Hobart ML-18887, ML-19689 User Manual

N

S

T

R

U

C

T

I

O

N

S

I

4732 & 4732A CHOPPERS

MODEL

4732 ML-18887 (Painted, Non-removable Pan)

ML-19282 (SST, Non-removable Pan)

MODEL 4732 CHOPPER

4732A ML-19689 (Painted, Removable Pan)

ML-19690 (SST, Removable Pan)

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 34747 (Feb. 2002)

Installation, Operation and Care of

4732 & 4732A CHOPPERS

SAVE THESE INSTRUCTIONS

GENERAL

The 4732 and 4732A Choppers are equipped with a 3 HP motor that rotates the worm at 151 RPM. The

4732 and 4732A are designed to use a #32 size knife and plate. Knives and plates, available at extra

cost, are not included with the chopper.

The stainless steel feed pan on the 4732 is not removable and must be cleaned in place. Model 4732A

has a removable stainless steel feed pan and an interlock that requires the feed pan to be in place

before the machine can be turned on. On both models, a cast aluminum guard is permanently mounted

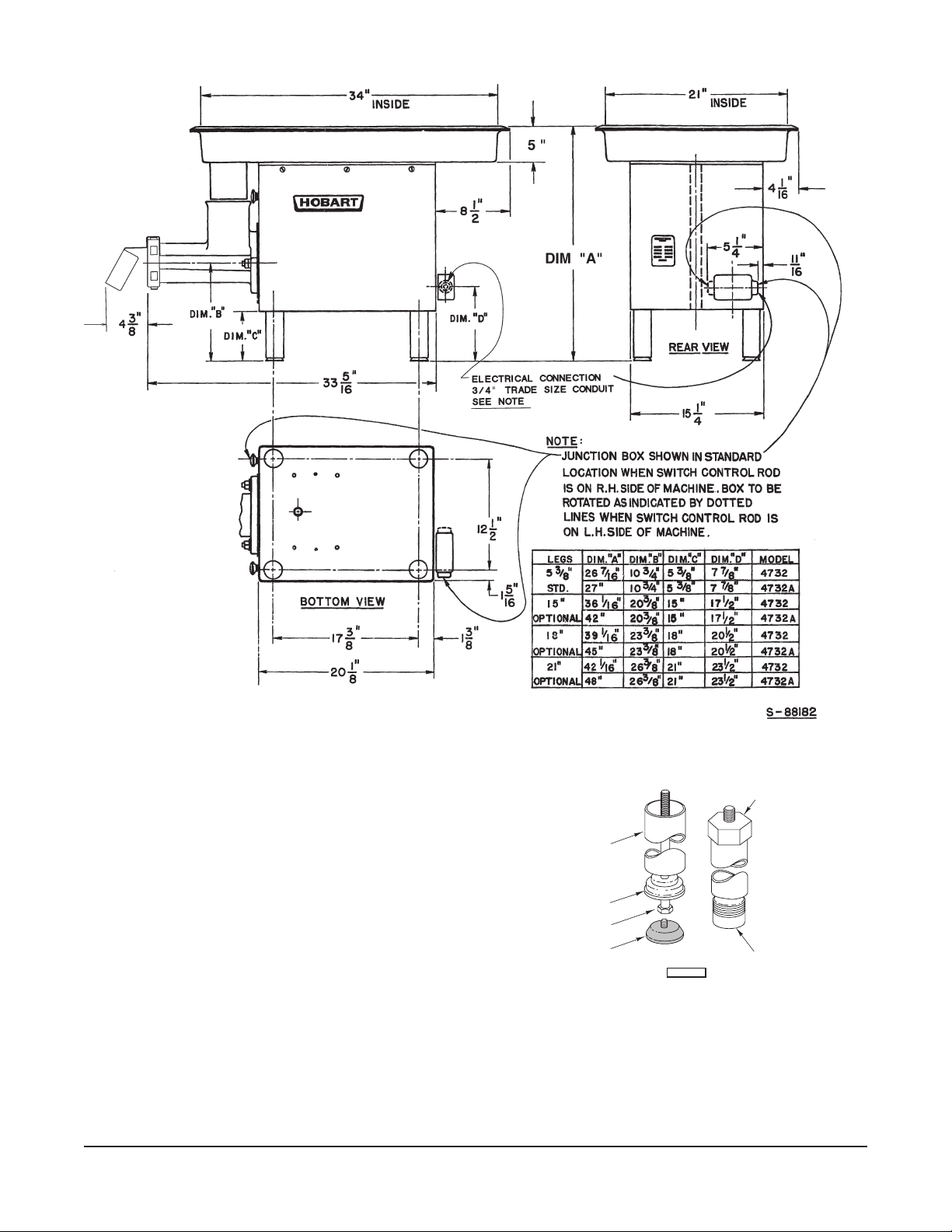

to the front and sides of the feed pan. Dimensions on the feed pan are 34" long x 21" wide x 5" deep.

The motor and switch housing is available in painted steel or stainless steel. The table models use 5

high legs that provide 8" clearance between the table and the lowest point on the adjusting ring. Leg

sets of other heights (15", 18" or 21") are available to convert the 4732 or 4732A into a floor model.

Sausage stuffers for hog or sheep casings are available accessories.

3

/8"

The chopper can grind 35 to 40 pounds of boneless beef per minute, first cut, through a 1/8" plate. The

second cut grind rate is 25 to 30 pounds per minute through a

O

F or higher before grinding and can be in either flake or stick form.

to 24

1

/8" plate. Frozen meat must be tempered

INSTALLATION

UNPACKING

Immediately after unpacking, check for possible shipping damage. If the chopper is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Remove the carton from around the machine. Remove the four bolts holding the machine to the skid.

Unpack the feed stomper.

Prior to installation, verify that the electrical service agrees with the specifications on the machine data

plate.

Use the spanner wrench to loosen the adjusting ring. Unscrew and remove the adjusting ring using both

hands. Remove and discard the retaining washer and rubber pad used at the front of the worm where

the knife and plate are to be installed.

The chopper must be thoroughly cleaned and sanitized after installation and before operation. Refer

to CLEANING (page 7).

© HOBART CORPORATION, 2002

– 2 –

LEGS (Figs. 1, 2)

Fig. 1

The four leg assemblies are packed in a separate

carton for shipment. The standard legs (5

3

/8" high)

allow the rim of the feed pan on the table model to

be 27" above the table surface. These legs have

neoprene feet and require assembly. To assemble

3

/8" high legs: Slide the Leg Stud through the Leg

5

End Cap and the Leg; then thread the Leg Stud into

the base of the machine (Fig. 2). Do not overtighten;

the legs need only be hand-tight. Thread the

Neoprene Foot into the Leg Stud (Fig. 2).

Floor model choppers are equipped with optional

15", 18" or 21" legs. Each Leg is one piece and

threads into the base of the machine at the four

corners. These Legs can be adjusted by threading

the Feet in or out as necessary (Fig. 2) to level and

stabilize the chopper.

– 3 –

LEG

LEG END CAP

LEG STUD

NEOPRENE FOOT

LEG (15", 18" or 21")

FOOT

PL-56170

Fig. 2

Loading...

Loading...