Page 1

Access PrePack System

Operator Manual

ML-29268 EPP Printer

ML-29269 EPCP Console

701 S. RIDGE AVENUE

TROY, OHIO 45374

www.hobartcorp.com

F-35512 (Mar. 2006)

Page 2

Page 3

Access PrePack System Operator Manual

TABLE OF CONTENTS

Chapter 1: Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Welcome. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

FCC Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Verify Correctness of Weight and Price. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Operator Manual Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Chapter 2: Understanding the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Console Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Using the Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Chapter 3: Using the Access PrePack System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Power Up the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Logging onto the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Shutting Down the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

Operator Main Menu Screen Softkeys and Flashkeys . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Modifying the Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Automatic Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Using Automatic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Manual Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Running a Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Using the Operator Main Menu Screen Drop-Down Menus . . . . . . . . . . . . . . . . . . . . .3-12

Product Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-13

Settings Drop-Down Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-18

Help Drop-Down Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Chapter 4: Maintenance & Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Removing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Loading Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

Setting the Label Size Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Cleaning the Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1

F-35512 (Mar. 2006) i Table of Contents

Page 4

Access PrePack System Operator Manual

Table of Contents ii F-35512 (Mar. 2006)

Page 5

Access PrePack System Operator Manual

Chapter 1: Introduction

Introduction

Welcome The Access PrePack System was designed as a meat room or pro-

duce back room scale. It gives you merchandising capabilities

with multiple fonts, graphics, and label types.

FCC Note

Verify Correctness of

Weight and Price

Access PrePack System

All necessary operator data appears on the touch screen.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference; in which

case, the user will be required to correct the interference at their

own expense.

Routinely verify label information. Check the multiplication of

price per pound times weight, and check the scale weight against

printed label weight. Weigh the same package several times to

verify outcome consistency. Packages that weigh near the middle

of the 0.01 lb. increment will normally vary up or down by

0.01 lb. Greater variation than 0.01 lb indicates the system needs

adjustment. In such a case, or whenever necessary, contact your

local Hobart Representative.

F-35512 (Mar. 2006) 1-1 Introduction

Page 6

Access PrePack System Operator Manual

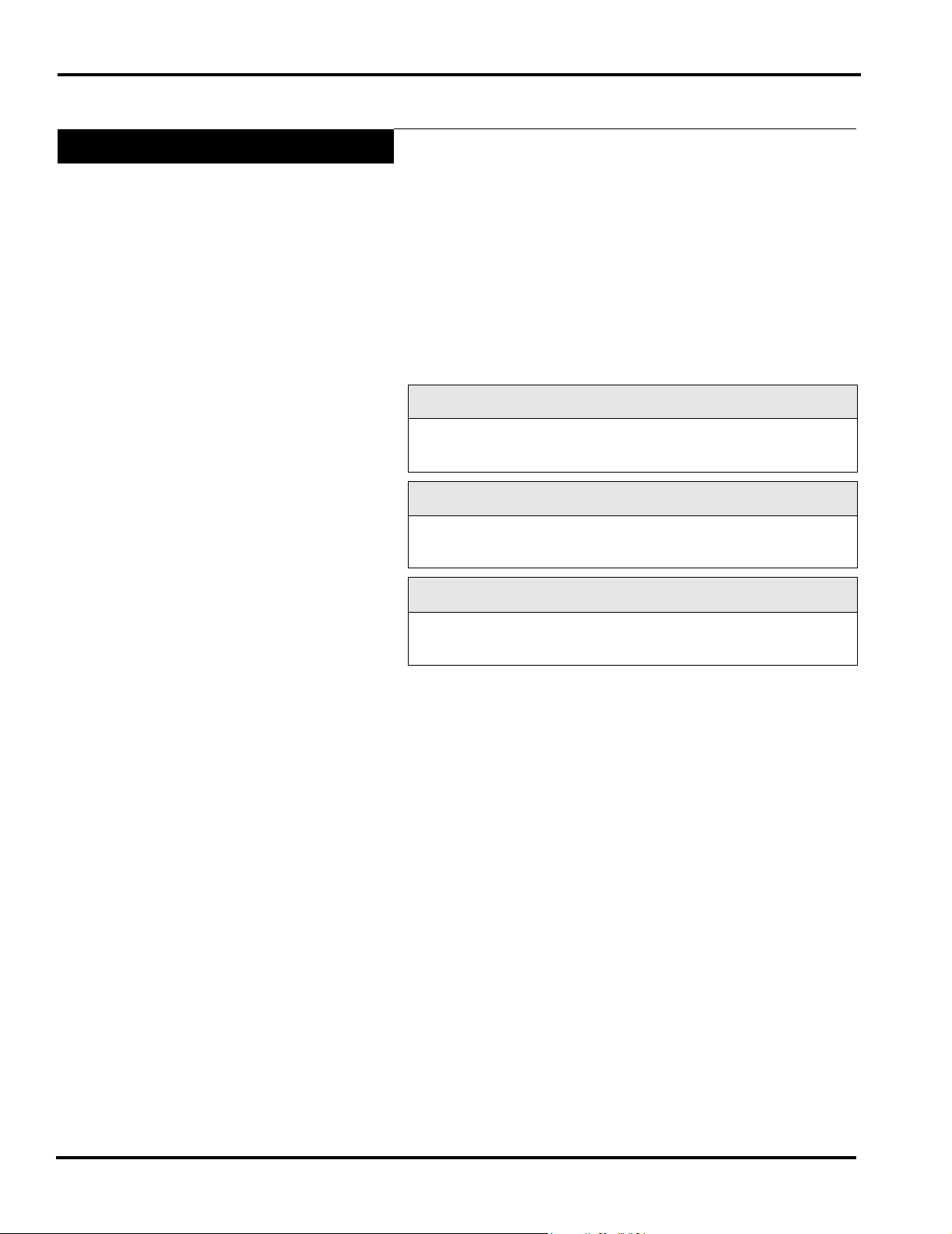

Operator Manual Terminology

This manual uses the following terminology for keystrokes and

data manipulation procedures:

• The word TYPE means to touch a series of keys on the Operator Screen Numeric Keypad or the Operator Screen Alpha

Keyboard.

• The word TOUCH means to activate an entry shown on the

Operator Display screen.

• The word SELECT means to activate one item from a list

brought up on the Operator Screen.

The following special instructions are used in the manual:

Note

A Note is information that you need to know, but is not an actual

step in the process.

Tip

A Tip is additional information that may be useful when you are

using the system.

Look At This

Look At This is information to alert you that you may be doing

something that will permanently alter your system.

Introduction 1-2 F-35512 (Mar. 2006)

Page 7

Chapter 2: Understanding the System

Understanding the System

Access PrePack System Operator Manual

The Access EPP Scale System can store information on thousands of products. Retail store information required for product

handling and processing, such as PLU number, UPC number,

Pricing, Tare, and Self Life is included. Consumer information

describing products, such as NutriFacts, Safe Handling,

Expanded Text, Health Tips, Meal Planners, Recipes, Cooking

Instructions, and Merchandising Graphics is also included.

The scale should be installed and moved only by qualified Hobart

Service Technicians. The system can operate in a temperature

range from 32°F to 104°F (0°C to 40°C).

The following topics are discussed in this chapter:

Electrical Connections

Console Communication Connections

Using the Console

Electrical Connections

Console Communication

Connections

Using the Console

A power cord is located on the back of the printer. Electric power

of 120 or 208/240 volts, 50 or 60 Hz, 1 phase (2-wire plus

ground) is required.

On the Access PrePack System, in addition to the electrical connections, there are several ports that can be configured:

• RJ-45 Jack for an Ethernet Connector (TCP/IP)

–OR–

• Wireless TCP/IP (located on the top of the console).

• 2 Type A USB Ports

Console features:

• Operator Main Menu Screen - a touch-activated screen that

provides access to product data and displays information to

the user.

F-35512 (Mar. 2006) 2-1 Understanding the System

Page 8

Access PrePack System Operator Manual

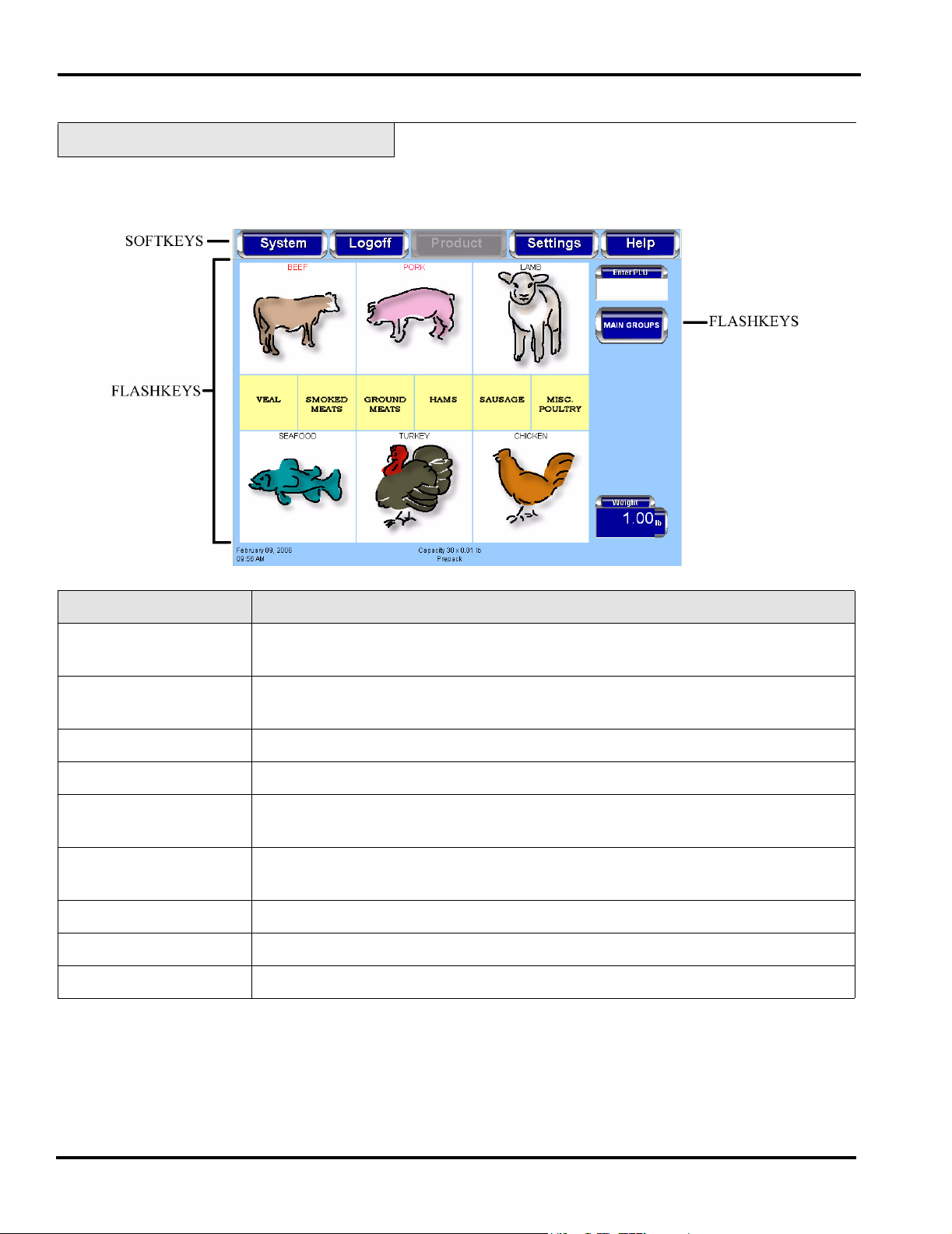

Operator Main Menu Screen

The Operator Main Menu Screen is a touch screen that enables

you to enter information and move through the display screens.

Attributes Functions

Softkeys The softkeys on the Operator Main Menu Screen are used to access the drop-down

menus, which show the subcategories of data available for selection.

Check Box A check box enables or disables optional functions. A check mark or circle appears in

the box when a function is enabled.

Text Box A text box is a field into which you enter data.

Grayed Field A grayed field indicates the field is not available for the current screen or transaction.

Flashing Cursor The flashing cursor in a text box indicates that the field is currently activated and is

available for data entry.

Light Blue Highlighted

Drop-Down Menu

A drop-down menu subcategory shown in light blue indicates the drop-down menu

subcategory has been activated and can be selected.

Flashkeys The Flashkeys provide quick access to frequently used products and functions.

Numeric Keypad The numeric keypad appears on the screen when numeric data is to be entered.

Alpha Keyboard The alpha keyboard appears on the screen when alpha data is to be entered.

Understanding the System 2-2 F-35512 (Mar. 2006)

Page 9

Chapter 3: Using the Access PrePack System

Using the Access PrePack System

Access PrePack System Operator Manual

Chapter 3:

Power Up the System

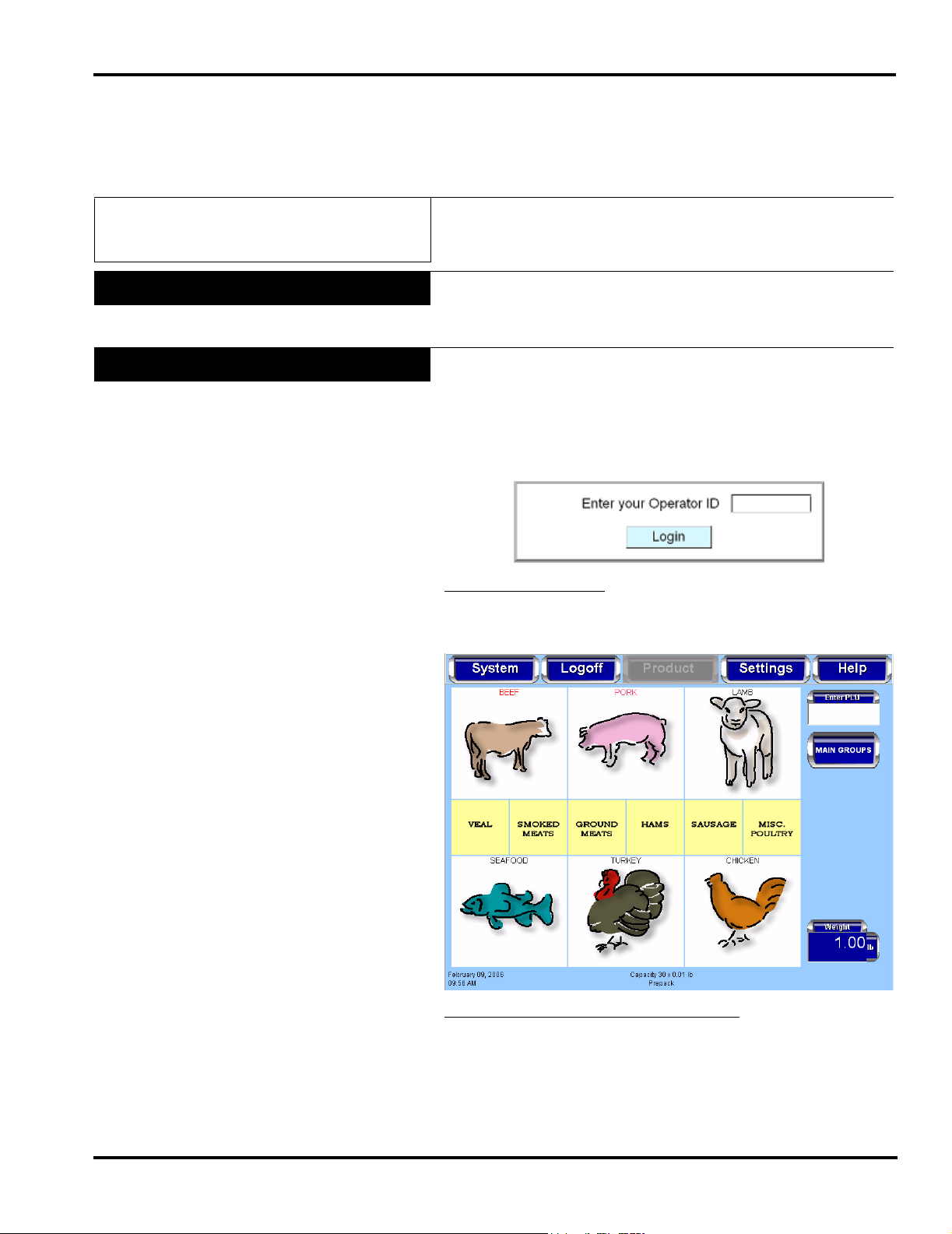

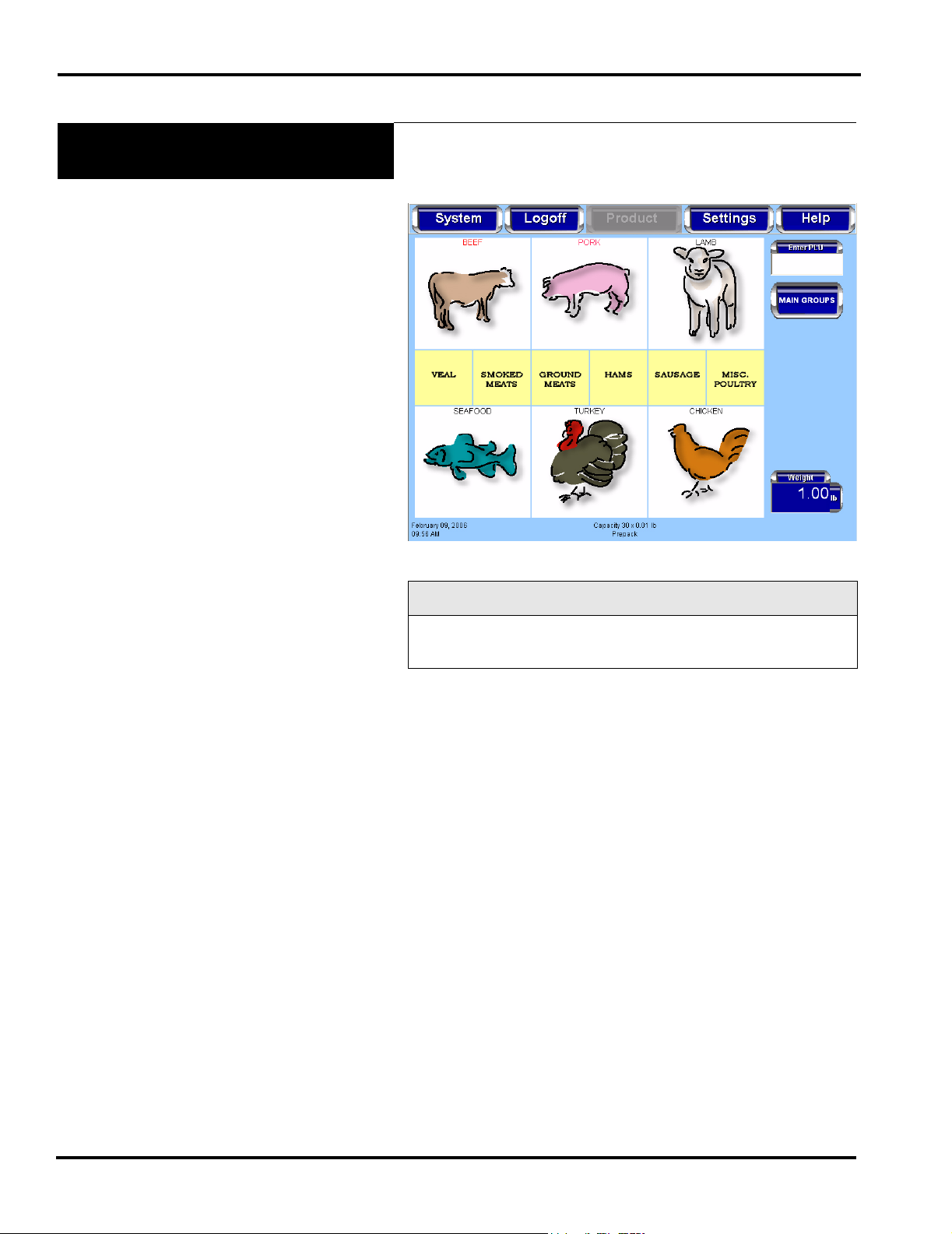

Logging onto the System

To power up the Access PrePack System, use the on/off switch

located on the back of the printer.

The Access PrePack System may require each operator to login

before use. Not all system are setup to have operator’s login.

The instructions for using this system are detailed in this chapter.

To login to the system you should be at the Operator Login

Screen shown below.

To Login to the System

TYPE your Operator ID. You should now be on the Operator

Main Menu Screen.

: TOUCH the Operator ID field and

To Logoff the Operator Main Menu Screen

the Operator Main Menu Screen. No further action is required.

The Operator Login Screen will be displayed.

F-35512 (Mar. 2006) 3-1 Using the Access PrePack System

: TOUCH Logoff on

Page 10

Access PrePack System Operator Manual

Shutting Down the System

The Shutdown feature is designed to stop all internal functions.

Shutdown is required before power can be disconnected from the

system.

To Shutdown the System:

1. From the Operator Main Menu Screen, TOUCH System.

2. From the System Menu, TOUCH Shutdown. A screen will

appear and ask, “Are you sure you want to shutdown?”

3. TOUCH OK. A screen will appear and say, “The scale is

shutting down. Please wait....”

Look At This

Shutdown may take a few minutes to complete depending on the

size of the database in the scale. DO NOT disconnect power to

the system during shutdown.

4. When the shutdown is complete, a screen will appear and

say, “The scale has been shutdown. You may remove power

from the scale.

–OR–

Press REBOOT to reboot now.”

5. Remove power by using the on/off switch on the back of the

printer.

Look At This

Do not remove power from the system by unplugging it. Always

use the on/off switch on the back of the printer to power down

the system.

Using the Access PrePack System 3-2 F-35512 (Mar. 2006)

Page 11

Access PrePack System Operator Manual

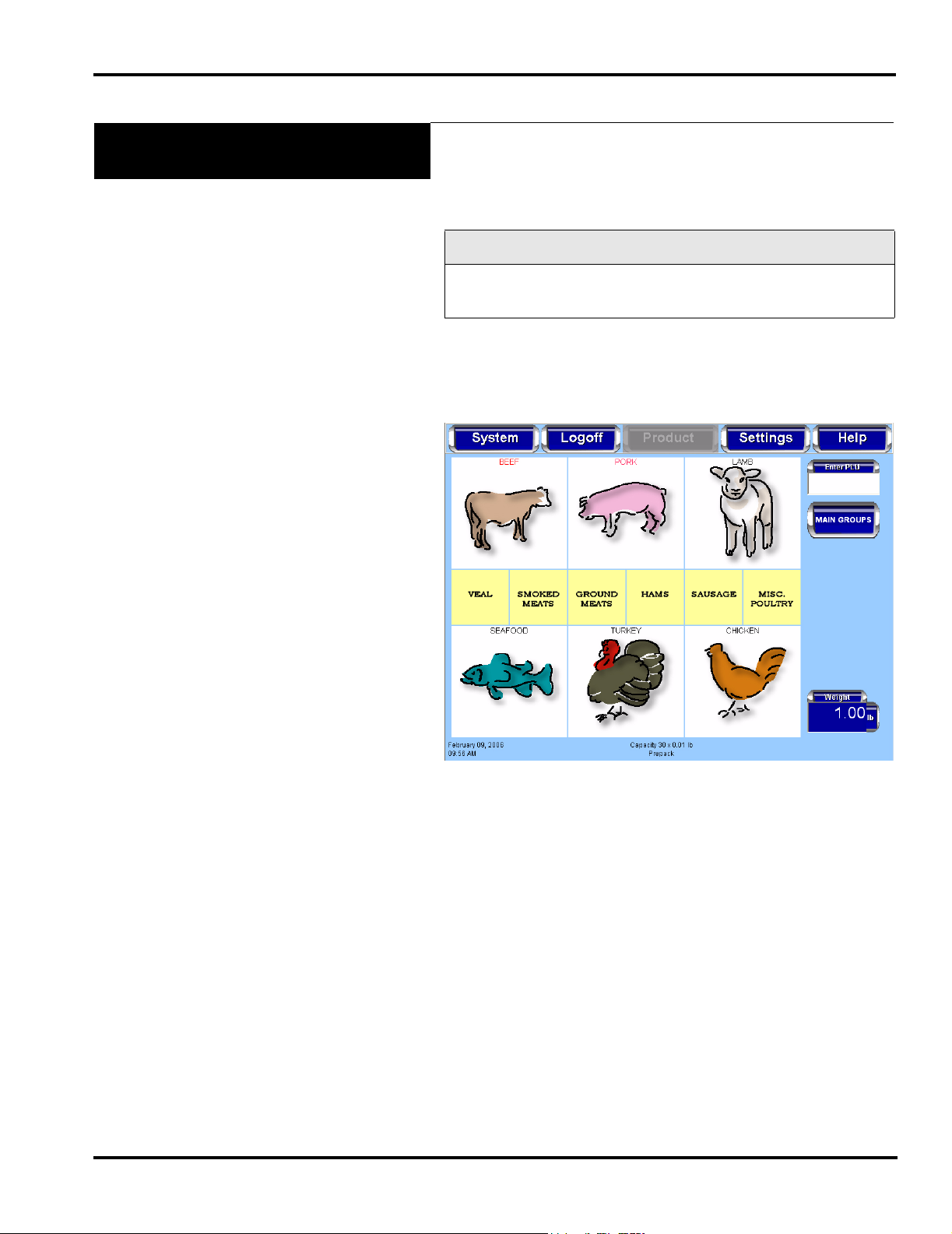

Operator Main Menu Screen

Softkeys and Flashkeys

The Operator Main Menu Screen Softkeys provide access to

drop-down menus showing available functions. The use of these

keys, the screens accessed, and the functions performed through

these keys are described in next section of this manual.

Note

The Product Softkey will only be available when a PLU is

entered.

Flashkeys are the keys located below the Operator Main Menu

Screen softkeys. These keys are configured individually for each

system to provide quick access to products and functions

frequently used.

F-35512 (Mar. 2006) 3-3 Using the Access PrePack System

Page 12

Access PrePack System Operator Manual

Run Screen

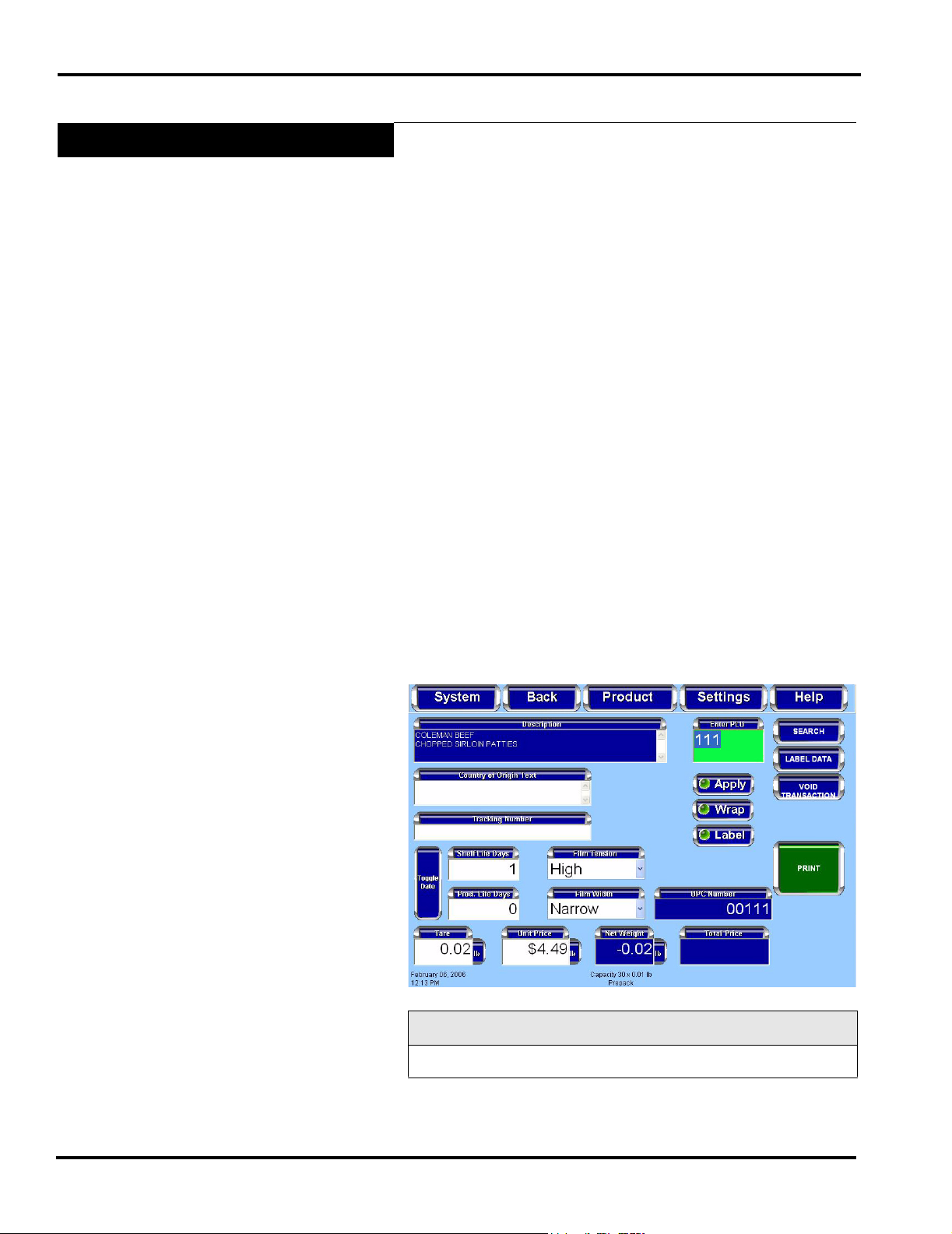

The Run Screen displays product information for the PLU that is

entered. The type of data displayed depends upon the product

weigh type of the PLU.

The Run Screen displays the following product information, if

applicable:

• Enter PLU Number

• Product Description

• Shelf Life Days (toggles to Sell By Date)

• Product Life Days (toggles to Best Before Date)

• Country of Origin Text (COOL)

•Tracking Number

• Product Image (optional)

•UPC Number

•Net Weight

•Total Price

•Print

• Film Tension (wrapper)

• Film Width (wrapper)

• Automatic Label Apply (toggles on/off)

• Automatic Wrap (toggles on/off)

• Automatic Label Print (toggles on/off)

• Tare (if applicable)

• Unit Price (if applicable)

• By Count (if applicable)

• Exception Price (if applicable)

• Volume (if applicable)

Note

System configuation may show different options.

Using the Access PrePack System 3-4 F-35512 (Mar. 2006)

Page 13

Modifying the Run Screen

Access PrePack System Operator Manual

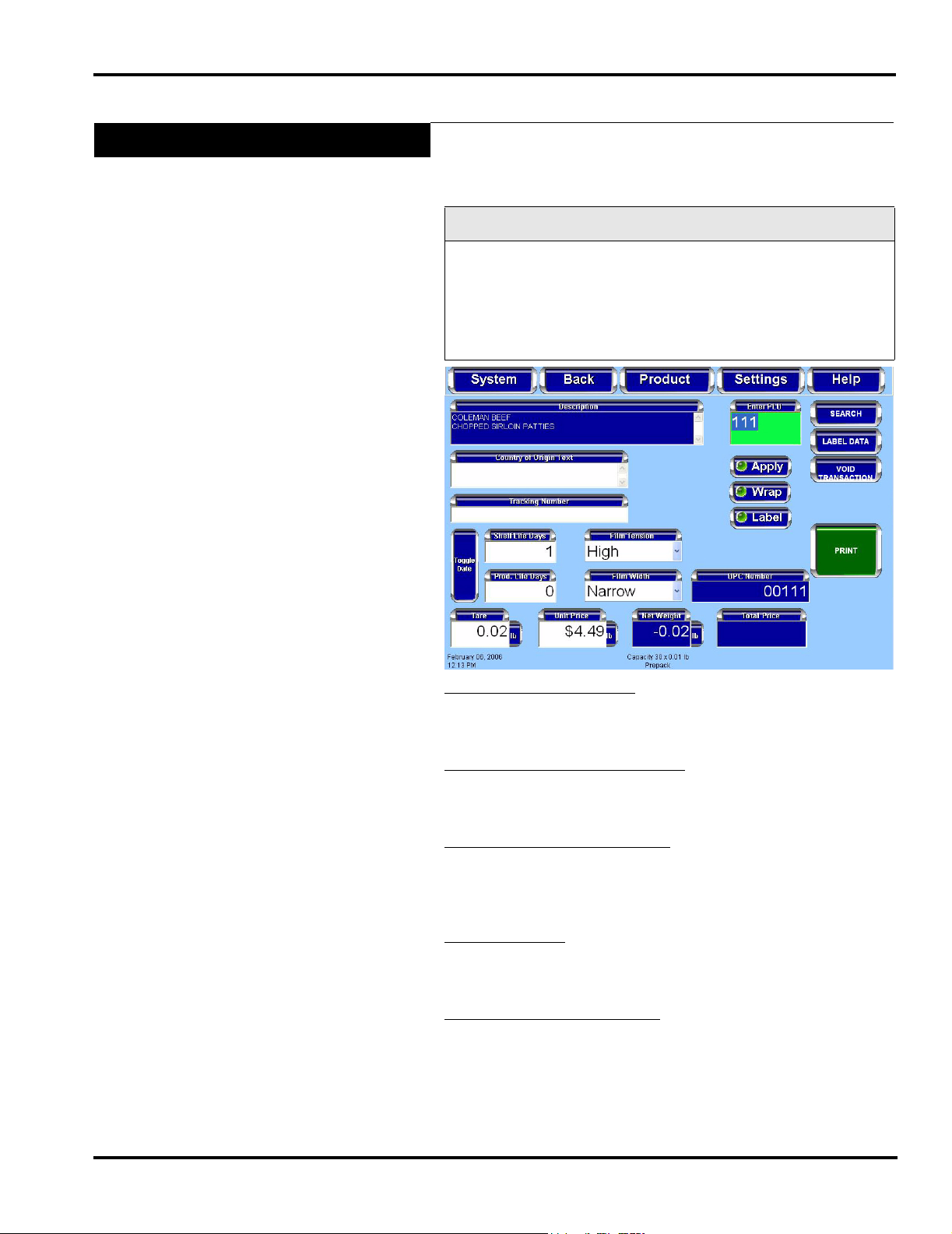

The operator can modify certain settings that display on the Run

Screen. Only text fields with a white background can be

modified. Text fields with a blue background cannot be edited

and provide information only.

Note

• Changes made at the Run Screen will be in effect for the

current product only. The scale will revert to the system

default settings when a different PLU is entered.

• The Apply button, Wrap button, and Wrapper settings are

only displayed on the Run Screen when a wrapper is

attached to the system.

To change Text Field values: TOUCH the text field and SELECT

the setting from the list –OR– TYPE the change on the pop-up

Numeric Keypad or Alpha Keyboard. TOUCH Enter. The value

change will be displayed in the text field.

To change the Film Tension setting

: TOUCH the Film Tension

field. The settings of High, Medium, and Low will be displayed.

SELECT the desired setting. The setting selected will be

displayed in the Film Tension field.

To change the Film Width setting

: TOUCH the Film Width field.

The settings of Narrow, Wide, and Automatic will be displayed.

SELECT the desired setting. The setting selected will be

displayed in the Film Width field. In the Automatic setting the

system will sense the film width needed.

To change COOL

: TOUCH the Country of Origin Text field. You

should now be on the COOL Screen. See Product Drop-Down

Menu - COOL Screen for information about modifying COOL.

The setting changes made will be displayed on the Run Screen.

To change Automatic functions

: TOUCH the automatic buttons

on the screen to turn them on or off. If the indicator is green, then

it is in automatic mode. If the indicator is red, then it is in manual

mode. See Automatic Settings for more information about the

automatic functions available on the Access PrePack System.

F-35512 (Mar. 2006) 3-5 Using the Access PrePack System

Page 14

Access PrePack System Operator Manual

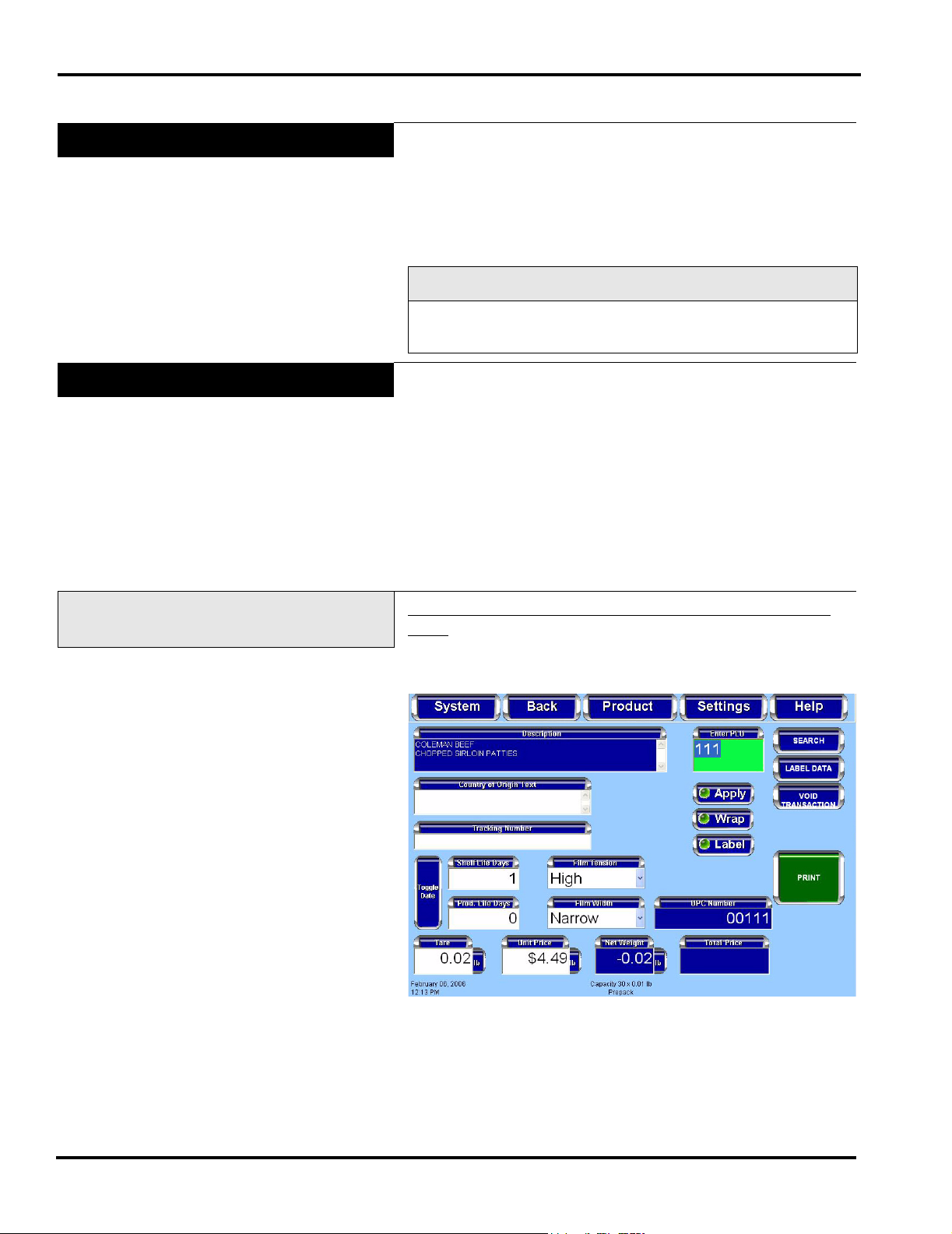

Automatic Settings

The Run Screen has settings for automatic or manual modes. In

Automatic Mode the operation will be performed without the

operator touching PRINT, as is required in Manual Mode. Automatic Mode is changed with the Apply, Wrap, and Label buttons.

The button is in the Automatic Mode when the indicator is green

and in Manual Mode when the indicator is red.

Note

The Apply and Wrap buttons are only displayed on the Run

Screen when a wrapper is included in the system configuration.

Using Automatic Mode

Automatically Wrap, Print and

Apply Label

There are different automatic modes available for use with the

Access PrePack System. If your system is attached to an

automatic wrapper you will have more functions available.

The automatic functions are:

Automatically Wrap, Print and Apply Label

Automatically Print Label Only

Automatically Print and Apply Label, No Wrap (Prepackaged

Products)

Automatically Wrap Only

To wrap the product and print and apply a label in Automatic

Mode: TOUCH the Apply, Wrap, and Label buttons until the

indicators are green. The Enter PLU text background color is

green.

A product is placed on the wrapper scale. The product will run

through the wrapper and will be wrapped. A label will be printed

when a stable weight has been sensed by the scale. The label will

be applied to the product as the product emerges from the

wrapper.

Using the Access PrePack System 3-6 F-35512 (Mar. 2006)

Page 15

Automatically Print Label Only

Access PrePack System Operator Manual

To print a label without applying the label in Automatic Mode:

TOUCH the Label button until the indicator is green. TOUCH the

Apply and Wrap buttons until the indicators are red. The Enter

PLU text background color is white.

Place the product on the wrapper scale. A label will print

automatically when a stable weight has been sensed by the scale.

The label will not be applied to the product. Manually remove the

label from the printer and apply to the product.

F-35512 (Mar. 2006) 3-7 Using the Access PrePack System

Page 16

Access PrePack System Operator Manual

Automatically Print and Apply

Label, No Wrap (Prepackaged

Products)

To print and apply a label to the product in Automatic Mode:

TOUCH the Apply and Label buttons until the indicators are

green. TOUCH the Wrap button until the indicator is red. The

Enter PLU text background is yellow.

Place the product on the wrapper scale. A label will print

automatically when a stable weight has been sensed by the scale.

The product will travel through the wrapper and the label will be

applied. The product will not be wrapped.

Using the Access PrePack System 3-8 F-35512 (Mar. 2006)

Page 17

Automatically Wrap Only

Access PrePack System Operator Manual

To wrap a product without printing or applying a label in

Automatic Mode: TOUCH the Wrap button until the indicator is

green. TOUCH the Apply and Label buttons until the indicators

are red. The Enter PLU text background color is white.

A product is placed on the wrapper scale. The product will run

through the wrapper and will be wrapped.

F-35512 (Mar. 2006) 3-9 Using the Access PrePack System

Page 18

Access PrePack System Operator Manual

Manual Mode

To use Manual Mode: TOUCH the Apply, Wrap, and Label

buttons until the indicators are red. The enter PLU text

background color is white.

A product is placed on the wrapper scale. TOUCH Print to print a

label.

Using the Access PrePack System 3-10 F-35512 (Mar. 2006)

Page 19

Running a Product

Access PrePack System Operator Manual

Running a product is the basic function of the operator. This

function allows the operator to select the PLU, weigh, wrap,

print, and apply the label.

From the Operator Main Menu Screen, TOUCH a Flashkey

–OR– TOUCH the Enter PLU field and TYPE the product

number on the Numeric Keypad. TOUCH Enter. You should now

be on the Run Screen.

Select the automatic setting for this run. See Using Automatic

Mode.

Note

Make sure the product settings are correct before starting a run.

To modify product settings, see Modifying the Run Screen.

To run in Automatic Mode

label will print automatically when a stable weight has been

sensed by the scale.

To run in Manual Mode

Print to print a label. The label will print when a stable weight has

been sensed by the scale.

: Place the product on the scale. The

: Place the product on the scale. TOUCH

F-35512 (Mar. 2006) 3-11 Using the Access PrePack System

Page 20

Access PrePack System Operator Manual

Using the Operator Main Menu

Screen Drop-Down Menus

Additional information is available through the softkeys Product,

Settings, and Help located on the Operator Screen menu bar as

shown on the Operator Main Menu Screen.

The Operator Main Menu Screen drop-down menus include:

Note

The Product Softkey will only be available when a PLU is

entered.

For Product

•Label Data

• Label Placement

• Product Note

• Product & Shelf Life

• COOL

• Void Transaction

For Settings

• Wrapper Settings

• Printer Settings

• Date and Time

• Total Types

• Rezero Weigher

For Help

•Search

• Describe this Page

• Questions

• Operator Note

• Weights & Measures

• About Access

Using the Access PrePack System 3-12 F-35512 (Mar. 2006)

Page 21

Product Drop-Down Menu

Access PrePack System Operator Manual

The Product Drop-Down Menu has the following selections:

Label Data Screen

Label Placement Screen

Product Note Screen

Product & Shelf Life Screen

COOL Screen

Void Transaction

Product Drop-Down Menu Label Data Screen

From the Operator Main Menu Screen, TOUCH Product.

TOUCH Label Data. You should now be on the Label Data

Screen.

To change the Label Type

Numeric Keypad will be displayed. TYPE the label number or

TOUCH clear to delete the label number and enter another one,

then TOUCH enter to complete the label number entry. The width

and length of the label will automatically be displayed below the

Label Type text box.

: TOUCH the Label Type text box. The

Note

If in manual mode, TOUCH Print.

To change the Graphic

from the list.

To exit this screen

F-35512 (Mar. 2006) 3-13 Using the Access PrePack System

: TOUCH the graphic field and SELECT

: TOUCH Back.

Page 22

Access PrePack System Operator Manual

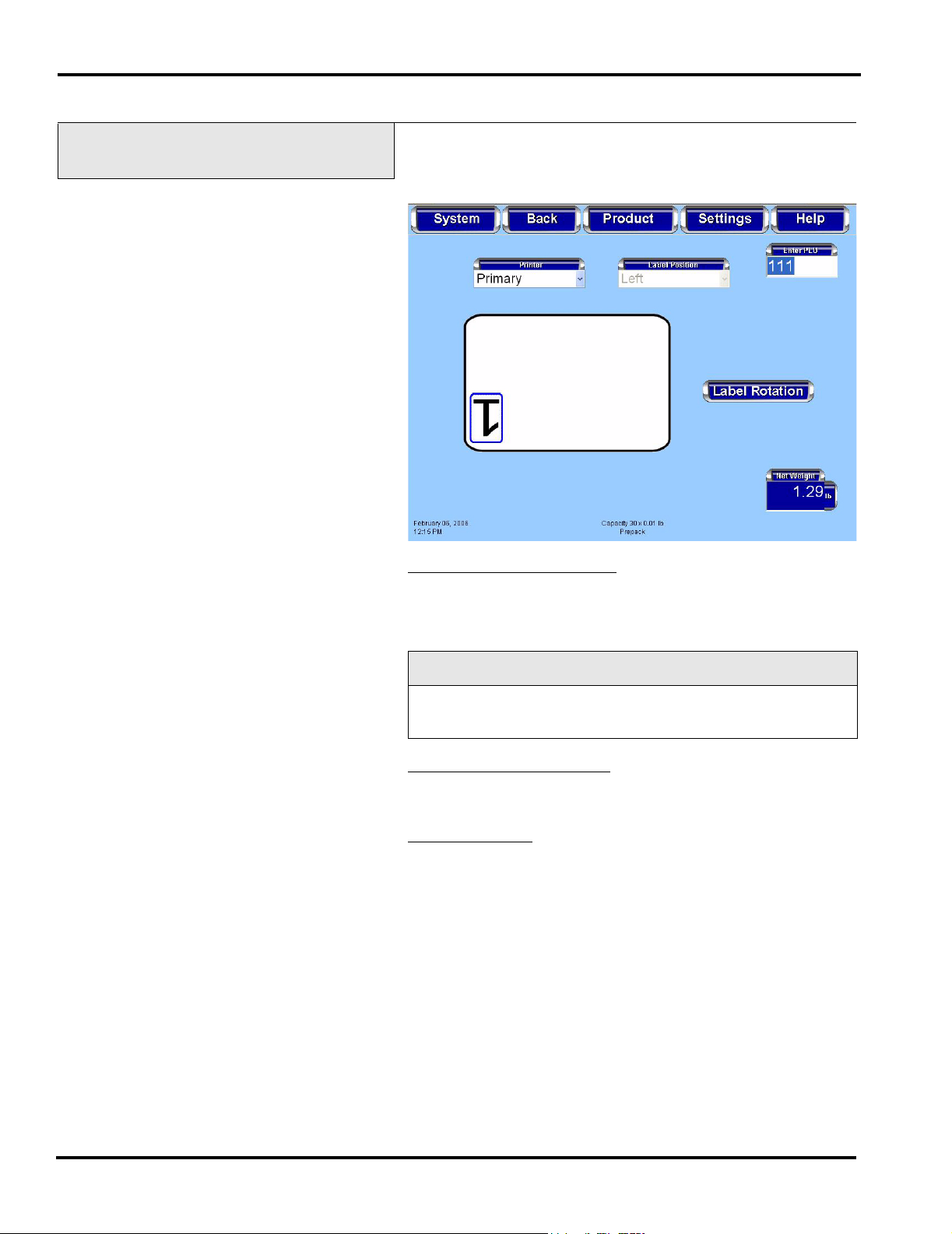

Product Drop-Down Menu Label Placement Screen

From the Operator Main Menu Screen, TOUCH Product.

TOUCH Label Placement. You should now be on the Label

Placement Screen.

To change the Printer Selected

: TOUCH the Printer field. The

printer drop-down selections of Primary and Secondary will be

displayed. SELECT the printer. The default settings for the

selected printer will be displayed.

Note

If only a Primary printer is available the Primary printer text box

will be disabled.

To change the Label Rotation

button until the label shown on the screen is in the desired

orientation.

To exit this screen

: TOUCH Back.

: TOUCH the Label Rotation

Using the Access PrePack System 3-14 F-35512 (Mar. 2006)

Page 23

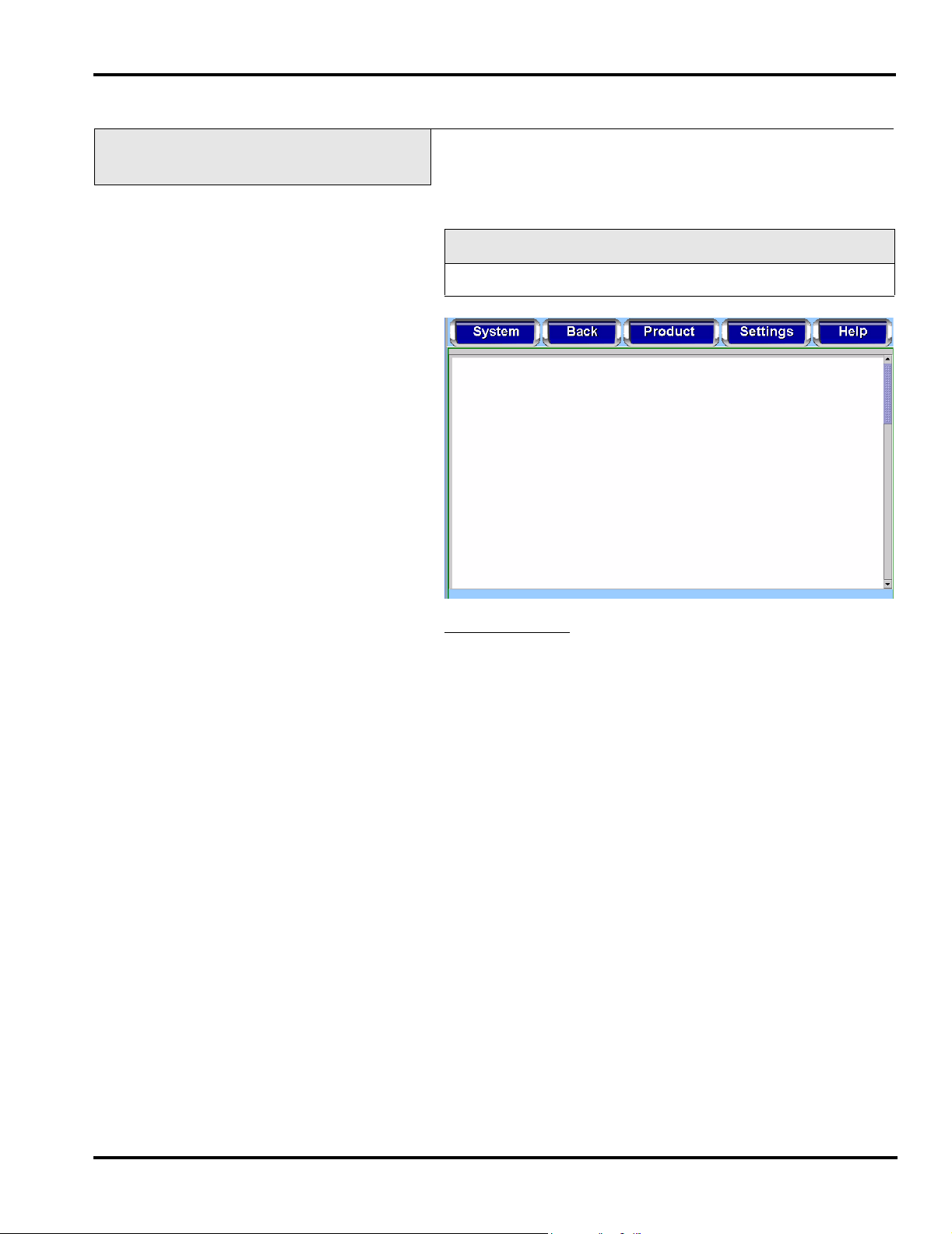

Product Drop-Down Menu Product Note Screen

Access PrePack System Operator Manual

From the Operator Main Menu Screen, TOUCH Product.

TOUCH Product Note. You should now be on the Product Note

Screen.

Note

Not all PLU’s have an associated Product Note.

To exit this screen

: TOUCH Back.

F-35512 (Mar. 2006) 3-15 Using the Access PrePack System

Page 24

Access PrePack System Operator Manual

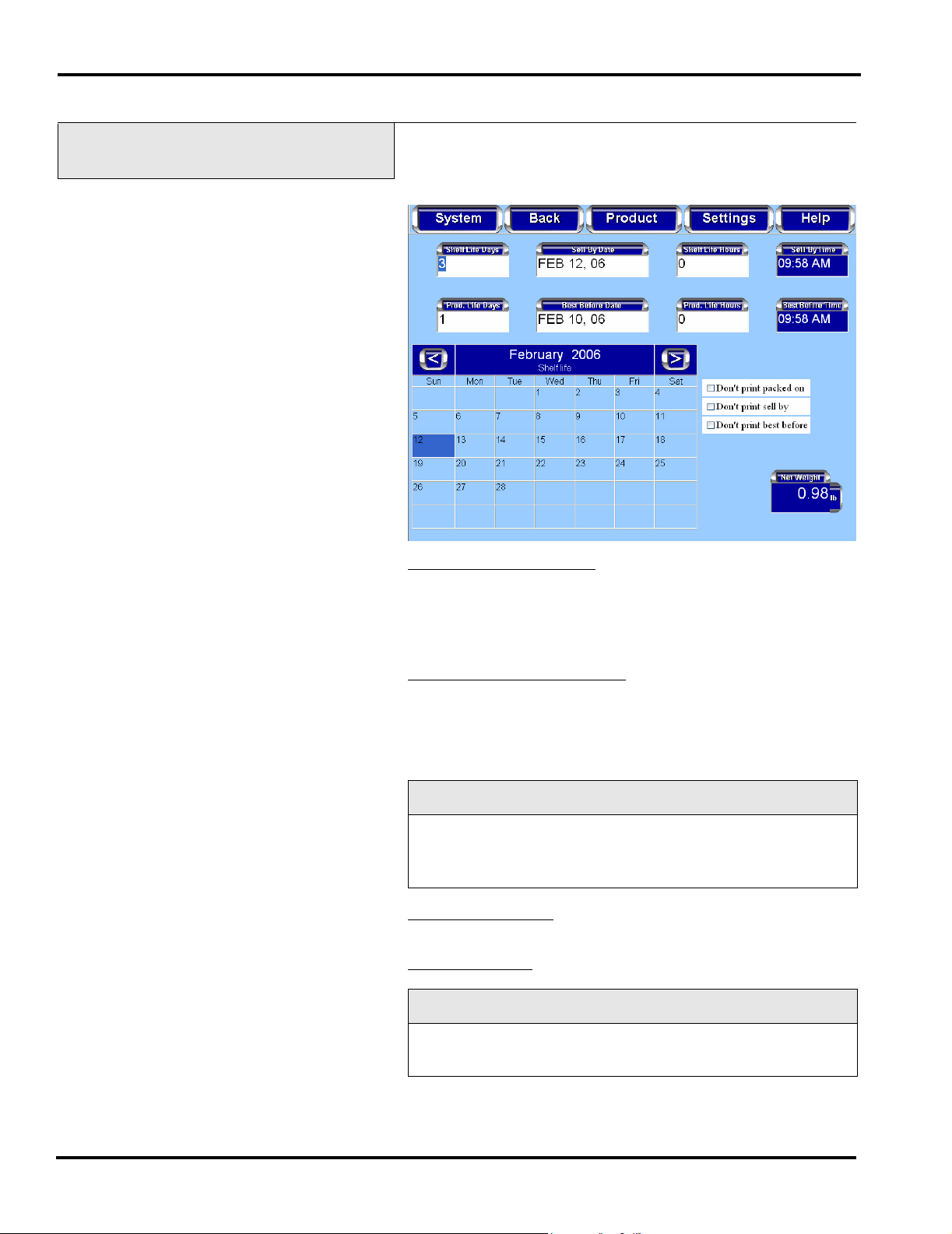

Product Drop-Down Menu Product & Shelf Life Screen

From the Operator Main Menu Screen, TOUCH Product.

TOUCH Product & Shelf Life. You should now be on the

Product & Shelf Life Screen.

To change the Sell By Date

: TOUCH the Sell By Date box to

activate it. The numeric keypad will be displayed. TYPE in the

date using two digits each for the day, month, and year. TOUCH

enter on the keypad. The new date will appear in the Sell By Date

box as well as be highlighted in the calendar.

To change the Best Before Date

: TOUCH the Best Before Date

box to activate it. The numberic keypad will be displayed. TYPE

in the date using two digits each for the day, month, and year.

TOUCH enter on the keypad. The new date will appear in the

Best Before Date box as well as be highlighted in the calendar.

Look At This

You can also use the calendar to change the best before or sell

by date. TOUCH the sell by or best before date field. TOUCH

cancel, then SELECT the date on the calendar.

To change the Month

: TOUCH the arrow keys to the right and

left at the top of the calendar.

To exit this screen

: TOUCH Back.

Note

The Best Before Date changes reflect a change in the Sell By

Date.

Using the Access PrePack System 3-16 F-35512 (Mar. 2006)

Page 25

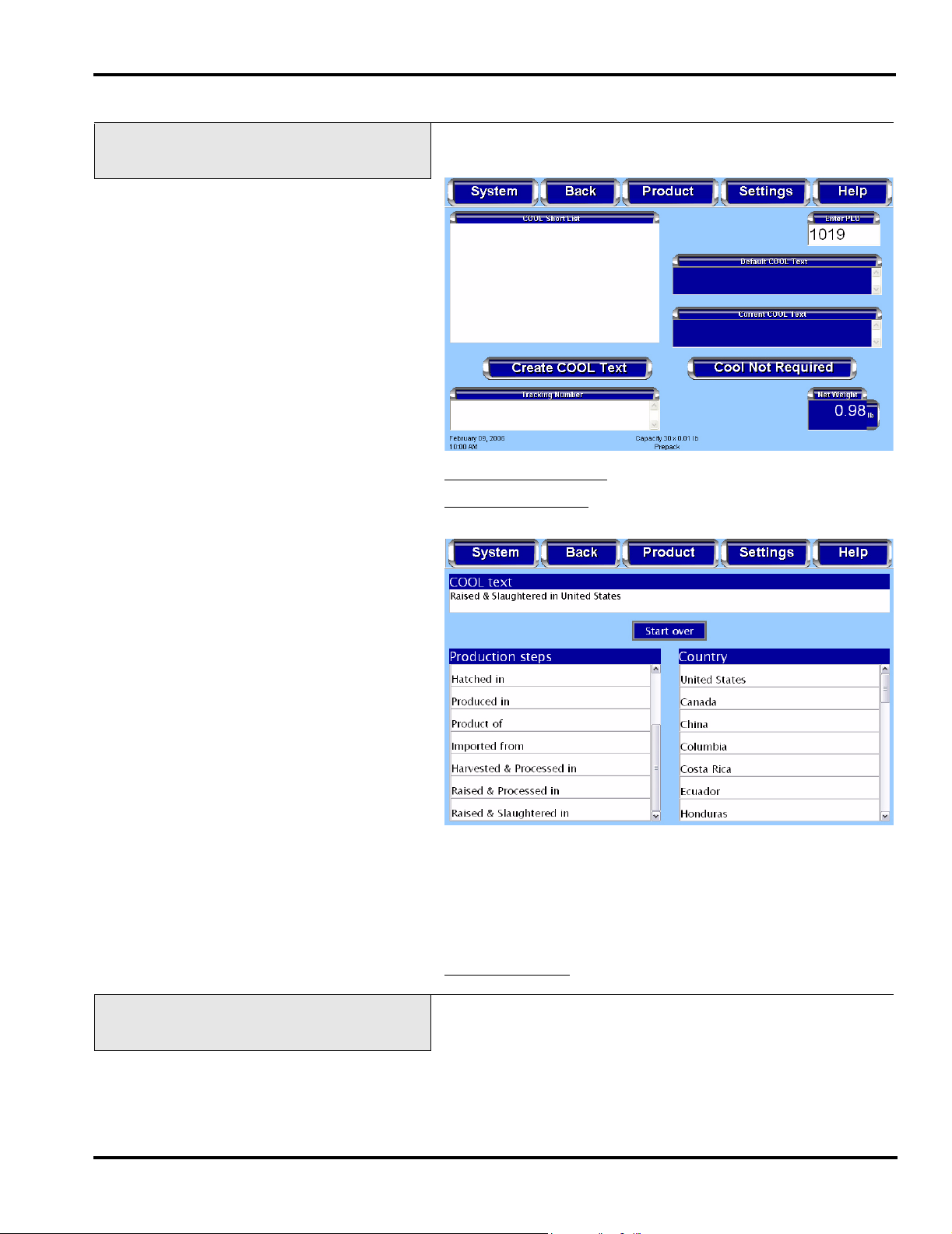

Product Drop-Down Menu COOL Screen

Access PrePack System Operator Manual

From the Operator Main Menu Screen, TOUCH Product.

TOUCH COOL. You should now be on the COOL Screen.

To exclude COOL Data

To create COOL text

: TOUCH the Cool Not Required button.

: TOUCH the Create COOL Text button.

You should now be on the Create COOL Text Screen.

SELECT the appropriate production step from those listed in the

Production Steps box. Repeat this procedure to SELECT the

country from the list in the Country box in which the production

step was performed. The production step and country selected

will be displayed in the COOL Text box. If needed, TOUCH the

Start Over button to delete the COOL text.

: TOUCH Back.

Product Drop-Down Menu Void Transaction

To exit this screen

From the Operator Main Menu Screen, TOUCH Product.

TOUCH Void Transation.

The current transaction will be voided. There will be no further

indication on the screen that the transaction has been completed.

F-35512 (Mar. 2006) 3-17 Using the Access PrePack System

Page 26

Access PrePack System Operator Manual

Settings Drop-Down Menu

The Setting Drop-Down Menu has the following selections:

Wrapper Screen

(only available when system connected to UWS)

Printer Settings Screen

Date and Time Screen

Total Type Screen

Rezero Weigher Screen

Settings Drop-Down Wrapper Screen

From the Operator Main Menu Screen, TOUCH Settings.

TOUCH Wrapper. You should now be on the Wrapper Screen.

To change the Intake Mode

bring up the Intake Mode drop-down selections either Normal,

Default, or Gentle.

: TOUCH the Intake Mode field and

To turn on/off the Sealer Belt

SELECT either On or Off.

To change the Belt Temperature

Setting field. The Numeric Keypad will be displayed. TYPE the

Belt Temperature Setting on the Numeric Keypad. TOUCH Enter.

To change Film Tension

SELECT either High, Medium, or Low.

To change the Film Width

SELECT either Narrow, Wide, or Automatic.

To load Wide Film

To load Narrow Film

To cut the Film

To exit this screen

Using the Access PrePack System 3-18 F-35512 (Mar. 2006)

: TOUCH the Load Wide Film button.

: TOUCH the Load Narrow Film button.

: TOUCH the Cut Film button.

: TOUCH Back.

: TOUCH the Sealer Belt field and

: TOUCH the Belt Temperautre

: TOUCH the Film Tension field and

: TOUCH the Film Width field and

Page 27

Settings Drop-Down Menu Printer Settings Screen

Access PrePack System Operator Manual

From the Operator Main Menu Screen, TOUCH Settings.

TOUCH Printer Settings. You should now be on the Printer

Settings Screen.

To change the Printer Type

: TOUCH the Printer Type field and

SELECT Primary, Second, Third, or None.

To change the Printer Contrast

: TOUCH the Printer Contrast

field and SELECT a number from 0-7. TOUCH the Apply

Changes & Print Label button to save changes and print a sample

label.

Note

Use the lowest contrast level that allows for acceptable print.

To change Label Width

SELECT the desired width. TOUCH the Apply Changes & Print

Label button to save changes and print a sample label.

To change the Horizontal Print Position

Right buttons on either side of the Horizontal Print Position field

to move the print to the left or the right on the label. TOUCH the

Apply Changes & Print Label button to save changes and print a

sample label.

To change the Vertical Print Position

buttons on either side of the Vertical Print Position field to move

the print up or down on the label. TOUCH the Apply Changes &

Print Label button to save changes and print a sample label.

: TOUCH the Label Width field and

: TOUCH the Left or

: TOUCH the Up or Down

To exit this screen

F-35512 (Mar. 2006) 3-19 Using the Access PrePack System

: TOUCH Back.

Page 28

Access PrePack System Operator Manual

Settings Drop-Down Menu Date and Time Screen

The current date and time set for the Access PrePack System is

shown on the Operator Main Menu Screen in the lower left hand

corner.

From the Operator Main Menu Screen, TOUCH Settings.

TOUCH Date and Time. You should now be on the Date and

Time Screen.

To change the Month

month.

To change the Year

: TOUCH the year field and SELECT the

year.

To change the Day

To change the Hour

: TOUCH the day on the calendar.

: TOUCH the HH field and TOUCH the up or

down arrow.

To change the Minute

up or down arrow.

To change AM/P M

: TOUCH the AM/PM field to toggle between

AM and PM.

To exit this screen

: TOUCH Back.

: TOUCH the month field and SELECT the

: TOUCH the MM field and TOUCH the

Using the Access PrePack System 3-20 F-35512 (Mar. 2006)

Page 29

Settings Drop-Down Menu Total Type Screen

Access PrePack System Operator Manual

From the Operator Main Menu Screen, TOUCH Settings.

TOUCH Total Type. You should now be on the Tota l Type

Screen.

Settings Drop-Down Menu Rezero Weigher Screen

To select a Total Type

: TOUCH the Total Type field and

SELECT a Total Type.

To exit this screen

: TOUCH Back.

Ensure that nothing is on the scale. From the Operator Main

Menu Screen, TOUCH Settings. TOUCH Rezero Weigher. A

process box will appear briefly; no other action is required.

F-35512 (Mar. 2006) 3-21 Using the Access PrePack System

Page 30

Access PrePack System Operator Manual

Help Drop-Down Menu

The Help Drop-Down Menu has the following selections:

Search Screen

Describe this Page Screen

Questions Screen

Operator Note Screen

About Access Screen

Weights & Measures Screen

Help Drop-Down Menu Search Screen

From the Operator Main Menu Screen, TOUCH Help. TOUCH

Search. You should now be on the Search Screen.

A search can be performed by a product number or by a product

description. TOUCH either the check box Search by character to

perform a search by product description or Search by PLU to

perform a search by product number.

To perform a Search by character

by Character. TOUCH the text field to the left of the check boxes

to activate it for data entry. The Alpha Keyboard will be

displayed on the screen. TYPE the letters on the keyboard

describing the product. If the search does not begin automatically,

TOUCH Done.

Using the Access PrePack System 3-22 F-35512 (Mar. 2006)

: TOUCH the check box Search

Page 31

Access PrePack System Operator Manual

As shown on the screen below, a list of products is displayed.

TOUCH the scroll bar arrows to the right of the box containing

the product list to scroll up or down and view all of the products

listed. TOUCH the scroll bar arrows below the box to view list

entries that are wider than the box.

SELECT the desired product on the list. The Run Screen for the

selected product will be displayed.

To perform a Search by PLU Range

: TOUCH the check box

Search by PLU. TOUCH the text field to the left of the check

boxes to activate it for data entry. The Numeric Keypad will be

displayed on the screen. TYPE the product number. If the search

does not begin automatically, TOUCH Enter.

F-35512 (Mar. 2006) 3-23 Using the Access PrePack System

Page 32

Access PrePack System Operator Manual

As shown on the screen below, a list of products is displayed.

TOUCH the scroll bar arrows to the right of the box containing

the product list to scroll up or down and view all of the products

listed. TOUCH the scroll bar arrows below the box to view list

entries that are wider than the box.

Help Drop-Down Menu Describe this Page Screen

SELECT the desired product on the list. The Run Screen for the

selected product will be displayed.

The Describe this Page Screen will give you tips about the current

screen.

From the Operator Main Menu Screen, TOUCH Help. TOUCH

Describe this Page. You should now be on the Describe this Page

Screen.

To exit this screen

: TOUCH Back.

Using the Access PrePack System 3-24 F-35512 (Mar. 2006)

Page 33

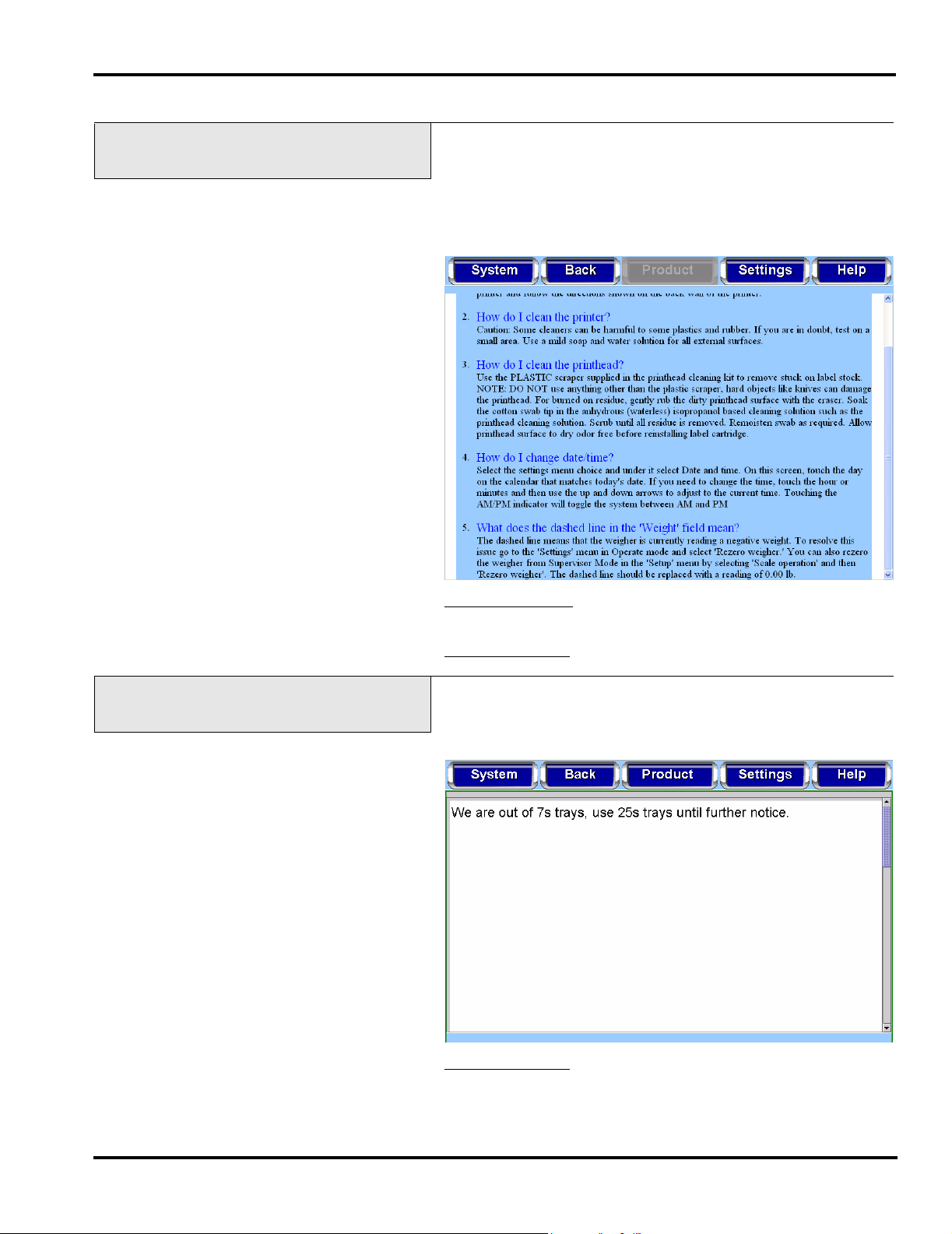

Help Drop-Down Menu Questions Screen

Access PrePack System Operator Manual

The Questions Screen will show a list of frequently asked

questions regarding the Access PrePack System operation and

maintenance.

From the Operator Main Menu Screen, TOUCH Help. TOUCH

Questions. You should now be on the Questions Screen.

Help Drop-Down Menu Operator Note Screen

To view Questions

: TOUCH the scroll bar on the right of the list

of questions to scroll up and the down the list of questions.

To exit this screen

: TOUCH Back.

From the Operator Main Menu Screen, TOUCH Help. TOUCH

Operator Note. You should now be on the Operator Note Screen.

This is only available if there is a note.

To exit this screen

F-35512 (Mar. 2006) 3-25 Using the Access PrePack System

: TOUCH Back.

Page 34

Access PrePack System Operator Manual

Help Drop-Down Menu About Access Screen

From the Operator Main Menu Screen, TOUCH Help. TOUCH

About Access. You should now be on the About Access Screen.

Help Drop-Down Menu Weights & Measures Screen

To exit this screen

: TOUCH Back.

From the Operator Main Menu Screen, TOUCH Help. TOUCH

Weights & Measures. You should now be on the Weight s &

Measures Screen.

Note

The information on this screen will vary depending on the

peripherals attached.

To exit this screen: TOUCH Back.

Using the Access PrePack System 3-26 F-35512 (Mar. 2006)

Page 35

Chapter 4: Maintenance & Cleaning

Maintenance & Cleaning

Access PrePack System Operator Manual

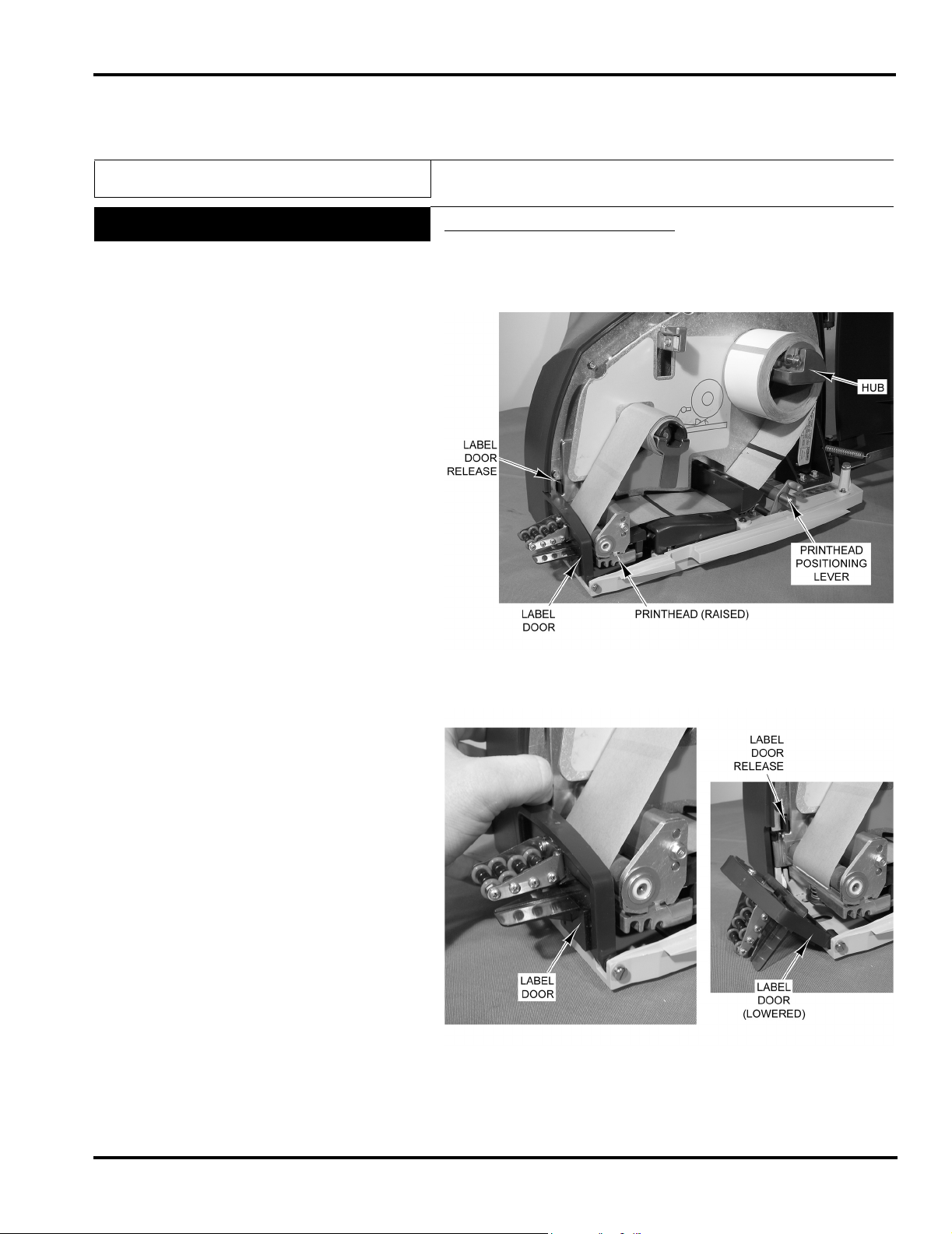

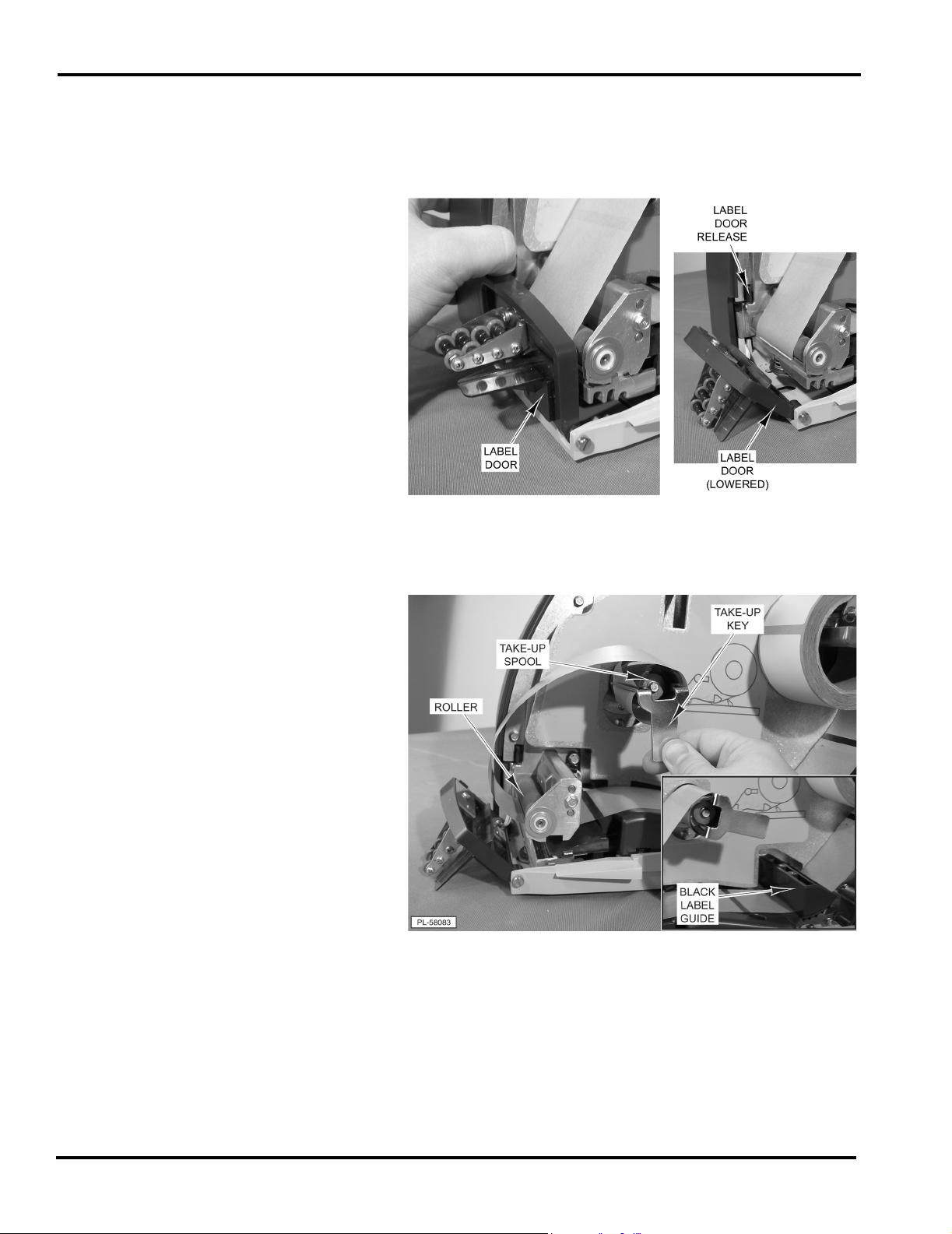

Removing Labels

To remove labels from the printer:

1. Open the printer label access door.

2. Pull the printhead positioning lever toward the printhead to

lower the printhead.

3. Push and hold in the label door release located on the interior

back wall behind the roller and lower the label door.

F-35512 (Mar. 2006) 4-1 Maintenance & Cleaning

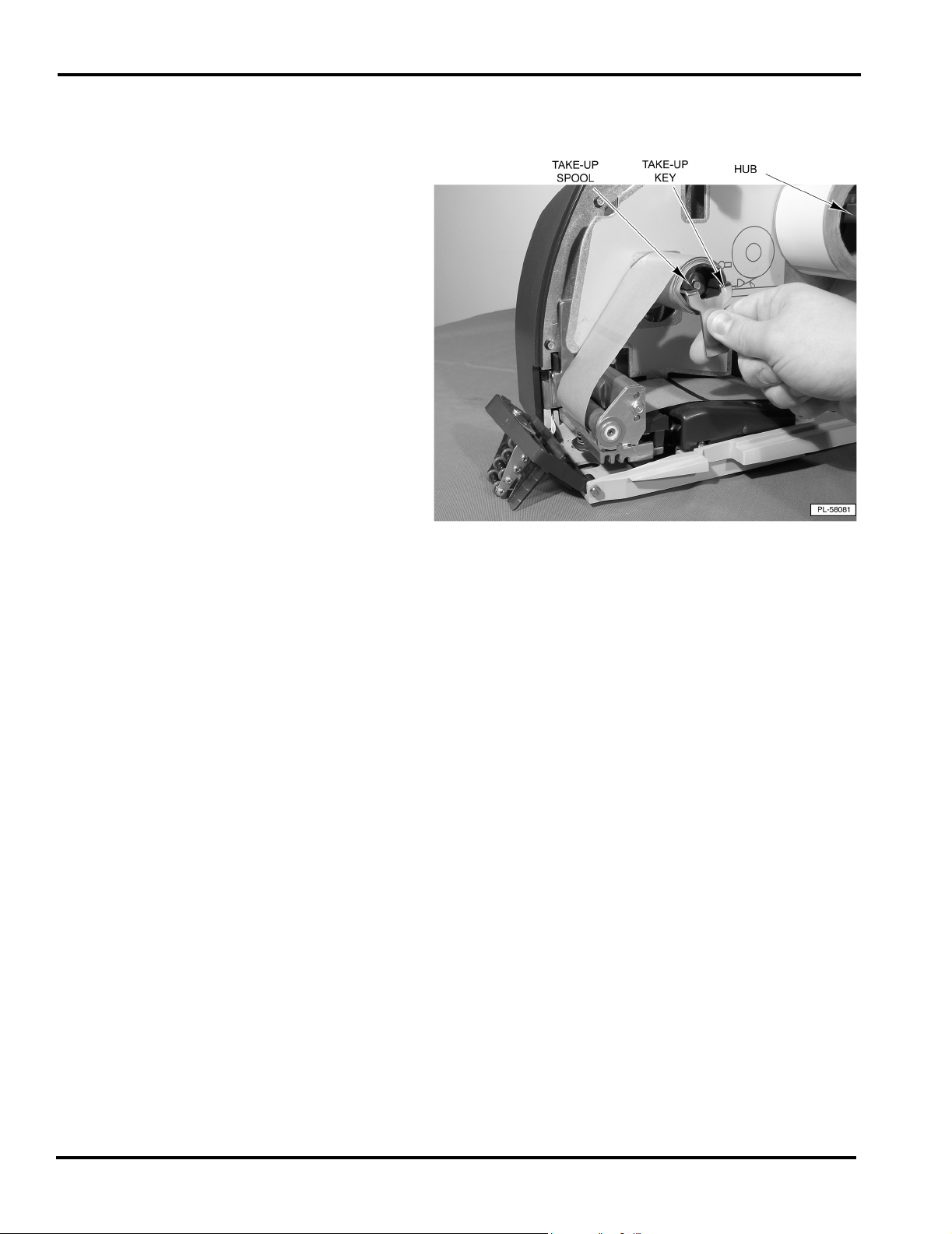

Page 36

Access PrePack System Operator Manual

4. Remove the take-up spool key.

5. Remove the label backing paper from the take-up spool and

the label roll from the hub.

Maintenance & Cleaning 4-2 F-35512 (Mar. 2006)

Page 37

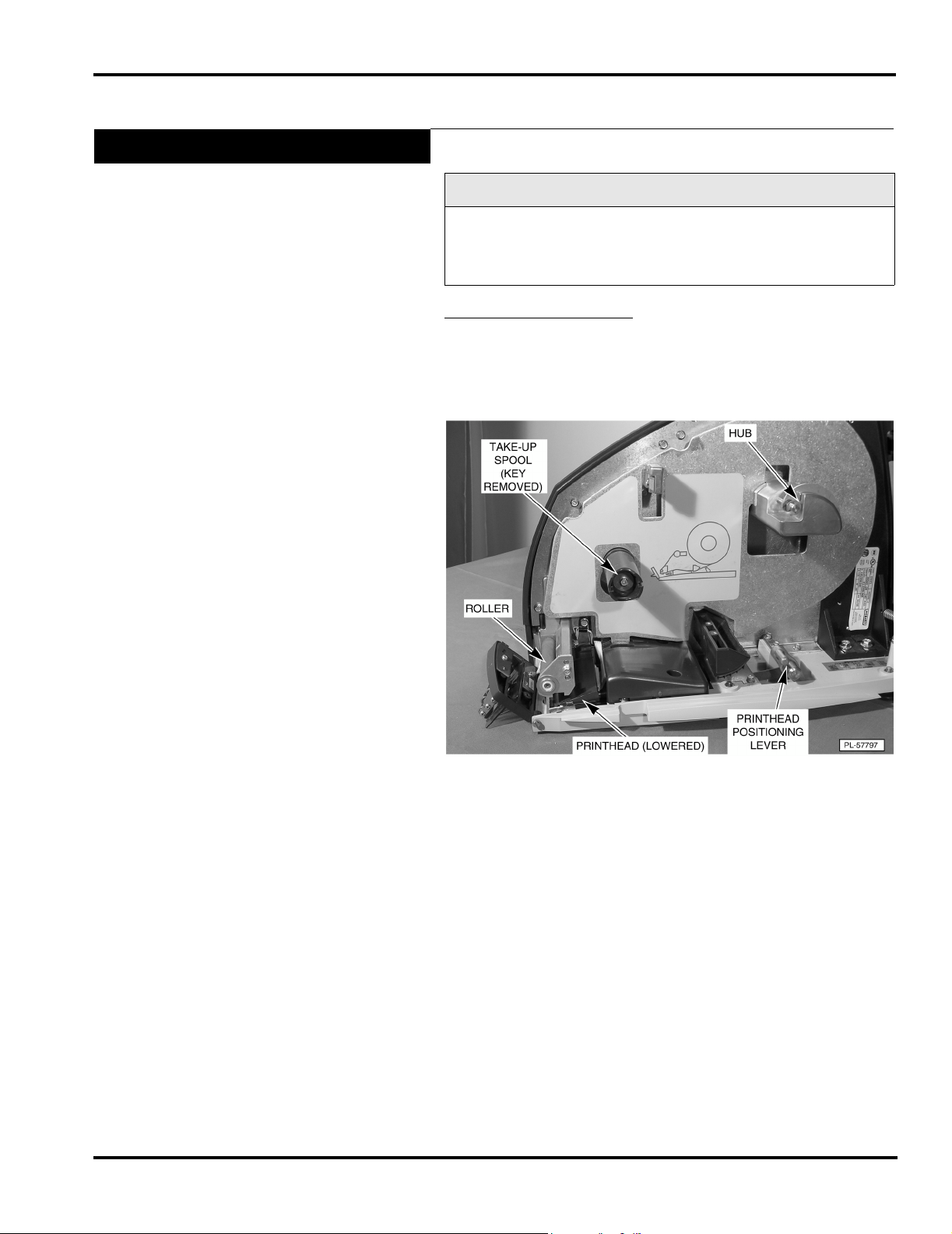

Loading Labels

Access PrePack System Operator Manual

Note

Before loading labels:

•See Cleaning the Printhead.

•See Setting the Label Size Plate.

To load labels in the printer

:

1. Remove labels from the first 12 inches of the new label roll.

This will create a leader to attach to the take-up spool.

2. Pull the printhead positioning lever toward the printhead to

lower the printhead.

F-35512 (Mar. 2006) 4-3 Maintenance & Cleaning

Page 38

Access PrePack System Operator Manual

3. Push and hold in the label door release located on the interior

back wall behind the roller and lower the label door.

4. Place the label roll on the hub. The leader feeds from the

bottom of the roll in a clockwise direction.

5. Remove the take-up spool key.

6. Wrap the leader under the black label guide, around the roller

and the take-up spool and insert the take-up spool key. Insert

the short side of the key first and catch the leader under the

long side of the key.

7. Take up the leader slack and align the leader on the spool.

Maintenance & Cleaning 4-4 F-35512 (Mar. 2006)

Page 39

Access PrePack System Operator Manual

8. Close the label door on the front of the printer.

9. Pull the printhead positioning lever away from the printhead

to raise the printhead into position. The printer will

automatically advance the labels through the printhead

setting the labels in the ready position.

10. Close the printer label access door.

F-35512 (Mar. 2006) 4-5 Maintenance & Cleaning

Page 40

Access PrePack System Operator Manual

Setting the Label Size Plate

To set the label size plate:

1. Lift the label plate and set it in the slots for the size labels

being used.

2. Move the lever on the hub to the slot for the size labels being

used.

Note

If you change the label size, make sure to adjust the printer settings (see Printer Settings Screen).

Maintenance & Cleaning 4-6 F-35512 (Mar. 2006)

Page 41

Access PrePack System Operator Manual

Cleaning the Printhead

The printhead of your Access PrePack System Printer should be

cleaned approximately once each week, or whenever labels are

obstructed due to a residue buildup on the printhead and/or roller.

It is a good idea to clean the printhead roller whenever a new

roll of labels is installed. To obtain a Printhead Cleaning Kit,

contact your local Hobart Representative; request

Part Number 00-184326.

Look At This

Do not use a metal tool on the printhead. This could scratch or

break the printhead. In addition, monitor the printer to look for

labels stuck on the printer parts. If found, remove these labels at

once following the instructions given below.

To clean the printhead

:

1. With the label door lowered, the labels removed and the

printhead in the lowered position, check to see if the printhead is clean and free of label stock and label adhesive.

2. Use the scrapper from the Printhead Cleaning Kit to remove

stuck-on label stock.

3. To remove burnt-on adhesive, gently rub the printhead surface with the eraser from the Printhead Cleaning Kit.

4. Using the cleaner and a swab from the Printhead Cleaning

Kit, scrub the printhead until all of the residue is removed.

5. Clean the roller with the cleaner and swabs.

6. Allow the printhead and roller to dry before loading the

labels.

F-35512 (Mar. 2006) 4-7 Maintenance & Cleaning

Page 42

Access PrePack System Operator Manual

Troubleshooting

Problem Possible Cause Action/Solution

In the event that your Access PrePack System does not operate as

expected, please reference the following troubleshooting steps

before calling for service.

If you are experiencing problems with the system, the following

scenarios may be of help.

There is no display on the

display unit.

The Operator ID was not

accepted.

Product number was not

found.

System prompts you to take

a label. No label is present.

You may not have power running to the

system.

Verify the following connections:

• Power cord is plugged into a working electrical outlet.

• Power cord is plugged into the

rear of the printer.

• Display unit power cord is plugged

into the printer.

• Display unit power cord is plugged

into the display unit.

• USB cable is plugged into the

printer.

• USB cable is plugged into the

display unit.

You may have entered the wrong ID. Verify that you are entering the proper

ID. If correct, have your supervisor

check the ID number.

You may have entered an invalid prod-

Verify the product number.

uct number.

A portion of the label may be ‘hidden’

Make sure that the label exit is clear.

in the label exit.

Partial non-printed label is

exposed.

System prints blank labels or

partially printed labels.

The labels may be improperly

threaded.

The labels may be improperly threaded

or the printhead or roller may be dirty.

Verify that labels are properly

threaded.

Check to see that labels are threaded

properly. If the problem persists,

clean the printhead using the Hobart

Printhead Cleaning Kit.

Maintenance & Cleaning 4-8 F-35512 (Mar. 2006)

Page 43

Index

Access PrePack System Operator Manual

A

About Access Screen, 3-26

Alpha Keyboard, 2-2

Automatic Settings, 3-6

Automatically Print and Apply Label, No Wrap

(Prepackaged Products), 3-8

Automatically Print Label Only, 3-7

Automatically Wrap Only, 3-9

Automatically Wrap, Print and Apply Label, 3-6

C

Cleaning the Printhead, 4-7

Console Communication Connections, 2-1

COOL Screen, 3-17

D

Date and Time Screen, 3-20

Date, Best Before, 3-16

Date, Sell By, 3-16

Describe This Page Screen, 3-24

E

Electrical Connections, 2-1

F

FCC Note, 1-1

Flashkeys, 2-2

G

Grayed Field, 2-2

O

Operator Main Menu Screen, 2-2

Operator Main Menu Screen Softkeys and Flashkeys, 3-3

Operator Manual Terminology, 1-2

Operator Note Screen, 3-25

P

Power up the scale system, 3-1

Printer Settings Screen, 3-19

Printhead Cleaning Kit, 4-7

Printhead cleaning kit part number, 4-7

Product & Shelf Life Screen, 3-16

Product Drop-Down Menu, 3-13

Product Note Screen, 3-15

Q – R

Questions Screen, 3-25

Removing Labels, 4-1

Rezero Weigher Screen, 3-21

Run Screen, 3-4

Running a Product, 3-11

S

Search by character, 3-22

Search by PLU Range, 3-23

Search Screen, 3-22

Select a Total Type, 3-21

Setting the Label Size Plate, 4-6

Settings Drop-Down Menu, 3-18

Shutting Down the System, 3-2

Softkeys, 2-2

H

Help Drop-Down Menu, 3-22

L

Label Data Screen, 3-13

Label Placement Screen, 3-14

Label Type, 3-13

Loading Labels, 4-3

Logging onto the System, 3-1

M

Maintenance & Cleaning, 4-1

Manual Mode, 3-10

Modifying the Run Screen, 3-5

N

Numeric Keypad, 2-2

F-35512 (Mar. 2006) I-1 Index

Text Box, 2-2

To Login to the System, 3-1

Total Type Screen, 3-21

Troubleshooting, 4-8

Understanding the System, 2-1

Using Automatic Mode, 3-6

Using the Access PrePack Service Counter System, 3-1

Using the Console, 2-1

Using the Operator Main Menu Screen Drop-Down Menus, 3-12

Verify Correctness of Weight and Price, 1-1

Void Transaction, 3-17

Weights & Measures Screen, 3-26

Wrapper Screen, 3-18

T

U

V – W

Page 44

Access PrePack System Operator Manual

Index I-2 F-35512 (Mar. 2006)

Loading...

Loading...