Hobart Welding Stickmate 205 AC User Manual

230 Volt

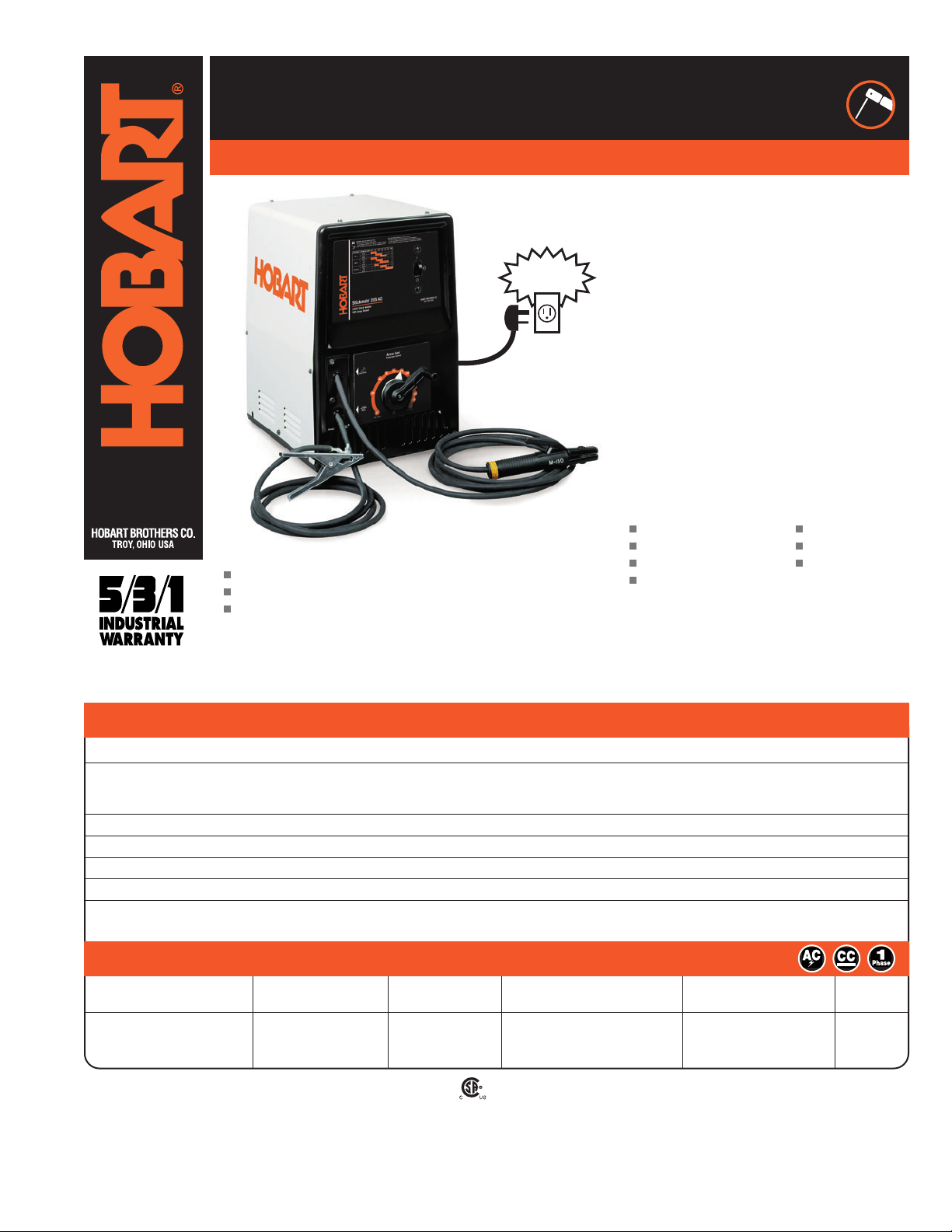

Stickmate®205 AC

AC Stick (SMAW) Arc Welding Power Source

Applications:

Farms Hobbyists

Ranches Maintenance

Ornamental Iron Individuals

Garages

Includes:

15-ft. (4.5 m) electrode cable with heavy-duty holder

10-ft. (3 m) work cable with clamp

Power cord with plug

Rated Welding Output

165 A at 25 VAC,

20% Duty Cycle, 50/60 Hz

Max. OpenCircuit Voltage

80 V

Welding Amperage

Range

30–205 A

Amps Input at Rated Output,

230 V, 50/60 Hz

47.5

Dimensions

H: 18-3/4 in. (476 mm)

W: 12-3/4 in. (323 mm)

D: 17-1/2 in. (445 mm)

Net

Weight

83 lb.

(38 kg)

Accu-Set is an exclusive design for accurately controlling amperage or heat output.

The precise control of the Stickmate allows the operator to adjust output by as little as 1-amp increments. Adjustments

can be made while welding to achieve desired heat level, unlike the step control design on

competitive products.

Duty cycle increases as amperage setting decreases. 100% duty cycle at 90 A, 25 V.

Assists with arc starting and arc stability.

Varnish protects and lengthens the life of the coils inside for increased reliability.

The cooling fan runs continuously and helps to extend the life of the power source.

Five-year warranty on transformers, stabilizers and generators; three years on electronics (drive motors, rectifiers);

and one year on guns.

Accu-Set™amperage indicator

Infinite current control

Increasing duty cycle

Max. 80 open-circuit voltage

Fully varnished magnetic coils

Forced-draft cooling fan

Hobart’s 5/3/1 Warranty

216440

June 2012

Features Benefits

Specifications

(SUBJECT TO CHANGE WITHOUT NOTICE.)

T

he Stickmate 205 AC Stick welding power

sources have the control to get the exact heat

you need — always. Also, these machines allow

weld time to increase when amperage decreases.

The

y have the range and muscle to handle many

Stick welding, hard surfacing, and cutting jobs.

At the same time, they have the precision for low

hydrogen and special alloy electrodes. Recommended

for a variety of electrodes 1/16 – 5/32 in diameter.

Accu-Set

™

design provides accurate heat control

with infinite amperage control. This Stick welder

also allows a higher duty cycle when amperages

decrease to give you more arc time when welding

thinner materials.

#500502

Certified by Canadian Standards Association to both the Canadian and U.S. Standards.

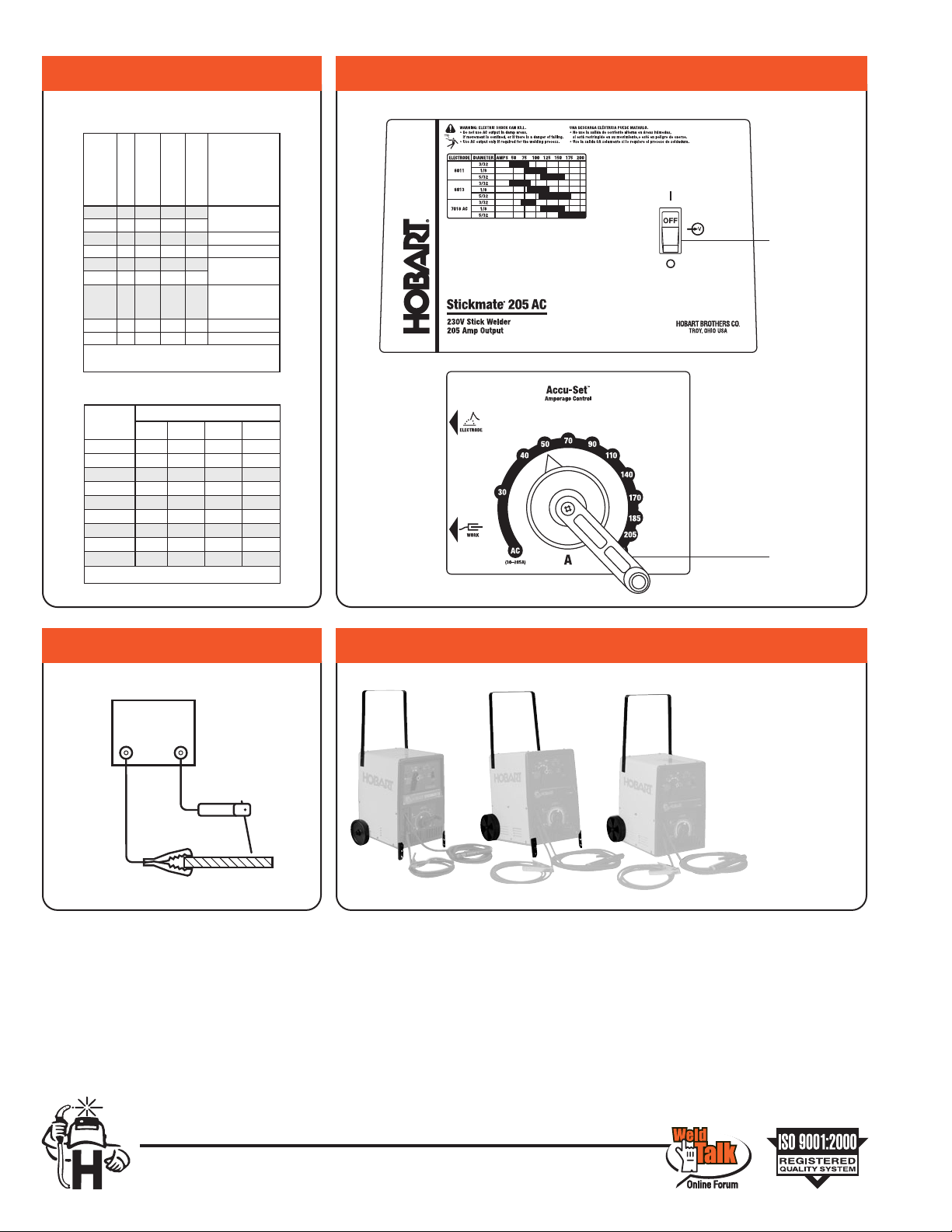

1. Power Switch

2. Amperage Adjustment

Control

Hobart Welders An Illinois Tool Works Company hobartwelders.com

Hobart Welding Products Service 800-332-3281 Sales 800-626-9420

Litho in USA

Control Panel

Accessories

Electrode Charts

Basic Equipment Setup

Running Gear

#043927

Mounts easily to

unit and provides

convenient

porta bility, with

various mounting

options to suit

user preference.

Includes two

wheels, two feet

and a handle.

ELECTRODE SELECTION CHART

AC

DC*

EP

EP

EP, EN

EP, EN

EP

EP

EP, EN

EP

EP

1/16

20-35

20-45

35-60

30-50

30-50

POSITION

ALL

DEEP

ALL

DEEP

ALL

LOW

ALL

MED

ALL

LOW

ALL

LOW

FLAT

HORIZ

LOW

FILLET

ALL

LOW

ALL

LOW

DIAMETERS

3/32

40-85

X

40-85

40-90

80-125

65-100

65-100

100-145

X

50-70

X

40-80

X

ELECTRODE

NO

6010

6011

YES

6013

YES

7014

YES

7018

YES

7018AC

YES

7024

YES

Ni-Cl

YES

308L

YES

*EP = ELECTRODE POSITIVE (REVERSE POLARITY)

*EN = ELECTRODE NEGATIVE (STRAIGHT POLARITY)

WELDING RANGE CHART

ELECTRODE

AWS CLASS

6010

6011

6013

7014

7018

7018 AC*

7024

Ni-Cl

308L

*7018 AC recommended for use with AC welders.

USAGE

PENETRATION

MIN. PREP, ROUGH,

HIGH SPATTER

GENERAL, EASY

SMOOTH, EASY, FAST

LOW HYDROGEN,

STRONG

SMOOTH, EASY,

FASTER

CAST IRON

STAINLESS

5/32

1/8

110-165

75-125

110-165

75-125

105-180

80-130

150-210

110-165

150-220

110-165

150-220

110-165

180-250

140-190

100-140

65-85

105-160

75-115

1

2

Stick (SMAW)

Power

Source

Stick Electrode

Work Clamp

Loading...

Loading...