Page 1

Quantum® Scale System

Quick-Start Guide

Operator

Models

Quantum Scale/Printer Quantum Printer

ML-29032 Wide

ML-29035 Narrow

ML-29037 Wide, Prepack ML-29207 Wide, TCP/IP

ML-29039 Linerless

ML-29191 Wide, TCP/IP

ML-29206 Wide, TCP/IP, Prepack

ML-29222 Wide, ML-29042 Narrow

w/Simplified Keyboard ML-29192 Control Panel,

Quantum Hanging Scale

ML-29188

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937-332-3000

www.hobartcorp.com

ML-29044 Wide

ML-29048 Narrow

Quantum Self Service

ML-29041 Wide

w/30 Speedkeys

FORM 34713 (Nov. 2001)

Page 2

Quantum System

Quick-Start Guide - Operator

Welcome!

This Quick-Start Guide is designed to get you up and running and to

use as a handy reference. Refer to the companion Operator and

Supervisor Manuals on CD for complete details.

The Quantum Scale Printer System is perfect for your over-the-counter

weighing applications. This state-of-the-art weighing system can

handle a broad variety of products for deli, bakery, produce, fish and

cheese departments. It can also function in a Prepack Scale mode

when necessary.

The easy-to-use control panel allows for productive operation. All

necessary operator data appears on the screen, and Function Keys (F1–

F8) provide easy access to PLU information.

Topics

FCC Note

The following topics are covered in this Quick-Start Guide:

Topic

Help

Reset

Power Up the System

Rezero the Scale

Load Labels

Cleaning & Sanitizing

Clean the Printhead

How to Start a Run

This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC rules.

These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference; in which case, the user will be

required to correct the interference at his own expense.

Page

3

3

3

5

5

6

7

7

Verify Correctness

of Weight & Price

Verification of information on labels should be made routinely. Check

the multiplication of price-per-pound times weight, and check the

indicated weight against printed weight. Weigh the same package

several times to verify consistency. Keep in mind that some packages

which weigh near the middle of the 0.01-lb increment will normally

vary up or down by 0.01-lb. Greater variation than 0.01-lb indicates a

need for adjustment of the system. In such cases, or whenever

necessary, contact your authorized Hobart service representative.

2

Page 3

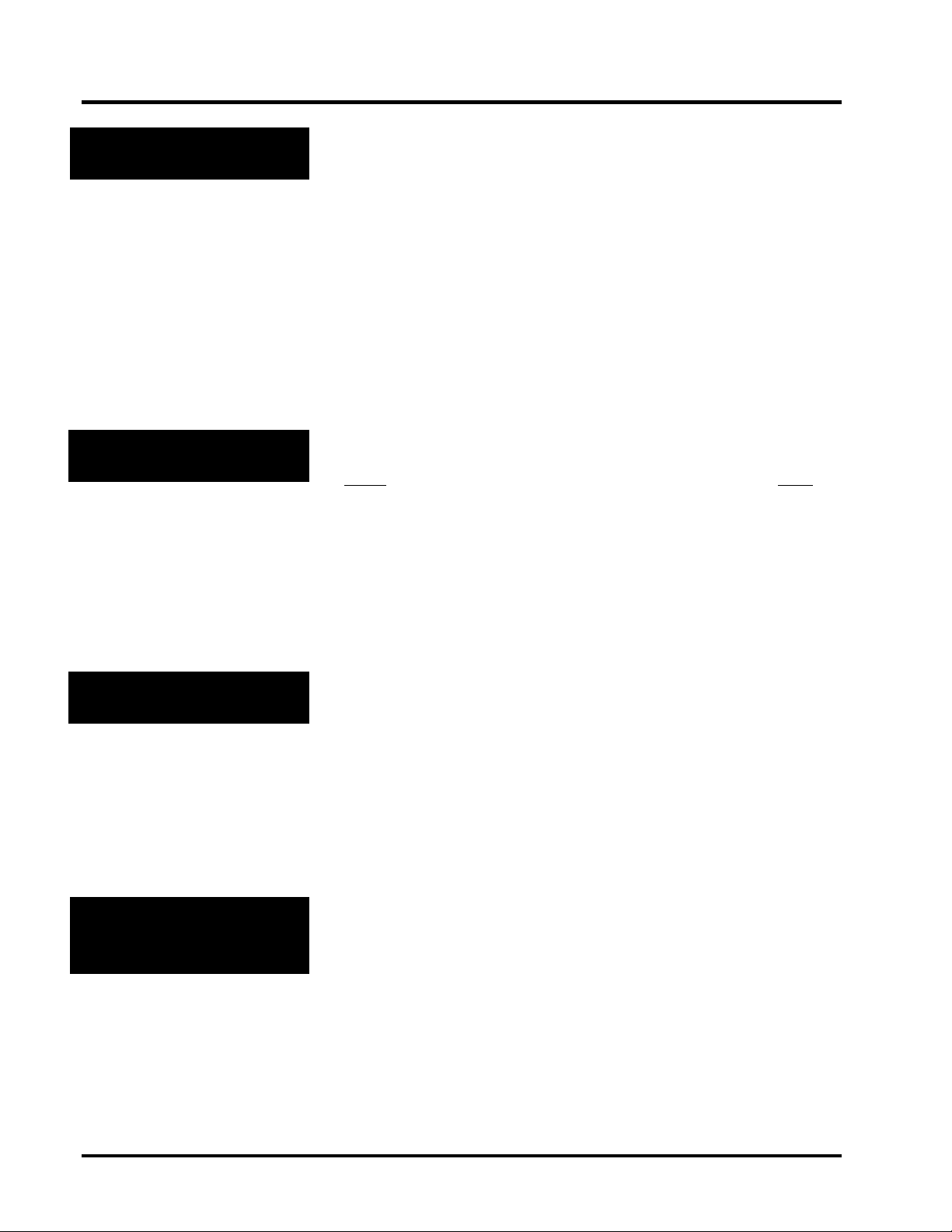

Help

Any time you PRESS [HELP] on the Console, a Help Screen

will appear. It is based on the location of your cursor. If you

have not entered anything and PRESS [HELP], you will get

the Basic Help Screen. If, for example, you TYPE a PLU

and PRESS [HELP], you will get the Product Lookup Help

Screen.

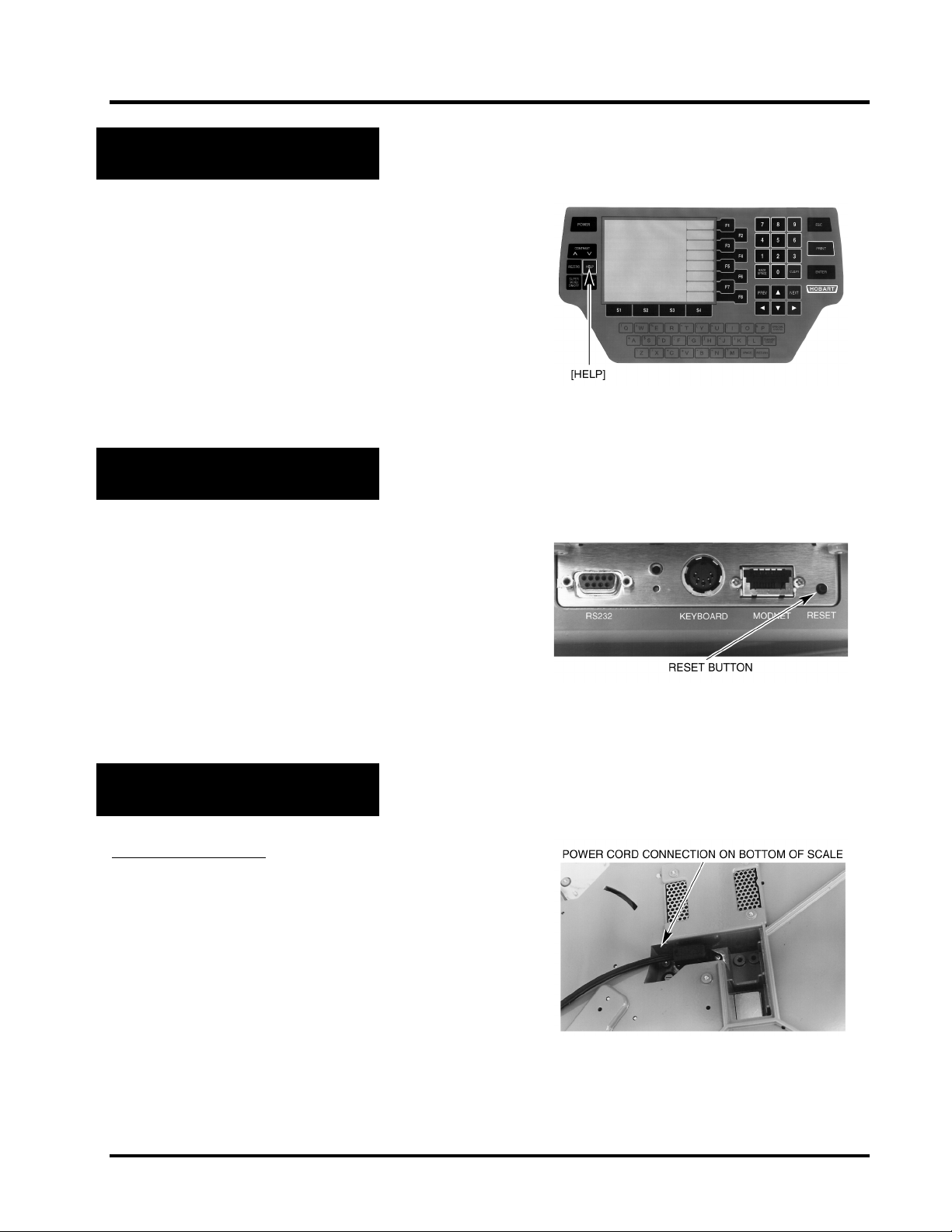

Reset

Quantum System

Quick-Start Guide - Operator

Located on the left side of the scale, to the right of the

Modnet port, is a small button. This is the Reset Button. If

the scale stops responding, use the Reset Button to reset the

scale back to the Start a Run Screen.

To reset the scale, PRESS and hold the Reset Button for 2 to

3 seconds.

Power Up the System

FIRST TIME ONLY

Normally this is already set up for you, but if necessary:

1. Connect the Power Cord located on the bottom side of the

scale.

2. Follow Daily Steps 1 through 3.

3. Set the Date & Time if necessary (see next page).

3

Page 4

Quantum System

Quick-Start Guide - Operator

TO SET THE DATE & TIME:

NOTE: If you do not see the Date/Time box in the upper

right corner of the Start a Run Screen, this means your

Supervisor must set the Date/Time. If so, skip these next

eight steps.

From the Start a Run Screen:

1. PRESS [F1] to access the Date/Time Screen.

2. With the cursor in the Date field, TYPE the Current Date.

].

].

3. PRESS [ENTER] or [

4. TYPE the Current Time.

5. PRESS [F1] if needed for AM/PM.

6. PRESS [ENTER] or [

7. PRESS [F3] to change the Current Day.

8. PRESS [ESC].

DAILY STEPS:

1. Remove objects from the scale.

2. PRESS [POWER] on the Console.

3. The System Screen displays Power-up test in progress.

The Start a Run Screen displays when the scale is ready.

There may be a slight delay (depending on room

temperature) until the Zero Weight appears on the screen.

NOTE: If Zero Weight does not appear on the screen, follow

the steps on the next page to Rezero the Scale.

4

Page 5

Quick-Start Guide - Operator

Rezero the Scale

If Zero Weight: 0.00 lb doesn’t display on the screen, you

must rezero the scale.

To rezero the scale:

1. Remove any item(s) from the weighing platform on the

scale.

2. PRESS [REZERO] on the Console.

Load Labels

♦ You should clean the Printhead and Pressure Roller when refilling the label supply.

Quantum System

To load standard or die-cut labels into

the scale, first remove the Label

Cassette:

1. Press down on the black Label

Cassette Eject Button.

2. Grasp the Label Cassette and

gently pull it out.

TO LOAD LABELS:

3. Remove the labels from the first 10” of the label roll to

create a Leader.

4. Place the roll of labels on the Hub in the Label Cassette.

5. Gently pull out the Take-Up Key.

6. Thread the Leader between the Peel Bar and the Cassette

Housing, as shown on the label instructions on the inside

of the Label Cassette.

7. Wrap the Leader completely around the Take-Up Spool

one time.

5

Page 6

Quantum System

Quick-Start Guide - Operator

8. Replace the Take-Up Key onto the Take-Up Spool,

making sure that it is on the outside of the Leader.

9. Turn the Take-Up Spool counterclockwise until the edge

of the first label is even with the Peel Bar.

10. Replace the Label Cassette.

Cleaning & Sanitizing

♦ Proper cleaning prolongs the life and productivity of the machine. Improper cleaning and sanitation will

adversely effect performance of the equipment.

♦ This machine should be cleaned routinely during the day and thoroughly cleaned at the end of the day.

If the system is not cleaned daily, it will not run consistently and will cause service problems.

♦ Refer to the following Cleaning and Sanitizing guidelines.

Do Don’t

DO cover the complete system during cleanup and

hosedown of surrounding areas. Remove cover after

hosedown to prevent condensation in the machine.

DO use mild soap and water solution to clean the

exterior of the Quantum (Palmolive Green or Ivory is

recommended).

DO apply EPA-registered sanitizer according to label

directions to disinfect surfaces.

DON’T dampen labels, electronic parts or connections.

DON’T use steam or a pressure (water) hose to clean the

system.

DON’T allow water to enter the openings in the housing.

DON’T use a hose or pour water in any area.

DON’T exceed EPA and registered recommended

concentrations for detergent or sanitizer.

DON’T operate and/or store the system in an environment

with relative humidity levels consistently in excess of 70%.

DON’T use:

Chloride-based cleaners

•

Formula 409

•

Glass cleaners (e.g., Scotty’s Glass Cleaner)

•

Citrus-based cleaners (e.g., Citro-Sol or Bio-T)

•

Caustic cleaners with high pH (e.g., Butchers Block,

•

concentrated Lysol or Pinesol)

6

Page 7

Quantum System

Quick-Start Guide - Operator

Clean the Printhead

♦ The Printhead should be cleaned approximately once each week, or whenever unclear labels are printed.

It is a good idea to clean the Pressure Roller whenever a new roll of labels is installed.

♦ Do not use a metal tool on the Printhead; this could scratch or break the Printhead.

♦ Labels should not become stuck on machine parts. If they do, remove the labels at once, following the

instructions in the Printhead Cleaning Kit.

♦ To obtain a Printhead Cleaning Kit, contact your local Hobart office; request Part Number 00-184326.

TO CLEAN THE PRINTHEAD OR

PRESSURE ROLLER:

1. Check the Printhead and Pressure Roller for

labels or adhesive before inserting every roll of

labels. Clean as needed.

2. Remove the Label Cassette.

3. Use the plastic “Lil’ ChiZler” in the Printhead

Cleaning Kit to remove stuck-on label stock.

4. To remove burned-on adhesive, gently rub the

Printhead or Pressure Roller surface with the

eraser.

5. Soak the cotton swab tip with the Printhead

Cleaning Solution.

6. Scrub the Printhead or Pressure Roller with the

swab until all residue is removed.

7. Moisten the swab as needed with Printhead

Cleaning Solution.

8. Allow the Printhead or Pressure Roller to dry.

9. Return the Cleaning Kit to its holding box.

10. Replace the Label Cassette.

How to Start a Run

The following list gives you a brief overview of how each Weigh Type selection functions within an

operation. Use the UP ARROW (

Type you require. The RIGHT ARROW (

) and DOWN ARROW () keys to move the cursor to the Weigh

) and LEFT ARROW () move between the columns.

7

Page 8

Quantum System

Quick-Start Guide - Operator

Weigh Type Description

Wait on a Customer Enables you to weigh a customer’s package and PRESS [PRINT] to print a single label.

Prepackaged Products Enables you to automatically print a label for each Random Weight package that is placed

on the scale platter. For Fixed Weight PLU’s, the Quantum screen prompts you for a

label count.

Print Multiple Labels Enables you to automatically print a predetermined number of fixed weight labels for one

item without stopping.

Production Entry Enables you to enter several items and then print multiple labels for each item. From this

mode, you TYPE each product number and quantity, then PRESS [ENTER]. PRESS

[PRINT] after you have entered all your items.

Accumulate Items Enables you to print separate labels for each item and a totals label.

Verify Fixed Weight No label is printed until the weight of the item is greater than the preset fixed weight.

Enables you to verify that the package weight is greater than or equal to the product’s

fixed weight. For all other products, Quantum automatically prints a label for each

package weighed.

Self Service Refer to

Quantum Self Service Manual

TO START A RUN:

1. SELECT Weigh Type (mode).

2. If you need a Total Type other than Production,

PRESS [

] to get to the Total Type column and

SELECT your Total Type.

for further details.

ENTER OPERATOR ID (if required)

If your scale is set up to require an Operator ID, you will see

the Operator ID field on your screen. Continue with Step 3.

--OR--

If the Operator ID field is not on your screen, skip to Step 4.

From the Start a Run Screen:

3. TYPE your Operator ID number.

4. PRESS [ENTER] to access the Run Screen.

5. TYPE the PLU.

6. Place the package on the weighing platform.

7. Depending on your mode of operation, you may have to

PRESS [PRINT] to generate a label. Certain Weigh Type

modes automatically generate a label when the product is

weighed.

FORM 34713 (Nov. 2001) 8 Printed in U.S.A.

Loading...

Loading...