Page 1

GAS & ELECTRIC COMBI,

CONVECTION & STEAM OVENS

DIRECT STEAM INDIRECT STEAM

(BOILERLESS) (WITH STEAM GENERATOR)

(LEFT HINGED DOOR)

CE6HD ML-138010

CE10HD ML-138012 CG10FI ML-138048-Z

CE10FD ML-138016

CE20HD ML-138014

CE20FD ML-138018

(RIGHT HINGED DOOR)

CE6HD ML-138011

CE10HD ML-138013

CE10FD ML-138017

CE20HD ML-138015

CE20FD ML-138019

701 S. RIDGE AVENUE

TROY, OHIO 45374-0001

937 332-3000

www.hobartcorp.com

FORM 35474 Rev. A (March 2010)

Page 2

IMPORTANT FOR YOUR SAFETY

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS

EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD START-UP AND ADJUSTMENTS

OF THE EQUIPMENT COVERED BY THIS MANUAL.

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT

THE SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE

LOCAL GAS SUPPLIER.

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS

AT MAIN SHUTOFF VALVE AND CONTACT THE LOCAL GAS

COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE.

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

IN THE EVENT OF A POWER FAILURE, DO NOT ATTEMPT TO

OPERATE THIS DEVICE.

KEEP AREA AROUND OVEN CLEAR OF COMBUSTIBLES. DO

NOT OBSTRUCT COMBUSTION AND VENTILATION OPENINGS

ON THE OVEN.

©HOBART, 2010

– 2 –

Page 3

TABLE OF CONTENTS

GENERAL ..............................................................................................................................................................5

INSTALLATION ......................................................................................................................................................5

Unpacking ........................................................................................................................................................5

Installation Codes and Standards ....................................................................................................................5

Location ...........................................................................................................................................................6

Door Opening ...................................................................................................................................................6

Stacking Kits ....................................................................................................................................................6

Leveling ............................................................................................................................................................6

Water Requirements ........................................................................................................................................6

Water Quality Statement ..................................................................................................................................6

Plumbing Connections .....................................................................................................................................6

Water Supply Connections ...............................................................................................................................7

Drain Connection .............................................................................................................................................7

Gas Supply Connections .................................................................................................................................7

Testing the Gas Supply System .......................................................................................................................8

Flue Gas Exhaust ............................................................................................................................................8

Electrical Connection .......................................................................................................................................9

Vent Hood ........................................................................................................................................................9

Before First Use ...............................................................................................................................................9

OPERATION .........................................................................................................................................................10

Door Switch ....................................................................................................................................................10

Door Opening and Closing .............................................................................................................................10

Loading the Oven ...........................................................................................................................................10

Unloading the Oven .......................................................................................................................................11

Cooking Modes .............................................................................................................................................. 11

Control Panel .................................................................................................................................................11

Initial Start-Up ................................................................................................................................................14

Setting the Internal Clock ...............................................................................................................................14

Setting the Temperature .................................................................................................................................14

Setting the Timer ............................................................................................................................................15

Setting the Humidity .......................................................................................................................................15

Setting the Vent Position ................................................................................................................................15

Setting the Fan Speed ...................................................................................................................................16

Fast Cool Down .............................................................................................................................................16

Selecting the Cooking Mode ..........................................................................................................................17

Preheating the Oven ......................................................................................................................................17

Using Convection Mode .................................................................................................................................17

Using Steam Mode ........................................................................................................................................18

Using Combi Mode ........................................................................................................................................18

Temperature Probe ........................................................................................................................................19

Using the Product Temperature Probe ...........................................................................................................20

Using the 10 Position Timer ...........................................................................................................................21

Writing a Cooking Phase................................................................................................................................22

– 3 –

Page 4

TABLE OF CONTENTS (CONT.)

Erasing a Cooking Phase ..............................................................................................................................22

Writing a Cooking Program ............................................................................................................................23

Modifying a Cooking Program ........................................................................................................................24

Reviewing a Cooking Program ......................................................................................................................24

Erasing a Cooking Program ...........................................................................................................................24

Using a Cooking Program ..............................................................................................................................25

Setting a Preheat Delayed Start ....................................................................................................................25

Add a Barcode to a Program (If Optional Barcode Scanner Was Ordered) ...................................................26

Remove a Barcode From a Program .............................................................................................................26

Using the Scanner .........................................................................................................................................27

Combi Oven Bluetooth Capabilities ...............................................................................................................27

MAINTENANCE ...................................................................................................................................................29

Service Adjustments ......................................................................................................................................29

Door Locking and Gasket Inspection .............................................................................................................29

Service and Parts Information ........................................................................................................................29

Shutting Down the Oven ................................................................................................................................29

STAINLESS STEEL EQUIPMENT CARE AND CLEANING .................................................................................30

CLEANING ...........................................................................................................................................................31

TROUBLESHOOTING .........................................................................................................................................34

Autodiagnostics ..............................................................................................................................................34

Service Parameter Setup ...............................................................................................................................35

– 4 –

Page 5

INSTALLATION, OPERATION AND CARE OF

GAS & ELECTRIC COMBI,

CONVECTION & STEAM OVENS

SAVE THESE INSTRUCTIONS

GENERAL

The Gas & Electric Combi, Convection & Steam Ovens are single compartment ovens that provide

convection heating and/or steaming in the cooking chamber.

The Hobart Combi Gas or Electric ovens are sized 6, 10, or 20 levels high. The 6 level ovens are Half depth

only. The 10 and 20 level ovens are either Full or Half depth. All models include a Digital programmable

control. The bold numbers and letters explain the model-number conventions.

The 6 or 10 level ovens can be installed on a suitable countertop using the 2" legs (standard) or the optional

6" legs. The 6 or 10 level ovens can also be installed on an accessory stand. The accessory stand may

be equipped with an accessory Pan Slide which provides rack or pan storage underneath the oven. On 6

or 10 level ovens, the accessory Landing Table can load or unload all racks in one motion when the oven

is mounted on the accessory stand. Additional racks are also available accessories. The 20 level ovens

are installed with legs and come with a Trolley to allow loading or unloading all racks in one motion. An

optional Hose Spray accessory supplied by others can be installed near the oven to facilitate easy cleaning

of the accessory racks.

INSTALLATION

UNPACKING

Immediately after unpacking the oven, check for possible shipping damage. If the oven is found to be

damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, verify that the electrical and water service agrees with the specifi cations on the oven

data plate and in this manual.

INSTALLATION CODES AND STANDARDS

In the United States, the Hobart Combi Oven must be installed in accordance with:

1. State and local codes.

2. National Fuel Gas Code, ANSI-Z223.1 (latest edition). Copies may be obtained from The American

Gas Association, Inc.; 1515 Wilson Blvd.; Arlington, VA 22209.

3. National Electrical Code (ANSI/NFPA No.70, latest edition) available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA 02269.

4. Vapor Removal from Cooking Equipment, (NFPA-96, latest edition) available from NFPA.

In Canada, the Hobart Combi Oven must be installed in accordance with:

1. Local codes.

2. CAN/CGA-B149.1 Natural Gas Installation Code (latest edition).

3. CAN/CGA-B149.1 National Fuel Gas Code (latest edition), available from The Canadian Gas

Association; 178 Rexdale Blvd.; Etobicoke, Ontario; Canada M9W 1R3.

4. Canadian Electrical Code (CSA C22.2 No.3, latest edition) available from the Canadian Standards

Association, 5060 Spectrum Way, Mississauga, Ontario, Canada L4W 5N6.

– 5 –

Page 6

LOCATION

Allow space for operating the oven. Do not obstruct the ventilation ports above the oven. To provide

ventilation access, allow 1" clearance on the left side of the oven and 2

1

/2" clearance at the rear. A suitable

amount of space (18" minimum) should be provided on the right side of the machine for operation, cleaning

and service. Ensure a level fl oor is available for operation of the 20 level units with trolley system.

DOOR OPENING

The standard oven is delivered with the door hinged on the left. If the door opening needs to be changed,

contact your authorized Hobart Service offi ce.

STACKING KITS

Stacking kits are available to allow ovens to stack, one on top of the other (available for 6 and 10 level

ovens only). Assembly Instructions are included with the kit.

LEVELING

Use a spirit level on a rack in the oven to make sure the oven is level, both front-to-back and side-to-side.

On 20 levels, accessory stands, and optional 6" legs, adjust the leveling feet on the bottom of the legs by

turning the feet in or out to level the oven. After the drain is connected, check for level by pouring water

onto the fl oor of the compartment. All water should drain through the drain opening.

WATER REQUIREMENTS

As with all steam related products, water fi ltration and regular fi lter replacements coupled with

routine deliming are required. Your local Hobart Service offi ce can recommend a water treatment system

to meet the needs of your local water conditions. Contact your local Hobart Service representative for

water treatment offerings.

WATER QUALITY STATEMENT

The fact that a water supply is potable is no guarantee that it is suitable for steam generation. Proper water

quality can improve the taste of the food prepared in the oven, reduce liming and extend equipment life.

Local water conditions vary from one location to another. The recommended proper water treatment for

effective and effi cient use of this equipment will also vary depending on the local water conditions. Your

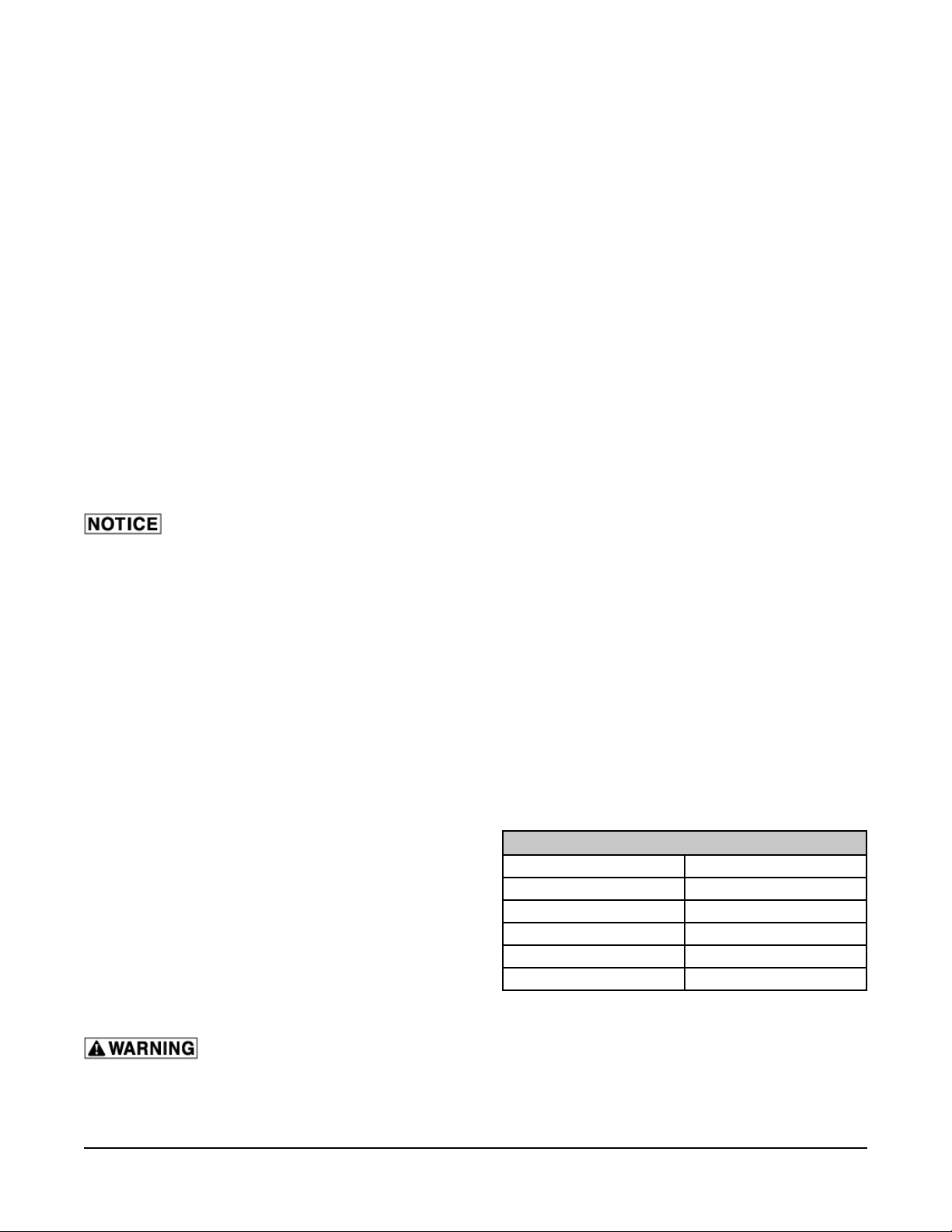

water supply must be within the general guidelines outlined in the chart below.

Other factors affecting steam generation are iron content, amount of chlorination, chlorine, and dissolved

gasses. Water supplies vary from state to state and from locations within a state. Therefore it is necessary

that the local water treatment specialist be consulted before the installation of any steam generating

equipment. Ask your municipal water supplier for details about your local water supply prior to installation

or contact your local Hobart representative.

Water hardness should be treated by a water

conditioner (water softener and/or in-line water

treatment). Low water hardness may also require a

water treatment system to reduce potential corrosion.

Water treatment has been shown to reduce costs

associated with machine cleaning, reduce deliming

and reduce corrosion of metallic surfaces.

WATER SUPPLY GENERAL GUIDELINES

Supply Pressure 30-60 psig

Hardness less than 3 grains*

Silica less than 13 ppm

Total Chloride less than 4.0 ppm

PH range 7-8

Un-Dissolved Solids less than 5 microns

* 17.1 ppm = 1 grain of hardness

PLUMBING CONNECTIONS

Plumbing connections must comply with applicable sanitary, safety and plumbing

codes.

– 6 –

Page 7

WATER SUPPLY CONNECTIONS

Connect treated potable water (cold) to the inlet. Untreated water contains scale producing minerals which,

if supplied, can precipitate and adhere to the surfaces inside the oven. This can result in early component

failure and reduced product life.

DRAIN CONNECTION

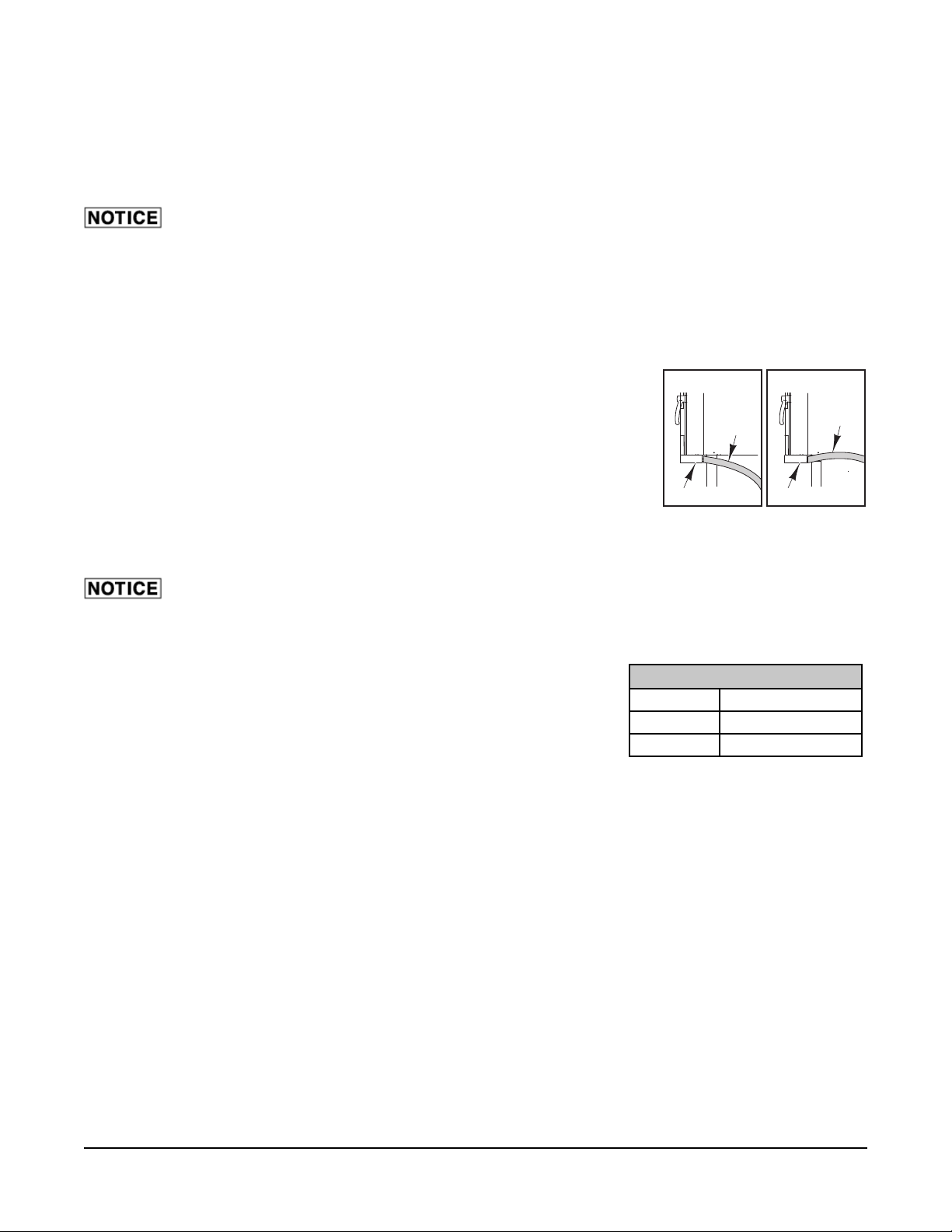

In order to avoid any back pressure in the oven, do not connect solidly to any drain.

The 1" NPT threaded fi tting on the condenser box must be extended a minimum of 12" (305 mm) - maximum

of 72" (1829 mm) away from combi base, to an open air gap type drain. Do not reduce the 1" NPT drain

piping throughout its length. Provide a suitable fl oor sink with a minimum depth of 12" (305 mm). The fl oor

sink is NOT to be directly under the combi and should be at a distance so that steam vapors will not enter

the combi from underneath. The drain should slope down away from the combi ¼" for every foot of drain

pipe length. The drain pipe should be either iron or copper. DO NOT use PVC pipe; PVC pipe may lose

its rigidity or glue may fail.

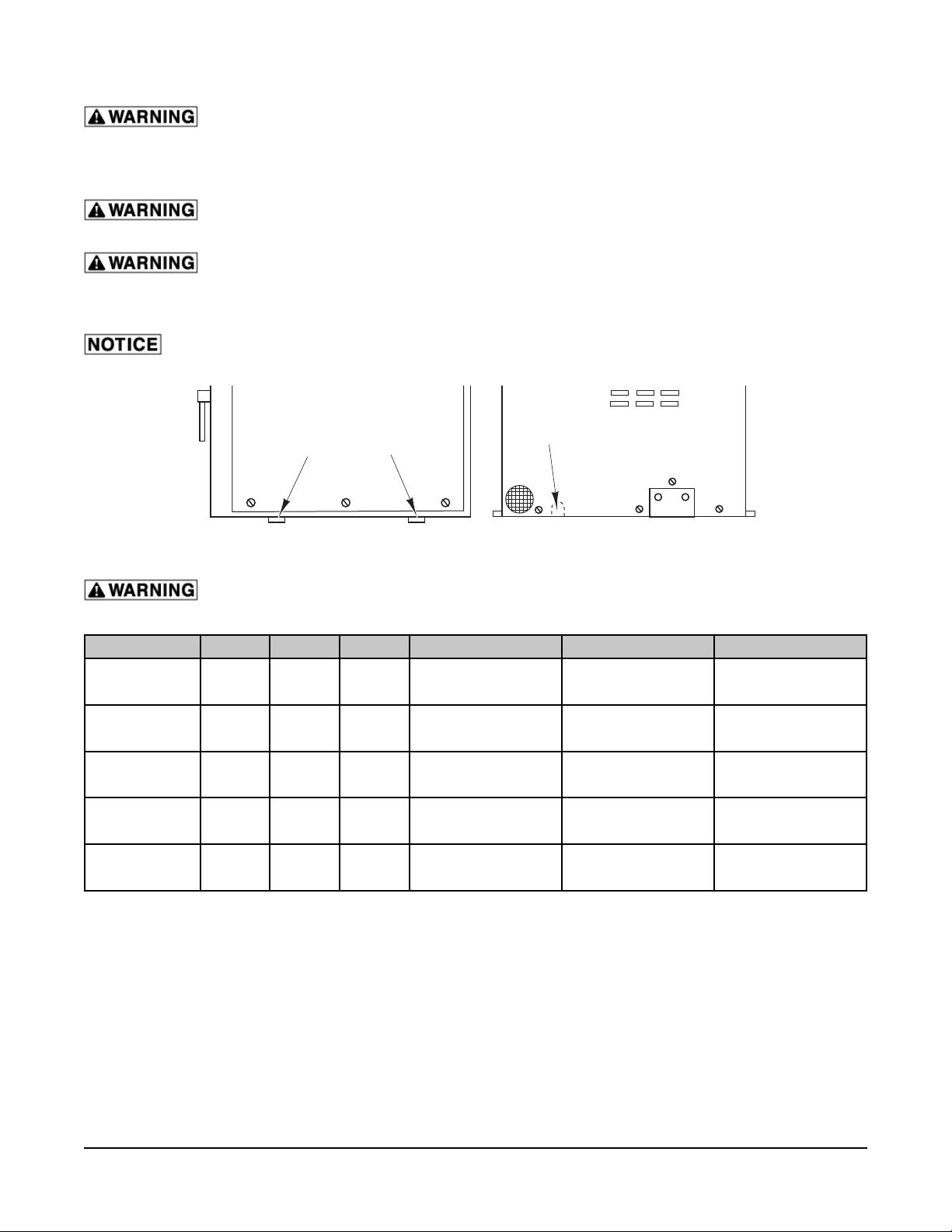

RIGHT

WRONG

Temperatures in the combi can reach as high as 212°F (l00°C). Local codes

may require that the temperature of drain water be no greater than 140°F

(60°C). At the end of the day, when purging the generator, some provision for

HOSE

HOSE

lowering the water temperature should be provided by the user or installer

to meet this code requirement.

The drain hose for the drip tray should be installed and routed with a constant

decline (Fig. 1).

DRIP TRAY

DRIP TRAY

Fig. 1

GAS SUPPLY CONNECTIONS

Gas supply connections and any pipe joint compound must be resistant to the action of propane

gases.

A ¾" NPT minimum inside diameter gas supply line is required. If quick disconnect devices are used, make

sure it is sized properly for data plate BTU/hr. rating.

Codes require that a manual gas shutoff valve be installed in the gas

line ahead of the combi oven. The gas line must be capable of delivering

gas to the combi oven without excessive pressure drop at the minimum

rate specifi ed on the rating plate.

Gas Input

Natural 5.5" - 10.5" W.C.

Propane 11" - 13" W.C.

MINIMUM RATE

3

/4" NPT

Inadequate gas supply could result in burner noise and poor burner performance.

The proper sizing and installation of the gas connection is important for the machine to operate within

its design specifi cations. In some installations, the gas supply may not be suffi cient enough to allow all

the gas equipment to operate properly at peak loads; or when other equipment with a high BTU/hr. input

requirement is operating. The connection to the machine becomes even more important in this type of

location. Flexible gas connectors with quick disconnect or swivel fi ttings (when used) and gas connectors

beyond the length necessary will reduce the BTU/hr. fl ow capacity to the machine.

– 7 –

Page 8

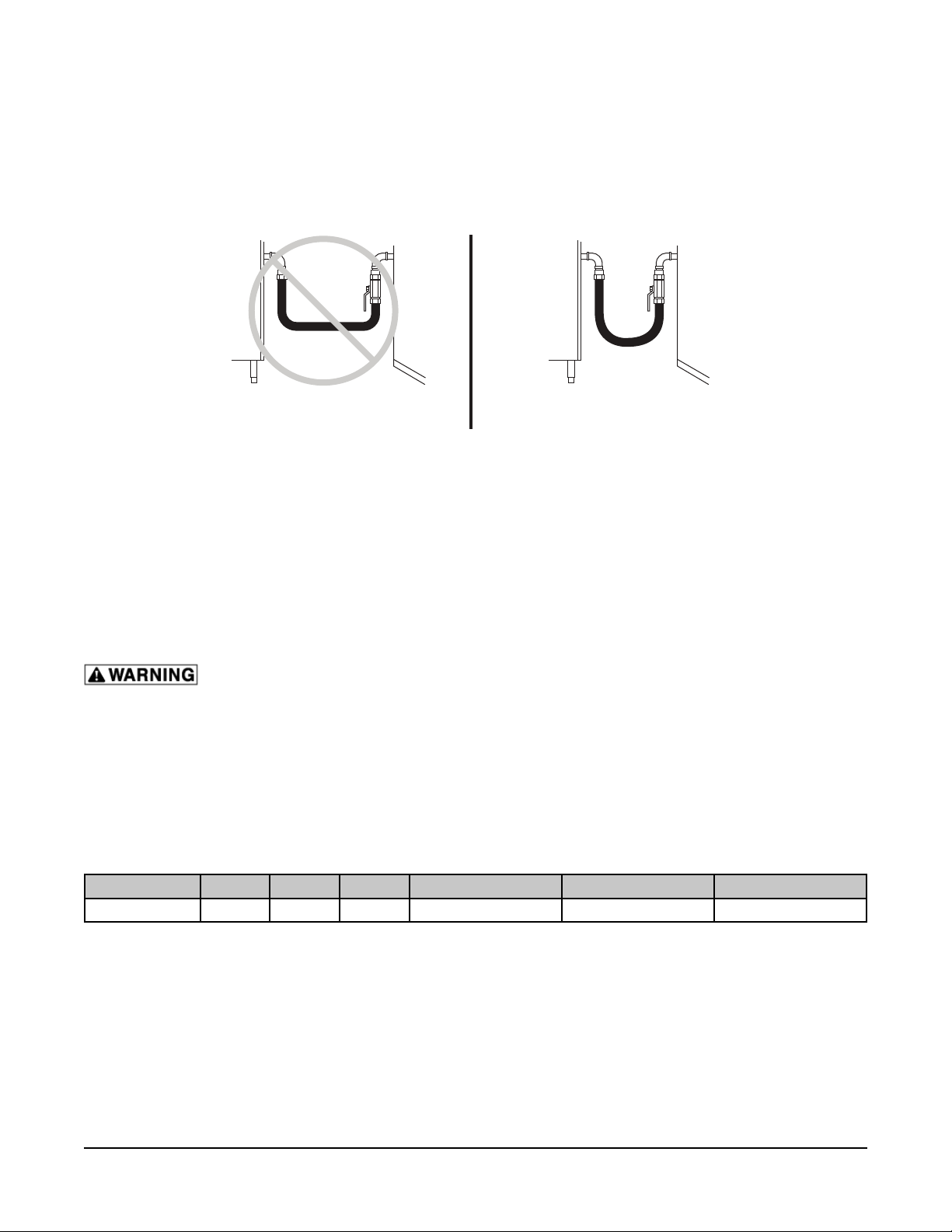

GAS SUPPLY CONNECTIONS (CONT.)

NOTE: Do not use corrugated stainless steel tubing for commercial gas equipment supply connections.

NOTE: A straight gas connection is the ideal condition for the rated BTU/hr. fl ow capacity of the connector.

If a straight connection is not possible and a fl exible gas connector is used, do not twist, kink or excessively

fl ex the connector beyond a U-shape. Flexing the gas connector as described will restrict gas fl ow or may

damage the connector.

COMBI WALL COMBI WALL

INCORRECT INSTALLATION CORRECT INSTALLATION

Changing a fl exible gas connector may raise the BTU/hr. fl ow capacity enough to allow the machine to

operate within its design specifi cations. (i.e. Removing the quick disconnect fi tting, installing a shorter gas

connector or installing a larger diameter gas connector.)

An alternative may be to move the equipment to a different gas supply location in the kitchen. (i.e. Closer

to the main supply into the kitchen or away from other equipment with high BTU/hr. input requirements.)

The combi oven is equipped with a factory preset pressure regulator. Natural gas pressure regulators are

preset for 5.0" W.C. (1.2 kPa). Propane gas pressure regulators are preset for 10.0" W.C. (2.46 kPa). No

further adjustment should be required. Check gas pressures with a manometer at time of installation to

verify that they agree with the pressures specifi ed.

Prior to lighting, check all joints in the gas supply line for leaks. Use soap and water

solution. Do not use an open fl ame. After piping has been checked for leaks, all piping receiving

gas should be fully purged to remove air.

TESTING THE GAS SUPPLY SYSTEM

1

When gas supply pressure exceeds

/2 psig (3.45 kPa), the oven and its individual shutoff valve must be

disconnected from the gas supply piping system.

When gas supply pressure is

1

/2 psig (3.45 kPa) or less, the oven should be isolated from the gas supply

system by closing its individual manual shutoff valve.

Model Volts Hertz Phase Amps (Max Used) BTU/Hr *Fuse (Amps)

CG10FI 120 60 1 5.0 60,000 1

* Fuse rating is based on electrical standard 125% increase over actual amps used.

FLUE GAS EXHAUST

DO NOT obstruct the fl ow of fl ue gases from the fl ue located on the top of the combi oven. It is recommended

that the fl ue gases be vented to the outside of the building through a ventilation system installed by

qualifi ed personnel. Information on the construction and installation of ventilating hoods may be obtained

from Vapor Removal from Cooking Equipment, NFPA-96 (latest edition) available from the National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

– 8 –

Page 9

ELECTRICAL CONNECTION

Appliances equipped with a fl exible electric supply cord are provided with a three-

prong grounding plug. It is imperative that this plug be connected into a properly grounded threeprong receptacle. If the receptacle is not the proper grounding type, contact an electrician. Do not

remove the grounding prong from this plug.

Electrical and grounding connections must comply with the applicable portions of

the National Electrical Code and/or other local electrical codes.

Disconnect electrical power supply and follow lockout / tagout procedures.

The wiring diagram is located on the inside surface of the right side panel as you face the oven. Use

copper wire rated for at least 194°F (90°C) for the connection.

Do not drill a hole in the back panel for electrical connection. Use the strain relief locations on

the lower right side or the knockout on the back panel (Fig. 2). This will allow proper access to components

for service.

STRAIN RELIEF

RIGHT SIDE

KNOCKOUT

REAR

Fig. 2

Do not connect the gas model to the electrical supply until after gas connections

have been made.

Model Volts Hertz Phase Amps (Max Used) Watts *Fuse (Amps)

CE6HD

CE10HD

CE10FD

CE20HD

CE20FD

208

230-240

480

208

230-240

480

208

230-240

480

208

230-240

480

208

230-240

480

60 3

60 3

60 3

60 3

60 3

22.2

20.1-21.9

9.6

44.4

40.2-43.7

19

59.4

53.6-58.4

26

88.8

80.3-87.5

39

103.8

93.8-102.1

45

8000

8000-8700

8000

16000

16000-17400

16000

21400

21400-23300

21400

32000

32000-34800

32000

37400

37400-40700

37400

* Fuse rating is based on electrical standard 125% increase over actual amps used.

30

30

15

60

60

25

80

80

35

125

110

50

150

150

60

NOTE: Single-phase blower motors are used on these ovens so there is no need to check direction of

motor rotation. The fan will rotate in the proper direction.

VENT HOOD

Some local codes may require the Combi oven to be located under an exhaust hood. Information on the

construction and installation of ventilating hoods may be obtained from Vapor Removal from Cooking

Equipment, NFPA Standard No. 96 (latest edition).

BEFORE FIRST USE

Before using the oven for the fi rst time, it must be "burned in" to release any odors that might result from

heating the new surfaces in the oven. Operate the oven at 482°F for 45 minutes in Convection Mode.

– 9 –

Page 10

OPERATION

The oven and its parts are hot. Use care when operating, cleaning or servicing the

oven. The cooking compartment contains live steam. Stay clear when opening door.

DOOR SWITCH

The oven is equipped with a feature that shuts off power to the oven cavity when the door is opened. The

oven will resume cooking once the door is closed.

DOOR OPENING AND CLOSING

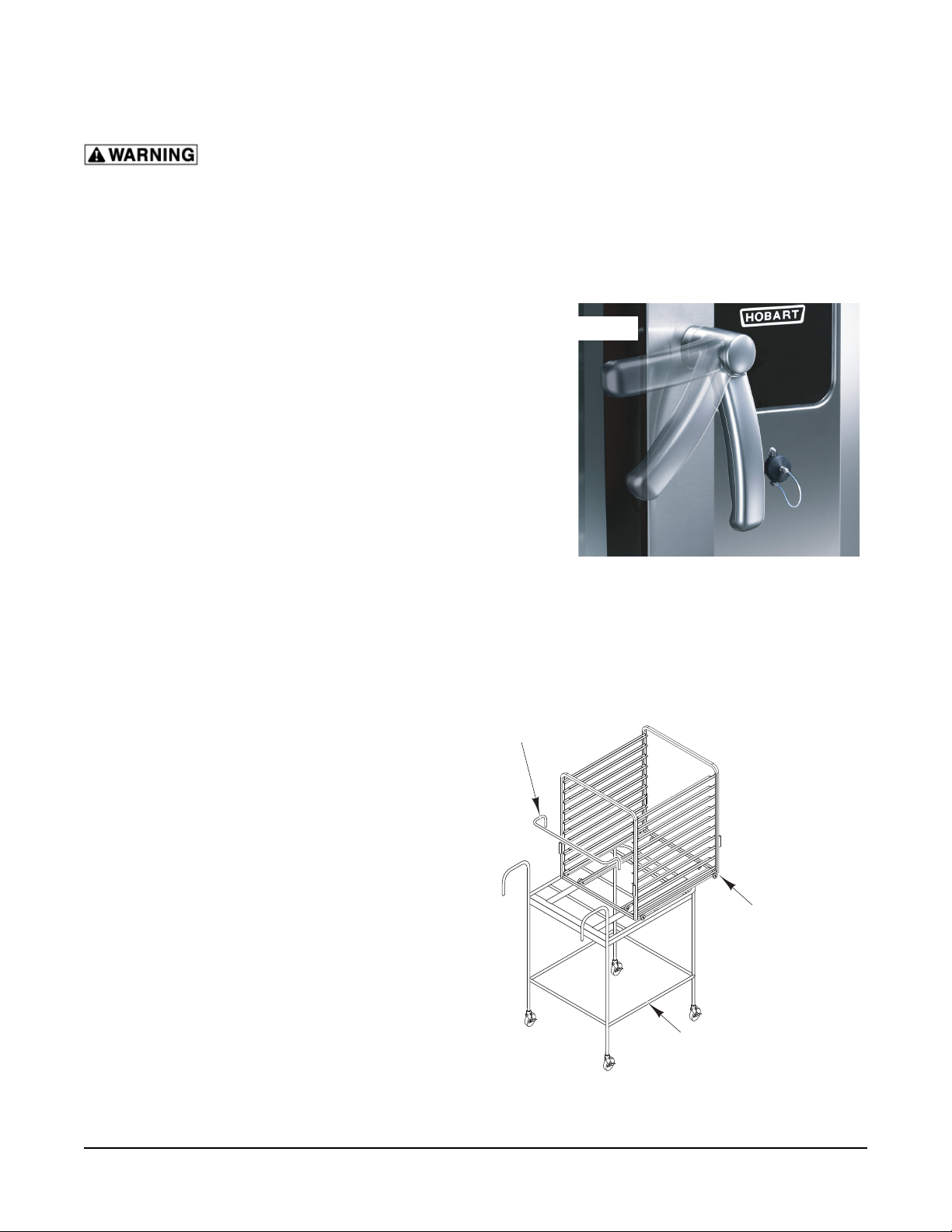

To open the door (Fig. 3), turn the handle to the

horizontal position. Allow a few seconds for steam

to escape before pulling the door open.

To close the door (Fig. 3), position handle in the

horizontal position and push the door closed. Rotate

handle to the vertical position to secure door.

LOADING THE OVEN

Loading 6 or 10 Level Ovens

Place the product to be cooked in suitable containers.

Open the door and slide into the rack guides or

place the containers securely on racks in the oven.

Close the door.

OPEN POSITION

CLOSED POSITION

Fig. 3

Loading 6 or 10 Level Ovens With Landing Table

And Removable Insert

Place removable insert on the landing table. Place

the product to be cooked in suitable containers and

slide into the rack guides or place the containers

securely on racks on the removable insert (Fig. 4).

Place the handle into the removable insert. Open

the door. Position the landing table directly in front

of the open oven cavity. While holding the landing

table in position with one hand, with the other hand,

release the insert and gently roll the removable insert

into the oven cavity. Make sure that the landing

table does not separate from the oven during the

transfer. Remove the handle from the insert and

close the door.

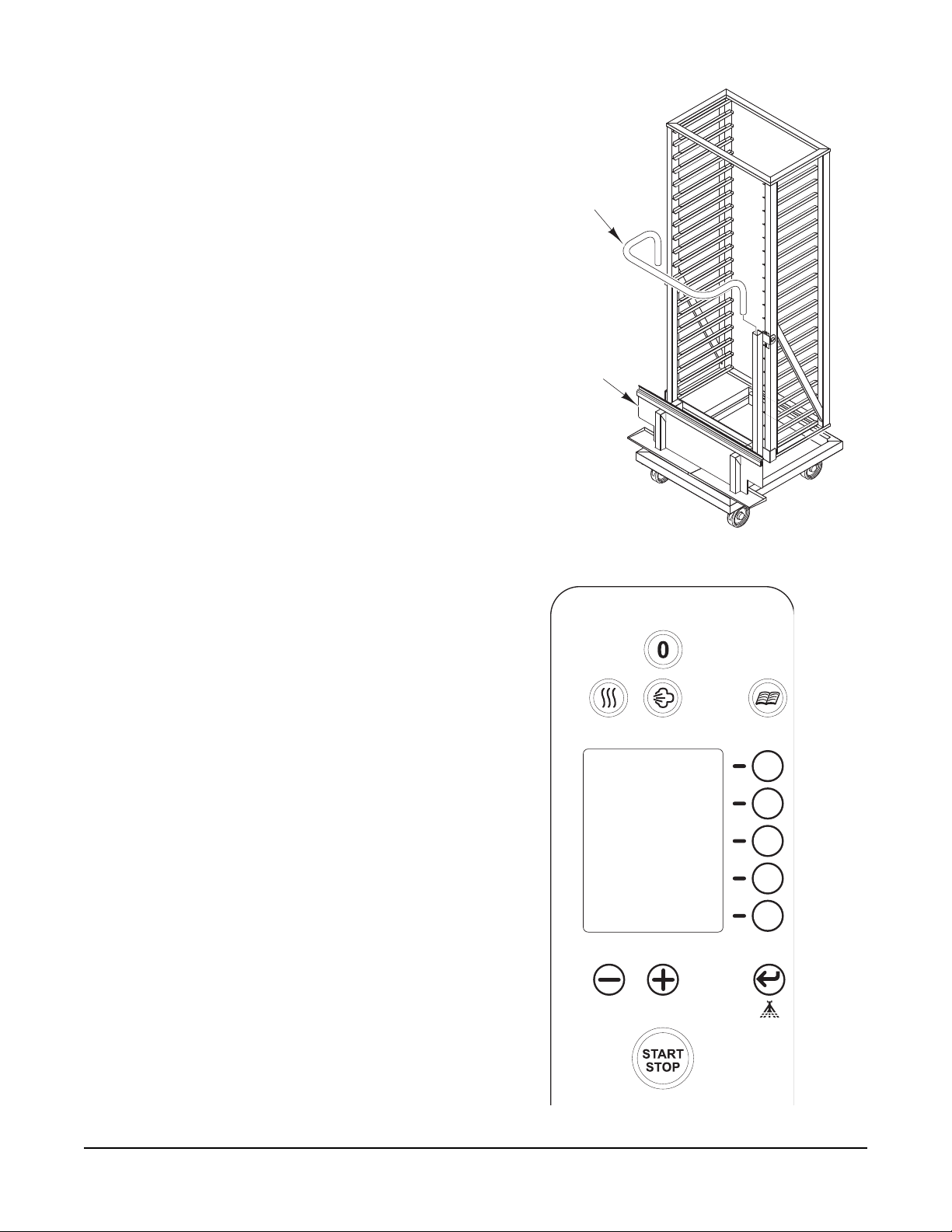

Loading 20 Level Ovens

Place the product to be cooked in suitable containers

and slide into the rack guides or place the containers

securely on racks on the trolley (Fig. 5). Place the

handle into the trolley. Open the door. Line up the

trolley with the trolley slots on the oven and push

the trolley into the oven cavity. Remove the handle

from the trolley and close the door.

HANDLE

REMOVABLE

INSERT

LANDING

TABLE

Fig. 4

– 10 –

Page 11

UNLOADING THE OVEN

Unloading 6 or 10 Level Ovens

Open door partially to allow hot air and steam to

escape. Remove the product from the rack guides

or racks in the oven. Close the door.

Unloading 6 or 10 Level Ovens With Landing

Table And Removable Insert

Open door partially to allow hot air and steam to

escape. Position the landing table (Fig. 4) directly

in front of the oven cavity. Insert the handle into the

removable insert. Using protective gear, carefully roll

the removable insert onto the landing table. Make

sure that the landing table does not separate from

the oven during transfer. Close the door.

Unloading 20 Level Ovens

Open door partially to allow hot air and steam to

escape. Insert the handle into the trolley. Using

protective gear, pull the trolley (Fig. 5) out of the

oven. Close the door.

HANDLE

TROLLEY

COOKING MODES

There are three modes of cooking available with

the Combi Oven.

Convection Mode

Convection Baking involves baking, browning,

roasting, etc. without adding steam or moisture to

the process. Hot air is circulated to maintain even

temperatures throughout the oven.

Steam Mode

Steam cooking is used for stewing, poaching,

and gentle cooking of products cooking in water.

Steam fl ows without pressure into the oven. The fan

circulates the steam to all parts of the oven.

Combi Mode

Combi baking/steaming is used for baking, roasting,

or braising when steam needs to be added to the

oven during a convection baking operation.

CONTROL PANEL

The control panel (Fig. 6) has a screen that displays

to the user the functions in progress. All features

are displayed on the screen and adjusted by using

the buttons on the control panel.

Fig. 5

– 11 –

Fig. 6

Page 12

CONTROL PANEL BUTTONS

ON/OFF Button Press this button to turn the oven on or off.

Convection Mode

Steam Mode

Combi Mode

Program Button

Enter Button

(also used as

Humidity Injector

Button)

Press this button to set the oven to Convection Mode. The

button will illuminate to indicate it has been selected.

Press this button to set the oven to Steam Mode. The button

will illuminate to indicate it has been selected.

Press both buttons to set the oven to Combi Mode. The buttons will illuminate to indicate they have been selected.

Press this button to use an existing program or to write a

new program. (Press and hold 3 seconds to name program.)

Also used to access 10 position timers.

Press this button to confi rm a program selection. When used

during Convection Mode, humidity will be injected into the

oven cavity. (Press and hold 3 seconds to save recipe.)

Minus Button

Plus Button

Selection Line

Button

(total of fi ve)

START/STOP

Button

Press this button to decrease setting feature such as temperature or time.

Press this button to increase setting feature such as temperature or time.

Press these buttons to select the feature displayed in the

control panel next to each Selection Line. These features will

change depending on the screen being displayed.

Press this button to start or stop a program or cooking cycle.

(Press and hold 3 seconds for preheat.)

– 12 –

Page 13

44

EXAMPLE

PH

1/10

DISPLAY SCREEN ICONS

Program Number

(Name)

Cooking Phase

This indicates the current program number, if used.

This indicates the cooking phase in progress. The

oven can be set from 1 to 10 phases.

START

Delayed Preheat

Timer

Temperature

(Delta T)

This icon indicates that the oven has a delayed timer

set for preheat. (Only displayed if no timer has been

selected.)

This icon is selected when adjustment of the temperature is needed.

This icon appears when Delta T is selected. Core

Delta T

probe readings control rising set temperatures on a set

scale.

Timer

(Core Probe)

Core Probe

This icon is selected when adjustment of the timer is

needed.

This icon appears when the core probe is being used

to monitor the internal temperature of a product.

This icon indicates that the oven cavity vent is open

Vent Open/Closed

or closed. Press the Selection Line Button next to the

icon to toggle. (Convection Mode only.)

Humidity This icon indicates that humidity is present in the oven.

An arrow may appear next to the humidity icon to in-

Humidity Arrow

dicate whether more or less humidity is needed in the

oven.

3

Fan Speed

Manual Operation/

No Timer

Cool Down

This icon indicates the fan speed in the oven. The

value range is 1 to 4.

This icon is used to show that a function is in continuous mode. It is commonly used when the timer is not

set or when the 10 position timer function is used.

This icon appears when the oven is set to cool down

from high temperatures.

These icons remind the operator to perform a service

500H

Service/Hours

Remaining

on the machine such as delime of the cavity or routine

service check. The machine will continue to operate

regardless of the number displayed.

Barcode

This icon appears when the oven has a program

assigned to a specifi c barcode.

– 13 –

Page 14

INITIAL START-UP

When the machine is connected to electrical power, the display screen will show the current time and date

as set in the oven and the countdown for service/deliming. The internal clock should be set at this time.

SETTING THE INTERNAL CLOCK

1. Press and hold the Selection Line Button next

to the time and date. The hour portion of the

time will fl ash.

2. Use the Plus/Minus Buttons to adjust the

hour.

3. Press the Enter Button. The minute portion of

the time will fl ash.

4. Repeat steps 2 and 3 until the time and date

are set.

NOTE: Press the Selection Line Button below the

time and date to toggle the time between 12 hour

and 24 hour time.

SETTING THE TEMPERATURE

1. Select the cooking mode by pressing the

Convection, Steam or Convection and Steam

(Combi) Button(s).

2. Press the Selection Line Button next to the

Temperature icon. The icon will be highlighted

to indicate that it has been selected and the

set temperature will be shown.

11:28 AM 05/19/07

500H

PH

1/1

110

°F

HOUR

FLASHING

11:28

PRESS TO

CHANGE TO

24 HOUR TIME

START

3. Use the Plus/Minus Buttons to adjust the

temperature. After a few seconds the

Temperature icon will change contrast and

the set oven cavity temperature will be

displayed.

NOTE: Press and hold the Selection Line Button

next to the Temperature icon to view the current

oven temperature.

NOTE: The degree symbol next to the temperature

will be solid when the oven is heating. The symbol

will be open when the oven temperature equals the

set temperature.

– 14 –

3

Page 15

SETTING THE TIMER

1. Select the cooking mode by pressing the

Convection, Steam or Convection and Steam

(Combi) Button(s).

2. Press the Selection Line Button next to the

Timer icon. The icon will be highlighted to

indicate that it has been selected and the set

timer will be shown.

3. Use the Plus/Minus Buttons to adjust the timer.

After a few seconds the Timer icon will change

contrast and the set timer will be displayed.

NOTE: The Hand icon indicates the timer is in

continuous mode and no timer is used or that the

10 position timer function is in use. (See Using the

10 Position Timer.)

SETTING THE HUMIDITY

1. Select Combi Mode by pressing the Convection

Button and Steam Button.

PH

1/1

350

START

°F

3

2. Press the Selection Line Button next to the

Humidity icon. The icon will be highlighted to

indicate that it has been selected and the set

humidity will be shown.

3. Use the Plus/Minus Buttons to adjust the

humidity. After a few seconds the Humidity

icon will change contrast and the set humidity

will be displayed.

SETTING THE VENT POSITION

1. Select Convection Mode by pressing the

Convection Button.

2. Press the Selection Line Button next to the Vent

Position icon. The icon will toggle between the

open and closed position.

PH

1/1

350

01:25

5

PH

1/1

350

01:25

°F

°F

3

VENT

OPEN

– 15 –

3

Page 16

SETTING THE FAN SPEED

1. Select the cooking mode by pressing the

Convection, Steam or Convection and Steam

(Combi) Button(s).

2. Press the Selection Line Button next to the

Fan Speed icon. The icon will be highlighted

to indicate that it has been selected.

3. Use the Plus/Minus Buttons to adjust the fan

speed. After a few seconds the Fan Speed

icon will change contrast.

FAST COOL DOWN

This feature is used to cool down the oven quickly.

It may be necessary to do this when changing from

a high temperature operation to one that requires

lower temperatures.

PH

1/1

350

01:25

PH

1/1

°F

FAN SPEED

1 TO 4

3

2

1. Press the Selection Line Button next to the

Timer icon. The icon will be highlighted to

indicate that it has been selected.

2. Press and hold the Minus Button until the Cool

Down icon appears.

3. Press the Selection Line Button next to the

Temperature icon. The icon will highlight to

indicate that it has been selected and the set

cool down temperature will be shown.

4. Use the Plus/Minus Buttons to adjust the oven

to the desired cool down temperature.

5. Press the START/STOP Button.

NOTE: Choosing another mode will stop above

process.

110

°F

4

– 16 –

Page 17

SELECTING THE COOKING MODE

After selecting one of the cooking modes, the default temperature for that cooking mode is displayed. The

oven cavity lights will be on (only if the door is closed).

PREHEATING THE OVEN

1. Set the cooking mode or use a program.

2. Press and hold the START/STOP Button for 3 seconds. The buzzer will sound and the oven will

automatically preheat to the correct cooking temperature. The timer, if set, will not count down.

When the set temperature is reached the buzzer will sound again to indicate the oven is ready to be

loaded.

3. Load the oven and press the START/STOP Button.

USING CONVECTION MODE

1. If the screen is blank (sleep mode), turn on

the oven by pressing the ON/OFF Button.

2. Press the Convection Button to select

convection mode. The button will illuminate

to indicate it has been selected.

PH

3. Set the oven temperature.

1/1

4. Set the timer.

5. Set the vent position.

6. Set the fan speed.

NOTE: Preheating the oven is recommended.

7. Load the oven and press the START/STOP

Button.

8. If called for in the recipe, press the Humidity

Injector Button to add a short blast of steam

to the cavity.

9. When the timer has counted down, the buzzer

will sound for 5 seconds and the oven cavity

lights will fl ash.

10. Press the START/STOP Button to silence the

buzzer and end the cooking session.

11. Unload the oven.

350

01:17

°F

2

– 17 –

Page 18

USING STEAM MODE

1. If the screen is blank (sleep mode), turn on

the oven by pressing the ON/OFF Button.

2. Press the Steam Button to select steam mode.

The button will illuminate to indicate it has been

selected.

3. Set the oven temperature.

PH

1/1

4. Set the timer.

5. Set the fan speed.

NOTE: Preheating the oven is recommended.

6. Load the oven and press the START/STOP

Button.

7. When the timer has counted down, the buzzer

will sound for 5 seconds and the oven cavity

lights will fl ash.

8. Press the START/STOP Button to silence the

timer and end the cooking session.

9. Unload the oven.

USING COMBI MODE

1. If the screen is blank (sleep mode), turn on

the oven by pressing the ON/OFF Button.

2. Press the Convection and Steam Button to

select combi mode. Both buttons will illuminate

to indicate they have been selected.

3. Set the oven temperature.

212

00:38

PH

1/1

°F

2

4. Set the timer.

5. Set the humidity level.

6. Set the fan speed.

NOTE: Preheating the oven is recommended.

7. Load the oven and press the START/STOP

Button.

8. When the timer has counted down, the buzzer

will sound for 5 seconds and the oven cavity

lights will fl ash.

9. Press the START/STOP Button to silence the

timer and end the cooking session.

10. Unload the oven.

– 18 –

350

00:47

5

°F

4

Page 19

TEMPERATURE PROBE

The probe temperature defi nes the fi nal temperature of the product for any cooking phase. The oven

cooking cycle stops when the product temperature reaches the probe temperature setting. Total cooking

time is not known or entered when using the probe.

There are two ways to control the oven temperature when using the probe:

• Setting the oven temperature at a constant value. The oven maintains the set temperature

throughout the cook cycle and ends when the product reaches the probe temperature

setting.

• Setting the probe using Delta T. The oven temperature gradually increases as the internal

temperature of the product increases, always maintaining the oven at a set number of

degrees warmer than the product. Delta T can provide a slow cooking process that allows

the product to reach the required fi nal internal temperature with maximum product yield.

The graph below shows the two ways of controlling the oven temperature when using the core probe. The

"100°F" value for Delta T is used to show how the oven works and is not typical of any particular cooking

program.

Final Oven Temperature

265°F

Initial Oven Temperature

140°F

Final Product Temperature

165°F

Initial Product Temperature

40°F

USING THE PROBE

WITH DELTA T

Oven Temperature

100°F=

Product Temperature

TEMPERATURE

TIME TIME

COOKING WITH PROBE AND

T

CONSTANT OVEN TEMPERATURE

265°F

Constant Oven Temperature

T

165°F

40°F

Product Temperature

DONE

TEMPERATURE

DONE

– 19 –

Page 20

USING THE PRODUCT TEMPERATURE PROBE

Setting the Cooking Core Probe Temperature

1. Insert the pointed end of the core probe into

the product so that the tip is approximately in

the middle of the product to be cooked.

2. Load the product into the oven.

3. Run the probe cable out the side of the door

opening and close the door.

4. Connect the temperature probe (Fig. 7) to the

connector below the control panel.

5. Press and hold the Selection Line Button next

to the Timer icon. The icon will change to the

Core Probe icon and display the set core probe

temperature.

6. Press the Selection Line Button next to the

Core Probe icon. The icon will be highlighted

to indicate that it has been selected.

7. Use the Plus/Minus Buttons to adjust the core

probe set temperature. After a few seconds the

Core Probe icon will change contrast and the

current temperature measured by the probe

will be displayed.

CORE PROBE

PH

1/1

350

°F

START

3

Fig. 7

CORE PROBE

ICON

8. Set all other cooking mode settings.

9. Press the START/STOP Button.

Setting Delta T

1. Select the cooking mode by pressing the

Convection Button and/or Steam Button.

2. Press and hold the Selection Line Button

next to the Temperature icon. The icon will

change to the Delta T icon and display the

set temperature difference between the oven

cavity and the core probe.

3. Press the Selection Line Button next to the

Delta T icon. The icon will be highlighted to

indicate that it has been selected.

4. Use the Plus/Minus Buttons to adjust the Delta

T set point temperature. After a few seconds

the Delta T icon will change contrast and

the current oven cavity temperature will be

displayed.

5. Set the core probe temperature by following

the instruction above.

PH

1/1

170

3

DE LTA T

ICON

START

°F

6. Set all other cooking mode settings.

7. Press the START/STOP Button.

– 20 –

Page 21

USING THE 10 POSITION TIMER

NOTE: The 10 position timers are only available in

standard cooking modes. This feature can not be

used with a cooking program, delta T, core probe

or standard timer.

1. Select the cooking mode by pressing the

Convection, Steam or Convection and Steam

(Combi) Button(s).

2. Set the oven temperature, fan speed, humidity

level and/or vent position.

3. Press the START/STOP Button.

4. Press the Program Button to enter the 10

position timer mode. (The Program Button

will fl ash and the screen will change to show

10 position timers.)

5. Press the Selection Line Button next to the

timer position to be set. The position timer

will be highlighted to indicate that it has been

selected.

NOTE: Each Selection Line Button controls two

positions. Press the button to toggle between each

timer position.

6. Use the Plus/Minus Buttons to adjust the timer

position setting. After a few seconds the timers

will begin countdown.

NOTE: Each position timer can be set from 0 to 59

minutes.

7. When a timer position reaches 0, the buzzer will

sound for fi ve seconds and the timer position

will fl ash.

PH

1/1

350

350

PROGRAM

BUTTON

(FLASHING)

START

°F

3

PROGRAM

BUTTON

(FLASHING)

01 15

02 15

03 15

04 10

05 10

06 10

07 05

09 01

08 05

10 20

3

03 15

04 10

TIMER

POSITION 03

SELECTED

8. Open door and remove the product from that

position.

NOTE: The other positions continue to countdown

while the door is open. Remove product quickly and

close door.

NOTE: If the START/STOP Button is pressed while

position timers are active, each timer will pause

and not continue countdown until the START/

STOP Button is pressed again. The START/STOP

Button will illuminate to indicate timer positions are

active.

NOTE: Cooking settings can be modifi ed while

position timers are active. Press the Program Button

and adjust the desired cooking settings. The timers

will continue to countdown while adjusting the

cooking settings.

– 21 –

Page 22

WRITING A COOKING PHASE

It is possible to link up to 10 cooking phases without

using the program function.

1. Select the cooking mode by pressing the

Convection Button and/or Steam Button.

2. Set cooking temperature or Delta T

temperature.

3. Set cooking time or use the core probe. The

Cooking Phase will indicate 1 of 1.

4. Set the vent position or the humidity level,

depending on the cooking mode being

used.

5. Set the fan speed.

6. Press the top Selection Line Button to add a

phase. The Cooking Phase will indicate that

is ready for the next phase 2 of 2.

7. Repeat steps 1 through 6 for each phase.

NOTE: Press the top Selection Line Button to review

the cooking phases.

8. Load product, close door and press the START/

STOP Button to begin cooking phases.

ERASING A COOKING PHASE

1. Press the top Selection Line Button until the

phase to be erased is displayed.

PH

1/1

350

01:17

°F

PH

1/1

2

2. Press and hold the top Selection Line Button.

The buzzer will sound and the phase will be

erased.

NOTE: Once a phase is erased the remaining

phases automatically renumber.

PH

2/2

350

00:47

85

PH 2/2

°F

4

– 22 –

Page 23

WRITING A COOKING PROGRAM

It is possible to write and store up to 100 cooking

programs with a maximum of 10 phases each.

NOTE: The oven is also equipped to use an optional

HCPC-HACCP recording system to facilitate fast,

easy and accurate data management via wireless

communication to a PC. Contact your local Hobart

representative for more information.

1. Press the Program Button to select program

mode. The button will illuminate to indicate

it has been selected and will display recipe

"00".

2. Use the Plus/Minus Buttons to select

the program number that will identify this

program.

3. Input all cooking phases. The program number

will blink to indicate that it has not been

stored.

4. Press and hold the Program Button. The display

will change and show the available characters

that can be used to name the program.

55

PH

2/2

350

01:17

°F

55

PROGRAM

NUMBER

2

5. Use the Plus/Minus Buttons to place the

fl ashing cursor over the character to be

used.

6. Press the Enter Button to add the character

to the name. The characters will be added to

the right of the program number on the display

screen.

7. Repeat steps 5 and 6 to add more characters

to the program name.

NOTE: Use the top Selection Line Button next to the

arrow icon to erase a character or to backspace.

8. After the program has been named, press and

hold the Enter Button to store the name with

the program number. The buzzer will sound

and the program number will stop blinking to

indicate that the program has been stored.

NOTE: A program can also be made after a cooking

cycle has been run. Press the Program Button, use

the Plus/Minus Buttons to navigate to a number to

store the program and press the Enter Button. Use

the steps above to name the program.

55 EXAMPLE

6308541402

0 1 2 3 4 5 6 7 8 9 - .

ABCDE FGHIJKLM

NOPQRSTUVWXYZ

55

PROGRAM

NUMBER

– 23 –

Page 24

MODIFYING A COOKING PROGRAM

1. Press the Program Button to select program

mode. The button will illuminate to indicate it

has been selected.

2. Use the Plus/Minus Buttons to select the

program to be modifi ed.

3. Modify the desired cooking phases. The

program number will blink to indicate that it

has not been stored.

NOTE: A modifi ed program can be run before

storing. After the program has run, it can then be

stored. It is not possible to insert a phase into a

program.

4. Press and hold the Enter Button. The buzzer

will sound and the program number will stop

blinking to indicate that the program has been

stored.

REVIEWING A COOKING PROGRAM

1. Press the Program Button to select program

mode. The button will illuminate to indicate it

has been selected.

55 EXAMPLE

PH

2/2

325

02:15

°F

55

PROGRAM

NUMBER

4

2. Use the Plus/Minus Buttons to select the

program number to be reviewed. The screen

will display the fi rst phase of the program.

3. Press the top Selection Line Button to scroll

through the phases of the program.

4. Press the Selection Line Button next to the

temperature icon to view the set temperature

on each phase.

5. Press the START/STOP Button to view total

cooking time for the selected program.

NOTE: The total cooking time for all phases will be

displayed unless one of the phases uses the core

probe or continuous timer mode.

ERASING A COOKING PROGRAM

1. Press the Program Button to select program

mode. The button will illuminate to indicate it

has been selected.

2. Use the Plus/Minus Buttons to select the

program to be erased.

3. Press and hold the Enter Button. The buzzer

will sound and the program will be erased.

– 24 –

Page 25

USING A COOKING PROGRAM

1. Press the Program Button to select program

mode. The button will illuminate to indicate it

has been selected.

2. Use the Plus/Minus Buttons to select the

program number to be used. The screen will

display the fi rst phase of the program.

3. Press the START/STOP Button to start the

program. The total time remaining will be

displayed and the buzzer will sound for one

second at the completion of each phase.

55 EXAMPLE

PH

2/2

325

02:15

°F

55

PROGRAM

NUMBER

NOTE: The total cooking time for all phases will be

displayed unless one of the phases uses the core

probe or continuous timer mode.

SETTING A PREHEAT DELAYED START

It is possible to program the oven to start preheating

at any set time. This feature can be used to conserve

energy and maximize effi ciency.

1. Select a cooking mode and set the preheat

temperature.

2. Press the Selection Line Button next to the

Delayed Timer icon. The actual time will be

displayed and the hour portion of the preheat

time will be fl ashing.

3. Use the Plus/Minus Buttons to adjust the

hour.

4. Press the Enter Button. The minute portion of

the time will fl ash.

5. Use the Plus/Minus Buttons to adjust the

minute.

PH

1/1

350

11:1 5 AM

12:30 PM

°F

START

4

ACTUAL TIME

11:15 AM

12:30 PM

SET TIME

6. Press the START/STOP Button.

3

– 25 –

Page 26

ADD A BARCODE TO A PROGRAM (IF OPTIONAL

BARCODE SCANNER WAS ORDERED)

1. Press the Program Button to select program

mode.

2. Use the Plus/Minus Buttons to select the

program number to add a barcode.

3. Press and hold the Program Button. The display

will change and show the available characters

that can be used to name the program.

4. Press the Selection Line Button next to Add

Barcode icon. The icon will be highlighted to

indicate that it has been selected.

5. Scan the barcode of the product within 10

seconds (Fig. 8). The scanned barcode will

now be displayed in a number code beneath

the program number and name.

6. Press and hold the Enter Button to store the

barcode with the program number. The buzzer

will sound and the program number will stop

blinking to indicate that the program has been

stored.

55 EXAMPLE

6308541402

0 1 2 3 4 5 6 7 8 9 - .

ABCDE FGHIJKLM

NOPQRSTUVWXYZ

PROGRAM

BUTTON

55

PROGRAM

NUMBER

DELETE

BARCODE

ADD

BARCODE

ENTER

BUTTON

NOTE: A barcode can only be associated with one

program. When adding a barcode, if it is already

associated with a recipe, the icon will change to a

stop icon and will display the program number that

barcode is associated to.

REMOVE A BARCODE FROM A PROGRAM

1. Press the Program Button to select program

mode.

2. Use the Plus/Minus Buttons to select the

program number to remove a barcode.

3. Press and hold the Program Button. The display

will change and show the available characters

that can be used to name the program.

4. Press and hold the Selection Line Button

next to Remove Barcode icon. The barcode

number will erase to indicate that the barcode

has been removed.

5. Press and hold the Enter Button to store the

program without a barcode.

55 EXAMPLE

6308541402

0 1 2 3 4 5 6 7 8 9 - .

ABCDE FGHIJKLM

NOPQRSTUVWXYZ

26

BARCODE

EXISTS ON

PROGRAM

No. 26

– 26 –

Page 27

USING THE SCANNER

The oven and its parts are hot.

Use care when operating, cleaning or servicing

the oven. The cooking compartment contains

live steam. Stay clear when opening door.

1. Scan barcode of product (Fig. 8). The oven

will activate the program associated and will

start automatically in preheat mode.

2. Once the oven is preheated, load the oven

and close the door. Once the door is shut, the

oven will start the timer and begin.

NOTE: If the combi is in use (start button activated);

scanning a barcode will not change operation.

NOTE: The optional barcode scanner comes

standard with a PC software program. This program

enables custom barcodes to be created and used

in conjunction with the methods described above.

Instructions for this method are in a separate

document.

Fig. 8

COMBI OVEN BLUETOOTH CAPABILITIES

The combi oven is equipped with a Bluetooth® device

that is always active. Typical range for connectivity

is approximately 10 feet.

The main use of this capability is transferring

programs to and from the oven. To transfer fi les,

a Bluetooth capable device is required such as a

phone, PDA, or laptop computer.

Pair with Bluetooth Enabled Device

1. Ensure Bluetooth is enabled on the device to

be paired with the oven.

2. In the Bluetooth setup application, click OK.

3. Search for devices (Fig. 9).

4. Select the device to pair with (Fig. 10).

5. Enter numeric passkey for the device. The

passkey is "0000". The device should now be

paired with the oven (Fig. 11).

Searching for devices

2 found

Stop

Fig. 9

Select device

F00078085596f3

Cancel

Fig. 10

Enter numeric passkey for

F00078085596f3:

****

Fig. 11

– 27 –

Page 28

Sending recipes via Bluetooth

All fi les to be transferred to the oven must be on

the device before pairing with the oven. Use the

software provided with the scanner to create recipes.

To get the fi les on the Bluetooth device, refer to the

instructions provided with the Bluetooth device in

use. Contact your local Hobart representative for

more information.

Folder

US Example Recipes.jpg

1. Ensure Bluetooth is activated on device and

already paired with combi.

2. In the media application, select pictures.

3. Navigate to the recipe fi le to be transferred.

4. Highlight the fi le (Fig. 12).

5 Press the Menu key.

6. Click Send Using Bluetooth (Fig. 13).

7. Click a Bluetooth enabled device.

8. Click Send (Fig. 14).

9. A progress bar will display and the oven

will make an audible sound to confi rm fi le

transfer.

NOTE: If an "Unable to connect" error occurs, verify

that Bluetooth is enabled on the device and that the

device is paired with the oven.

Fig. 12

New Folder

Folder

Delete

Copy

Move

Rename

Properties

Download Images

Send As Email

Send Using Bluetooth

Receive Using Bluetooth

US Example Recipes.jpg

Set As Caller ID

Fig. 13

Folder

Select a device:

F00078085596f3

– 28 –

US Example Recipes.jpg

Fig. 14

Page 29

MAINTENANCE

Disconnect electrical power supply and follow lockout / tagout procedures.

Fluorescent lamp in display panel contains a small amount of mercury. Please dispose of

according to local, state or federal laws.

SERVICE ADJUSTMENTS

The Combi Oven default settings can be customized to fi t your own personal needs using service parameter

setup. Contact your local Hobart Service offi ce for any adjustments needed on this equipment.

DOOR LOCKING AND GASKET INSPECTION

During oven operation, if air or steam blows out from the top, sides, or underneath to door, the door may

need adjustment. Inspect the door locking movement and the door gasket.

Door Locking Inspection

When closing door, the locking action should be smooth with no binding and not require excessive force

to turn the door handle. The door must exert enough pressure on the gasket to prevent steam from exiting

the oven cavity. If the door locking is extremely tight, contact your local Hobart

Service offi ce for any repairs or adjustments needed on this equipment.

Door Gasket Inspection

Visually inspect the door gasket for cracks, splits, and missing sections.

Using a dollar bill or a strip of plain paper approximately the same size, position

the paper between door and gasket then close the door. The paper should

STOP

fi t tightly and not be easily removed when pulled. Check tightness near the

corners and in the center locations at the left, top and right sides of door. If the

door gasket is not sealing properly, contact your local Hobart Service offi ce for

any repairs or adjustments needed on this equipment.

SERVICE AND PARTS INFORMATION

Contact your local Hobart Service offi ce for any repairs or adjustments needed

on this equipment.

SHUTTING DOWN THE OVEN

1. Press the ON/OFF Button. The display screen will show the Cleaning and Shutdown icons.

2. Press the Selection Line Button next to the icon to be performed.

DISPLAY SCREEN CLEANING AND SHUTDOWN ICONS

STOP

Stop Only Select this feature if the oven will be shutdown and not cleaned.

STOP

Stop and Drain

Stop and Do Not

STOP

Drain

Select this feature if the oven boiler (if equipped) should be

drained before shutdown.

Select this feature if the oven boiler (if equipped) should not be

drained before shutdown.

Manual Clean Cycle Select this feature if the oven cavity is to be cleaned manually.

Auto Clean Cycle Select this feature if the oven cavity is to be cleaned automatically.

– 29 –

Page 30

STAINLESS STEEL EQUIPMENT CARE AND CLEANING

(Supplied courtesy of NAFEM. For more information, visit their web site at www.nafem.org)

Contrary to popular belief, stainless steels ARE susceptible to

rusting.

Corrosion on metals is everywhere. It is recognized quickly on iron

and steel as unsightly yellow/orange rust. Such metals are called

“active” because they actively corrode in a natural environment when

their atoms combine with oxygen to form rust.

Stainless steels are passive metals because they contain other metals,

like chromium, nickel and manganese that stabilize the atoms. 400

series stainless steels are called ferritic, contain chromium, and are

magnetic; 300 series stainless steels are called austenitic, contain

chromium and nickel; and 200 series stainless, also austenitic,

contains manganese, nitrogen and carbon. Austenitic types of

stainless are not magnetic, and generally provide greater resistance

to corrosion than ferritic types.

With 12-30 percent chromium, an invisible passive fi lm covers the

steel’s surface acting as a shield against corrosion. As long as the

fi lm is intact and not broken or contaminated, the metal is passive

and stain-less. If the passive fi lm of stainless steel has been broken,

equipment starts to corrode. At its end, it rusts.

Enemies of Stainless Steel

There are three basic things which can break down stainless steel’s

passivity layer and allow corrosion to occur.

1. Mechanical abrasion

2. Deposits and water

3. Chlorides

Mechanical abrasion means those things that will scratch a steel

surface. Steel pads, wire brushes and scrapers are prime examples.

Water comes out of the faucet in varying degrees of hardness.

Depending on what part of the country you live in, you may have hard

or soft water. Hard water may leave spots, and when heated leave

deposits behind that if left to sit, will break down the passive layer and

rust stainless steel. Other deposits from food preparation and service

must be properly removed.

Chlorides are found nearly everywhere. They are in water, food

and table salt. One of the worst chloride perpetrators can come from

household and industrial cleaners.

So what does all this mean? Don’t Despair!

Here are a few steps that can help prevent stainless steel rust.

1. Use the proper tools.

When cleaning stainless steel products, use non-abrasive tools.

Soft cloths and plastic scouring pads will not harm steel’s passive

layer. Stainless steel pads also can be used but the scrubbing

motion must be in the direction of the manufacturers’ polishing

marks.

2. Clean with the polish lines.

Some stainless steel comes with visible polishing lines or “grain.”

When visible lines are present, always scrub in a motion parallel

to the lines. When the grain cannot be seen, play it safe and use

a soft cloth or plastic scouring pad.

3. Use alkaline, alkaline chlorinated or non-chloride

containing cleaners.

While many traditional cleaners are loaded with chlorides, the

industry is providing an ever-increasing choice of non-chloride

cleaners. If you are not sure of chloride content in the cleaner

used, contact your cleaner supplier. If your present cleaner

contains chlorides, ask your supplier if they have an alternative.

Avoid cleaners containing quaternary salts; it also can attack

stainless steel and cause pitting and rusting.

4. Treat your water.

Though this is not always practical, softening hard water can do

much to reduce deposits. There are certain fi lters that can be

installed to remove distasteful and corrosive elements. To insure

proper water treatment, call a treatment specialist.

5. Keep your food equipment clean.

Use alkaline, alkaline chlorinated or non-chloride cleaners

at recommended strength. Clean frequently to avoid buildup of hard, stubborn stains. If you boil water in stainless steel

equipment, remember the single most likely cause of damage

is chlorides in the water. Heating cleaners that contain chlorides

have a similar effect.

6. Rinse, rinse, rinse.

If chlorinated cleaners are used, rinse and wipe equipment and

supplies dry immediately. The sooner you wipe off standing water,

especially when it contains cleaning agents, the better. After

wiping equipment down, allow it to air dry; oxygen helps maintain

the stainless steel’s passivity fi lm.

7. Never use hydrochloric acid (muriatic acid) on stainless

steel.

8. Regularly restore/passivate stainless steel.

Job Cleaning Agent Comments

Routine cleaning Soap, ammonia,

Fingerprints

and smears

Stubborn stains

and discoloration

Grease and fatty

acids, blood,

burnt-on foods

Grease and Oil Any good

Restoration/

Passivation

Review

1. Stainless steels rust when passivity (fi lm-shield) breaks down

as a result of scrapes, scratches, deposits and chlorides.

2. Stainless steel rust starts with pits and cracks.

3. Use the proper tools. Do not use steel pads, wire brushes or

scrapers to clean stainless steel.

4. Use non-chlorinated cleaners at recommended concentrations.

Use only chloridefree cleaners.

5. Soften your water. Use fi lters and softeners whenever

possible.

6. Wipe off cleaning agent(s) and standing water as soon as

possible. Prolonged contact causes eventual problems.

To learn more about chloride-stress corrosion and how to prevent it,

contact the equipment manufacturer or cleaning materials supplier.

Developed by Packer Engineering, Naperville, Ill., an independent

testing laboratory.

detergent, Medallion

Arcal 20, Lac-O-

Nu Ecoshine

Cameo, Talc, Zud,

First Impression

Easy-off, DeGrease

It Oven Aid

commercial

detergent

Benefi t, Super

Sheen

Apply with soft

cloth or sponge.

Provides barrier fi lm

Rub in direction

of polish lines.

Excellent removal

on all fi nishes

Apply with soft

cloth or sponge.

– 30 –

Page 31

CLEANING

The oven and its parts are hot. Always allow the oven to cool before cleaning.

The Combi oven must be cleaned regularly in order to maintain performance. The automatic clean function

provides a quick and easy way to keep the oven cavity clean. However, periodic cleaning is required to

the exterior to ensure continued safe, reliable operation. Review the cleaning instruction provided.

The oven has considerable amounts of stainless steel that will require proper care. Review the section

Stainless Steel Equipment Care and Cleaning for additional information about proper care for stainless

steel.

Daily Cleaning

1. Remove any large pieces of food that may be in the oven cavity before starting a cleaning cycle.

2. Perform one of the cleaning cycles.

3. Clean the door gasket with a soft, clean, damp cloth after every cleaning cycle. This will ensure a

long life for the gasket.

4. Do not use cleaners containing grit, abrasive materials,

bleach, harsh chemicals, chlorides, acidic based detergents

or chlorinated cleaners.

5. Do not use steel wool on stainless steel or glass surfaces.

6. Be cautious with new or improved cleaning formulas; use only

after being well tested in an inconspicuous place.

7. Clean the door glass exterior.

Weekly Cleaning

1. Clean any air vents on the exterior of the oven. Dust can

collect on the vent openings. Clogged vents can cause oven

components to overheat.

2. Remove wire racks and wipe the rack support rails.

Changing the Chemical Bottle (Fig. 15)

1. Remove cap and tube from empty bottle.

2. Place tube with fi lter and weight into new bottle until it reaches the bottom

of the bottle.

3. Slide cap down the tube and tighten cap on the bottle.

Quick Rinse Cycle

TUBE

Fig. 15

95

CAP

(With Hole)

FILTER

(With Weight)

°F

NOTE: The quick rinse cycle is an automatic cycle that does not use detergent.

This feature can be used to give the oven cavity a quick rinse between product

uses.

1. Press the Selection Line Button next to the Auto Clean Cycle icon.

2. Use the Minus Button to select "0" detergent to be used.

3. Press and hold the Minus Button until an "R" appears instead of a "0".

4. Press the START/STOP Button to begin the quick rinse cycle.

– 31 –

R

Page 32

Manual Clean Cycle

1. Press the Selection Line Button next to the Manual Clean Cycle

icon.

2. Press the START/STOP Button to begin the clean cycle. The buzzer

will sound to indicate that the interior is ready to be sprayed with an

appropriate detergent.

3. Open the door and spray the detergent.

4. Close the door, the clean cycle will restart and end with the appropriate

rinse of the cavity.

Automatic Clean Cycle

NOTE: Before using the auto clean cycle, make sure that the detergent

pump tube is inserted correctly into the detergent container and that enough

detergent is available.

1. Press the Selection Line Button next to the Auto Clean Cycle icon.

2. Use the Plus/Minus Buttons to select the clean cycle time and amount

of detergent to be used. The time and detergent values are preset.

Select the preset value depending on the level of cleaning needed.

3. Press the START/STOP Button to begin the clean cycle.

STOP

NOTE: There may not be any visible signs that the automatic clean cycle has begun. This will depend

on the temperature of the oven cavity.

Preset Automatic Clean Cycle Values

(times may vary depending on automatic cool down)

Level Detergent Dose Time Level Detergent Dose Time Level Detergent Dose Time

0 0 0:25 3 15 0:47 6 30 1:12

1 5 0:30 4 20 0:55 7 35 1:20

2 10 0:38 5 25 1:04 8 45 1:29

Descaling the Boiler

1. Press the ON/OFF Button and press the Selection Line Button next

to the Stop and Drain icon. The boiler will drain.

2. Fill the boiler with white vinegar or similar descaling product using

the steam inlet at the top right hand side of the cavity. Use 5 quarts

for 6-Pan ovens, 6 quarts for 10-Pan ovens, or 10 quarts for 20-Pan

ovens.

3. Select Steam Mode and wait 30 to 45 minutes. Do not start the steam

cycle.

4. Press the ON/OFF Button and press the Selection Line Button next

to the Stop and Drain icon. The boiler will drain.

5. Select Steam Mode again to rinse the boiler. Do not start the steam

cycle.

6. Select a clean cycle to fi nalize the descaling process.

– 32 –

Page 33

Deliming the Cavity

Oven cavity deliming should be done on a regular basis. The frequency depends on oven use, quality

of the local water supply and what type of water treatment system is used. Even with the use of a water

treatment system, periodic deliming of the oven cavity is still required. If lime scale build up becomes

visibly noticeable, then the oven cavity deliming should be performed.

Deliming should only be performed on a cool oven after a clean cycle has occurred.

NOTE: All components inside the oven cavity, such as the heating elements, racks, rack guides and interior

glass, can be sprayed with white vinegar or a deliming product.

1. Spray the entire oven cavity with white vinegar (full strength) and let it stand for 15 minutes. Or use

a deliming product. When using a deliming product other than white vinegar, follow the directions

on the product label.

2. Close the oven door.

3. Rinse the oven cavity using the automatic clean cycle and set the cycle to "0".

– 33 –

Page 34

TROUBLESHOOTING

AUTODIAGNOSTICS

The microprocessor of the oven constantly checks the

proper functioning of the machine and indicates any

problems with a number inside a symbol located in

place of the fan speed. See the Fault Symbols Chart

for more information.

• Faults must be corrected, otherwise they will be

displayed each time a function using the faulty

component is selected.

• The fault display stays on if the corresponding

mode or function cannot be used.

• The last 99 faults are stored in the control board

memory.

• If a fault occurs during a cooking program, the

program will stop.

• If a fault is displayed before starting a program,

it will not be possible to start that program.

PH

1/1