Hobart Welding 250 User Manual

IronMan™250

Complete Single-Phase MIG Welding Package

211805

May 2008

PROCESSES

MIG (GMAW)

Welding

Flux Cored (FCAW)

Welding

T

he IronMan™250 is a powerful welding package

that is versatile and easy to use. It is equipped

with many outstanding features.

Welds 22 gauge up to 1/2 in. (13 mm) thick steel.

Excellent aluminum welding with optional

Hobart Spool Gun 3545-20.

Seven-tap voltage control allows for a smooth,

easy-to-control arc.

Infinite wire feed speed control for precise

adjustment of penetration and weld bead shape.

Comes complete with 250 amp gun and built-in

running gear/cylinder rack.

Handles wire spools up to 45 lb. — wire feed

speed adjusts from 90 to 750 IPM.

Built-in thermal overload protects the unit.

Reversible drive rolls: two grooves for three wire

sizes on one drive roll. Decreases spare parts and

changeover time.

Hinged door for easy access to wire drive system

for spool and drive roll changes.

FEATURES BENEFITS

Makes controls easy to see and access.

Excellent short arc performance with easy to control weld puddle.

Increases machine output for higher productivity.

Higher machine output duty cycle, increasing productivity with longer welding periods. Versatile for MIG and

Flux Cored, gas or gasless welding applications. Can weld at higher amps at lower duty cycle.

Simplified and accurate adjustments. Maximizes amount of control. Allows for smooth arc with high operator appeal.

Excellent for pushing soft aluminum wires.

50% less stocking of drive rolls. Standard, one-piece drive roll decreases spare parts and changeover time,

reducing overall costs.

For greater accessibility to wire feeder panel for spool and feed roll changes, increasing productivity and operator appeal.

Allows for precise adjustment of penetration and weld bead shape.

Amperage draw of 35 amps at rated load of 230 V input saves energy.

Ready to set up and weld: comes complete with wire feeder, running gear, cylinder rack, regulator/flow gauge,

MIG gun, cable and clamp, extra tips.

Five-year warranty on transformers, stabilizers and generators; three years on electronics (drive motors, rectifiers);

and one year on guns (MIG and plasma torches).

Sloped front panel

Arc performance

Increased amperage output

Increased duty cycle: rated at

200 amps @ 60% duty cycle,

and wide amperage range

7-position voltage control

Optional Hobart Spool Gun 3545-20

Reversible drive rolls: two grooves for

two wire sizes on one drive roll

Hinged feeder panel

Infinite wire feed control

Low amperage draw

Comes complete with

factory installed features

Hobart’s 5/3/1 Industrial Warranty

Hobart Welders An Illinois Tool Works Company

U.S. Distributor Sales Phone 920-735-4576 FAX 800-637-2315

Hobart Retail Sales Phone 800-332-3281 FAX 937-332-4161

Canadian Sales Phone 888-489-9353 FAX 519-421-0480

International Sales Phone 920-735-4509 FAX 920-735-4125

Web Site HobartWelders.com

Rated Output

200 A, 24 V DC at 60% duty cycle

Open Circuit

Voltage

35 V

Current Range

30 –250 amps

Dimensions

H: 31-1/4 in. (794 mm)

W: 18-7/8 in. (479 mm)

D: 36-1/2 in. (927 mm)

Amperes Input at Rated Load

200 V 230 V KVA KW

40 35 8 6.8

Wire Feed

Speed Range

90 –750 IPM

Net Weight

195 lb. (88 kg)

SPECIFICATIONS

(SUBJECT TO CHANGE WITHOUT NOTICE.)

INDUSTRIAL

Certified by Canadian Standards Association to both Canadian and U.S. Standards.

2

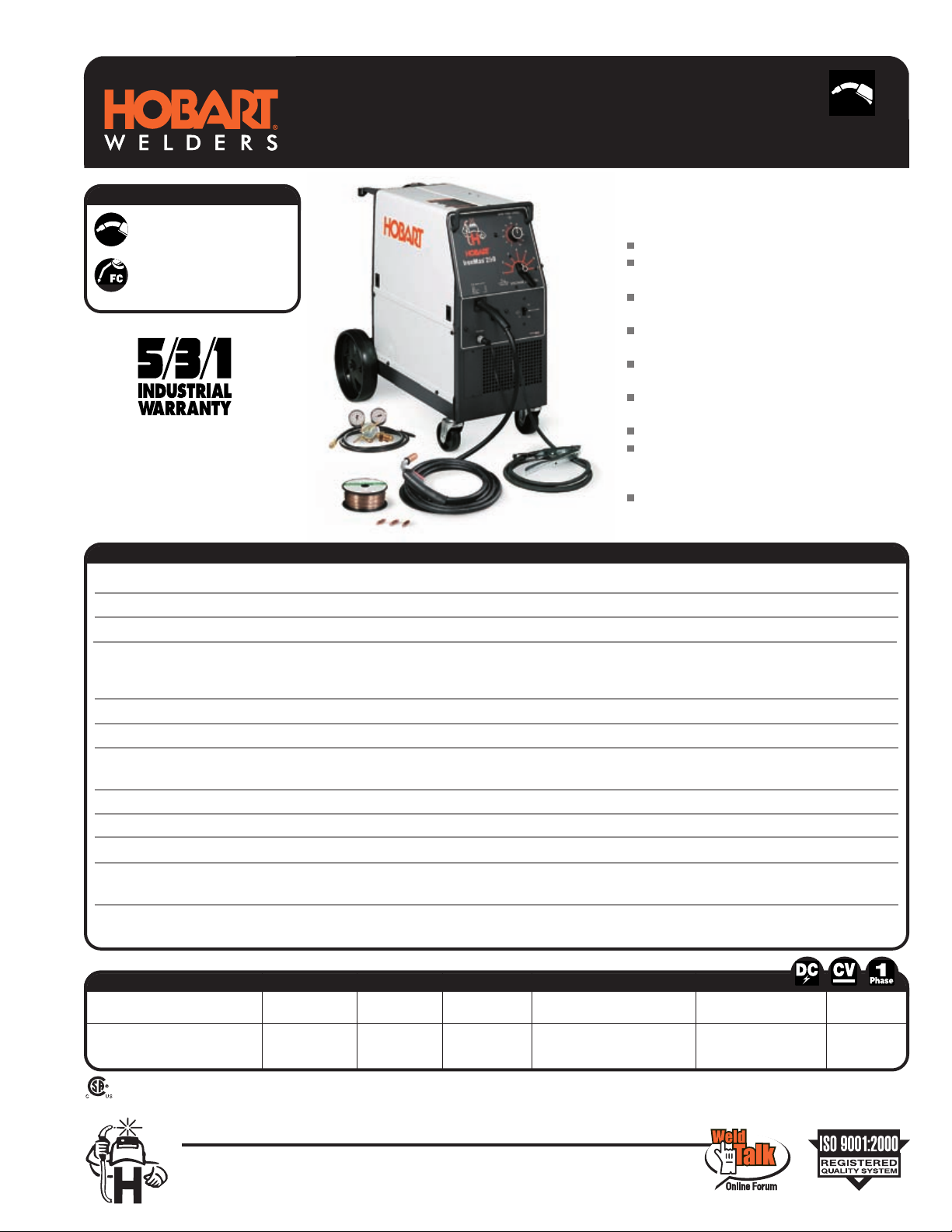

CONTROL PANEL

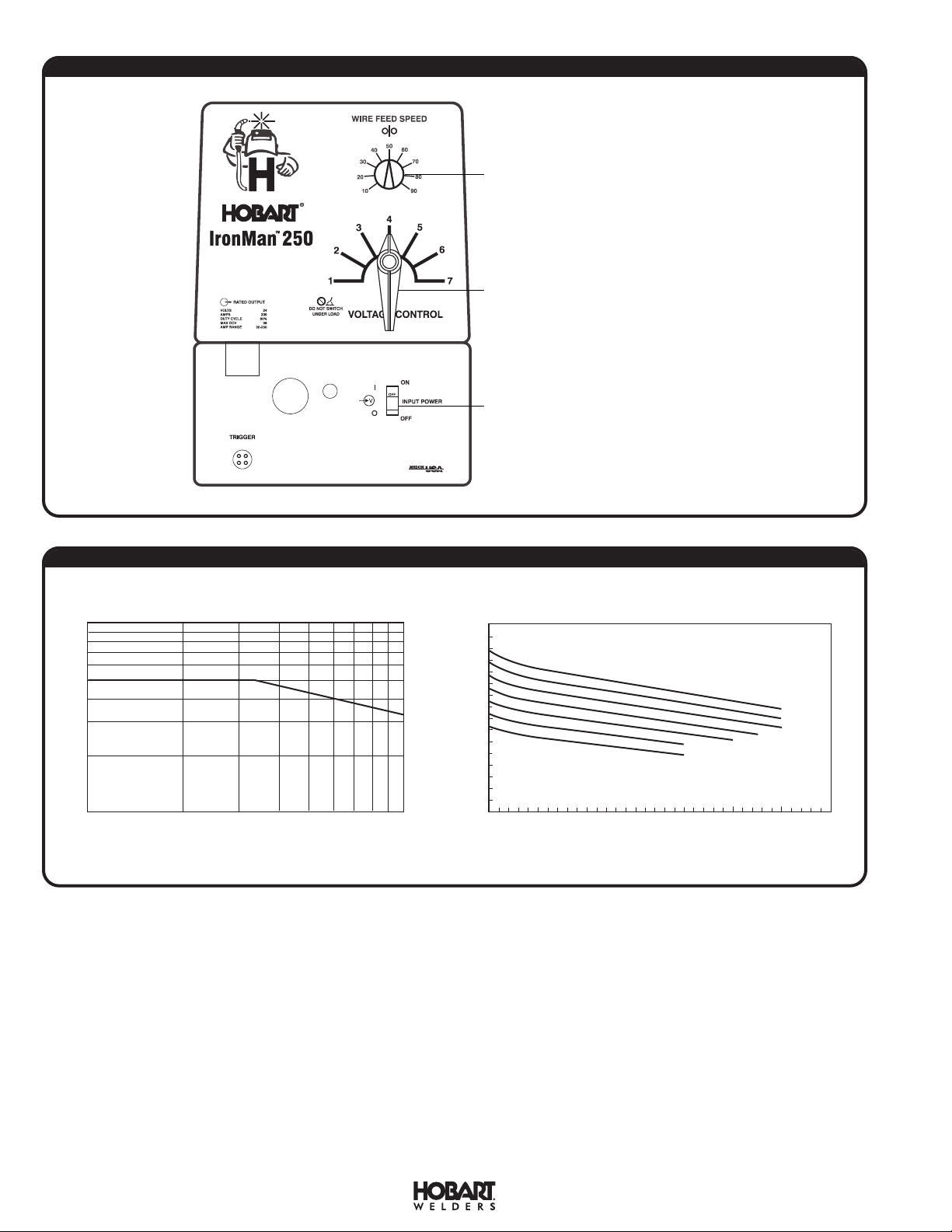

PERFORMANCE DATA

% DUTY CYCLE

10

20 30 40 50 60 70 80

90 100

500

450

400

350

300

250

200

150

100

50

DUTY CYCLE CHART

DC AMPERES

0

100

150

200 250

300

350

40

35

30

25

20

15

10

5

VOLT/AMP CURVES

50

0

DC VOLTS

1

2

3

1. Wire Speed Control

2. Voltage Control

3. Power Switch

Loading...

Loading...