of Noise Levels and Absorption Rating

Model Engine Type Engine Output Noise Level dB(A) Absorption rating

Cabin

open*

C 9700 BF4M1011 53.5 kW (72 HP) 79 78 2.1

C 9700 H BF4M1011 53.5 kW (72 HP) 79 78 2.1

C 9800 H BF4M1011F 61 kW (83 HP) 79 78 2.1

C 9.72 BF4M1011 53.5 kW (72 HP) 79 78 2.1

C 9.72 H BF4M1011 53.5 kW (72 HP) 79 78 2.1

C 9.83 H BF4M1011F 61 kW (83 HP) 79 79 2.1

C 9.78 H BF4M2011 57 kW (78 HP) 79 79 1.8

C 9.88 H BF4M2011F 65 kW (88 HP) 79 79 2.0

*Roof vent and side window open

Cabin

closed

Exhaust Gas Identification

The absorption rating is stated on the identification plate.

145 052 27

Page 29

Description

Views of Tractor

Operating Instructions

1

2

C 9700 ... C 9.88 H

3

4

5

Front Left View

1 Turn signal, position

light

2 Headlight, top

3 Driver's cab

4 Dump body (dump)

5 Rear of vehicle

6 Engine oil dipstick

7 Battery isolating switch

8 Rear axle

9 Hydraulic oil tank and

filler neck (drive

hydraulics)

10 Front axle

11 Hydraulic couplings for

implements*

12 Front lift - lower link

support

13 Upper link support

14 Headlight

15 Windshieldwiper /

washer

* Option

28 145 052

15

14

13

12

11

10

9

8

6

7

Page 30

C 9700 ... C 9.88 H

Tractor

Rear Right View

1 Dump Body

2 Fuel filler neck

3 Oil filler neck

for implement hydraulics

4 Intake screen

for fresh air blower

5 Support for

rotating beacon

6 Flood light*

7 Driver's cab

8 Front part of tractor

9 Front axle

10 Intake screen for drive

oil cooler

11 Air vent for drive oil

cooler

12 Oil level gauge for

implement hydraulics

and steering

13 Rear axle

14 Hydraulic couplings for

implements*

15 Trailer hitch

16 Socket for trailer lighting

17 Tail light, LH/RH

17

16

15

Operating Instructions

1

5

432

Description

6

7

8

* Option

145 052 29

14

13

12

11

10

9

Bild_002

Page 31

Description

Driver's Station

Operating controls

Operating Instructions

C 9700 ... C 9.88 H

1 Light switch

2 Differential lock switch

3 Pressure gauge for hydraulic carrier*

4 Steering wheel

5 Brake fluid reservoir

6 Control lever for dump support*

7 Implement* control lever

8 Multi-function display

9 Multi-function lever* (front lift and direction of travel)

10 Digital instrument switch (ground speed in km/h or

PTO rpm)

11 Hazard warning flasher switch

12 Heater fan switch

13 Power Socket

14 Implement lock switch*

30 145 052

15 Tilt lock switch*

16 Preheat/starter switch

17 Hydraulic carrier* control

18 Passenger seat

(water reservoir for windshield washer system is

located under the seat)

19 Parking brake lever

20 Driver's seat

(warning triangle is mounted behind the seat)

21 Accelerator pedal

22 Steering wheel tilt adjustment knob

23 Driving program switch

24 Inch knob for ground speed

25 Turn signal lever

* Option

Page 32

C 9700 ... C 9.88 H

Operating Instructions

Description

25

24

23

22

21

1

2

4

3

5

6

8

7

9 10

11

12

13

14

15

16

17

18

20

145 052 31

19

Page 33

Operating Instructions

Description

Implement* and Engine Controls (Details)

1 Control lever for dump/rear lift*

2 Control lever functions plate

3 Multi-function lever functions plate

4 Multi-function lever* (front lift and travel direction)

5 Hand throttle

- Outer ring for fine adjustment:

Turn clockwise to decrease rpm

Turn counter-clockwise to increase rpm

- Inner knob for coarse adjustment:

Pull out to increase rpm

Push in to decrease rpm

Push in fast for emergency reset to idling rpm

6 Preheat/starter switch

7 Lock knob for longitudinal motion of multi-function

lever:

- Depressed - locked

- Centre position - free movement

- Pulled out - float position

8 Lock knob for lateral motion of multi-function lever

9 Lock knob for longitudinal motion of control lever

10 Lock knob functions plate

1

10

C 9700 ... C 9.88 H

2

9

3

8

7

4

56

Bild_004

* Option

32 145 052

Page 34

C 9700 ... C 9.88 H

Multi-function Lever

NOTE

Various types of multi-function levers can be

installed.

Multi-function Lever (Variant 1)

1 Multi-function lever without forward reverse selector

lever (Forward-reverse selector installed on instrument board)

Operating Instructions

Description

1

Bild_193

2 Forward/reverse selector lever

3 Note plate

Driving direction

2

3

145 052 33

Page 35

Operating Instructions

Description

Multi-function Lever* (Variant 2)

NOTE

The coloured buttons control the function of the

implements attached to the related hydraulic couplings

C 9700 ... C 9.88 H

5

6

7

1 Multi-function lever

2 Blue hydraulic couplings on

3 Blue hydraulic couplings off - float position

4 LED indicator, red or green

5 Functions off

6 LED indicator, red

7 Functions on

8 LED indicator, red

9 LED indicator, red or green

10 Yellow hydraulic couplings, off

11 Green hydraulic couplings off - float position

12 Green hydraulic couplings on

13 Yellow hydraulic couplings on

4

blue yellow

green

3

2

1

* Option

34 145 052

Bild_020

8

9

10

11

12

13

Page 36

C 9700 ... C 9.88 H

Multi-function Lever* (Variant 3)

1 Forward direction arrow (illuminated if selected)

2 Reverse direction arrow (illuminated if selected)

3 Forward/reverse selector switch (left for forward -

right for reverse)

4 Multi-function lever

Multi-function Lever* (Variant 4)

1 Forward direction arrow (illuminated if selected)

2 Reverse direction arrow (illuminated if selected)

3 Forward/reverse selector switch (left forward - right

reverse)

4 Front lift float position pushbutton

5 Multi-function lever

6 Front lift pushbutton

7 Yellow pushbutton, left (front when looking forward)

(movements at yellow hydraulic couplings on)

8 Yellow pushbutton, right (front when looking forward)

(movements at green hydraulic couplings on)

Operating Instructions

1

Bild_068

6

Description

2

3

4

2

1

Bild_021

3

4

* Option

145 052 35

8

7

5

Page 37

Operating Instructions

Description

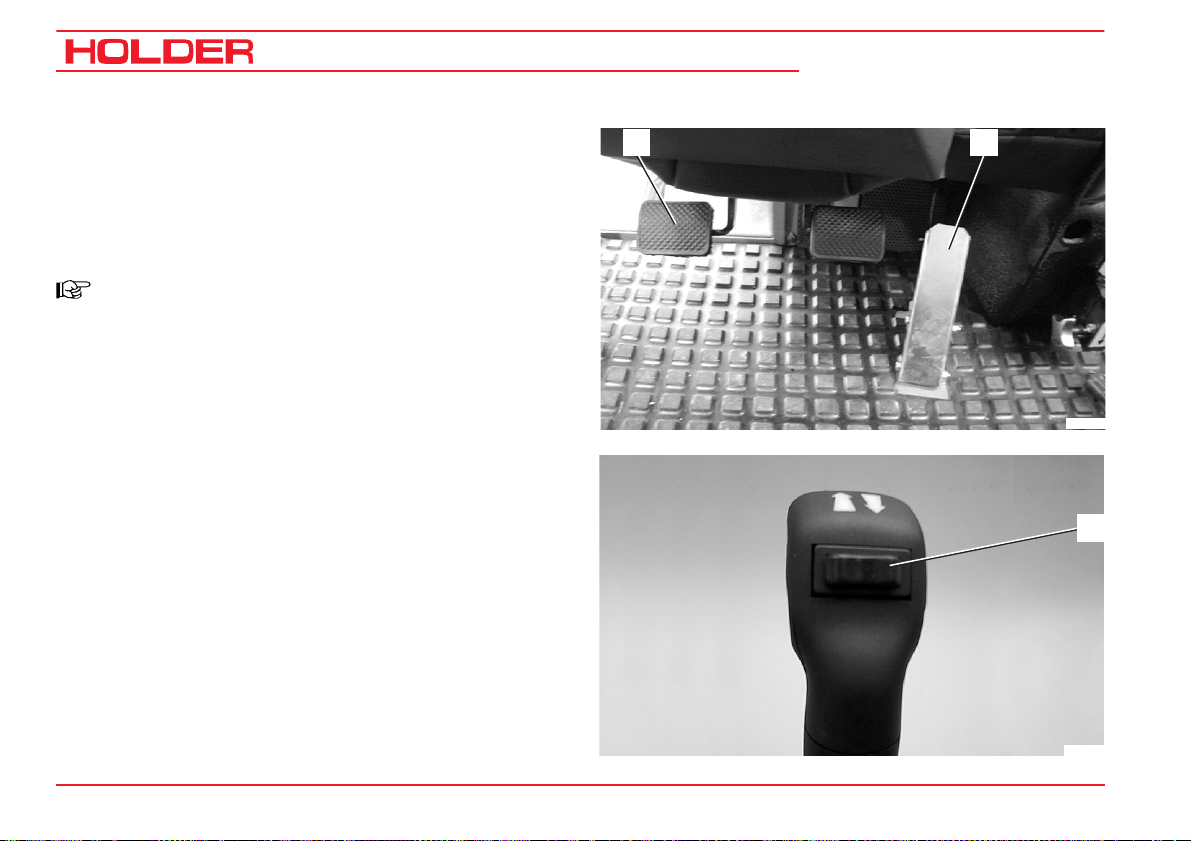

Foot Pedals

1 Inch pedal (clutch pedal if gearbox is fitted)

2 Brake pedal

3 Accelerator pedal

C 9700 ... C 9.88 H

1

2

3

Bild_005

Hydraulic Carrier* Control (Power Lifter)

1 Pressure adjuster

2 ON-OFF label

3 Star knob for turning on/off

* Option

36 145 052

3

1

2

Page 38

C 9700 ... C 9.88 H

Operating Controls Behind the Seat

1 PTO clutch lever, ON-OFF

2 Device selector lever:

- Position for dump on

3 - Position for rear lift on

4 Emergency start

(Hydrostatic Drive with Dual-Drive only)

Drive Range Pre-selection Lever between Seats

1 Drive range pre-selection lever

2 Drive range label

- Position S - Fast Driving range

(low tractive force)

- Centre position 0 - Drive off - Towing

- Position L - Slow Working range

(high tractive force)

Operating Instructions

Description

1

2

4 3

1

Bild_069

145 052 37

Page 39

Operating Instructions

Taking into Service

Front PTO Selector

1 PTO rpm label

- Top position (up) - 540 rpm

- Centre position - Neutral

- Lower position (down) - 1000 rpm

2 PTO selector lever

C 9700 ... C 9.88 H

1

2

Heater

1 Heater temperature control

2 Heating temperature label

- lever up - warmer

- lever down - cooler

2

38 145 052

1

Bild_009

Page 40

C 9700 ... C 9.88 H

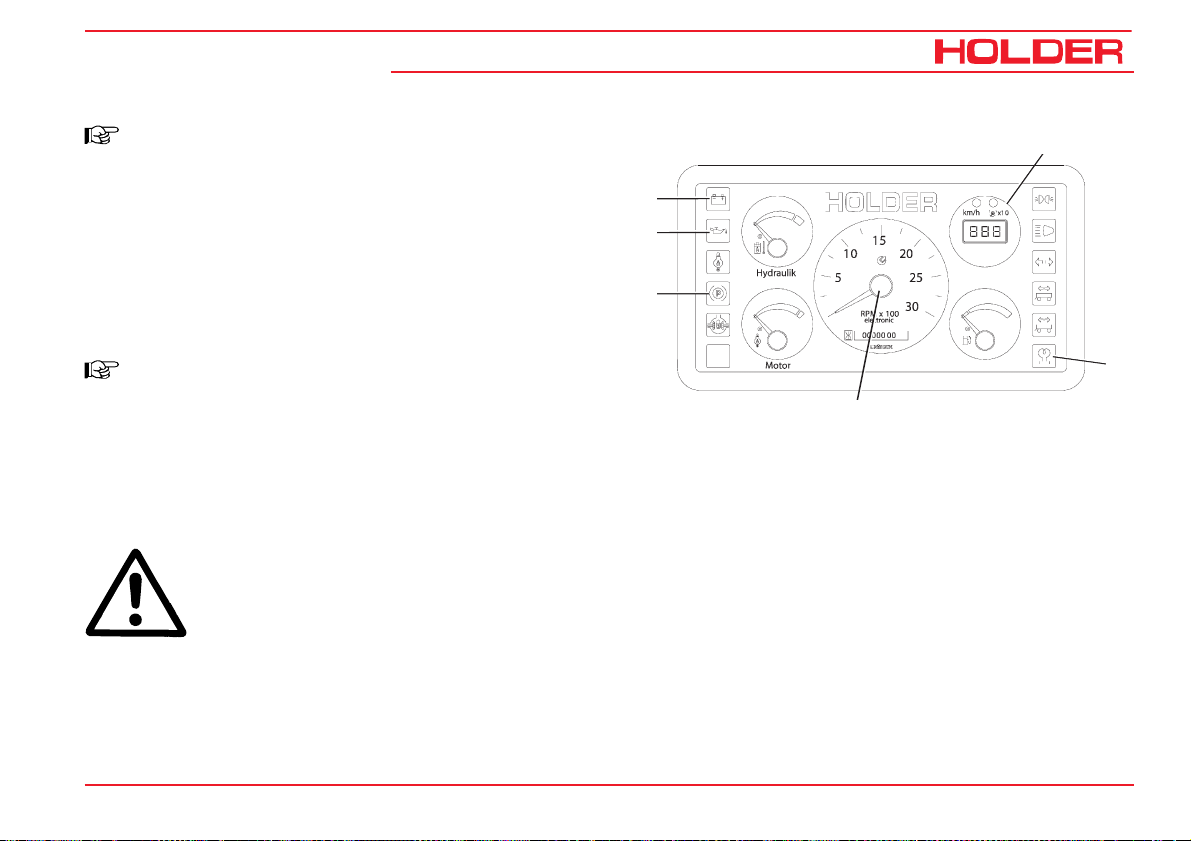

Legend for Multi-function

Display

1 Display for

- Ground speed in km/h or

- PTO rpm x10

2 Position light indicator

3 High beam indicator

4 Turn signal indicator

5 Turn signal indicator

for trailer 1

6 Turn signal indicator

for trailer 2

7 Preheating indicator

8 Fuel gauge

9 Hour meter

10 Tachometer

11 Engine temperature gauge

12 Spare

13 Differential lock engaged

indicator

14 Parking brake engaged indicator

15 Engine oil temperature indicator

16 Engine oil pressure indicator

17 Battery charge indicator

18 Hydraulic oil temperature gauge

17

16

15

14

13

12

Operating Instructions

18

Taking into Service

1

2

3

4

5

6

7

891011

145 052 39

Page 41

Operating Instructions

6

Description

Controls for Mechanical Gearbox

1 Gearshift lever (left looking forward) with 4 synchroni-

zed gears 1-2-3-4

2 Range selector lever (right looking forward)

with 4 speed ranges:

S - Highway driving

M - Medium speed

L- Slow speed

LL - Very slow speed

3 Gearshift label

C 9700 ... C 9.88 H

1

2

Bild_17

21

3

40 145 052

Bild_017

Page 42

C 9700 ... C 9.88 H

3

Controls on Cabin Console at Front Left

1 Front wiper/washer switch

2 Rear wiper/washer switch

3 Sun blind

4 Air vent nozzle

Operating Instructions

1

4

2

Description

3

Controls on Cabin Console at Front Right

1 Rotating beacon switch

2 Fresh air blower switch, top

3 Headlight switch, top

4 Rear floodlight switch

5 Air vent nozzle

145 052 41

1

2

3

4

5

Bild_01

Page 43

Description

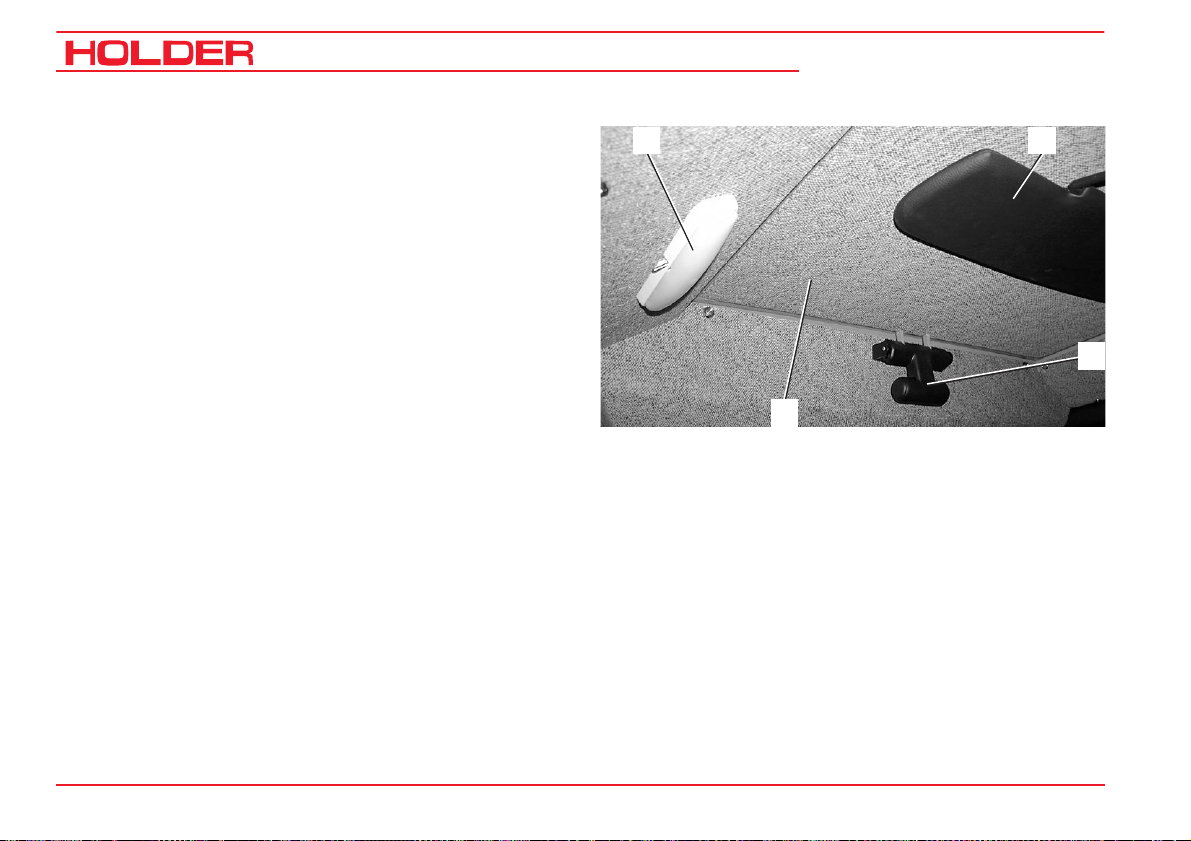

Controls in Cabin at Rear

1 Interior light

2 Sun visor

3 Roof hatch handle

4 Roof hatch

Operating Instructions

C 9700 ... C 9.88 H

1

4

2

3

42 145 052

Page 44

C 9700 ... C 9.88 H

Location of Plates and

Labels

Identification Plates

Operating Instructions

Description

1 Variable motor type plate

2 Engine type plate

3 Variable pump type plate

4 Machine type plate

5 Chassis Serial Number

(on front RH support

looking forward)

6 Cabin type plate

6

1

2

5

4

145 052 43

3

Bild_098

Page 45

Operating Instructions

Description

Mounting Instructions for License Plate

- Install the front license plate (1) above the upper link

support at the front cabin wall.

- Install the rear license plate (2) at the rear below the

left tail light.

C 9700 ... C 9.88 H

2

44 145 052

Page 46

Operating Instructions

C 9700 ... C 9.88 H

Description

Overview of Options and Variants

Assembly Suppl. Information Dimension /Order No./Type

Charcoal filter For cabin ventilation 131667

Pneumatic braking system For trailer operation 526-34-60, 524-34-63

Rear lift 524-51-4

Oil heating element from - 20°C 230 VAC

Hydraulic carrying equipment (power lifter) 524-80-19

Creep speed gearbox with hand lever

Variable pump for implements 0-100 l /min adjustable 524-80-34

- Pump

- Delivery capacity 0-40 cm³/rev

- Flow rate 0-100 l/min

- Maximum pressure 280 bar

Super

For mechanical gearbox only

5262-11, 524-62-70

145 052 45

Page 47

Operating Instructions

C 9700 ... C 9.88 H

Description

Assembly Suppl. Information Dimension /Order No./Type

Power hydraulics 75 l/min fixed displacement 524-80-35

- Pump Mounted on drive pump Gear pump

- Delivery capacity 22 cm³/rev

- Flow rate 75 l/min

- Maximum pressure 210 bar

Flow divider I. Circuit 524-80-25

- Pump Standard pump

- Delivery capacity 17 cm³/rev

- Flow rate 0-25 l/min

- Maximum pressure 200 bar

Flow divider II. Circuit 524-80-47

- Pump Tandem pump

- Delivery capacity 14 cm³/rev

- Flow rate 0-25 l/min

- Maximum pressure 200 bar

46 145 052

Page 48

Operating Instructions

C 9700 ... C 9.88 H

Description

Assembly Suppl. Information Dimension /Order No./Type

Circulating oil device rear, uncontrolled 524-80-45

- Pump Tandem pump

- Delivery capacity 14 cm³/rev

- Flow rate 35 l/min

- Maximum pressure 200 bar

Reduction gearbox

Reduction of rear PTO rpm to

540 rpm

526-62-1

145 052 47

Page 49

Operating Instructions

Description

Accessories

The tractor is delivered with the following accessories:

1 Operating Instructions

2 Bio-Pass for certification of filling with environment-

friendly hydraulic oil

3 Key holder

4 2 ignition keys

5 4 door keys

6 Upper link

7 2 reducers for category II implements

C 9700 ... C 9.88 H

1

2

4

5

3

6

7

48 145 052

Page 50

C 9700 ... C 9.88 H

Operating Instructions

Taking into Service

Daily Checks and Activities before Taking

into Service

If damages or defects are found during the following checks,

they must be eliminated before taking the vehicle into

service. Do not operate the tractor before proper repairs are

carried out. Safety and protective devices should not be

removed or disabled. Fixed specified settings may not be

changed.

Before starting work, make yourself familiar with all the

functions and protective devices of the tractor.

Checking and Cleaning the Cooler and Radiator

Screen Guards

NOTE

- Check if the mud guards (2, 3, 4, 5 and 6)

are clean.

- Clean the mud guards if necessary. The

guard (6) can be pulled out laterally to the

left after releasing the bayonet screw (7)

and then cleaned easily.

- The air intake of the air filter (1) must be

clean.

1 2

6

5

34

6

7

Bild_071

145 052 49

Page 51

Operating Instructions

Taking into Service

Turning on the Battery Isolating Switch

NOTE

The battery can be switched off completely

with the removable key.

- Insert the key (1) in the battery isolating switch and

set it to the vertical position.

The battery circuit is turned on.

Checking Engine Oil Level

NOTE

Check the engine oil level only when the

tractor is on level ground.

C 9700 ... C 9.88 H

1

Bild_022

- Let the engine run approx. 2 minutes with the heat

shut-off valve open.

- Stop the engine and pull the oil dipstick (1) out after

approx. 1 minute .

- The oil level should be between the Min (2) and Max

marking (3).

- If necessary, fill oil according to the maintenance

manual.

ATTENTION

Do not fill too much oil.

50 145 052

1

3

2

Page 52

Operating Instructions

C 9700 ... C 9.88 H

Checking the Trailer Hitch (Optional), if required

- Check the trailer hitch for proper condition and wor-

king. Carry out the check according to the instructions

in the section "Operating the Trailer Hitch".

Checking Tire Inflation Pressure

NOTE

Your tractor can be equipped with different

types of tires. The specified inflation pressure

for your tires is given in the table entitled

"Tires" in the technical data section.

- Check the inflation pressure of all four tires. All tires must

have the same pressure. If the pressure is too low, the

rolling resistance increases. This causes an increase in

fuel consumption and tire wear, the driving characteristics

become poorer.

DANGER

If the inflation pressure is too high, the tires

can explode.

Taking into Service

- The tires should not be damaged or worn.

- Have damaged tires replaced without delay. Due to the

longer braking distance the risk of an accident is increased.

145 052 51

Page 53

Operating Instructions

Taking into Service

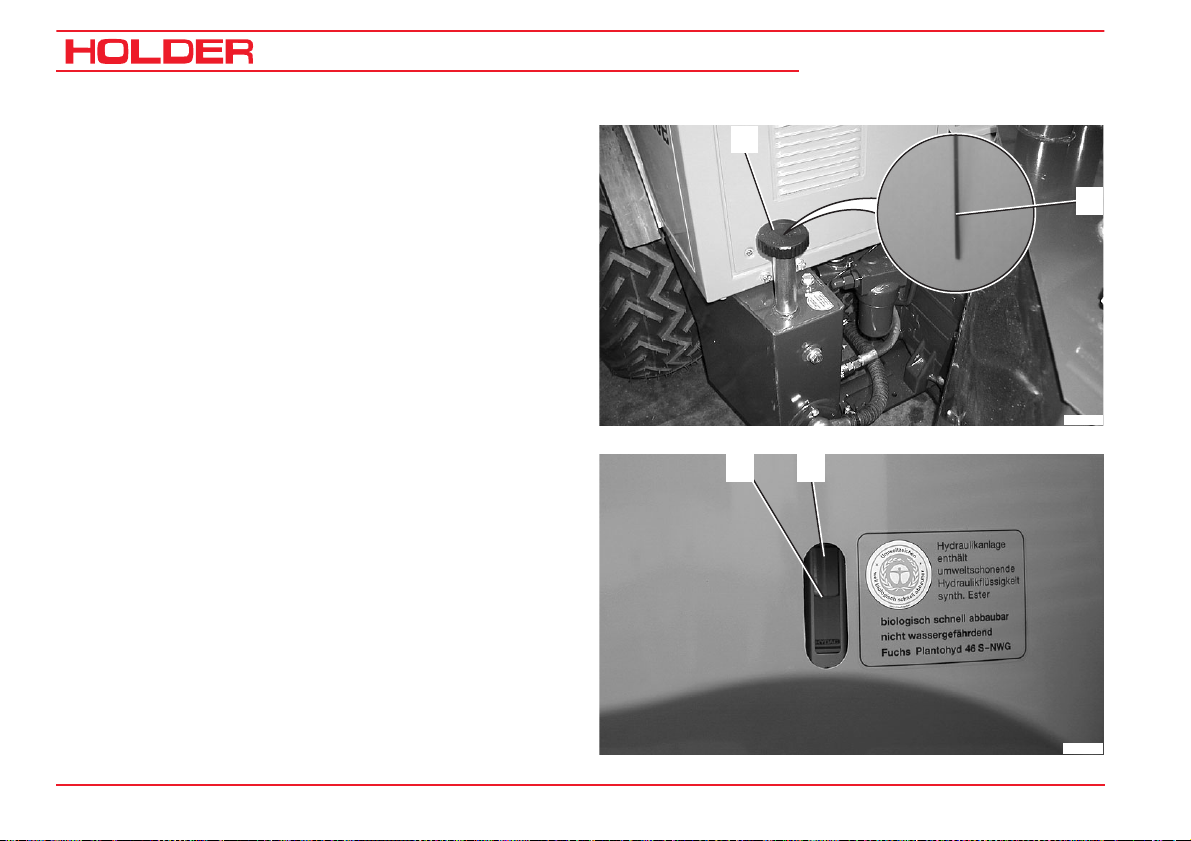

Checking the Drive Hydraulics Oil Level

- Withdraw the oil dipstick (1).

- The oil level must be at the marking (2).

- Top up oil as specified in the maintenance manual.

C 9700 ... C 9.88 H

1

2

Bild_026

Checking the Implement Hydraulics Oil Level

- Retract all hydraulic cylinders.

- Check the oil level at the sight glass (2).

The oil level must be at the centre (1) of the sight

glass.

- Top up oil as specified in the maintenance manual.

52 145 052

1

2

Bild_027

Page 54

C 9700 ... C 9.88 H

Filling Fuel

- If necessary, read the fuel level (1) on the multi-

function display.

CAUTION

Danger of fire when handling fuels. Turn off

the engine. Do not fill any fuels in the vicinity

of naked flames, ignition sparks or hot engine

parts. Do not smoke during refuelling.

- Remove the fuel tank filler cap (2).

- Top up Diesel fuel as specified in the maintenance

manual.

Operating Instructions

Taking into Service

1

Bild_073

Filling quantities ............approx. 86 litres (22.7 USGAL.)

- Refit the filler cap (2).

145 052 53

2

Bild_028

Page 55

Operating Instructions

Taking into Service

Checking the Brake Fluid Level

- Check the brake fluid level at the brake fluid reservoir

(2).

- The brake fluid level must be between the Min and

Max marking at the reservoir.

- Top up the brake fluid as specified in the maintenance

manual.

Adjusting the Steering Wheel

NOTE

The tilt of the steering wheel can be set to a

comfortable position.

DANGER

Do not adjust the steering wheel while driving.

- Loosen the star knob (3).

- Pull the slider (4) to the right.

- Adjust the tilt of the steering wheel (1) and release the

slider again.

- Retighten the star knob.

C 9700 ... C 9.88 H

1 2

34

54 145 052

Page 56

C 9700 ... C 9.88 H

Adjusting the Driver's Seat

1 Backrest

2 Adjustment knob for lumbar padding

3 Backrest adjustment

4 Weight adjustment

5 Horizontal cushioning

6 Horizontal adjustment

DANGER

Do not adjust the seat while driving. Risk of

accidents!

- Adjust the seat so that all controls can be reached

and operated safely.

NOTE

Observe the operating manual for the seat

supplied with your tractor.

Operating Instructions

Taking into Service

1

Bild_010

2

456

3

Adjusting the Lumbar Padding

- Sit down on the seat and lean against the backrest

(1).

- Turn the adjustment knob for lumbar padding (2) until

the most comfortable position is reached.

145 052 55

Adjusting the Backrest

- Pull the tilt lever (3) up.

- Adjust the inclination of the backrest with your back.

- Release the tilt lever.

Page 57

Operating Instructions

Taking into Service

Adjusting the Driver's Weight

- Sit down on the driver's seat.

- Pull the weight adjustment handle (4) up.

NOTE

An alert sounds. The seat is automatically

set to the weight of the driver; The alert

ceases.

- Release the lever.

Adjusting the Horizontal Suspension

- Push the horizontal suspension lever (5) back:

the seat suspension is unlocked in horizontal direction.

- Move the horizontal suspension lever (4) forward: the

seat suspension is locked in the horizontal direction.

Adjusting the Seat Horizontally

- Pull the horizontal adjustment lever (6) up.

- Slide the seat horizontally forward or rear to the

suitable seat position.

- Release the horizontal adjustment lever.

Bild_010

C 9700 ... C 9.88 H

1

456

2

3

56 145 052

Page 58

C 9700 ... C 9.88 H

Adjusting the Passenger Seat

1 Backrest

2 Weight adjustment

3 Horizontal adjustment lever

4 Backrest tilt adjustment

Adjusting the Weight

- Sit down on the seat.

- Press the weight adjustment knob (2) from the top

down until the weight is reached on the scale; The

weight can be adjusted in 9 stages of 50 to 130 kg.

- Release the knob when your weight is indicated.

NOTE

Only push the knob from the top down.

- At the bottom press the knob against the stop - the

weigh adjuster automatically resets the seat to 50 kg.

- Release the knob.

Adjusting the Seat Horizontally

- Pull the horizontal adjustment lever (3) up.

- Slide the seat horizontally forward or rear to the

suitable seat position.

- Release the horizontal adjustment lever.

Adjusting the Backrest Horizontally

- Pull the tilt lever (4) up.

- Adjust the inclination of the backrest with your back.

- Release the tilt lever.

Operating Instructions

Taking into Service

1

2

4

3

145 052 57

Page 59

Operating Instructions

Taking into Service

Filling Washing Water

NOTE

The washing water reservoir for the windshield

washer is located beneath the passenger

seat.

- Tilt the seat forward.

- Open the filler cap (1) and add washing water into the

reservoir (2).

Filling capacity ............approx. 2.5 litres (0.66 USGAL.)

Checking the Lights and Rear View Mirror

- Check that the lighting is functioning properly. Carry

out the check according to the instructions in the

section entitled "Lights".

- Adjust the rear view mirror so that the roadway behind

the tractor and the working area are easily seen.

C 9700 ... C 9.88 H

1

2

58 145 052

Page 60

C 9700 ... C 9.88 H

Operating Instructions

Taking into Service

Starting the Engine

Instructions before Starting the Engine

DANGER

Do not start or run the engine in enclosed

spaces. Danger of poisoning through exhaust

gases!

Instructions before Starting

CAUTION

Before starting, check to ensure no one is in

the vicinity of the tractor.

ATTENTION

Do not use a starting aid such as Startpilot

or similar means. Turn off the drive or driven

attaching implements.

CAUTION

Start the engine only from the driver's station.

145 052 59

Page 61

Operating Instructions

Taking into Service

Starting the Engine

- Shift the gearshift lever (gearbox) to neutral.

- Set the forward/reverse selector lever (1) to the

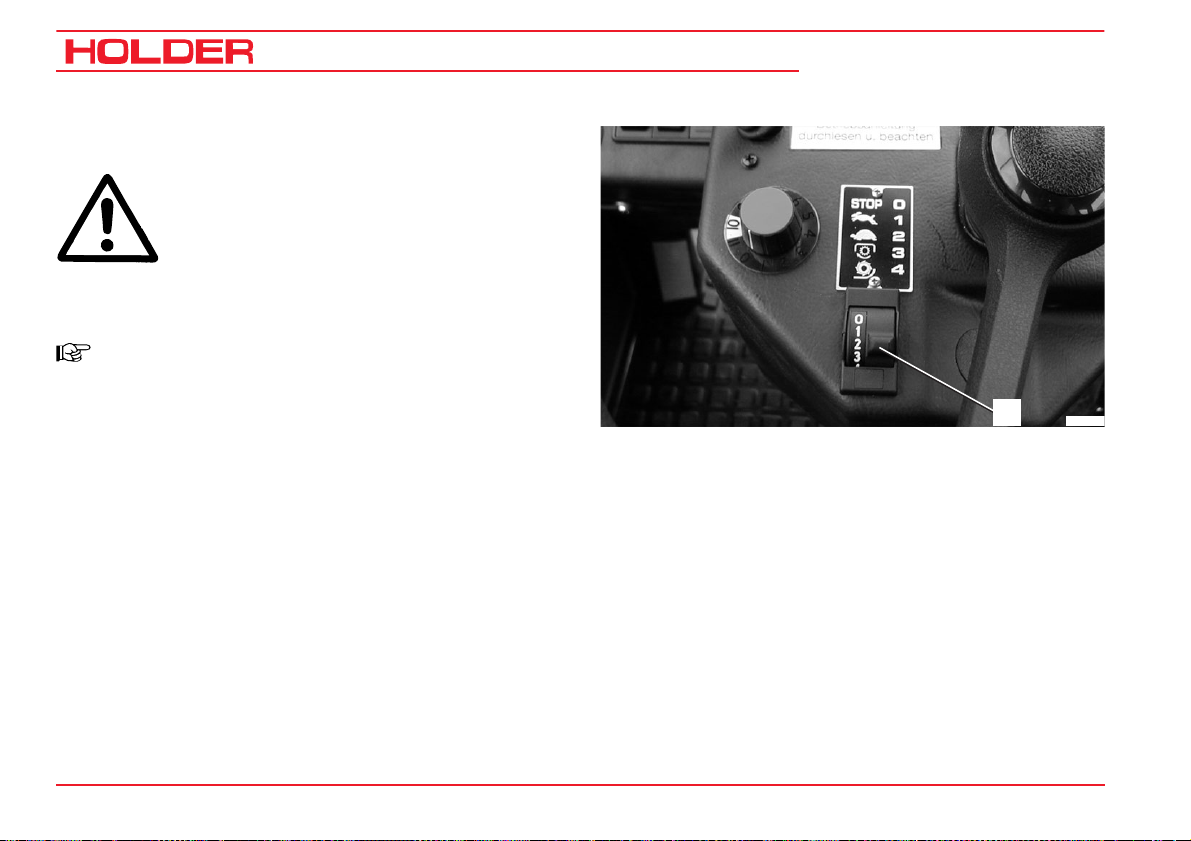

neutral position (centre).

- Depress the clutch pedal (gearbox) or inch pedal

(hydrostatic drive).

NOTE

The engine can only be started if the pedal is

fully depressed (starting safety switch).

- Set the hand throttle (2) to idle (push in fully).

- Insert the ignition key and turn the preheat/starter

switch (3) to position 1.

C 9700 ... C 9.88 H

1

1

Bild_180

3

60 145 052

2

Bild_113

Page 62

C 9700 ... C 9.88 H

NOTE

The battery charge indicator (8), engine oil

pressure indicator (7), parking brake indicator(6) (if parking brake is engaged) and the

red indicator for km/h or x10 (3) in the multifunction display come on.

Operating Instructions

Taking into Service

3

8

7

- Turn the ignition key to position 2 to preheat the

engine. The preheating indicator (4) comes on.

NOTE

When starting at low temperatures, hold the

ignition key longer (approx. 1 minute) in position

2.

- When the preheating indicator goes out, turn the

ignition key to position 3 to start the engine.

ATTENTION

Operate the starter for a maximum of 20 seconds. Wait one minute, then repeat the starting procedure. Repeat the starting procedure

only twice at most. In case the engine does

not start, carry out a troubleshooting according to the section entitled "Problems, Causes,

Remedy".

145 052 61

6

4

5

Bild_033

Page 63

Operating Instructions

Taking into Service

- Release the ignition key as soon as the engine turns

over. The battery charge indicator (8) and the engine oil

pressure indicator (7) will go out.

- Set the engine speed with the hand throttle (1) or

accelerator pedal to the desired RPM (5) .

C 9700 ... C 9.88 H

3

8

7

6

4

5

Checking the Brakes and Steering for Proper Operation

- Make a short trial run and check the steering and

brakes for proper operation.

DANGER

Do not drive a tractor with a defective steering

and/or braking system.

1

62 145 052

Bild_033

Bild_032

Page 64

C 9700 ... C 9.88 H

Operation

Before Starting to Drive

Operating Instructions

When driving on public highways, observe the regulations

of the highway code.

Driving Safety Rules

• Drive the tractor only from the driver's station with the

cab doors closed.

• Always adjust your speed to the driving conditions

and the load you are carrying.

• Never drive downhill without having the tractor in gear

or with the engine stopped.

• Before driving, check that no-one is standing in the

immediate vicinity of the vehicle.

• The driving behaviour of the tractor is strongly affec-

ted by the weight and swing range of the implements,

trailers and, if fitted, ballasting. Therefore drive slowly

with heavy equipment and take the longer braking

distance into consideration.

145 052 63

• When following a curve with a trailer or other attachments, don't forget to take the added length and drag into

consideration.

DANGER

Parts of implements posing a danger to traffic

must be covered before driving or identified

with warning signs.

• Switch off the differential lock when travelling along a

curve.

• When driving on slopes, drive downhill if possible; if

you have to turn, turn only when driving uphill.

• On steep slopes you can improve traction by activating the differential lock.

• Drive across slopes only in accordance with the notes

at the end of this chapter.

Page 65

Operating Instructions

Operation

Driving

Driving with Hydrostatic Drive and Digital Electronics

- Start the engine.

- Select the direction of travel with the forward/reverse

selector lever (3) (forward left or reverse right).

- The direction arrow for forward (1) or reverse (2) travel

comes on.

NOTE

After starting the engine, the forward/reverse

selector lever must be operated once if it was

in the forward or reverse position when starting.

This prevents any accidental movement of the

tractor when starting the engine.

NOTE

You can also select the new direction while

travelling at reduced speed.

CAUTION

The tractor will brake strongly and accelerate

in the opposite direction.

- Set the drive range pre-selection lever (4) (between

the seats) to the desired driving range:

ATTENTION

This must only be done when the tractor is

stationary.

1 2

C 9700 ... C 9.88 H

3

3

Bild_181

4

Bild_108

64 145 052

Page 66

Operating Instructions

C 9700 ... C 9.88 H

Operation

Table of Driving Ranges

Position Symbol Function Travel Speed* Use

Top position S Fast speed 0 - 30 / 36 km/h Low tractive force, eg for highway driving

Centre position 0 Drive off Towing

Bottom position L Slow speed 0 - 11.5 km/h

- Select the desired driving program at the driving

program switch (6). The selected position is illuminated:

You can select 4 programs:

Stage 1 and 2 programs eg road travel

Stage 3 and 4 programs eg working operation

* Depending upon the model

145 052 65

High tractive force, eg for working

operation or pulling trailers on gradients

5

6

Bild_075

Page 67

Operating Instructions

C 9700 ... C 9.88 H

Operation

Table of Driving Programs*

Position Symbol Function Use

Range 0 STOP Drive off

Range 1 Rabbit symbol Maximum speed eg for highway driving

Range 2 Turtle symbol Maximum speed eg for highway driving

Travel speed adjustable with fine adjustment

Range 3 PTO symbol

Range 4

* The driving programs can be optimised for special operations by your Service,

eg controlled constant driving speed

Snow blower

symbol

knob, is controlled automatically in case of high

power demand of implement

Travel speed adjustable with fine adjustment

knob, is controlled automatically in case of high

power demand of implement

eg for mowing

eg special setting for

snow blower

66 145 052

Page 68

C 9700 ... C 9.88 H

Selecting Road Speed (Transport Speed)

The tractor is stationary.

- Set the program switch (6) to range 1 or 2.

NOTE

The driving range can also be switched while

driving at reduced ground speed.

- Disengage the parking brake.

- Depress the accelerator pedal for the desired ground

speed.

The tractor starts driving and can be driven up to

maximum ground speed of the selected range.

- You can read the engine speed (8) and ground speed

(7) on the multi-function display.

Setting the Working Speed of Programs 3 and 4

NOTE

With programs 3 and 4 you can select the

ground speed independent of the PTO rpm.

Operating Instructions

5

Operation

6

Bild_075

7

8

145 052 67

Bild_076

Page 69

Operating Instructions

Operation

The tractor is stationary.

- Set the inch knob (5) to 0.

- Set the program switch (6) to range 3 or 4.

- Adjust the PTO rpm with the hand throttle.

NOTE

The engine speed must reach at least 1500 rpm

as the control is only effective beginning at this

speed. You can read the speed on the multifunction display.

NOTE

You can also switch ranges while driving.

C 9700 ... C 9.88 H

5

6

Bild_075

The ranges 3 and 4 provide a speed as required by the load

on the PTO.

This means that if, for example, the snow blower requires

more power when meeting high resistance, the tractor drives

more slowly. As the resistance decreases, the tractor accelerates again to the previously selected ground speed.

Driving range 4 is especially adapted for particular applications.

- Set the PTO clutch lever (7) fast to the vertical

position to engage the PTO.

- Disengage the parking brake.

68 145 052

7

Bild_077

Page 70

Operating Instructions

C 9700 ... C 9.88 H

Adjusting the Inch Knob

NOTE

While driving you can adjust the inch knob

(5) at any time for fine and infinitely variable

control of the ground speed.

- In position 0 the tractor is stationary. When turned

further clockwise, the tractor starts driving and at the

maximum scale position 11, the maximum ground

speed of the driving range is achieved.

- You can read the engine speed and ground speed at

the multi-function display.

NOTE

In this operating mode, the tractor drives

automatically and needs only to be steered.

This mode is best for operating an implement as you can

concentrate fully on controlling the implements.

Operation

5

6

Bild_075

145 052 69

Page 71

Operating Instructions

Operation

Operating the Inch Pedal

7 Inch pedal

8 Accelerator pedal

This function is active for all driving programs.

NOTE

The inch pedal allows driving speed to be

reduced temporarily.

- Depress the inch pedal (7) to reduce driving speed

and to stop completely.

- Release the inch pedal again behind the obstacle.

The tractor will resume the previously selected driving

speed.

C 9700 ... C 9.88 H

7

8

Bild_078

Changing the Direction of Travel

- Preselect the new direction with the forward/reverse

selector lever (9).

- The tractor will come to a standstill and accelerate

again in the opposite direction.

Bild_081

70 145 052

9

Page 72

C 9700 ... C 9.88 H

Driving with Hydrostatic Drive, Digital Electronics

and Dual Drive

- Set the drive range pre-selection lever (1) to "S".

The DUAL Drive will work only in this driving range.

Operating Instructions

Operation

1

Table of Driving Ranges with Dual Drive

Position Symbol Function Hydrostatic Speed* DUAL Drive Speed* Use

Top position S Fast range 0 - 30 / 36 km/h 0 - 30 / 42 km/h

Centre position 0 Drive off For towing

Bottom position L Slow range

* Depending on the version

145 052 71

0 - 11.5 km/h/ 14.5

km/h

-

Low tractive force,

eg for road travel

High tractive force, eg

for working or pulling

trailers on gradients

Bild_069

Page 73

Operating Instructions

Operation

- Set the program switch (2) to driving range 2.

ATTENTION

Drive the tractor warm for approx. 10-12 min.

at driving range 2.

- Set the program switch to driving range 1.

NOTE

The functions of the drive are same except

for the overdrive:

When the driving speed* exceeds 25 km/h,

the transmission automatically shifts from the

hydrostatic drive to the mechanical gear.

If the driving speed drops again, the

transmission shifts back to the hydrostatic

drive.

C 9700 ... C 9.88 H

2

Bild_192

* Depending on the version

72 145 052

Page 74

C 9700 ... C 9.88 H

Driving with the Mechanical Gearbox

- Set the gearshift lever to the neutral position.

- Start the engine.

- Select the direction of travel with the forward/reverse

selector lever (1) (forward or reverse). The indicator

will flash green (forward or reverse).

- Fully depress the clutch pedal (2) (buzzer sounds

until shifting is completed). The indicator is now

illuminated green.

Operating Instructions

1

2

Operation

3

Bild_079

- Shift the gearshift lever (4) left (looking forward) into

the desired gear.

4 gears 1-2-3-4 are available.

- Shift the range selector lever (5) right (looking forward)

in the desired speed range.

4 speed ranges are available:

S - Fast

M - Medium

L - Slow

LL - Very slow

145 052 73

4

5

Bild_082

Page 75

Operating Instructions

Operation

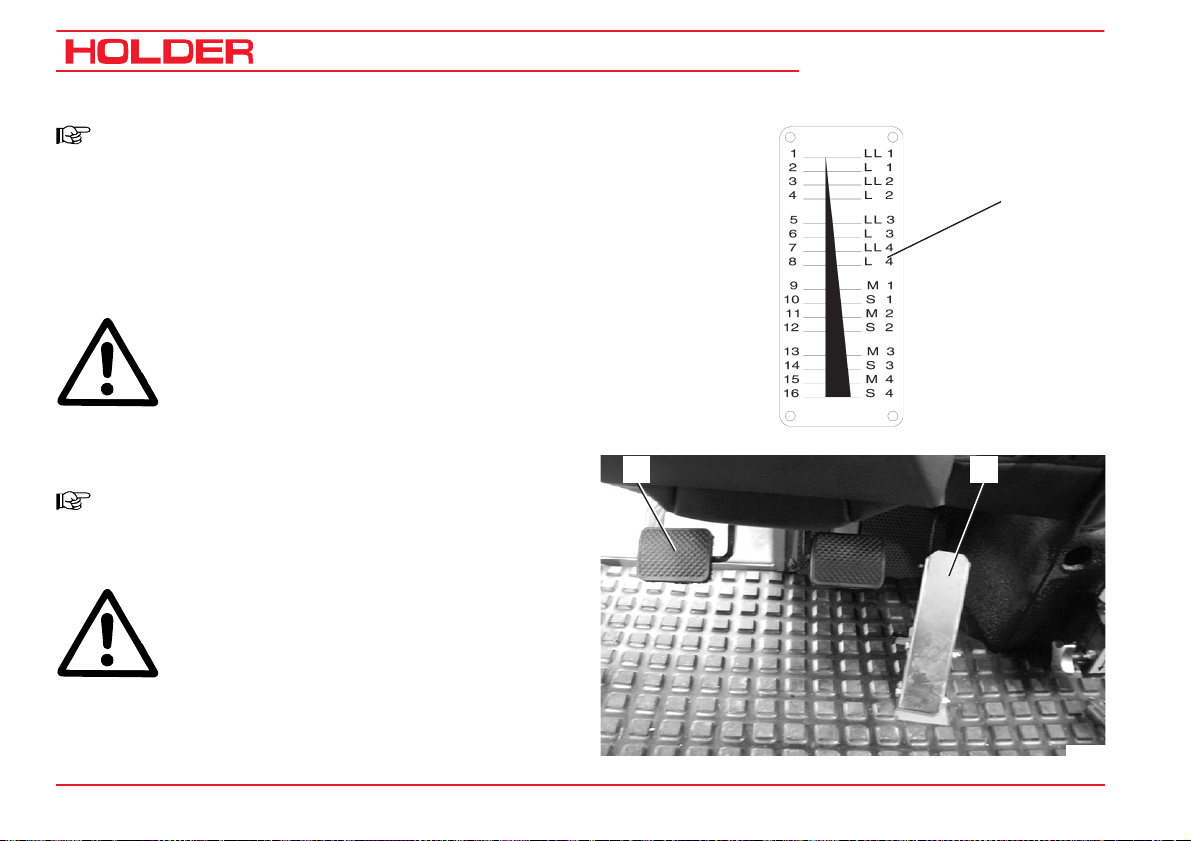

NOTE

The label (4) shows the possible shift

combinations. You have a total of 16 gears

available, both for forward and for reverse

travel.

- Release the clutch pedal (5) to start driving.

ATTENTION

Do not keep the foot on the clutch pedal when

driving.

C 9700 ... C 9.88 H

4

- Control the driving speed with the accelerator pedal

(6) or the hand throttle.

5

NOTE

The attainable driving speeds can be read in

the table in the technical data section.

ATTENTION

When downshifting, the driving speed must

be reduced and lie in the area of the low speed

range. As the transmission is synchronized,

you do not have to give gas when

downshifting.

74 145 052

6

Bild_083

Bild_109

Page 76

C 9700 ... C 9.88 H

Changing the Direction of Travel

ATTENTION

The direction of travel can be changed when

driving slowly.

- To change the driving direction from forward to

reverse, the forward/reverse selector lever (1) must

be pulled back.

- The indicator (3) flashes green and shows the selec-

ted direction of travel.

- As soon as the clutch pedal is fully depressed, a

buzzer sounds until shifting is completed. Then the

indicator (3) is steadily illuminated green.

- Release the clutch pedal to drive in reverse.

NOTE

When working, we recommend preselection

of the direction of travel while driving.

ATTENTION

If the clutch pedal is released before the

shifting is completed, the mechanical gear

shifts into neutral (0). Both arrows are flashing

(2 and 3).

- Depress the clutch pedal again.

The green indicator is on steadily, shifting is completed.

Operating Instructions

Operation

1

2

3

Bild_182

145 052 75

Page 77

Operating Instructions

Operation

Engaging the Differential Lock

NOTE

With the differential lock you can improve

traction on soft , slippery ground. The lock is

engaged when the engine speed is over 1000

rpm. You can keep the differential lock

engaged steadily and also only briefly by

toggling the switch momentarily.

ATTENTION

The differential lock may only be used when

driving straight.

- Toggle the differential lock switch (1) down and hold

it.

The indicator (2) in the multi-function display comes

on red. An intermittent alert sounds at the same time.

The differentials of both axles are locked and power is

transferred to all 4 wheels equally.

- Toggle the differential lock switch (1) up. The switch

remains on until you return it to the middle position

again.

C 9700 ... C 9.88 H

1

Bild_085

2

Disengaging the Differential Lock

- Return the differential lock switch (1) to the middle

position. The differentials are in operation again.

The indicator (2) goes out and the alert in the multifunction display ceases.

76 145 052

Bild_084

Page 78

Operating Instructions

C 9700 ... C 9.88 H

Steering

The articulated steering is operated hydraulically. The wheels

also stay in track in curves, so that implements are guided

without any lateral offset.

Steering

- Turn the steering wheel (1) in the desired direction.

The possible turning radii depend on the tires and track widths

of your tractor. For exact information refer to the track width

table in the section "Technical Data".

Braking

The service brake is a wet disc brake mounted in the front

axle. It is operated hydraulically and acts on all four wheels.

The parking brake is mechanical and operated with the

parking brake lever.

Operating the Service Brake

ATTENTION

The engine can stall if you brake too hard in

the mechanical gear.

Operation

1

2

- Depress the brake pedal (2).

NOTE

If the mechanical gearbox is fitted, the clutch

pedal must also be operated.

145 052 77

Bild_035

Page 79

Operating Instructions

Operation

Engaging the Parking Brake

ATTENTION

The parking brake is not intended to be used

for braking while driving.

- Pull the parking brake lever (2) up.

The parking brake is engaged, the parking brake

indicator (3) in the multi-function display comes on

red.

Disengaging the Parking Brake

- Pull on the parking brake lever (2) slightly. While

depressing the release button (1) in the lever, push

the lever downwards.

The parking brake is disengaged, the parking brake

indicator goes out.

ATTENTION

An alert is sounded when driving with the

parking brake applied.

C 9700 ... C 9.88 H

1 2

3

Bild_086

78 145 052

Page 80

Operating Instructions

C 9700 ... C 9.88 H

Driving on Slopes

DANGER

Driving on slopes is dangerous as the tractor

can tip over if the centre of gravity exceeds

the tip-over limit on an extreme slope.

The following factors reduce the hazard:

- small or no load

- low ground speed

- low gradient

- low tire inflation pressure

NOTE

The driving comfort and the traction of the

tractor can be improved by reducing the