Page 1

INCLUDES

REPLACEMENT

PARTS

HOBART HOBHL2 Heat Lamp

ML-136134

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

F-35216 (Dec. 2006)

Page 2

Installation, Operation and Care of

the Hobart HOBHL2 Heat Lamp

SAVE THESE INSTRUCTIONS

GENERAL

The HOBHL2 Heat Lamp is used in conjunction with a 2912B Slicer to maintain cooked roast beef to an

internal temperature above 140°F for up to 30 minutes while slicing. The Heat Lamp is designed to hold

this temperature with roasts placed on the slicer carriage tray at a minimum temperature of 150°F for up

to 30 minutes. Additional heating lamps placed on the slicer platter and the weighing scale will prevent

additional temperature loss beyond the 20°F drop from sliced product temperature.

INSTALLATION

UNPACKING

Immediately after unpacking the Heat Lamp, check for possible shipping damage. If the Heat Lamp is

found to be damaged after unpacking, save the packaging material and contact the carrier within 15 days

of delivery to fi le a claim.

ASSEMBLY

The tools needed for this installation are an electric drill, a center punch and a

9

/32" drill bit.

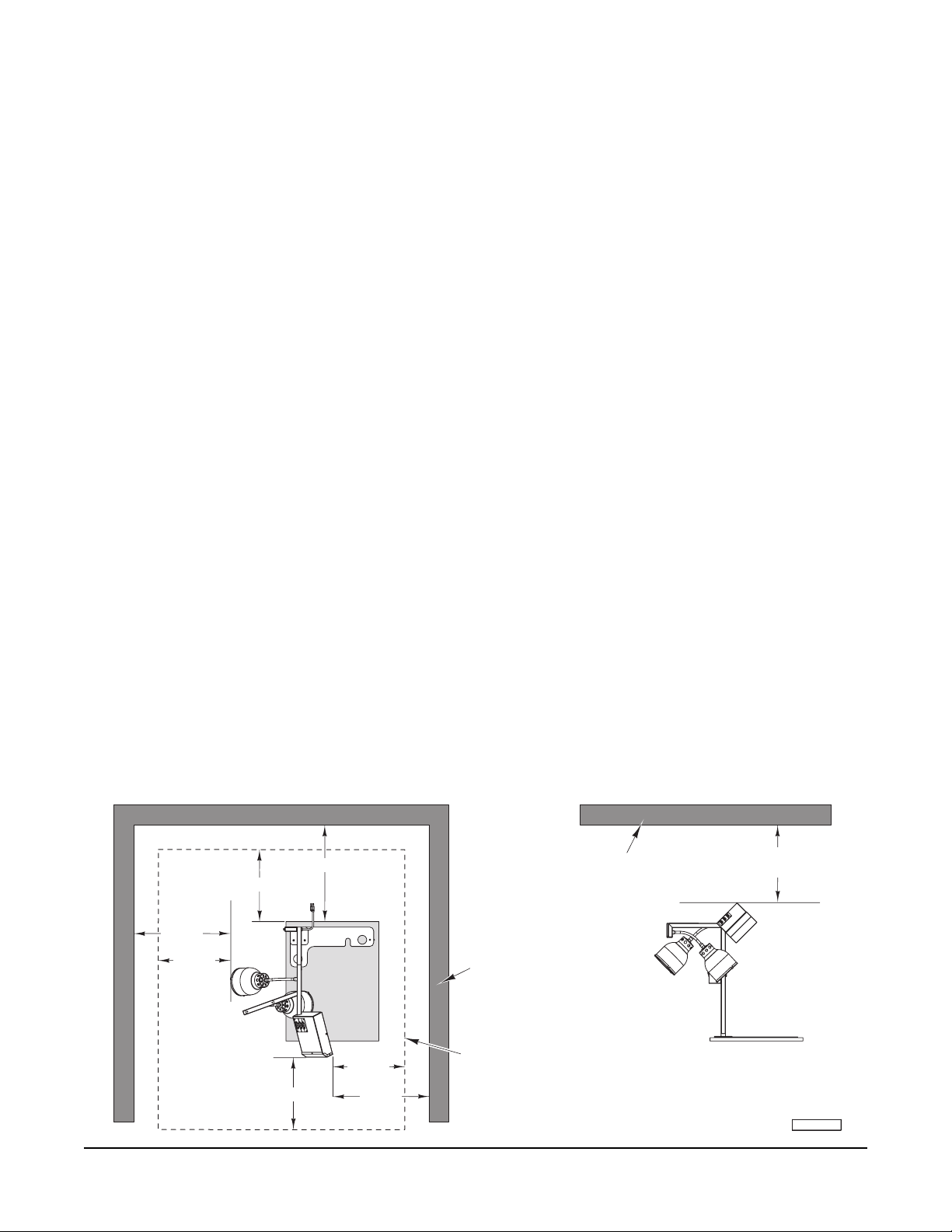

CAUTION: To reduce the risk of fi re, the Heat Lamp is to be installed in non-combustible surroundings

only, with minimum clearances to combustible walls, ceilings, countertops and other combustible

materials as noted in the diagram below.

40" MIN.

OVERHEAD CLEARANCE

18" MIN.

12" MIN.

12" MIN.

18" MIN.

COMBUSTIBLE

CEILING

COMBUSTIBLE

WALLS

18" MIN.

CLEARANCE

(ALL SIDES)

TOP VIEW

© HOBART, 2006

12" MIN.

12" MIN.

18" MIN.

COUNTERTOPS WITHIN

12 IN. (ALL SIDES) MUST

BE METAL OR OTHER

NON-COMBUSTIBLE MATERIAL

– 2 –

FRONT VIEW

PL- 58302

Page 3

1. Place skid plate on table where slicer is to be

located.

2. Make sure there is suffi cient room on the table

to support the front feet of the slicer (the feet

on the index knob end of slicer) before drilling

holes for the skid plate.

3. Check beneath the tabletop to be sure there are

no hazards before drilling holes for mounting the

heat lamp. Make sure there is suffi cient room

for the reinforcement base plate.

4. Mark and center punch the fi ve

9

/32" holes to be

drilled (Fig. 1).

5. Drill the fi ve 9/32" holes.

6. Line up four holes in mounting base plate with

holes in skid plate, table and reinforcement base

plate. Attach with hardware provided.

NOTE: Reinforcement base plate, lockwashers and

nuts are to be installed underneath tabletop, not on

top.

7. Install screw to secure right side of skid plate

(Fig. 1).

8. Insert heat lamp assembly onto Mounting Base

Plate (Fig. 2). Secure with thumbscrew.

9. Install four short feet on slicer and put slicer

in position with rear feet sitting in holes in skid

plate.

10. Check to be sure the two 250 watt infrared bulbs

are tight in the socket. Remove one Cushion

Spring and hand tighten the bulb to be sure it is

secure. Reinstall the Cushion Spring as shown

in Fig. 3.

Fig. 1

Fig. 2

WARNING: ELECTRICAL AND GROUNDING

CONNECTIONS MUST COMPLY WITH THE

APPLICABLE PORTIONS OF THE NATIONAL

ELECTRICAL CODE AND/OR OTHER LOCAL

ELECTRICAL CODES.

11. Plug power cord into nearest outlet.

– 3 –

Fig. 3

Page 4

OPERATION

WARNING: THE HEAT LAMP AND ITS PARTS ARE HOT AND CAN CAUSE BURNS. USE CARE

WHEN OPERATING, CLEANING AND SERVICING.

Set-Up

1. Place Optional Portable Platter on the slicer (Fig. 4).

2. The Main Heat Source is fi xed in position over the slicer Carriage Tray (Fig. 4). No adjustment is

necessary.

3. Adjust the Front Heat Lamp Gooseneck (Fig. 4) at approximately a 45 degree angle to "shine" on

the optional portable platter. Allow enough clearance to be able to reach into this area and remove

the sliced beef without contacting the Heat Lamp housing.

4. Adjust the Rear Heat Lamp Gooseneck (Fig. 4) at approximately a 45 degree angle to "shine" on

the Weighing Scale Platter, again allowing enough room to work without contacting the Heat Lamp

housing.

Fig. 4

– 4 –

Page 5

Preheating

The Heat Lamp should be turned on and allowed to

preheat for 30 minutes prior to placing a roast on the

slicer.

Controls

The Heat Lamp is equipped with a rocker switch (Fig. 5)

on the main support post. This switch turns the heating

sources on or off.

Fig. 5

CLEANING

WARNING: UNPLUG POWER CORD AND ALLOW HEAT LAMP TO COOL.

CAUTION: Do not raise slicer until cool to prevent damage to plastic components on the slicer.

Remove the optional portable platter and move the front heat lamp gooseneck away from the slicer before

raising the slicer up on the lift lever.

Wash all surfaces with a damp cloth or sponge and a mild detergent.

Exercise care when cleaning around the louvers in the main heat source housing or the cooling holes in

the gooseneck lampshades so water does not enter those areas.

Do NOT wash inside lampshades or the bulbs and sockets.

Do NOT immerse unit in water.

Rinse with a cloth or sponge and clean water.

Sanitize.

Excessive amounts of sanitizer and use of products not formulated for stainless steel or aluminum may

void your Hobart warranty.

Chlorinated sanitizer not to exceed 200 ppm.

– 5 –

Page 6

MAINTENANCE

SERVICE

Contact your local Hobart authorized service offi ce for any repairs, adjustments or replacement parts. The

Infrared Lamps are considered expendable items and are not covered by the Hobart warranty.

6

5

42

4

3

2

1

48

45

44

43

41

46

47

40

7

8

9

10

12

39

11

38

13

14

36-37

35

15-16

17

18

19

20

28

30

33

31-32

29

27

HOBART HEAT LAMP

– 6 –

34

26

25

24

21

23

22

PL-58198

Page 7

HOBART HEAT LAMP

ILLUS. PART NO. NAME OF PART AMT.

PL-58198

1 00-914161 Emitter – Full Trough (FTE) (With Spring Clip) .......................................................................... 1

2 00-914137 Defl ector – Emitter ..................................................................................................................... 1

3 00-914136 Cover – Front Housing ...............................................................................................................1

4 00-914159 Rivet – Nut ................................................................................................................................10

5 WL-006-06 Lockwasher #10 Helical ............................................................................................................. 3

6 SC-125-54 Mach. Screw 10-32 x 1/2 Phil. Rd. Hd. (SST) .............................................................................3

7 00-914134 Housing – Heat Lamp ................................................................................................................1

8 00-438131-00003 Label – Warning .........................................................................................................................1

9 00-914174 Cover – Front Top ......................................................................................................................1

10 WL-006-06 Lockwasher #10 Helical ............................................................................................................. 4

11 SC-125-54 Mach. Screw 10-32 x 1/2 Phil. Rd. Hd. (SST) .............................................................................4

12 NS-011-23 Nut 10-32 Hex (SST) .................................................................................................................1

13 00-914180 Caplug – Square (1 In.) .............................................................................................................1

14 00-914190-00001 Arm – Flex (Short Run) ..............................................................................................................1

15 00-914167 Shade – Infrared Lamp ..............................................................................................................1

16 00-914212 Label – Max (120 V., 250 Watts) ................................................................................................1

17 00-914166 Spring – Cushion ....................................................................................................................... 3

18 00-914170-00002 Socket Assy. (250 Watt Lamp) (Long Run) ................................................................................ 1

19 00-914200 Lamp – Infrared (120 V., 250 Watts) .......................................................................................... 1

20 00-914542 Switch – Rocker .........................................................................................................................1

21 00-914205-00002 Cover – Switch Box Assy. .......................................................................................................... 1

22 SC-021-14 Mach. Screw 8-32 x 3/8 Slotted Rd. Hd. (SST) ...........................................................................4

23 WL-006-01 Lockwasher #8 Helical ............................................................................................................... 4

24 SC-127-28 Mach. Screw 10-32 x 3/8 Hex Hd. (SST) ....................................................................................2

25 WL-006-06 Lockwasher #10 Helical ............................................................................................................. 2

26 00-914173 Base – Mounting Assy................................................................................................................ 1

27 00-914187 Screw – Thumb ..........................................................................................................................1

28 00-914200 Lamp – Infrared (120 V., 250 Watts) .......................................................................................... 1

29 00-914170-00001 Socket Assy. (250 Watt Lamp) (Short Run) ............................................................................... 1

30 00-914166 Spring – Cushion ....................................................................................................................... 3

31 00-914167 Shade – Infrared Lamp ..............................................................................................................1

32 00-914212 Label – Max (120 V., 250 Watts) ................................................................................................1

33 00-117542-00021 Cord & Plug .............................................................................................................................. 1

34 FE-017-41 Relief – Strain ............................................................................................................................1

35 00-914204-00003 Box – Switch Assy. ..................................................................................................................... 1

36 00-438131-00183 Label (ON) .................................................................................................................................1

37 00-438131-00184 Label (OFF) ............................................................................................................................... 1

38 00-914182 Support – Frame Assy................................................................................................................ 1

39 00-914190-00002 Arm – Flex (Long Run) .............................................................................................................. 1

40 00-914154 Cover – Support Frame ............................................................................................................. 2

41 SC-129-61 Mach. Screw 10-32 x 1/4 Phil. Truss Hd. (SST) .......................................................................... 4

42 00-914140 Grate – Heat Lamp Housing ......................................................................................................1

43 SC-127-28 Mach. Screw 10-32 x 3/8 Hex Hd. (SST) ....................................................................................2

44 WL-006-06 Lockwasher #10 Helical ............................................................................................................. 2

45 NS-011-12 Nut 8-32 Hex (SST) ...................................................................................................................1

46 WL-006-01 Lockwasher #8 Helical ............................................................................................................... 1

47 SC-021-16 Mach. Screw 8-32 x 7/8 Slotted Rd. Hd. (SST) ...........................................................................1

48 00-914169 Block – Terminal (Emitter) ..........................................................................................................1

00-873255 Kit – Tall Foot & Skid Plate.........................................................................................................1

00-914194 Reinforcement – Base Plate ...................................................................................................... 1

00-914160 Plate – Skid ................................................................................................................................1

00-914183 Platter – Portable .......................................................................................................................1

00-914540 Housing – Heat Lamp Assy. (Incls. Items 1, 3 thru 7, & 42) ......................................................1

FE-026-54 Connector – Wire Nut (High Temperature) ................................................................................2

– 7 –

Page 8

NOTES

FORM 35216 (Dec. 2006) PRINTED IN U.S.A.

– 8 –

Loading...

Loading...