Page 1

DECLARATION

Thanks for purchasing our Electronic Speed Controller (ESC). High power system for RC models can

be very dangerous, so please read this manual carefully. In that we have no control over the correct

use, installation, application, or maintenance of our products, no liability shall be assumed nor

accepted for any damages, losses or costs resulting from the use of the product. Any claims arising

from the operating, failure or malfunctioning etc. will be denied. We assume no liability for personal

injury, property damage or consequential damages resulting from our products or workmanship.

As far as is legally permitted, the obligation to compensation is limited to the invoice amount of the

aected product.

User Manual

Brushless Speed Controller

Platinum V3 (50A / 100A)

• High-performance microprocessor with the operating frequency up to 50MHz brings excellent compatibility (with most motors in the market) and high driving efficiency.

• The maximum motor speed can reach 210000 RPM (for 2-poles), 70000 RPM (for 6-poles) and 35000 RPM (for 12-poles).

• Multiple flight modes: Airplane Fixed Wing / Heli Governor Off / Heli Governor (Elf) / Heli Governor Store.

• Adjustable throttle range, compatible with various transmitters. It brings smooth, soft & linear speed adjustment and rapid throttle response.

• Microprocessor powered by independent DC regulator has better anti-interference performance, which greatly reduces the risk of losing control.

• Built-in high-efficient & high-power (switch mode) BEC can make the output voltage switched among 5.2V / 6.0V / 7.4V / 8.4V.

(For the specic output voltage, please refer to the parameter list .)

• Brand new governor program, easy to operate; and its excellent speed-governing effect can make big rotor blades more stable even under rapid load change.

• "Restart in auto rotation" can manually interrupt the auto rotation and quickly restart the motor to avoid crashes caused by incorrect operations.

• Independent output port for RPM (that is: motor speed) signals.

• Compatible LCD program box

(For detailed information, please refer to User Manual of LCD Program Box.)

• Upgradeable firmware, you can upgrade the ESC after connecting it to a PC via the USB cable on the program box.

• The independent port, for connecting the program box and setting parameters, can also be the output port of the running status data of the ESC. When coordinating with the data transmission module,

it can make the real-time data monitoring and logging possible.

• Multiple protection features including input voltage abnormality protection / low-voltage cutoff protection / throttle signal loss protection effectively prolong the service life of the ESC.

(optional accessory)

, its simple and visual interface allows users to set/revise all the ESC parameters easily.

HW-SM008DUL-20140213

FEATURES

Model Platinum-100A-V3 Platinum-50A-V3

Main Application

Battery Count

Cont. / Burst Current

Switch Mode BEC, 6.0V / 7.4V / 8.4V; Cont.: 10A, Burst: 25A

BEC Output

BEC has the cut-through protection (which means the battery voltage

won’t get through to the receiver if the BEC is accidentally damaged)

Input / Output Wire Input: 12AWG / Output:12AWG Input: 14AWG / Output: 14AWG

104g / 70mm x 35mm x 21mm(W/O Fan)

110g / 70mm x 35mm x 32mm(With Fan)

HOBBBYWING

LCD PROGRAM BOX

RPM

THRO

Weight/Size

Battery

HOBBYWING

Platinum-50A-V3

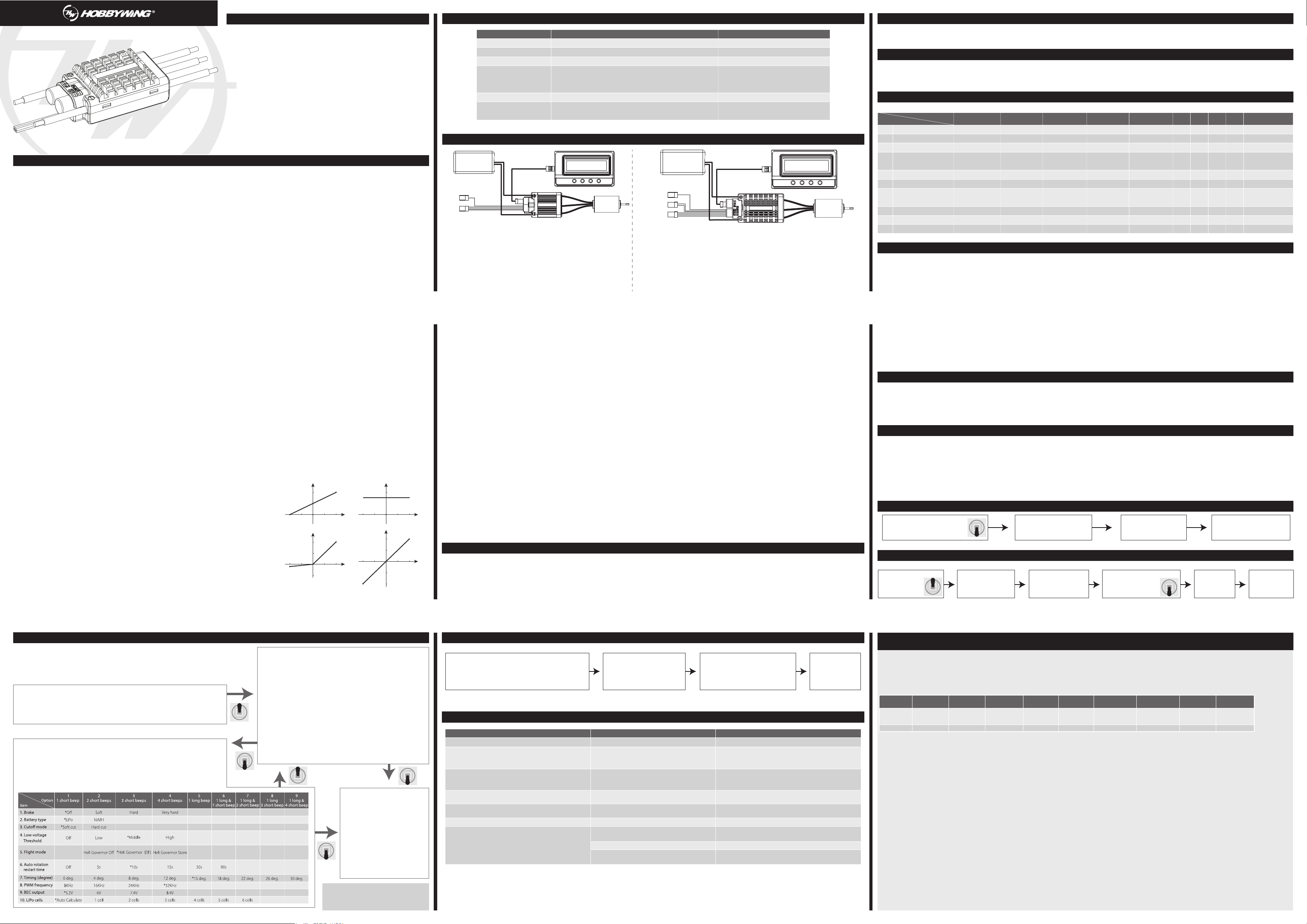

Platinum-50A-V3:

• The tricolor (WRB) cable here is the throttle cable

(WHITE: throttle signal wire, RED: BEC output wire, Black: ground wire);

• The thin Orange wire is for RPM signal output;

• The 3-pin port (marked with - + P) is an independent port for parameter setting;

it can connect the LCD Program Box, or be the output port of running status data

of the ESC.

SPECIFICATIONS

480-550 heli (425-550mm blade)

2-6S Lipo, 5.2V-25.2V

100A /150A (burst in 10 sec)

WIRING DIAGRAM

RPM

Motor

BEC

THRO

Platinum-100A-V3:

• The tricolor (WRB) cable here is the throttle cable

(WHITE: throttle signal wire, RED: BEC output wire, BLACK: ground wire);

• The bicolor (RB) cable here is the BEC cable (RED: BEC output wire, BLACK: ground wire);

• Hence, there are 2 Black wires & 2 Red wires are connected in parallel to the output end of the BEC to make the

higher current get through;

• The thin Orange wire is for RPM signal output;

• The 3-pin port (marked with - + P) is an independent port for parameter setting; it can connect LCD Program

Box, or be the output port of the ESC running status data. 2 pins corresponding to “+” & “-” in the program port

are also connected to the output end of the built-in BEC, so that it can power the cooling fan of the ESC.

Battery

450&450L heli (325-380mm blade)

2-6S Lipo, 5.2V-25.2V

50A /75A (burst in 10 sec)

Switch Mode BEC, 5.2V / 6.0V / 7.4V

Cont.: 7A, Burst: 15A

49g / 48mm x 30mm x 15.5mm

HOBBBYWING

LCD PROGRAM BOX

HOBBYWING

Platinum-100A-V3

OUTPUT PORT FOR RPM SIGNALS

Platinum V3 series speed controllers have independent output ports / interfaces for RPM signals, so it can connect to flybarless systems like Mikado V-Bar as RPM signal source. Undoubtedly, this reduces

peripheral devices which need to be connected to the flybarless helicopter and simplifies the wiring.

OUTPUT THE REAL-TIME RUNNING STATUS DATA OF THE ESC

Platinum V3 series speed controllers have independent ports for parameter setting, which can also be the output ports of the running status data of the ESCs. When coordinating with the data transmission

module, it can make the real-time data monitoring and logging possible.

For more information, please read detailed explanations in 《Developer’s Guide》.

PROGRAMMABLE ITEMS

“*”in the form below indicate factory defaults.

Item

1

Brake

2

Battery Type

3

Cuto Mode

Low-voltage

4

Cuto Threshold

Flight Mode

5

Auto Rotation Restart Time

6

Advanced Timing

7

Motor

8

PWM Frequency

9

BEC Voltage

Lipo Cells

10

Option

1

*Off

*LiPo

*Soft cut

Off

Airplane Fixed Wing

Off

0deg

8KHz

*5.2V

*Auto calculate

2 3 4 5 6 7 8 9 10

Soft

Hard

Very hard

NiMH

Hard cut

Low

Heli Governor Off

5sec

16KHz

6.0V

1 cells

*Heli Governor (Elf )

*10sec

24KHz

7.4V

2 cells

High*Middle

Heli Governor Store

15sec

*32KHz

8.4V

3 cells

Customized:

2.8V-25.2V, Step:0.1V

30sec

*15deg8deg 12deg4deg

90sec

18deg 30deg22deg 26deg

5 cells 6 cells4 cells

Customized:

0deg-30deg, Step:1deg

PROGRAMMABLE ITEMS

“*”in explanations below indicate factory defaults.

1, Brake:

*Off / Soft / Hard / Very hard

2, Battery Type:

3, Cuto Mode:

4, Low-voltage Cuto Threshold:

*LiPo / NiMH

*Soft cut / Hard cut. Soft means gradually reduce the output power. Hard means cut off the output immediately.

Off / Low / *Middle / High / Customized: 2.8V~25.2V,Step: 0.1V

1)

When set as “LiPo battery”, the ESC will automatically calculate the cutoff threshold of the battery pack according to the amount of LiPo cells. The low / middle / high cutoff voltage per cell is 2.85V / 3.15V /

3.30V. For example, when using a 3S LiPo, if set the cutoff voltage as “middle”, the cutoff threshold of this battery pack should be 3.15×3=9.45V.

2)

When set as “NiMH battery”, then the low / middle / high cutoff voltage is 50% / 62.5% / 75% of the initial input voltage (at boot/starting up) . For example, when using a 6-cell NiMH battery pack,

the voltage at starting up is 1.44×6=8.64V; and if set the cutoff threshold as “low”, the cutoff threshold of this battery pack should be 8.64×50%=4.3V.

3)

When set as “Customized: 2.8V~25.2V”, the cutoff threshold of the battery pack can be precisely set (the precision can reach 0.1V). But you need a LCD program box (optional accessory) or USB cable on

the LCD program box to connect the ESC to a PC, then set relevant parameters via a special program (Hobbywing USB Link Software).

5, Flight Mode: Airplane Fixed Wing / Heli Governor O

1) Airplane Fixed Wing:

The motor starts to spin at 5% throttle, then speeds up quickly and reaches the full speed from standstill in 300µs. In this mode, the ESC will be enforced to set the “Auto Rotation

/

*Heli Governor (Elf) / Heli Governor Store

Restart Time” to “OFF”.

2) Heli Governor O:

When the motor starts at 5% throttle, the startup is very soft and it takes 11 seconds to reach the full speed from standstill. In this mode, if the transmitter is in NORMAL state, then

usually the throttle curve is a slash (the start point is the lowest point / 0% throttle, the end point is the highest point / 100% throttle of the throttle range. And this throttle curve is often used by

beginners). As the start point is only 5% of the full throttle, the motor rotates slowly that greatly reduces psychological pressure for beginners, so pilots can select this mode for basic practices like

“frog leap”. In this mode, the ESC will automatically set the “Auto Rotation Restart Time” to “Off”.

3) Heli Governor (Elf) & Heli Governor Store:

The motor only starts at 40% (or above) throttle (in governor mode, the motor won’t start when the throttle value is within 0%-40%); its startup is very soft

and needs 11 seconds to reach the full speed from standstill. Besides, it has speed-governing function (works at 40%-100% throttle). As the motor rotates quickly in “governor” mode, so it isn’t suitable

for beginner anymore but experienced pilots. In these two modes, the setting about “Auto Rotation Restart Time” comes into effect (please refer to “Auto Rotation Restart Time” for more information).

4) Heli Governor (Elf) & Heli Governor Store

have different ways of storing target rev data. In “Governor Store” mode, the data are saved into the FLASH of the microprocessor (and the data won’t disappear

after powered off); while in “Governor (Elf )” mode, data of the nominal target rev are saved into the RAM of the microprocessor (and the data will disappear after powered off).

• In “Governor (Elf)” mode, the ESC will automatically start the RPM standardization & regain the target rev data after powered on.

• In “Governor Store” mode, if it needs to re-standardize the target RPM, pilots must modify and save the flight mode as any option except "Heli Govornor Store"first (without restarting the ESC at this

moment), then modify and save it as "Heli Govornor Store"; the ESC will enter the RPM standardization and regain the target RPM data after it’s powered on. After the first activation of the

“speed-governing” function or changed accessories (like motor, battery cells amount, gear and different type of main/big rotor blades) on the plane, pilots need to standardize the RPM again next time.

Here we suggest pilots take the “Governor Store” mode as their rst option to avoid standardizing rev every time.

a) RPM standardization in “Governor (Elf)” mode:

when the throttle value switches to over 40% from 0%, the motor starts in a

super soft way and accelerates slowly; it completes RPM standardization in 11 seconds and then enters the “governor” mode.

After changed batteries, the ESC will standardize the RPM again.

b) RPM standardization in “Governor Store” mode:

when the throttle value switches to over 40% from 0%, the motor starts in a

super soft way and accelerates slowly; it completes RPM standardization in 11 seconds and then enters the “governor” mode.

After flight, please move the transmitter throttle stick to the bottom position, the motor stops spinning and the ESC will save

the standardized (target) RPM into the FLASH. After changed batteries, the ESC will read the target RPM from the FLASH, so

there is no need to standardize the rev again.

c) Example for RPM Standardization:

In this example, we take the neutral point (50%) of the throttle stick as reference points for standardizing RPM.

-100%

Throttle (NORMAL)

100%

50%

100%

Neutral

Point

Pitch(NORMAL)

12°

Throttle

Stick

Position

-100%

Throttle (IDLE)

100%

50%

Neutral

Point

Pitch(IDLE)

12°

100%

Throttle

Stick

Position

• Set the throttle curve (throttle value at the neutral point=50%) & pitch curve (the pitch at the neutral point is 0) in “NORMAL”

mode, and keep the throttle HOLD switch “locked” to ensure safety.

• Connect the fully charged battery to the ESC, let the ESC complete the initialization, then move the transmitter throttle stick to

the neutral point (here the throttle value at the neutral point is 50% and the pitch of main rotor blades is 0 degree), and then

-100%

Neutral

Point

100%

Throttle

Stick

Position

-100%

Neutral

Point

100%

Throttle

Stick

Position

“unlock” the throttle HOLD switch; the motor will start from standstill in a super soft way, accelerate slowly and completes the

target rev standardization 11 seconds later.

• Trial flight. If the target rev is too low, then raise the throttle curve; if the target rev is too high, and then lower the throttle

The example of throttle curve and pitch curve for RPM standardization

curve. E.g. set the throttle curve in IDLE1 / IDLE2 / IDLE3 mode to 65% / 75% / 85% respectively to experience different RPM, and then adjust the value according to the actual situation or preference.

5)

As the battery voltage decreases & the pitch of main rotor blades varies in flight, so we recommend setting the throttle curve between 60%~85% (here we strongly suggest not set the value exceeds 85%) on

the transmitter to guarantee the speed -governing effect and sufficient compensating room to keep the motor’s constant speed. If still can’t reach that target rev when the throttle value exceeds 85%, please

change the motor pinion.

6)

For guaranteeing the speed-governing effect, we strongly recommend setting the PWM frequency as 32 kHz.

6, Autorotation Restart Time:

Off / 5s / *10s / 15s / 30s / 90s.

This parameter is only used in “Governor (Elf )” and “Governor Store” modes, and works when the throttle value is within 5%~40%.

During the period of auto rotating (to land), pilots still have the chance to cancel the operation by interrupting the process and restarting the motor quickly. E.g. when set the parameter to 10 seconds,

enabling the throttle HOLD switch (to activate the throttle protection) in flight, the motor will cut off the output and let the helicopter land. While, if you want to end this process immediately, then you need

to “unlock” the HOLD switch (to exit the throttle protection) and increase the throttle value to over 40%, and the ESC will temporarily switch the acceleration time to 1.5 seconds (that is: it reaches the full

speed from standstill in 1.5s) and output power quickly. This action protects the helicopter from crashing caused by the motor’s slow acceleration. However, if “lock” the throttle HOLD switch over 10 seconds,

the ESC will still output power slowly at a super soft acceleration rate (that means it will take 11s to reach the full speed from standstill) even if you “unlock” the throttle HOLD switch and increase the throttle

value promptly.

Security Warning: For safety, please pay attention to the following points.

• When the landing process ends early and the helicopter gets back to ground before the “autorotation restart time”, it’s prohibited to “unlock” the throttle HOLD switch before disconnecting the battery.

Otherwise, the helicopter may rotate and accelerate to a high speed in 1.5s and cause accidents. E.g., if “unlock” the throttle HOLD switch in the “Auto rotation restart time” with the helicopter is still in “IDLE”

mode, main rotor blades will spin rapidly and the helicopter may drift and tilt even on the ground.

• If switch the flight mode from “IDLE” to “NORMAL” and move the throttle stick to the bottom position (0% throttle) or “lock” the “Throttle Cut” switch on the transmitter, main rotor blades will not rotate even if

you accidentally “unlocked” the throttle HOLD switch.

• In “governor ” mode, if set “Auto Rotation Restar t Time” to “Off”, the motor will always restart at the super soft acceleration rate (it takes 11 seconds to reach the full speed from standstill). Please attention!

7, Advanced Timing:

0deg / 4deg / 8deg / 12deg / *15deg / 18deg / 22deg / 26deg / 30deg / Customized: 0deg~30deg, step: 1 deg.

In general, the low timing works fine for most motors. While as great differences exist among motors, so please try different timing(s) to get the best driving effect. For increasing the speed, you can set the

timing higher. After the timing adjustment, we recommend having a trial on the ground first, and then fly in the sky.

8, PWM Frequency:

8KHz / 16KHz / 24KHz / *32KHz

The rise of PWM frequency can make the motor driving smoother and the noise lower; certainly, this will bring more switching loss for the MOSFET & more heat to the ESC.

9, BEC Voltage:

*5.2V / 6.0V / 7.4V / 8.4V

For Platinum-50A-V3 ESCs, the BEC output voltage is selectable among 5.2V / 6.0V / 7.4V; and the actual output will be 7.4V even if you selected 8.4V as the nominal output.

For Platinum-100A-V3 ESCs, the BEC output voltage is selectable among 6.0V / 7.4V / 8.4V; but the actual output will be 6.0V even if you selected 5.2V as the nominal output.

10, LiPo Cells:

*Auto calculation / 1 cell / 2 cells / 3 cells / 4 cells / 5 cells / 6 cells

The parameter is valid only when the battery pack is LiPo. After powered on, the ESC will make the motor beep the amount of cells in your LiPo pack according to auto-detection or cell count manually set.

For Platinum 50A/100A V3 ESCs, the range which can be auto-calculated or manually set is 2~6S; if exceeds, the ESC will warn.

BEGIN TO USE A NEW BRUSHLESS ESC

Before using a new ESC, you need to check all the connections to make sure they are correct and reliable before connecting the ESC to the battery. When ensured everything is ok, then start the ESC in the

sequence:

following

1, Move the throttle stick to the bottom position (throttle value=0%), then turn on the transmitter;

2, Connect the battery pack to the ESC, then the ESC starts self-test; the motor issues “♪ 123” indicating the system is powered on, and N short “beeps” indicating the amount of LiPo cells of the battery pack,

then a long “beep—“indicating the self-test is completed successfully and the system is ready to fly.

• If no response is received, please check the battery and battery connections to ensure they are ok and reliable.

• If the motor doesn’t beep after powered on, it means the battery voltage is too low or too high. Please check the battery voltage.

• If the motor sounds “beep-beep-” 2 seconds after powered on, and “♪ 56712 ” 5 seconds later to indicate the ESC is entering the “programming” mode, it means the throttle channel direction in your

. .

transmitter is reversed, in such a case you need to reset the “Normal / Reverse” direction of the throttle channel by referring to the transmitter’s manual.

Attention!

3,

To ensure the ESC fits well with the throttle range on your transmitter, you need to reset the throttle range when using this ESC for the first time or changed another transmitter for the optimum throttle

linearity. For detailed operation, please refer to the explanation in 《Set the Throttle Range》.

EXPLANATIONS FOR WARNING TONE

:

1. Warning tone for abnormal input voltage

when powered on the ESC, it will start testing the input voltage. If the voltage is not in the normal scope, the motor will emit the warning “beep beep, beep beep,

beep beep” till the voltage returns to normal (the time interval among each group of “beep beep” is 1 second).

:

2. Warning tone for throttle signal loss

3. Warning tone if the throttle stick is not at the bottom position when the ESC is powered up

when detected no throttle signal, the ESC will issue the following warning: “beep-, beep, beep-” (the time interval among these “beeps” is 2 seconds).

:

When the throttle is not at the bottom position, the ESC will issue the following warning:

“beep-beep-beep-beep-beep-” (every “beep” is very short and hurried).

EXPLANATION FOR OTHER PROTECTIONS

1. Startup Protection: the ESC will shut down the motor after failed to start the motor normally in 2 seconds by increasing the throttle value, then you need to move the transmitter throttle stick to the

bottom position again and restart.

:

(Causes to this problem

2. Overheat Protection

poor wire connection between the ESC and the motor or disconnection of some output wire, propellers are blocked by other objects, gears are blocked and cannot move and etc.)

:

When the internal operating temperature exceeds 110 Celsius degree, the ESC will reduce its output power and start protection; it won’t cut off the output, but reduce it to 50% to

ensure that the motor still has some power for avoiding crash caused by insufficient power. And the ESC will gradually resume its maximum power after the temperature returns to the safe level.

:

3. Throttle Signal Loss Protection

When detected the signal loss for over 0.25 second, the ESC will cut off the output immediately to avoid even greater loss which may caused by the continuous high-speed

rotation of propellers or rotor blades.

:

4. Overload Protection

The ESC will cut off the power or restart automatically when the load suddenly increases to a very high value. And the common cause of load soar is the lockout of propellers.

NORMAL START-UP PROCESS

Turn on the transmitter and move the

throttle stick to the bottom position

(Throttle value=0%).

Connect battery to the ESC, the

motor will emit “♪123” indicating

the ESC is powered on normally.

Then motor emits several

short “beeps” to indicate the

amount of LiPo cells.

And a long “beep” indicating the

system is ready and you can fly the

helicopter or airplane now.

SET THE THROTTLE RANGE

Attention! It is necessary to reset the throttle range when using a new ESC or changed another transmitter.

Turn on the transmitter, and

move the throttle

stick to the top

position (full throttle).

Connect battery to the

ESC, and the motor emits

“♪123” indicating the ESC is

powered on normally.

2 seconds later, the motor

emits 2 short “beep-beep-”

indicating the top position is

calibrated successfully.

Move the throttle stick to the bottom

position, await 1 second

then the bottom position

is calibrated Successfully.

The motor emits N

beeps to indicate

the amount of

Lipo cells.

Then a long “beep”

indicates the system

is ready and you can

fly the aircraft now.

PARAMETERS PROGRAMMING/SET TING VIA THE TRANSMITTER

4 steps to set parameters via the throttle stick:

I, enter “programming” mode,

II, select item(s),

III, select option(s) / parameters under item(s),

IV, exit “setting”.

I, Enter “Programming / Setting” Mode

1. Turn on the transmitter, move the throttle stick to the top position (full throttle);

2. Connect battery to the ESC, then the motor emits “♪ 123” indicating the ESC is powered on normally .

3. 2 seconds later, the motor emits two short “beep-beep- ”;

4. 5 seconds later, the motor emits “♪ 56712” indicating it’s already entered the “programming” mode.

III, Select Options / Parameter Values

The motor beeps in loops, move the throttle stick to the top position when heard some “beep(s)” tone

indicating you selected its corresponding option value; then the motor will sound “♪ 1515” means the

value has been saved. (And if you don’t want to set other items but quickly exit “setting”, please move the

throttle stick to the bottom position in 3 seconds ; while if you still want to set other items, please wait

for returning to Step II and choose other items.

(“*” in the form below indicate factory defaults)

Airplane

Fixed Wing

. .

. .

II, Select Items

After entered the “programming” mode, you can hear 12 sets of tone repeat

sequentially. Move the throttle stick to the bottom position in 3 seconds after the

motor emitted certain set of tone, and then you enter the corresponding item.

1. Brake (1 short) “B”

2. Battery Type (2 short) “BB”

3. Cutoff (3 short) “BBB”

4. Low-voltage Cutoff Threshold (4 short) “BBBB”

5. Flight Mode (1 long) “B—”

6. Auto Rotation Restart Time (1 long & 1 short) “B—B”

7. Timing (1 long & 2 short) “B—BB”

8. PWM Frequency (1 long & 3 short) “B—BBB”

9. BEC Voltage (1 long & 4 short) “B—BBBB”

10.LiPo Cells (2 long) “B—B—”

11. Reset to Factory Default (3 long & 1 short) “B—B—B—B”

12.Exit (3 long & 2 short) “B—B—B—BB”

Note: as 1 long “Beep—” equals to 5 short “beep-”, e.g, in step II “Select Items” , 1

long & 1 short (“Beep—Beep”) represents option 6.

IV, Exit “Setting”

Two ways to exit “setting” mode:

a) In Step III, after heard the special tone

. .

“♪ 1515” while selecting optional values,

move the throttle stick to the bottom

position in 2 seconds, then you exit

“setting”.

b) After heard 3 long & 2 short beeps

which represent item 12 while selecting

options in Step II, move the throttle

stick to the bottom position in 3

seconds, then you exit “setting”.

Note: After revised ESC parameters via the transmitter

throttle stick or program card/box, please save those

settings and exit; then the motor emits 5 long

“beep-“ and 5 seconds later you can restart the ESC.

ESC PROGRAMMING SAMPLE

In the example below, it set the “flight mode” to “Heli Governor Off” , that is the 2nd parameter of item 5.

I, Enter “programming” mode:Move the throttle stick to the top

position and then turn on the transmitter, connect ESC to battery, the

motor emits “♪ 123” indicating it’s normally powered on. 2 seconds

later, it emits “beep-beep-” and then 5 seconds later it emits “♪ 56712 ”

. .

which indicates it’s already entered the “programming” mode.

II, Select items: motor starts to sound,

when heard a long “beep—” (which

represent Item #5—flight mode), move

the throttle stick to the bottom

position, then you entered this item

TROUBLESHOOTING

Trouble SolutionCause

After powered on, the motor doesn’t rotate and there is no sound emitted. Poor connection between power connectors.

After powered on, the motor doesn’t spin, but emits the warning tone

“beep beep, beep beep, beep beep” (the inter val between each group of

“beep beep” is 1 second).

After powered on, the motor doesn’t spin but emits the warning tone

“beep-, beep-, beep-” (the time inter val each “beep-” is 2 seconds).

After powered on, the motor doesn’t run but emits “beep, beep, beep,

beep, beep” (each beep is ver y short and hurried).

After powered on, the motor doesn’t run but emits “beep-beep” then the

special tone “♪ 56712 ”.

The motor rotates in the wrong direction.

The motor stops halfway.

. .

The battery voltage is abnormal.

No signal output from the throttle channel of the receiver.

Didn’t move the throttle stick to the bottom position or

the throttle range is too narrow.

Incorrect “Normal / Reverse” direction of the throttle channel.

Connected ESC output wires to motor wires in the wrong order.

Throttle signal loss protection is activated.

Low-voltage cutoff protection is activated.

Poor wire connections.

III, Select Options:motor emits a short

“beep-“, 3 seconds later, two shor t

“beep-beep-“, then move the throttle stick to

the top position, and the motor emits “♪ 1515”

. .

indicating it has set to “Heli Governor Off”.

Re-plug or change the connectors.

Please check the battery voltage.

Please check whether the communication between the transmitter

& receiver is normal or not, and if the control wire (that is, Rx wire) has

been firmly plugged into the throttle channel in the correct direction.

Move the throttle stick to the bottom position or reset the throttle range.

Please refer to the transmitter’s user manual and reset the “Normal /

Reverse” direction of the throttle channel.

Swap any of two wire connections.

Please check the communication between the transmitter & receiver,

and also check the connection between ESC and the receiver.

Charge the battery pack or change a new one.

Please check the battery connector and the connection between ESC

output wires and motor wires.

IV, Exit “setting”: After

the 3rd step completed,

move the throttle to the

bottom position again

in 2 seconds.

(Note: This guide is only for developers, common users needn’t read it.)

DEVELOPER’S GUIDE

【Output the real-time running data of the ESC】

The PLATINUM V3 series of ESC has independent port for connecting the LCD program box and output the running status data of the ESC via the SCI (Serial Communication interface). When coordinating with the data

transmission module, they can make the real-time data monitoring and logging possible.

Here, we open this functionality to the public so users can redevelop this ESC to expand its application fields.

When motor rotates, the parameter setting port works as single-way mode SCI (Serial Communication Interface), the baud rate is 19200bps. The port outputs 1 data package (/frame) every 20 milliseconds.

The format of each data frame is shown as below:

1

First Byte

2 3 4 5 6

Package Head Package Number

High Octet

Package Number

Mid Octet

Package Number

Low Octet

Rx Throttle Value

High Octet

Rx Throttle Value

Low Octet

7 8 9

Actual Output PWM

High Octet

Actual Output PWM

Low Octet

Actual RPM Cycle

High Octet

0x9B 0xXX 0xXX 0xXX 0xXX 0xXX 0xXX 0xXX 0xXX 0xXX

• Package Head: Each data package ( / frame) is always started with the code “0x9B”.

• Package Number: number of each data package.

• Rx Throttle Value: throttle signal value got from the receiver. Now, the “high octet of the Rx throttle value” is temporarily set at 0, and the valid scope of the low octet of Rx Throttle Value is 0~255, that means the entire

throttle range (0~100%) is equally divided into 255 parts. For example, when the low octet value is 85, it means the throttle signal got from the receiver is 33% of the maximum; when it’s 128, the throttle signal received

from the receiver is 50% of the maximum.

• Actual Output PWM: throttle signal value actually output by the ESC. Its high octet is also temporarily set at 0, and the valid range of the low octet is 0~255, that means the entire output range (0~100%) is equally divided

into 255 parts.

• Actual RPM Cycle: actual electric RPM signal cycle of the motor (µs).

For example: The actual rev of a 8-pole motor is 600 RPM, then its electric rev is 600 x 8 ÷ 2 = 2400RPM, which means the ESC commutates 2400 times in 60 seconds to drive the motor,

and the commutation cycle = 60 ÷ 2400 = 0.025s = 25000µs. Therefore, the decimal digit represented by the actual RPM Cycle is 25000.

【Output Port for RPM Signals】

• Platinum V3 series of speed controllers have independent output ports for RPM signals.

Specication for interface signals:

•

• It represents the electric rev of the brushless motor (electric rev means the rev of a 2-pole brushless motor). And here is the formula used for converting the actual rev of multi-pole brushless motor into the

electric rev of 2-pole brushless motor:

Electric rev = Actual rev of the multi-pole brushless motor × Pole number ÷2

E.g. the actual rev of a 12-pole motor is 5000rpm, so its corresponding electric rev is: 5000 × 12 ÷ 2 = 30000rpm

【ESC throttle Rang & Throttle Signal Specication】

• Factory default of the ESC throttle range is 1100 ~1940µs, the acceptable minimum time of high level is 815µs and the acceptable maximum time of high level is 2256µs. The acceptable minimum signal cycle equals to the

high level time (µs) plus 10µs.

• In PPM throttle signals, only signal cycle & high level time impact; changes of the high level time correspond to the notion of throttle value (0%~100%), here whether the low level time changes or not is not taken into consideration.

• Different manufacturers have varied definitions of the high level time of throttle signal. For FUTABA radio system, it is 1100µs~1940µs and 1520µs is the midpoint (or so called “neutral point”); while for JR radio system,

it’s 1100µs~1900µs and the midpoint is 1500µs.

• The receiver outputs analog signals, and the ESC converts the analog signals into 8 to 12bits digital signals (the resolution for 8 bits is 0~255, and it is 0~4095 for 12 bits.).

• Because of the above differences exist among different radio systems; so it’s necessary to calibrate the throttle range on the ESC if users want to utilize the whole throttle range of the transmitter.

It is the periodic signal with duty ratio of 17%, and 0V for low level, 3.3V for high level.

10

Last Byte

Actual RPM Cycle

Low Octet

Loading...

Loading...