Hobart Welding 250ci User Manual

AirForce™250ci

Portable Air Plasma Cutter

N

eed to cut steel? Thinking about an oxy acetylene

cutting torch to do the job? Consider a plasma

cutter. This simple technology uses an electrical arc

and compressed air to cut steel, aluminum, and

other conductive metals.

Designed to cut up to 1/4 inch mild steel, the AirForce

™

250ci is powered by standard household voltage

(115 VAC). A built-in air compressor and lightweight

inverter power supply make this plasma cutter the most

convenient, totally portable cutting system available.

The AirForce

™

250ci excels at cutting sheet metal and

1/8 inch mild steel, and can even sever 1/4 inch steel.

Compared to the complexities of an oxy fuel cutting

torch system, plasma cutting is easy:

Cuts faster than oxy fuel

More precise cut, thinner kerf, less slag to clean up

Smaller heat-affected zone for less warping

No gas pressure settings or flame tuning needed

No preheating of metal prior to cutting

No pressurized gas cylinders to transport

No worries about running out of gas on the job

No expense for gas refills... ever

The AirForce

™

250ci comes ready to cut out of the

box, with extra replacement tips and a convenient

cable management strap for easy transportation.

Just pull the trigger and cut.

Comes Complete With:

HP-25 16.4 ft (5 m) hand-held torch

Heavy-duty work clamp with 16.4 ft (5 m) cable

7 ft (2.1 m) power cord with 115 VAC plug

Extra consumables (2 tips, 2 electrodes)

Applications

Sheet metal HVAC duct work

Auto body repair Home hobby

Plumbing

PROCESS

Air Plasma Cutting

Rated Output

12 Amps at 110 VDC,

35% Duty Cycle

Max. OpenCircuit Voltage

375 VDC

Amps Input at Rated Output, 60 Hz, Single-Phase

120 V KVA KW

20 2.27 2.0

Dimensions

H: 10 in (254 mm)

W: 7-1/2 in (191 mm)

D: 13 in (330 mm)

Net Weight

with torch

27 lb (12.3 kg)

Ship Weight

30 lb (13.6 kg)

SPECIFICATIONS

(SUBJECT TO CHANGE WITHOUT NOTICE.)

FEATURES BENEFITS

Powerful cutting ability at half the weight of prior model (AirForce 250A.) Weighs only 27 lbs.

Internal piston-driven air compressor makes the system highly portable. No additional compressor to

purchase or transport. Pressure is preset… ready to cut, right out of the box.

The new HP-25 torch is designed for increased comfort, more efficient cooling and economical replacement

cutting tips.

Runs on standard household power. No need for 230 volt hookup by utility company.

Cools the torch and tip after cutting, extending life of replaceable tip and electrode.

Runs only when needed reducing dust/debris pulled into unit.

Ensures consistent arc starts prior to each cut, minimizes tip burnout.

LED lights indicate system status for power, temperature, and torch readiness eliminating

unnecessary downtime.

Built to withstand tough working environments. Rated for 35% duty cycle at 104° Fahrenheit.

Duty cycle will increase as environmental temperature decreases.

Secures torch, work cable and power cord to make transporting easy and convenient.

No other manufacturer offers a better warranty than Hobart. Power source is warranted for three years,

parts and labor. Original rectifier parts have a five-year warranty and the HP-25 torches have a one-year parts

and labor warranty.

New inverter design

Built-in air compressor

New ergonomic torch

Powered by 120 V, 20 amp circuit

Post-flow air cooling

Fan-On-Demand

Pilot Arc Control

Diagnostic lights

Thermal overload protection

Cable management strap

Hobart 5/3/1 Warranty

233240

June 2007

Hobart Welders An Illinois Tool Works Company

Technical Assistance Phone 800-332-3281

Web Site HobartWelders.com

Litho in USA

DISTRIBUTED BY:

Power Source Stock No. Description Qty. Price

AirForce 250ci #500534 Single-phase, 120 VAC, 60 Hz

UPC: #715959372183; Shipping Weight: 30 lb (13.6 kg); Carton Dimensions: 18-1/4 x 11-5/8 x 17 in (464 x 295 x 432 mm); Pallet Qty: 12

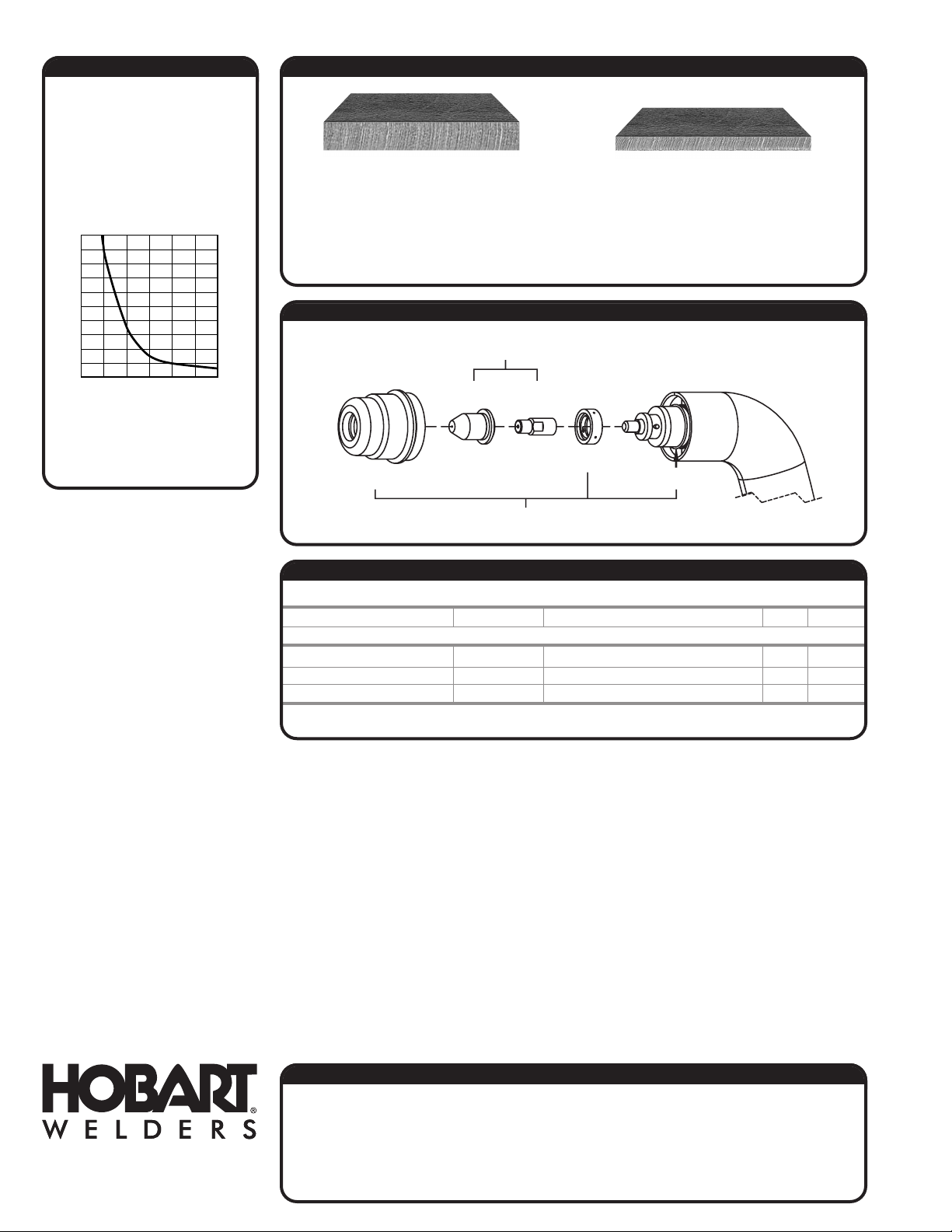

Torch Consumable Kits

Contact Tip and Electrode Kit #770496

Cup, Swirl Ring, O-ring Kit #770497

Date: Total Quoted Price:

ORDERING INFORMATION AND SYSTEM CHECKLIST

TORCH CONSUMABLE KITS

Retaining Cup

Tip

Electrode

O-Ring

Swirl Ring

#770496

#770497

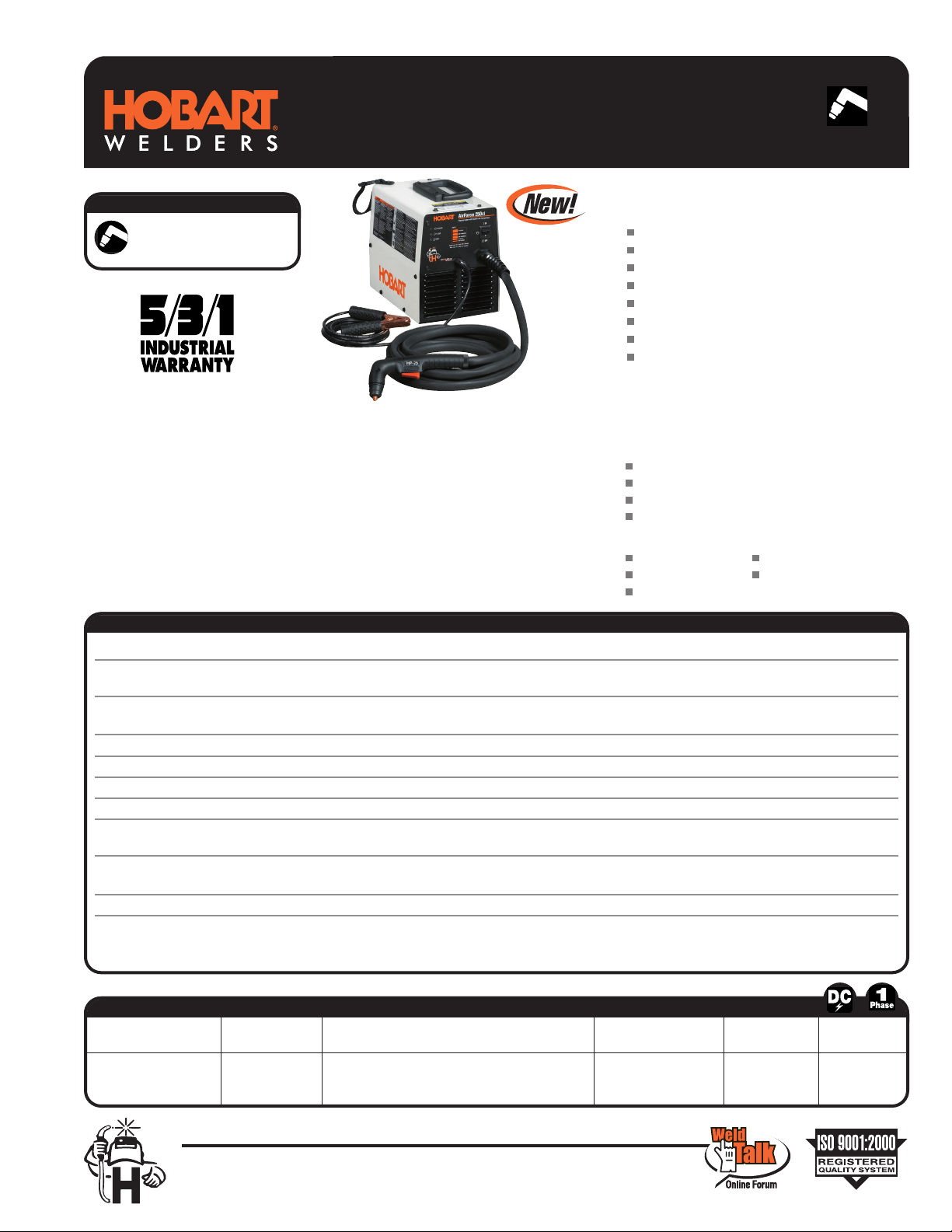

MILD STEEL CUTTING CAPACITY (Thickness to scale.)

CUTTING PERFORMANCE

To determine the maximum rated

cutting thick ness of mild steel, follow

the line from the 10 IPM (inches per

minute) point on the cutting chart.

The point at which this line intersects

the cutting curve determines the

maximum recommended production

cutting thickness of the unit.

Note: The rating is based on 10 IPM because

this is the minimum speed at which the

operator achieves a smooth, steady cut when

using a hand-held torch.

100

90

80

70

60

50

40

30

20

10

0

0.0

0.5

1.0

1.5

2.0

2.5

Cutting Speed Meters/Minute

Mild Steel Thickness Inches (mm)

Cutting Speed Inches/Minute

Cutting Speed vs. Material Thickness

0

18 ga.

(1.2)

12 ga.

(2.7)

7 ga.

(4.6)

1/8

(3.2)

1/4

(6.4)

3/16

(4.8)

Rated Cutting Capacity*

10 inches per minute (minimum speed at

which an operator achieves a smooth, steady

cut using a hand-held torch).

*Ratings for stainless and aluminum reduced by 30%.

Max Cut 1/4 inch (6.4 mm)

Rated Cut 1/8 inch (3.2 mm)

Maximum Cutting Capacity*

3 inches per minute at ideal conditions

Loading...

Loading...